Patents

Literature

111results about "Putting meat on skewers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

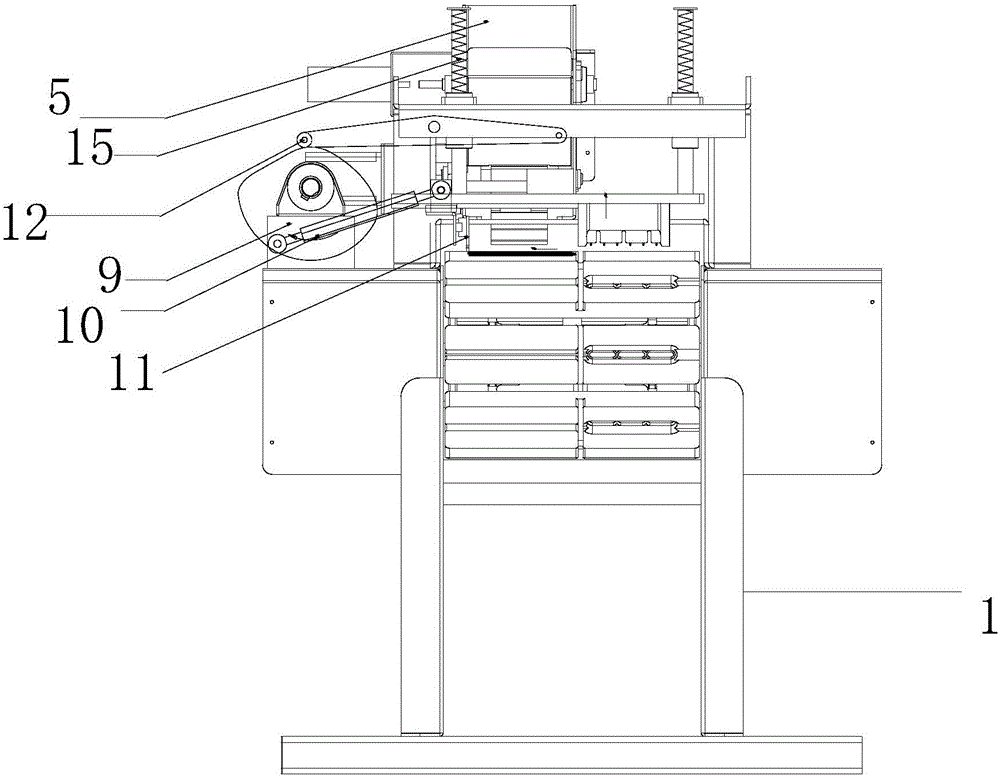

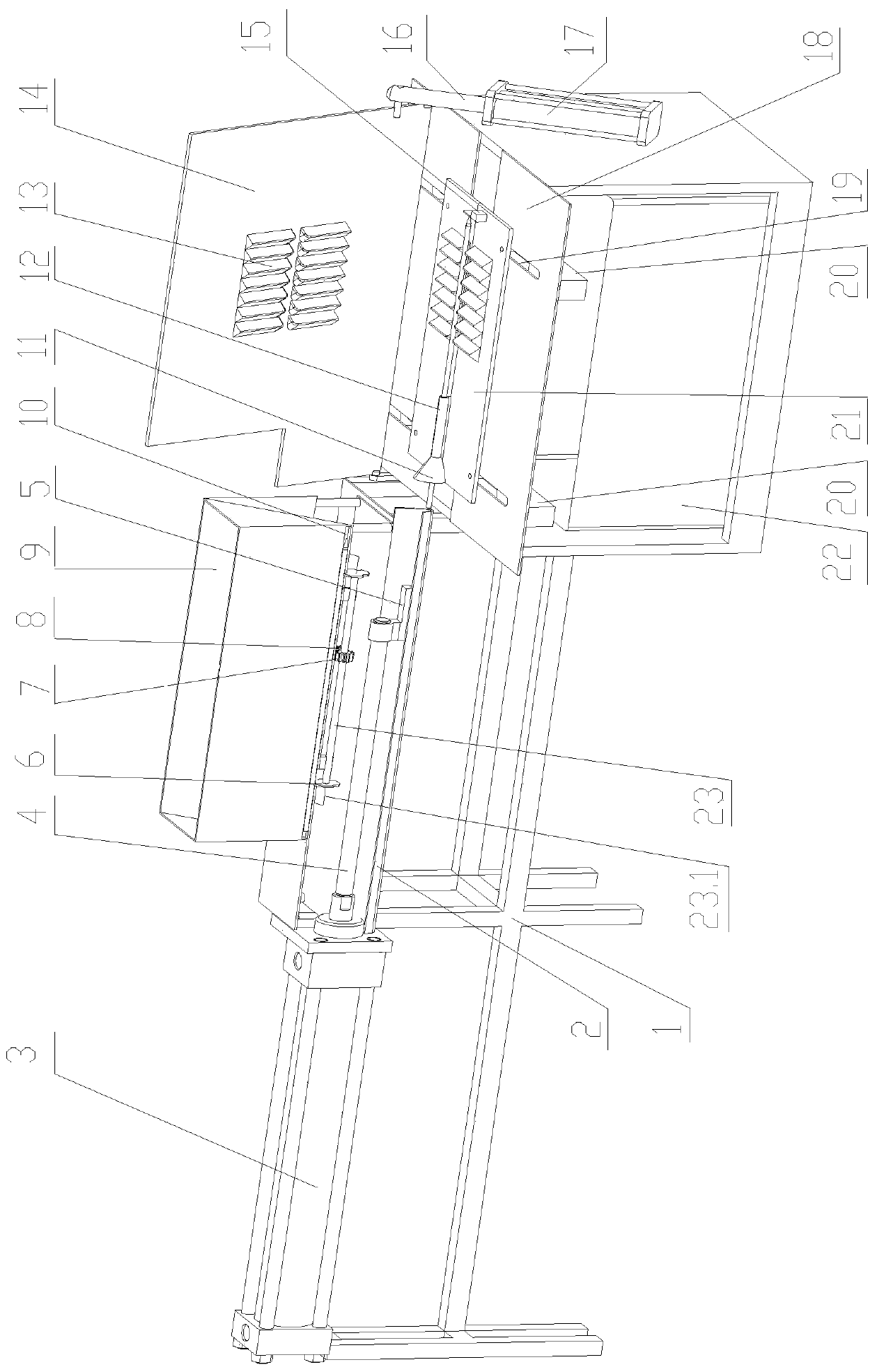

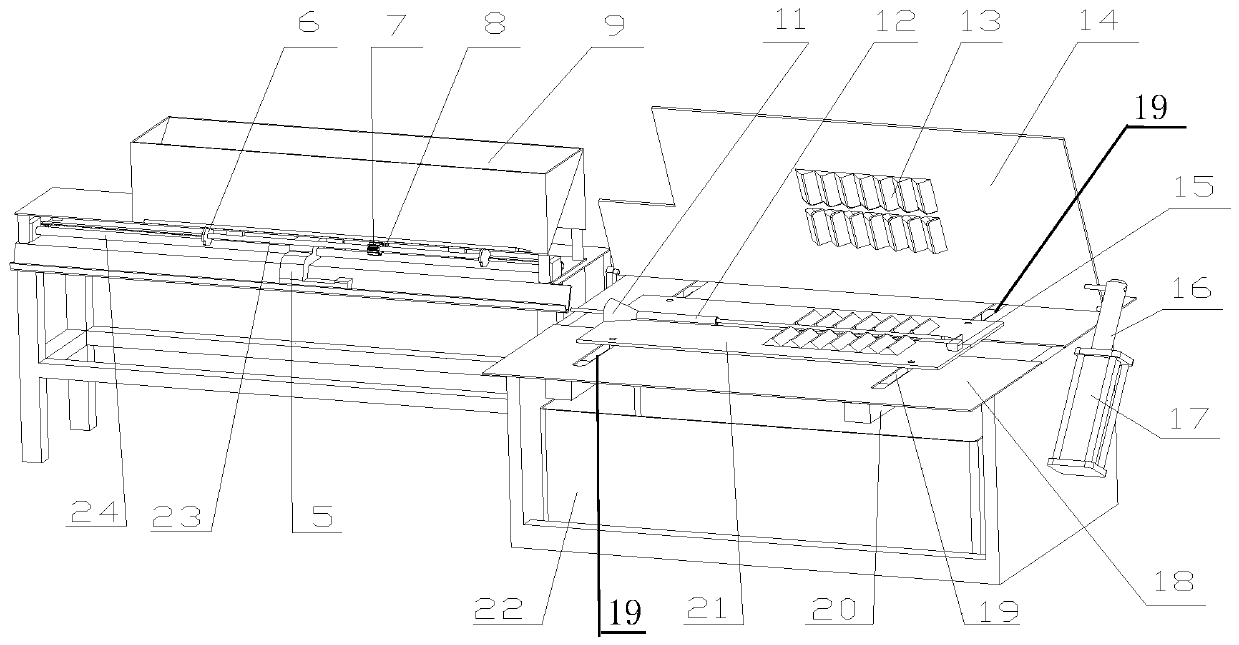

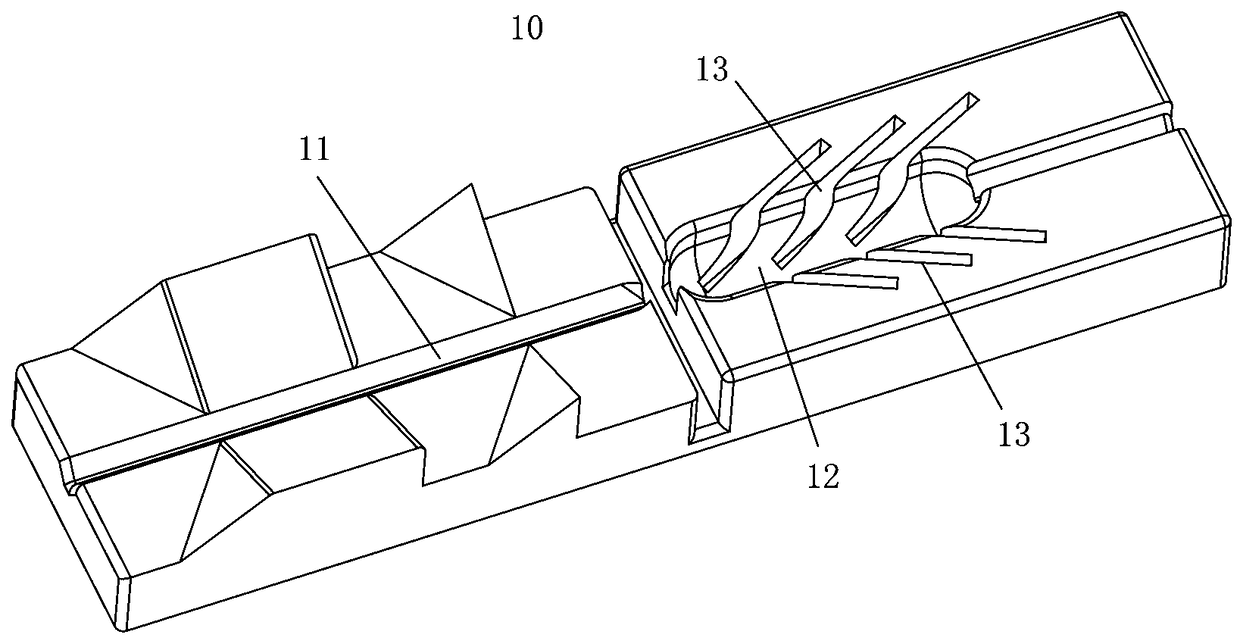

Automatic stringer

InactiveCN104920572AReduce in quantityControl running speedMeat/sausage hanging-upPutting meat on skewersPunchingKnurling

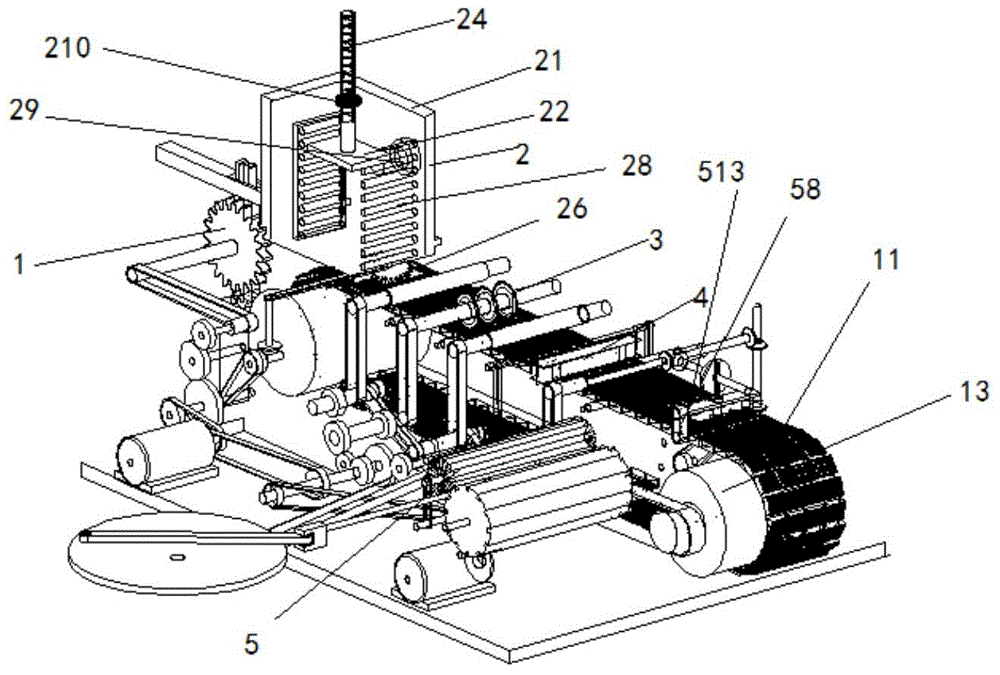

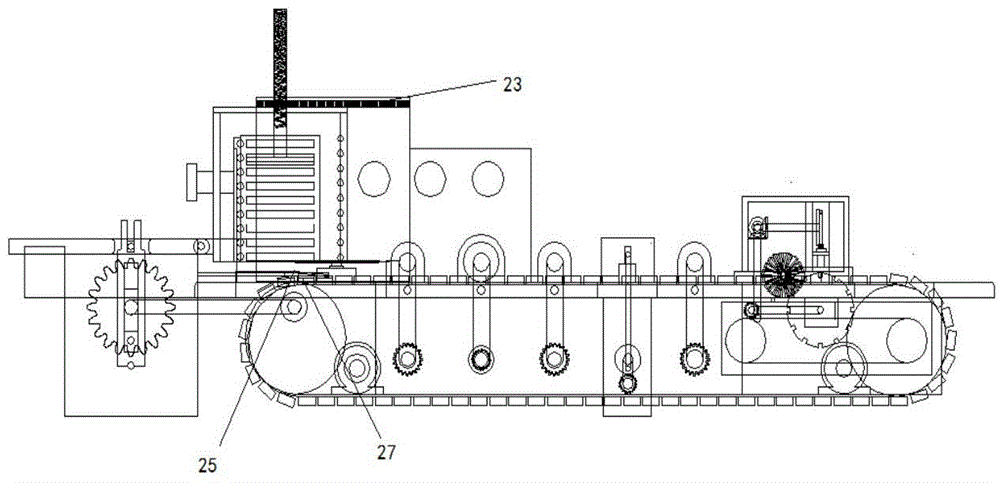

The invention relates to an automatic stringer which comprises a power transmission device, an automatic meat slicing device with a propelling automatic meat locking box, a knurling tool meat cutting device, a shearing and feeding device and an automatic prod punching device, wherein the device integrates slicing, slitting, bar-cutting and prod-stringing, so that the production efficiency is improved, automation and multi-functionalization can be further realized, the automatic stringer is multipurpose, and the consumption of manpower and material resources as well as financial resources is greatly reduced. The automatic stringer not only can string meat, but also can string various foods such as balls and the like. Moreover, meat in different thicknesses and different sizes can be stringed. The mechanical degree and the production efficiency are improved, and the automatic stringer is easy to operate and maintain, low in cost, small in size and high in degree of automation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

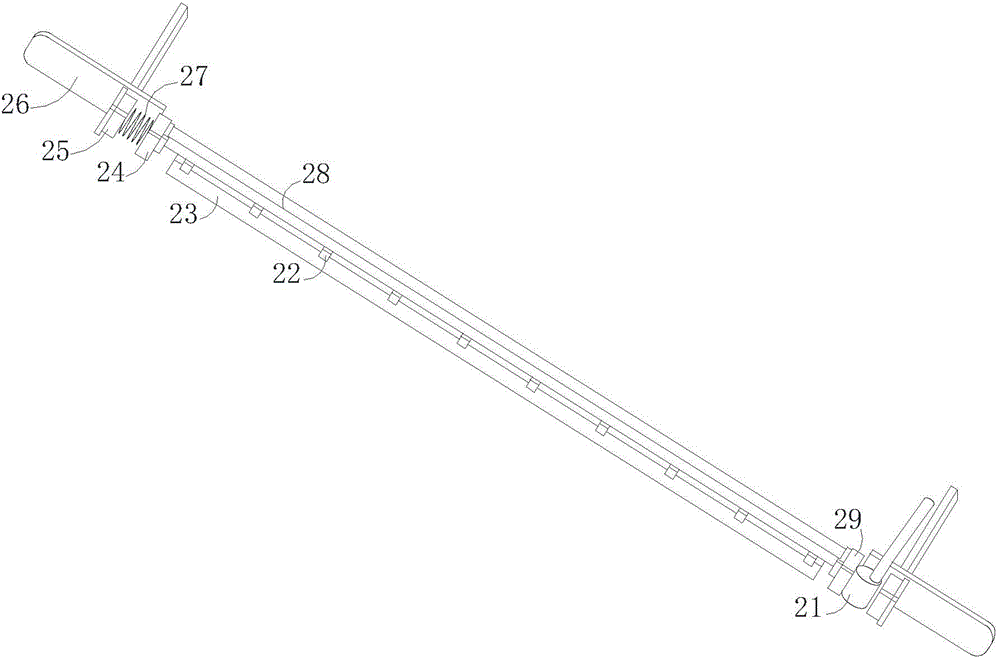

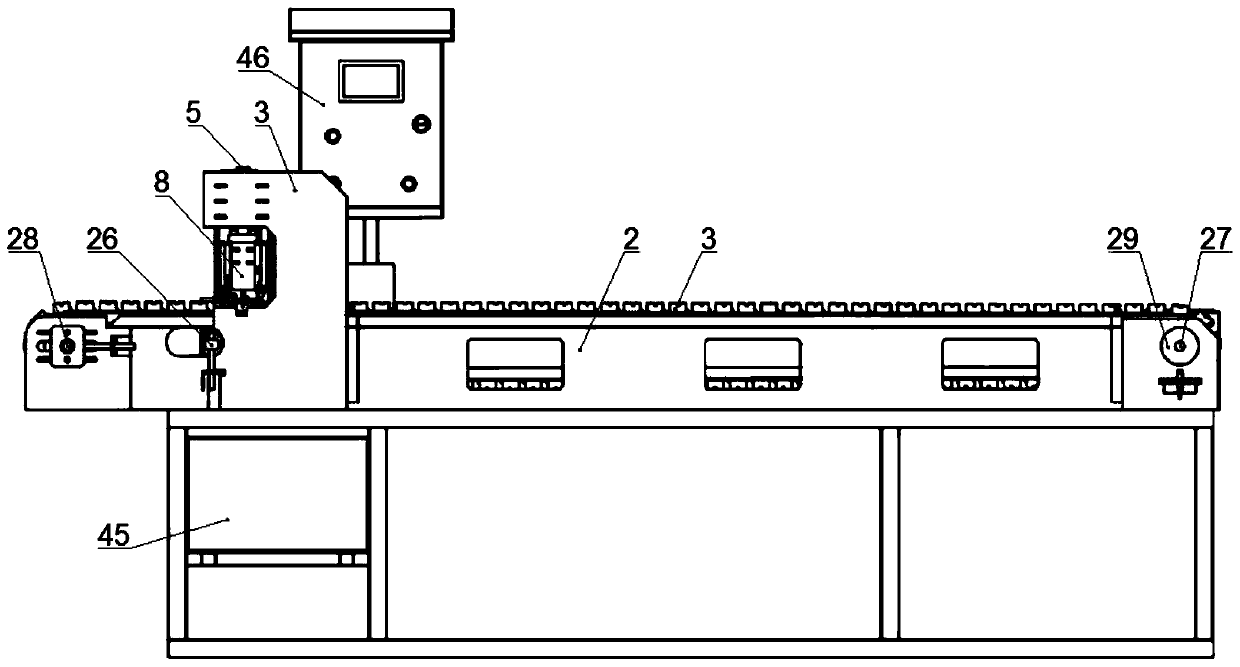

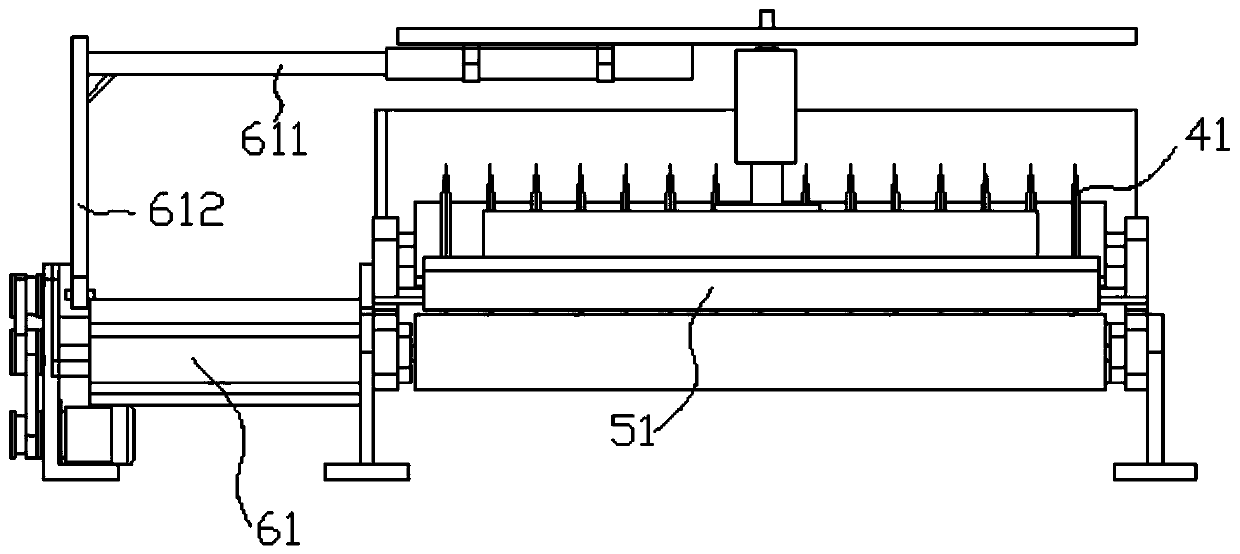

Full-automatic skewer penetrating machine

ActiveCN105360267AImprove the accuracy of labelingIncrease productivityPutting meat on skewersElectric machineryDrive motor

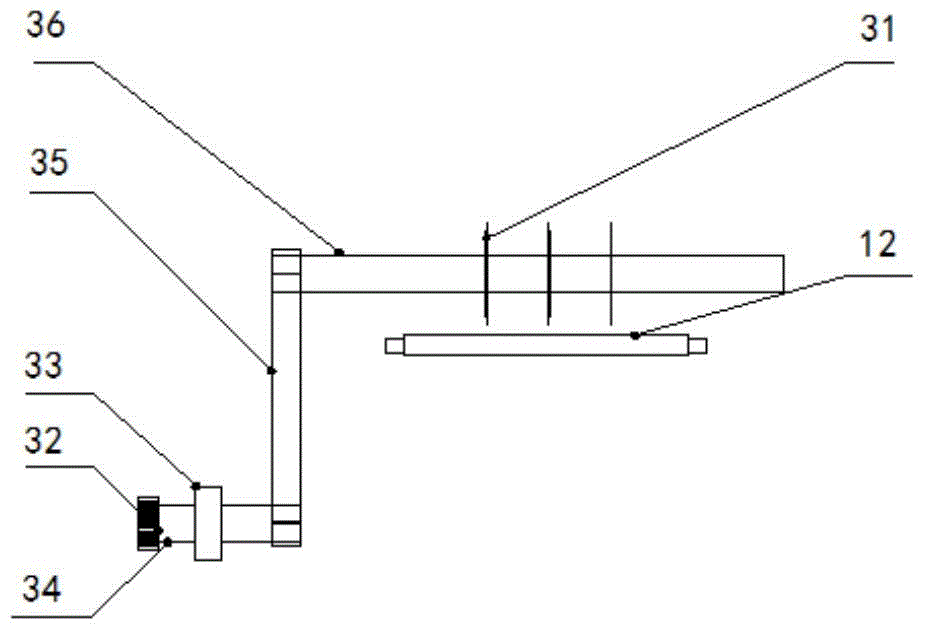

The invention discloses a full-automatic skewer penetrating machine comprising a machine frame and a material conveying device, a material fixing device, a skewer distribution device, a skewer pushing device and a driving motor which are arranged on the machine frame. The material conveying device is provided with a material conveying belt. The material fixing device comprises a material fixing conveying belt and a height adjusting mechanism. The skewer distribution device comprises a skewer distributor and a skewer conveying belt. The skewer pushing device comprises a plurality of pushing rods, sliding rods, sliding rails and a first transmission chain. The driving motor is in synchronous driving connection with the first transmission chain, the skewer conveying belt and the material conveying belt in sequence through a first connecting rod and a second connecting rod. The skewer pushing device, the skewer distribution device, the material fixing device and the material conveying device are in synchronous driving connection, it is ensured that meat pieces and skewers synchronously move on the same straight line all the time, the skewer penetrating accuracy is improved, the skewer breakage phenomenon caused in the skewer penetrating process is avoided, and production efficiency is improved to a large extent.

Owner:青岛国易食品科技有限公司

Novel full-electric stringing machine

The invention relates to the technical field of stringing machines, in particular to a novel full-electric stringing machine which comprises a framework. A conveyor belt is arranged on the framework and can be driven by a first motor, a lower mold is fixedly arranged on the conveyor belt and comprises a plurality of groups of material grooves, a bamboo stick groove is formed in a side of each material groove, the quantity of the bamboo stick grooves is identical to that of the material grooves, the bamboo stick grooves are communicated with the material grooves, a bamboo stick mechanism is arranged above the bamboo stick grooves, a motor base and an upper mold base are arranged on the framework, a second motor is arranged on the motor base and is connected with a cam, a connecting rod is connected with a side of the cam and is connected with a stick pushing mechanism, a pressure rod is arranged above the cam, an upper mold plate is fixedly arranged on the upper mold base, sleeves are arranged on the upper mold plate, elastic components are arranged in the sleeves, the tops of guide rods are butted to the elastic components, an upper mold pressure plate is connected with the lower ends of the guide rods, an upper mold is fixedly connected with the bottom surface of the upper mold pressure plate, and the pressure rod is rotationally connected to a side surface of the upper mold base. The novel full-electric stringing machine has the advantages that the novel full-electric stringing machine is fully electrically driven by the motors instead of cylinders, sensors can be completely replaced by mechanical structures, and accordingly the failure rate of the novel full-electric stringing machine can be reduced to a great extent.

