Patents

Literature

141results about How to "Improve threading efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

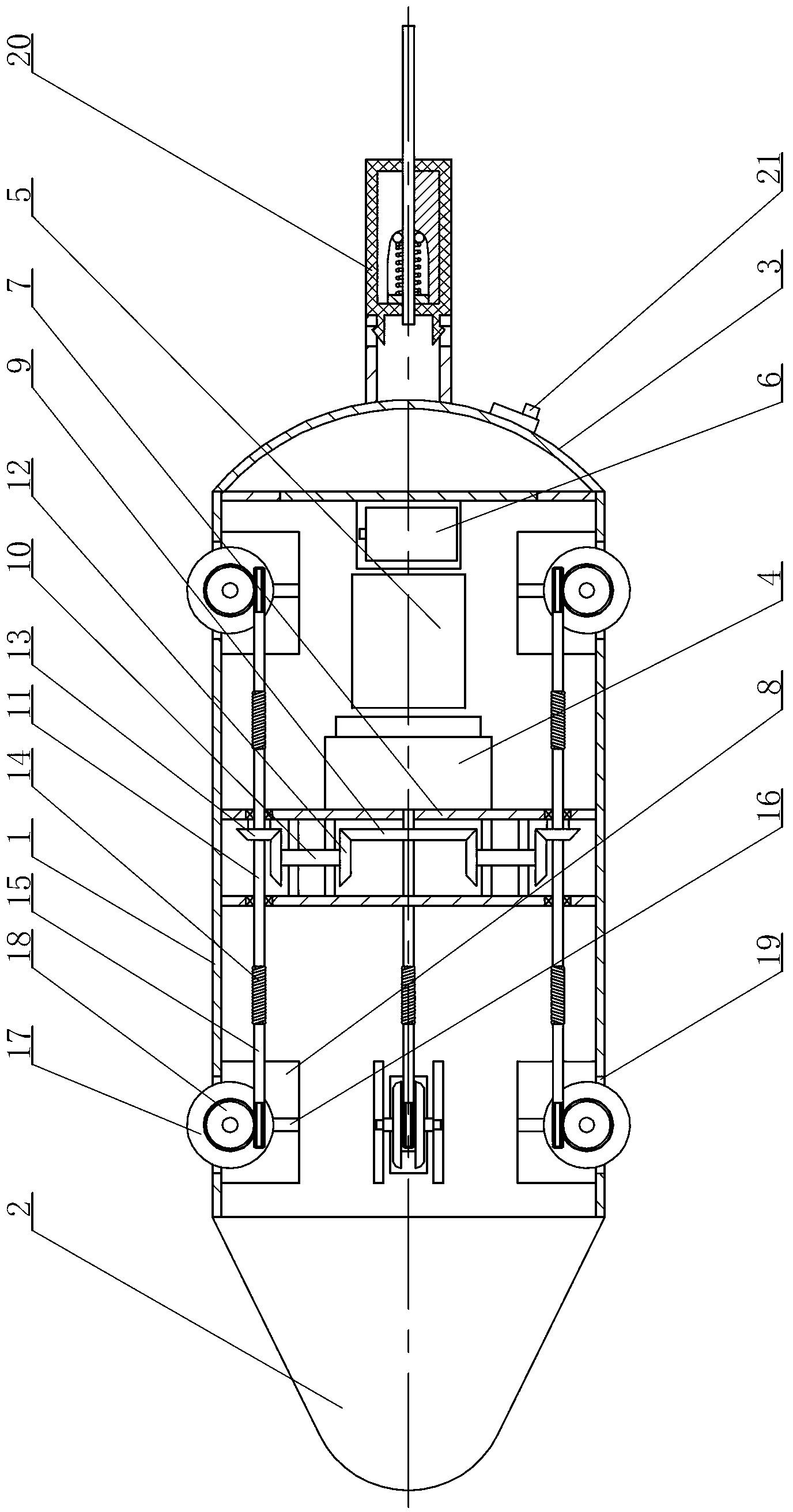

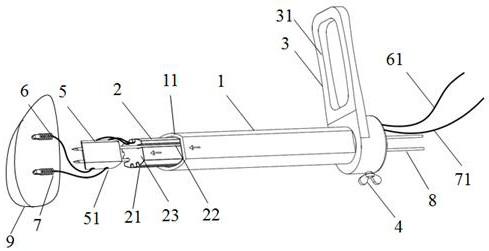

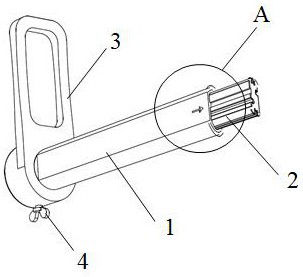

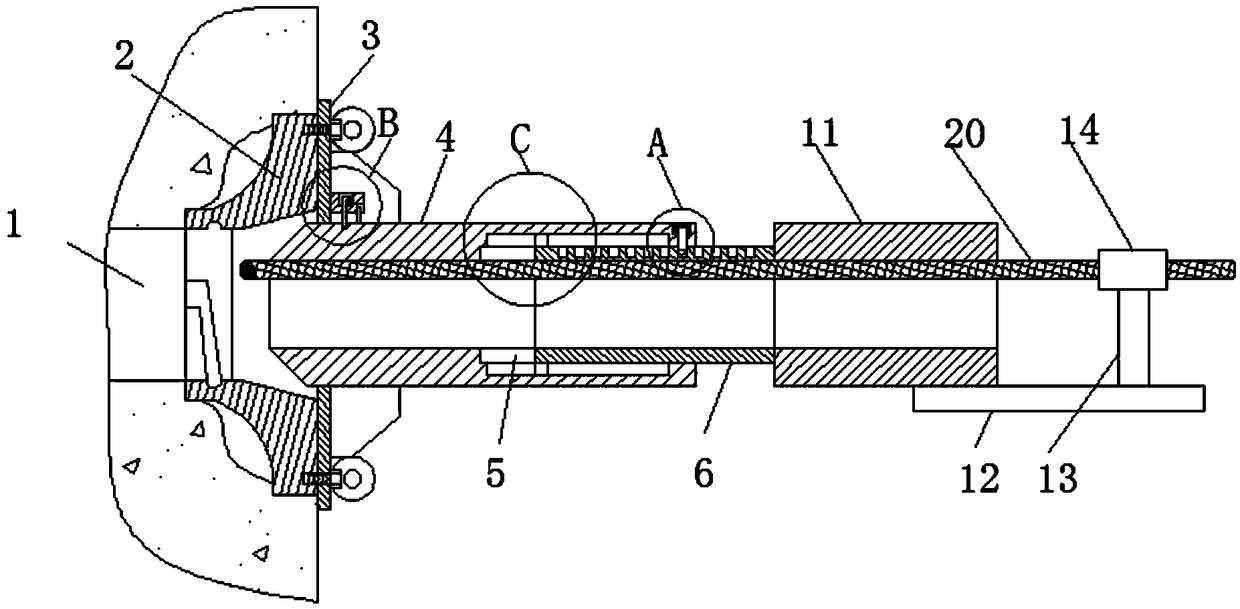

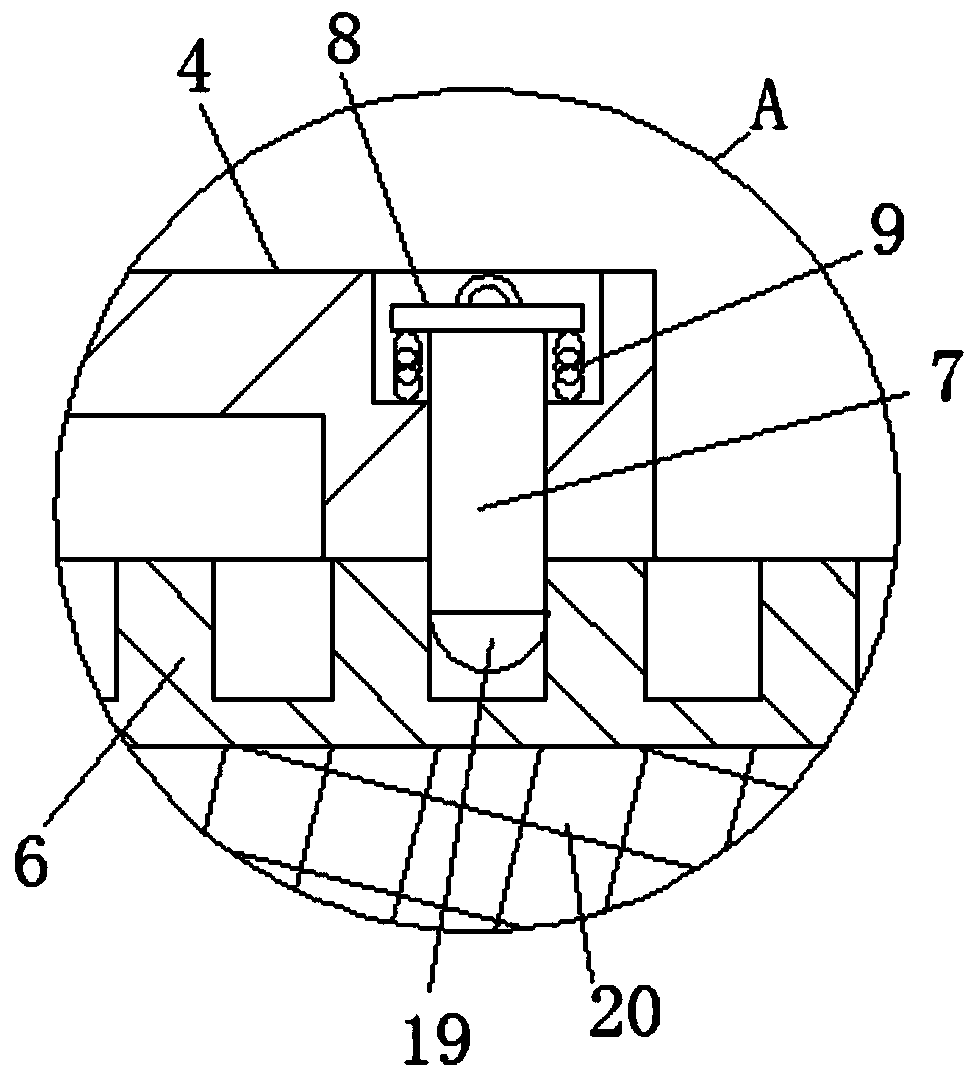

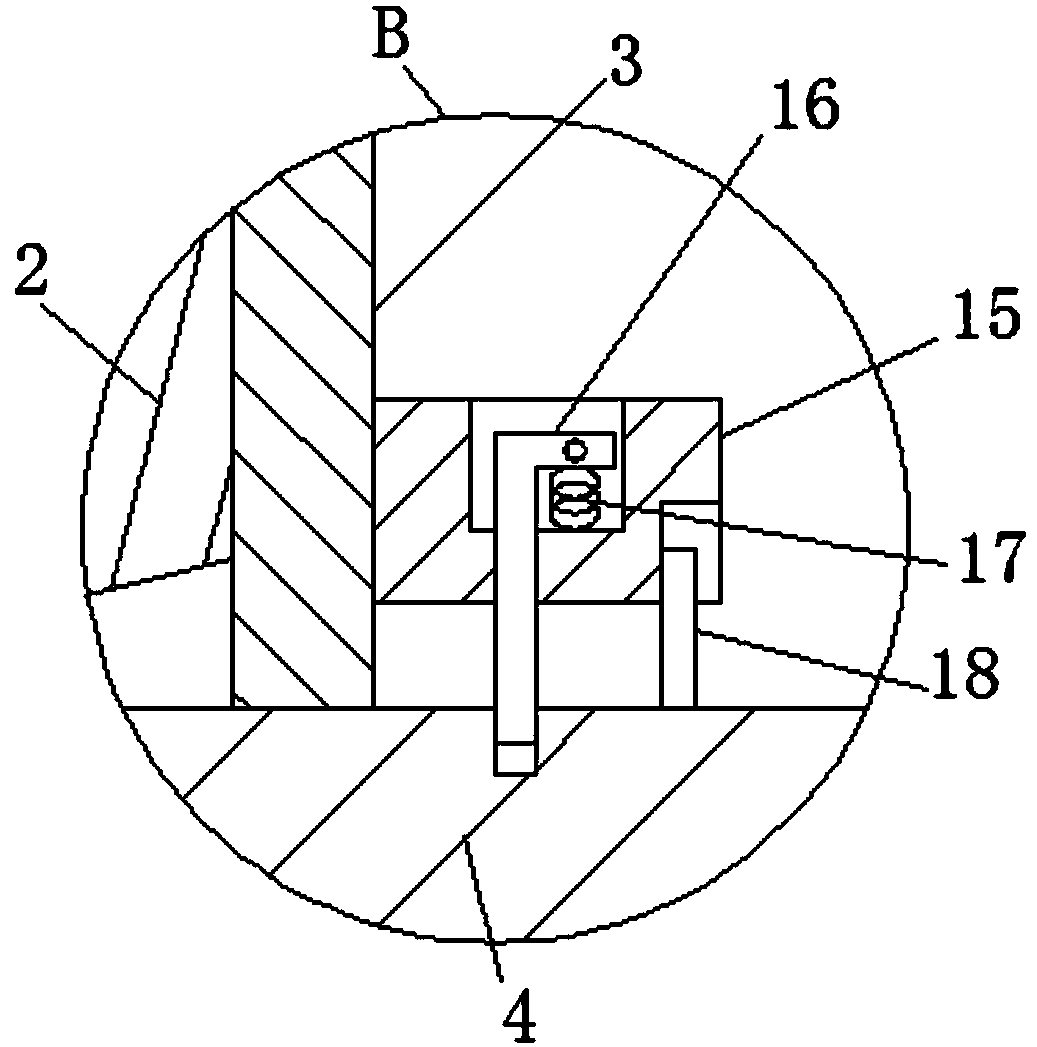

Long-casing-pipe automatic line threading device

InactiveCN103227435ATime-saving and labor-saving threading operationEasy to useApparatus for laying cablesDrive shaftBusbar

The invention discloses a long-casing-pipe automatic line threading device, in order to mainly solve the problems that an existing line threading tool is time-consuming and labor-consuming and is inconvenient to use. The long-casing-pipe automatic line threading device is characterized in that a DC (direct current) motor, a circuit board (5) and a battery are fixed in a main body (1); the main body (1) is internally provided with a gear chamber (7) and a rolling wheel installation frame (8); the gear chamber (7) is internally provided with a large fluted disc (9), a reversing shaft (10) as well as a driving shaft (11) penetrating through the gear chamber; two ends of the reversing shaft (10) are respectively connected with an intermediate bevel gear (12); a driving shaft (11) is provided with an output bevel gear (13); the side wall of the main body (1) is provided with a through groove (19) along the direction of a busbar; and a wheel body in a rolling wheel assembly (17) is positioned in the through groove (19). The long-casing-pipe automatic line threading device draws a flexible conductor by adopting an electric vehicle body, and has the characteristics of time and labor saving, convenience in use and high line threading efficiency.

Owner:南通市德美电机玻璃纤维有限公司

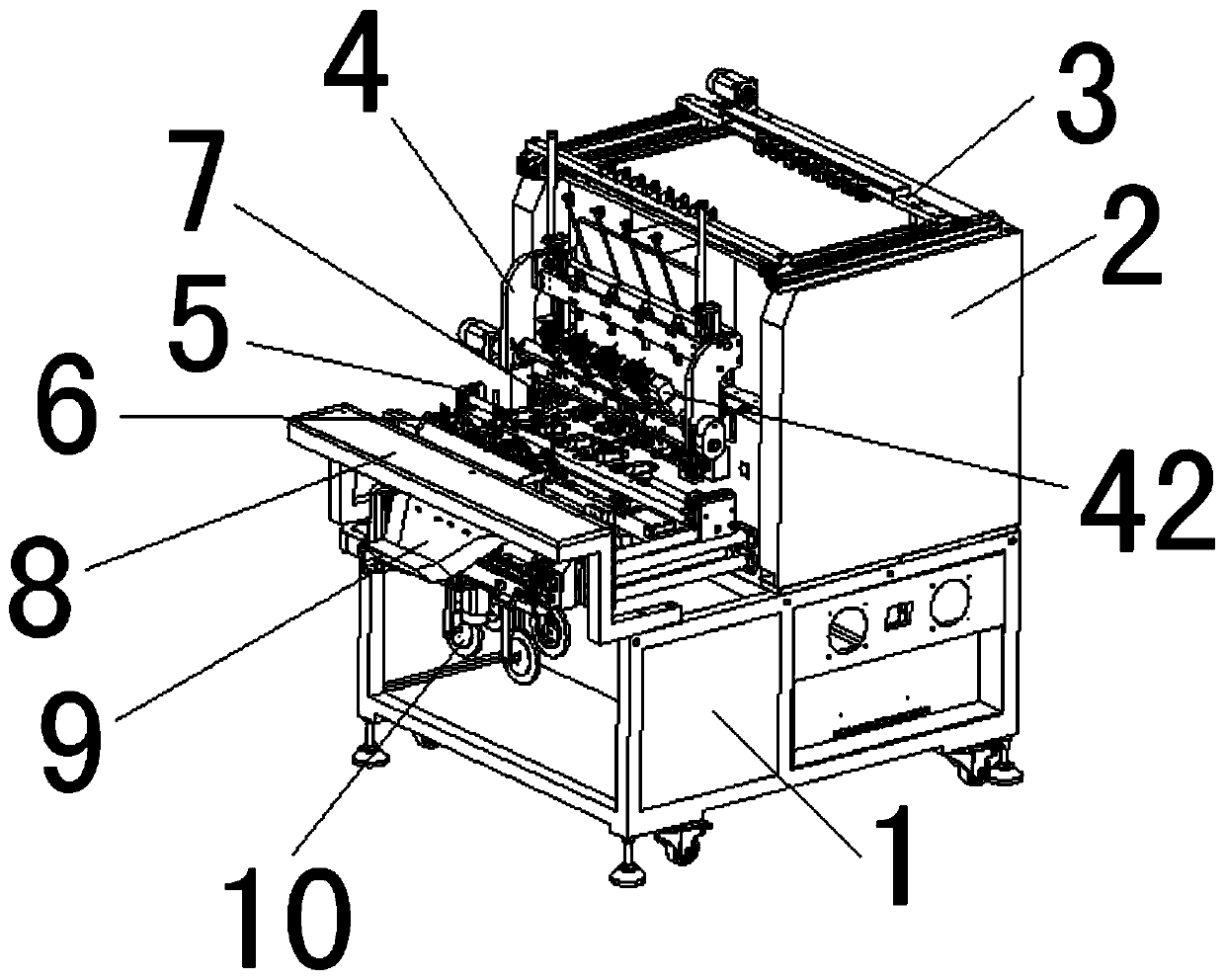

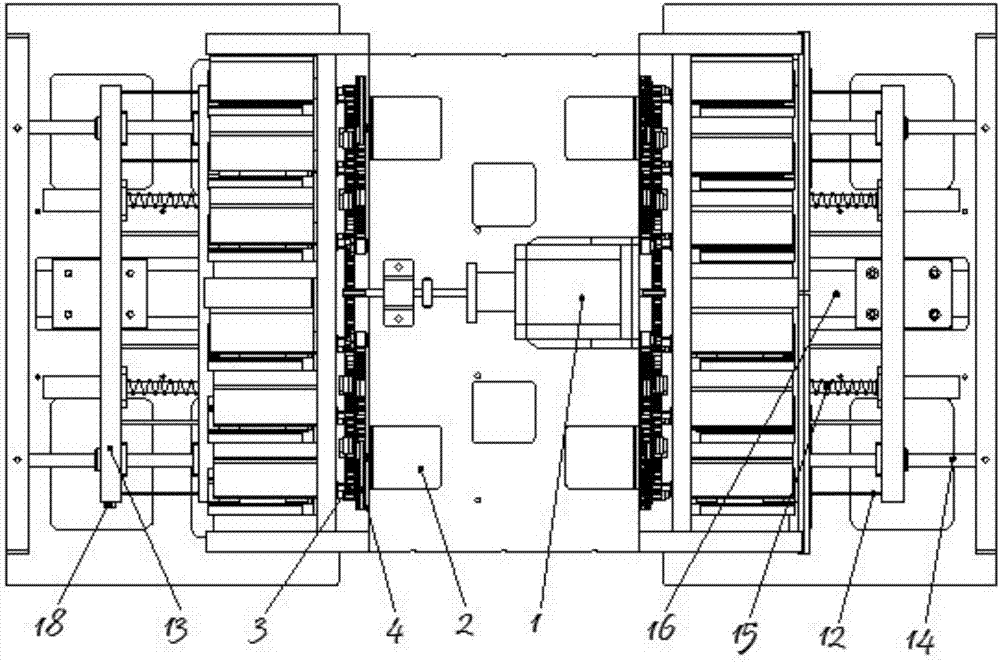

Automatic sleeve penetrating winding machine

ActiveCN111354567AImprove winding efficiencyGood winding effectCoils manufactureWinding machineEngineering

The invention discloses an automatic sleeve penetrating winding machine which comprises an attenuation mechanism, a three-axis movement mechanism, a wire clamp mechanism, a feeding mechanism, a discharging mechanism, a rubber coating mechanism and the like. According to the automatic sleeve penetrating winding machine, a framework can be automatically fed on one mechanism; a wire is sleeved with asleeve, the sleeve is cut into sections according to the production requirement, the sleeve is stored, the tension of the wire is attenuated, an initial end of the sleeve is pushed to be wound with aPIN, framework winding is conducted, a tail end of the framework winding is subjected to right-angle shaping, a tail end of the sleeve is pushed to be wound with the PIN, the rubber coating of the framework is conducted, and a finished product is discharged. Therefore, the problems of low efficiency, high labor intensity of workers and high labor cost of enterprises in a traditional manual operation mode for pulling the wire into the sleeve are solved; and the problems that due to the fact that an existing sleeve conveying mechanism is imperfect in structural design, so a sleeve is often flattened and pressed to deform such that the sleeve is not conveyed smoothly, and multiple different procedures cannot be conducted on one mechanism are solved.

Owner:东莞市纵易智能装备有限公司

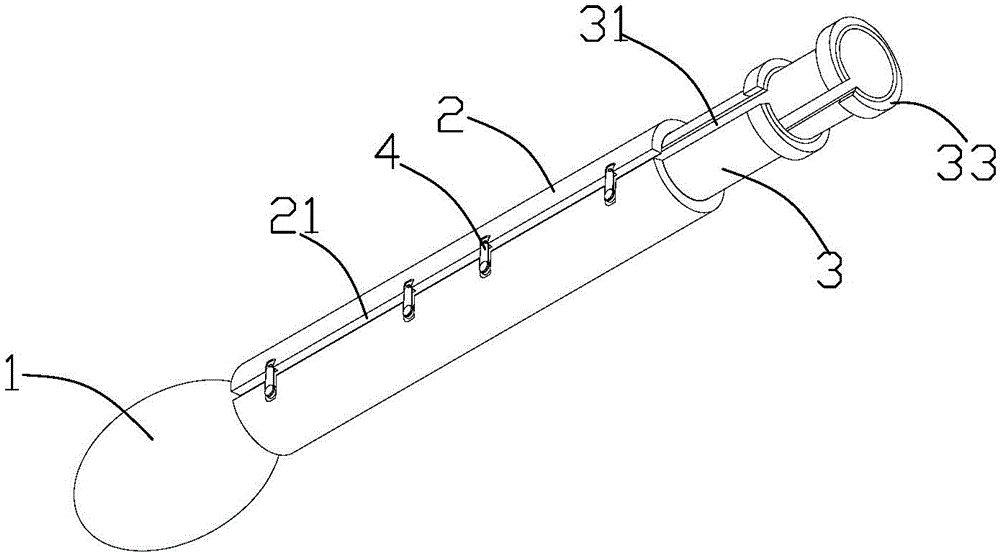

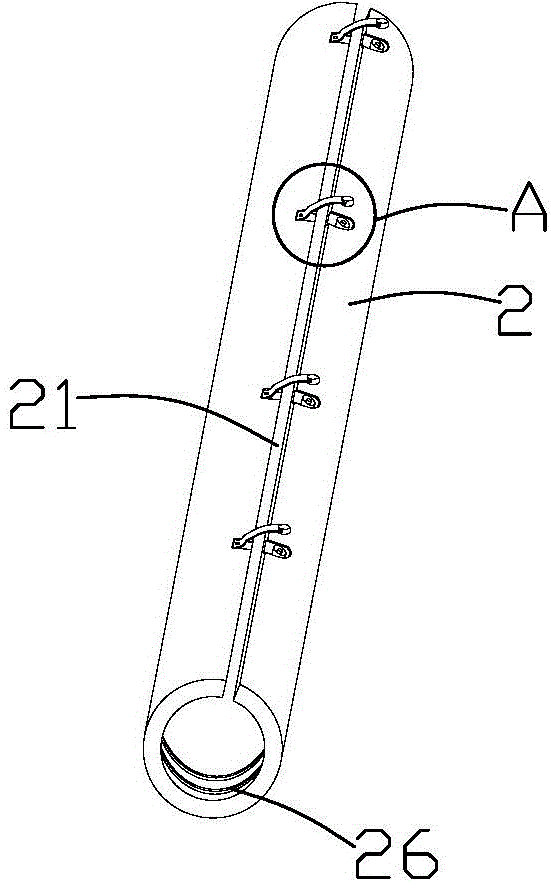

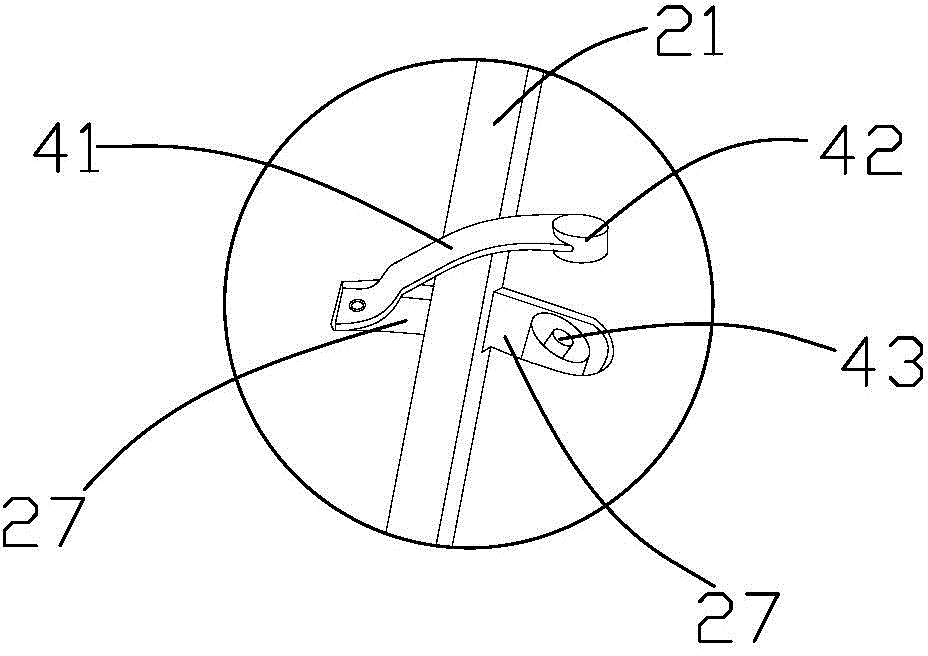

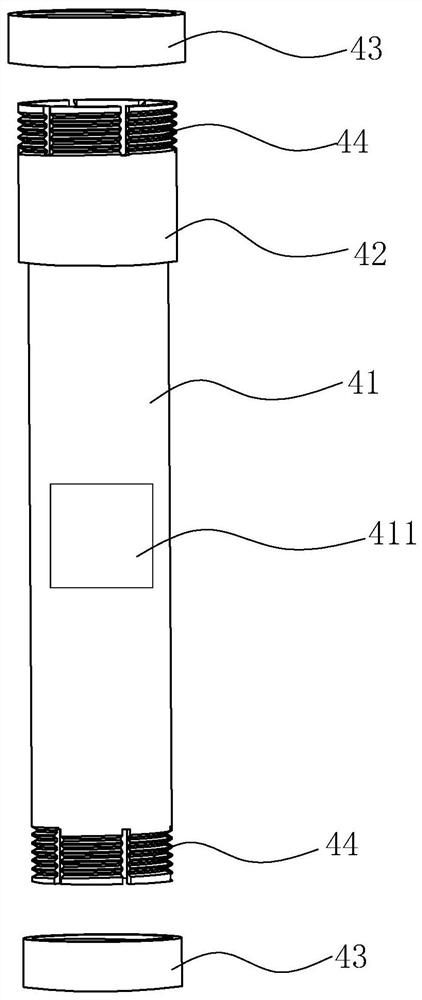

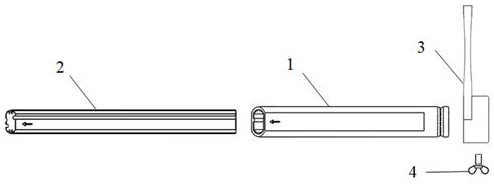

Threader for information room

A threader for an information room comprises a guide head and a telescopic rod body formed by at least two sleeves sleeved together; the guide head comprises two semi-shells, a placement block is arranged in one semi-shell, a cable groove is formed in the placement block, and a pressing block is arranged in the other semi-shell; one semi-cylinder is arranged at the tail end of each semi-shell, and a groove is formed in each semi-cylinder; each sleeve is provided with a strip-shaped opening; a first chute and a second chute are arranged on the inner side of each sleeve, and a first through hole and a second through hole are respectively formed in the first chute and the second chute; except the outermost sleeve, a wave bead screw is arranged at the front end of each sleeve. According to the threader for the information room, the floor with large area is not required to be lifted, the threading is convenient and damage-free, cables can be arranged in order, and the wiring is facilitated.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

