Patents

Literature

84results about How to "Avoid structural interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

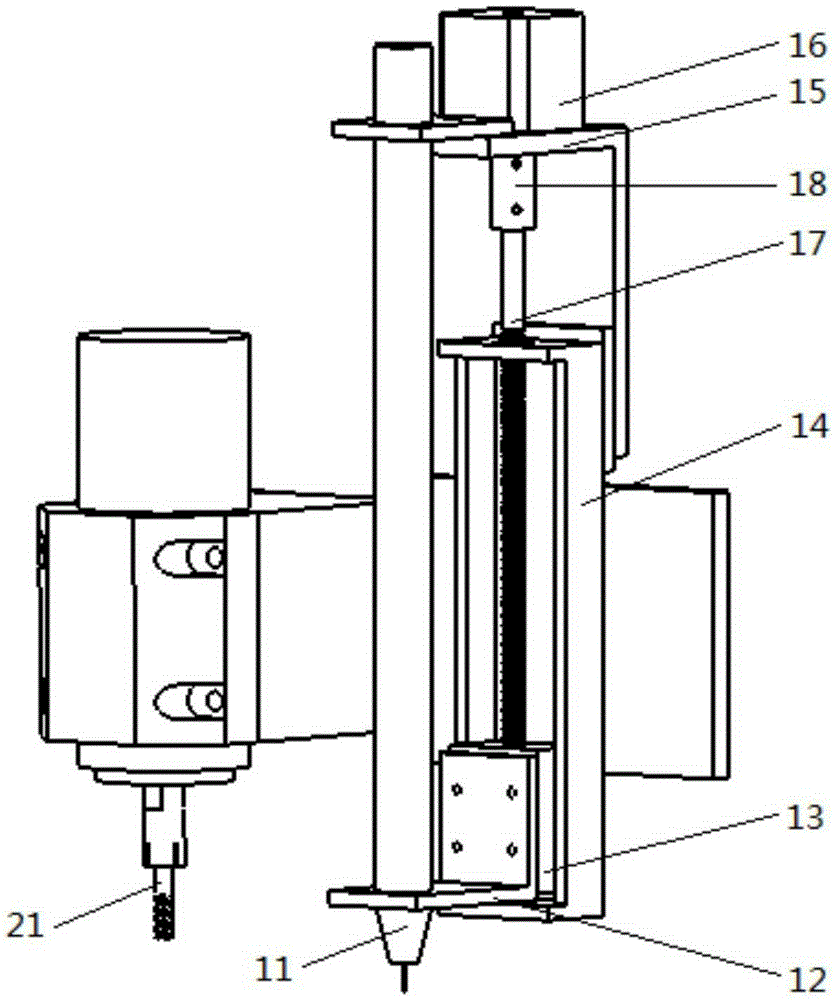

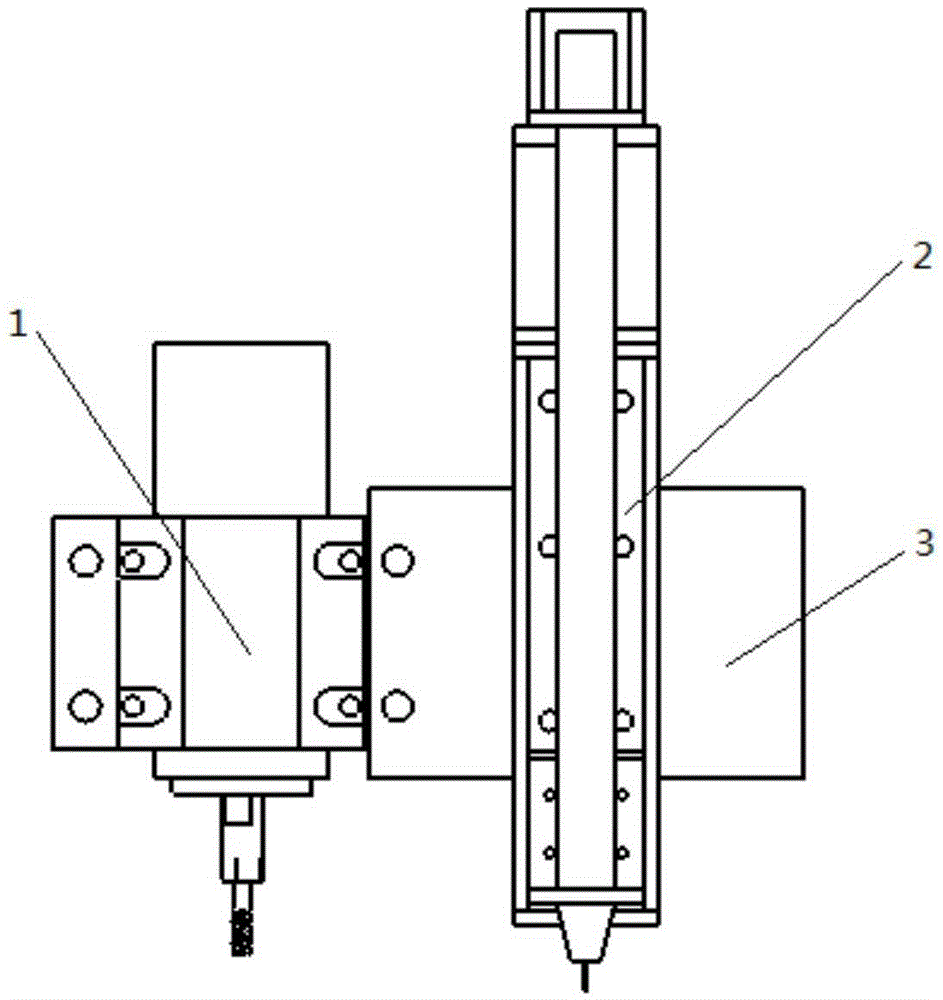

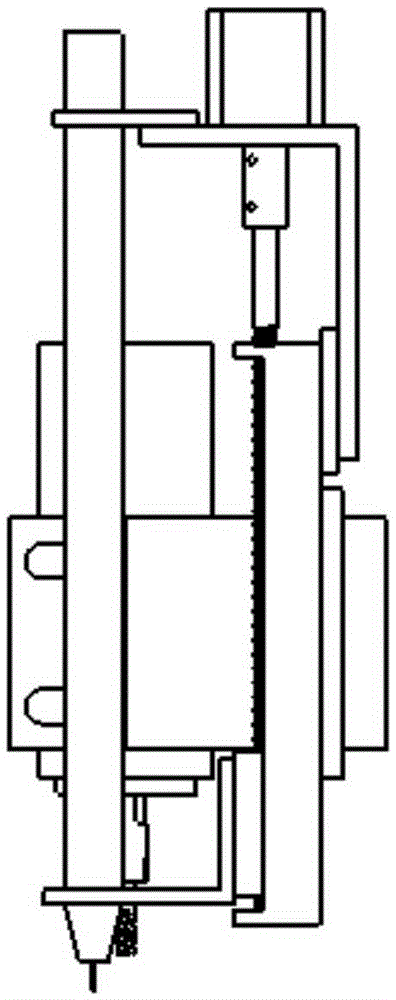

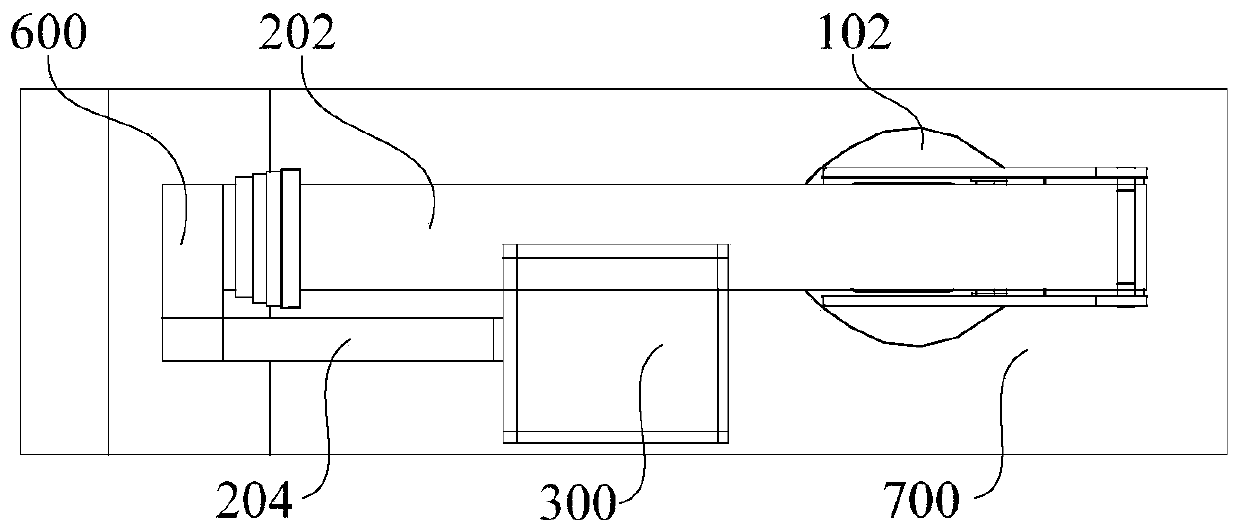

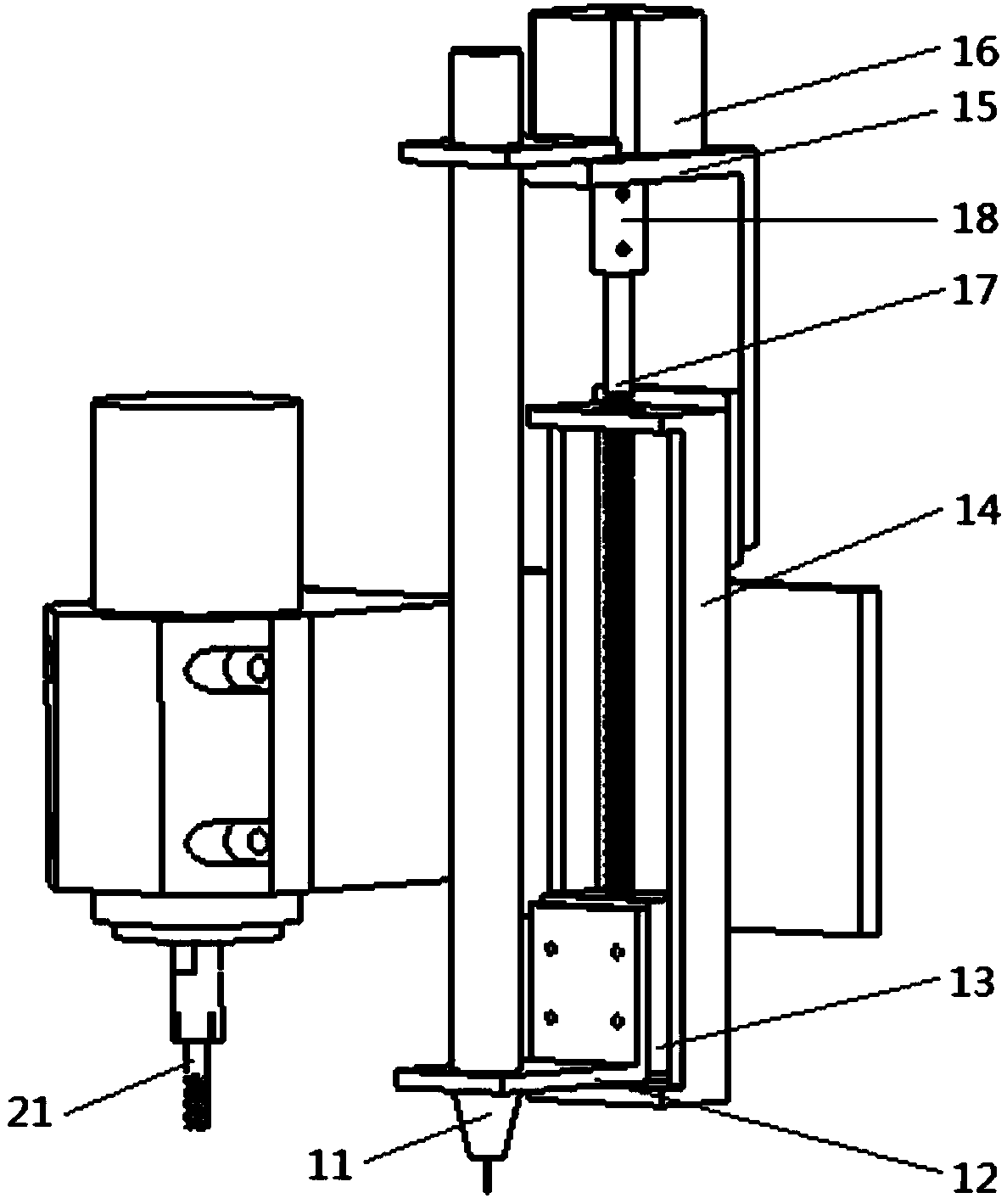

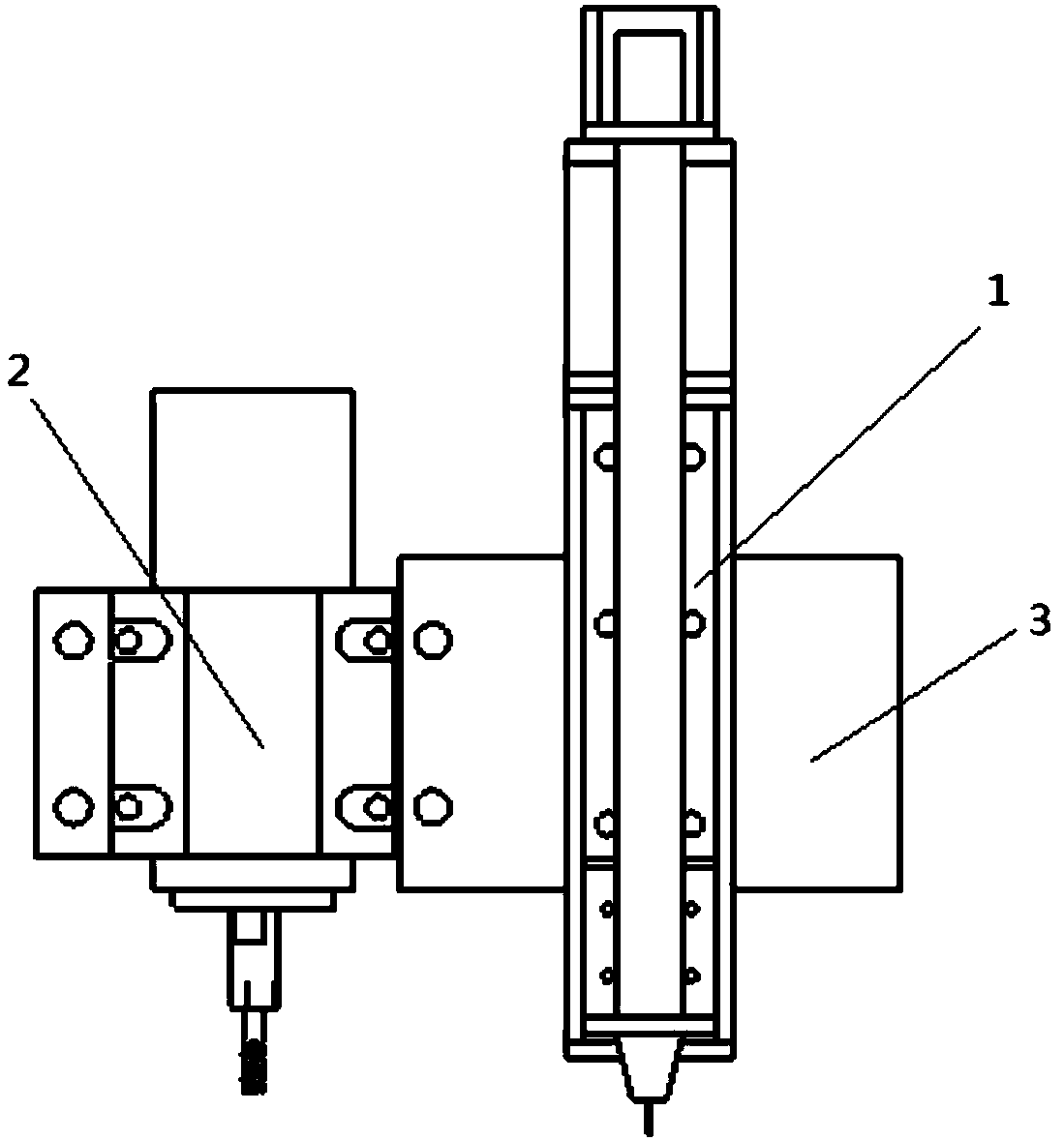

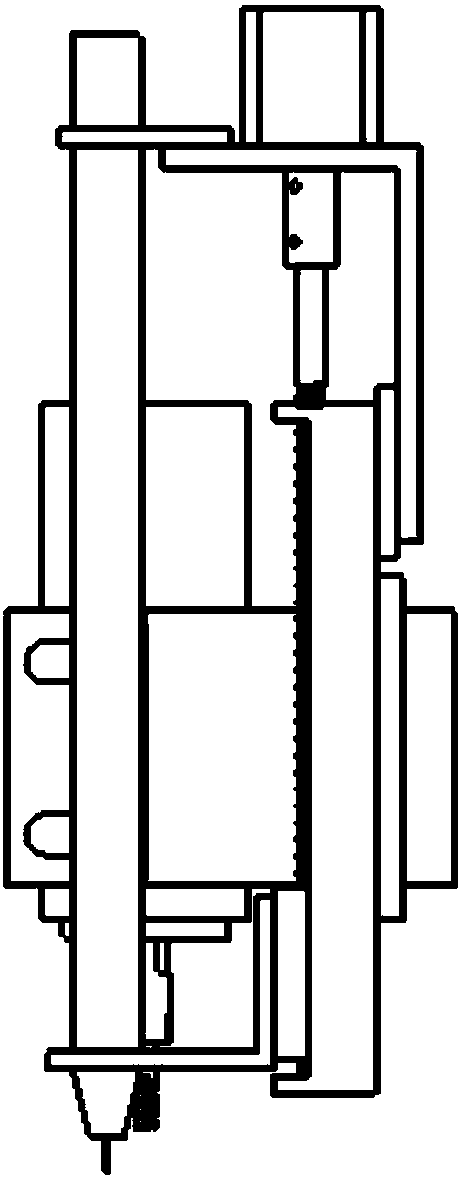

Electric arc adding and milling device

ActiveCN105414981ASolve the problem of insufficient machining accuracySimple processOther manufacturing equipments/toolsEngineeringAdditive layer manufacturing

The invention discloses an electric arc adding and milling device belonging to the technical field of electric arc adding. The electric arc adding and milling device comprises an electric arc adding unit and a milling unit, wherein the milling unit comprises a milling head; the milling unit is connected with the electric arc adding unit; and the electric arc adding unit comprises a welding gun, a supporting plate, a slide block, a fixing groove, a fixing plate, a stepping motor and a lead screw, wherein one end of the welding gun is fixed together with the slide block, the other end of the welding gun passes through a through hole of the supporting plate, both the supporting plate and the fixing plate are fixed together with the stepping motor, the fixing groove is fixed together with the fixing plate, an output shaft of the stepping motor is connected with the lead screw, and the lead screw passes through a threaded through hole formed in the slide block. The electric arc adding and milling device can be used for realizing additive manufacturing and cutting at one step, so that workpieces are more precisely machined, and the using requirement is met.

