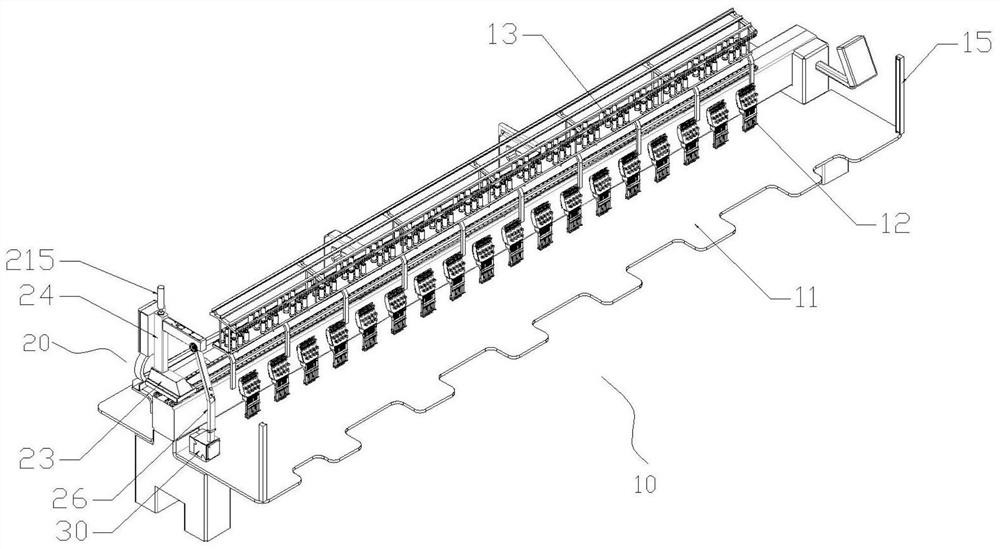

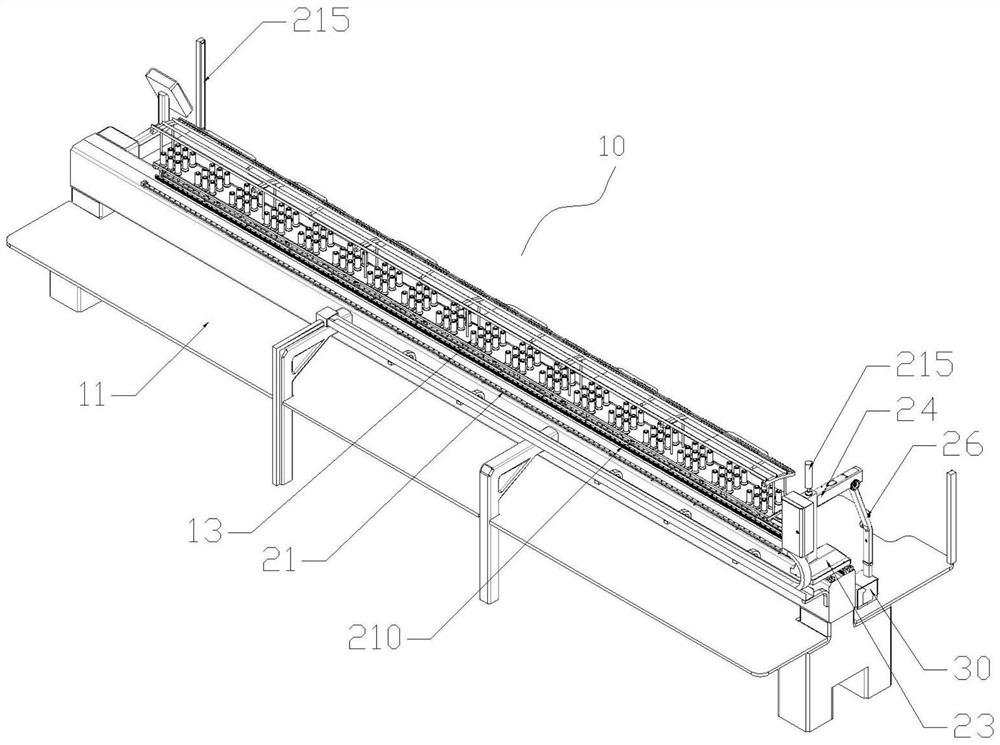

Threading device and automatic threading equipment

A technology of threader and threader, which is applied in sewing equipment, embroidery machine mechanism, embroidery machine, etc., can solve the problems of automatic threading failure, affecting threading efficiency, troublesome operation, etc., to improve threading success rate, fast and convenient operation, The effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

