Patents

Literature

101results about How to "Ensure processing consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

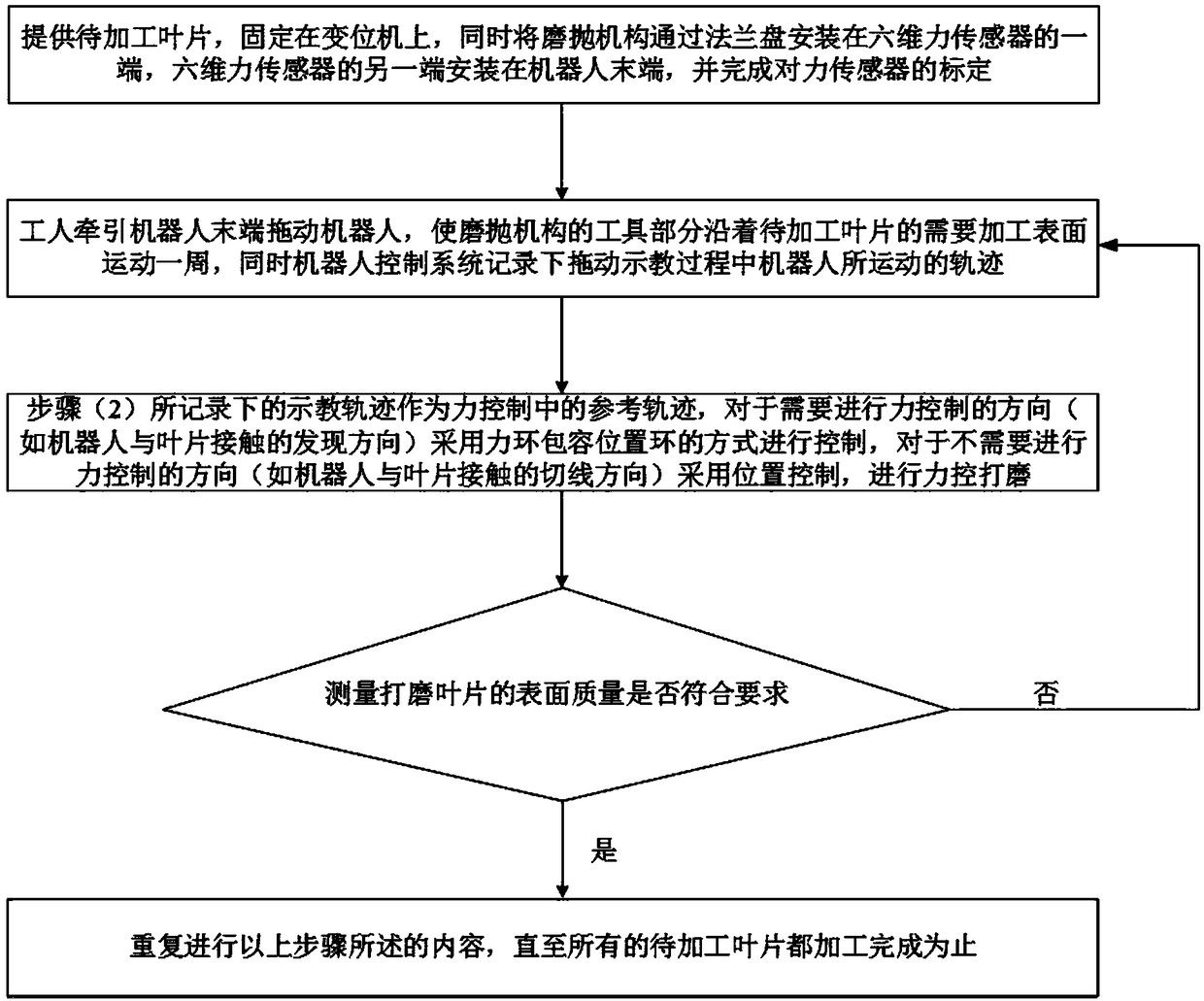

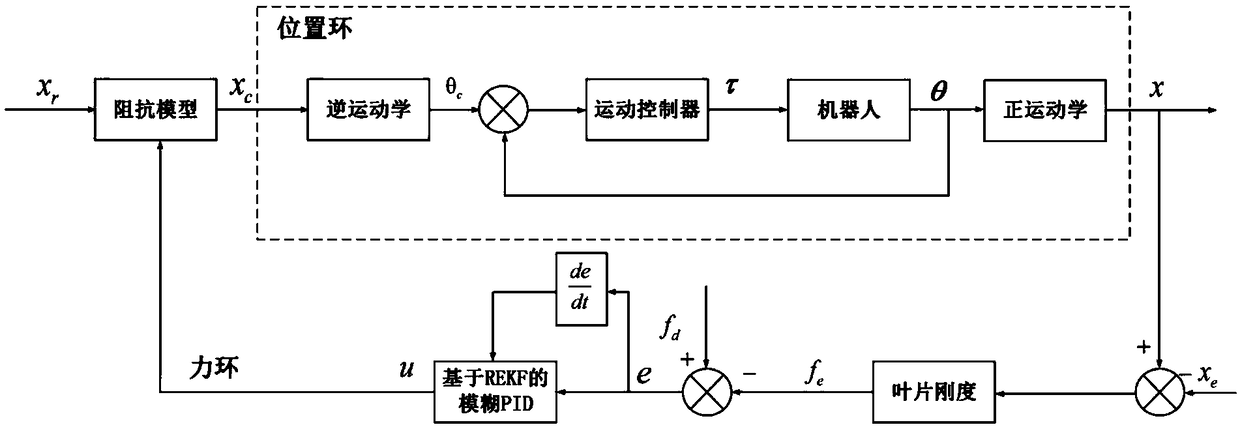

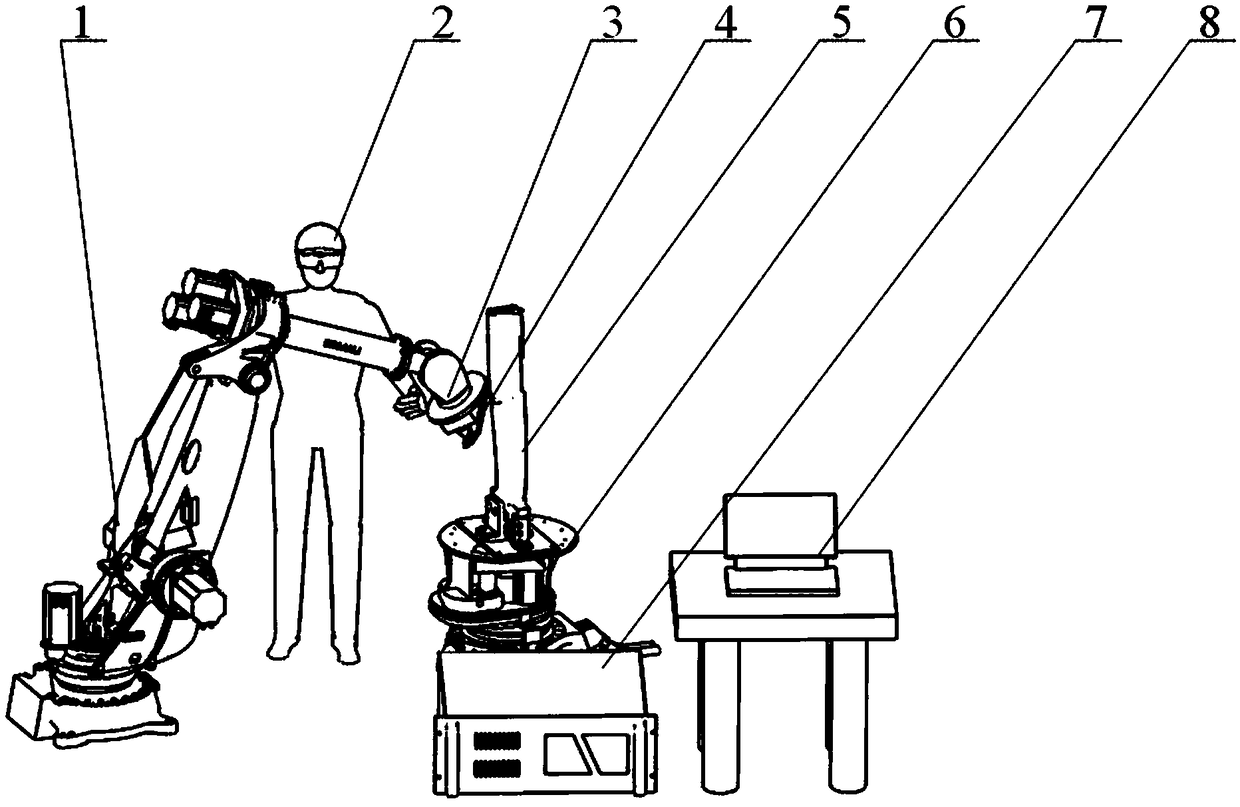

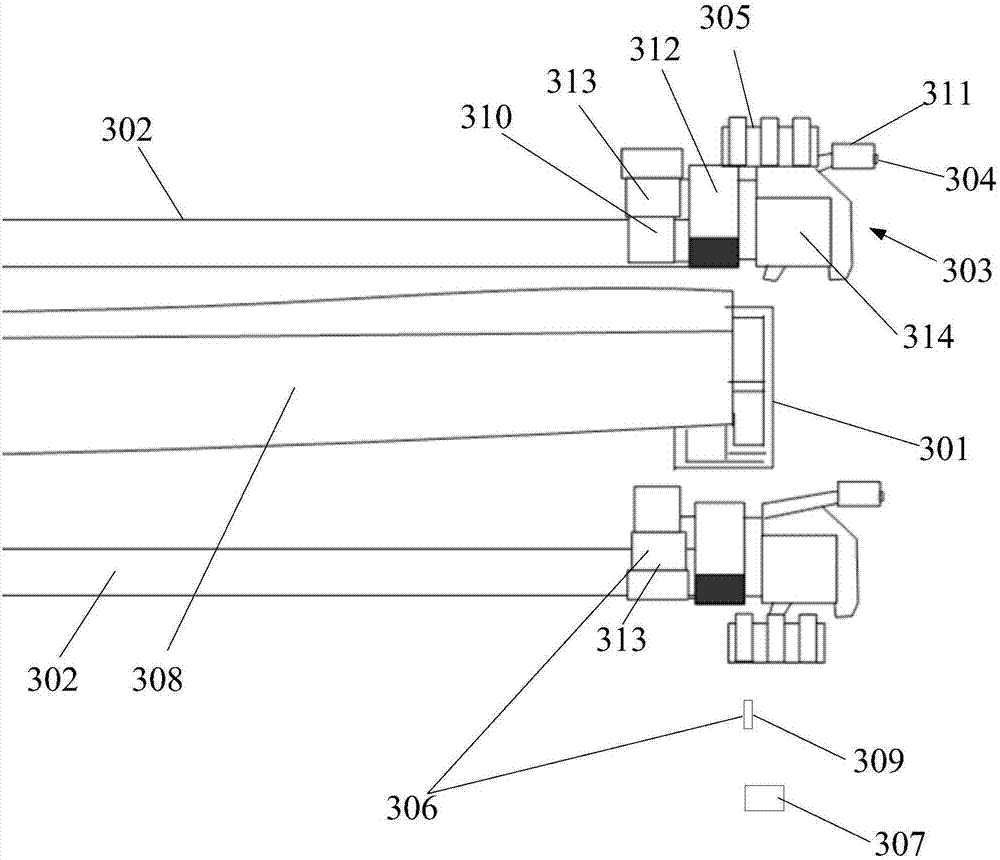

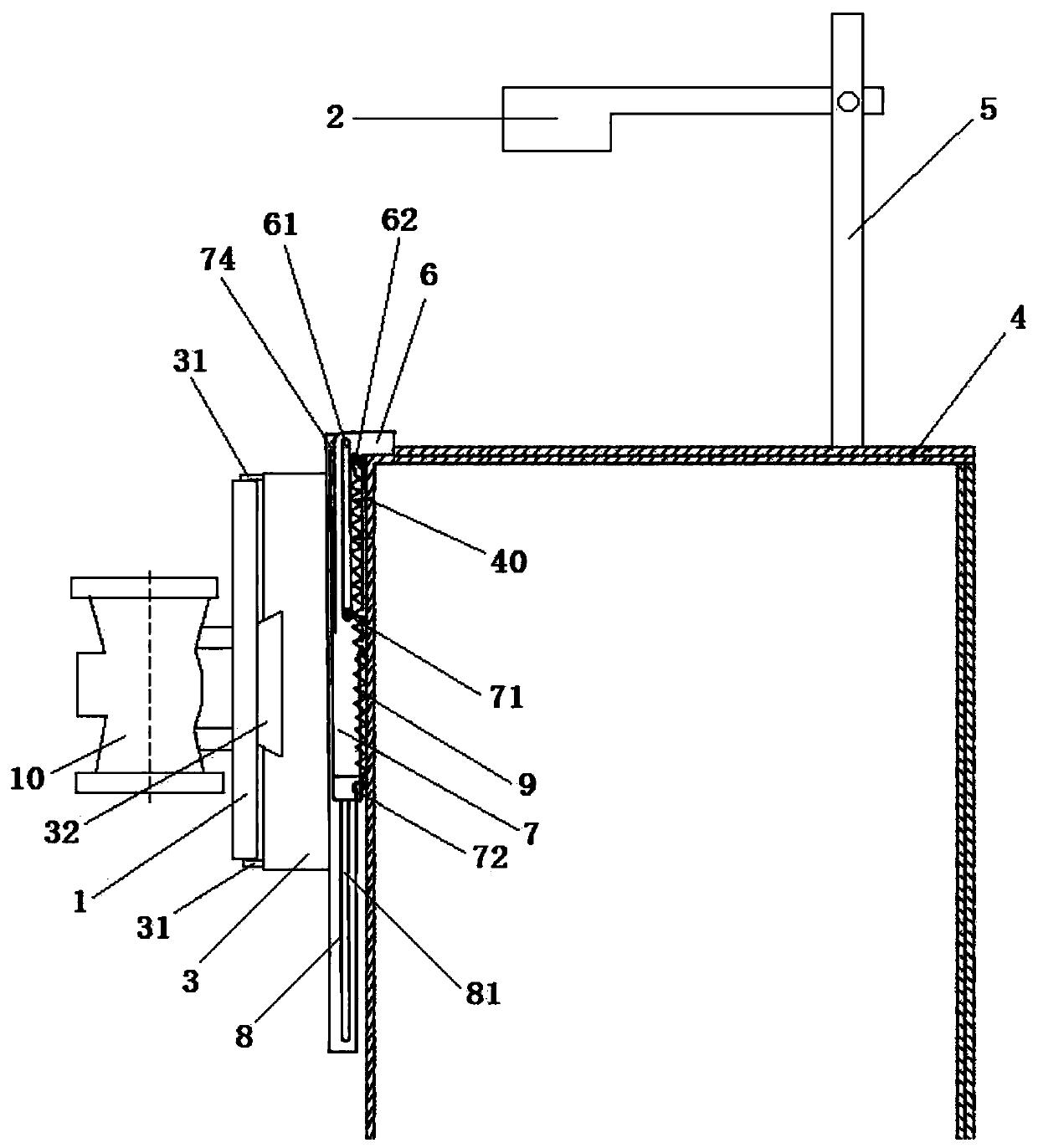

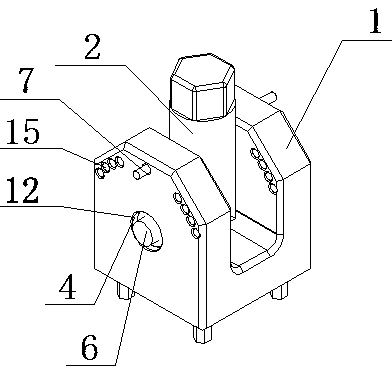

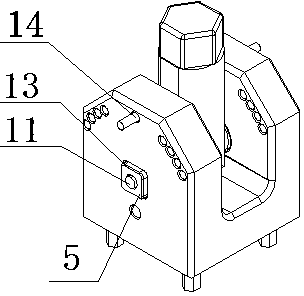

Device and method for force controlling polishing blade through dragging teaching robot

ActiveCN109434843AHigh degree of integrationImprove automationProgramme-controlled manipulatorControl systemContact force

The invention belongs to the related technical field of intelligent machining, and discloses a device and a method for force controlling polishing a blade through dragging a teaching robot. The devicecomprises the robot, a six-dimensional force sensor, a polishing mechanism, a position changing machine, and a robot control system; the six-dimensional force sensor is connected with a tail end executor of the robot and the polishing mechanism; the position changing machine is used for bearing the to-be-machined blade; the robot, the six-dimensional force sensor and the polishing mechanism are connected to the robot control system; the six-dimensional force sensor is used for measuring the contact force between the blade and the polishing mechanism in the blade polishing process, and transmitting the detected data to the robot control system; the robot control system is further used for receiving the tail end position information data of the robot, processing the received data to obtainthe corresponding control quantity, and then controlling the robot to drive the polishing mechanism to carry out corresponding motion. According to the device and the method, the skill requirement foran operator is reduced, and the machining consistency and the machining precision are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

