Threading machine and threading method for threading steel wire into ferrule

A technology of threading machine and steel wire, applied in the direction of coupling of optical waveguides, etc., can solve the problems of difficulty in adapting to large-scale production work, time-consuming and labor-intensive, and low reliability.

Active Publication Date: 2019-10-01

深圳市雅合科技有限公司

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, this work is mainly done manually, which is time-consuming and labor-intensive, with low reliability, and it is difficult to adapt to mass production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

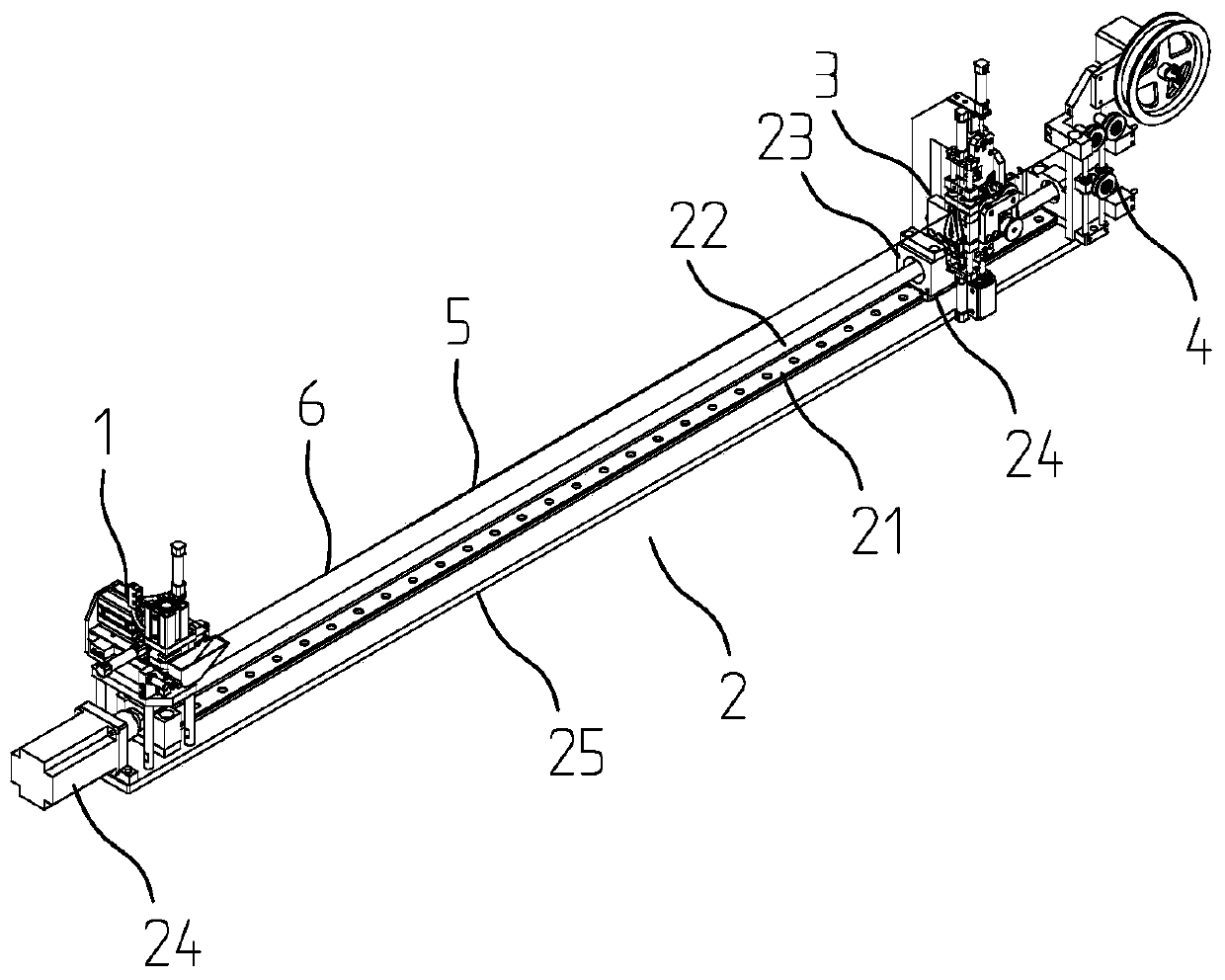

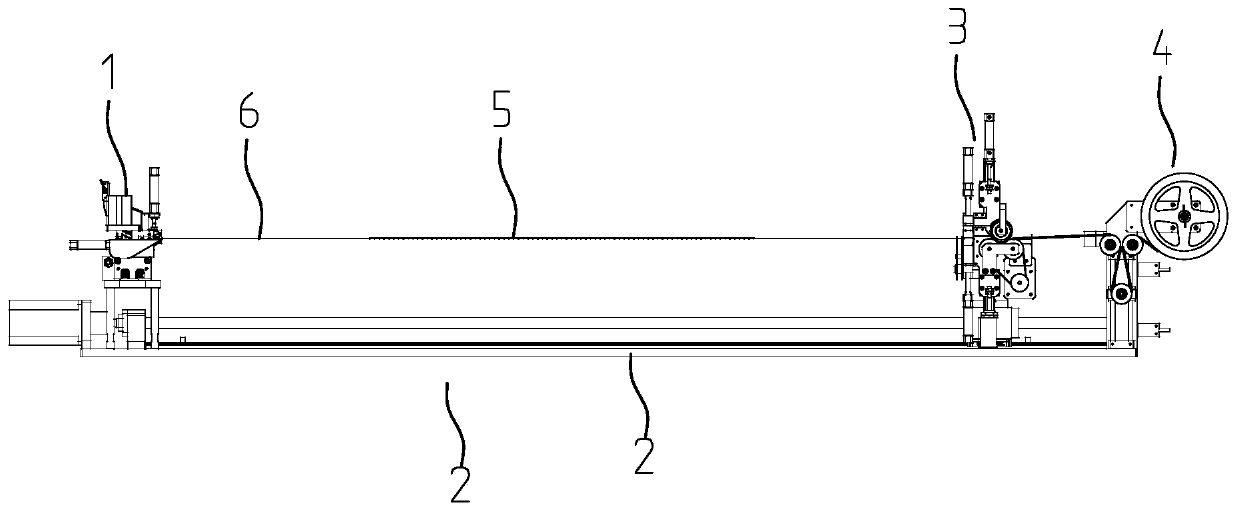

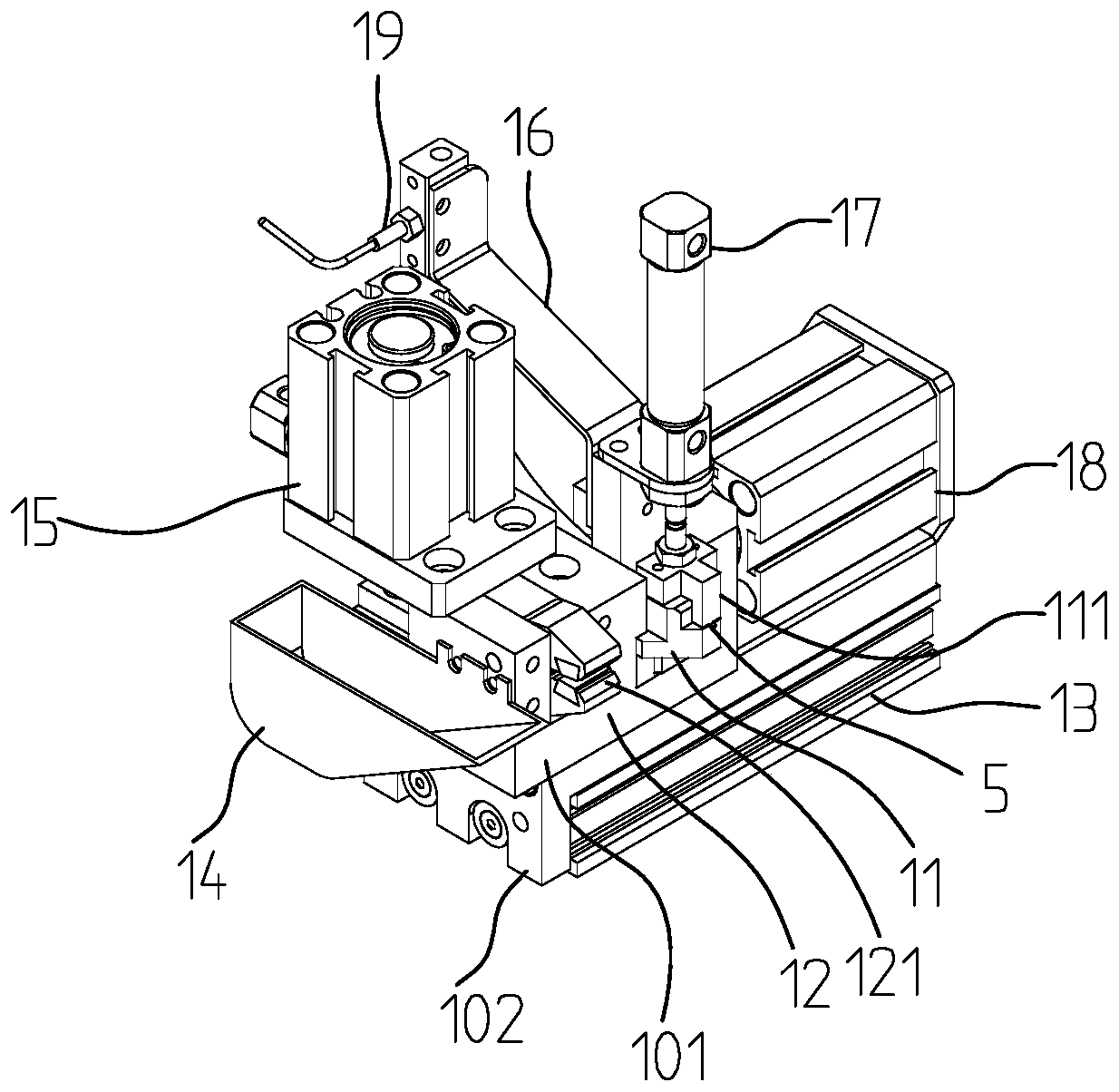

The invention provides a threading machine used for inserting a steel wire into a core and a threading method. The threading machine comprises a frame having a first end and a second end, a feeding device arranged at the first end of the frame, a material clamping device connected with the feeding device, a steel wire uncoiling and coiling