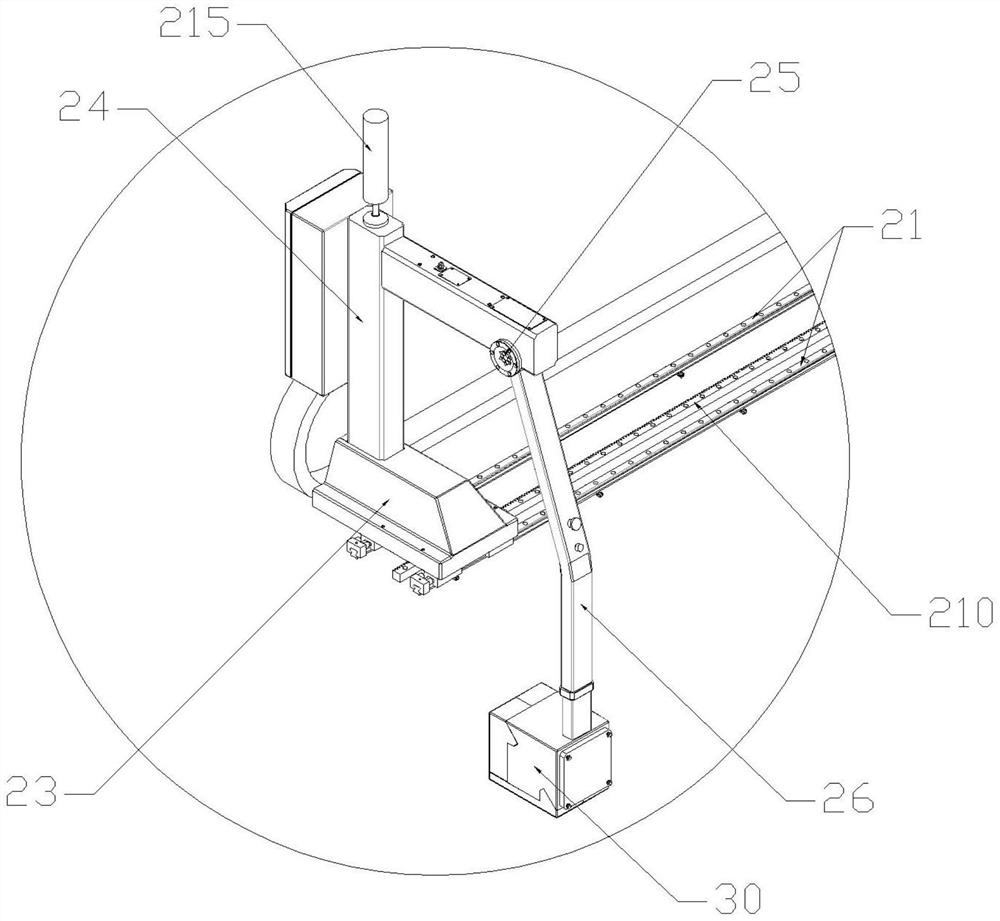

[0163] Embodiment one: if Figure 9 As shown, a needle threader includes a threading mechanism 40, a lead wire and a wire feeding mechanism, a calibration robot mechanism 80 and a thread hooking mechanism 90 on it. The thread pulling mechanism 40 is used to pull the sewing thread 14 down to a sufficient length for threading, and the lead wire And the thread feeding mechanism is used to guide the sewing thread 14 to the sewing needle to be threaded, the calibration robot mechanism 80 is used to adjust the position of the thread hooking mechanism 90 to align with the needle hole of the sewing needle, and the thread threading mechanism 90 is used to pass the sewing thread 14 through Sewing needle pinhole.

Embodiment 2

[0164] Embodiment two: if Figure 9 , Figure 15-17 and Figure 19-20 As shown, on the basis of Embodiment 1, the cable pulling mechanism 40 includes a driver fixing case 42 located on the installation base plate 32, a first driver 43 is fixed on one side of the driver fixing case 42, and the other side is sequentially arranged from top to bottom. A second driver 44, a third driver 45 and a fourth driver 46 are provided, and the movable ends of the first driver 43, the second driver 44, the third driver 45 and the fourth driver 46 extend into the driver In the fixed shell 42 and respectively connected with the first pull plate 47, the second pull plate 48, the third pull plate 49 and the fourth pull plate 410, the first pull plate 47, the second pull plate 48, the third pull plate 49 and the second pull plate The outer ends of the four pull-wire plates 410 protrude from the driver fixing case 42, and the inner surfaces of the outer ends of the first pull-wire plate 47 and th...

Embodiment 3

[0167] Example Three: Combining Figure 15-18 and Figure 21 As shown, on the basis of Embodiment 2, L-shaped connecting plates 412 are provided on both sides of the fixed housing 42 of the driving part, and a number of longitudinal strip holes 412.1 are provided on the bonding part of the connecting plate 412 and the mounting base plate 32, and the mounting base plate Corresponding positions on the 32 are provided with bottom plate strip-shaped holes 32.1 whose outer ends are inclined downward and are arc-shaped, and the back of the installation bottom plate 32 is provided with a fixed block 41 . A plurality of horizontal strip-shaped holes 412.1 are provided on the bonding portion of the connecting plate 412 and the fixed housing 42 of the driving element.

[0168] Wherein, there is a fixed shell hole 32.2 in the middle of the installation bottom plate 32 for the driver fixed shell 42 to pass through, and the fixed shell hole 32.2 is fan-shaped with a wide top and a narrow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com