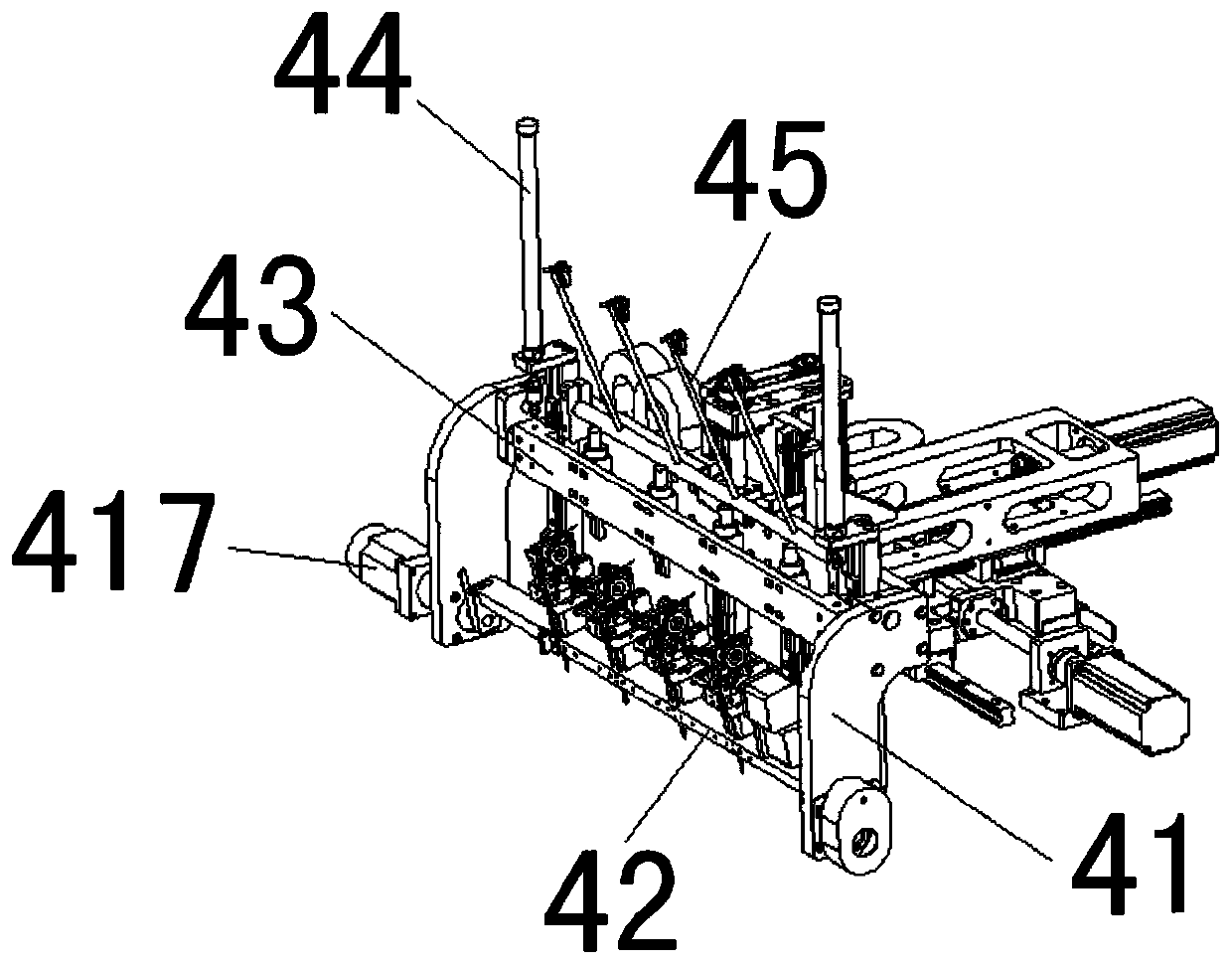

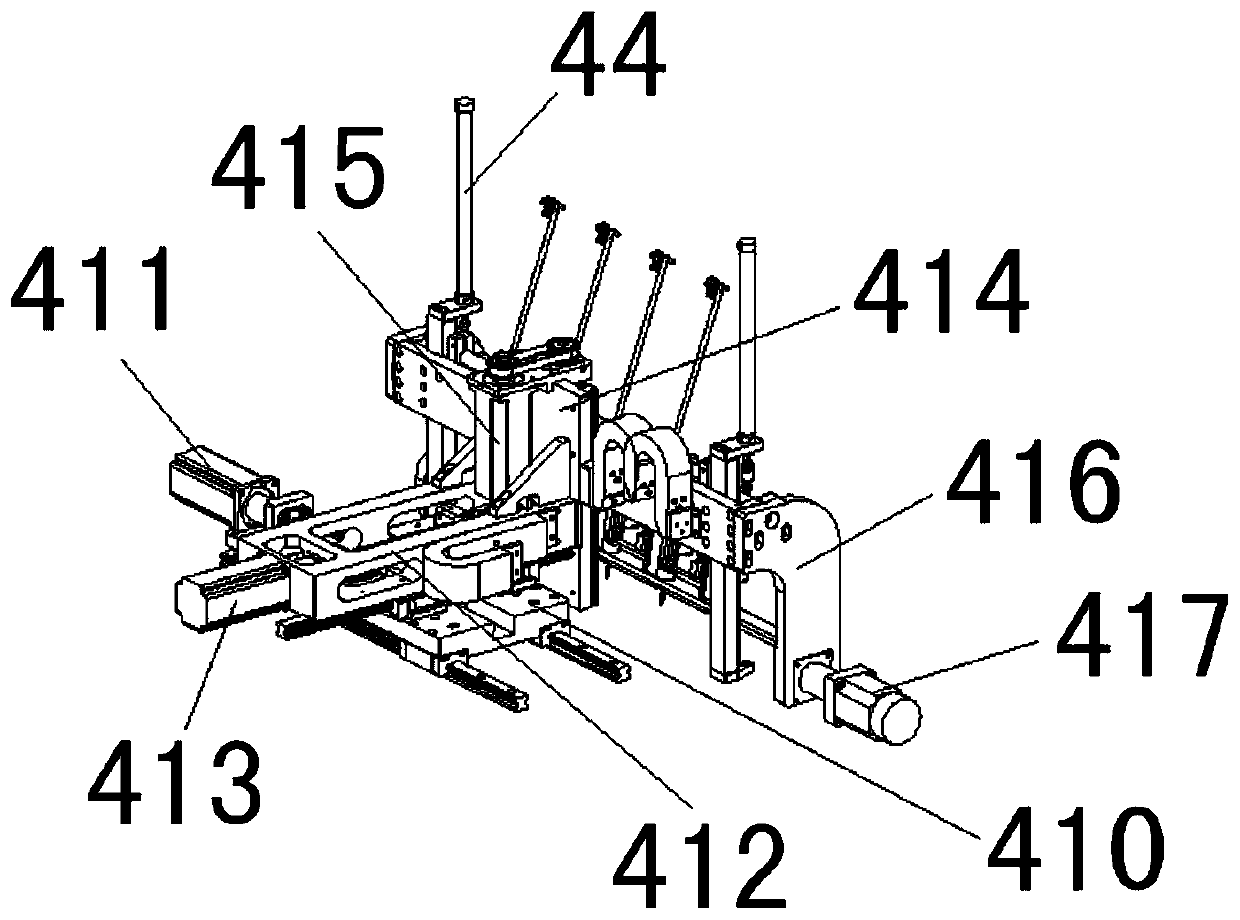

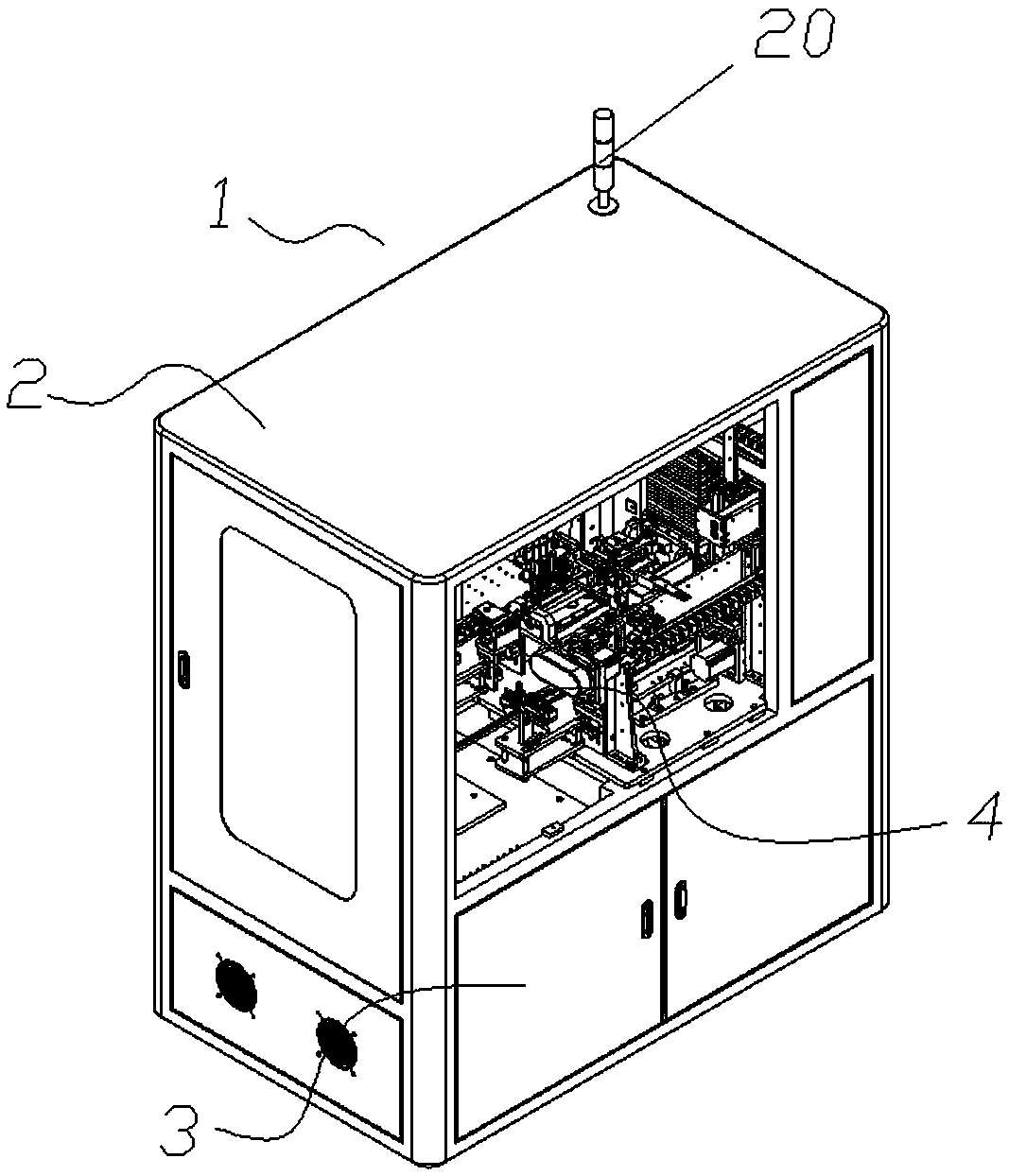

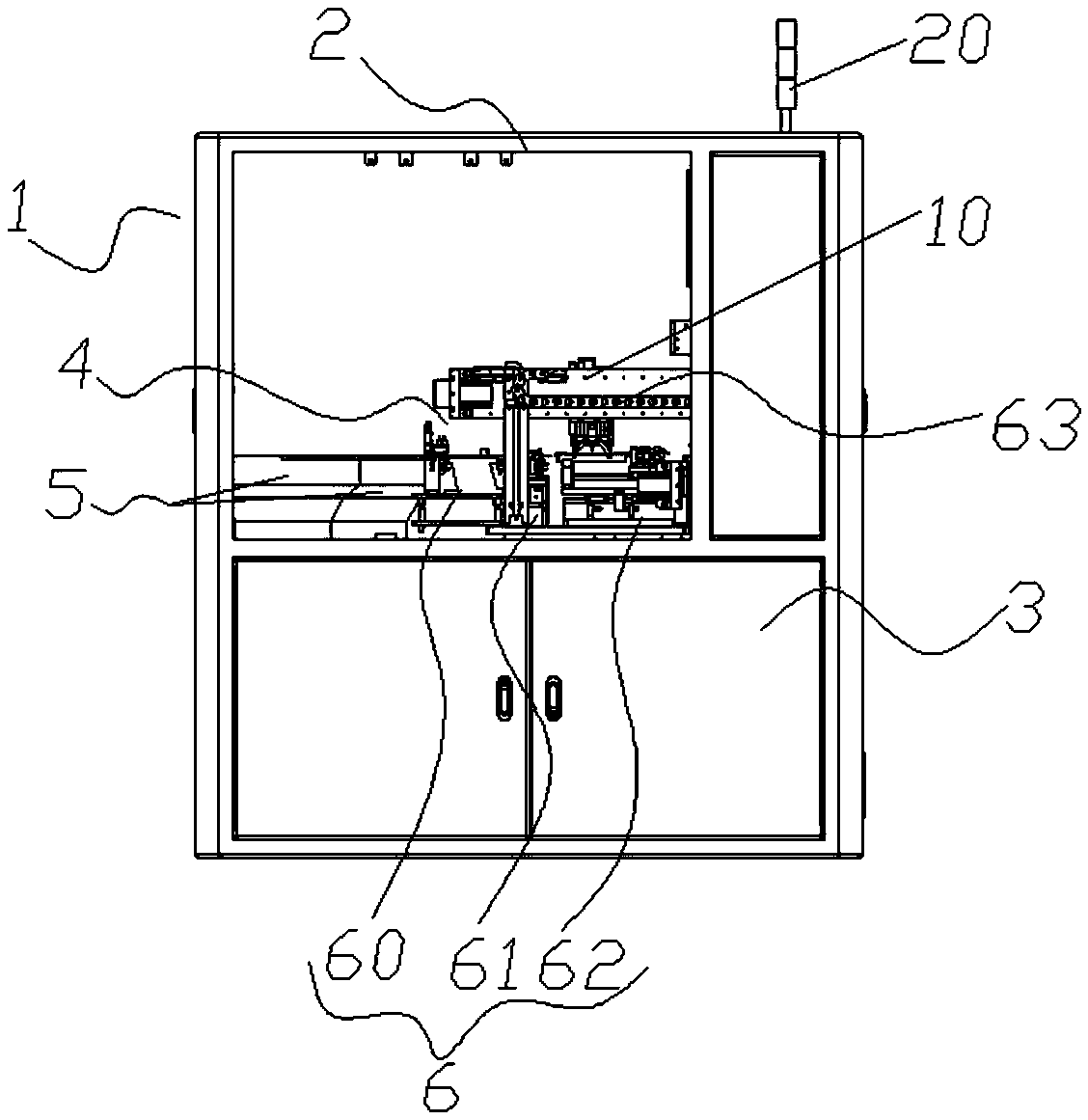

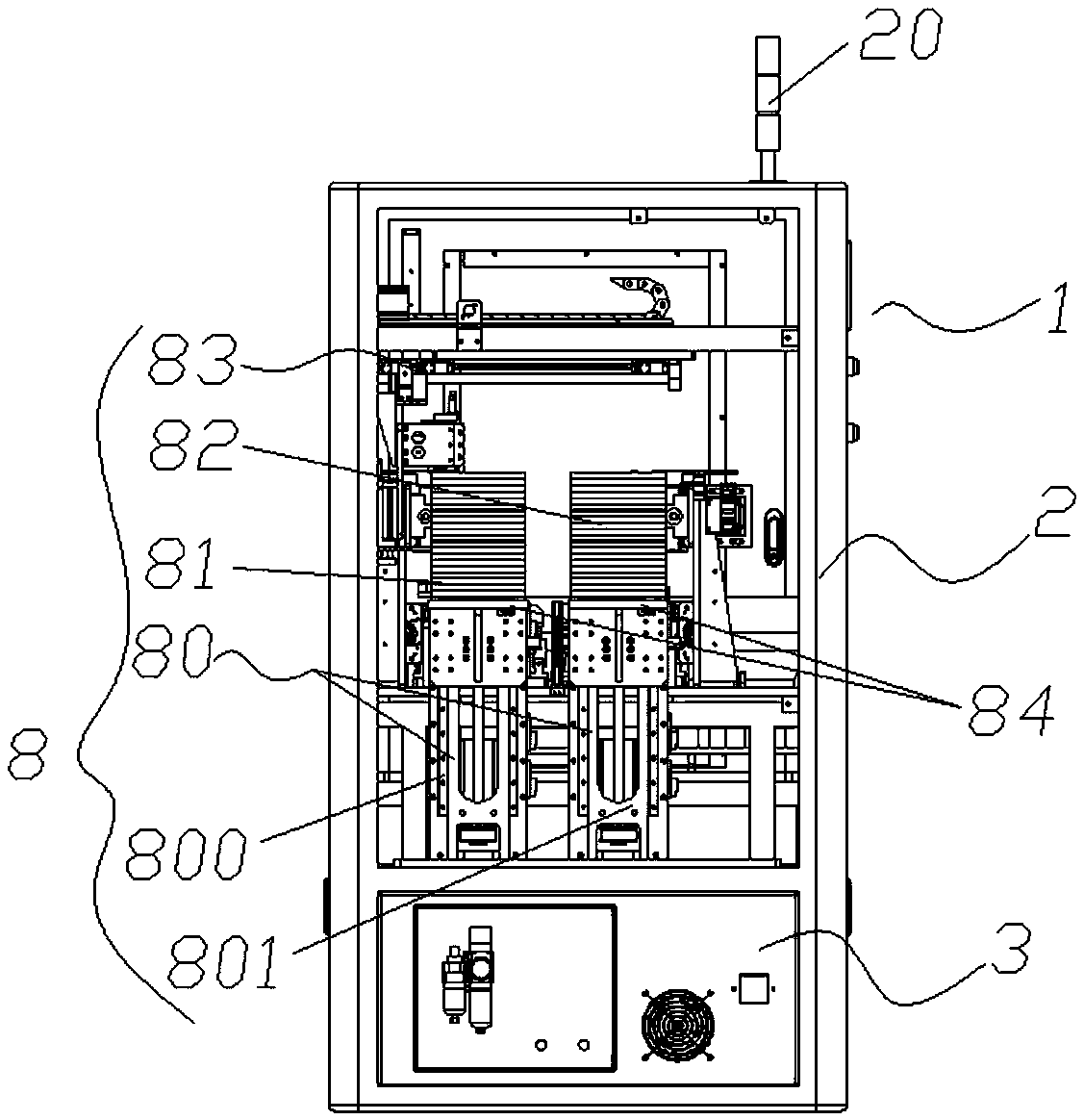

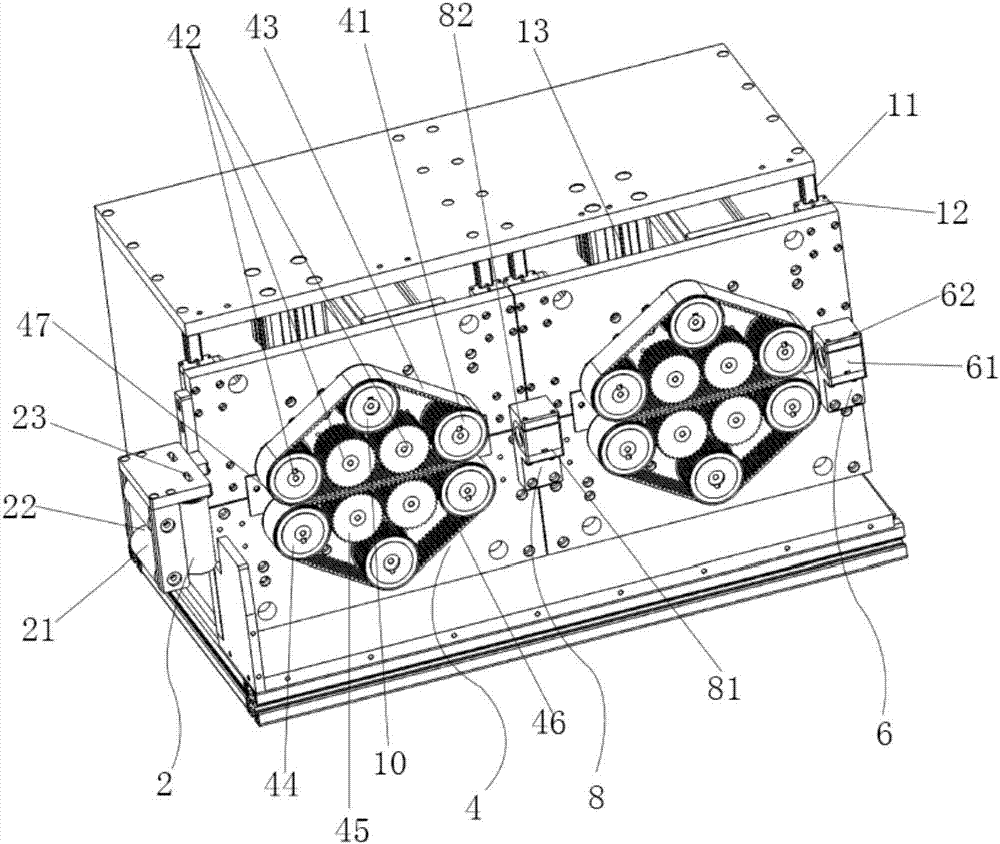

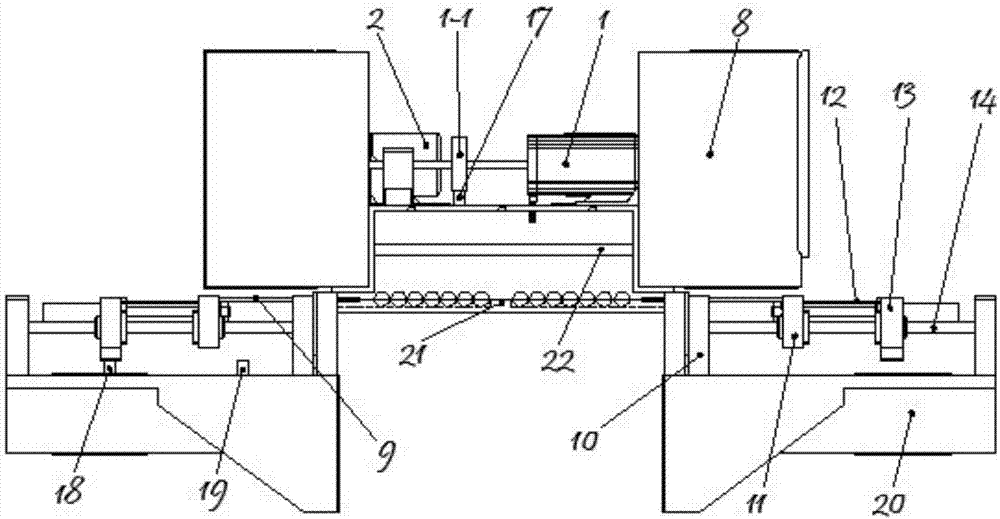

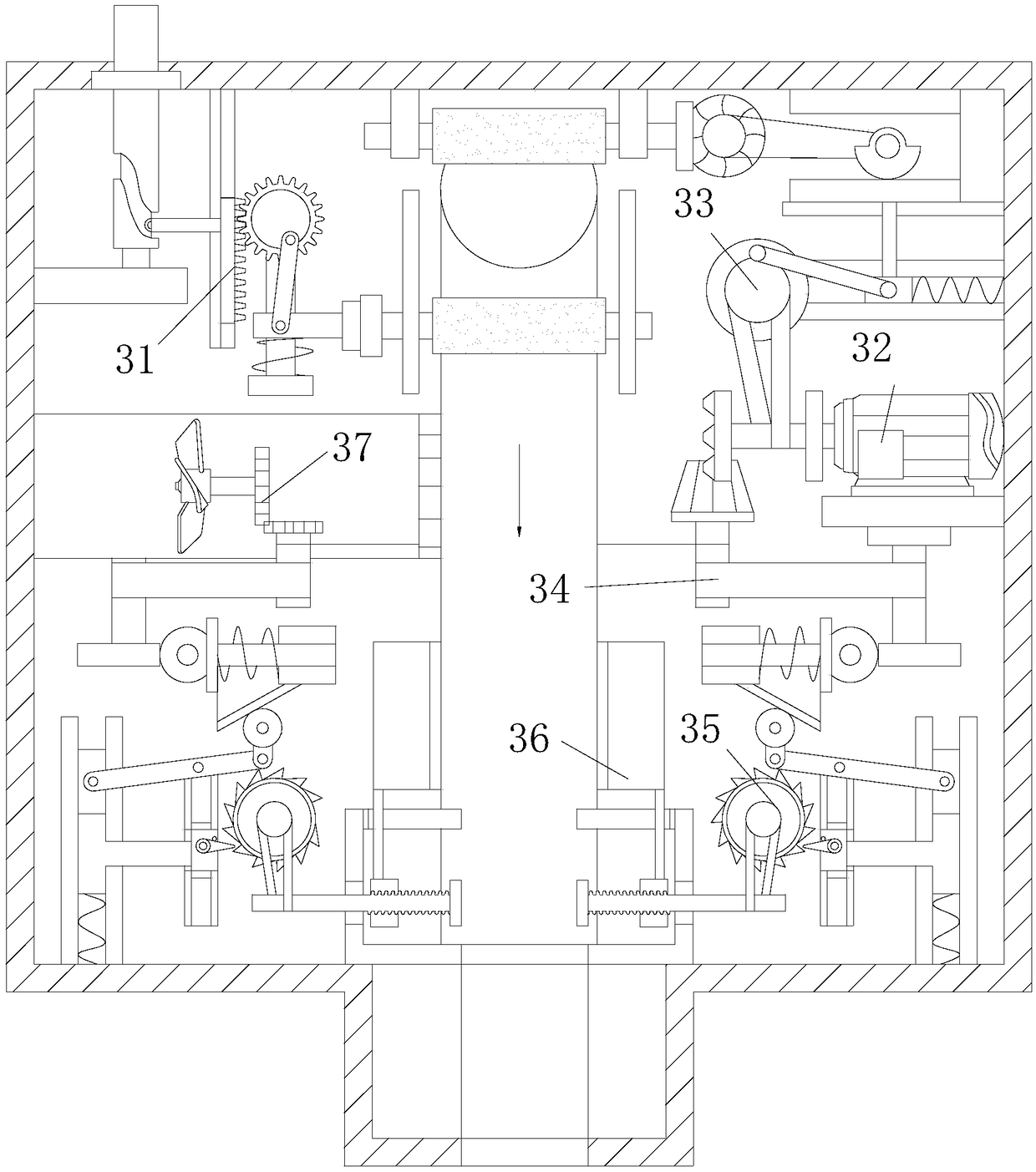

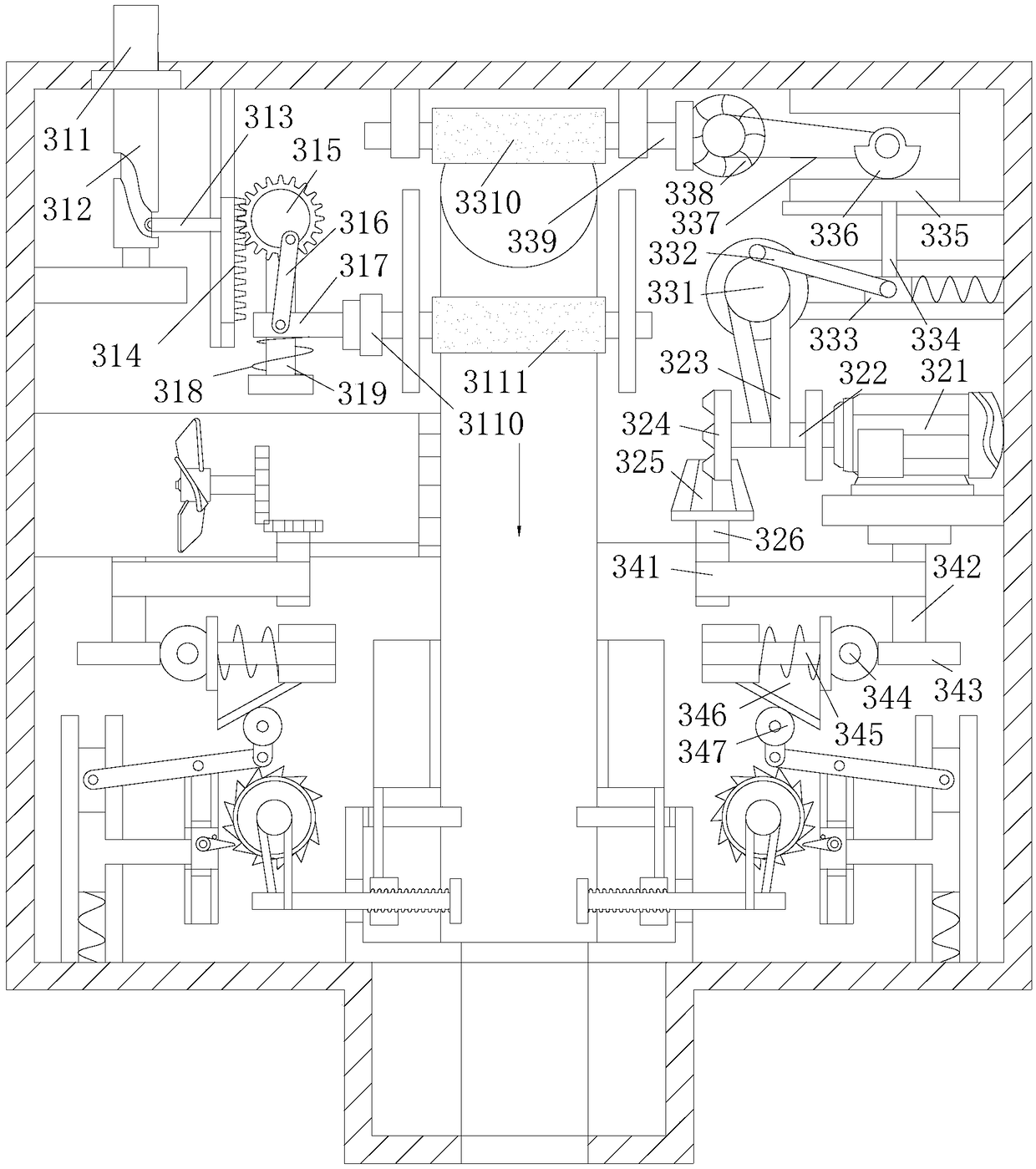

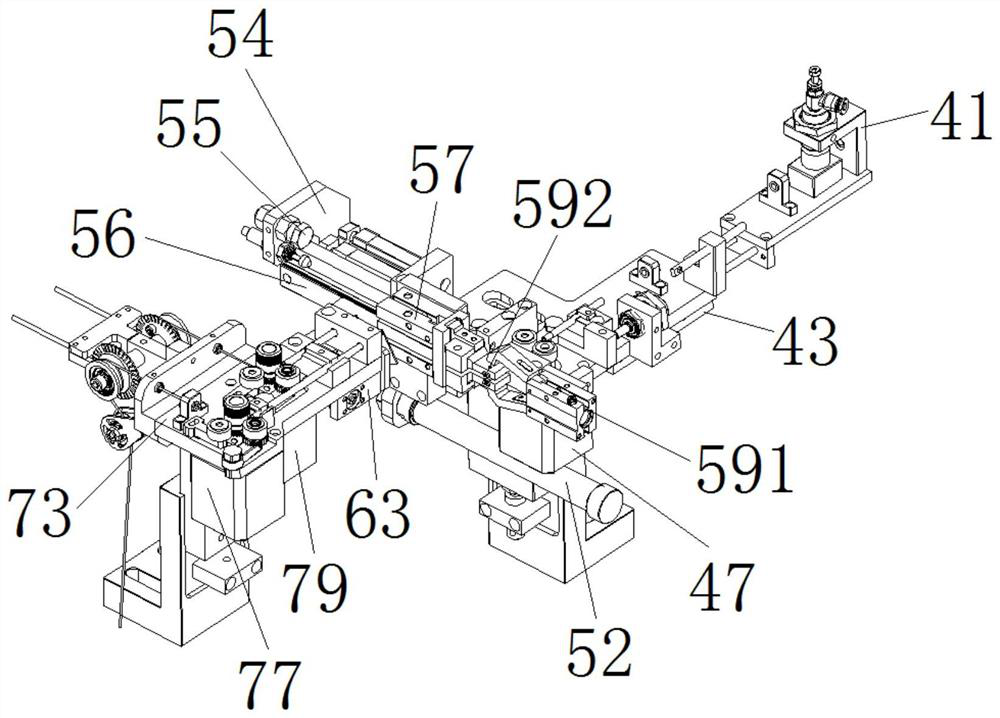

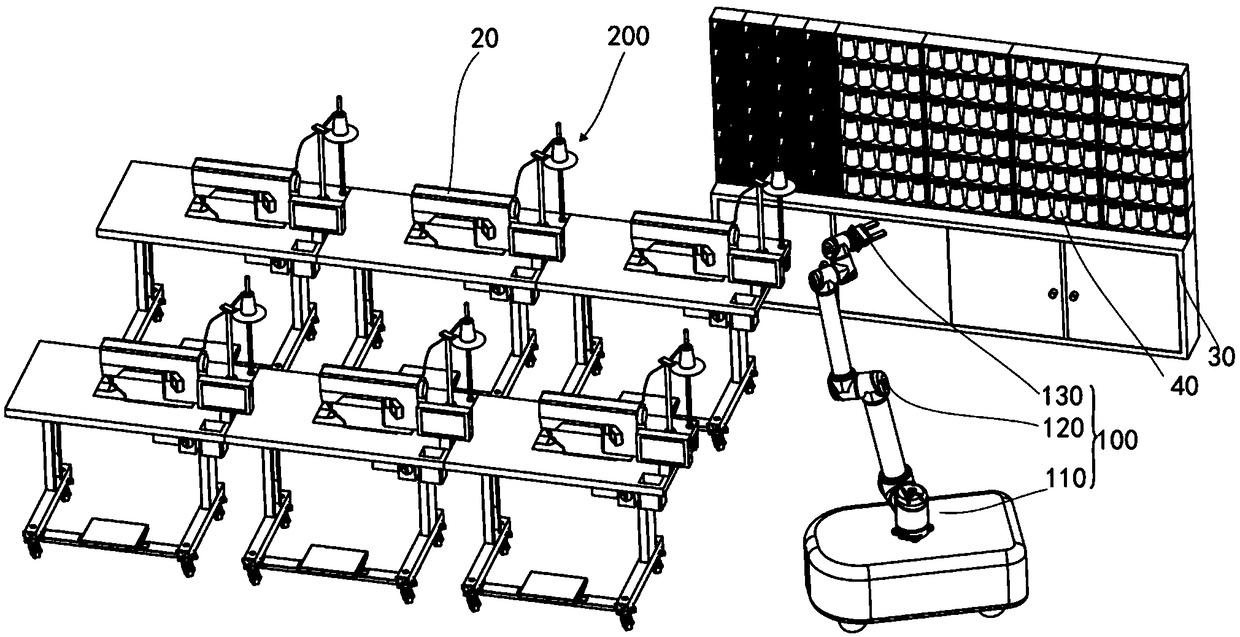

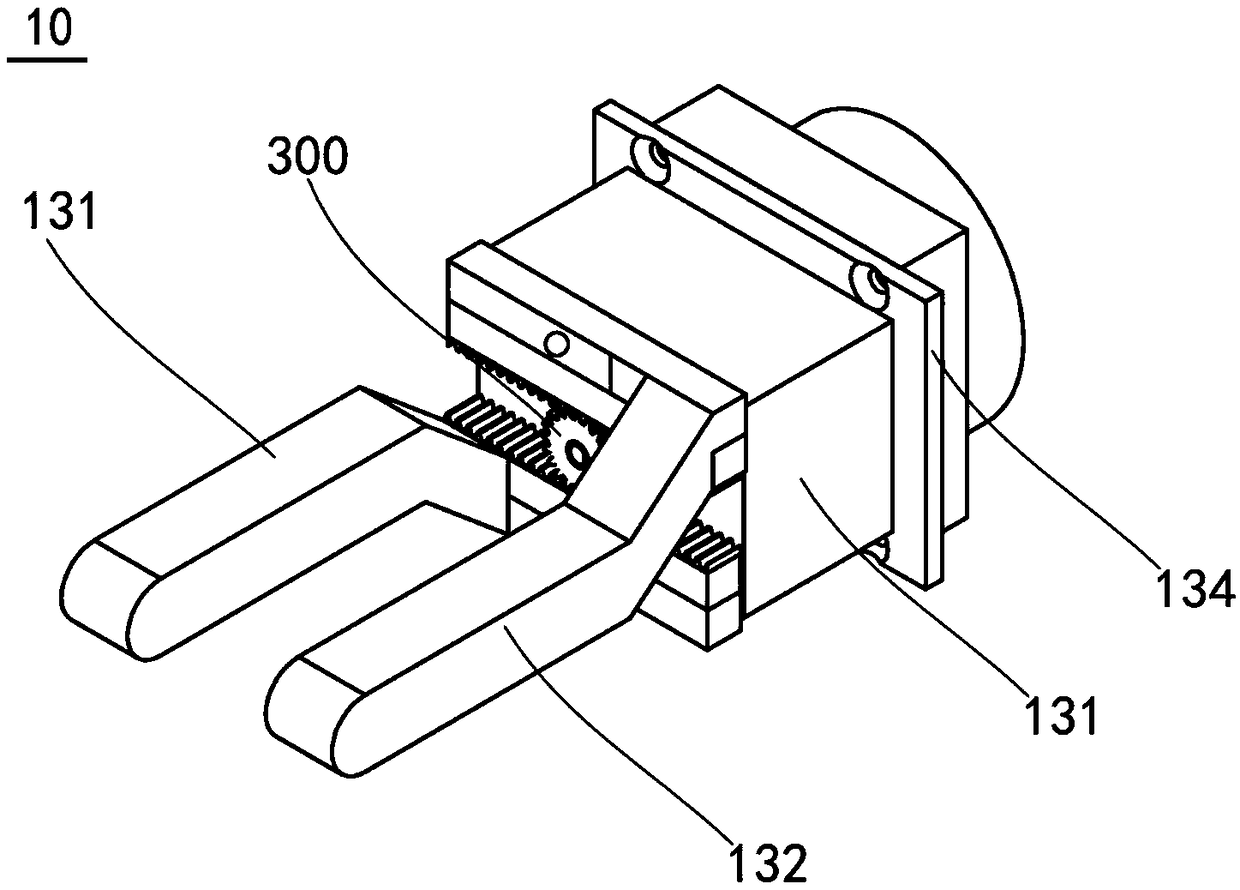

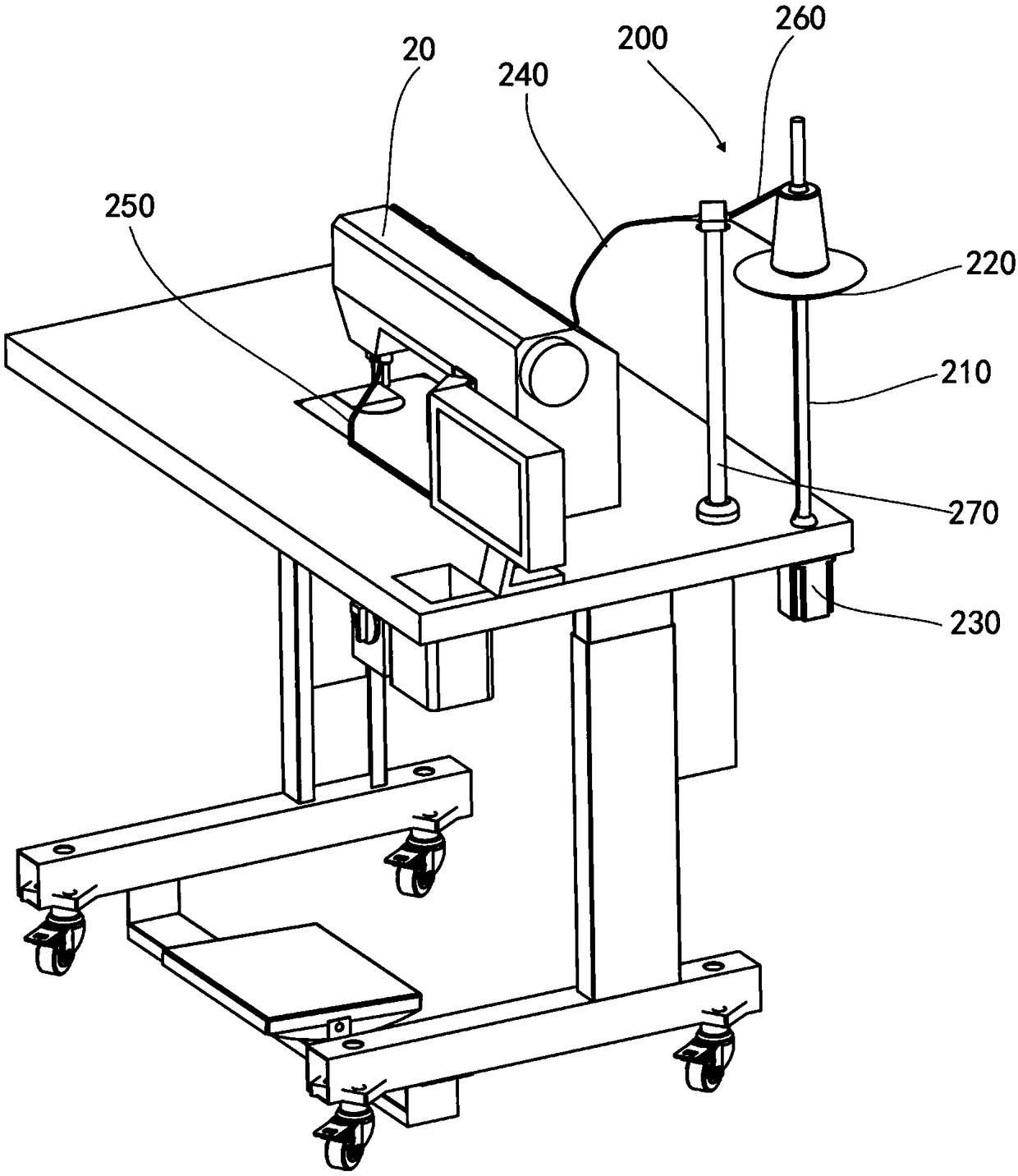

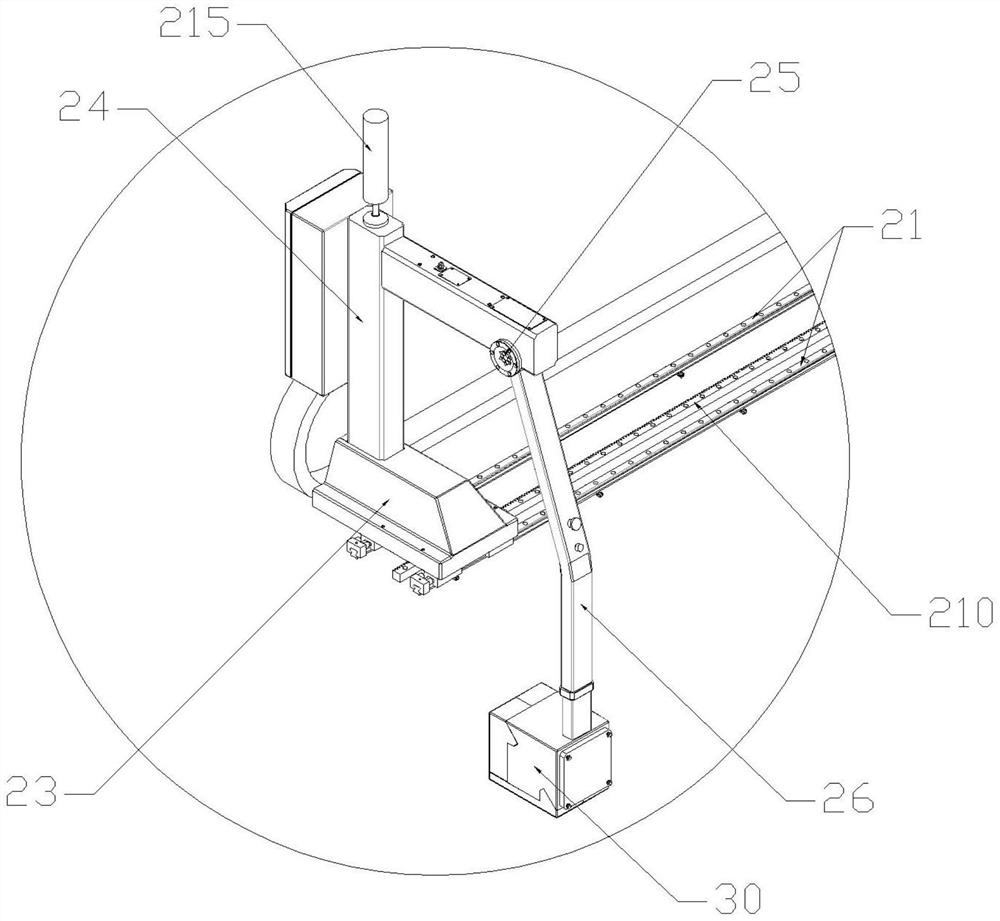

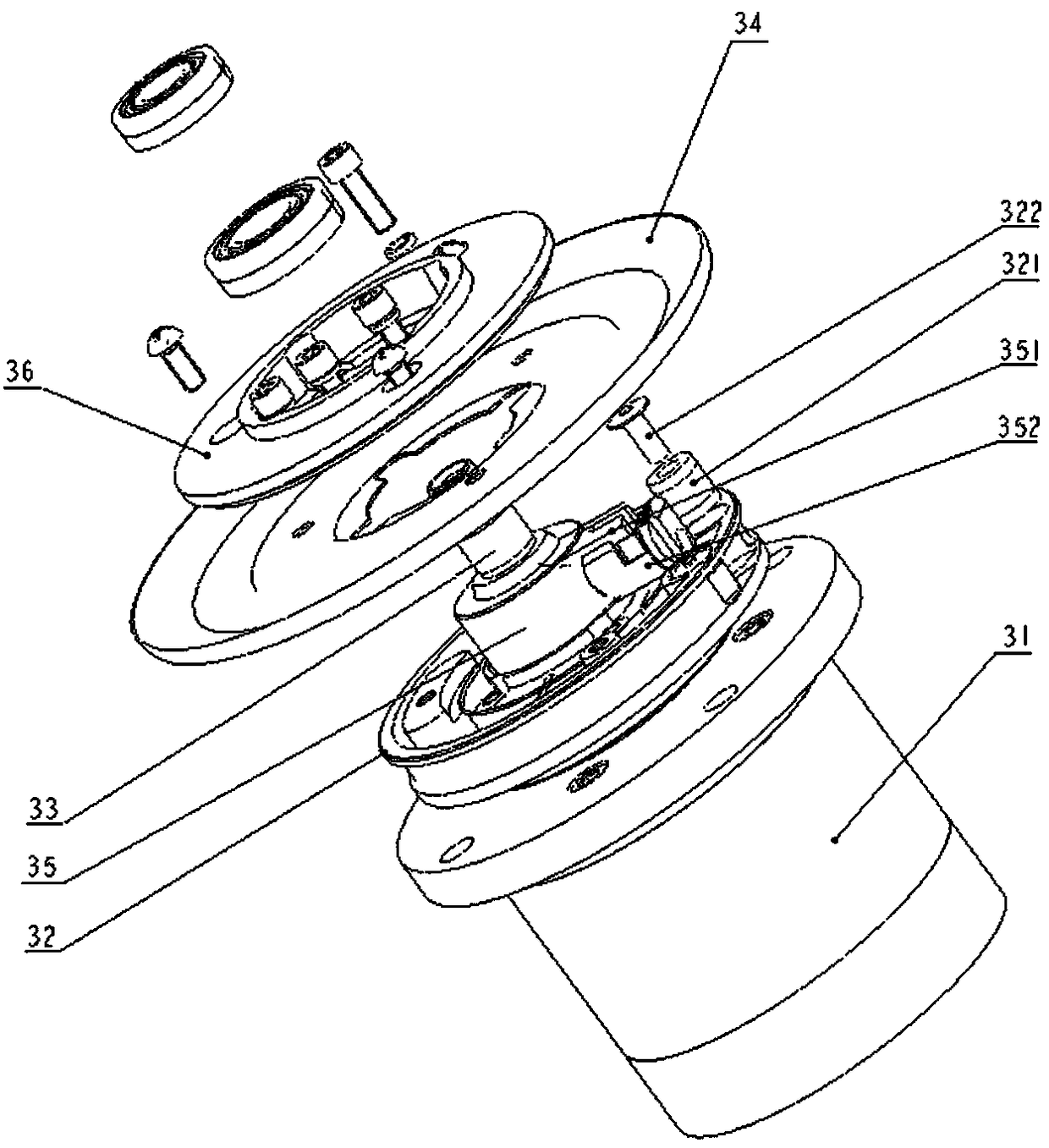

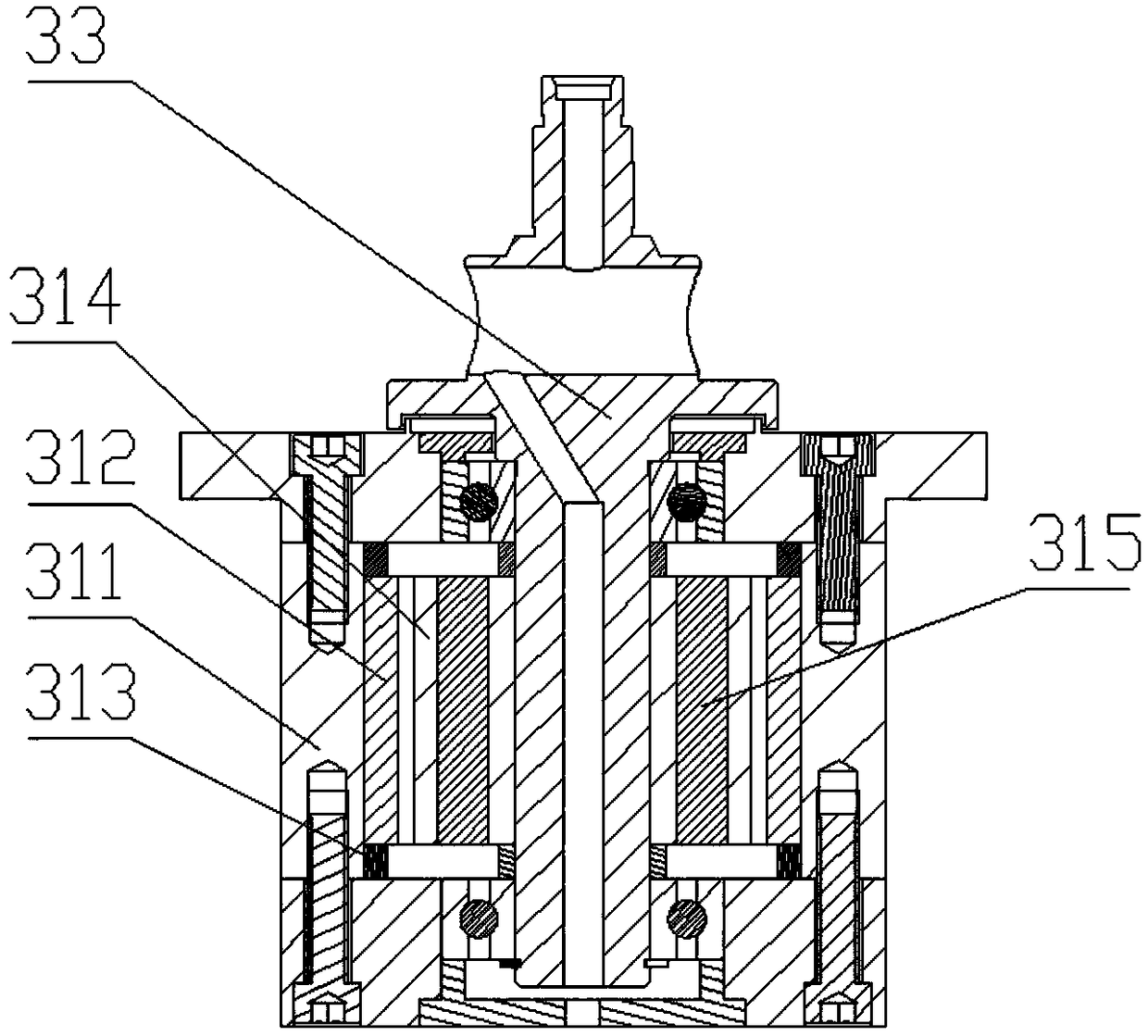

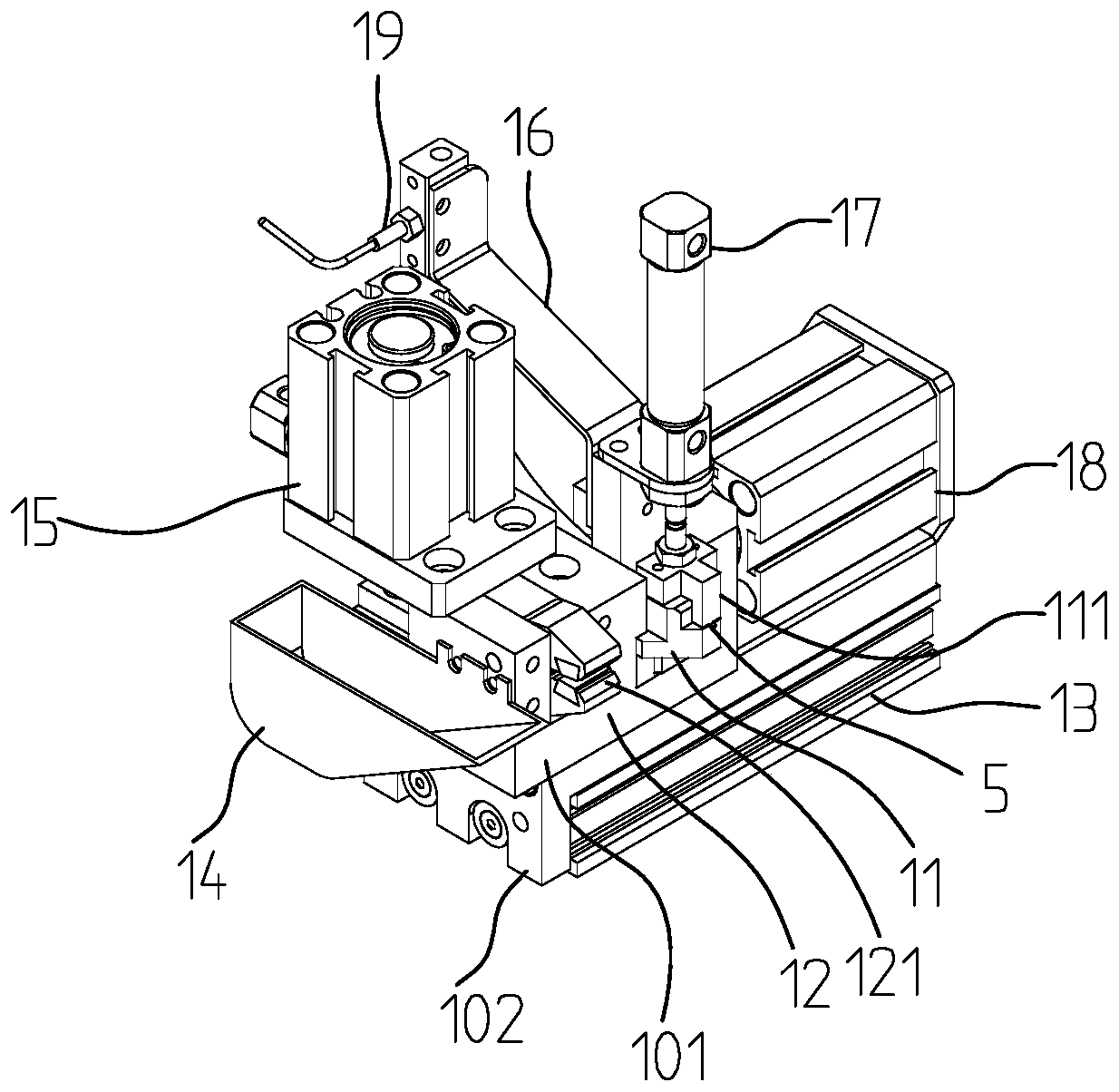

Automatic bead stringing equipment and automatic bead stringing method of stainless steel watchband parts

PendingCN109531138AImprove production and processing efficiencyImprove subsequent grinding qualityAssembly machinesAutomatic processingManipulator

The invention discloses automatic bead stringing equipment of stainless steel watchband parts. The automatic bead stringing equipment comprises a machine frame, a control cabinet and two groups of processing stations; each of the two processing stations comprises a sequencing vibration disc, a rapid positioning threading device, a placing device and a feeding and discharging device, wherein each of the sequencing vibration disc, the rapid positioning threading device, the placing device and the feeding and discharging device is provided with a detection sensor; and each rapid positioning threading device comprises a feeding mechanism, a material clamping mechanism, a silk yarn placing mechanism, a carrying mechanical arm and a fixing support, wherein the carrying mechanical arm is arrangedon the fixing support. The invention further discloses an automatic bead stringing method. According to the equipment and the method, two processing stations are arranged, the production processing efficiency is improved, full automatic processing such as automatic feeding, stringing, positioning and discharging of a processing part and a silk yarn can be realized through the sequencing vibrationdiscs, the rapid positioning threading devices, the placing devices and the feeding and discharging devices, the labor intensity and the cost are reduced, the production efficiency is improved, the stringing quality is guaranteed, and the subsequent grinding quality is improved.