Owner:CLOUDFOCUS DONGGUAN AUTOMATION EQUIP CO LTD

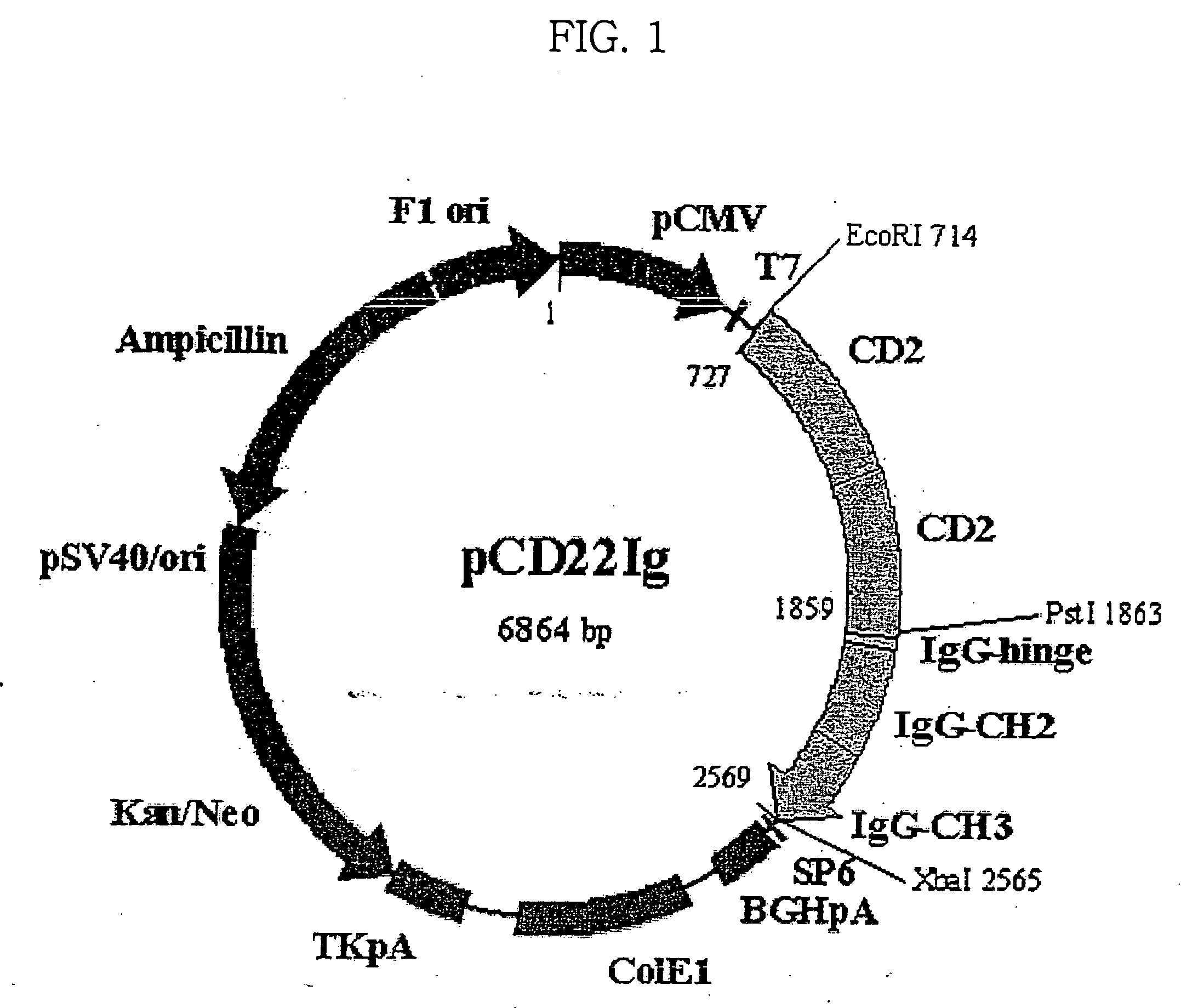

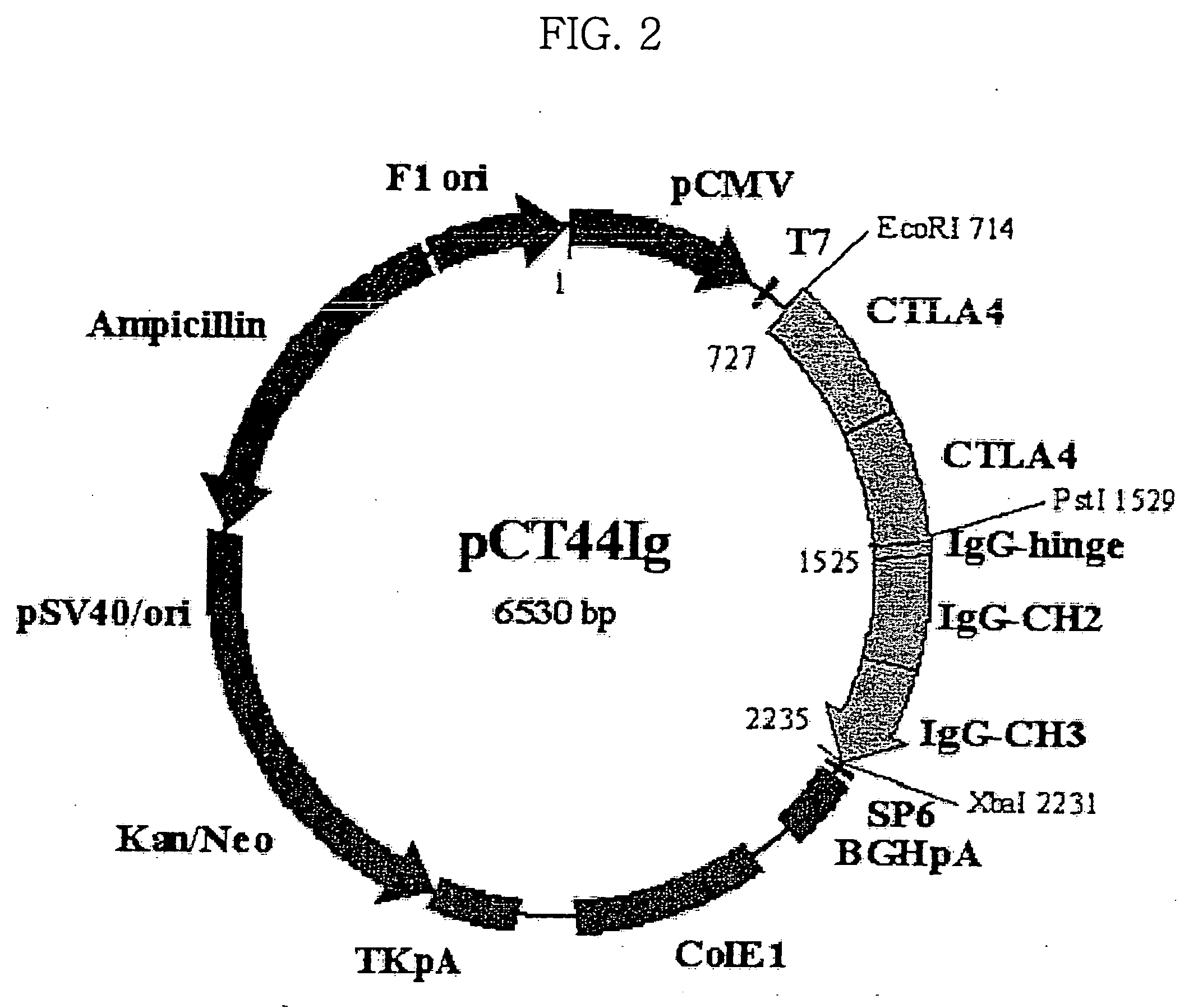

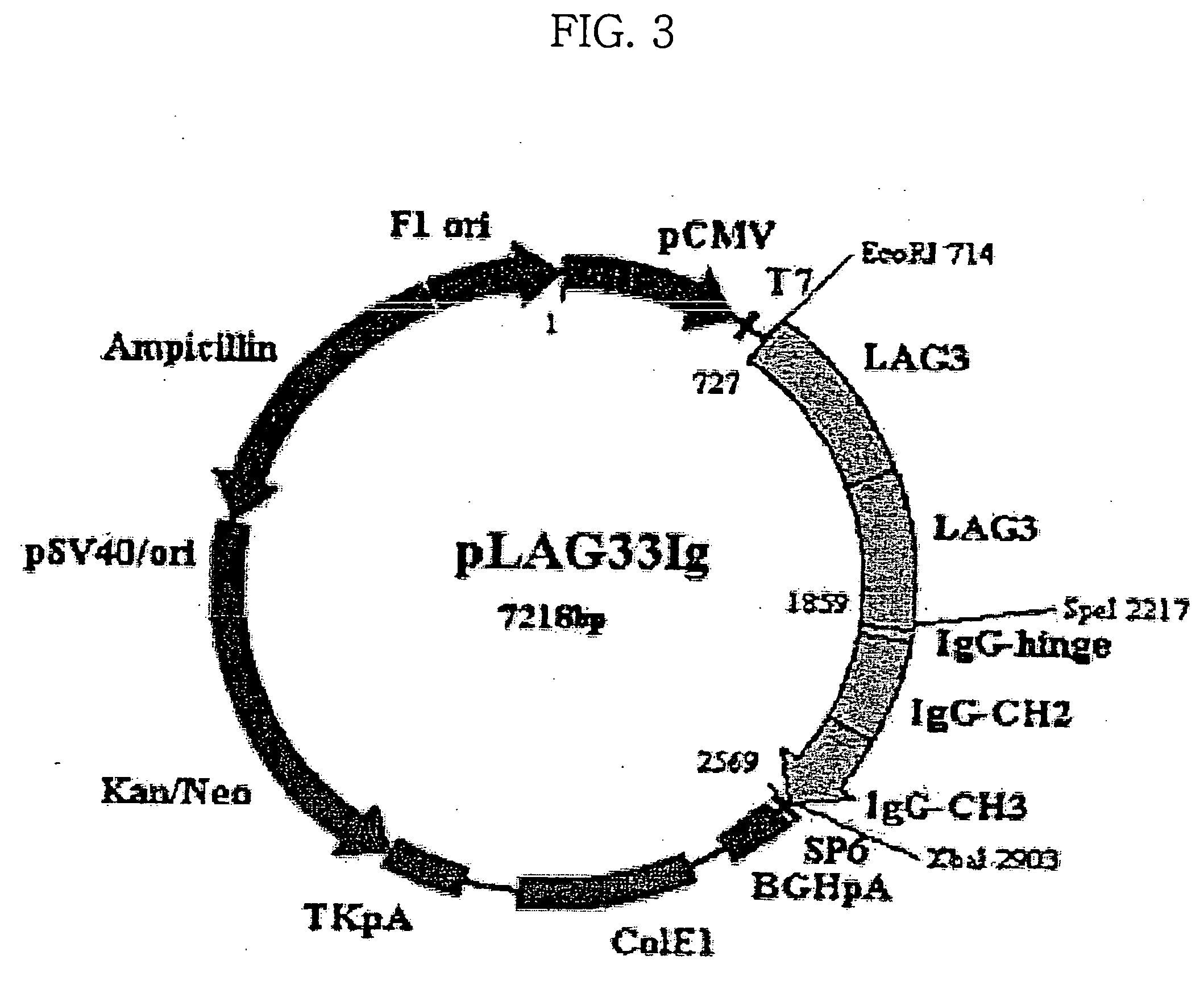

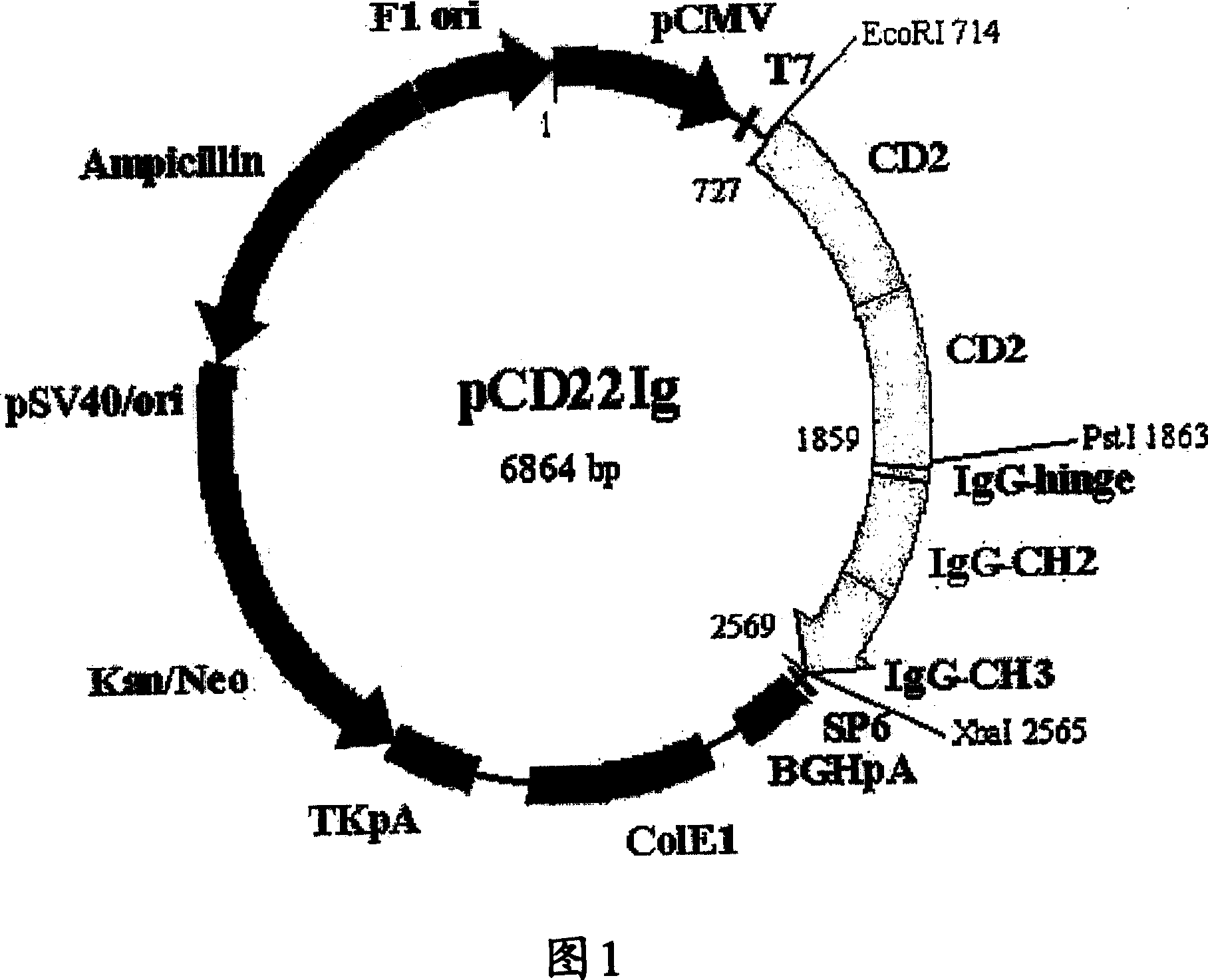

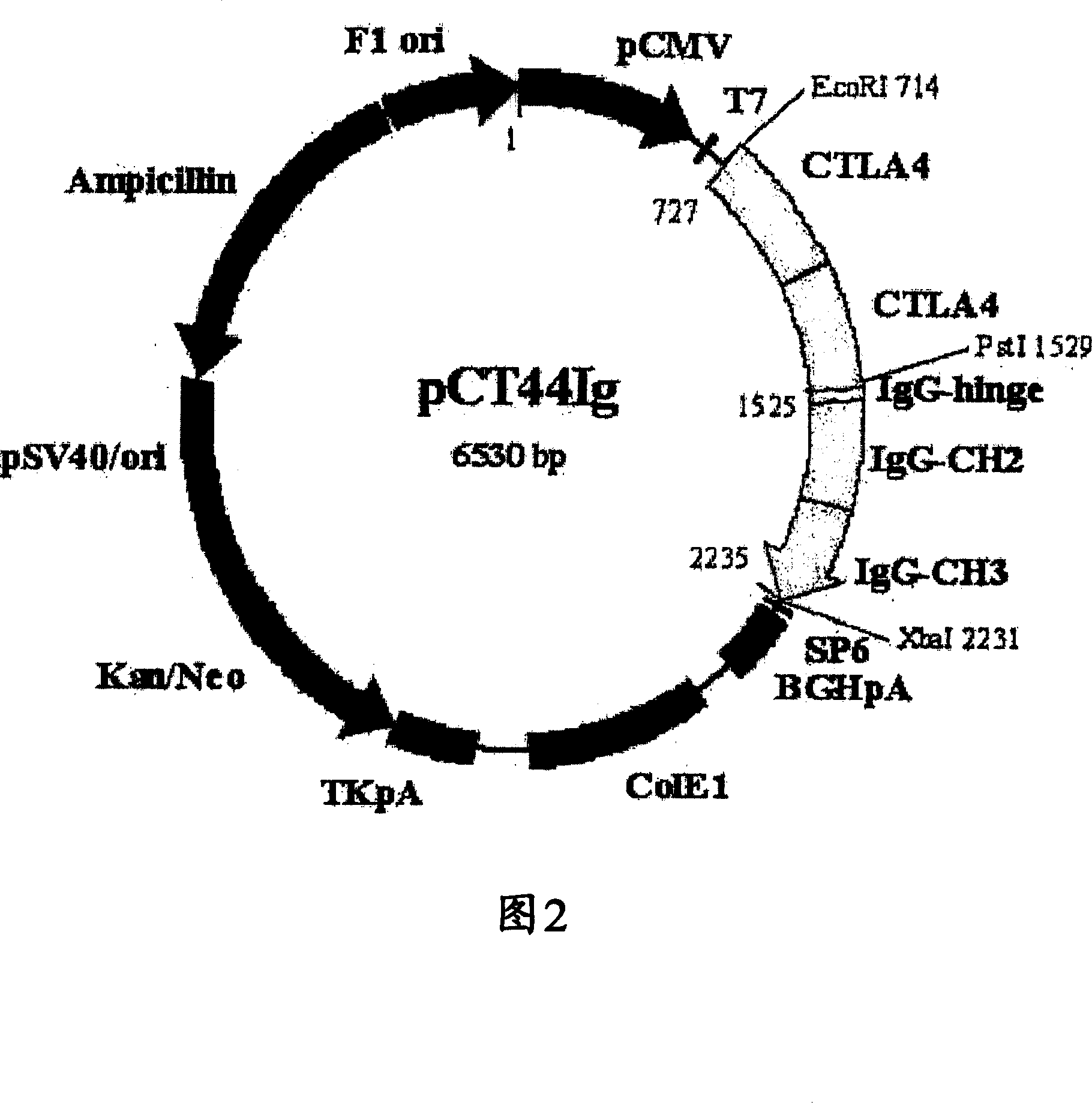

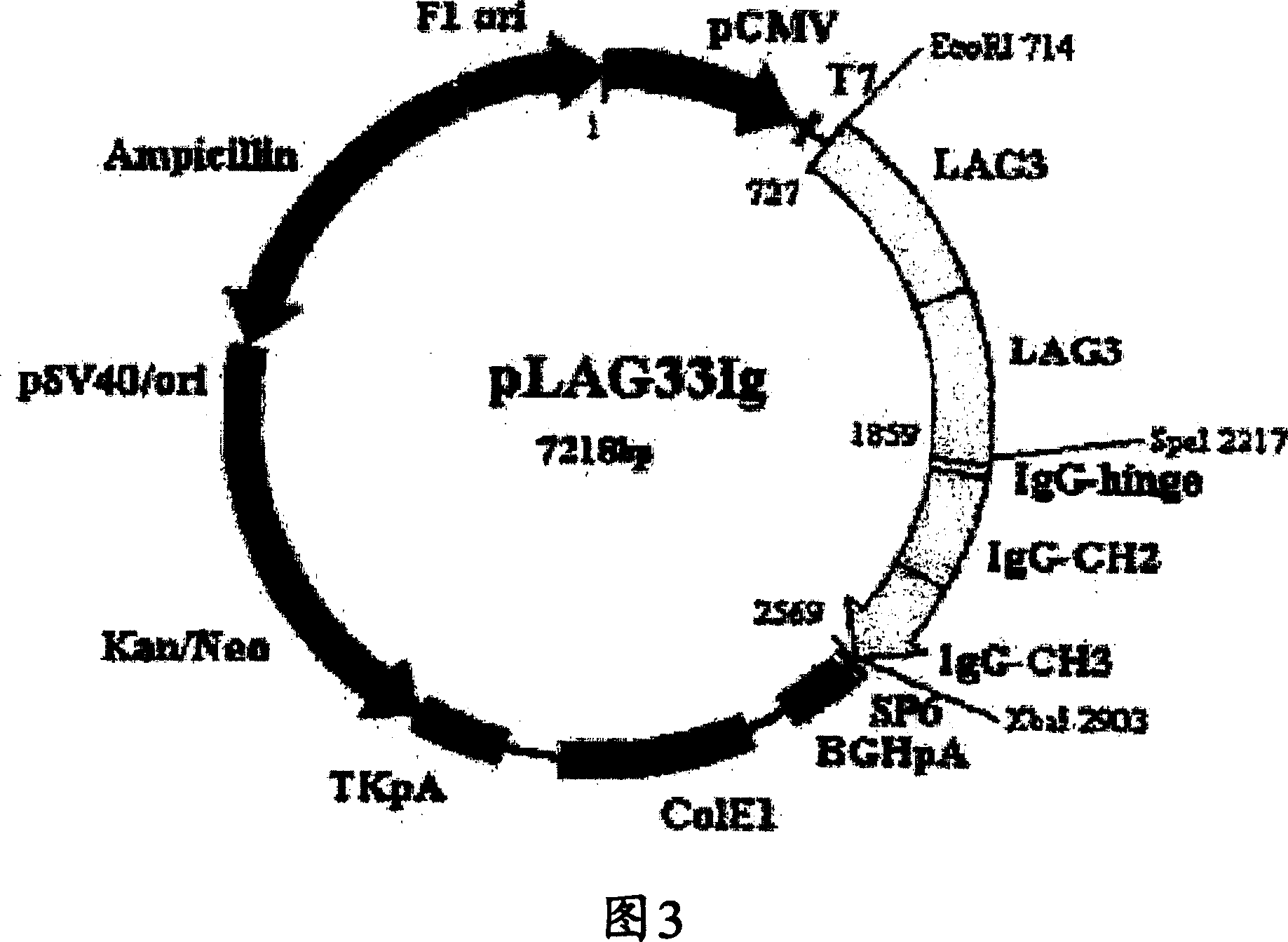

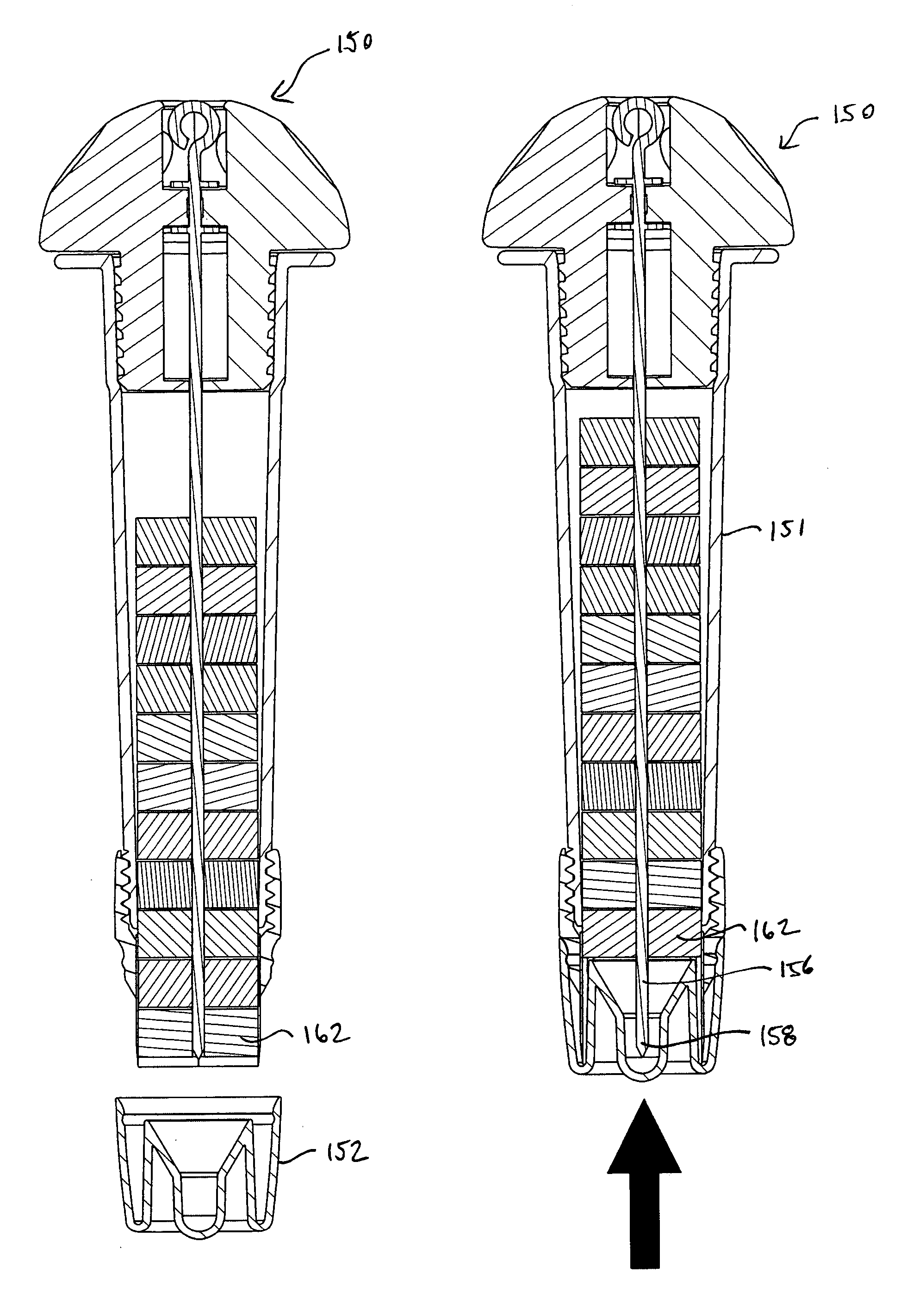

Pharmaceutical composition for treatment of immunological disorders

InactiveUS20070110746A1Inhibition of activationSenses disorderNervous disorderDiseaseMajor histocompatibility

Disclosed is a pharmaceutical composition for treating immunological disorders by inhibiting the activation of T lymphocytes, comprising, as active ingredients, two or more selected from the group consisting of a substance capable of blocking binding of an MHC (Major Histocompatibility Complex) Class II molecule and a receptor thereof, a substance capable of blocking binding of a costimulatory molecule and a receptor thereof, a substance capable of blocking binding of an adhesion molecule and a receptor thereof, and a substance capable of blocking binding of a cytokine and a receptor thereof.

Owner:MEDEXGEN

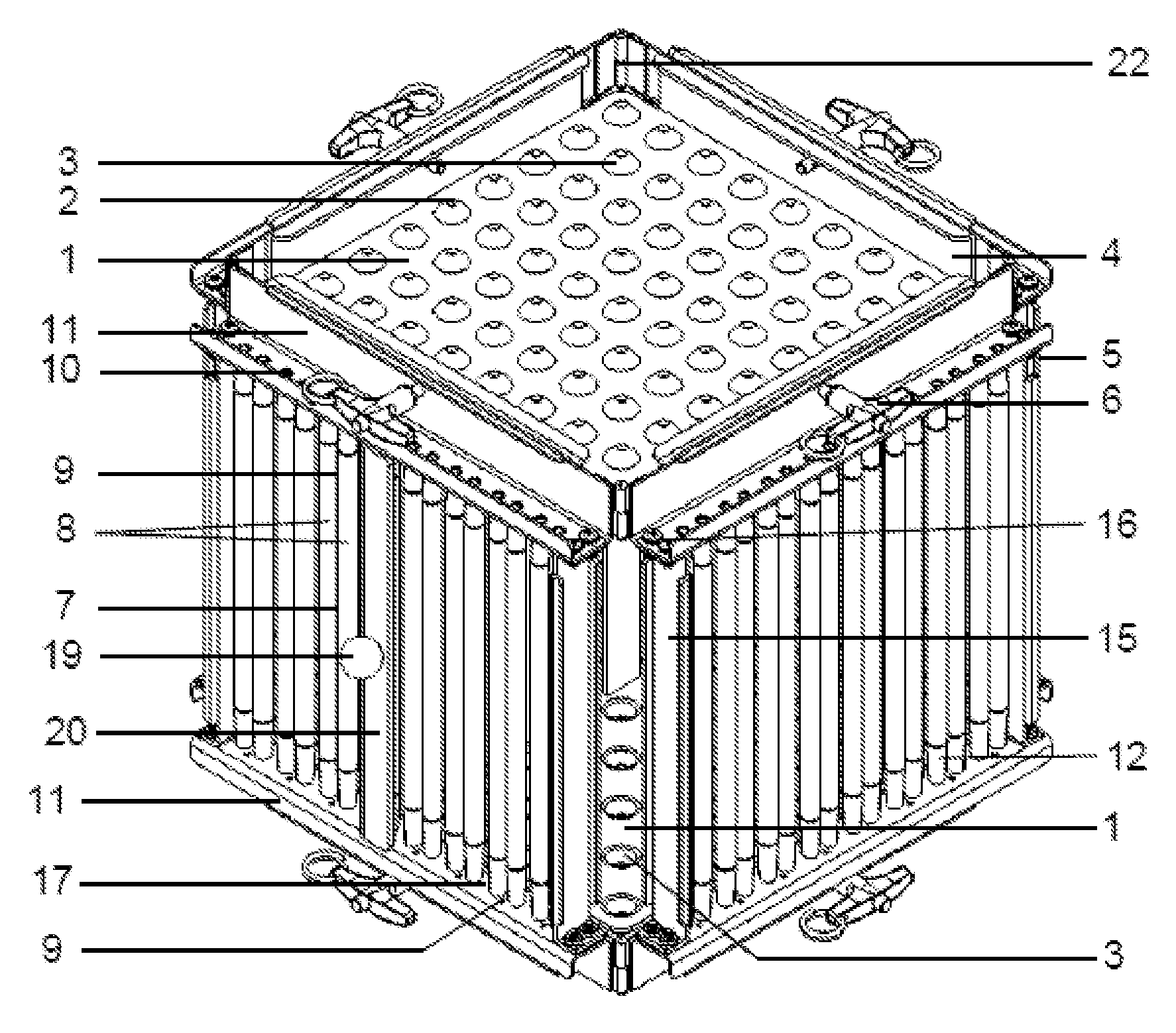

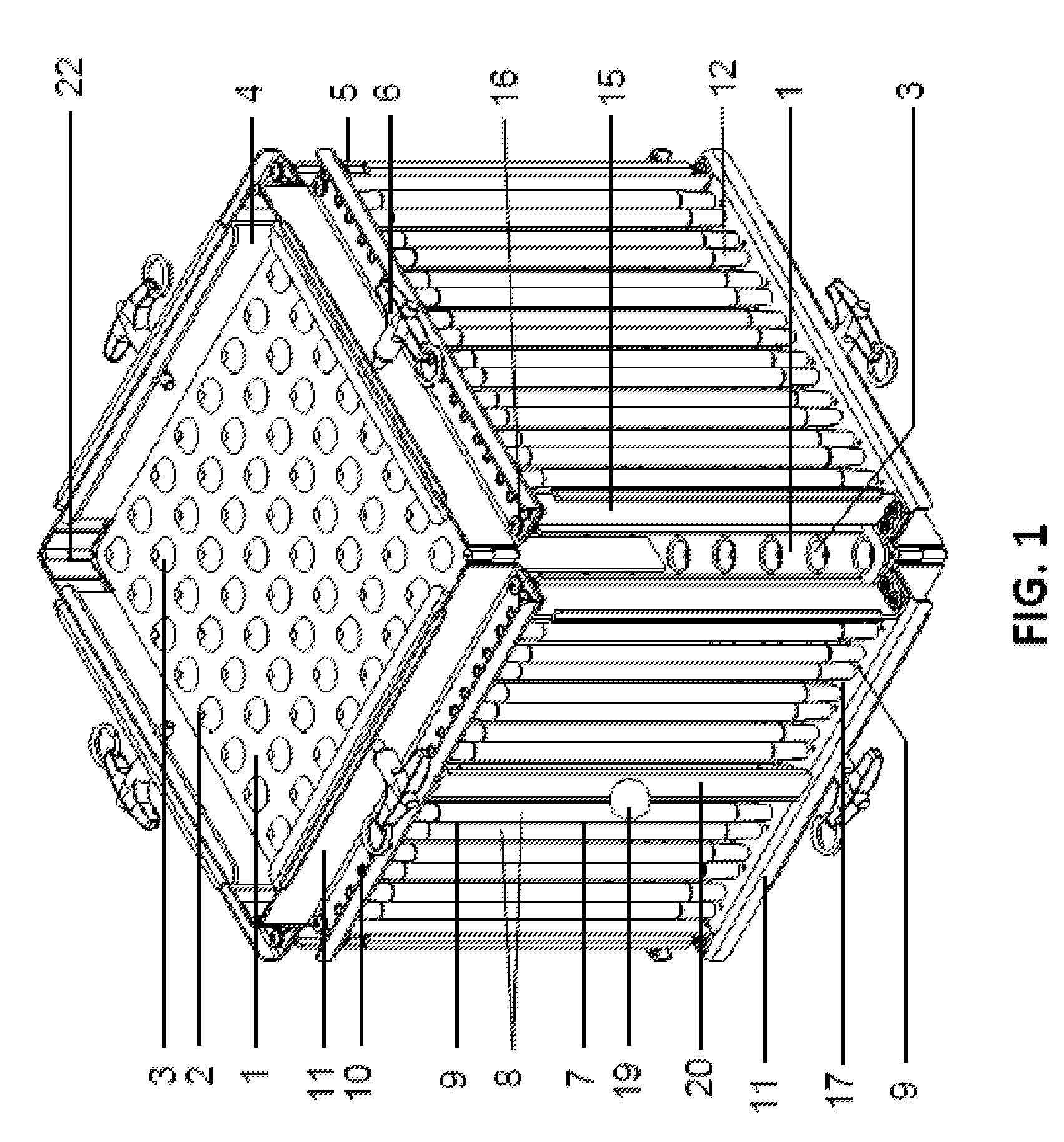

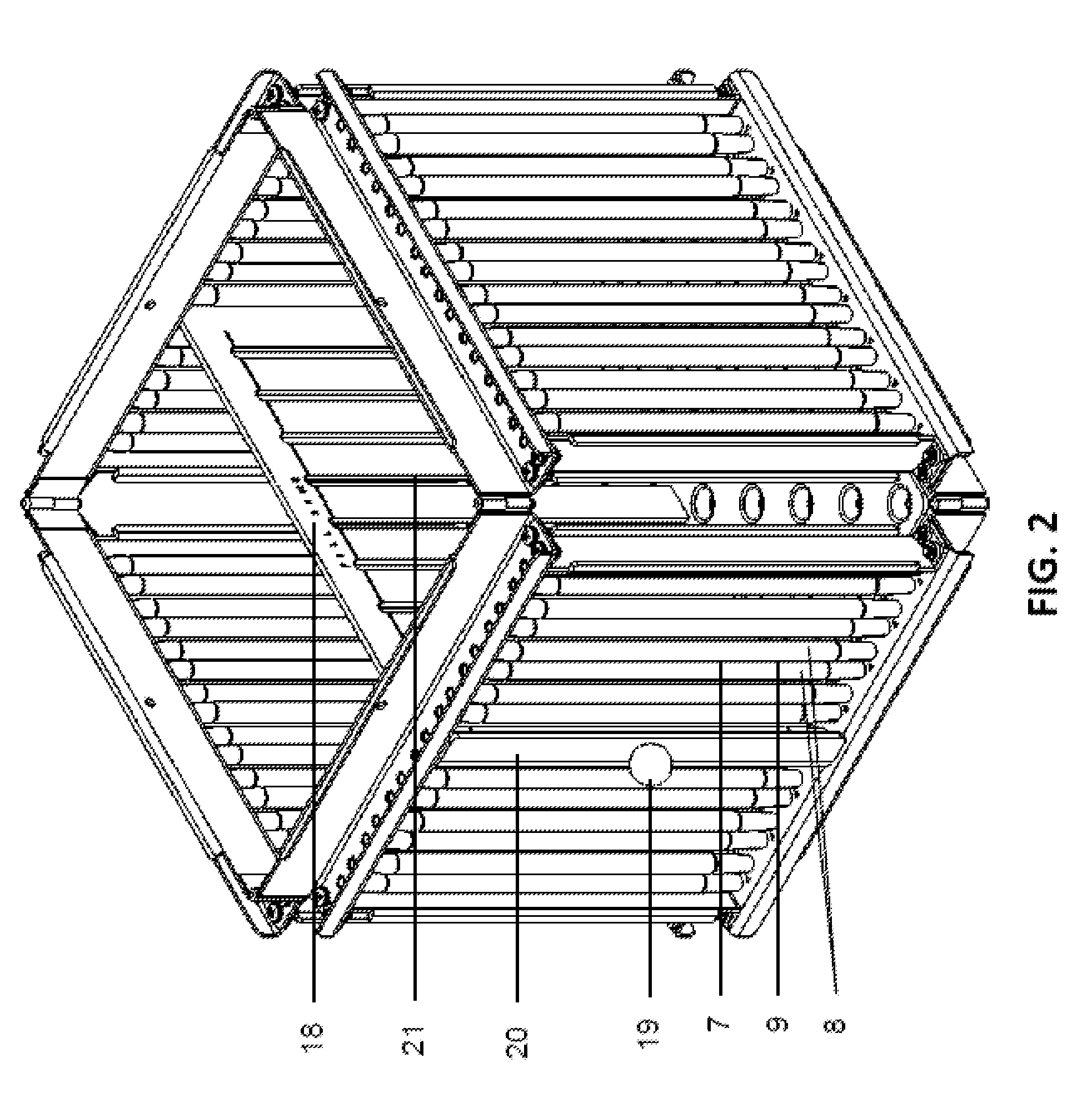

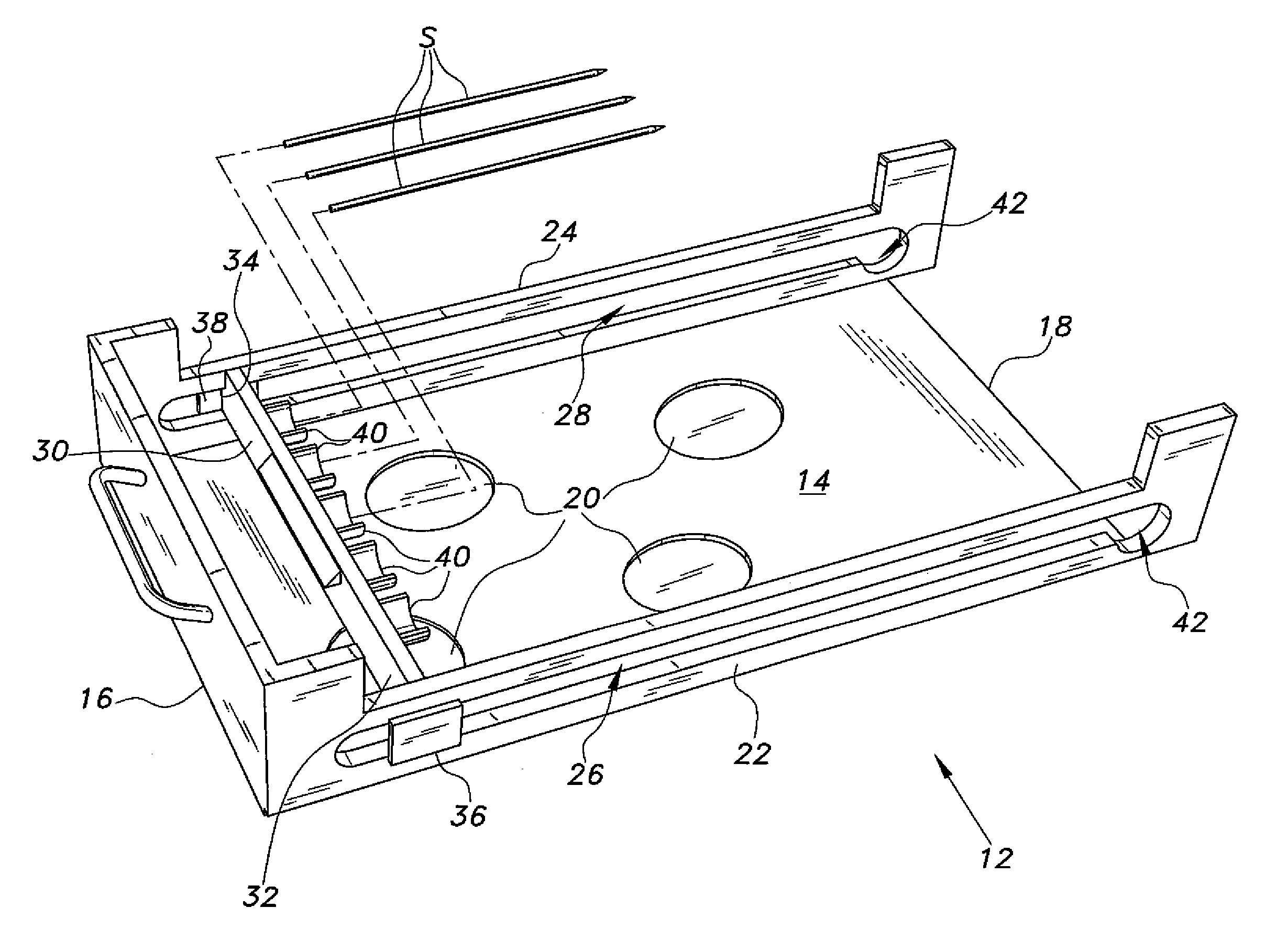

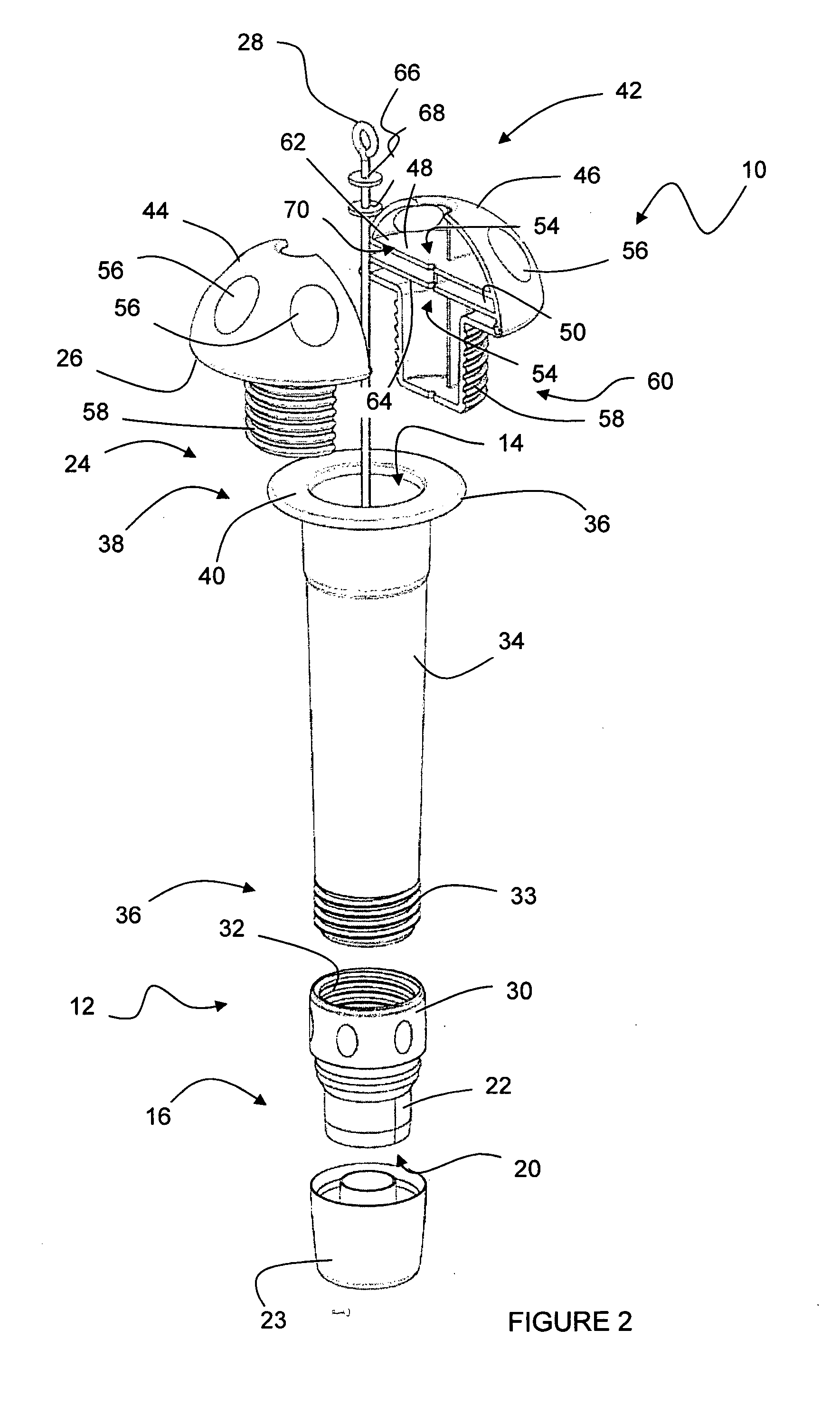

Meat cubing and skewering device

InactiveUS20120279371A1Easy to cleanLow volume storageCross-cut reciprocating sawsMetal working apparatusEngineeringCutting guide

This meat cubing and skewering device utilizes a low friction guide system along two axes to facilitate the cutting of meat slabs into cubes for the purpose of making shish kebobs or Souvlaki. The device also provides for a means of skewering the cubes using an array of dimpled apertures in equivalent top and bottom plates that minimizes the multiple skewer interference that can occur at the bottom of such devices. The four vertical sides are made up of a series of paired elongated rods or rollers that serve as cutting guides and these four vertical sides are hinged in such a way as to keep them all together and yet fold flat for easy storage and cleaning within a dishwasher.

