Patents

Literature

45results about How to "Guaranteed accuracy consistency" patented technology

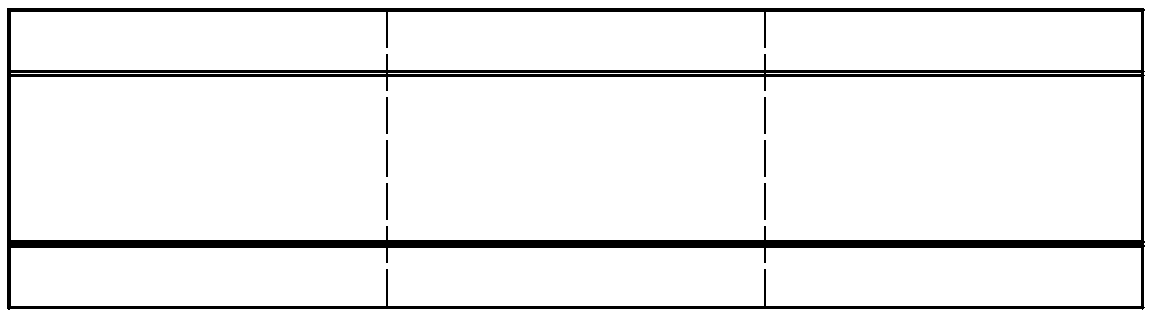

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

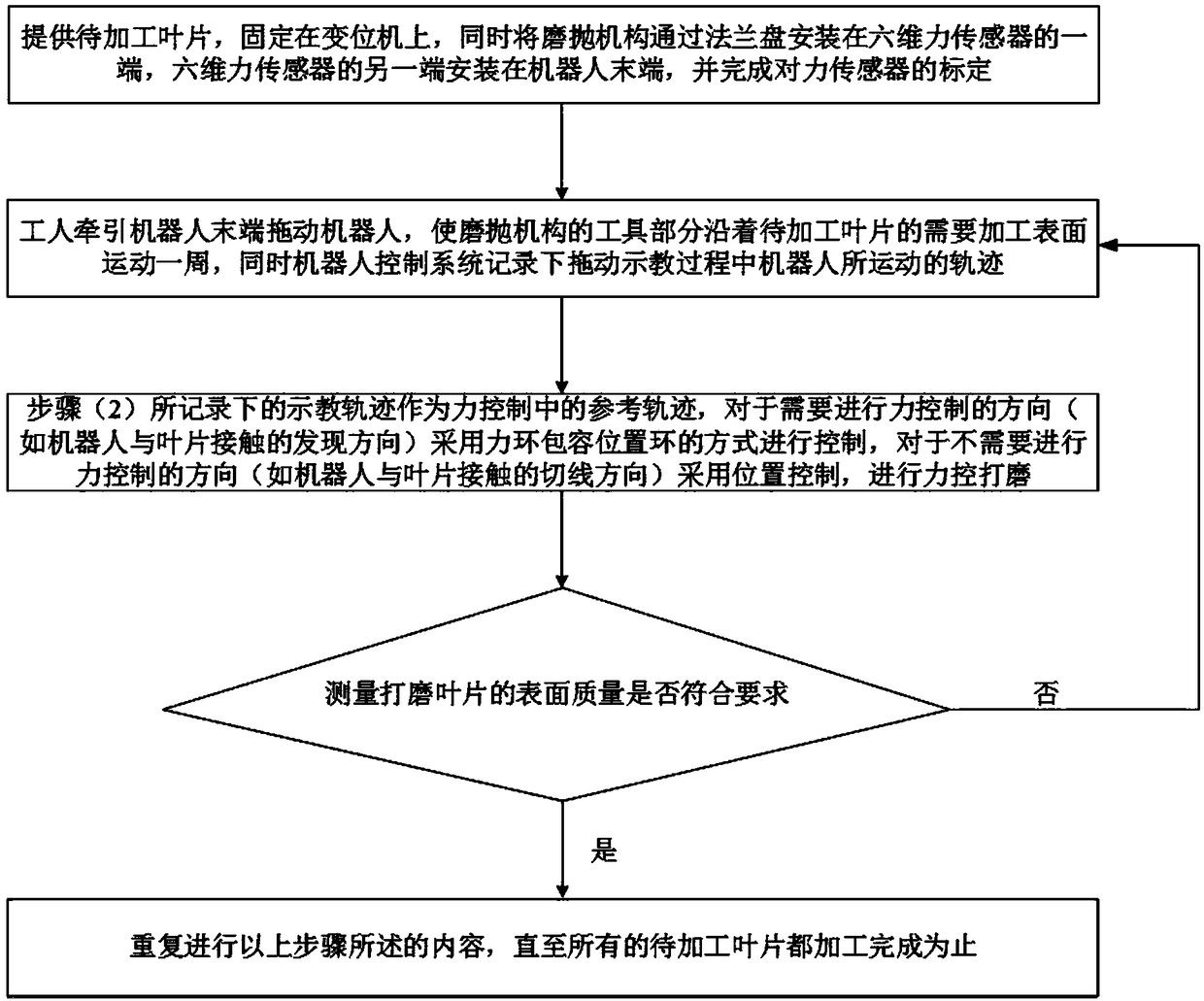

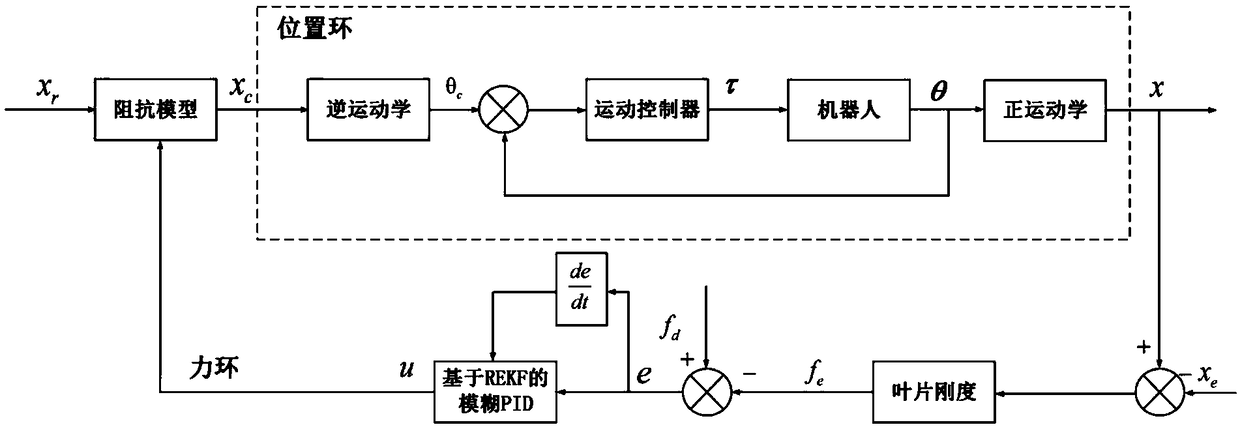

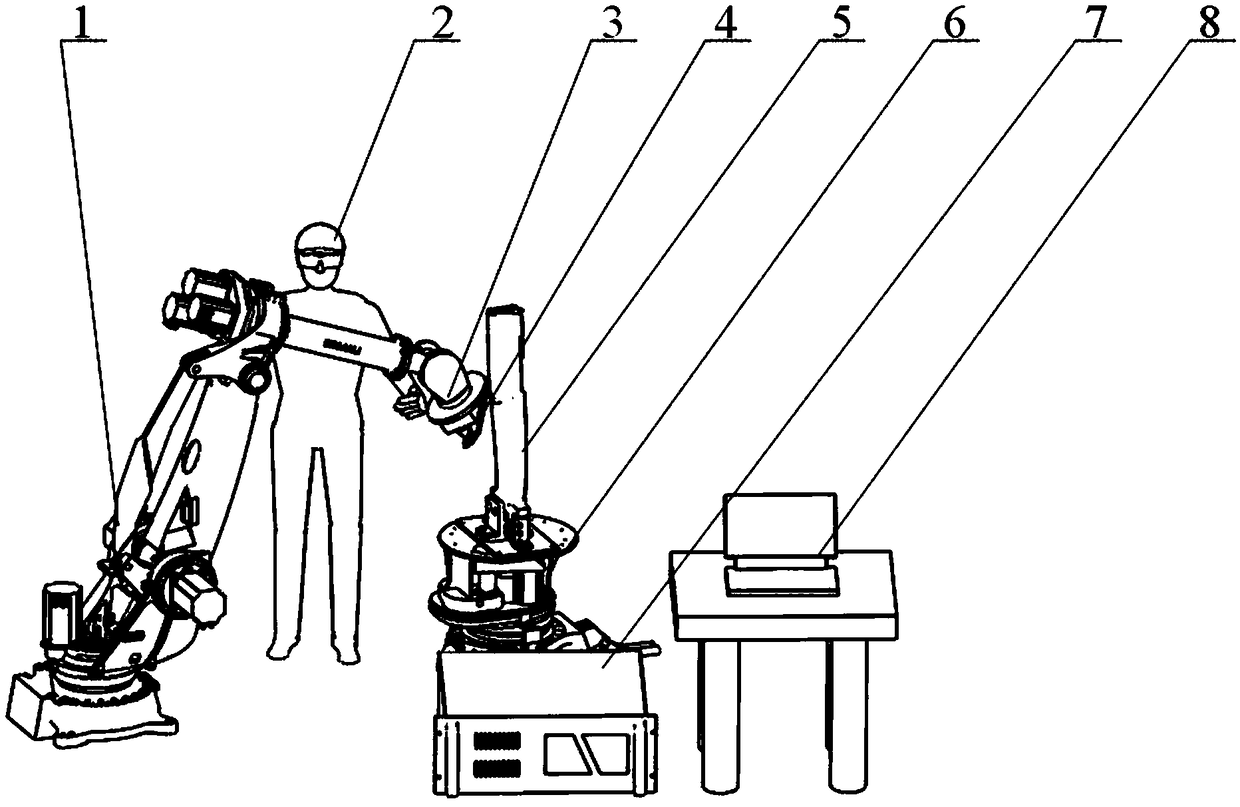

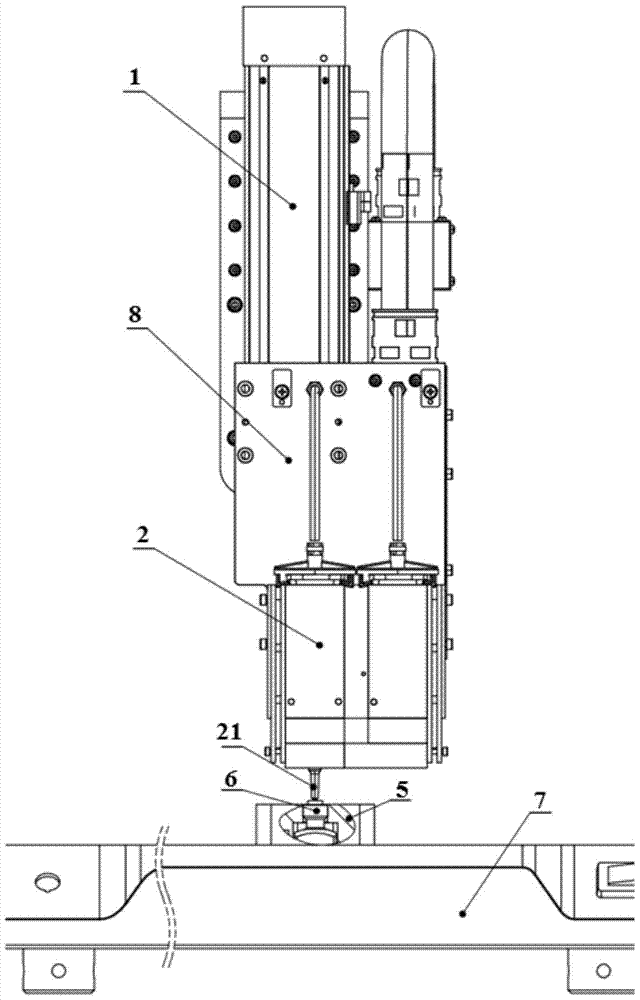

Device and method for force controlling polishing blade through dragging teaching robot

ActiveCN109434843AHigh degree of integrationImprove automationProgramme-controlled manipulatorControl systemContact force

The invention belongs to the related technical field of intelligent machining, and discloses a device and a method for force controlling polishing a blade through dragging a teaching robot. The devicecomprises the robot, a six-dimensional force sensor, a polishing mechanism, a position changing machine, and a robot control system; the six-dimensional force sensor is connected with a tail end executor of the robot and the polishing mechanism; the position changing machine is used for bearing the to-be-machined blade; the robot, the six-dimensional force sensor and the polishing mechanism are connected to the robot control system; the six-dimensional force sensor is used for measuring the contact force between the blade and the polishing mechanism in the blade polishing process, and transmitting the detected data to the robot control system; the robot control system is further used for receiving the tail end position information data of the robot, processing the received data to obtainthe corresponding control quantity, and then controlling the robot to drive the polishing mechanism to carry out corresponding motion. According to the device and the method, the skill requirement foran operator is reduced, and the machining consistency and the machining precision are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

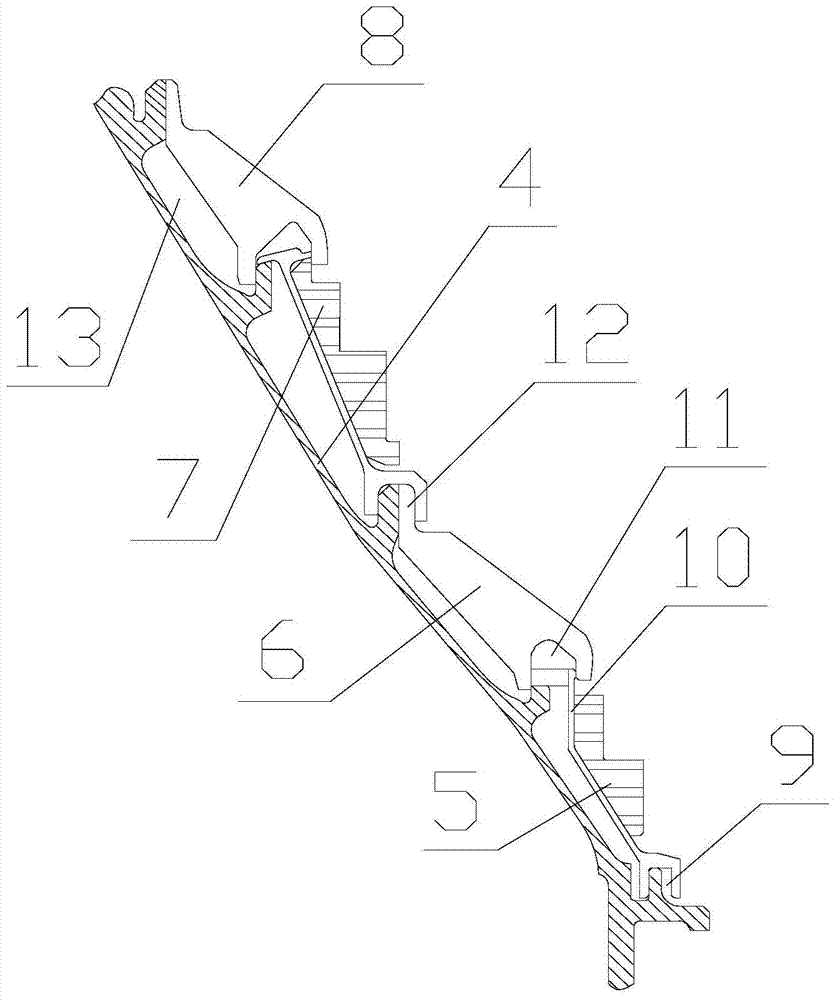

Acceptance check detecting tool for automobile sheet metal parts

InactiveCN102759314AEasy to detectEasy to controlMechanical measuring arrangementsEngineeringMechanical engineering

The invention discloses an acceptance check detecting tool for automobile sheet metal parts, which comprises a detecting tool body, a measuring knife, positioning columns and a clamping device, wherein upper part structures of characteristic blocks in the detecting tool body are characteristic structures matched with structural characteristics at matching parts of the detected sheet metal parts and the characteristic blocks. Due to the use of the acceptance check detecting tool, the sheet metal parts entering and leaving a factory can be rapidly detected with high precision, precision changing points of important characteristics of the sheet metal parts can be effectively discovered, and the precision consistency of the sheet metal parts during the life cycles of automobile types can be guaranteed. The acceptance check detecting tool can be used for detecting the sheet metal parts during acceptance check of the sheet metal parts.

Owner:GREAT WALL MOTOR CO LTD

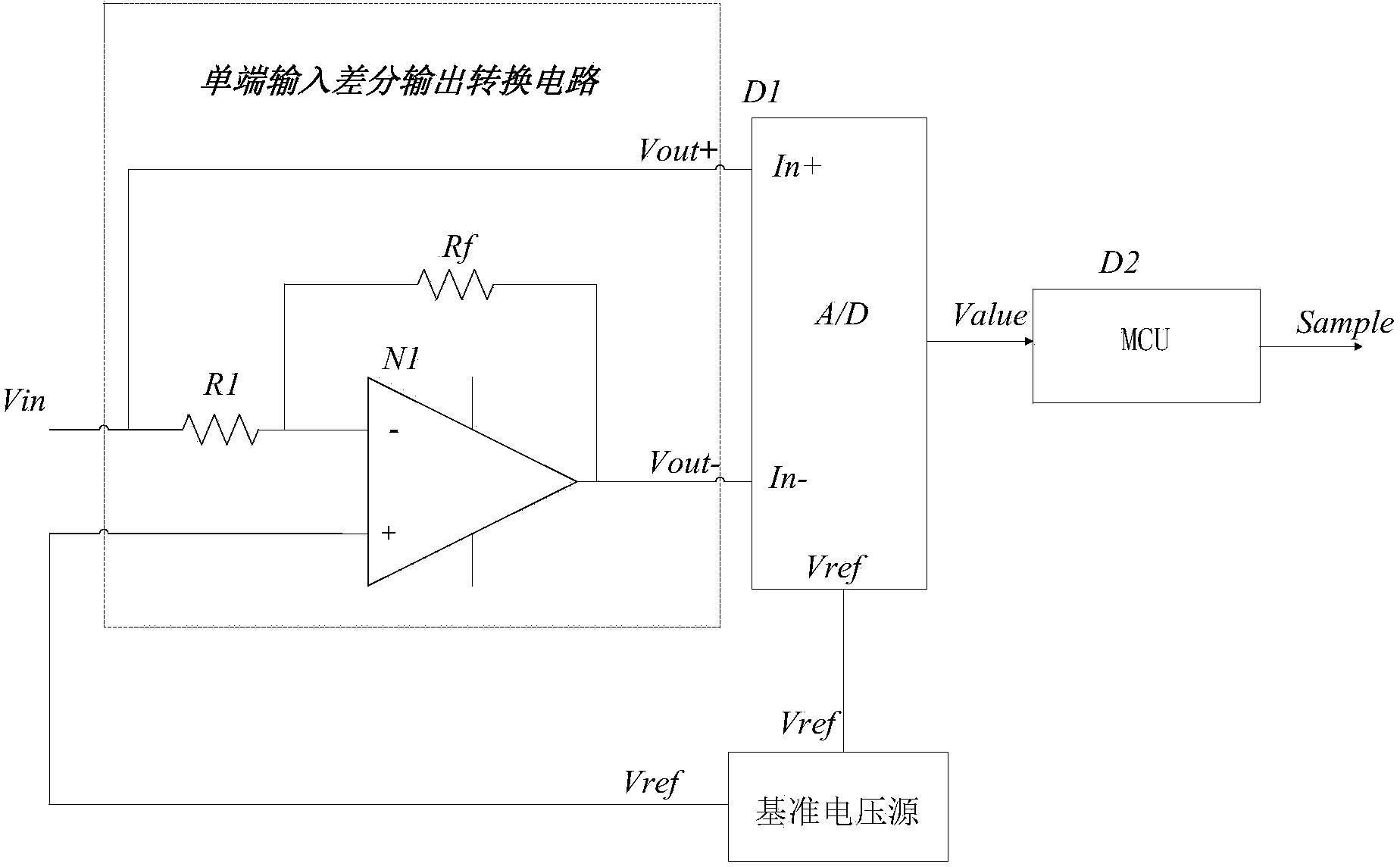

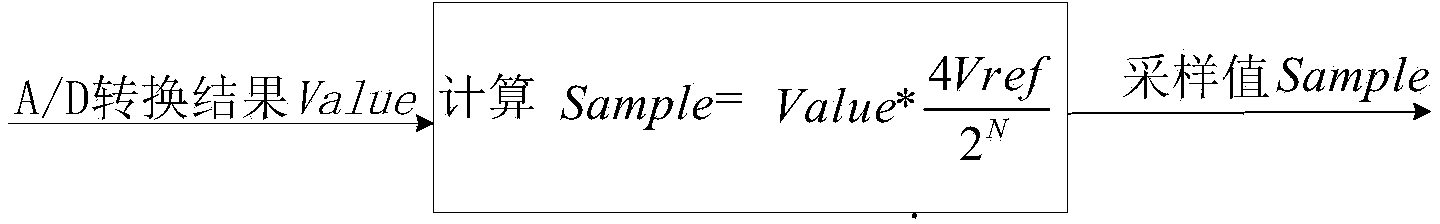

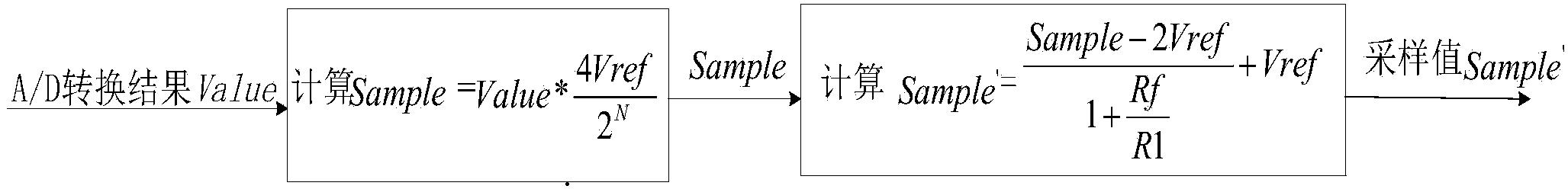

Method for correcting single-ended input differential AD converter circuit

ActiveCN104333387AEliminate effects of conversion precisionImprove sampling accuracyDelta modulationCorrection algorithmData acquisition

The invention relates to a method for correcting a single-ended input differential AD converter circuit. The method is used for eliminating conversion errors caused by the single-ended to differential circuit parameter deviation of the input end of the circuit. In a single-ended input data acquisition system of the differential AD converter circuit, the conversion accuracy of a single-ended input and differential output converting circuit is affected by the resistance derivation of a resistor. According to the method for correcting the single-ended input differential AD converter circuit, the resistor resistance having the resistance deviation is introduced as a parameter for calculating the sampled voltage value on the basis of a conventional sampled voltage value computing algorithm and a correction algorithm for correcting the conventional sampled voltage value computing algorithm is obtained, and therefore, the influence of the resistor resistance deviation on the accuracy of sampled voltage value computation is eliminated, and the accuracy consistency of the data acquisition system is guaranteed.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

