Pawl pole of automobile generator and its manufactura

A technology of automobile generator and manufacturing process, which is applied to other manufacturing equipment/tools, manufacturing tools, manufacturing motor generators, etc., can solve problems affecting generator power, inclusion of chemical components, high production costs, etc., and achieve high dimensional accuracy of finished products , high dimensional accuracy and high mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

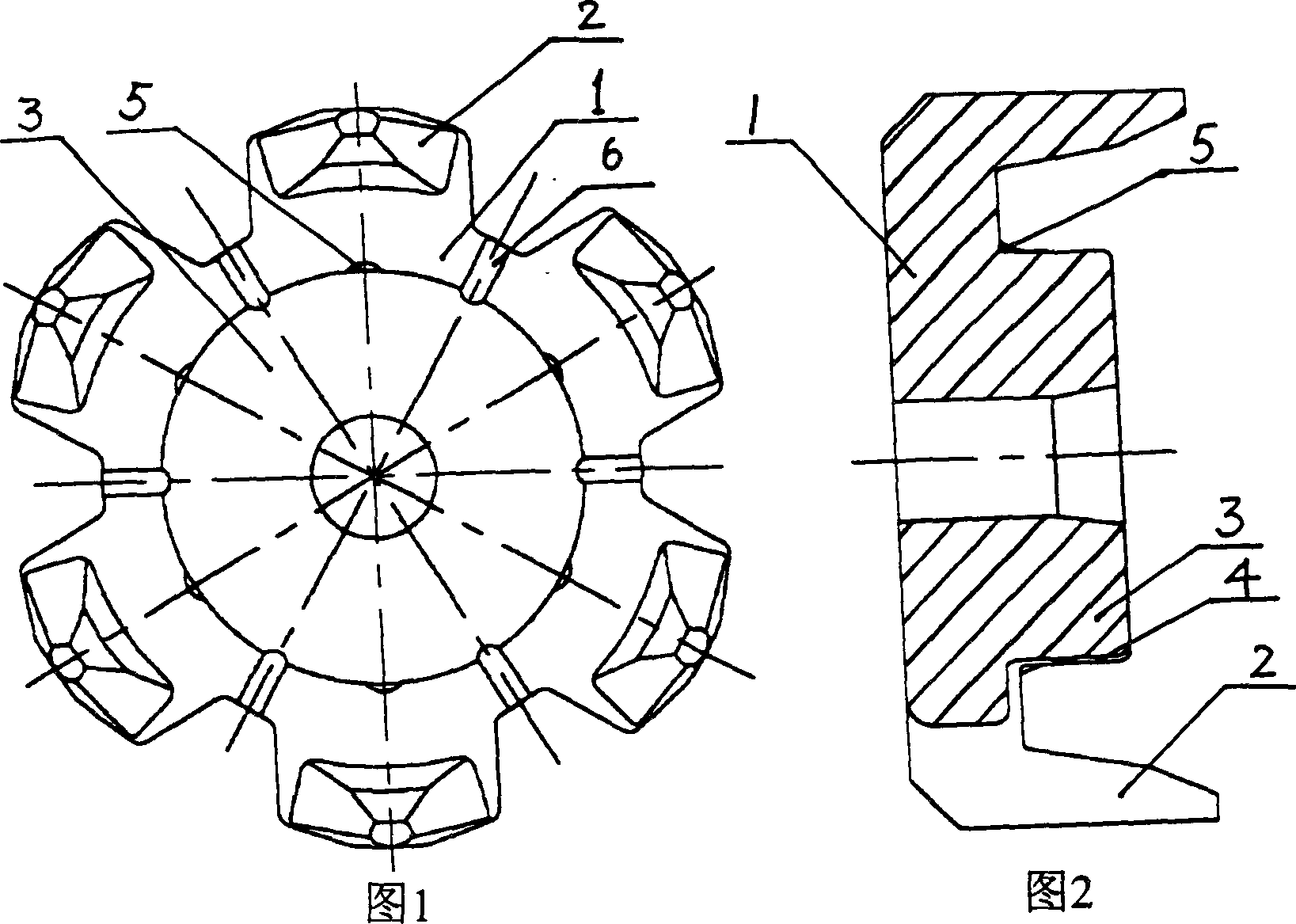

[0031] As shown in Fig. 1 and Fig. 2, the automobile generator claw pole of the present invention has a base plate 1, six bird's beak-shaped claws 2 are evenly distributed on the base plate 1, and a yoke 3 is arranged in the middle of the base plate 1, On the circumference of the yoke 3 are evenly distributed six insulating varnish drainage grooves 4 , and on the bottom of the yoke 3 are distributed six coil anti-rotation protrusions 5 and six lead-out grooves 6 for insulating wires.

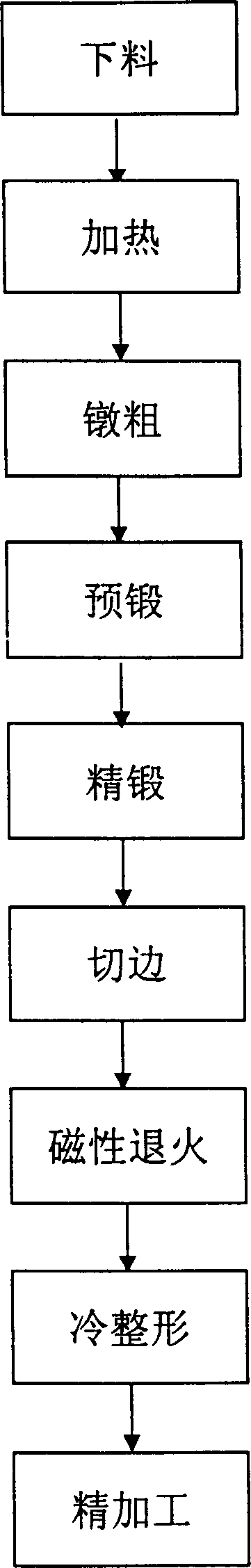

[0032] Such as image 3 The manufacturing process of the claw pole of the shown automobile generator of the present invention has the following process steps:

[0033] a. Blanking: choose raw material 08# low carbon steel with good electromagnetic performance, according to the weight requirements, use a sawing machine to saw the raw material into such Figure 4 the raw material shown;

[0034] b. Heating: Put the raw material into the heating furnace and heat it to 1050℃~1100℃; after repeated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com