Patents

Literature

83results about How to "Guaranteed dimensional accuracy requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

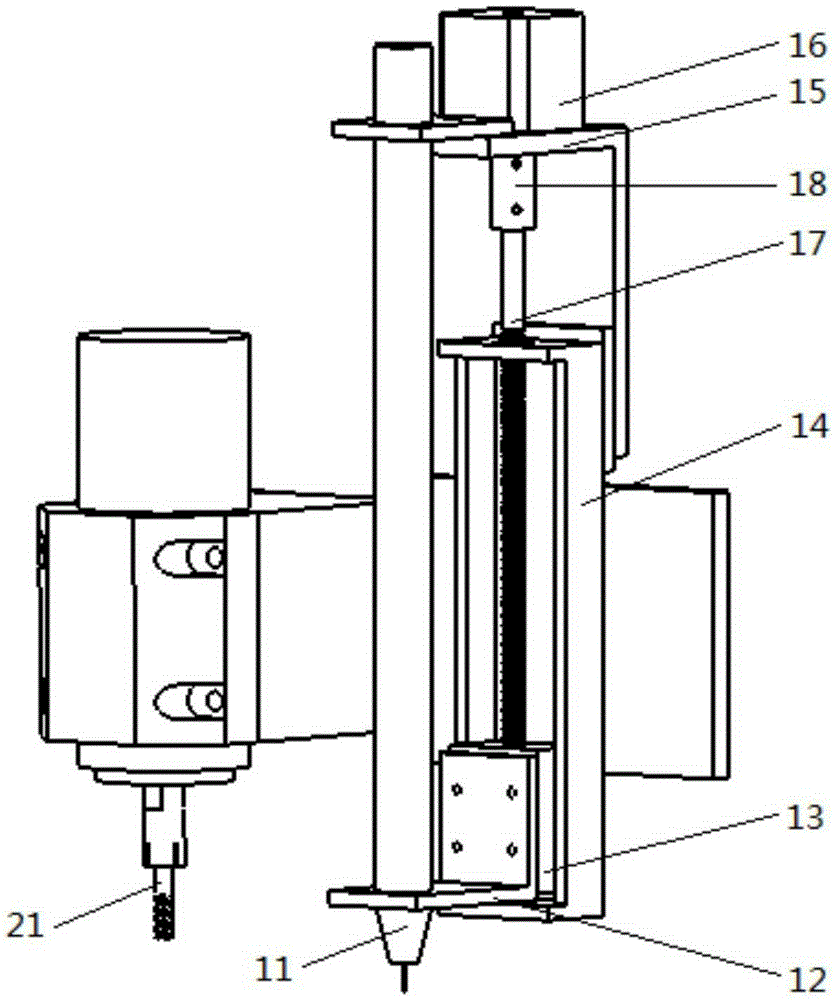

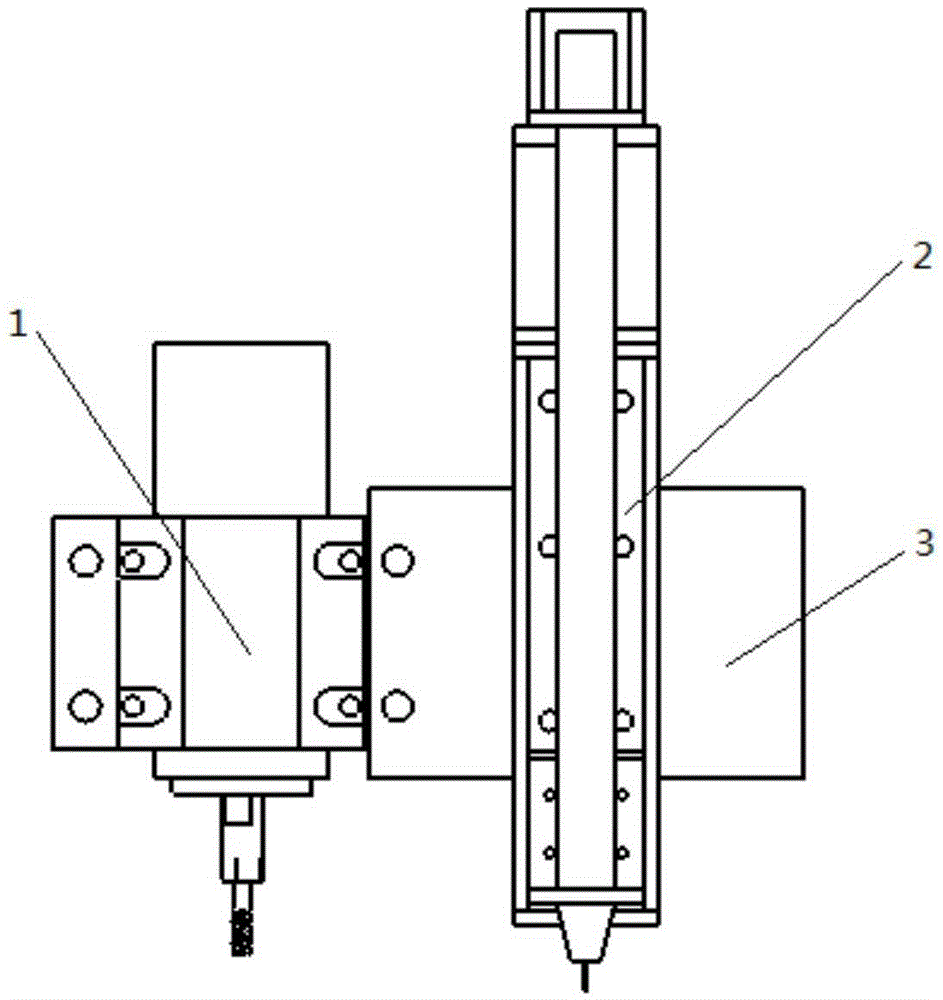

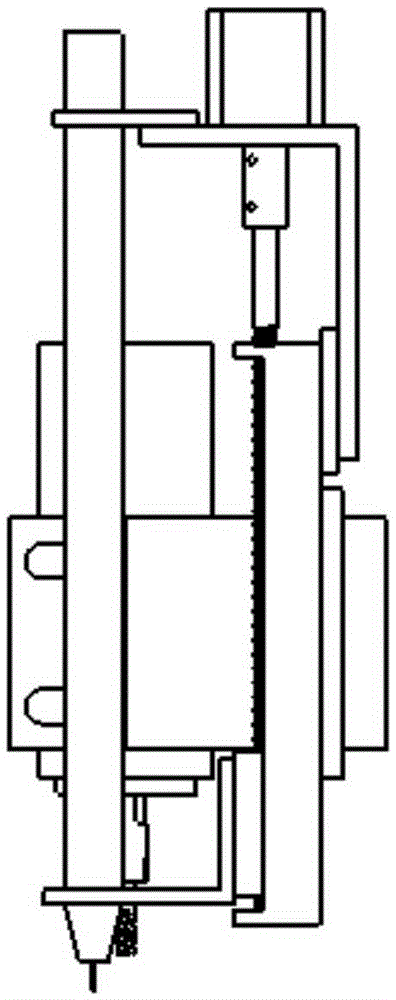

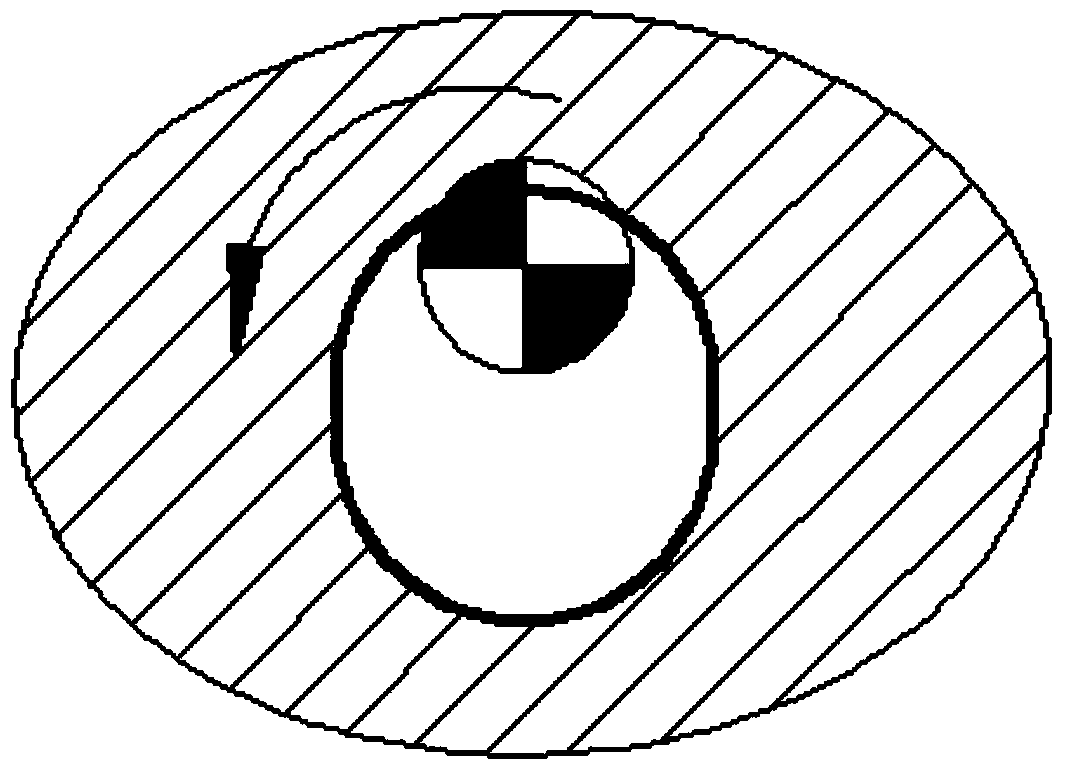

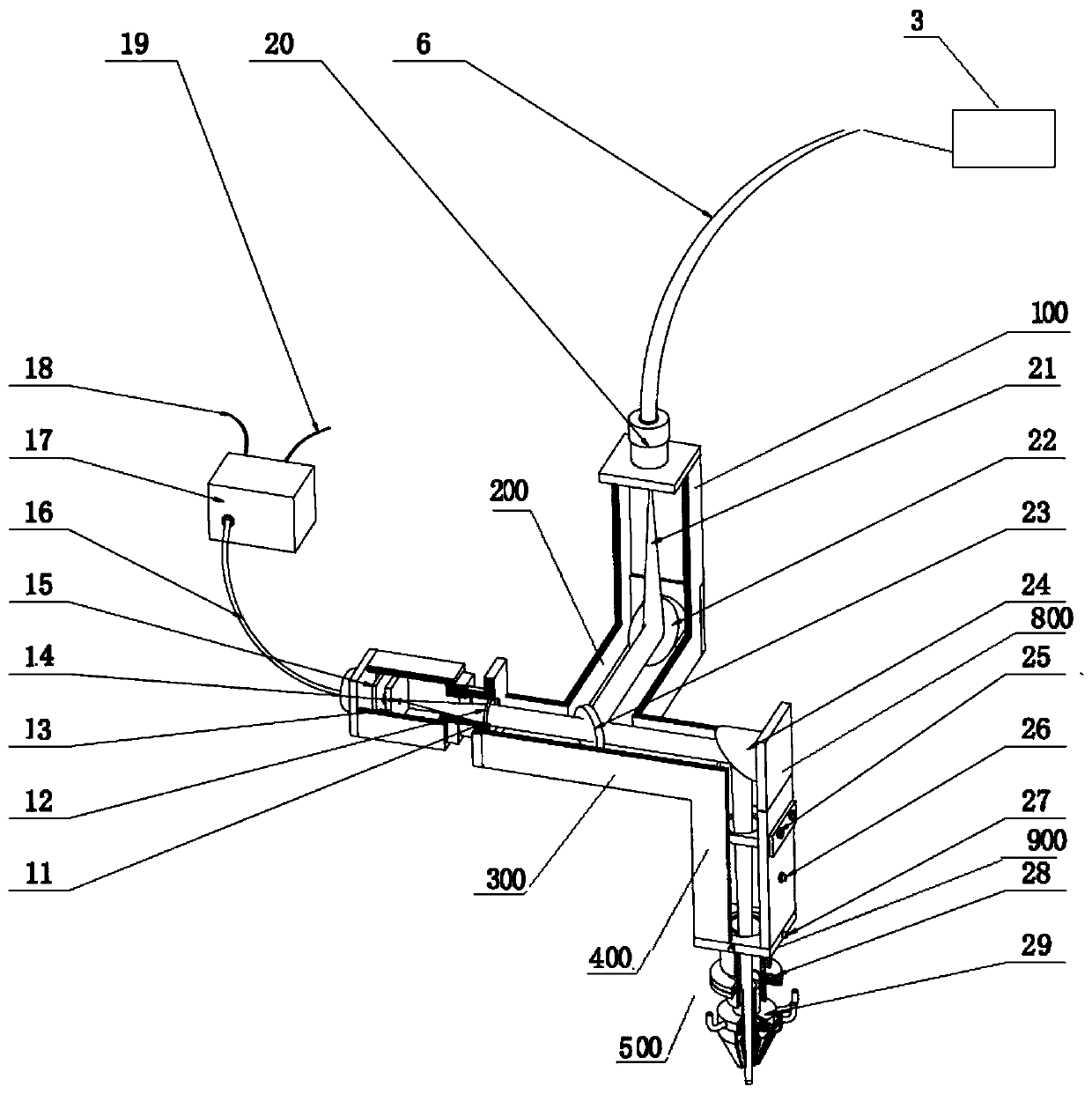

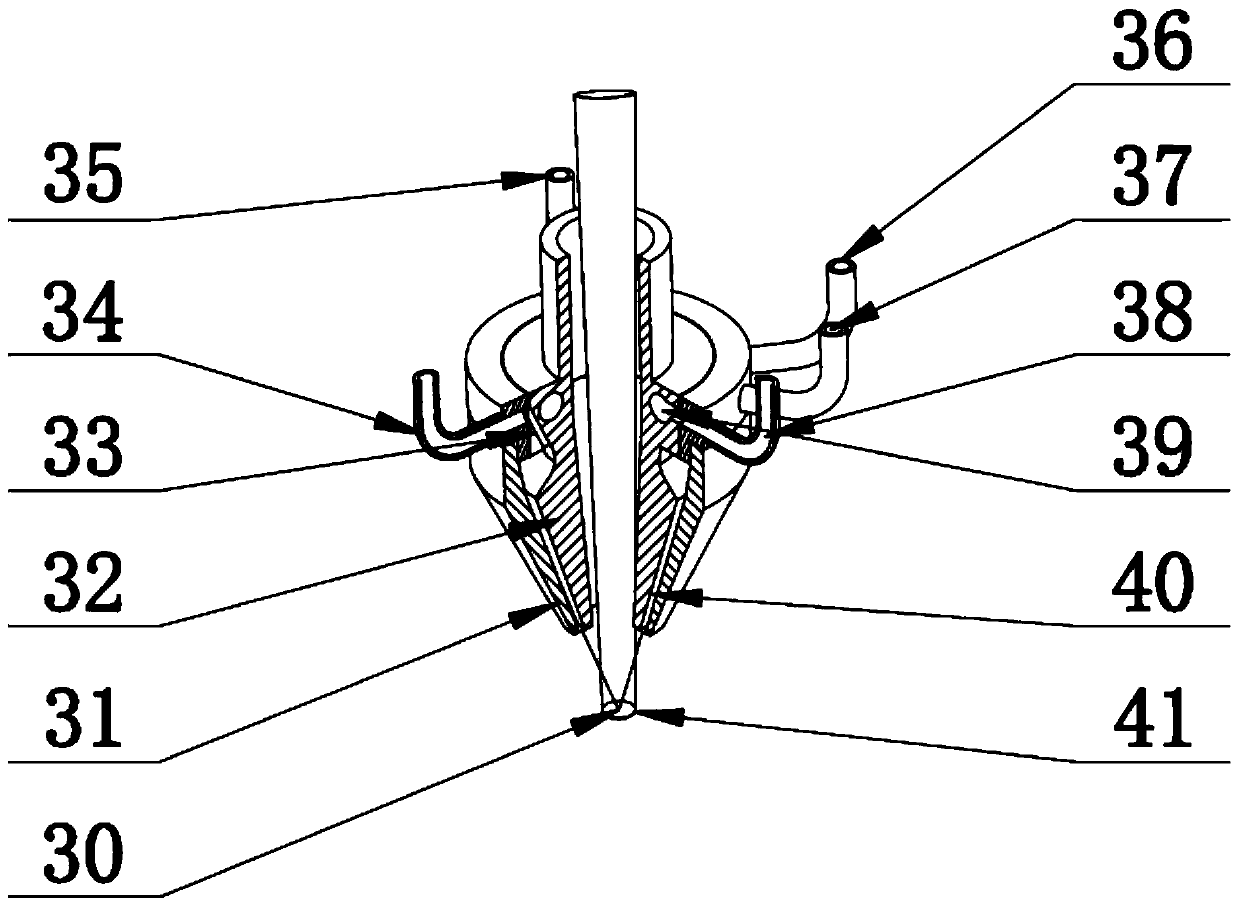

Electric arc adding and milling device

ActiveCN105414981ASolve the problem of insufficient machining accuracySimple processOther manufacturing equipments/toolsEngineeringAdditive layer manufacturing

The invention discloses an electric arc adding and milling device belonging to the technical field of electric arc adding. The electric arc adding and milling device comprises an electric arc adding unit and a milling unit, wherein the milling unit comprises a milling head; the milling unit is connected with the electric arc adding unit; and the electric arc adding unit comprises a welding gun, a supporting plate, a slide block, a fixing groove, a fixing plate, a stepping motor and a lead screw, wherein one end of the welding gun is fixed together with the slide block, the other end of the welding gun passes through a through hole of the supporting plate, both the supporting plate and the fixing plate are fixed together with the stepping motor, the fixing groove is fixed together with the fixing plate, an output shaft of the stepping motor is connected with the lead screw, and the lead screw passes through a threaded through hole formed in the slide block. The electric arc adding and milling device can be used for realizing additive manufacturing and cutting at one step, so that workpieces are more precisely machined, and the using requirement is met.

