Automatic Silk Reeling Locomotive Thread Thread Adding Device and Its Control Technology

A silk reeling locomotive head and process technology, applied in silk reeling, etc., can solve the problems of affecting the threading effect, increasing the roughness of 10,000 meters, and restricting product quality, so as to avoid low threading efficiency, reduce raw material cocoon consumption, and improve The effect of Saussure's efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

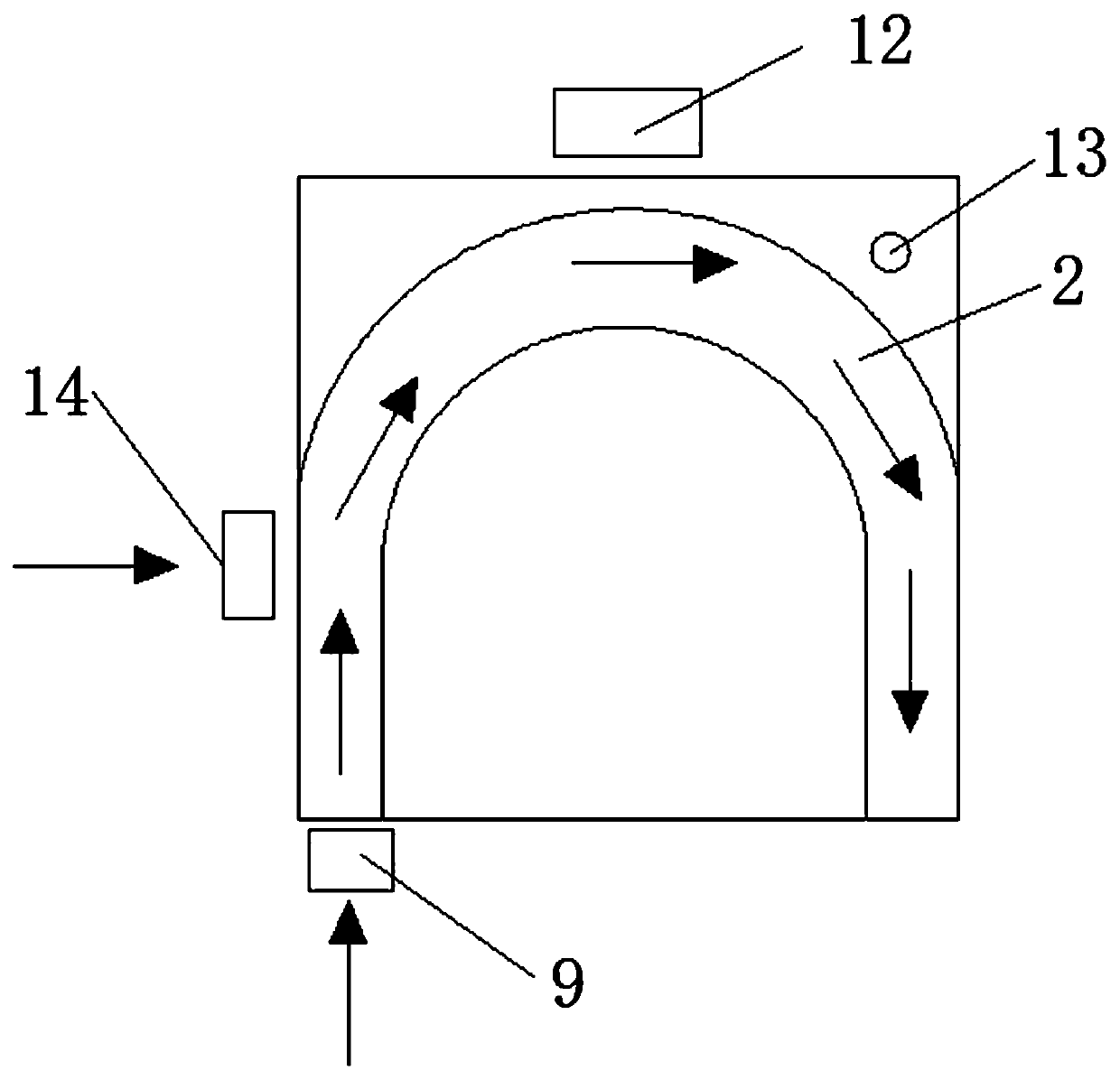

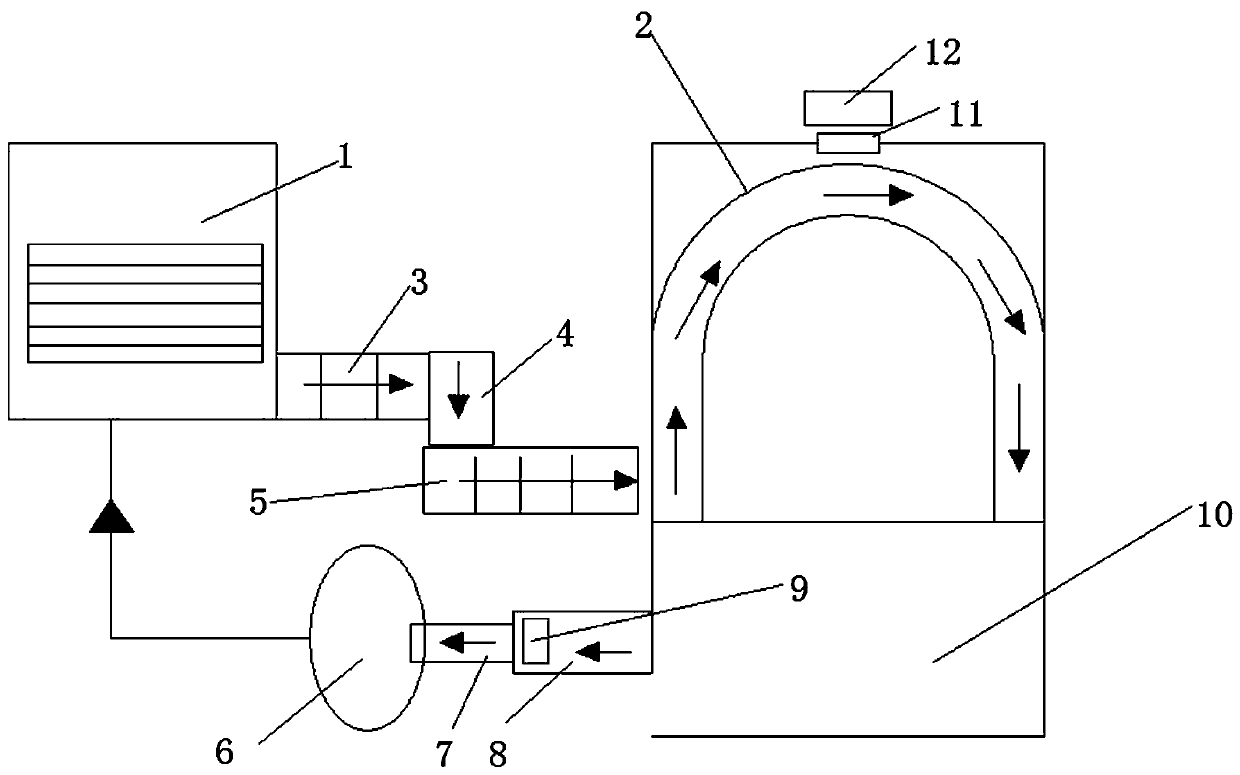

[0065] The present invention proposes an automatic silk reeling locomotive head threading cocooning device, which can mix the threadless cocoons in the threading pot after cooling with the threading cocoons in the silk reeling pot, and then add them to the threading pot. Cocoon volume stability, reducing temperature fluctuations such as figure 2 As shown, the following arrangement structure is adopted in particular: the automatic silk reeling locomotive head threading and cocooning device, including the threading and threadless cocoon cooling mechanism arranged on the side of the threading pot 10, connected with the threading and threadless cocoon cooling mechanism The mixed cocoon conveying mechanism, the output side of the mixed cocoon conveying mechanism is set at the high-temperature cocoon adding port of the Suoxu pot 2, and a water flow system is also matched between the tidying pot 10 and the Solixu non-threaded cocoon cooling mechanism.

[0066] When designing and usi...

Embodiment 2