Owner:HUAZHONG UNIV OF SCI & TECH

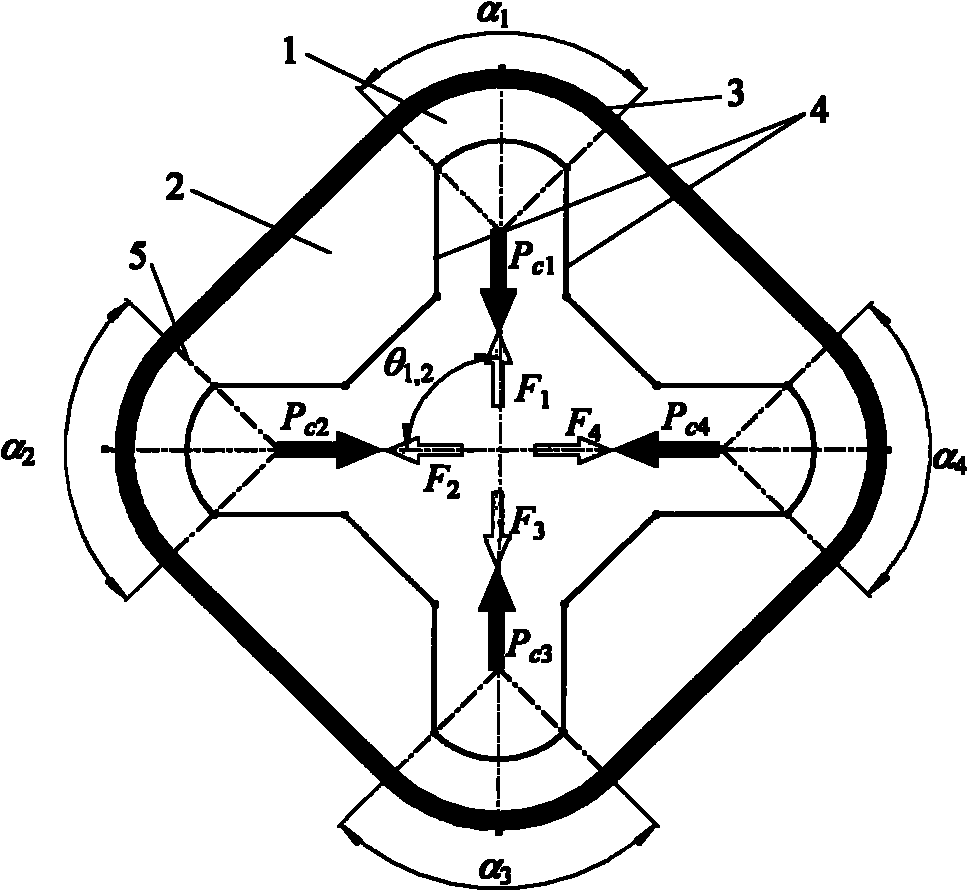

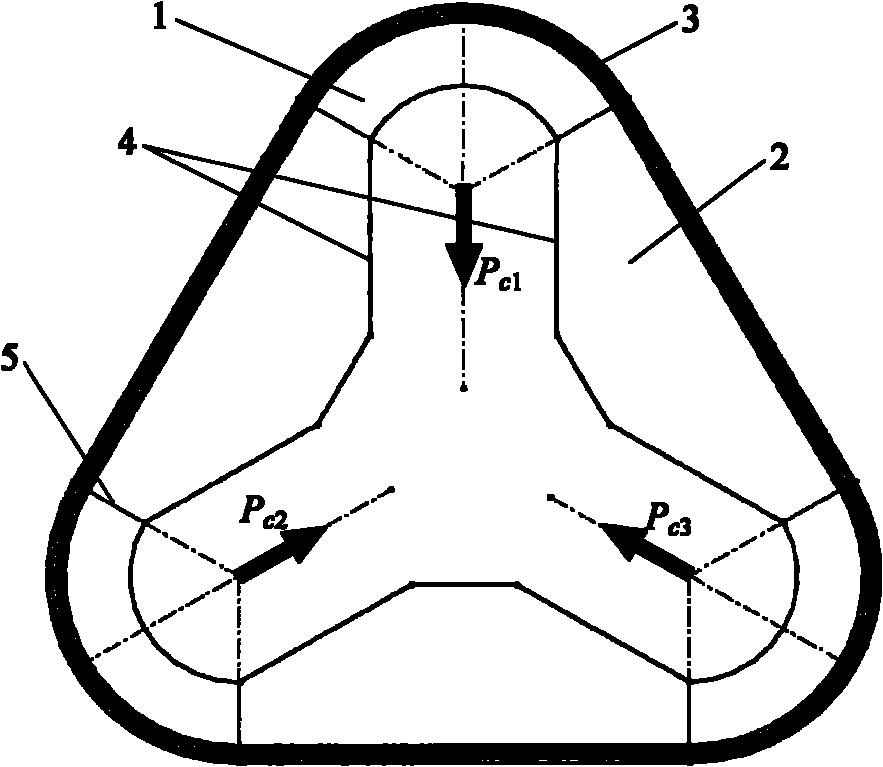

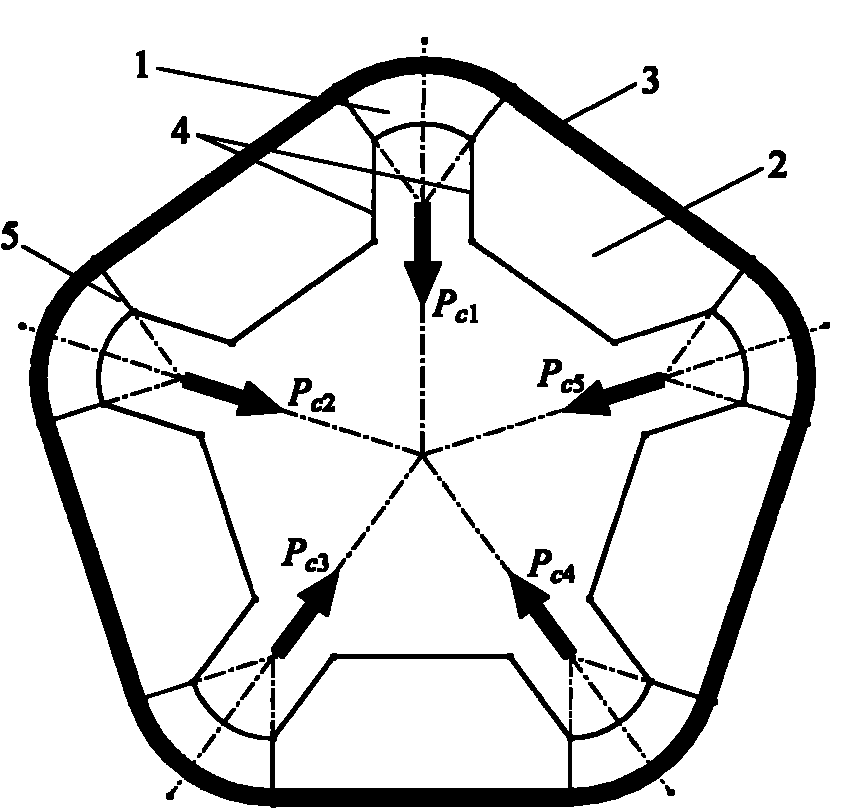

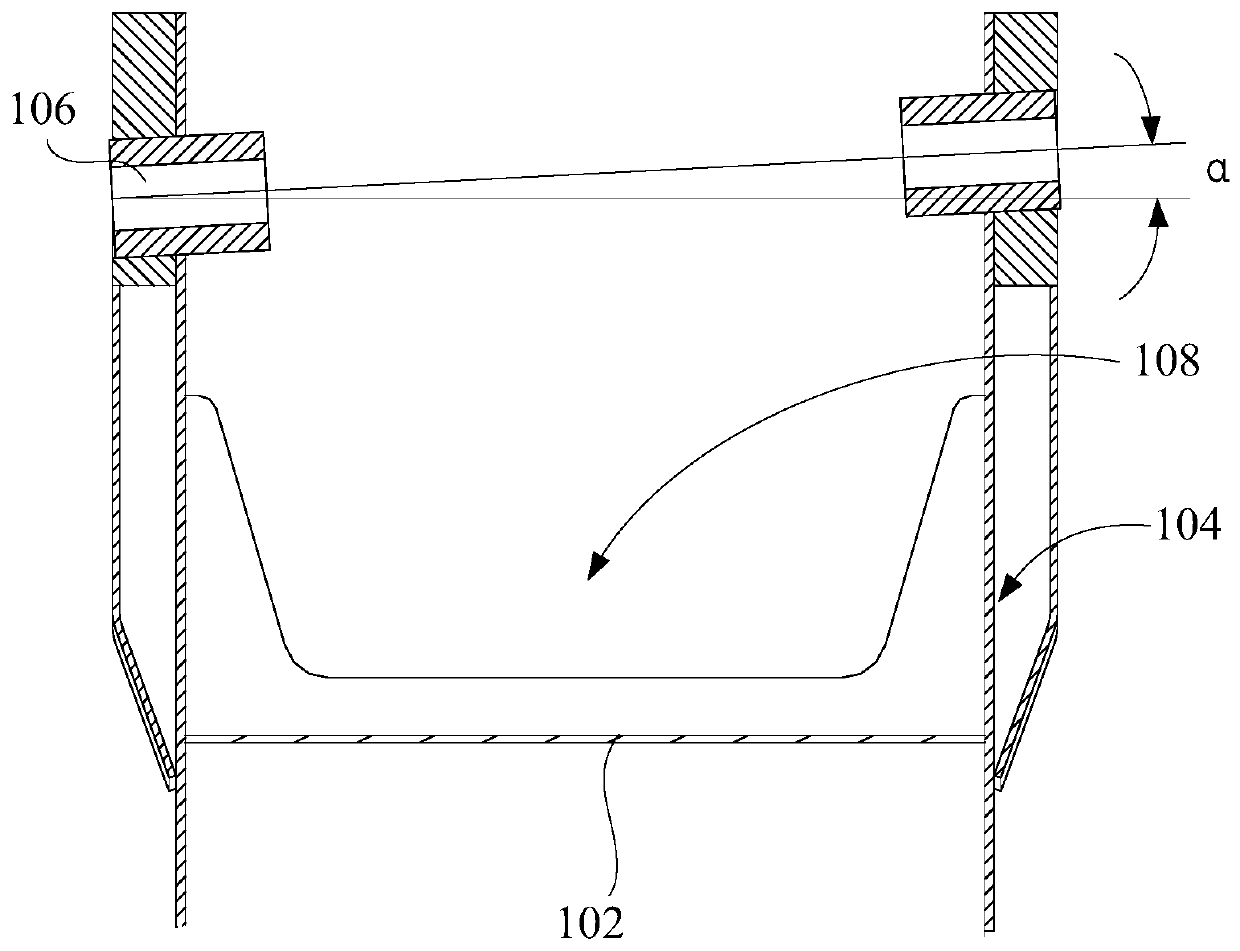

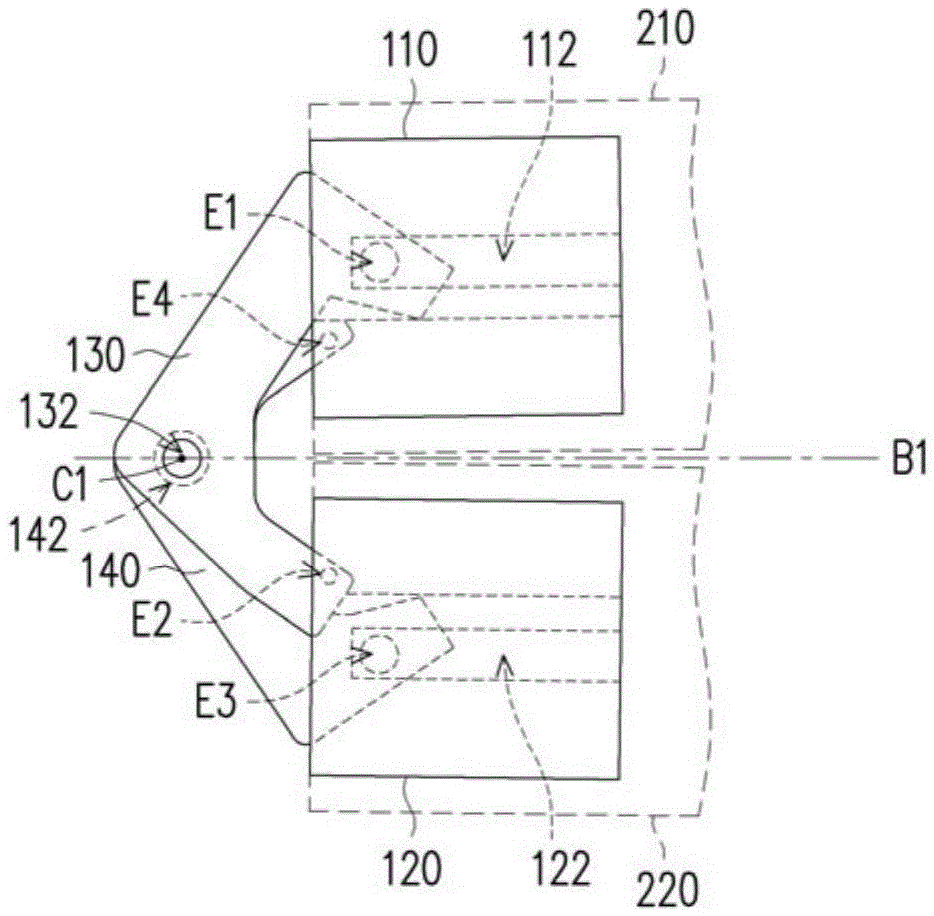

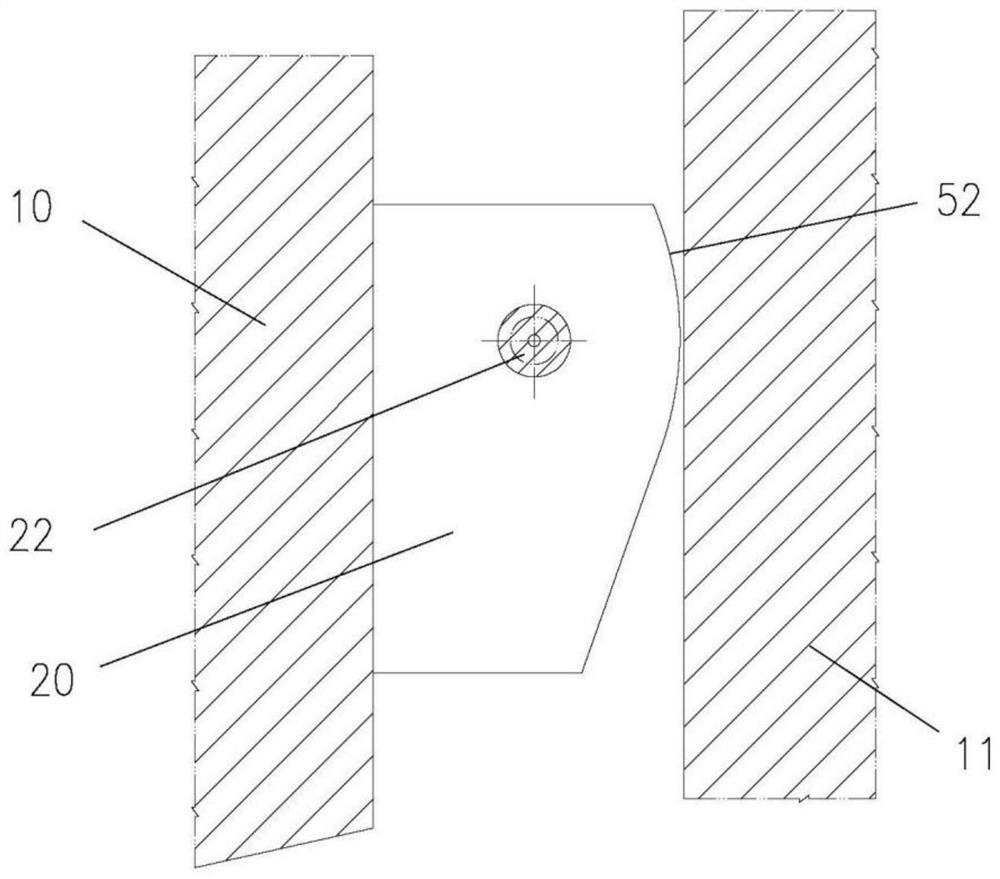

Multidirectional load bearing prestressed wire winding pre-tightening frame

ActiveCN101982251AAvoid structural interferenceImproved ability to withstand multi-directional compressive loadsForging/hammering/pressing machinesPressesPre stressInterference problem

The invention relates to a multidirectional load bearing prestressed wire winding pre-tightening frame, belonging to the technical field of heavy type pressure processing equipment. The pre-tightening frame at least comprises three arc beams which are the same in pressing counter force quantity and are in opposite directions as well as at least three straight beams, the arc beams and the straightbeams are arranged alternately, the outline of the straight beam is tangent with the outer arc outline of two adjacent arc beams, so as to form a frame, and the periphery outline of the frame is wound with prestressed wire. In the invention, structure composed of arc beam and straight beam is reasonably arranged on the periphery outline of the load bearing frame, so that prestressed wire is woundand pre-tightening forces in multiple directions are produced, so as to balance multidirectional pressing counter force, thus the frame can bear multidirectional loads without a tensioning construction member provided with through structure, thereby avoiding structural interference problem.

Owner:TSINGHUA UNIV +1

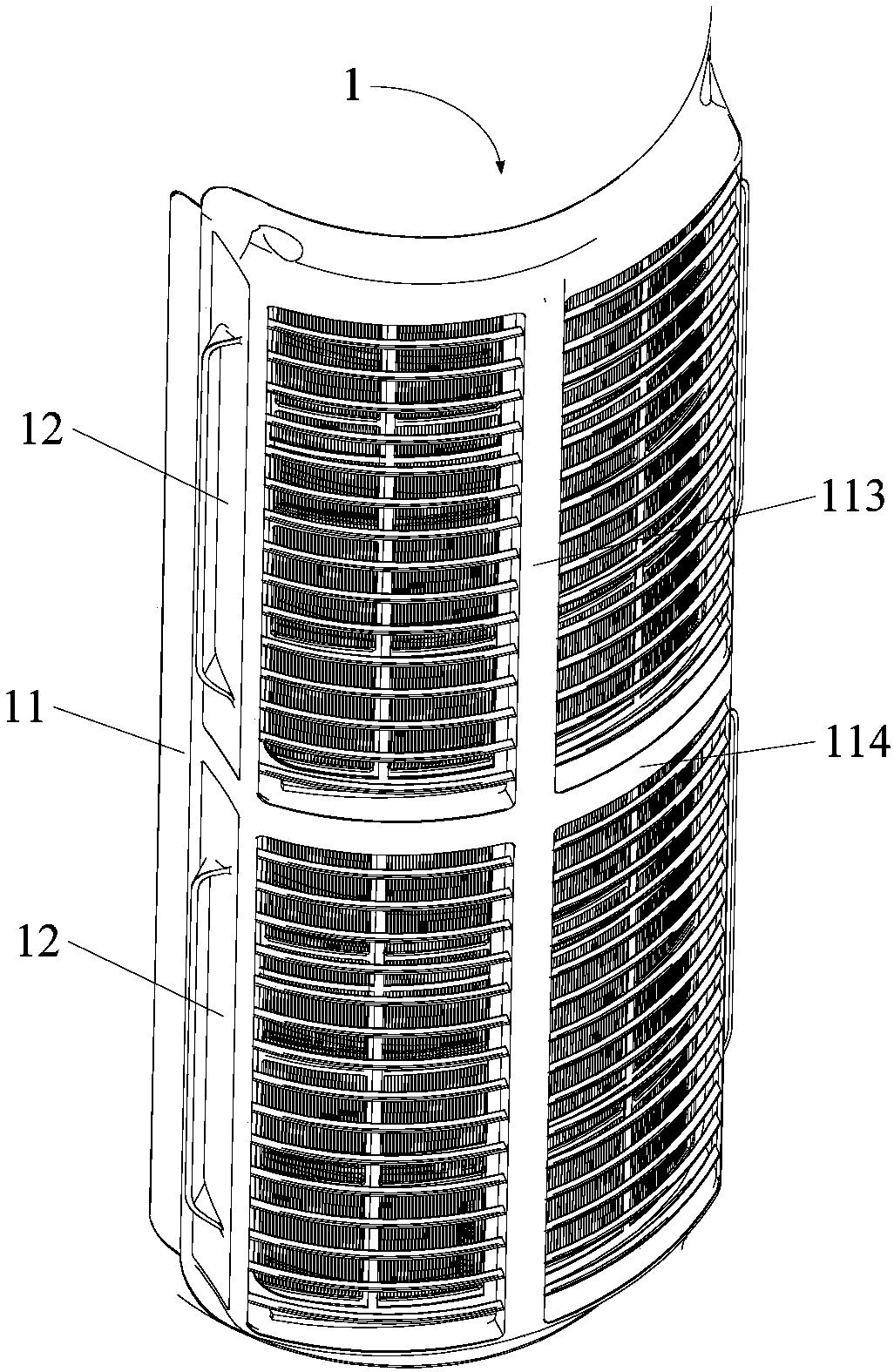

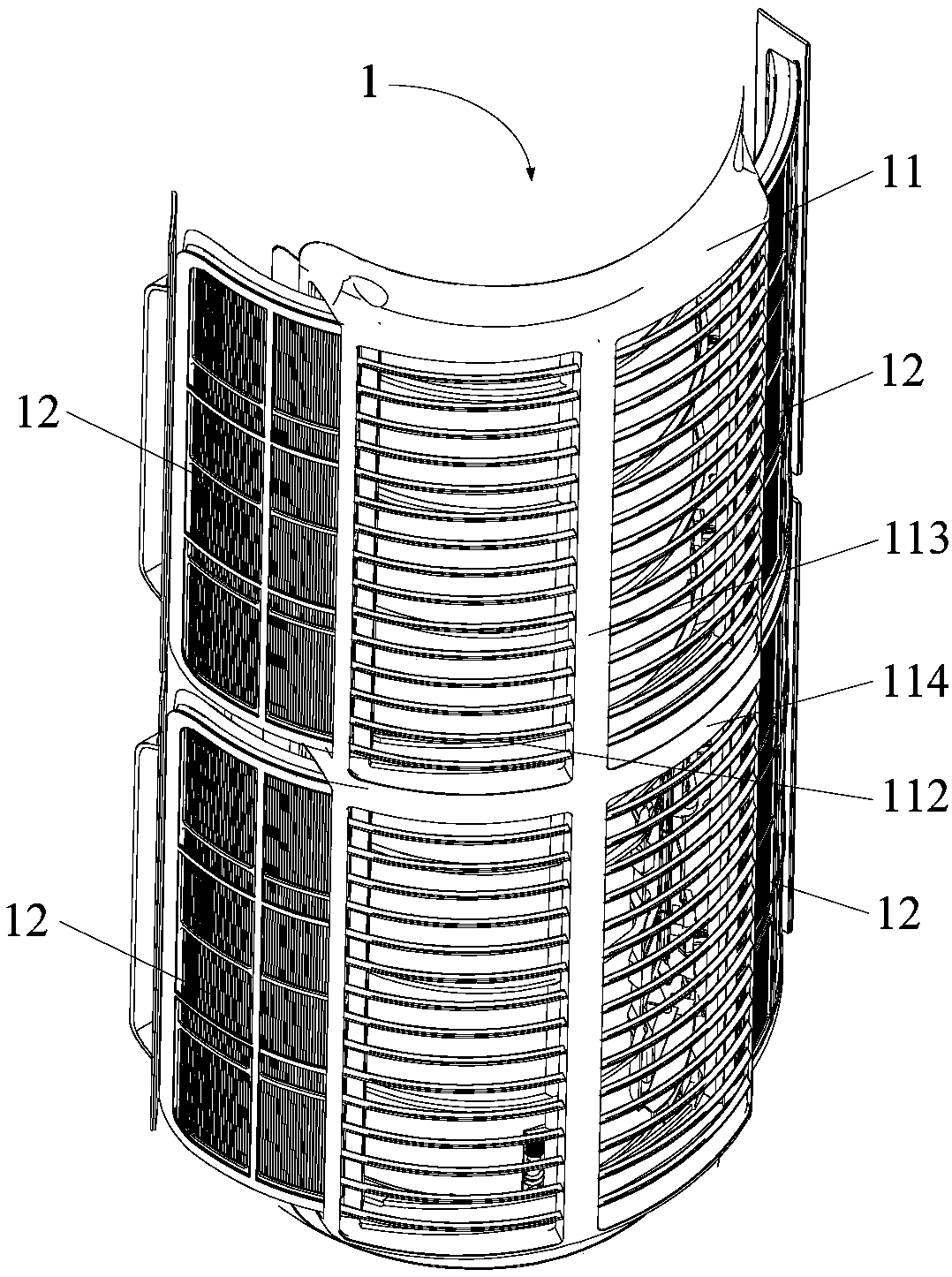

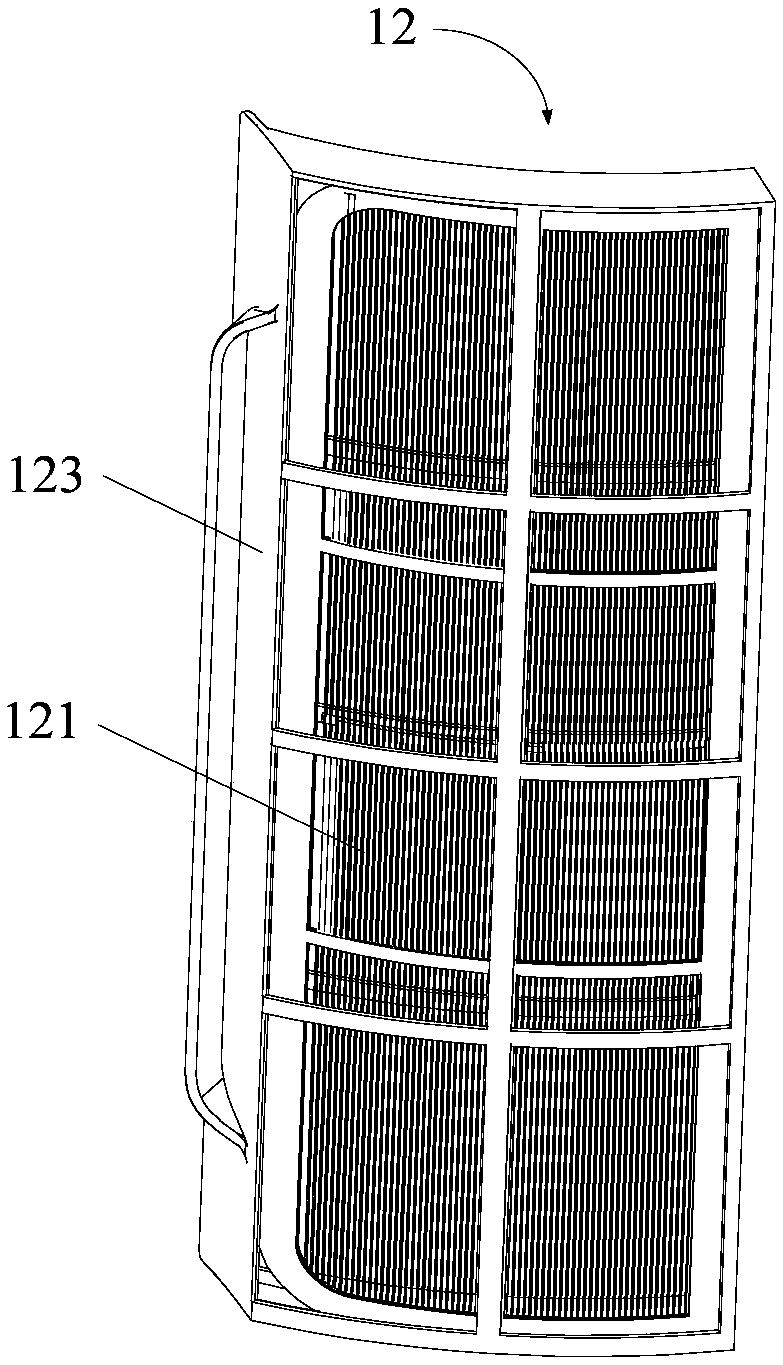

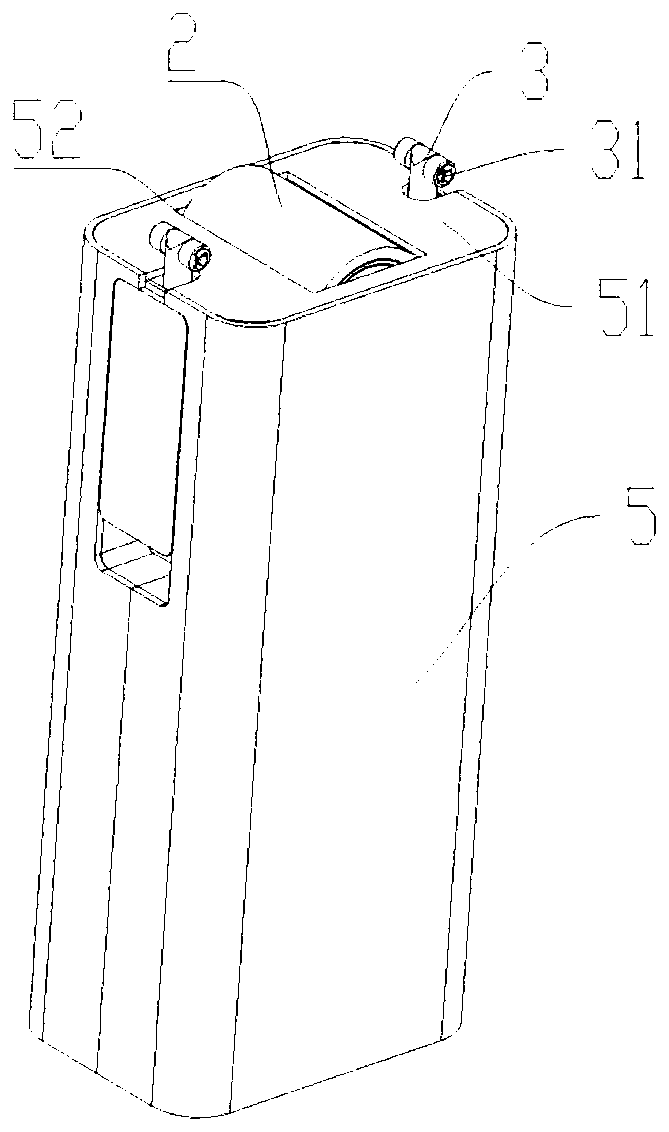

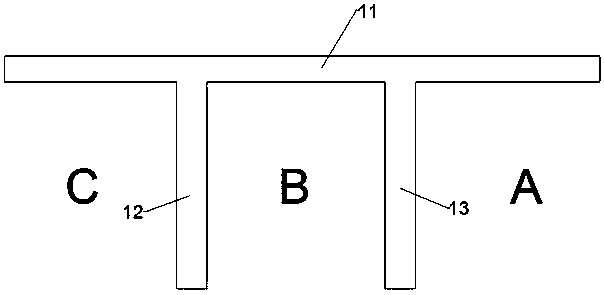

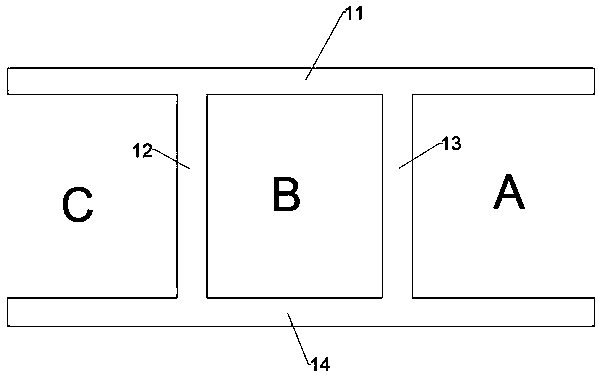

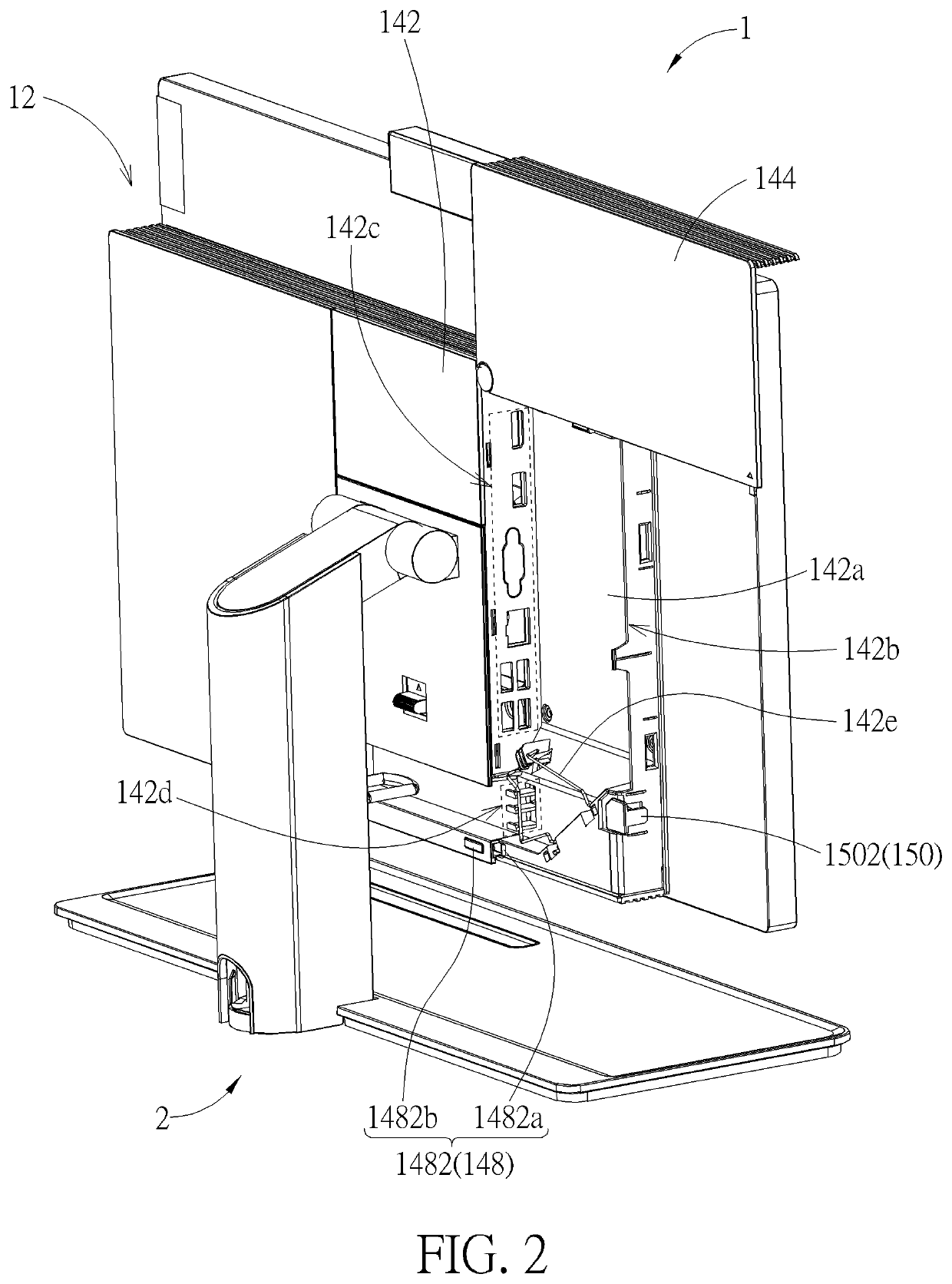

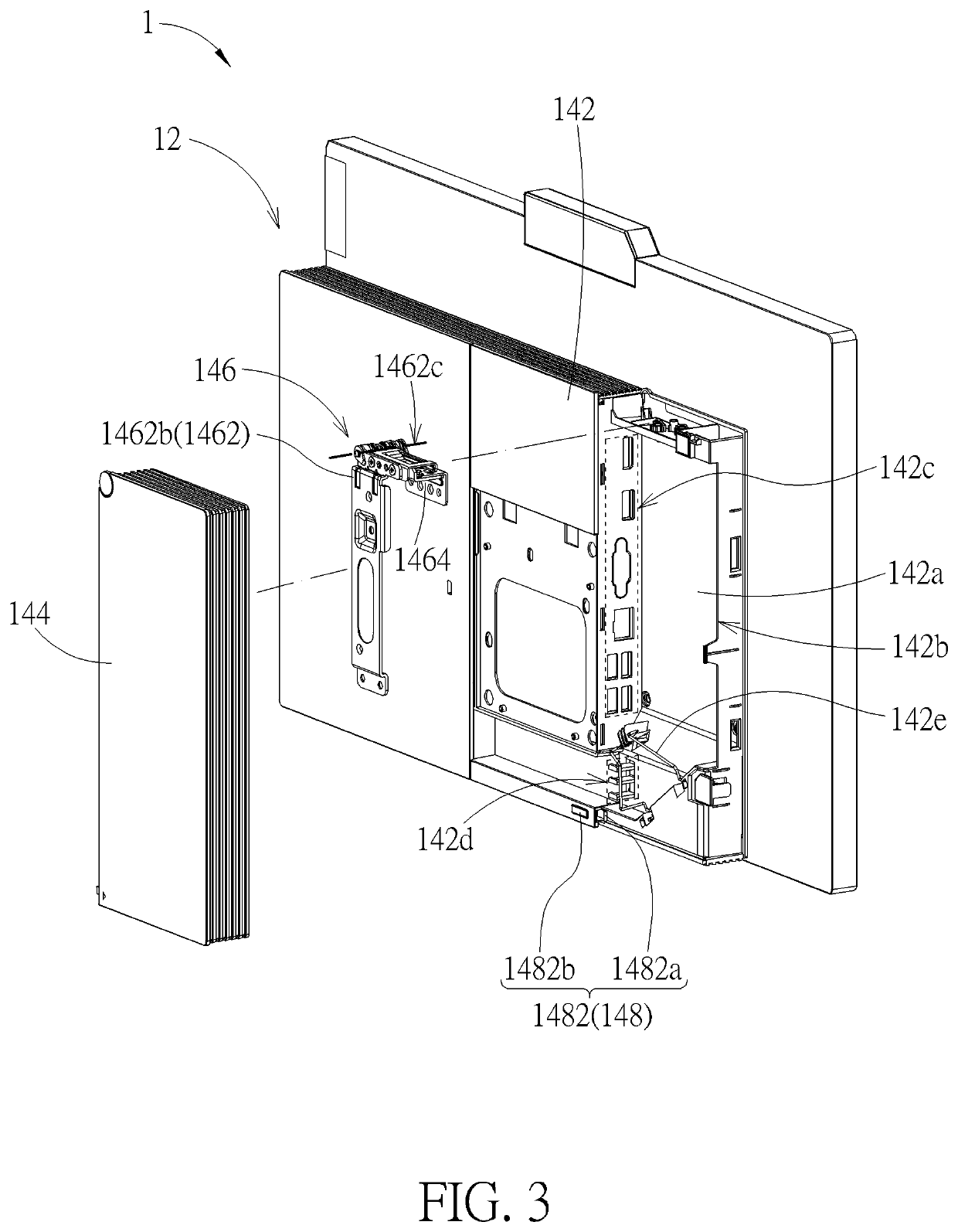

Purifying module and air conditioner

PendingCN108278756AAvoid structural interferenceAvoid installation difficultiesMechanical apparatusLighting and heating apparatusProduction lineWaste management