Owner:盈利时表业(东莞)有限公司

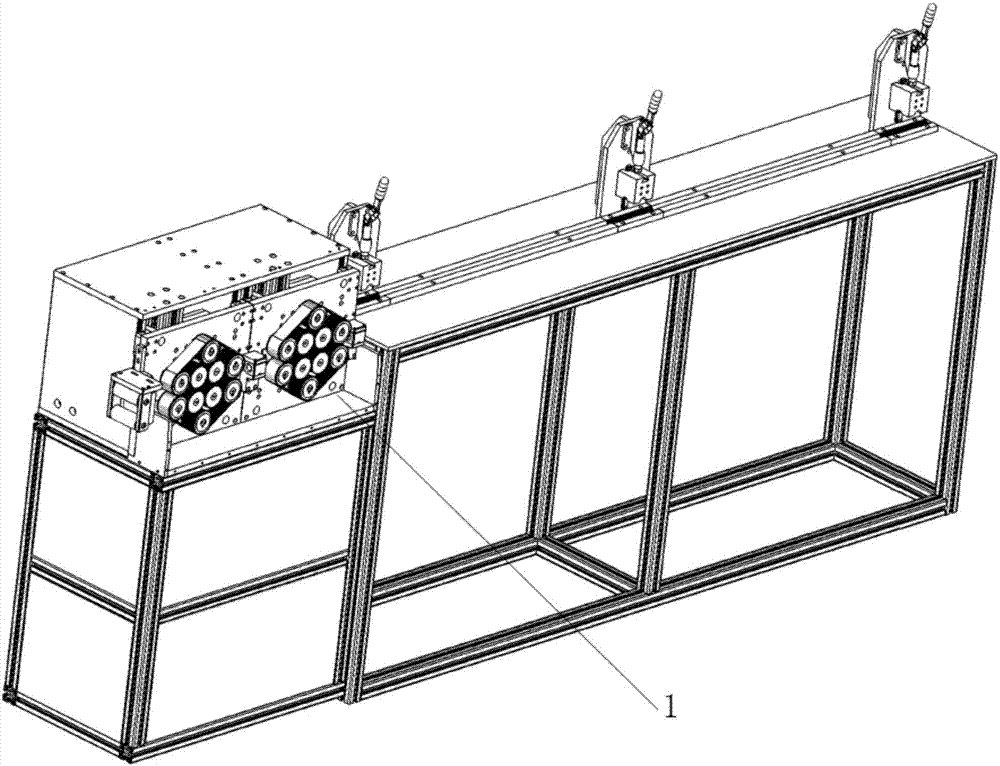

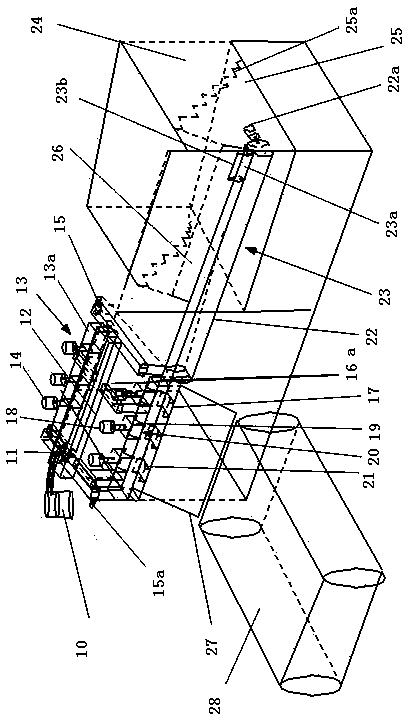

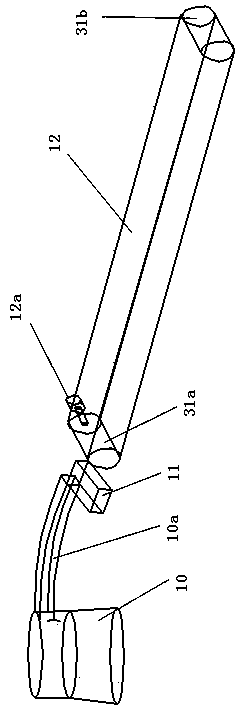

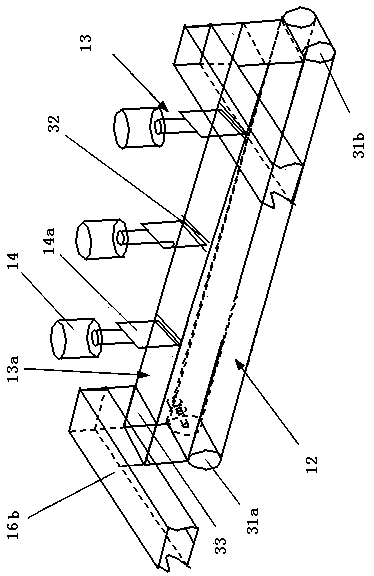

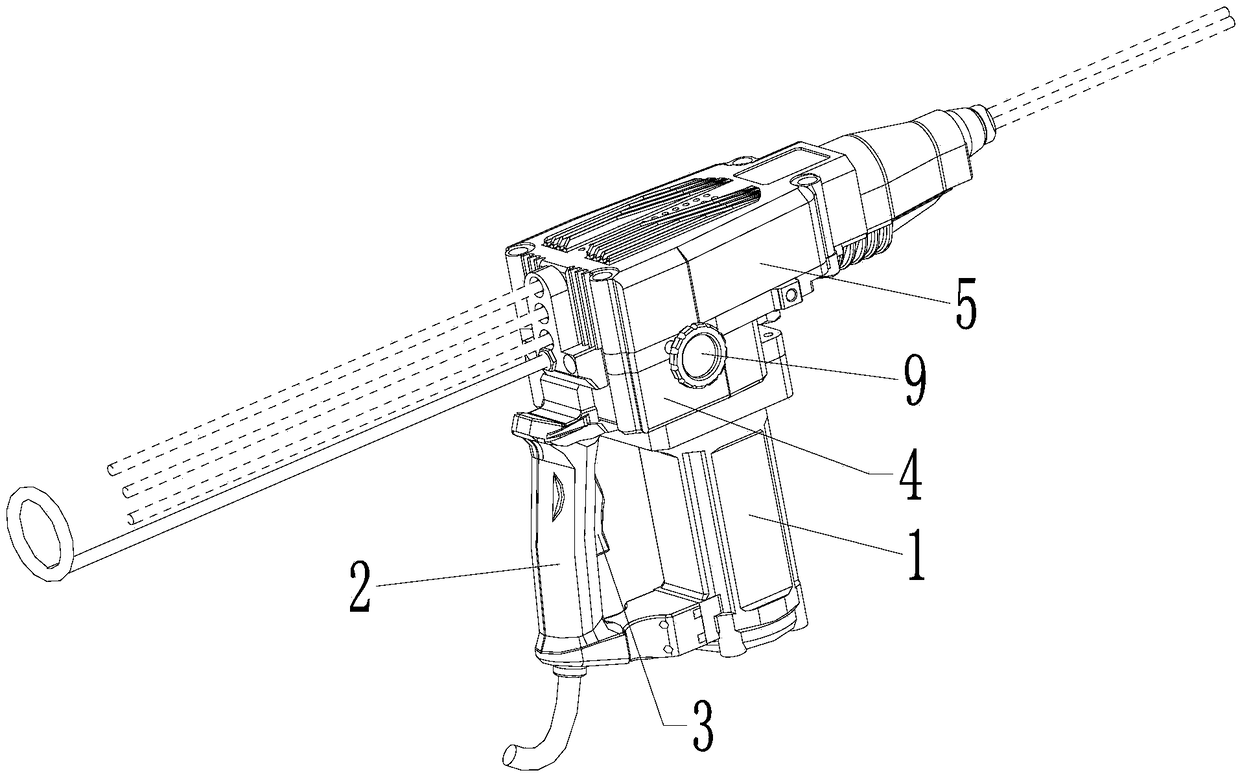

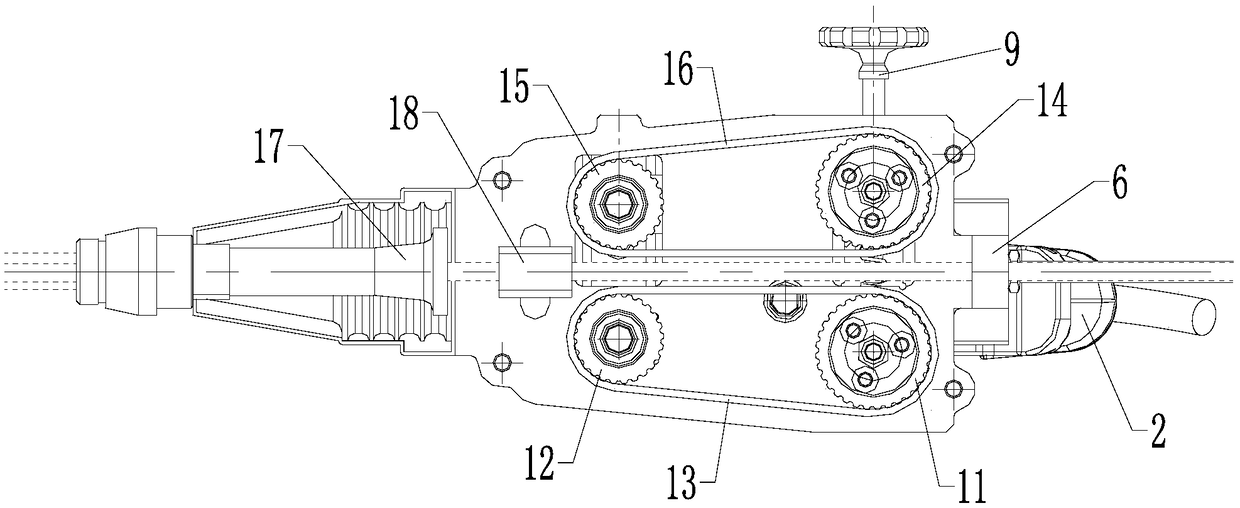

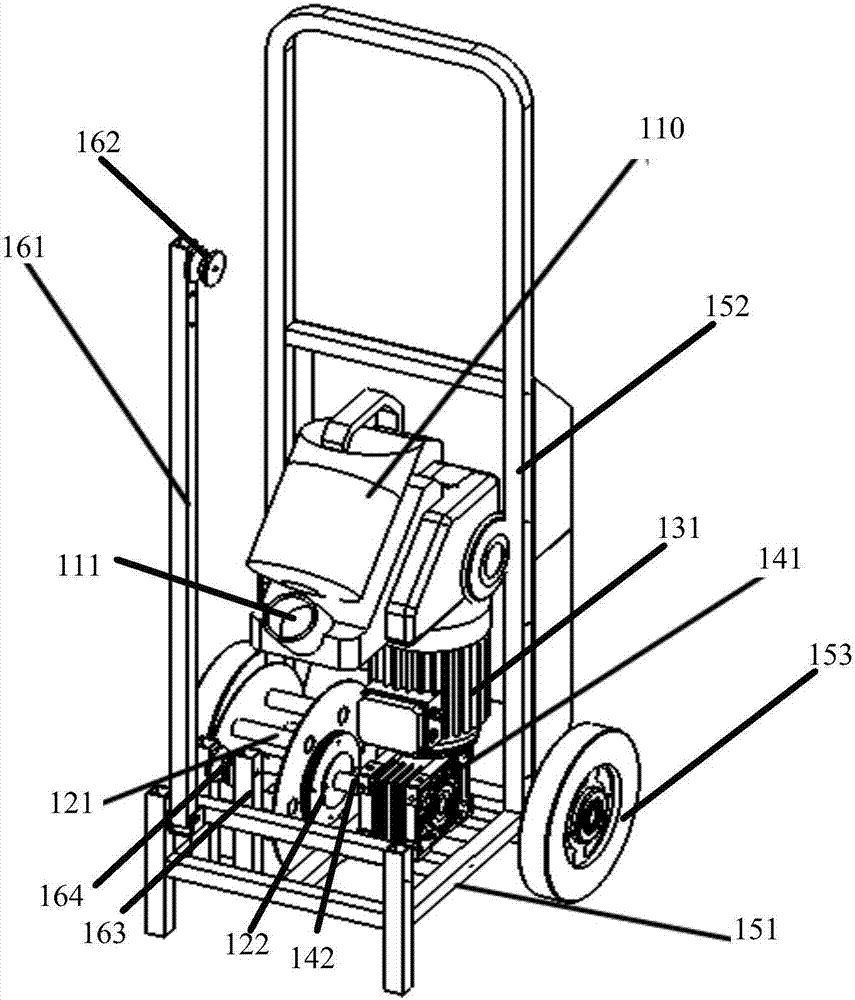

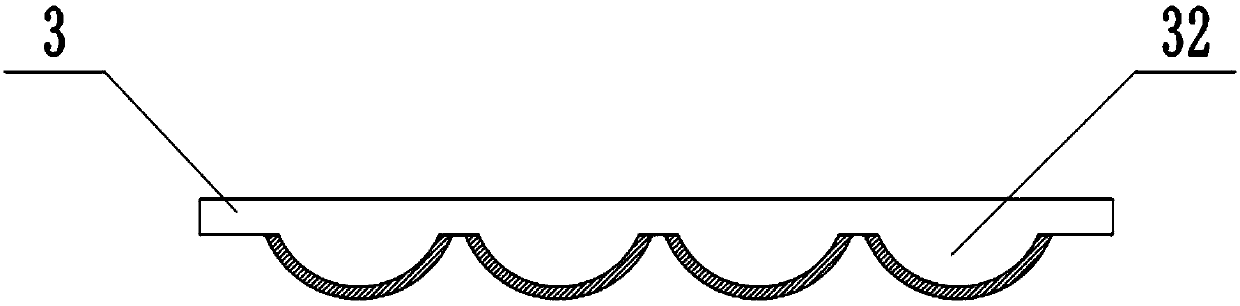

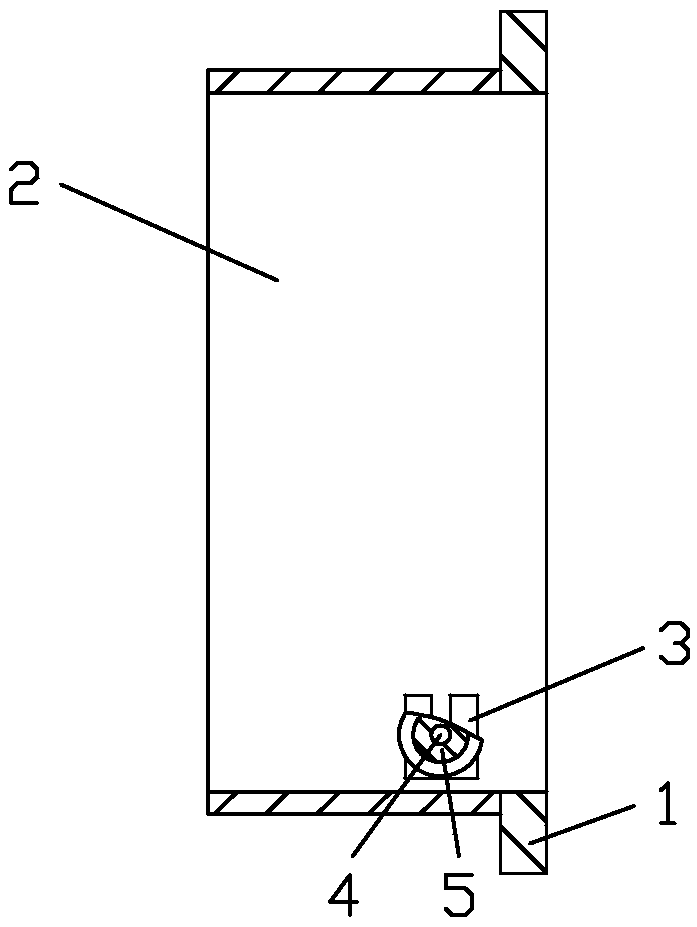

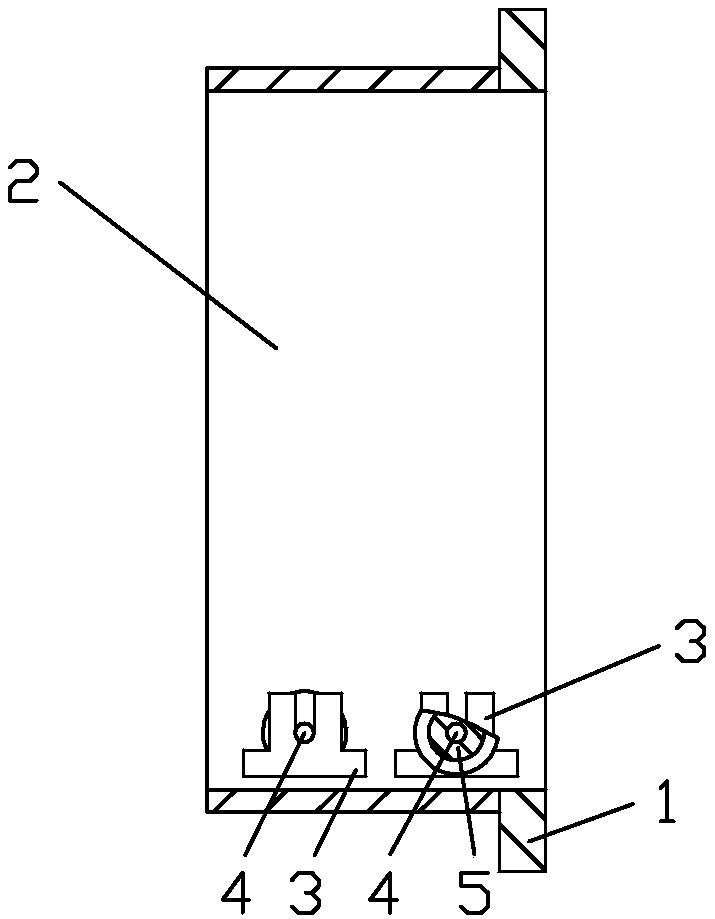

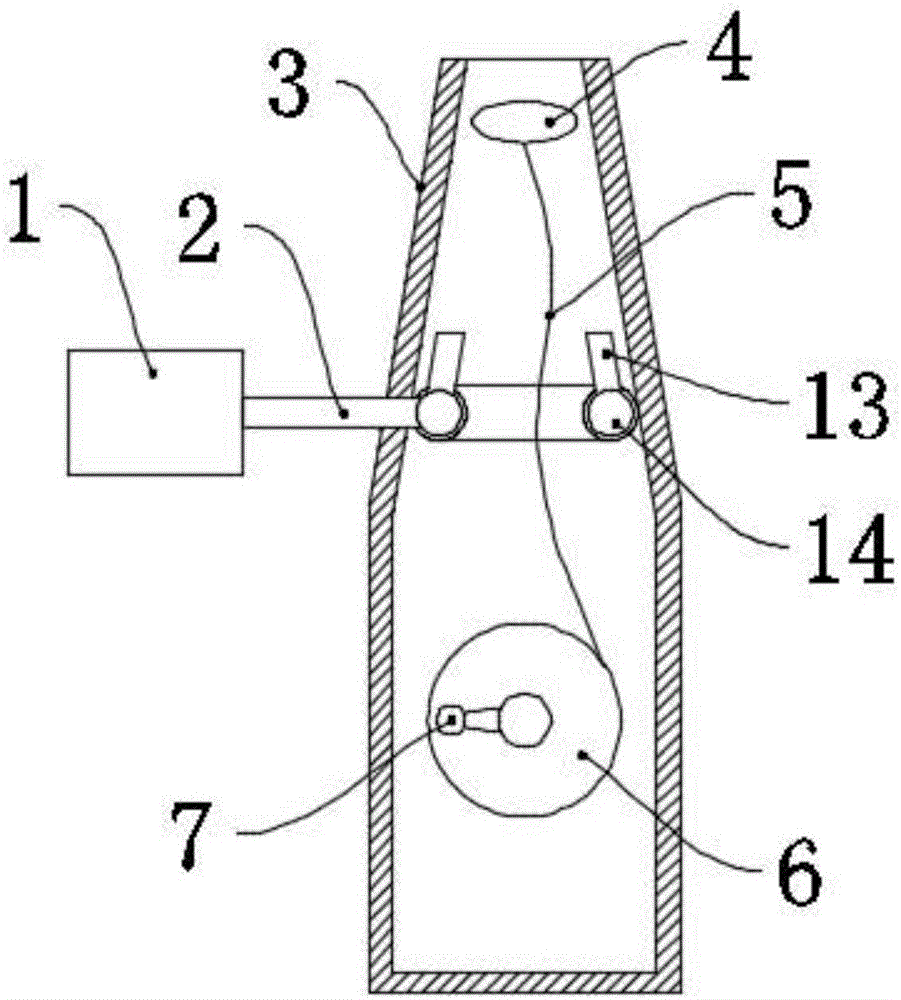

Corrugated pipe threading device

PendingCN107248438AImprove threading efficiencyReduce manual labor intensityCable/conductor manufactureApparatus for laying cablesEngineeringStructural engineering

The invention provides a corrugated pipe threading device. The corrugated pipe threading device comprises a cable input and guide mechanism, a cable traction mechanism and a cable output and guide mechanism, which are sequentially arranged along the cable moving direction; the cable input and guide mechanism comprises two pairs of guide rollers; a first clearance for a cable to pass is between each pair of guide rollers; the cable traction mechanism comprises a first traction component and a second traction component, which are matched to pull the cable to move; a second clearance for the cable to pass is between the first traction component and the second traction component; the cable output and guide mechanism comprises a wire outgoing base; a wire outgoing hole is formed on the wire outgoing base; and, under the drive of a driver, the cable is axially threaded in a corrugated pipe after being pulled to pass through the first clearance, the second clearance and the wire outgoing hole sequentially and linearly. By means of the corrugated pipe threading device disclosed by the invention, artificial threading is replaced; the threading efficiency is increased; the manual labour intensity is reduced; a cable, the length of which is beyond 10 M, can be smoothly threaded; and the corrugated pipe threading device is steady to operate, reliable and safe, and suitable for threading cables having multiple pipe diameters and sizes.

Owner:江苏亨通新能源智控科技有限公司

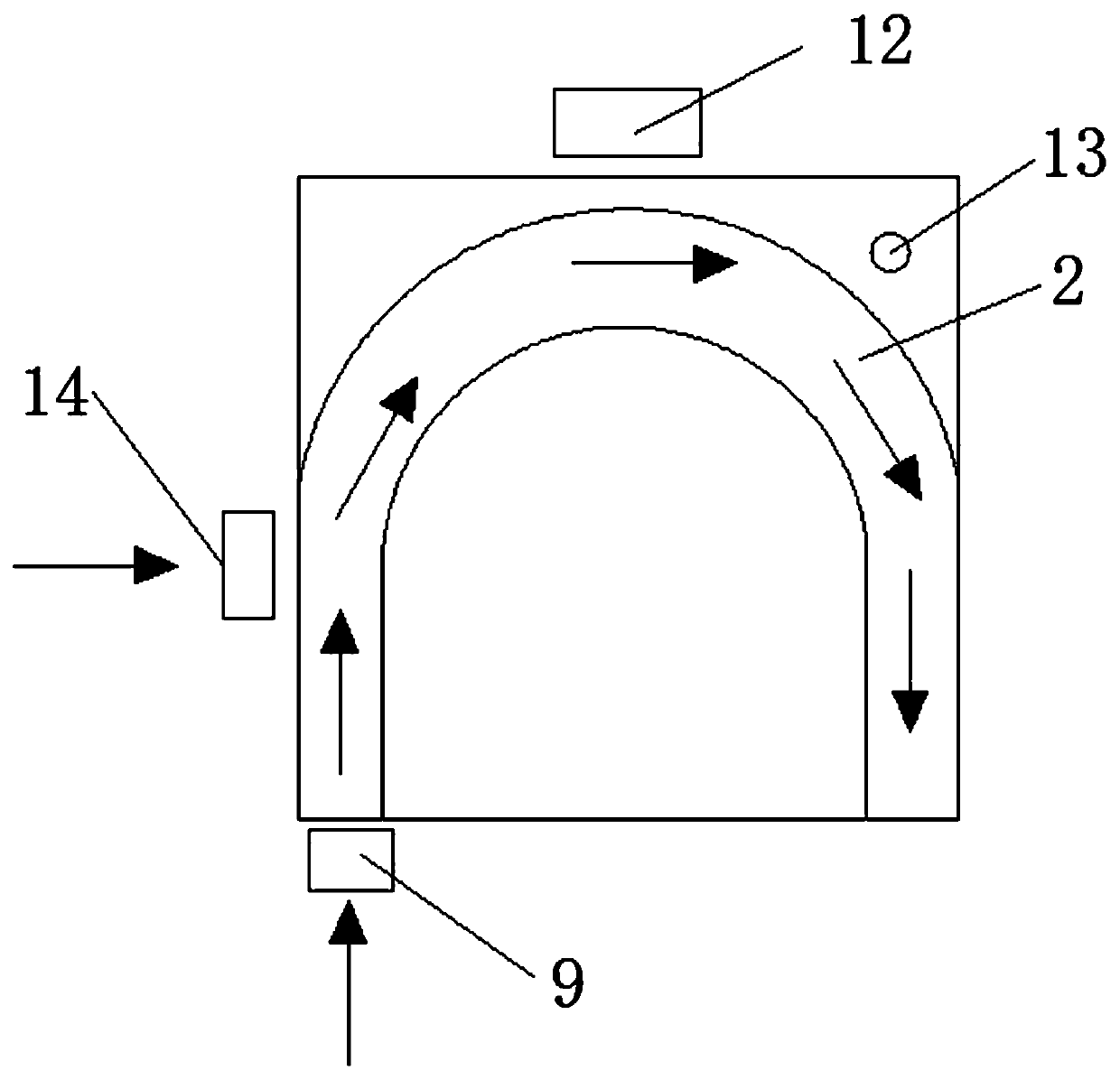

Installation method of reinforcing steel bar insulated sleeve

The invention discloses an installation method of a reinforcing steel bar insulated sleeve, and belongs to the field of HSR (High-Speed Rail). The reinforcing steel bar insulated sleeve comprises a vibrating hopper. The installation method of the reinforcing steel bar insulated sleeve is implemented in a reinforcing steel bar insulated sleeve installation device, wherein the reinforcing steel barinsulated sleeve installation device comprises a carrying and separating device of an insulated sleeve, a carrying and transmitting device of reinforcing steel bars, a sleeve heating and shrinking device and a controller, wherein after the insulated sleeve is separated on the carrying and separating device, the insulated sleeve is transmitted into a groove for fixing after separating, the reinforcing steel bars are installed in the insulated sleeve by utilizing the carrying and transmitting device of the reinforcing steel bars; heating and shrinking can be realized by the sleeve heating and shrinking device. According to the installation method disclosed by the invention, manual installation is replaced, the installation efficiency of a sleeve can be increased, the labor intensity of a worker is reduced, vortex generated when a train passes through a ballastless track can be removed, and the running stability of a passenger transport line can be increased.

Owner:河南省鼎鼎实业有限公司

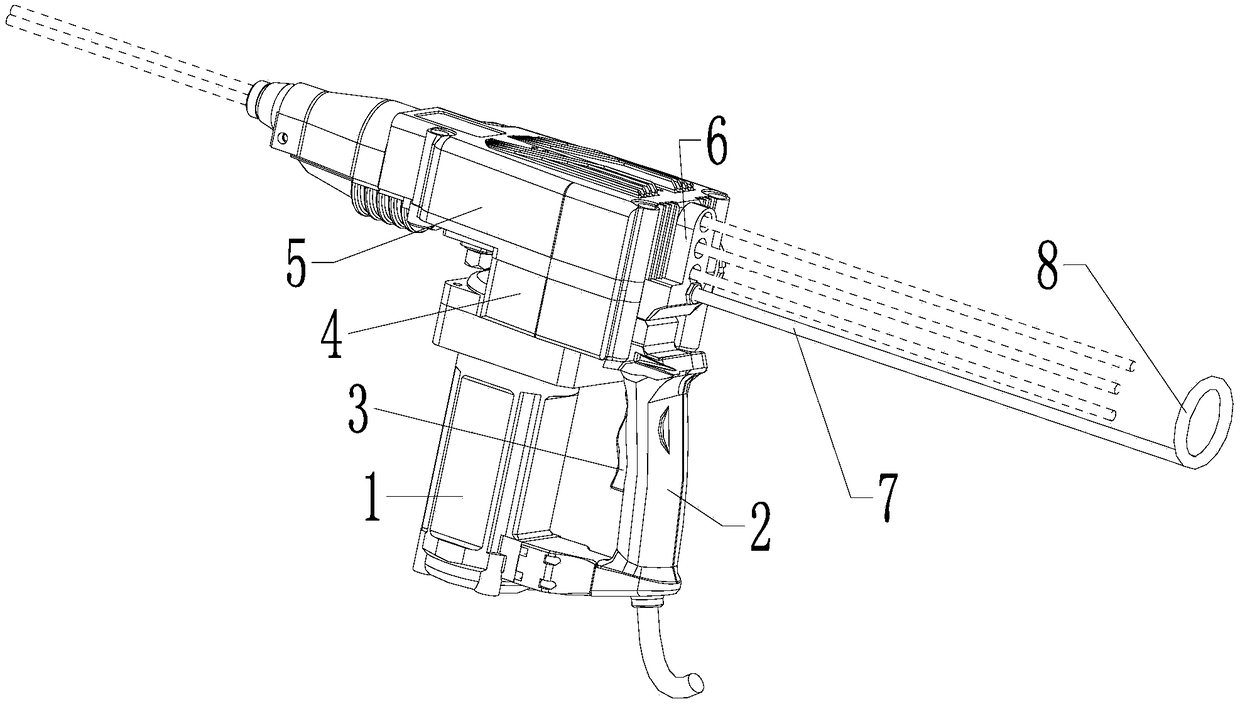

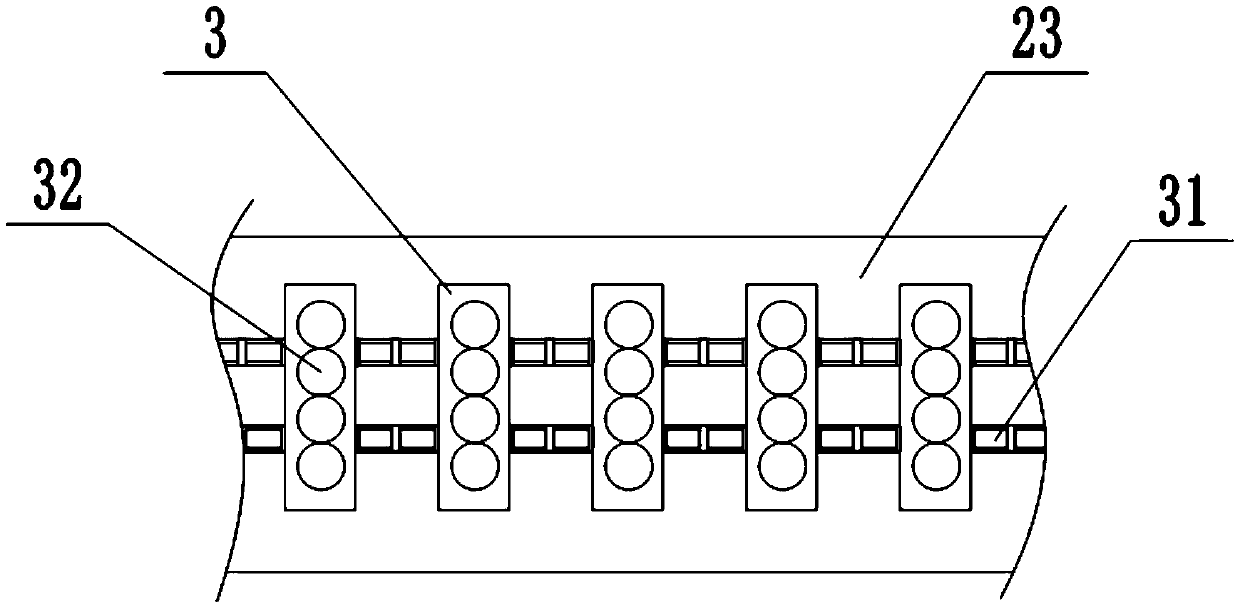

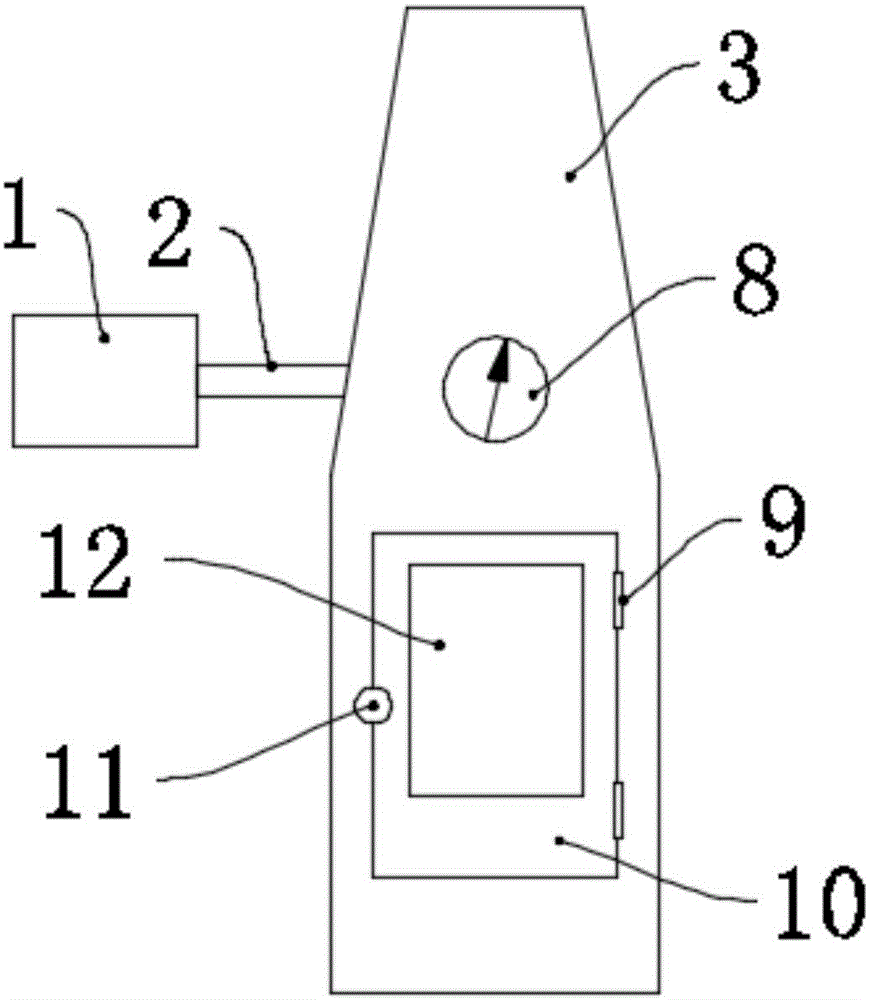

Pre-buried pipe threader

PendingCN109038377AAccelerated injectionAvoid damageApparatus for laying cablesEngineeringSynchronizing

The invention discloses a pre-buried pipe threader, which includes symmetrically mounted first synchronizing belt and second synchronizing belt, at least one annular groove is for on that first synchronization belt, a groove corresponding to the surface of the first synchronizing belt is formed on the second synchronizing belt, the corresponding grooves on the first synchronization belt and the second synchronization belt form an over-line channel, the first synchronous belt and the second synchronous belt rotate in the opposite direction synchronously, and a conductor plate is mounted on theinlet side of the conductor passage, a small via hole corresponding to the conductor passage is formed on the conductor plate, a conductor sleeve is mounted on the outlet side of the conductor passage, and a large via hole is formed on the conductor sleeve. Such that the cable is clamped and accelerated using the over-wire channel formed between the first and second synchronization belts, the cable penetrates through the pre-buried pipe, not only time and labor are saved, but also the threading efficiency is remarkably improved, the labor cost is saved, control of the construction cost is facilitated, and the threader has the characteristics of ingenious conception, simple structure, wide application range, convenient use and the like.