[0068] This embodiment is further optimized on the basis of the above-mentioned embodiments, such as figure 2 As shown, further in order to better realize the cocoon adding device of the headstock of the automatic silk reeling locomotive according to the present invention, the following arrangement structure is adopted in particular: the cocoon cooling mechanism without thread is provided with cocoon transfer without thread Box 8, thread-free cocoon track 7 and silk reeling cocoon collection bucket 6, the input port of thread-free cocoon transfer box 8 is connected to the thread-free cocoon pot 10, and the thread-free cocoon transfer box 8 The output port communicates with the threadless cocoon track 7, and the outlet of the threadless cocoon track 7 is arranged above the cocoon collecting bucket 6 for reeling silk.

[0069] When designing and using, preferably, the thread-free cocoons in the thread-free pot 10 are transported to the thread-free cocoon transfer box 8, and the...

Embodiment 3

[0071] This embodiment is further optimized on the basis of any of the above-mentioned embodiments, further to better realize the automatic silk reeling locomotive thread thread adding device of the present invention, such as figure 2 As shown, the following configuration structure is adopted in particular: the bottom of the wok 10 is provided with 1 to 6 water flow systems, and the inside of the unthreaded cocoon transfer box 8 is provided with 1 to 7 water flow systems, and A cocoon lifting bucket 9 that can freely enter and exit the ribo pot 10 and the ribo cocoon transfer box 8 is also provided at the joint between the ribo pot 10 and the ribo cocoon transfer box 8 .

[0072]When designing and using, the cable-free cocoon utilizes the cable-free cocoon cooling mechanism to carry out proper cooling and recovery. 8", communicated with the thread-free pot 10, preferably 6 water flow systems are designed at the bottom of the pot 10, and 7 water flow systems are set in the "t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com