The invention provides a purifying module and an air conditioner. The purifying module is totally and detachably mounted on a shell of the air conditioner, and is used for purifying and filtering airentering the shell; the purifying module comprises a main frame and a purifying module; mounting space opened on the side surface is limited on the main frame; the purifying module comprises an accommodating frame, and an electric purifying module and a filter screen accommodated in the accommodating frame; and the purifying module can be detachably mounted in the mounting space from the opening on the side surface of the main frame. The purifying module is convenient to totally disassemble for cleaning, so that the air conditioner is more convenient to assemble on a production line; the electric purifying module and the filter screen serve as one module for overall installation on the main frame of the purifying module, so that the electric purifying module and the filter screen are moreconvenient to disassemble on the main frame; and when the electric purifying module and the filter screen need to be cleaned, the electric purifying module and the filter screen can be pulled out together, so that the operation is more convenient.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

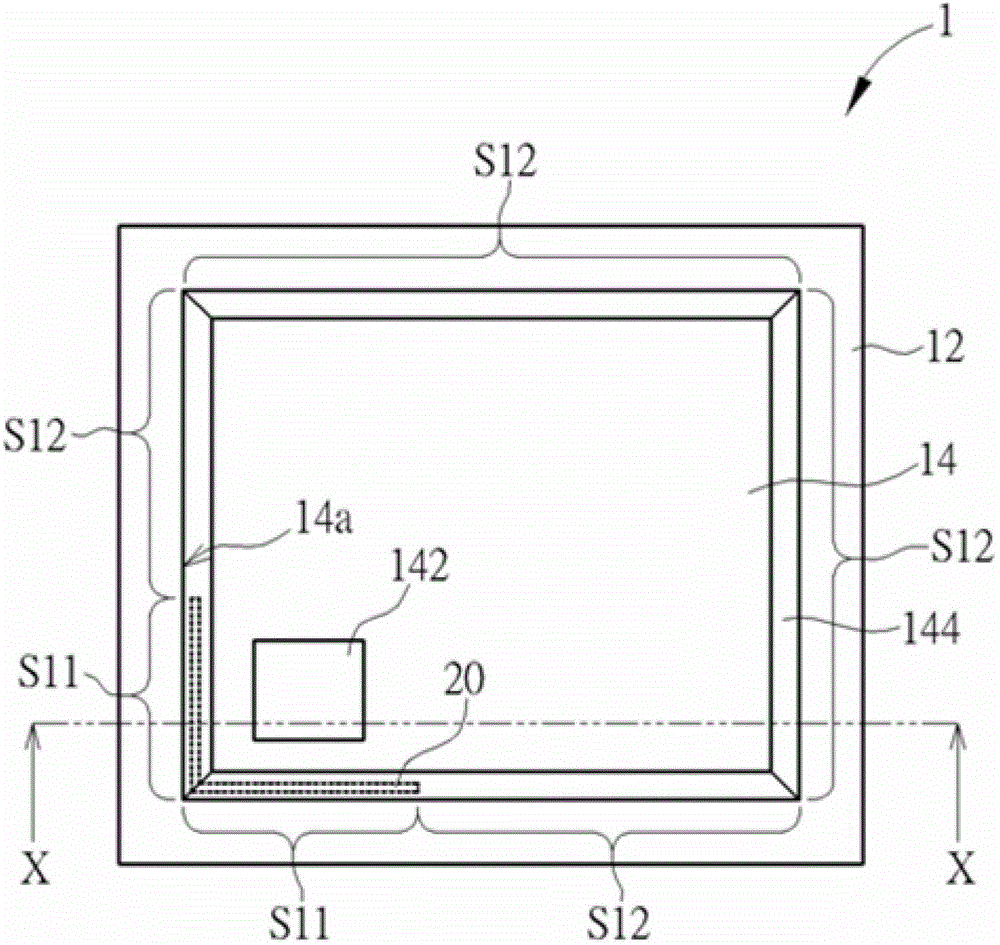

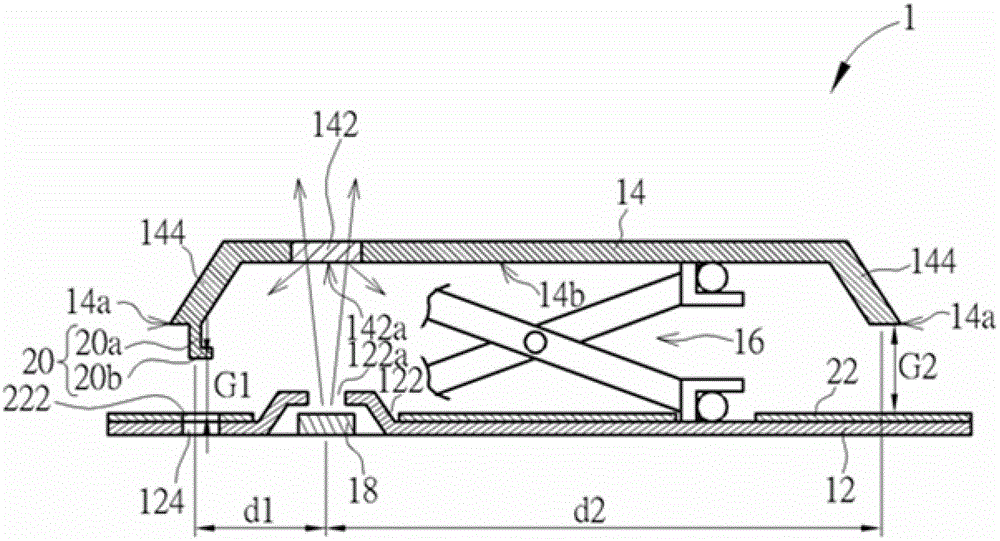

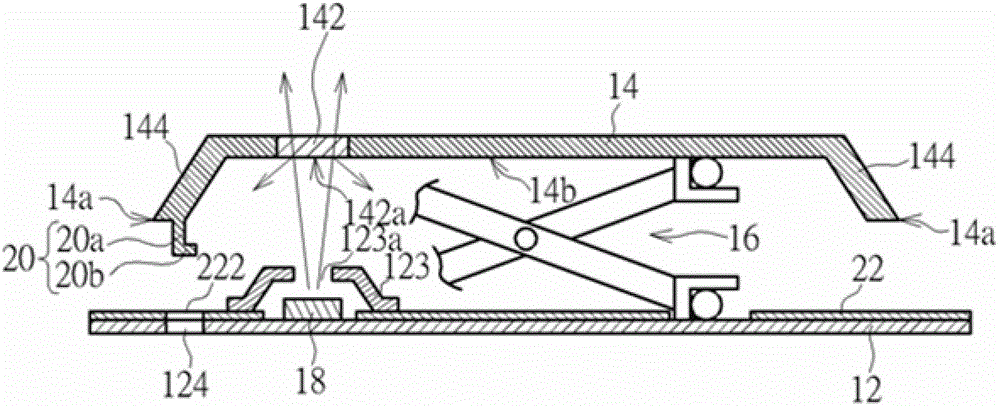

Light-emitting key structure

ActiveCN103151206AReduce overflowDegree to which operational impacts are mitigated or eliminatedElectric switchesEngineeringMechanical engineering

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

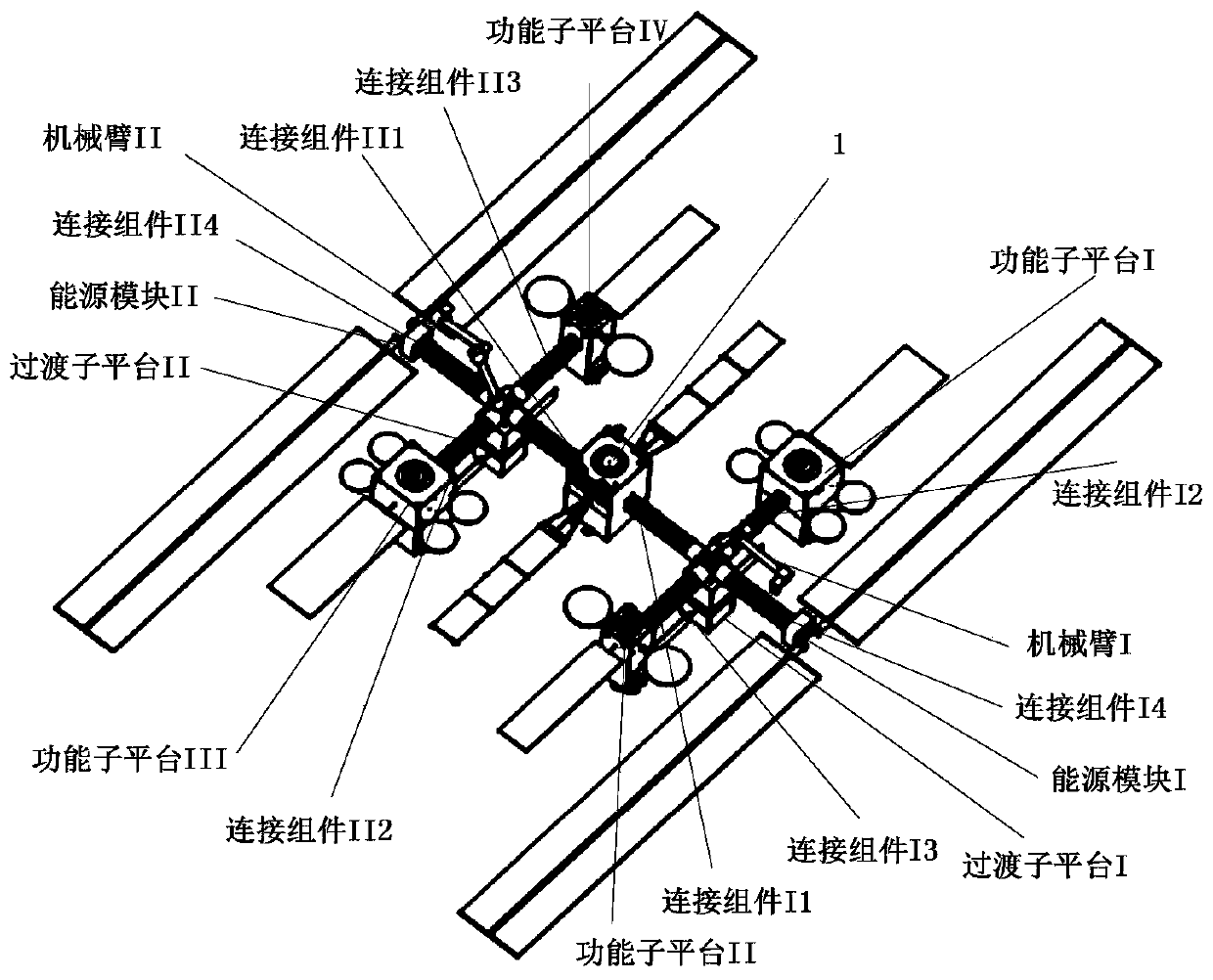

Stationary orbit ultra-large type assemblable satellite platform configuration and on-orbit assembly method

ActiveCN111422378AMeet the comprehensive bearing requirements of multiple types of loadsMeet the comprehensive bearing requirementsCosmonautic partsArtificial satellitesMechanical engineeringSatellite bus

The invention provides a stationary orbit ultra-large type assemblable satellite platform configuration, which belongs to the technical field of spacecrafts, and comprises a mother platform, a transition sub-platform I and a transition sub-platform II, a functional sub-platform I and a functional sub-platform II, a functional sub-platform III and a functional sub-platform IV, an energy module I and an energy module II, and a mechanical arm I and a mechanical arm II, wherein the mother platform is a control center of a whole satellite; the transition sub-platform I and the transition sub-platform II are respectively connected with the mother platform through connecting devices; the functional sub-platform I and the functional sub-platform II are respectively connected with the transition sub-platform I through connecting devices; the functional sub-platform III and the functional sub-platform IV are respectively connected with the transition sub-platform II through connecting devices; the energy module I and the energy module II are respectively connected with the transition sub-platform I and the transition sub-platform II through connecting devices to supply power; the mechanicalarm I and the mechanical arm II are installed on the transition sub-platform I and the transition sub-platform II correspondingly to execute an on-orbit assembling task. The platform configuration issuitable for expansion, can adapt to on-orbit construction of large satellites with the on-orbit flight weight of 10-20 t, is applied to various types of satellites and service stations, and is wide in application range.

Owner:SHANGHAI SATELLITE ENG INST

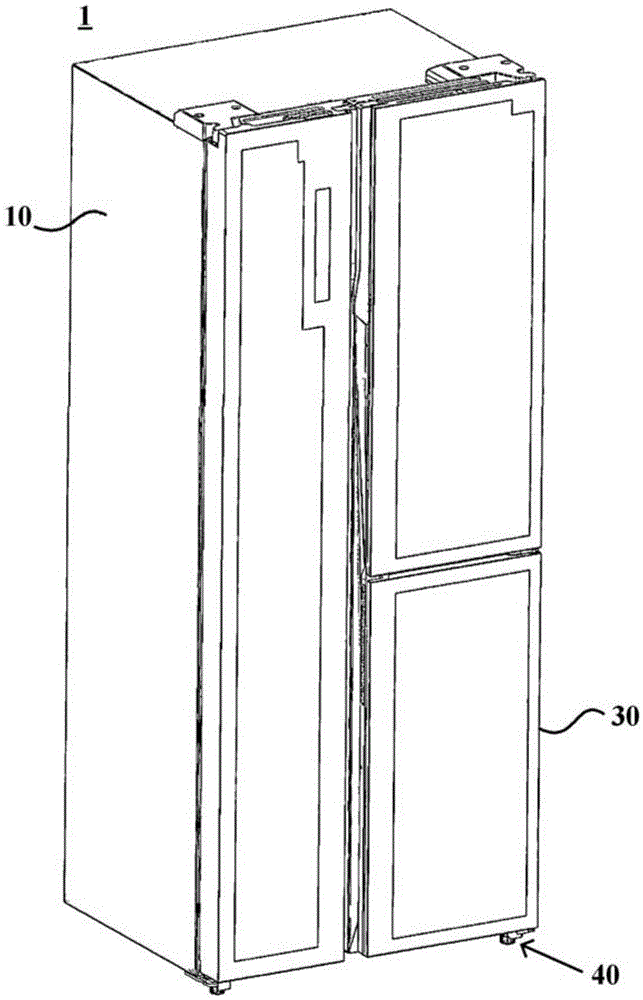

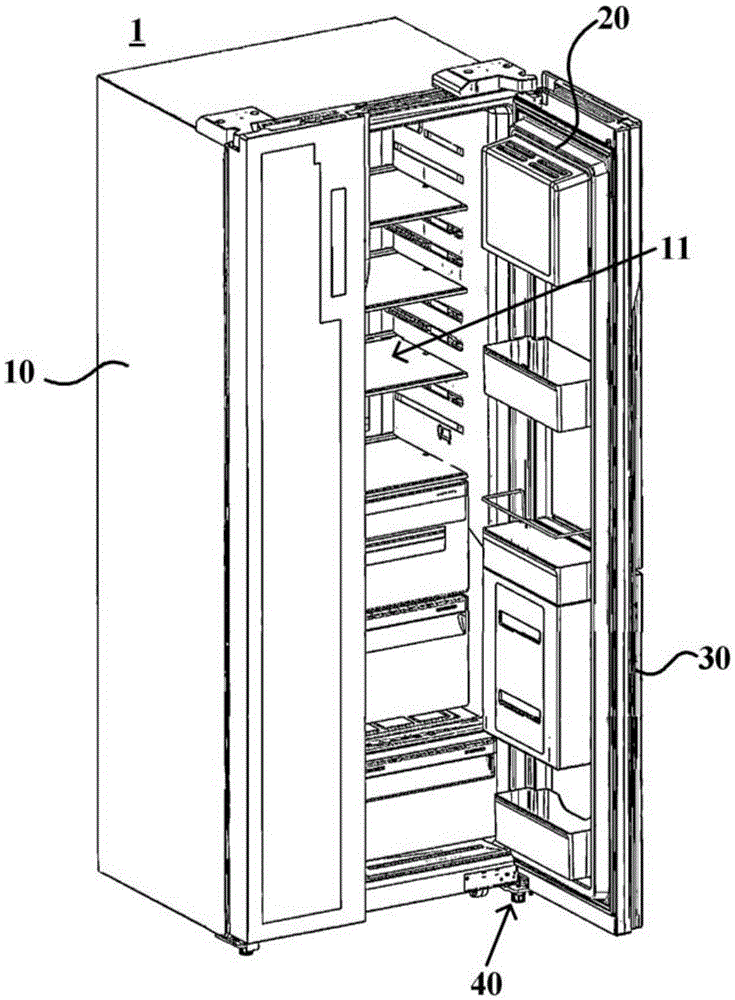

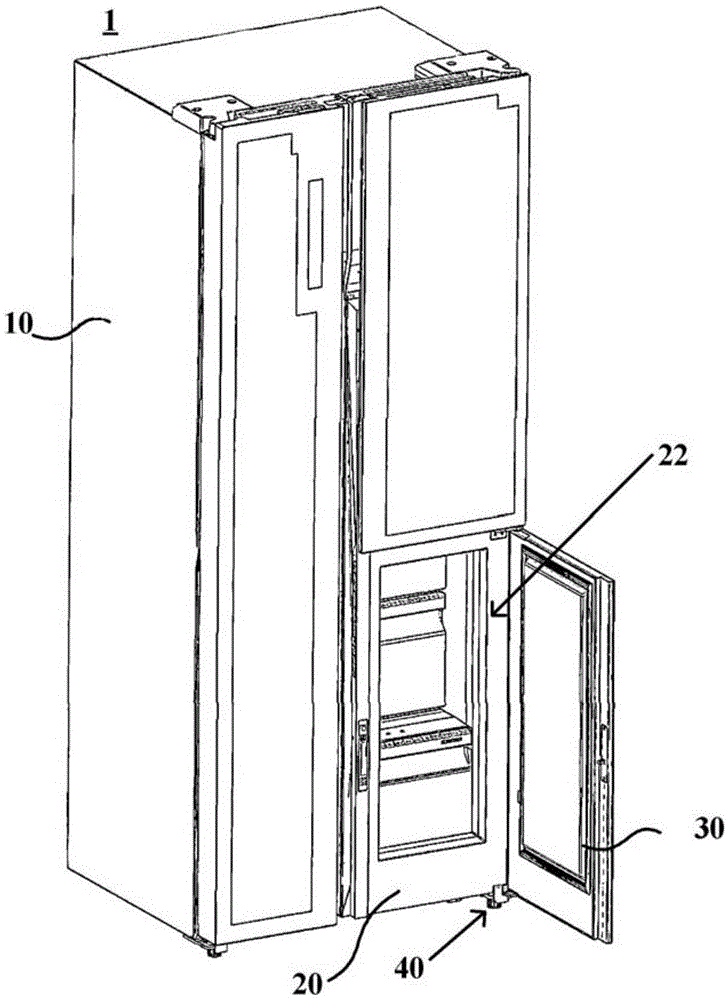

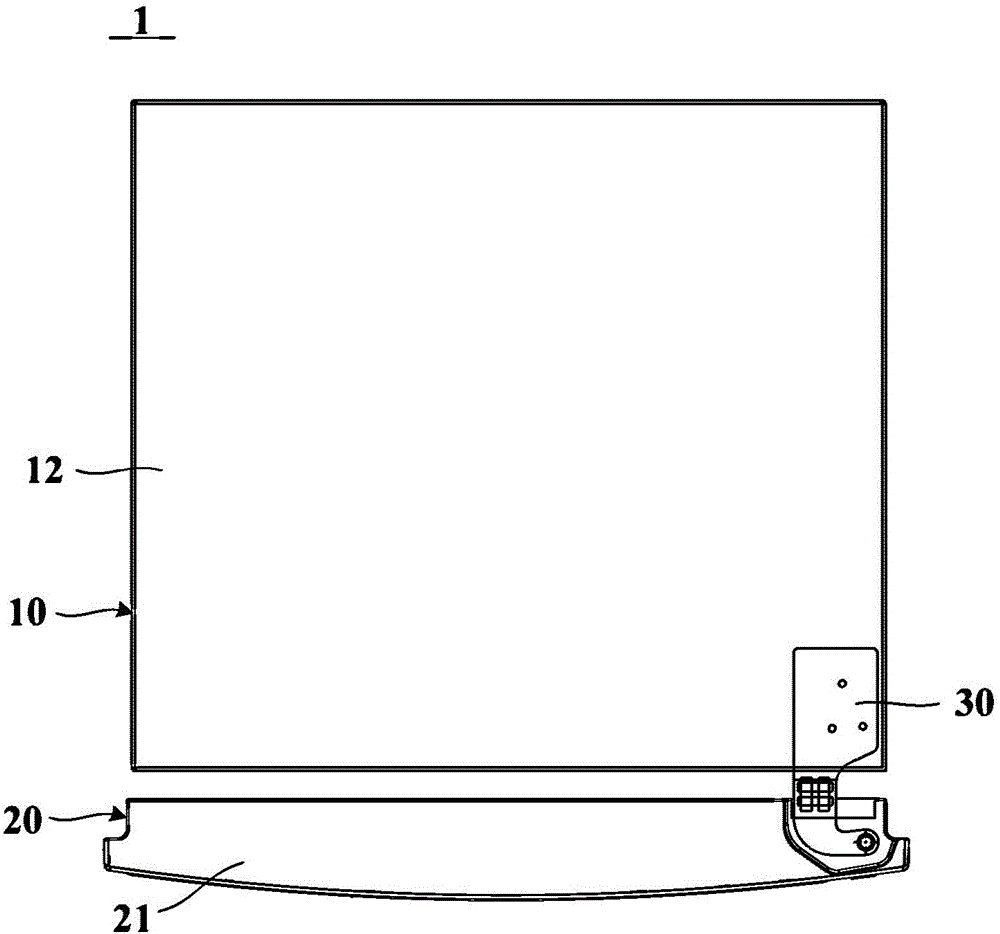

Refrigerator

ActiveCN105466105AImprove sealingImprove aestheticsLighting and heating apparatusDomestic refrigeratorsEngineeringObject storage

The invention provides a refrigerator. The refrigerator comprises a refrigerator body, a first door and a second door, wherein a first object storage chamber is defined in the refrigerator body; the first door is pivotally arranged on the front surface of the refrigerator body; a second object storage chamber is defined through the first door; the second door is pivotally arranged in front of the first door and used for sealing the second object storage chamber; an arc-shaped recession is formed in the surface, located behind a pivotal shaft of the second door, of the first door so as to provide a rotation space for the door body corners of the side, close to the pivotal shaft, of the second door. When the second door pivotally rotates relative to the first door, the door body corners of the side, close to the pivotal shaft, of the second door are prevented from structural interference with the first door by means of the arc-shaped recession. Besides, a gap between the first door and the second door can be reduced, and the good leakproofness and the overall aesthetic property of the refrigerator are ensured. The whole occupied space of the refrigerator is reduced.

Owner:HAIER SMART HOME CO LTD

A ground wire assembly

ActiveCN105703097AGuaranteed path of movementAvoid offsetElectric connection structural associationsSwitchgearEngineeringMechanical engineering

The invention discloses a ground wire assembly comprising a main rod body and an auxiliary rod body which are arranged in parallel. The top end of the main rod body is provided with a fixing head restraint matched with a wiring terminal. The top end of the auxiliary rod body is provided with a movable head restraint clamped and matched with the fixing head restraint. A guiding aperture is arranged in the fixing head restraint along an axial direction of the main rod body. The tail end of the movable head restraint is movably inserted in the guiding aperture and is in hinged connection with the auxiliary rod body. The middle portion of the main rod body is provided with an adjusting gear in a rotatable mode. The axis of the adjusting gear is perpendicular to the axis of the main rod body. A matched surface between the tail end of the auxiliary rod body and the main rod body is provided with a tooth bar engaged with the adjusting gear in a matched mode. The connection structure of the ground wire assembly is safe and reliable, and the operation process is simple to perform.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +2

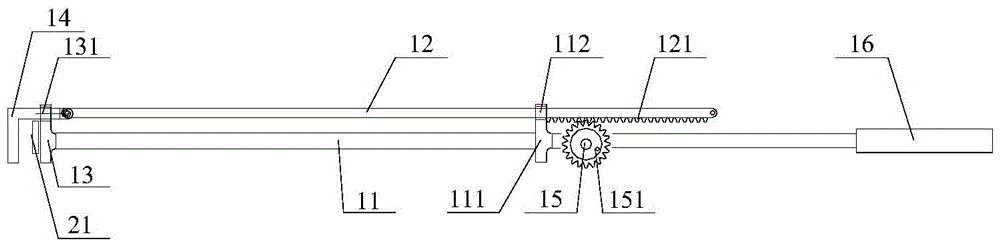

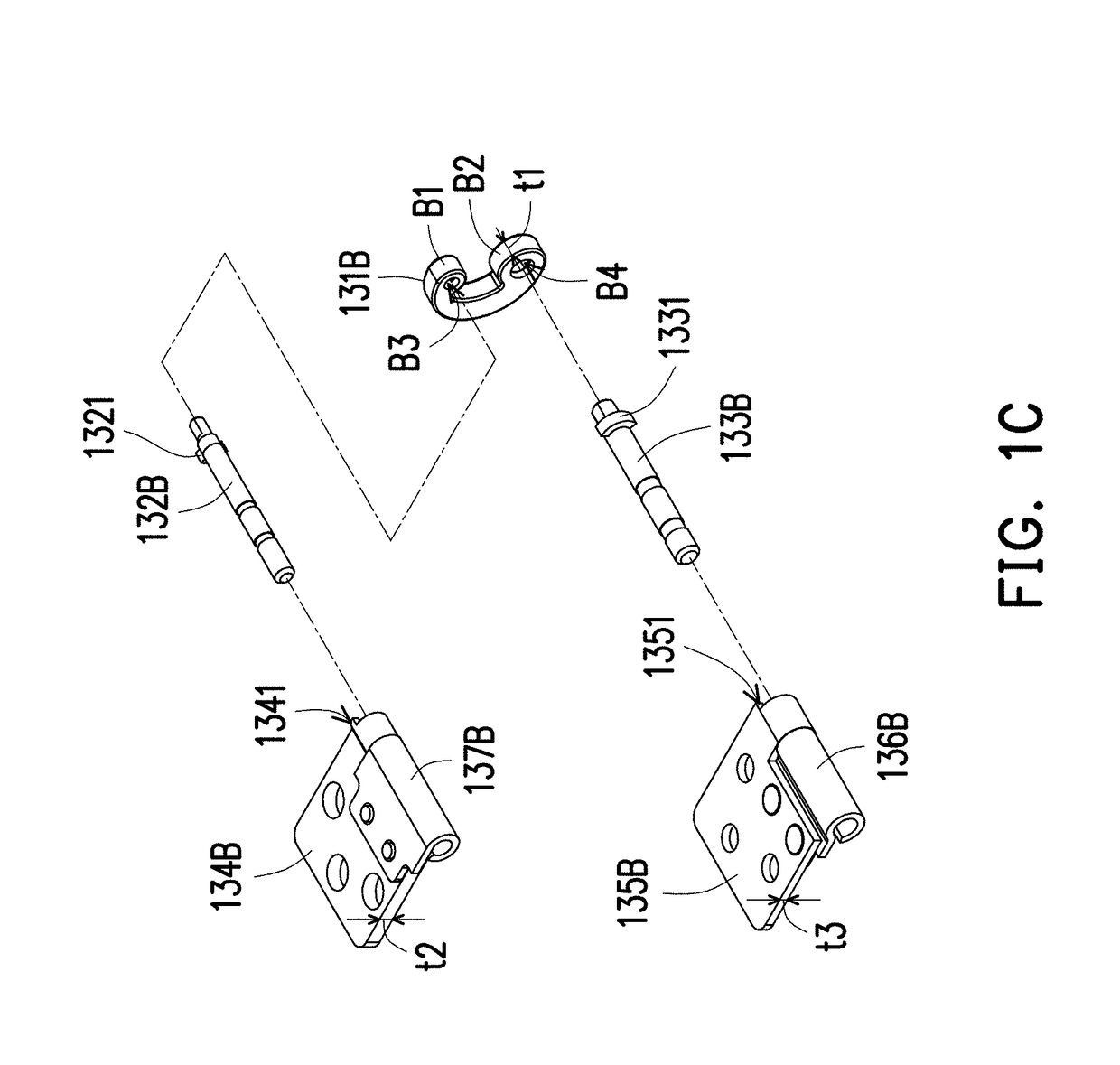

Hinge assembly for refrigeration and freezing device and refrigeration and freezing device

InactiveCN105888418AIncrease productivityReduce mold typesWing accessoriesPin hingesFastenerEngineering

The invention relates to a hinge assembly for a refrigeration and freezing device and the refrigeration and freezing device. The refrigeration and freezing device comprise a box, a door and the hinge assembly. The hinge assembly comprises a base part and an adjusting part with a hinge part. The base part is provided with at least two fixed strip-shaped holes extending in the depth direction of the box, and the adjusting part is provided with at least one movable strip-shaped hole extending in the transverse direction. Or the base part is provided with at least one fixed strip-shaped hole extending in the transverse direction, and the adjusting part is provided with at least two movable strip-shaped holes extending in the depth direction. The base part and the adjusting part are fastened through fasteners penetrating overlapped areas of the fixed strip-shaped holes and the movable strip-shaped holes in the vertical direction, and accordingly the vertical distance between the hinge part and the forward surface of the box in the depth direction and / or the vertical distance between the hinge part and the outer surface of a side plate, adjacent to the hinge assembly, of the box in the transverse direction are / is adjusted by adjusting the positions of the overlapped areas between the fixed strip-shaped holes and the movable strip-shaped holes.