Owner:HUAZHONG UNIV OF SCI & TECH

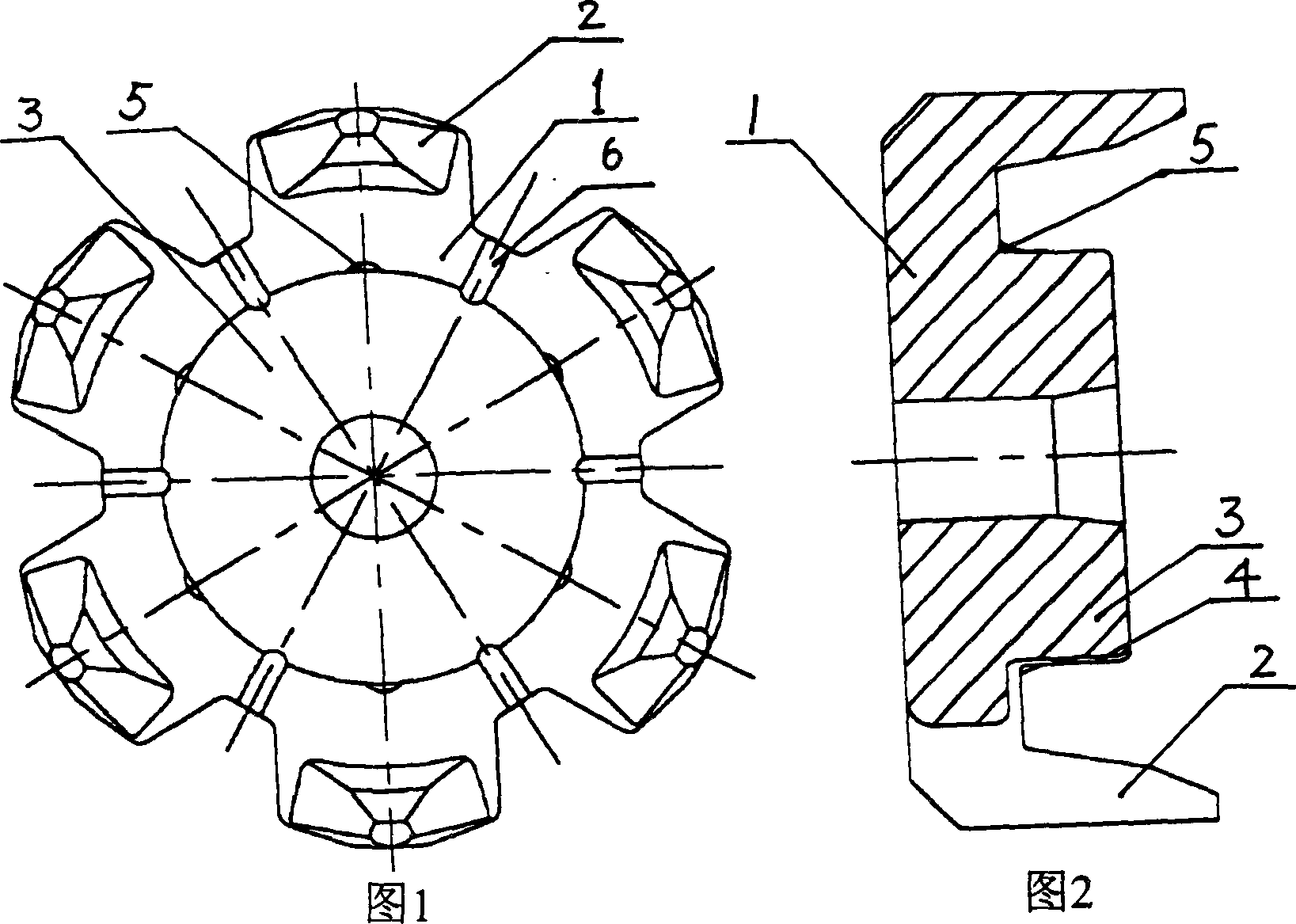

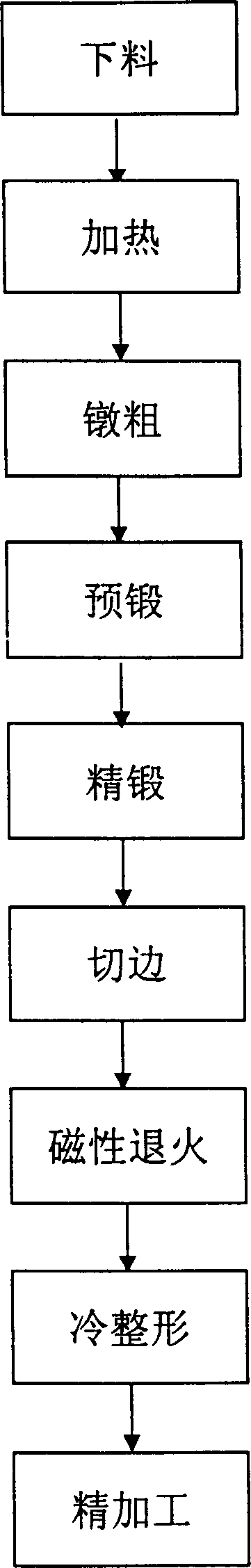

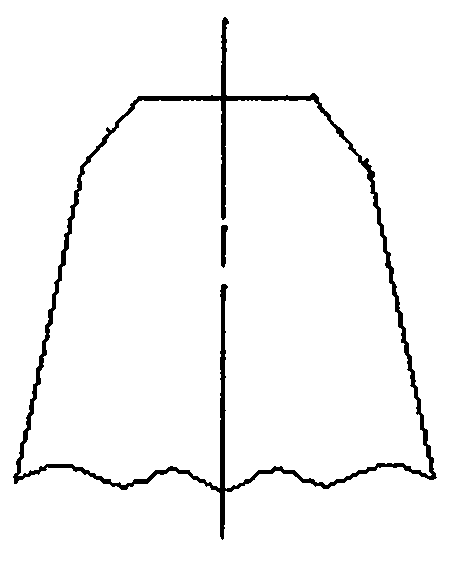

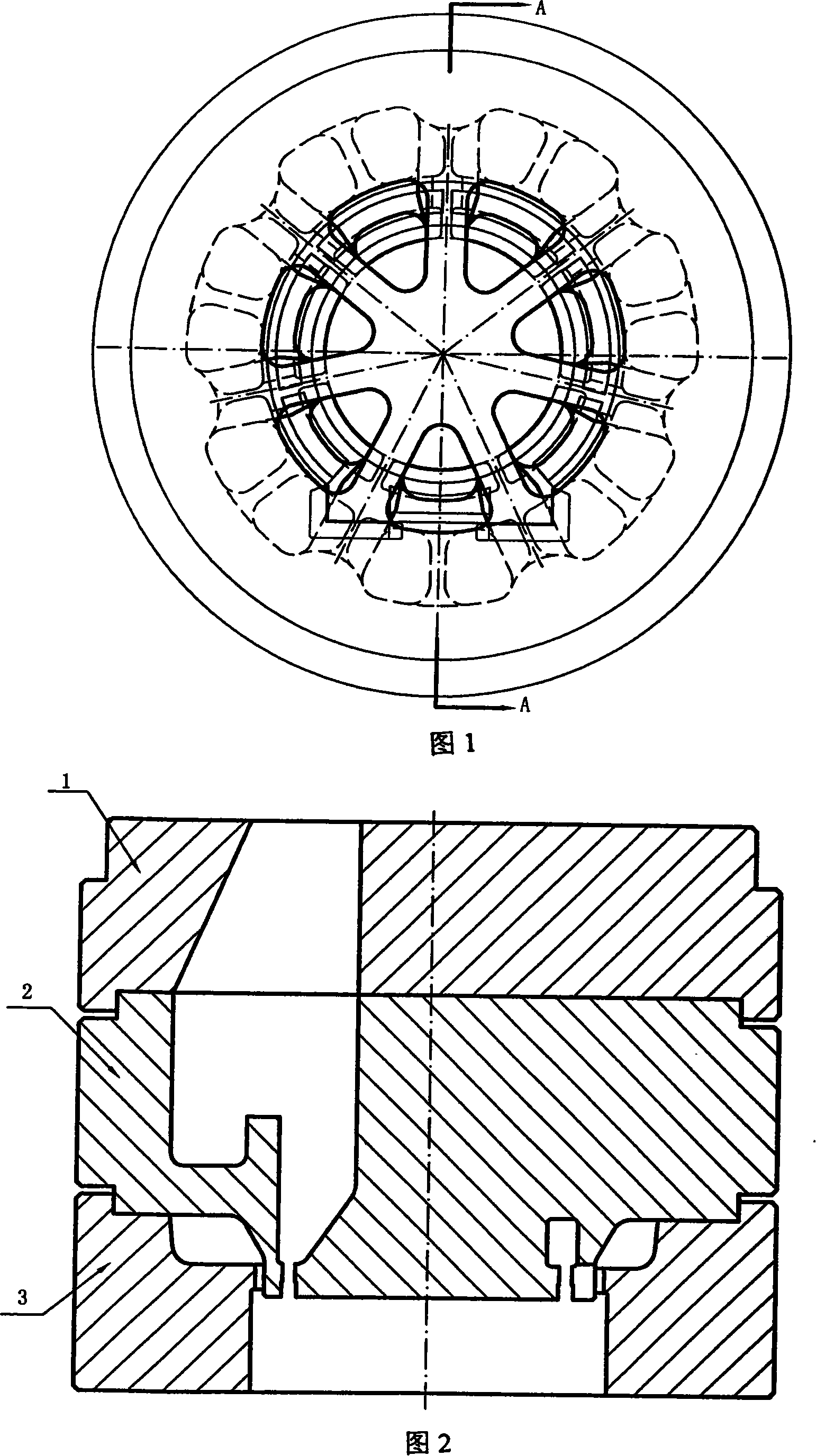

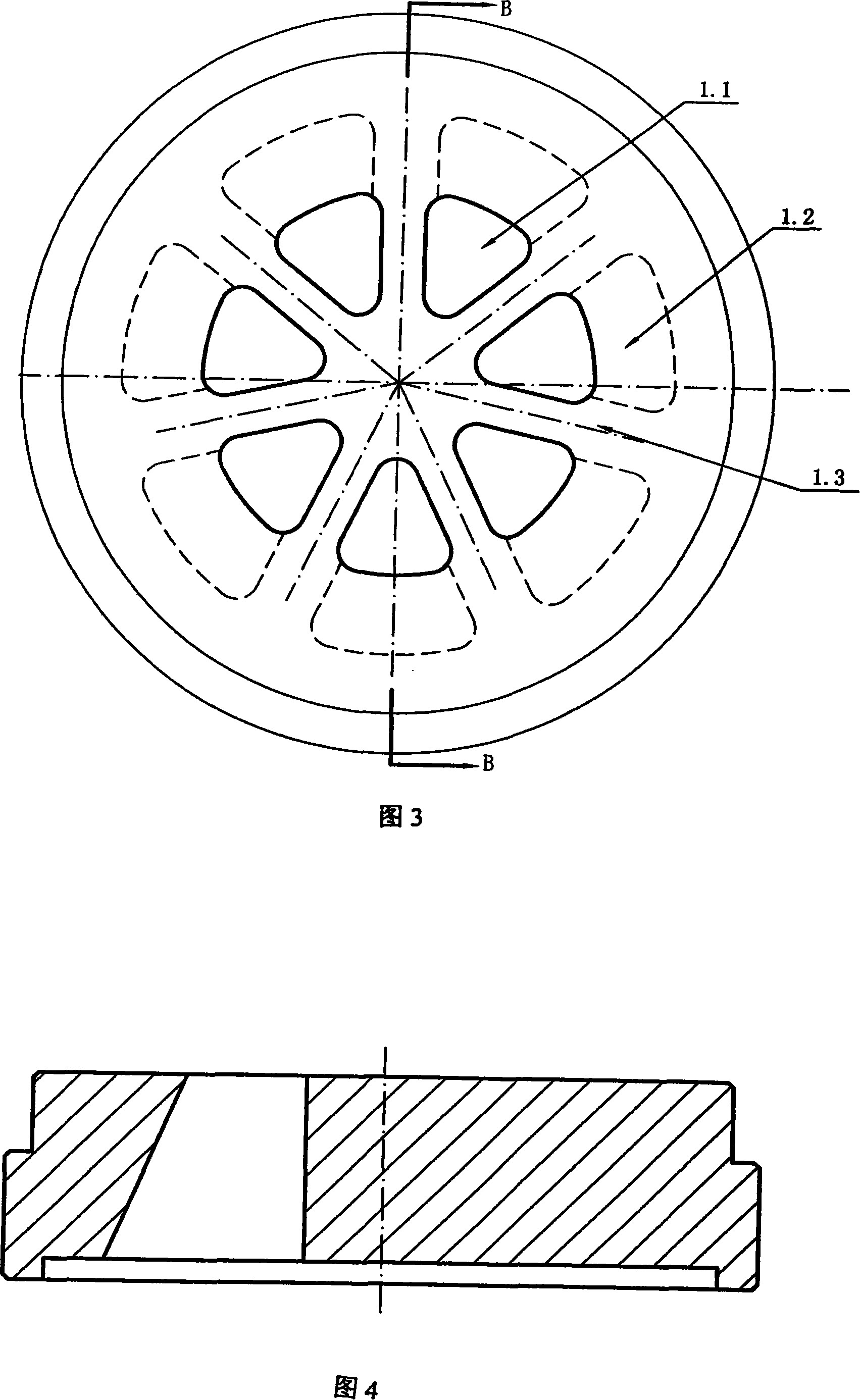

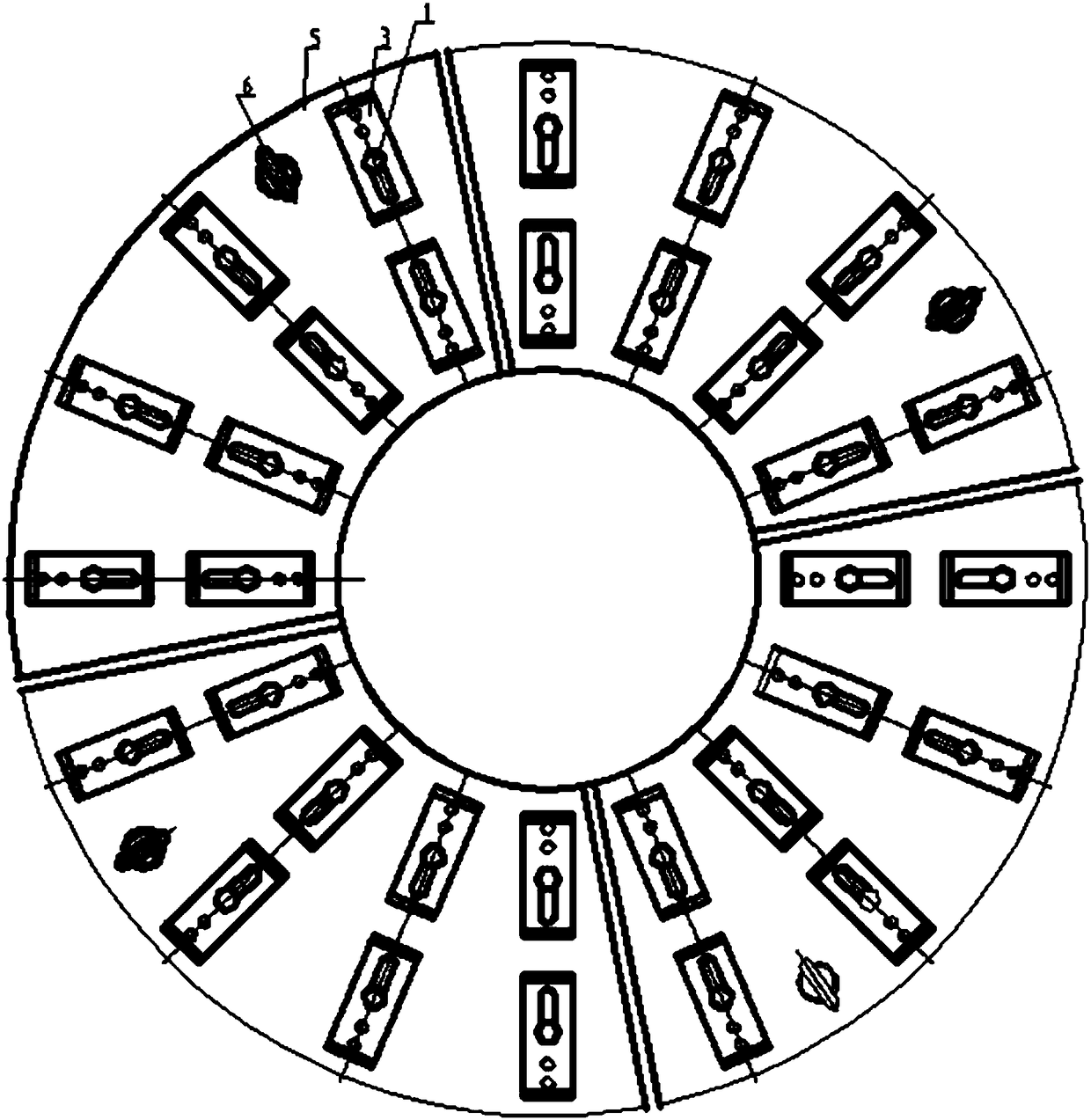

Pawl pole of automobile generator and its manufactura

ActiveCN1772413AIncrease power generationHigh dimensional accuracyManufacturing dynamo-electric machinesOther manufacturing equipments/toolsLacquerEngineering

The present invention relates to one kind of of automobile generator and its manufacture. The pawl pole has one bottom plate, one magnetic yoke on the bottom plate, six or eight insulating varnish conducting slots distributed homogeneously on the circumference of the magnetic yoke, six or eight lugs for preventing the rotation of coil, and six or eight insulated wire leading out slots in the bottom of the magnetic yoke. The manufacture of the pawl pole includes the steps of: cutting material, heating, upsetting, pre-forging, finish forging, cutting edge, magnetically annealing, cold shaping, and finishing machining. The manufacture process has low apparatus investment, low mold cost, low heating cost, high output and high product quality. The AC generator with the pawl poles of the present invention has induced electromotive force waveform of quasi-sinusoid wave and great generating power.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

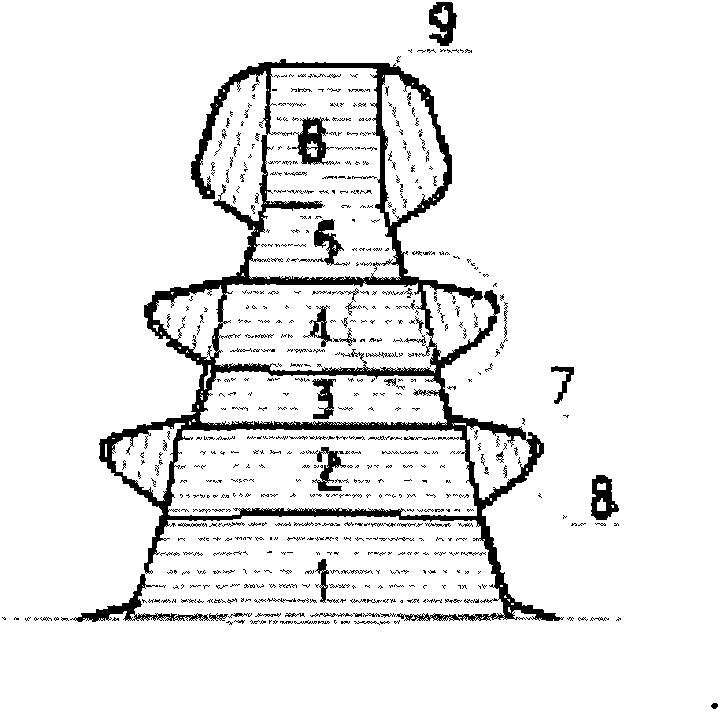

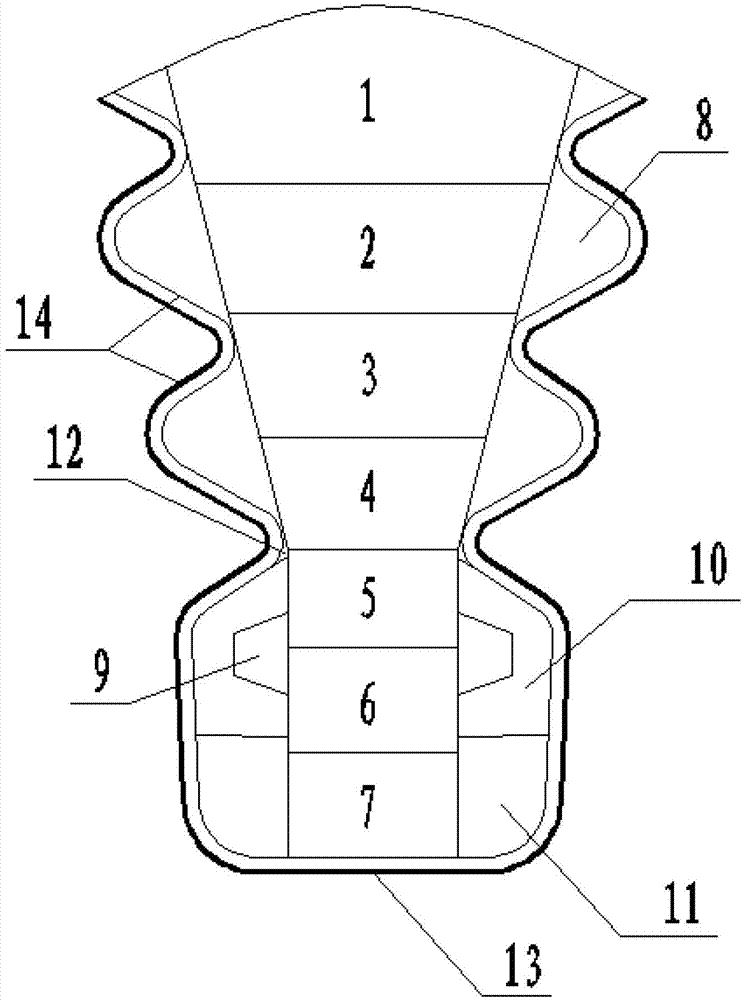

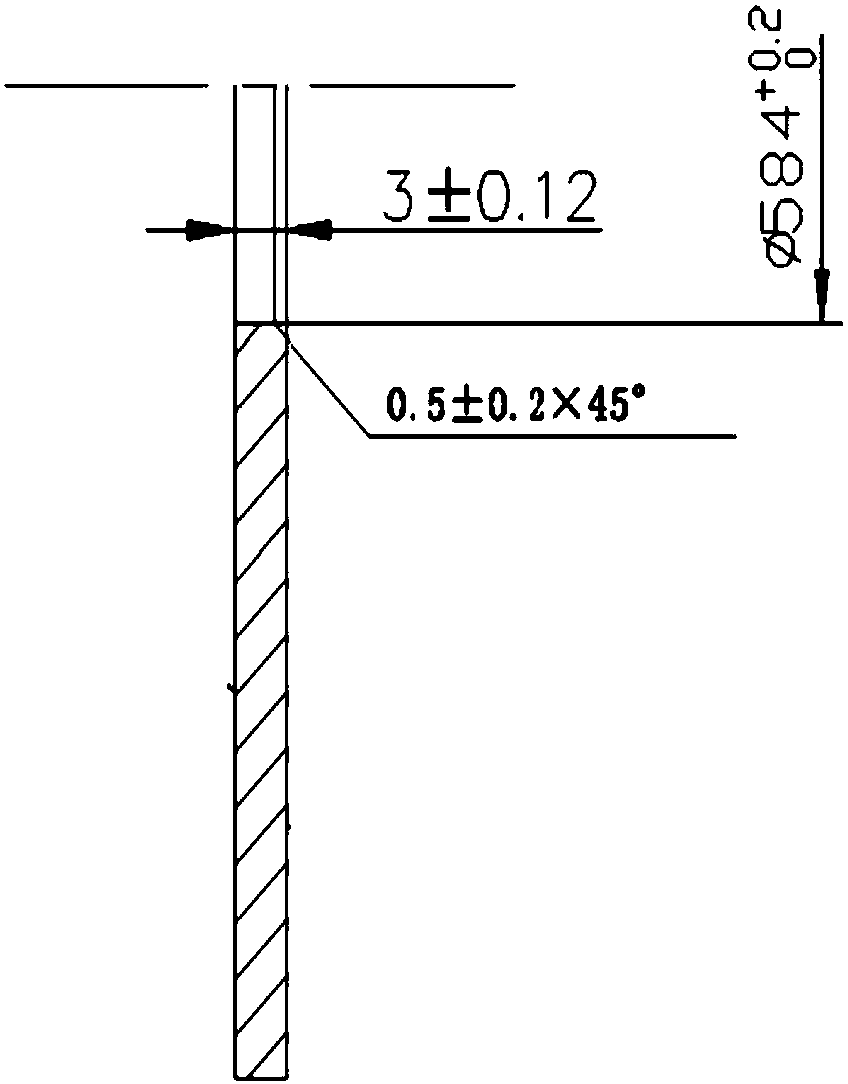

Turbine disk fir-shaped mortise broaching tool

InactiveCN101774045AShorten the lengthIncreased durabilityBroaching toolsPositioning apparatusEngineeringTurbine

The invention relates to a turbine disk fir-shaped mortise broaching tool, which is characterized in that a milled chamfer angle of 0.2x45 DEG is arranged on a sharp corner at two sides of the bladewidth of the turbine disk fir-shaped mortise broaching tool, parts 1 to 6 are slotted roughly, a seventh part is roughly broached with a mortise thread shape, an eighth part is precisely broached with a mortise thread-form sectional surface, and the top surface of a ninth part is precisely broached; the parts 1 to 6 adopt six slotting cutters, the seventh part adopts one rough-broaching thread-form cutter, the eighth part adopts one precise-broaching thread-form cutter, and the ninth part adopts one top-surface broach which is also named cap knife. The turbine disk fir-shaped mortise broaching tool has the advantages that the design structure of the broach is changed, the service life of the slotting broach is improved, and the manufacturing precision and the product complete qualification rate of the thread-form precise broach are broken through. The debugging period is successfully shortened, the trial broaching at one time is completely qualified, the production efficiency is improved by 30 percent, and the service life of the broach is prolonged. Compared with the combination-type broach and the powder metallurgy broach, the broaching tool with the above structure has simpler manufacturing process, good interchangeability, safe application and low cost.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

