Threading auxiliary device for glass steel tube production and rapid threading method

An auxiliary device, the technology of glass steel pipes, applied in applications, household utensils, tubular objects, etc., can solve the problems of low efficiency and difficult quality control of manual threading, and achieve the effects of reducing difficulties, shortening threading time, and eliminating operational errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

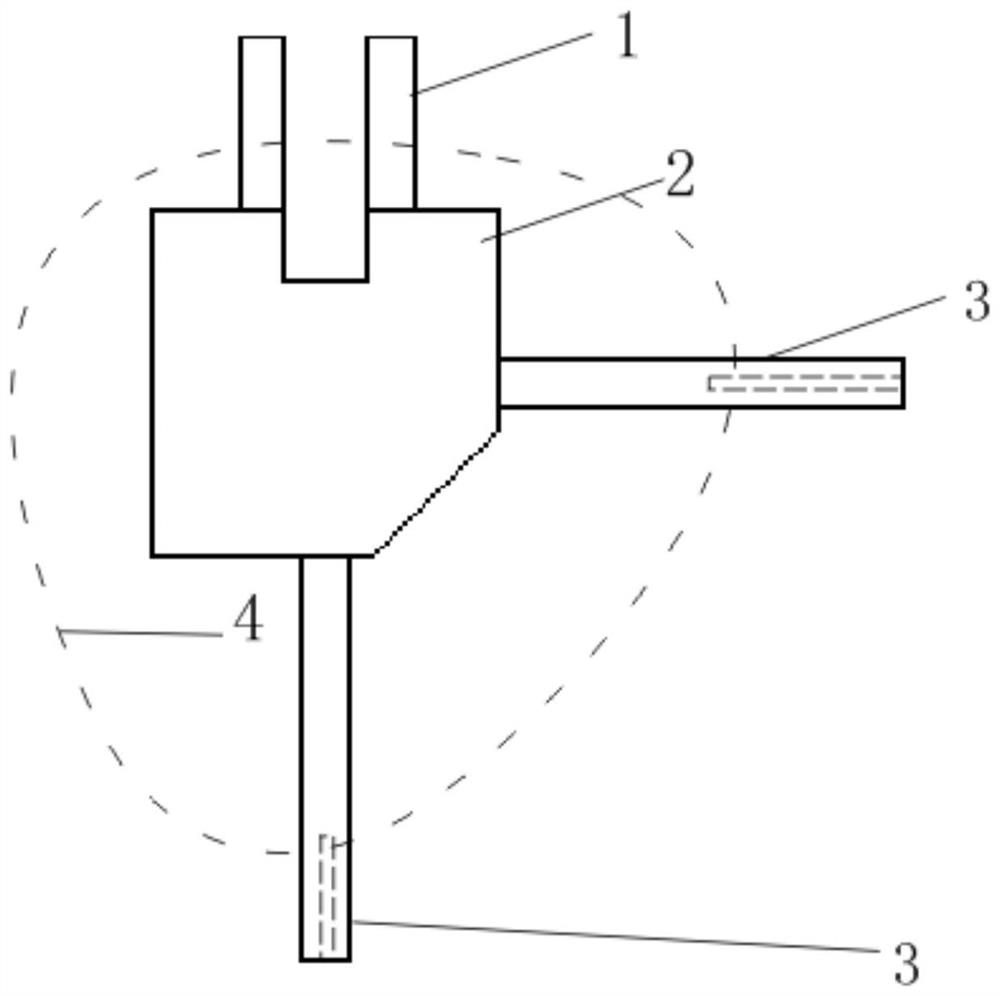

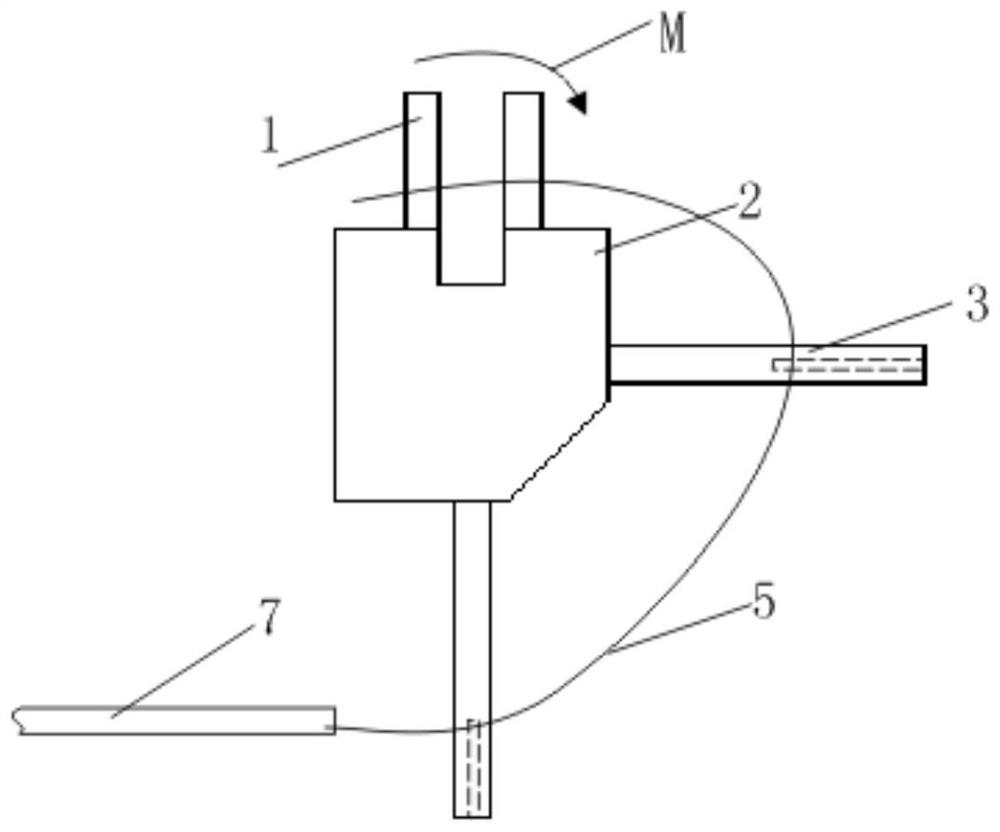

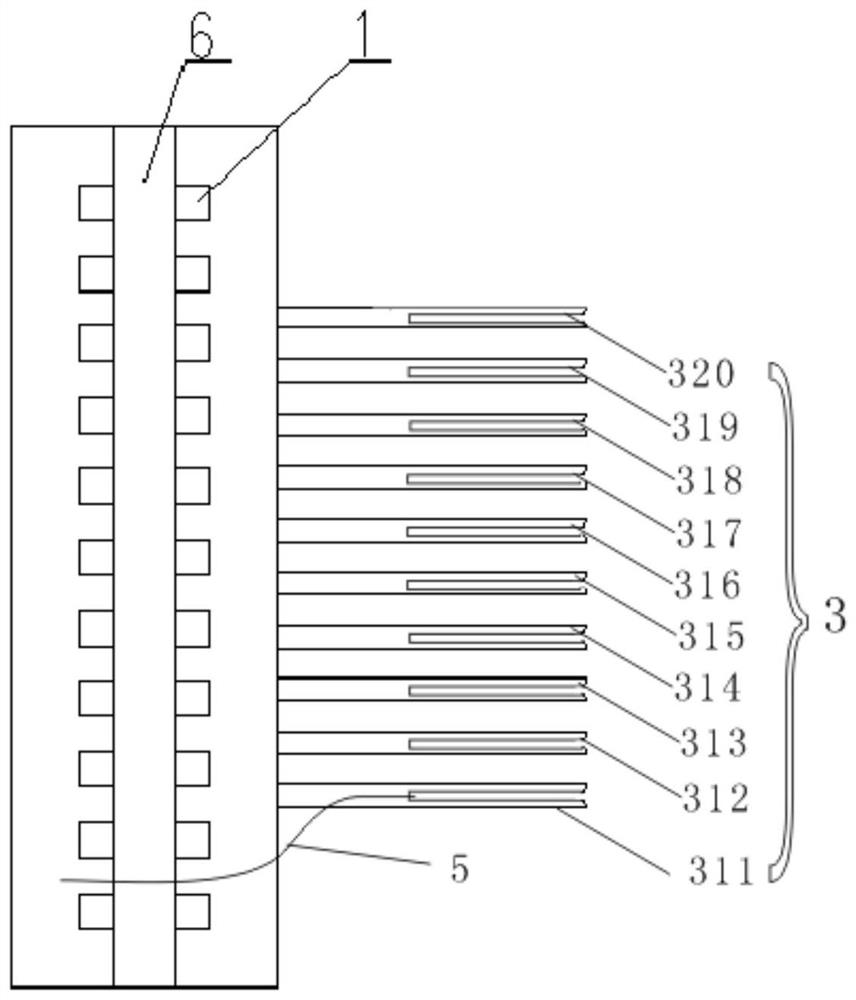

[0033] A guide tooth group with a vertical comb structure corresponding to the number of teeth on the guide wire comb on the winding machine is adopted, and a 0.2mm wire slot is opened on a single tooth, so that the distance between each wire is always in a controllable state. Through the guide of the threading auxiliary device The tooth set is used to realize the pitch change, so that the threading auxiliary device guides the glass fiber filaments to smoothly pass through two sets of guide wire bars with different spacing on the winding machine, so as to achieve the purpose of fast threading.

[0034] Figure 1-4 Among them, the threader body 2 is a straight prism, and the bottom surface of the straight prism is a square surface. The threader body 2 has four sides, and the joints of two adjacent sides are chamfered, and the two adjacent sides near the chamfers are respectively A set of guide teeth 3 is provided, each set of guide teeth 3 includes 10 guide teeth 311, 312, 313,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com