Film-coating pipe cleaner with emergency start-up system

A technology for starting systems and pigs, which is applied in the direction of control/regulation systems, electric fluid pressure control, instruments, etc., to achieve the effect of increasing the anti-corrosion effect and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

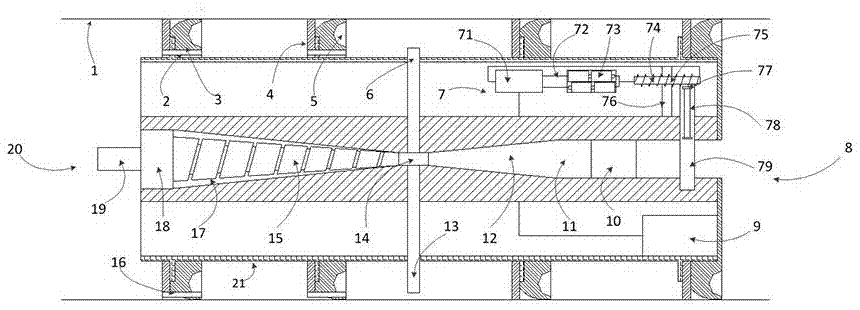

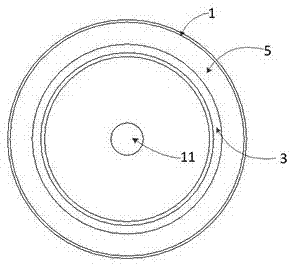

[0060] Such as figure 1 , 2 As shown, a film-coated pipe pig with an emergency start system includes a pipeline 1, an elastic leather cup 3, a hard leather cup 4 and a cylindrical frame 21. The pig is arranged in the pipeline 1, and the elastic leather cup The bowl 3 and the hard leather bowl 4 are annularly installed on the outside of the cylindrical frame 21, and the pig is characterized in that the pig also includes an emergency start system 7, a speed control device 10, a pressure sensing device 9 and a corrosion inhibitor collection and spraying system.

[0061] The emergency start system 7 includes a control unit 71, a wire 72, a battery pack 73, a coil 74, a magnetizable iron core 75, a pillar 76, a permanent magnet 77, a baffle plate 78, a baffle plate chamber 79, and a control unit 71. The battery pack 73 and the coil 74 are sequenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com