device arranged at the second end of the frame, a threading device capable of moving between the first end and the second end, a wire clamping device arranged at the first end of the frame, and a burning device used for heating the steel wire dragged by the threading device, wherein the material clamping device and the wire clamping device can selectively align at the position of the threading device. The threading machine is advantaged in that material conveying is realized through the feeding device, the core is clamped through the material clamping device, the steel wire is released by the steel wire uncoiling and coiling device, the steel wire is dragged by the threading device to realize threading, the steel wire is clamped by the wire clamping device, the steel wire is heated by the burning device, the threading machine used for inserting the steel wire into the core is commonly formed through the parts, compared with a traditional manual threading method, the threading machine further is more reliable, and threading efficiency is substantially improved.

Description

technical field The utility model relates to the technical field of optical fiber ceramic ferrule processing, in particular to a threading machine and a threading method for threading steel wires into the ferrule. Background technique During the production process of optical fiber ceramic ferrules, the ferrules need to be threaded into a string with steel wires in a certain order to facilitate subsequent efficient processing. At present, this work is mainly done manually, which is time-consuming and labor-intensive, with low reliability, and it is difficult to adapt to mass production. Contents of the invention The technical problem to be solved by the present invention is to provide a reliable, efficient and pollution-free threading machine and a threading method, and the threading machine can perform manual or automatic core insertion and threading operations. A technical solution provided by the invention to solve the technical problem is: a threading machine for thr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G02B6/38G02B6/36

Inventor 王胜玲梁俊

Owner 深圳市雅合科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com