Electro-hydraulic control system capable of achieving ultralow-speed stable running of hydraulic machine

An electro-hydraulic control system, stable operation technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of small discharge flow of the return cylinder, unstable running speed of the main hydraulic cylinder and slider, affecting the quality of workpiece forming, etc. The effect of ensuring the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

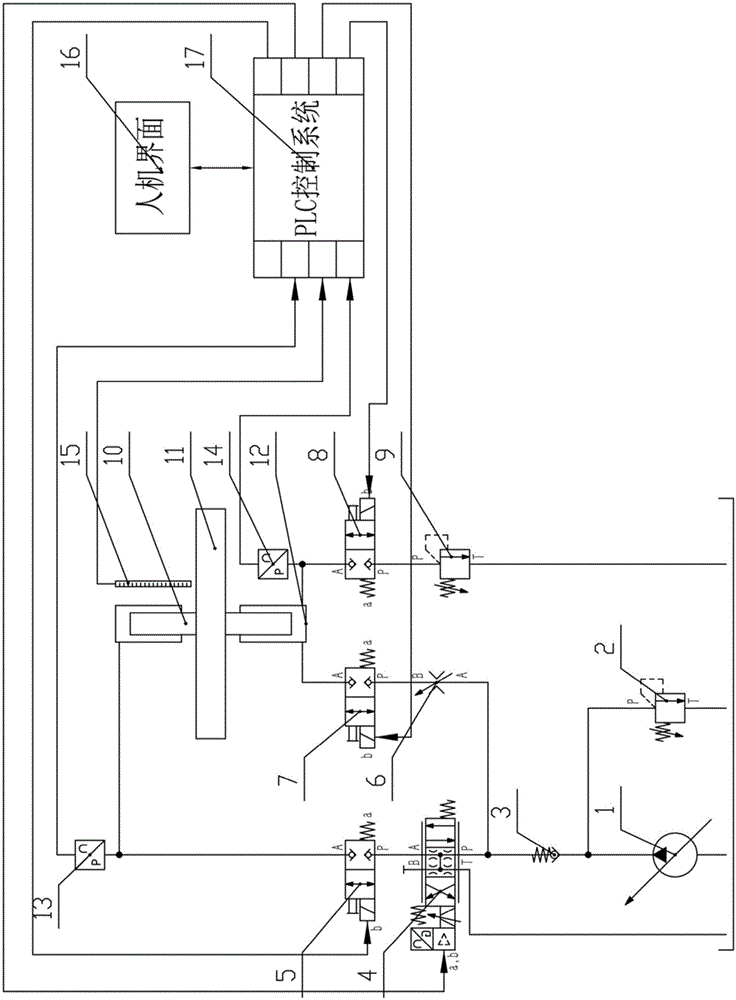

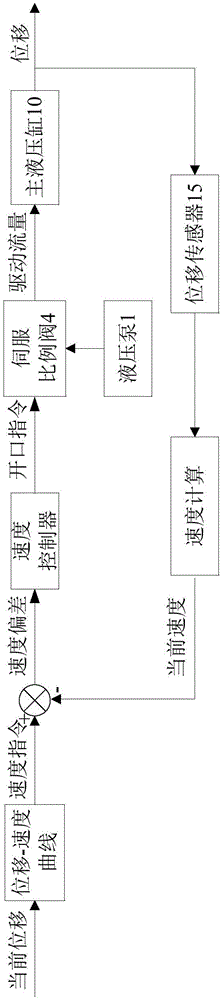

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] In the present invention, the three-way flow control valve can be one of servo proportional valve 4, proportional valve, servo valve and the like. Hereinafter, the structure of the electro-hydraulic control system of the present invention will be described in detail by taking the three-way flow control valve as the servo proportional valve 4 as an example.

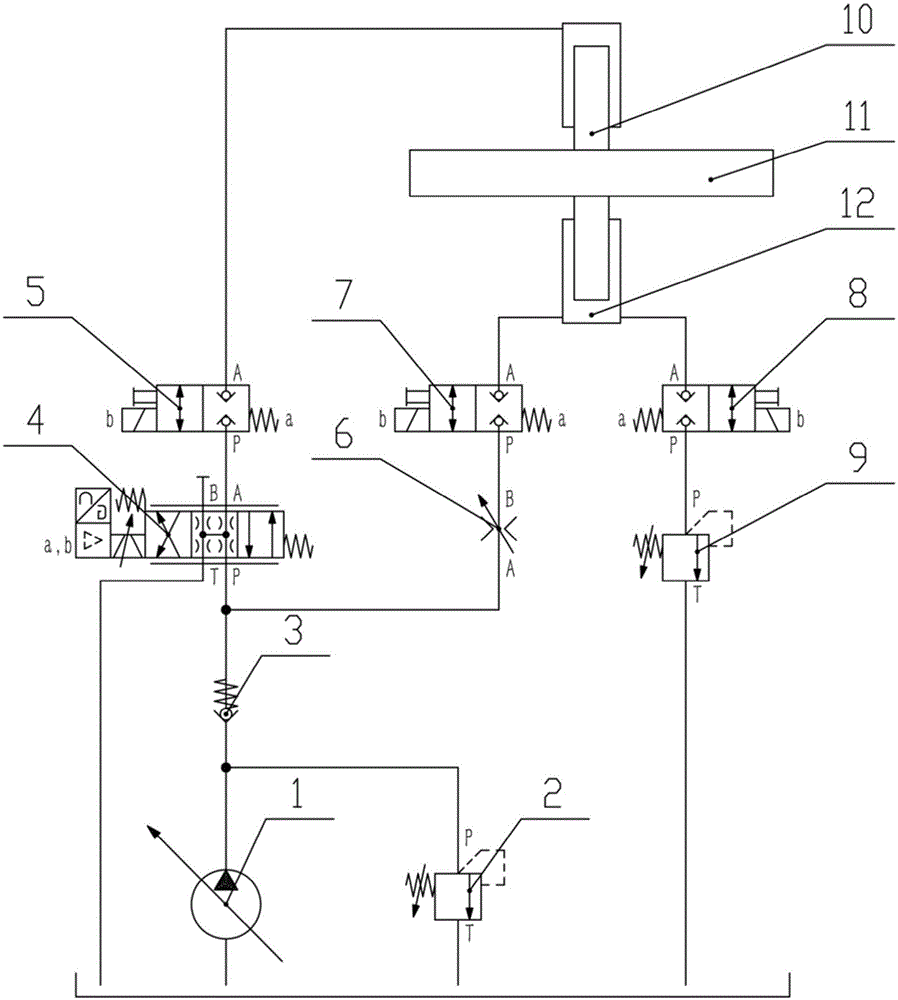

[0024] see figure 1 , as an embodiment of the electro-hydraulic control system of the present invention, the present invention mainly includes a hydraulic pump 1, a relief valve 2, a one-way valve 3, a servo proportional valve 4, a first two-way ball valve 5, an adjustable hydraulic resistance 6, The second two-way ball valve 7, the third two-way ball valve 8, the support valve 9, the main hydraulic cylinder 10 and the return cylinder 12. Wherein, the oil outlet of the hydraulic pump 1 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com