Owner:MULCHI JR CHARLES LEE +1

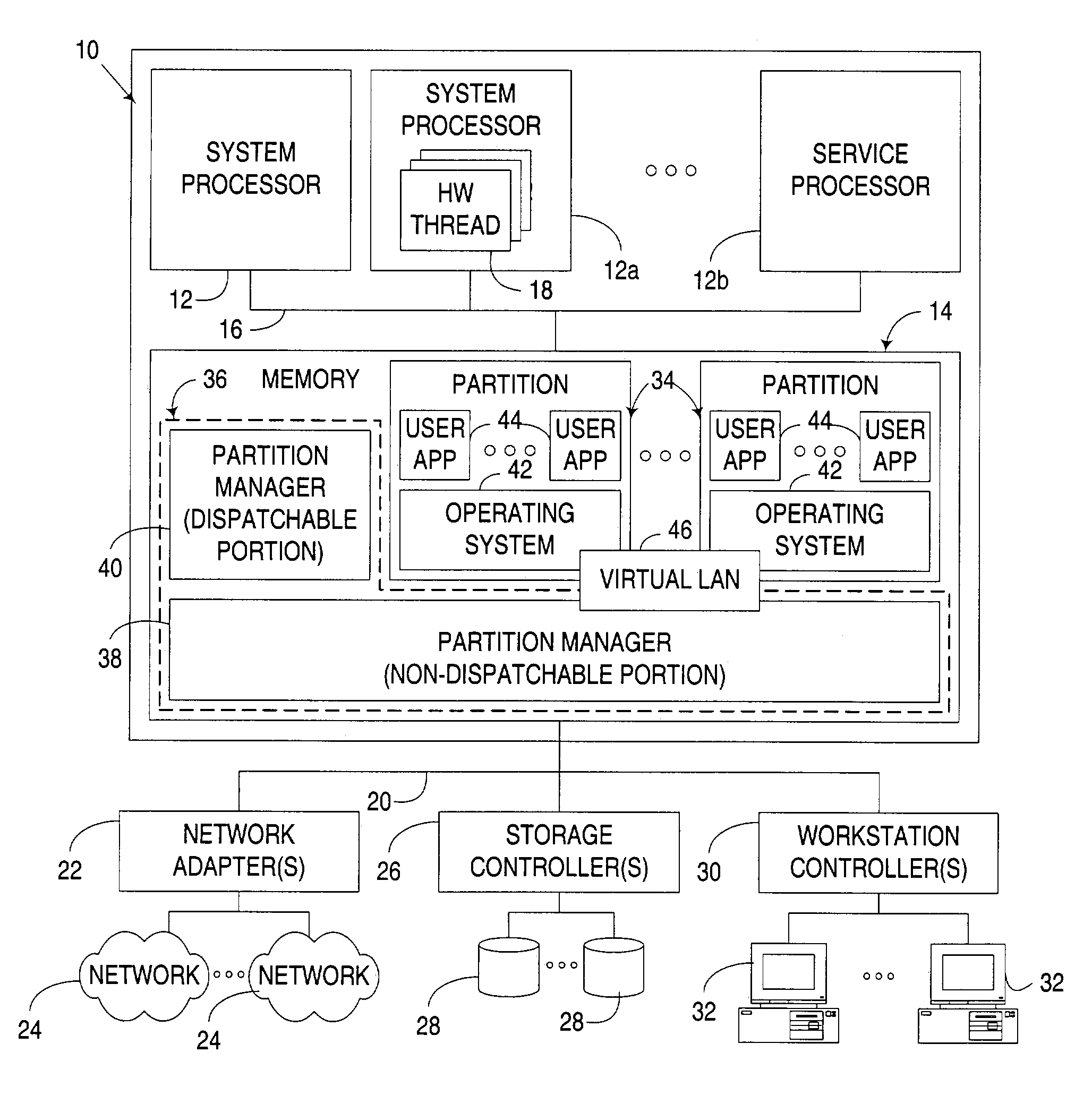

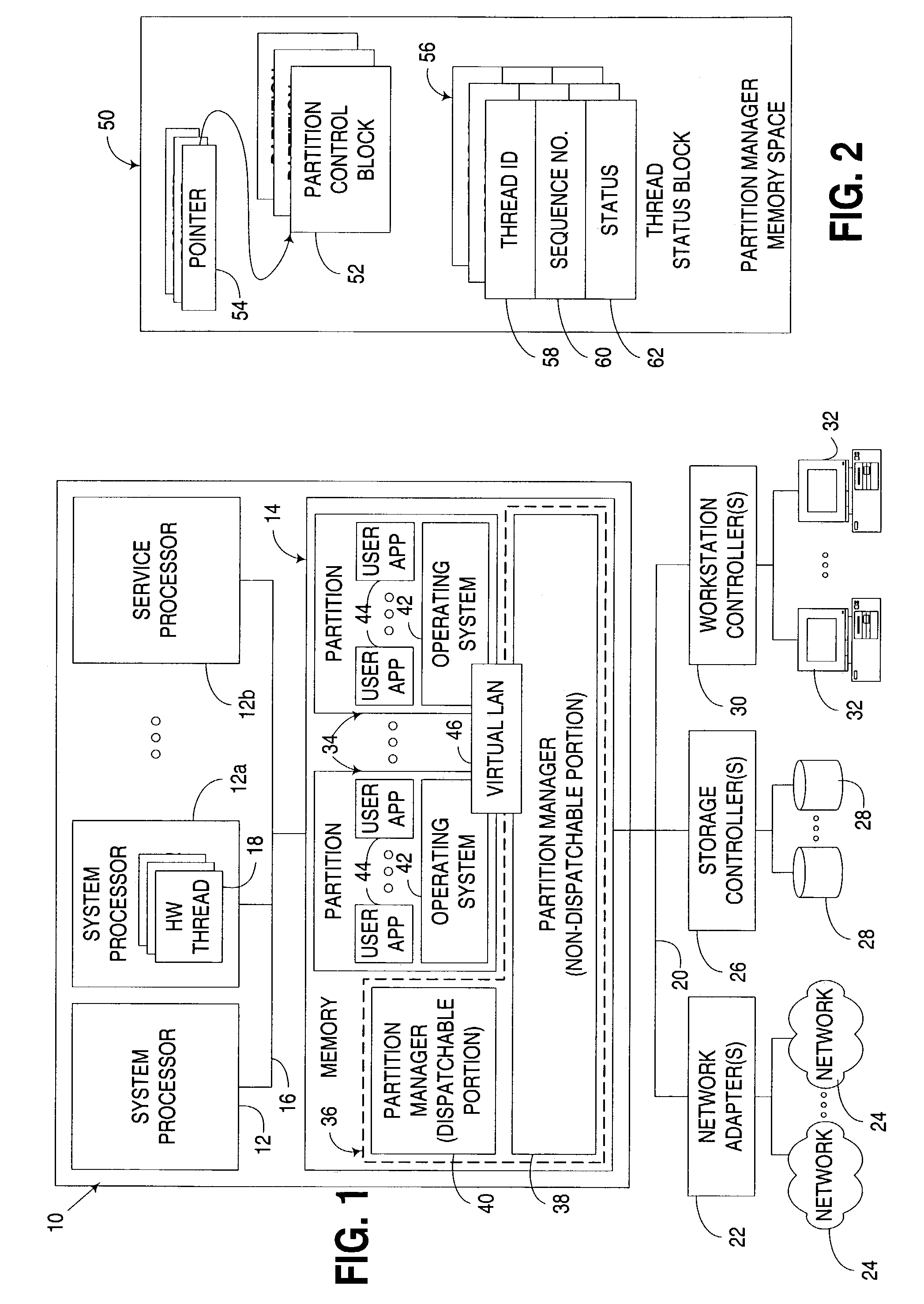

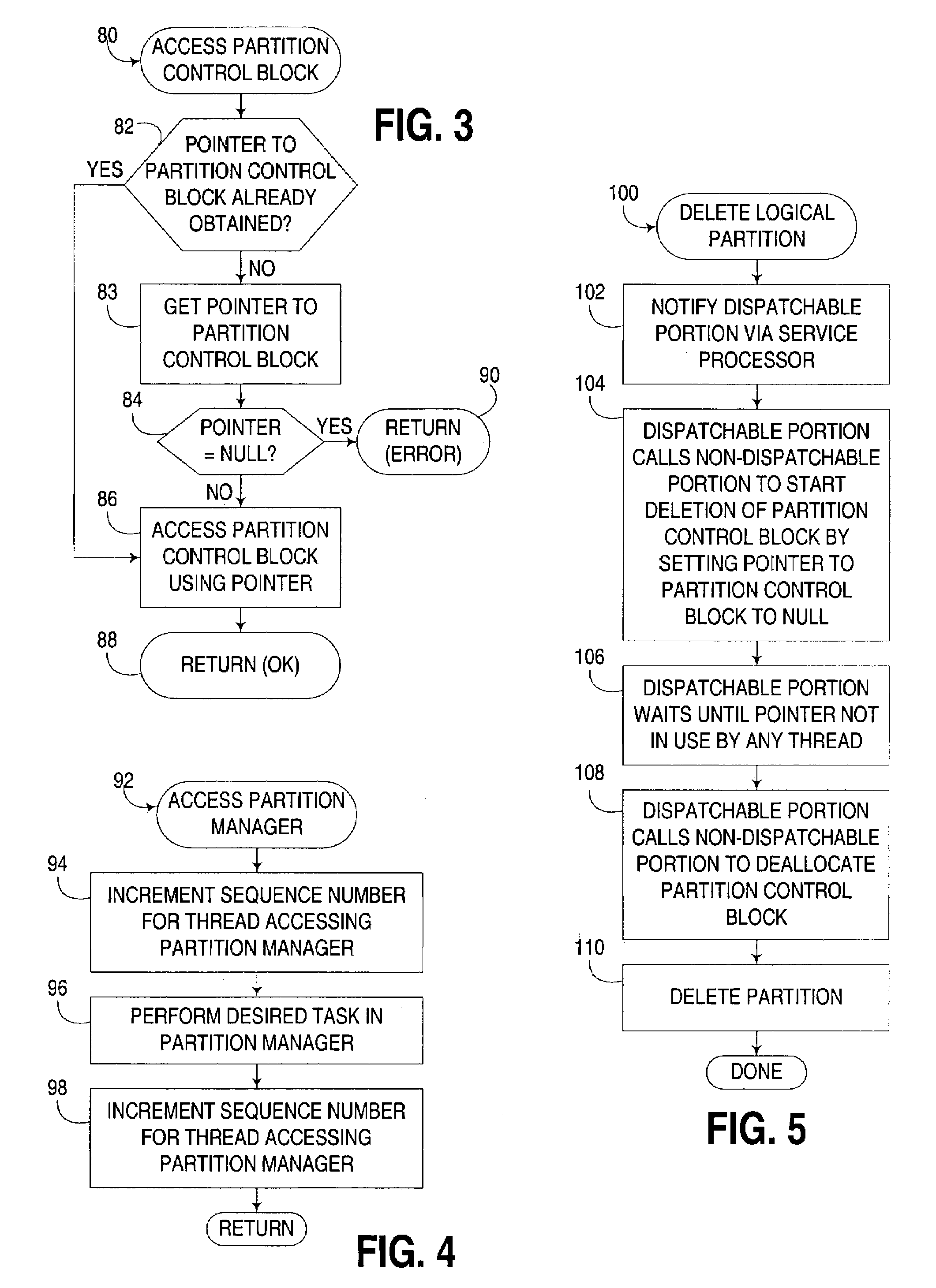

Deallocation of computer data in a multithreaded computer

ActiveUS7328438B2Faster access to dataReduce overheadData processing applicationsProgram synchronisationParallel computingSpin locks

An apparatus, program product and method support the deallocation of a data structure in a multithreaded computer without requiring the use of computationally expensive semaphores or spin locks. Specifically, access to a data structure is governed by a shared pointer that, when a request is received to deallocate the data structure, is initially set to a value that indicates to any thread that later accesses the pointer that the data structure is not available. In addition, to address any thread that already holds a copy of the shared pointer, and thus is capable of accessing the data structure via the shared pointer after the initiation of the request, all such threads are monitored to determine whether any thread is still using the shared pointer by determining whether any thread is executing program code that is capable of using the shared pointer to access the data structure. Once this condition is met, it is ensured that no thread can potentially access the data structure via the shared pointer, and as such, the data structure may then be deallocated.

