Capsule sorting mechanism with high sorting efficiency

A high-efficiency and sorting technology, applied in sorting and other directions, can solve the problems of reducing the number of qualified capsules, increasing labor intensity, increasing processing procedures, etc., and achieve the effect of good production process, reducing labor intensity and improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

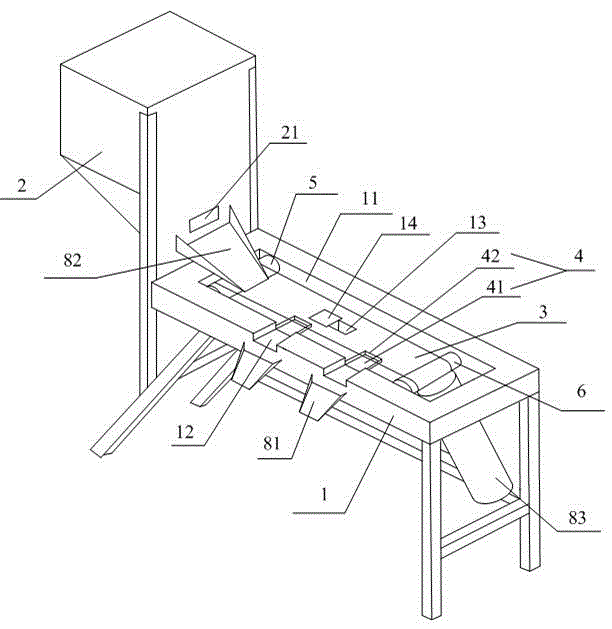

[0027] Such as figure 1 As shown, the capsule sorting mechanism with high sorting efficiency includes a frame, a driving roller 5, a driven roller 6, a transparent conveyor belt 3 wrapped around the driving roller 5 and the driven roller 6, and the driving roller 5 is connected to There is a motor; the frame includes a support and a rectangular mount 1 fixed on the support.

[0028] The upper surface of the mounting seat 1 is provided with a rectangular cavity 11, the length direction of the rectangular cavity 11 is consistent with the length direction of the rectangular mounting seat 1; the driving roller 5 and the driven roller 6 are arranged in the rectangular cavity 11. The roller 5 is located at the front end of the rectangular cavity 11 , and the driven roller 6 is located at the rear end of the rectangular cavity 11 ; the rectangular cavity 11 is provided with an illumination source under the transparent transmission belt 3 .

[0029] The upper end of the front side of...

Embodiment 2

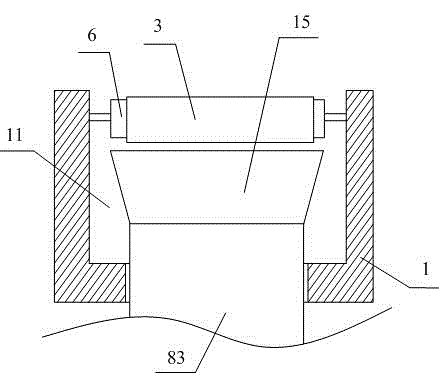

[0037] On the basis of Embodiment 1, in order to make the capsules on the transparent conveying belt 3 at the upper end of the driven roller 6 better enter the conveying pipe 83 and reduce the number of capsules falling into the rectangular cavity 11, in this embodiment, the A conical hopper 15 is also provided in the cavity 11 . figure 2 It is a schematic diagram of the connection of the conical hopper in this embodiment, which is a cross-sectional view of the base 1 along the left and right directions, such as figure 2 As shown, the small end of the conical hopper 15 is connected to the upper end of the conveying pipe 83 , and the large end is located directly below the driven roller 6 . The function of the conical hopper 15 is mainly to collect the capsules into the conveying pipe 83 .

Embodiment 3

[0039] On the basis of embodiment 1 or embodiment 2, in this embodiment, in order to make the sorting of the operator more labor-saving and convenient, a waste material box 4 is also arranged at the entrance of the waste material conveying groove 12 in the described rectangular cavity 11, Described waste box 4 is made of bottom plate 41 and the side plate 42 that is connected on three sides of bottom plate 41, and the side of bottom plate 41 that is not connected with side plate 42 is connected on the side of rectangular cavity 11 below the inlet of waste conveying groove 12, waste material The side plate of the box 4 opposite to the entrance of the waste conveying trough 12 is located directly below the transparent conveyor belt 3;

[0040] In this embodiment, when the operator selects defective capsules, he only needs to use a tool directly above the waste box 4 to push the defective capsules down the transparent conveyor belt 3, which is more convenient and labor-saving than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com