Owner:HAIER SMART HOME CO LTD

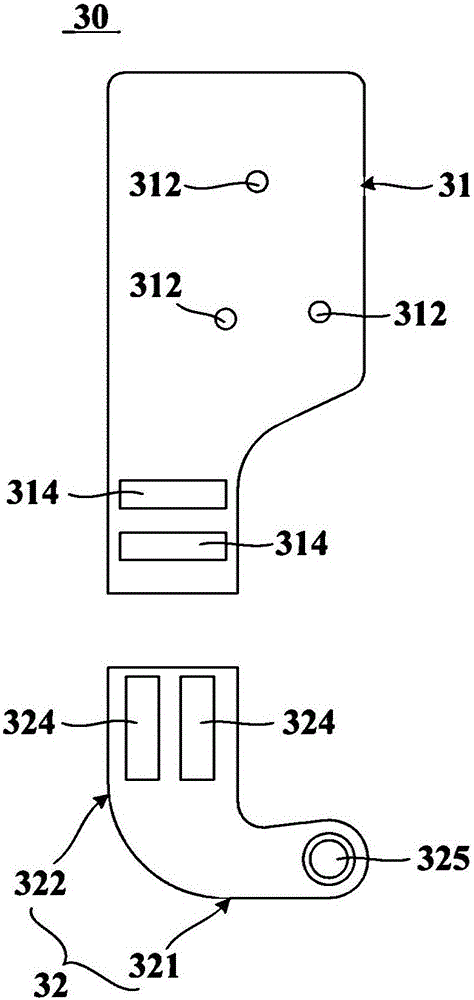

Fully-independent servo drive rapier loom

ActiveCN102634910AReal-time adjustment of reciprocating motionLight in massLoomsYarnElectric machinery

The invention relates to the field of spinning equipment, in particular to a fully-independent servo drive rapier loom which comprises an electronic yarn letting-off part, an electronic taking-up part, an electronic beating-up part and an electronic weft insertion part, and is mainly composed of a servo motor, a beating-up shaft, a steel buckle, a beating-up shaft support seat, a rapier belt wheel, a speed reducer, a gear, a yarn letting-off shaft, a cloth roller and a servo motor shaft. The fully-independent servo drive rapier loom is characterized by being controlled by full servo, the weftinsertion, beating-up, yarn letting-off and rolling of the loom are completely driven by a servo driver and are accurately located, the whole loom works by cooperation of a main control unit, a high-performance servo system can provide flexible, convenient, accurate and rapid drive, and complex linkage and digital interlocking are carried out in the electric aspect; and compared with the conventional loom, the fully-independent servo drive rapier loom has the advantages of convenience in process regulation, simplicity, reliability, no quick-wear part and maintenance cost saving, and is suitable for all fields in the spinning industry.

Owner:JIANGSU S&S INTELLIGENT SCI & TECH CO LTD

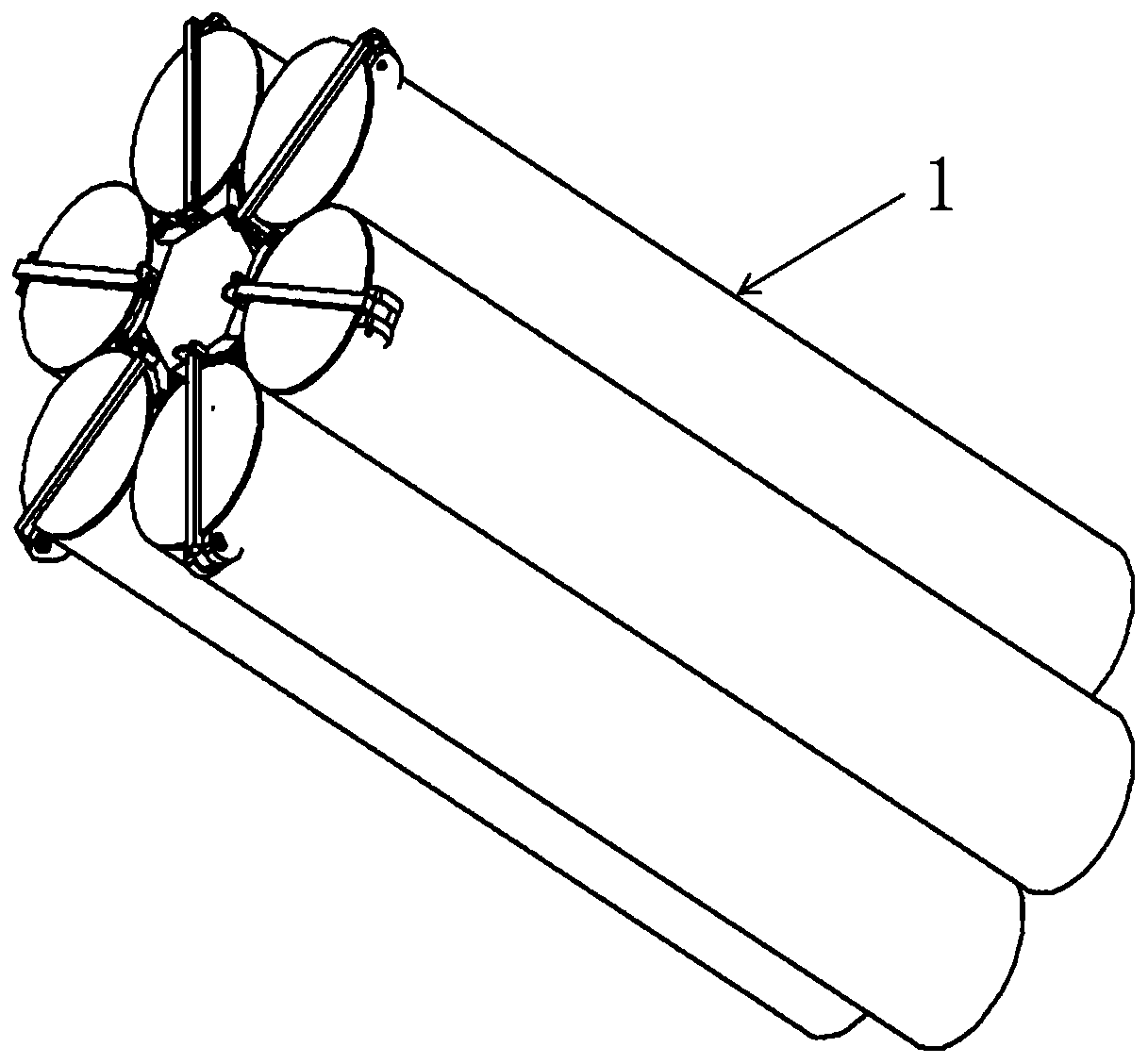

Projection device and method suitable for unmanned aerial vehicle sondes and detection system

ActiveCN110203396AAccurate predictionGet it in real timeAircraft componentsMeasurement devicesPopulationEngineering

The invention discloses a projection device suitable for unmanned aerial vehicle sondes. The sondes are placed in a plurality of sonde loading mechanisms, when an unmanned aerial vehicle reaches a preset location, thrust applied to movable bases by projection hubs is removed by a pushing mechanism, the movable bases are opened under the action of own gravity and / or the gravity of the sondes, the sondes are projected into the atmosphere under the own gravity, and environmental data is collected by a plurality of detecting devices carried. According to the projection device suitable for the unmanned aerial vehicle sondes, numerous unnecessary structures are reduced under the action of the gravity, so that the high-efficiency projection device suitable for mass population and with a simple structure, light weight, saved materials and low cost is achieved; since projection is performed under the action of the gravity, fluctuations of the projection direction caused by the device or an external environment when the sondes are projected is avoided, and the accuracy of measurement is greatly improved; and thus, data received by sensors in the sondes can be obtained accurately in real time, and changes in the atmosphere can be accurately predicted.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

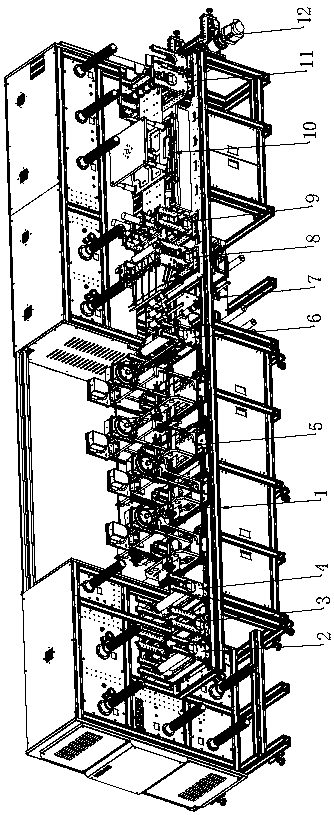

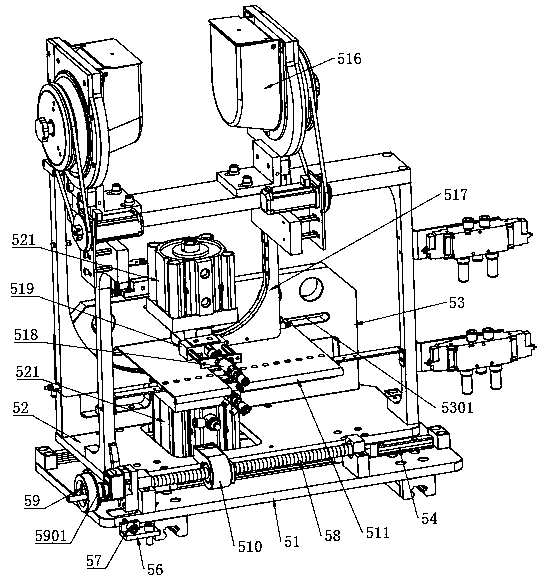

Button punching and coating equipment

ActiveCN111180662AAvoid structural interferenceCompact structureManufacture by sprayingStampingUltrasonic welding

The invention belongs to the technical field of electrode plate production equipment and provides button punching and coating equipment. A machine frame is included, anda die-cutting tool apron, a conveying tool apron and a composite tool apron are sequentially arranged on the machine frame. At least one group of button punching devices are arranged at a downstream of the composite tool apron; a testing device is arranged at the downstream of thebutton punching device; and a buffer storage device is arranged on the downstream of the testing device, a coating and gluing device is arranged on the downstream of the buffer storage device, an ultrasonic welding device is arranged on the downstream of the coating and gluing device, a synchronous stamping device is arranged on the downstream of the ultrasonic welding device, a traction slitting device is arranged on the downstream of the synchronous stamping device, and a transverse cutting tool apron is arranged on the downstream of the traction slitting device. All the devices are matched to act; die cutting, button punching, testing, coating, ultrasonic welding, stamping and shape cutting integrated machining production of an electrodeplate can be achieved; andan interference phenomenon of an electrode buckle accessory structure is effectively avoided, electrode buckle accessory abrasion or material tension changes and material deformation cannot be caused in a machining process, and production efficiency and a percent of pass are greatly improved.

Owner:SHANDONG HOACO AUTOMATION TECH

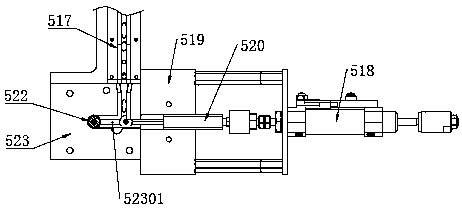

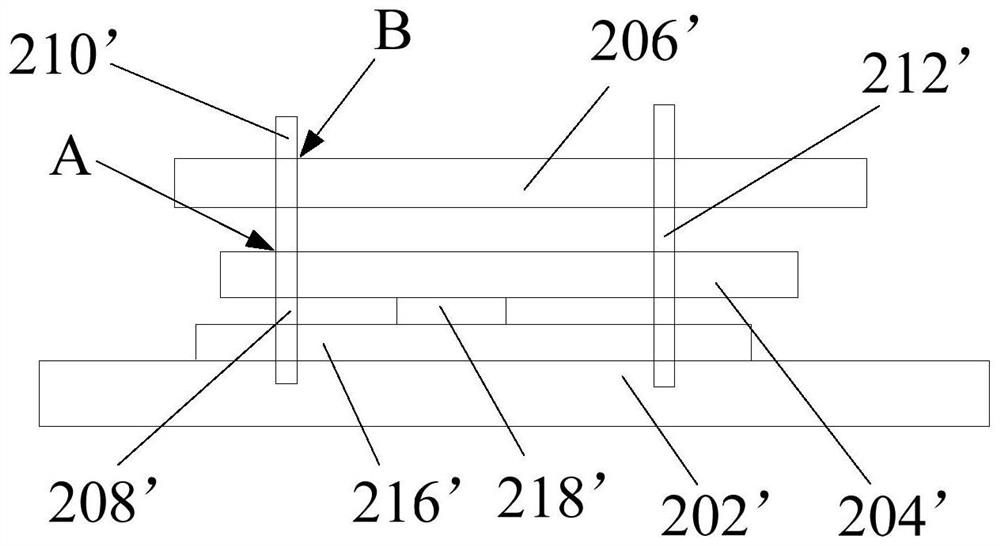

Device and method for processing welding strip

ActiveCN105643159AReduce processing timeAvoid structural interferenceWelding/cutting auxillary devicesShearing machinesHeight differenceFixed length

The invention relates to a device and method for processing a welding strip. The device for processing the welding strip comprises a first welding strip pressure head, a welding strip transfer platform and a second welding strip pressure head. The welding strip pulling position of a first welding strip pulling pressure head and the welding strip pulling position of a second welding strip pulling pressure head have a height difference. According to the method for processing the welding strip, the welding strip is drawn through the first welding strip pulling pressure head and waits for cutting off; the welding strip transfer platform enables the welding strip to be positioned and undertakes the welding strip; and the fixed length welding strip having been cut off is drawn from the welding strip transfer platform through the second welding strip pulling pressure head. The process of pulling the welding strip and cutting the welding strip into the fixed length welding strip in the conventional process is independent from the process of feeding the fixed length welding strip to a battery piece placing position and waiting for piece placing by a robot, so that continuous process steps of the conventional process are disconnected, and thus the time sequences are overlaid. The welding strip pulling position of the first welding strip pulling pressure head and the welding strip pulling position of the second welding strip pulling pressure head have a height difference, so that the structural interference of the time sequence overlaying position in the working process is avoided, the welding strip processing time is reduced, and the working efficiency is improved.

Owner:WUXI AUTOWELL TECH

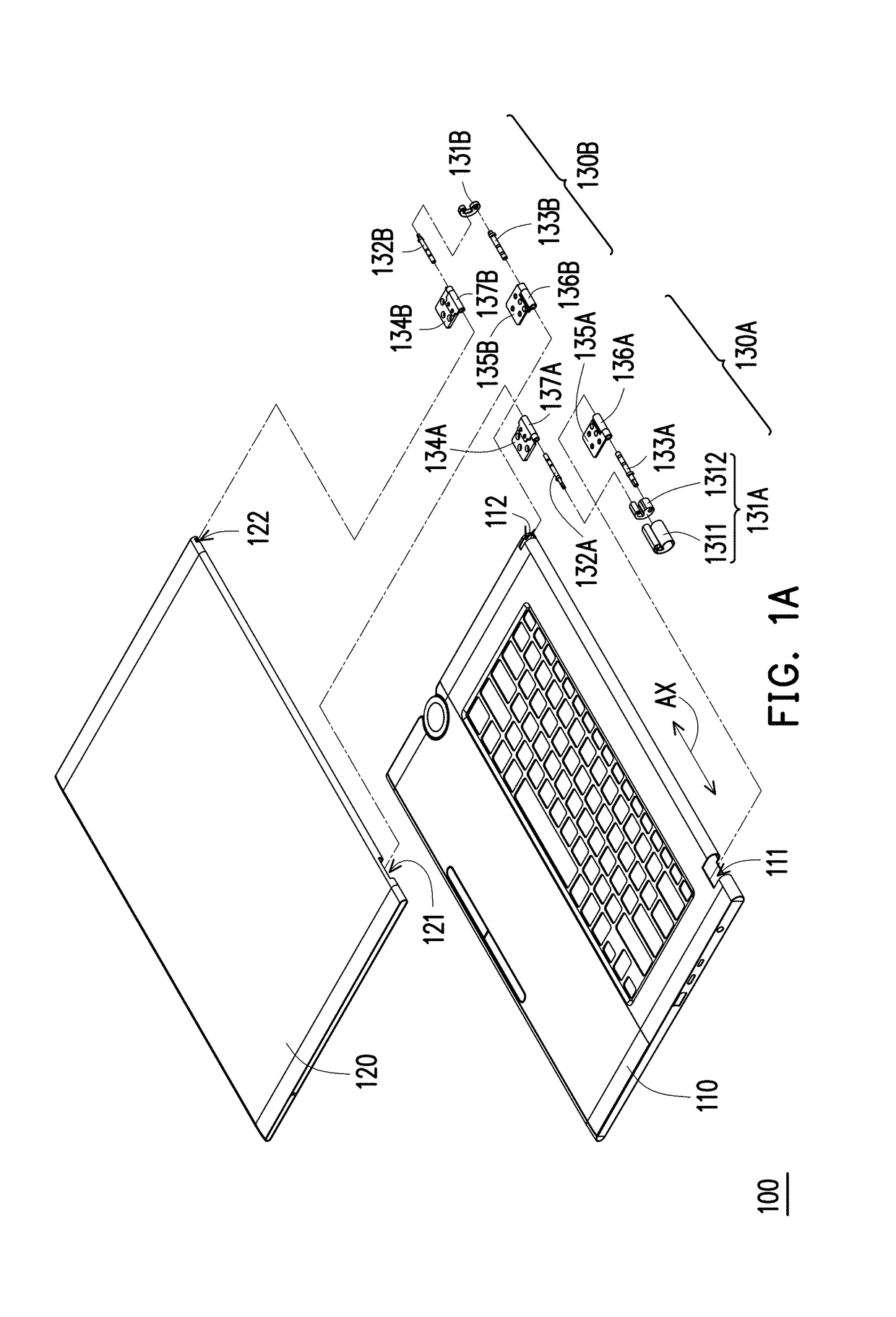

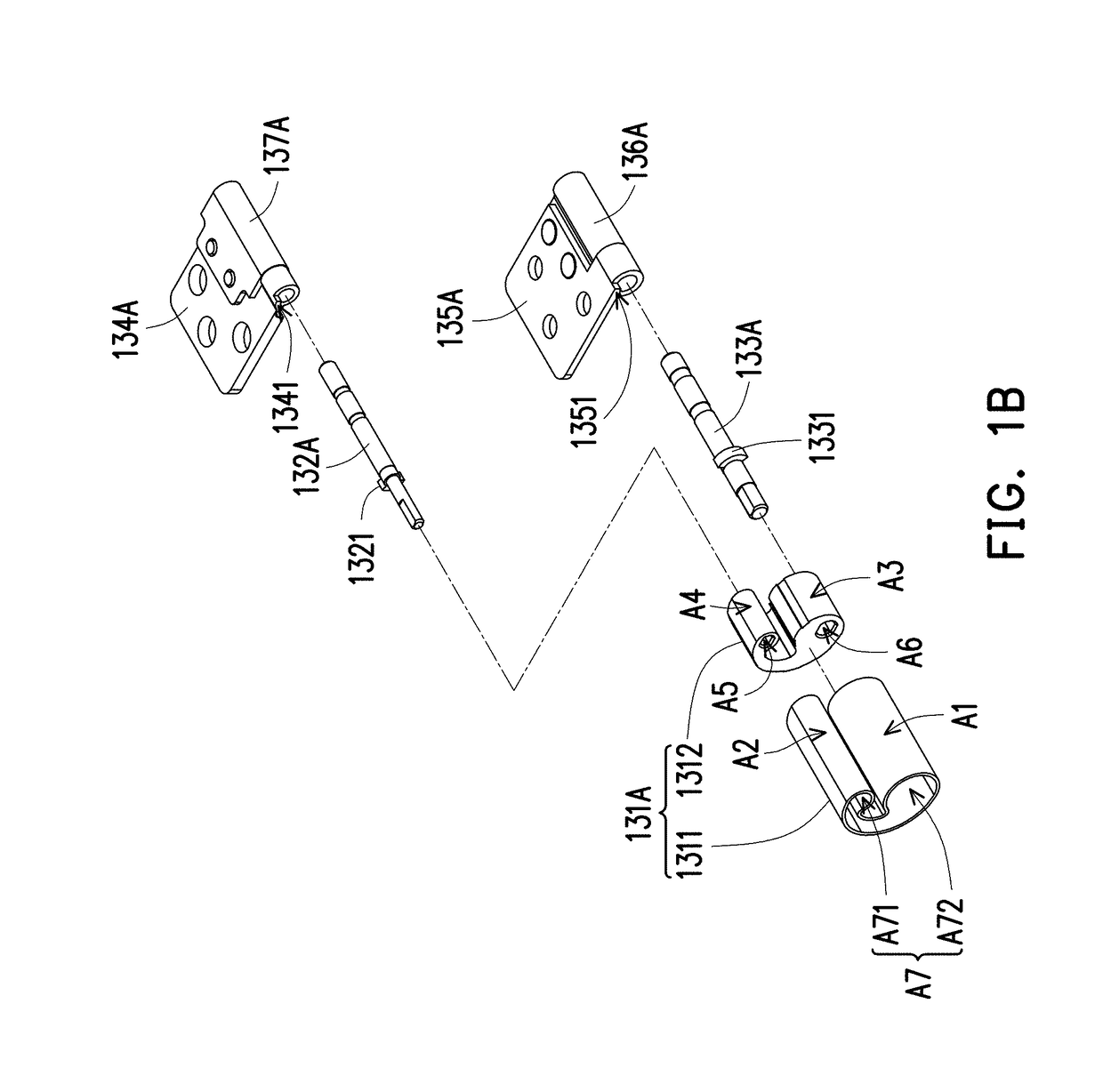

Electronic device

ActiveUS20190018460A1Neat appearanceAvoid structural interferenceDetails for portable computersDual axisElectron device

Owner:COMPAL ELECTRONICS INC

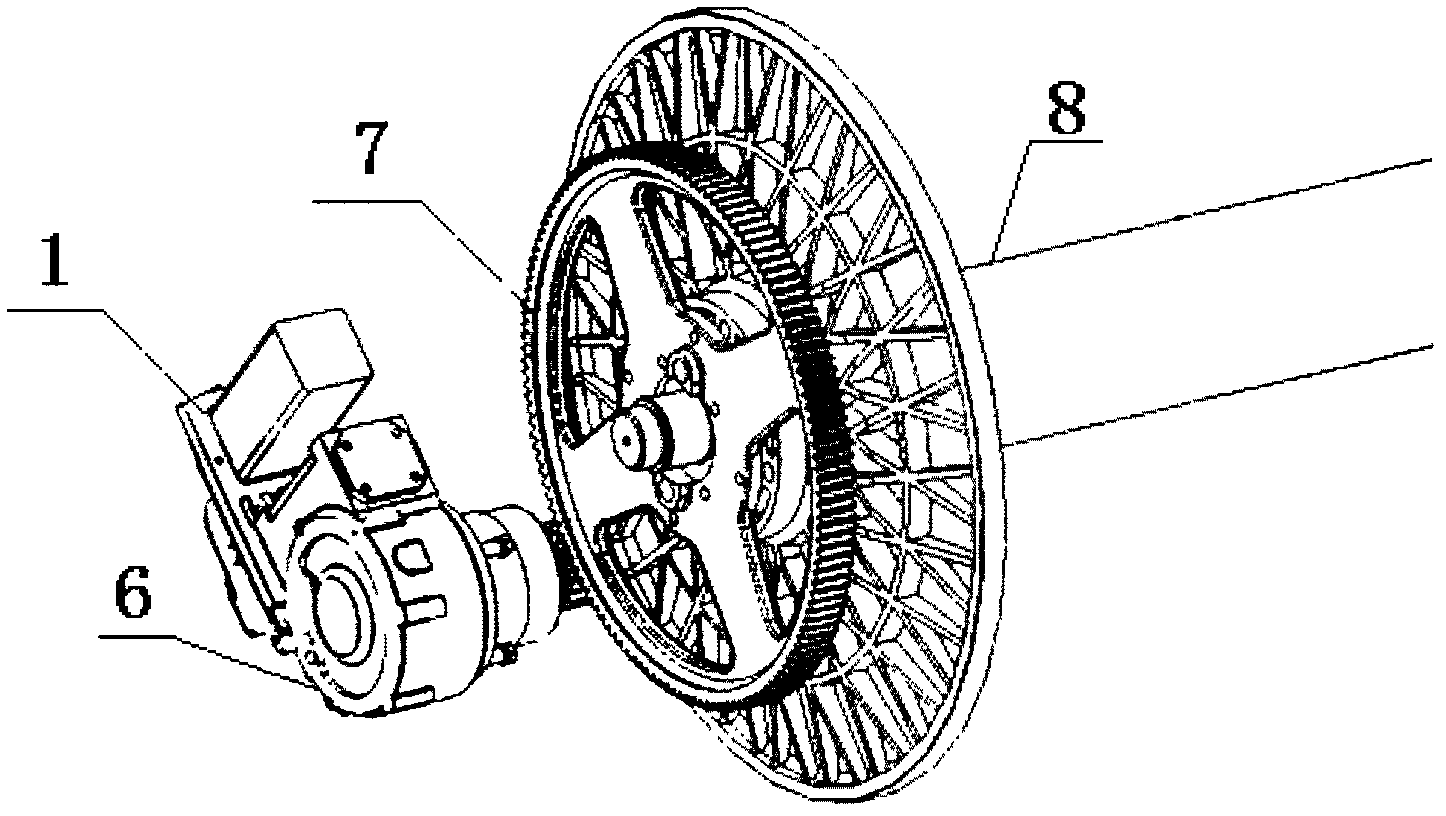

Curtain driving device and control method

InactiveCN111329320AImprove smart experienceEnable light pull to startCurtain accessoriesMechanical energy handlingAutomatic controlControl mode

The invention relates to a curtain driving device and a control method thereof. The curtain driving device comprises a wheel assembly and a hook assembly, and the hook assembly is in butt joint with acurtain sliding rail and slides relative to the curtain sliding rail under driving of a roller assembly; the roller assembly is connected with a driving mechanism through a clutch mechanism, the driving mechanism is provided with an output shaft, the outer side of the output shaft is concentrically sleeved with an annular supporting frame, and the clutch mechanism is connected with the supportingframe; and the driving mechanism is started to enable the output shaft to rotate, and the clutch mechanism drives the roller assembly to rotate. By means of the mode, the curtain can be lightly pulled and started, structural interference is avoided by reasonably arranging the sensing mechanism and the sensing device, and occupied space is reduced; effective linkage of the induction mechanism andthe clutch device is achieved, and the curtain can be driven in an unimpeded mode in a manual control mode and an automatic control mode.