Owner:META PLATFORMS INC

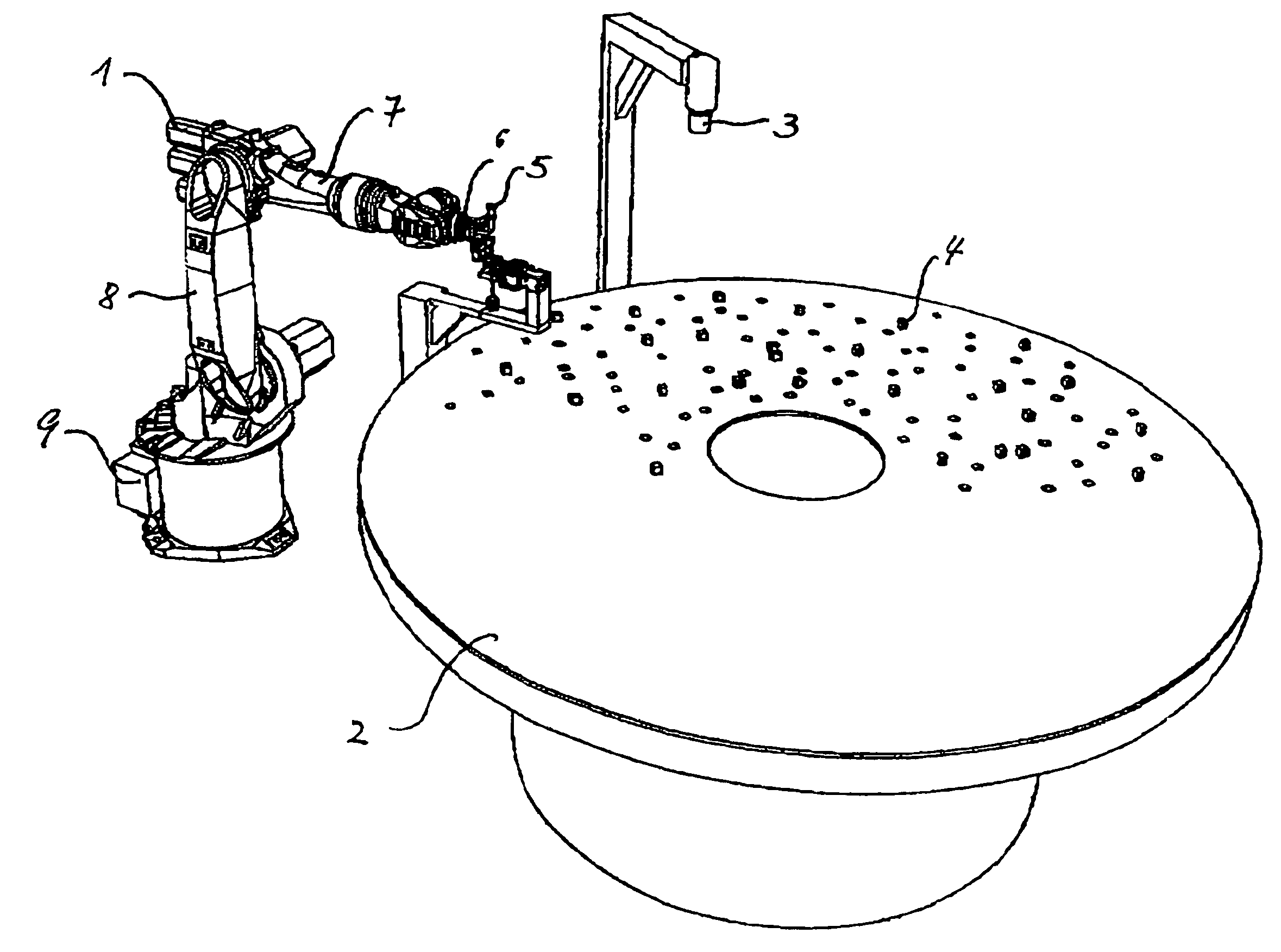

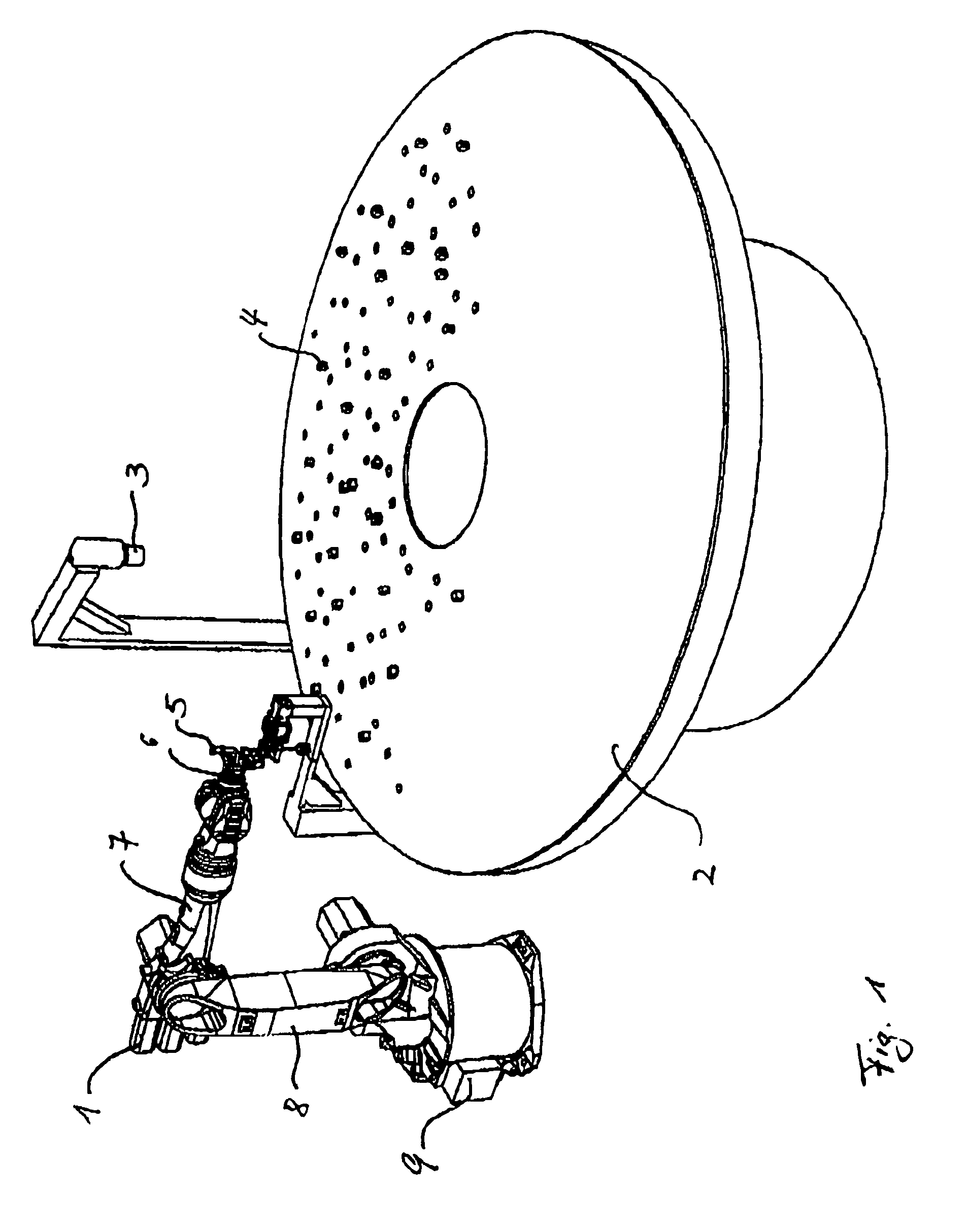

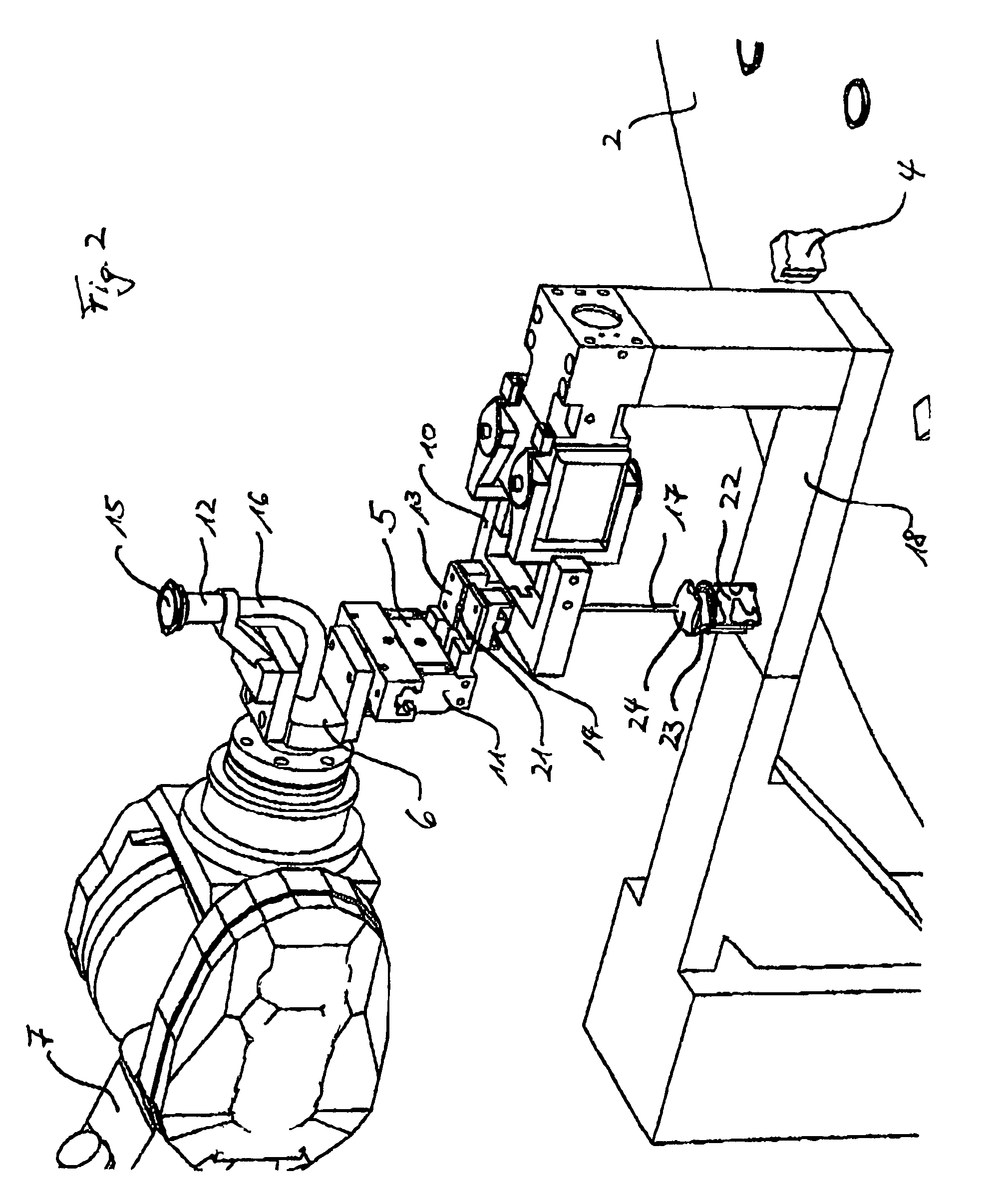

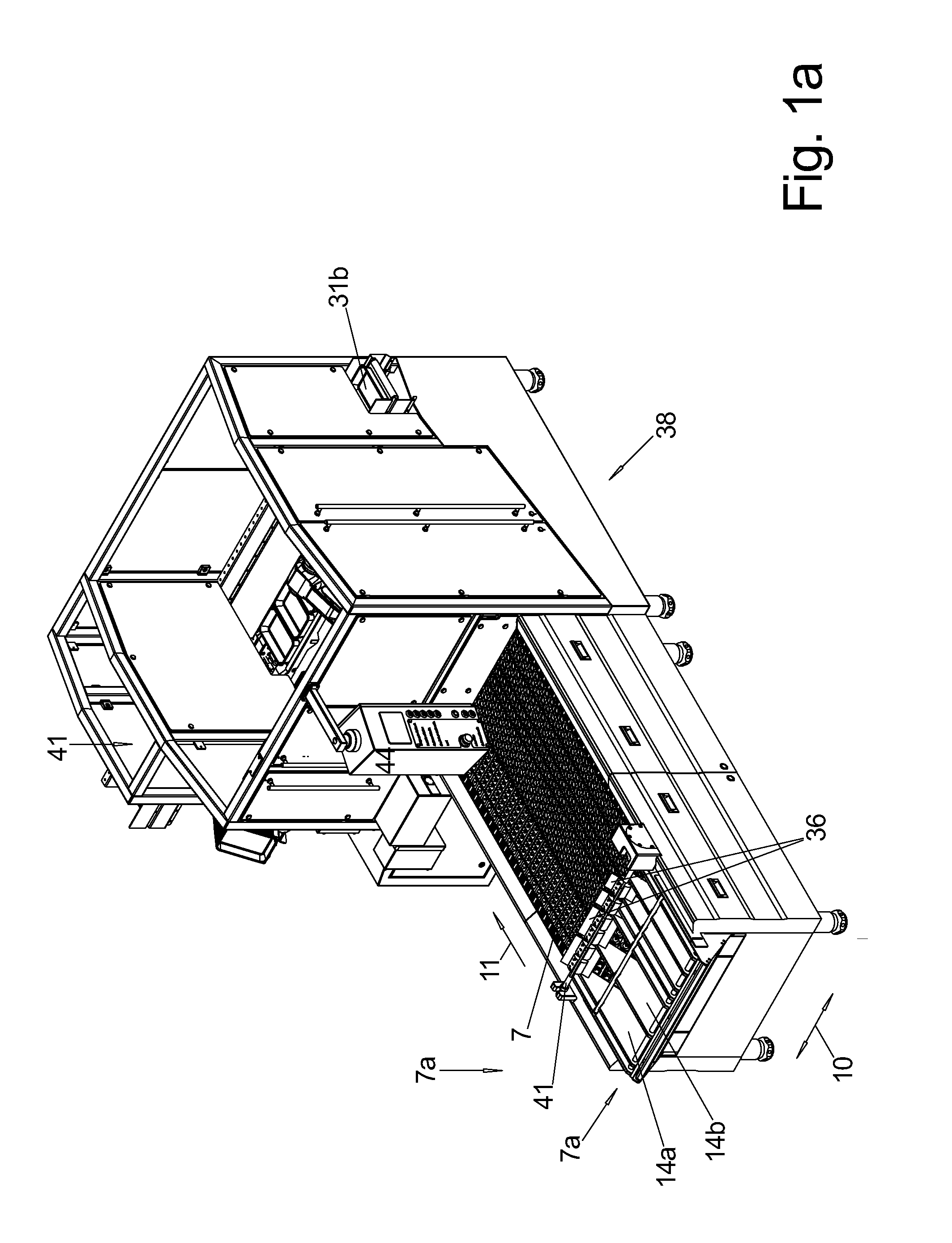

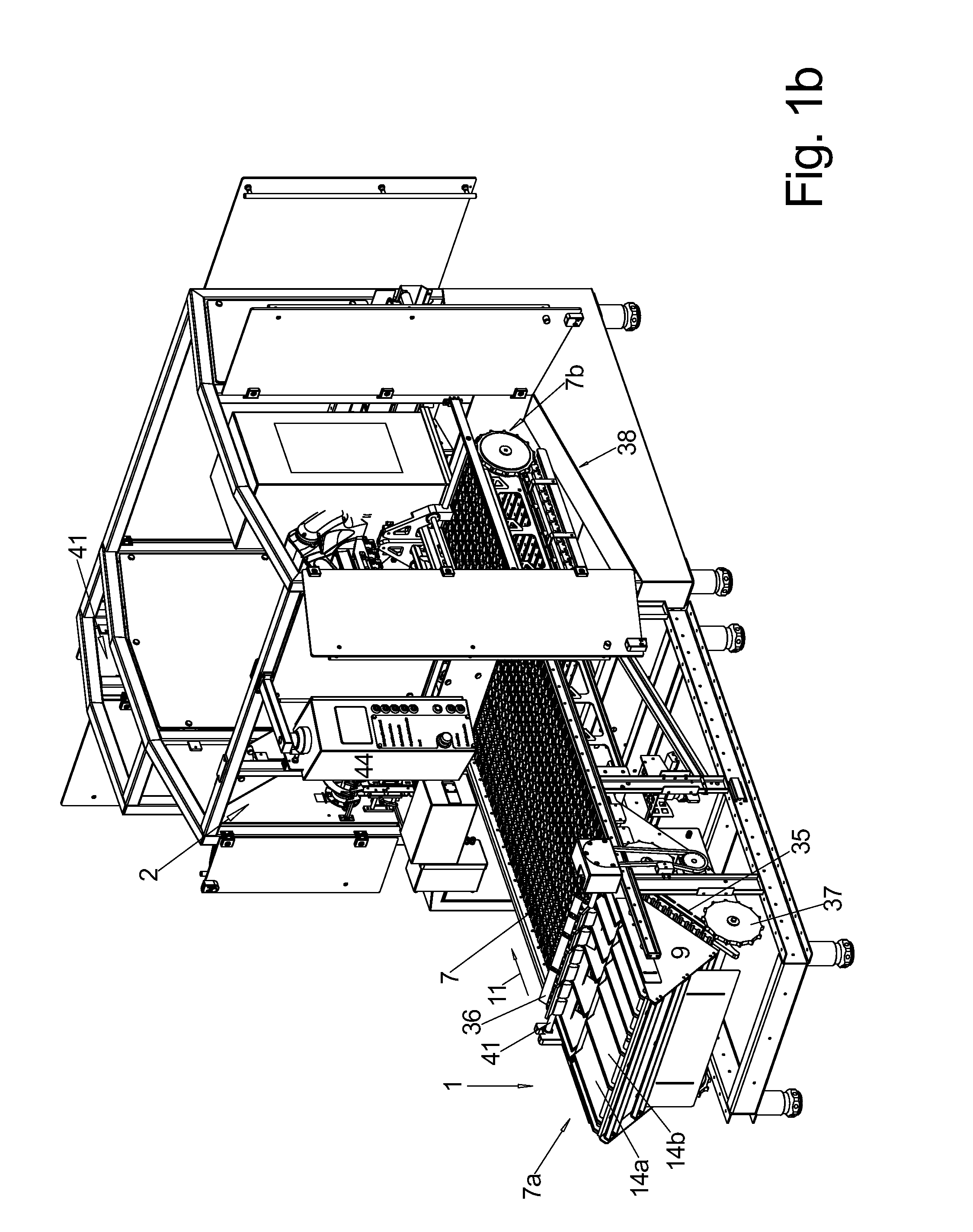

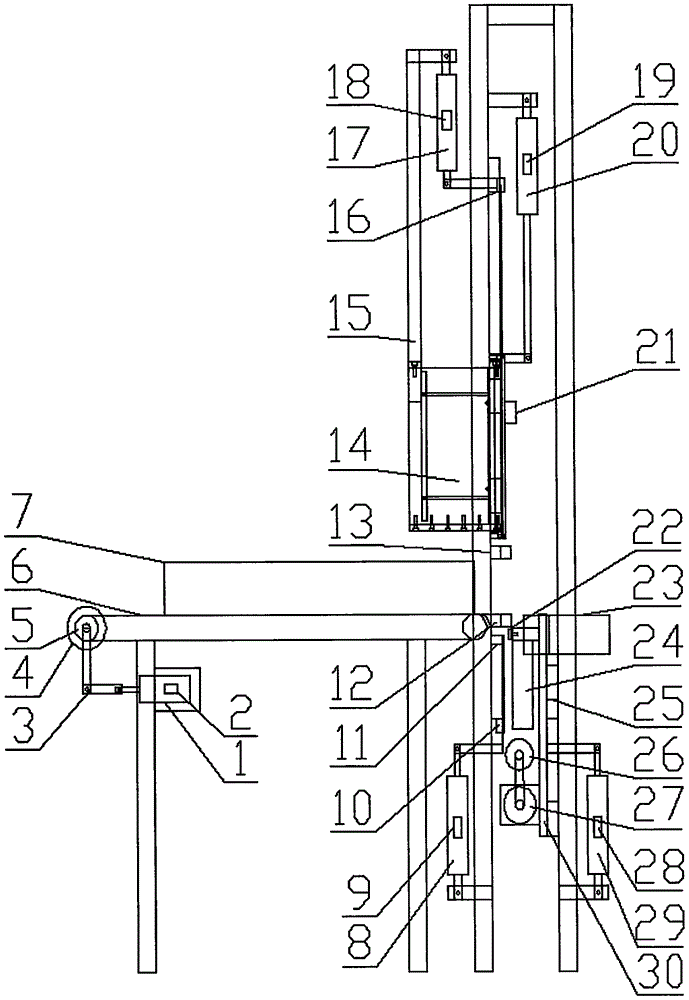

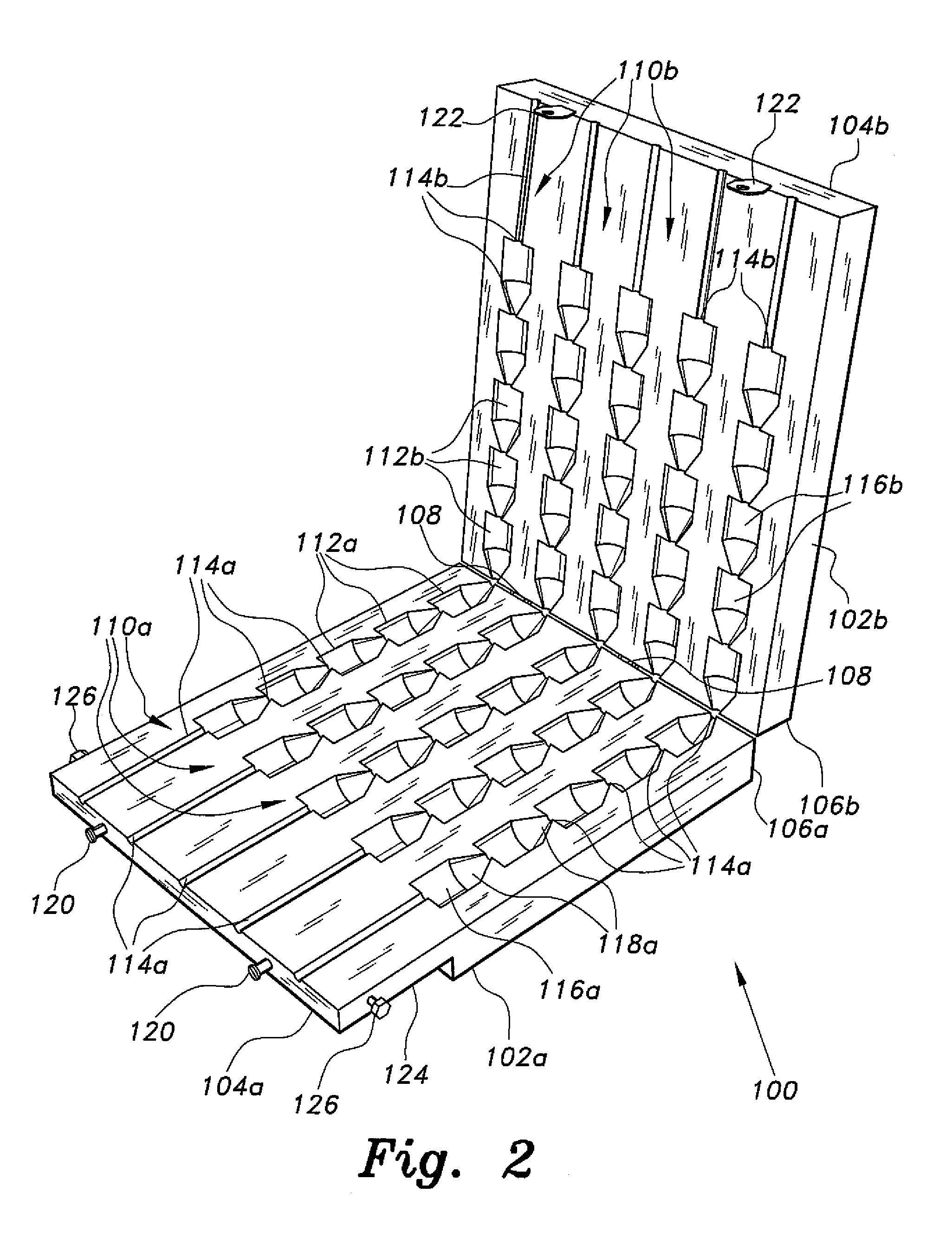

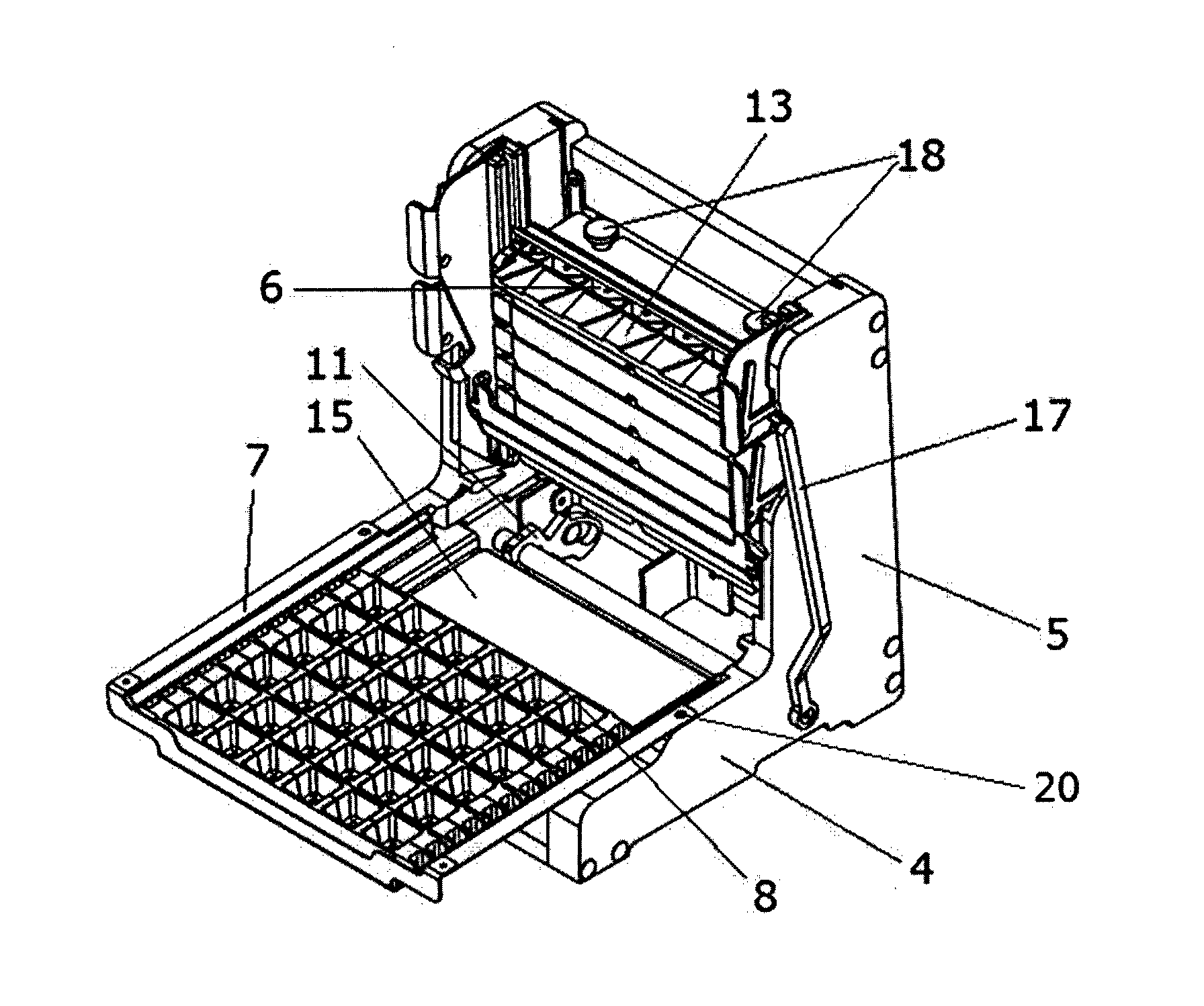

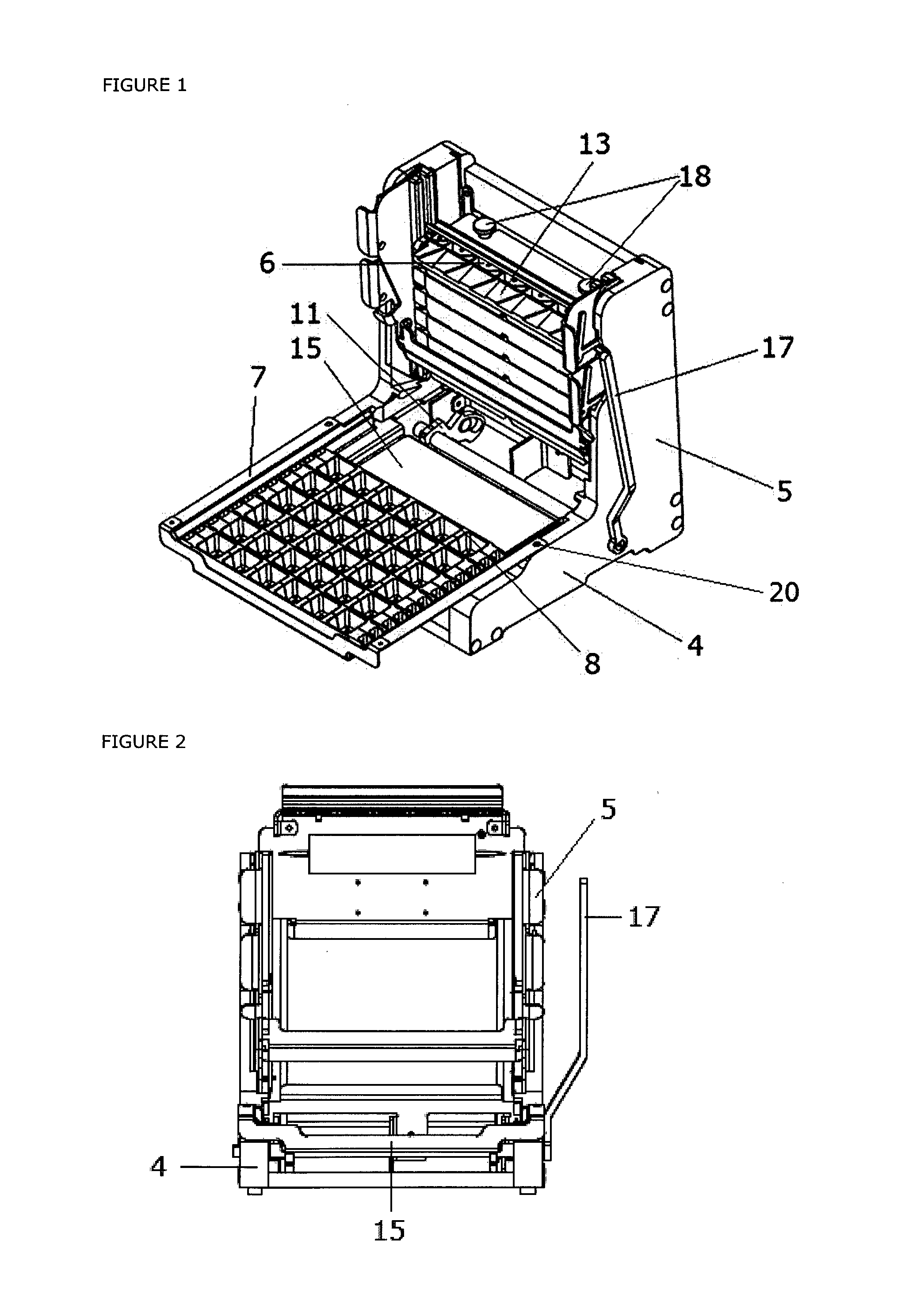

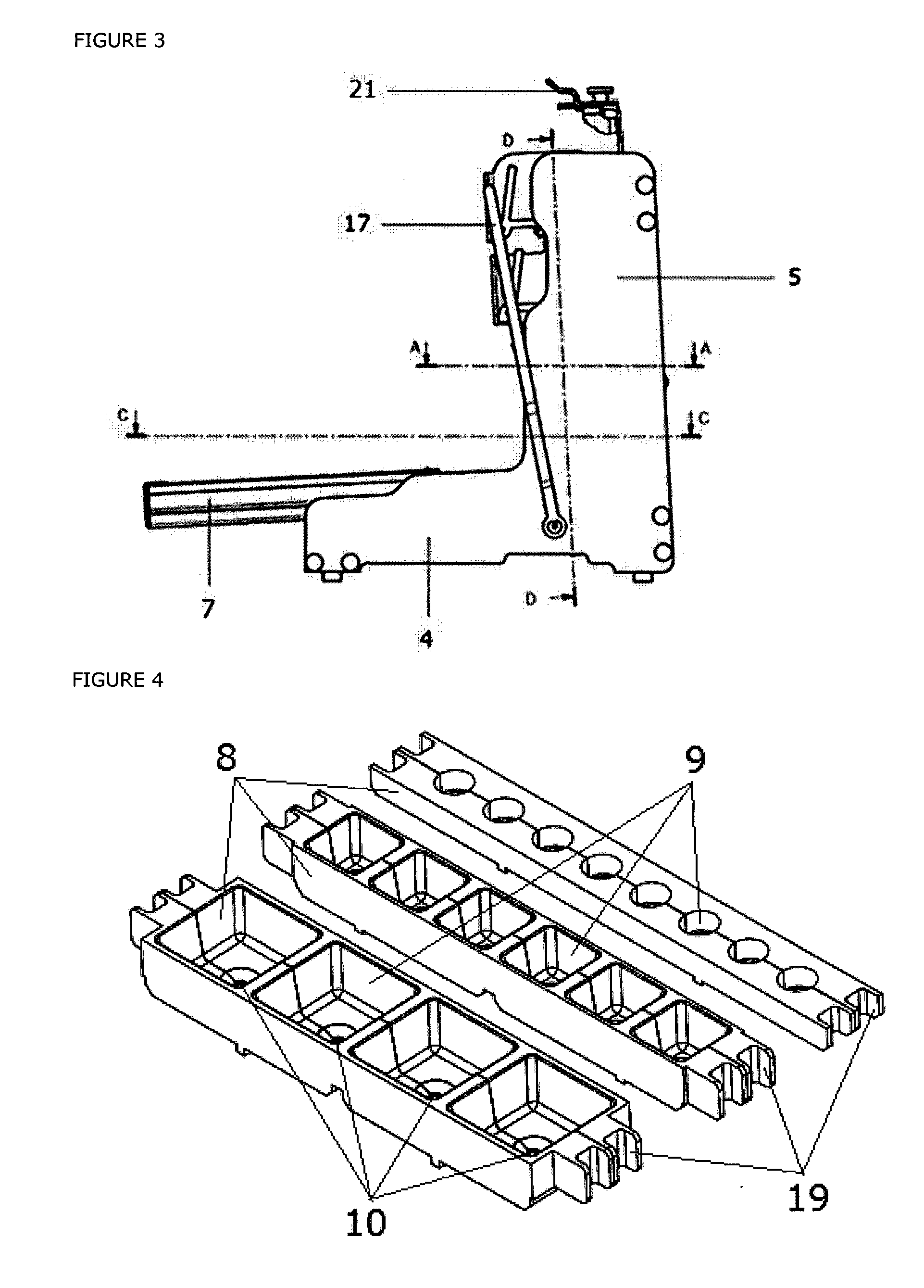

Device and method for preparing brochettes with picked-and-placed food

InactiveUS7476150B2Manual filling processGripping headsSlaughtering accessoriesAdditive ingredientEngineering

The invention proposes a device and method for the preparation of brochettes with picked-and-placed food consisting of a brochette (17) and one or more pieces of foodstuff (4). The brochette (17) is held by a brochette holder. The pieces of foodstuff (4) are picked up from a transport device (2) by ingredient grippers (5, 11, 12) and slipped onto the brochette (17) or placed in a mold, into which the brochette is subsequently introduced.

Owner:MAJA-MASCHINENFABRIK HERMAN SCHILL KG

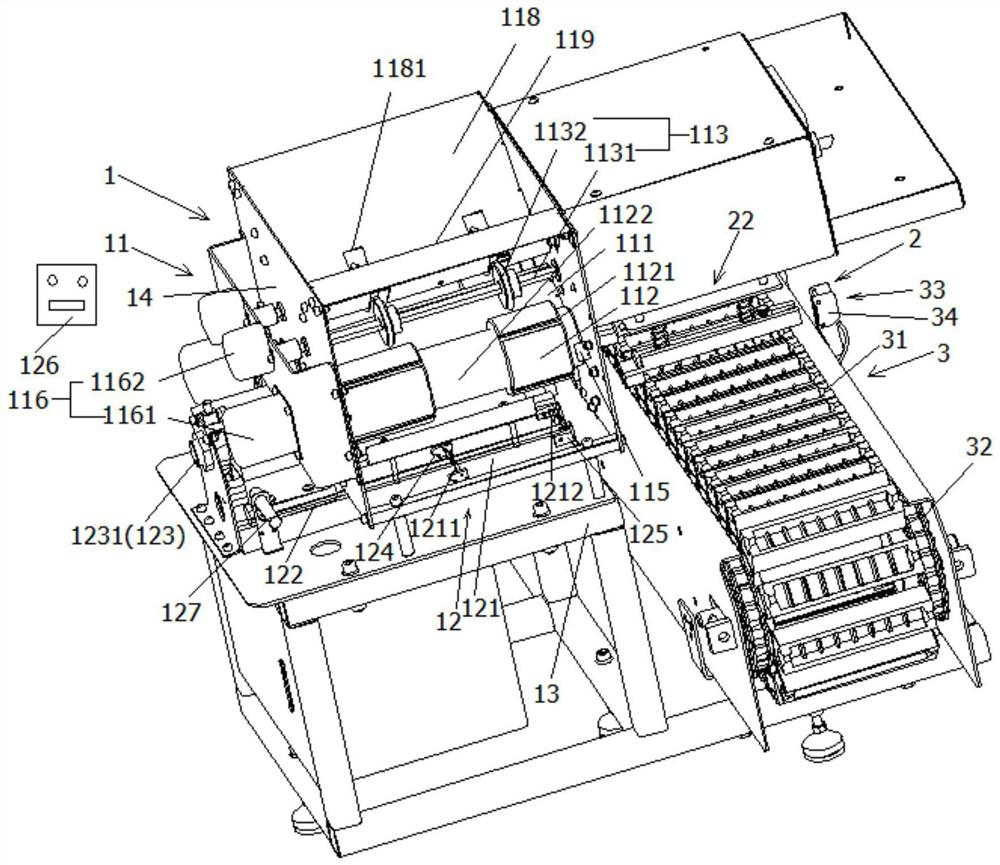

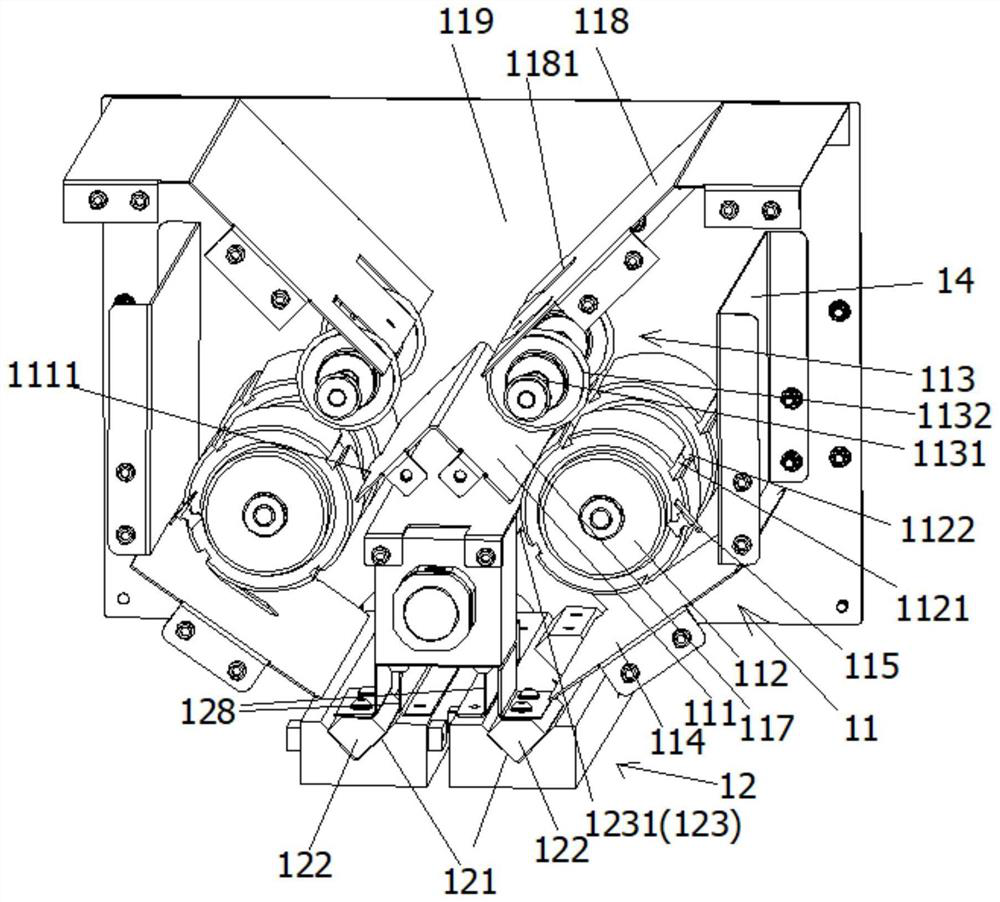

Meat product skewering robot

ActiveCN108522620ARealize the purpose of automatic threadingReduce the chance of breakagePutting meat on skewersEngineeringRobot

The invention discloses a meat product skewering robot. The meat product skewering robot comprises a machine frame, two bamboo stick feeding modules and a meat skewering module, wherein the bamboo stick feeding modules are symmetrically arranged separately on the left and right sides on the machine frame, the bamboo stick feeding modules comprise bamboo stick brackets, the bamboo stick brackets are mounted on one side of the machine frame, bamboo stick barrels are arranged at the upper parts of the bamboo stick brackets, bamboo stick feeding rollers are also arranged below the bamboo stick barrels, and the bamboo stick feeding rollers are mounted on the bamboo stick brackets; bamboo stick slide rails are also arranged at the front part of the bamboo stick brackets and the bamboo stick slide rails are positioned below the front sides of the bamboo stick feeding rollers; rectangular through holes are symmetrically and separately formed in the left and right sides of the upper part of themachine frame, the two bamboo stick feeding modules are positioned on the same sides of the two rectangular through holes, and the meat skewering module is arranged on the other sides of the two rectangular through holes. A reciprocating meat cutting structure and a meat skewering structure are arranged, the purpose of automatic skewering of barbecue meat skewers is realized and the working efficiency is higher; and a claw structure and a positioning structure are arranged and well imitate the action of manual skewering, and the probability of breaking of bamboo sticks is obviously reduced.