Owner:李洪

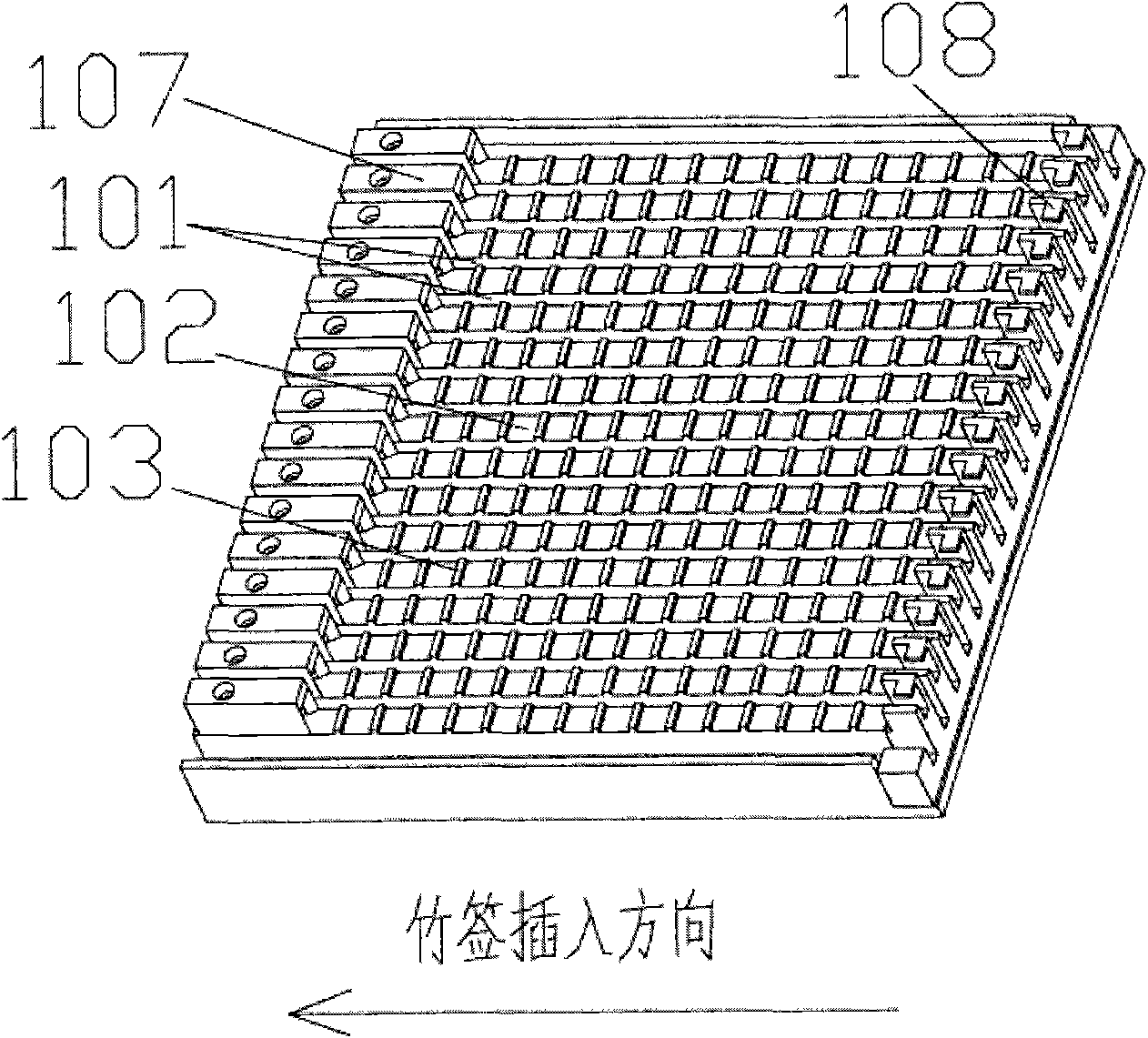

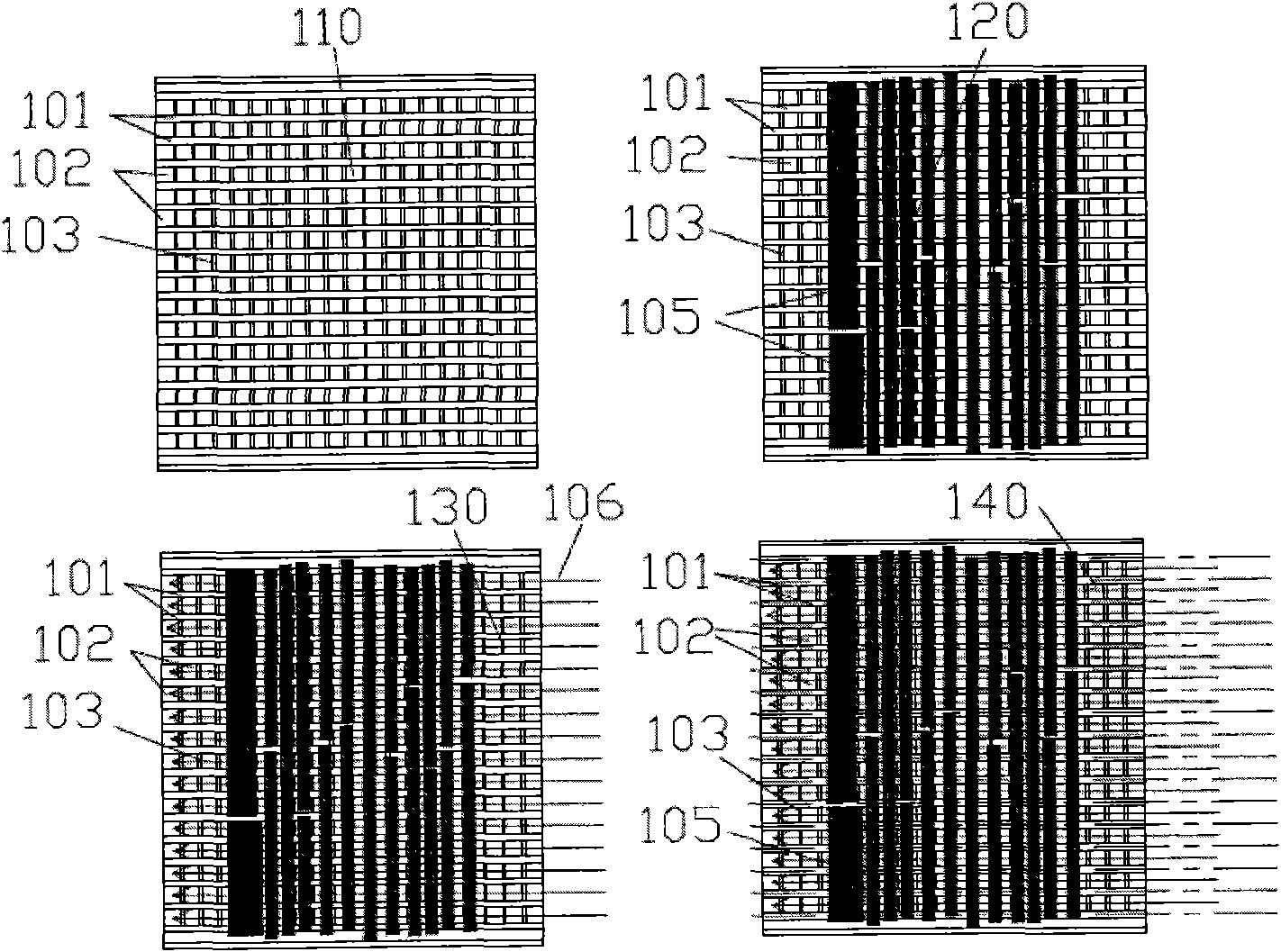

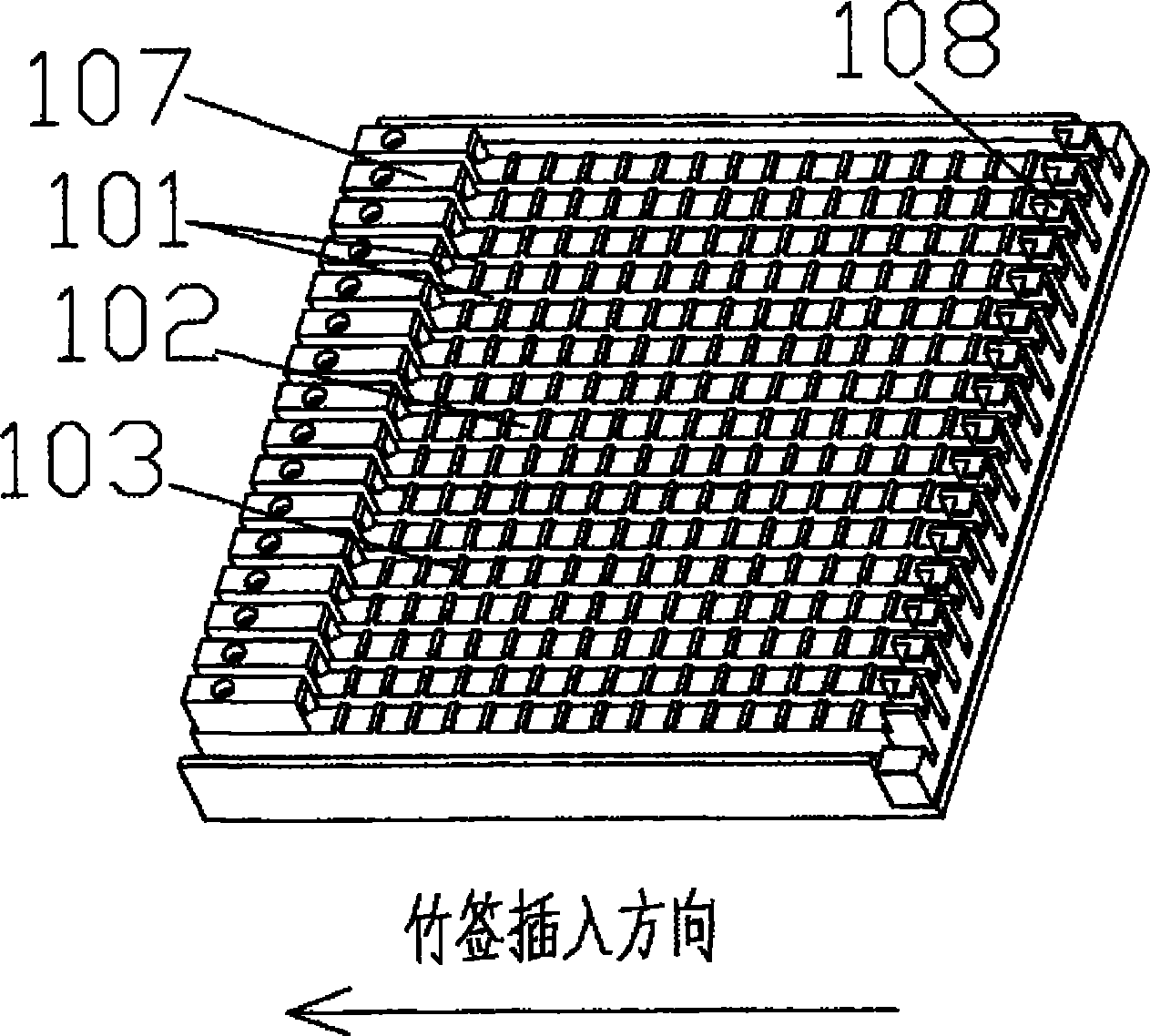

Stringing machine and method for stringing string foods by using machine

InactiveCN101843273ARegular shapeGood weight consistencyPutting meat on skewersEngineeringUniform - quality

The invention relates to a stringing machine and a method for stringing string foods comprising meat strings and the like by using a machine. The method has the cores of The core of the method is that firstly stringing a prod strung into meat, and then cutting meat strips (blocks) strung with the prod are cut apart to form a meat string. The method mainly comprises the following steps of: 1 tiling the meat strips or the meat blocks on a meat-placing template; 2 penetrating the prod into the meat on the meat-placing template; and 3 making a cutter passes through a cutter passage positioned on the meat-placing template to separate the meat penetrated on the prod on the template to form a single meat string. The meat string strung by adopting the stringing machine of the method has good shape and uniform quality, and the stringing machine can greatly reduce the working intensity of stringing workers, improve the string efficiency and is suitable for large-scale meat string production.

Owner:王荣帅 +2

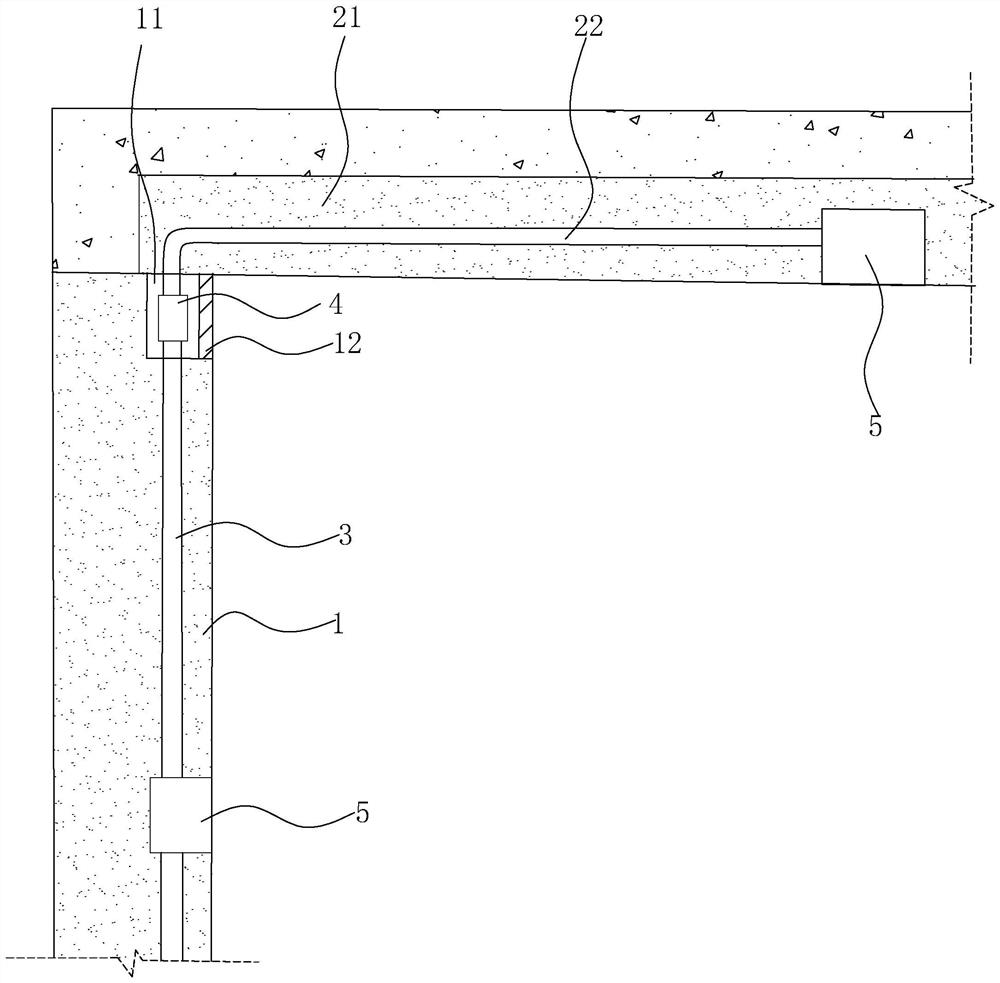

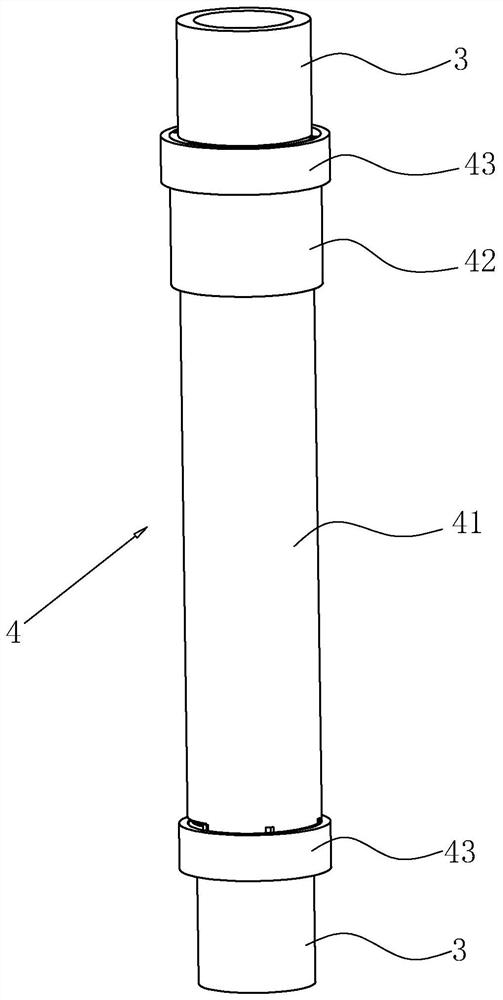

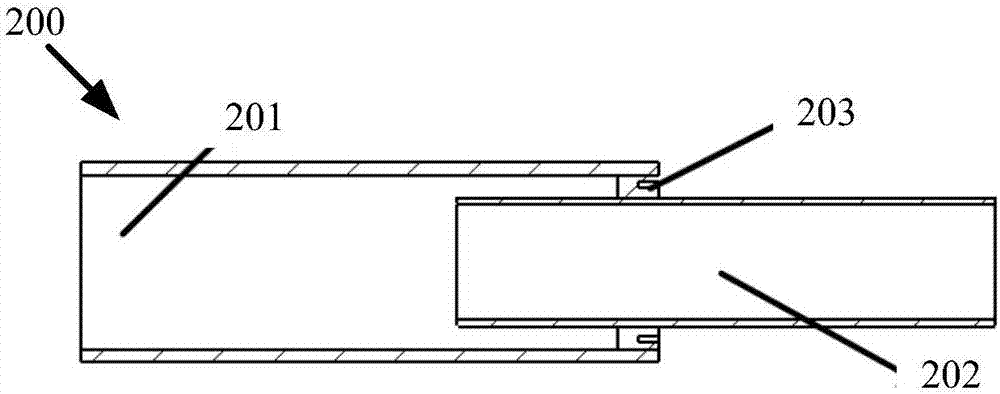

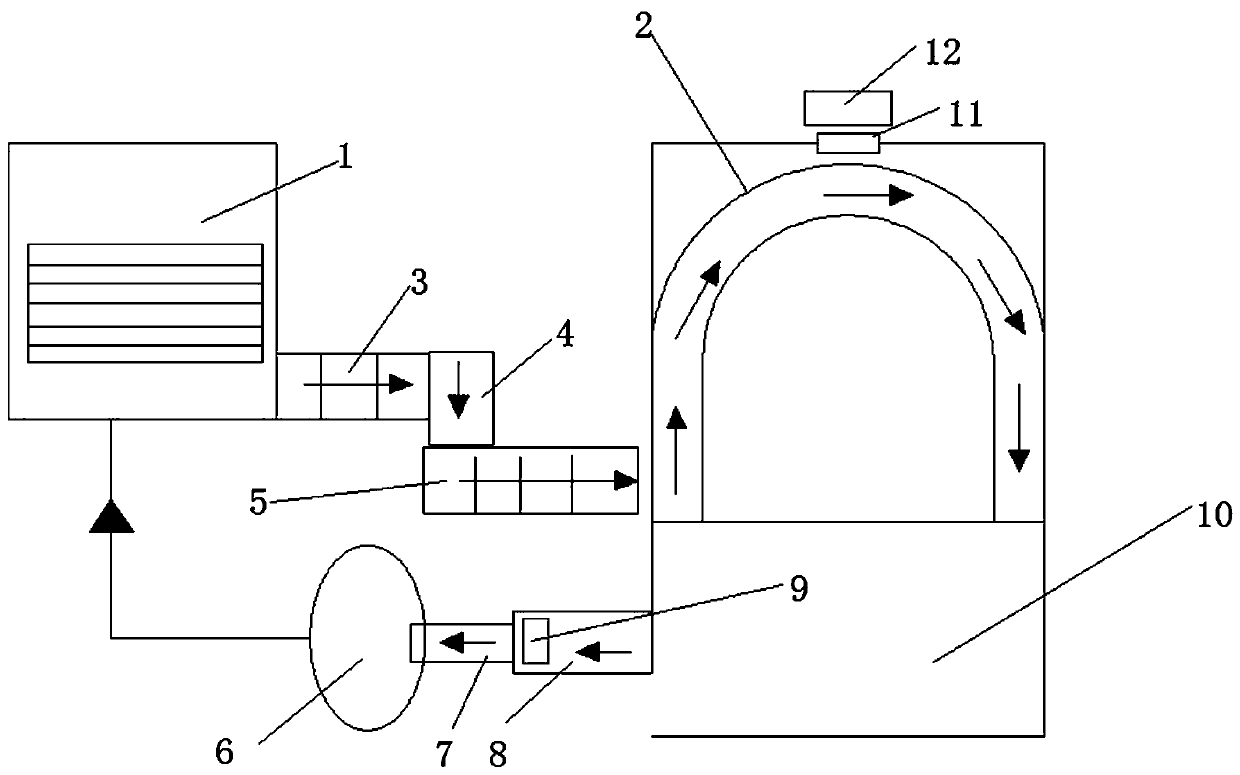

Assembly type building pre-embedded electrical pipeline system

ActiveCN112177223AImprove installation efficiencyImprove threading efficiencyWallsFloorsFloor slabLine tubing

The invention relates to an assembly type building pre-embedded electrical pipeline system which comprises a prefabricated wall body and a composite floor slab. The prefabricated wall body is perpendicularly connected with the composite floor slab, wire pipes are pre-embedded in the prefabricated wall body and the composite floor slab, and connecting grooves are pre-formed in the connecting positions of the prefabricated wall body and the composite floor slab; and the wire pipes of the prefabricated wall body and the composite floor slab extend into the connecting grooves, connecting pipe fittings used for being connected with the wire pipes are arranged in the connecting grooves, and junction boxes are preset on the prefabricated wall body and the composite floor slab. The assembly type building pre-embedded electrical pipeline system has the effect of improving the electric pipeline mounting efficiency.

Owner:福建万山水利水电设计有限公司

Threading equipment and threading method therefor

PendingCN107492841AImprove toughnessImprove cornering abilityApparatus for laying cablesElectric machineryEngineering

Disclosed are threading equipment and a threading method therefor. The threading equipment comprises an air suction apparatus, a wire drawing apparatus and a motor, wherein the air suction apparatus is connected to one end of a wire pipe for performing an air suction operation to the interior of the wire pipe and providing wire conveying power for a first lead; the wire drawing apparatus is used for winding a second lead and performing a wire drawing operation, wherein the flexibility of the second lead is higher than that of the first lead; and the motor is connected with the wire drawing apparatus and used for providing wire drawing power for the wire drawing apparatus. By virtue of the threading equipment and the threading method therefor, threading efficiency can be improved.