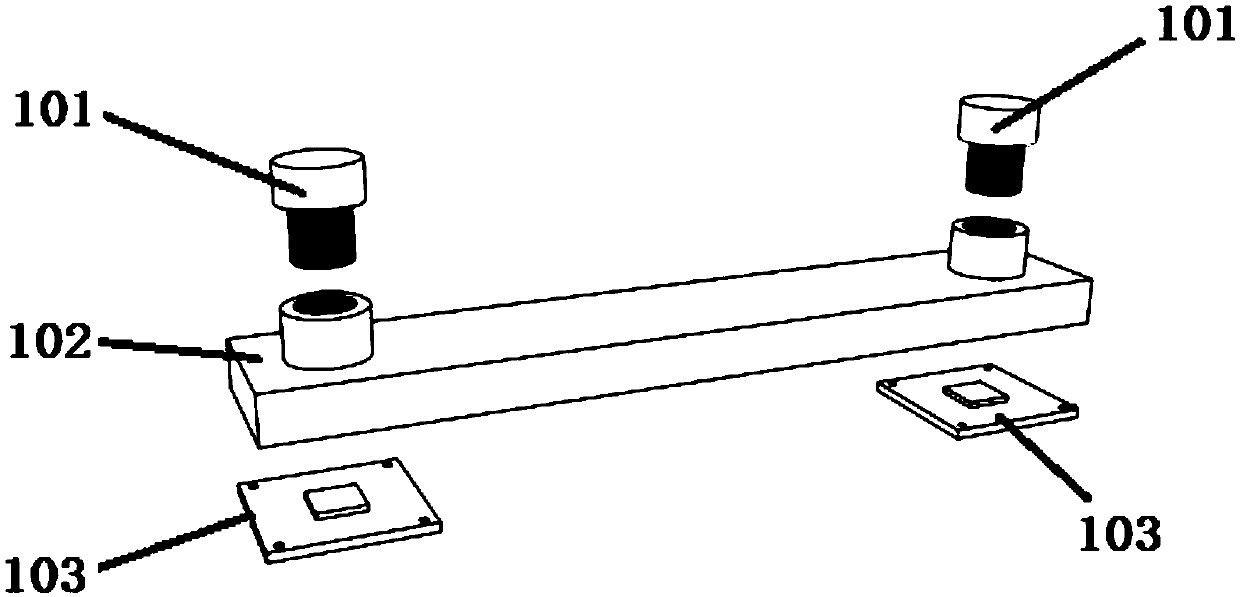

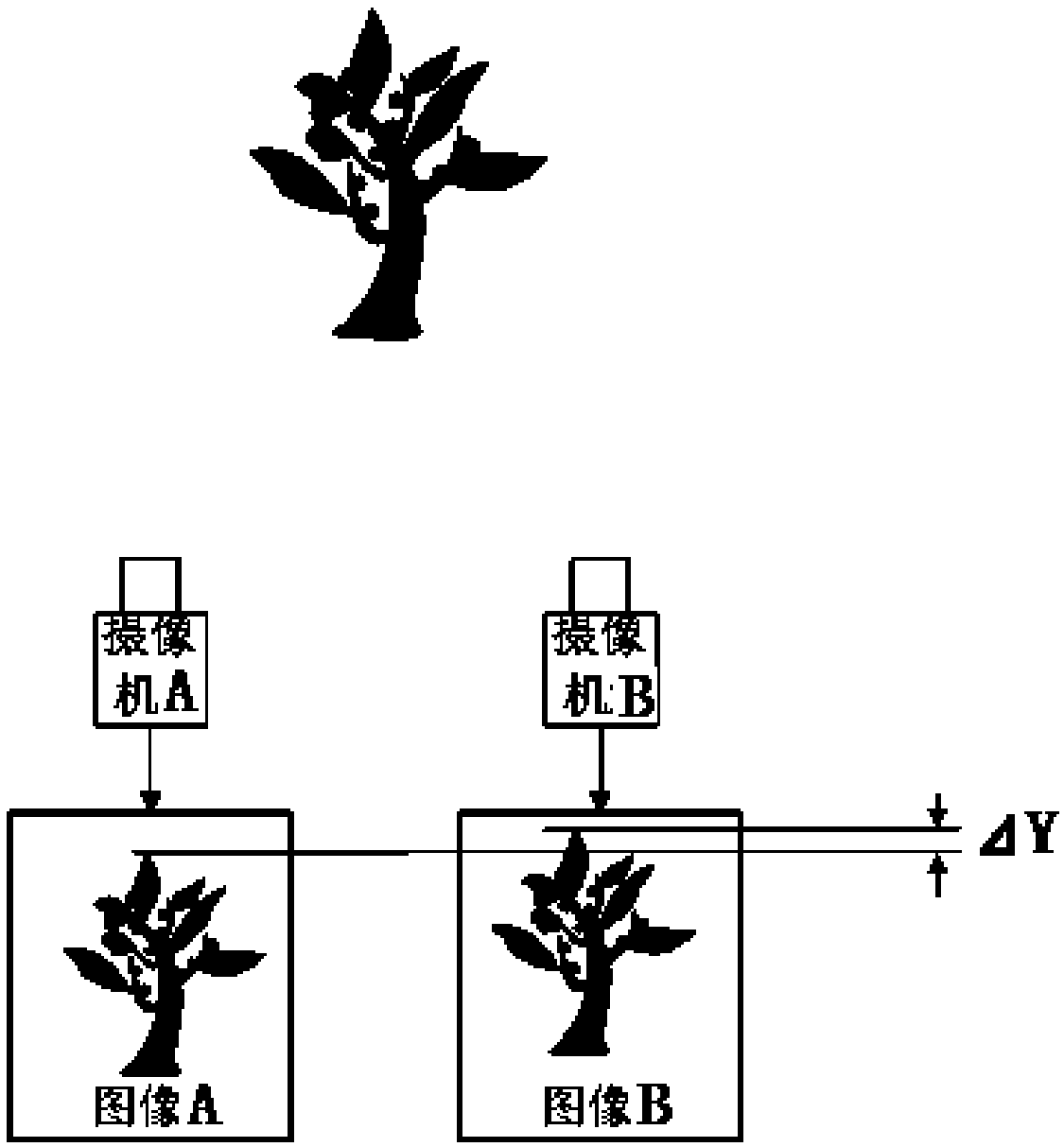

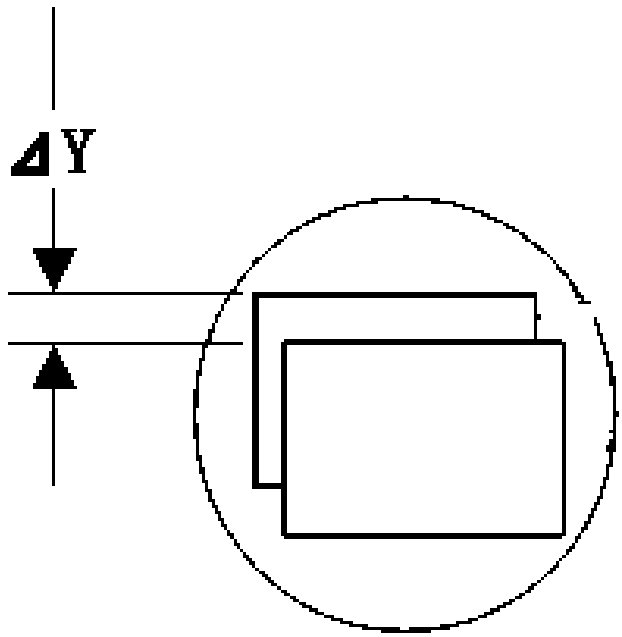

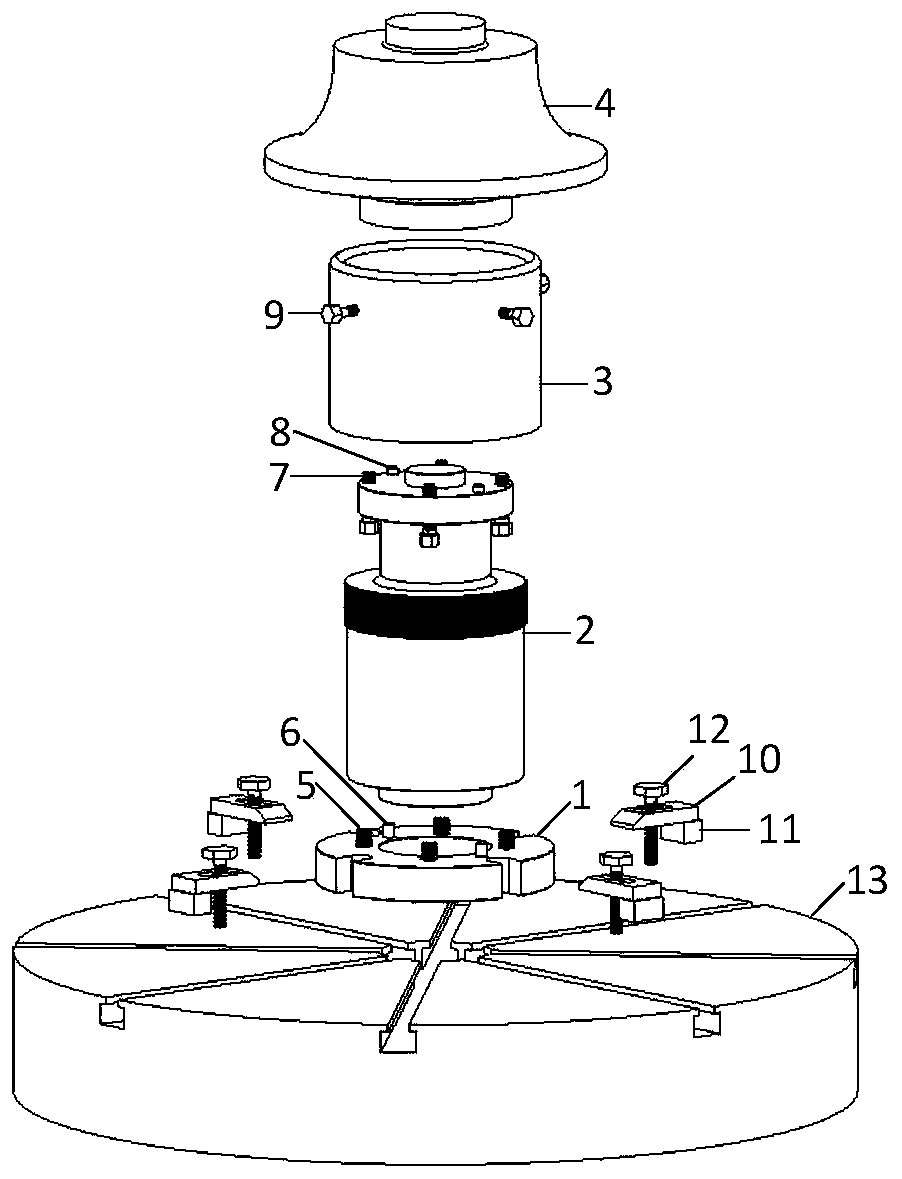

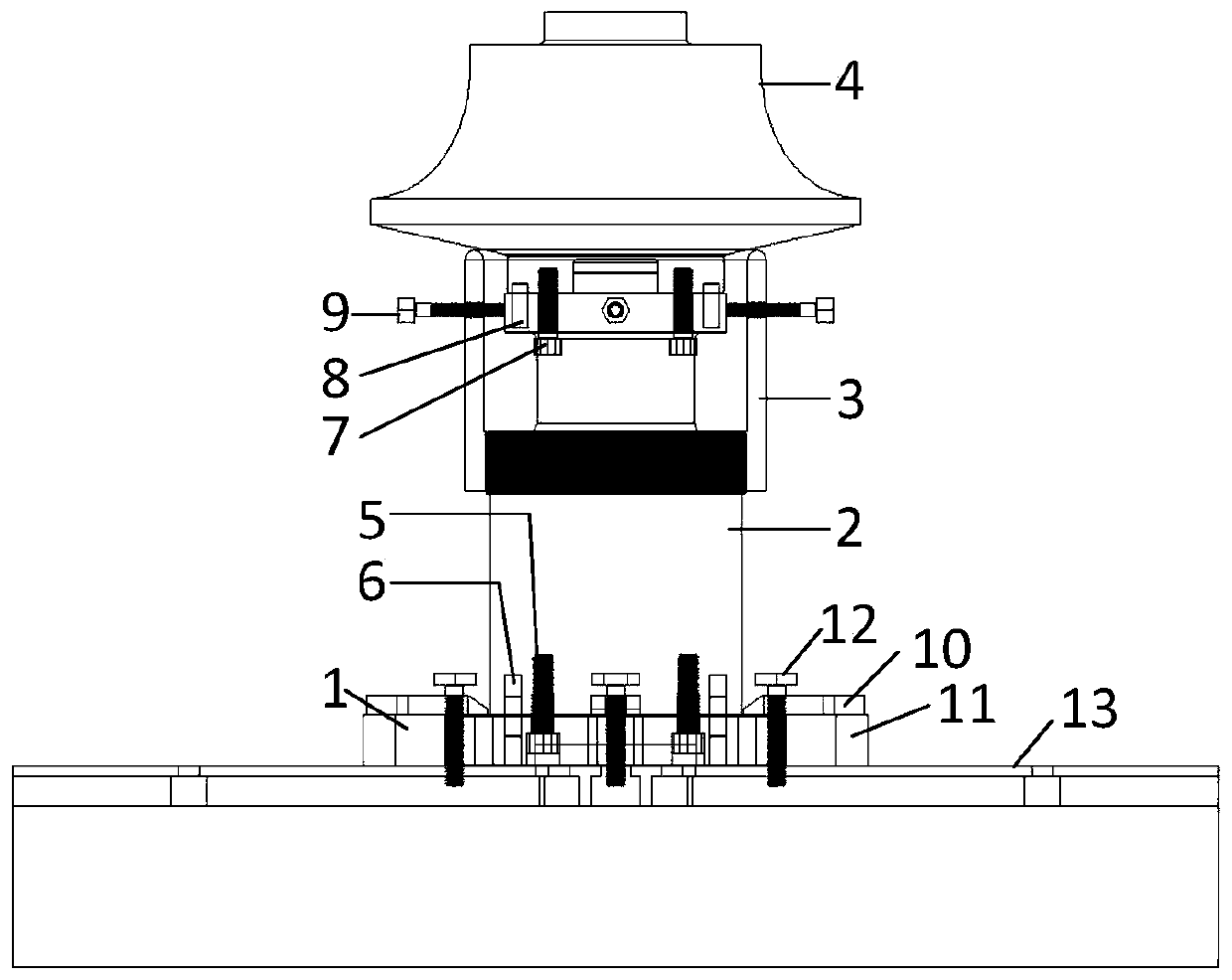

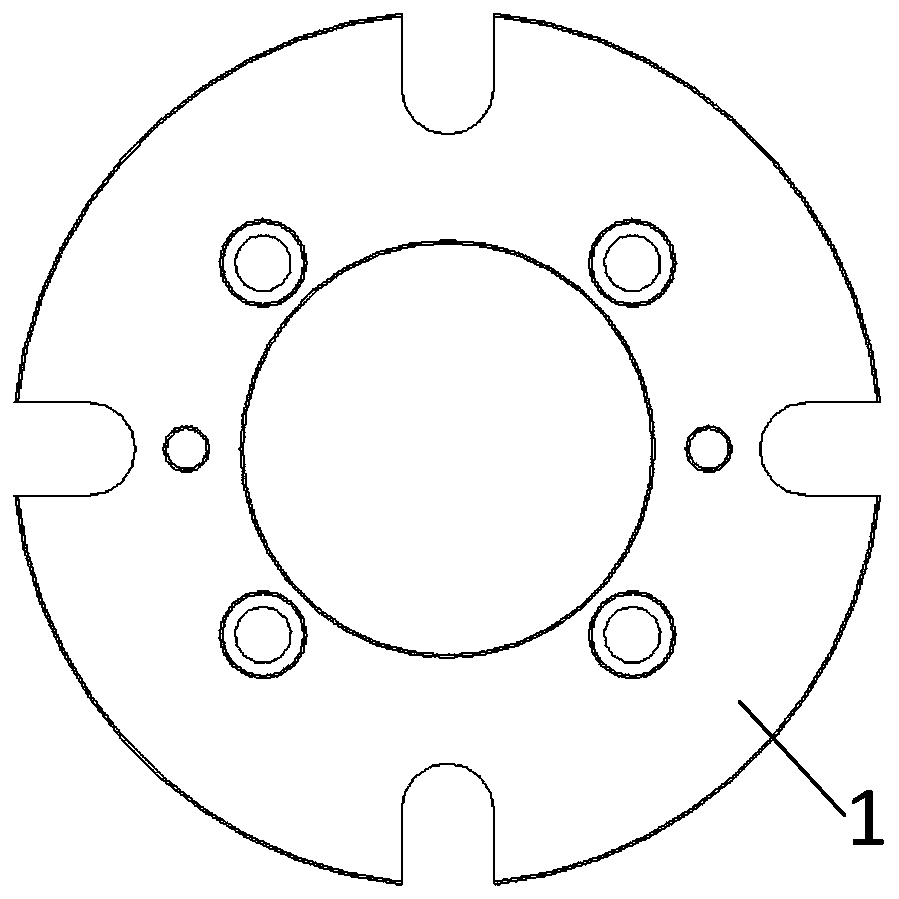

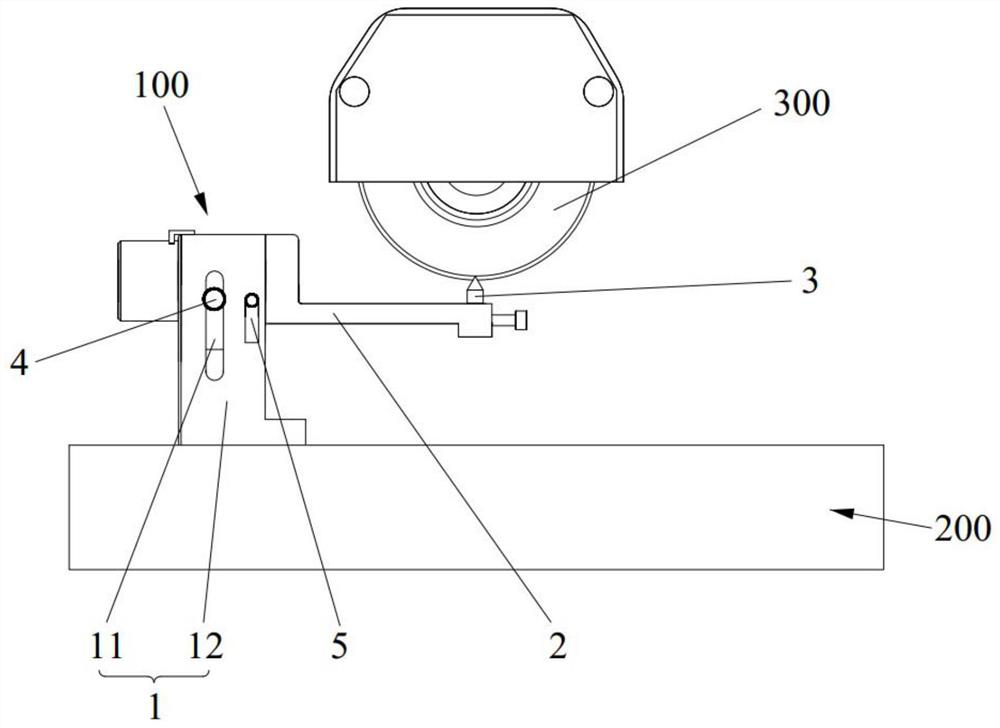

Automatic leveling device of binocular stereo camera, and leveling control system and control method thereof

PendingCN107896326ASimplify the leveling processReduce workloadSteroscopic systemsEmbedded systemTarget level

The invention discloses an automatic leveling device of a binocular stereo camera, and a leveling control system and control method thereof. The device comprises a leveling target, a control system, aclamping system and movement adjustment systems; the control system controls the action of the clamping system and / or the movement adjustment systems according to an image position signal of the leveling target shot by the binocular stereo camera; the clamping system clamps or releases two circuit boards according to the instruction of the control system; and two movement adjustment systems abutagainst the two circuit boards in a one-to-one correspondence manner and respectively drive the circuit boards on the corresponding sides to reciprocate to preset displacements on the vertical direction according to the instruction of the control system. The automatic leveling device of the binocular stereo camera can realize automatic leveling without the manual leveling of the worker, thereby simplifying the camera leveling operation process and reducing the camera leveling workload.

Owner:BEIJING SMARTER EYE TECH CO LTD

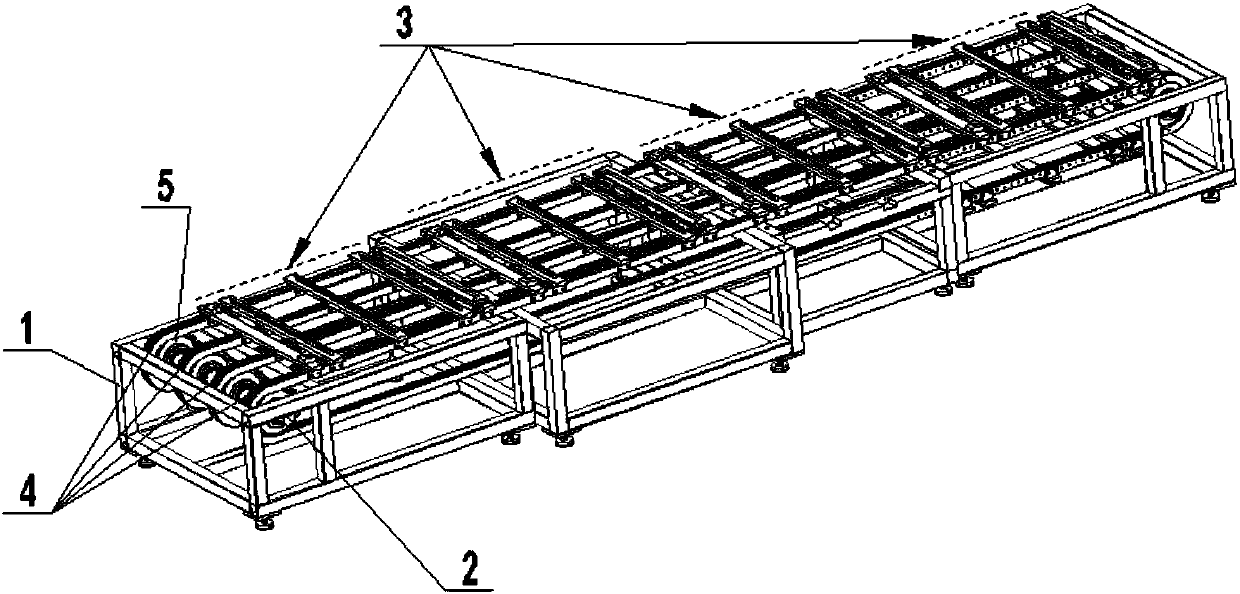

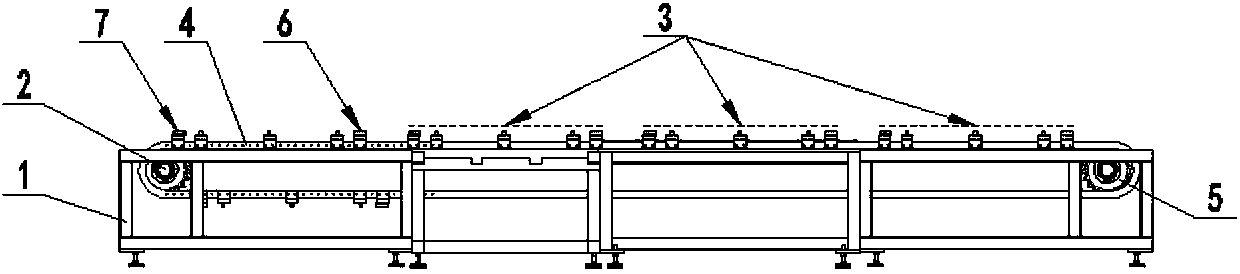

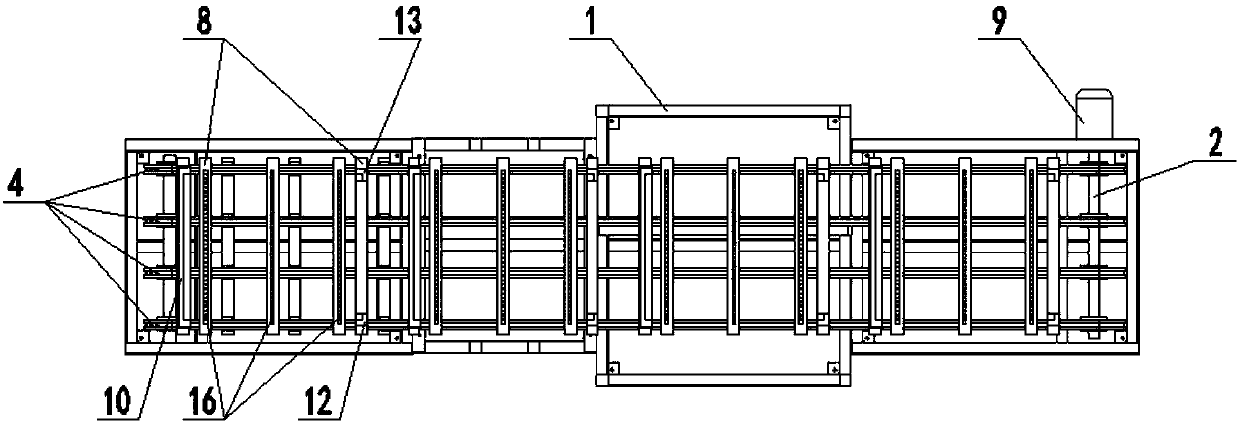

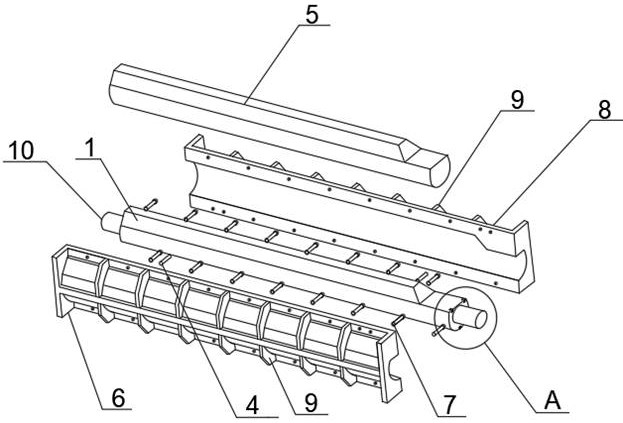

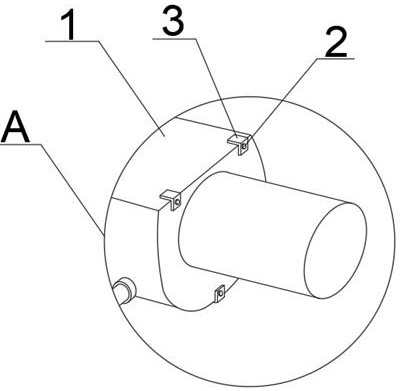

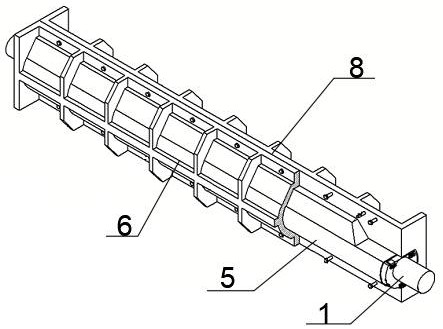

Conveying equipment for automated production line for steel grid plates

The invention provides conveying equipment for an automated production line for steel grid plates. The conveying equipment comprises a rack, transmission shafts, multiple clamp mechanisms and multipletransmission belts. The two ends of the transmission shafts are mounted at the two sides of the rack through bearing seats correspondingly. Each transmission shaft is provided with multiple transmission wheels, wherein the number of the transmission wheels on one transmission shaft is the same as that of the transmission wheels on another transmission shaft. Each transmission belt is connected with the transmission wheels at the corresponding positions of all the transmission shafts an engaged manner. Each clamp mechanism comprises a limiting device A, a limiting device B and two or more clamp bearing plates. Each clamp bearing plate is mounted on the corresponding transmission belt. Each limiting device A and the corresponding limiting device B are mounted on the corresponding clamp bearing plates correspondingly. By means of the conveying equipment, all the clamp mechanisms used in all procedures for producing the steel grid plates are unified into the fixed form and mounted on an annular conveying belt of a conveying mechanism, so that the clamp mechanisms enable the manufacturing procedure positions to be changed with operation of the conveying belt; the automation level of steel grid plate production is raised; and product precision, quality and conformance are improved.