Owner:安徽靖童科技农业发展有限公司

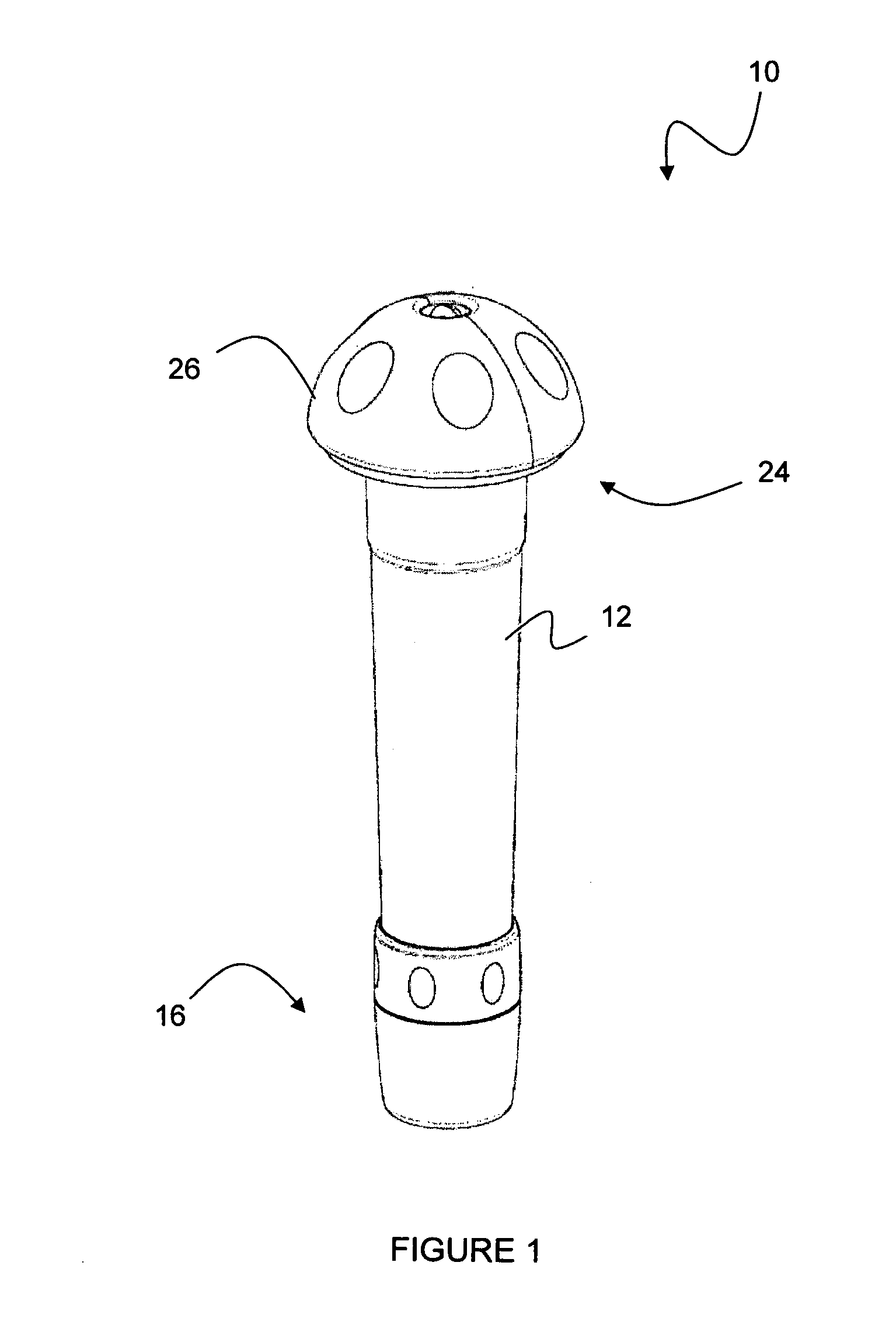

Food preparation device

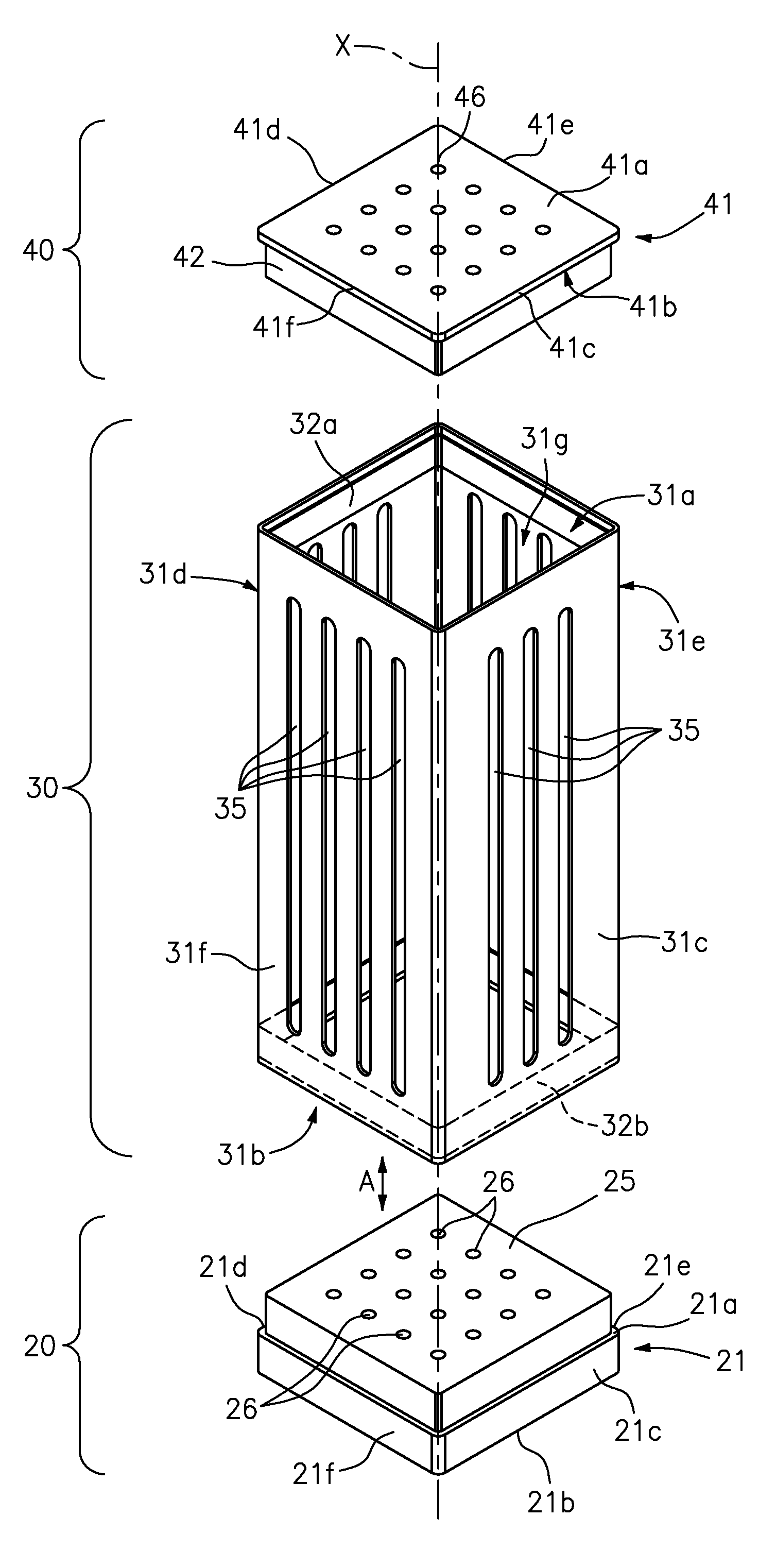

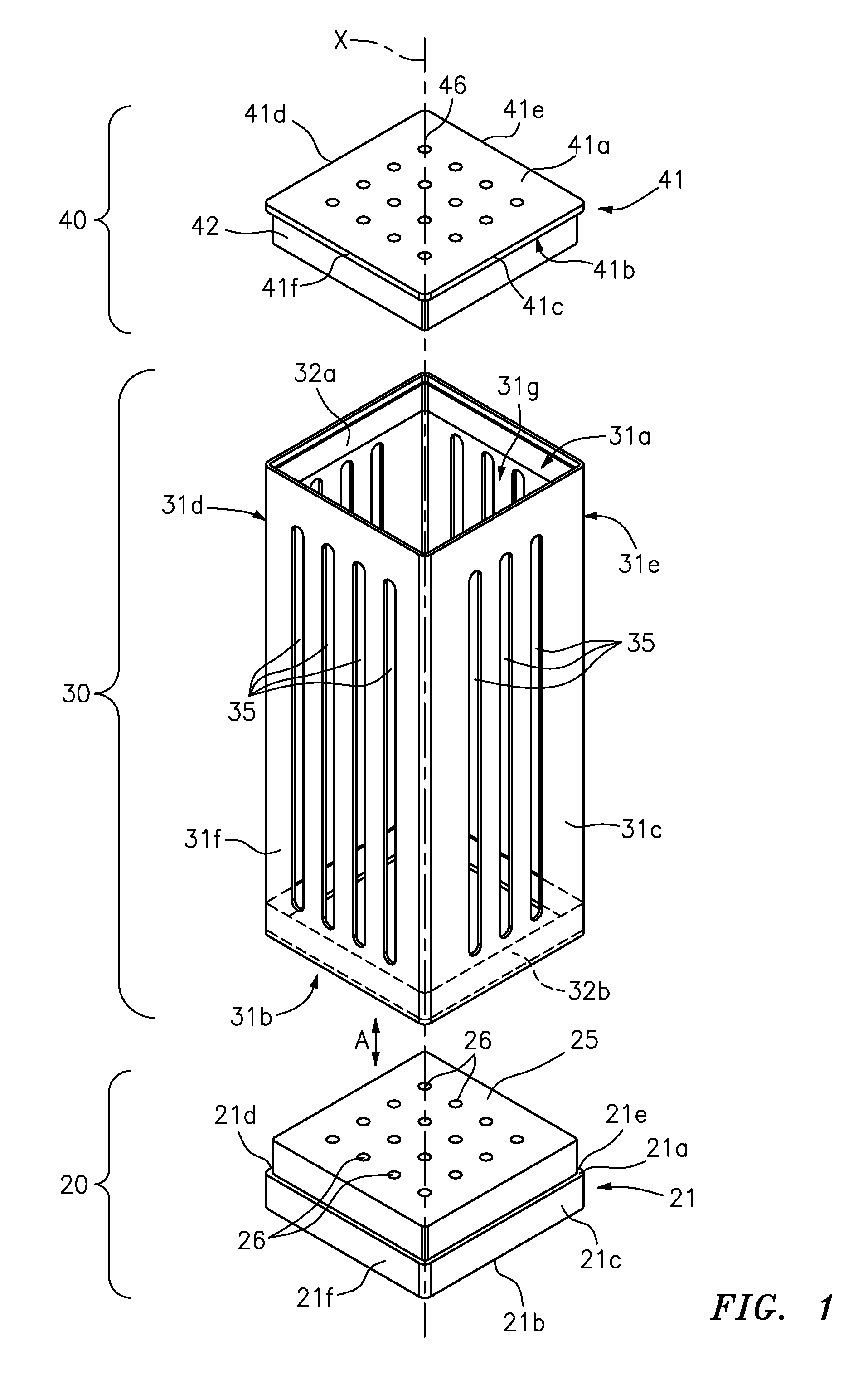

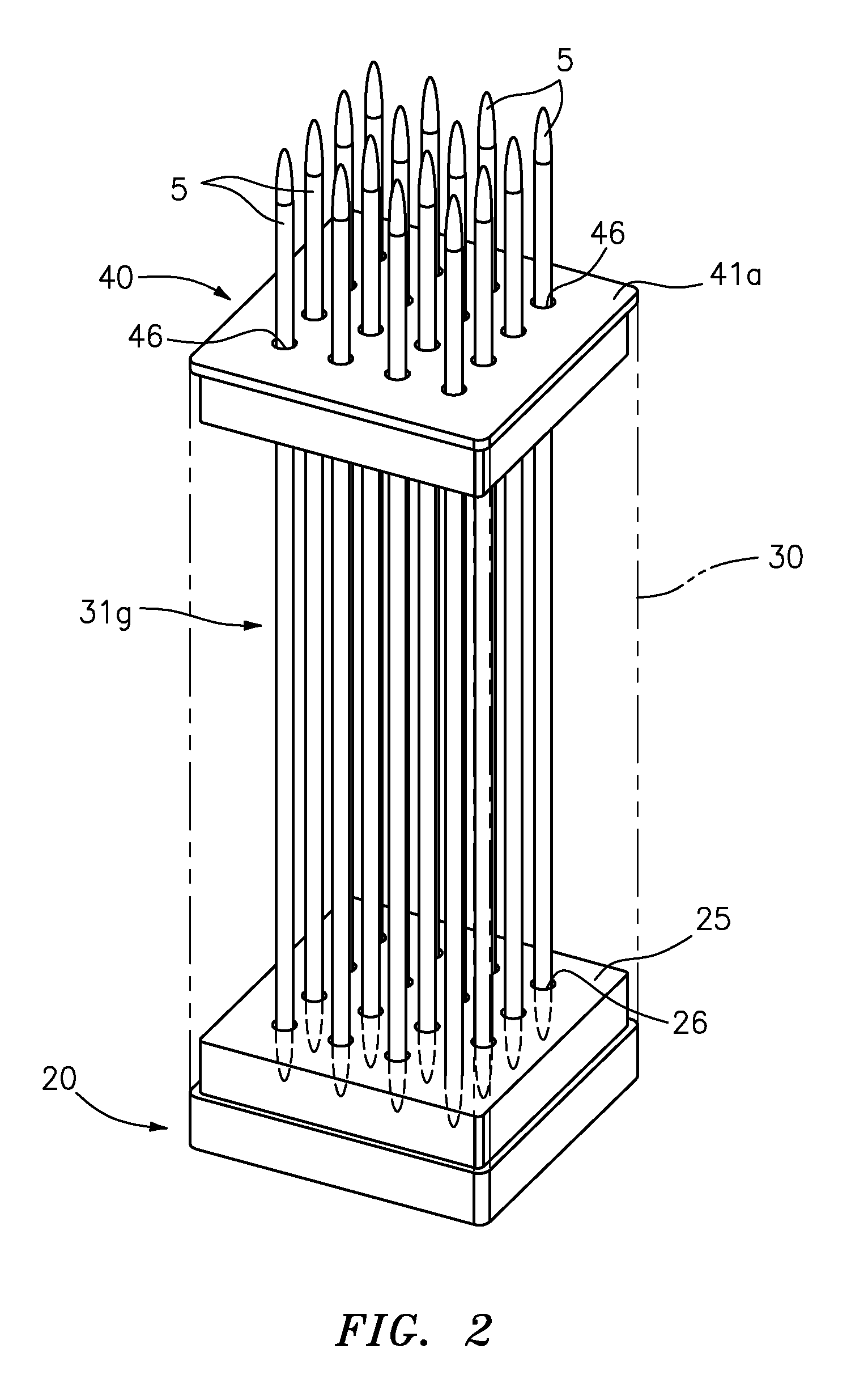

InactiveUS20130025421A1Unified positionCross-cut reciprocating sawsKitchen equipmentEngineeringBiomedical engineering

A food preparation device includes an elongated, generally tubular rectangular main body having a top opening, a bottom opening, and a plurality of elongated grooves extending vertically along the main body. The device also includes a cap and base section for being removably positioned onto the main body, each of the cap and base sections including a plurality of openings for receiving and positioning a plurality of skewers.

Owner:TRIDI

Skewer stringing machine

PendingCN110881676ASimple structureSimple and fast operationFood shapingPutting meat on skewersEngineeringFood material

The invention discloses a skewer stringing machine, and relates to a device for stringing food materials into skewers in the catering industry. The device comprises a food material fixing device, a skewer putting-in device, a skewer pushing device and a skewer collecting box. The food material fixing device is technically characterized in that food material grooves are formed in a left clamping plate and a right clamping plate respectively. The skewer putting-in device is technically characterized in that a skewer box is installed on a bottom frame; a skewer outlet is formed below the skewer box; and a rotating shaft is installed on the bottom frame and located below the skewer outlet. The skewer pushing device is technically characterized in that a skewer groove is arranged below a turntable on the bottom frame; the outlet of the skewer groove is connected with a taper hole; a push rod is arranged on the bottom frame; one end of the push rod is connected with a pushing power device; and the other end is provided with a push plate. The device provided by the invention has the advantages that the structure is simple; food materials are fixed by an upper clamping plate, a lower clamping plate and food material grooves; the operation is easy and convenient; the work efficiency is improved; labor cost is saved; the skewer putting-in device and the skewer pushing devices are ingenious in design; food materials are stringed at a time; and the cost of the catering industry is greatly reduced.

Owner:黄文芳

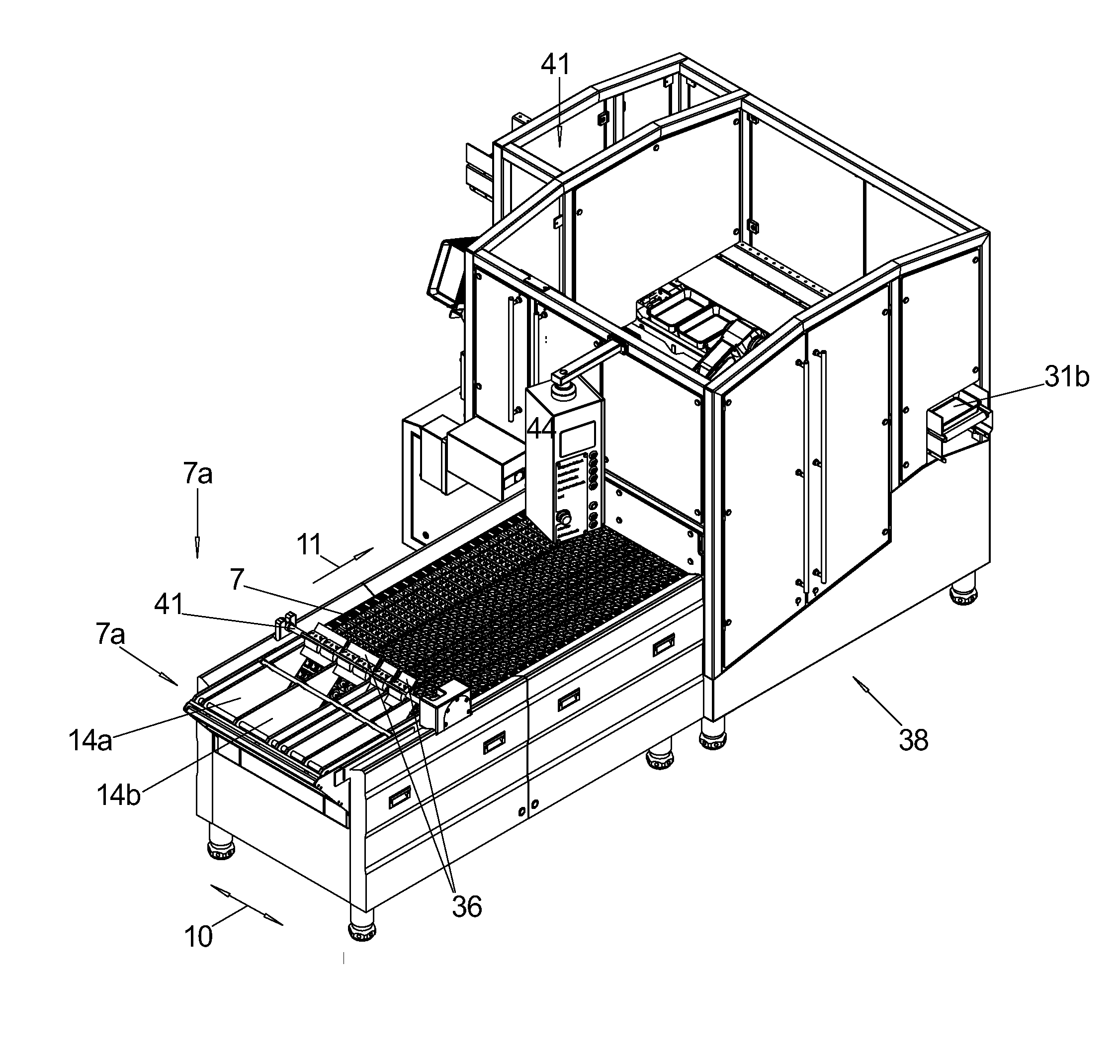

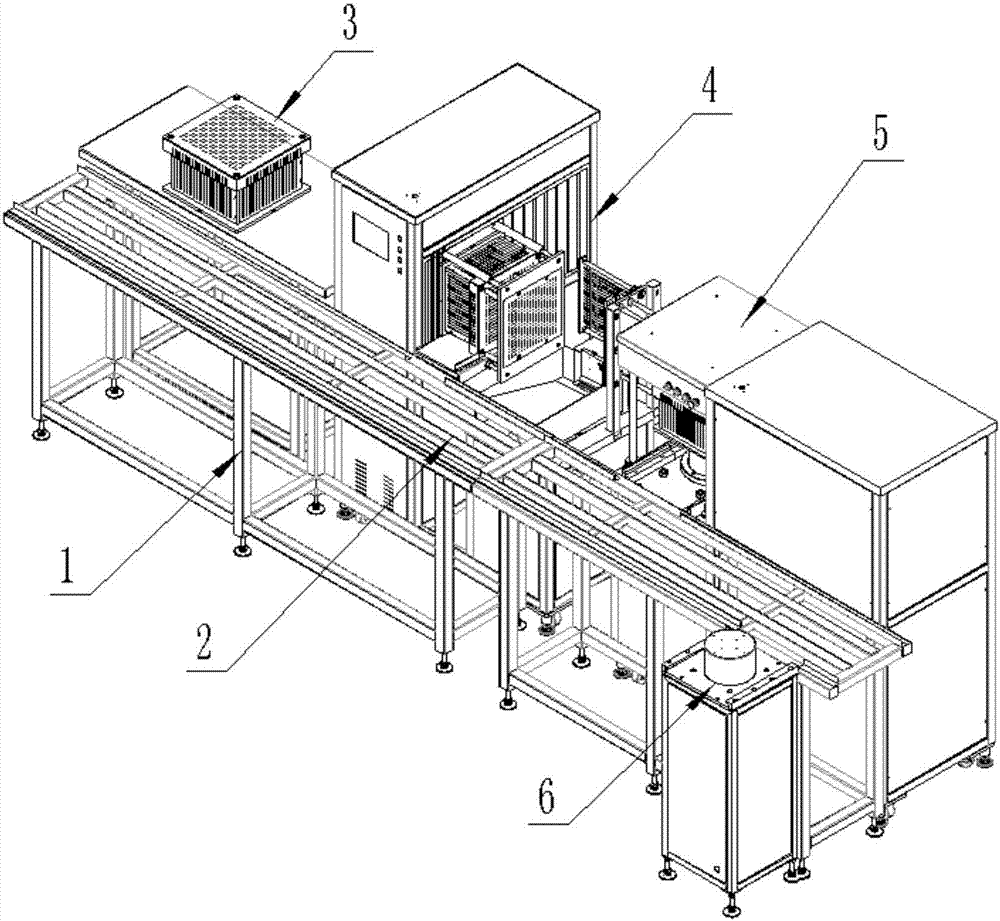

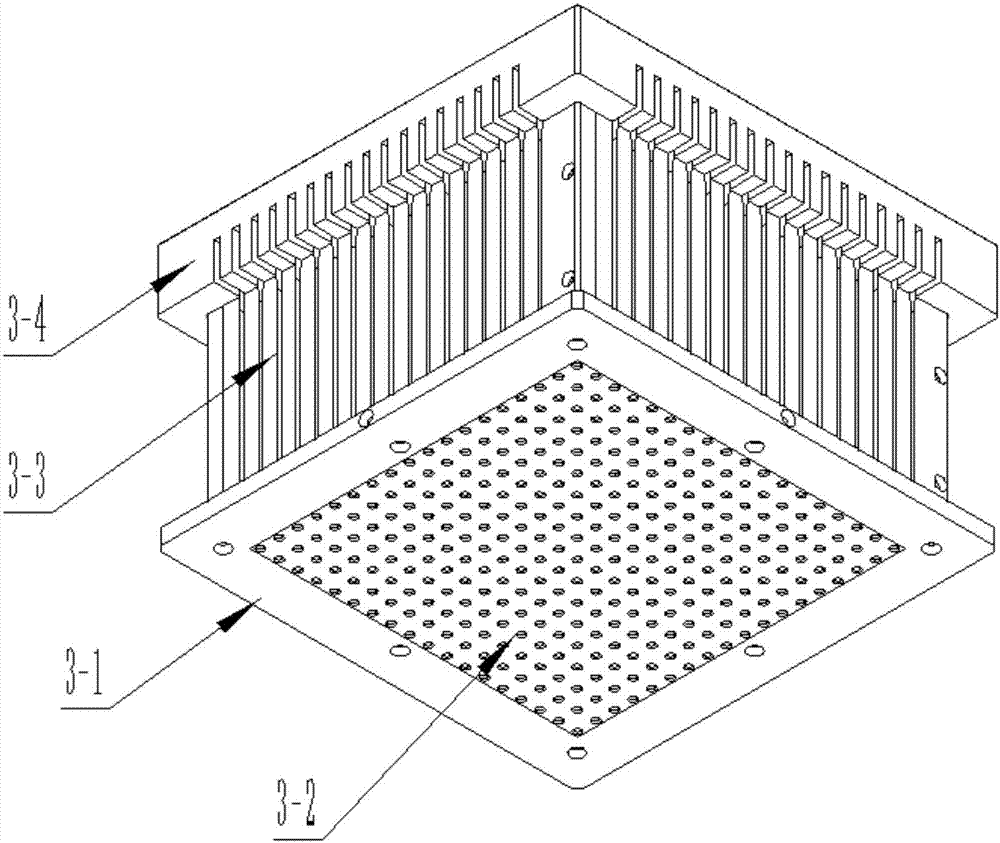

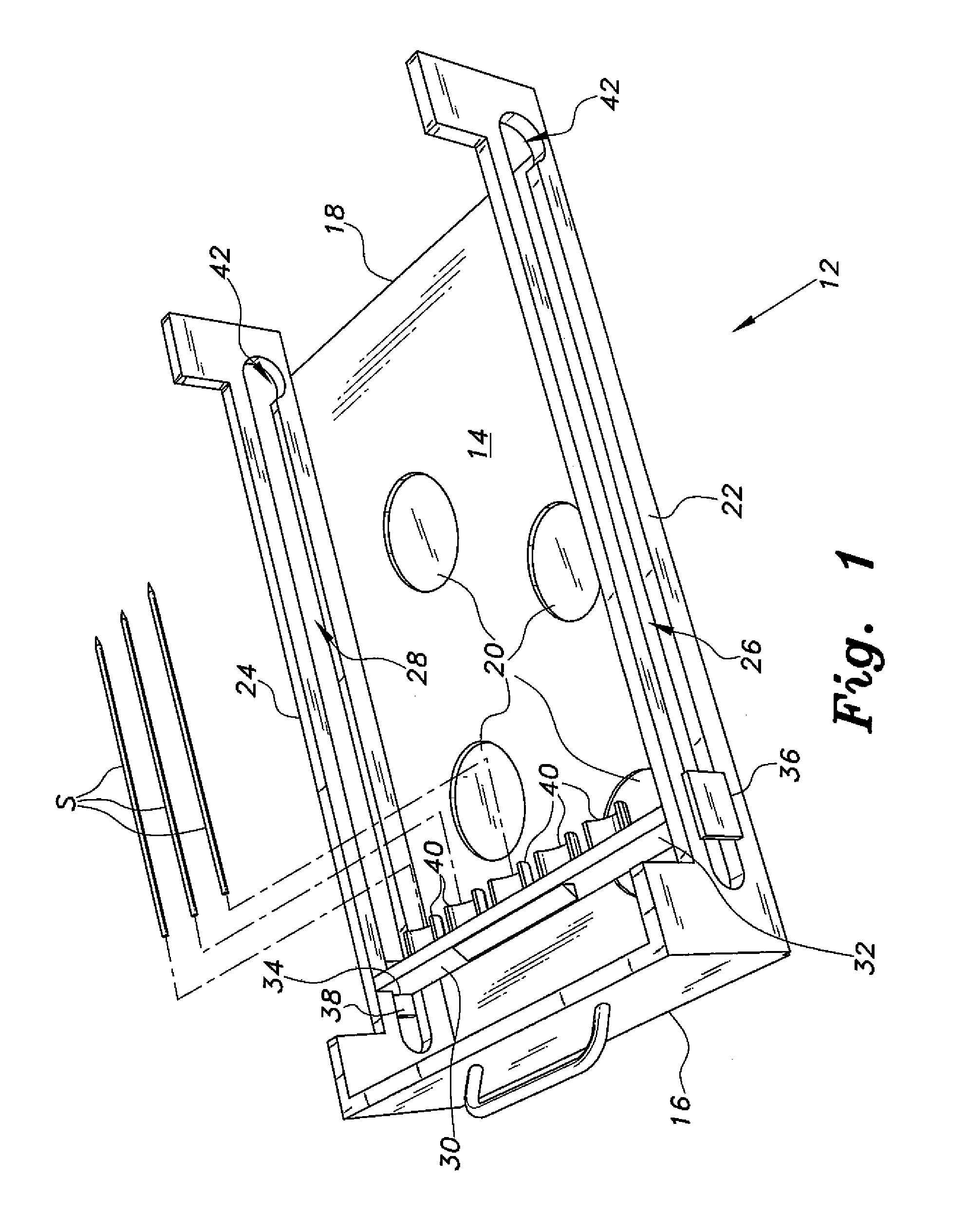

Shashlyk machine and method for making shashlyks

ActiveUS20150282495A1Low rateControl complexityAutomatic control devicesMeat/fish preservationAdditive ingredientShish kebab

In order to produce shish kebab skewers (100) in a substantially automated manner, the individual ingredients (98) are individually provided in cups (6) of a cup arrangement (7) including sequential cup rows (8a, b) and cup lines (12a, b) so that a skewer holder (3) in which plural skewers (99) are received in a row adjacent to one another respectively prongs the same ingredient (98) onto all its skewers (99) simultaneously in that it lowers relative to the cups in whose bases (17) pass through openings (32) are arranged so that the ingredients (98) in the cups (6) are pronged onto the skewers (99).

Owner:TVI ENTWICKLUNG & PROD GMBH

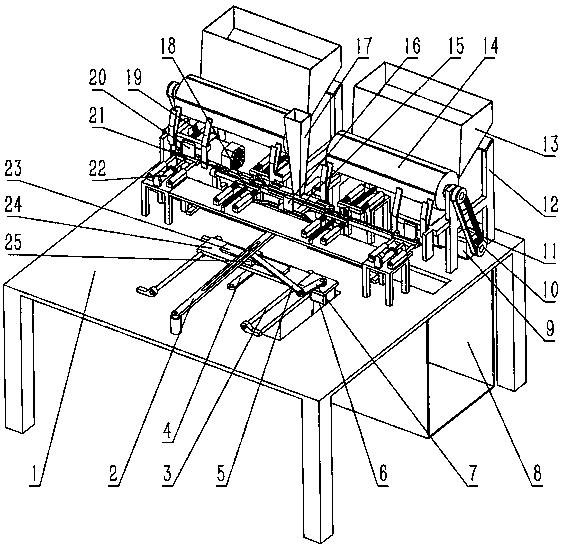

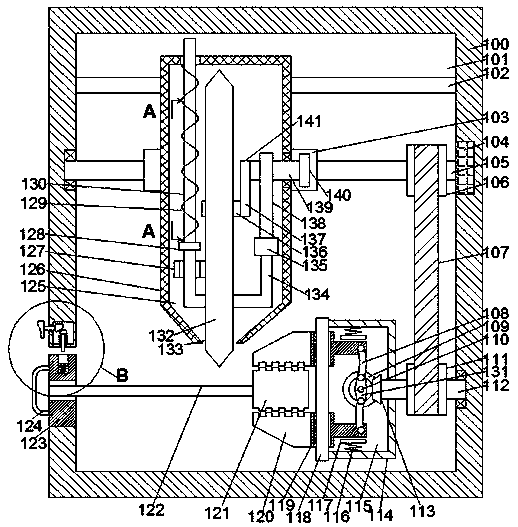

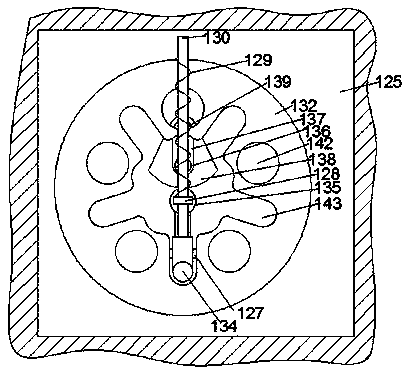

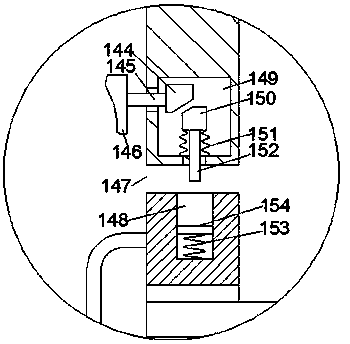

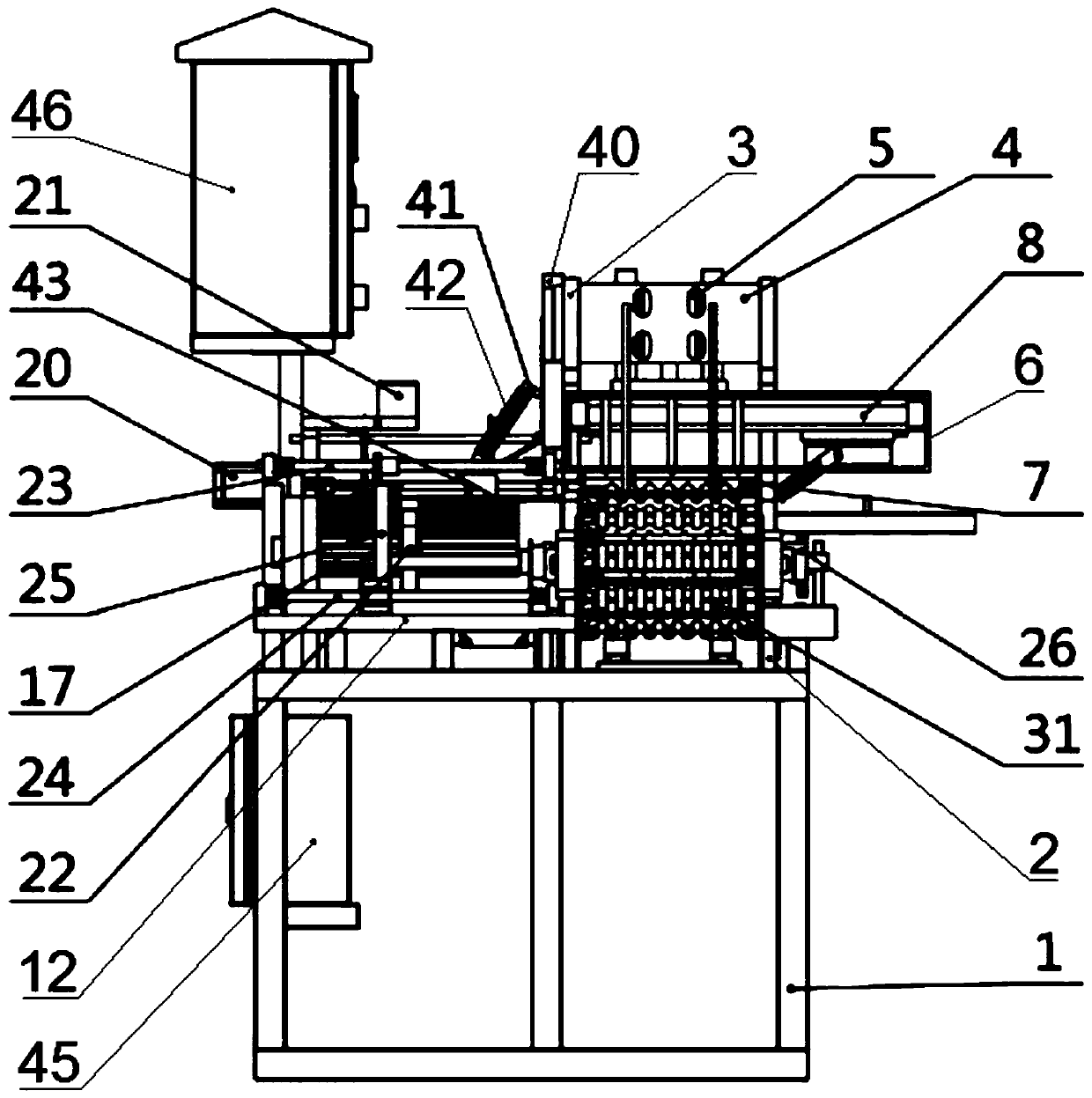

Multifunctional automatic skewering machine

ActiveCN106070508AReasonable designEasy to operateFood shapingPutting meat on skewersAutomatic controlControl system

The invention relates to a multifunctional automatic skewering machine. The steps of feeding, skewering and cutting to form skewers can be completed on the skewering machine. The multifunctional automatic skewering machine is mainly composed of an automatic belt conveying mechanism 1, an automatic skewer loading and skewering mechanism 2, an automatic skewer cutting mechanism 3 and an automatic control system 4. According to the multifunctional automatic skewering machine, stacked materials can be automatically conveyed in place, then, automatic skewering is performed, and the skewed materials are cut into skewers and automatically separated from the machine. The machine can achieving skewering of 10 or more skewers at a time circularly, the skewering speed is greatly increased, the obtained skewers are attractive in appearance, a large amount of manpower and material resources are saved, and the machine is more sanitary.