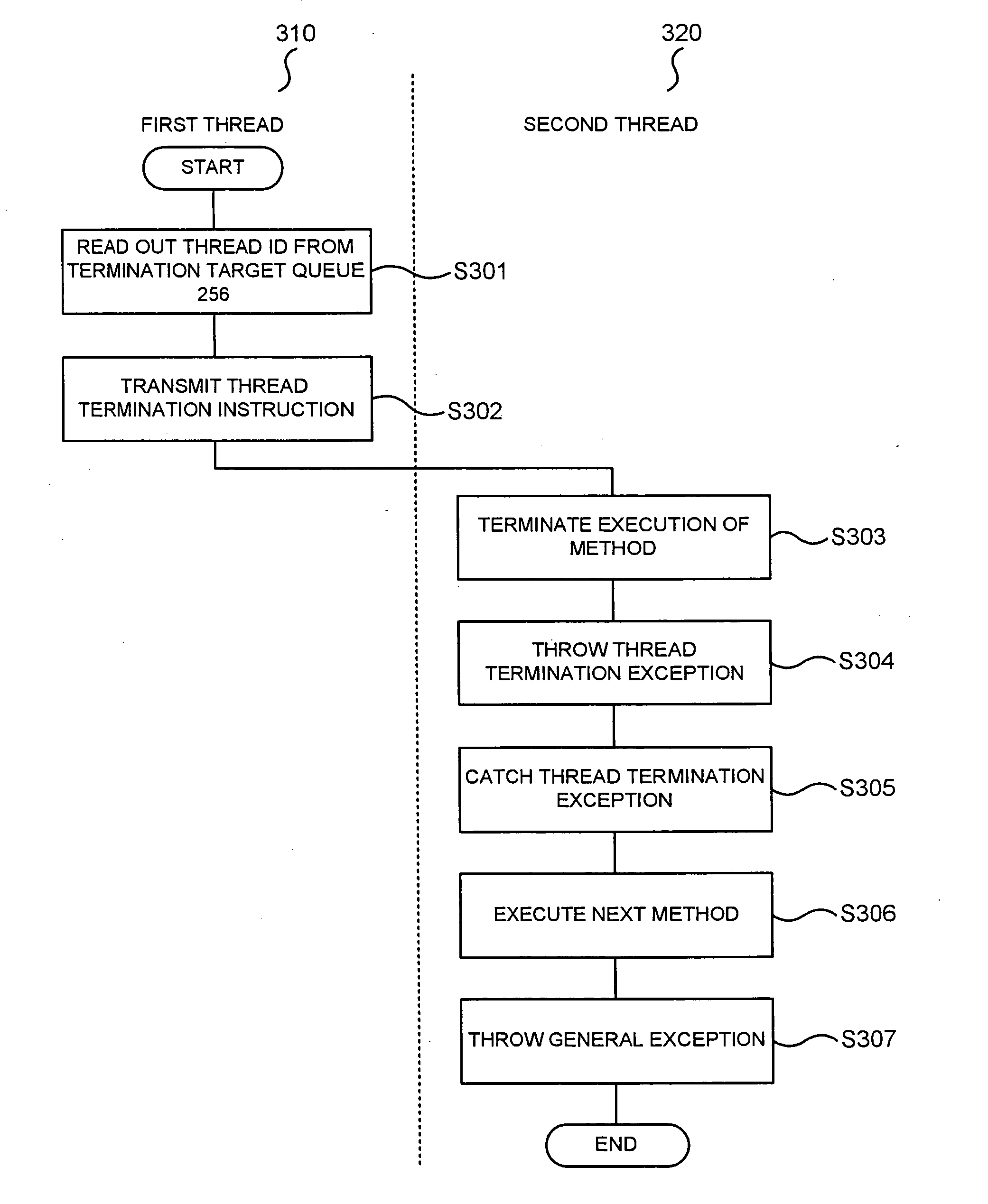

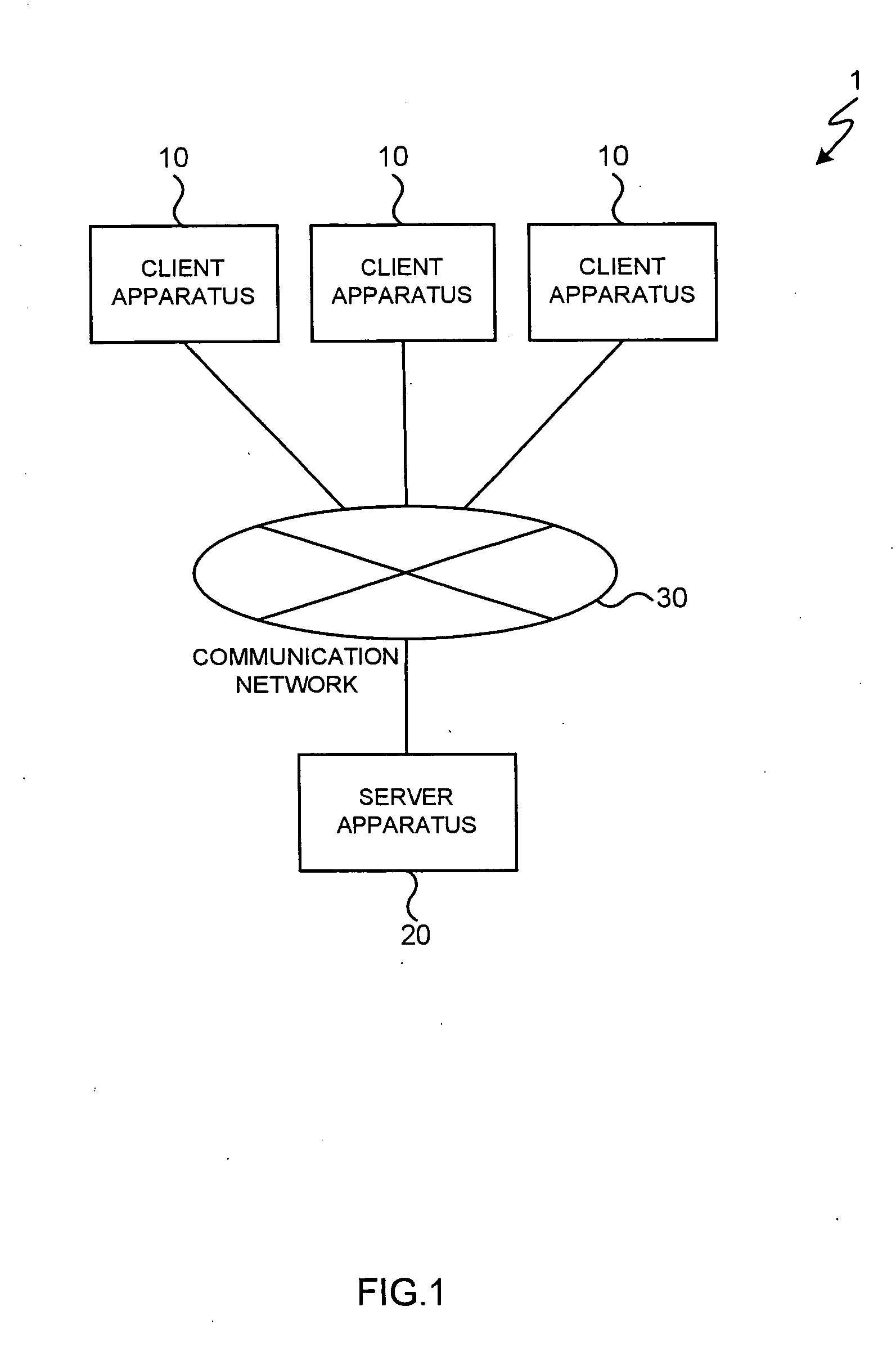

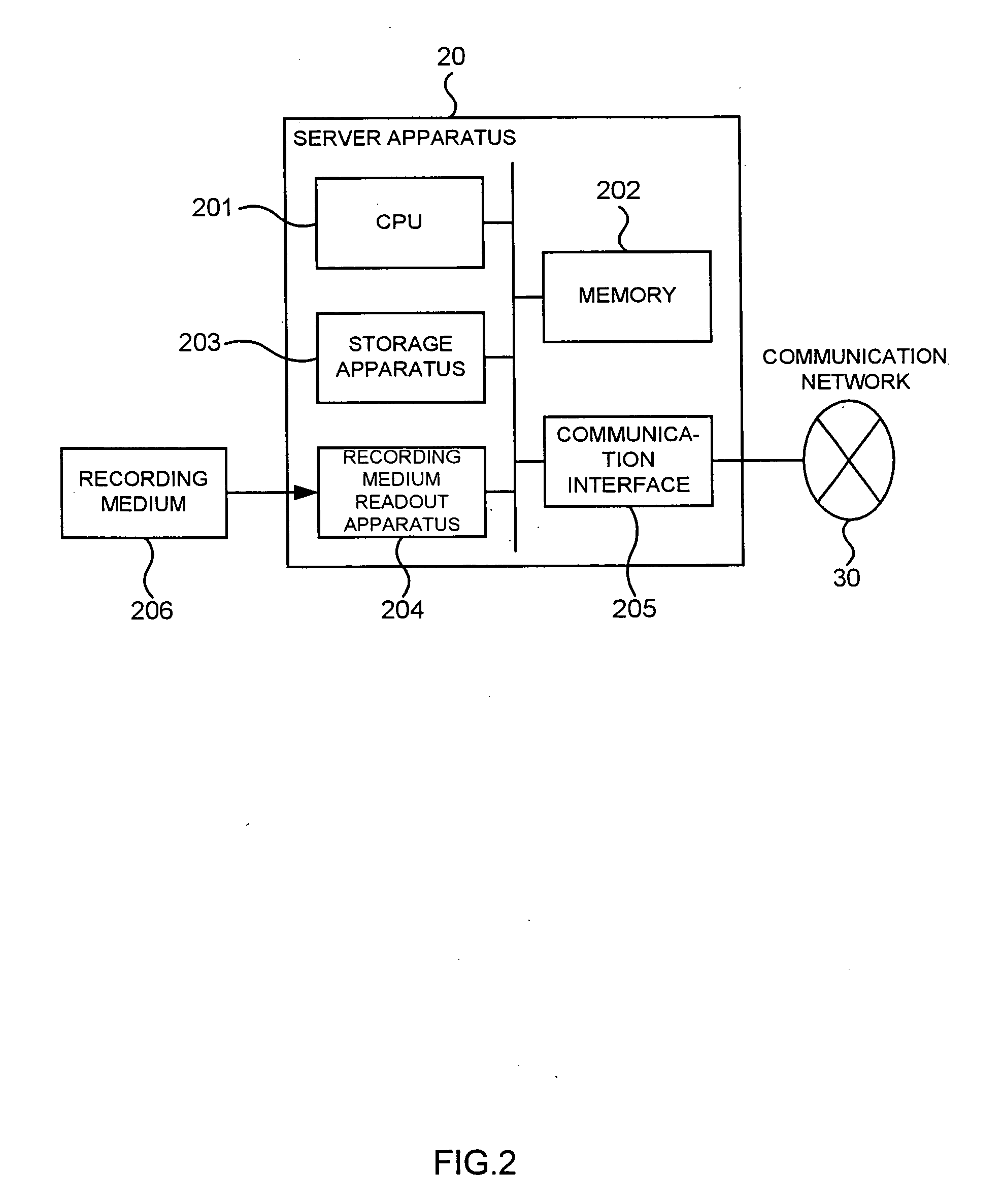

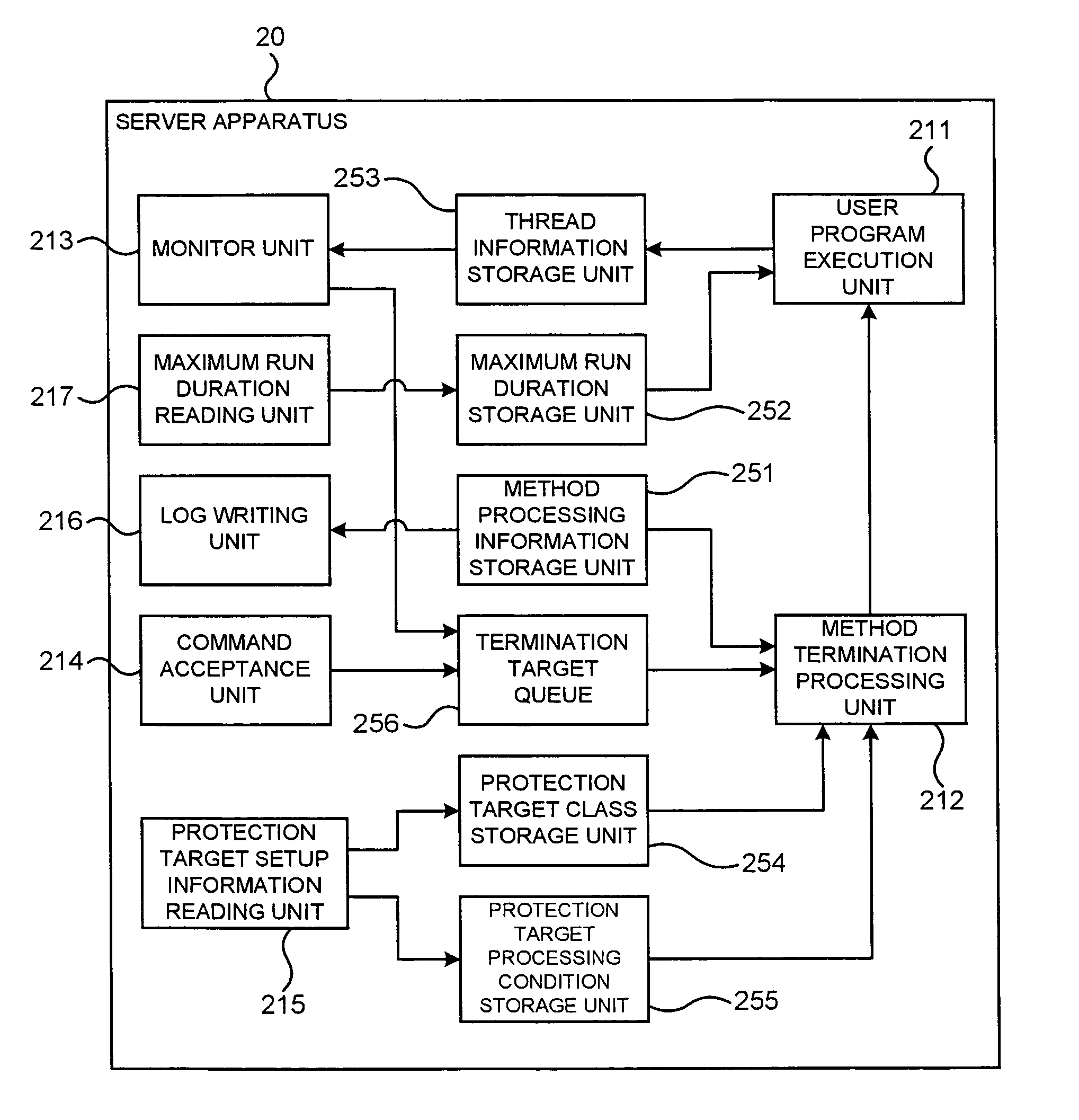

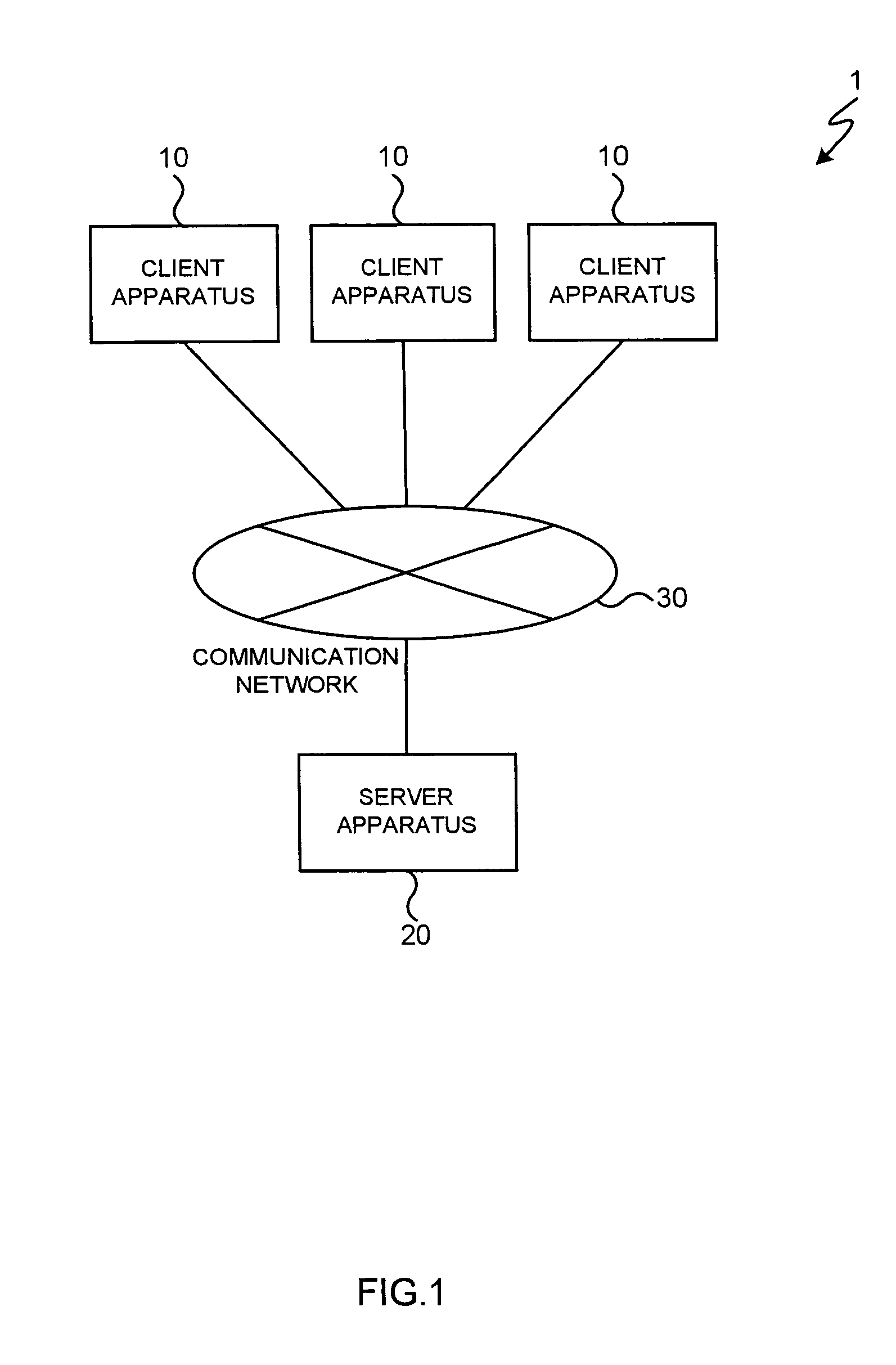

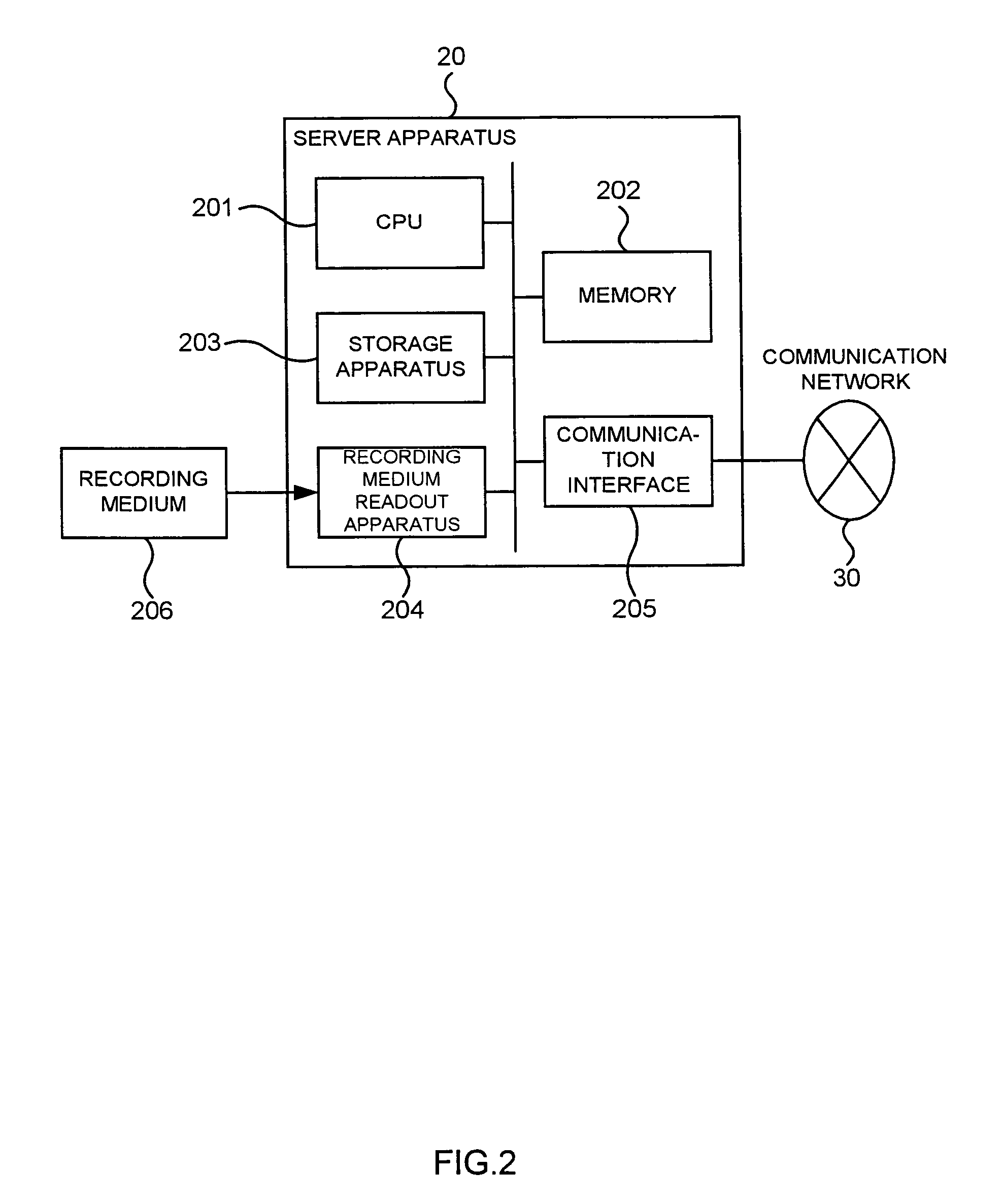

Program control process for an information processing apparatus

InactiveUS20060136920A1Ensure consistencyEnsure processing consistencyMultiprogramming arrangementsMemory systemsInformation processingComputer architecture

In an information processing apparatus which executes first and second threads which executes methods, the first thread transmits a stop instruction for terminating execution of the second thread to the second thread. In response to the reception of the stop instruction, the second thread terminates execution of a first method in execution and initiates execution of the second method which should be executed subsequent to the first method.

Owner:HITACHI LTD

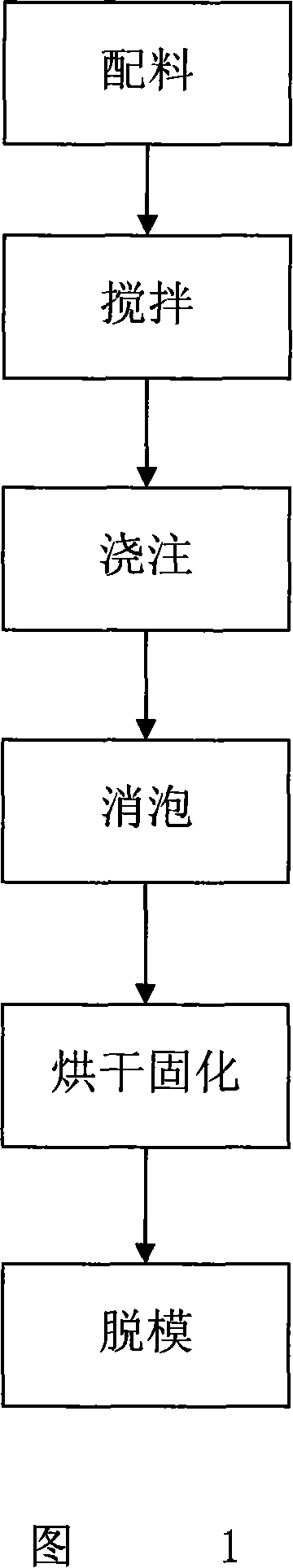

Semi-fixing abrasive grain grinding tool and method of producing the same

InactiveCN101134298AHigh bonding strengthImprove material removal rateAbrasion apparatusGrinding devicesWear particleAdhesive

The present invention is one kind of grinding tool with semi-fixed abrasive particle and its making process. The grinding tool consists of abrasive grain in 80-90 wt%, adhesive 1-10 wt% and additive 5-15 wt%. Its making process includes the following steps: 1. mixing abrasive grain, adhesive and additive, sieving and mixing with water; 2. molding the mixture in a mold; 3. eliminating bubbles from the molded grinding tool; and 4. stoving the grinding toll in a stove for curing and demolding to obtain the grinding tool with semi-fixed abrasive particle. The present invention has high processing precision and high processing efficiency.

Owner:ZHEJIANG UNIV OF TECH +1

Program control process for an information processing apparatus

InactiveUS7886297B2Ensure processing consistencyMultiprogramming arrangementsMemory systemsInformation processingParallel computing

In an information processing apparatus which executes first and second threads which executes methods, the first thread transmits a stop instruction for terminating execution of the second thread to the second thread. In response to the reception of the stop instruction, the second thread terminates execution of a first method in execution and initiates execution of the second method which should be executed subsequent to the first method.

