Coiled pipe bundling device and method

A bundling device and coil tube technology, which is applied in the direction of packaging and bundling machine parts, etc., can solve the problems of plastic belt passing through, achieve the effect of liberating labor force, realizing a fully automated process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

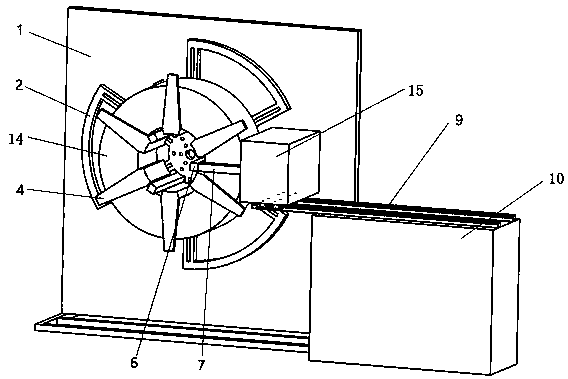

[0037] Such as Figure 1-Figure 5 A coil bundling device includes a frame 1, and a coil support 2 is mounted on the frame 1 through a rotating shaft and a bearing assembly. The rear end of the coil support 2 is driven by a high-power servo motor 3 .

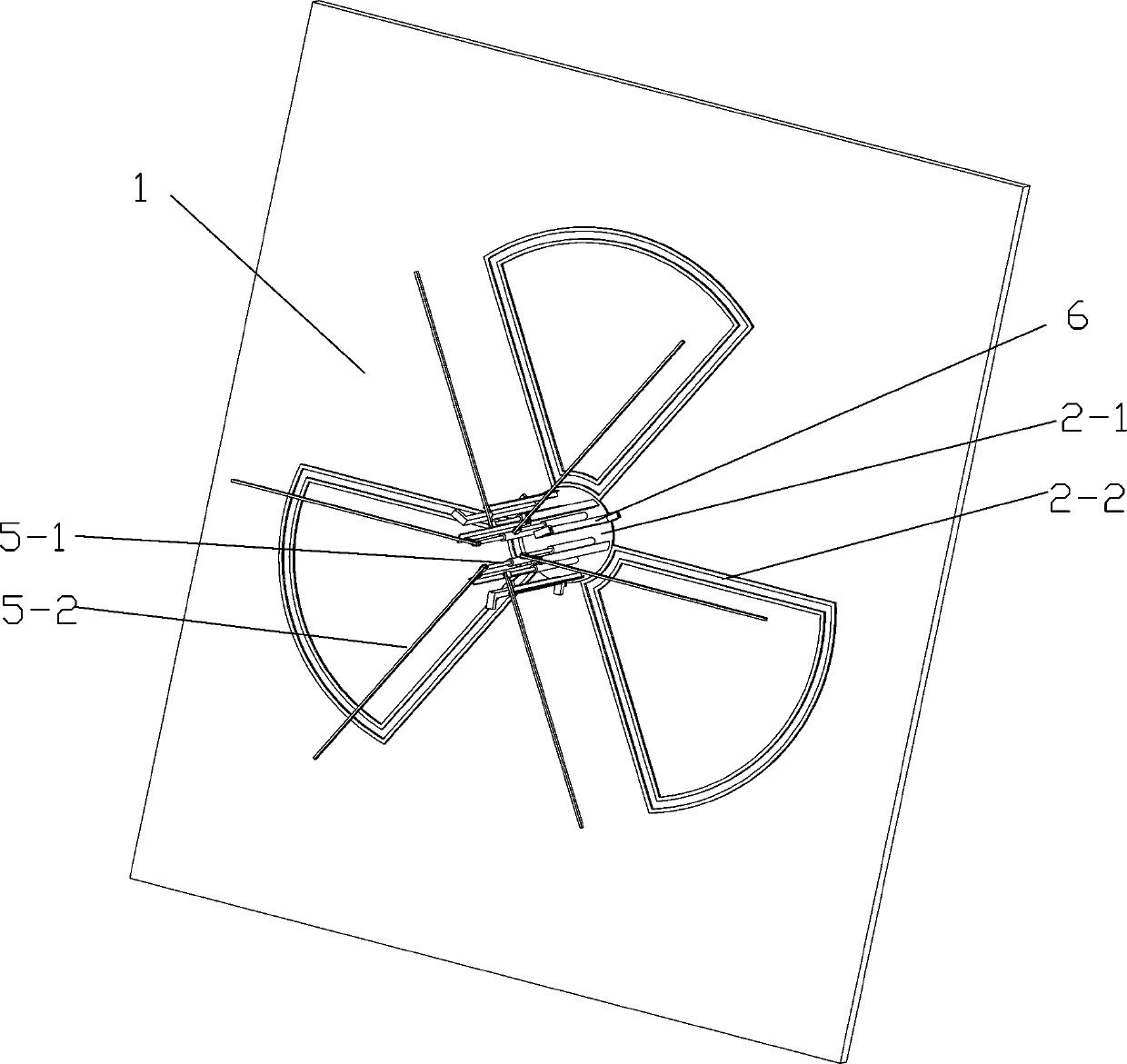

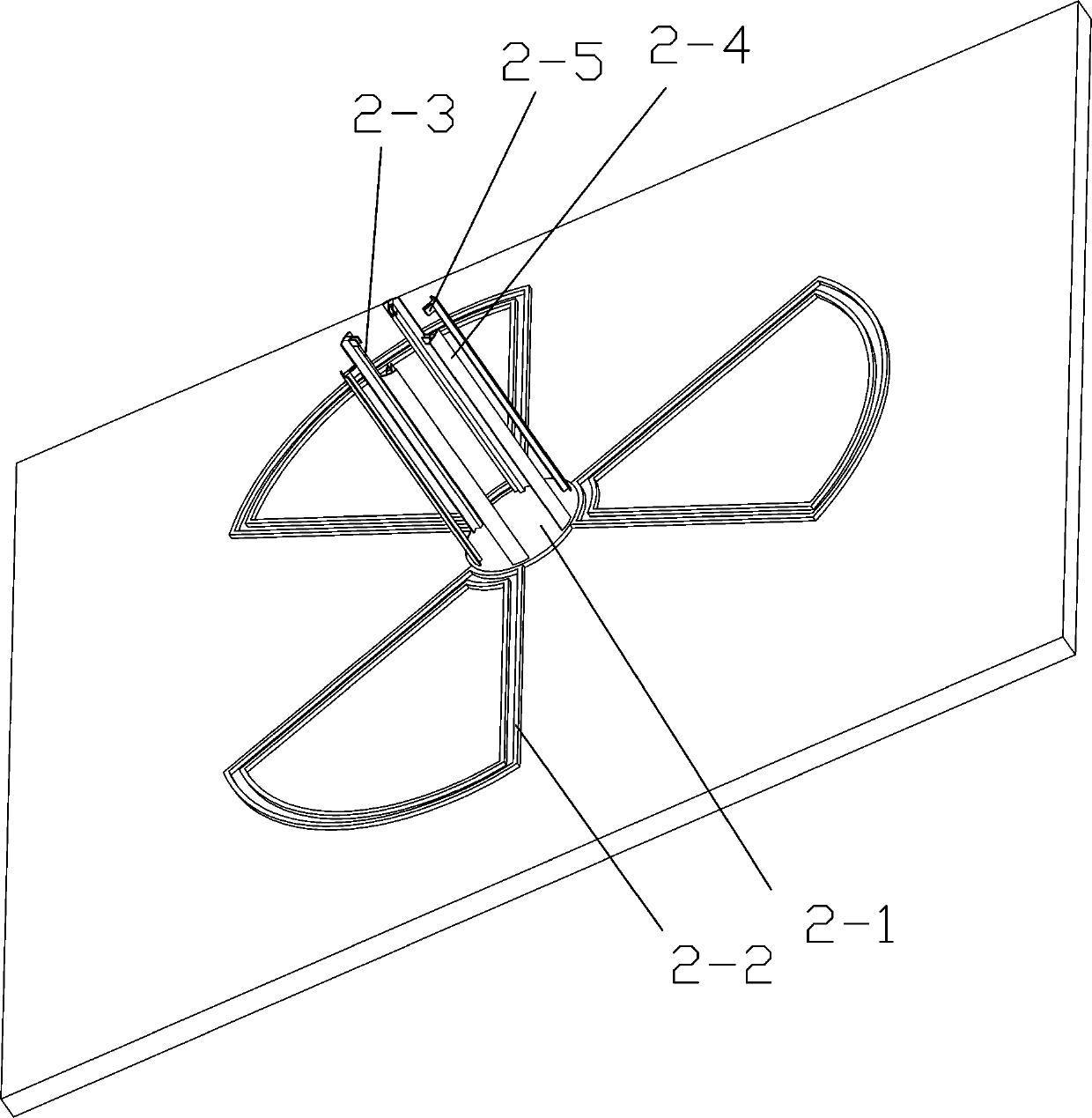

[0038] Described coil support 2 comprises circular base 2-1, and base 2-1 is arranged with 3 fan-shaped frames 2-2 in parallel in the upper direction, and the interval between fan-shaped frames 2-2 is greater than the width of strapping machine 15, like this Facilitate the passage of the baler. Six support columns 2-3 are evenly and vertically installed on the base 2-1, and each support column 2-3 is welded with an arc-shaped plate 2-4 on the outside, and the tracks of the six arc-shaped plates 2-4 are located in a circle Above, the curved plates 2-4 are convenient for pipe winding. The inner side of the upper end of the support column 2-3 is provided with a hinged ear plate 2-5, and the hinged ear plate 2-5 is used for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com