Owner:DREAME TECH (SHANGHAI) CO LTD

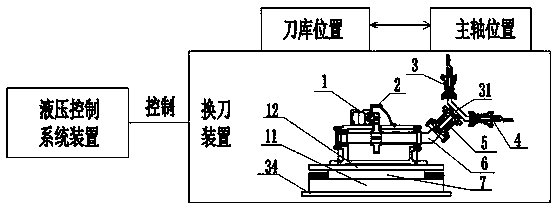

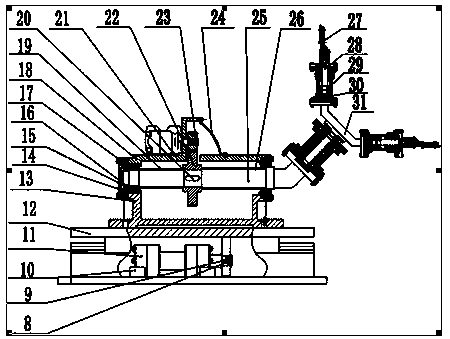

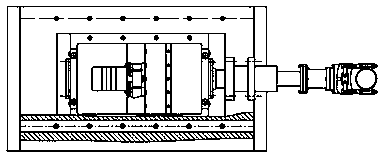

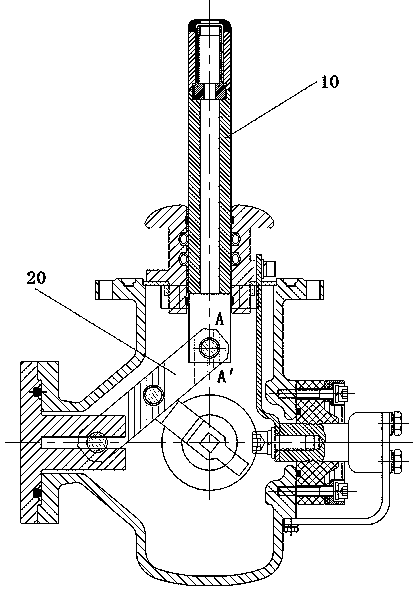

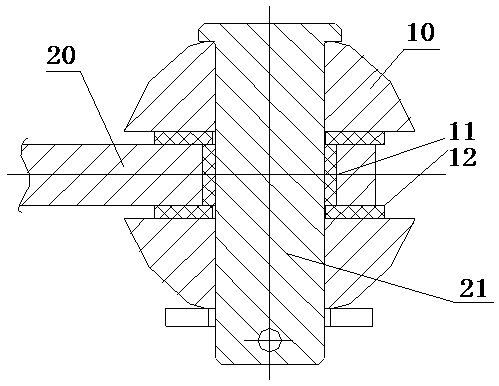

Tool change device with vertical and horizontal conversion function and tool change method thereof

PendingCN109176106AWith vertical and horizontal conversion functionEasy and flexible controlPositioning apparatusMetal-working holdersHydraulic cylinderGear wheel

The invention discloses a tool change device with a vertical and horizontal conversion function and a tool change method thereof. The technical scheme of the tool change device and method is that thetool change device with the vertical and horizontal conversion function includes a hydraulic control system device; an open gear retarding mechanism is connected with a workbench by bolting; the workbench and a linear guide are connected by bolting; the linear guide and a plunger hydraulic cylinder are correspondingly and fixedly connected with the base by bolting; the plunger hydraulic cylinder and the workbench are connected through flat keys and slotted countersunk flat head screws; the front end of a crankshaft is connected with a drive open gear retarding mechanism; the tail end of the crankshaft is connected with a rotary hydraulic cylinder by bolting; the rotary hydraulic cylinder and a connecting plate are connected by bolting; mechanical arms include the first mechanical arm and the second mechanical arm; and the first and second mechanical arms present a spatial distribution of 90 degrees. The tool change device meets the needs of the current large five-axis machining center,and the tool change method has simple processes and high operability, and can fit with the tool change device to realize the tool change function and the vertical and horizontal conversion function.

Owner:SHAANXI UNIV OF SCI & TECH

High-speed grounding switch and GIS device

ActiveCN110428996AThe connection structure is stableSimple structureSwitchgear arrangementsAir-break switch detailsCrankSwitchgear

The invention relates to the technical field of high-voltage switchgear and provides a high-speed grounding switch and a GIS device to solve the problem in the prior art that the installation error ofthe high-speed grounding switch causes wear and failure. The high-speed grounding switch comprises a housing, a movable contact and a rotary connecting member, wherein the rotary connecting member has a movable contact connecting end connected with the movable contact, a guiding end adaptive to a guiding structure on the housing; the movable contact connecting end of the rotary connecting memberis hinged to a slide block, the movable contact is correspondingly provided with a matching sliding slot for assembling the slide block in a guided manner, the guiding direction of the slide block issimultaneously perpendicular to the guiding direction of the movable contact and the axis of rotation of an input crank; or the movable contact connecting end of the rotary connecting member is hingedto a rotating body, the rotating body is provided with a sliding slot, the movable contact is correspondingly provided with a matching slide block in guiding fitting the sliding slot, and the guidingdirections of the matching slide block and the sliding slot are simultaneously perpendicular to the guiding direction of the movable contact and the axis of rotation of the input crank.