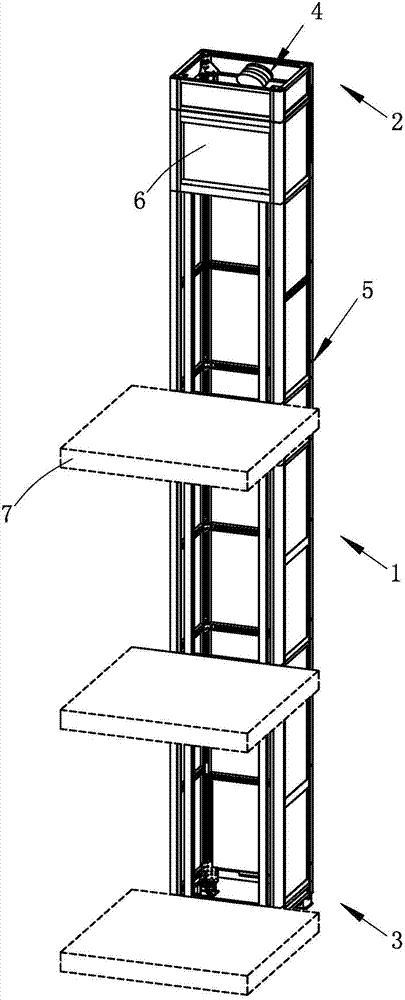

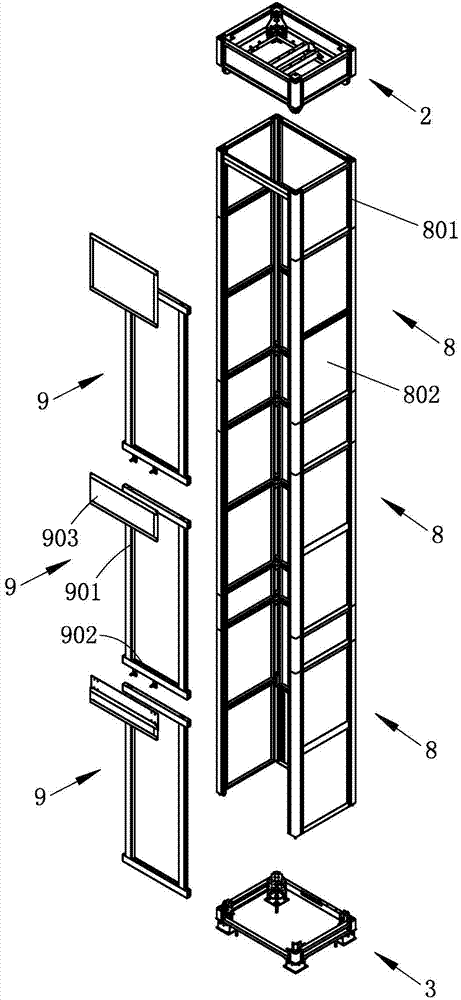

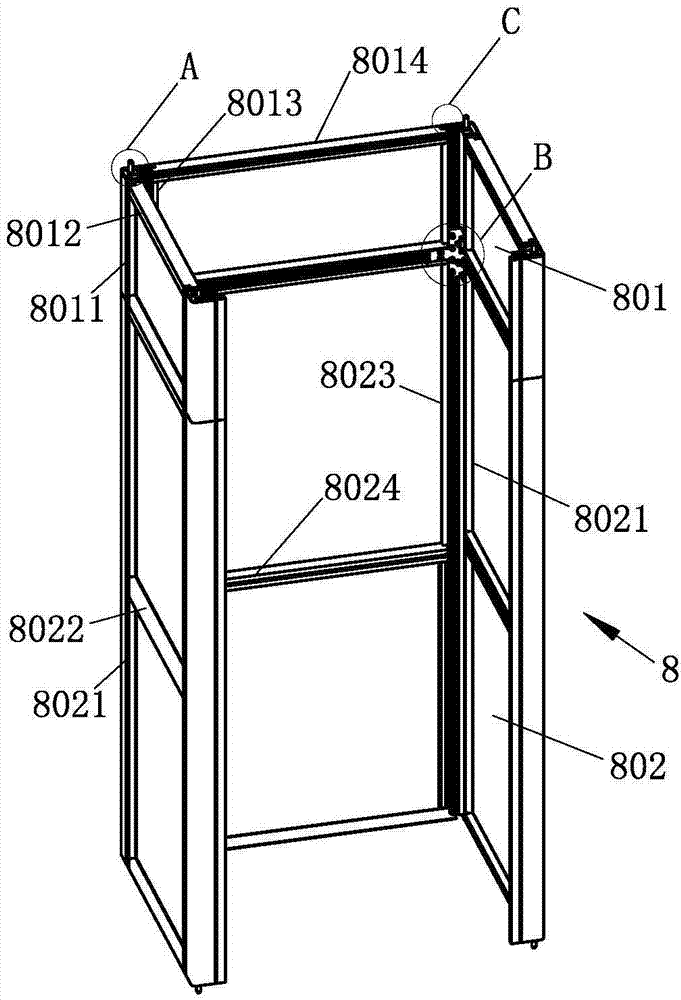

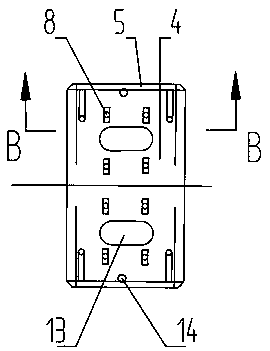

Well frame, elevator with well frame and well frame mounting method

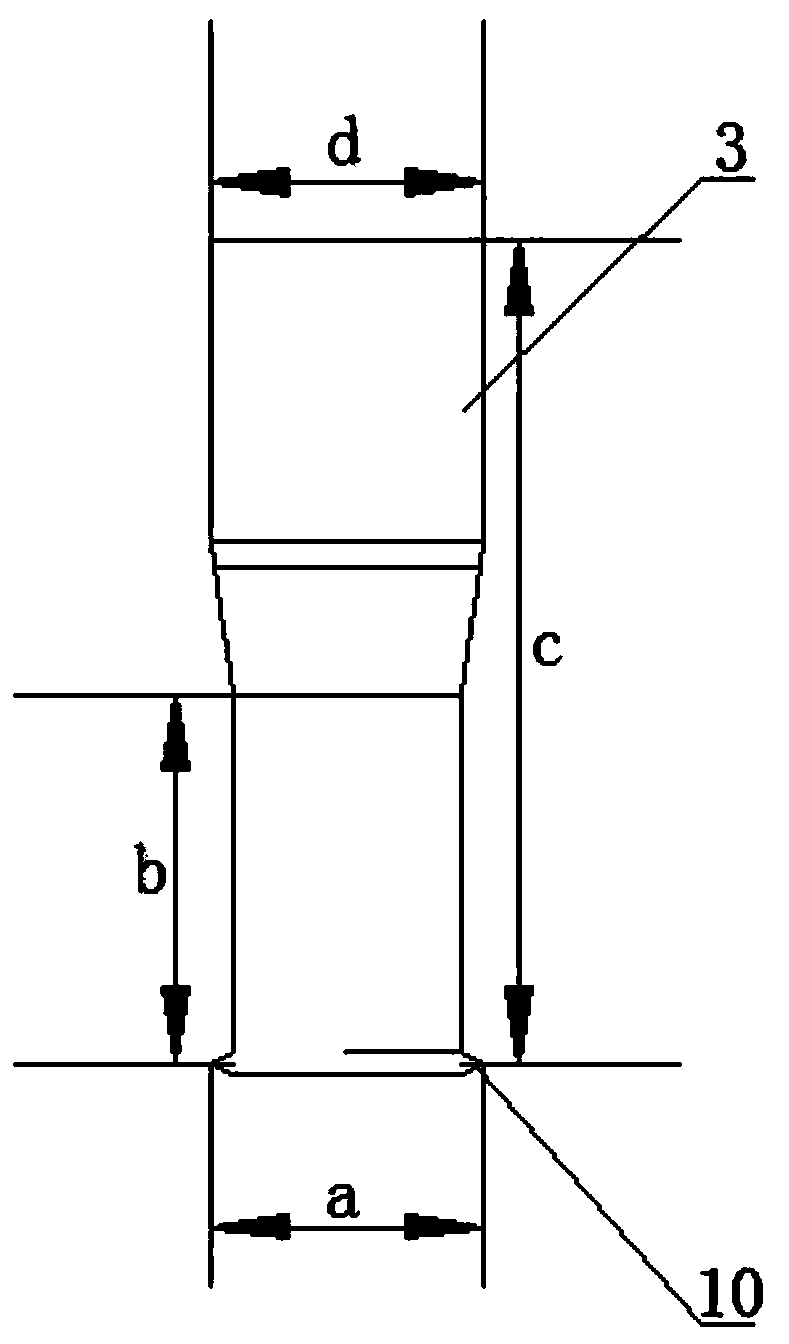

ActiveCN104760860AGuaranteed dimensional accuracy requirementsShorten the timeElevatorsBuilding liftsEngineering

The invention discloses a well frame, an elevator with well frame and a well frame mounting method. The well frame comprises a frame top component, a frame bottom component and a frame middle component; a vertical opening is formed in the frame middle component; a transitional section mounting block is arranged above a fixed section mounting block; the frame middle component is divided into a plurality of transitional section mounting blocks and fixed section mounting blocks, all of which are orderly connected together; the transitional section mounting block is divided into two transitional sidewall frames and two transitional rear wall frames; the fixed section mounting block is divided into two fixed sidewall frames and two fixed rear wall frames; the transitional rear wall frames and the fixed rear wall frames are all opposite to the vertical opening; each of the transitional sidewall frames, the transitional rear wall frames, the fixed sidewall frames and the fixed rear wall frames is correspondingly provided with a well wallboard; the well wallboard is a PC board. The well frame is mounted on the elevator to from the elevator with the well frame; the well frame is low in overall weight, convenient to mount, high in safety performance, and widely applied to passenger elevators.

Owner:SUZHOU TRANS ELEVATOR

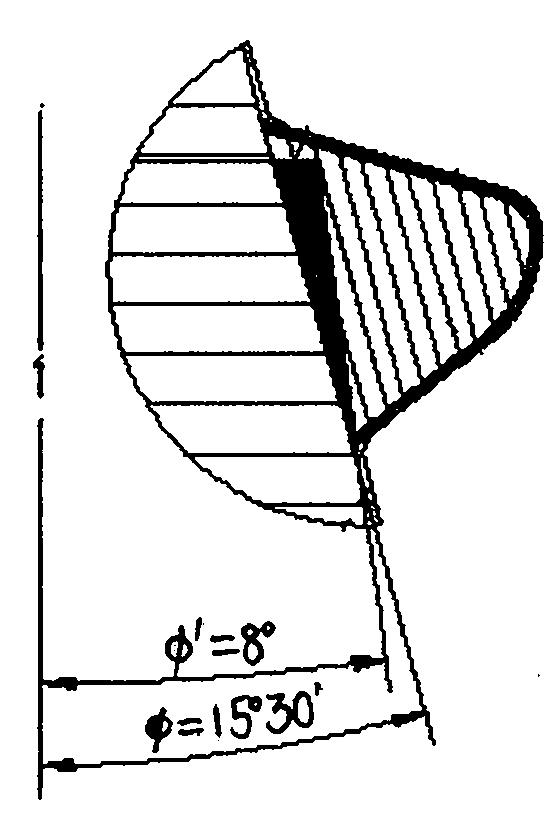

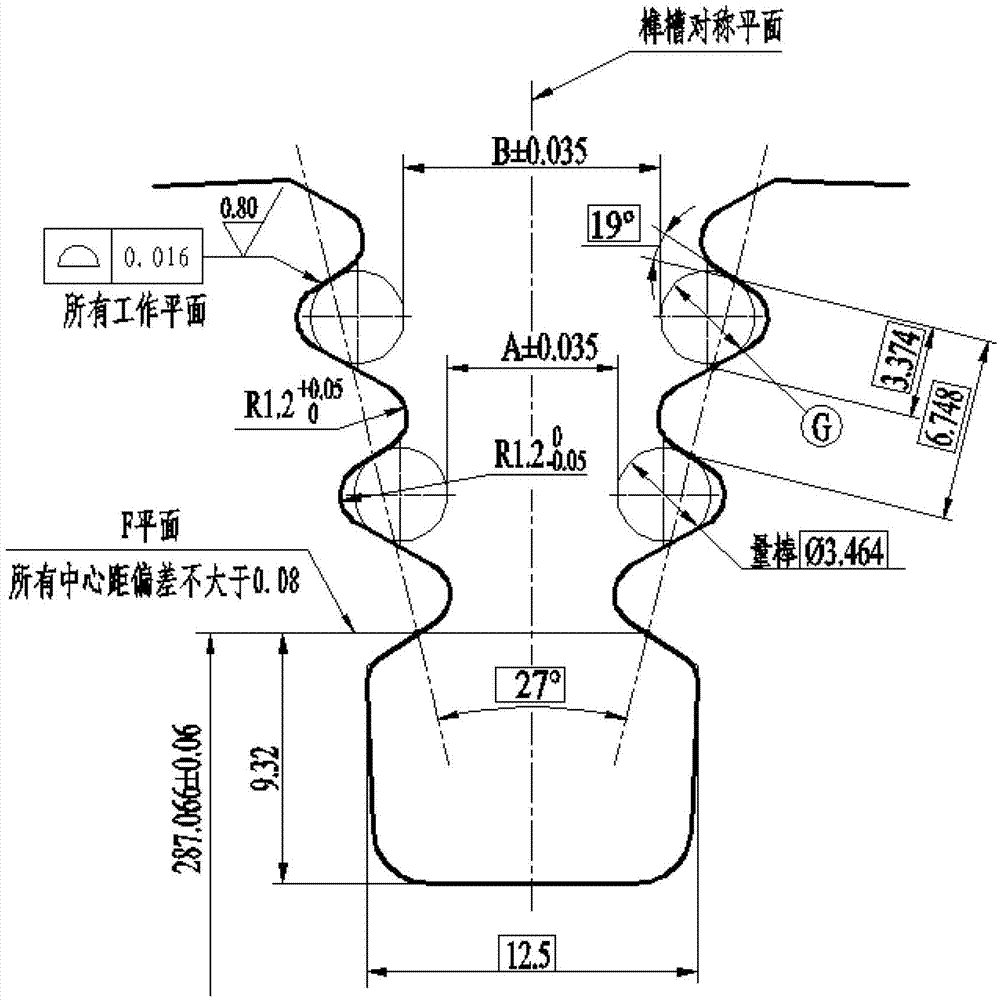

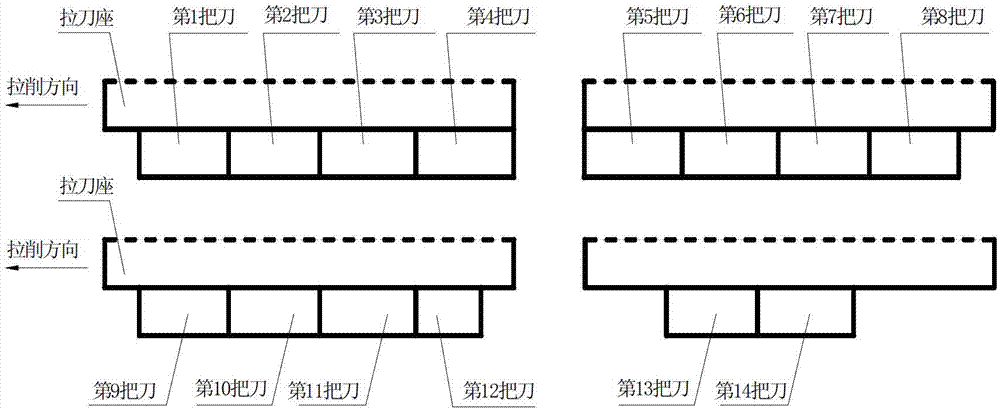

High-accuracy mortise broaching processing method for turbine disk made of powder high-temperature alloy material

InactiveCN102962513AControl and reduce broaching distortionMeet processing needsBroaching toolsBroaching machinesHardnessSuperalloy

The invention discloses a high-accuracy mortise broaching processing method for a turbine disk made of a powder high-temperature alloy material. Broaching tools made of an imported powder high-speed steel material ASP2060 are adopted; the hardness HRC of the broaching tools is 66-68; 14 fourteen broaching tools in a complete set are adopted; first to seventh broaching tools are necking tools; an eighth broaching tool is a roughing tooth type tool; ninth to eleventh broaching tools are roughing tooth bottom cut tools; a twelfth broaching tool is a roughing tooth top circular arc tool; a thirteenth broaching tool is a finish broaching tank bottom circular arc tool; a fourteenth broaching tool is a finish broaching tooth type tool; the broaching tools are made of an ASP2060 powder high-temperature alloy material; the front angles of the broaching tools are 15 degrees; the back angles of the broaching tools are 3 degrees; the rise per teeth of the rough necking tools are 0.045-0.06 millimeters; the rise per tooth of the roughing tooth type tool is 0.02-0.035 millimeters; the rise per tooth of the finish broaching tank bottom circular arc tool is 0.02 millimeters; the rise per tooth of the finish broaching tooth type toolfourteenth broaching tool is 0-0.03 millimeters; gradual cutting and complete molding are adopted in a broaching way; the rough broaching speed is 1 meter per minute; and the finish broaching speed is 1-1.5 meters per minute. The high-accuracy mortise broaching processing method has the advantages that: broaching deformation of parts is controlled and reduced effectively, the processing requirements of a high-accuracy powder metallurgy disk are met, and the requirement of a high-accuracy mortise on size accuracy on a high-accuracy mortise is met effectively.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