Owner:重庆市钦鼎农业集团有限公司

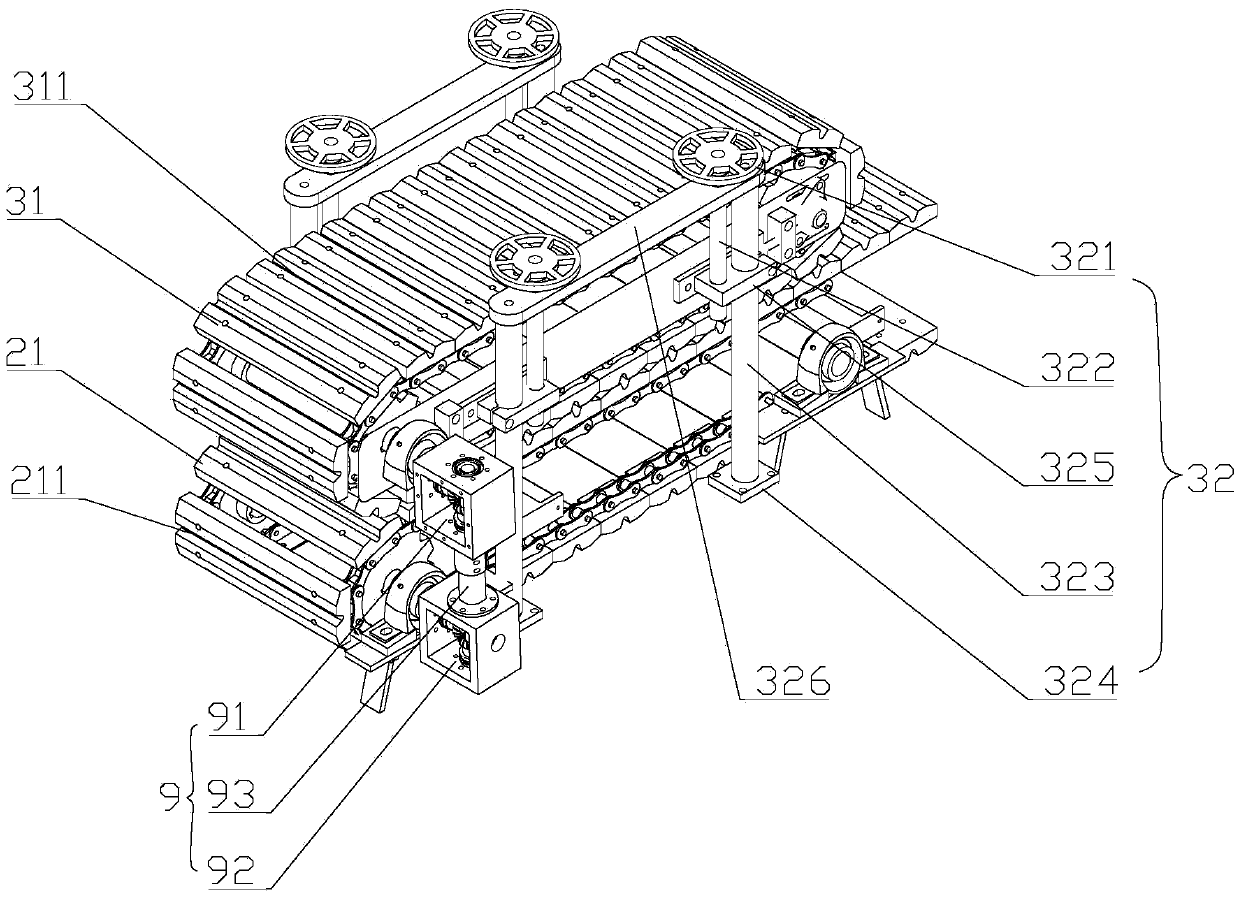

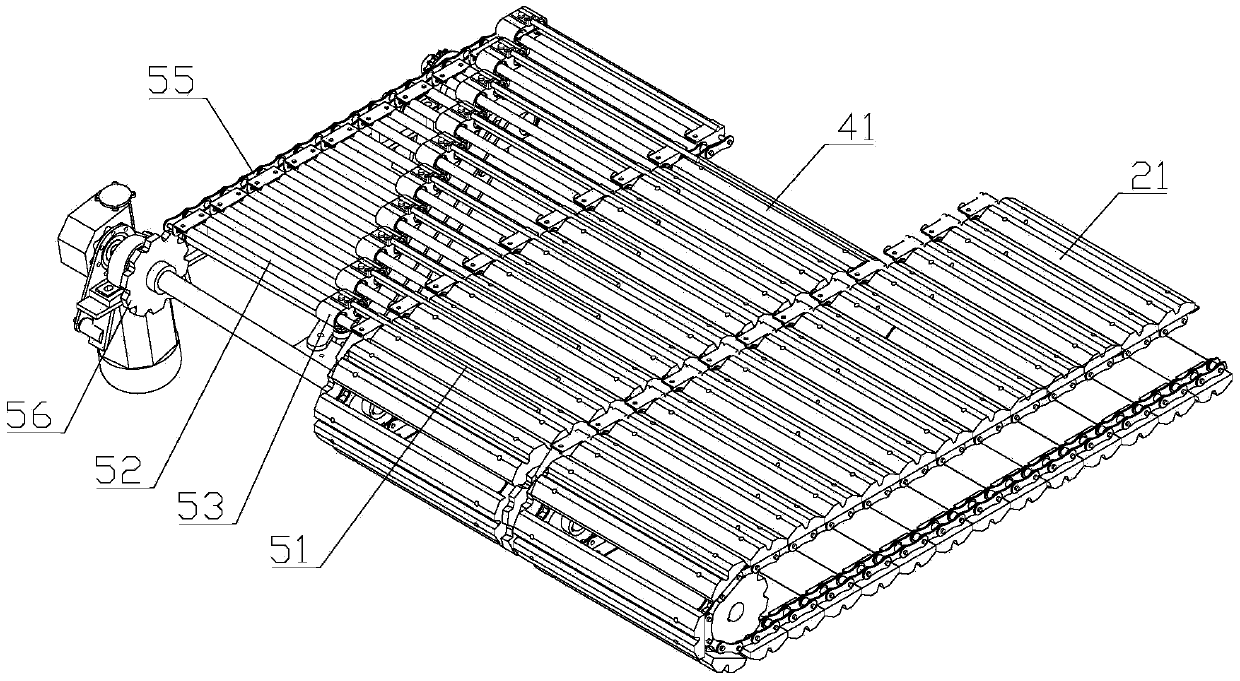

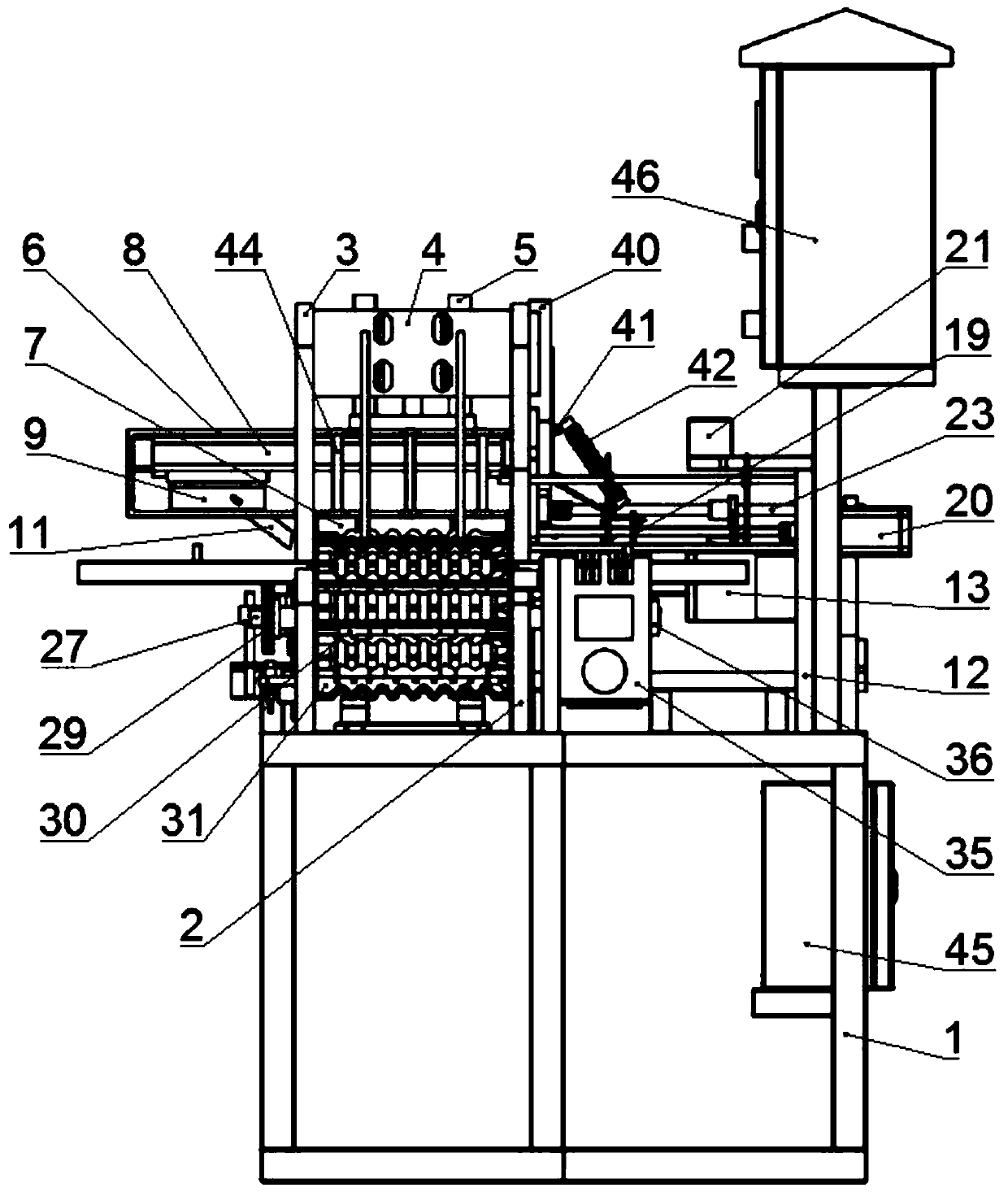

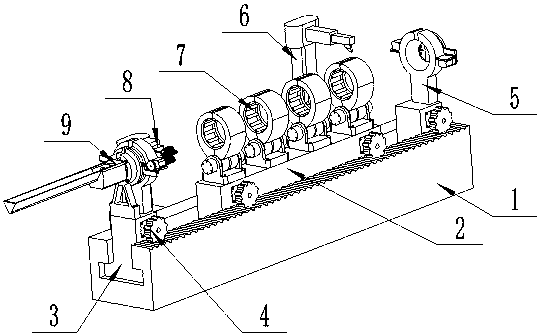

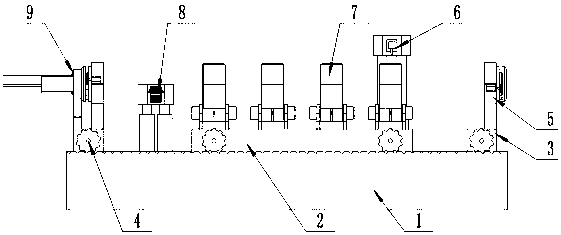

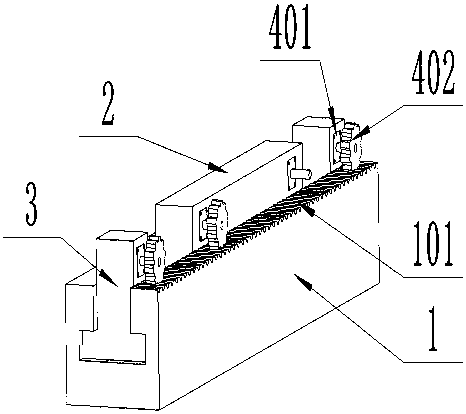

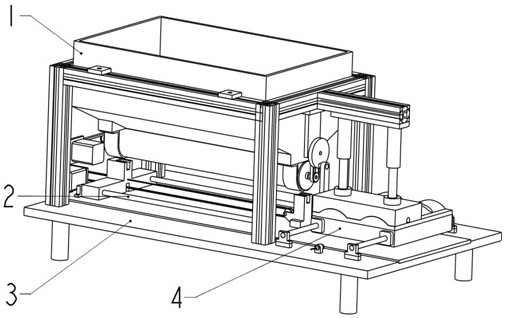

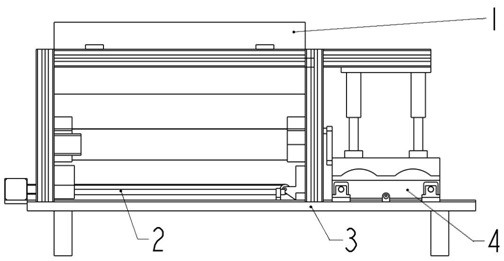

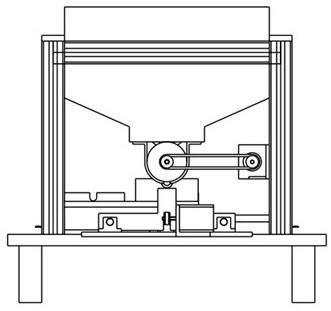

Automatic meat cutting and bunching machine

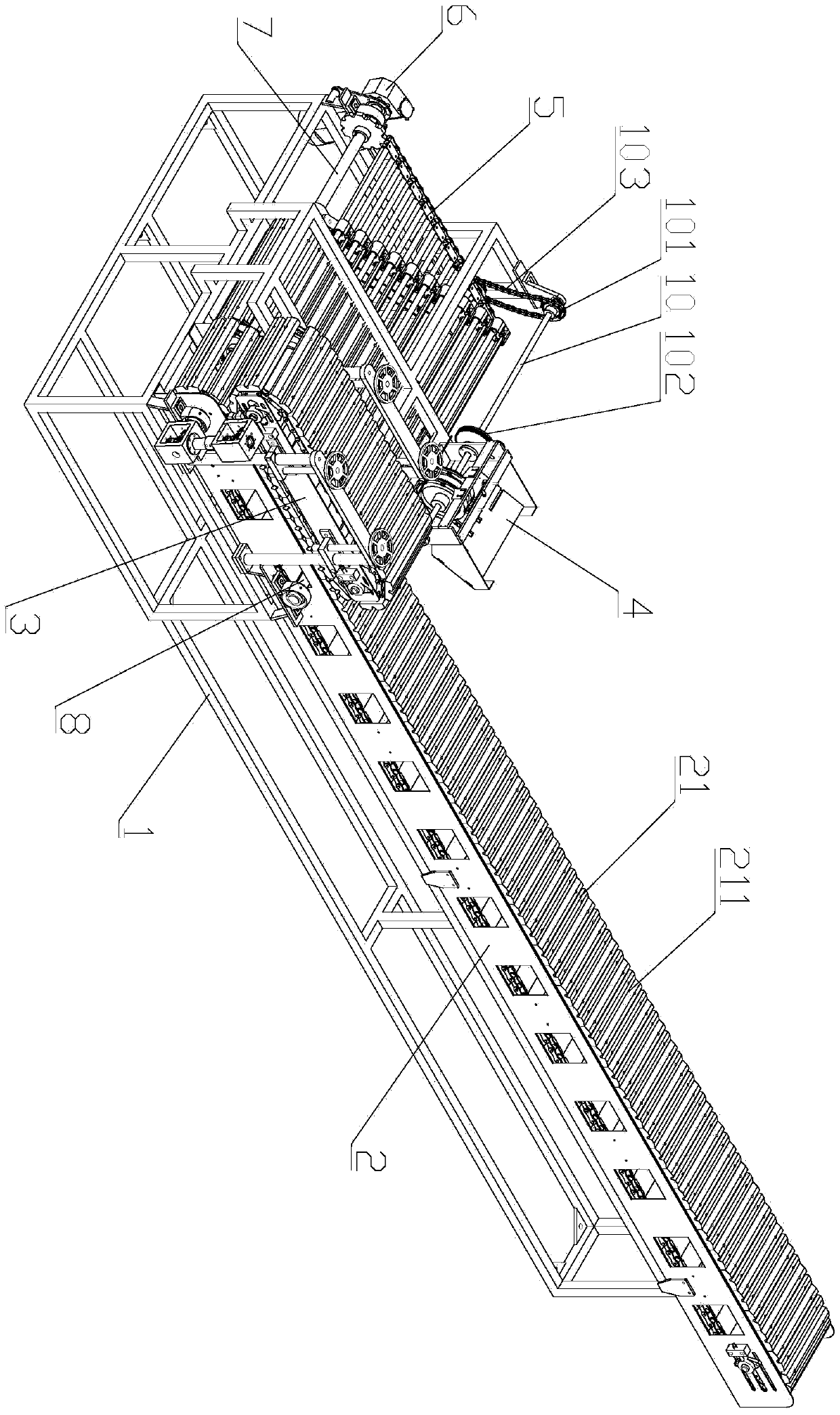

ActiveCN107950627ACompact structureSimple and fast operationMeat packaging/handling/transportingPutting meat on skewersEngineeringSmall footprint

The invention relates to the technical field of meat processing machinery, in particular to an automatic meat cutting and bunching machine. The automatic meat cutting and bunching machine comprises asliding chute 2 arranged on a rack 1, a meat piling device 3, as well as an automatic bunching device 4, an automatic cutting device 5 and a meat bunch ejector device 6 which are arranged near the sliding chute 2 in sequence. The automatic meat cutting and bunching machine is simple in structure, simple and convenient to operate, low in cost, small in occupied area, stable in operation, safe, reliable, high in efficiency and long in service life, bunching and meat cutting can be realized safely and automatically, and the efficiency is high, so that the defect that the traditional operation ofmanual meat cutting and manual bunching is low in efficiency and unsafe is solved.

Owner:北京正兴天宝自动化科技有限公司

Food skewering machine

The food skewering machine includes a base and a food holding tray that is removably installed within the base. The tray includes two portions that are hingedly attached together. Each portion of the tray includes a series of receptacles for holding meat or other foods to be skewered when the two hinged portions are closed. A skewer driver can travel back and forth along the length of the base to drive or push skewers into the tray, thereby skewering the contents of the receptacles within the tray. The food holding receptacles within the tray may include any practicable number and are arranged in rows to provide for the simultaneous skewering of food using multiple skewers. Each row has a plurality of receptacles therein to allow each skewer to impale a plurality of food elements during a single skewering operation.

Owner:SULTAN QABOOS UNIVERSITY

Device and method for composing satays

ActiveUS20150313407A1Less cumbersomeMore hygienicSausage casingsFood shapingComputer engineeringEngineering

Owner:SMO

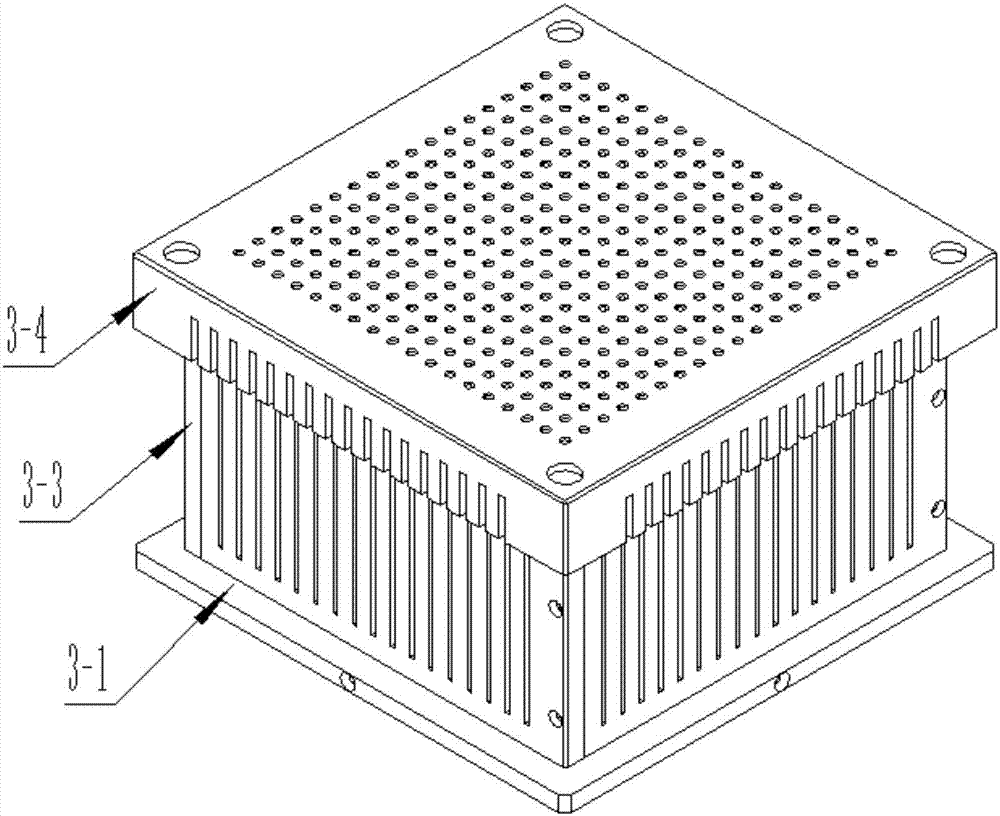

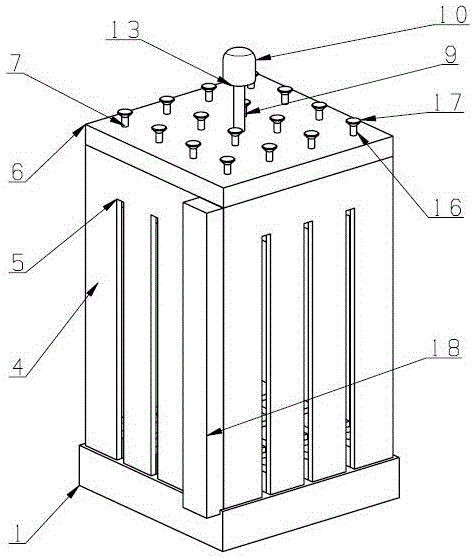

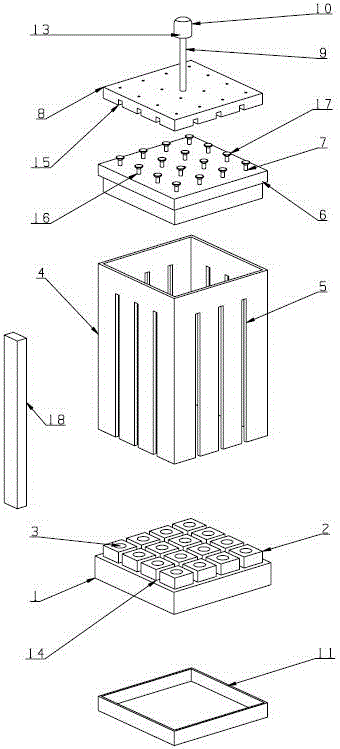

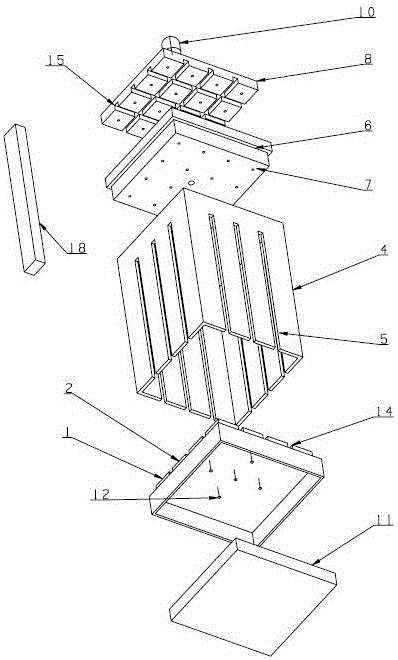

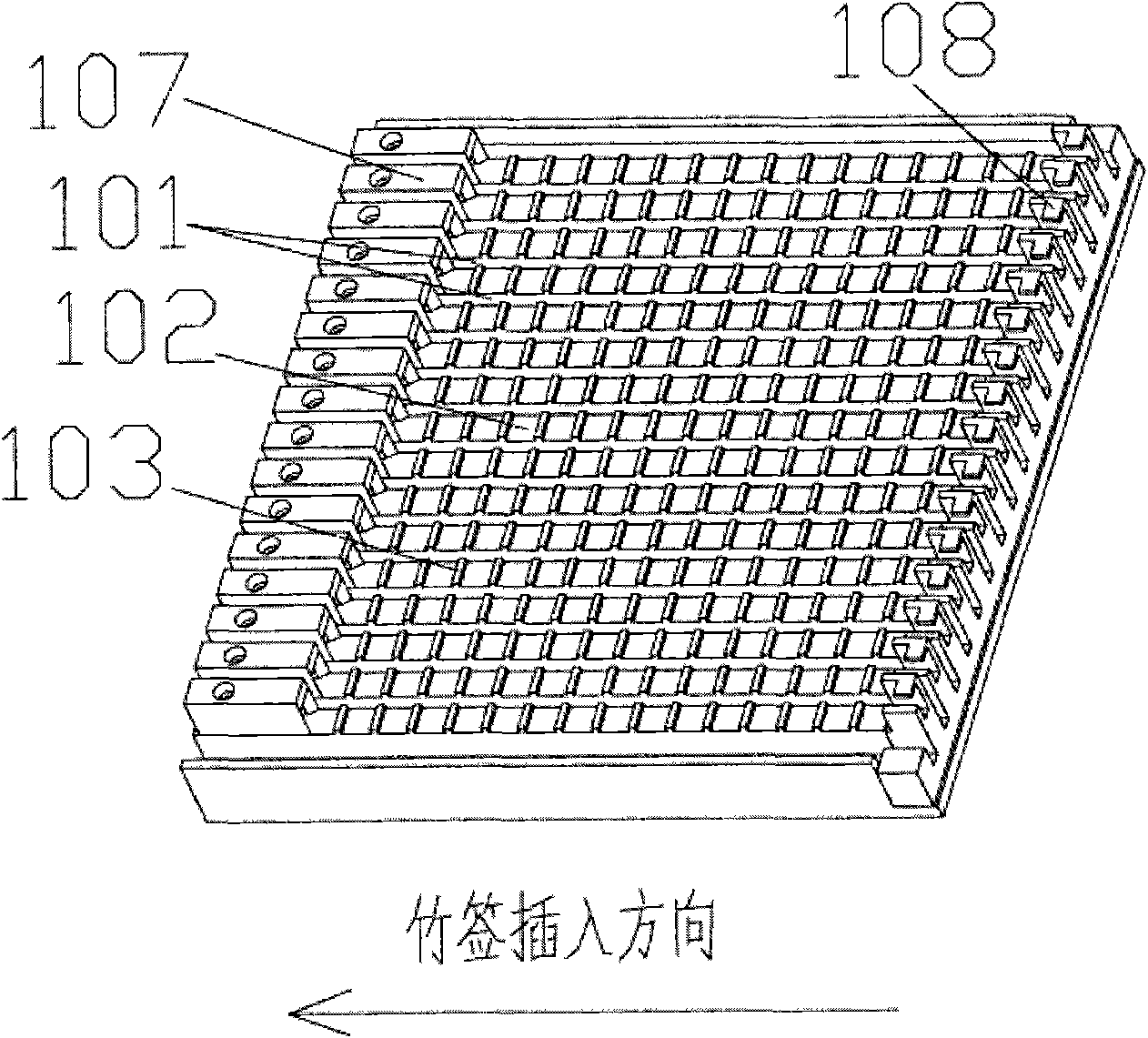

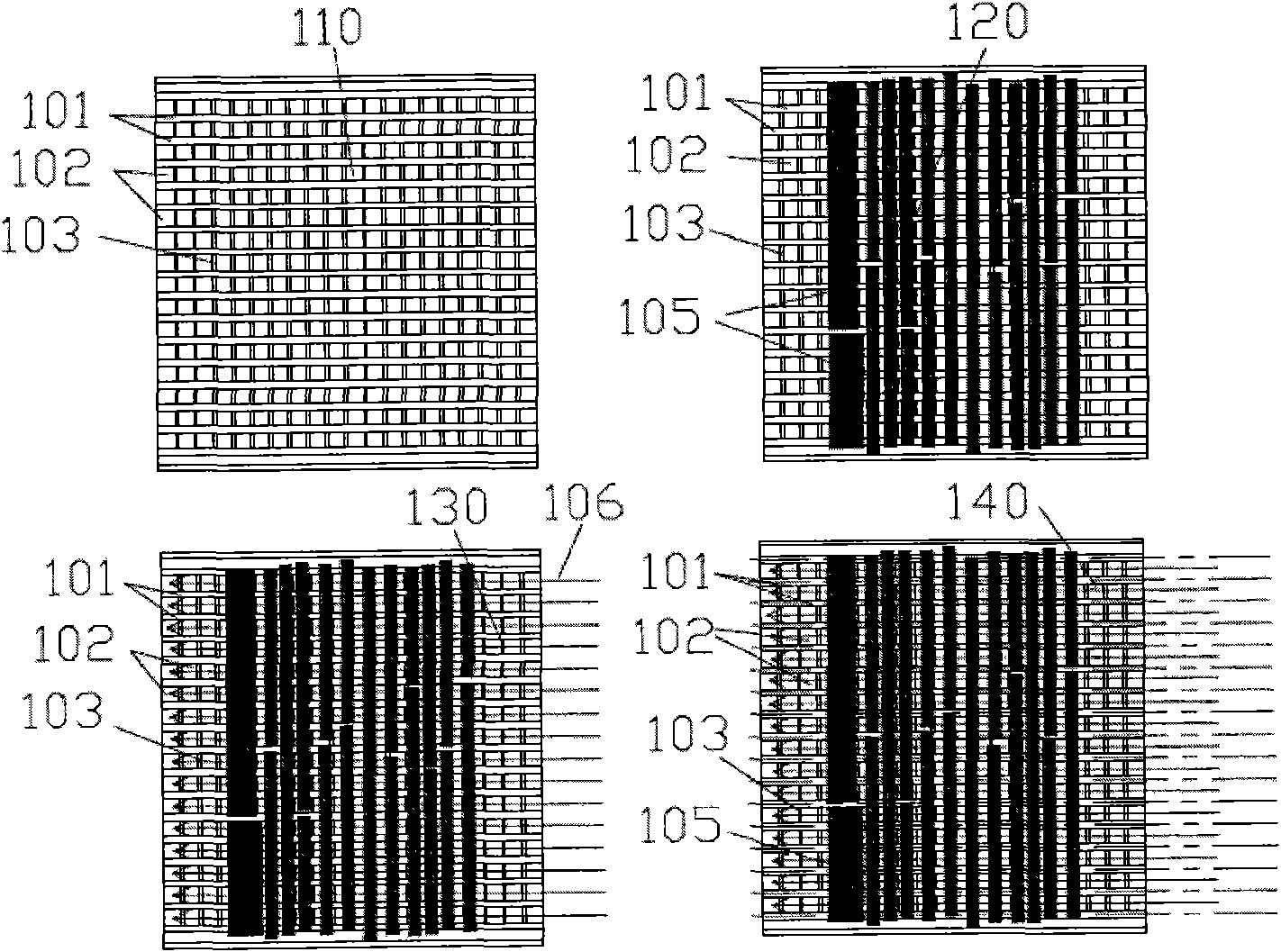

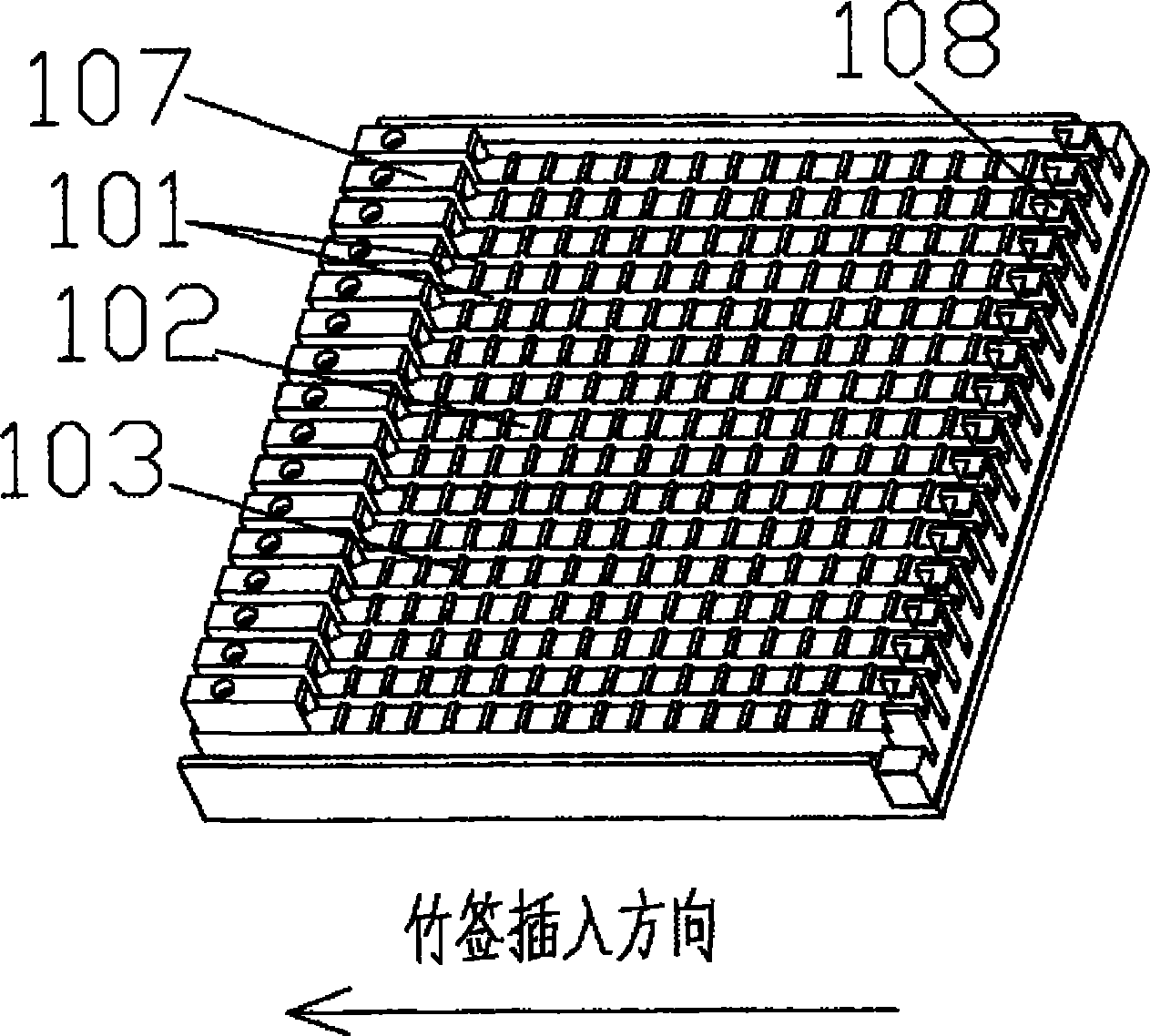

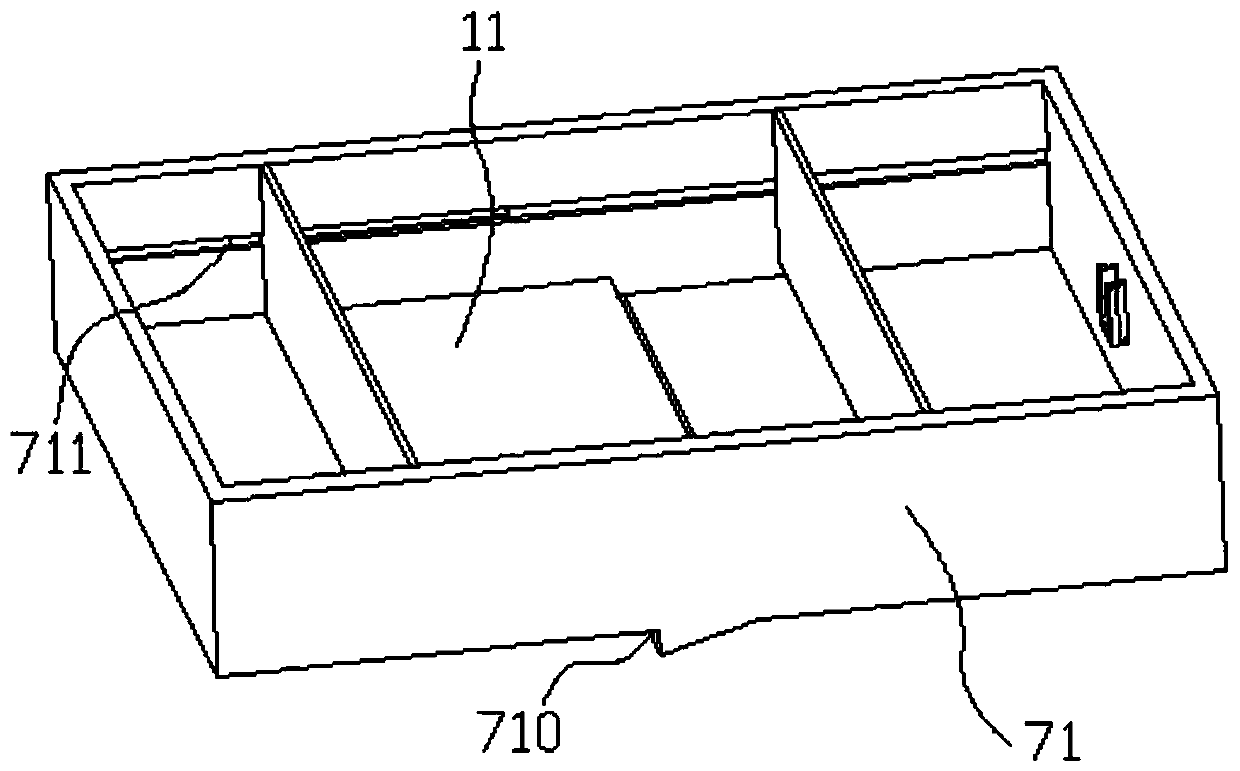

Skewered food preparation box

InactiveCN106035599AGuaranteed stabilityImprove work efficiencyPutting meat on skewersEngineeringFood preparation

The invention discloses a skewered food preparation box. The skewered food preparation box comprises a base; multiple convex rectangular blocks are formed on the base; through holes are formed at the middle parts of the rectangular blocks; grooves are arranged between adjacent rectangular blocks; fences are arranged above the base, wherein the fences are composed of four panels and the bottoms of the fences enclose the base; multiple strip-shaped channels are arranged on the sides of the fences; the strip-shaped channels and the groove positions between the adjacent rectangular blocks are aligned; top caps are arranged at the upper end covers of the fences; multiple through holes are formed on the top caps, wherein the through holes are respectively correspondence to the through holes of the rectangular blocks at the bottom; press panels are further arranged at the lower ends of top caps; and the press panels are connected to a handle arranged at the upper part by using a connecting bar. To-be-processed meat or fruits are placed in an inner chamber enclosed by the fences; the to-be-processed materials are regulated and pressed by the press panels at the upper ends; and wooden skewers orderly penetrate through the through holes, the to-be-processed materials and the through holes, so that multiple skewers of the to-be-processed materials are prepared; and then, the meat is cut by using a cutter, so that the purposes of uniform cutting and rapid skewering are achieved.