Owner:SHENZHEN GUANGTIAN ROBOT CO LTD

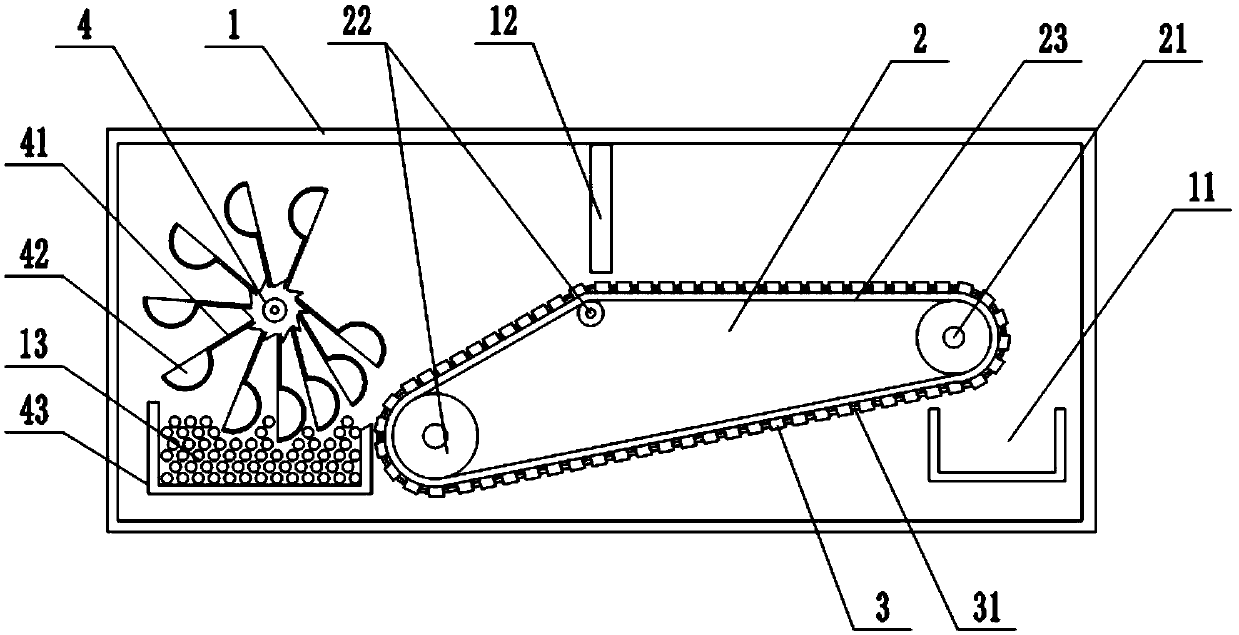

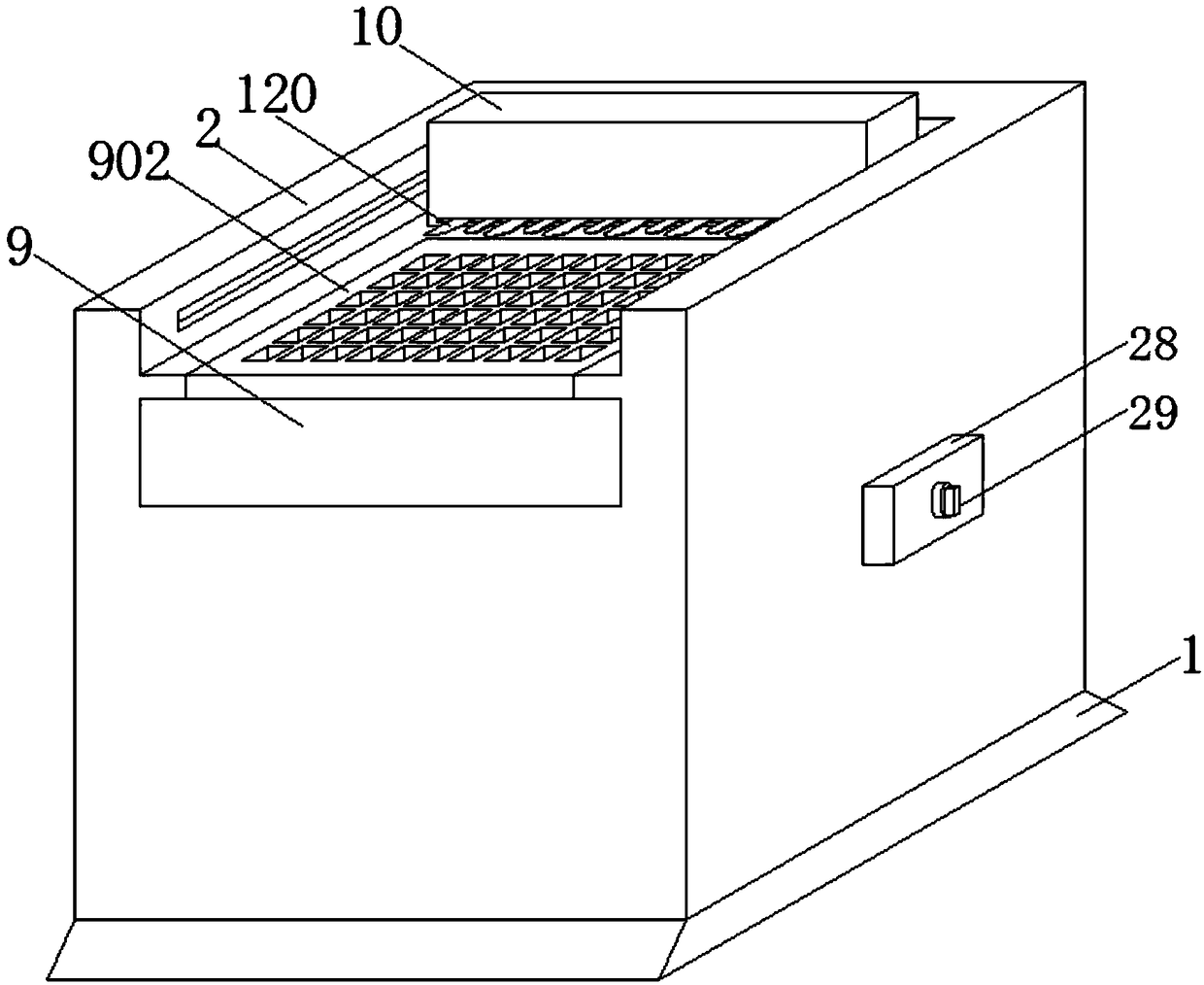

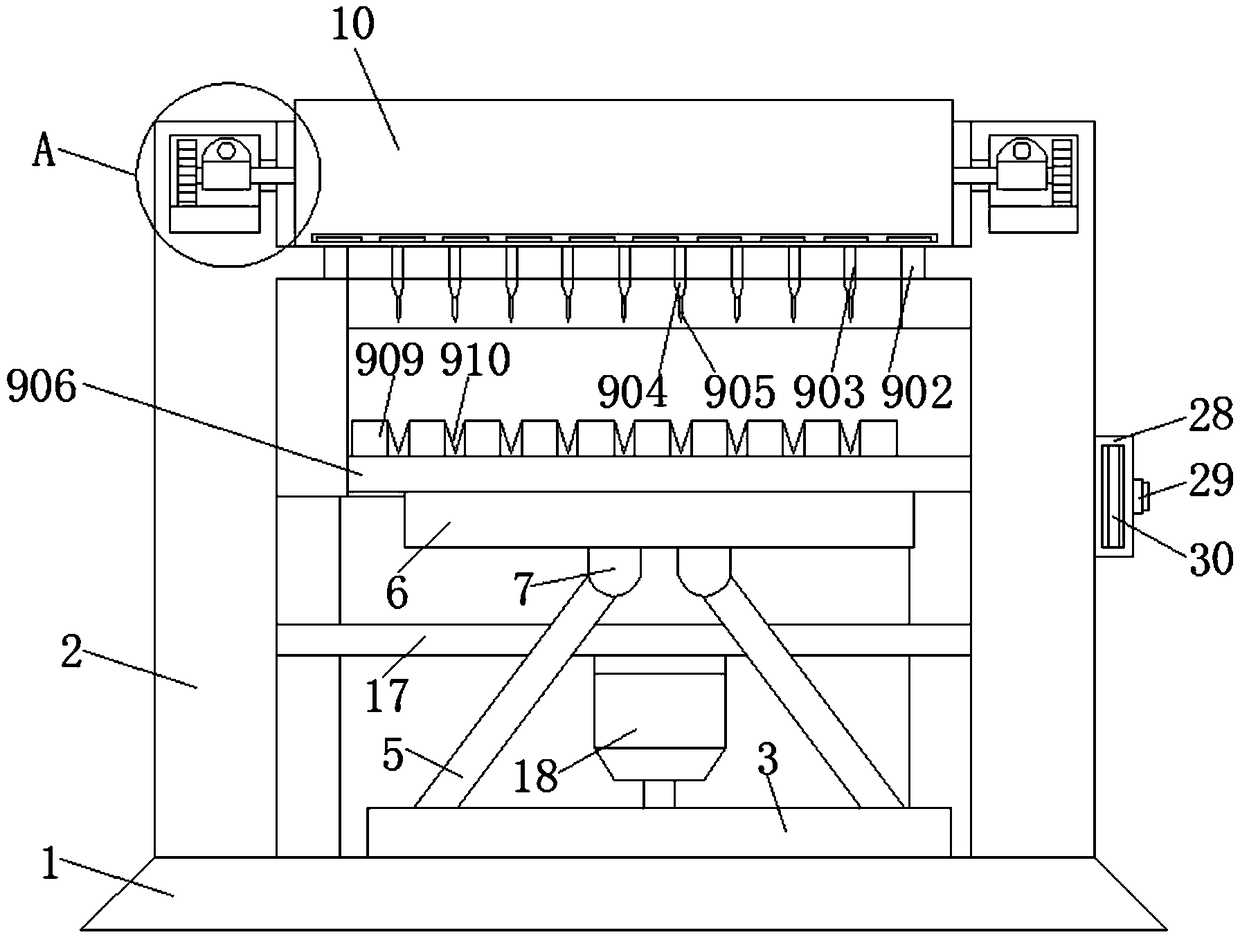

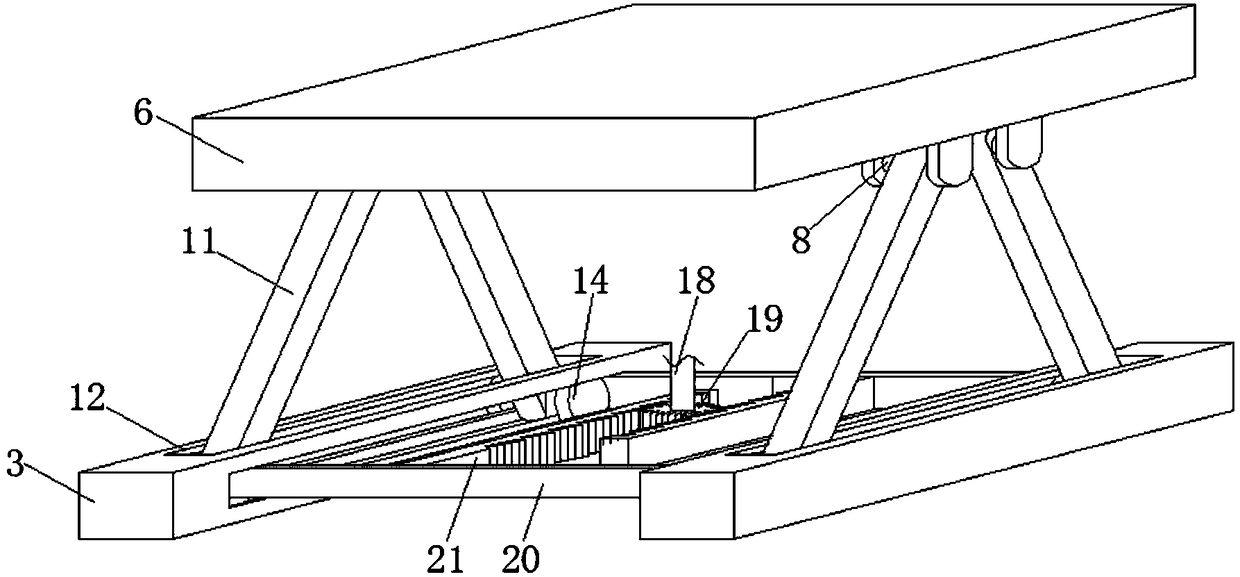

Automatic ball stringing machine

InactiveCN109662131AImprove threading efficiencyImprove securityFood shapingPutting meat on skewersEngineeringMechanical engineering

The invention relates to the technical field of food processing equipment, and discloses an automatic ball stringing machine. The machine includes a box body, the box body is internally and fixedly provided with a feeding device, a conveying belt and a collection box, several storage molds are installed at equal intervals on the conveying belt, several accommodation grooves are formed in the storage molds, and each accommodation groove only can accommodate one ball; one side of the horizontal part of the conveying belt is provided with a stringing device, the stringing device includes a bamboostick box, a second motor, a placement table and a stick pushing mechanism. The balls are placed in the storage molds through the feeding device, under action of the conveying belt, the storage moldscontaining the balls are conveyed to the horizontal part of the conveying belt, bamboo sticks in the bamboo stick box sequentially pass through the balls on the storage molds through the stick pushing mechanism, and the balls are stringed on a bamboo stick. The machine can achieve continuous stringing operation of the balls and the work efficiency is improved.

Owner:象山锦绣升平食品有限公司

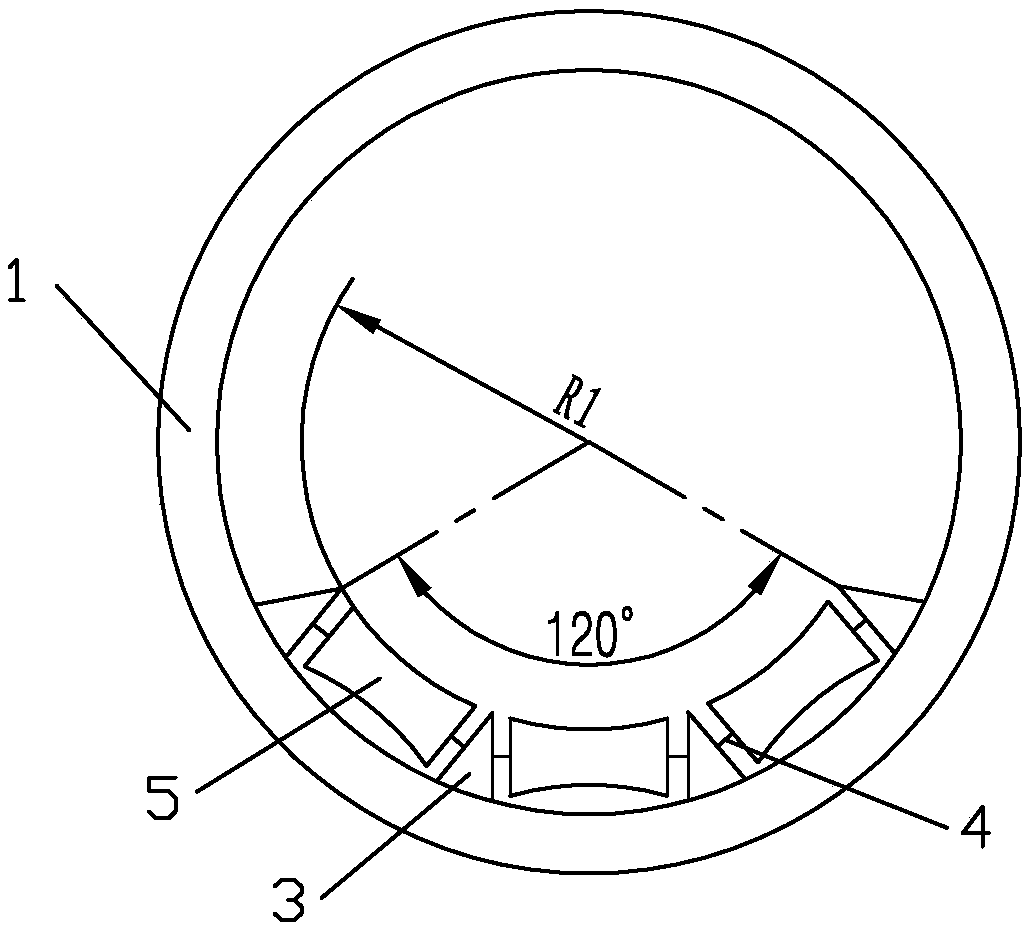

Groove roller-type cable pipe mouth sheath device

InactiveCN109616954AImprove threading efficiencyAvoid contactApparatus for laying cablesRolling resistanceBuilding construction

The invention discloses a groove roller-type cable pipe mouth sheath device. The groove roller-type cable pipe mouth sheath device comprises a pipe mouth baffle ring and a positioning short pipe, wherein the positioning short pipe is inserted into a cable protection pipe, a plurality of roller bases are arranged on an inner wall of the positioning short pipe, an arc groove roller is arranged between adjacent roller bases by a roller shaft, the groove arcs of the plurality of groove rollers are concentric with equal radius, preferably, and an angle of a fan-shaped coverage region of the plurality of groove rollers in the cable protection pipe is larger than or equal to 120 degrees. The grove roller-type cable pipe mouth sheath device has the beneficial effects of simple structure and low fabrication cost, can be repeatedly used and is convenient to carry and disassemble; sliding friction between a cable at a cable protection pipe inlet and the cable protection pipe is changed to rollingfriction, the resistance during the construction process is greatly reduced, meanwhile, direct contact of the cable and the cable protection pipe is prevented, and the risk that the cable is damagedis reduced.

Owner:CRRC CONSTR ENG CO LTD

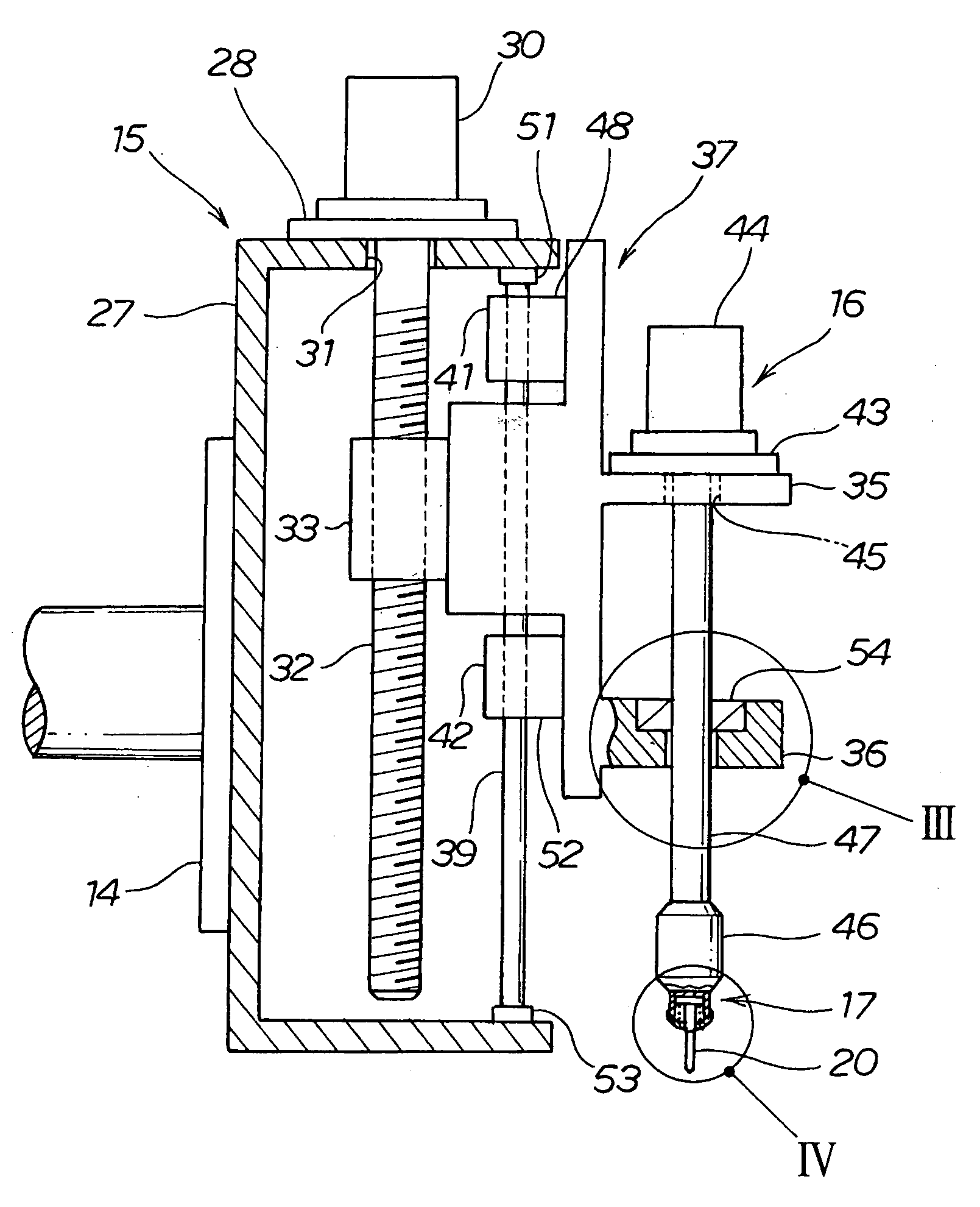

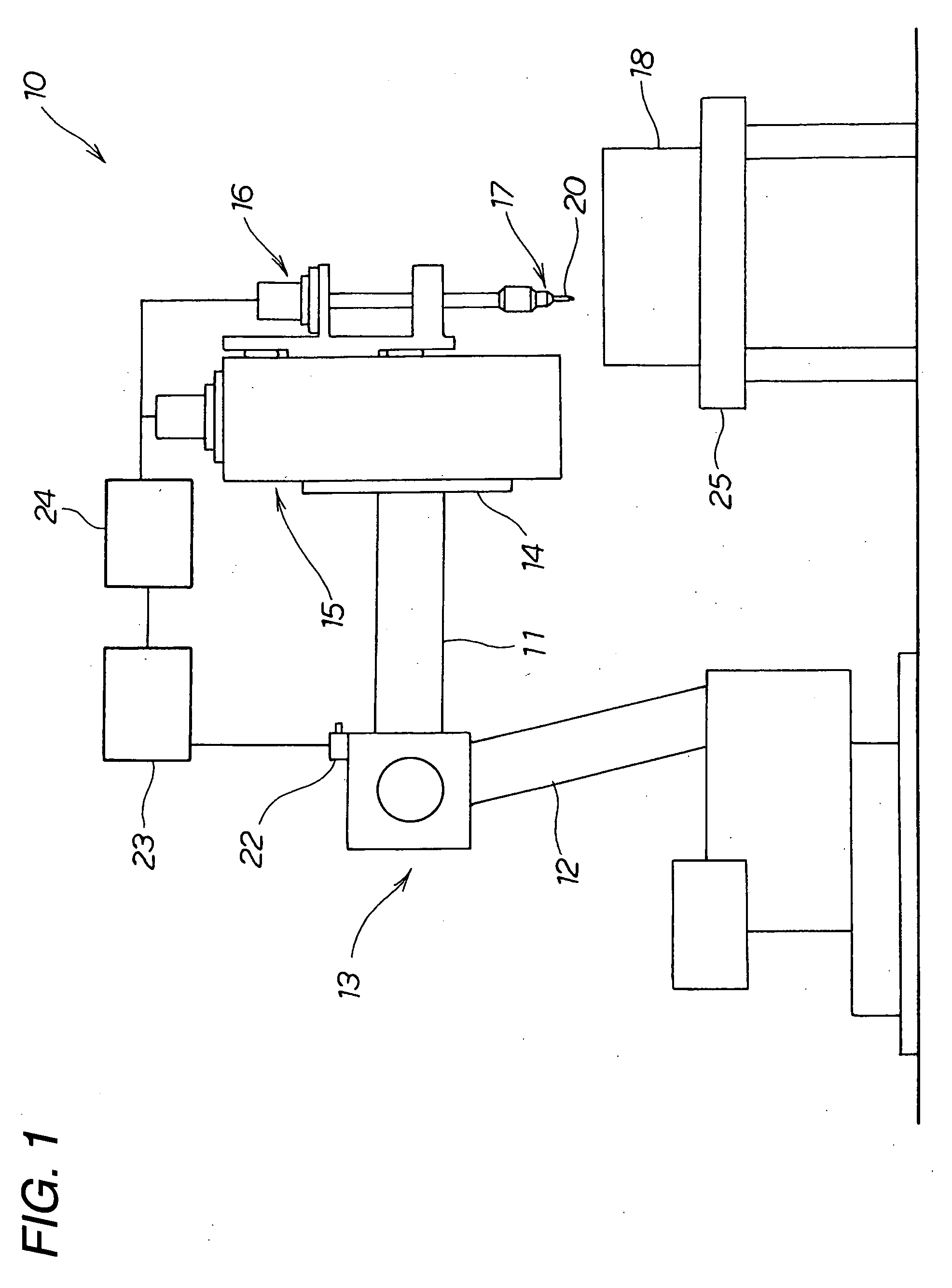

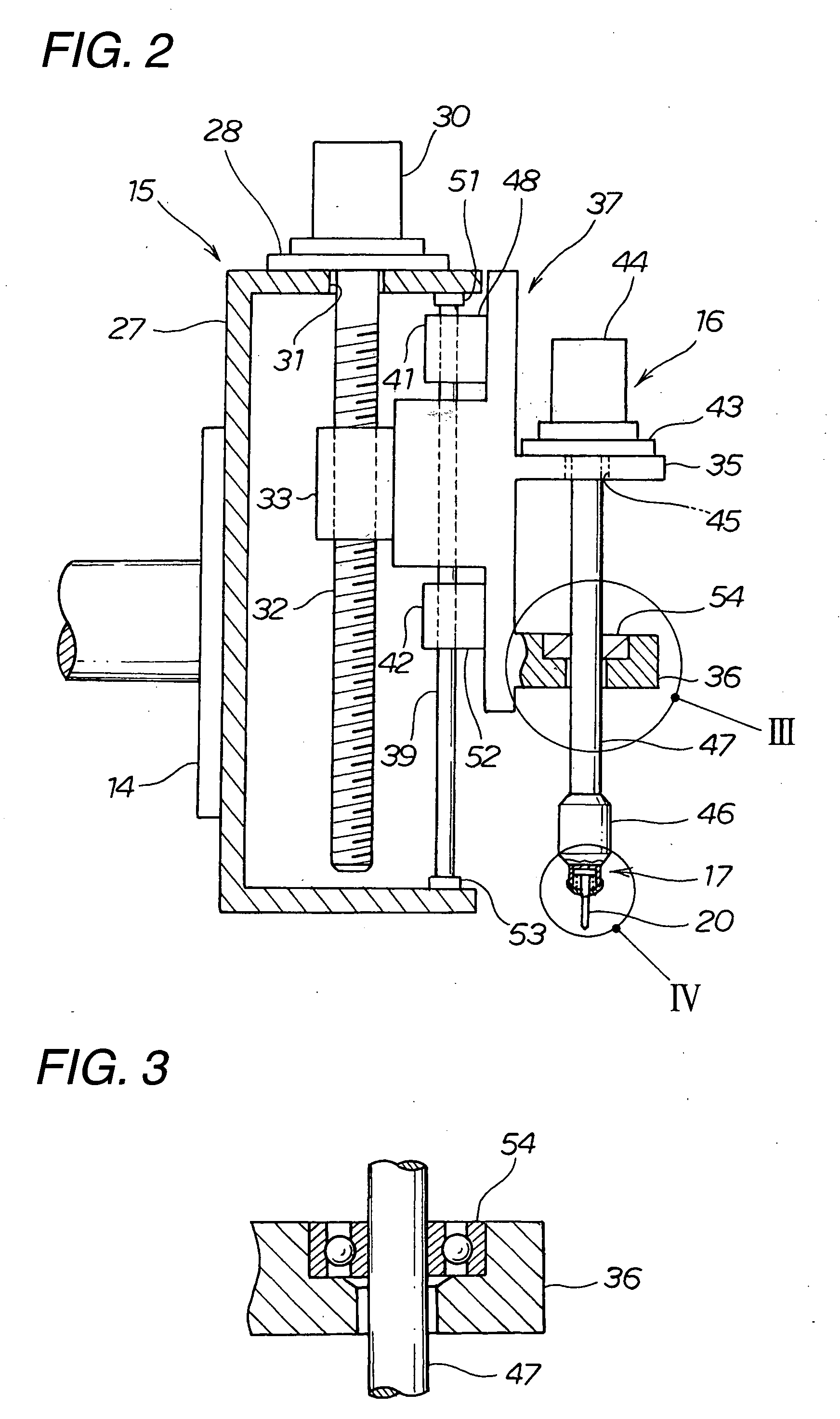

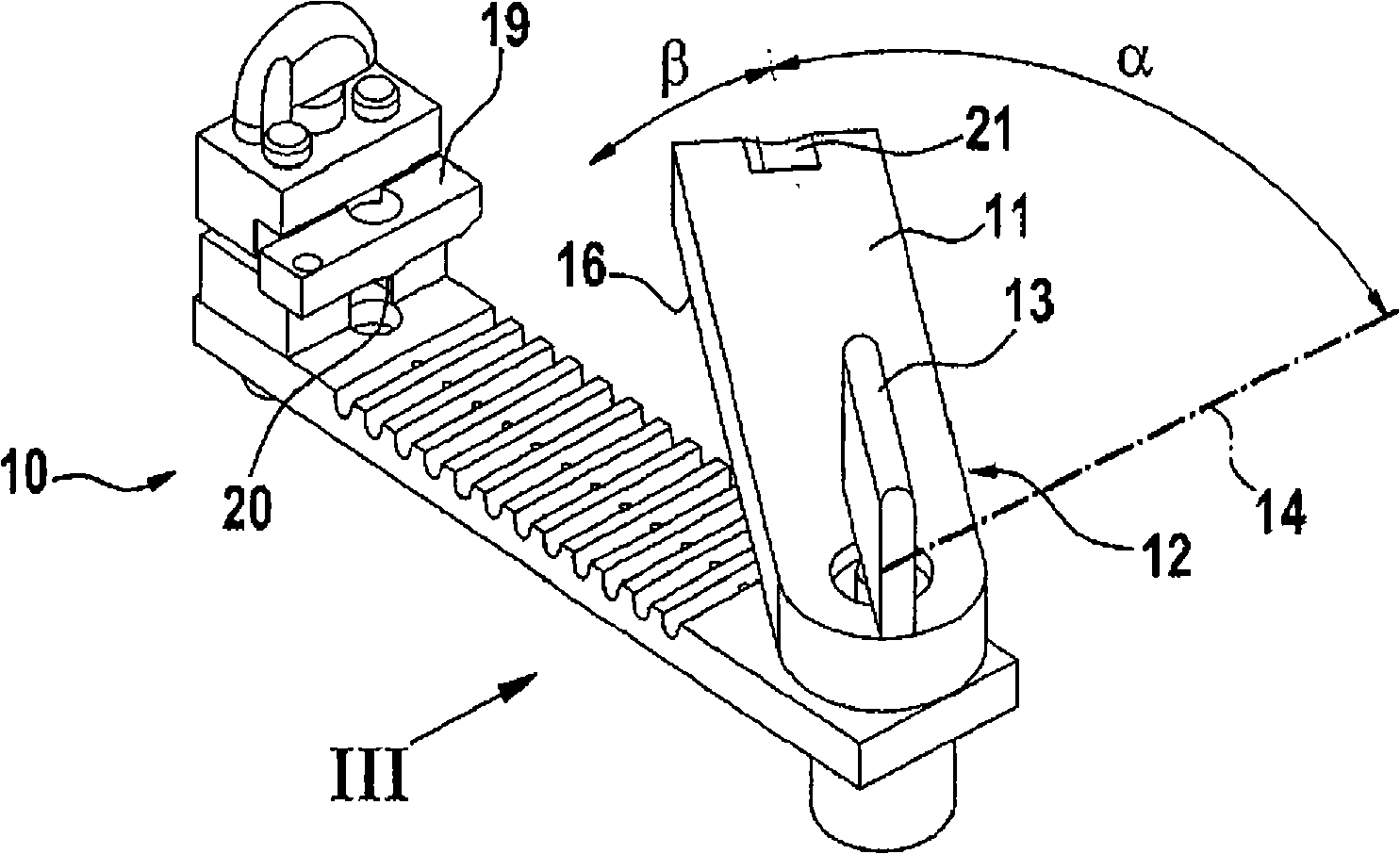

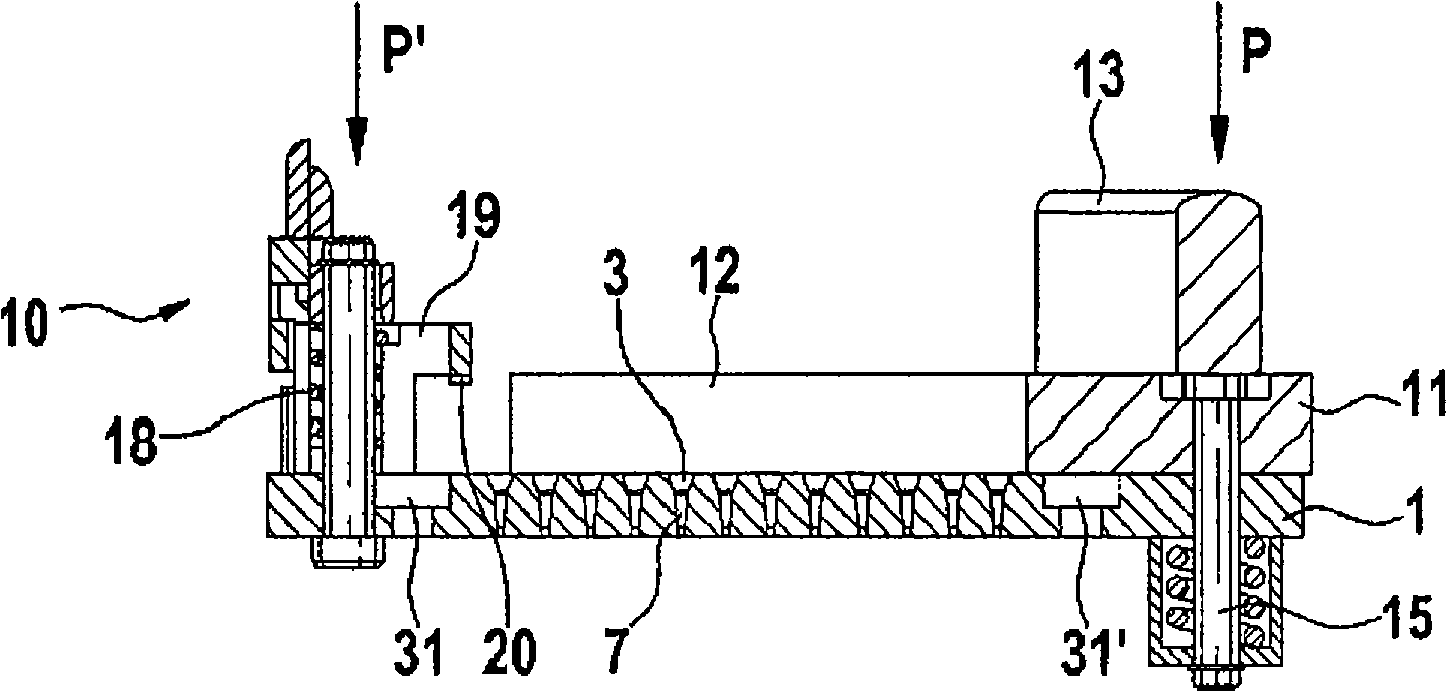

Threading method and threading apparatus

InactiveUS20090257837A1Improve efficiencyImprove processing efficiencyThread cutting machinesPrinted circuit manufactureEngineeringMechanical engineering

A threading method for threading a work 18 includes a supporting portion moving-up step for moving a supporting portion 17 upward by a predetermined distance by using an elevational mechanism 15 without rotating a tap 20 inserted into the work 18. Thus, the bent state of the robot arm 11 can be eliminated by moving the supporting portion 17 upward. In this case, since the supporting portion 17 is moved upward artificially, the supporting portion 17 can be moved up in a short time. That is, the bent state of the robot arm 11 can be eliminated in a short time and so the processing efficiency of the threading step can be improved.