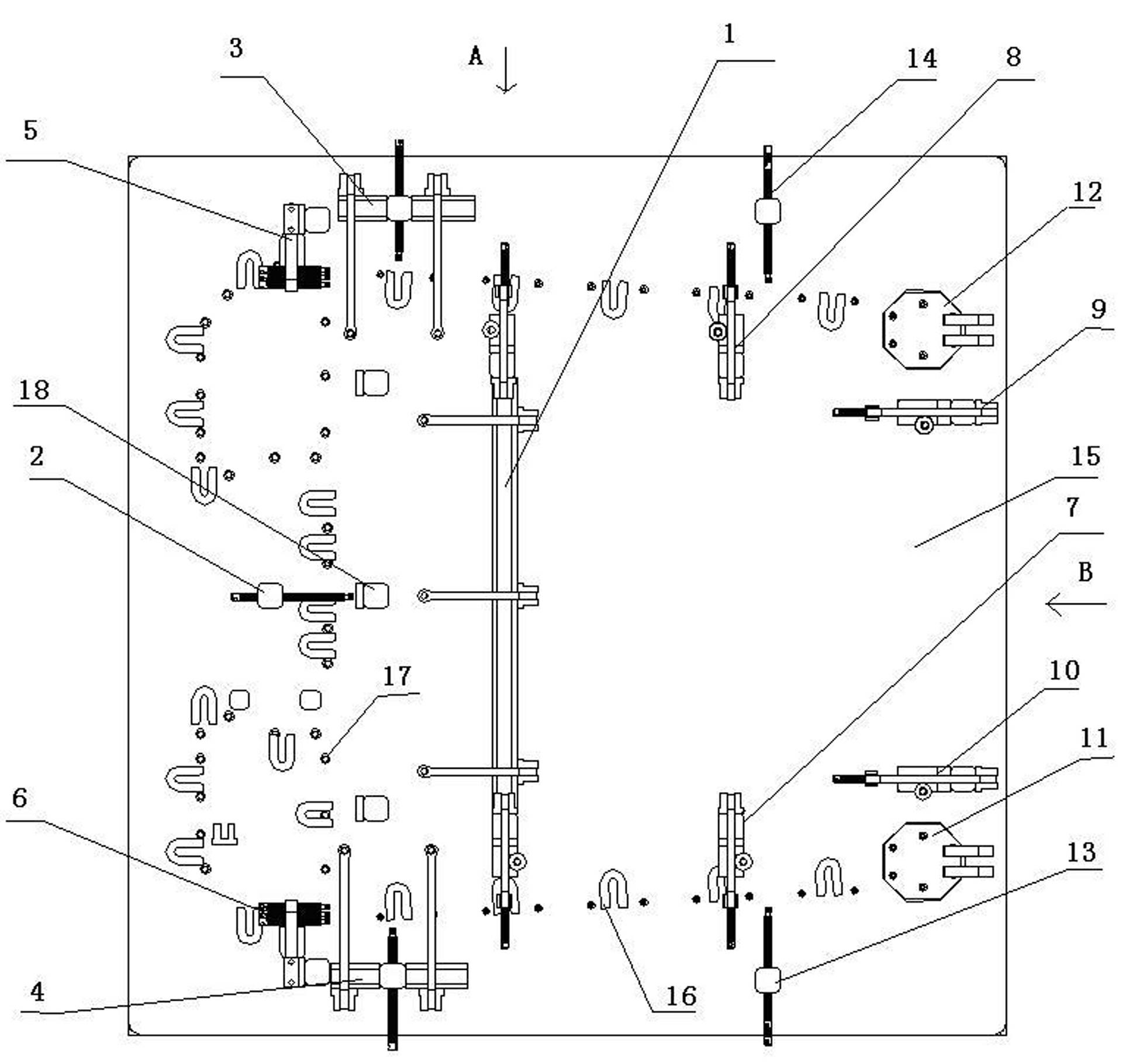

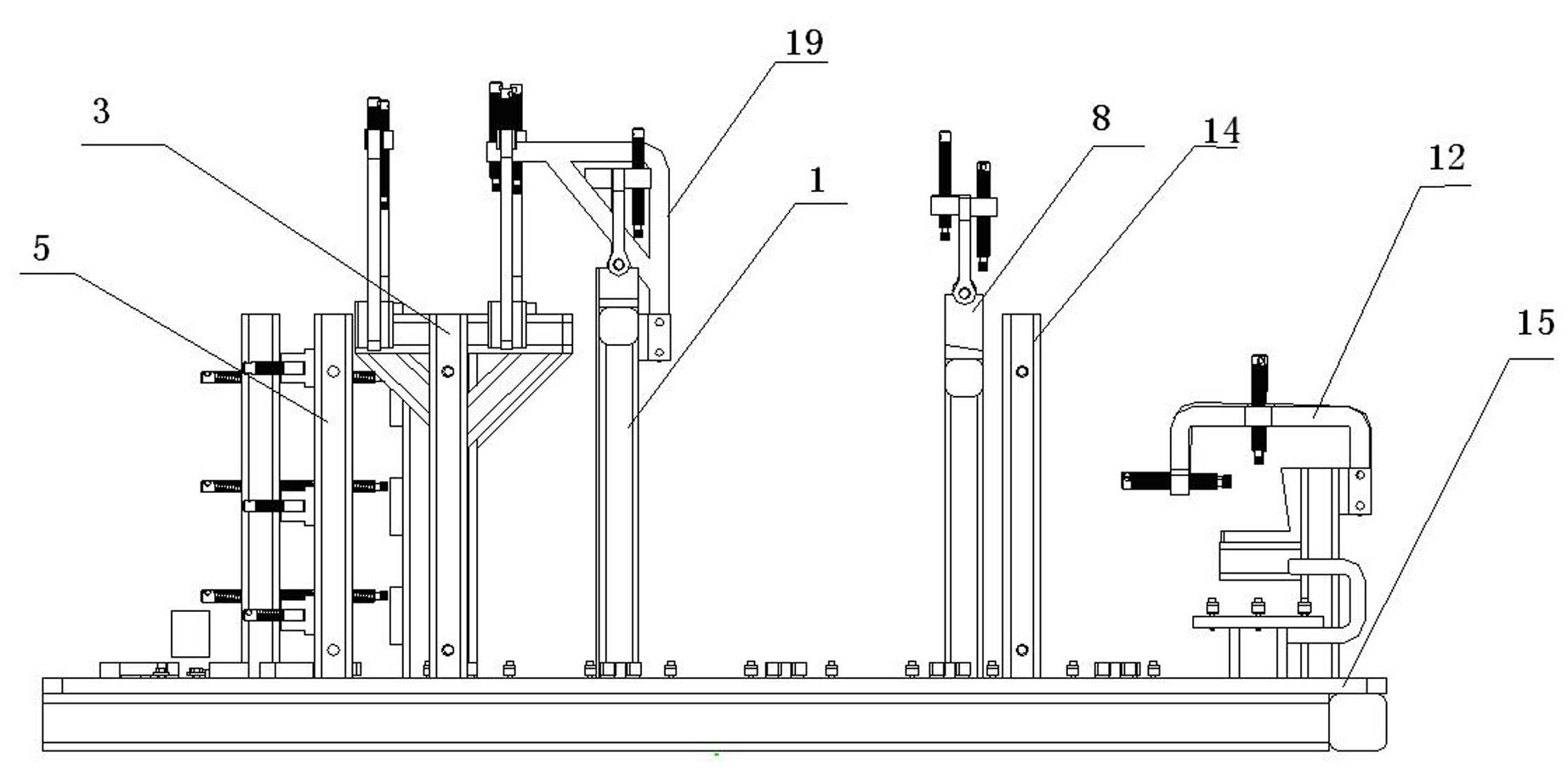

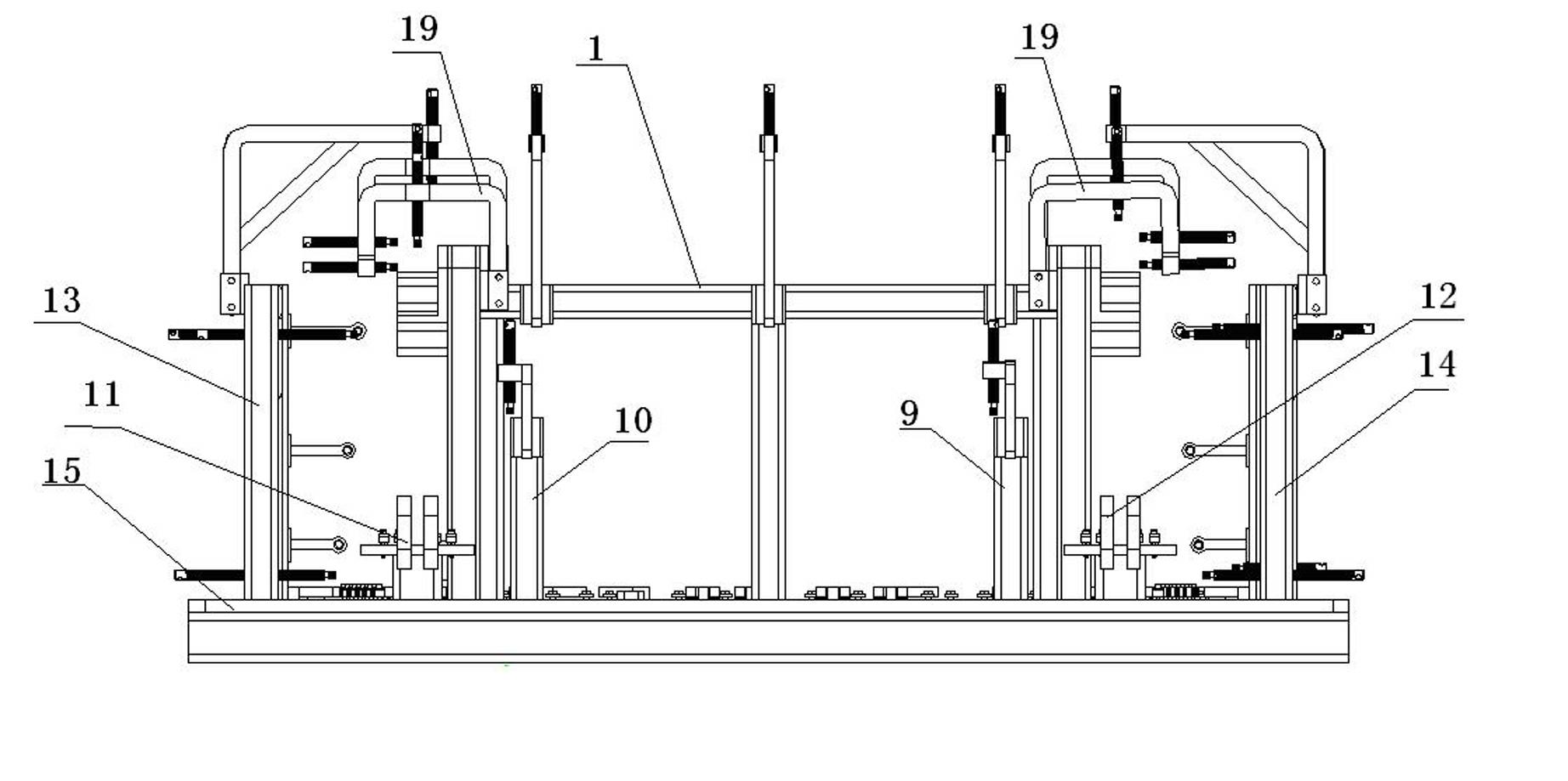

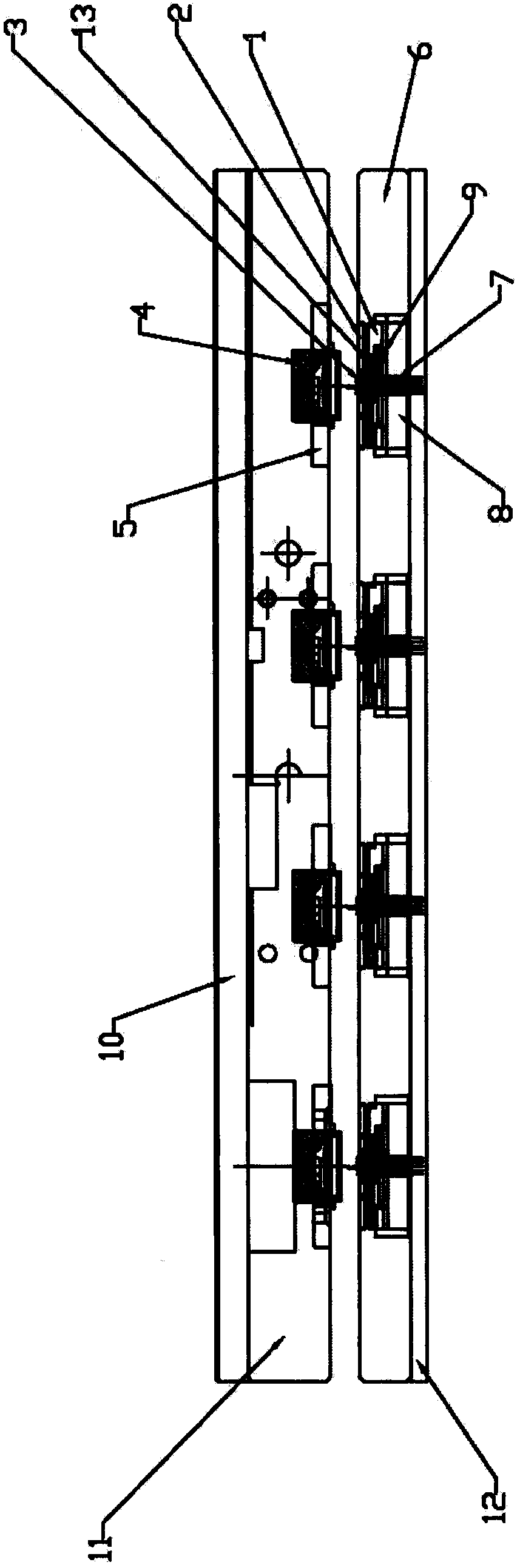

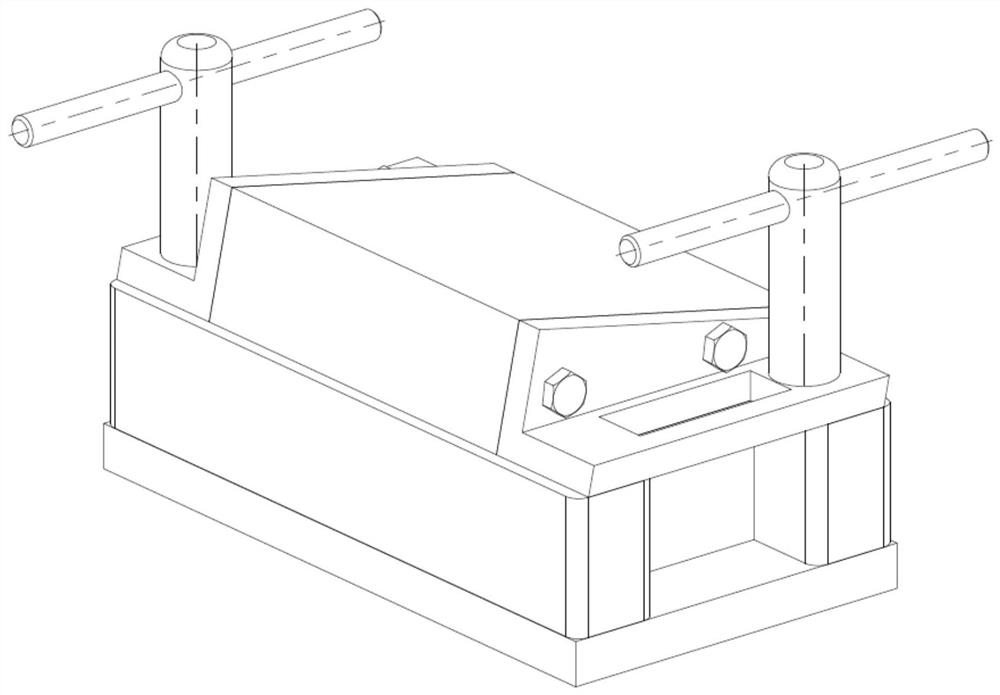

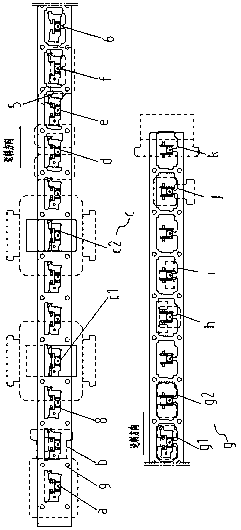

Installing and welding tool for cab

ActiveCN102152050AGuaranteed dimensional accuracy requirementsNo lateral bendingWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringVertical Dimensions

The invention relates to an installing and welding tool for a cab, which comprises a baseplate, a three-direction pressing and positioning device arranged on the baseplate, a large-floor middle pressing device, a crash barrier positioning and pressing device, a left pressing device, a right pressing device, a camber beam positioning and pressing device, a doorframe pressing device, a cross beam positioning and pressing device and an end chuck positioning block, wherein the large-floor middle pressing device, the crash barrier positioning and pressing device, the left pressing device and the right pressing device are arranged on one side of the three-direction pressing and positioning device, the camber beam positioning and pressing device, the doorframe pressing device, the cross beam positioning and pressing device and the end chuck positioning block are arranged on the other side of the three-direction pressing and positioning device, the left pressing device and the right pressing device are respectively arranged on two ends of the three-direction pressing and positioning device, the large-floor middle pressing device is arranged between the left pressing device and the right pressing device, one end of the large-floor middle pressing device is further provided with a large-floor rear positioning device, and the two ends of the three-direction pressing and positioning device are provided with pressing and positioning mechanisms. By means of the invention, the vertical dimensions of end parts of a cross beam and a camber beam are ensured, the cross beam is prevented fromlateral bending, and the installing and welding tool has the advantages of convenience for operation and bodilessness, good generality and capability of clamping manually and is convenient, flexible and reliable to mount and dismount.

Owner:南京雷尔伟新技术股份有限公司

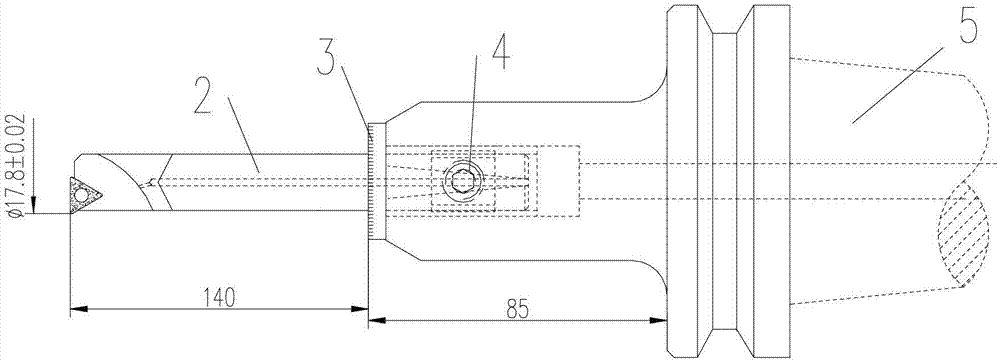

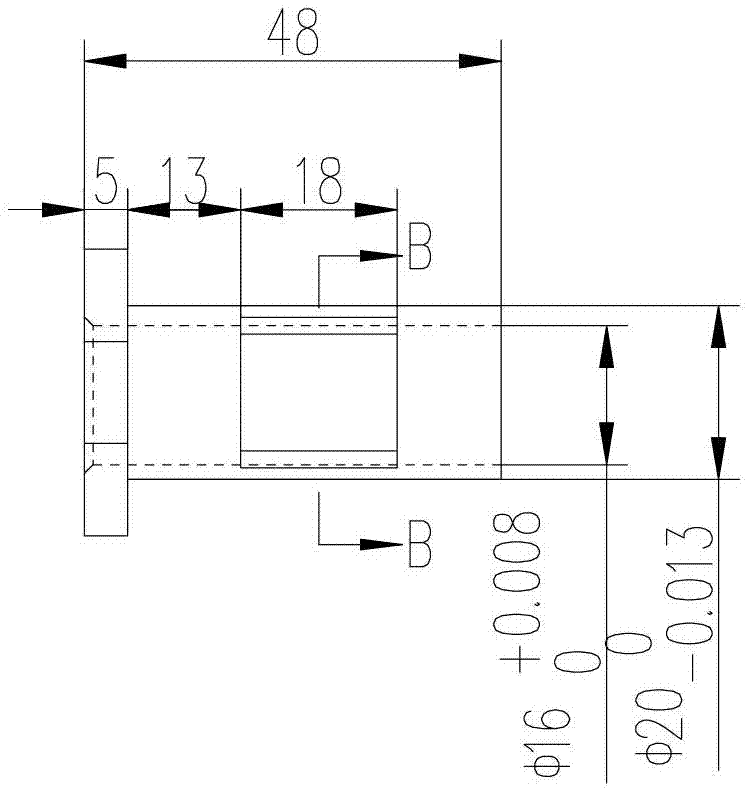

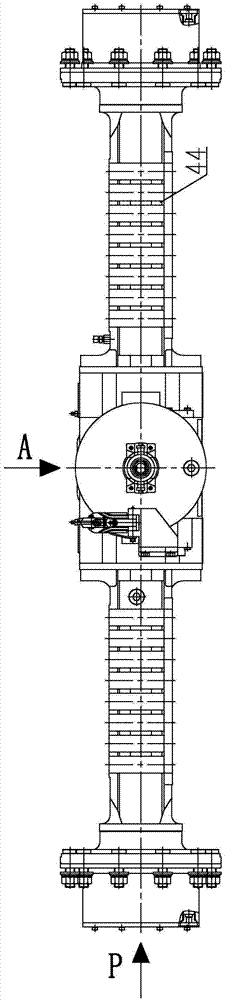

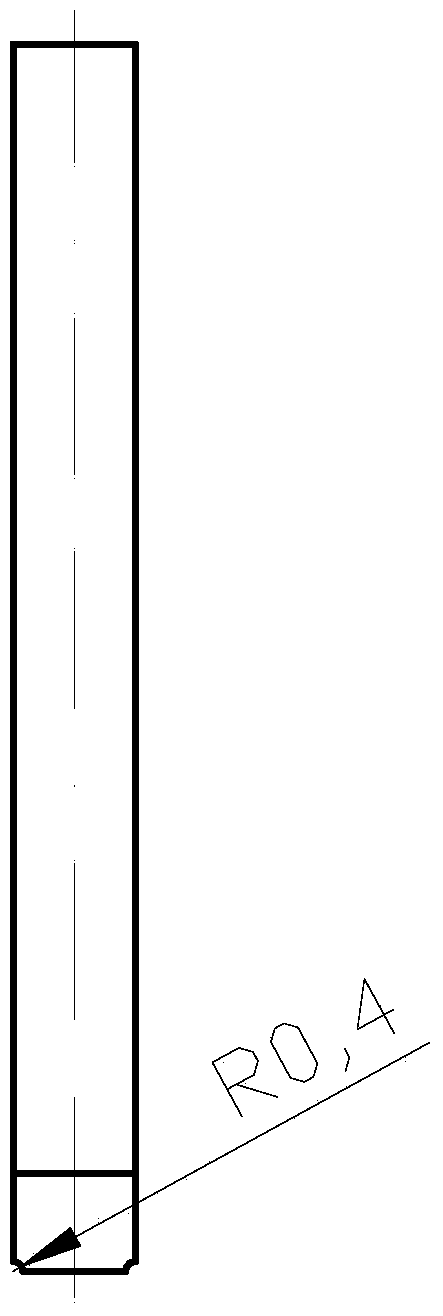

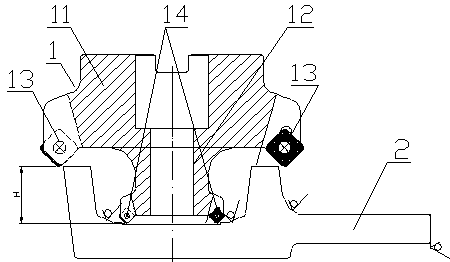

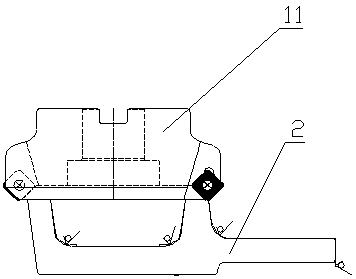

Superhard tungsten carbide deep hole shock-resistant inner-cooling adjustable boring tool

InactiveCN103028747AGuaranteed dimensional accuracy requirementsLow costBoring barsTurning toolsDiameter ratioCemented carbide

The invention discloses a superhard tungsten carbide deep hole shock-resistant inner-cooling adjustable boring tool. The tool comprises a cemented carbide toolbar which is connected with a scale end of an eccentric bushing with scales through a screw, the other end of the eccentric bushing with the scales is connected with a non-standard side fixed toolbar, and the diameter of the eccentric bushing with the scales can be adjusted. According to the tool, the tool does not need to be directly adjusted through a tool setting gauge, and according to the required hole size precision and length-diameter ratio, the boring toolbar and the adjustable eccentric bushing with accurate scales are designed; according to the processed material, machine tool configuration, connection mode and rotation angle during the process, the cutting parameters of the tool in a static state are designed; and dimensional accuracy requirements can be ensured, and the tool is low in cost, is convenient and the manufacturing period is short.

Owner:TIANCHANG CYLINDER HEAD

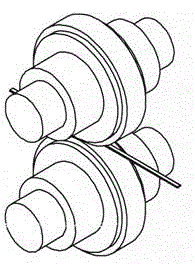

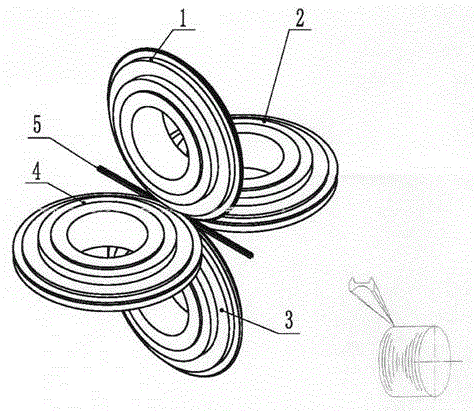

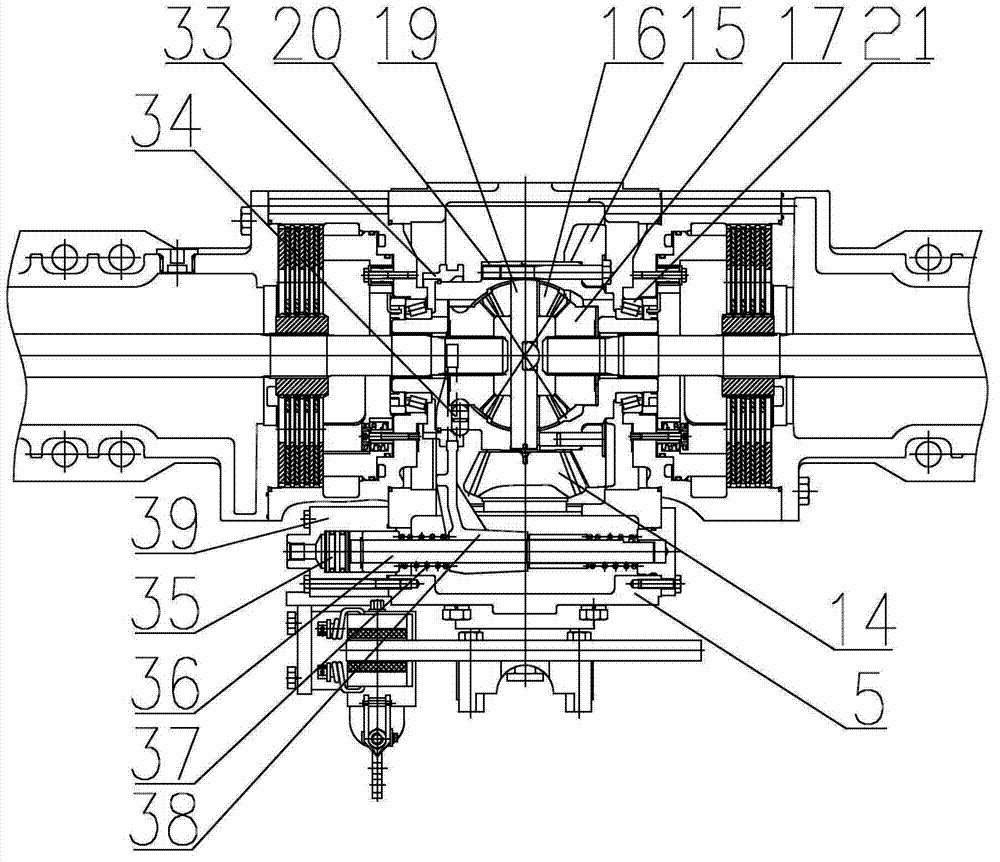

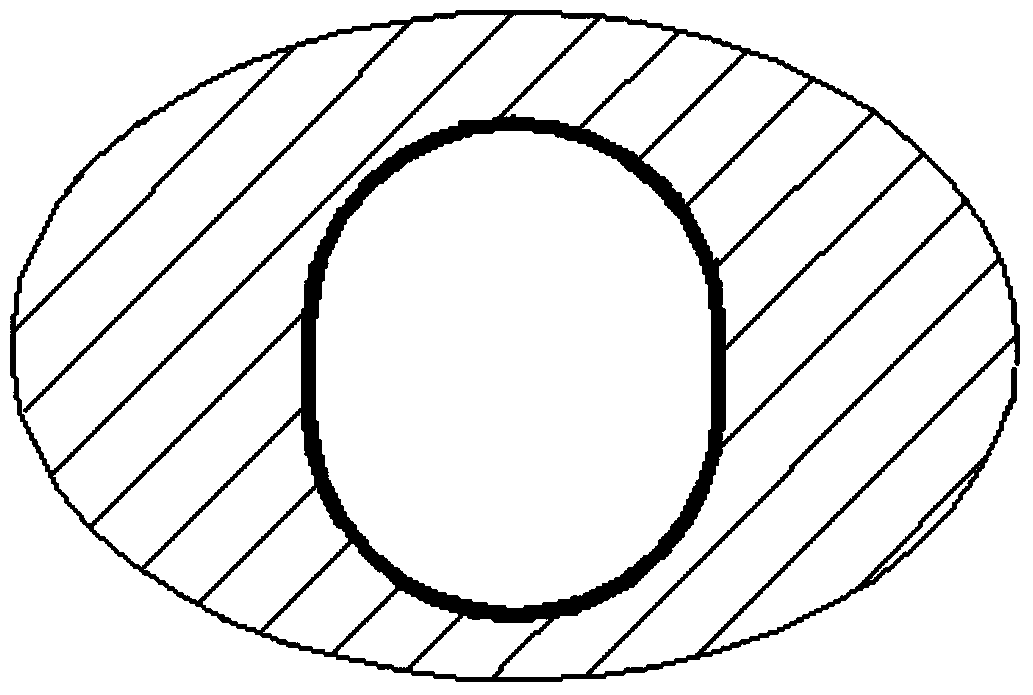

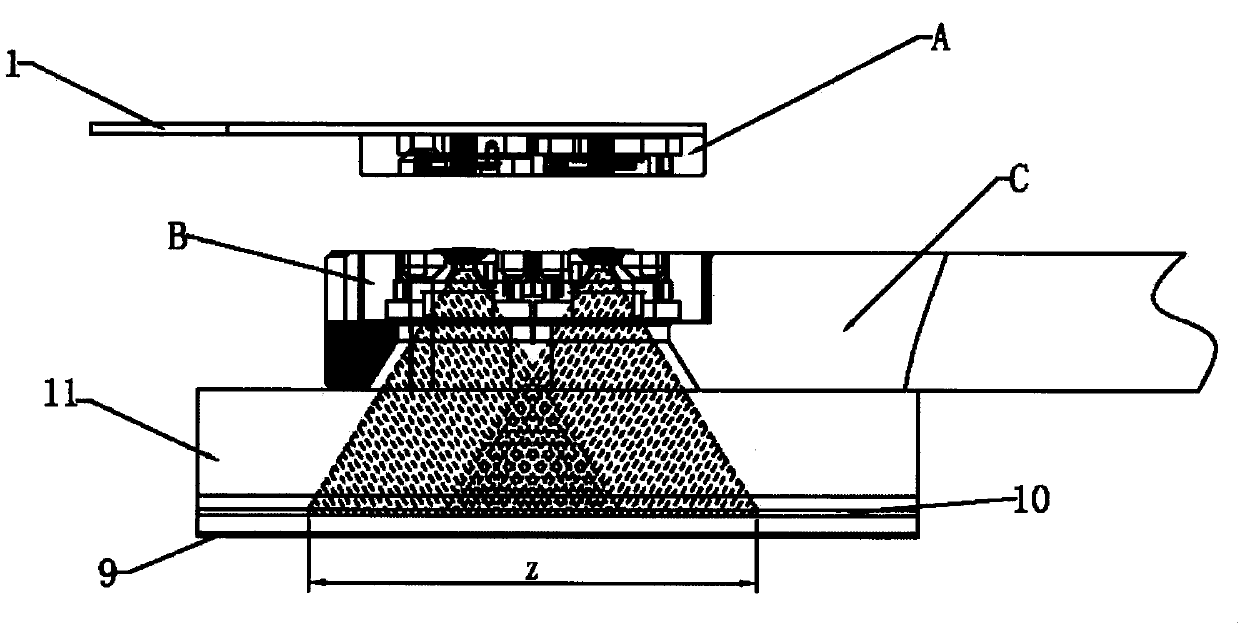

Processing technology and equipment for steel integral heterotype oil control ring wire rod moulding

ActiveCN104028575AGuaranteed accuracy requirementsGuaranteed dimensional accuracy requirementsWire rodCombustion

The invention relates to a manufacturing method of a steel integral heterotype oil control ring wire rod. The method includes: (1) selecting a round steel wire raw material; (2) rolling, namely, rolling a steel wire rod into a rectangular cross-section shape; (3) annealing, namely, subjecting the rolled wire rod to annealing, rolling and annealing again; (4) rolling a heterotype wire rod, namely, subjecting the wire rod to steps of pre-moulding, primary-moulding and refined moulding, and rolling to obtain a needed heterotype cross-section shape; (5) annealing, namely, subjecting the pre-moulded and primarily-moulded heterotype wire rod to annealing and rolling respectively; (6) quenching and tempering, namely, subjecting the heterotype wire rod after refined moulding to quenching and tempering treatment; and (7) performing laser drilling, namely, subjecting the wire rod after quenching tempering and moulding to oil return hole laser cutting so as to obtain the steel integral heterotype oil control ring wire rod. The method has characteristics of high machining precision, low cost, high yield of finished products, good product shape, high dimension precision and good quality, and can be used for manufacturing oil control rings of piston rings of internal combustion engines, thus meeting the technical requirements of the piston rings of the internal combustion engines.

