Device and method for processing welding strip

A processing device and processing method technology, applied in auxiliary devices, shearing devices, welding equipment, etc., can solve problems such as low production efficiency and time-consuming, and achieve the effects of improving work efficiency, reducing processing time, and avoiding structural interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

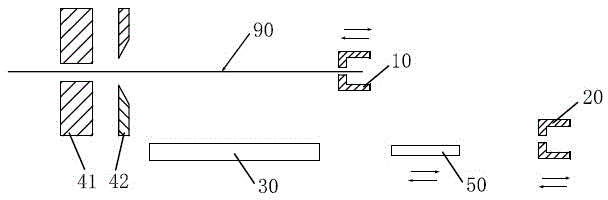

[0040] Such as figure 1As shown, a welding ribbon processing device described in the embodiment of the present invention includes a movable first welding ribbon press head for pulling the welding ribbon 90; a welding ribbon transfer platform 30 for positioning and receiving the welding ribbon 90 , the welding ribbon transfer platform 30 has a positioning part; and the second welding ribbon pressure head capable of translational movement is used to pull the cut-off fixed-length welding ribbon from the welding ribbon transfer platform 30; There is a height difference between the position of the soldering tape and the position of the soldering tape of the second soldering tape press head 20 .

[0041] A welding ribbon processing method, comprising the following steps: pulling the welding ribbon 90 through a first welding ribbon pulling head 10, and waiting for cutting; positioning and accepting the welding ribbon through a welding ribbon transfer platform 30, and the welding ribb...

Embodiment 2

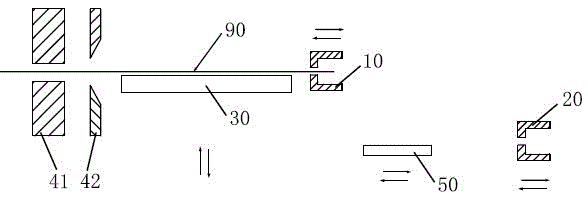

[0047] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the first welding ribbon pulling head 10 is set for translational movement, the welding ribbon transfer platform 30 is vertically moved, and the second welding ribbon pulling device and the welding ribbon transfer platform 30 are set. There is a ribbon guide plate that can move in translation. After pulling the welding strip, the welding strip pressure head can choose to rise and position the welding strip through the welding strip transfer platform 30 and accept the welding strip, and then cut it; The second welding ribbon pressing head 20 is located at the same height, which is convenient for the second welding ribbon pressing head 20 to pull the welding ribbon 90 . The front road of the first draw-bonding head 10 is provided with a cutting knife 42 device for cutting and forming a fixed-length welding strip. The cutting knife 42 device includes a welding-bonding device 41 and a...

Embodiment 3

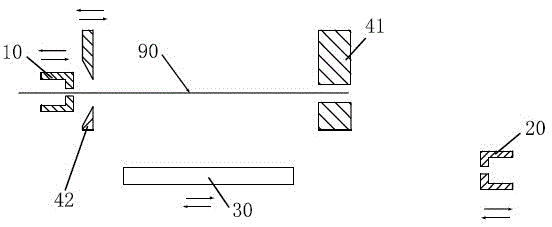

[0050] Such as image 3 As shown, the difference between the present embodiment and the first embodiment is that the first welding ribbon pressing head 10 is set to move in translation, and the welding ribbon transfer platform 30 is set to move in translation. The ribbon transfer platform 30 capable of translational movement can be used as a guide, thereby eliminating the need for a ribbon guide plate and saving costs.

[0051] The rear track of the first welding strip pressure head 10 is provided with a cutting knife 42 device for cutting and forming a fixed-length welding strip. The cutting knife 42 device includes a welding strip device 41 and a cutting knife 42. The welding strip device 41 is fixedly arranged and cut. Knife 42 translational motion setting. The fixed welding strip device 41 presses the welding strip at the back of the cutter 42, the first pulling welding strip pressure head 10 pulls against the direction in which the welding strip is fed, and then the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com