Owner:张文安

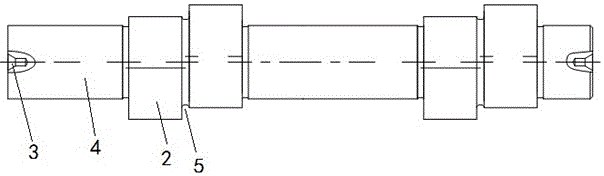

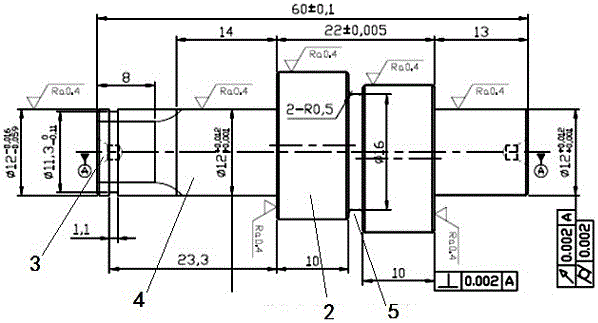

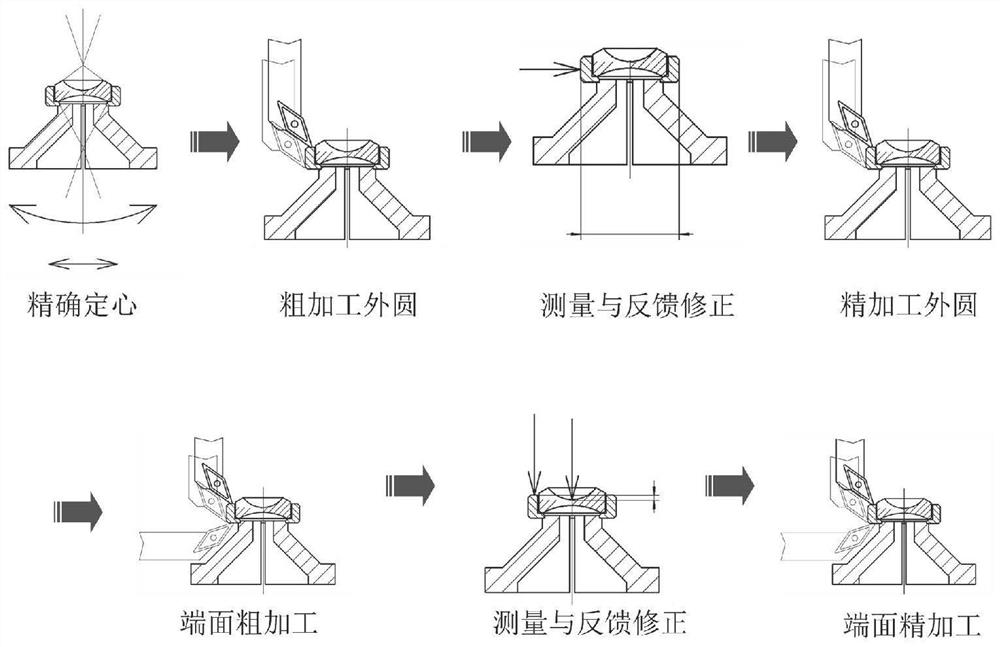

High-precision crank shaft for speed reducer and machining method thereof

Owner:JOUDER PRECISION INDAL KUSN

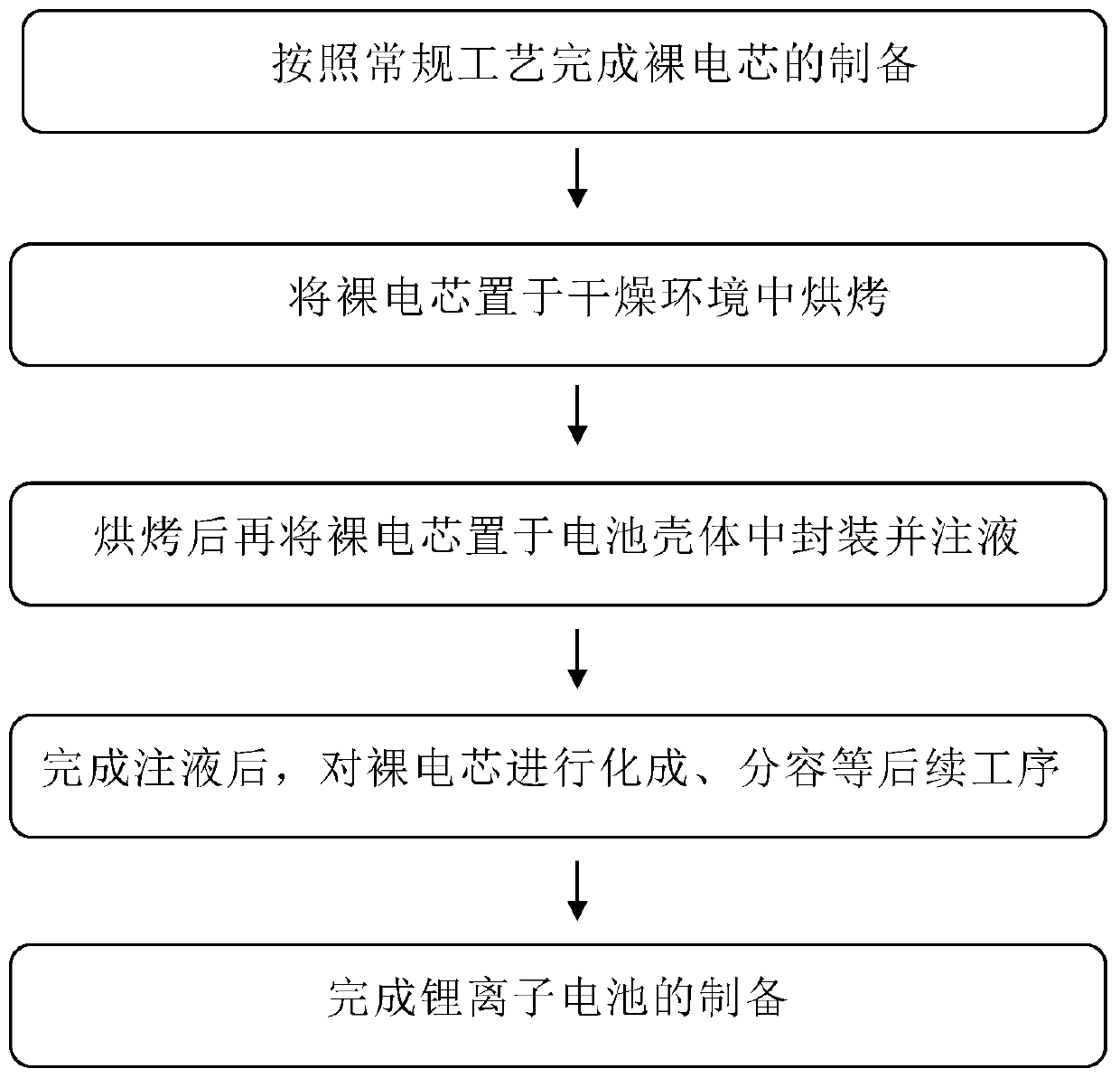

Manufacturing method of lithium ion battery

InactiveCN110828905AReduce usageReduce areaFinal product manufactureCell component detailsPhysical chemistryPlastic film

A manufacturing method of a lithium ion battery comprises the following steps of S1, placing a bare cell in a dry environment for baking, placing the bare cell in a battery shell after baking, and injecting a liquid in the dry environment, wherein the bare cell is connected with a tab with a channel, and the channel is used for a liquid injection process of the bare cell; and S2, after liquid injection is completed, carrying out a formation process, discharging a gas generated by formation from the channel, then sealing the channel, and completing manufacturing of the lithium ion battery. Compared with the prior art, by using the method of the invention, the bare cell is baked firstly, and a baking speed of the unpackaged bare cell is greatly increased due to a fact that the unpackaged bare cell is not wrapped by an external aluminum-plastic film. Besides, the tab with the channel is adopted for liquid injection so that an electrolyte is injected into the battery from an internal channel of the tab, and meanwhile, the gas generated by formation is discharged from the channel so that use of the aluminum-plastic films can be reduced, a large number of aluminum-plastic films are saved, and production cost is reduced.

Owner:东莞汇洋动力科技有限公司

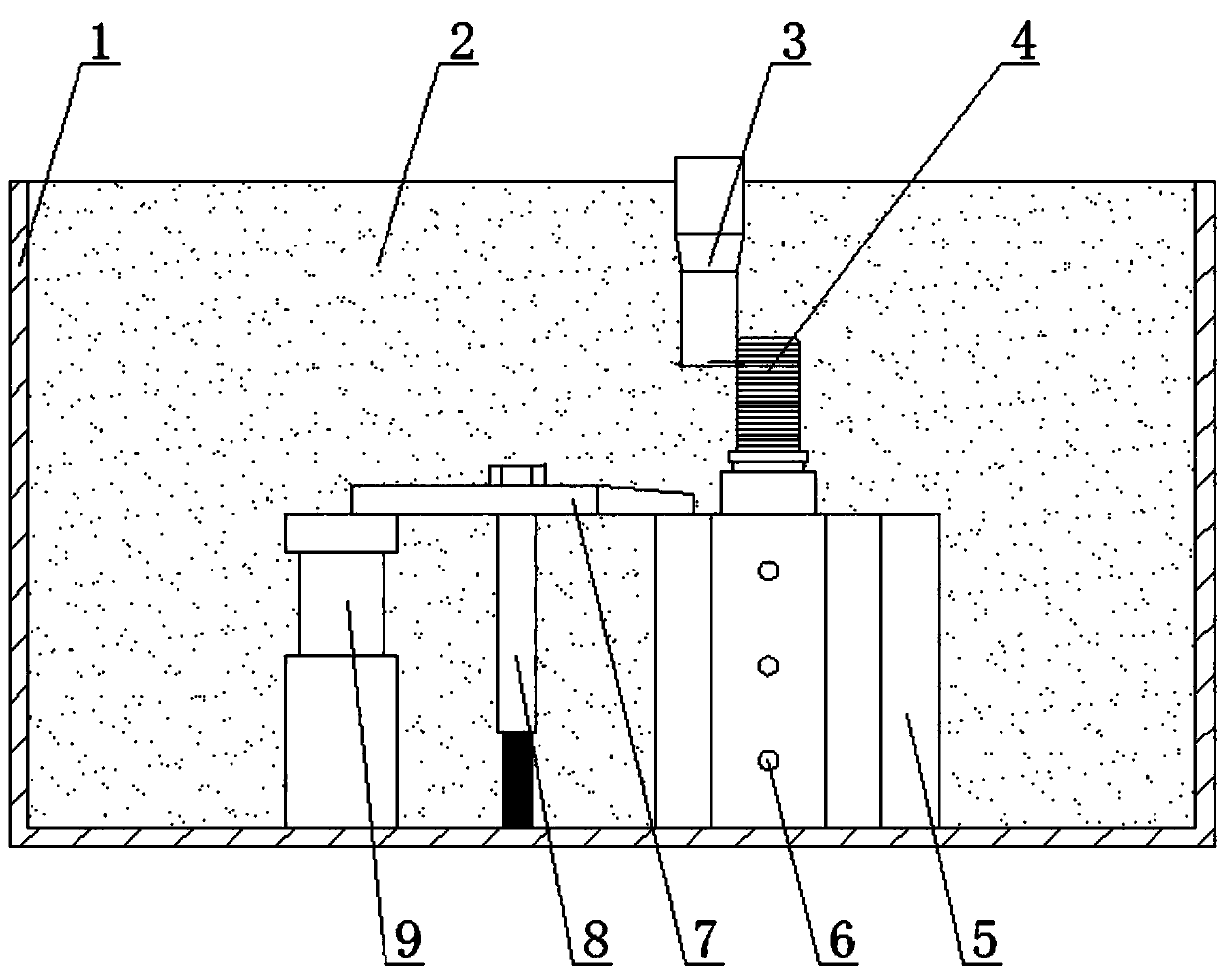

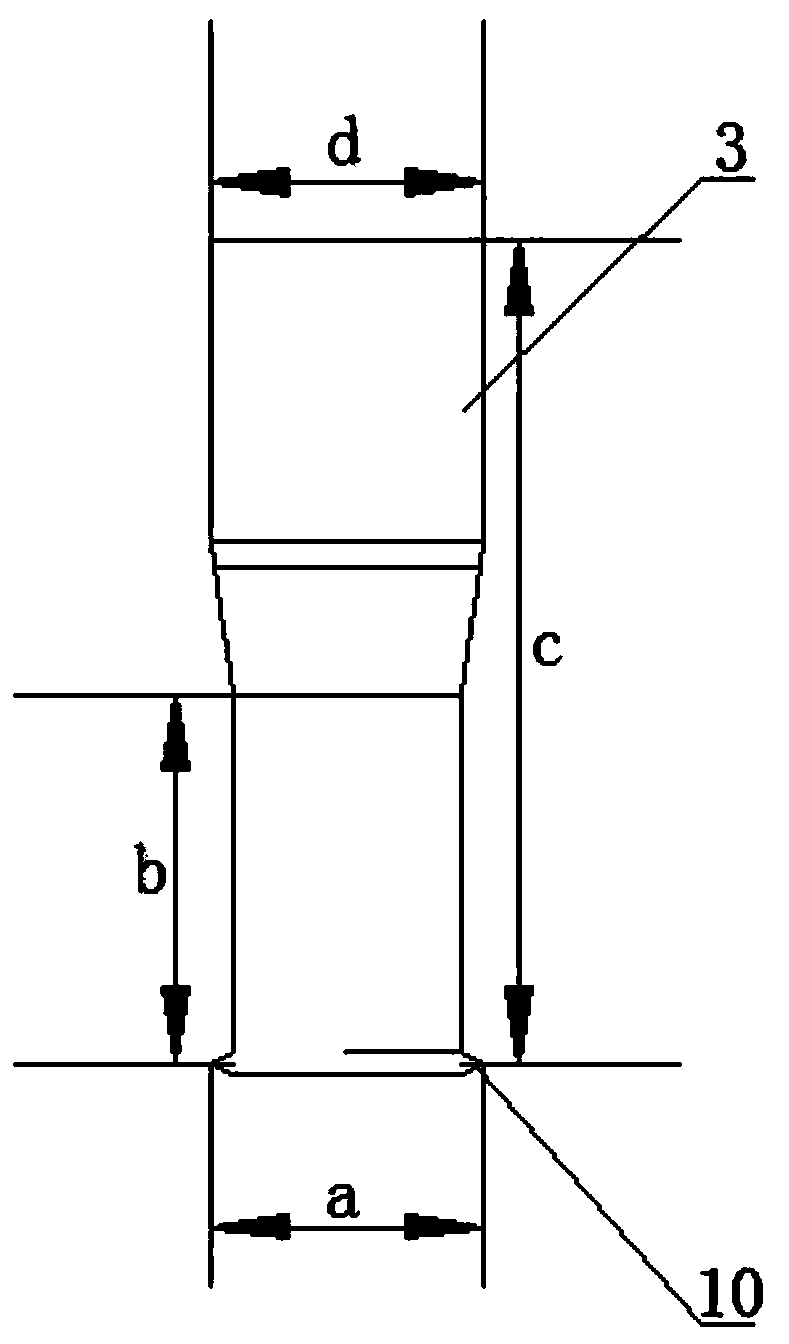

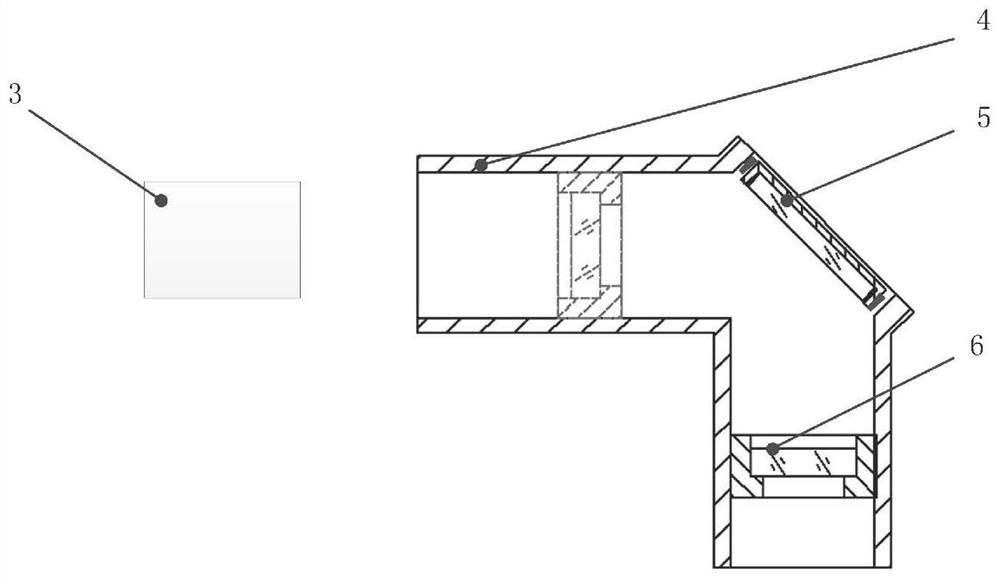

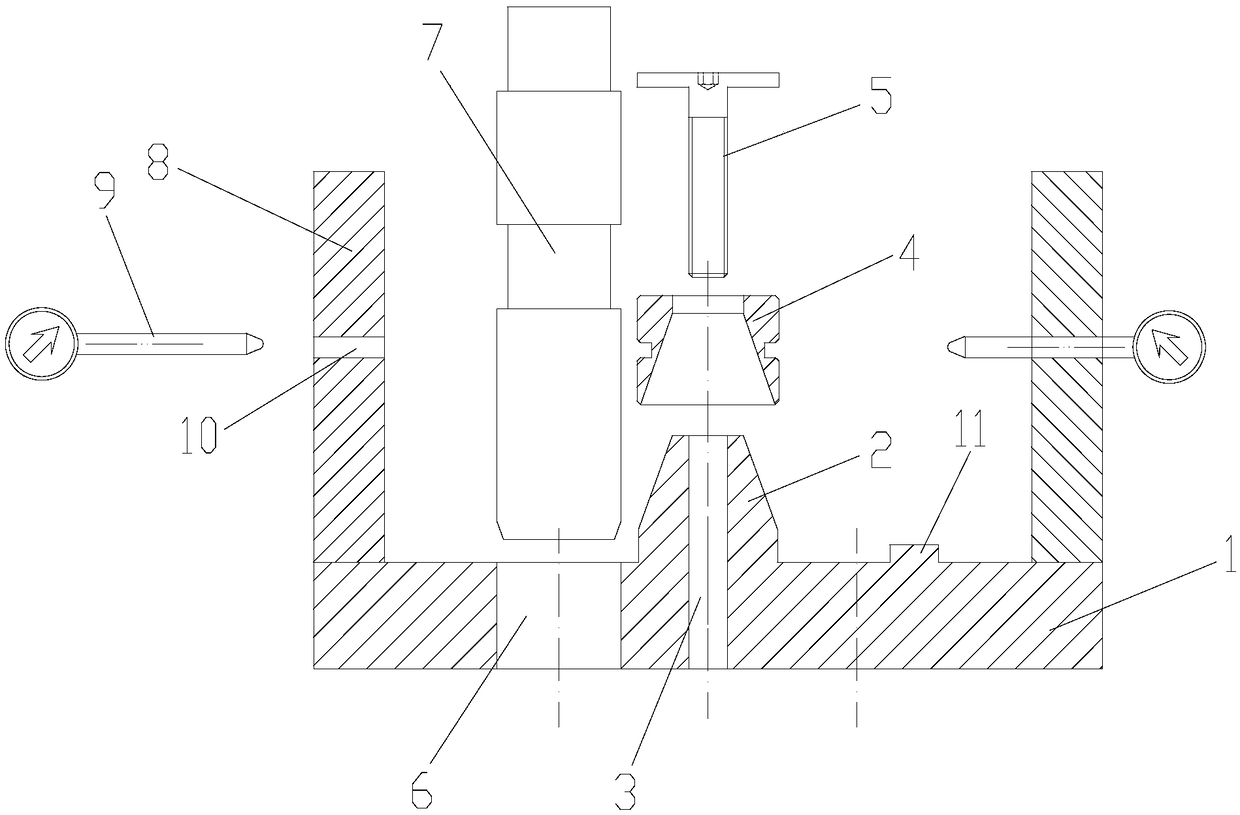

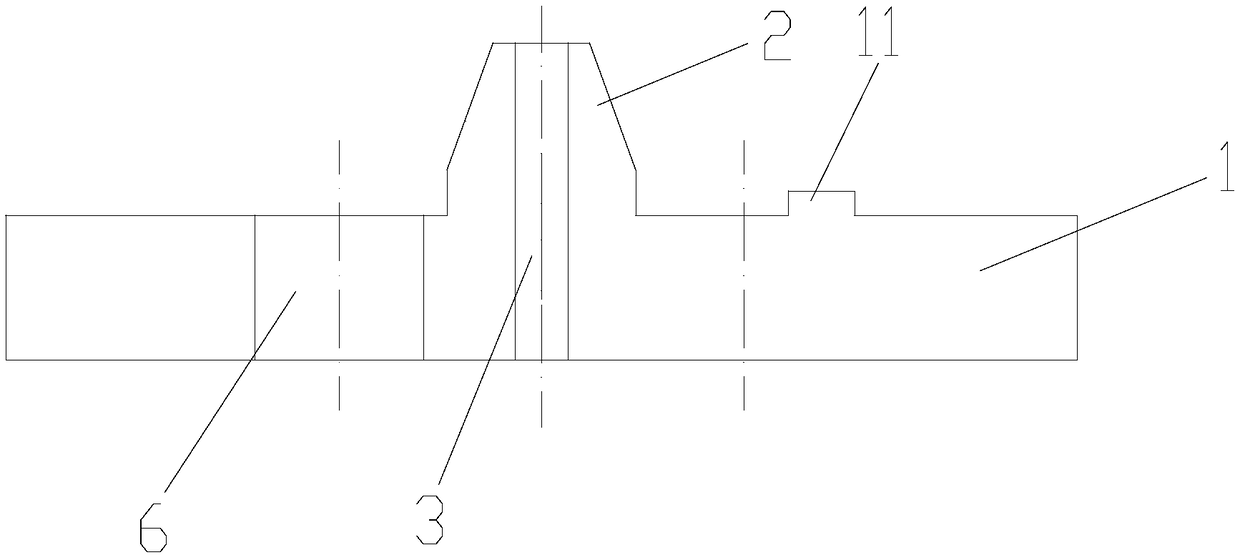

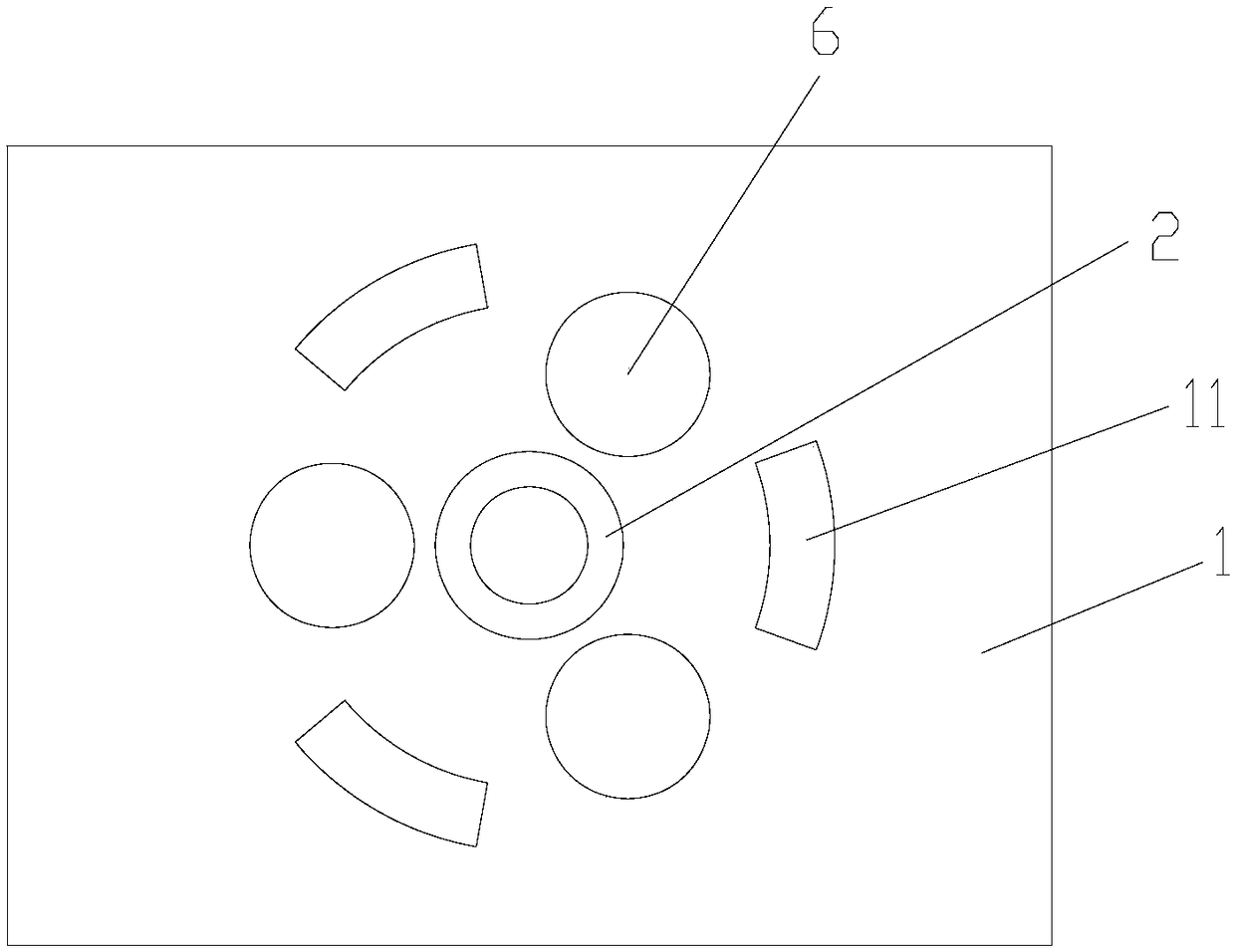

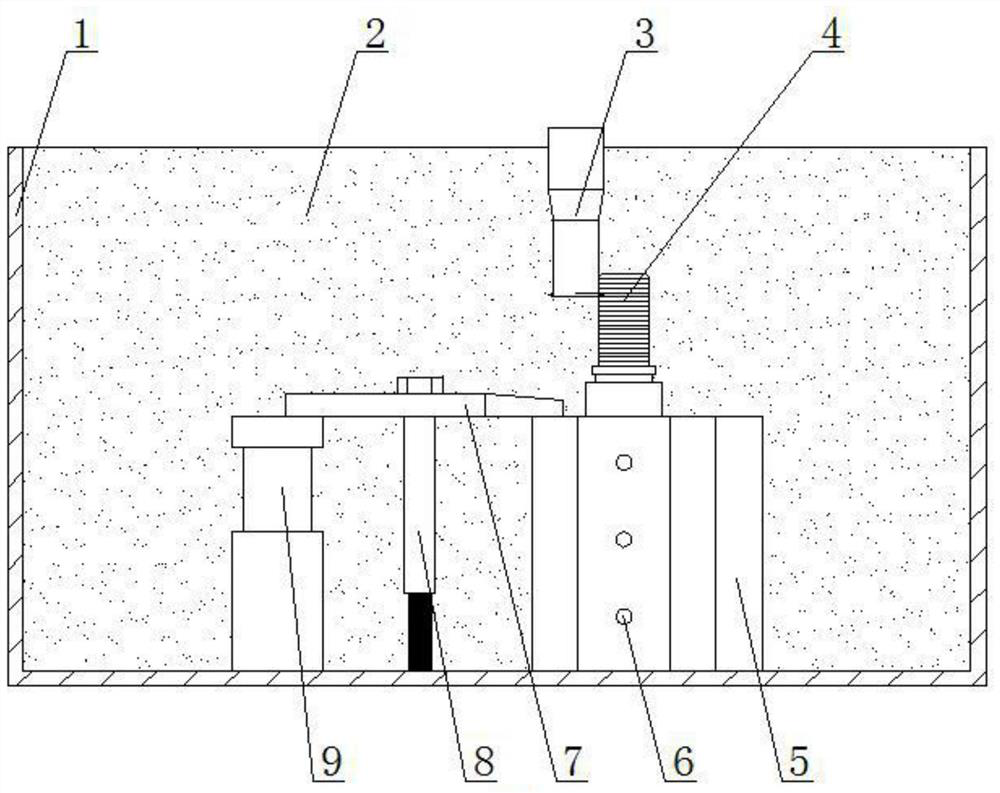

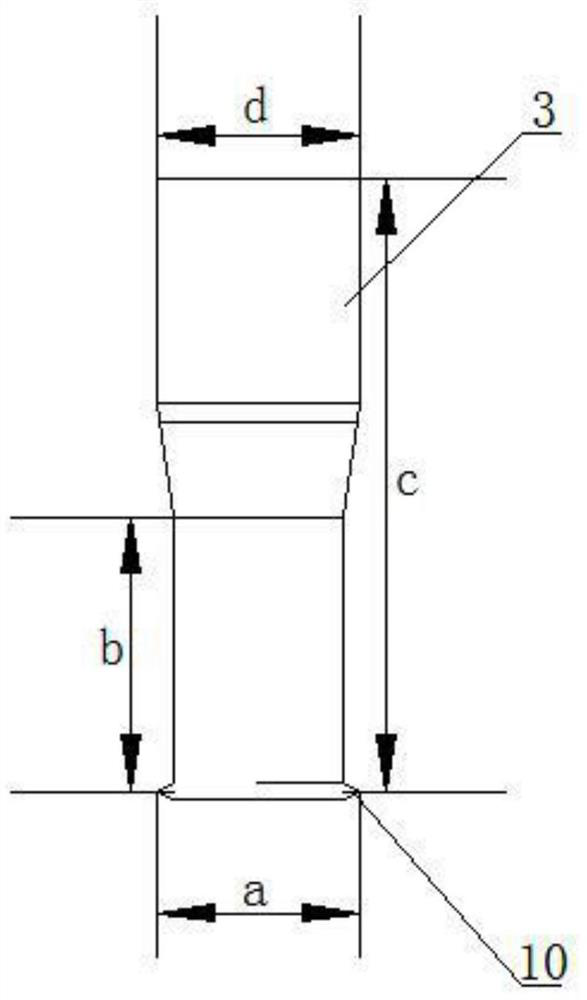

TiC-based steel bonded hard alloy fine external thread milling device and numerical control milling method thereof