Owner:福建东亚机械有限公司

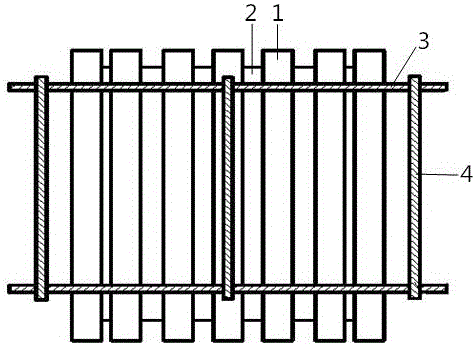

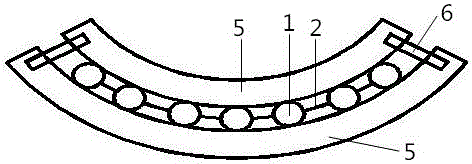

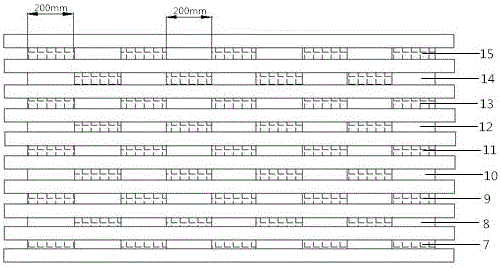

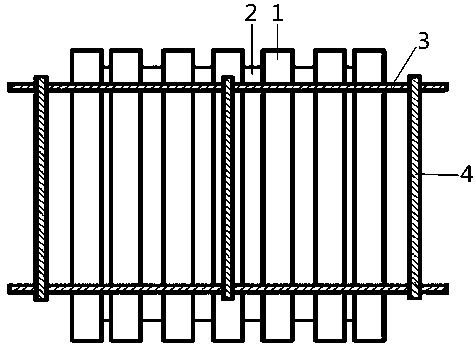

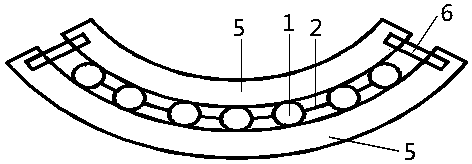

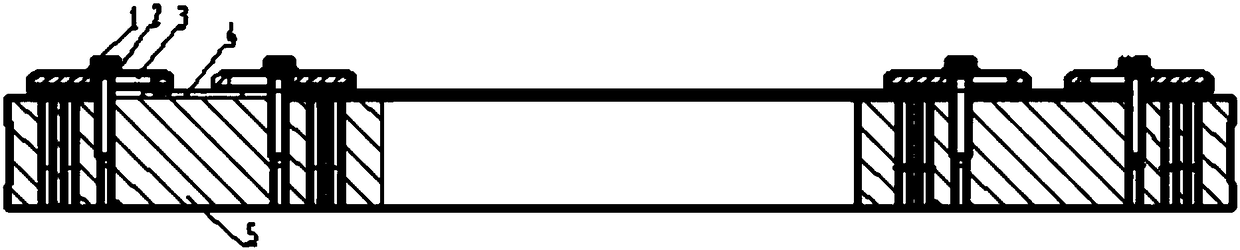

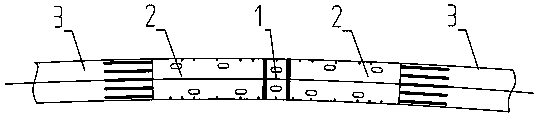

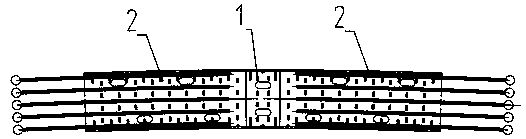

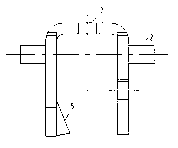

Welding method for nickel-based membrane type wall tube panel

ActiveCN106238866AAvoid deformationGuaranteed dimensional accuracy requirementsCooled electrode holdersEngineeringWeld line

The invention discloses a welding method for a nickel-based membrane type wall tube panel. The welding method includes the following steps that a tube panel is formed by nickel-based tubes (1) and nickel-based flat steel (2), and an anti-deformation tool (3) is arranged at each of the two ends of the tube panel; during welding, a specific welding sequence, a specific welding mode and specific welding line energy are adopted; and it is always kept that flowing cooling water exists in the tube panel in the welding process. The nickel-based tube panel is welded through the welding method, deformation and heat cracks, generated in the welding process, of the nickel-based tube panel can be effectively avoided, therefore, the dimensional precision requirement of the nickel-based tube panel is guaranteed, the repair amount of the nickel-based tube panel is reduced, the production period of the nickel-based tube panel is shortened, and the quality of the nickel-based tube panel is improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

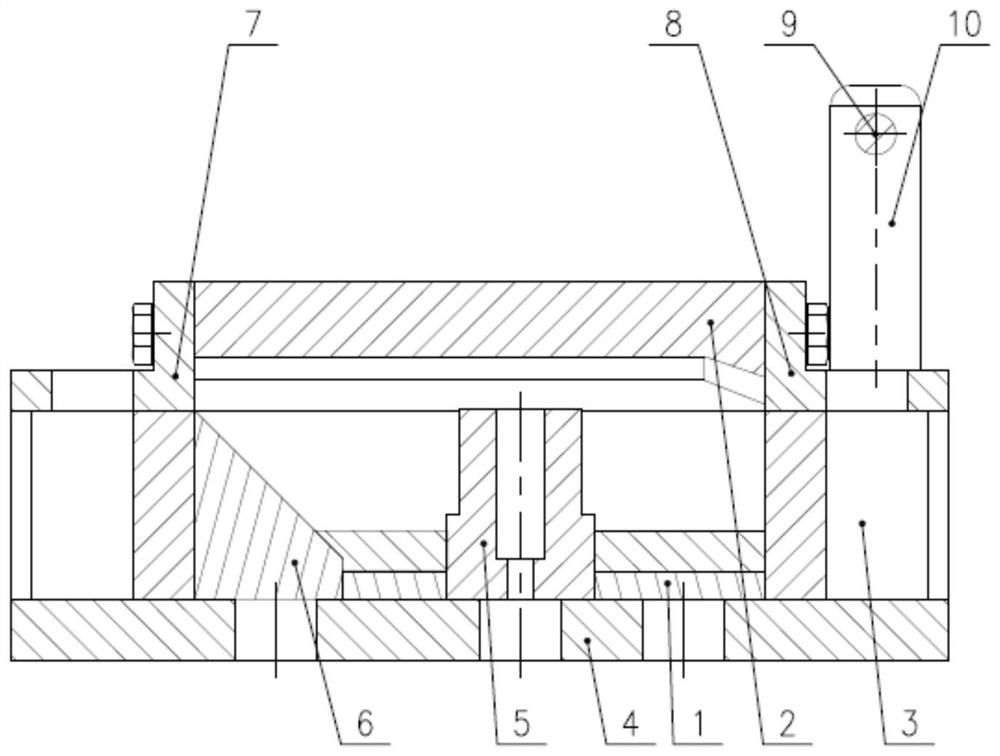

Automatic locating and testing socket for CMOS camera shooting chip floating carrier plate

ActiveCN103439541AEasy to operateEasy to useMeasurement instrument housingIndividual semiconductor device testingCamera lensEngineering

The invention discloses an automatic locating and testing socket for a CMOS camera shooting chip floating carrier plate. The automatic locating and testing socket comprises an upper cover and a base which are mutually matched. A PCB pinboard, a testing unit and the floating carrier plate are sequentially distributed on the base from bottom to top. The upper cover comprises a testing camera lens and a camera lens pressing plate, wherein a light source is arranged in a dark room in front of the testing camera lens, and a comparison image is positioned between the testing camera lens and the light source. The testing unit comprises a plurality of testing probes, a testing probe retention main body, a probe retention plate and a probe retention frame, wherein the testing probe retention main body, the probe retention plate and the probe retention frame are used for installing the testing probes. Furthermore, when the upper cover and the base are buckled, the floating carrier plate is in contact with the camera lens pressing plate, and the floating carrier plate is pushed by the camera lens pressing plate to move downwards. Meanwhile, the floating carrier plate is at least connected with an elastic element which is used for providing force driving the floating carrier plate to move upwards. The automatic locating and testing socket is suitable for different testing machines, can test CMOS chips automatically, efficiently and accurately and is not prone to damaging the CMOS chips.

Owner:SUZHOU CHUANGRUI MACHINERY & ELECTRICAL TECH

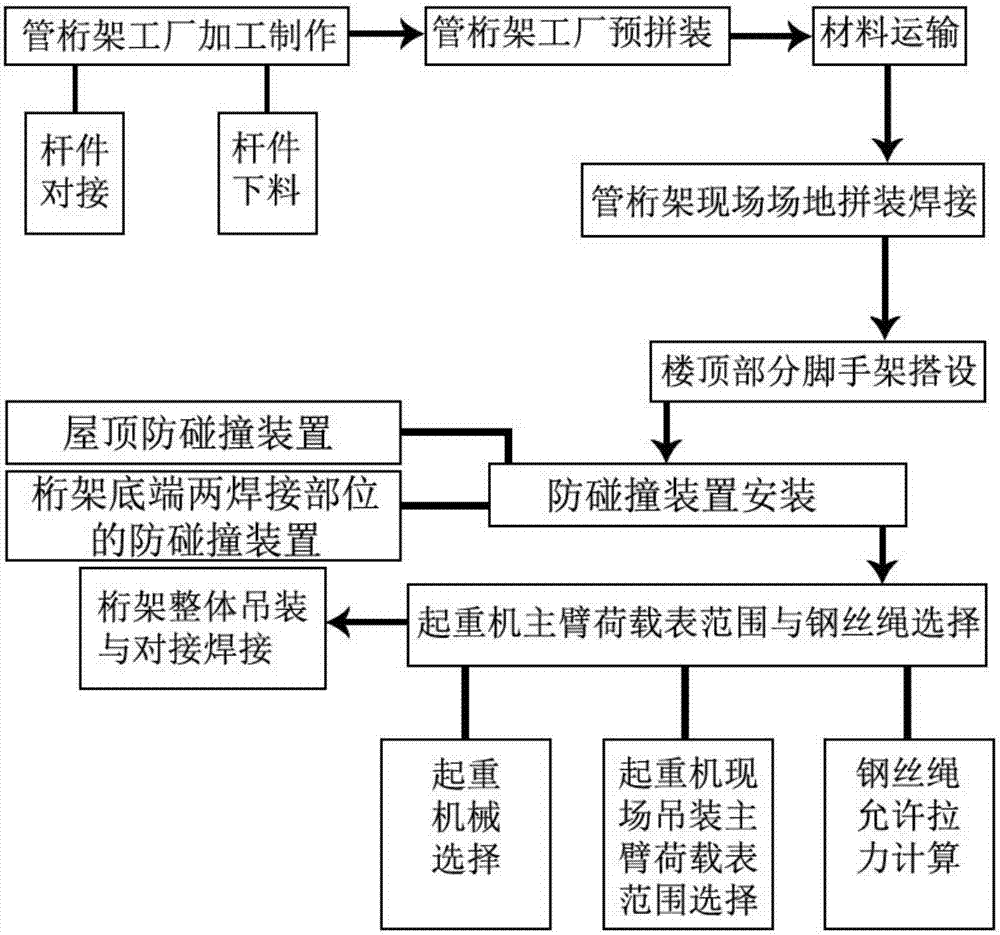

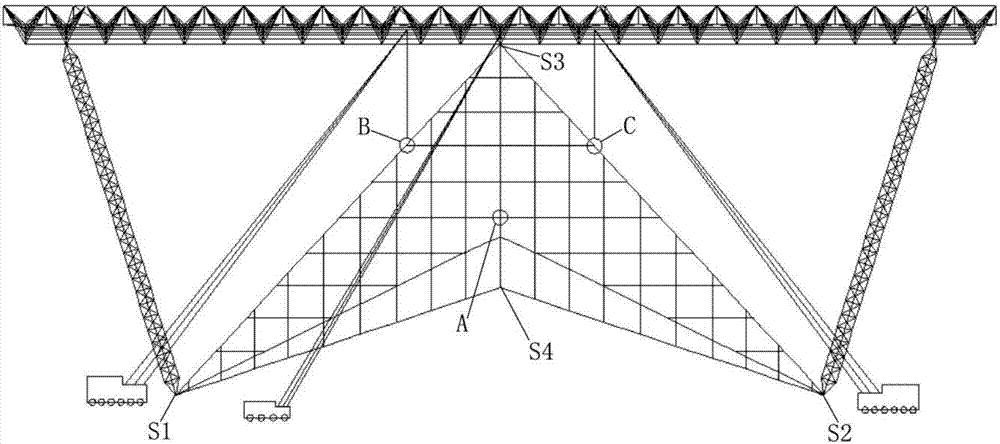

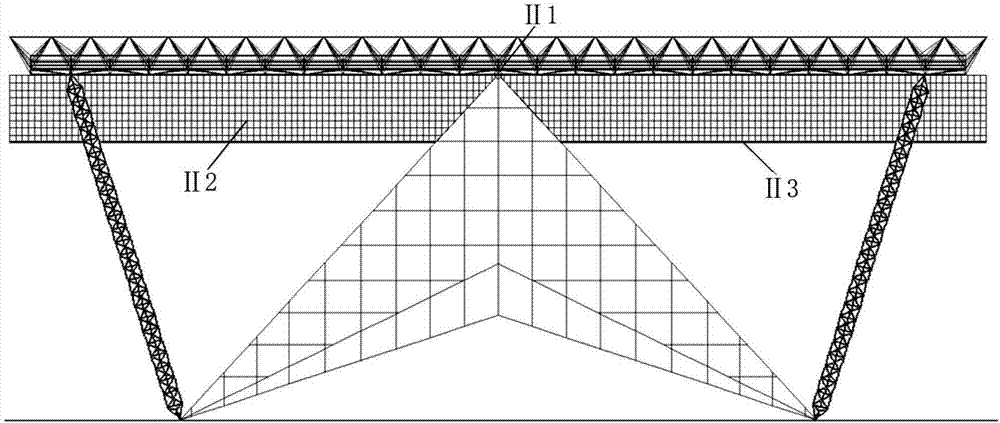

Construction method for integrally hoisting large-size multi-edge-and-corner overhanging truss

ActiveCN107100309AImprove assembly efficiencyEasy constructionBuilding roofsBuilding material handlingTerrainButt welding

A construction method for integrally hoisting a large-size multi-edge-and-corner overhanging truss is disclosed. Integral assembling of a steel pipe truss is conducted on site, and integral hoisting is conducted after assembling is completed; the truss is connected with three welding positions in a butt-joint mode and then is welded firmly; two 500 t all-terrain cranes and a 350 t all-terrain crane are adopted to hoist the whole truss simultaneously, and step-by-step hoisting is conducted from south to north; the truss is totally provided with three main stress support joints which are all fixed by adopting butt welding, a third calibration point support is located at the top of the truss, a welded ball joint at the position of the third calibration point is a support point of a steel rainshed grid frame actually, a first calibration point support and a second calibration point support are located on both the left and right sides of the bottom of the truss correspondingly, and the first calibration point support and the second calibration point support are global stress supporting points of the truss. The construction method for integrally hoisting the large-size multi-edge-and-corner overhanging truss has the characteristics that the construction safety is high, the construction period is short, the engineering quality is easy to guarantee, the ground integral assembling efficiency is high, and the construction cost is reduced greatly.

Owner:FUJIAN MINNAN CONSTR ENG

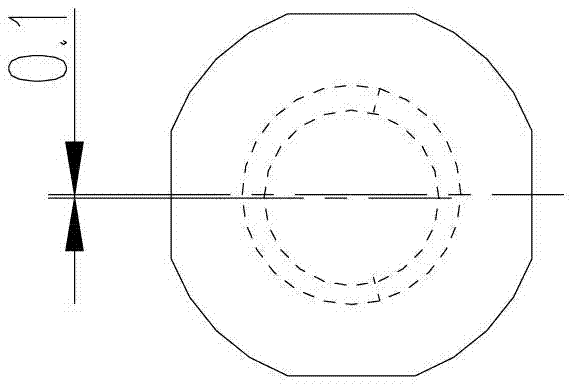

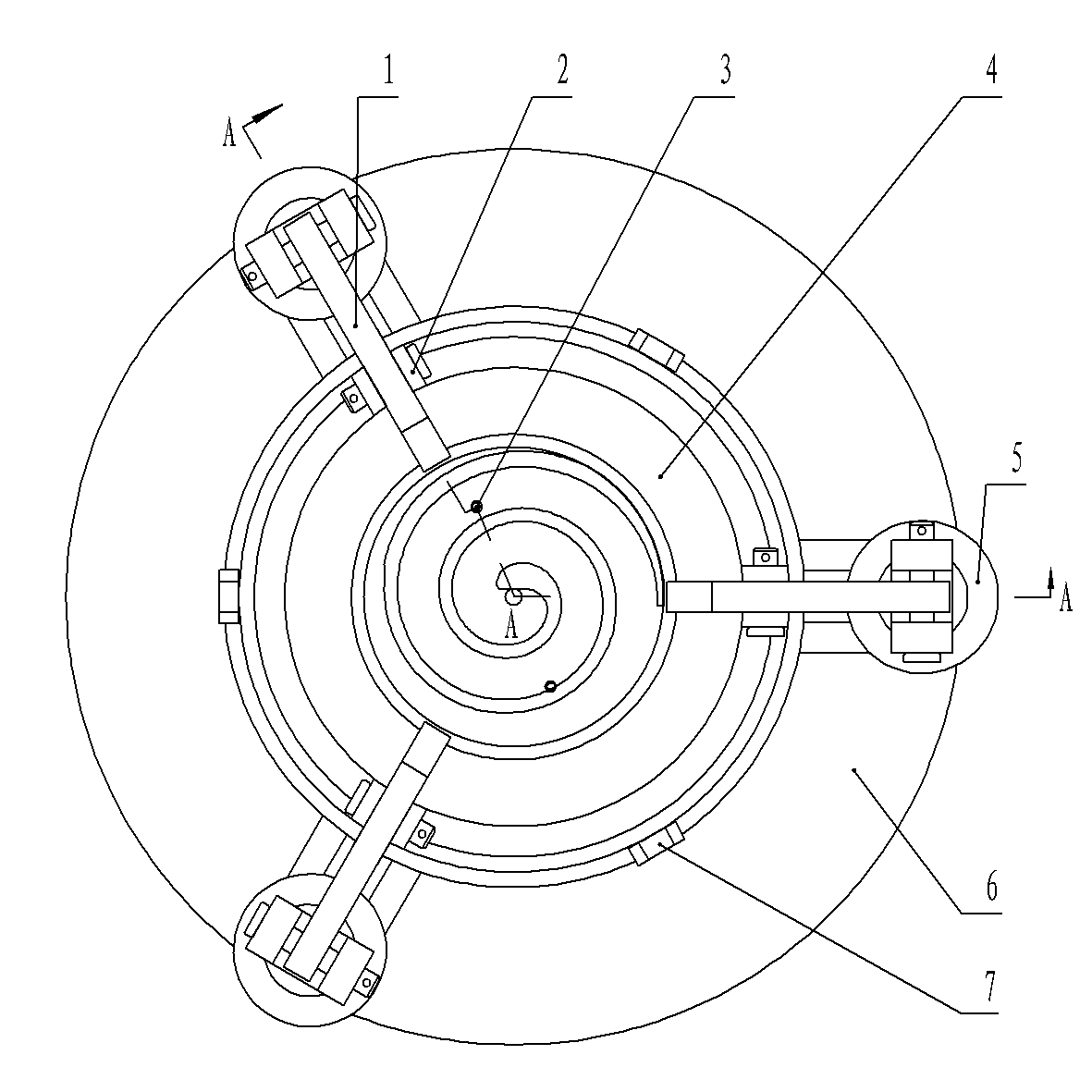

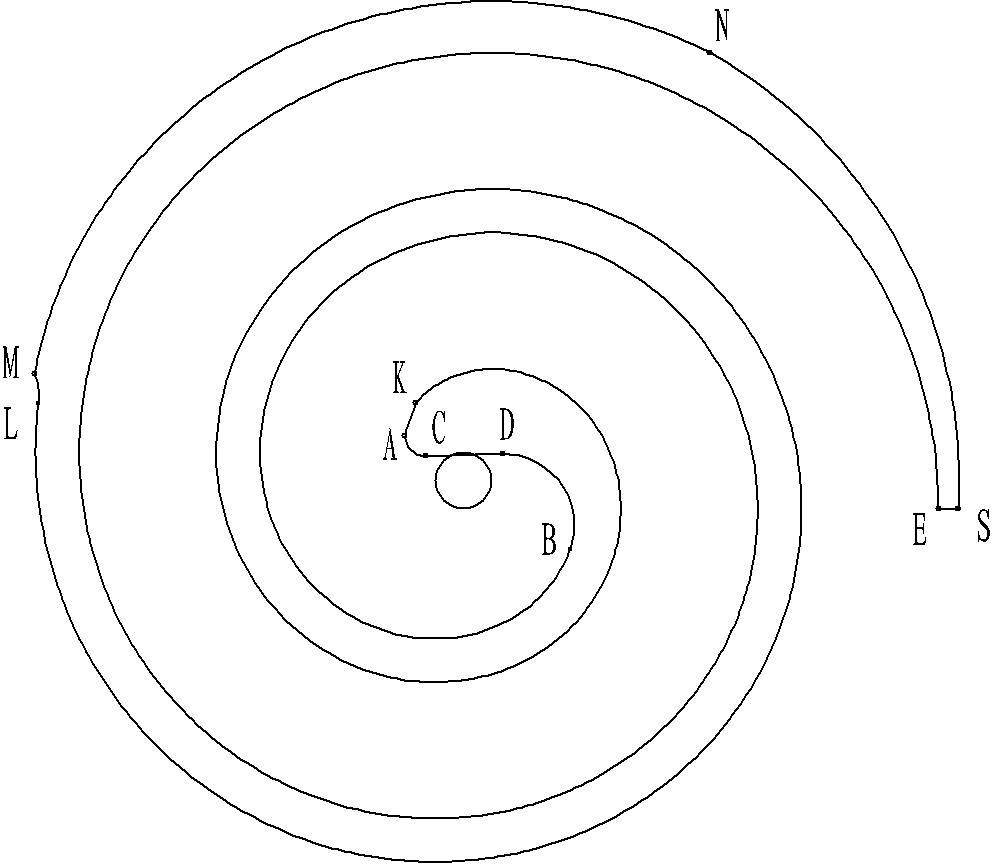

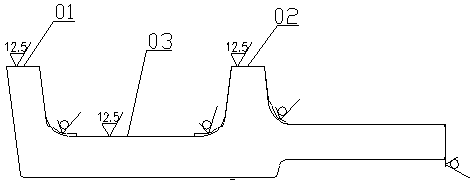

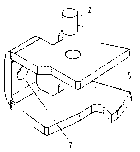

Method for machining molded line of scroll plate

ActiveCN103084888AReduce processing timeImprove processing efficiencyMilling equipment detailsPositioning apparatusEngineeringMachining

The invention discloses a method for machining a molded line of a scroll plate, and relates to the technical field of mechanical machining. The scroll plate is provided with an end plate and a scroll wall thereon, wherein an annular groove is formed in the periphery of the end plate; and a positioning hole is formed in the lower end face of the end plate. According to the method, a clamp for machining the molded line of the scroll plate is fixedly arranged on a workbench of a vertical machining center; the scroll plate is fixed on the clamp for machining the molded line of the scroll plate by a spring check ring; according to rough machining and semifinishing, a cutter feeding instruction of a cutter is set into fifth-degree step lengths; and according to finish machining, a cutter feeding instruction of the cutter is set into first-degree step lengths. Compared with the prior art, the method has the advantages that the cutter feeding instruction of the cutter is set from large to small, the machining accuracy is improved gradually, and machining equipment and the cutter are used reasonably while the machining accuracy of the molded line is ensured, so that the efficiency of machining the molded line is improved.

Owner:LIUZHOU YIZHOU AUTOMOBILE AIR CONDITIONER

Rear drive axle assembly

ActiveCN102774240ASimple structureEffective decelerationBraking element arrangementsAxle unitsDrive shaftReduction drive

The invention discloses a rear drive axle assembly. The rear drive axle assembly comprises an axle casing which is in a girder structure, two wheel hubs, a main reducing gear and differential mechanism assembly, a braking assembly, a hub reduction gear, a forced differential lock and a parking brake, wherein the forced differential lock comprises a sliding meshing sleeve, a differential mechanism lockpin, a piston, a selector rod, a back-moving spring and a shifting fork, the shifting fork is connected fixedly with a shifting fork shaft, the back-moving spring is arranged between the shifting fork and the shifting fork shaft, a groove which is matched with the shifting fork is arranged on the sliding meshing sleeve, grooves which are matched with the differential mechanism lockpin are arranged on the sliding meshing sleeve and a driving shaft gear of the main reducing gear and differential mechanism assembly correspondingly, the parking brake comprises a brake body and a brake disk, the brake body is arranged on a main reducing gear casing of the main reducing gear and differential mechanism assembly, the brake disk is arranged on a main tooth flange, and a plane and an installation hole, which are connected with the machine base plate, are arranged on the axle casing. The rear drive axle assembly has the advantages of being good in parking and heat radiation performance, large in bearing capacity, simple in structure and convenient to process and produce.