Owner:HITACHI LTD

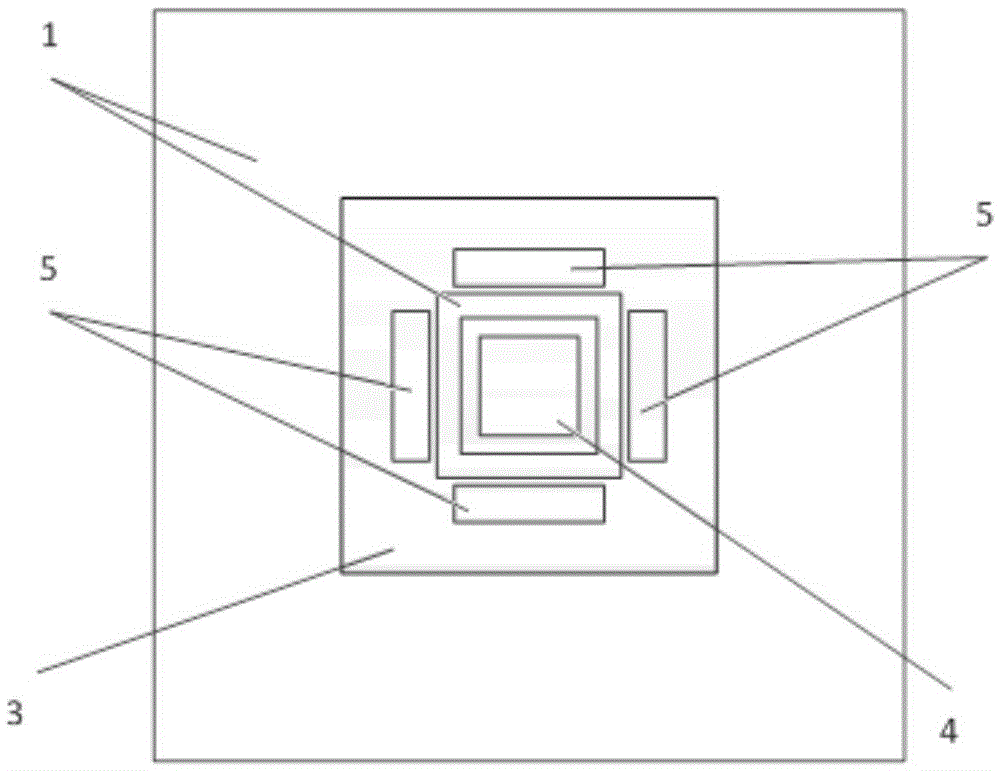

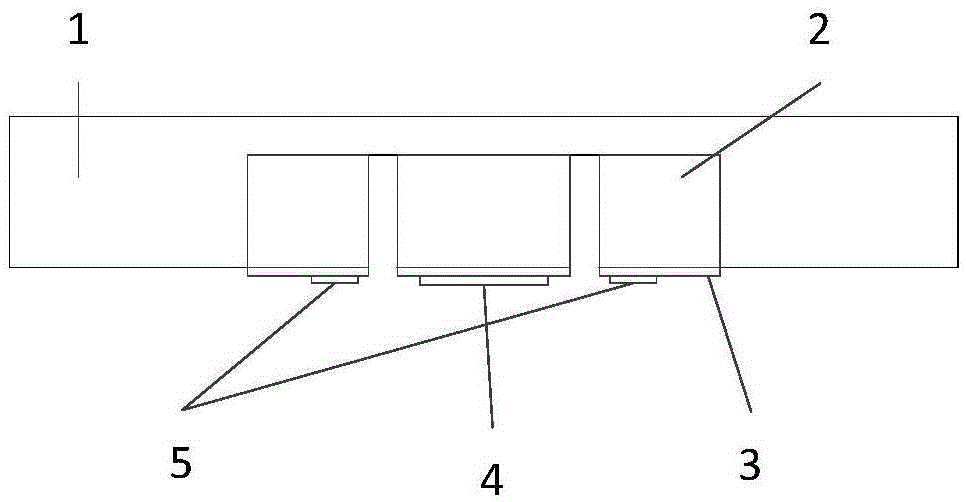

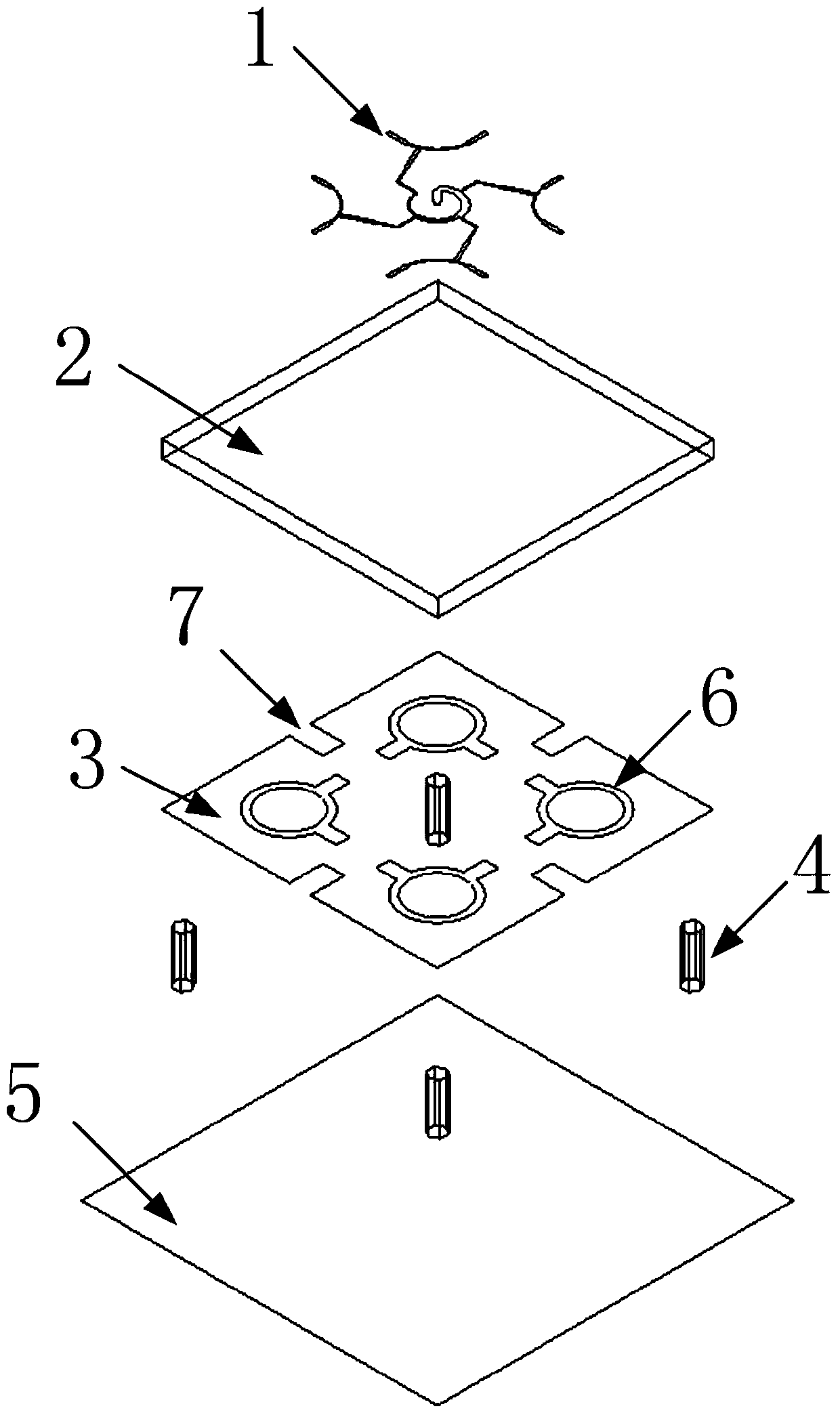

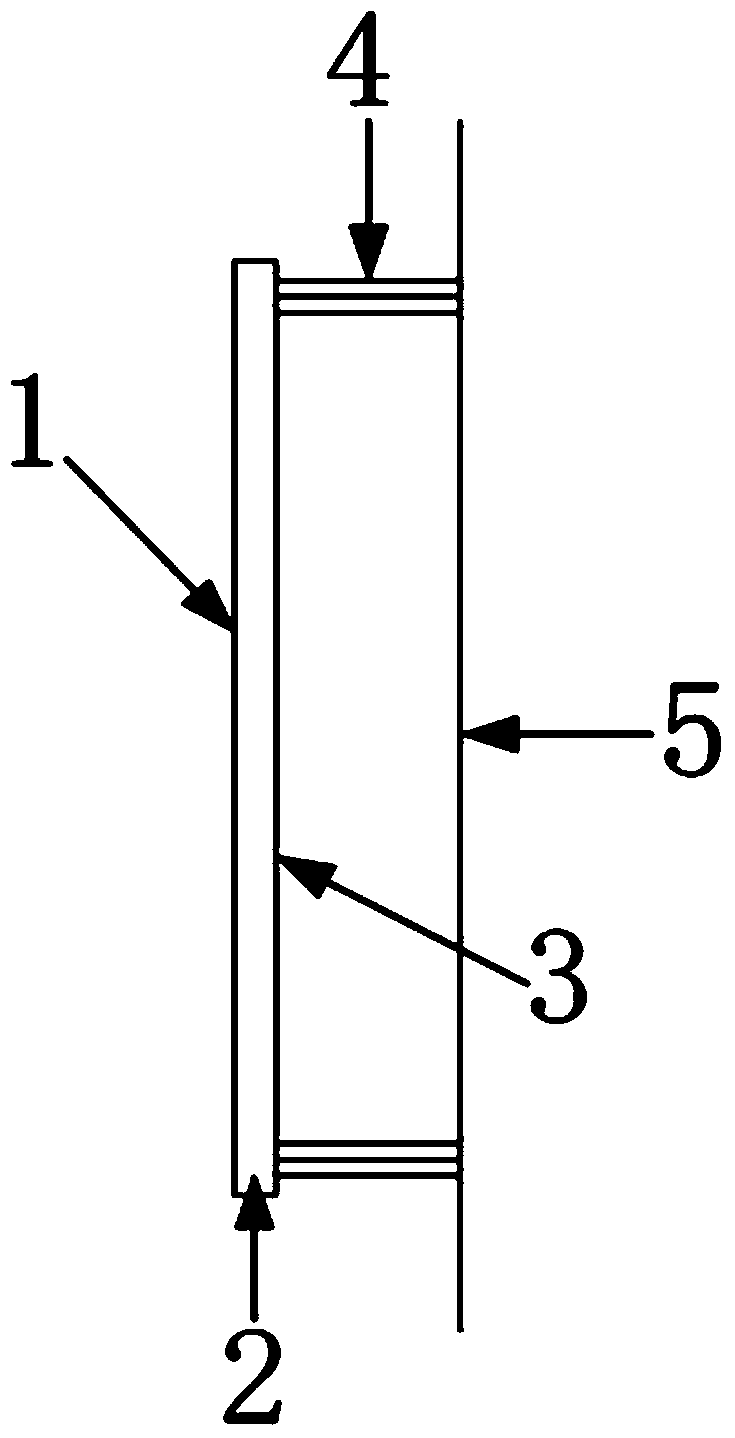

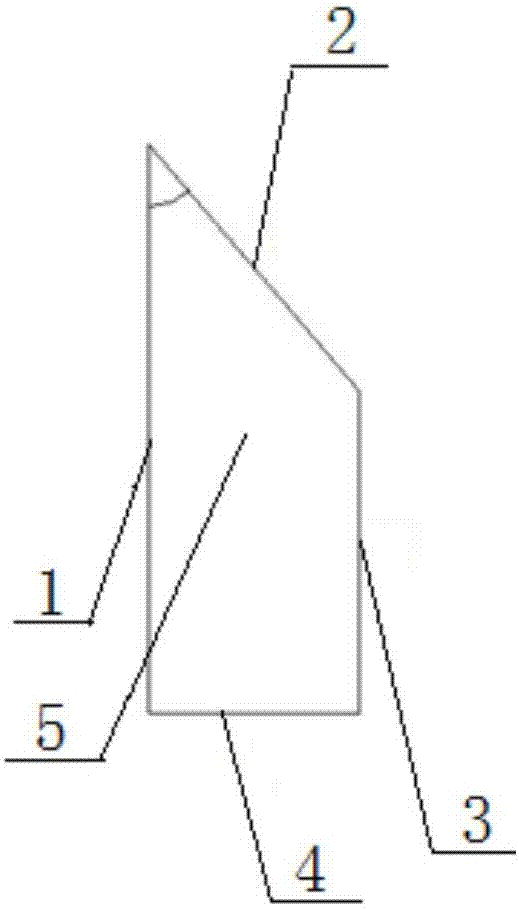

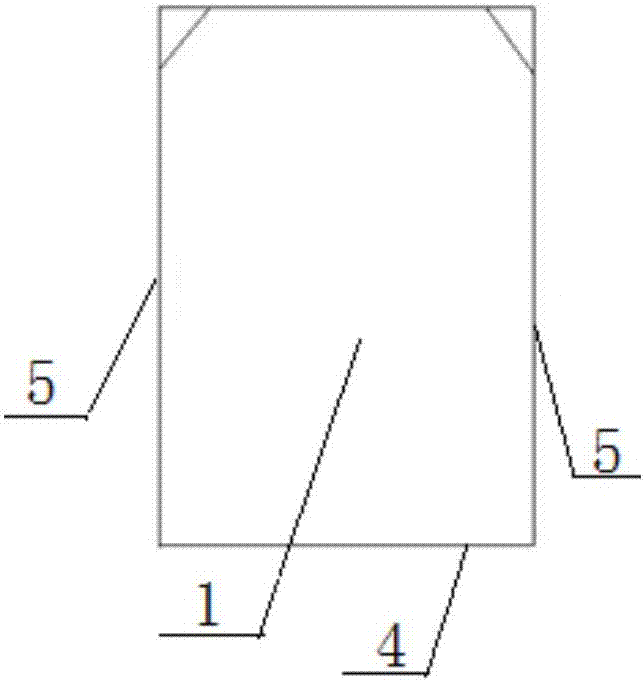

Two-dimensional thermal-type wind speed and directions sensor based on ceramic packaging, and manufacturing method therefor

ActiveCN105547371AGuaranteed machining accuracy and consistencyReduce lateral heat conductionIndication/recording movementFluid speed measurement using thermal variablesTemperature measurementHeating element

The invention provides a two-dimensional thermal-type wind speed and directions sensor based on ceramic packaging, and a manufacturing method therefor. The sensor comprises a ceramic substrate (1), an embedded silicon substrate (2), an insulating layer (3), a heating element (4), and four symmetric temperature measurement elements. The embedded silicon substrate (2) is embedded into the ceramic substrate (1), and the thickness of the part, above the embedded silicon substrate (2), of the ceramic substrate (1) is less than the whole thickness of ceramic. The embedded silicon substrate (2) is disposed in a cavity of the central ceramic substrate (1) in a central symmetry manner, and the lower surface of the embedded silicon substrate (2) is provided with the insulating layer (3). The lower surface of the insulating layer (3) is provided with the heating element (4) and four orthogonal temperature measurement elements. The sensor improves the sensitivity, and reduces the power consumption.

Owner:SOUTHEAST UNIV

Stator blade finish forging automatic machining method

ActiveCN108747232AImprove machining accuracyUnobstructed walking pathMilling equipment detailsSelf adaptiveMultiple pass

The invention discloses a stator blade finish forging automatic machining method. The method adopts a self-adaption machining technology, and blade deviation, torsion, profile surface tolerance and machining consistency are ensured. The method is simple in machining procedure, computer control and management are adopted, controlled devices completely automatically finish the sequential operation,the degree of automatic operation is improved, multiple devices, multiple