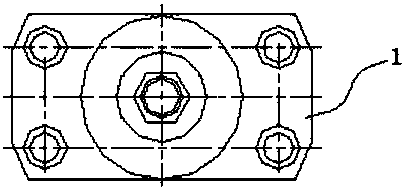

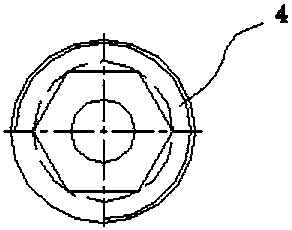

ActiveCN110052671AGuaranteed accuracy consistencyFast conductionThread cutting toolsThread cutting machinesNumerical controlMilling cutter

The invention relates to the technical field of precise machining of a TiC -based steel bonded hard alloy, and in particular relates to a TiC-based steel bonded hard alloy fine external thread millingdevice and a numerical control milling method thereof. The milling device comprises a box body with an opening at the upper end, the box body is filled with cooling liquid, a fixing base is arrangedin the bottom surface of the box body, a spring chuck is arranged at the upper end of the fixing base, and the spring chuck is used for fixing a part to be milled; Under the fixed state of the part, the height of the upper end part of the part is lower than the height of the side wall of the box body, the side of the part is suspended with a milling cutter, the milling cutter adopts a polycrystalline diamond coating, the main cutting edge part of the milling cutter adopts a two-edge mode, and the two edges are arranged in a coplanar manner.

Owner:TIANJIN NAVIGATION INSTR RES INST

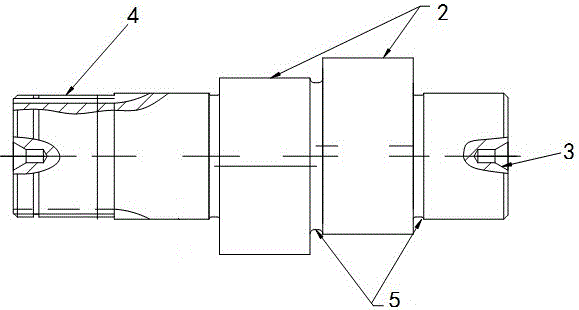

Equipment for shearing diode pins

The invention discloses a device for cutting diode pins, which comprises a base, and the base is provided with a moving seat and a fixed seat oppositely arranged, and a T-shaped template is plugged into the fixed seat, and the T-shaped The formwork is formed with two jacks that run through the front and rear ends of the T-shaped formwork, the bottom of the moving seat is formed with guiding protrusions, and the base is formed with moving grooves, and the guiding protrusions are inserted into the moving grooves; A vertical positioning plate is formed on the side of the moving seat close to the fixed seat, and two positioning holes are formed on the upper surface of the positioning plate, and a number of vertical guide posts are plugged into the moving seat on one side of the positioning plate, so that The upper end of the guide column is fixed on the supporting plate, and an adjusting stud is screwed inside the supporting plate, and the lower end of the adjusting stud is fixedly sleeved with a driven gear, and the driven gear is meshed with a driving gear. The invention can be applied to cutting pins on diodes of various specifications, and can ensure the cutting length accuracy and length consistency.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

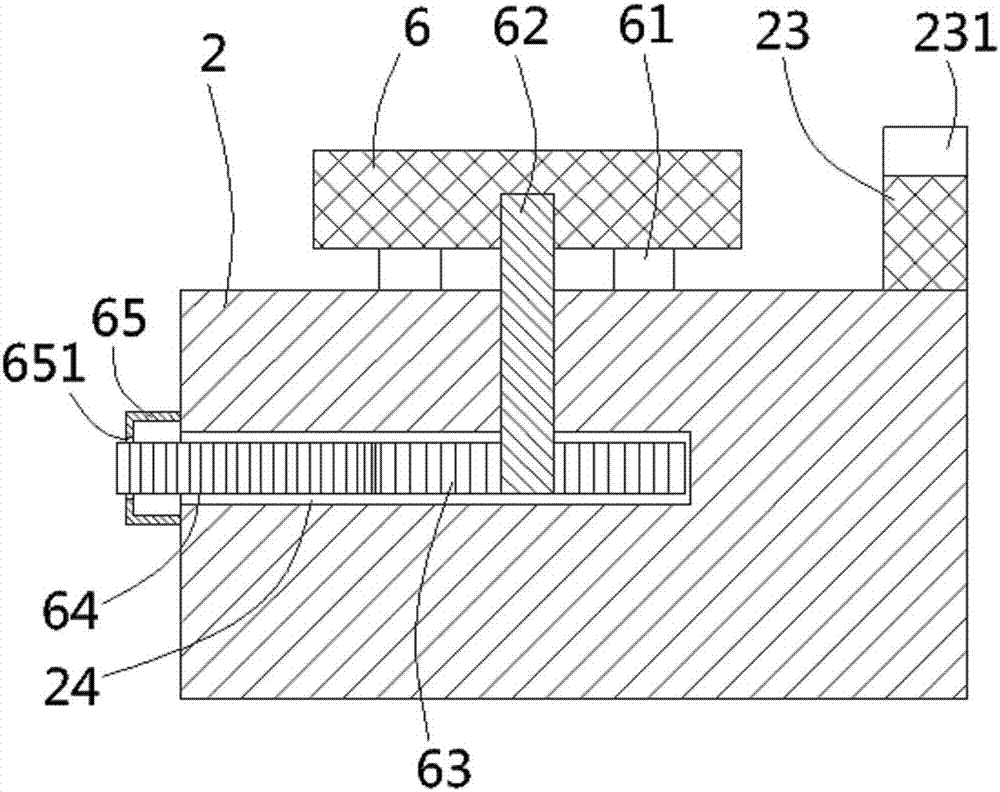

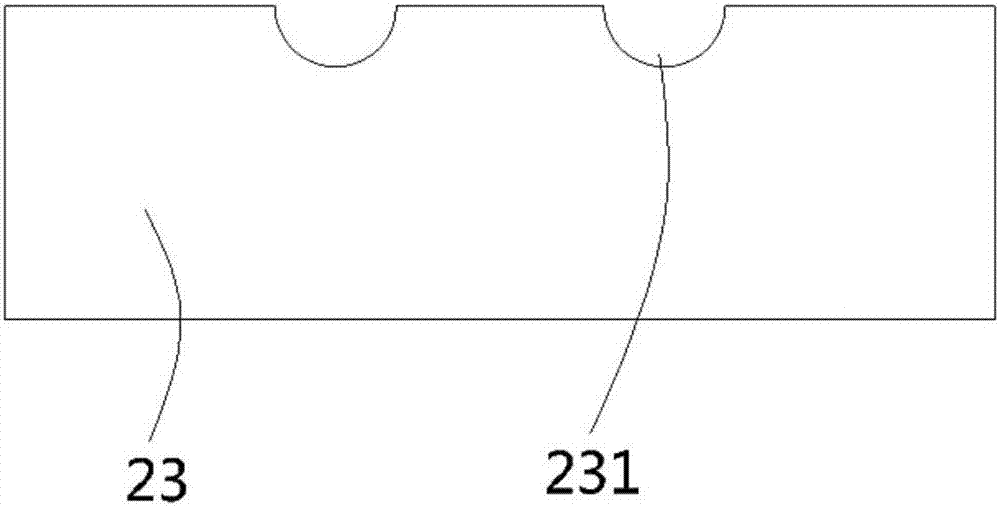

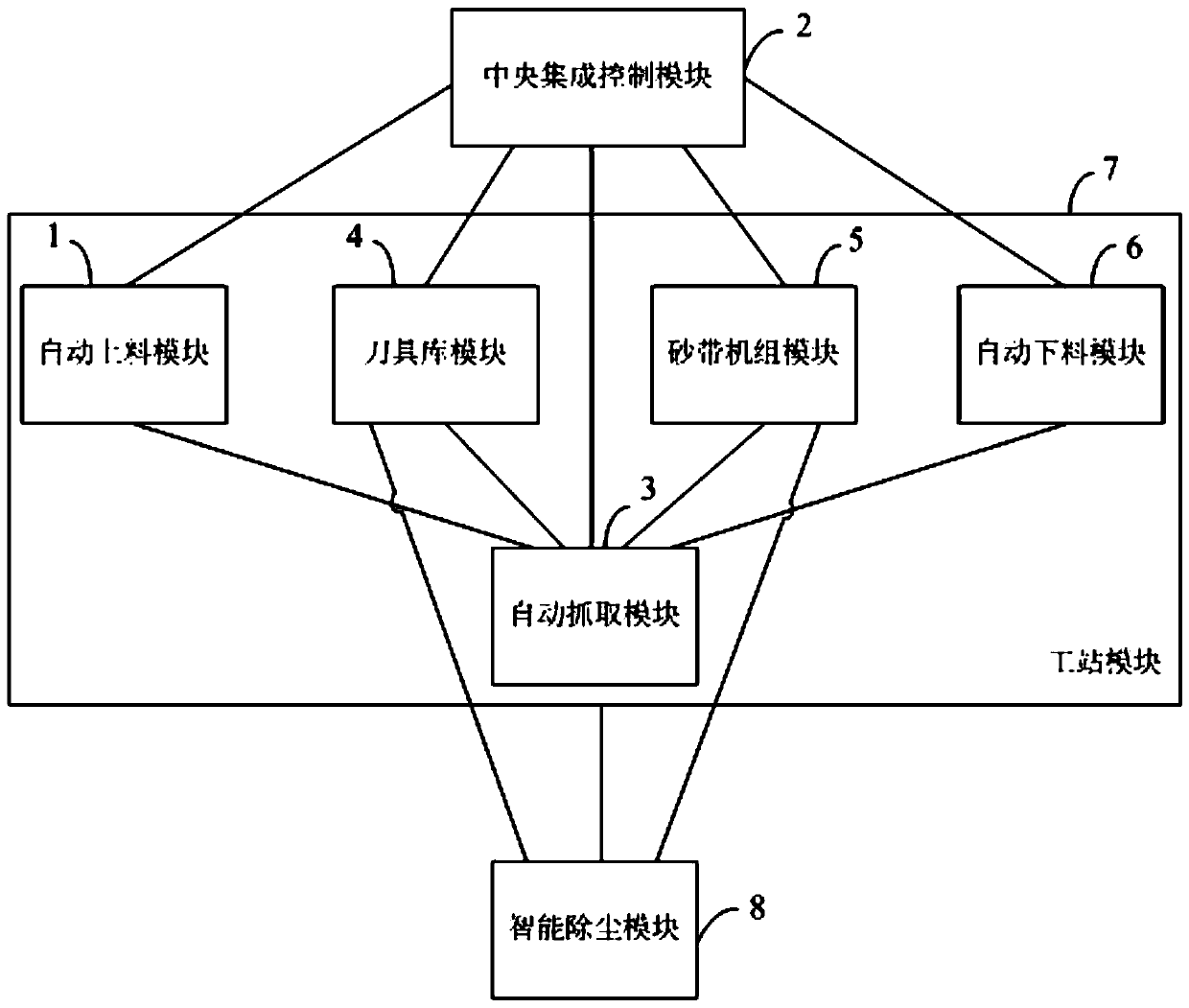

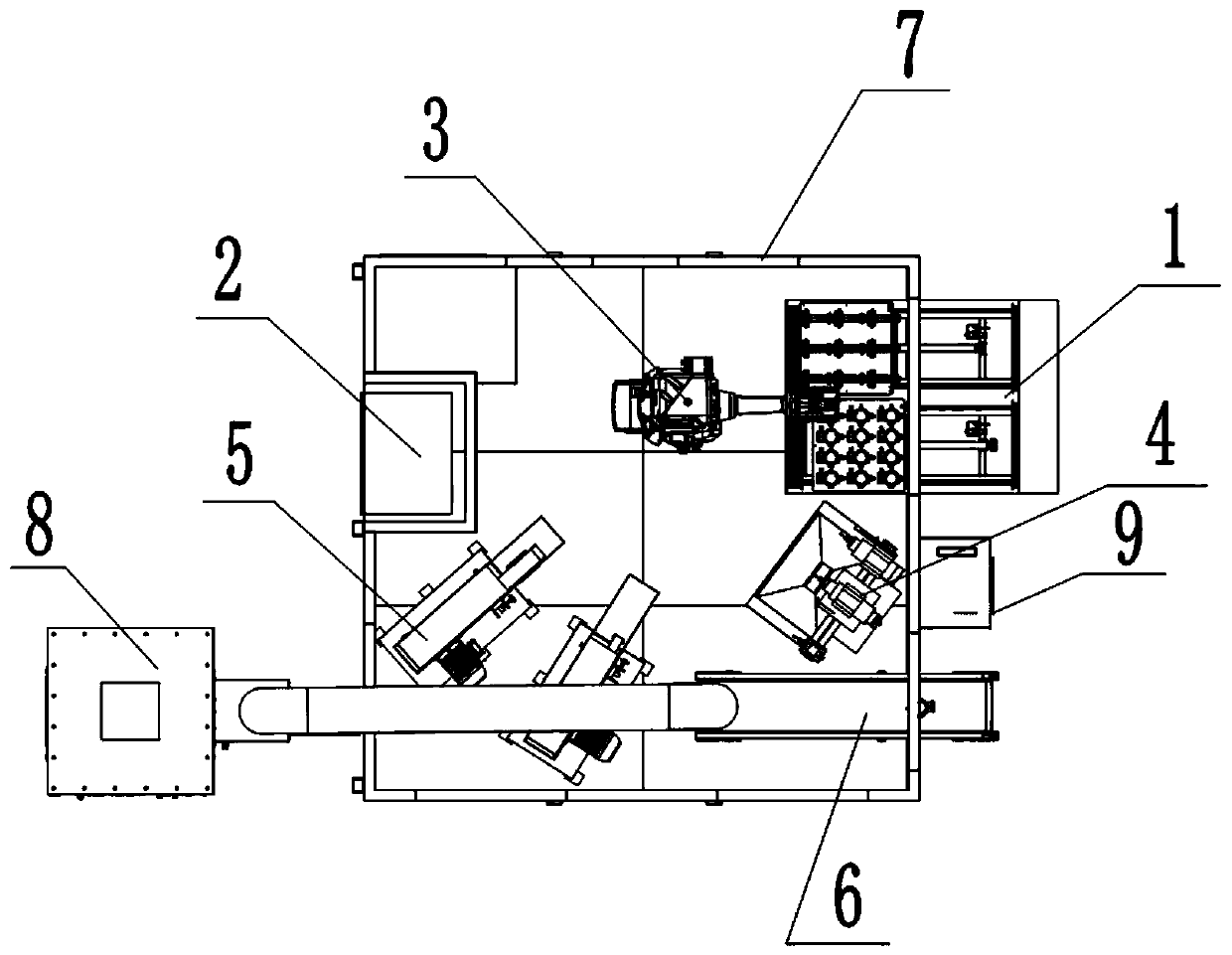

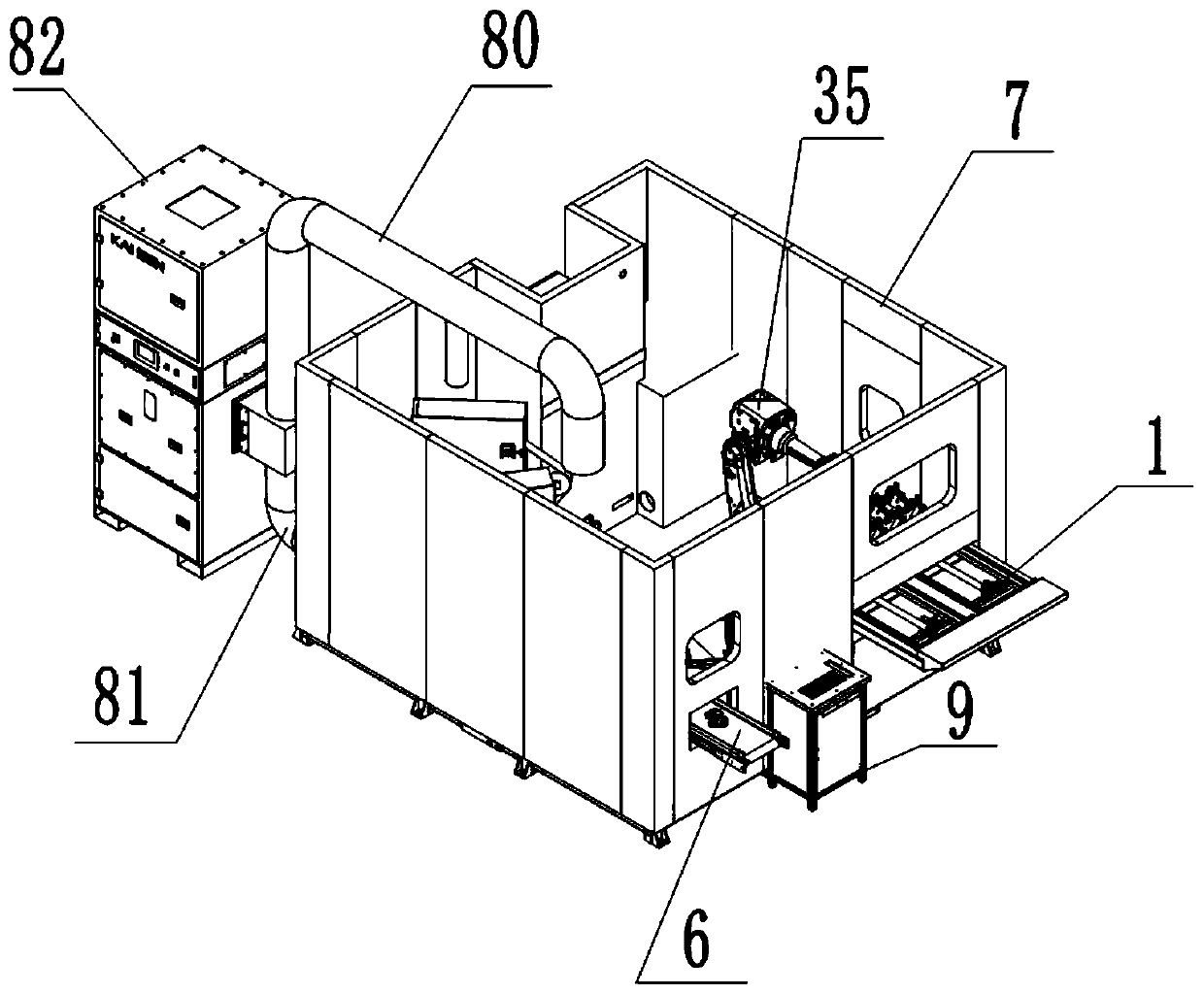

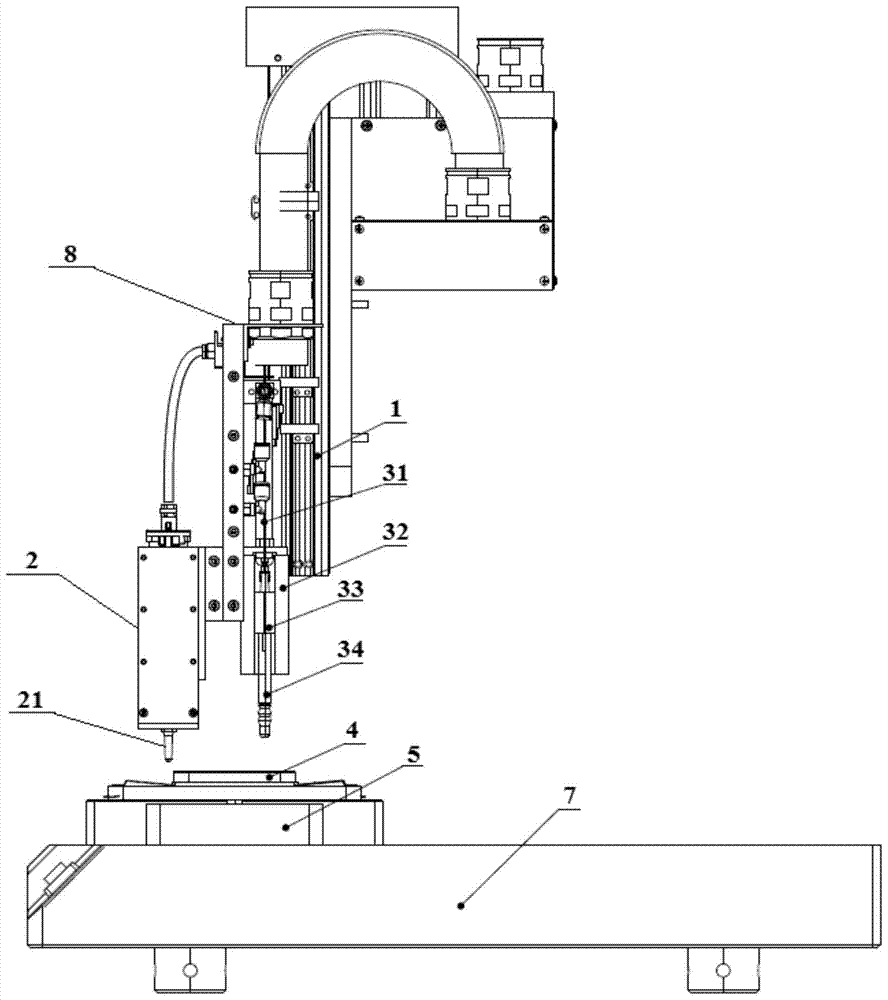

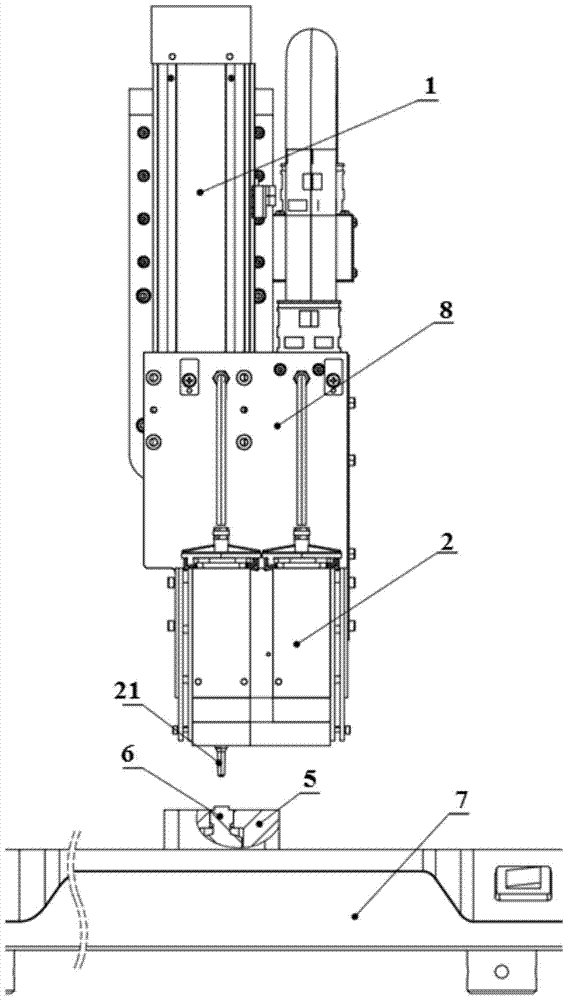

Automatic grinding device for aluminum alloy parts of high-speed rail overhead line system

PendingCN110524253AGuaranteed accuracy consistencyEnsure appearance consistencyDirt cleaningOther manufacturing equipments/toolsEngineeringOverhead line

The invention discloses an automatic grinding device for aluminum alloy parts of a high-speed rail overhead line system. The automatic grinding device is characterized in that a central integrated control module sends different signals to an automatic feeding module, an automatic grabbing module, a cutter module, an abrasive belt unit module and an automatic discharging module, the automatic feeding module feeds the aluminum alloy castings to a grabbing position, and the automatic grabbing module sequentially grabs the grabbed aluminum alloy castings at the grapping position to the cutter module, the abrasive belt unit module and the automatic discharging module; the cutter module and the abrasive belt unit module grind the aluminum alloy castings separately to obtain the aluminum alloy parts, the automatic discharging module conveys the aluminum alloy parts, the automatic feeding and discharging module, the automatic grabbing module, the cutter module and the abrasive belt unit moduleare placed on a work station module, and an intelligent dust removal module is used for removing the dust in the cutter module, the abrasive belt unit module and the work station module. The parts ground by the device are small in die assembly seam and tidy in burrs and seams, and the labor cost is greatly saved.