Owner:南京创捷和信汽车零部件有限公司

Processing methods of High temperature alloy GH4169 special-shaped hole and hole edge fillet

The invention relates to processing methods of a high temperature alloy GH4169 special-shaped hole and a hole edge fillet. The molded special-shaped hole has the biggest outline size of (1mm-3.5mm)* (2mm-8mm); the processing method of the special-shaped hole comprises the following steps: (1) dotting and drilling a bottom hole, namely, firstly dotting by a center drill, then selecting a phi 3 drill bit to drill the bottom hole, and removing most of the margin; (2) rough milling, namely, carrying out rough milling by a phi 3 milling cutter. After the processing methods of the high temperature alloy GH4169 special-shaped hole and the hole edge fillet are adopted, the problems that the small-sized special-shaped holes and the hole edge fillets of high temperature alloy GH4169 material disc ring parts are low in processing efficiency and instable in processing quality, the milling cutter is short in service life, the cutting edge of the milling cutter is easily broken, and the like can be solved. The processing methods of the high temperature alloy GH4169 special-shaped hole and the hole edge fillet can be popularized and used in similar parts, and have wide application prospect in manufacture of an aero-engine and a ground turbine combustion engine.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

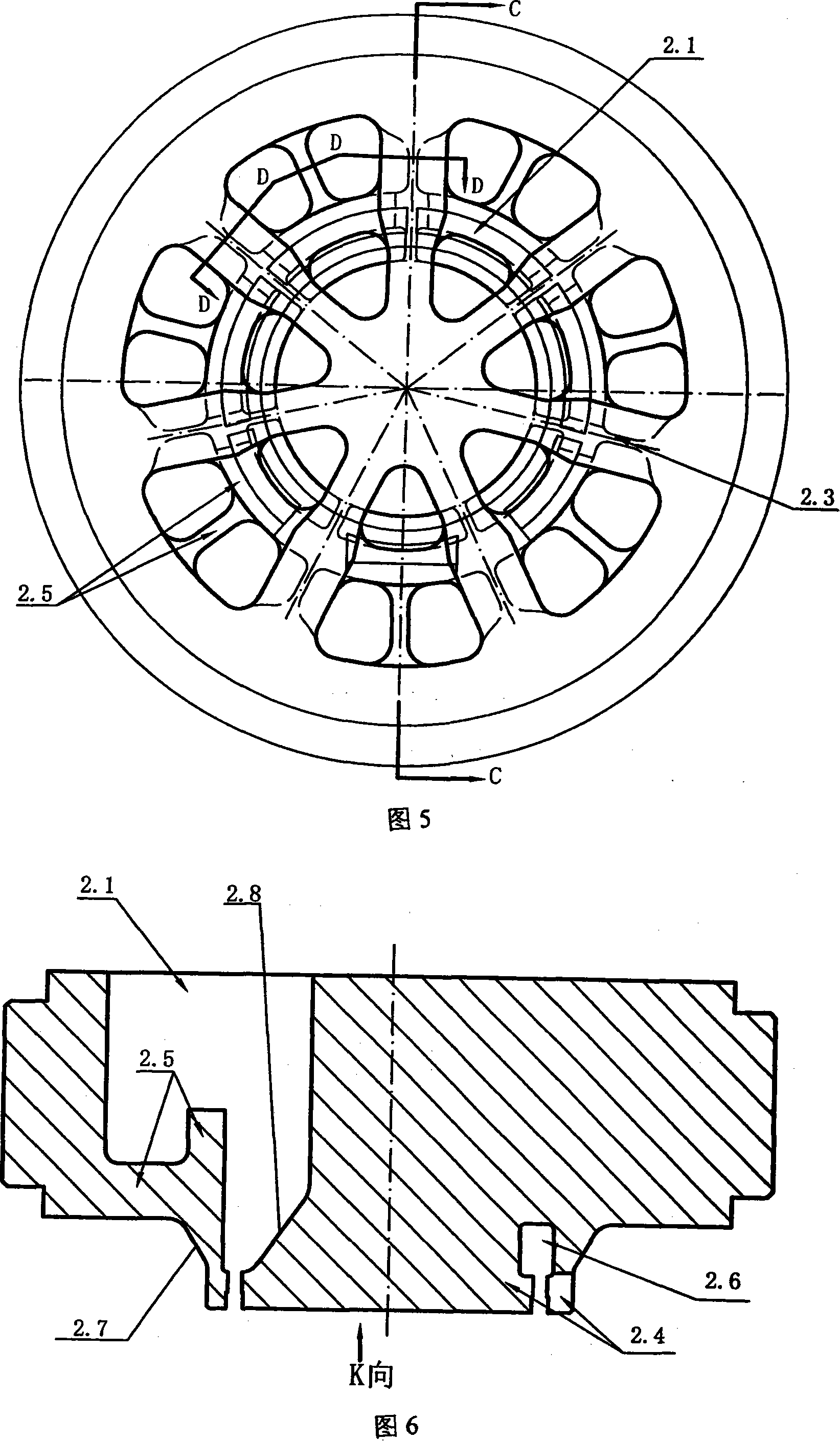

Multi- structure motor enclosure aluminium alloy hot-extrusion die

InactiveCN101081412AMeet the feed requirementsPlay a protective effectExtrusion diesManufacturing dynamo-electric machinesMetal flowAluminium alloy

The hot extruding die for producing hollow motor housing of aluminum alloy consists of one guide die, one upper die and one lower die superposed together. The guide die has in the feeding side seven bridge sites and seven shunting holes; the upper die has seven bridge sites and seven material shunting holes in the feeding side, and 21 discharge shunting holes separately in two circles, inner bridge sites and eight die cores in the discharge side; and the lower die has one welding chamber and two choking lugs in the feeding side. The hot extruding die can equalize the metal flow, capacity of ensuring high product quality and yield, and long service life.

Owner:JIANGYIN GIANSUN MOLD

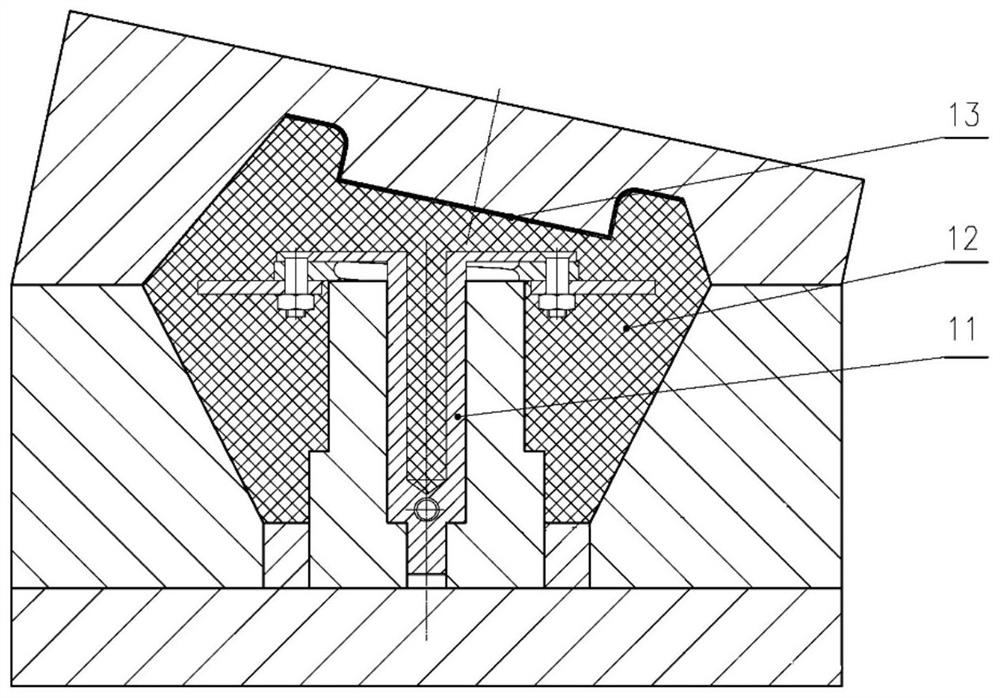

Wafer level camera shooting module WLC automatic testing socket

InactiveCN103439540AEasy to operateEasy to useMeasurement instrument housingIndividual semiconductor device testingCamera lensEngineering

The invention discloses a wafer level camera shooting module WLC automatic testing socket which comprises a base, a module placing structure and a light source unit. The base is connected with a PCB pinboard. The base comprises a test unit which is mounted in a socket maintaining frame. The test unit comprises a plurality of test probes, a probe maintaining main body and a probe maintaining plate, wherein the probe maintaining main body and the probe maintaining plate are sequentially distributed in the direction far away from the PCB pinboard. The module placing structure comprises a placing maintaining frame and a floating plate, the placing maintaining frame is provided with at least one module placing groove, and the floating plate is arranged between the module placing groove and the probe maintaining main body. The light source unit comprises an LED lamp panel and a standard plate which are arranged inside a camera obscura. The module placing groove, a lens connected to the placing maintaining frame, the LED lamp panel and the standard plate are sequentially distributed in the direction far away from the PCB pinboard. The wafer level camera shooting module WLC automatic testing socket can be compatible with different testing machines, automatic, efficient and accurate testing of a WLC module can be achieved, and the module and a chip can not be damaged.

Owner:SUZHOU CHUANGRUI MACHINERY & ELECTRICAL TECH

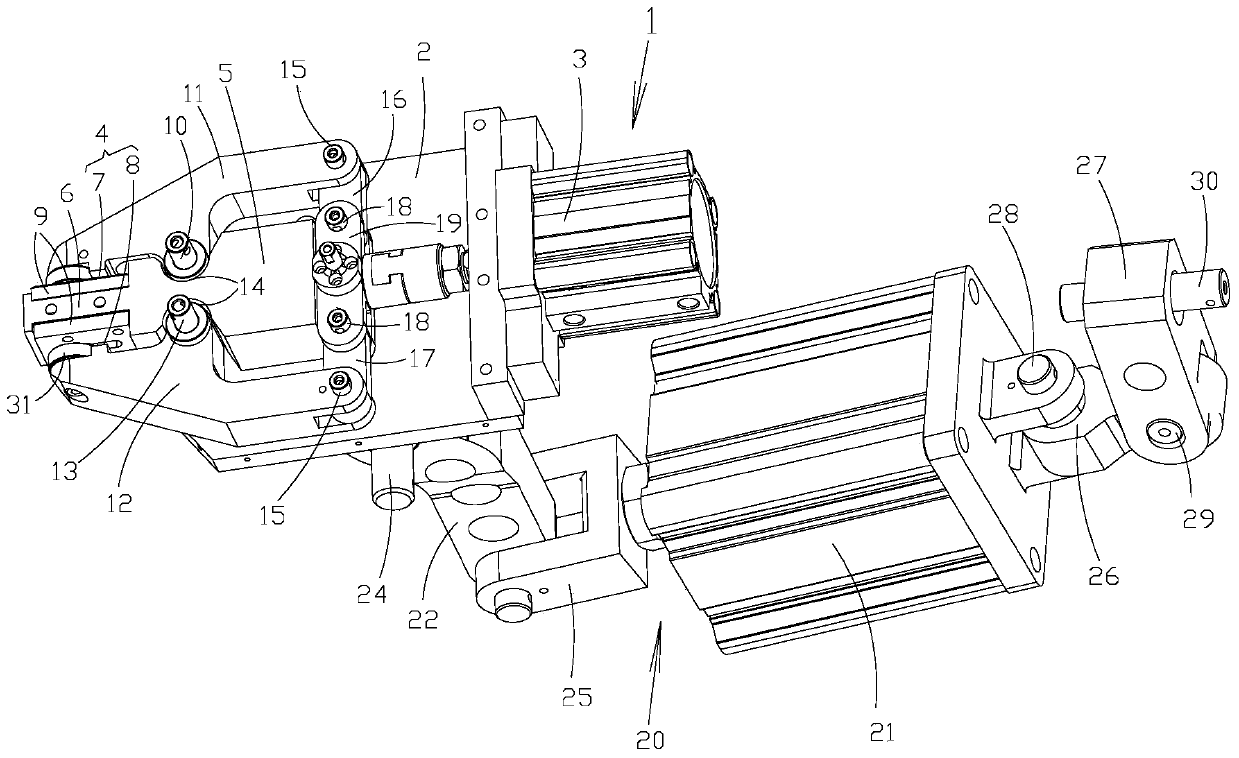

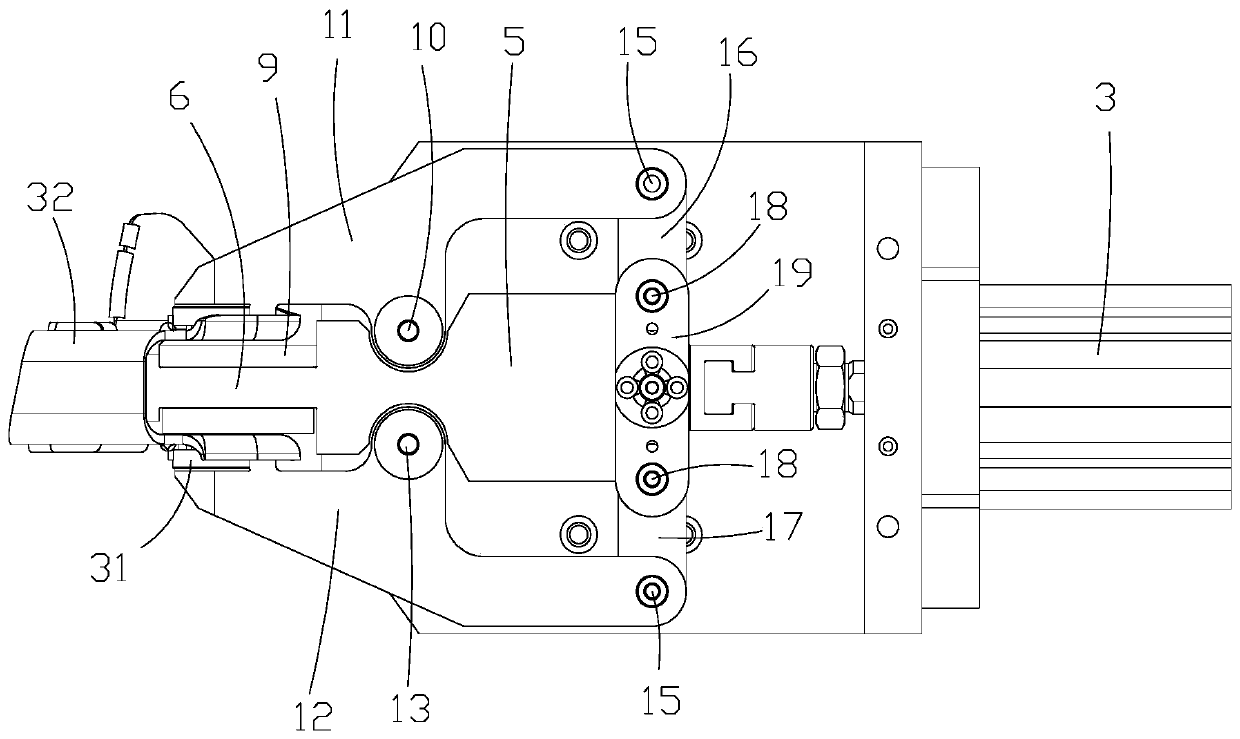

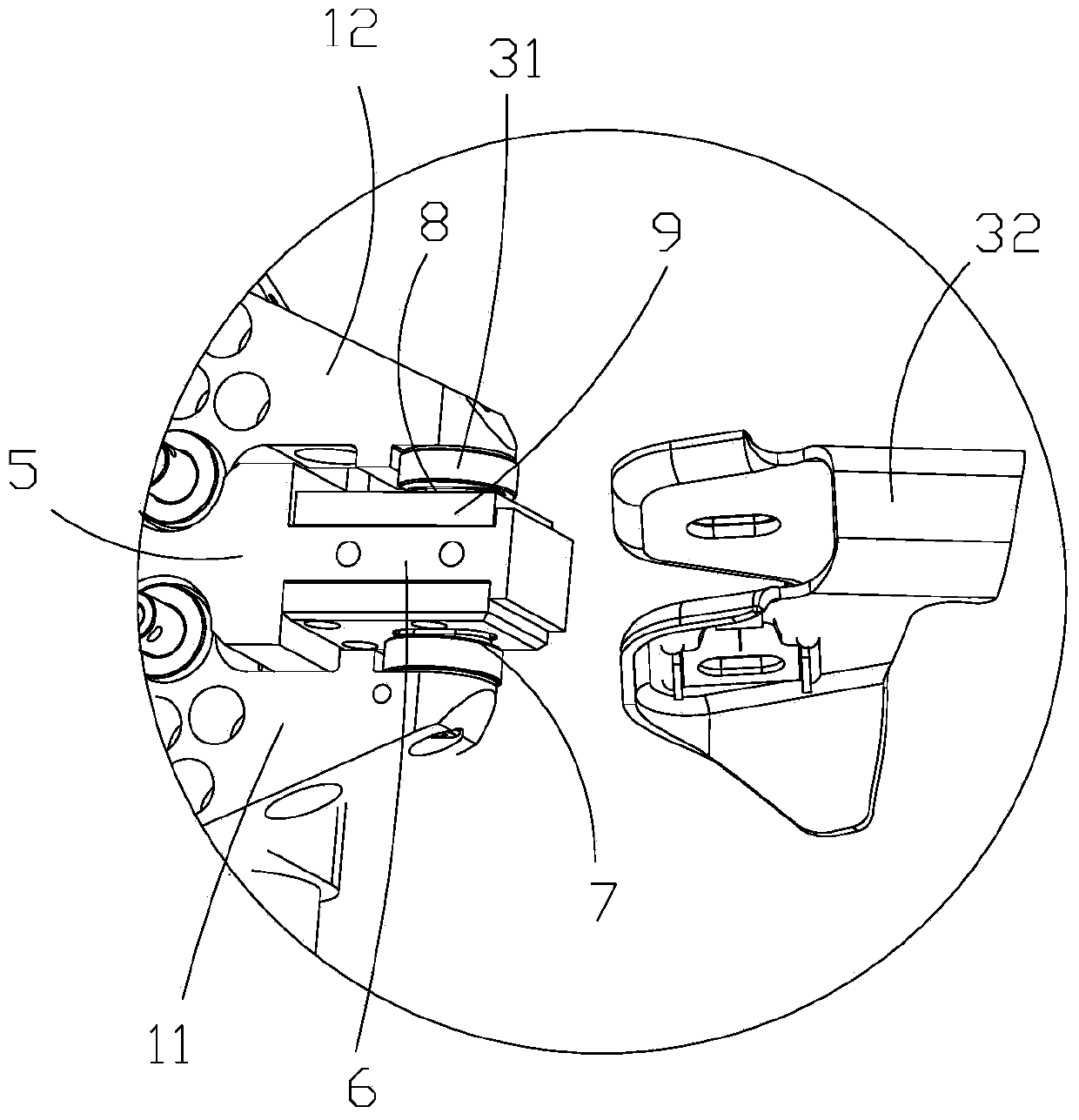

Workpiece clamping and positioning mechanism and workpiece clamping and positioning assembly

ActiveCN106141527BRealize the clamping effectAchieve releaseWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringRobot welding

The invention relates to the technical field of fixtures, and provides a workpiece clamping and positioning mechanism and a workpiece clamping and positioning assembly. The workpiece clamping and positioning mechanism includes a clamping device, and the clamping device includes a base, a first clamping arm, a second clamping arm and a first power source arranged on the base, and the first The front end of the clamping arm and the front end of the second clamping arm jointly form a clamping opening for clamping the workpiece, and the first power source is simultaneously connected with the first clamping arm and the second clamping arm The transmission connection is used to drive the first clamping arm and the second clamping arm to switch between the clamping position and the release position, so as to realize precise positioning of the workpiece and ensure the dimensional accuracy requirements of positioning, so as to ensure that the robotic welding torch is In the best welding condition.

