An electric spindle pneumatic spindle

A spindle and electric spindle technology, applied in textiles and papermaking, can solve the problems of low degree of automation, inability to synchronize electric and pneumatic yarn pulling functions, etc., to increase energy consumption, save generation time, and reduce airflow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

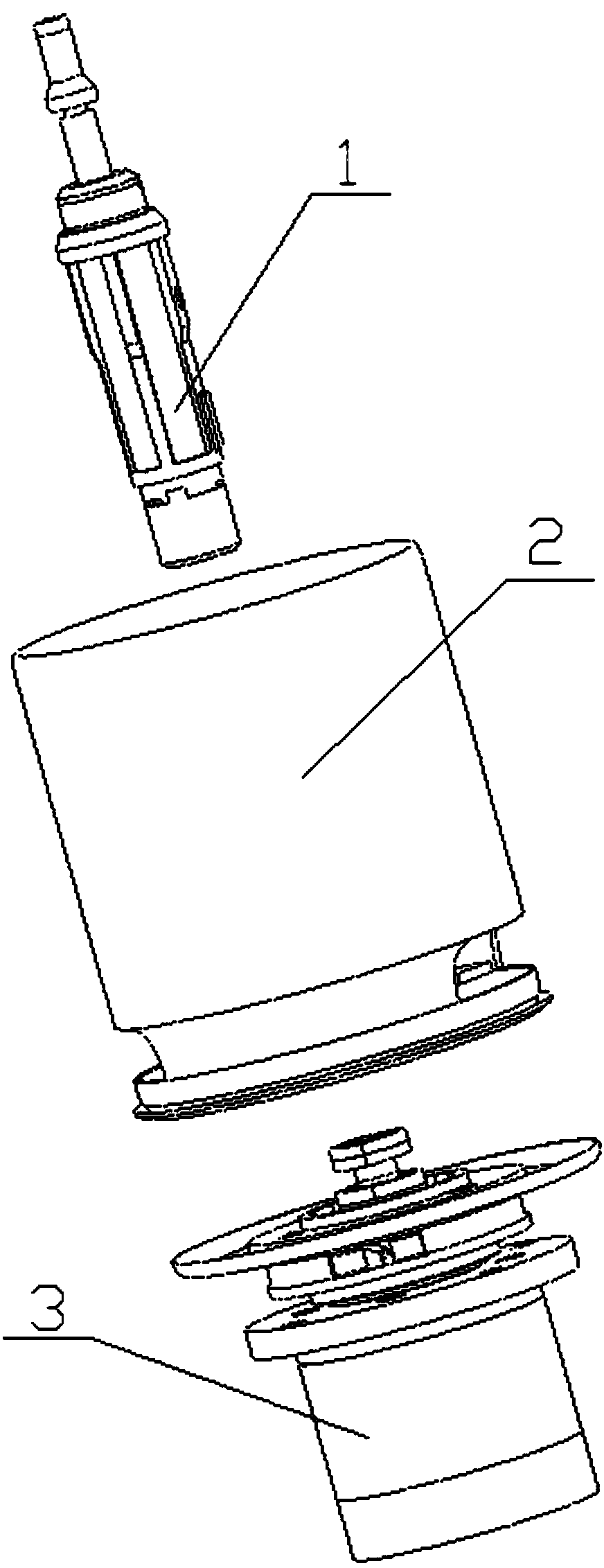

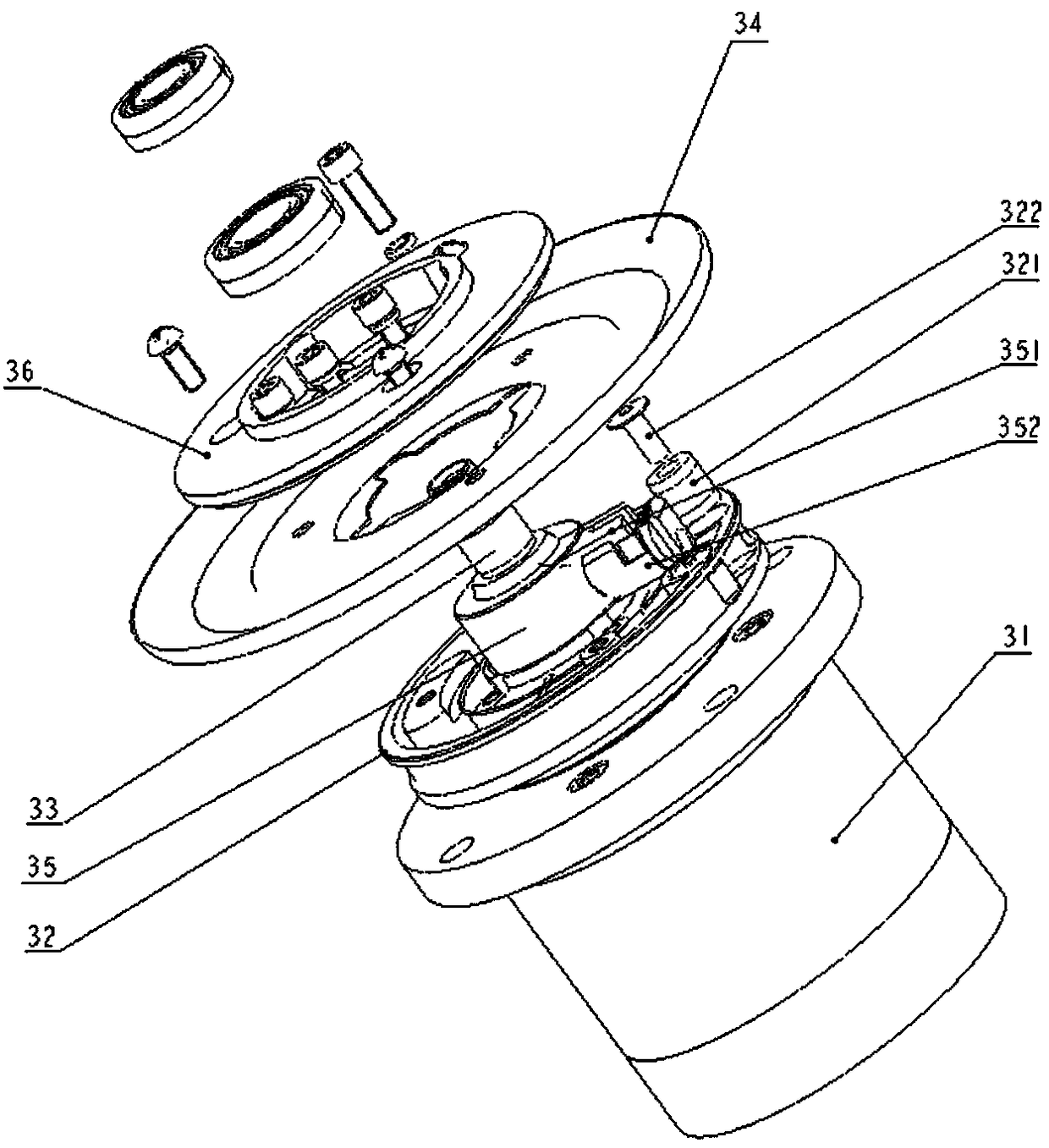

[0045] Such as figure 1 Shown, a kind of electro-spindle pneumatic spindle comprises lining spindle assembly 1, bobbin assembly 2 and rotor assembly 3, and lining spindle assembly 1, bobbin assembly 2 are identical with the component structure in existing common spindle; figure 2As shown, the rotor assembly 3 includes a rotor motor 31, a twisting disk 32, a spindle rod 33, a wire separator disk 34 and a gland 36; Connected, the lower end of the spindle rod 33 passes through the gland 36, the wire separation disc 34, the twisting disc 32 in turn and extends into the rotor motor 31, the spindle rod 33 is relatively fixed with the gland 36, the wire separation disc 34, and the twisting disc 32;