Owner:宝鸡保德利电气设备有限责任公司

Method for accurately adjusting concentricity of telephoto folding axis lens group

PendingCN114236867AEnsure assembly accuracy and quality consistencySolve alignment difficultiesMountingsEngineeringOptical axis

The invention belongs to the technical field of light machine precision adjustment, and discloses a telephoto folding axis lens group concentricity precision adjustment method, which comprises the following steps: S1, designing a semi-reflecting and semi-transmitting tool partition, and carrying out position calibration by adopting a centering turning calibration method to meet the condition that a partition scribed line on the surface of partition glass is concentric with the outer circle of a tool lens frame; the outer circle of the tool lens frame is matched with the inner hole of the folding-axis lens barrel of the telephoto folding-axis lens group; s2, calibrating the mechanical axis of the folding-axis lens barrel to be consistent with an internal focusing axis in an internal focusing and centering mode, adjusting the position of a reflector group at the folding position of the folding-axis lens barrel, ensuring that the graduation lines of the tool graduation fall on the internal focusing axis, and realizing that the assembling and adjusting precision of the folding-axis reflector meets the requirement; and S3, calibrating the consistency of the optical axis of the lens assembly and the mechanical axis through a centering turning calibration method, assembling the transmitting mirror into the lens barrel, and ensuring that the assembling and adjusting quality of the telephoto folding-axis mirror meets the requirements. According to the invention, the performance and the imaging quality consistency of the folding-axis optical lens group product are greatly improved.

Owner:西安应用光学研究所

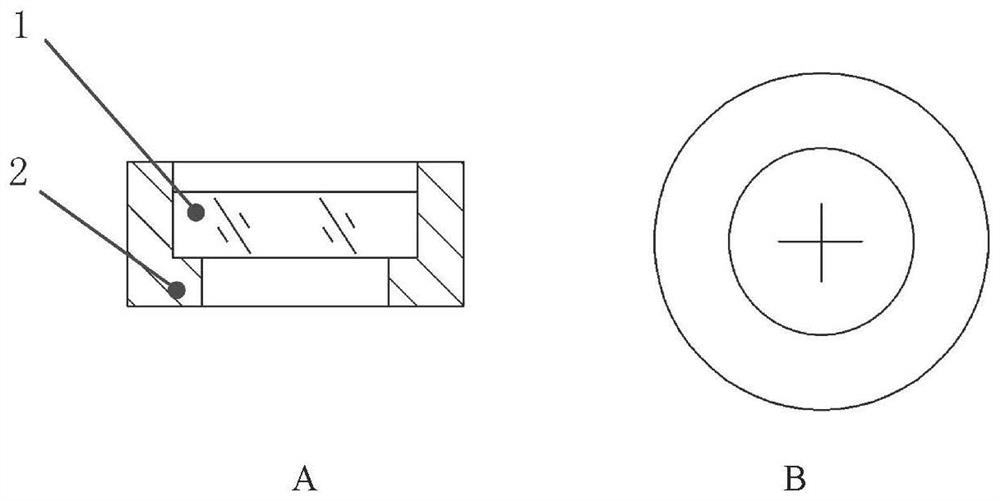

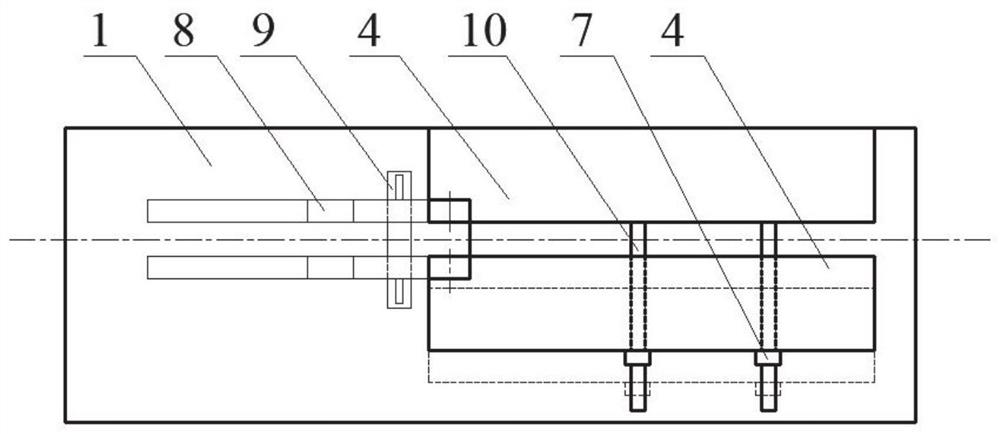

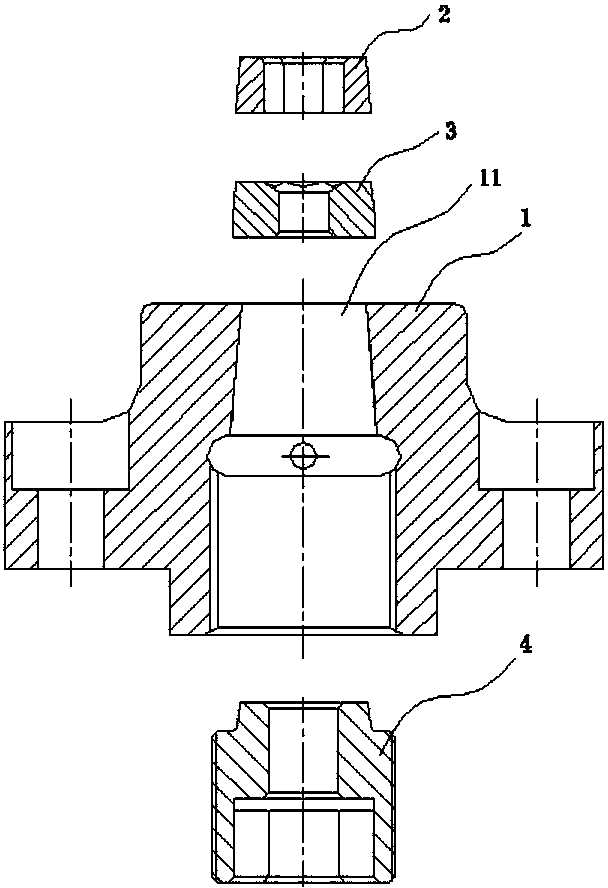

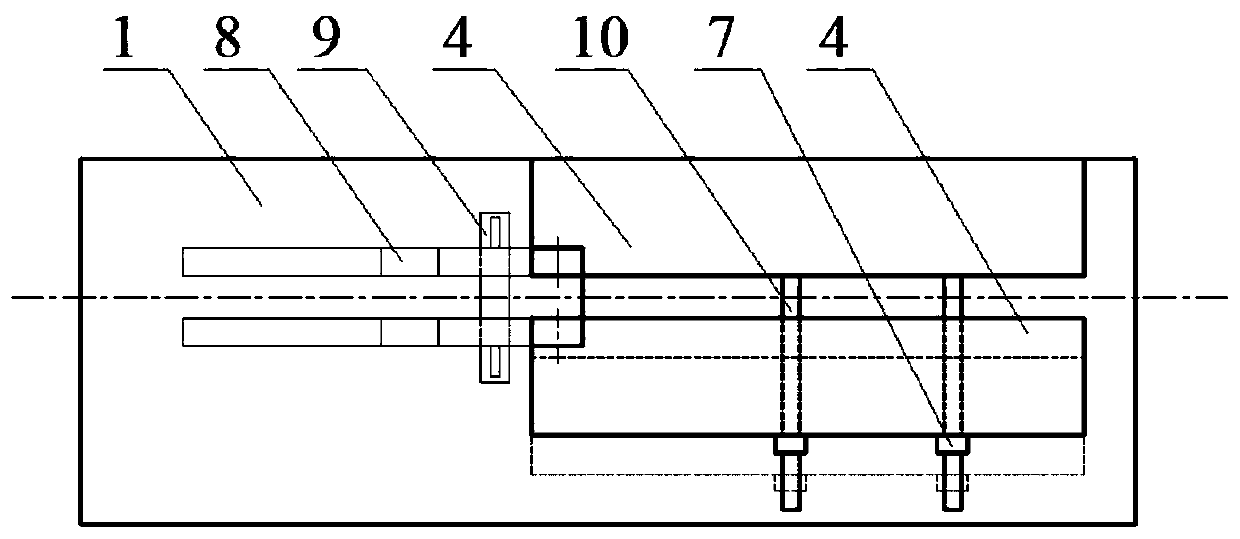

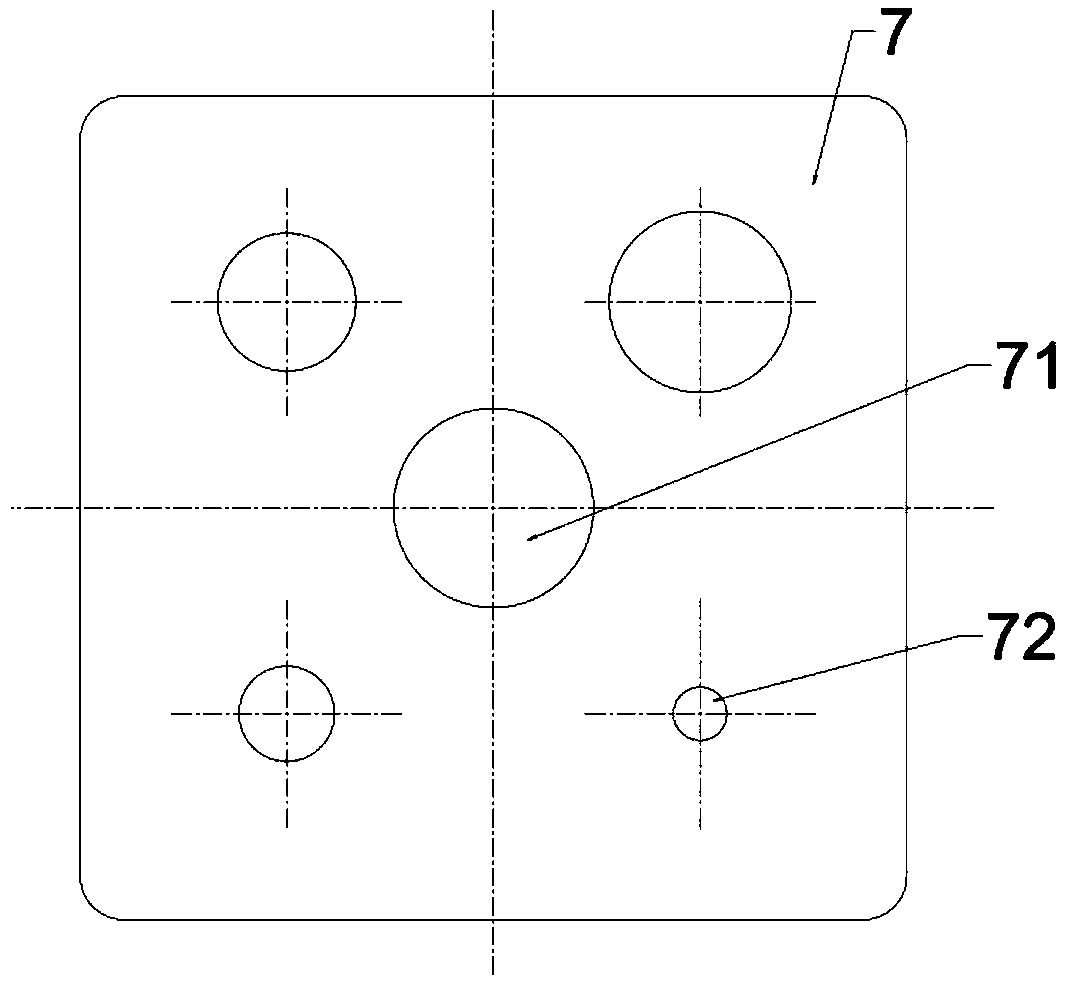

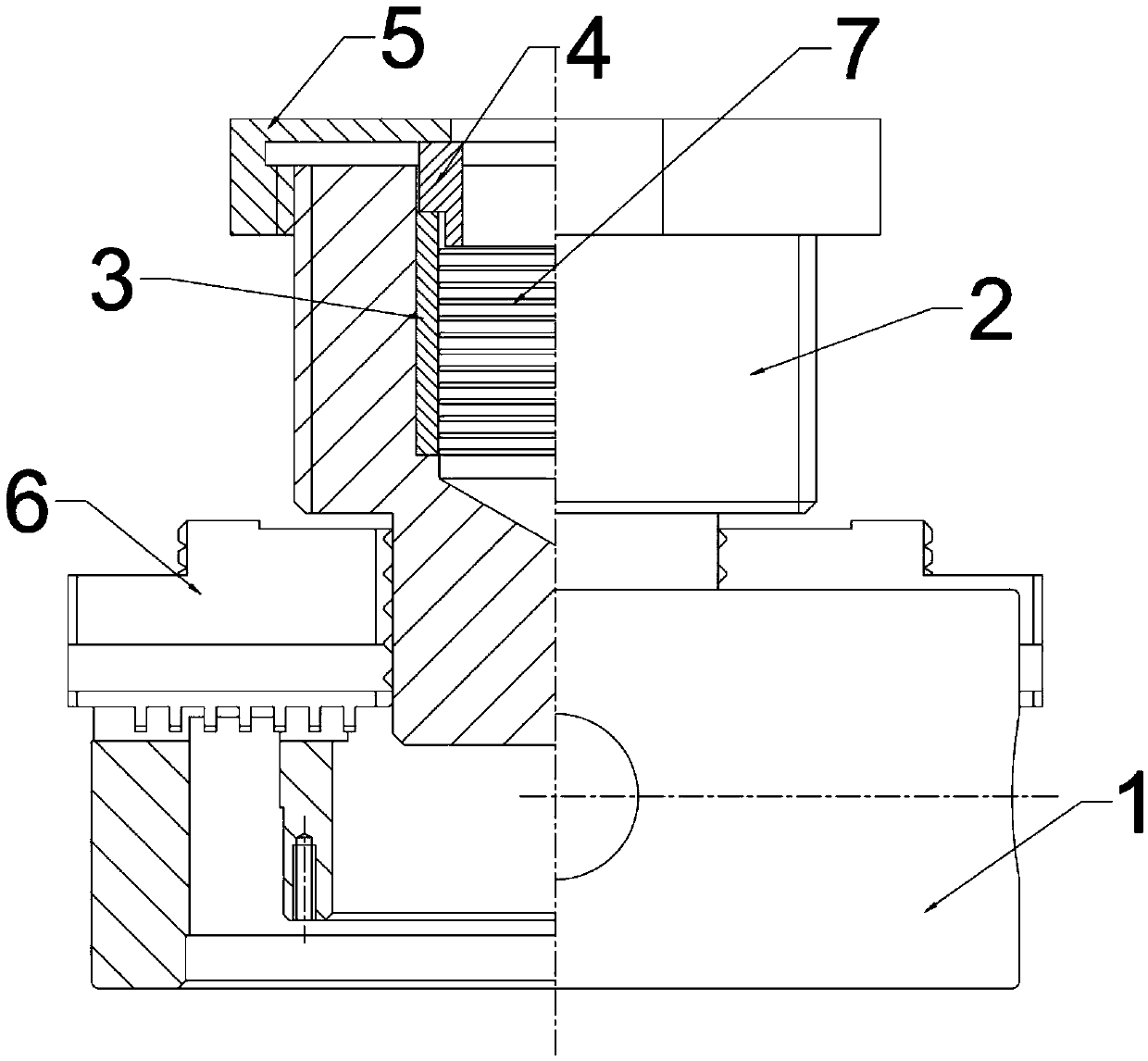

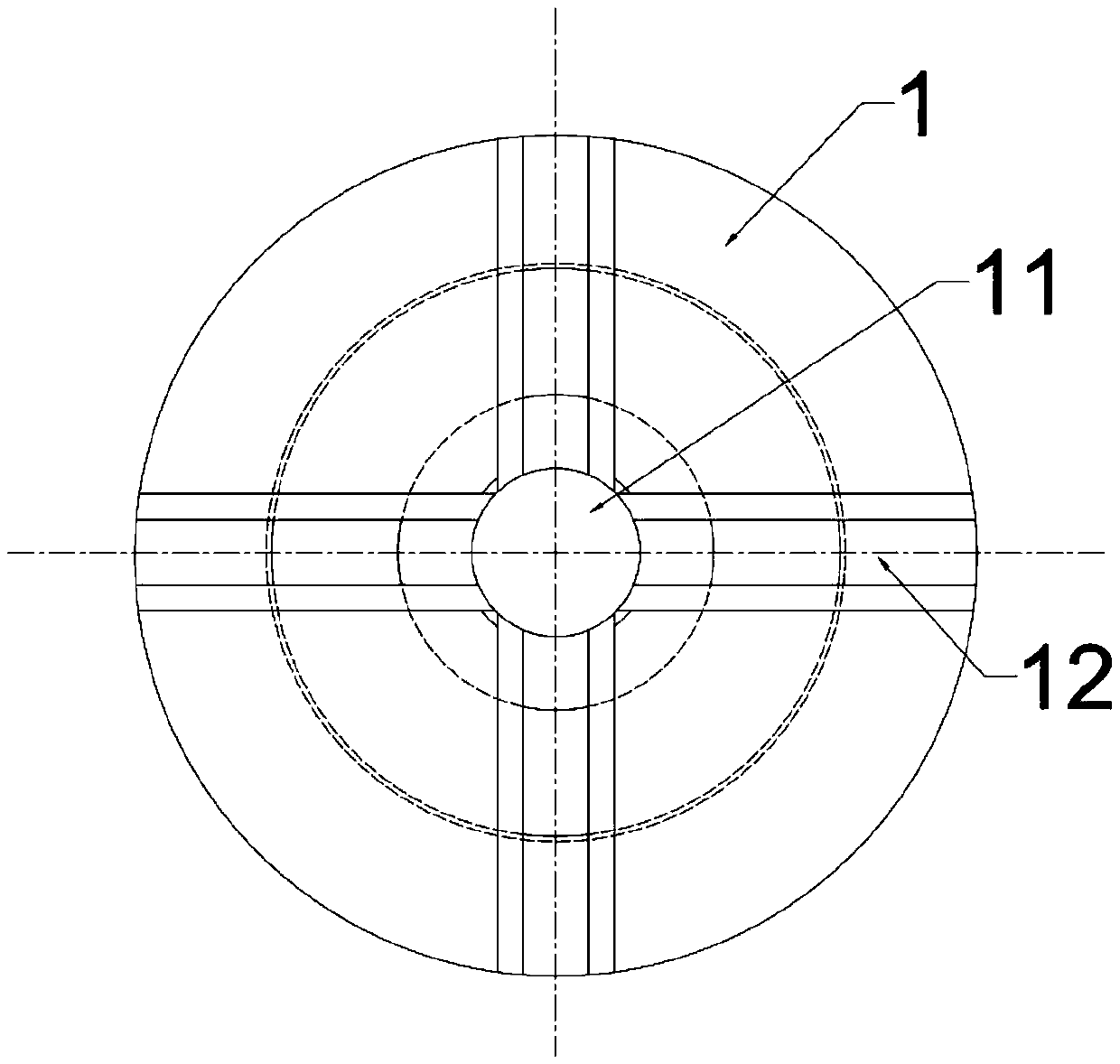

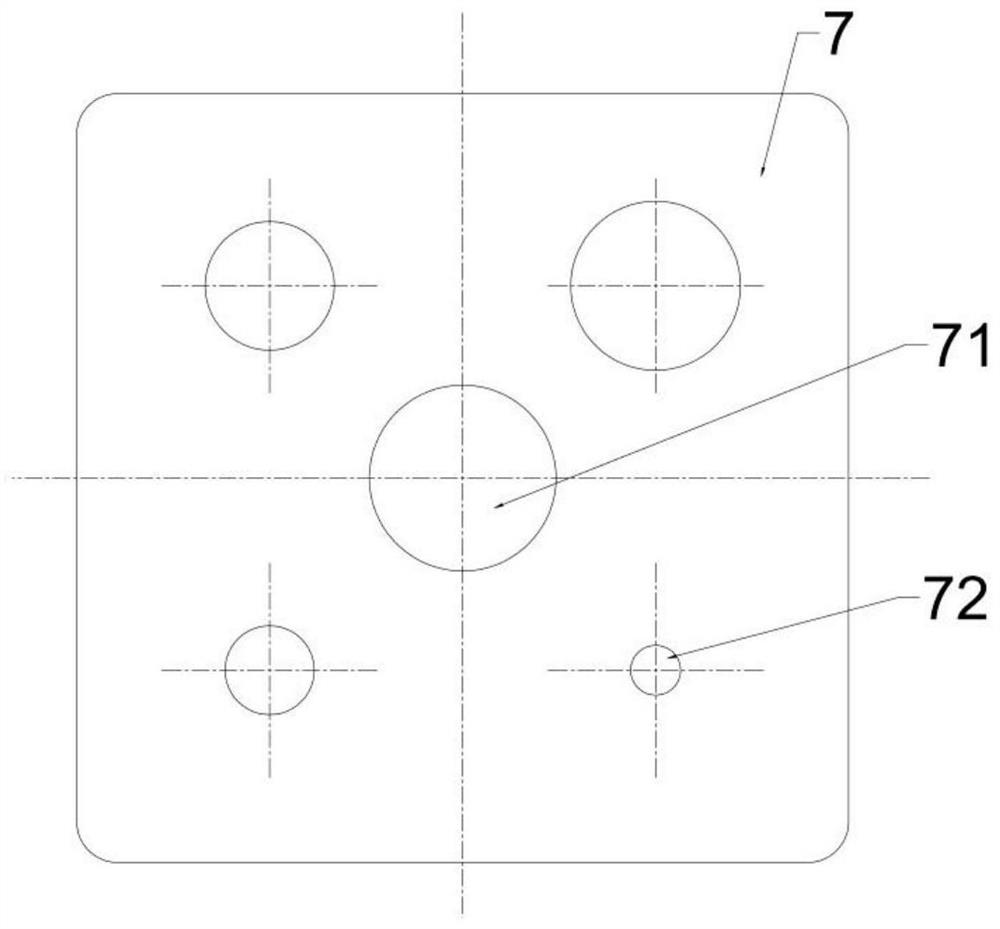

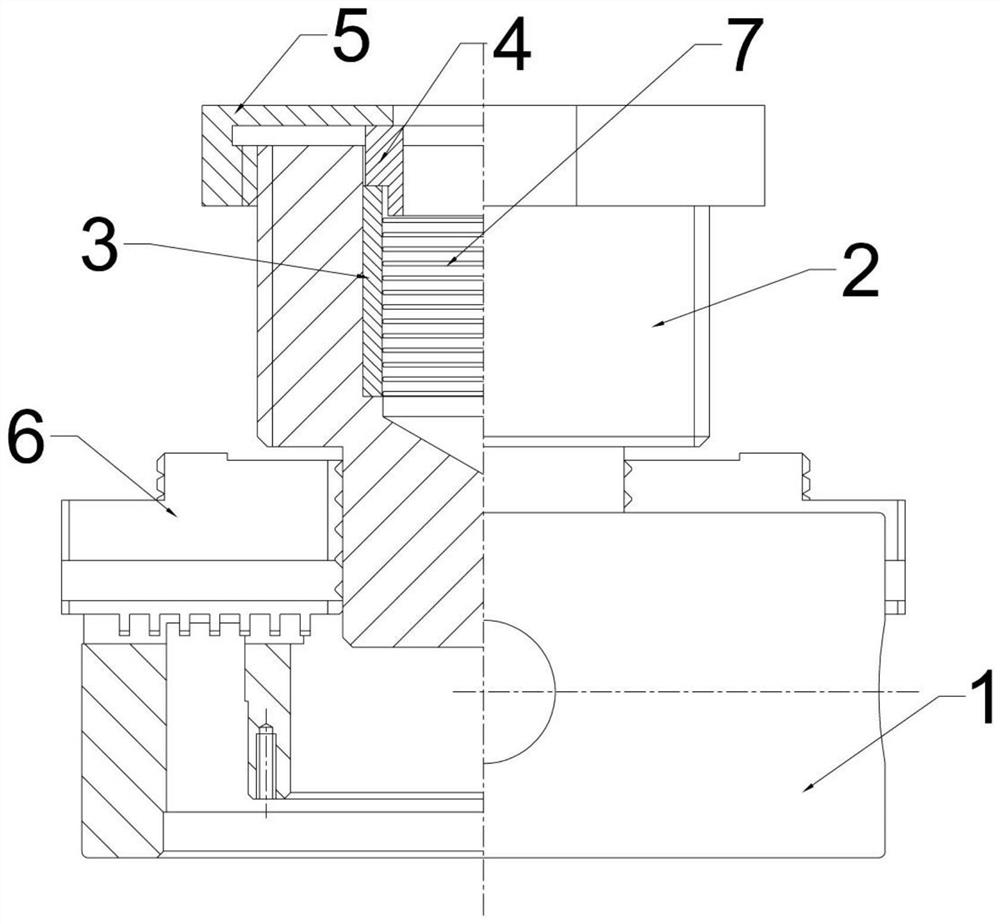

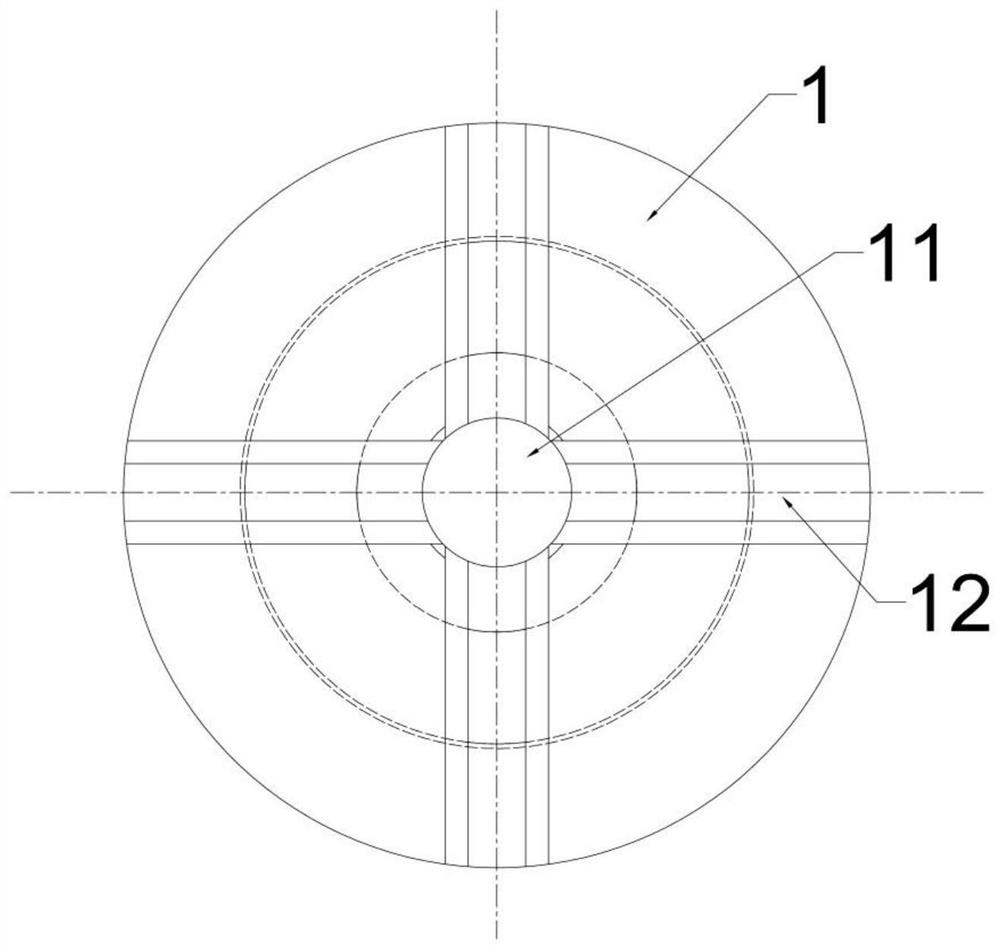

Special fixture for batch numerical control machining of centrifugal impeller with non-through-hole center and mounting method