Owner:GREAT WALL MOTOR CO LTD

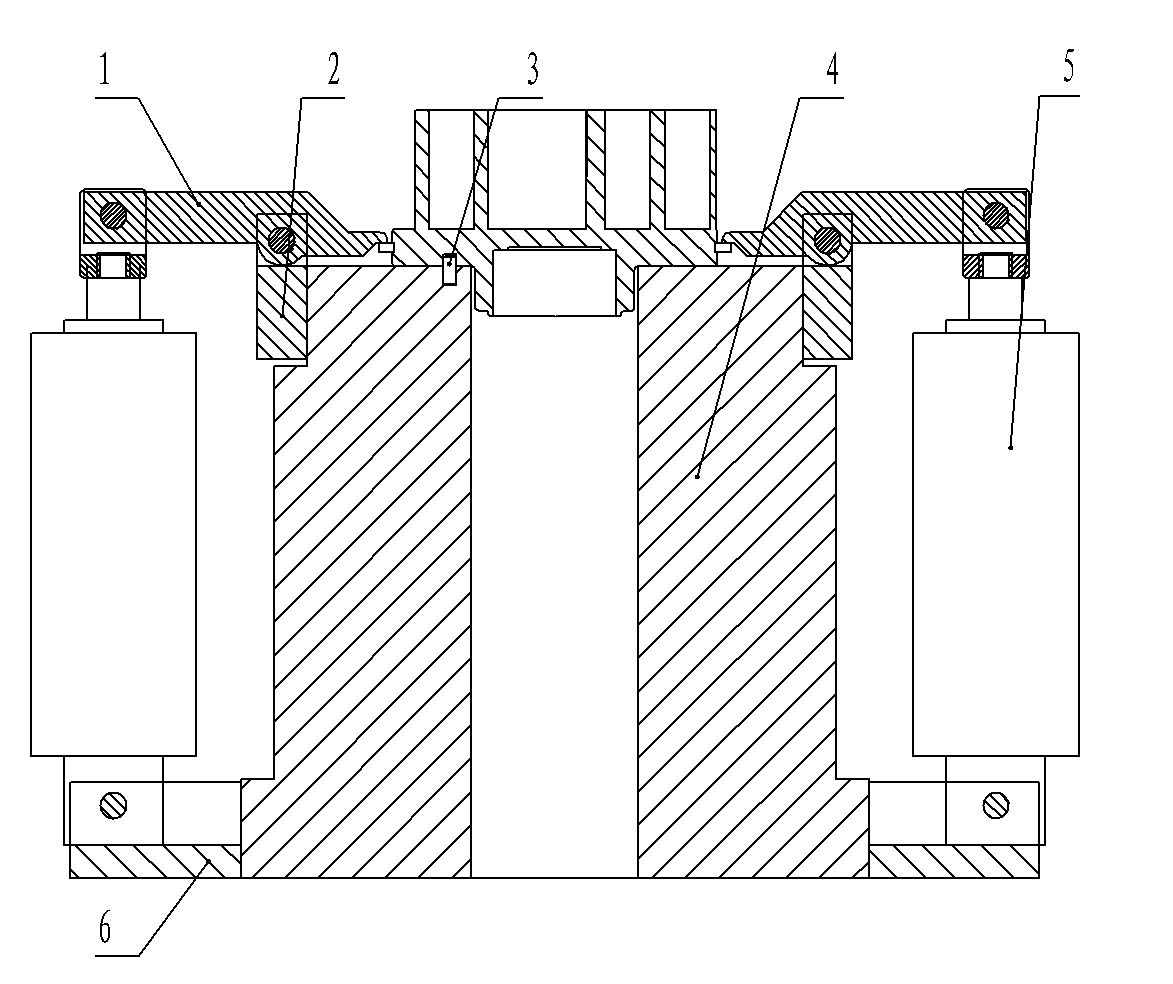

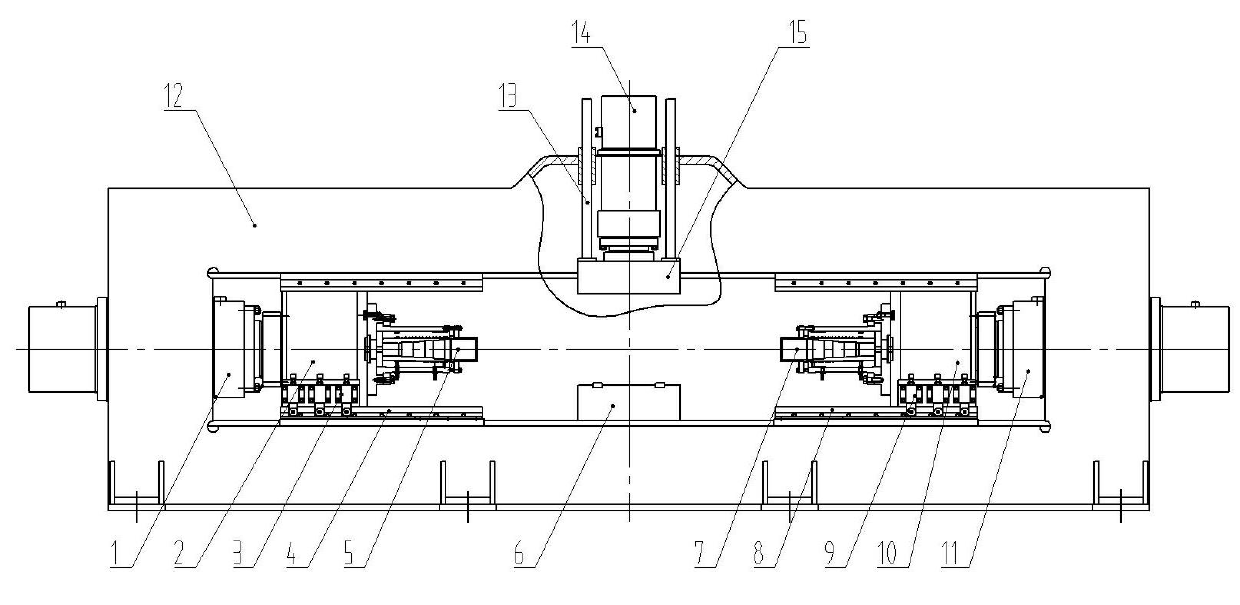

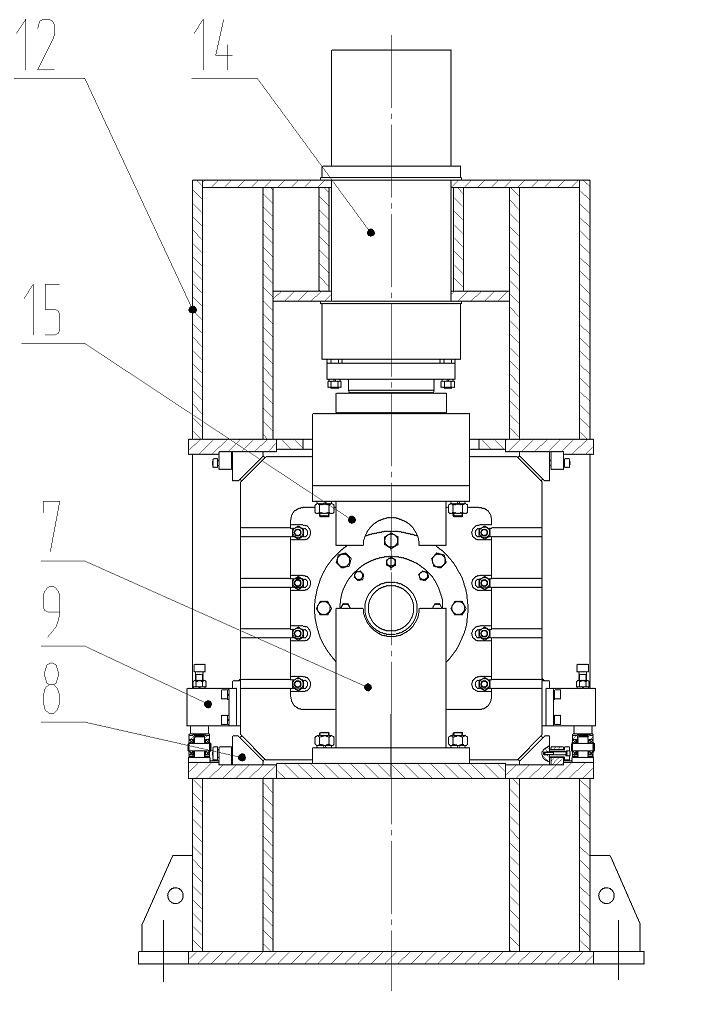

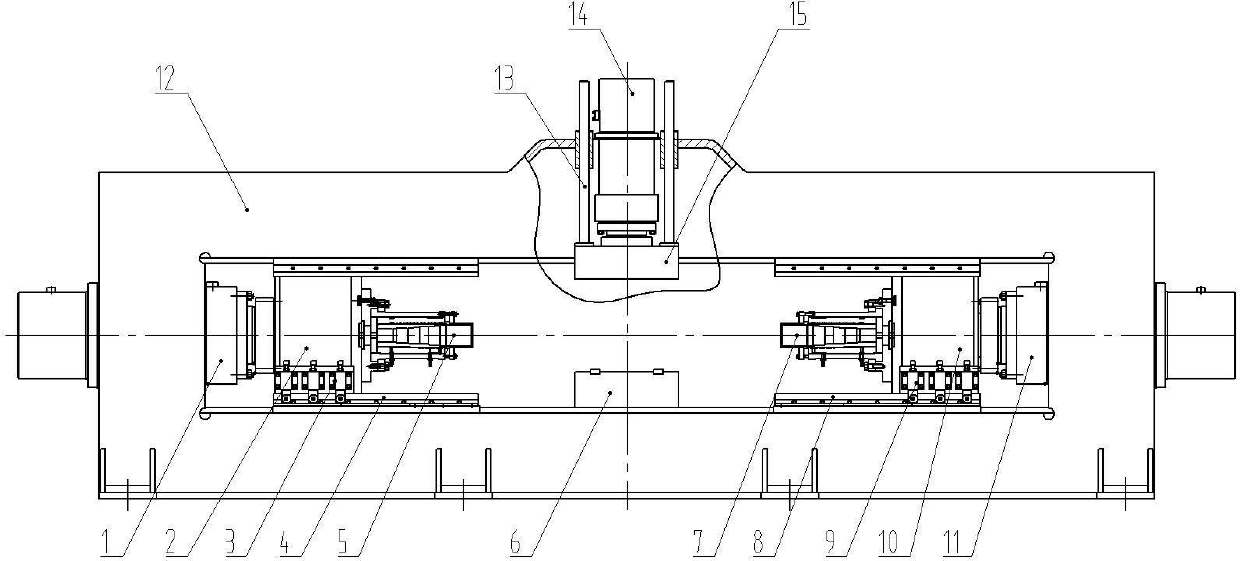

Once-forming extruding machine for tubular axle blank of heavy truck

The invention discloses a once-forming extruding machine for a tubular axle blank of a heavy truck and belongs to the field of equipment manufacturing. The machine comprises a rack, left and right horizontal thrust oil cylinders, left and right extrusion forming dies, a clamping oil cylinder and upper and lower clamping dies. The rack is of a T-shaped steel-structure framework; the left and right horizontal thrust oil cylinders are mounted at the left and right ends of the rack respectively; and the left and right extrusion forming dies are connected with piston rods of the left and right horizontal thrust oil cylinders respectively. The clamping oil cylinder is vertically mounted at the upper end of the middle part of the rack; the upper clamping die is connected with the piston rod of the clamping oil cylinder; and the upper clamping die is connected with the rack through a guide sleeve of a guide rod. The lower clamping die is mounted at the lower part of the rack. Sliders are arranged between the horizontal thrust oil cylinders and the extrusion forming dies; and the sliders are connected with the rack through a sliding guide rail and a wheel-type guide rail. The once-forming extruding machine disclosed by the invention has the advantages that the axle blank has high strength, the manufacturing processes of the axle blank are reduced, the production rate is improved, the blank material is easily prepared and can adopt a round pipe, and the material is saved.

Owner:XUZHOU DAYI METALFORMING EQUIP

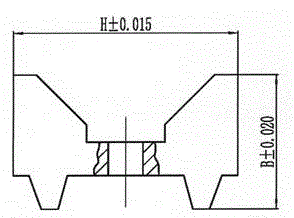

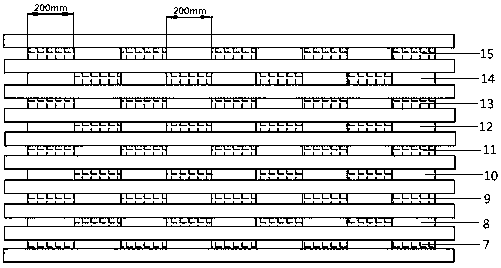

Tool capable of simultaneously machining magnetic pole face and detection face of medium- and low-speed magnetic levitation F rail

PendingCN108436161AGuaranteed dimensional accuracy requirementsAvoid errorsMilling cuttersMilling cutterMagnetic poles

The invention relates to a tool capable of simultaneously machining the magnetic pole face and the detection face of a medium- and low-speed magnetic levitation F rail. The tool is characterized in that the tool bodies of an F rail magnetic pole face milling tool and a detection face milling tool are integrated into an integral tool body with the bottom end face of the upper tool body being largerthan the upper end face of the lower tool body, magnetic pole face milling cutters are mounted on two sides of the bottom of the upper tool body, detection face milling tools are mounted on two sidesof the bottom of the lower tool body, and the distance H between a magnetic pole face milling cutter machining face and a detection face milling cutter machining face is equal to the distance betweenthe magnetic pole face and the detection face. The tool has the advantages that machining efficiency is doubled; the problems that the magnetic pole face and the detection face are machined separately in an original machining, two-step machining is needed, and cutter replacement or machine tool replacement is needed during the machining are solved; by the combined tool, the magnetic pole face andthe detection face can be machined simultaneously, cutting feeding time of another machining is saved, and cutter replacement is not needed during the machining; the dimension H from the magnetic pole face to the detection face is guaranteed by the dimension of the combined tool, cutter alignment errors during two-step machining are avoided, and the dimension precision requirements from the magnetic pole face to the detection face are guaranteed reliably and effectively.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP +1

Welding method of nickel base membrane wall tube panel

ActiveCN106238866BAvoid deformationGuaranteed dimensional accuracy requirementsCooled electrode holdersEngineeringWeld line

The invention discloses a welding method for a nickel-based membrane type wall tube panel. The welding method includes the following steps that a tube panel is formed by nickel-based tubes (1) and nickel-based flat steel (2), and an anti-deformation tool (3) is arranged at each of the two ends of the tube panel; during welding, a specific welding sequence, a specific welding mode and specific welding line energy are adopted; and it is always kept that flowing cooling water exists in the tube panel in the welding process. The nickel-based tube panel is welded through the welding method, deformation and heat cracks, generated in the welding process, of the nickel-based tube panel can be effectively avoided, therefore, the dimensional precision requirement of the nickel-based tube panel is guaranteed, the repair amount of the nickel-based tube panel is reduced, the production period of the nickel-based tube panel is shortened, and the quality of the nickel-based tube panel is improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

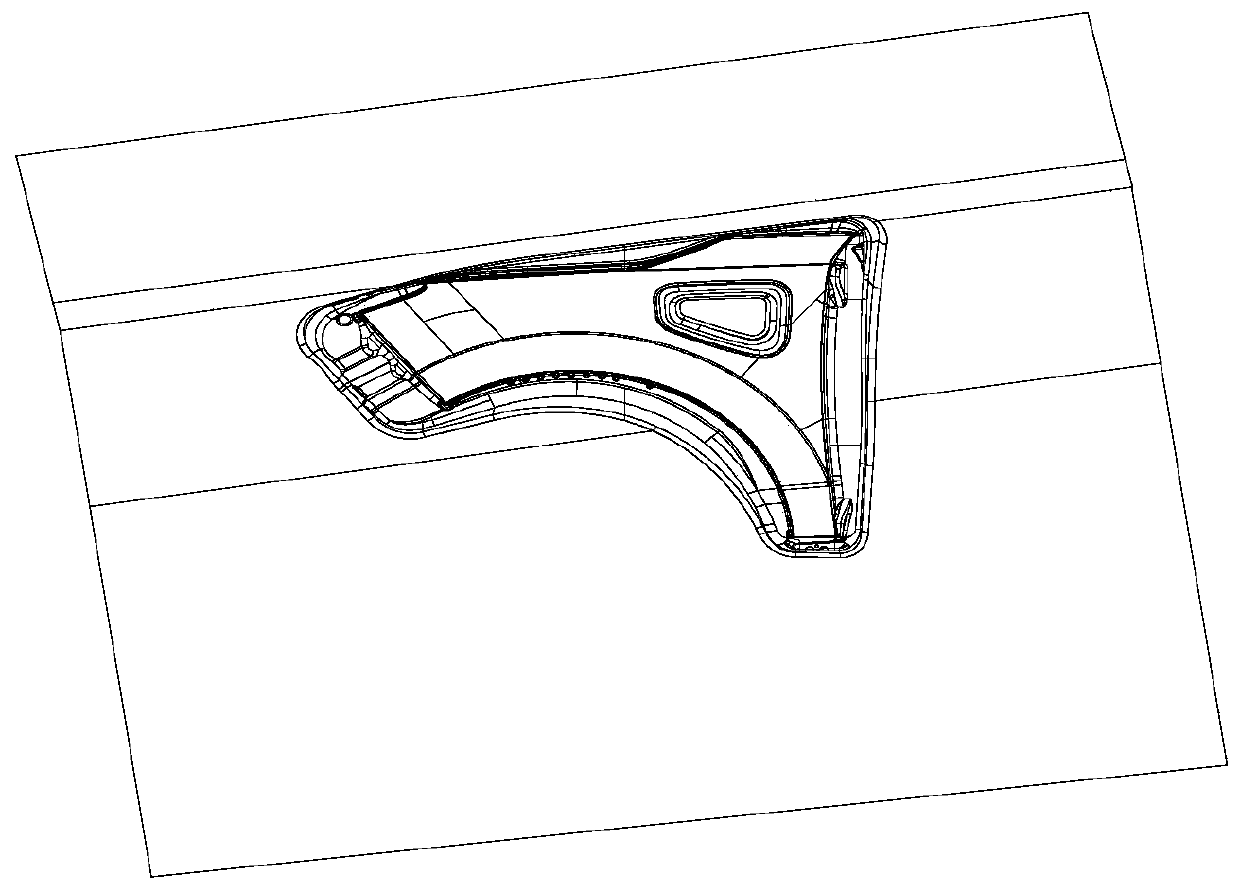

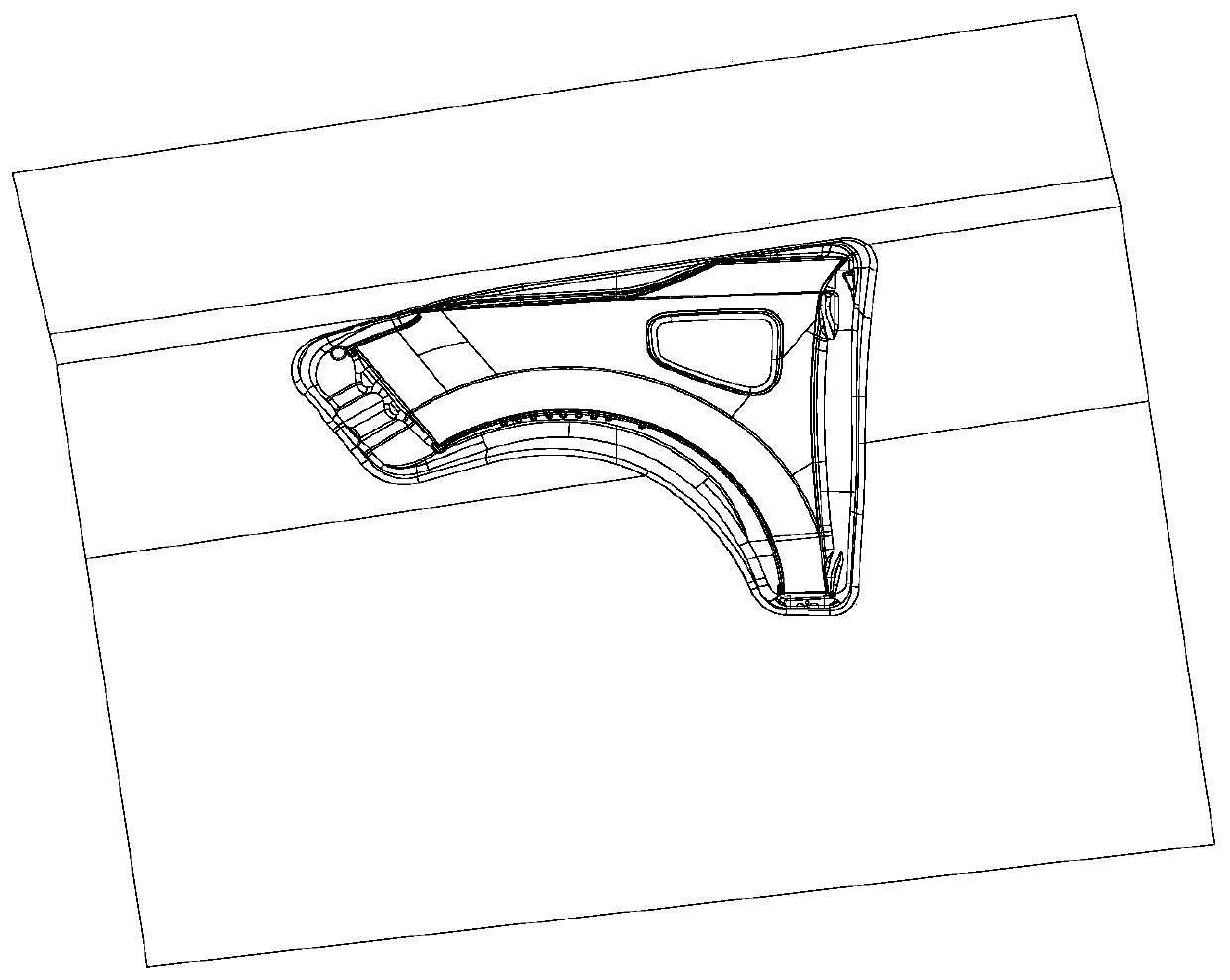

Technology for fender with charging port

InactiveCN111468603AReduce mold investmentIncrease productivityShaping toolsVehicle componentsProcess engineeringFender

The invention belongs to the technical field of stamping, and particularly relates to a technology for a fender with a charging port. The process comprises the following steps of 1, designing a drawing technology; 2, carrying out product modification; and 3, optimizing a structure. According to the technology, the problem that the process of the product is long can be primarily solved, five-process production is thoroughly realized through whole-process technology improvement, and the technology has great popularization and application significance in lowering the mold investment and improvingthe production efficiency; and secondly, the technology improvement scheme is also put forward for the defects of the appearance surface quality, which plays a guiding role in shorting the debuggingperiod of a mold and improving the appearance surface quality of a workpiece.

Owner:FAW CAR CO LTD

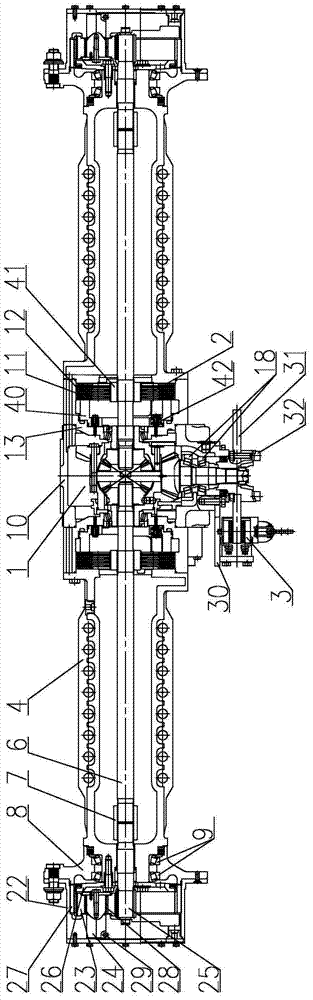

TiC-based steel bonded hard alloy fine external thread milling device and numerical control milling method thereof

ActiveCN110052671AGuaranteed accuracy consistencyFast conductionThread cutting toolsThread cutting machinesNumerical controlMilling cutter

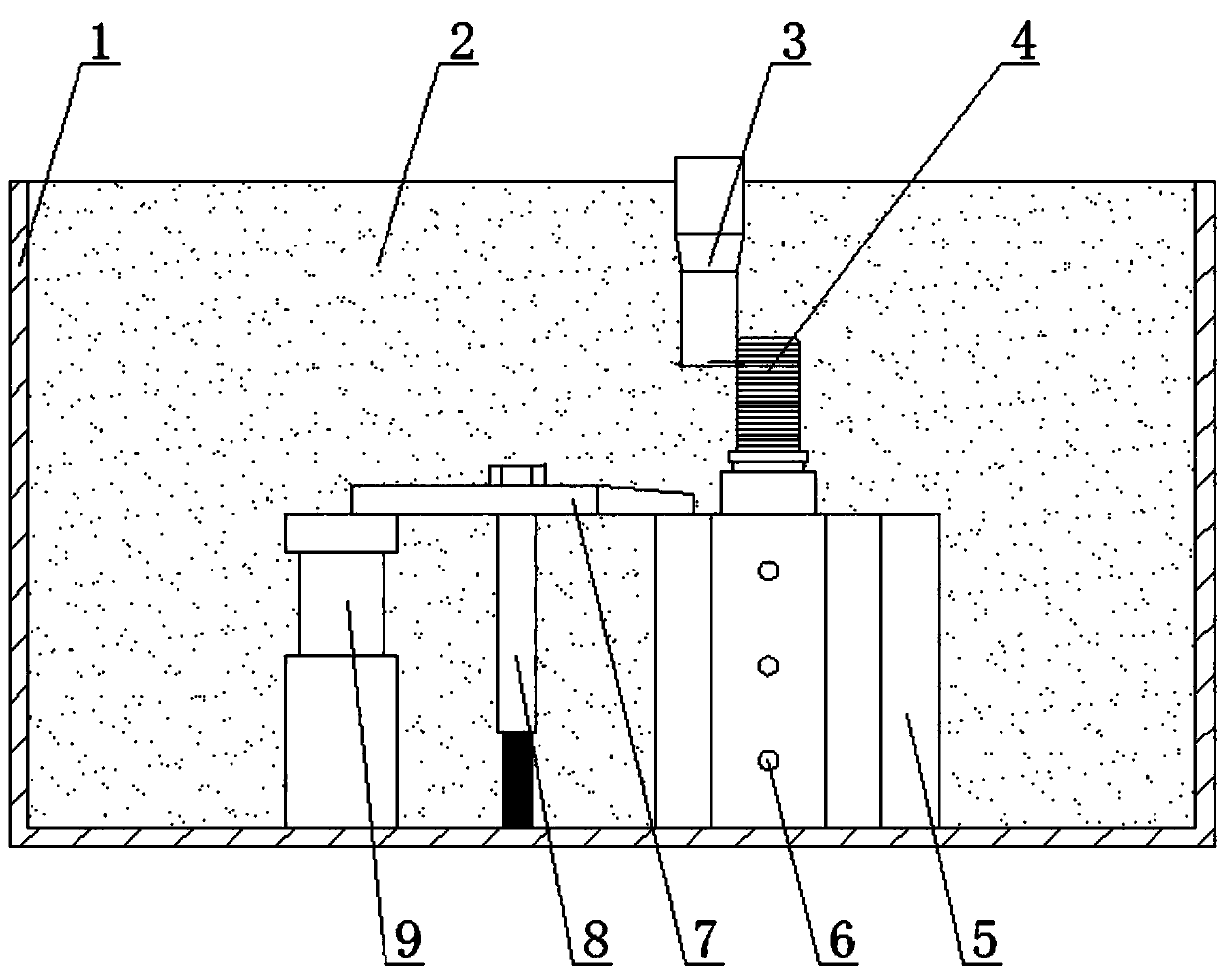

The invention relates to the technical field of precise machining of a TiC -based steel bonded hard alloy, and in particular relates to a TiC-based steel bonded hard alloy fine external thread millingdevice and a numerical control milling method thereof. The milling device comprises a box body with an opening at the upper end, the box body is filled with cooling liquid, a fixing base is arrangedin the bottom surface of the box body, a spring chuck is arranged at the upper end of the fixing base, and the spring chuck is used for fixing a part to be milled; Under the fixed state of the part, the height of the upper end part of the part is lower than the height of the side wall of the box body, the side of the part is suspended with a milling cutter, the milling cutter adopts a polycrystalline diamond coating, the main cutting edge part of the milling cutter adopts a two-edge mode, and the two edges are arranged in a coplanar manner.