Owner:HENAN PINGGAO ELECTRIC +2

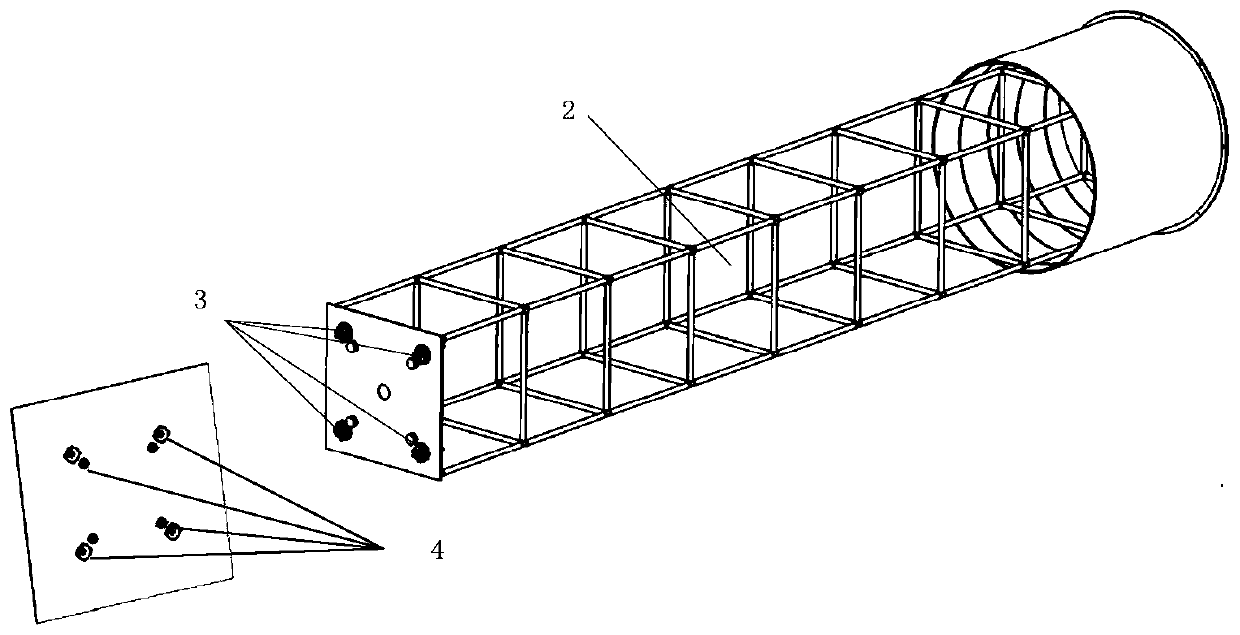

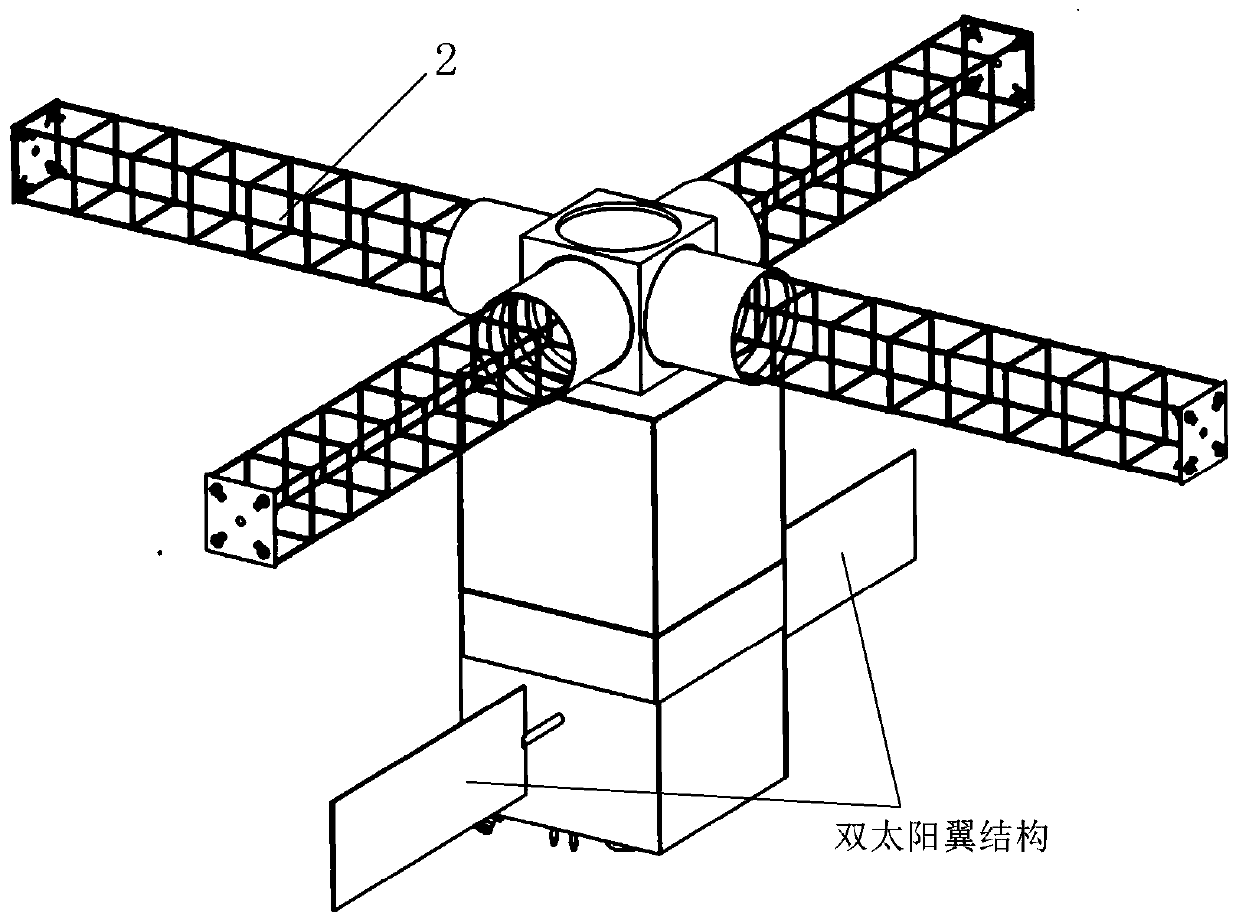

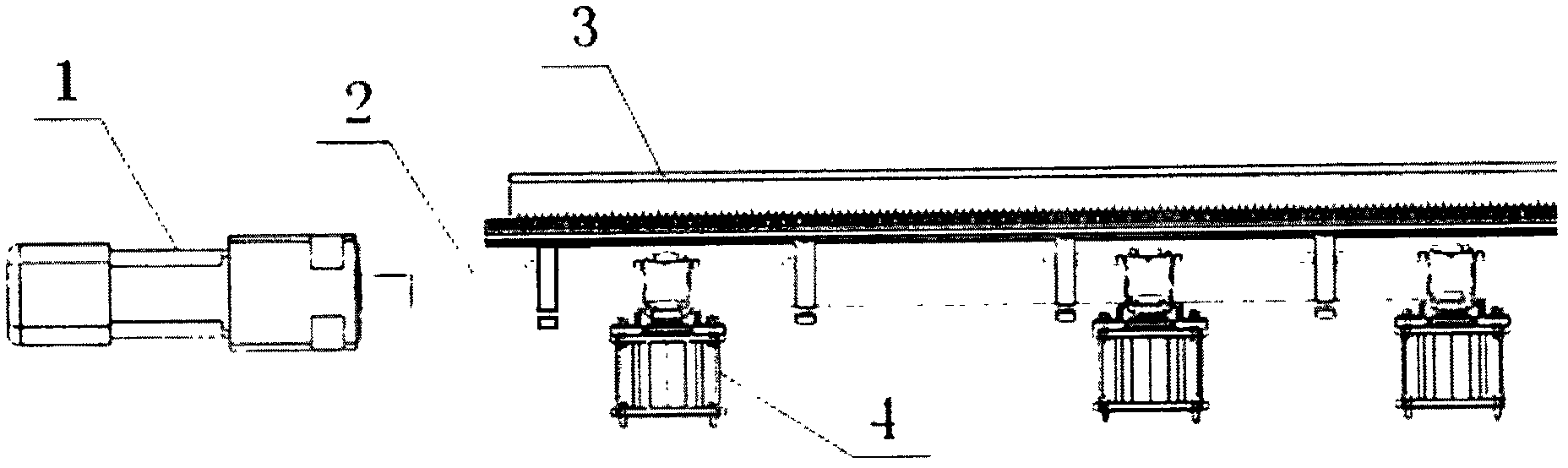

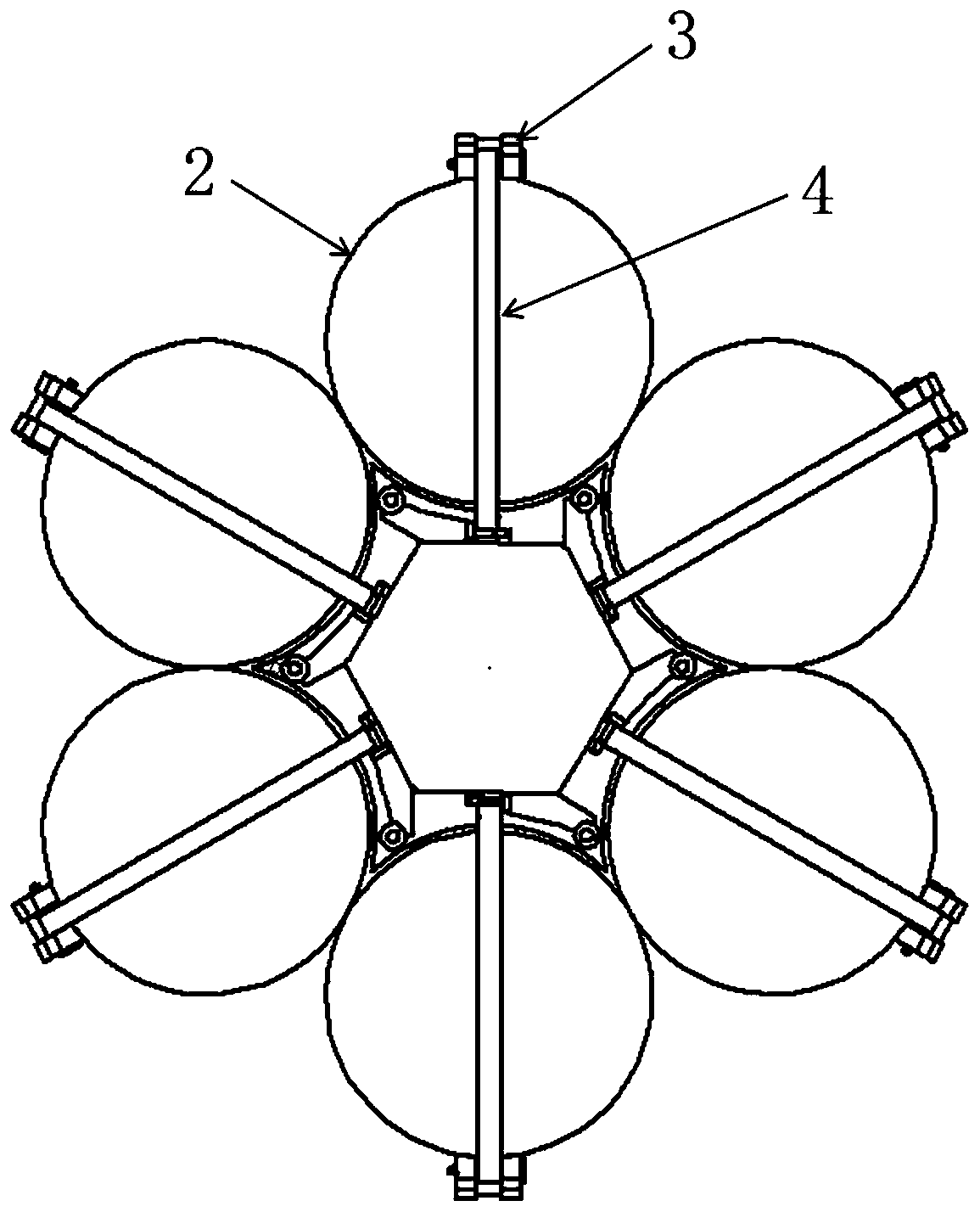

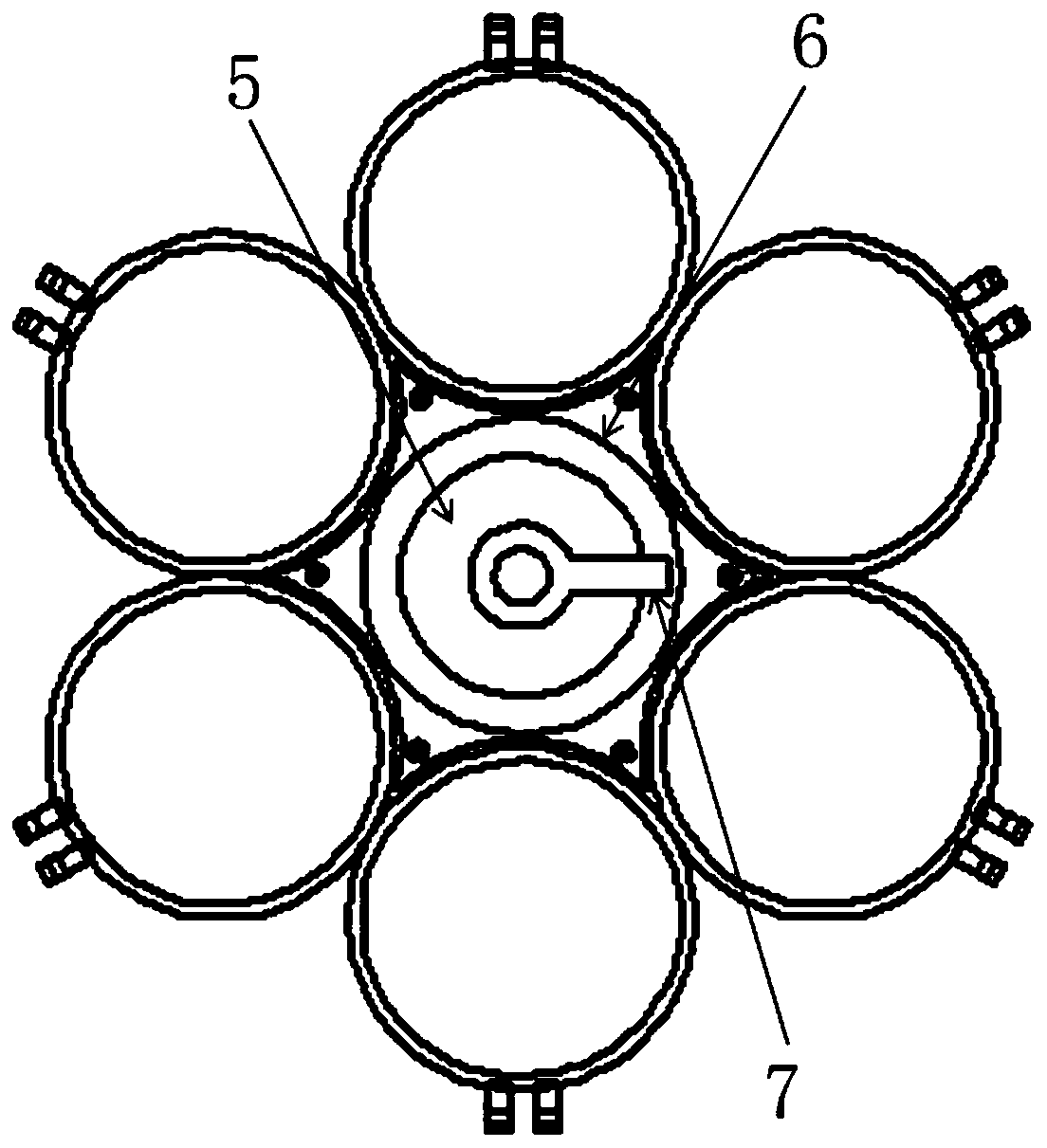

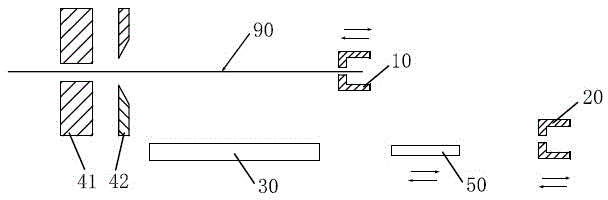

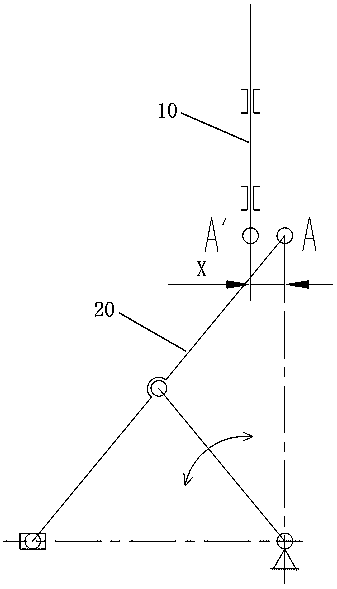

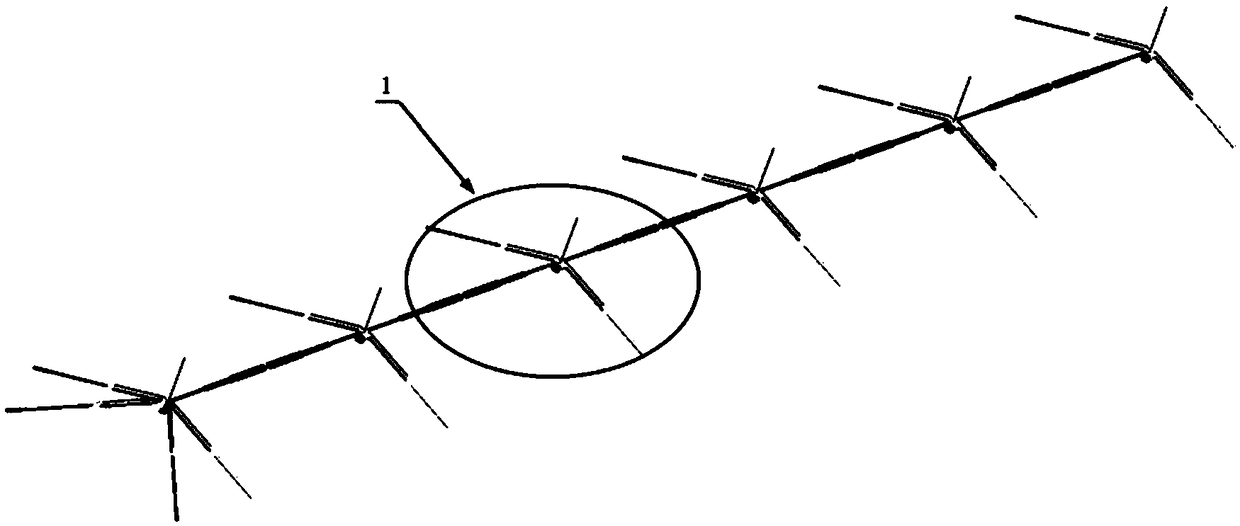

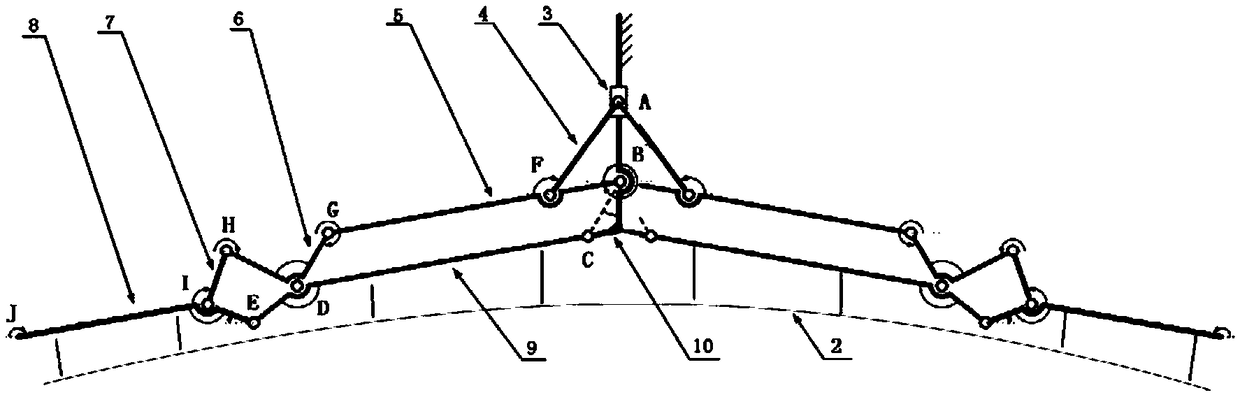

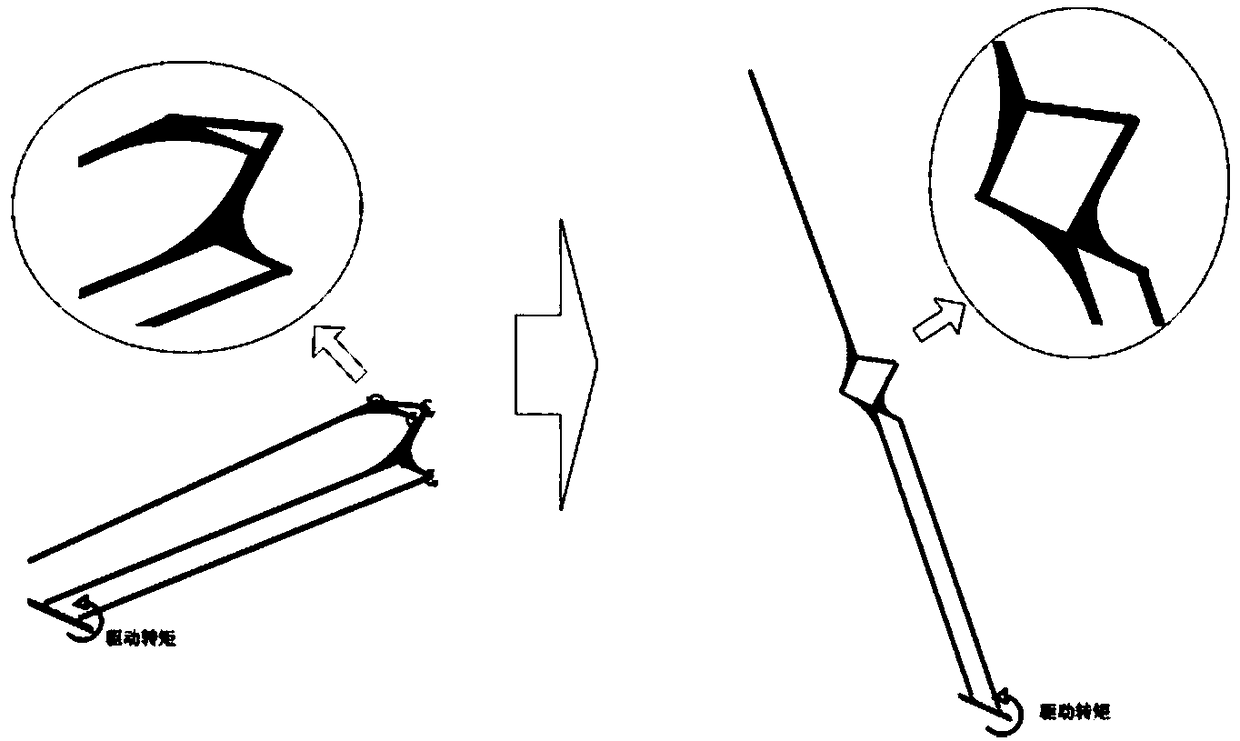

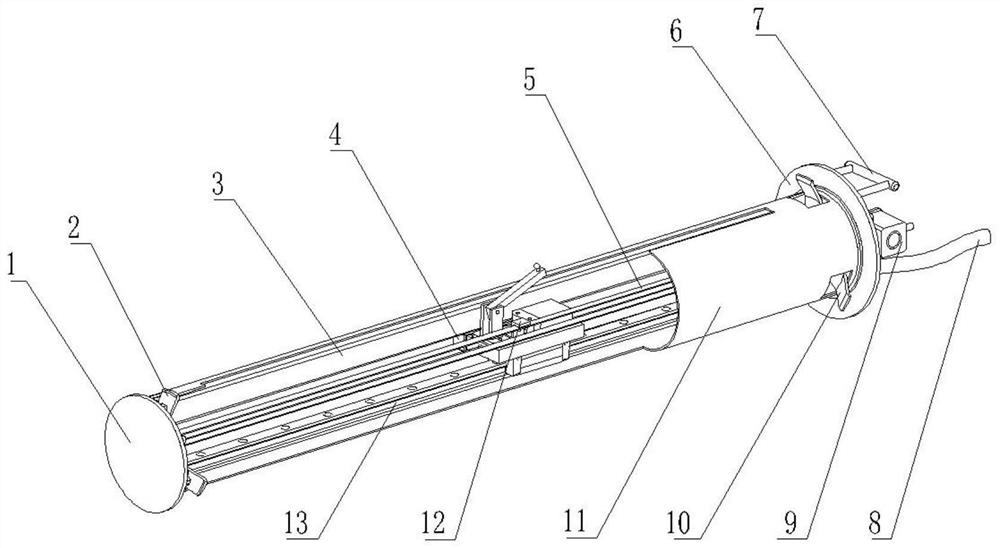

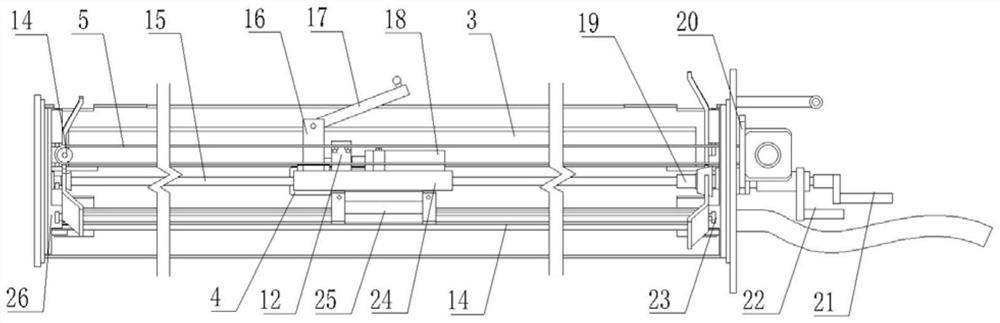

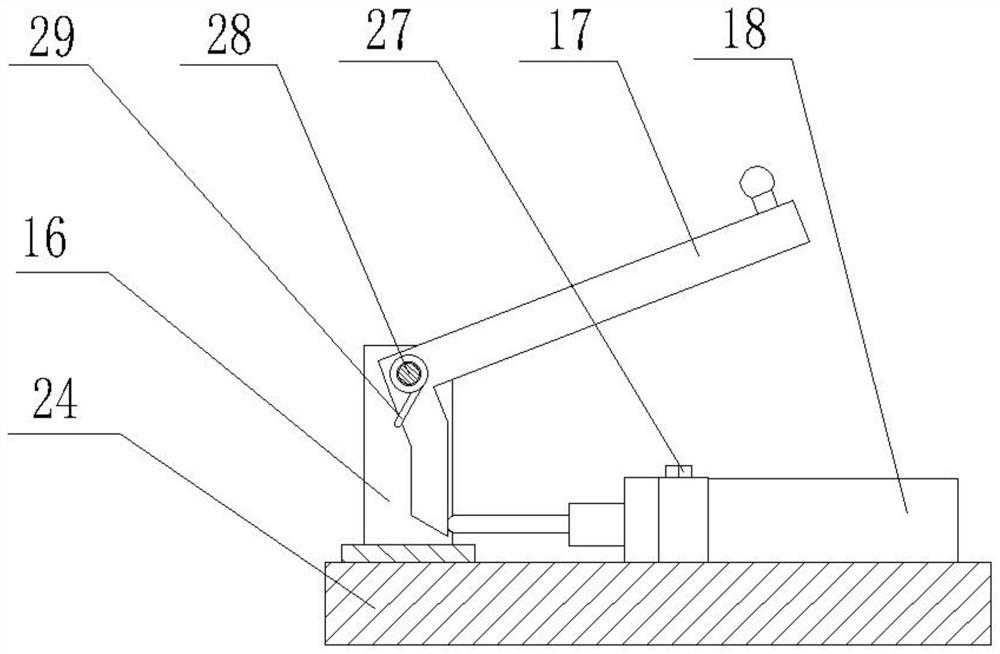

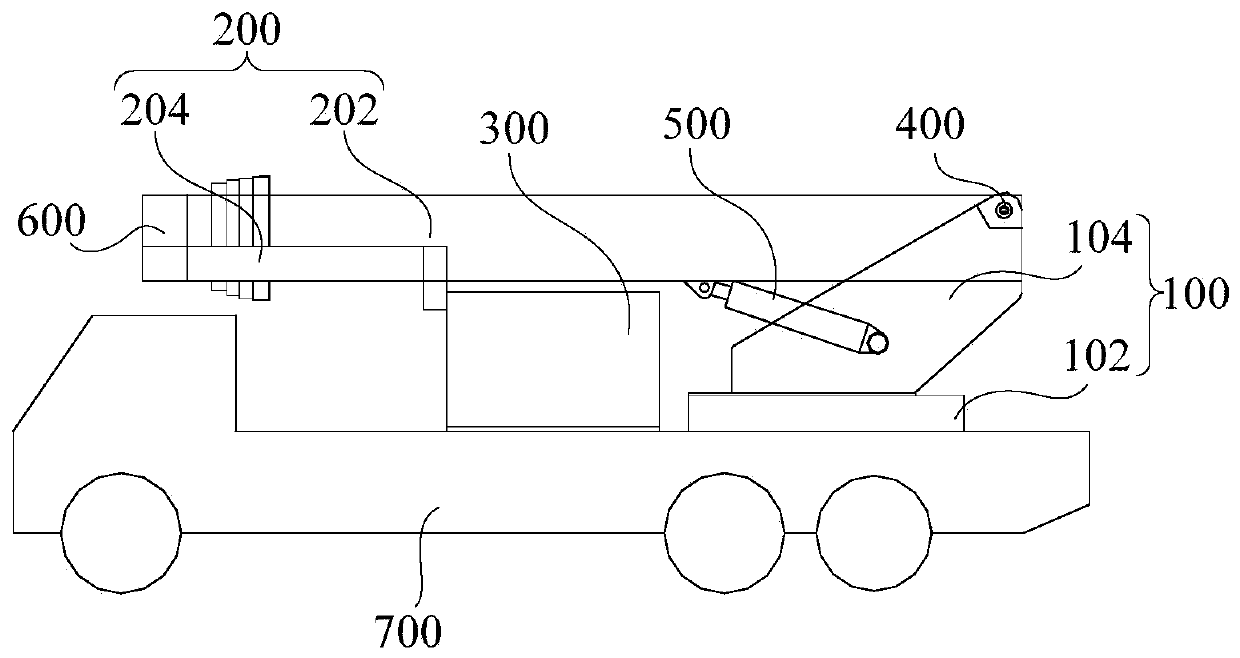

A deployment mechanism of a parabolic cylindrical antenna reflector with high accommodation ratio

A deployment mechanism of a parabolic cylindrical antenna reflector with a high accommodation ratio comprises a plurality of groups of M-shaped antenna reflector deployment mechanisms (1); Each groupof M-shaped antenna reflector deployment mechanism (1) is installed on the support truss; The M-shaped antenna reflector deployment mechanism (1) is of a symmetrical structure and comprises a power source (3), a middle fixed mandrel (10) and a linkage mechanism; A sliding pair is established between the power source (3) and the intermediate fixed mandrel (10), A linkage mechanism is connected withthat central fixed mandrel (10) and the power source (3) through a rotating pair, the linkage mechanism is symmetrical about the central fixed mandrel (10), and under the driving action of the powersource (3), the power source (3) slides along the central fixed mandrel (10), thereby driving the linkage mechanism to expand in a plane. The invention solves the parabolic cylindrical surface application problem that 50m or longer size is difficult to realize in the current space mission, and provides a solution for a space large parabolic cylindrical deployable antenna.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

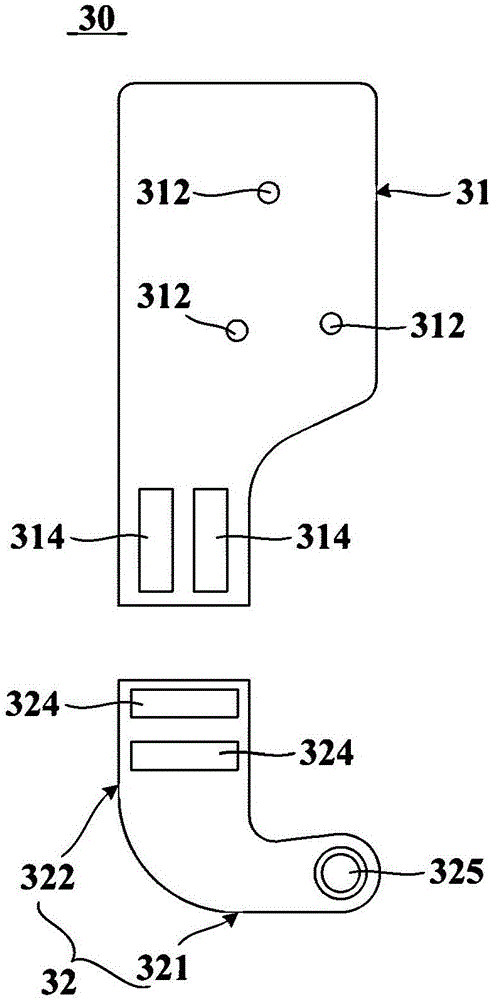

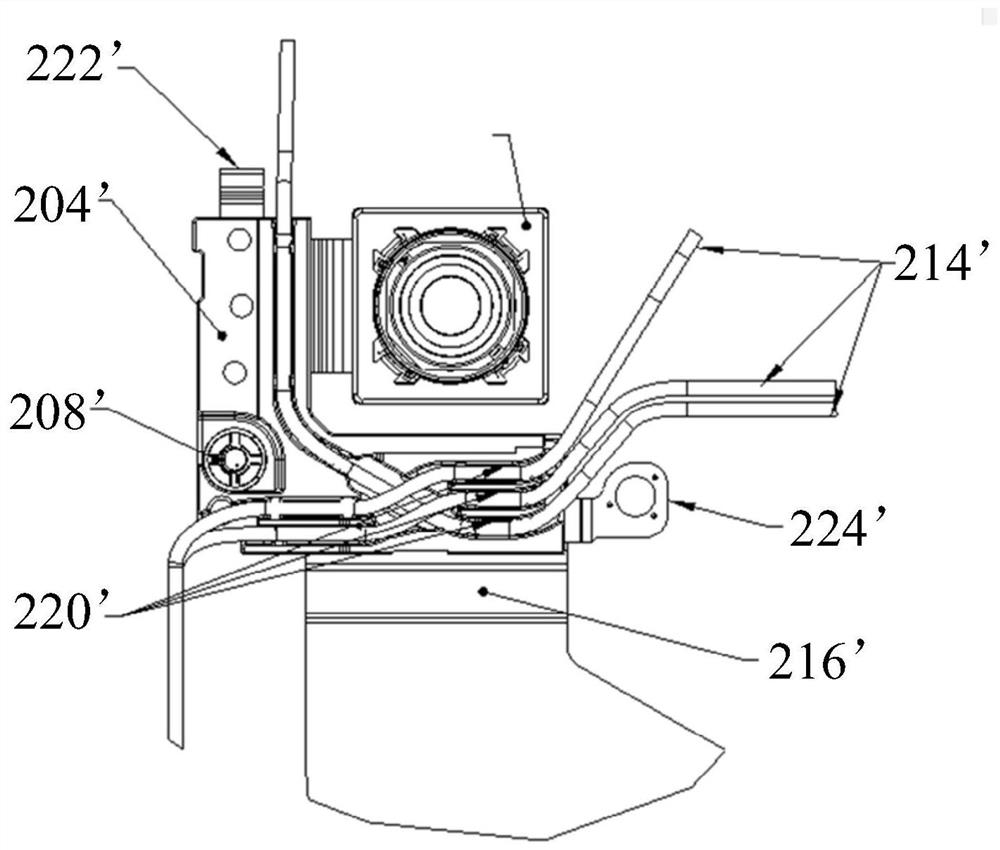

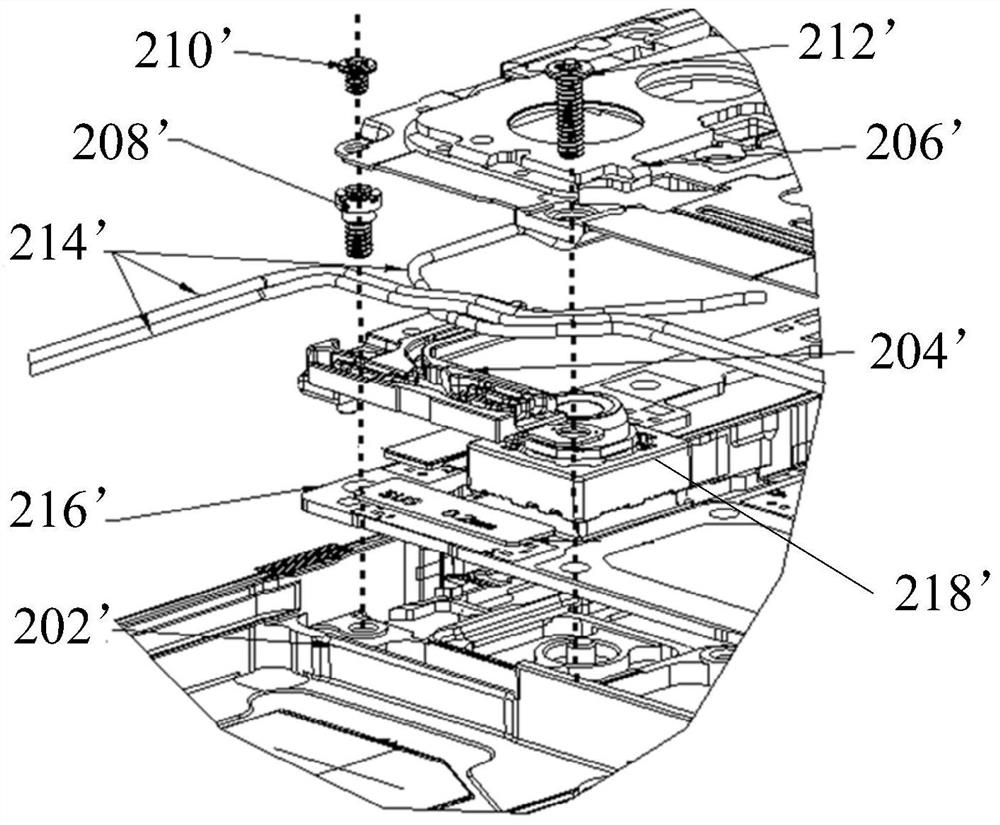

Assembly bracket for structured light 3D module, structured light 3D module and assembly method

InactiveCN108965662AReduce volumeAvoid structural interferenceAdhesive processesTelevision system detailsMiniaturizationEngineering

The invention discloses an assembly bracket for a structured light 3D module. The assembly bracket comprises a first assembly frame for assembling a structured light camera, a second assembly frame for assembling a structured light projector, and a third assembly for assembling an RGB camera, wherein at least one of the first assembly frame, the second assembly frame and the third assembly frame forms an outward side opening structure. The assembly bracket occupies smaller space, is conductive to reducing the size of the structured light 3D module, realizes miniaturization and thinning, and can avoid structural interference of the assembly frames with a device of the structured light 3D module at the side opening structure.

Owner:TRULY OPTO ELECTRONICS

Multi-cone-section deep hole measuring device and using method thereof

ActiveCN111829468AAchieve precise positioningAvoid structural interferenceMeasurement devicesRadial displacementDeep hole

The invention discloses a multi-cone-section deep hole measuring device and a using method thereof. According to the multi-cone-section deep hole measuring device and the using method thereof, a three-jaw expansion mechanism is adopted, a front clamping jaw and a rear clamping jaw can move in the radial direction of a deep hole part through cooperation of a front center adjusting shaft, a rear center adjusting shaft, a large conical block and a small conical block, so that the front clamping jaw and the rear clamping jaw can make contact with the inner wall of a deep and long hole, and therefore accurate positioning of the measuring device in the deep and long hole is achieved; an explosive chamber aperture measuring mechanism with a horizontally-arranged detection gauge is adopted; the bottom of a swing type measuring head is contacted with the contact of the gauge, and the radial displacement change in the measuring process can be transmitted to the contact of the horizontally placedprobe gauge in a certain proportional relation, so that a precise measuring element with a larger structural size can be used in a narrow deep hole space, and the structural interference is avoided;the design that a measuring unit is independent of the whole measuring device is adopted, and the precision guarantee of axial movement of the measuring unit is achieved.

Owner:DALIAN UNIV OF TECH

Boom frame system and operation vehicle

InactiveCN111591911ASimple structureReduce manufacturing difficultyFire rescueLifting devicesMarine engineeringGravity center

The invention provides a boom frame system and an operation vehicle. The boom frame system comprises a rotary table and boom frames, wherein the boom frames comprise a first boom frame assembly and asecond boom frame assembly, the first boom frame assembly is hinged to the rotary table, and the second boom frame assembly is located on one side of the first boom frame assembly; and a hinge axis ofthe first boom frame assembly and the rotary table form a preset included angle with the horizontal plane, and the hinge axis is inclined upwards from one side of the first boom frame assembly to oneside of the second boom frame assembly. According to the system, only an installation mode of the first boom frame assembly relative to the rotary table is changed, so that the problem of unbalance loading, torque or side bending moment caused by gravity center offset of the boom frame can be solved, great structural improvement is not needed for the boom frame, and excessive other structures need not be added.

Owner:SANY AUTOMOBILE MFG CO LTD

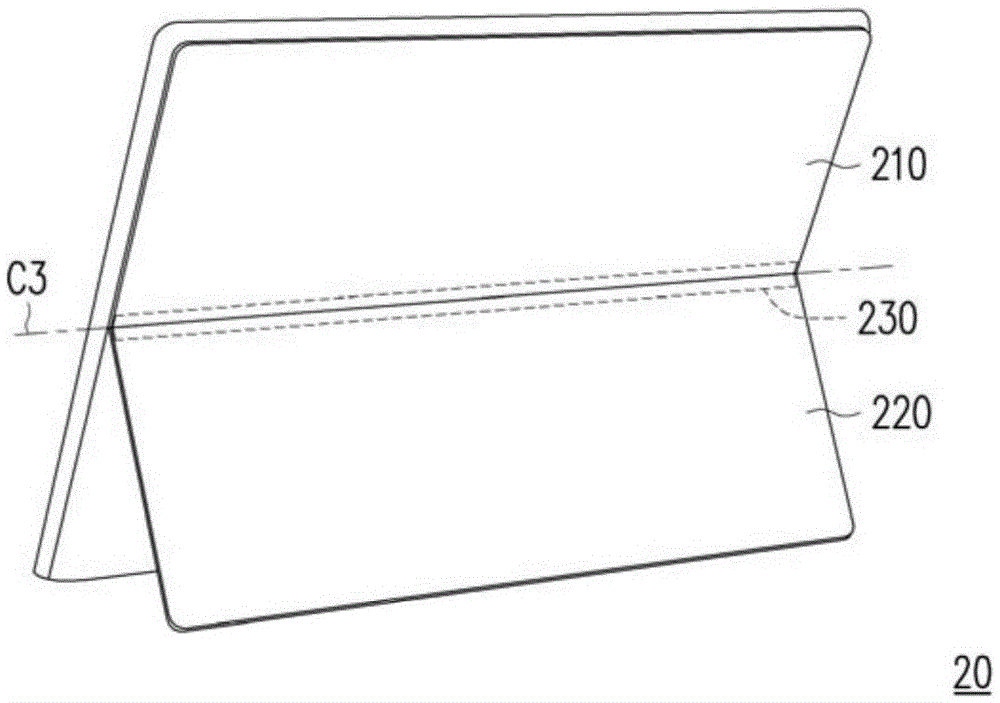

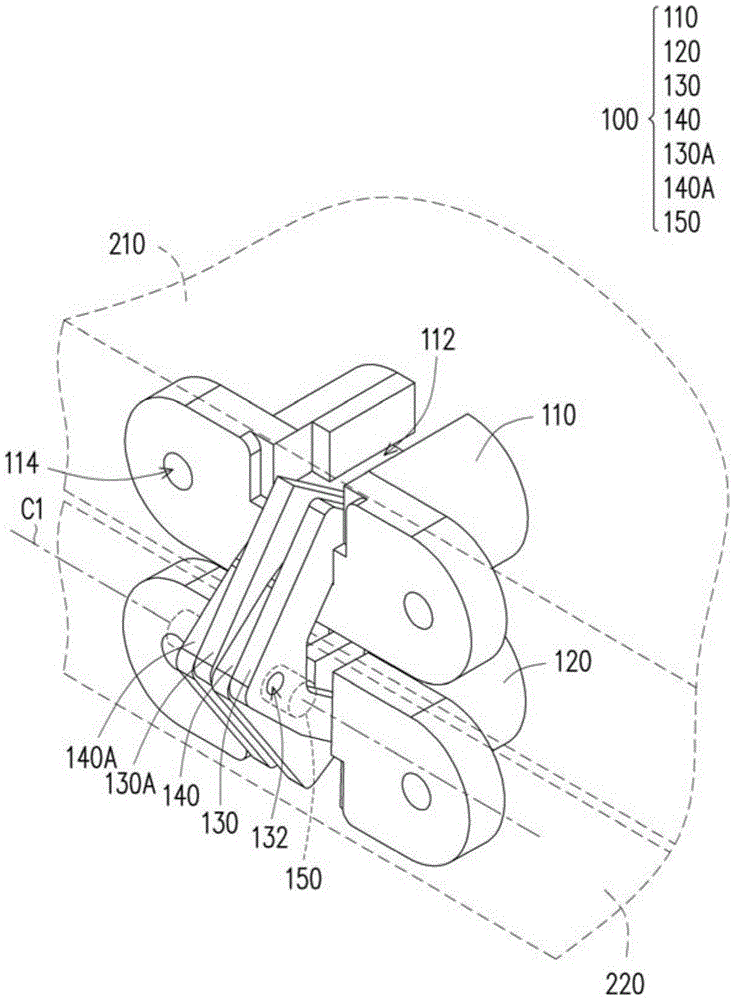

Pivoting mechanism

InactiveCN106802691AImprove aestheticsPivot action is smoothDetails for portable computersPivotal connectionsEngineeringMechanical engineering

The invention provides a pivoting mechanism. The pivoting mechanism includes a first support, a second support, at least one first crank, and at least one second crank; the first support is connected to a first body of an electronic device and has a first slide groove; the second support is connected to a second body of the electronic device and has a second slide groove; the first crank has a first end, a second end and a first pivoting portion, wherein the first end is slidingly and rotatably coupled to the first slide groove, and the second end is pivoted to the second support; the second crank has a third end, a fourth end and a second pivoting portion, wherein the third end is slidingly and rotatably coupled to the second slide groove, the fourth end is pivoted to the first support, and the second pivoting portion is pivoted to the first pivoting portion to form a rotation center; the first crank and the second crank rotates oppositely with respect to the rotation center; and the first end and the second end slide in the first slide groove and the second slide groove respectively. The pivoting mechanism is beautiful in appearance, can pivot at a large angle, and can improve the operation convenience of the electronic device.

Owner:ACER INC

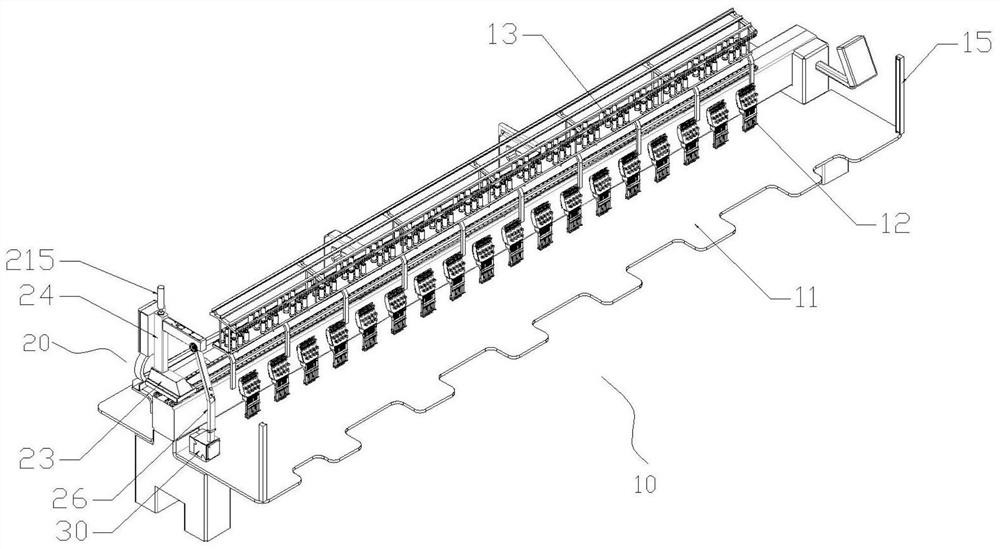

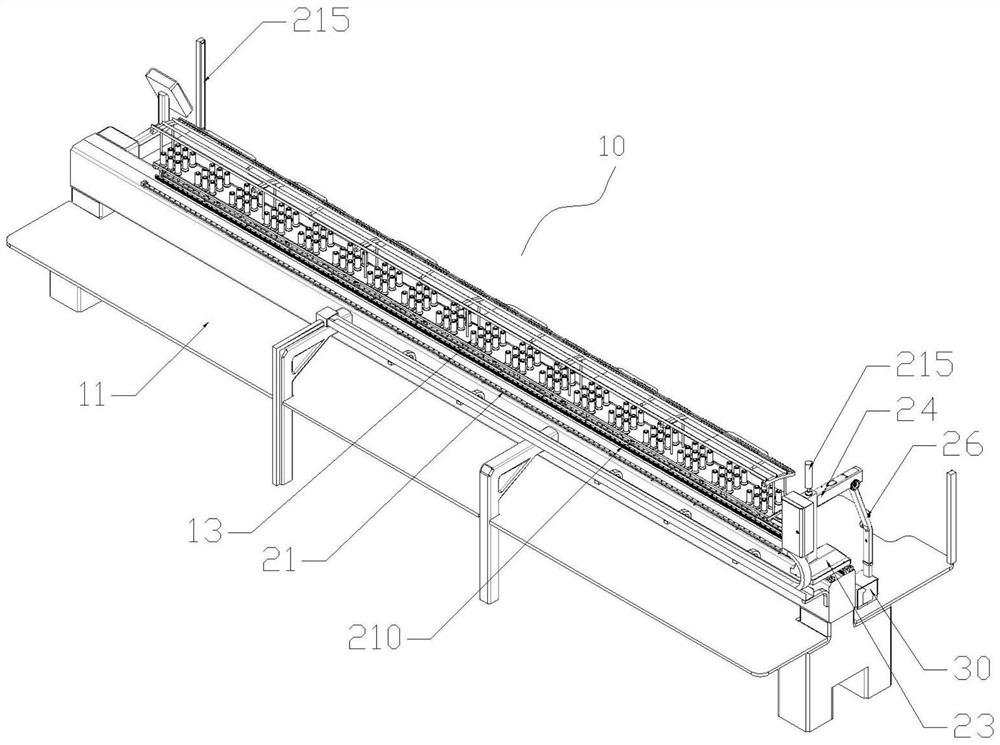

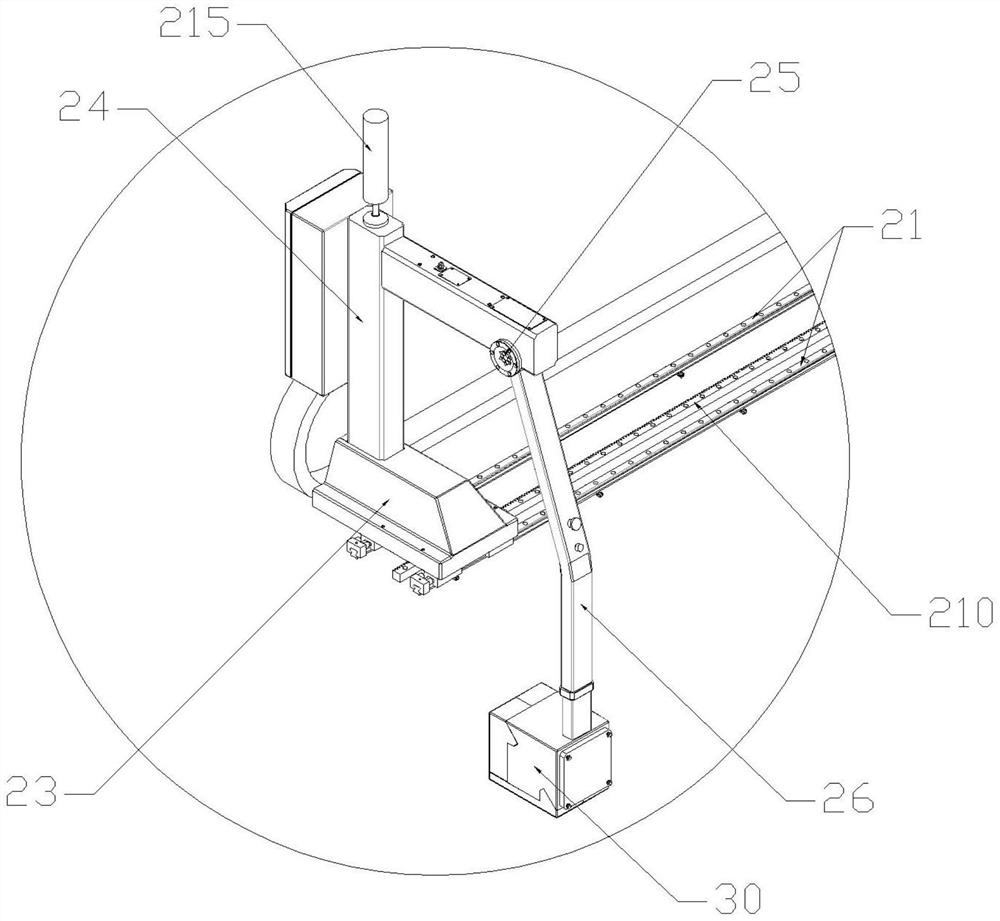

Threading device and automatic threading equipment

PendingCN113308814AImprove efficiencyReduce labor costsEmbroidering machines apparatusEngineeringMechanical engineering

The invention discloses a threading device and automatic threading equipment. The threading device and the automatic threading equipment are installed on an embroidery machine; the embroidery machine comprises a rack, a certain number of machine heads and thread shafts arranged on the rack, and sewing threads between the machine heads and the thread shafts; a translation and swing mechanism is installed on the rack; the tail end of the translation and swing mechanism is connected with an installation and protection assembly; the installation and protection assembly comprises a shell and an installation bottom plate; the threading device is installed on the installation and protection assembly; the translation and swing mechanism is used for driving the threading device to move to the position of the machine head where threading is to be conducted and to be close to the machine head; and the threading device comprises a thread pulling mechanism, a thread leading and feeding mechanism, a calibration robot mechanism and a thread hooking mechanism on the calibration robot mechanism. The threading equipment moves to the machine head where threads are broken for threading after the threads of the embroidery machine and other textile equipment are broken, automatic threading is achieved, the efficiency of the textile equipment is improved, the labor cost is reduced, the mechanism can be directly and additionally installed on the existing embroidery machine, the interference with an existing structure is avoided, and the modification cost is low.