Owner:HONDA MOTOR CO LTD

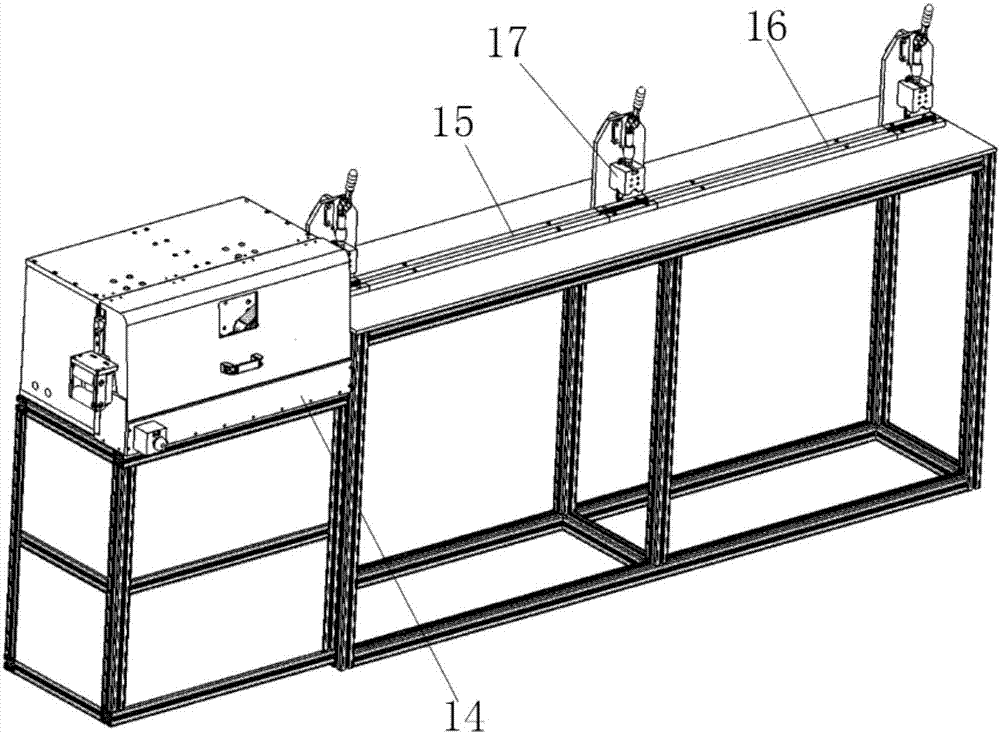

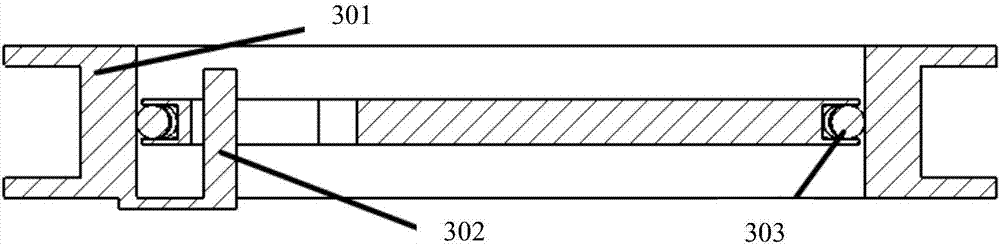

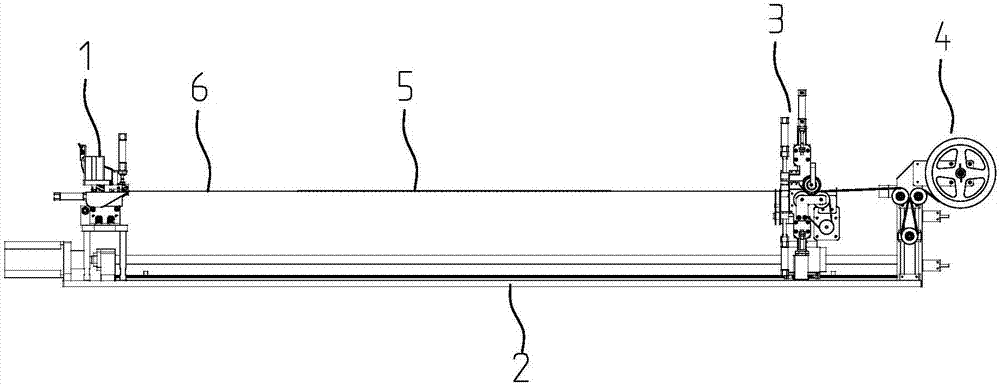

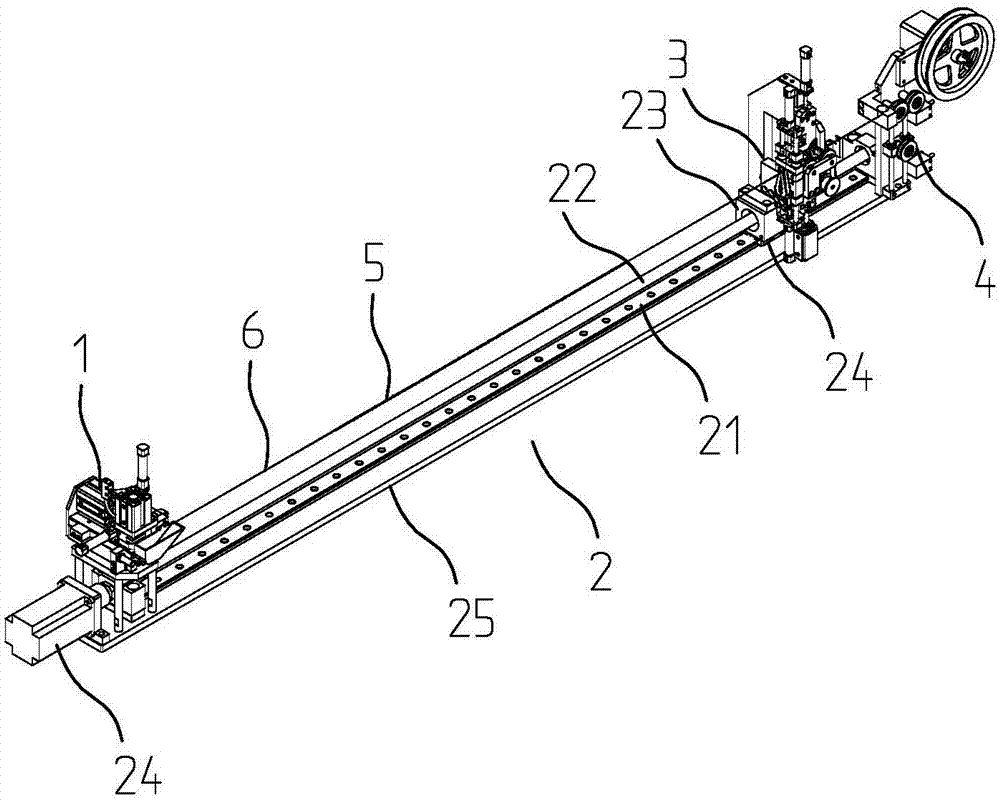

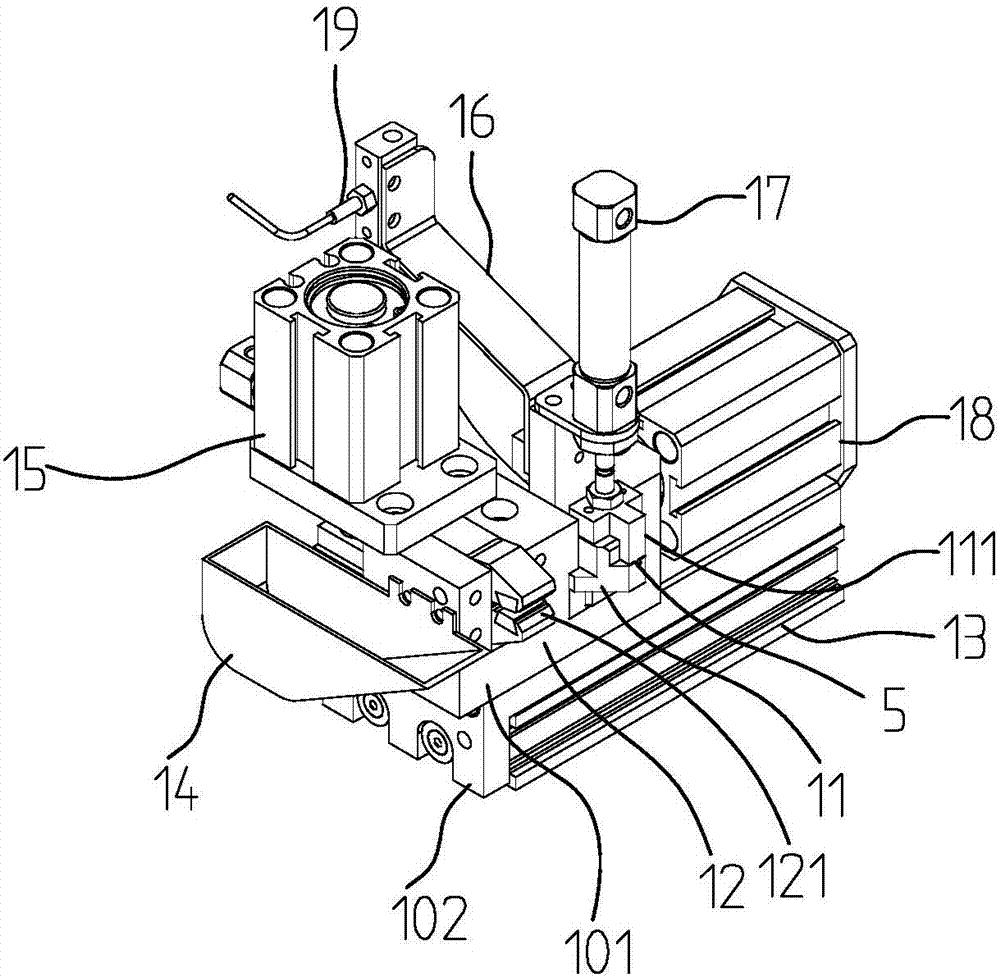

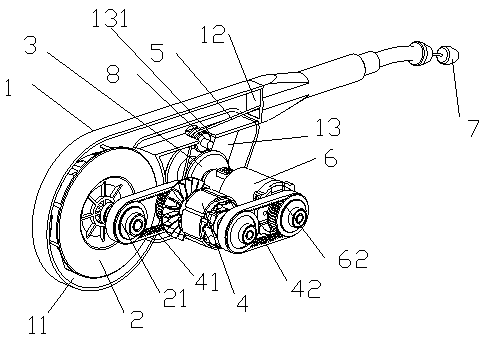

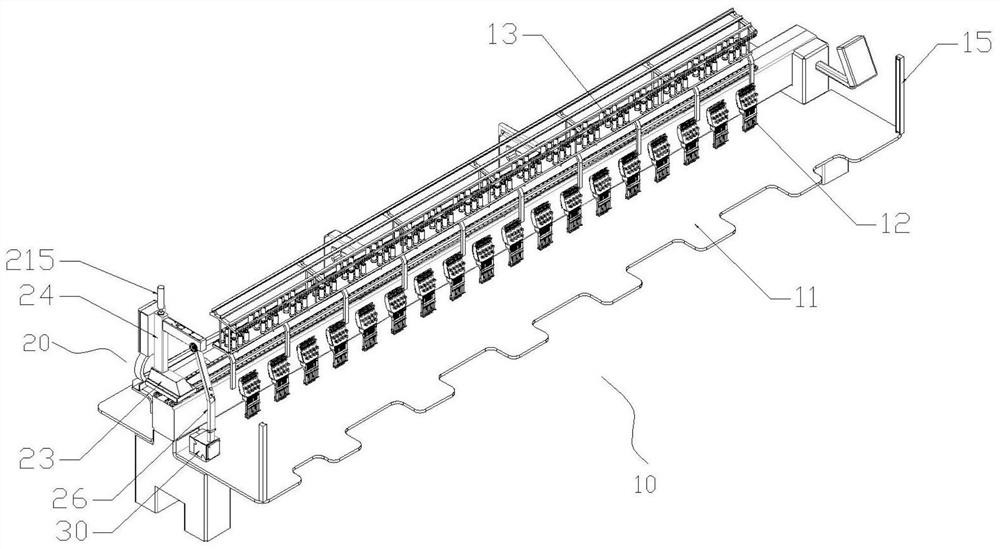

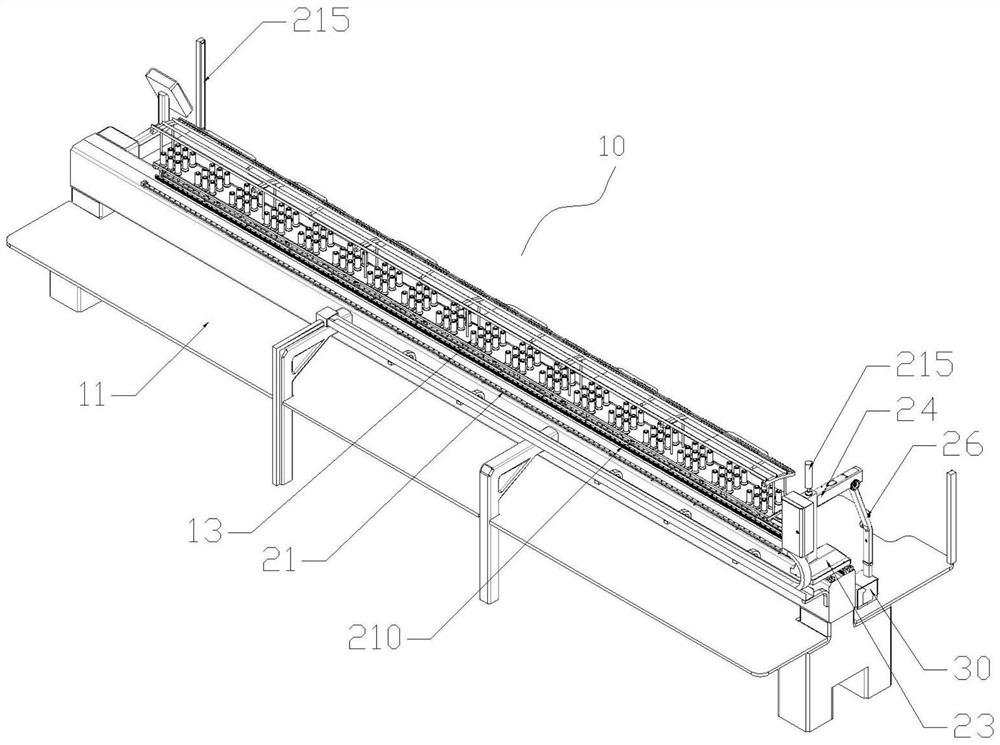

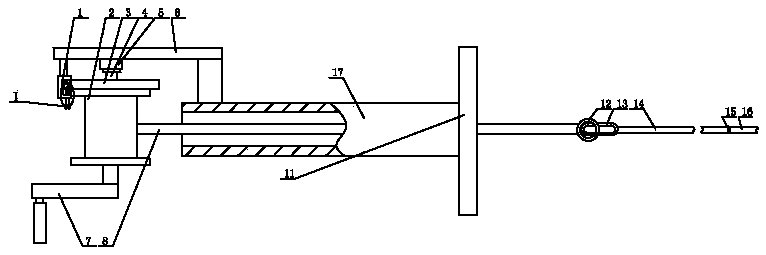

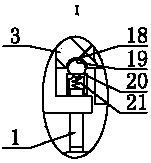

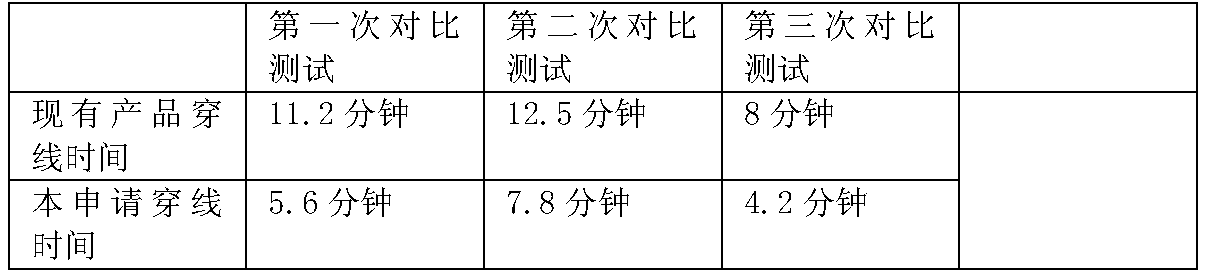

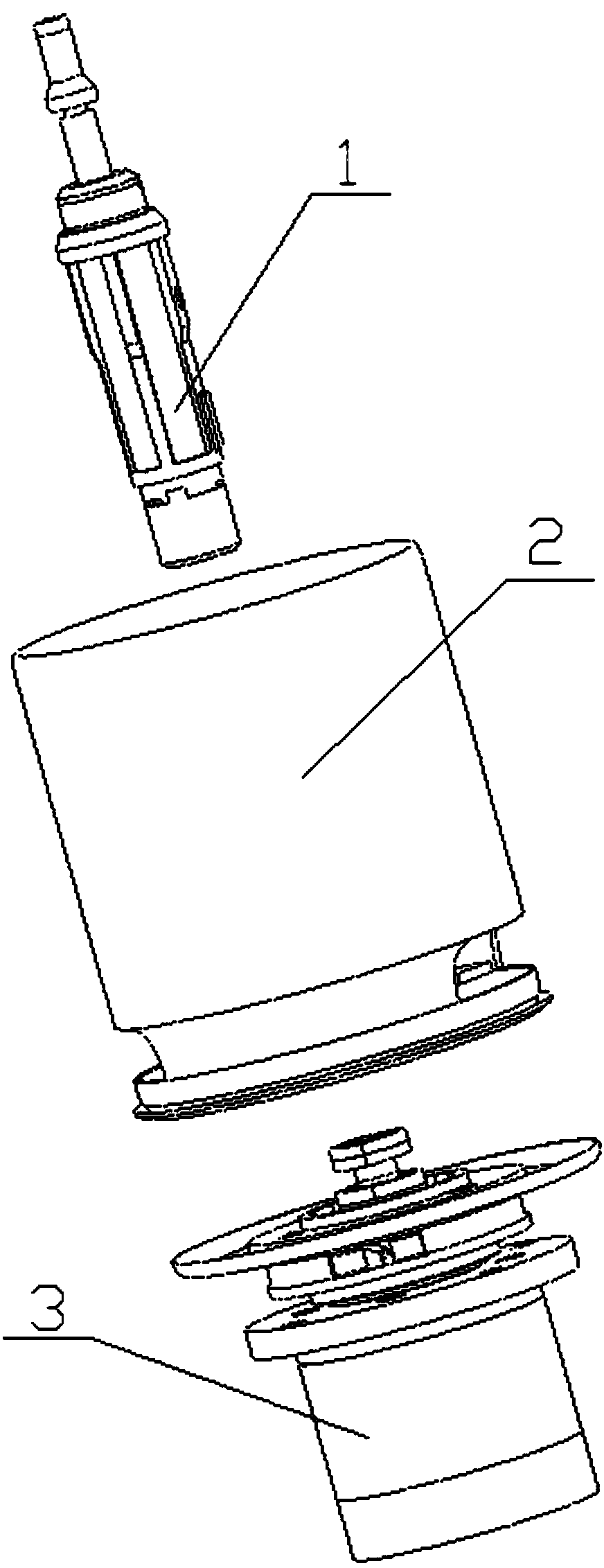

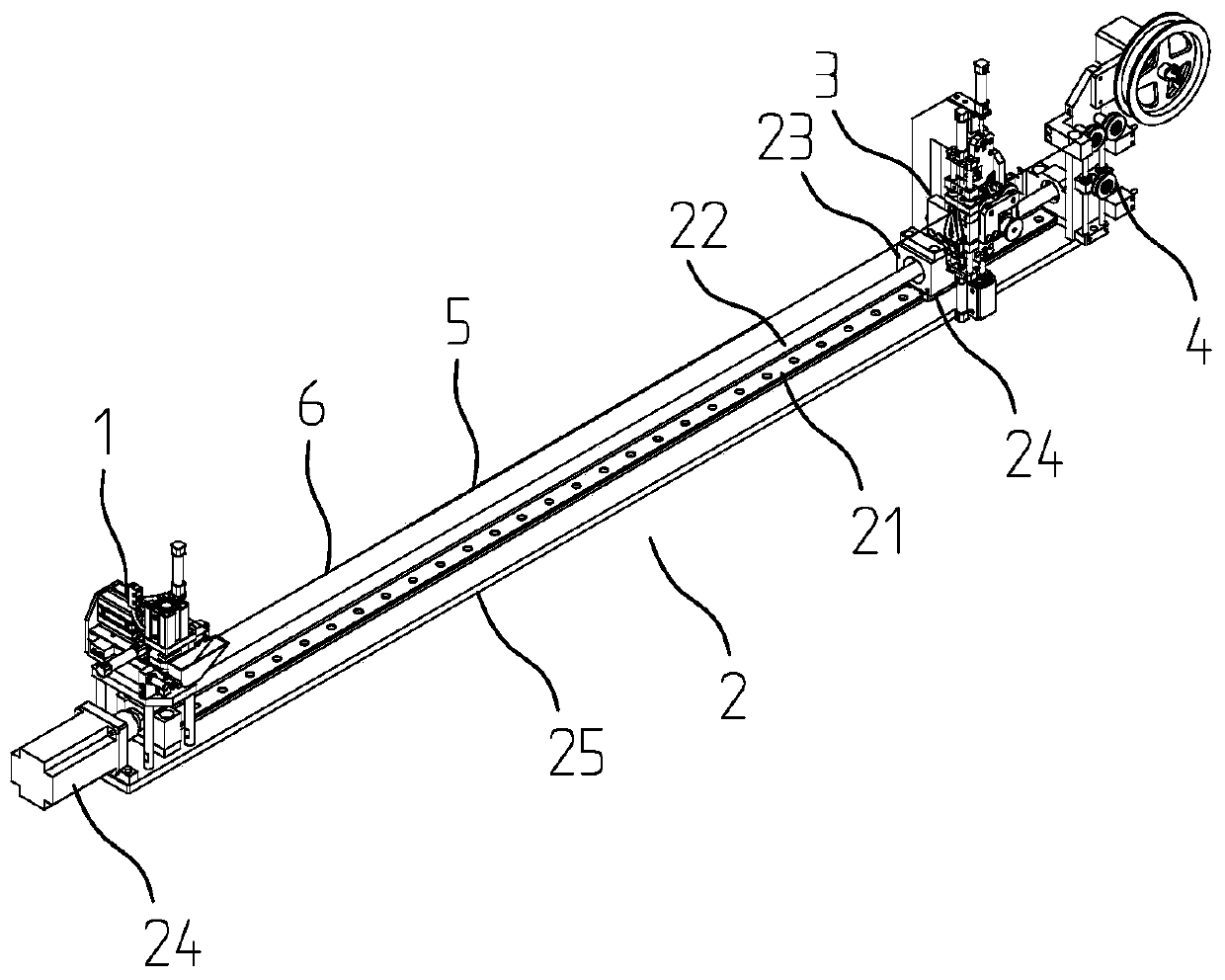

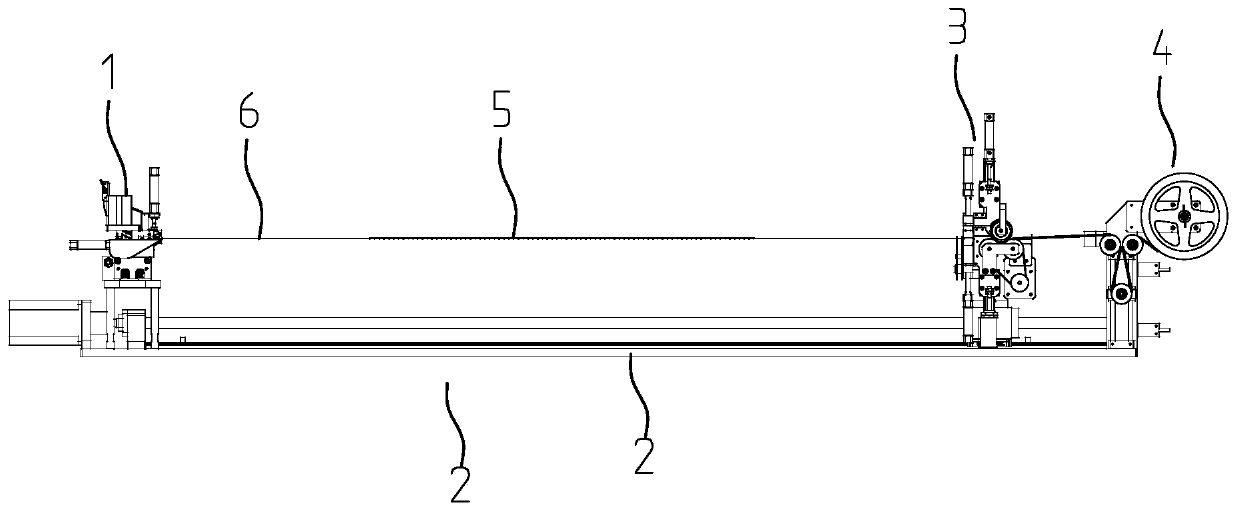

Threading machine used for inserting steel wire into core and threading method

ActiveCN107065078AImprove threading efficiencyReliable manual threadingCoupling light guidesEngineeringMechanical engineering

The invention provides a threading machine used for inserting a steel wire into a core and a threading method. The threading machine comprises a frame having a first end and a second end, a feeding device arranged at the first end of the frame, a material clamping device connected with the feeding device, a steel wire uncoiling and coiling device arranged at the second end of the frame, a threading device capable of moving between the first end and the second end, a wire clamping device arranged at the first end of the frame, and a burning device used for heating the steel wire dragged by the threading device, wherein the material clamping device and the wire clamping device can selectively align at the position of the threading device. The threading machine is advantaged in that material conveying is realized through the feeding device, the core is clamped through the material clamping device, the steel wire is released by the steel wire uncoiling and coiling device, the steel wire is dragged by the threading device to realize threading, the steel wire is clamped by the wire clamping device, the steel wire is heated by the burning device, the threading machine used for inserting the steel wire into the core is commonly formed through the parts, compared with a traditional manual threading method, the threading machine further is more reliable, and threading efficiency is substantially improved.

