Air blowing type threading structure

A threading and pneumatic technology, applied in the field of threading machines, can solve the problems of low threading efficiency, lack of bending performance, slow speed, etc., and achieve the effect of high threading efficiency, excellent bending performance, and simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

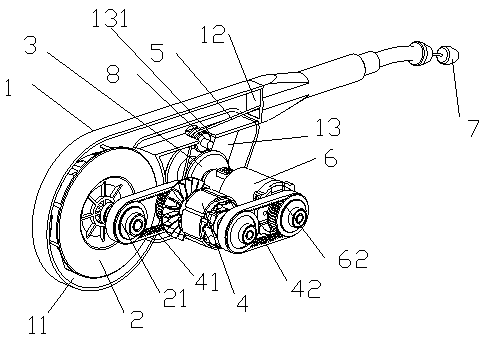

[0018] An air-blown threading structure such as figure 1 As shown, a frame body 1 is included, and the frame body 1 includes an impeller cavity 11 at the rear end, a wire tube 12 at the upper side of the front end, and a wire disc cavity 13 at the lower side of the front end.

[0019] Wherein, the impeller 2 is hinged in the impeller cavity 11, and the impeller rotates to compress the air and blow the air with a certain pressure into the line pipe.

[0020] A wire reel 3 is provided in the wire reel cavity 13, and the wire reel is used as a storage and winding device for wires, and has a degree of freedom in the circumferential direction.

[0021] And the wire 5 that is wound around on the wire reel 3 passes through the opening 131 from the wire pipe 12, and the opening 131 is also provided with a guide wheel 8, which reduces the resistance of the wire to advance and improves the threading speed.

[0022] The wire 5 is a high-strength light wire, preferably a nylon wire, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com