ActiveCN110000579AAvoid Interfering CollisionsIncrease the support areaWork clamping meansPositioning apparatusNumerical controlImpeller

The invention discloses a special fixture for batch numerical control machining of a centrifugal impeller with a non-through-hole center and a mounting method of the special fixture. The mounting method comprises the following steps that a fixture shaft sleeve sleeves a fixture connecting shaft from the bottom of the fixture connecting shaft, the fixture connecting shaft is connected with a fixture base through base bolts, and the fixture connecting shaft is positioned through base pins; the fixedly-connected fixture base is fixed on a machine tool workbench, and a fixture connecting shaft outer circle is aligned on a machine tool; when each centrifugal impeller is machined, a centrifugal impeller blank is placed on the fixture connecting shaft, connecting shaft bolts are used for connecting the centrifugal impeller blank with the fixture connecting shaft, and meanwhile, connecting shaft pins are used for positioning the centrifugal impeller blank; and the fixture shaft sleeve is screwed from bottom to top until the upper end face of the fixture shaft sleeve abuts against the bottom of the centrifugal impeller blank, and shaft sleeve bolts are tightened to prevent the fixture shaftsleeve from loosening. According to the special fixture for batch numerical control machining of the centrifugal impeller with the non-through-hole center and the mounting method of the special fixture, numerical control machining clamping positioning of the centrifugal impeller can be realized, repeated alignment of a part is avoided, and then the machining precision and the machining consistency of the centrifugal impeller are ensured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

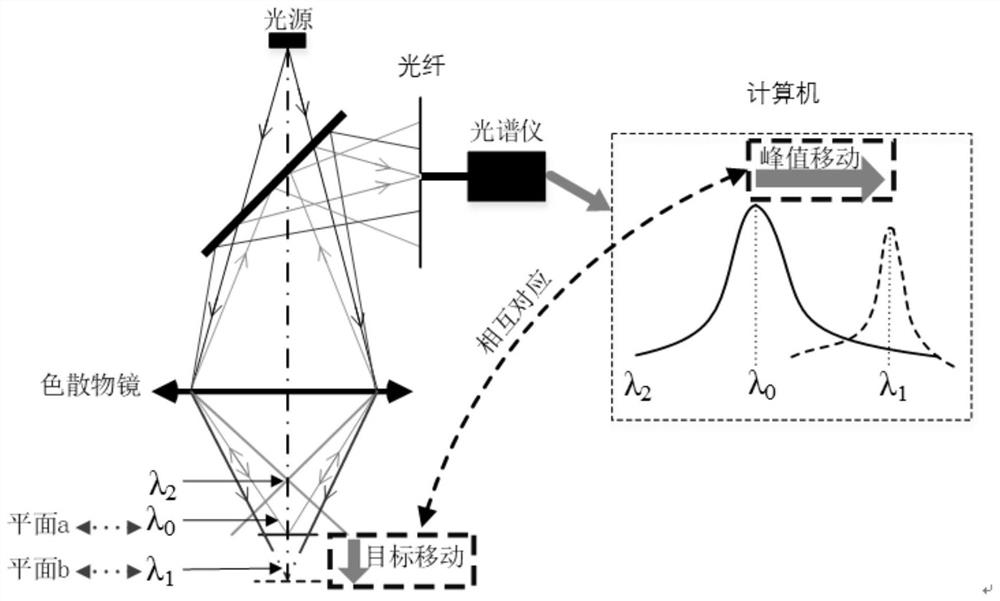

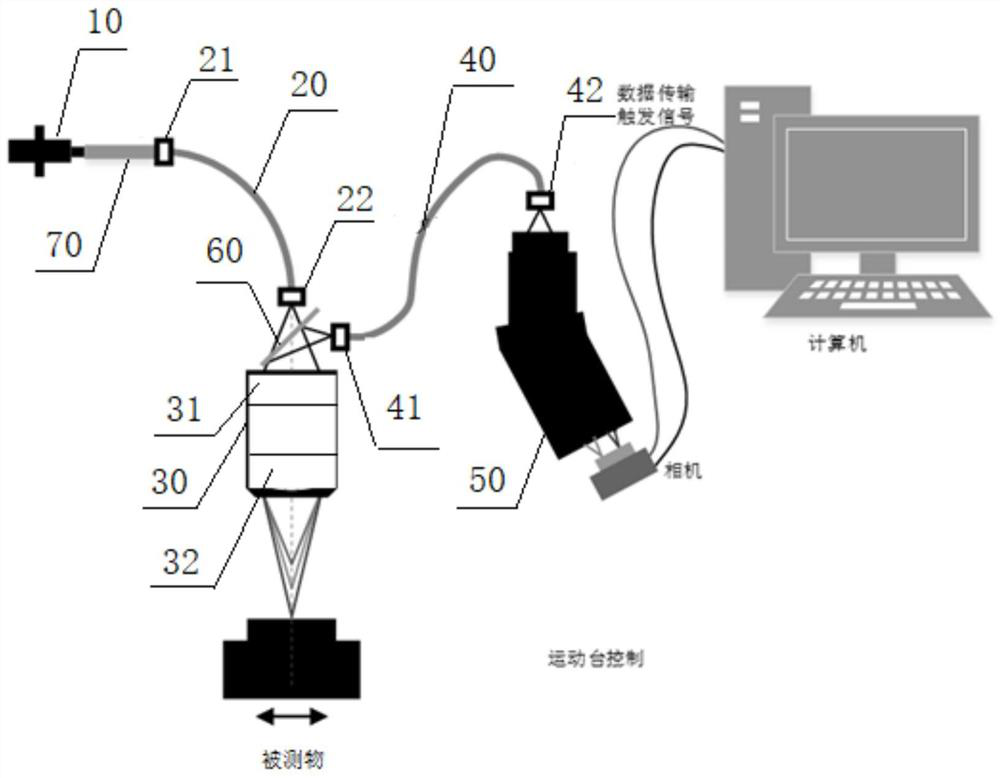

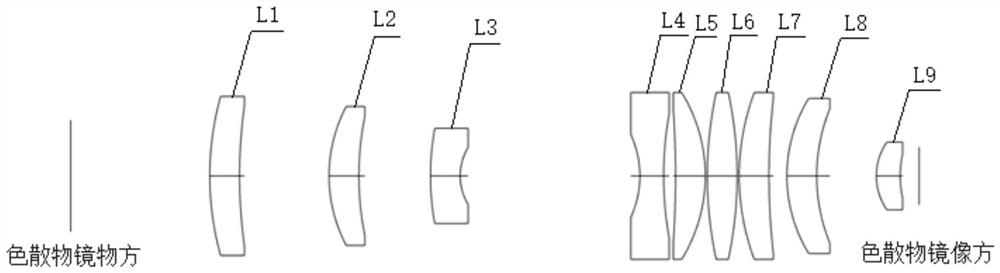

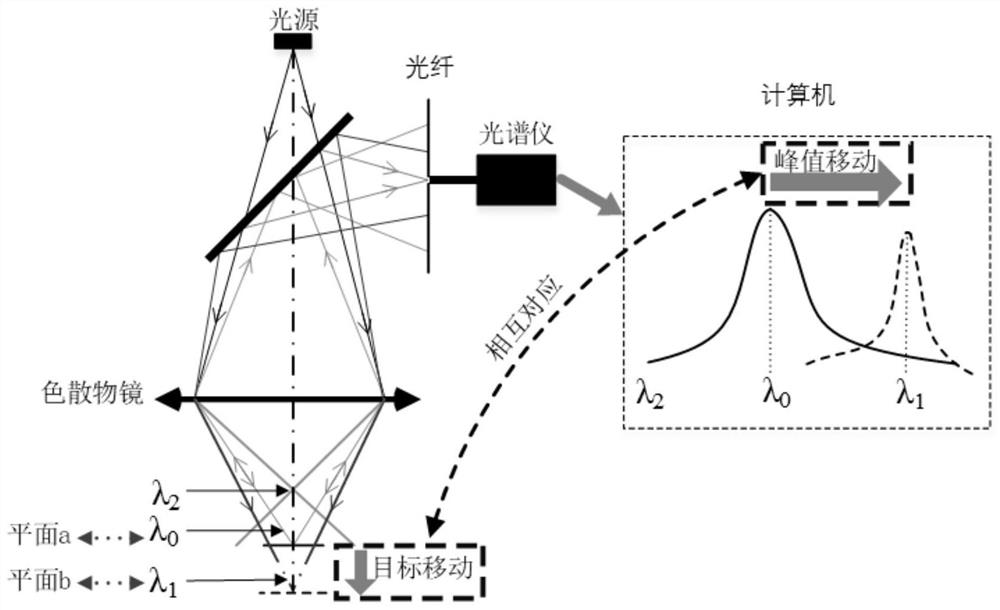

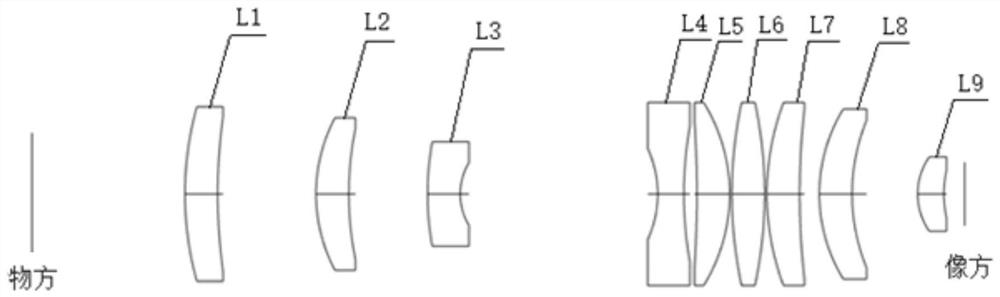

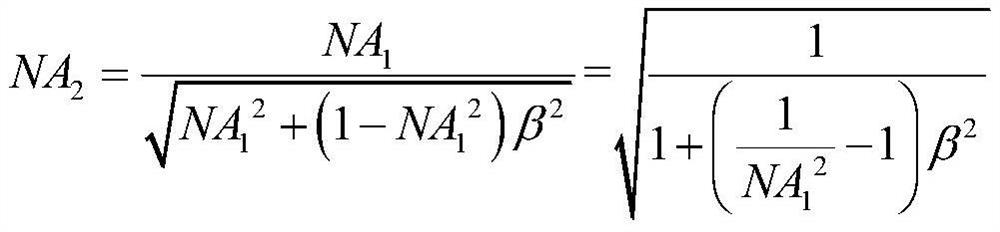

Line spectrum confocal sensor

ActiveCN113447119AGuaranteed brightnessGuaranteed accuracy consistencyRadiation pyrometrySpectrum investigationOptical spectrometerOphthalmology

A line spectrum confocal sensor comprises a light source, a light source optical fiber, a dispersion objective lens, a spectrograph optical fiber and a spectrograph, wherein the dispersion objective lens comprises a first lens group and a second lens group which are sequentially arranged from the object space of the dispersion objective lens to the image space of the dispersion objective lens, the first lens group is used for controlling telecentricity of the object space and carrying out preliminary dispersion on modulation detection light, the second lens group is used for controlling the telecentricity of the image space and further dispersing the modulated detection light, the long focal length of the first lens group and the short focal length of the second lens group are matched to control the zoom ratio between the object space of the dispersion objective lens and the image space of the dispersion objective lens, and the spectrograph is used for distinguishing the wavelength of an echo and generating images at different pixel positions on the camera. According to the line spectrum confocal sensor system, the dispersion objective lens is designed into a double-telecentric structure, so that the consistency of the brightness and the precision of a measurement light spot projected on a measured object can be effectively ensured.

Owner:SEIZET TECH SHEN ZHEN CO LTD

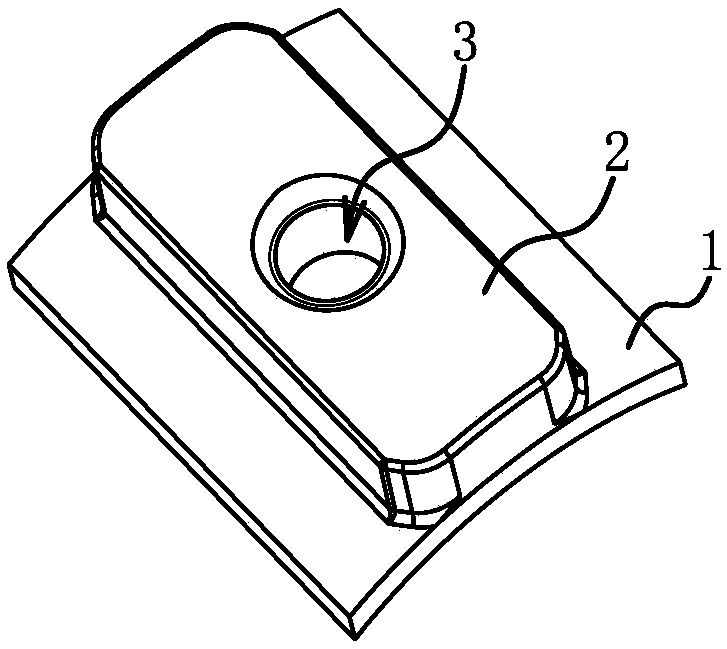

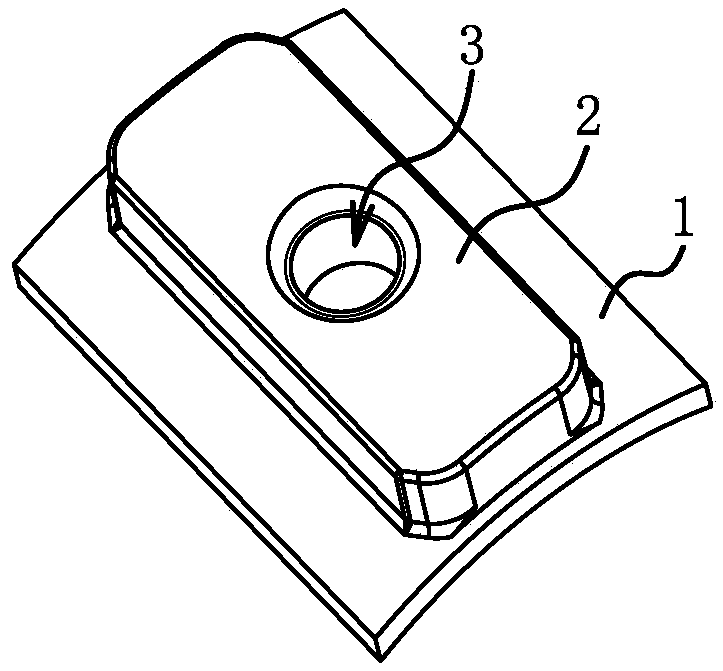

Motor magnetic pole manufacturing method

ActiveCN107626759AIncrease productivityLow costExtrusion diesManufacturing dynamo-electric machinesMagnetic polesPole piece

The invention provides a motor magnetic pole manufacturing method and belongs to the technical field of motors. The problems that existing motor magnetic pole machining is high in cost and low in production efficiency are solved. A magnetic pole comprises a pole shoe which is in a circular arc sheet shape, and a pole core located on the middle portion of a convex surface of the pole shoe. The motor magnetic pole manufacturing method comprises the following sequential steps that firstly, a billet is selected; secondly, preforming is performed, specifically, the billet is placed into a first cold extruding die to be subjected to cold extrusion, and the billet is preformed to be a preformed component; thirdly, forming is performed, specifically, the preformed component is placed into a secondcold extruding die to be subjected to cold extrusion, and the preformed component is formed to be a formed component; and fourthly, side cutting is performed, specifically, scrap portions of the formed component are cut off to obtain the magnetic pole. According to the motor magnetic pole, the method that the pole core is subjected to cold extrusion forming firstly and then the pole shoe is subjected to cold extrusion forming is adopted, the pole shoe forming precision and the pole shoe portion metal structure density uniformity are effectively guaranteed, and accordingly, it is effectively guaranteed that motor magnetic fields are distributed uniformly.