Owner:深圳市雅合科技有限公司

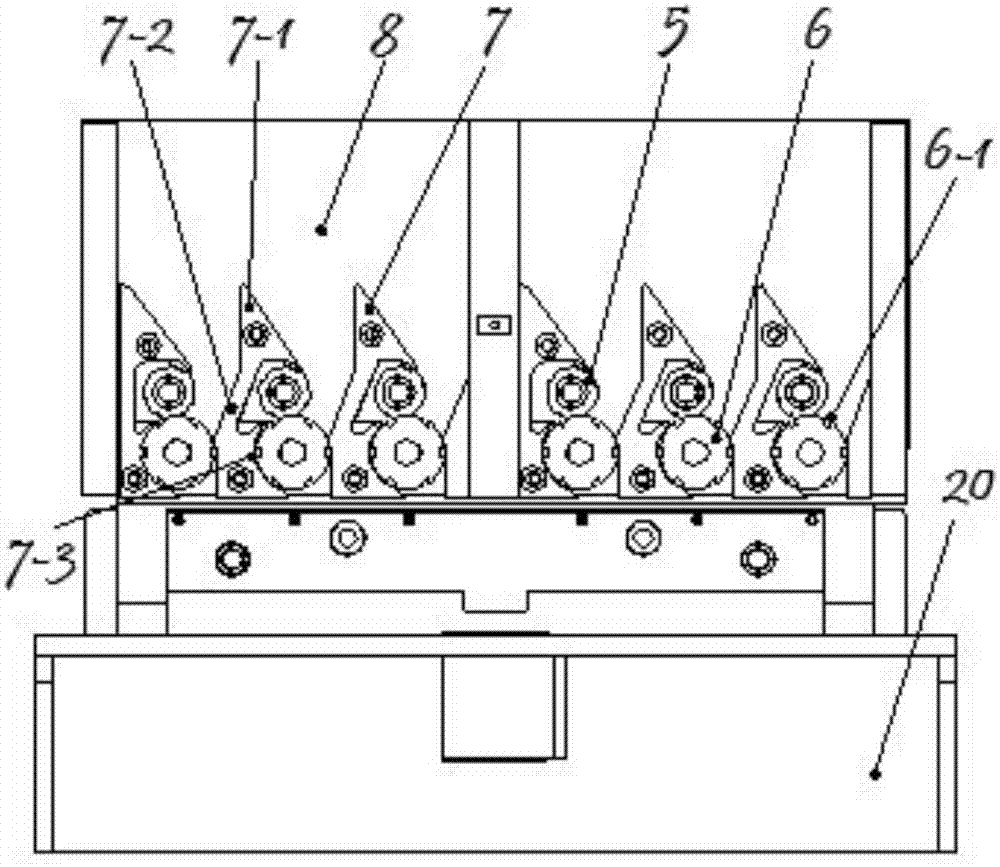

Prod falling and penetrating mechanism of novel and full-automatic stringing machine

PendingCN107265139ASimple structureLow costConveyorsControl devices for conveyorsMechanical wearEngineering

The invention provides a prod falling and penetrating mechanism of a novel and full-automatic stringing machine. The mechanism has the advantages that multiple strings of food can be stringed at a time, and prod falling can be accurately controlled. The mechanism comprises prod falling mechanism bodies and prod penetrating mechanism bodies, wherein the prod falling mechanism bodies are formed by arranging a plurality of prod falling units in parallel in prod hoppers, each prod falling unit consists of a prod shifting wheel, a prod groove roller and a prod separating baffle, and the prod penetrating mechanism bodies are located under the prod falling mechanism bodies, push prods to move through rod-free air cylinders and are reset through reset springs. According to the mechanism, specifically, the twelve prod falling units and the corresponding prod penetrating mechanism bodies are arranged, then operation of the prod falling units is controlled through stepping motors, operation of the prod falling mechanism bodies, the prod penetrating mechanism bodies and a food conveying part are coordinated through inductive switches so that stringing operation can be carried out coherently, smoothly and circularly, and therefore the food stringing efficiency can be greatly improved.

Owner:CHANGSHA FURURE QINGLIAN TECH CO LTD

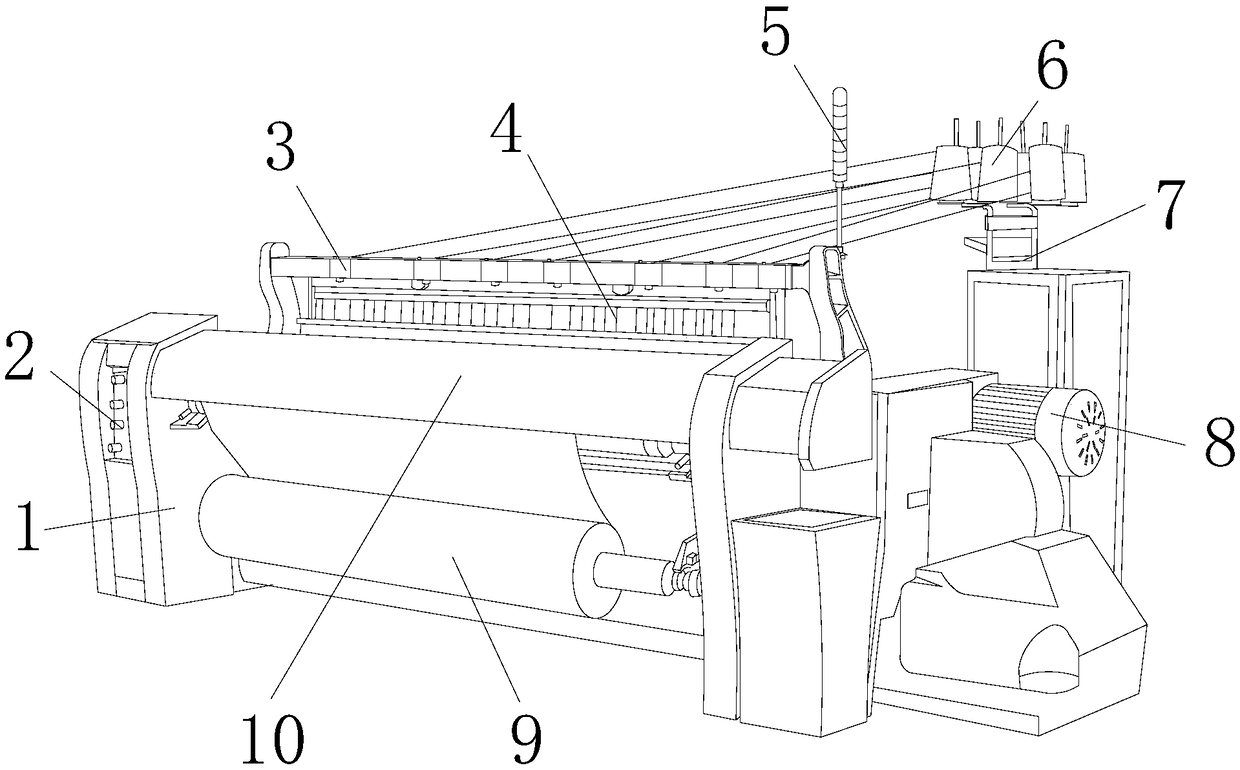

Cotton yarn knitting machine

InactiveCN108625033AImprove stabilityPrevent disconnectionWeft knittingWarp knittingElectric machineryEmbedded system

The invention discloses a cotton yarn knitting machine. The cotton yarn knitting machine structurally comprises a support frame, a control panel, a thread change break-proof device, a knitting plate,a warning light, a cotton yarn spool, a fixing frame, a motor, a cotton yarn roll and a main body; the control panel is embedded in the front side of the support frame, the control panel is electrically connected with the motor through a wire; the thread change break-proof device is embedded at the upper part of the main body; and the knitting plate is embedded in the main body. The thread changebreak-proof device comprises a thread change device, a starting device, a thread feeding mechanism, a transmission gear, a regulating mechanism, a thread break-proof device and a thin thread removingmechanism; the diameter of a threading hole is manually changed when a thread is changed, the threading efficiency is improved, a thread residue is fixed, the thread conveying stability is improved, the thread is stabilized in the knitting, the dramatic shaking is avoided, the condition that cotton yarn is broken is prevented, thin thread dust produced by friction with the inner part of the deviceis sucked out when a needle and the thread are transferred, and the thread jamming is avoided.

Owner:佛山市翠微自动化科技有限公司

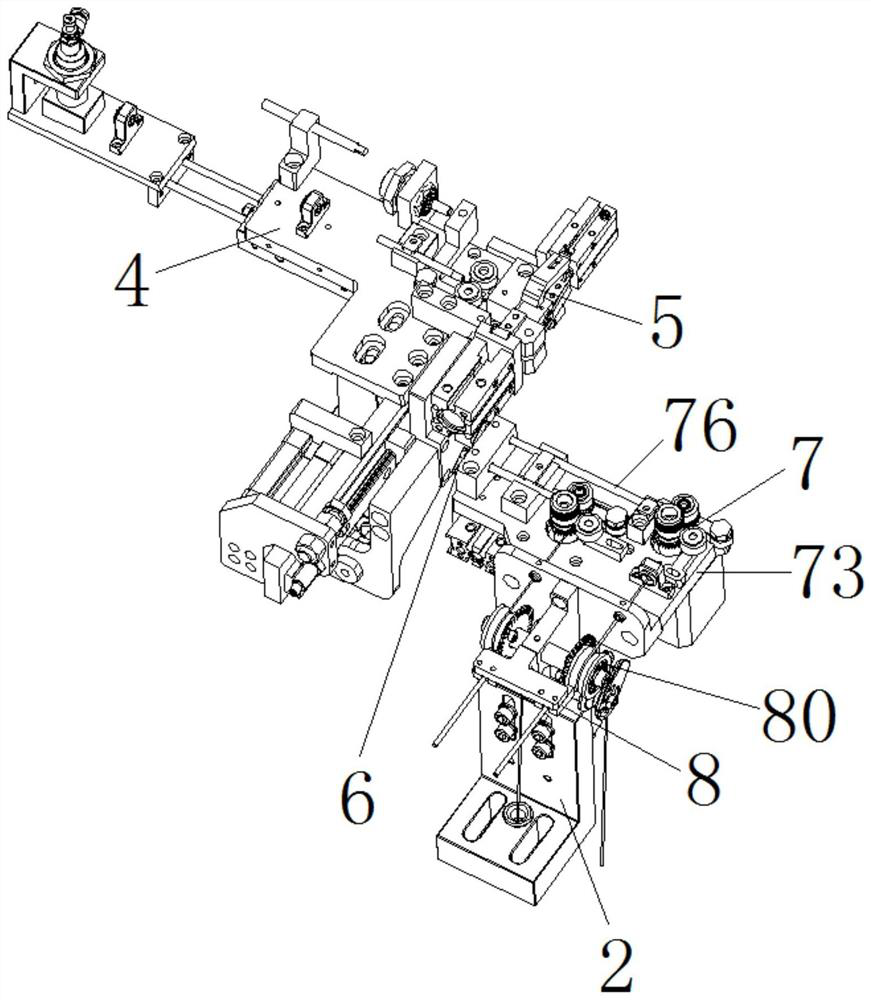

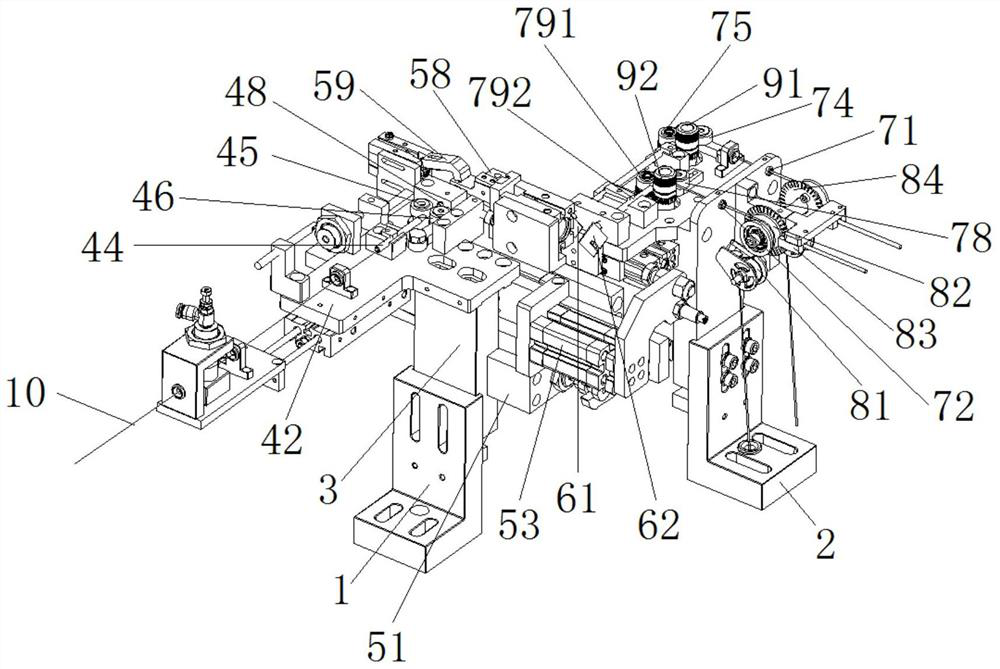

Transformer double-color sleeve feeding and threading structure and production process thereof

ActiveCN112605457AAvoid the problem of being squeezed and deformedPrevent running outTube shearing machinesShearing machine accessoriesWire rodTransformer

The invention discloses a transformer double-color sleeve feeding and threading structure and a production process thereof. The transformer double-color sleeve feeding and threading structure comprises a plurality of supporting seats, a wire feeding and threading mechanism, a sleeve moving mechanism, a sleeve cutting mechanism, a sleeve threading mechanism and a sleeve detection mechanism. By means of the overall structural design of the transformer double-color sleeve feeding and threading structure, a series of operations such as feeding conveying, feeding continuity detection, limiting, 90-degree turning conveying, cutting, shifting, wire feeding, wire tension attenuation control and threading can be automatically completed on the double-color sleeves on one mechanism, and the phenomenon that the sleeves are extruded and deformed in the 90-degree turning conveying process can be avoided; the transformer double-color sleeve feeding and threading structure has the advantages of being good in conveying effect, high in threading efficiency, small in equipment occupied space and the like, and the problems that a sleeve mechanism of an existing structure cannot conduct 90-degree turning conveying on the sleeves and cannot prevent the sleeves from being extruded and deformed in the conveying process are solved. and the transformer double-color sleeve feeding and threading structure further solves the problem that the sleeve mechanism of the existing structure cannot conduct multiple different machining procedures on the sleeves on one mechanism.

Owner:苏州创易技研股份有限公司

Bean product stringing method

InactiveCN102986903AImprove threading efficiencyHigh hygiene requirementsCheese manufactureFood scienceHealth conditionMaterial storage

The invention belongs to the technical field of bean product combination processing, and especially relates to a bean product stringing method. The method is characterized in that the method comprises the following steps: 1, slitting a cooked bean product, seasoning by a plurality of seasonings, and putting the seasoned bean product into a container for material storage; 2, putting the seasoned bean product into a groove; 3, compacting the bean product by putting the groove containing the bean product under a press block; 4, stringing the combined bean product by bamboo sticks; and 5, packaging the stringed bean product. The bean product stringing method has the advantages of high stringing efficiency, simplicity, high health condition requirement, easy realization of the industrialized production, and popularization deserving.

Owner:HENAN JINPAI IND

Block producing machine based on coldness dispelling and warm tonifying food

ActiveCN108835198AFast cutting speedIncrease the speed of threadingMeat shaping/cuttingParallel plateMechanical engineering

The invention discloses a block producing machine based on coldness dispelling and warm tonifying food and relates to the field of food processing. The block producing machine based on the coldness dispelling and warm tonifying food comprises a base and a tank body welded at the top of the base, wherein two parallel plates are welded to the front part and the rear part of the top of the base; empty slots are respectively formed inside the two parallel plates; the two parallel plates are connected with a push top plate through supporting rod lifting devices; two groups of shaft seats and two shafts are respectively connected to the bottoms, which correspond to the upper parts of the two parallel plates, of the push top plate; two ends of each shaft are respectively sheathed with one group of shaft seats; bearing equipment is inserted into the front side of the tank body and is connected with a block producing groove formed in the top of the tank body; a walking and slicing device is arranged in the block producing groove. The block producing machine can cut meat extruded from an extrusion port at high cutting speed, and is suitable for existing large stall barbecue restaurants, so that the stringing speed of assistants in the large stall barbecue restaurants can be increased and the stringing efficiency is improved.

Owner:龙庄润集团有限公司

Thread changing and penetrating mechanism and method

PendingCN108729051AReduce workloadImprove efficiencySpool-pin assembliesNeedle-threading devicesBobbinEngineering

The invention discloses a thread changing and penetrating mechanism and method. The thread changing and penetrating mechanism comprises a thread changing device and a thread penetrating device, the thread changing device comprises a moving part, a thread-changing driving part and a clamping component, the thread-changing driving part is connected to the clamping component to drive the same to move, and the clamping component is used for clamping a bobbin; the thread penetrating device comprises a rotating rod, a tray, a rotation driving part, a thread feeding pipe and a thread penetrating pipe, the tray is connected on the rotating rod in a sleeved manner, the rotation driving part is connected to the rotating rod to driving the same to rotate, one end of the thread feeding pipe faces therotating rod while the other end of the same can be connected and communicated with one end of the thread penetrating pipe, and the other end of the thread penetrating pipe is used for being connectedwith a suction fan. The thread changing and penetrating mechanism can improve thread changing and penetrating efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Automatic Silk Reeling Locomotive Thread Thread Adding Device and Its Control Technology

ActiveCN108754628BImprove threading efficiencyReduce volatilitySilk reelingWater flowMechanical engineering

The invention discloses an automatic silk reeling machine headstock brushing end cocoon feeding device and a control technology thereof. The cocoon feeding device comprises a brushing-picking end cocoon without end cooling mechanism arranged on an end picking pot (10) and a mixed cocoon conveying mechanism connected with the brushing-picking end cocoon without end cooling mechanism, the output side of the mixed cocoon conveying mechanism is arranged on a high-temperature cocoon feeding opening of an end brushing pot (2), and a water flow system cooperates with the end picking pot (10) and thebrushing-picking end cocoon without end cooling mechanism; the control technology comprises the following steps that 1) the brushing-picking end cocoon without end cooling mechanism cools brushing-picking end cocoons without ends in the end picking pot (10); 2) the mixed cocoon conveying mechanism mixes the cooled brushing-picking end cocoons without ends and reeling silk dropping end cocoons andconveys the cooled brushing-picking end cocoons without ends and the reeling silk dropping end cocoons to the end brushing pot (2) for end brushing; 3) new cocoons are supplemented to the end brushingpot (2); the cooled brushing-picking end cocoons without ends in the end picking pot and the reeling silk dropping end cocoons are mixed and added in the end brushing pot, and therefore the stabilityof the brushing end cocoon setting quantity is improved, and the temperature fluctuation is reduced.

Owner:SICHUAN RES INST OF SILK SCI +1

Air blowing type threading structure

PendingCN111509624AFast outSimple and reasonable structureApparatus for laying cablesImpellerElectric machinery

The invention discloses an air blowing type threading structure. A frame body comprises an impeller cavity at the rear end, a wire pipe on the upper side of the front end and a wire coil cavity on thelower side of the front end. An impeller is hinged into the impeller cavity, a wire coil is arranged in the wire coil cavity, a wire wound on the wire coil penetrates out of the wire pipe through theopening, the motor is fixed to the frame body and acts on the impeller and the wire coil at the same time, one-way bearings are arranged in the impeller and the wire coil, and the motor is connectedwith the one-way bearings of the wire coil through a reduction gear box fixed into the frame body and provided with one-way bearings. The air blowing type threading structure is simple and reasonablein structure, air is compressed through the impeller to form air blowing type threading, a wire can rapidly penetrate out, threading efficiency is high, and the turning performance is excellent.

Owner:SUZHOU GONGYILIAN ELECTROMECHANICAL TECH CO LTD

Air blowing type threading device for construction installation

InactiveCN107437771AWide threading efficiencyImprove threading efficiencyApparatus for laying cablesAtmospheric pressureCotton balls

The invention discloses an air-blowing threader for building installation, which comprises a threading cylinder and an air source. A winding disk is arranged at the inner lower part of the threading cylinder, and a rotating handle is arranged at the front end of the central axis of the winding disk. A wide wire is wound around, and the other end of the wide wire is connected to the cotton ball. An air gauge is provided on the outer upper part of the threading barrel, a sealing cover is arranged on the outer lower part of the threading barrel, and an air inlet pipe is provided on the upper side of the threading barrel. One end of the air inlet pipe is connected with an air source, the other end of the air inlet pipe extends into the threading barrel and is connected with the ring pipe, and a plurality of air blow pipes are circumferentially installed on the upper side of the ring pipe. The invention has stable structure, high threading efficiency, wide application range, safety and reliability, and is favorable for popularization and application.

Owner:龙里县逸轩生产力促进中心

Scapular glenoid bone grafting device under minimally invasive condition

PendingCN112545629AEffective diversion exportReduce the chance of no progressBone implantJoint implantsBone graftingArthroscopy

The invention provides a scapular glenoid bone grafting device under a minimally invasive condition. The device comprises a sleeve, a threading rod and a handle, wherein the sleeve is provided with achannel; the threading rod is movably inserted into the channel in a penetrating mode; the sleeve is detachably connected with the handle; a first wedge-shaped face is arranged at one end of the sleeve; a thin groove and a wide groove are formed in the side wall of the threading rod; and a second wedge-shaped face is arranged at the end, close to a bone grafting block, of the threading rod. A method for the device comprises the following steps of S1, driving an anchor into a corresponding area under an arthroscope; S2, enabling the sleeve to be contacted and matched with the bone grafting area; S3, placing the bone grafting block into the sleeve; S4, pushing the bone grafting block into the bone grafting area; S5, fixing the bone grafting block; and S6, after the bone grafting block is fixed, removing a Kirschner wire, and suturing a wound. The bone grafting device is high in threading efficiency, high in positioning precision and capable of effectively avoiding slippage, rotation anddisplacement of the bone grafting block in the bone grafting process and reducing the damage to blood vessels, nerves and other tissues of shoulder joints due to the bad phenomenon of the bone grafting block in the bone grafting process.

Owner:XIAN HONGHUI HOSPITAL +1

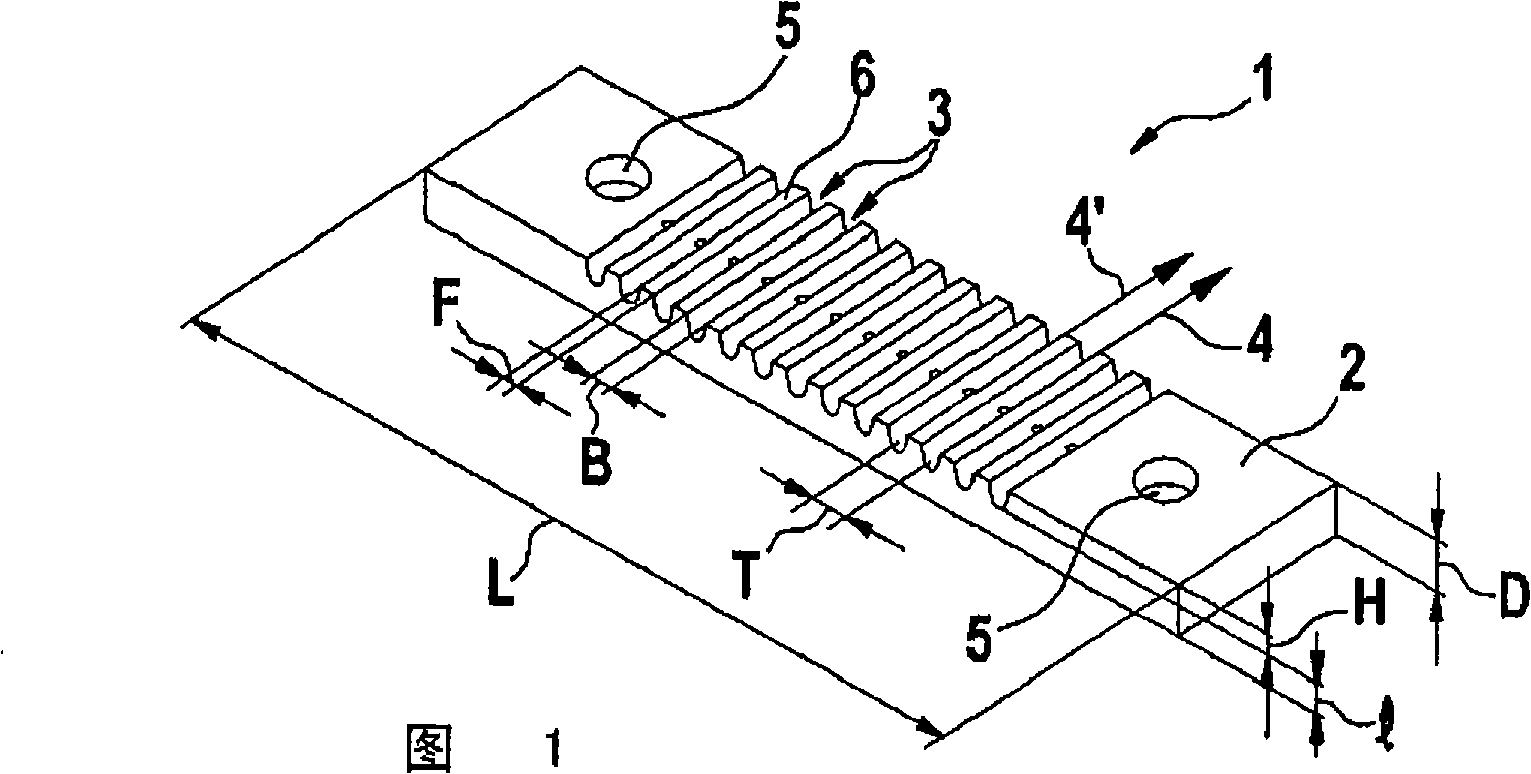

Device for simultaneous handling of several multi-filament threads

The invention relates to a novel apparatus used for simultaneously treating a plurality of multifilament yarns in yarn channels (3) through a spinning nozzle (10), at least one air supply pipe (7) is installed in each yarn channel (3). The spinning nozzle (10) is designed to split a nozzle into two parts, having a basic body or a nozzle body (1) with yarn channel (3) and corresponding air supply pipe (7). The air supply pipe (7) is guided into the yarn channel (3). The novel apparatus can provide a yarn channel cross section configuration used for a single best nozzle, and have the same knot quality as the single nozzle. The apparatus can be used in the spinning process, or the threading device, or the warping machine.

Owner:OERLIKON HEBERLEIN TEMCO WATTWIL

Threading device and automatic threading equipment

PendingCN113308814AImprove efficiencyReduce labor costsEmbroidering machines apparatusEngineeringMechanical engineering

The invention discloses a threading device and automatic threading equipment. The threading device and the automatic threading equipment are installed on an embroidery machine; the embroidery machine comprises a rack, a certain number of machine heads and thread shafts arranged on the rack, and sewing threads between the machine heads and the thread shafts; a translation and swing mechanism is installed on the rack; the tail end of the translation and swing mechanism is connected with an installation and protection assembly; the installation and protection assembly comprises a shell and an installation bottom plate; the threading device is installed on the installation and protection assembly; the translation and swing mechanism is used for driving the threading device to move to the position of the machine head where threading is to be conducted and to be close to the machine head; and the threading device comprises a thread pulling mechanism, a thread leading and feeding mechanism, a calibration robot mechanism and a thread hooking mechanism on the calibration robot mechanism. The threading equipment moves to the machine head where threads are broken for threading after the threads of the embroidery machine and other textile equipment are broken, automatic threading is achieved, the efficiency of the textile equipment is improved, the labor cost is reduced, the mechanism can be directly and additionally installed on the existing embroidery machine, the interference with an existing structure is avoided, and the modification cost is low.

Owner:杭州衡论科技有限公司

Concrete prestressed steel strand threading guide device with high cable treading efficiency

InactiveCN109386138AHigh threading efficiencyChange lengthBuilding material handlingPre stressArchitectural engineering

The invention relates to the technical field of building construction and discloses a concrete prestressed steel strand threading guide device with high cable treading efficiency. The device comprisesa pre-embedded anchor base mounted at the end part of a cable threading pipe, wherein the side wall of the pre-embedded anchor base is fixedly connected with a fixing base through a plurality of bolts, the fixing base is provided with a mounting hole, and a first guide pipe is inserted into the mounting hole; the side wall of the fixing base is provided with a fixing mechanism for mounting the first guide pipe, one end of the first guide pipe extends into the pre-embedded anchor base, and the inner side wall of the end, away from the pre-embedded anchor base, of the first guide pipe is provided with an annular connecting groove; the interior of the connecting groove is slidably connected with a connecting pipe, the top of the connecting pipe is provided with a plurality of first limitinggrooves which are uniformly distributed, and the top of the first guide pipe is provided with a mounting groove. According to the concrete prestressed steel strand threading guide device with the highcable treading efficiency, the length of a reserved steel strand can be conveniently changed, and the first guide pipe is conveniently separated from the fixing base.

Owner:马鞍山市顺泰稀土新材料有限公司

Narrow-slit cable threading tool

PendingCN110336222AImprove rigidityStrong penetrating powerApparatus for laying cablesArchitectural engineeringGuide wires

The invention discloses a narrow-slit cable threading tool. The narrow-slit cable threading tool comprises a fixed pipe, one side of the fixed pipe is connected with a bracket, the bracket is connected with a winder, and the winding end of the winder is connected with a steel wire rope. The narrow-slit cable threading tool takes the steel wire rope as a guide wire of a cable, and a detachable rigid guide rod device is additionally arranged at the end portion of the steel wire rope, and can form a guide rod structure by adopting the guide rod to allow an operator to conveniently hold the guiderod by a hand to allow the guide rod to penetrate the protection pipe of the cable, because the guide rod has good rigidity relative to the steel wire rope to more conveniently break through the blocking and the friction in the protection pipe of the cable and avoid that the steel wire rope is easily blocked in the protection pipe of the cable and cannot pass through the protection pipe of the cable so as to improve the wire penetrating efficiency.

Owner:STATE GRID CORP OF CHINA +1

An electric spindle pneumatic spindle

Owner:ANHUI RIFA TEXTILE MACHINERY

Threading machine and threading method for threading steel wire into ferrule

ActiveCN107065078BReliable manual threadingImprove threading efficiencyCoupling light guidesEngineeringMechanical engineering

The invention provides a threading machine used for inserting a steel wire into a core and a threading method. The threading machine comprises a frame having a first end and a second end, a feeding device arranged at the first end of the frame, a material clamping device connected with the feeding device, a steel wire uncoiling and coiling device arranged at the second end of the frame, a threading device capable of moving between the first end and the second end, a wire clamping device arranged at the first end of the frame, and a burning device used for heating the steel wire dragged by the threading device, wherein the material clamping device and the wire clamping device can selectively align at the position of the threading device. The threading machine is advantaged in that material conveying is realized through the feeding device, the core is clamped through the material clamping device, the steel wire is released by the steel wire uncoiling and coiling device, the steel wire is dragged by the threading device to realize threading, the steel wire is clamped by the wire clamping device, the steel wire is heated by the burning device, the threading machine used for inserting the steel wire into the core is commonly formed through the parts, compared with a traditional manual threading method, the threading machine further is more reliable, and threading efficiency is substantially improved.

Owner:深圳市雅合科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com