passes of procedures, repeated clamping and repeated standard conversion for original stator blade machining are reduced intotwo passes of procedures of machining, two times of clamping and one time of standard conversion on one kind of equipment, labor is saved, the production period of parts is shortened, and the production efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

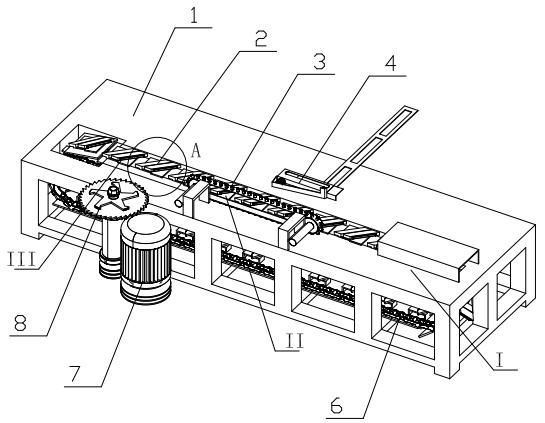

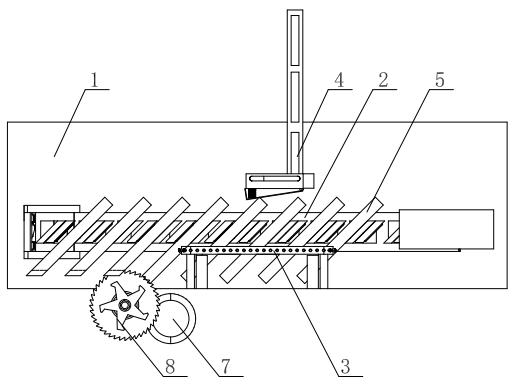

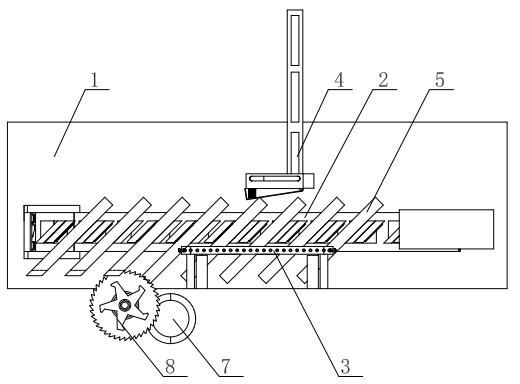

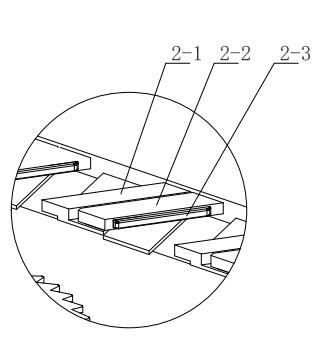

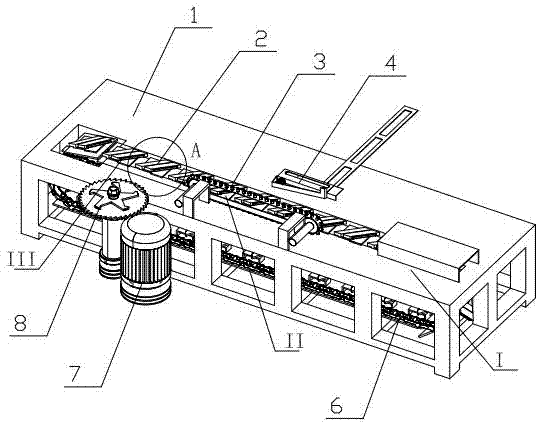

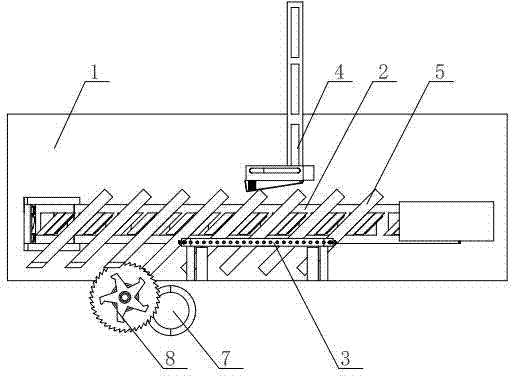

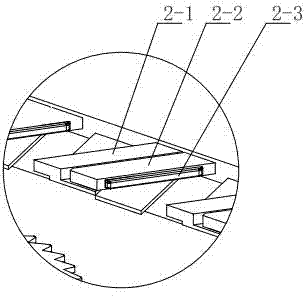

Automatic processing machine for timber tenon

ActiveCN102490221AProtect personal safetyPrecise positioningTongue/grooves making apparatusTenon making apparatusDrive motorOperation mode

The invention discloses an automatic processing machine for a timber tenon. The edge side of a rack is provided with a motor and a saw blade; the rack is provided with a rotary clamping block caterpillar track; the rotary clamping block caterpillar track is driven by a driving motor and a chain and is composed of multiple groups of fixed blocks and movable blocks forming an inclined angle of 45 degrees with the transmission direction; and a vertical clamping belt and a pushing elastic rack are respectively arranged on two sides of the rotary clamping block caterpillar track. According to the automatic processing machine for the timber tenon, the dangerous operation mode of mutually feeding and cutting gradually at present can be changed, only one operation person needs to be arranged to feed on the caterpillar track at low intensity on the safe position far away from the saw blade so as to greatly lower the labor danger and protect the personal safety; and the output within the unit time is greatly improved. The relative movement of the fixed blocks and the movable blocks is utilized to clamp and release the timber, the vertical clamping belt and the pushing elastic rack are arranged in front of the clamping point to accurately position and locate the timber before the timber is clamped, and the machining precision and the consistency of the product are reliably guaranteed.

