High-accuracy mortise broaching processing method for turbine disk made of powder high-temperature alloy material

A high-temperature alloy and processing method technology, applied in metal processing equipment, broaching machines, broaching tools, etc., can solve problems such as easy deformation, increased part deformation, and large cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

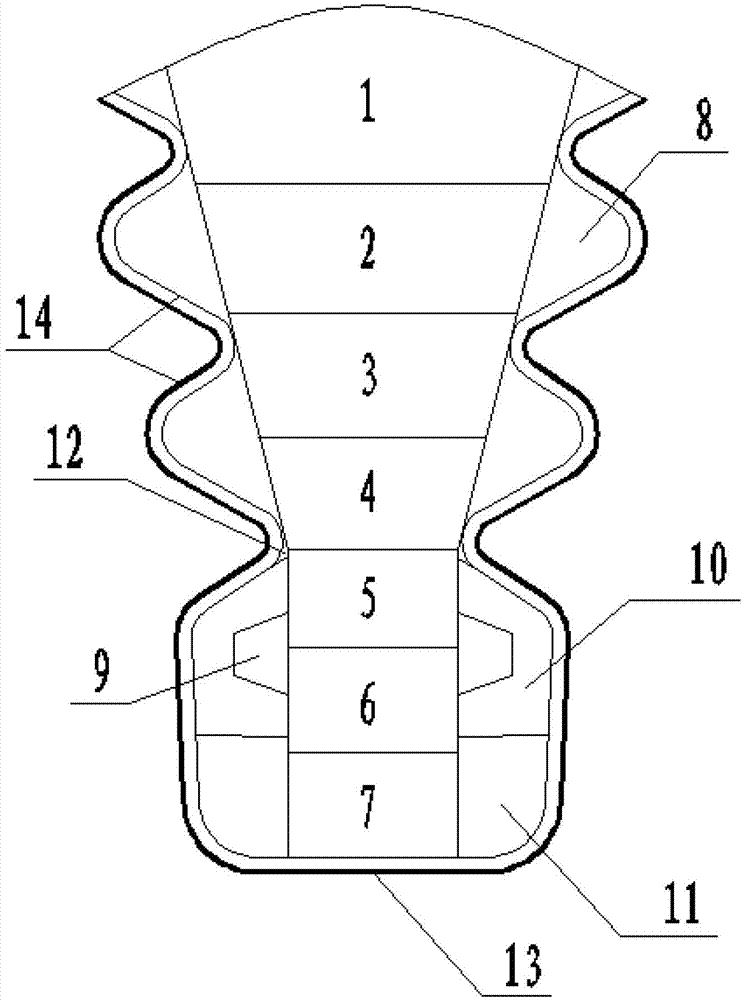

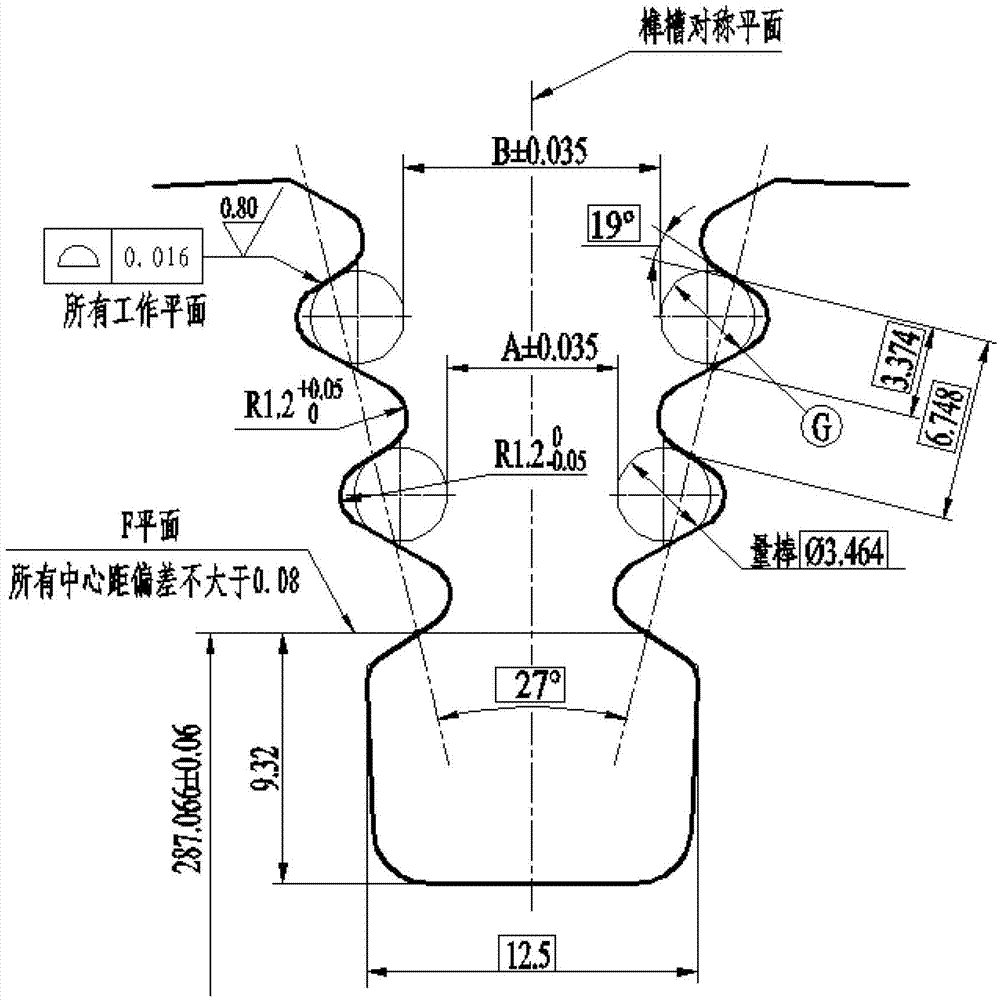

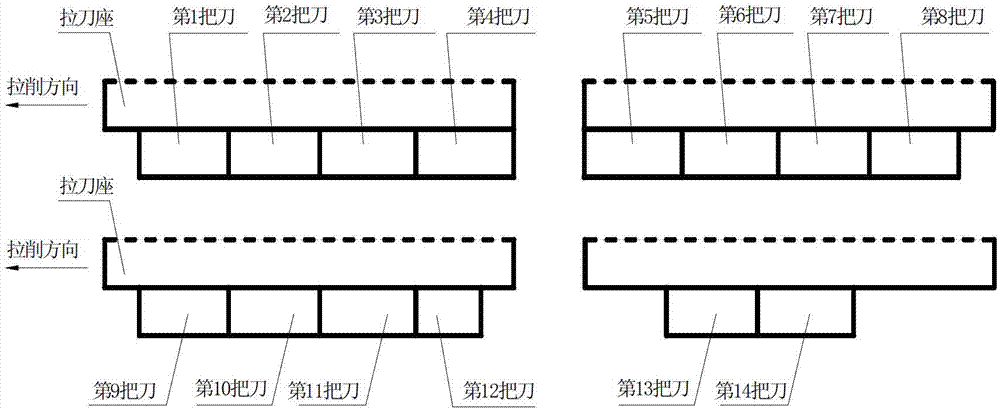

[0019] This embodiment provides a high-precision tenon-groove broaching processing method for a powder superalloy material turbine disk, which is characterized in that: the high-precision tenon-groove broaching processing method for a powder superalloy material turbine disk is that the center hole of the part is used The double insurance fixture structure is combined with tensioning and tenon and groove end face axial compression, the broaches are made of imported powder high-speed steel material ASP2060, the broach hardness is HRC66-68, a complete set of 14 broaches are used, arranged in two rows and divided into two broaching is complete. The 1st to 7th are slotting knives, the 8th is rough drawing tooth type, the 9th to 11th are rough drawing tooth bottom groove knives, the 12th rough drawing tooth top arc knife, the 13th fine drawing groove bottom circle Arc, the 14th is a fine toothed knife;

[0020] Process parameters of broaches:

[0021] Broach material: ASP2060 powd...

Embodiment 2