Owner:杭州衡论科技有限公司

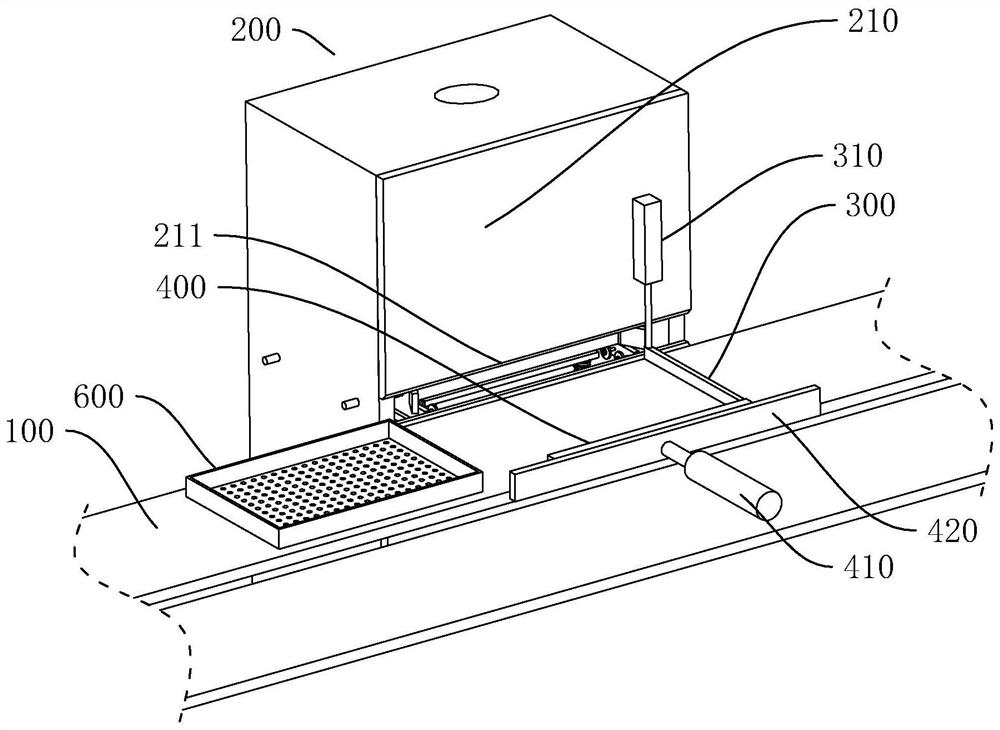

Anti-spilling flow rate standard device and calibration method applicable to large flow rate liquid entrance

PendingCN106568491AImprove flow patternAvoid spill lossTesting/calibration apparatusEngineeringDistributor

The invention relates to an anti-spilling flow rate standard device and a calibration method applicable to large flow rate liquid entrance. The flow rate standard device is used mainly aiming at the large flow rate fluid entrance; and the large flow rate generally exceeds 15 kg / s. The invention especially relates to anti-spilling design of a water distributor of the standard device applicable to calibration and metering a liquid flow rate, wherein the anti-spilling water distributor is connected to an open type diverter and a container; through two working states of "suspension" and "sedimentation", different demands of the flow rate standard device under two working states including flow rate calibration and weighing appliance checking calibration can be satisfied; the problem about liquid spilling of a traditional water distributor is solved; and reliability and accuracy of flow rate calibration work are ensured.

Owner:BEIJING AEROSPACE PROPULSION INST

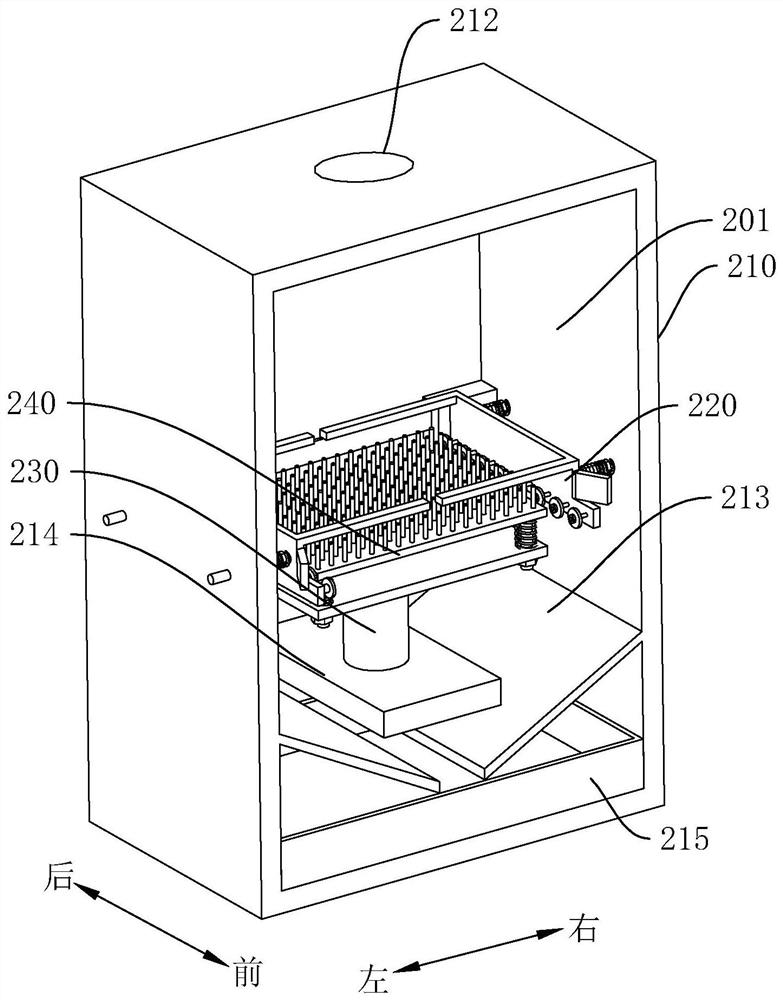

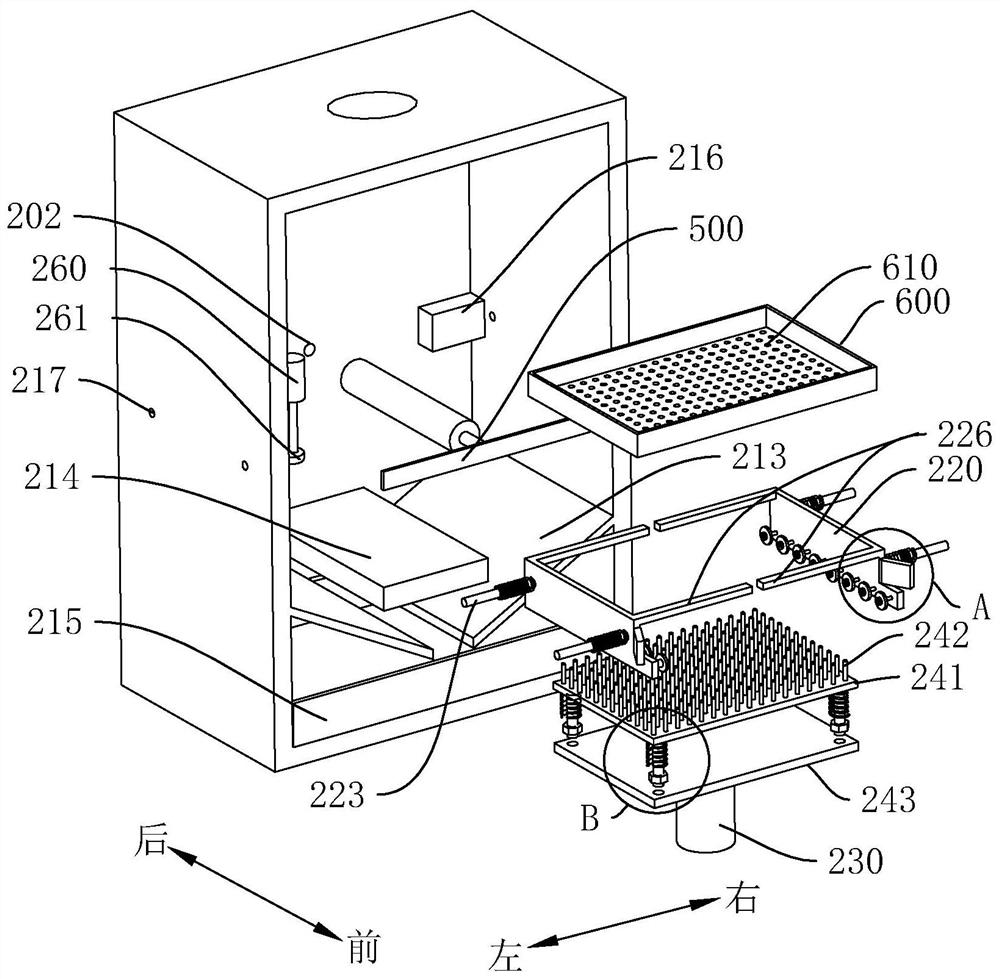

Automatic shrimp shell drying equipment

InactiveCN113532085AAvoid structural interferenceRealize the whole process of automatic processingDrying gas arrangementsDrying chambers/containersFisheryStructural engineering

The invention discloses automatic shrimp shell drying equipment. The equipment comprises a conveying belt used for bearing and conveying trays, a drying box, a stop lever, a pushing plate and a pushing-out plate; the drying box is arranged on one side of the conveying belt, a drying cavity is formed in the drying box, a bearing plate used for bearing the trays is arranged in the drying cavity, an inlet allowing the trays to enter is formed in the front side of the drying cavity, and a drying structure is arranged at the top of the drying cavity and used for drying shrimp shells in the trays; the stop lever is located above the conveying belt and is connected with a lifting driving mechanism capable of driving the stop lever to rise and fall; the pushing plate is connected with a pushing-in driving mechanism for driving the pushing plate to move towards the inlet; and the pushing-out plate is connected with a pushing-out driving mechanism which drives the pushing-out plate to move towards the inlet so as to push the trays staying on the bearing plate back to the conveying belt. Full-process automatic processing is achieved, manual auxiliary operation is not needed, the efficiency is improved, and the labor cost is reduced.

Owner:湖南文和友乔口小龙虾养殖有限公司

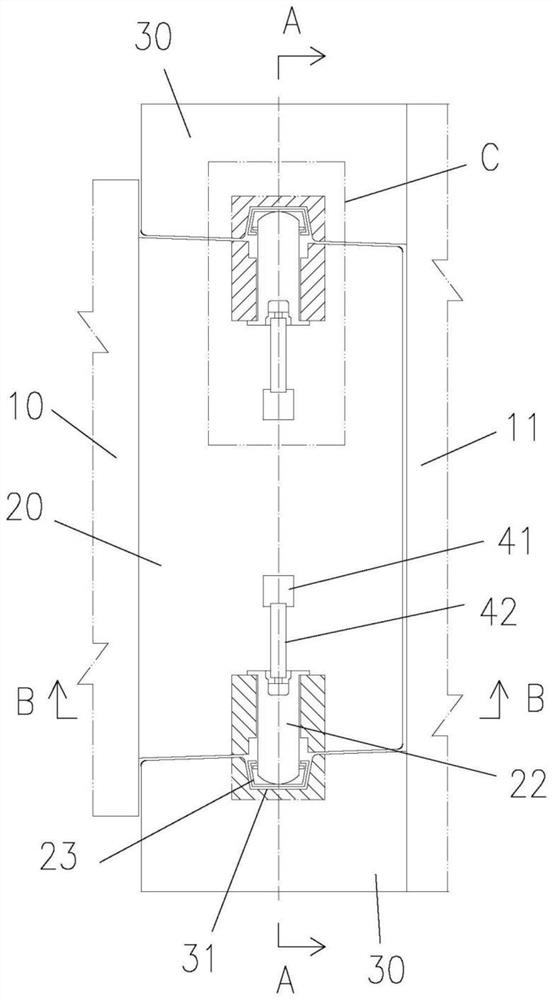

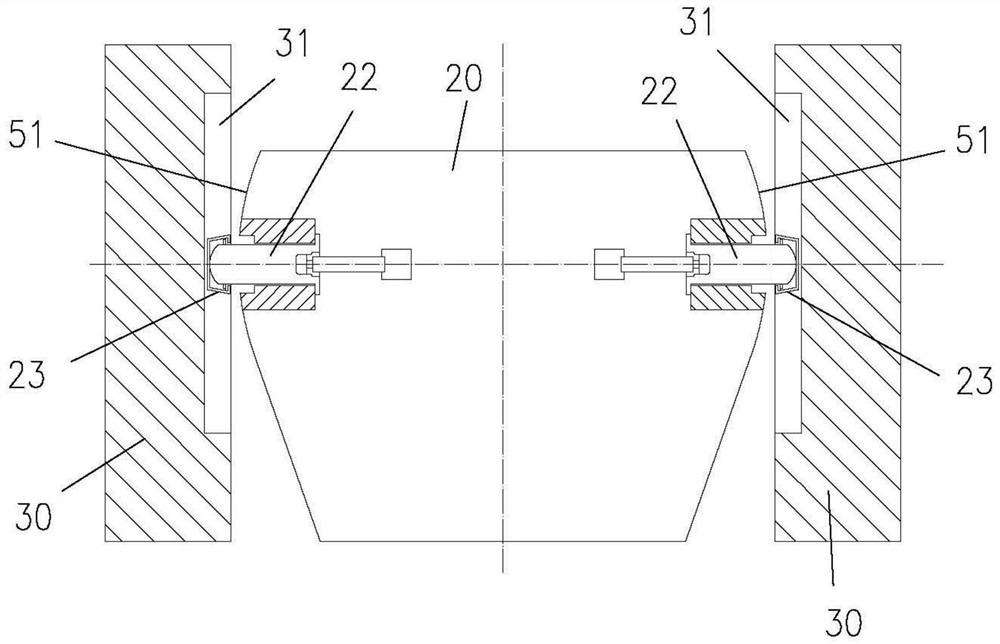

Three-degree-of-freedom sliding groove type connector for connecting transfer barge and semi-submersible platform

PendingCN112793710APrecise dockingQuick Shuttle TransferVessel partsBarges/lightersMarine engineeringButt joint

The invention discloses a three-degree-of-freedom sliding groove type connector for connecting a transfer barge and a semi-submersible platform. The connector comprises a boss appendage arranged on the transfer barge and two channel appendages arranged on the semi-submersible platform, wherein the number of the channel appendages is two, and the boss appendage is inserted between the two channel appendages; vertically distributed sliding grooves are formed in the two channel appendages; the cross section of the sliding groove is trapezoidal; the two side faces of the boss appendage are each provided with a pin shaft hole, and a pin shaft is arranged in each pin shaft hole in a penetrating mode; a telescopic mechanism is arranged at the tail part of the pin shaft; the two pin shafts are respectively inserted into the sliding grooves; the central axes of the two pin shafts coincide with each other; and the two side faces of the boss appendage and the front end face, close to the semi-submersible platform, of the boss appendage are each provided with an arc-shaped face. Accurate butt joint, rapid connection and tight connection can be achieved, and the vertical degree of freedom, the rolling degree of freedom and the pitching degree of freedom between connecting interfaces can be released.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

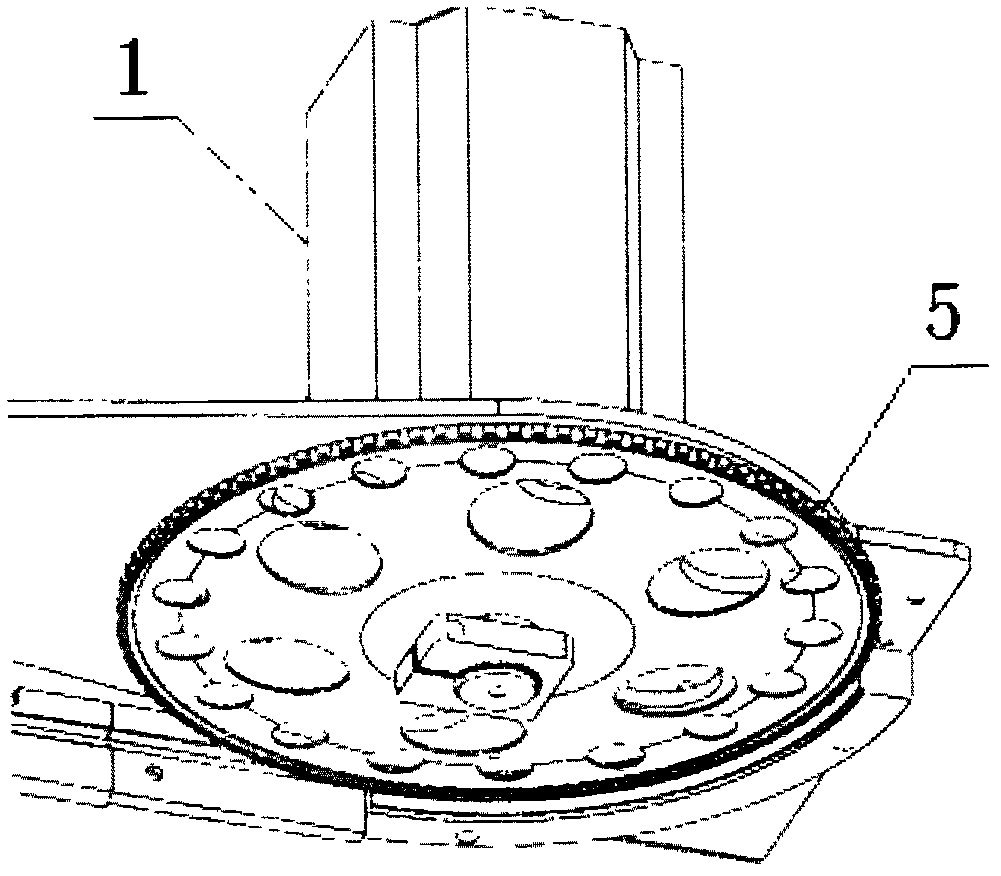

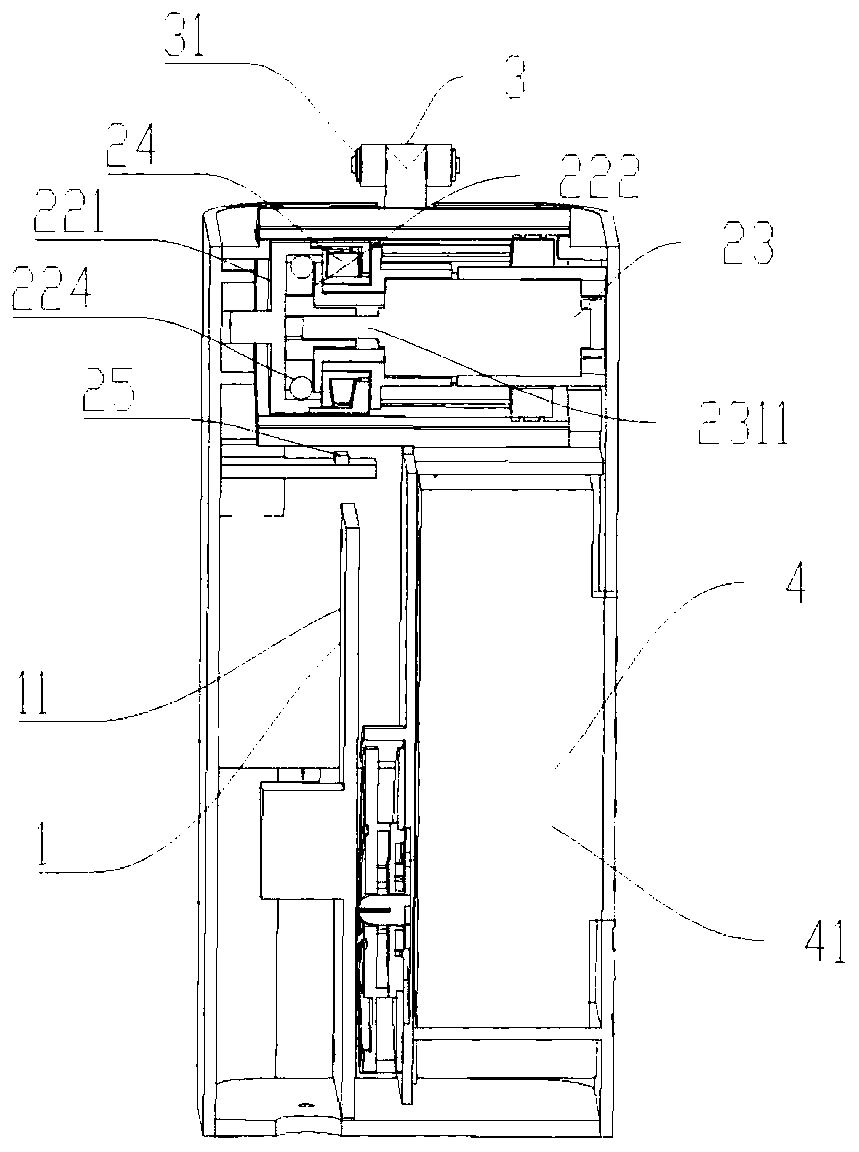

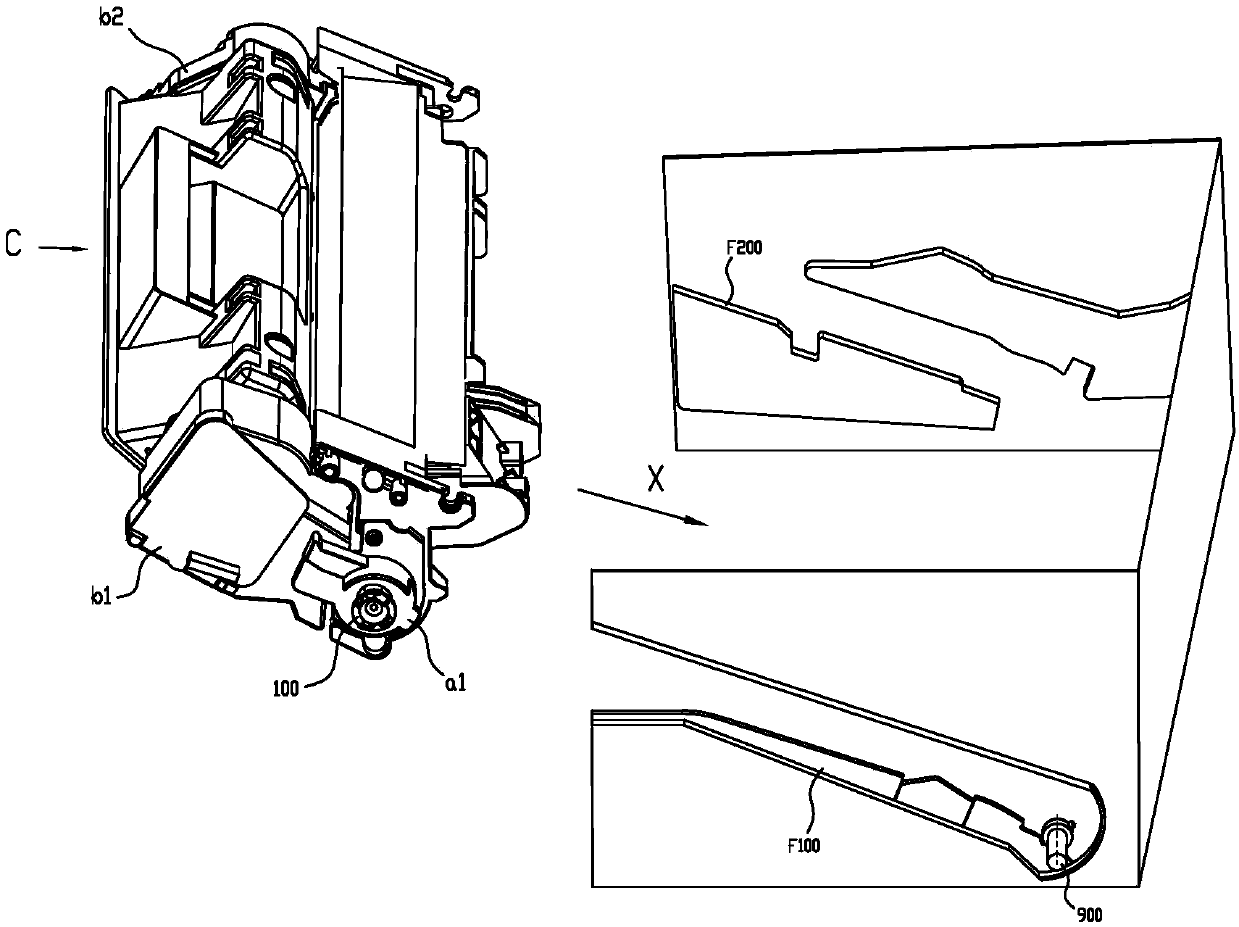

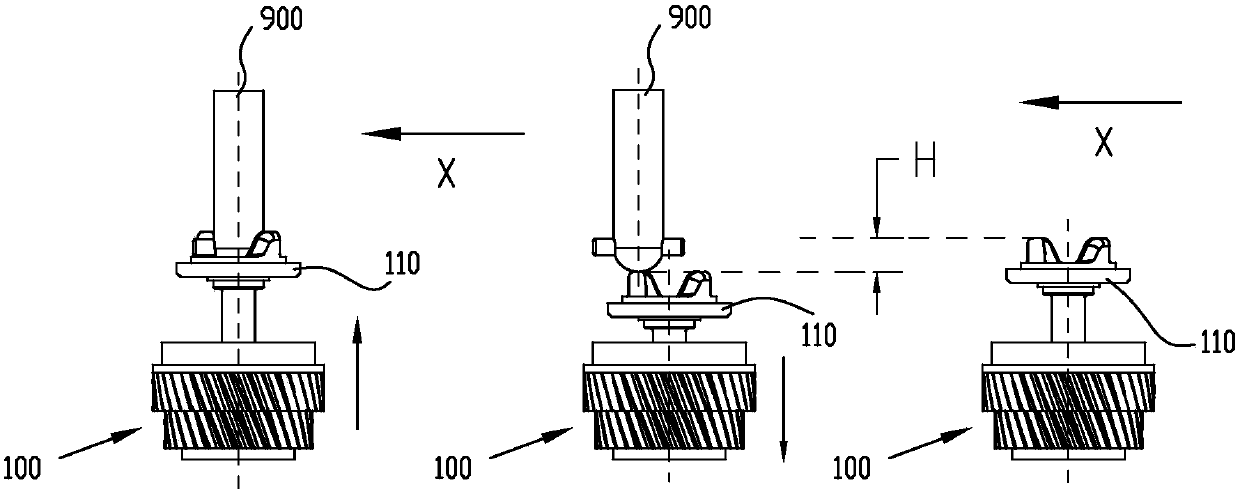

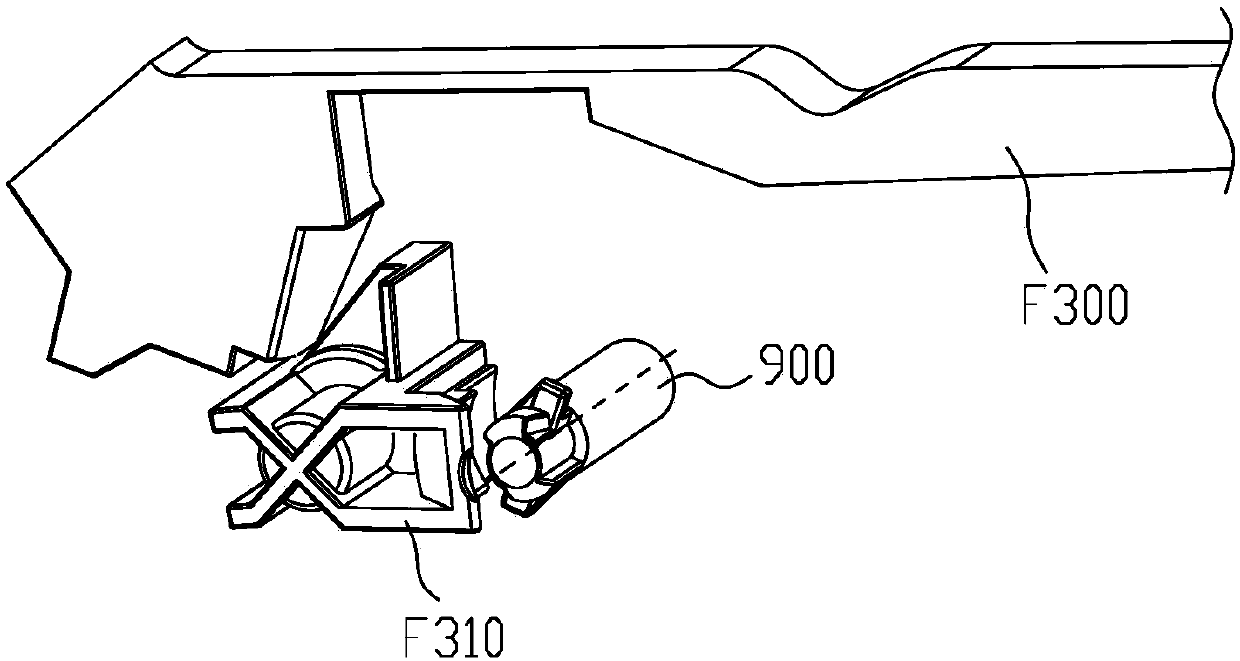

Processing box and driving component

PendingCN107621768AApplication cannot be restrictedAvoid structural interferenceElectrography/magnetographyDrive shaftEngineering