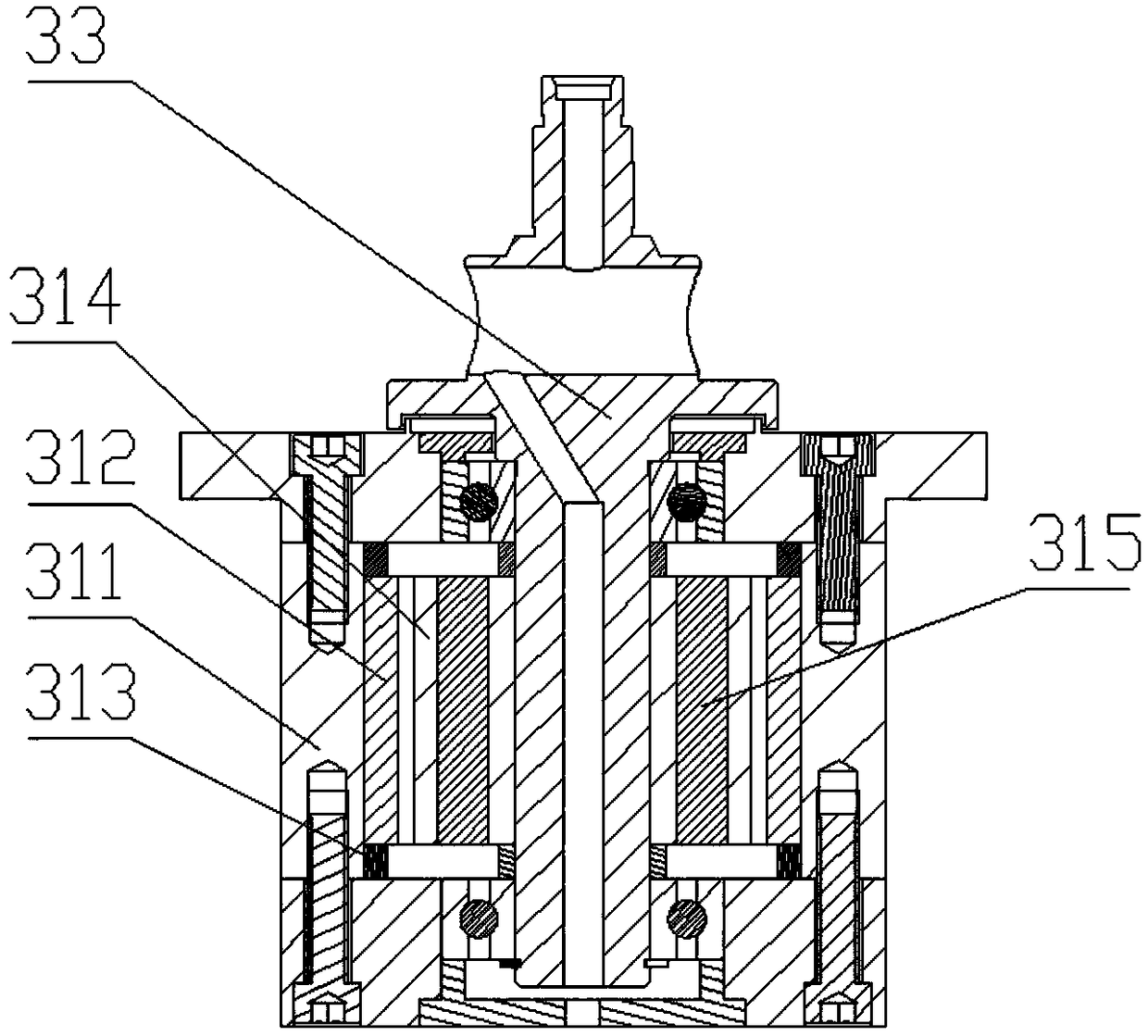

[0046] Such as image 3 As shown, the rotor motor 31 includes a motor casing 311, a stator core 312, a stator winding 313, a rotor core 314 and a permanent magnet 315; On the inner wall, the rotor core 314 is set at the center of the stator core 312; the spindle bar 33 is fixedly conn...

Embodiment 2

[0053] Same as Embodiment 1, the difference is that: in this embodiment, the angle between the air inlet inclined passage 332 and the air inlet straight passage 331 is 60°; 2 directions raise an acute angle with a slope of 3°;

[0054] More importantly: in order to improve the threading effect and improve efficiency, in this embodiment, a silk outlet step groove 356 is also provided at the confluence of the intake horizontal section 354 and the wire inlet bend 355; the wire outlet step groove 356 and the wire outlet channel 323 connection, which increases the volume of the cavity at the confluence of the airflow and increases the negative pressure during the pneumatic yarn threading process, thus enhancing the reliability of automatic yarn threading and improving the efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com