Owner:王景明

Pharmaceutical composition for treatment of immunological disorders

Disclosed is a pharmaceutical composition for treating immunological disorders by inhibiting the activation of T lymphocytes, comprising, as active ingredients, two or more selected from the group consisting of a substance capable of blocking binding of an MHC (Major Histocompatibility Complex) Class II molecule and a receptor thereof, a substance capable of blocking binding of a costimulatory molecule and a receptor thereof a substance capable of blocking binding of an adhesion molecule and a receptor thereof, and a substance capable of blocking binding of a cytokine and a receptor thereof.

Owner:MEDEXGEN INC (KR)

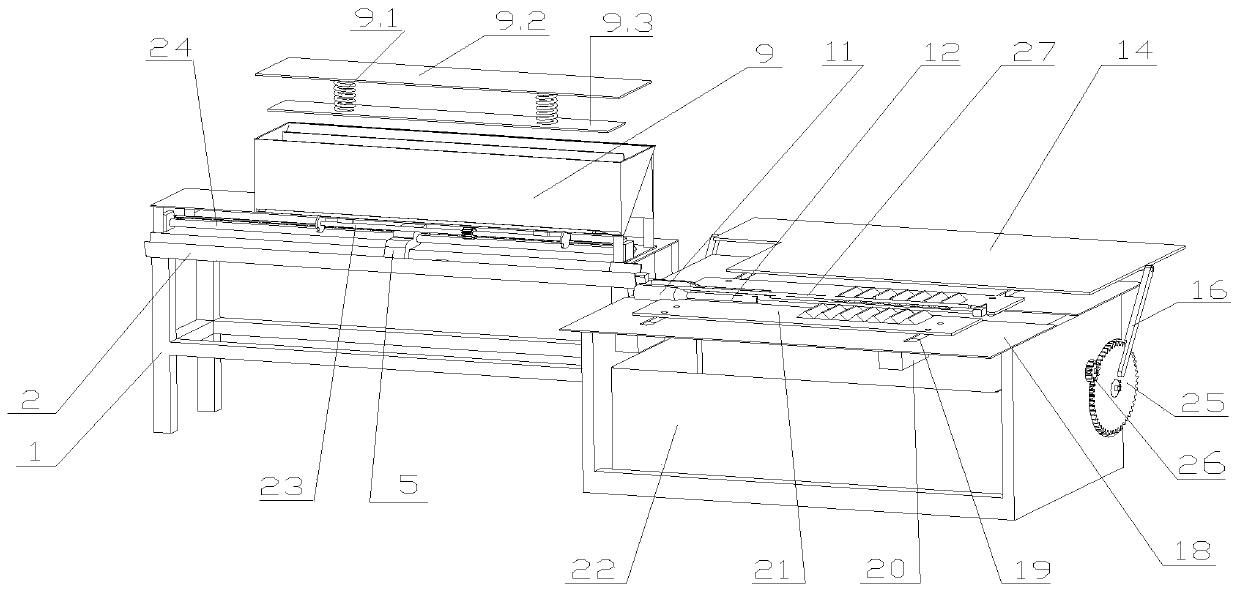

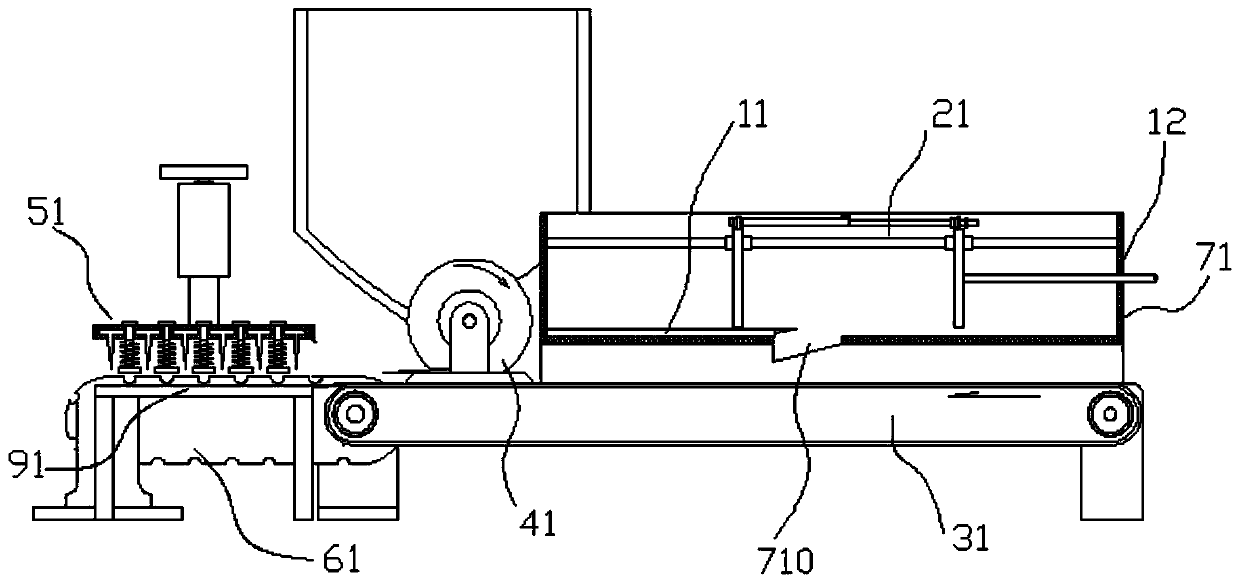

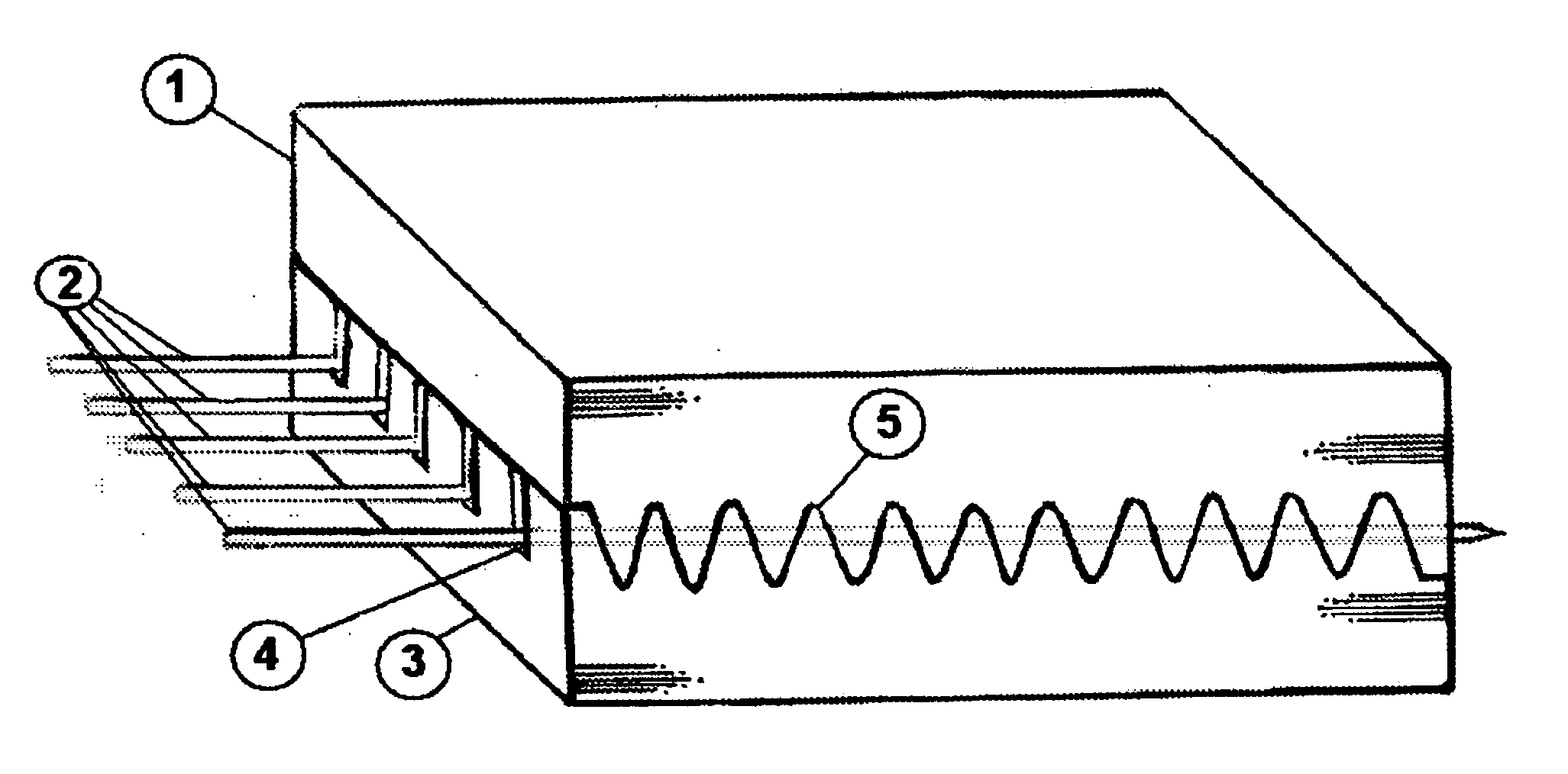

Stringing machine and method for stringing string foods by using machine

InactiveCN101843273ARegular shapeGood weight consistencyPutting meat on skewersEngineeringUniform - quality

The invention relates to a stringing machine and a method for stringing string foods comprising meat strings and the like by using a machine. The method has the cores of The core of the method is that firstly stringing a prod strung into meat, and then cutting meat strips (blocks) strung with the prod are cut apart to form a meat string. The method mainly comprises the following steps of: 1 tiling the meat strips or the meat blocks on a meat-placing template; 2 penetrating the prod into the meat on the meat-placing template; and 3 making a cutter passes through a cutter passage positioned on the meat-placing template to separate the meat penetrated on the prod on the template to form a single meat string. The meat string strung by adopting the stringing machine of the method has good shape and uniform quality, and the stringing machine can greatly reduce the working intensity of stringing workers, improve the string efficiency and is suitable for large-scale meat string production.

Owner:王荣帅 +2

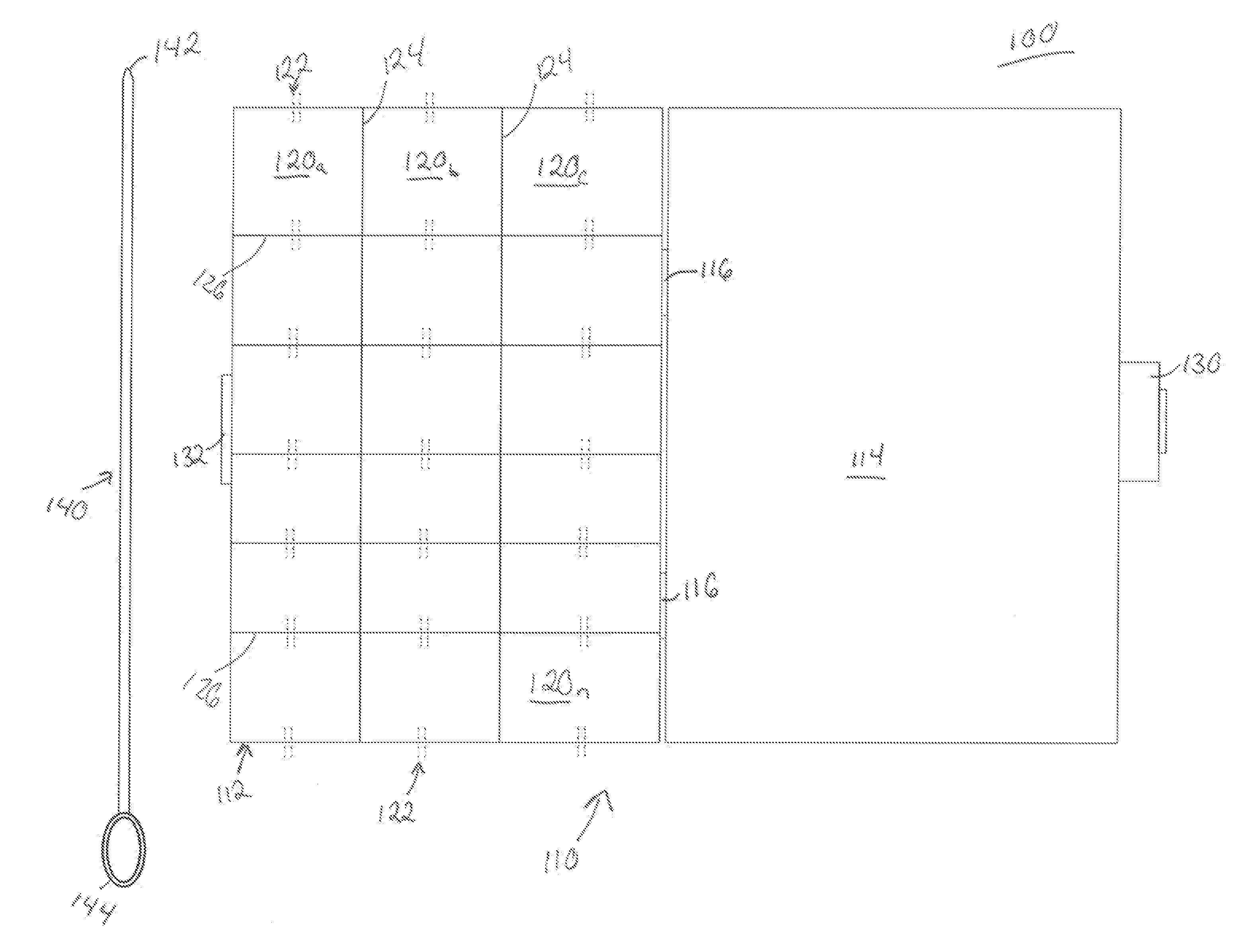

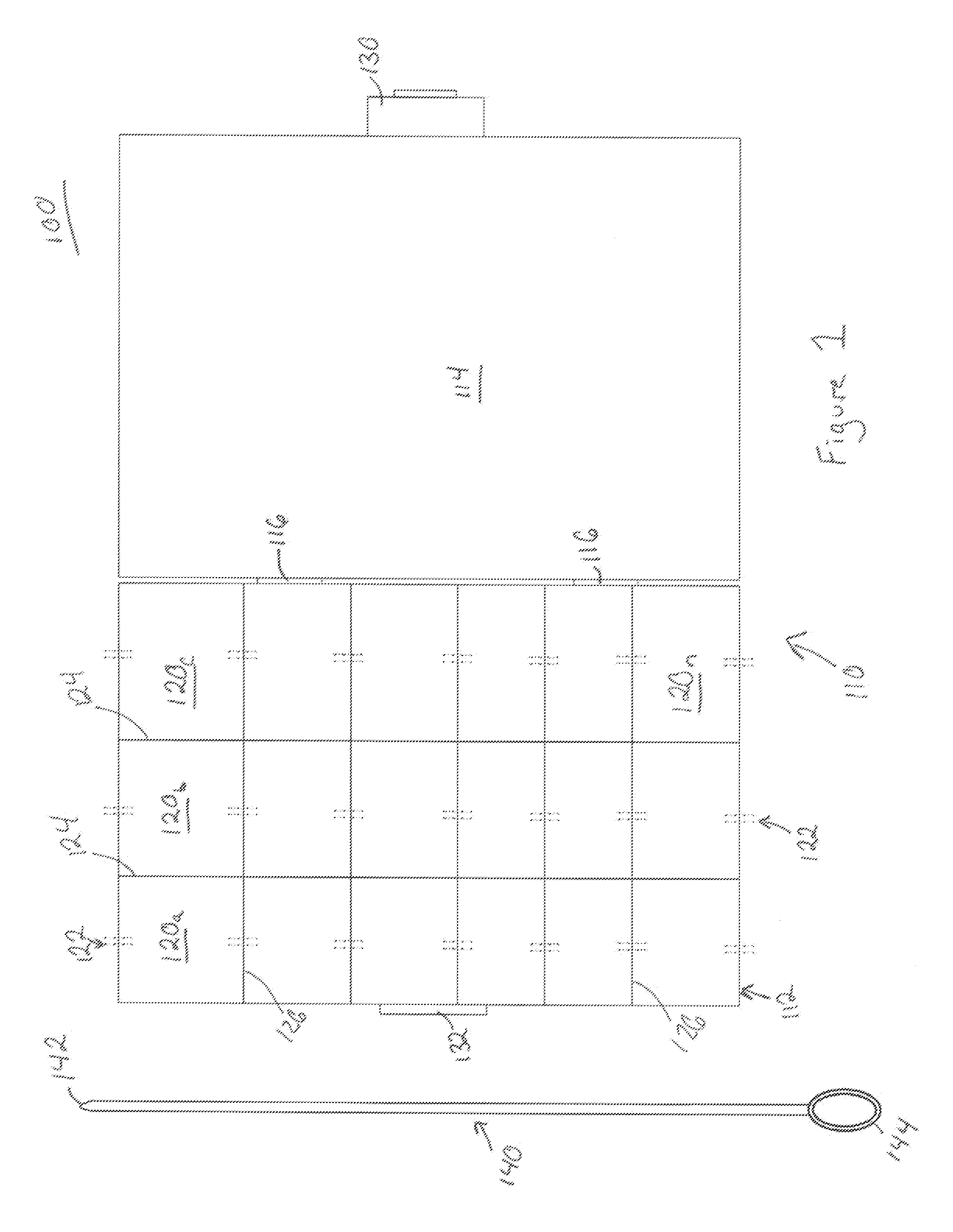

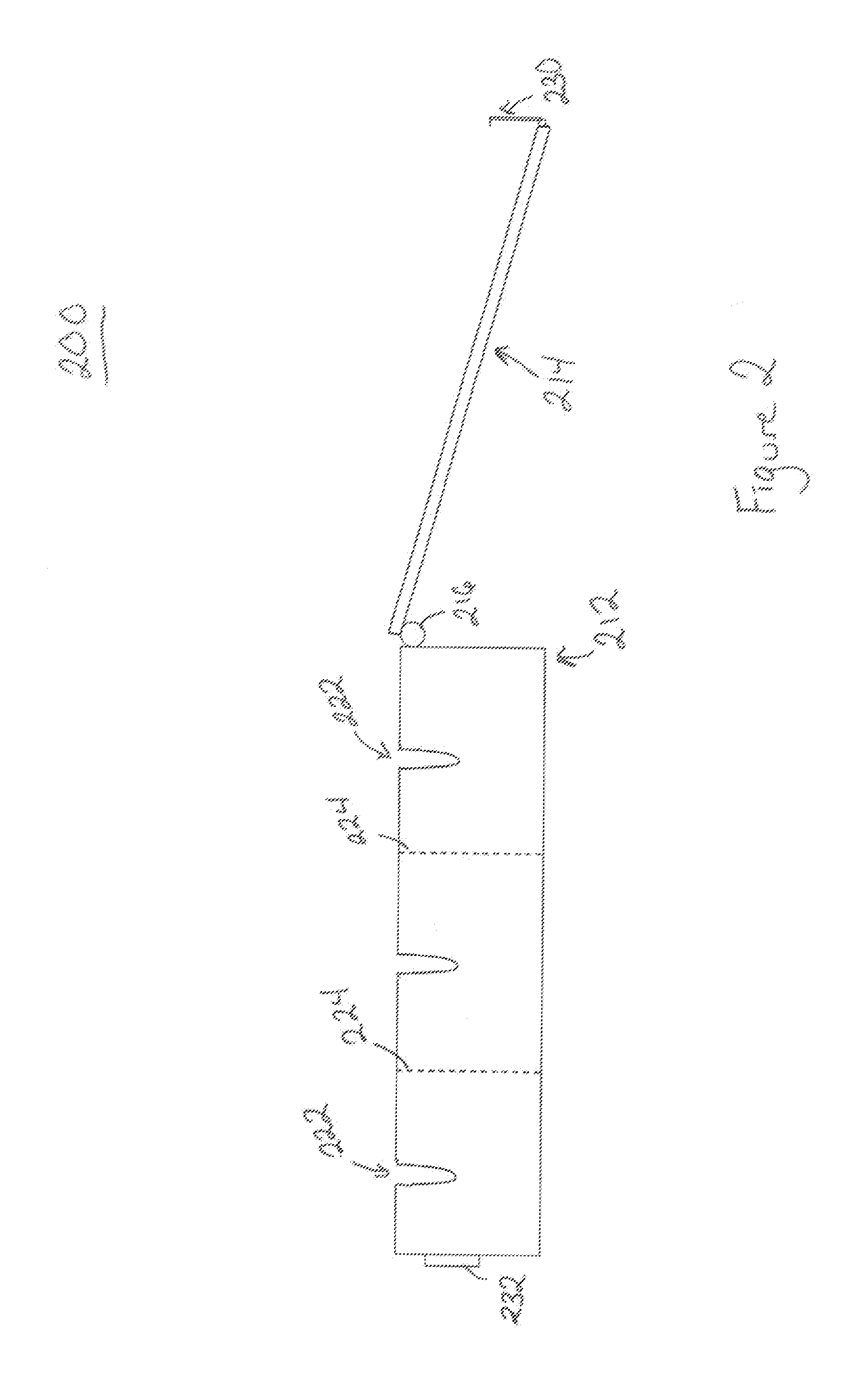

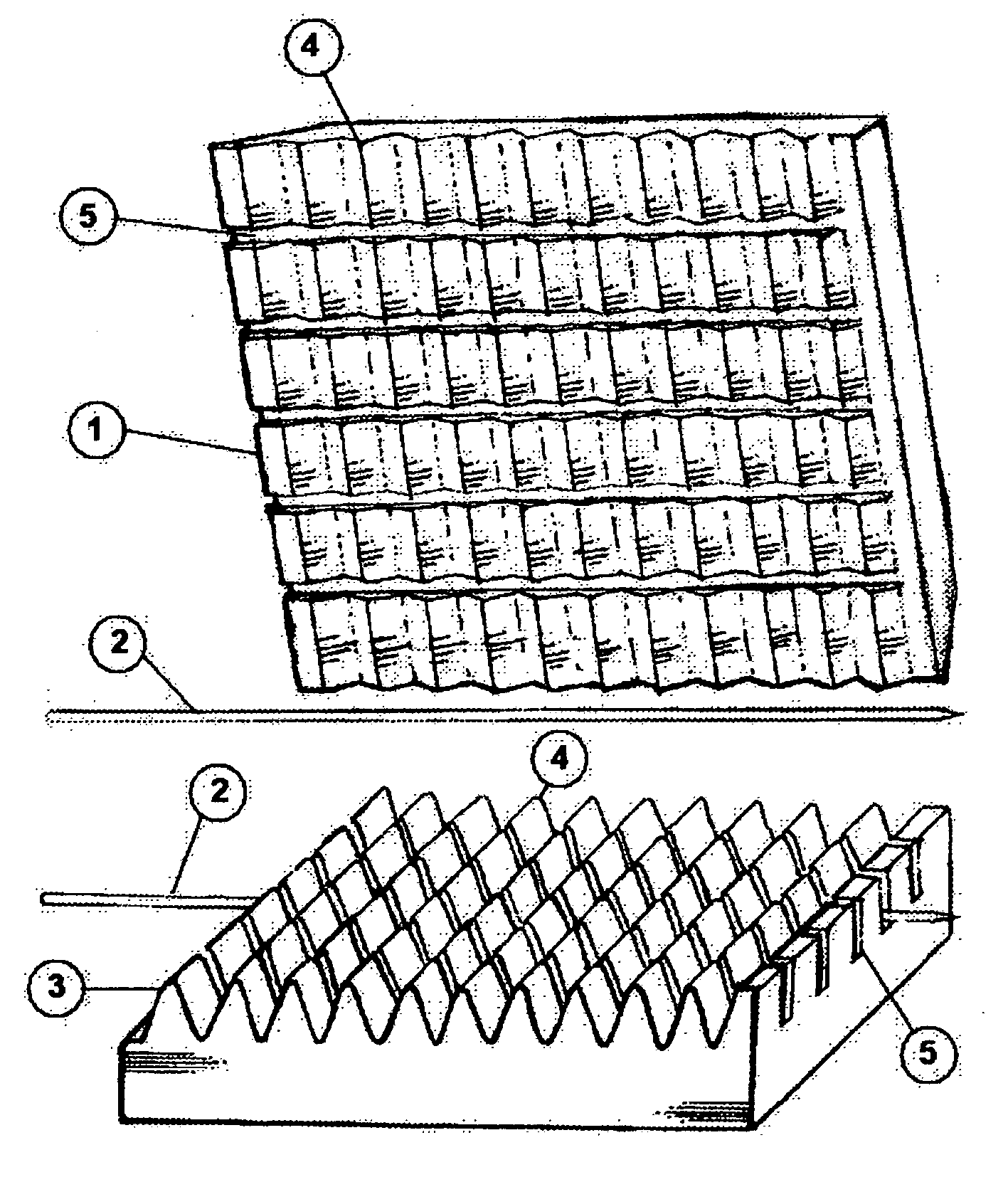

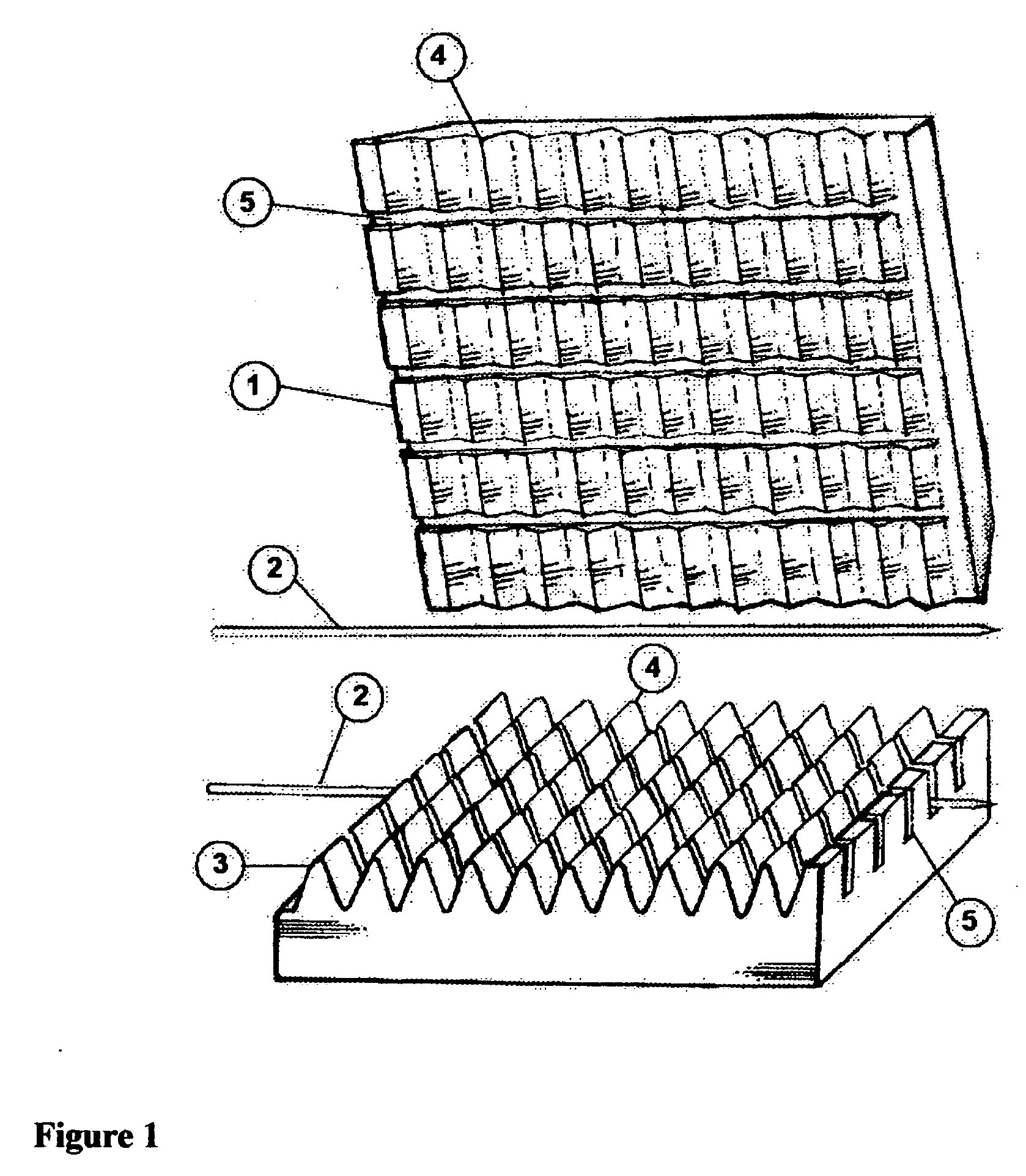

System and method for preparing skewered food products

Embodiments of the present invention relate to an apparatus for facilitating the skewering of meats, vegetables, fish, fruits, and other food products in connection with the preparation of kabobs and the like. In one embodiment of the present invention, an apparatus for skewering food products comprising: a tray portion having at least two opposing sidewalls having skewer passageways extending therethrough, and a plurality of food sections provided therein, each food section defined by at least one length divider and at least one width divider, the width divider having a skewer passageway extending therethrough and aligning with the skewer passageways of the two opposing sidewalls; and a lid portion, rotatably connected to the tray portion, the lid portion comprising a substantially flat inner surface for covering the food sections of the tray portion in a closed position.

Owner:DEALTO JOHN

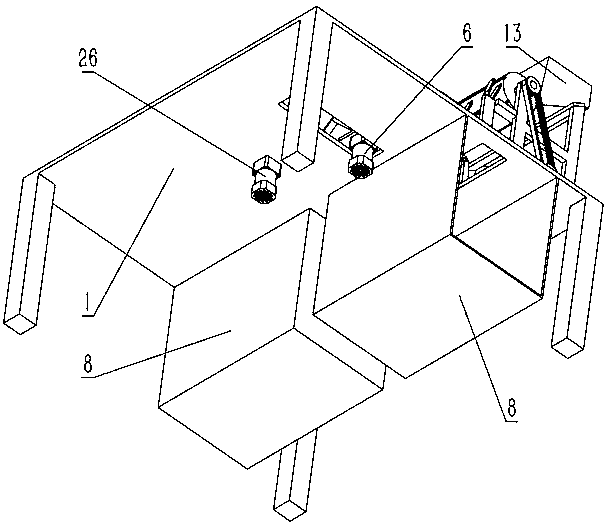

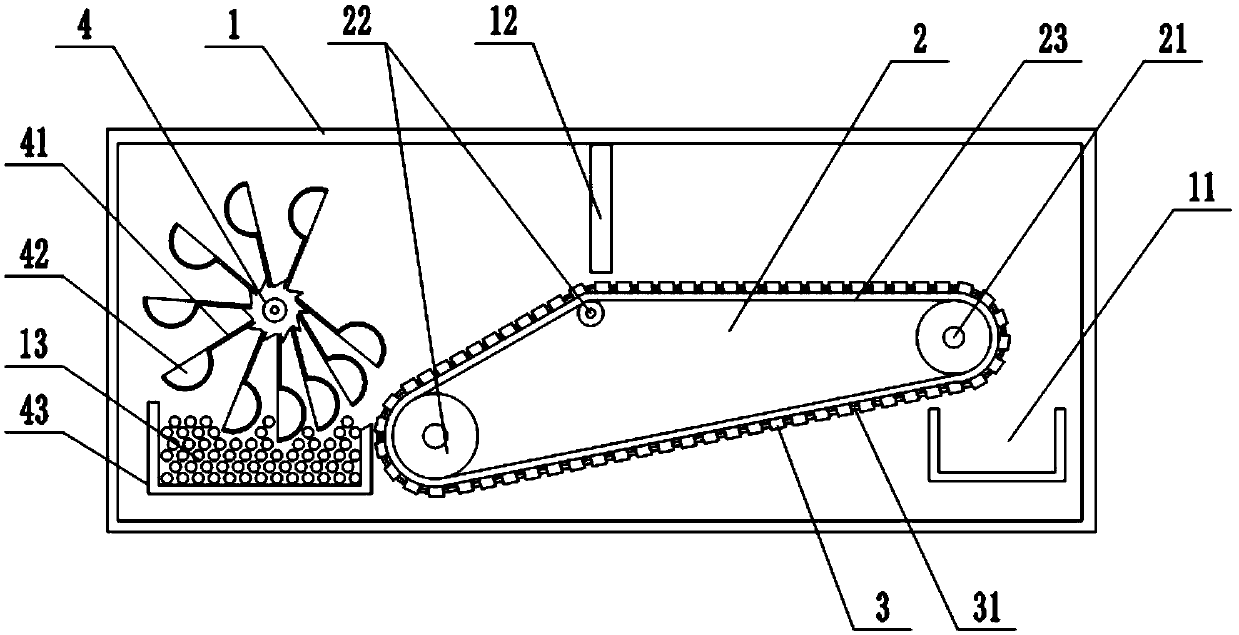

Automatic ball stringing machine

InactiveCN109662131AImprove threading efficiencyImprove securityFood shapingPutting meat on skewersEngineeringMechanical engineering

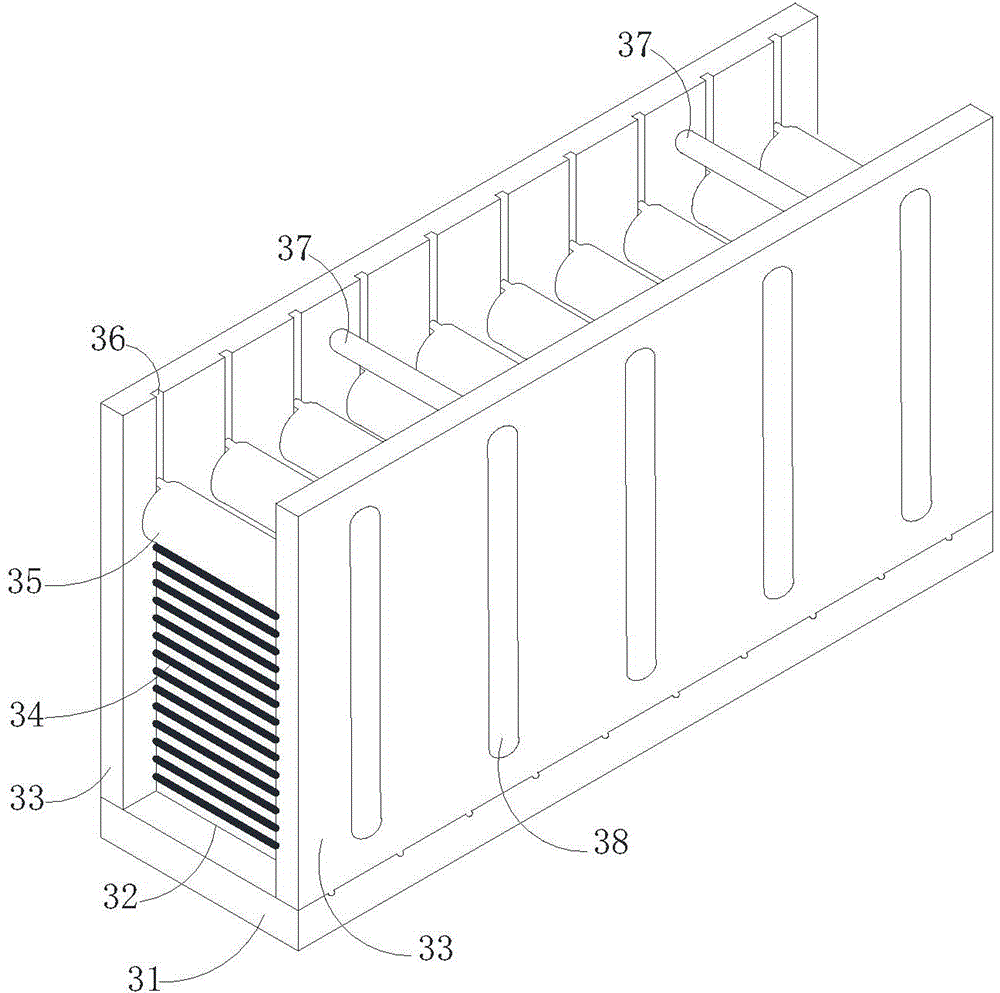

The invention relates to the technical field of food processing equipment, and discloses an automatic ball stringing machine. The machine includes a box body, the box body is internally and fixedly provided with a feeding device, a conveying belt and a collection box, several storage molds are installed at equal intervals on the conveying belt, several accommodation grooves are formed in the storage molds, and each accommodation groove only can accommodate one ball; one side of the horizontal part of the conveying belt is provided with a stringing device, the stringing device includes a bamboostick box, a second motor, a placement table and a stick pushing mechanism. The balls are placed in the storage molds through the feeding device, under action of the conveying belt, the storage moldscontaining the balls are conveyed to the horizontal part of the conveying belt, bamboo sticks in the bamboo stick box sequentially pass through the balls on the storage molds through the stick pushing mechanism, and the balls are stringed on a bamboo stick. The machine can achieve continuous stringing operation of the balls and the work efficiency is improved.