The application relates to the technical field of the electrostatic printing, and in particular relates to a processing box and a driving component. The processing box or the driving component is detachably arranged in an electronic imaging device, and comprises a rotary power receiving part and a hub, wherein the rotary power receiving part receives driving force from a driving head of the electronic imaging device and transmits the driving force to the hub, and comprises a power driving part; the power receiving part has a pre-engaging position before receiving the rotary driving force fromthe driving head and a force transmission position when receiving the rotary driving force from the driving head in the electronic imaging device; when the power receiving part is in the pre-engagingposition, the power receiving part is located below the driving head and a rotating shaft of the power receiving part is parallel to and deviated from the rotating shaft of the driving head by observing from the axial direction of the power receiving part, thereby avoiding the structure interference produced between the power receiving part and the driving shaft when performing the contact engaging with the driving head; a technical problem that the rotary power driving part in the driving component cannot engage with the driving head in the electronic imaging device in the prior art is solved.

Owner:NINESTAR CORP

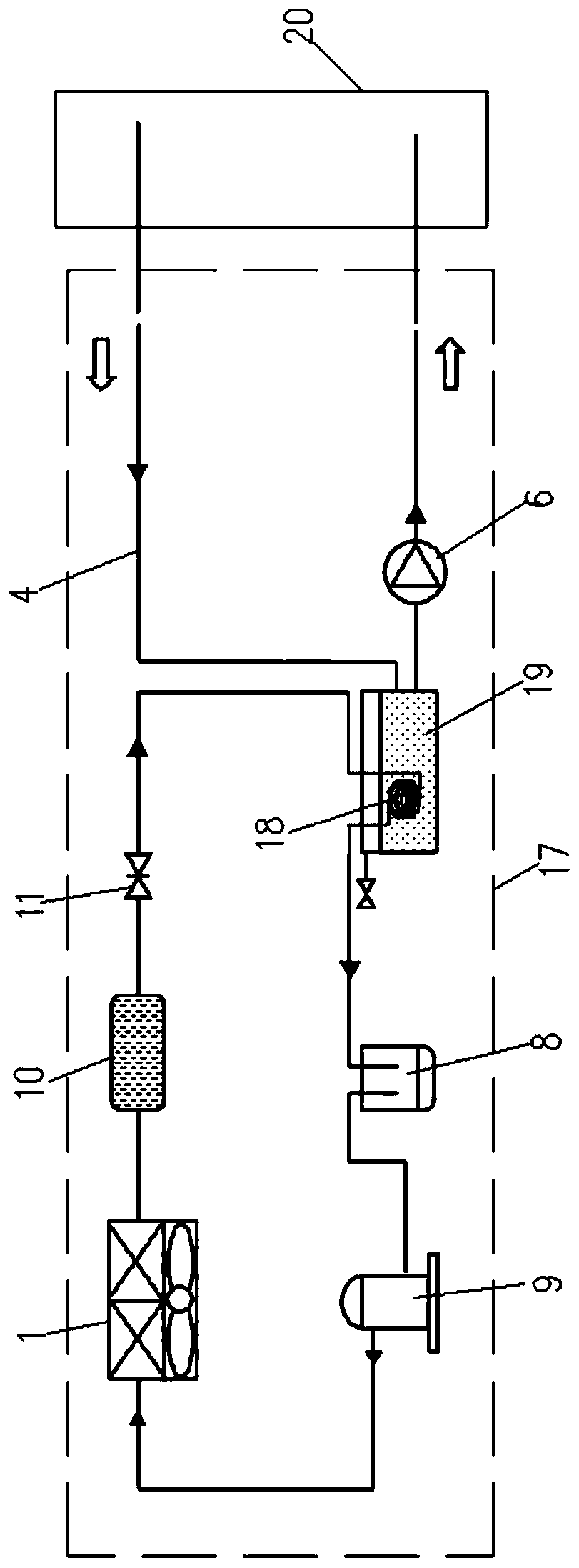

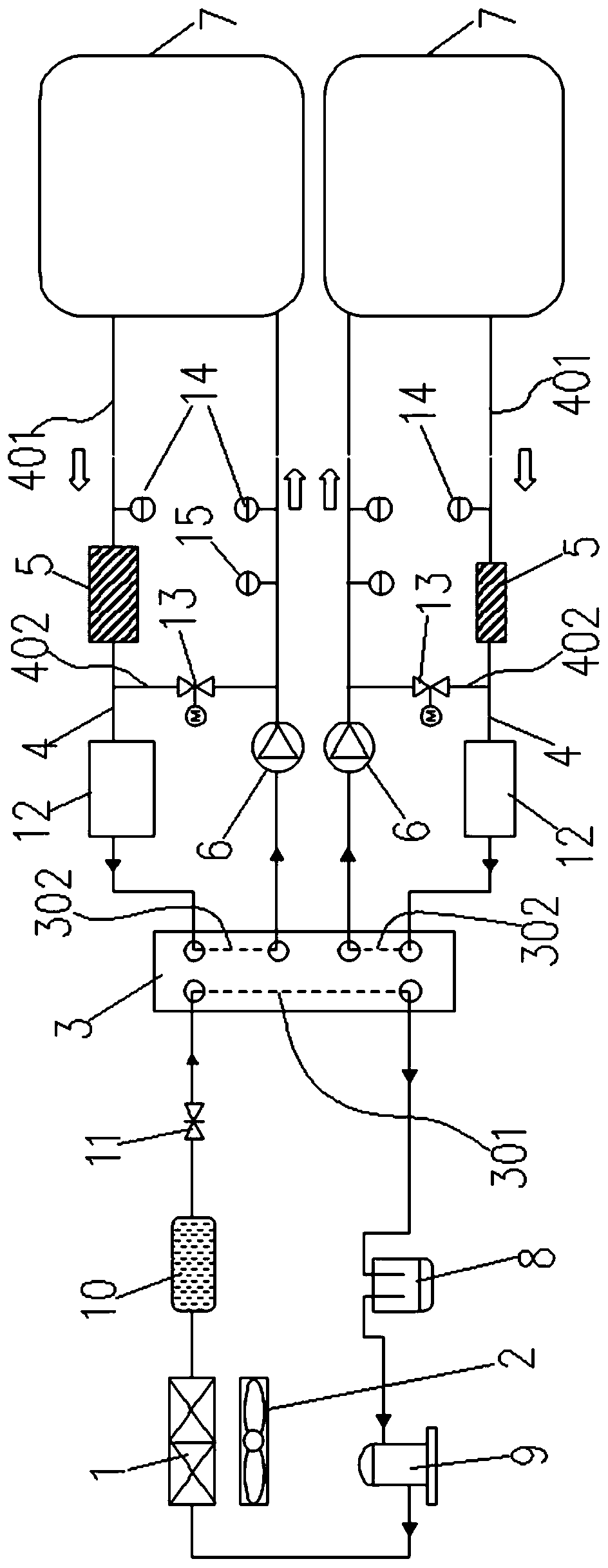

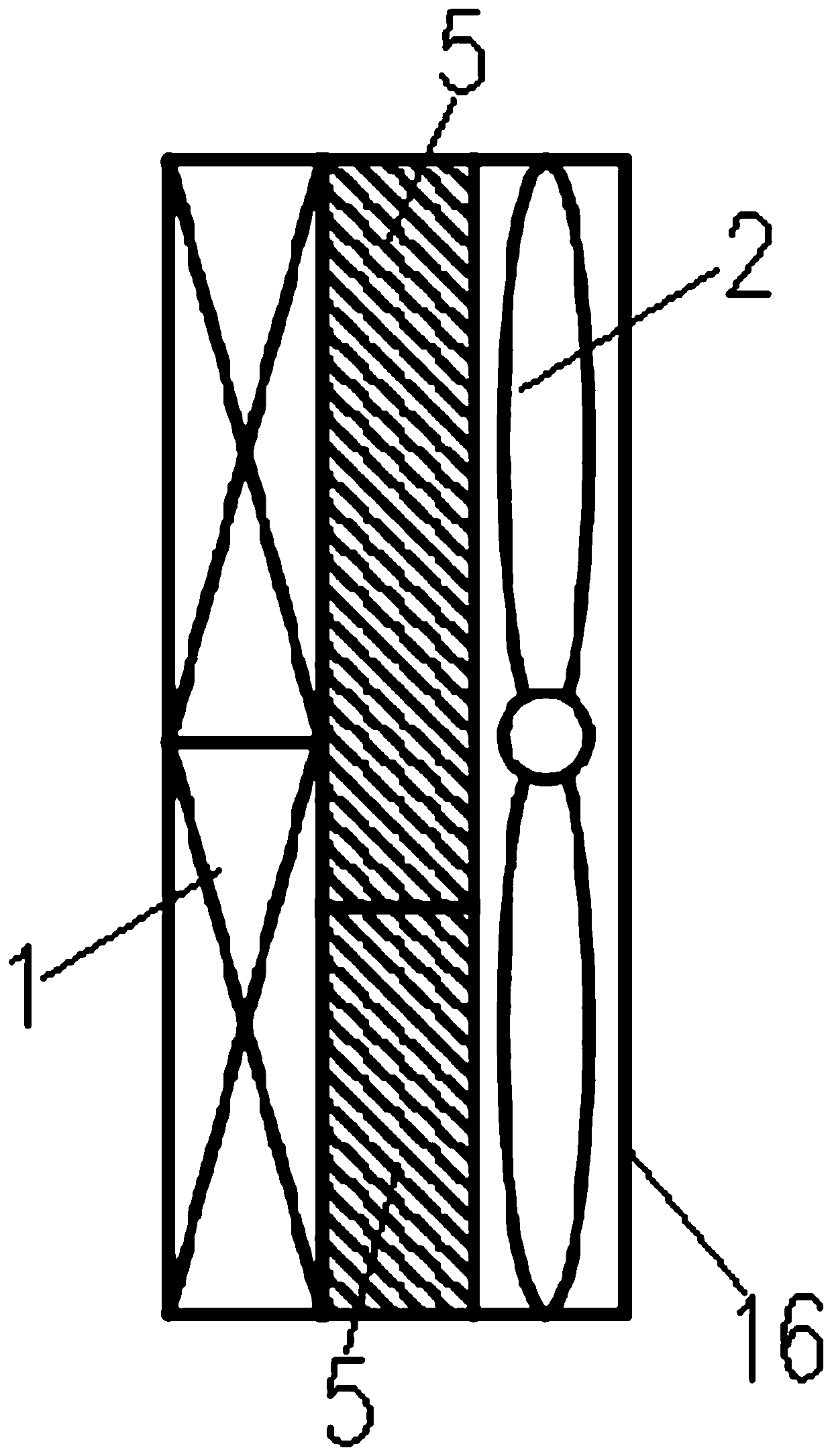

Large-power charging and cooling device with high energy efficiency ratio and high cooling efficiency

ActiveCN109703403AImprove cooling energy efficiency ratioReduce energy consumptionCharging stationsCompression machines with non-reversible cycleBusiness efficiencyHigh energy

The invention belongs to the technical field of cooling, and specifically relates to a large-power charging and cooling device with high energy efficiency ratio and high cooling efficiency. The large-power charging and cooling device with high energy efficiency ratio and high cooling efficiency includes a steam compression-type refrigerating system and two cooling circuits, wherein a fan is arranged at one side of a condenser of the steam compression-type refrigerating system; an evaporator of the steam compression-type refrigerating system is a three-medium plate type heat exchanger; one cooling stroke and two heating strokes are arranged in the three-medium plate type heat exchanger; the cooling stroke is arranged in the cooling circuits of the steam compression-type refrigerating system; each heating stroke is correspondingly arranged in each cooling circuit one to one; each cooling circuit is provided with a finned tube radiator and a pump body; and each finned tube radiator is clamped between the fan and the condenser. The large-power charging and cooling device with high energy efficiency ratio and high cooling efficiency has the advantages that: cooling and cooling, each finned tube radiator and the condenser are cooled step by step by the air cooling technology while performing compression cooling, thus improving the cooling energy efficiency ratio, reducing the energyconsumption, improving the cooling rate of each liquid cooling terminal, being high in the cooling efficiency, and having no start-up preparation time.

Owner:JIANGSU WANBANG DEHE NEW ENERGY TECH CO LTD

Rotatable door structure and electronic device casing therewith

ActiveUS20210247801A1Avoid structural interferenceDoor/window applicationsDigital processing power distributionRotational axisClassical mechanics

A rotatable door structure includes a fixed casing, a door cover, and a hinge. The fixed casing has an opening. The door cover is pivotally connected to the fixed casing through the hinge. The hinge includes a shaft and a connection part. The shaft has a cam surface. The connection part has another cam surface and is rotatably connected to the shaft relative to a rotation axis. When the door cover rotates relative to the fixed casing through the hinge so as to expose the opening, the two cam surfaces abut against each other to move the door cover away relative to the fixed casing along the rotation axis. An electronic device casing includes the above rotatable door structure. Therein, the fixed casing includes an accommodating recess, which forms the opening and has at least one peripheral interface window.

Owner:WISTRON CORP

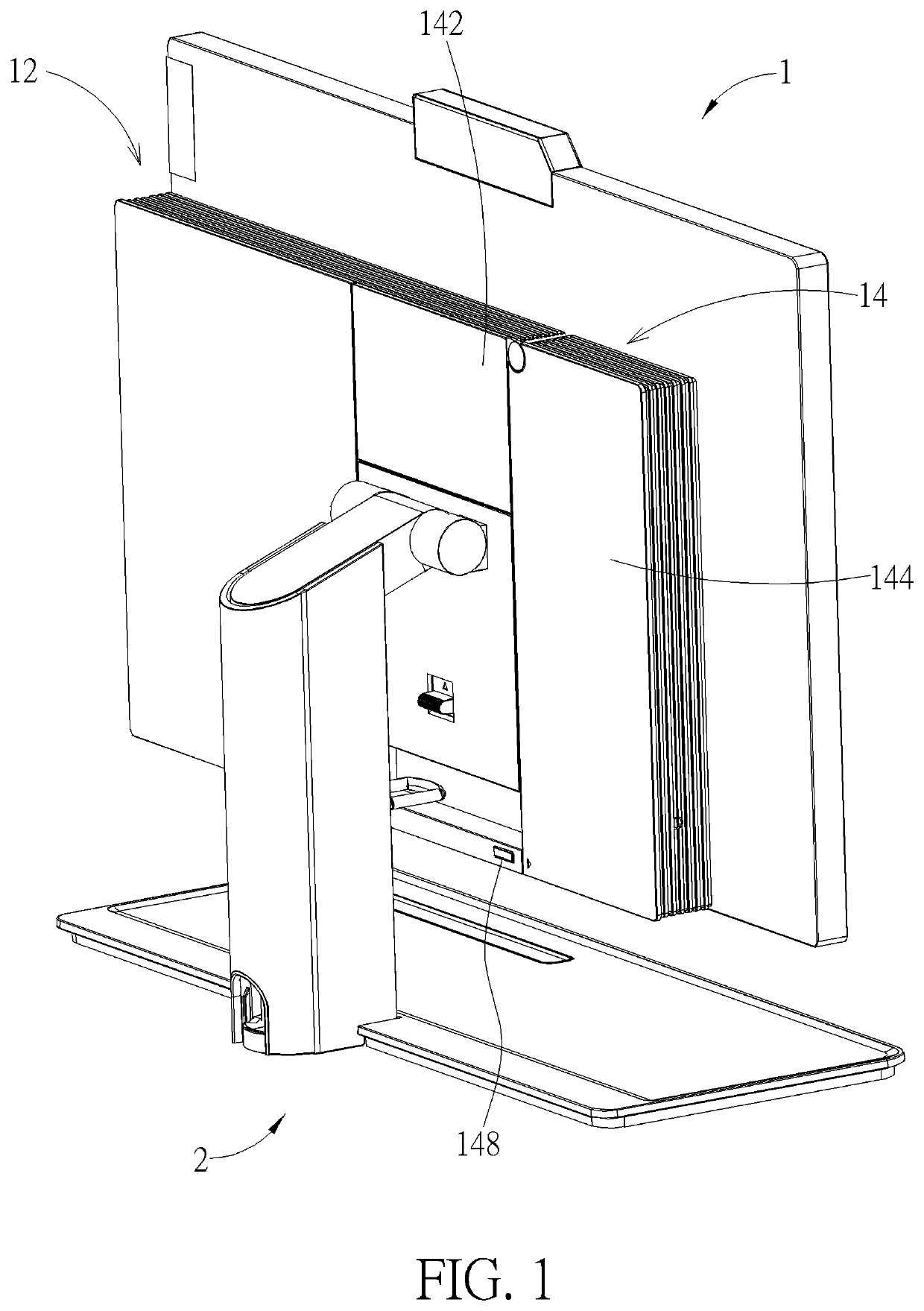

Support assembly and electronic equipment

ActiveCN112653818ATo achieve the purpose of preloadingEasy to installTelevision system detailsColor television detailsEngineeringMechanical engineering

The invention discloses a support assembly and electronic equipment. The support assembly comprises a bottom plate, a first support, a second support, a first electrical appliance element, a first connecting piece, and a second connecting piece; the first connecting piece penetrates through the first support, and the bottom plate is fixedly connected with the first support through the first connecting piece; the second connecting piece penetrates through the second support, and the first support is fixedly connected with the second support through the second connecting piece; the connecting position of the first connecting piece on the first support is a first position, the connecting position of the second connecting piece on the second support is a second position, and the first position is different from the second position; the first electric appliance element is arranged at a third position of the second support, and the third position is located on the extension line of the first connecting piece. According to the support assembly, the first connecting piece and the second connecting piece can be distributed in a staggered mode, the design flexibility of all parts in the support assembly is improved, it is guaranteed that the second connecting piece avoids the first electric appliance element, and the problem of structural interference is prevented.

Owner:VIVO MOBILE COMM CO LTD

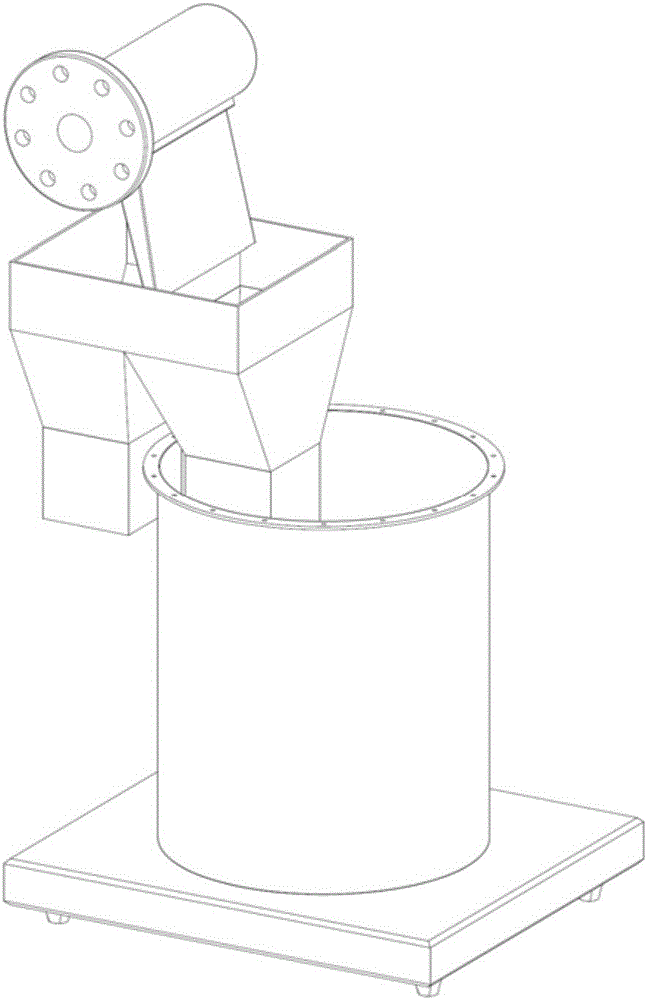

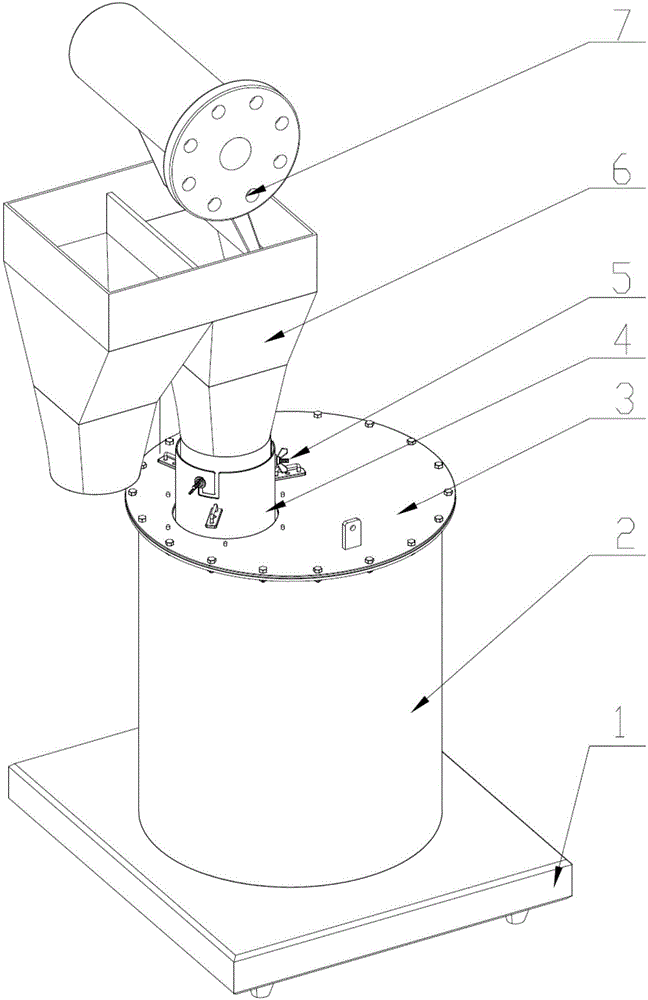

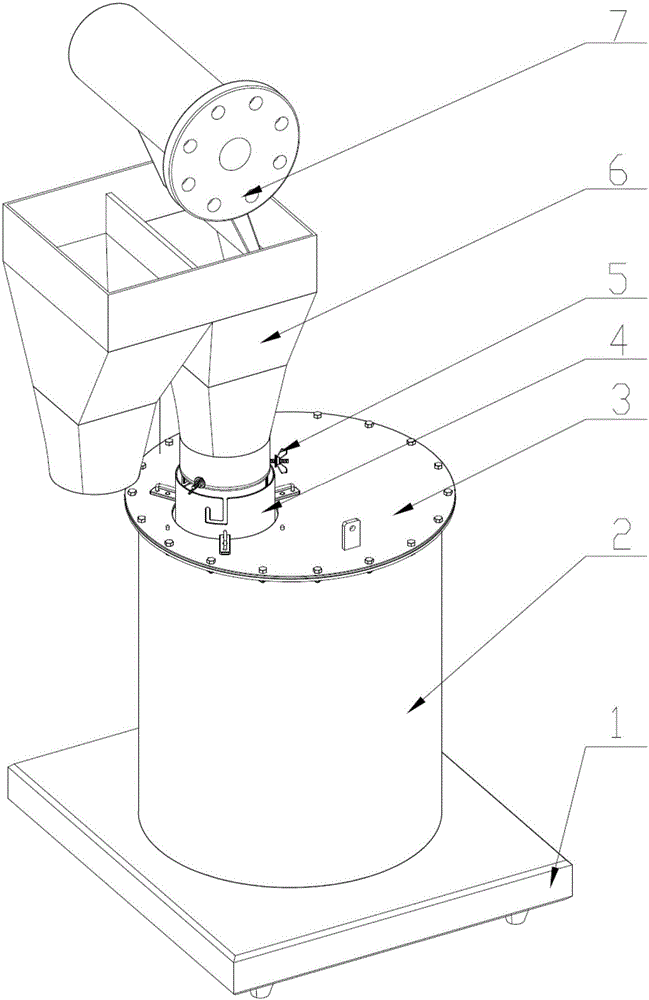

An electric arc additive and milling device

ActiveCN105414981BSolve the problem of insufficient machining accuracySimple processOther manufacturing equipments/toolsEngineeringAdditive layer manufacturing

The invention discloses an electric arc adding and milling device belonging to the technical field of electric arc adding. The electric arc adding and milling device comprises an electric arc adding unit and a milling unit, wherein the milling unit comprises a milling head; the milling unit is connected with the electric arc adding unit; and the electric arc adding unit comprises a welding gun, a supporting plate, a slide block, a fixing groove, a fixing plate, a stepping motor and a lead screw, wherein one end of the welding gun is fixed together with the slide block, the other end of the welding gun passes through a through hole of the supporting plate, both the supporting plate and the fixing plate are fixed together with the stepping motor, the fixing groove is fixed together with the fixing plate, an output shaft of the stepping motor is connected with the lead screw, and the lead screw passes through a threaded through hole formed in the slide block. The electric arc adding and milling device can be used for realizing additive manufacturing and cutting at one step, so that workpieces are more precisely machined, and the using requirement is met.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com