Owner:TIANJIN NAVIGATION INSTR RES INST

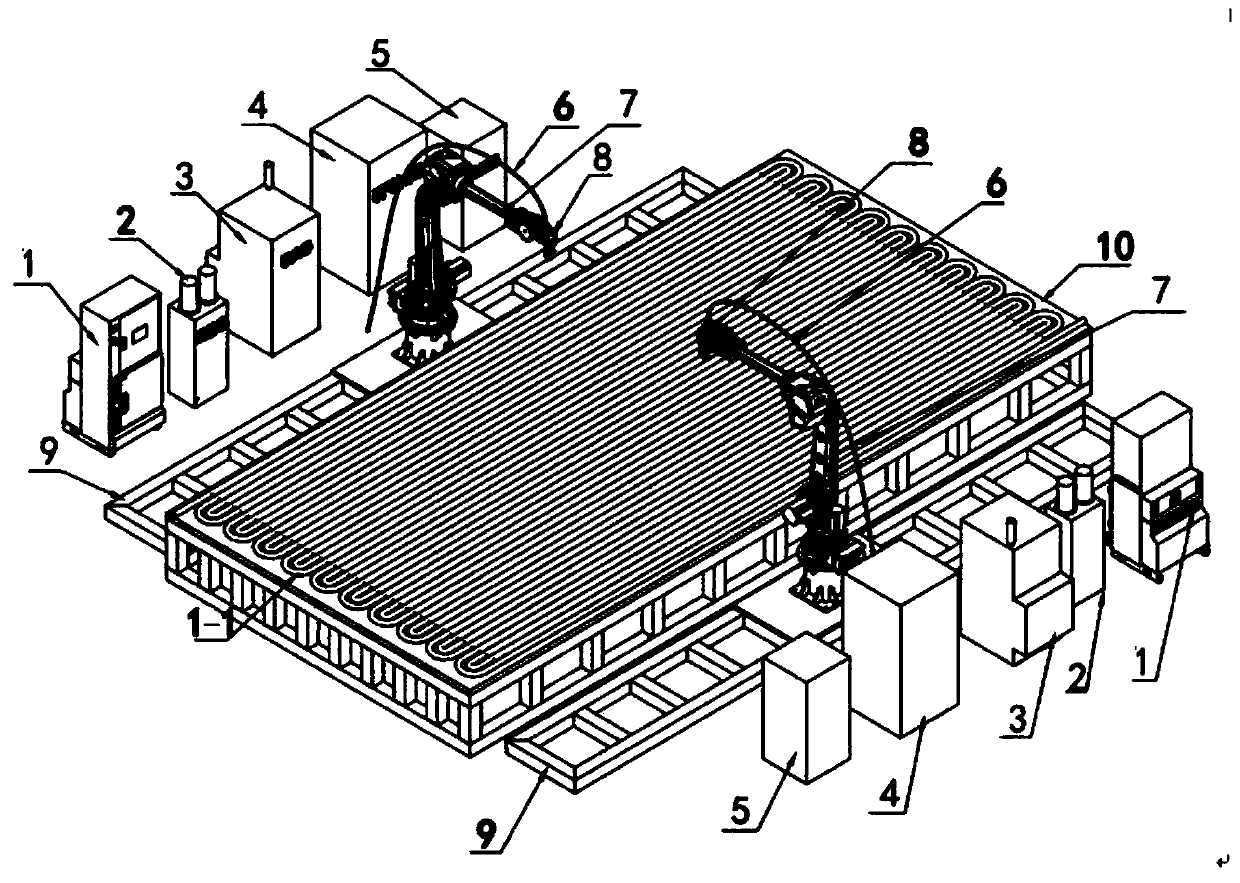

Optical fiber laser double-rail cladding equipment for membrane water wall of high-parameter waste incineration boiler

ActiveCN111560609ASave resourcesLow input costMetallic material coating processesLoop controlLaser light

The invention provides optical fiber laser double-rail cladding equipment for a membrane water wall of a high-parameter waste incineration boiler. The optical fiber laser double-rail cladding equipment comprises a machine tool platform, sliding rails, robots, laser cladding heads and optical fibers; the machine tool platform is fixedly arranged on the horizontal plane, and one sliding rail is independently arranged along each of the side edges parallel to the two sides of the machine tool platform; the robots are fixedly arranged on the sliding rails, and after arms of the two robots stretch out to work, the cladding width between the robots is not smaller than 6 m; and laser cladding units are fixedly arranged at the tops of the robots, one ends inside the laser cladding units are connected with the optical fibers, and the laser cladding units comprise the optical fibers, laser light path adjusting modules and molten pool light path detecting modules. According to the equipment, a closed-loop control system is arranged, under the ultra-low heat input amount, the cladding layer thickness can reach 0.8 - 1.5 mm, the height is consistent, uniform and attractive, the powder utilization rate of laser cladding and the stable state of a molten pool are scientifically and reasonably controlled through adjustment, and a solid foundation is laid for large-scale and long-time unmanned operation.

Owner:熔创金属表面科技(常州)有限公司

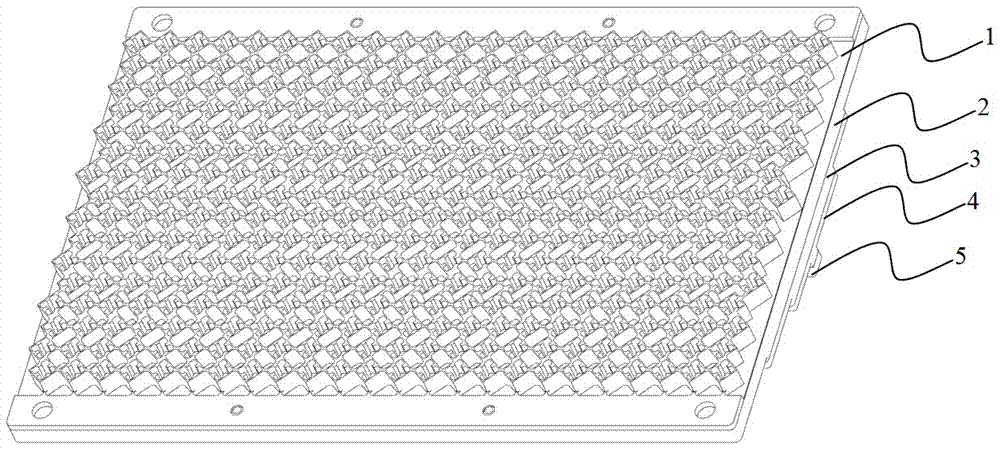

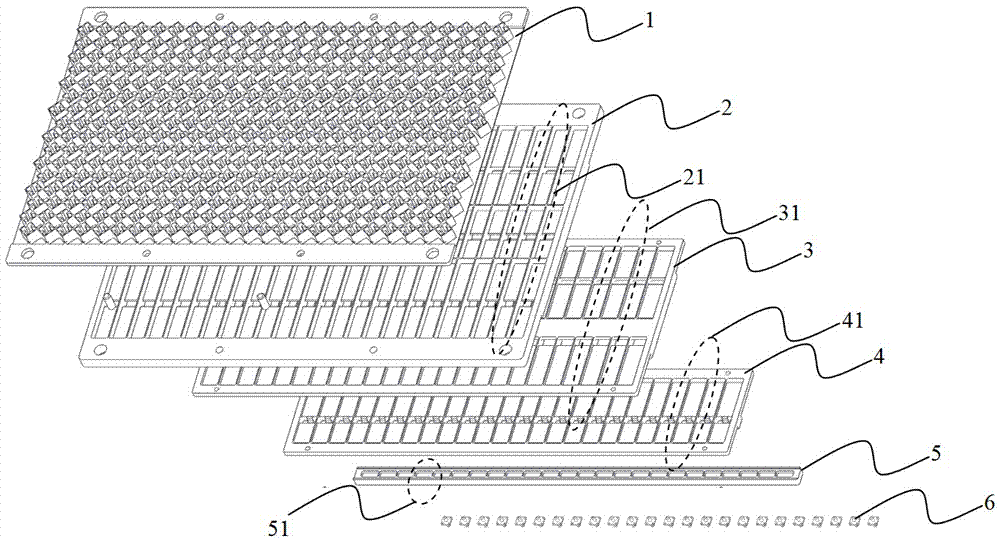

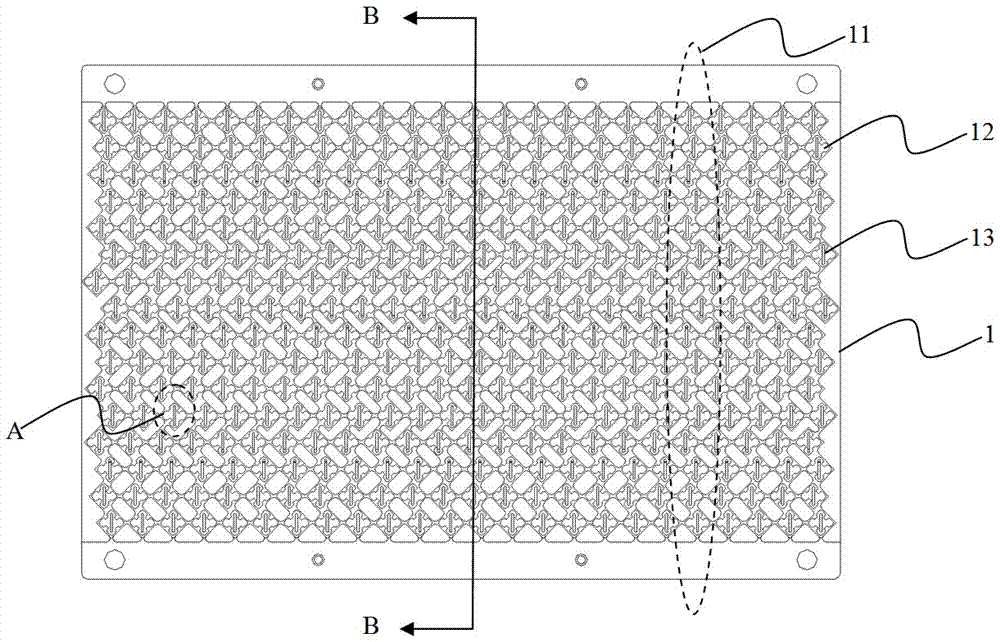

X-waveband phased-array waveguide antenna

ActiveCN105449375AGuaranteed dimensional accuracy requirementsGuaranteed High Gain RequirementsWaveguide mouthsAntenna arraysLayered structurePhysics

The invention provides an X-waveband phased-array waveguide antenna. A whole waveguide array is taken as a transmission body to substitute the traditional radar antenna combined by a line source transmission body and a crack waveguide. The X-waveband phased-array waveguide antenna is an aggregation body formed by sequentially connecting a reflector, an intermediate body, a conversion body, a coupling body and a radio-frequency connector and comprises a plurality of waveguide monomers. The X-waveband phased-array waveguide antenna has the technical effects that a layered structure is adopted, the antenna is partitioned to five layers of single-layer bodies and is formed through vacuum brazing in one time, the processing is simple, time and labor are saved, and the assembly accuracy is high. The X-waveband phased-array waveguide antenna is compact and attractive in the whole appearance, has the characteristics of small volume, high precision and high gain, and is suitably used for the structural design of a phased-array system radar antenna in the ground, aviation and the like.

Owner:ANHUI SUN CREATE ELECTRONICS

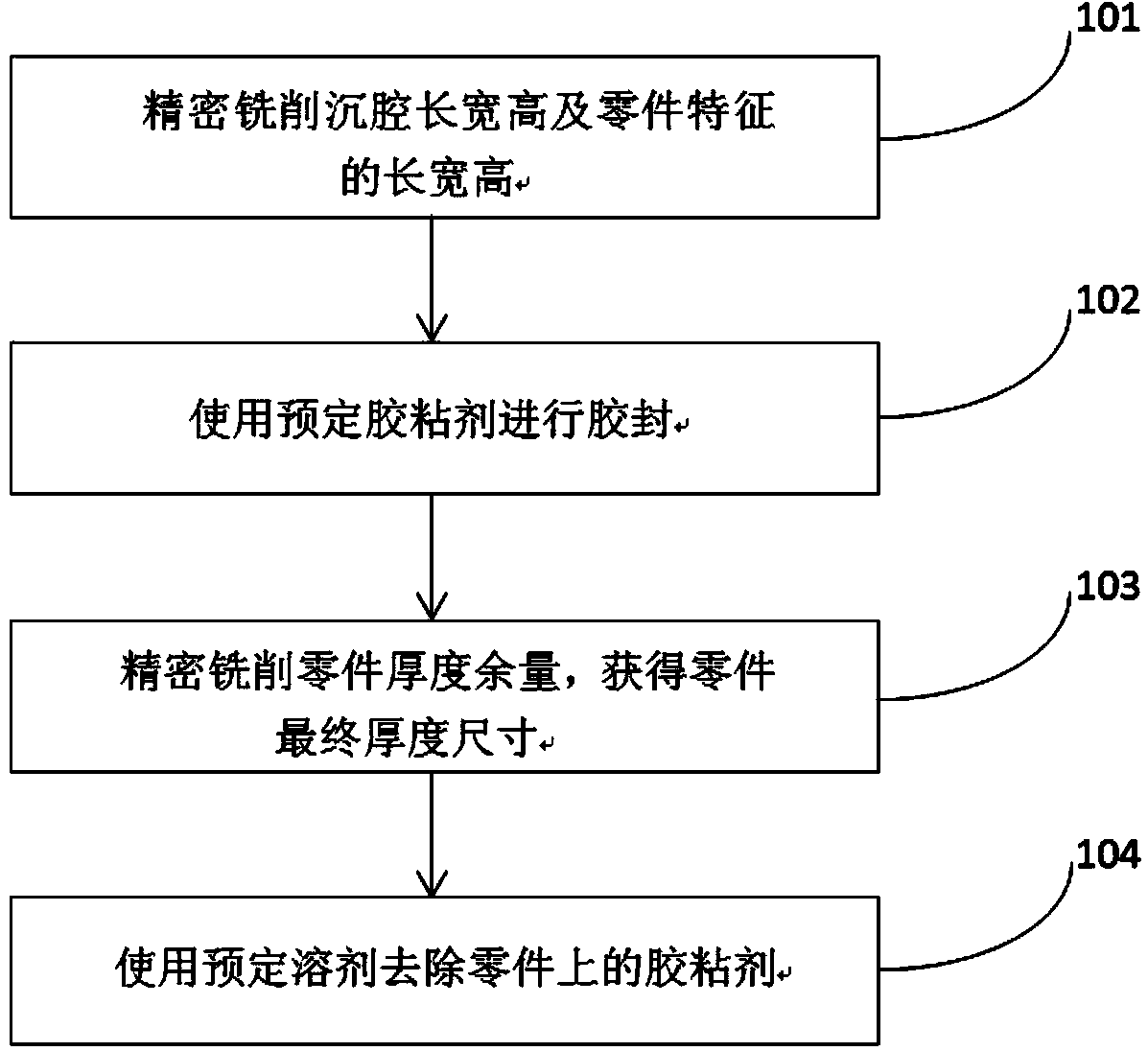

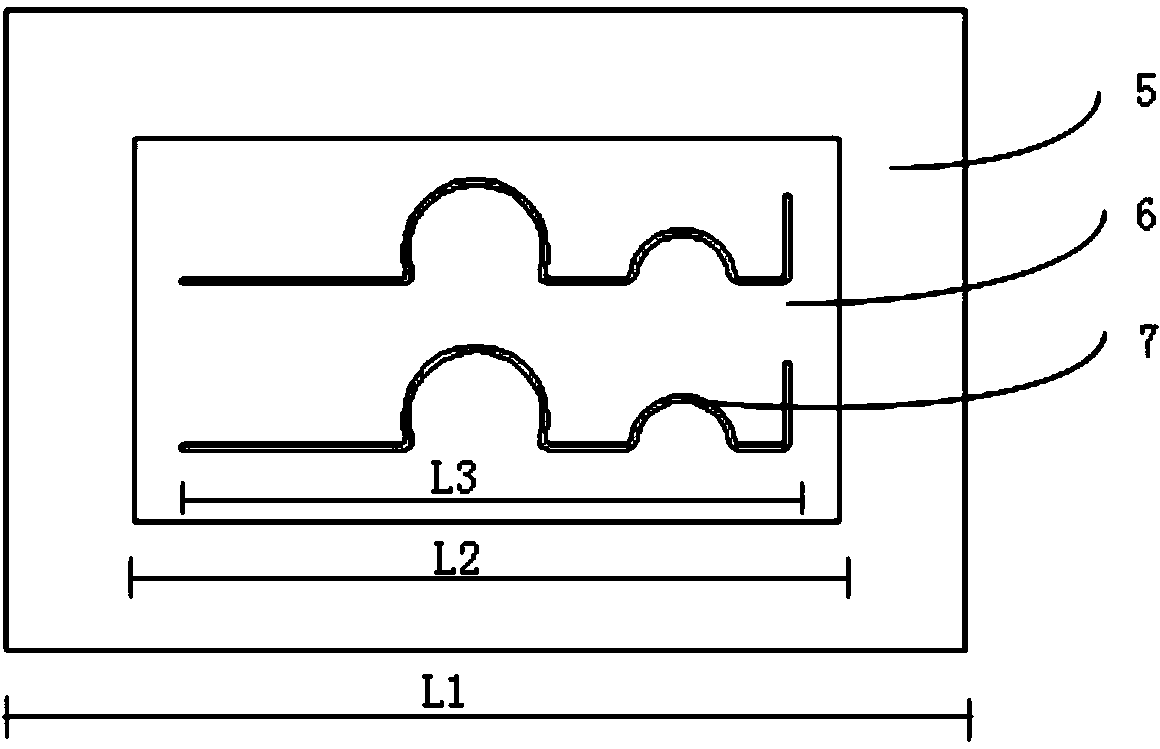

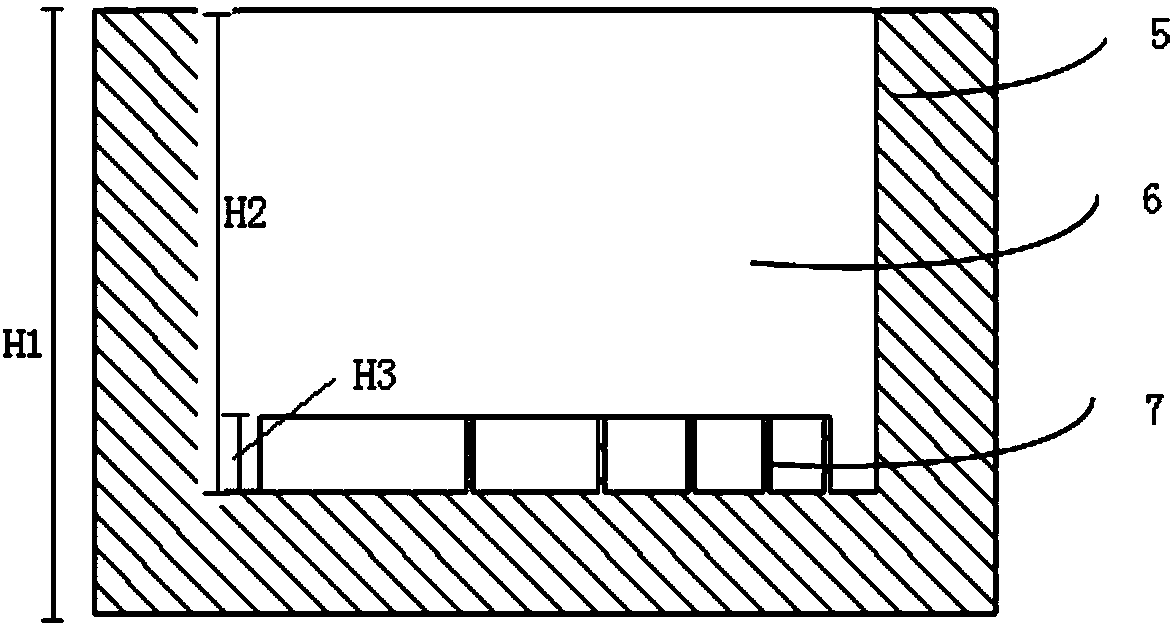

Method for milling microwave parts with irregular structure through micro-stress

ActiveCN103639497AImprove surface qualityReduce deformationMilling equipment detailsMicrowaveAdhesive

The invention provides a method for milling microwave parts with an irregular structure through micro-stress. The method comprises the following steps: (101) precisely milling the length, width and height of a sunken cavity and the length, width and height of part features; (102) performing adhesive sealing through a predetermined adhesive; (103) precisely milling the thickness allowance of parts to obtain the final thickness size of the parts; and (104) removing the adhesive on the parts through a predetermined solvent. According to the scheme, the microwave parts with the irregular structure can be precisely machined, the surface quality of the microwave parts is improved, and the signal transmission performance is improved; according to a micro-stress clamping method, the deformation of the parts in a machining process can be reduced, and the size accuracy requirements of the parts are effectively met; the production efficiency and the yield of the parts are improved.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

A process method for lathe processing of large-diameter, precision and complex-shaped thin-section parts

ActiveCN105397108BSolve the out-of-tolerance problemSolve technical problems that cannot be groundPositioning apparatusTurning machinesEngineeringMachining process

The invention discloses a method for turning a large-diameter precision complex molded surface thin sheet part and belongs to the technical field of machining. The method comprises the following steps that (1), it is ensured that the part leakage length is greater than or equal to a half of the width of the whole part, and the molded surface of the outer side of the first surface of the part is turned, namely a half of the molded surface of the outer side of the first surface of the part; (2), the molded surface of the inner side of the first surface of the part is turned, and smooth adaptation connection between a connection knife and the molded surface is noticed; (3), the molded surface of the outer side of the second surface of the part is turned, namely one third of the molded surface of the outer side of the first face of the part; (4), turning of part of the molded surface of the middle of the second surface of the part is finished under the state that the inner side and the outer side are compressed at the same time; and (5), machining of the molded surface of the left of the second surface is finished, smooth adaptation connection between the connection knife and the molded surface is noticed, and the whole machining process is finished. The technical bottleneck of turning of thin-walled sealed washers of high-precision, novel-structure and precision complex molded surfaces is effectively solved, and the far-reaching significance is achieved for improvement of the manufacturing technical level of a new generation of engines.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Designing and preparing method for conversion-free preliminary processing reference integral sand core

ActiveCN103658544ASmall size deviationGuaranteed dimensional accuracy requirementsFoundry mouldsFoundry coresProcess engineeringRoughcast

The invention relates to a designing and preparing method for a conversion-free preliminary processing reference integral sand core. According to the invention, preliminary processing references are designed in a processing reference plane, then the preliminary processing reference are integrated with sand cores where key workblank surfaces are located to form an integral sand core, so dimensional deviations between the workblank surfaces and machining surfaces are controlled to be in a small range. With the method provided by the invention, dimensional deviations between preliminary processing references, between the preliminary processing references and the workblank surfaces and between the workblank surfaces are reduced, so requirements on dimensional accuracy of a casting are met.

Owner:HARBIN DONGAN ENGINE GRP

Special-shaped adapter integrated forming die and method

PendingCN111645248AGuaranteed dimensional accuracy requirementsGuaranteed functional requirementsDomestic articlesIntegrated designWear resistance

The invention provides a special-shaped adapter integrated forming die. The special-shaped adapter integrated forming die comprises a bottom plate, wherein a die frame is vertically and fixedly connected to the bottom plate, an upper die is rotatably fixed in the middle of the die frame, and the upper die, the die frame and the bottom plate form a hollow cavity; the top face of the upper die is parallel to the plane of an adapter guide rail groove to be formed, and the top face of the upper die is not parallel to the upper surface of the bottom plate. The invention further provides a special-shaped adapter integrated forming method. According to the forming die, various dimensional precision requirements and functional requirements of an adapter are ensured, and the economical efficiency and the practicability are high; a polytetrafluoroethylene film is effectively prevented from falling off, and the integrity of the adapter is ensured; not only is the effective sliding of the adapteron the guide rail surface ensured, but also the requirements of wear resistance, high temperature resistance and adhesion resistance are met; the positioning requirement is guaranteed, the inclined drawing design is met, and the structure and function integrated design is met; and the requirements of economical efficiency, manufacturability, practicability and operability of die design are met.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

Connection method of curve concrete rail beams

ActiveCN109371766AFirmly connectedGuaranteed dimensional accuracy requirementsRailway tracksStructural component

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

Low-voltage circuit breaker energy storage lock machining process and multi-station progressive die used in low-voltage circuit breaker energy storage lock machining process

PendingCN111215513AEnsure critical dimensionsEnsuring Geometric TolerancesShaping toolsPerforating toolsStructural engineeringMachining process

The invention discloses a low-voltage circuit breaker energy storage lock machining process and a multi-station progressive die used in the low-voltage circuit breaker energy storage lock machining process. The process comprises the following steps that a, a guide pin hole and a flash are punched, specifically, the flash on the upper edge of an unfolded part is punched, and the guide pin hole is punched in a strip; b, leveling is conducted, and specifically, the verticality of the plane and a cylinder of the unfolded part is ensured; c, forming is conducted, specifically, the cylinder is formed, and the diameter size and form and location tolerance of the cylinder are ensured; d, trimming is conducted, and specifically, the left edge and the right edge of the unfolded part are simultaneously punched; e, bending is conducted, and specifically, the upper right corner of the unfolded part is bent to form a warped corner; f, trimming is conducted, specifically, the lower edge of the unfolded part is punched, and a connecting rib is reserved to be connected with the strip; g, forming and bending are conducted, and specifically, the unfolded part is bent to form a bent part; h, punchingis conducted, specifically, a central hole of the bent part is punched, and the cylinder is punched to ensure the length size of the cylinder; i, shaping is conducted, specifically, the bent part is shaped to ensure the bending angle of the bent part, and the shaped bent part is a finished product; and j, product falling is conducted, and specifically, the connecting rib is punched to enable the finished product to fall from the strip. The low-voltage circuit breaker energy storage lock machining process and the multi-station progressive die used in the low-voltage circuit breaker energy storage lock machining process have the characteristic of improving the product yield and the production efficiency.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com