Owner:TAIZHOU BAIDA ELECTRICAL APPLIANCE CO LTD

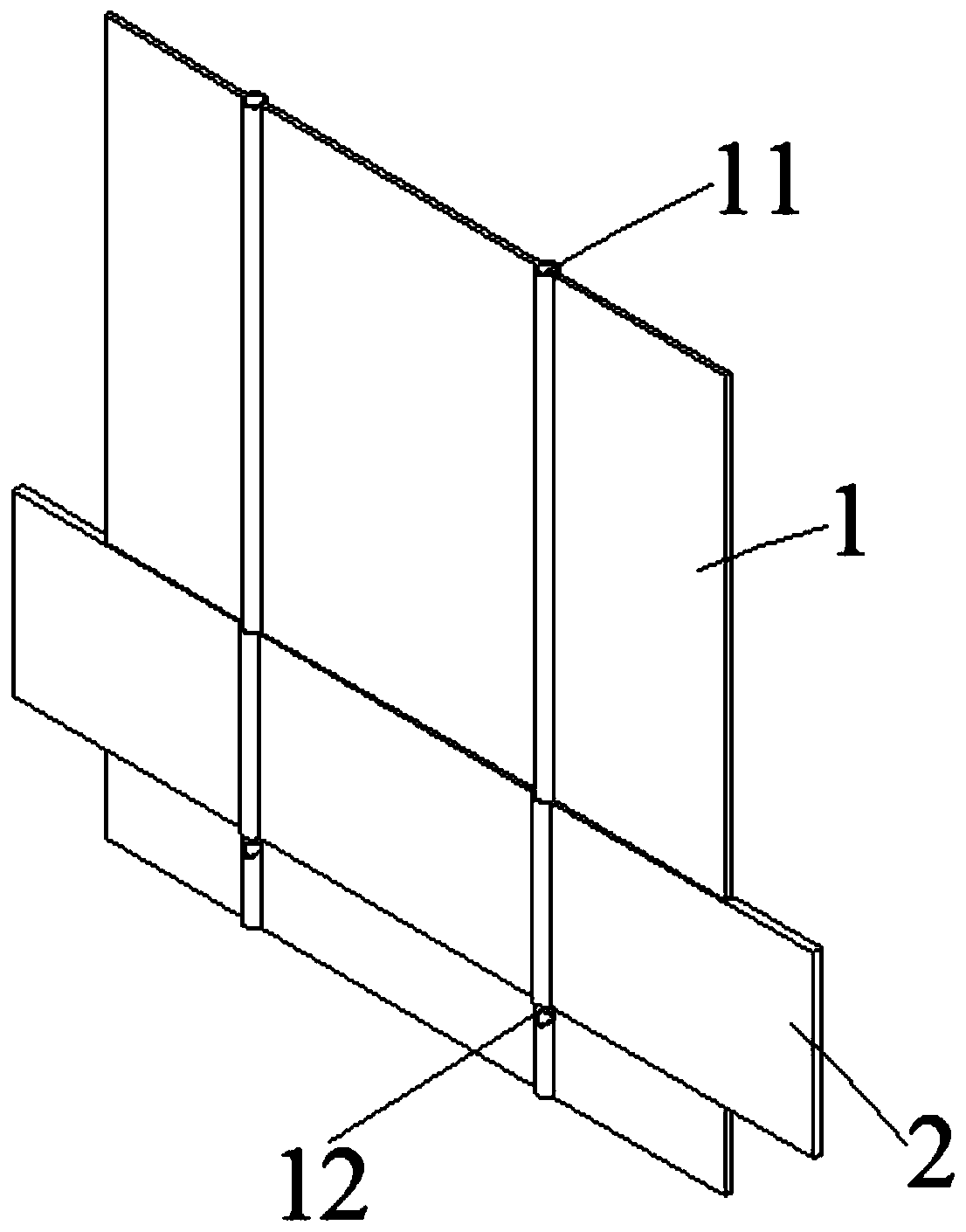

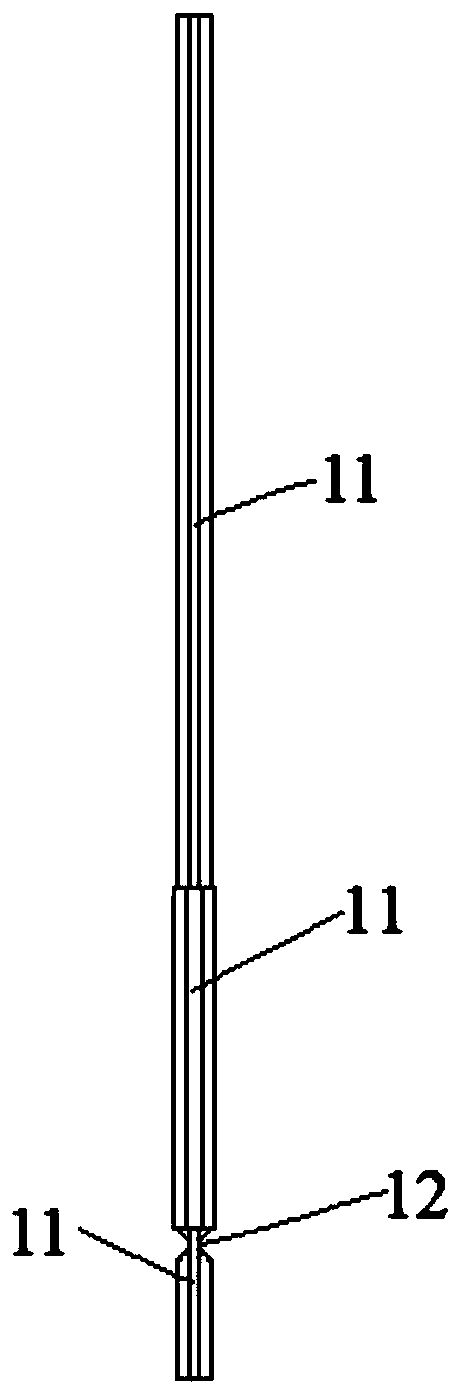

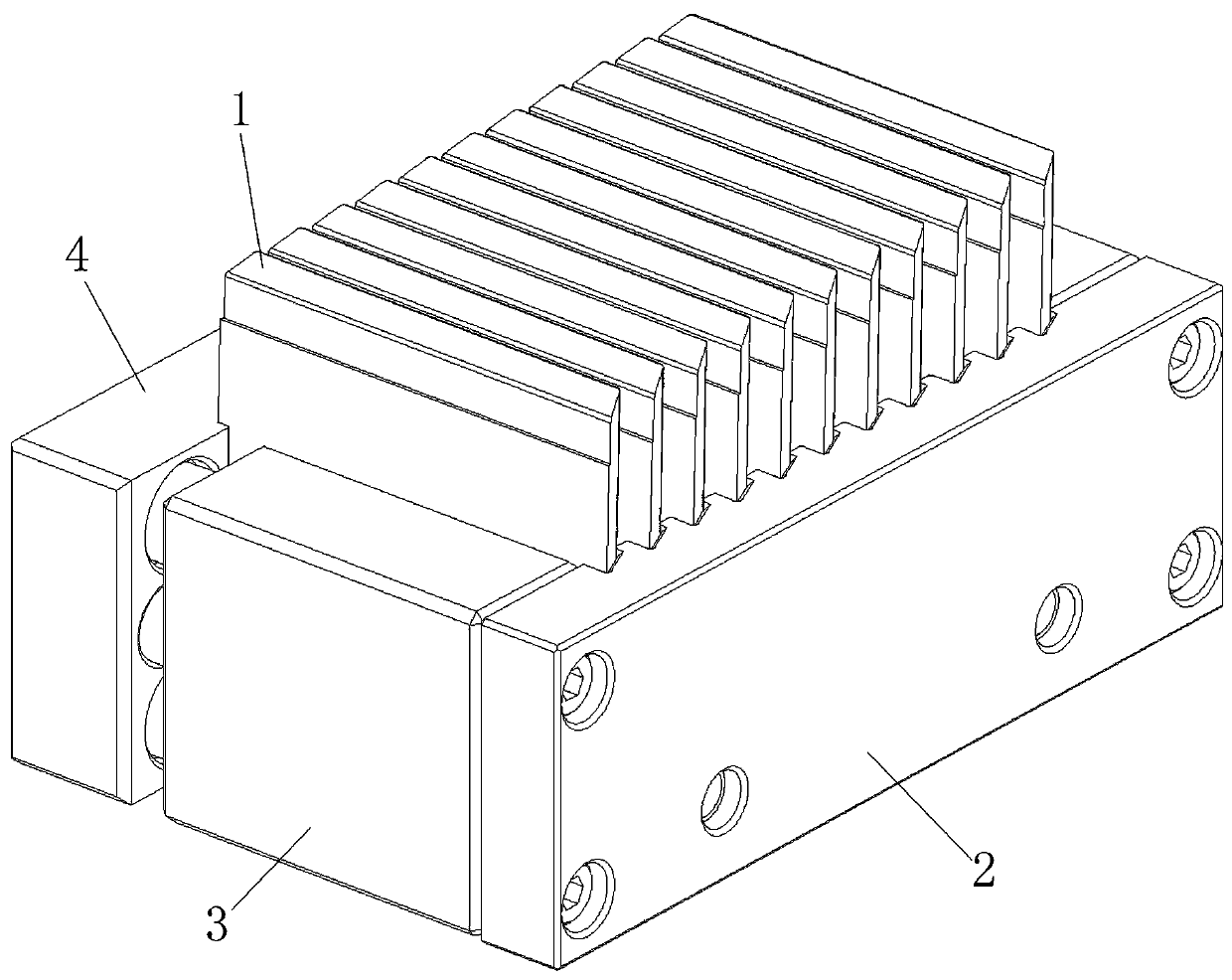

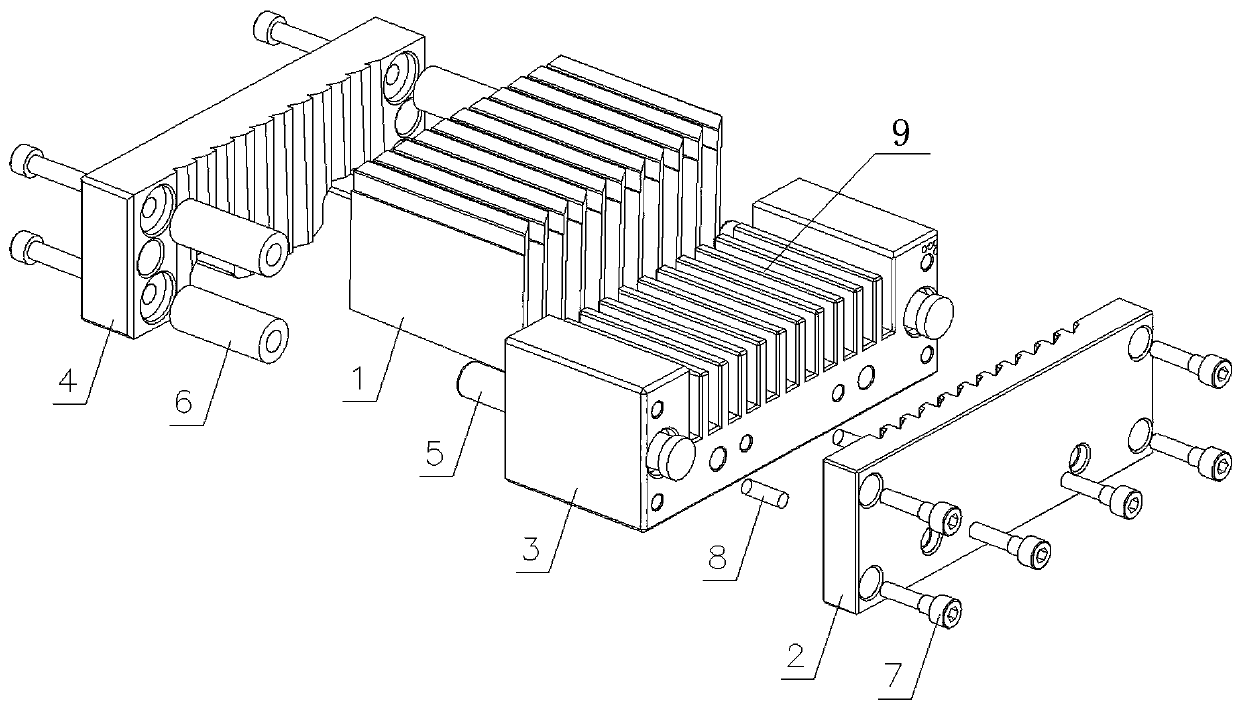

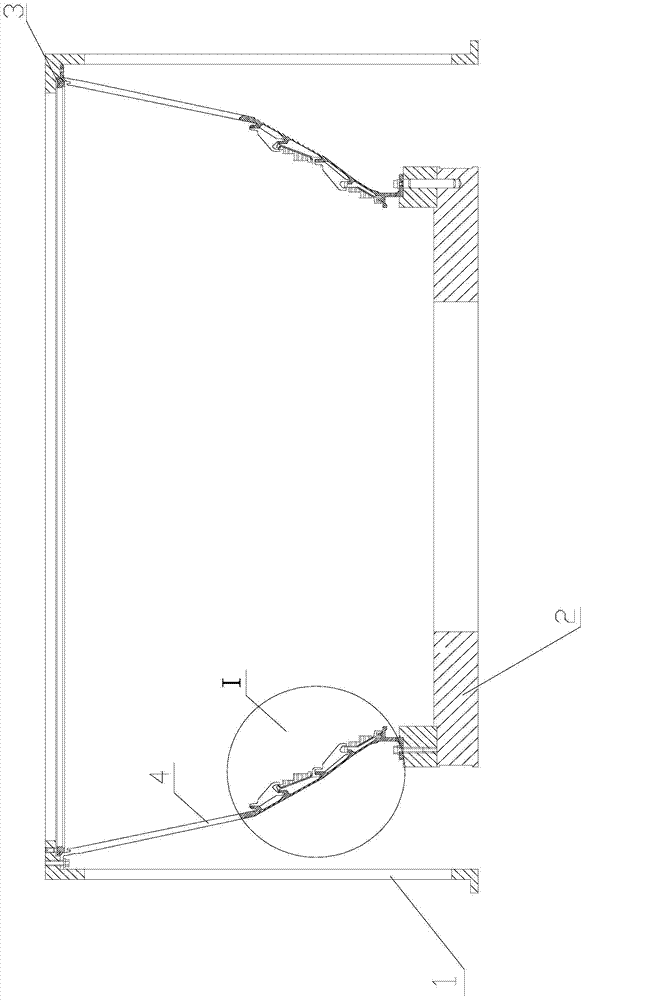

Processing device and method for louver blades

PendingCN111203601AFast processingEfficient processingElectrical-based auxillary apparatusStructural engineeringKnife blades

The invention provides a processing device and method for louver blades. The processing device includes a first clamp plate, a second clamp plate and a third clamp plate, the first clamp plate, the second clamp plate and the third clamp plate are assembled in sequence from right to left, the second clamp plate is provided with a plurality of blade grooves, an inclination angle is arranged on the bottom surface of each blade groove, the blade grooves are used for installing the louver blades to be processed, the first clamp plate and the third clamp plate are each provided with fixing grooves,and the fixing grooves are used for assembling the louver blades to be processed. The multiple louver blades to be processed are assembled at the same time through the multiple blade grooves, the problem of wasted time of multiple times of clamping in a single time of processing of the blades is solved, meanwhile, the problems of waste and large processing volume of multiple accurate grinding processes are solved, high-efficiency batch processing which can be completed by one-time clamping and one line cutting is realized, and the production and processing efficiency is greatly improved.

Owner:ZHUHAI GREE PRECISION MOLD CO LTD +1

Clamping tooling for three bearing holes on bearings for fine boring rv reducers

ActiveCN106736713BGuaranteed accuracy consistencyGuaranteed assembly accuracyPositioning apparatusMetal-working holdersEngineeringReducer

Owner:CHANGZHOU NRB CORP

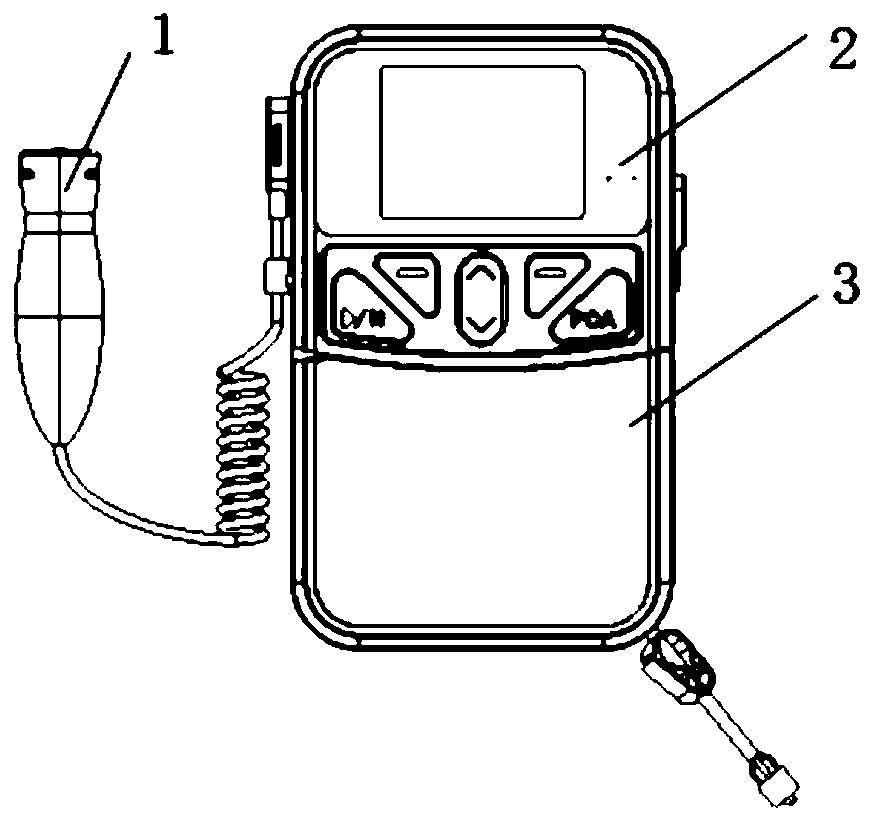

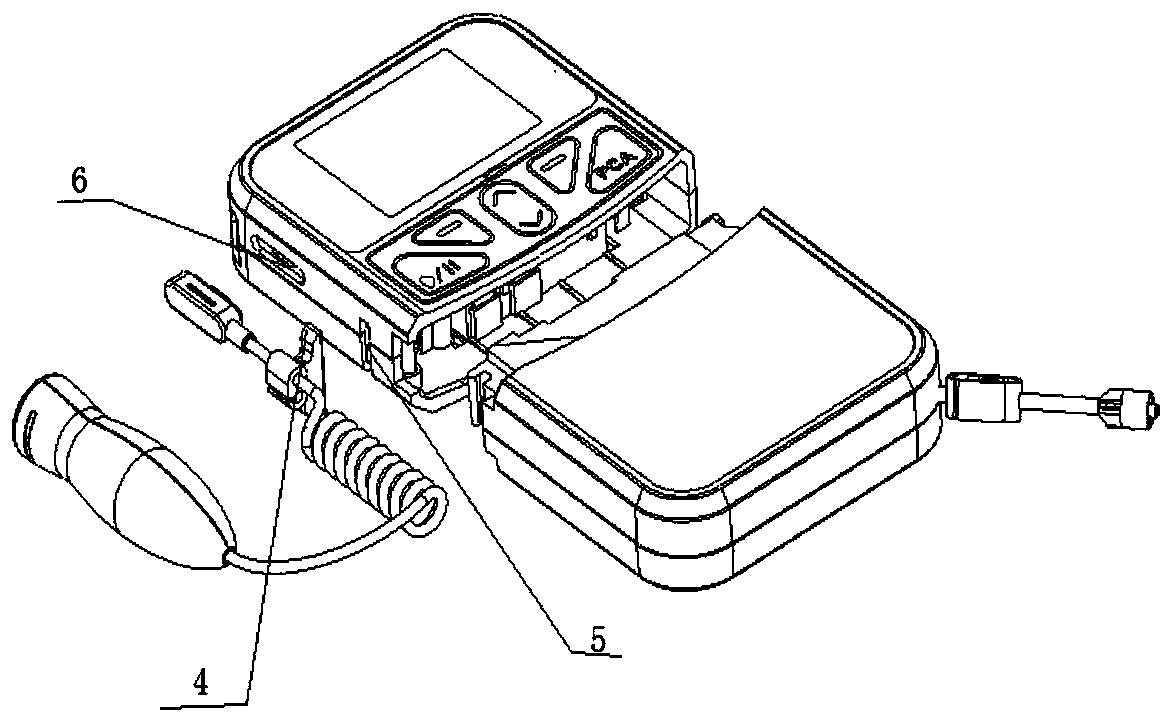

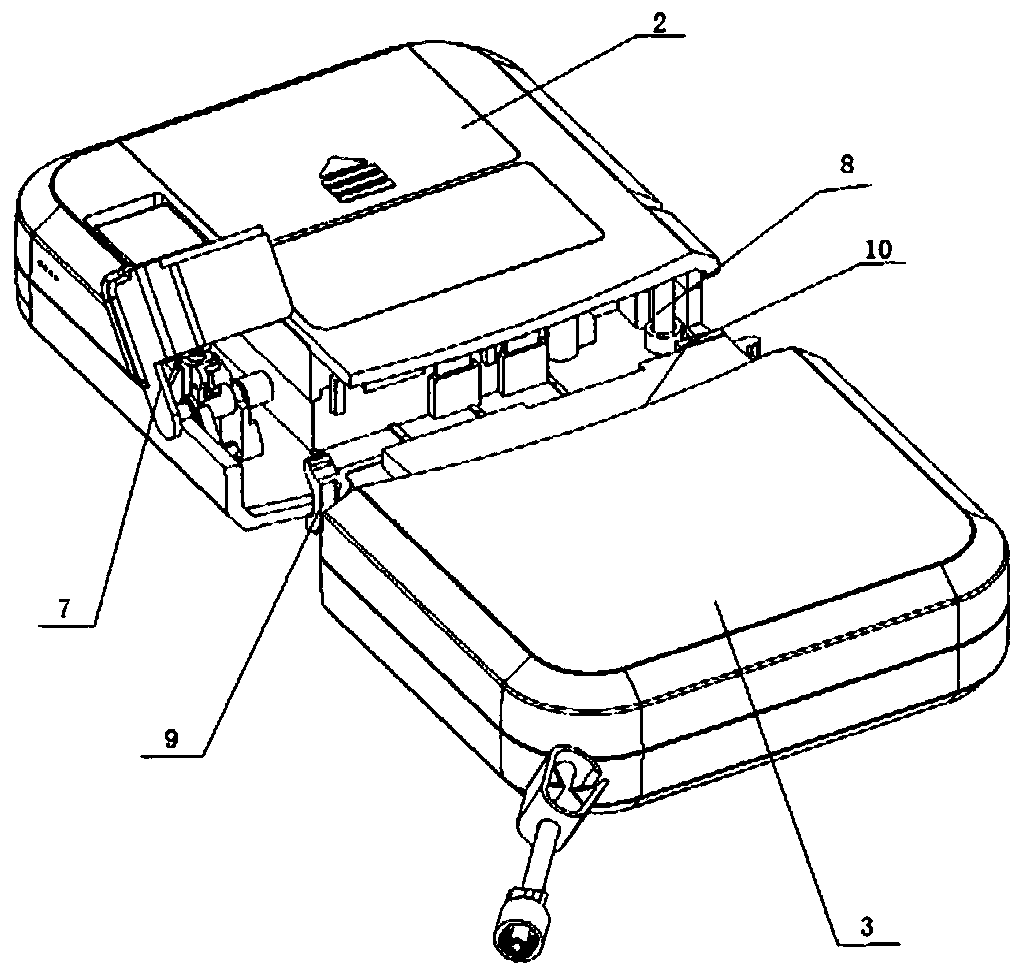

A portable injection device

ActiveCN110368549BWon't leaveFit closelyMedical devicesFlow monitorsApparatus instrumentsBiomedical engineering

The invention relates to the technical field of medical instruments, and discloses a portable liquid medicine injection instrument which comprises a handle, a driving device and a liquid storage device. The portable liquid medicine injection instrument is characterized in that a fastener is arranged on the handle, a first clamping groove and a magnetic suction line connector are formed in the sidewall of the driving device, the fastener is connected with the first clamping groove in a matched manner, the a handle signal is connected with a driving device signal by the magnetic suction line connector, a pin and a spanner arranged at the lower end of the driving device, the upper end of the liquid storage device is provided with a clamping position and a second clamping groove, the pin is connected with the second clamping groove in a matched manner, and the spanner is connected with the clamping position in a matched manner. The portable liquid medicine injection instrument is high inaccuracy and stable, small, portable and easy to carry, and accurate pill amount input can be achieved through user operation.

Owner:巨翊科瑞医疗技术(上海)有限公司 +1

Vehicle air-conditioning pipe mold assembly, brazing device and working method thereof

ActiveCN111545864BGuaranteed accuracy consistencyReduce labor costsMetal working apparatusTubular articlesMachine buildingAir conditioning

The invention belongs to the field of mechanical manufacturing, and in particular relates to a vehicle air-conditioning pipe template assembly, a brazing device and a working method thereof. In order to solve the problem that it is difficult to adapt to the brazing of air-conditioning copper pipes with different specifications and angle requirements at the same time, the invention provides a vehicle air-conditioning pipe profiling assembly, which includes two clamping parts with adjustable spacing to clamp different diameters Standard air-conditioning pipe; two equivalent profiles, the distance between the two equivalent profiles and the distance between the two clamping parts can be adjusted synchronously, and the distance between the two equivalent profiles and the clamping parts The angles are the same and synchronously adjustable to support air-conditioning pipes with different welding angles.

Owner:CRRC QINGDAO SIFANG CO LTD

A tic-based steel-bonded cemented carbide fine-tooth external thread milling device

ActiveCN110052671BGuaranteed accuracy consistencyFast conductionThread cutting toolsThread cutting machinesMilling cutterPolycrystalline diamond

The invention relates to the technical field of TiC-based steel-bonded hard alloy precision machining, in particular to a TiC-based steel-bonded hard alloy fine-tooth external thread milling device, which includes a box with an opening on the upper end, and the box is filled with cooling liquid. A fixing seat is installed in the bottom surface of the box body, and a spring chuck is installed on the upper end of the fixing seat. The spring chuck is used to fix the parts to be milled. When the parts are fixed, the height of the upper end of the parts is lower than that of the box body. The height of the side wall, a milling cutter is hung on the side of the part, the milling cutter is coated with polycrystalline diamond, the main cutting edge of the milling cutter is in the form of two edges, and the two edges are coplanar.

Owner:TIANJIN NAVIGATION INSTR RES INST

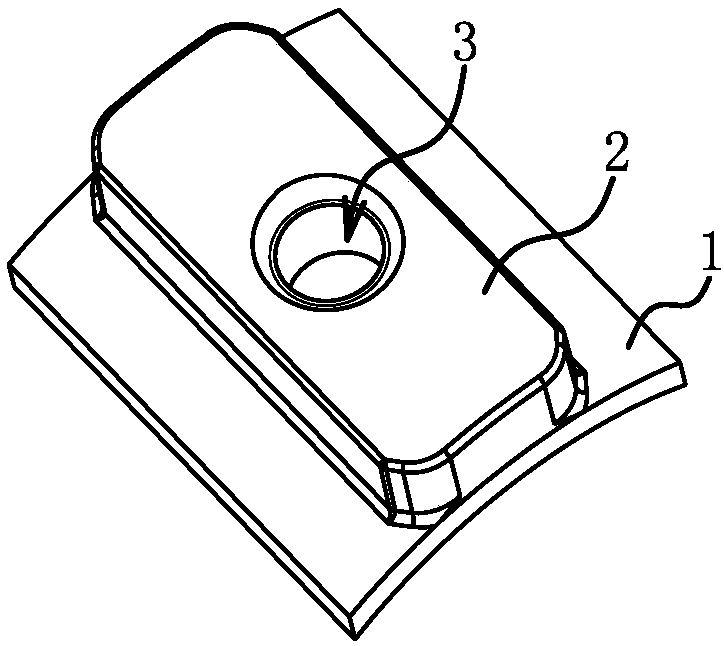

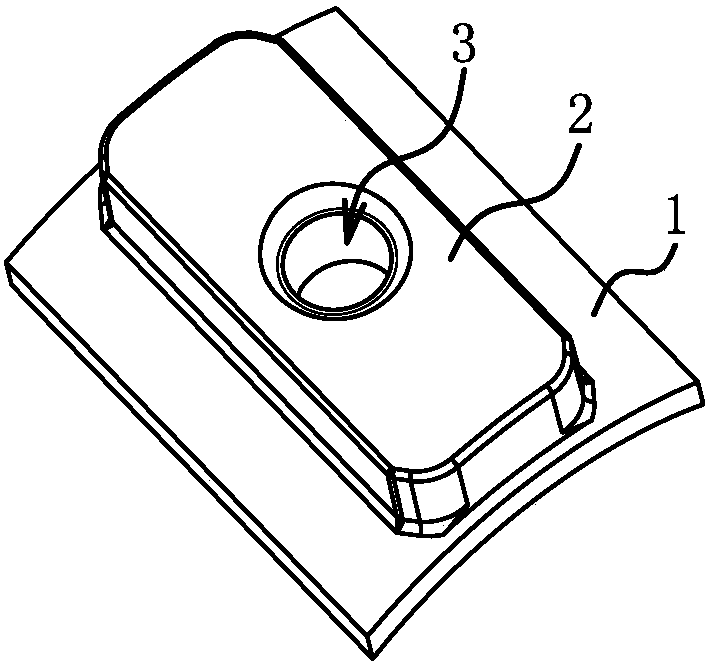

Mold shell and mold core same mill group modular surface taper method and system

PendingCN108081114AIncrease compressive stressGuaranteed angleLapping machinesWork carriersMaterials sciencePressure stress

The invention discloses a mold shell and mold core same mill group modular surface taper method. A mold shell and a mold core are located on same equipment, and machined by using a same fixture and asame angle. The invention further discloses a mold shell and mold core same mill group modular surface taper system which comprises the equipment and the fixture, and the mold shell and mold core samemill group modular surface taper system is used for machining the mold shell and the mold core which are matched with each other. Compared with the prior art, the mold shell and mold core same mill group modular surface taper method and system ensure the consistency of the angle and precision of the group modular surface, the group modular surface is completely surface contact, generated frictionis sharply increased, in addition, pressure stress to the mold core by the mold shell is increased, and the fatigue life value of a mold is sharply increased.

Owner:LENGSHUIJIANG TIANBAO IND

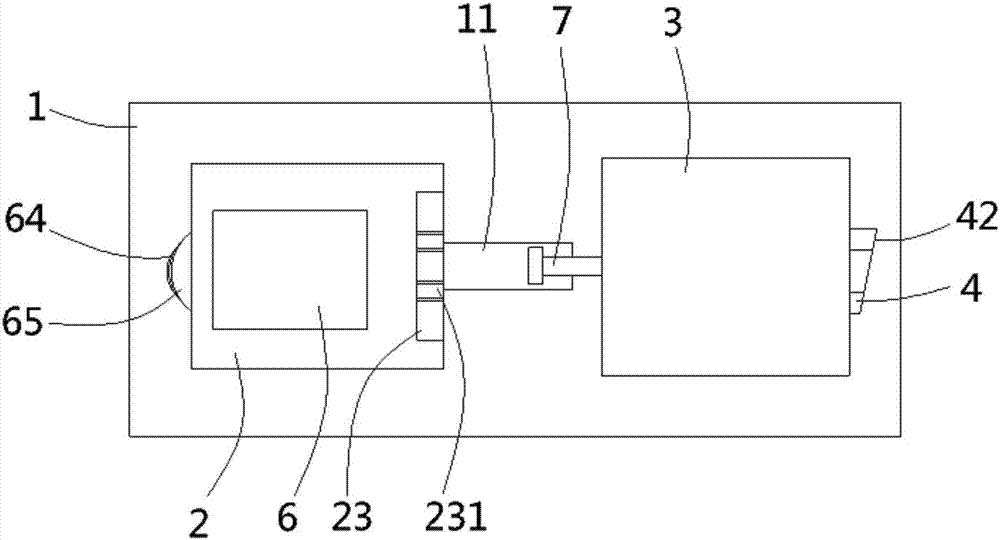

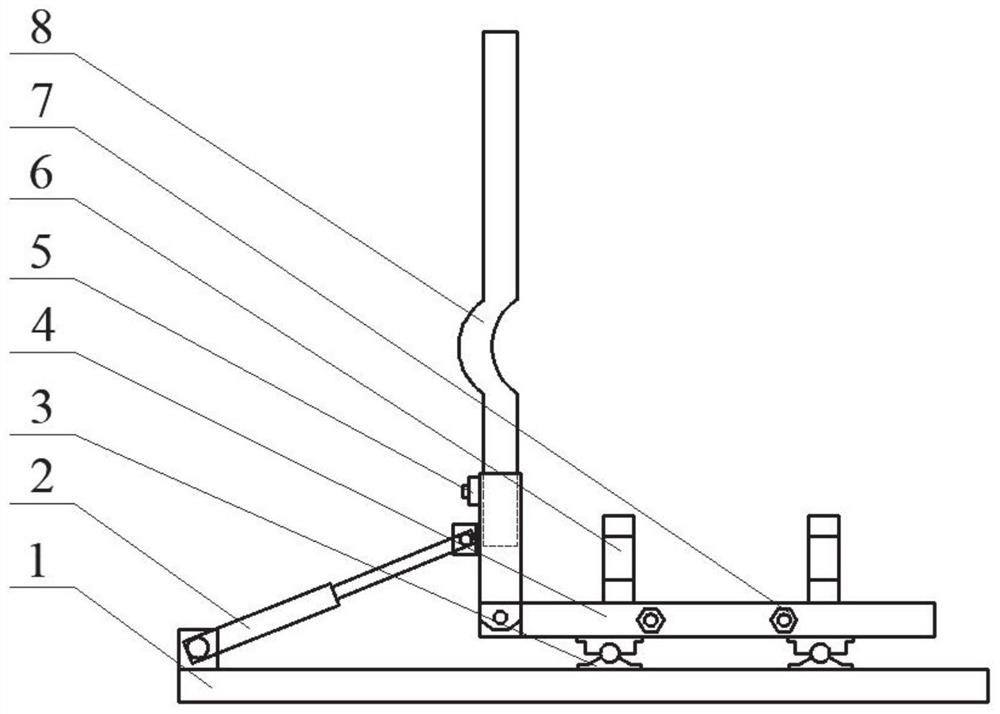

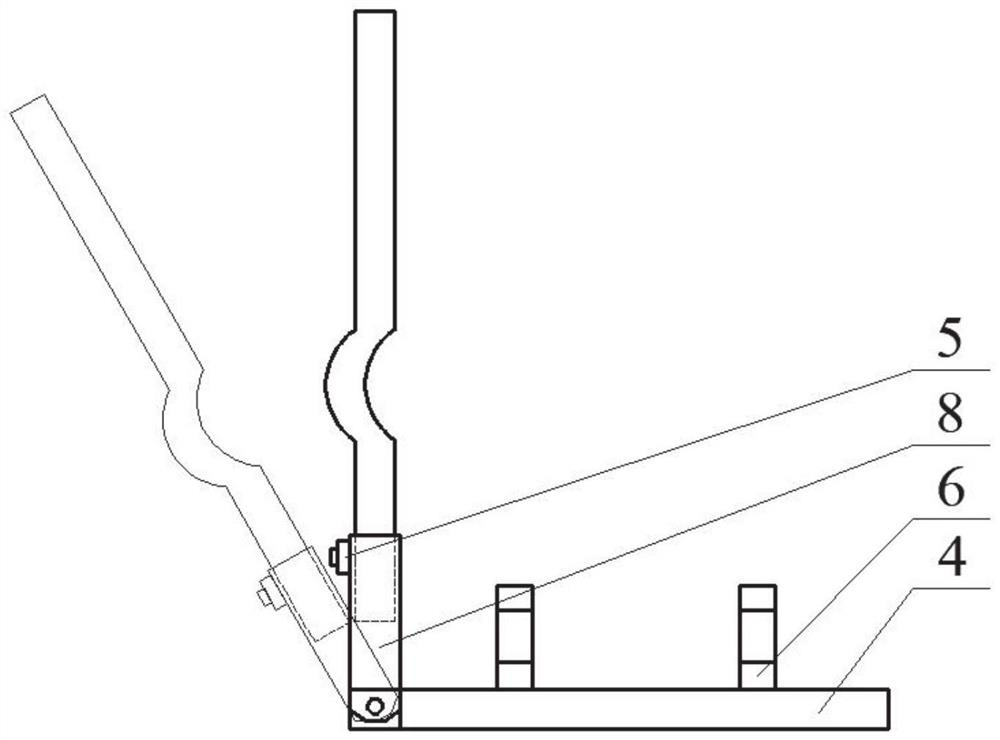

Bioprinter and its calibration method

ActiveCN105662648BReduce labor intensityRealize automatic calibrationProsthesisEngineeringUltimate tensile strength

The invention relates to the technical field of bio-printing, and in particular to a bio-printer and a calibration method thereof. The bio-printer of the invention includes a control apparatus, a first detection apparatus and a second detection apparatus. The first detection apparatus can send a first signal to the control apparatus when an injection apparatus moves to a first position in a Z axis direction so as to enable the control apparatus to calibrate a predetermined value of the length of the injection apparatus. The second detection apparatus can send a second signal to the control apparatus when the injection apparatus moves to a second position in the Z axis direction so as to enable the control apparatus to calibrate a predetermined value of the height of an initial attachment surface of a printing material. The bio-printer and calibration method of the invention can realize automatic calibration of the predetermined value of the length of the injection apparatus and the predetermined value of the height of the initial attachment surface of the printing material, which not only simplifies operation, lowers labor intensity of operation personnel, and also can effectively increase measuring precision, can guarantee precision consistency among a plurality of measurement, and can increase work reliability.

