Alternating current servo drive fine blanking machine

A technology of AC servo and fine blanking machine, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing fine blanking processing efficiency and affecting processing accuracy, and achieve the effect of improving processing accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

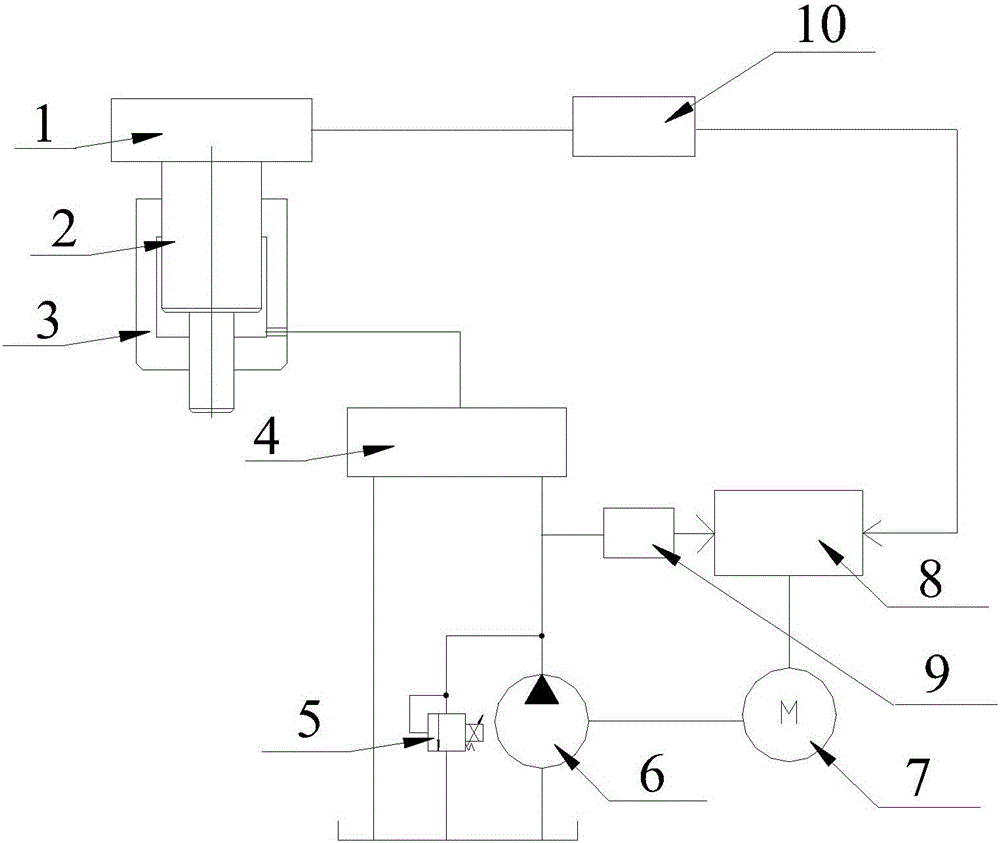

Method used

Image

Examples

Embodiment 1

[0017] During the fine blanking of the 45# steel plate with a thickness of 12mm, if the traditional constant blanking speed processing method is used, the steel plate will tear. The AC servo-driven fine blanking machine of the present invention passes through the grating fixed on the worktable. Ruler, monitors and feedbacks the position information of the worktable, when the displacement of the worktable is less than 8mm, the servo motor controller controls the speed of the AC servo motor and then controls the flow of the oil pump, and controls the punching speed to 20mm / s; When the moving displacement is 8mm, the position sensor will feedback its position signal to the servo motor controller. At the same time, the servo motor controller will output the signal corresponding to the fine blanking speed of the position, and finally control the speed of the AC servo motor. The punching speed is 5mm / s, until finishing the subsequent 4mm fine-blanking. By changing the fine-blanking s...

Embodiment 2

[0019] In the fine blanking process of the composite material of 45# steel with a thickness of 6mm and bronze with a thickness of 2mm, due to the different hardness of 45# steel and bronze, different punching speeds are required. The AC servo-driven fine blanking machine of the present invention The position information of the worktable is monitored and fed back by the grating ruler fixed on the worktable. When the upward displacement of the worktable is 0-2mm, that is, when the bronze plate is processed, the servo motor controller controls the speed of the AC servo motor and then controls the oil pump Control the punching speed of the fine-blanking machine to 30mm / s. When the worktable’s rising displacement is 2-8mm, that is, when processing the 45# steel plate part, control the punching speed of the worktable to 15mm / s, It greatly improves the machining accuracy of the traditional constant-speed fine blanking of composite materials, and at the same time improves the production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com