[0027] This embodiment provides a high-precision tenon-groove broaching processing method for a powder superalloy material turbine disk, which is characterized in that: the high-precision tenon-groove broaching processing method for a powder superalloy material turbine disk is that the center hole of the part is used The double insurance fixture structure is combined with tensioning and tenon and groove end face axial compression, the broaches are made of imported powder high-speed steel material ASP2060, the broach hardness is HRC66-68, a complete set of 14 broaches are used, arranged in two rows and divided into two broaching is complete. The 17th is a slotting knife, the 8th is a rough-drawing tooth type, the 9th-11th is a rough-drawing bottom groove knife, the 12th is a rough-drawing tooth top arc knife, and the 13th is a fine-drawing groove bottom arc. The 14th is a fine toothed knife;

[0028] Process parameters of broaches:

[0029] Broach material: ASP2060 powder hig...

Embodiment 3

[0035] This embodiment provides a high-precision tenon-groove broaching processing method for a powder superalloy material turbine disk, which is characterized in that: the high-precision tenon-groove broaching processing method for a powder superalloy material turbine disk is that the center hole of the part is used The double insurance fixture structure is combined with tensioning and tenon and groove end face axial compression, the broaches are made of imported powder high-speed steel material ASP2060, the broach hardness is HRC66-68, a complete set of 14 broaches are used, arranged in two rows and divided into two broaching is complete. The 1st to 7th are slotting knives, the 8th is rough drawing tooth type, the 9th to 11th are rough drawing tooth bottom groove knives, the 12th rough drawing tooth top arc knife, the 13th fine drawing groove bottom circle Arc, the 14th is a fine toothed knife;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com