Owner:SICHUAN REVOTEK CO LTD

Multistage outer tightly-sealed ring component combined machining method

The invention belongs to the technical field of machining and provides a multistage outer tightly-sealed ring component combined machining method through which surface machining quality and accuracy uniformity of outer tightly-sealed ring components can be guaranteed after mounting and demounting for many times. The multistage outer tightly-sealed ring component combined machining method can solve the machining problem of multistage outer tightly-sealed ring components, and is convenient to operate and simple in machining. The method includes the following steps: step 1, placing a connecting shell on a base, and fixing the connecting shell, wherein a plurality of mounting grooves of the outer tightly-sealed ring components and connecting members are continuously formed in the inner side wall of the connecting shell; step 2, alternatively mounting the outer tightly-sealed ring components and the connecting members in the mounting grooves of the connecting shell sequentially until the outer tightly-sealed ring components and the connecting members at each stage are mounted fully; step 3, placing parts after combined mounting into machining equipment for machining.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

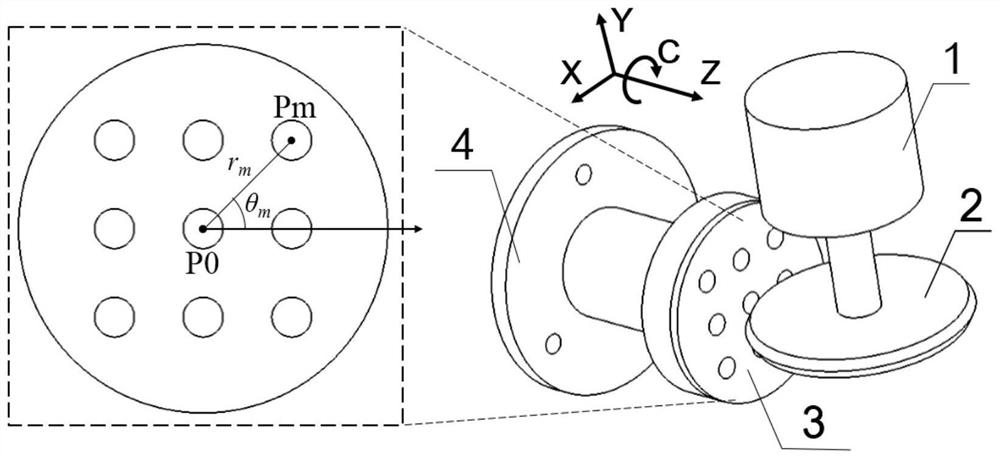

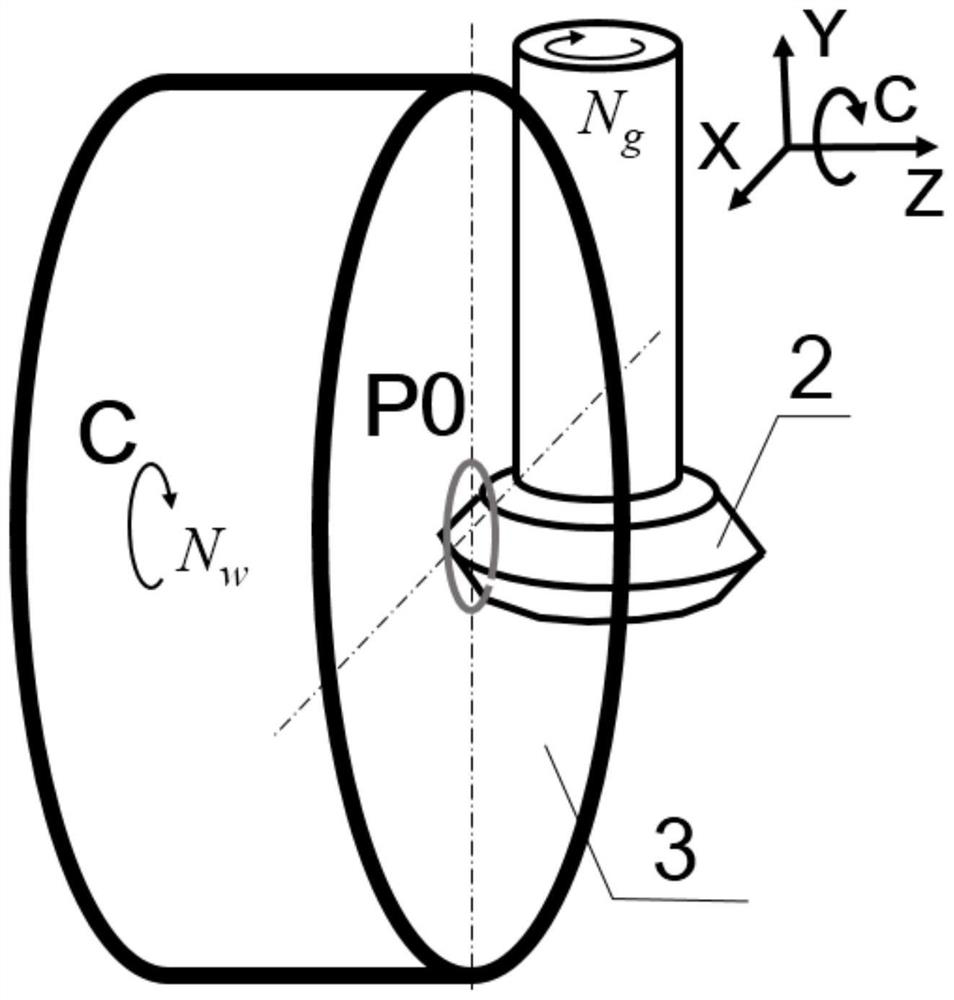

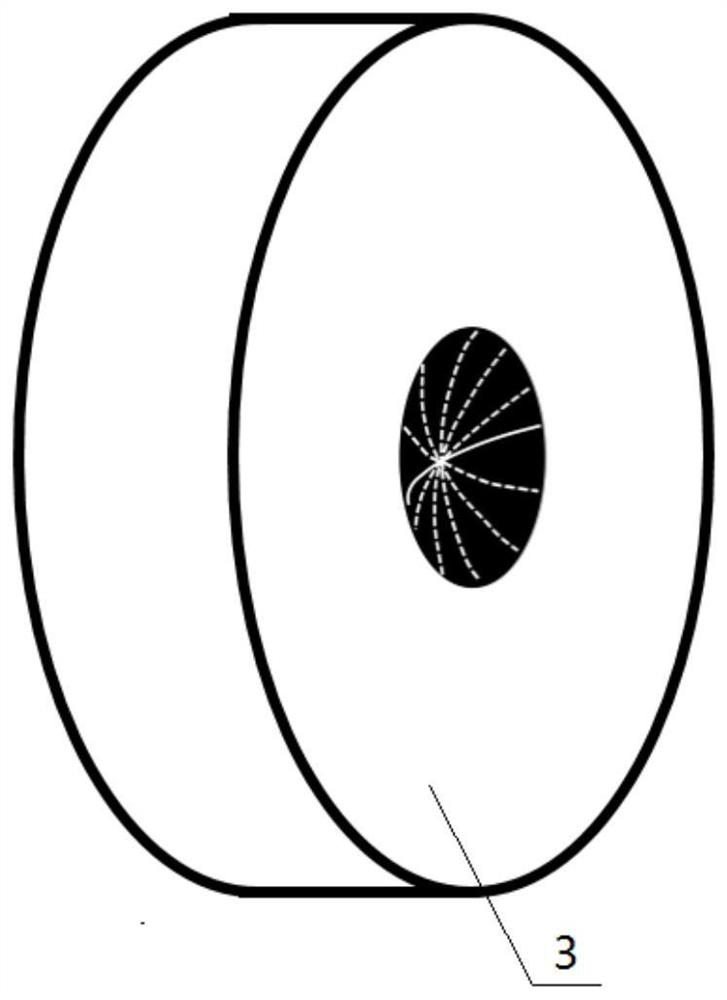

A Fan Formed Processing Method of Microlens Array Optical Components

ActiveCN109807720BAchieve precision machiningStrong wear resistanceOptical surface grinding machinesGrinding drivesEngineeringMachine

The invention relates to a fan-form processing method of a microlens array optical element, relating to a fan-form processing method. The invention solves the problems of tool wear, limited material and poor surface precision in the existing microlens array processing method. The present invention selects the V-shaped grinding wheel whose radius is greater than the microlens ball diameter Rs and trims it; the sharp point of the V-shaped grinding wheel along the negative Z axis of the machine tool just coincides with the center line of the C axis of the machine tool; Microlens P0, set the speed of the V-shaped grinding wheel to N g , the feed rate is V f , so that the V-shaped grinding wheel is fed in the negative direction along the Z-axis of the machine tool until a depth of a is produced on the workpiece. p wear marks, then the Z-axis of the machine tool stops feeding and remains still, and the C-axis of the machine tool rotates at N w Rotate 360° clockwise, retract the tool in the positive direction of the Z axis; use the Fancheng method to process any microlens P that is not at the center of the workpiece m ; Processing in sequence to form a microlens array optical element. The invention is used for the processing of microlens array optical elements.

Owner:HARBIN INST OF TECH

Vehicle air-conditioner pipe profiling assembly, brazing device and working method of brazing device

ActiveCN111545864AGuaranteed accuracy consistencyReduce labor costsMetal working apparatusTubular articlesMachine buildingCopper tubing

The invention belongs to the field of machinery manufacturing and particularly relates to a vehicle air-conditioner pipe profiling assembly, a brazing device and a working method of the brazing device. In order to solve the problem that brazing of air-conditioner copper pipes with different specification and angle requirements is hardly achieved at the same time, the vehicle air-conditioner pipe profiling assembly provided by the invention comprises two clamping parts between which the interval can be adjusted and which are used for clamping air-conditioner pipes with the different diameter specifications, and two equivalent profiling molds, wherein the interval between the two equivalent profiling molds and the interval between the clamping parts can be adjusted synchronously, the anglesbetween the two equivalent profiling molds and the clamping parts are equal and can be adjusted synchronously, and thus the air-conditioner pipes with the different welding angles can be supported.

Owner:CRRC QINGDAO SIFANG CO LTD

Clamping tool for drilling and reaming thin-wall parts

ActiveCN109551008AGuaranteed thicknessAvoid deformationPositioning apparatusBoring/drilling componentsMechanical engineeringThin walled

The invention relates to a clamping tool for drilling and reaming thin-wall parts. The clamping tool for drilling and reaming the thin-wall parts comprises a supporting table, wherein a positioning hole is formed in the supporting table, the axis of the positioning hole is defined to be in the up-down direction, a positioning inner wall surface which is used for accommodating a plurality of the thin-wall parts stacked up and down and is circumferentially in location fit with the thin-wall parts is arranged in the positioning hole, the supporting table is further provided with a limiting structure which is arranged on the lower part of the thin-wall parts at the lowest layer in a blocking mode, and a receding space which of a receding drill bit is arranged at the position, located on the lower part of the limiting structure, of an accommodating hole. The clamping tool further comprises a pressing structure fixed on a supporting seat, wherein the pressing structure is provided with a pressing end extending from top to bottom into the positioning hole and pressing the thin-wall parts on the limiting structure, and the pressing structure is provided with a receding channel for the receding drill bit. The whole positioning and clamping of the thin-wall parts is realized, and the structure is relatively simple.

Owner:河南航天精工制造有限公司

A clamping tool for drilling and reaming of thin-walled parts

ActiveCN109551008BGuaranteed thicknessAvoid deformationPositioning apparatusBoring/drilling componentsClassical mechanicsMechanical engineering

Owner:河南航天精工制造有限公司

Dispersion objective optical path

ActiveCN113433678AGuaranteed brightness and accuracy consistencyGuaranteed brightness close toOptical elementsOptical pathMicroscope objective

The invention discloses a dispersion objective optical path. The optical path comprises a first lens group and a second lens group which are sequentially arranged from an object space to an image space, and is characterized in that the first lens group is used for controlling telecentric object space and carrying out preliminary dispersion on modulation detection light projected by an optical fiber array; the second lens group is used for controlling telecentric image space and performing secondary dispersion on the modulated detection light, and is used for zoom control from the object space to the image space through cooperation of the long focal length of the first lens group and the short focal length of the second lens group, the object space / image space zoom ratio= f1 / f2, f1 is the focal length of the first lens group, f2 is the focal length of the second lens group, the object space is an optical fiber array, and the image space is the line length projected by the dispersion objective lens light path. According to the dispersion objective lens light path disclosed by the invention, dispersion is generated by using a double telecentric light path, and consistency of brightness and precision of a measurement light spot projected on a measured object can be effectively ensured.

Owner:SEIZET TECH SHEN ZHEN CO LTD

Mold and method for manufacturing special-shaped composite material rotary body by using mold

PendingCN113954272AIncrease isotropic strengthImprove lateral strengthSurface finishSurface smoothness

The invention provides a mold and a method for manufacturing a special-shaped and variable-cross-section composite material rotary body by using the mold, and belongs to the technical field of special-shaped variable-cross-section thin-wall rotary body manufacturing. The mold comprises a rotary body outer mold a and a rotary body outer mold b; the rotary body outer mold a and the rotary body outer mold b are detachably connected; a rotary body inner mold is arranged in a cavity formed after the rotary body outer mold a and the rotary body outer mold b are connected; and gaps are formed between the rotary body inner mold and the inner wall of the rotary body outer mold a and between the rotary body inner mold and the inner wall of the rotary body outer mold b. The special-shaped variable-cross-section thin-wall rotary body with the length-diameter ratio larger than 10 and the wall thickness smaller than 4 mm is manufactured through the mold. The large-length-diameter-ratio thin-wall special-shaped variable-cross-section composite material rotary body manufactured according to the invention has the advantages of being not prone to deformation, high in size precision, high in inner surface smoothness and outer surface smoothness, simple in subsequent surface treatment process and high in economical efficiency.

Owner:开封市新亚实业有限公司

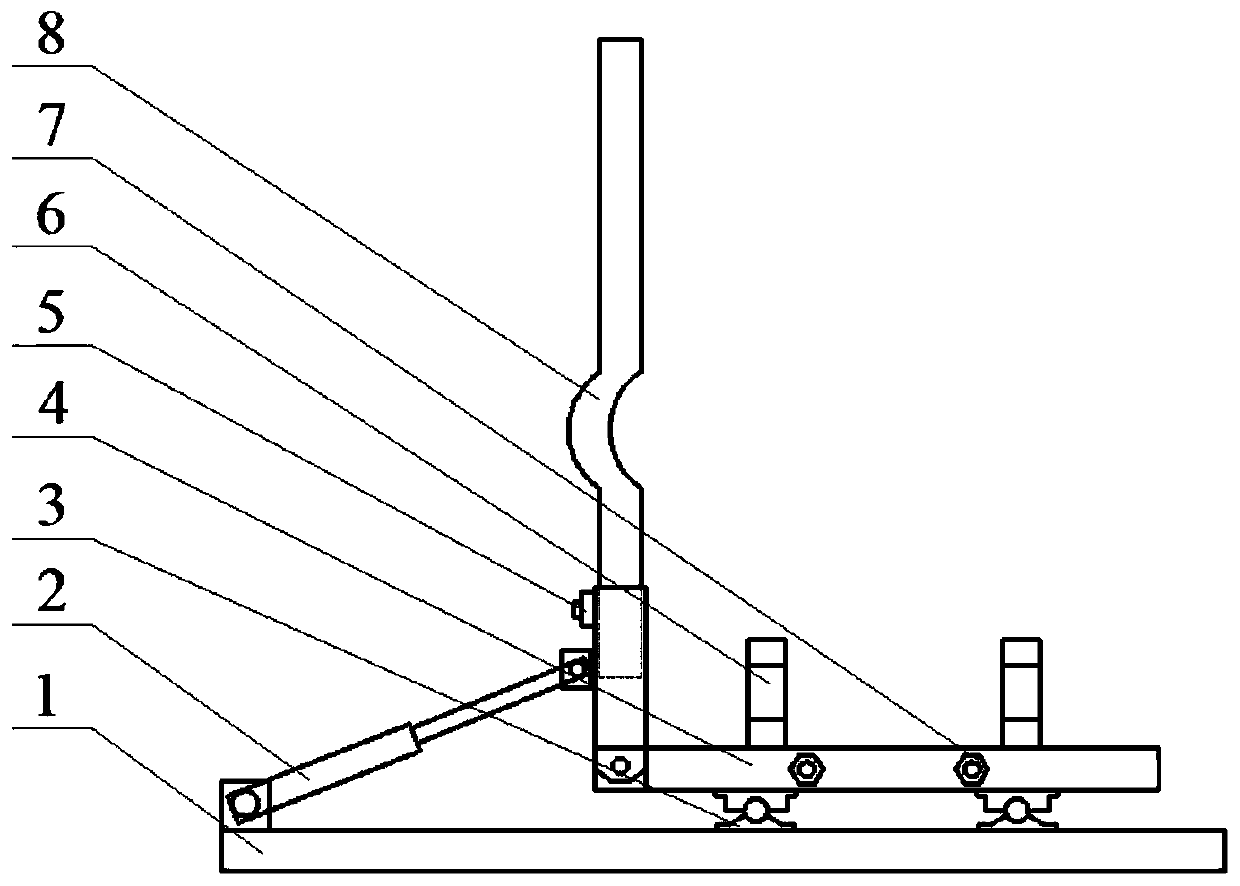

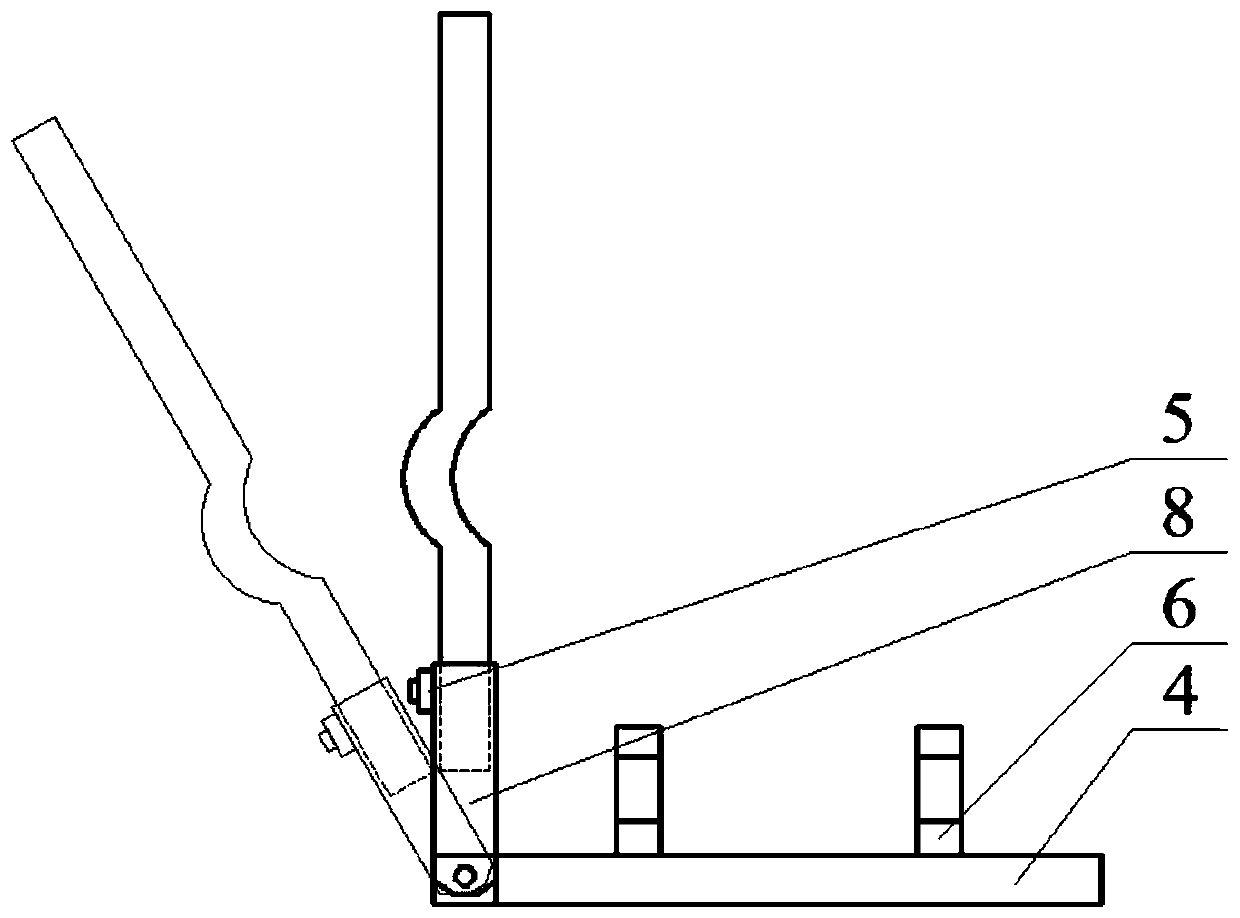

Grinding wheel R-angle former

PendingCN112338803AGuaranteed accuracy consistencyGuaranteed Dimensional ConsistencyAbrasive surface conditioning devicesMachineGrinding wheel

The invention relates to the technical field of grinding, and discloses a grinding wheel R-angle former. The grinding wheel R-angle former is used for grinding an R angle of a grinding wheel and comprises a base, a rotating shaft, an L-shaped plate and a diamond pen. The base is arranged on a grinding machine, and the grinding wheel is rotationally arranged on the grinding machine; the rotating shaft is rotationally arranged on the base, and the distance between the rotating shaft and the grinding wheel in the vertical direction is adjustable; and one end of the L-shaped plate is connected with the rotating shaft, and the other end of the L-shaped plate is detachably connected with the diamond pen. When the grinding wheel R-angle former is used for grinding the R-angle of the grinding wheel, the R-angle meeting the machining requirement can be ground by driving the diamond pen to swing through the rotating shaft, and the machining precision and the size consistency of the R angle of the grinding wheel can be guaranteed. Moreover, by adjusting the distance between the rotating shaft and the grinding wheel in the vertical direction, tool setting can be conducted conveniently, the grinding wheel R-angle former and the grinding wheel do not need to be adjusted at the same time, operation is convenient to carry out, and the machining efficiency is high.

Owner:无锡市金杨新材料股份有限公司

How to make a magnetic pole of a motor

ActiveCN107626759BHigh dimensional consistencyHigh degree of fitExtrusion diesManufacturing dynamo-electric machinesMagnetic polesPole piece

The invention provides a motor magnetic pole manufacturing method and belongs to the technical field of motors. The problems that existing motor magnetic pole machining is high in cost and low in production efficiency are solved. A magnetic pole comprises a pole shoe which is in a circular arc sheet shape, and a pole core located on the middle portion of a convex surface of the pole shoe. The motor magnetic pole manufacturing method comprises the following sequential steps that firstly, a billet is selected; secondly, preforming is performed, specifically, the billet is placed into a first cold extruding die to be subjected to cold extrusion, and the billet is preformed to be a preformed component; thirdly, forming is performed, specifically, the preformed component is placed into a secondcold extruding die to be subjected to cold extrusion, and the preformed component is formed to be a formed component; and fourthly, side cutting is performed, specifically, scrap portions of the formed component are cut off to obtain the magnetic pole. According to the motor magnetic pole, the method that the pole core is subjected to cold extrusion forming firstly and then the pole shoe is subjected to cold extrusion forming is adopted, the pole shoe forming precision and the pole shoe portion metal structure density uniformity are effectively guaranteed, and accordingly, it is effectively guaranteed that motor magnetic fields are distributed uniformly.

Owner:TAIZHOU BAIDA ELECTRICAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com