Owner:象山锦绣升平食品有限公司

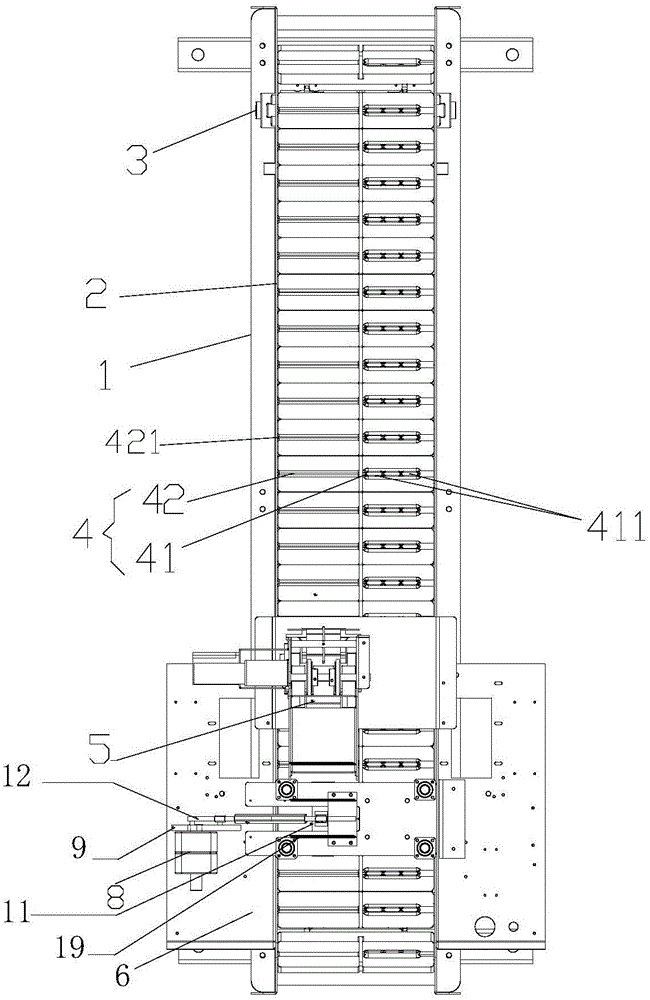

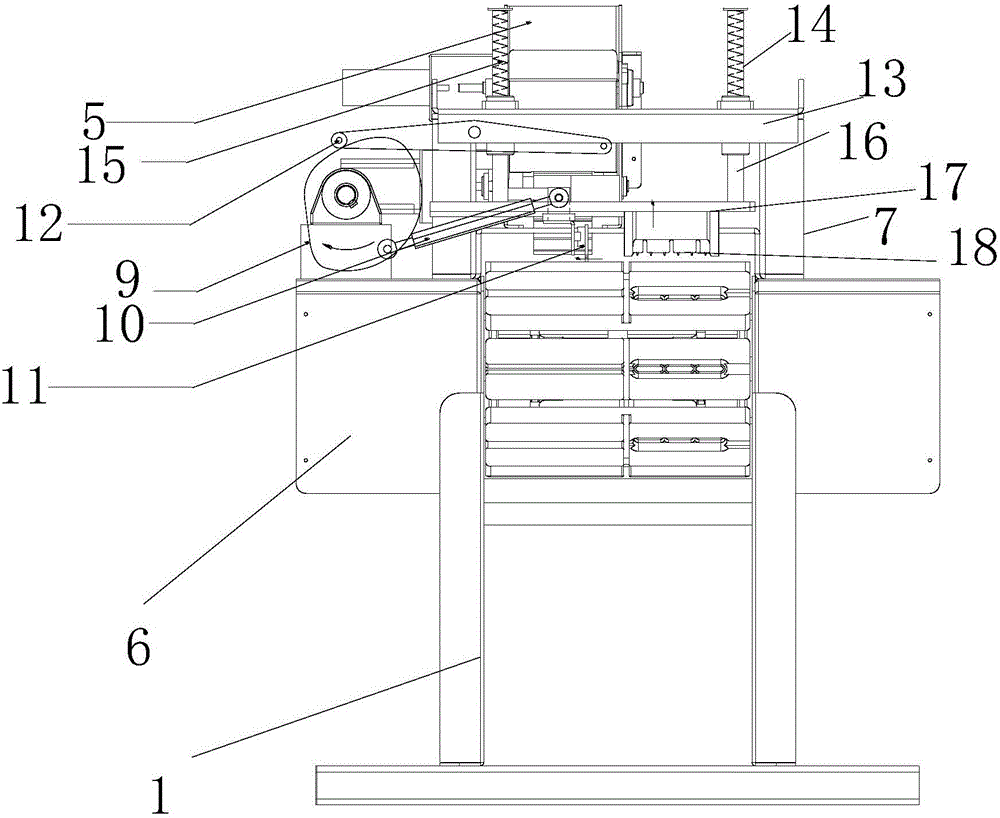

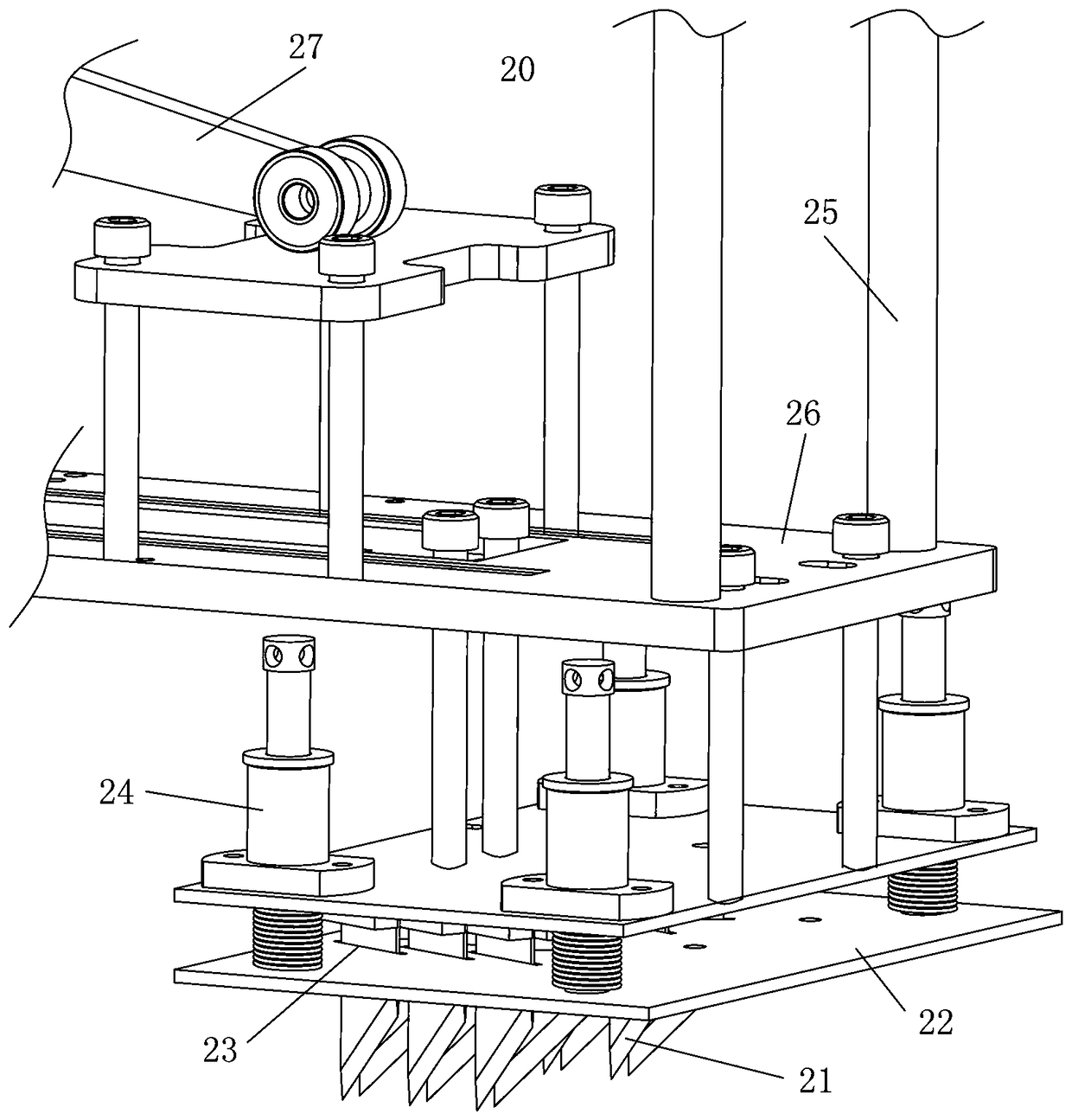

Machine for threading hot dog sausages with sticks

InactiveCN104824111ASimple designGuaranteed uptimePutting meat on skewersEngineeringUltimate tensile strength

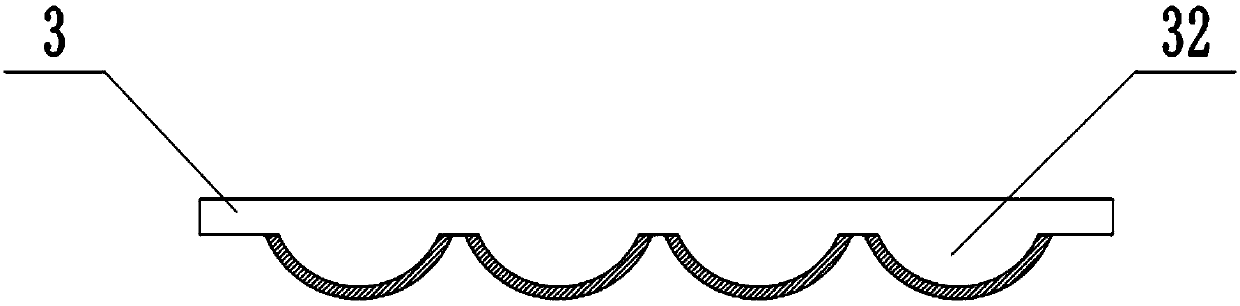

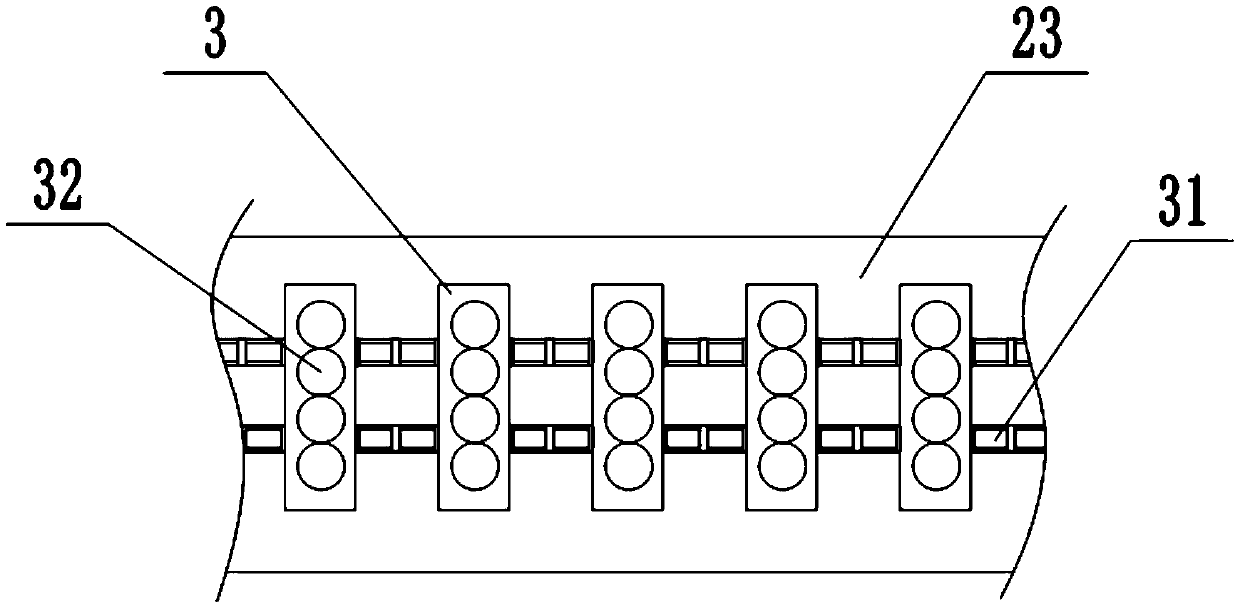

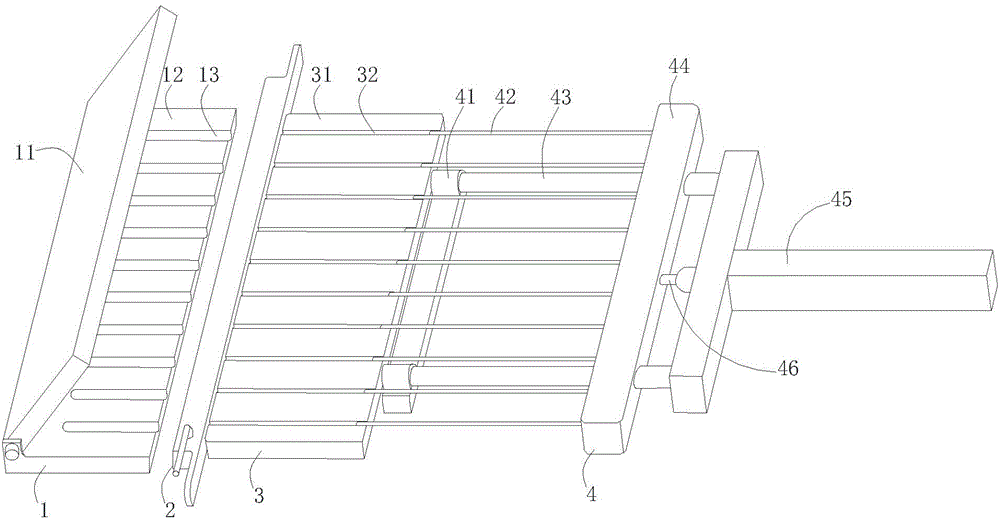

The present invention belongs to the field of food processing machinery, and specifically provides a machine for threading hot dog sausages with sticks. The machine comprises: a hot dog sausage fixing mechanism (1) for fixing and positioning hot dog sausages, wherein multiple hot dog sausage fixing grooves (13) are arranged at one end of the hot dog sausage fixing mechanism (1) in parallel; a bamboo stick pressing and conveying mechanism (3) for conveying bamboo sticks, wherein bamboo stick sliding grooves (32) corresponding to the hot dog sausage fixing grooves (13) are arranged on the bamboo stick pressing and conveying mechanism (3); and a stick threading power mechanism (4) for pushing bamboo sticks in the bamboo stick sliding grooves (32) into the hot dog sausage fixing grooves (13). The machine for threading hot dog sausage with sticks provided by the present invention has beneficial effects of being high in mechanical automation degree; compact in structure, low in manufacturing cost, easy in popularization; stable in system, capable of obviously reducing labor intensity and waste rate; and obviously improving production efficiency, and the like.

Owner:LUOHE SHUANGHUI MEAT IND

Cutting equipment

InactiveCN109169809ACut evenlyProtection securityPutting meat on skewersMeat shaping/cuttingDrive shaftFood material

The invention discloses cutting equipment. The cutting equipment comprises a body and a first cavity arranged in the body, wherein a material inlet is formed in the left end of the first cavity in a communicating mode; a barbecue skewer frame is connected with the inner wall of the bottom end of the material inlet in a sliding fit mode; a handle is fixedly connected with the end surface of the left end of the barbecue skewer frame; skewers extending from the left side to the right side are connected with the barbecue skewer frame in a rotary fit mode; elastic tooth hooks are fixedly connectedwith the skewers; a groove open upward is formed in the barbecue skewer frame; a stop block is connected with the inside of the groove in a sliding fit mode; a first spring is connected between the stop block and the groove in a push pressing mode; and a first transmission shaft which is positioned at the left end of the material inlet and extends from the left side to the right side is connectedwith the inner wall of the left end of the first cavity in a rotary fit mode. The cutting equipment has simple structure and convenient operation, a pause type cutting structure realizes uniform cutting of food materials, and the safety of users is protected because cutting is performed inside the cavity.

Owner:朱顺华

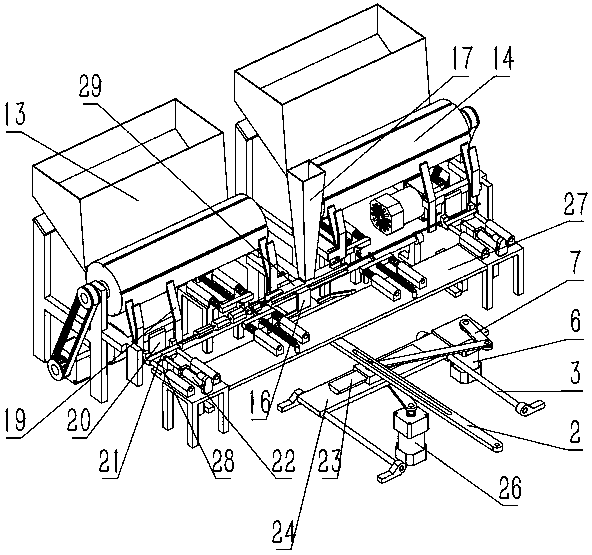

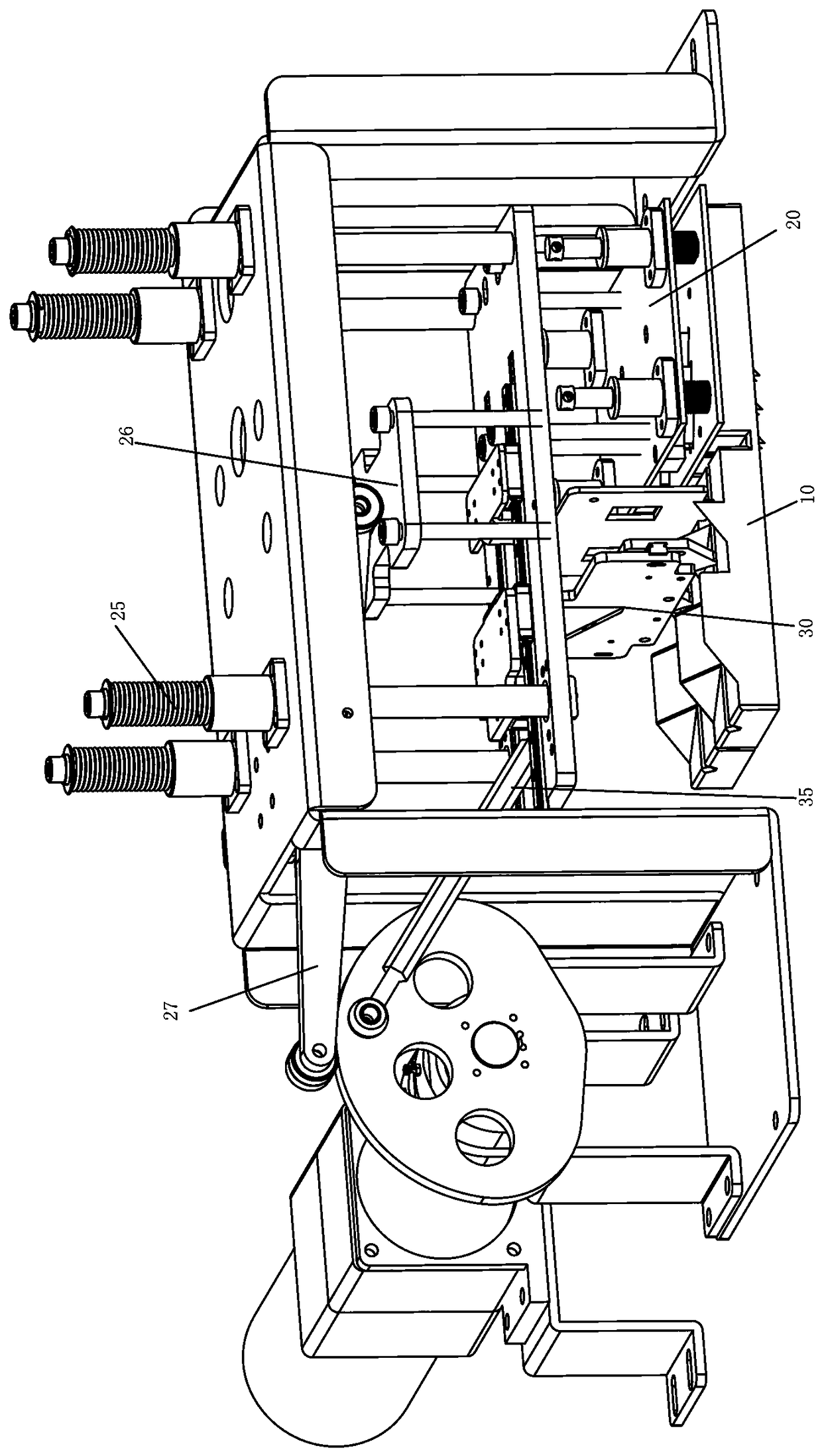

Novel automatic cutting and sticking integrated sticking machine assembly line

PendingCN111358028AReduce lossIncrease success rateFood shapingPutting meat on skewersFood materialAssembly line

The invention discloses a novel automatic cutting and sticking integrated sticking machine assembly line. The sticking machine assembly line comprises a main body frame, a feeding frame, a knife groupframe, an upper die, a sticking frame, a stick feeding rotating wheel, a stick feeding auxiliary wheel, an upper sliding track, a lower sliding track, a stick pushing plate, a lower die, an origin plate, a butt-joint stick pressing plate, an auxiliary stick pressing plate, a bamboo stick guide horn mouth, a main stick pressing plate, a spring and a pressing oblique corner. According to the invention, the effects of cutting and sticking are achieved, and the automation degree of food processing is improved, so that labor cost is saved, and production efficiency is improved; the use condition of bamboo sticks is conveniently known by personnel in real time, so that the problems of sticking mixing or excessive sticking of the bamboo sticks in a production process are solved, and synchronouscooperation of cutting and sticking is ensured; and the moving track of the stick pushing plate is limited, so that the problem of offset of the bamboo sticks in a stick pushing process is avoided. The bamboo sticks smoothly penetrates through the center of a food material, faults such as sticking, jumping, breaking and the like are avoided, the precision of sticking is guaranteed, and thus the success rate of sticking is improved.

Owner:诸城市胜青食品机械有限公司

Frozen meat stringing machine for hotel kitchens

ActiveCN110771670AReduce intensityHigh degree of automationPutting meat on skewersEngineeringMechanical engineering

The invention discloses a frozen meat stringing machine for hotel kitchens. A slicing cutter and a slitting cutter are arranged above a conveying belt and sequentially arranged in parallel in a conveying direction of the conveying belt from left to right, a dicing table is disposed on the left side of the conveying belt, a dicing cutter is positioned above the dicing table, a steel stick mechanismis arranged on the back side of the dicing cutter, a reciprocating unit is arranged above the slicing cutter, frozen meat frozen in a rectangular block shape is placed on the reciprocating unit, thereciprocating unit pushes the frozen meat to reciprocate on the slicing cutter, the slicing cutter slices the frozen meat into frozen meat slices, the frozen meat slices are conveyed by the conveyingbelt to the lower side of the slitting cutter and cut into frozen meat strips, the frozen meat strips slide to the dicing table, the dicing cutter cuts the frozen meat strips into string meat blocks,and the steel stick mechanism inserts steel sticks into the string meat blocks to form meat strings. The frozen meat stringing machine for hotel kitchens makes up defects of existing frozen meat stringing machines in the market, can string frozen meat, can reduce the intensity of workers, and is high in automation degree, high in efficiency and good in user effects.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

Food preparation device

InactiveUS20110223306A1Improve protectionHand protectionFood preservationRoasting apparatusEngineeringFood preparation

A food preparation device including: a body defining a passage; and a mount or head portion for holding a skewer within the passage. The passage has an opening for receiving portions of food such that when a skewer is held by the mount, portions of food entering the opening become impaled on the skewer within the passage. The device is provided with a cutter to cut portions of food such as meat for use in the device.

Owner:ALLEN NEIL ANDREW

Robot for removing sausage casing of ham sausage

ActiveCN108263696ASimple structurePowerfulFood shapingPutting meat on skewersPulp and paper industryInverted t

The invention provides a robot for removing a sausage casing of a ham sausage. The robot comprises a first sliding rail part, a first sliding block, a second sliding block, a first stepping motor part, an end cutting knife part, a sausage casing cutting knife part 6, a sausage body rolling, rotating and clamping part, a sausage casing reeling part and a bamboo stick screwing-in part. The robot ischaracterized in that a sliding rail is a cuboid with the middle being provided with an inverted-T-shaped groove, and a gear column is arranged on one side of the upper portion of the sliding rail; the first sliding block is an inverted-T-shaped sliding block provided with two stepping motor mounting holes and can be directly embedded into the sliding rail; and the second sliding rail is an inverted-T-shaped sliding block provided with a stepping motor mounting hole and can be directly embedded into the sliding rail. According to the robot, a full-automatic operating mode is adopted, in the sausage one-time propelling and one-time returning processes, the sausage casing of the sausage can be successfully stripped, bamboo sticks can be successfully inserted into the sausage, and great convenience is brought.

Owner:烟台中科恩吉科创新产业园管理有限公司

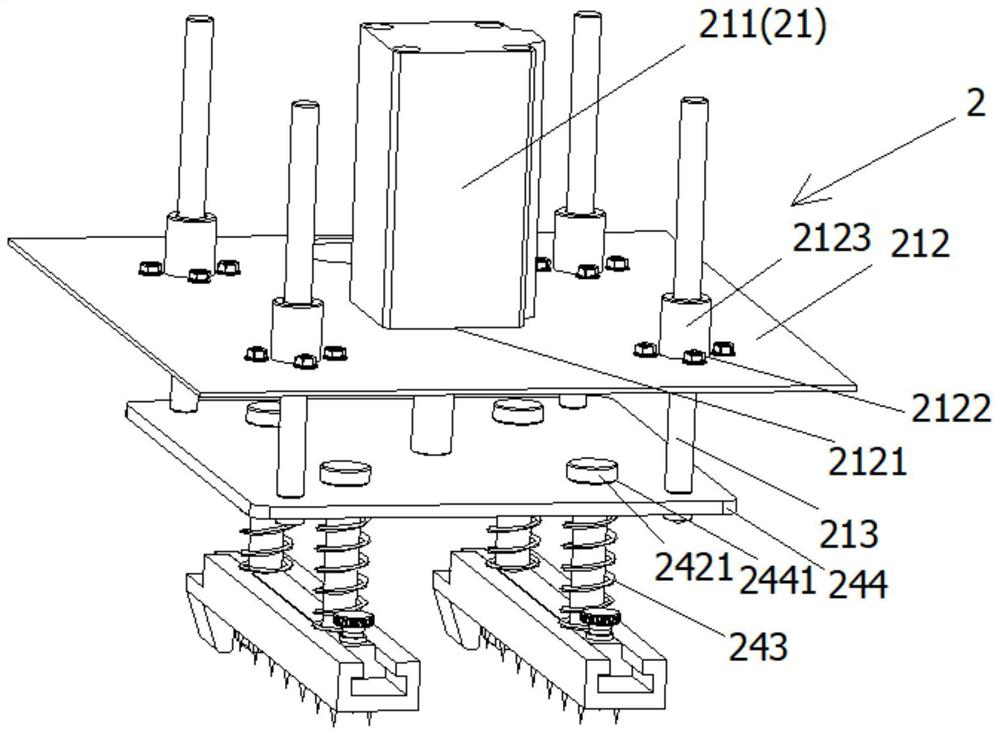

Automatic stringing machine

ActiveCN112352814AImprove work efficiencyCompact structurePutting meat on skewersTransmission beltStructural engineering

The invention discloses an automatic stringing machine. The automatic skewering machine comprises a skewering device, a pressing device and a raw material conveying device; a plurality of storage tankbodies of the raw material conveying device are arranged on a conveying belt at intervals, a first driving mechanism drives the conveying belt to move, and corresponding skewer penetrating openings are formed in the tank walls of the two ends of each storage tank body. The pressing device comprises two pressing pieces and a second driving mechanism, the two pressing pieces are arranged above theconveying belt, and the second driving mechanism is in transmission connection with the two pressing pieces; the skewering device comprises two skewer falling mechanisms, a skewer pushing mechanism and a bearing table, the bearing table is arranged at one end of the storage tank body, the skewer pushing mechanism is arranged on the bearing table, and the two skewer falling mechanisms are arrangedabove the left side and the right side of the skewer pushing mechanism respectively; two skewers can be pushed out at a specific distance, that is, two strings of raw materials are strung at the sametime, and compared with an automatic stringing machine for stringing a single string on the market, the working efficiency is nearly doubled, the structure is compact, and the space utilization rate is high.

Owner:正大食品研发有限公司

Flower cutting cluster threading machine

PendingCN109156501APrevent fallingComplete appearancePutting meat on skewersEngineeringMechanical engineering

The invention provides a flower cutting cluster threading machine which comprises a carrying mold, wherein a flower cutting pressing mechanism is arranged above the carrying mold; a stick push mechanism is arranged on the left side of the carrying mold; stick grooves and at least one material tank are arranged on the left side and the right side of the carrying mold; avoiding cutter grooves are formed in the front side and the rear side of the material tank; the avoiding cutter grooves are communicated with the material tank and extend into the material tank; the flower cutting pressing mechanism comprises cutters and a first transmission component; the cutters are positioned right above the avoiding cutter grooves; the first transmission component is used for driving the cutters to move up and down to enable the cutters to be inserted into or withdraw from the avoiding cutter grooves. By adopting the flower cutting cluster threading machine, foods on the material tank can be cut by using the cutters of the flower cutting pressing mechanism, an automatic flower cutting function can be achieved, the flower cutting efficiency can be improved, stable flower cutting quality can be achieved, and the pass percent can be increased; foods on the material tank can be pressed and positioned by using a pressing plate on the flower cutting pressing mechanism, food falling can be avoided, and the pass percent of cluster threading can be improved.

Owner:CLOUDFOCUS DONGGUAN AUTOMATION EQUIP CO LTD

Staty maker: apparatus for the perpetration of Satay

A method and apparatus is disclosed for the perpetration of a variety of foods in Satay style. The apparatus comprises two manually positioned platens (upper and lower) and a plurality of food elongated retaining spikes or skewers. The foodstuff is held in the retaining protrusions on the upper and lower platens and spikes or skewering device are pushed into the guiding slots to secure the foodstuff on the spikes or skewers. This unique apparatus can be made of wood, stainless steel, aluminium, carbon fibre, plastic, or any material, which can be worked or machined into the correct configuration, that provide a textured or smooth surface, which can be cleaned and sanitized. The invention provides a quick and safe method of preparing Satay style food.

Owner:ROE JOHN PAUL

Automatic stringing machine for flaky food

PendingCN111743180AWork rhythm is clearEasy to operateFood shapingPutting meat on skewersProcess engineeringFood material

An automatic stringing machine for flaky food is characterized by comprising a stick discharging device, a stick pushing device, a base and a position changing device; the stick pushing device is mounted on one side above the base; the pushing-in action of the bamboo sticks can be realized; the position changing device is mounted on the other side above the base; the stick discharging device is mounted above the sticker pushing device and the position changing device; by designing the position changing device with the mold and the stick discharging device in linkage with the position changingdevice, efficient and accurate skewer penetrating operation is achieved; in addition, the special mold is designed, the reliable state of slice food materials in the stick penetrating operation is determined, the quality of sticker finished products is guaranteed, and the stick penetrating work efficiency and the finished product rate are greatly improved.

Owner:李万枝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com