Owner:WUXI PHOENIX ARTIST MATERIALS

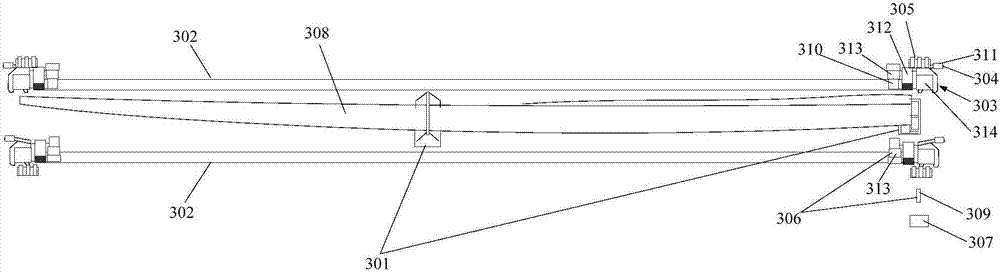

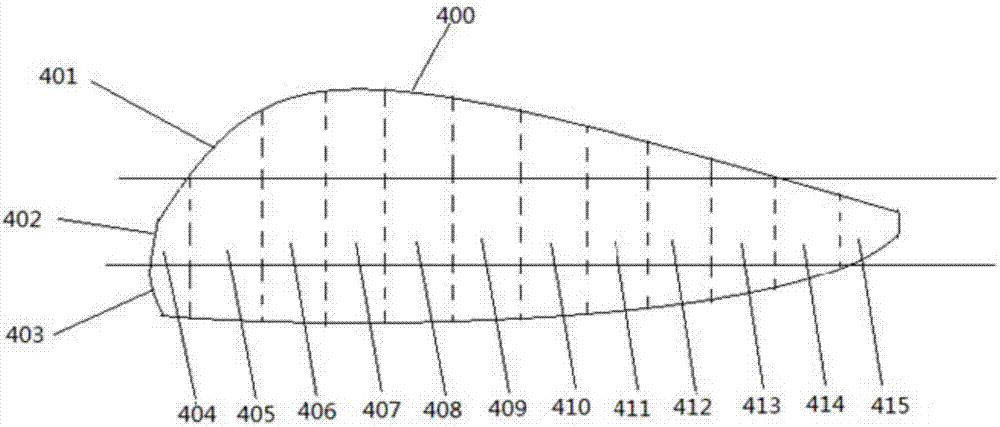

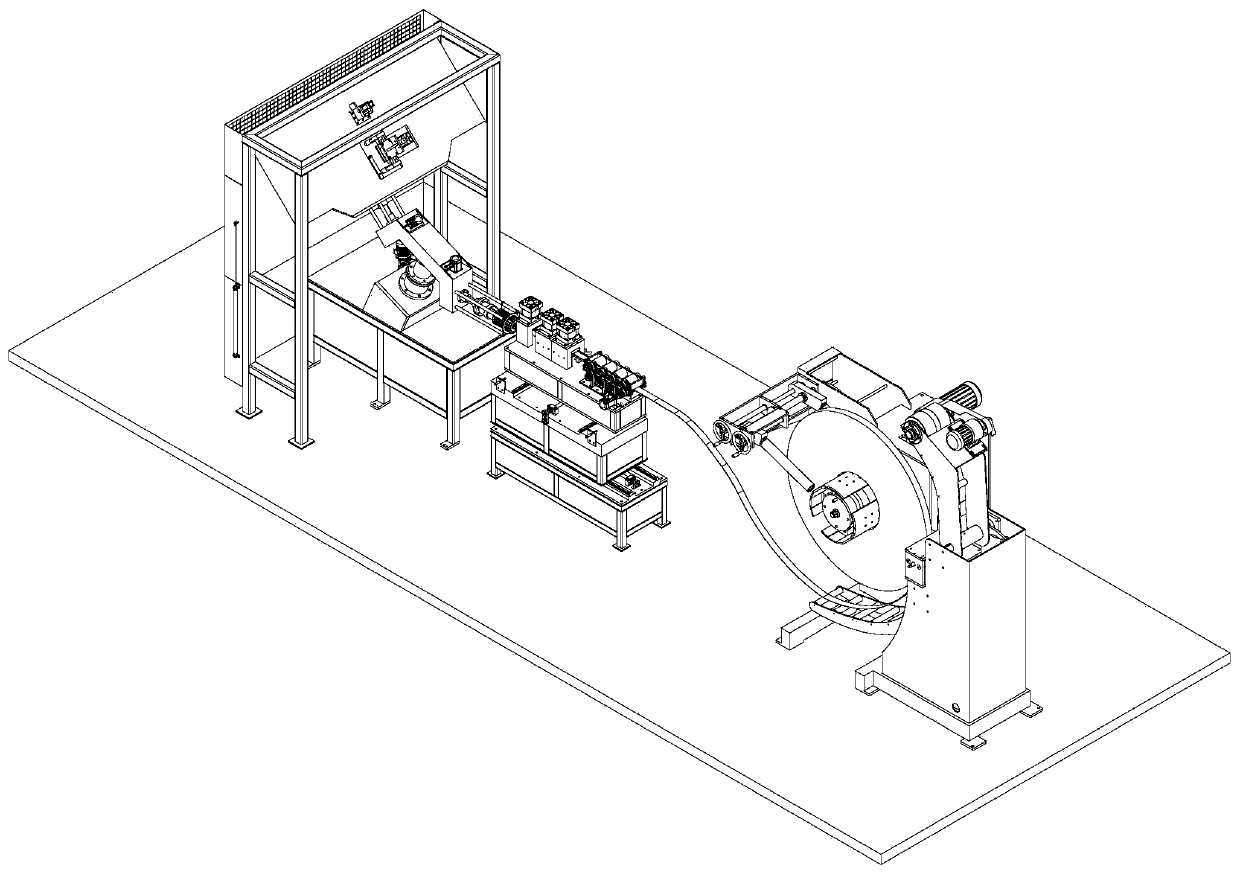

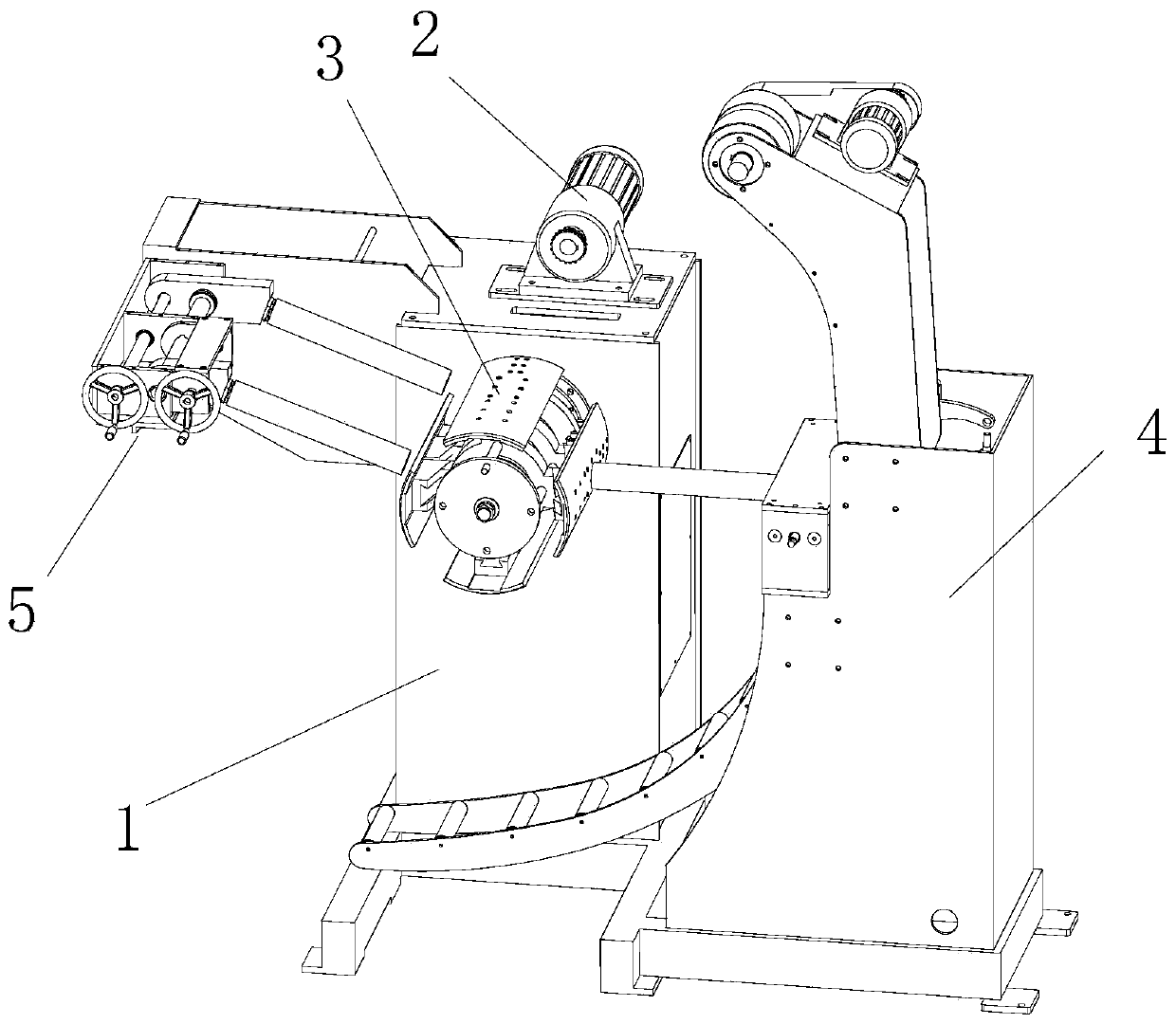

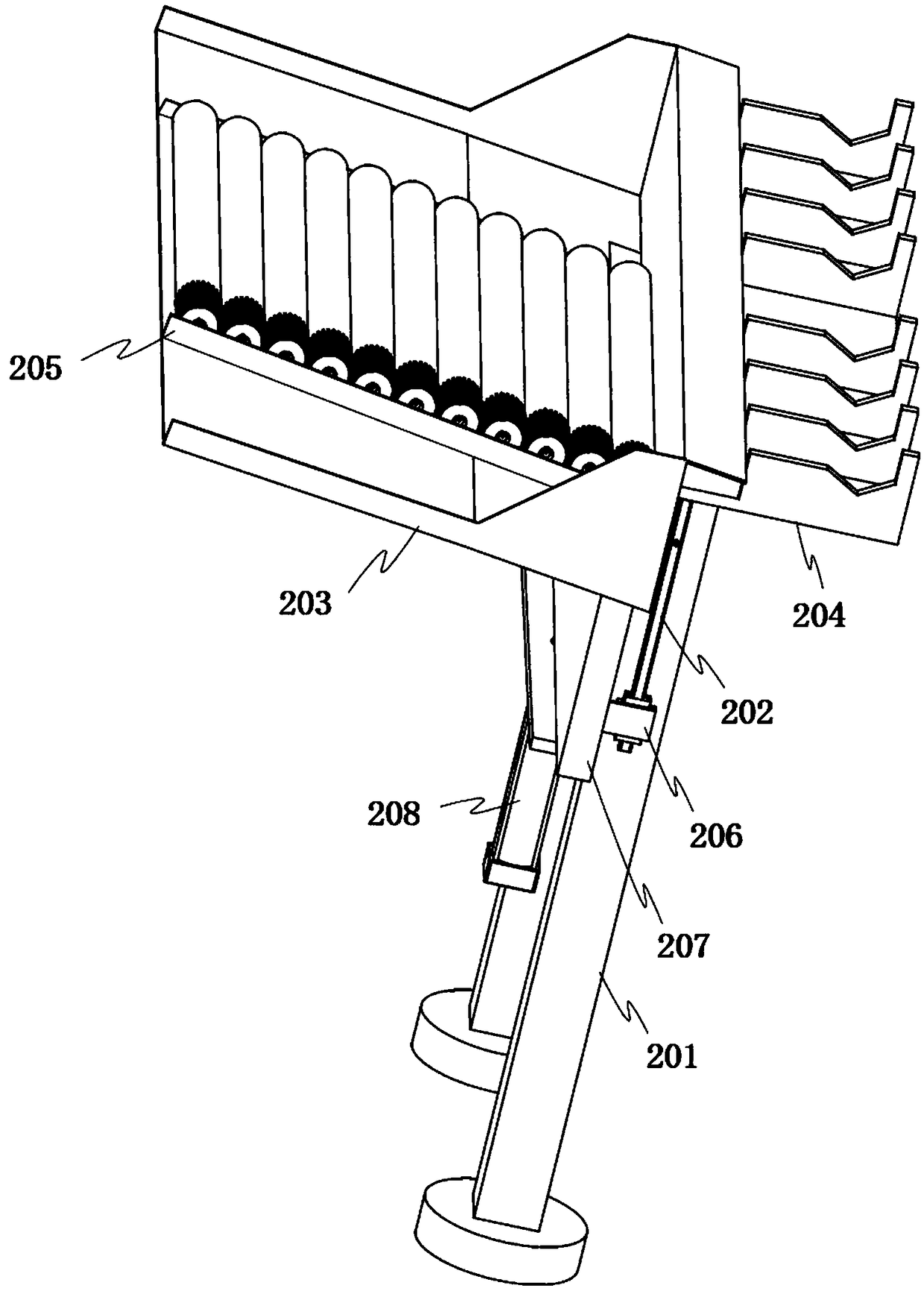

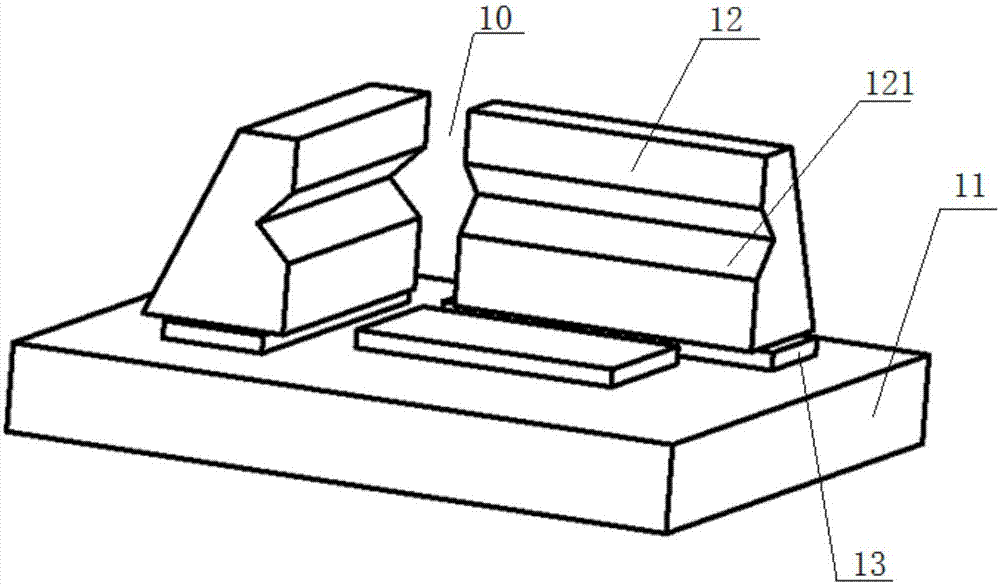

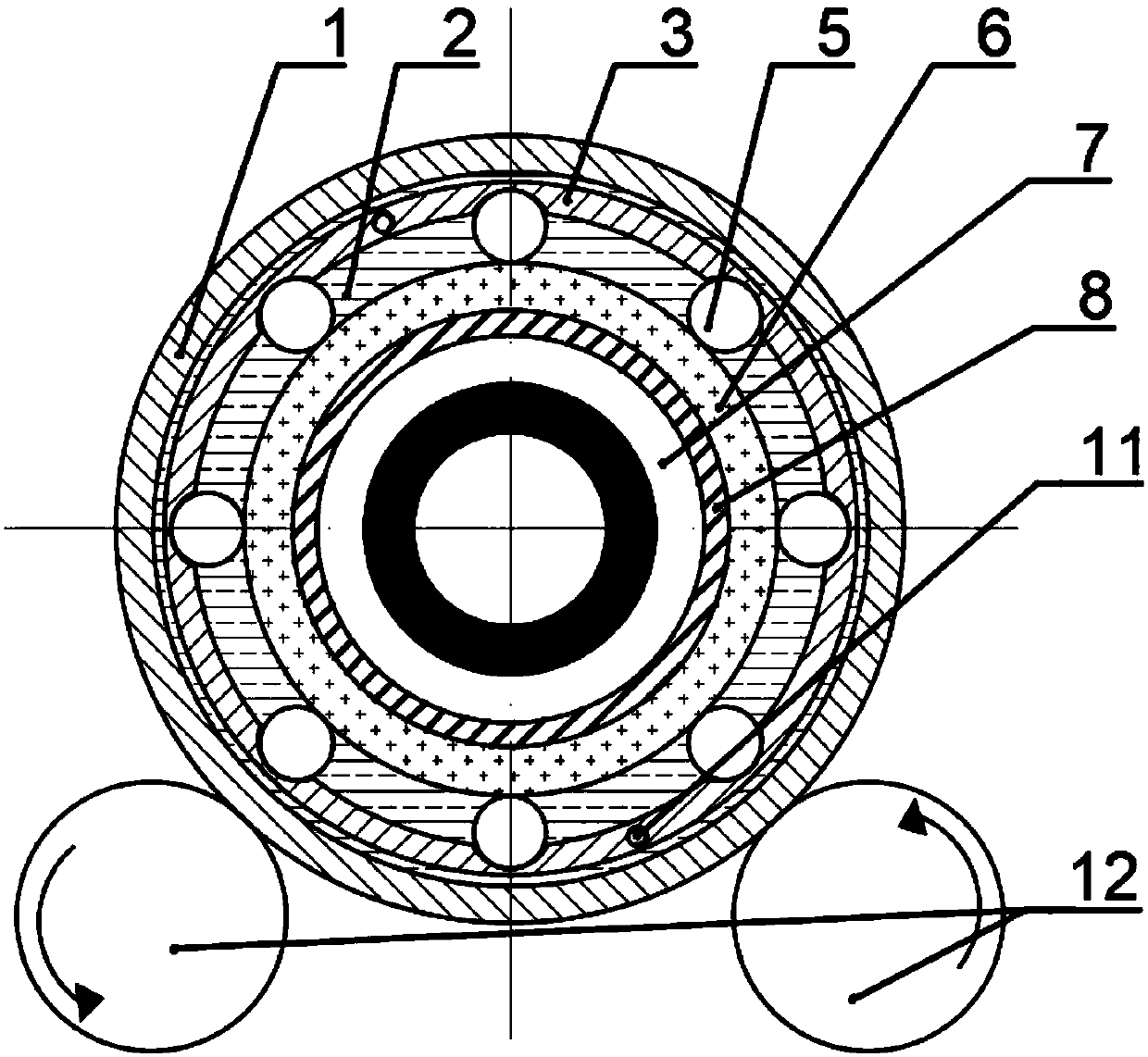

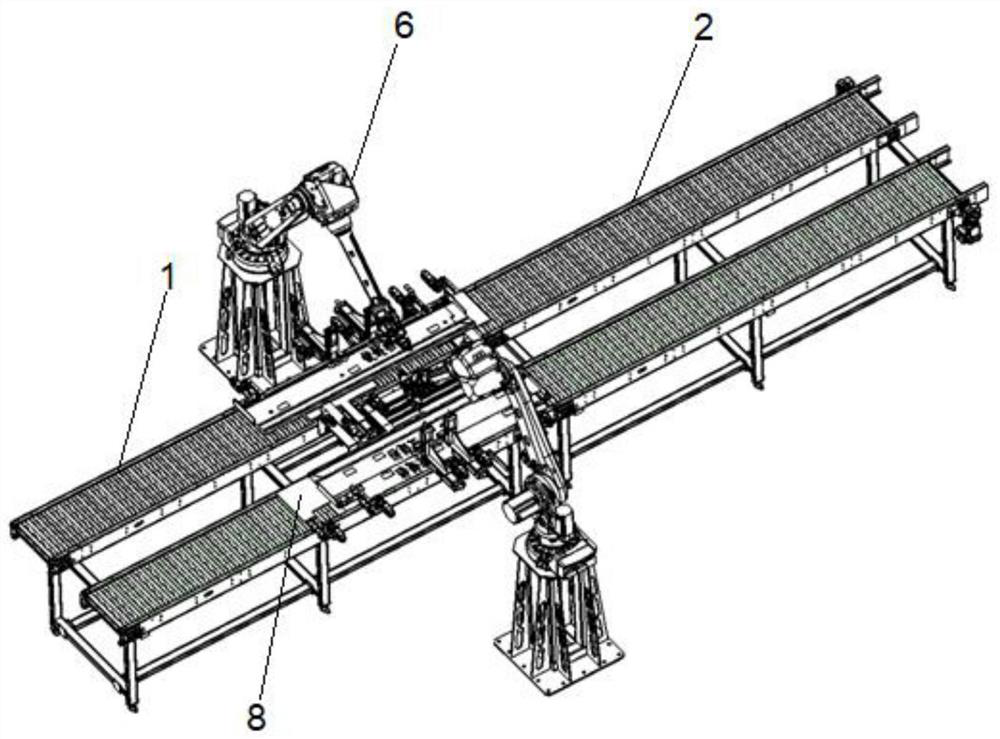

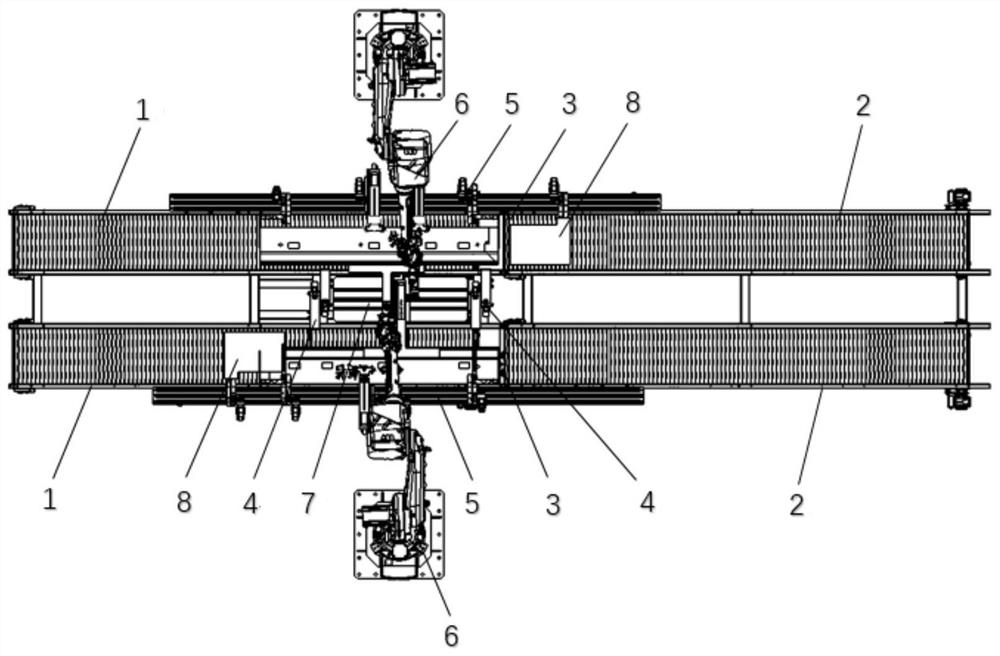

Large blade type workpiece robot collaborative grinding system and method

PendingCN107263255AGuarantee processing quality and consistencyHigh degree of automationGrinding feed controlAutomatic grinding controlCorner angleControl theory

The invention provides a large blade type workpiece robot collaborative grinding system. The large blade type workpiece robot collaborative grinding system comprises a blade turnover clamping module, horizontal guide rails, N robot grinding units, N measuring modules corresponding to the robot grinding units, a control module and an upper computer module, wherein the control module comprises a tool control submodule and N robot grinding unit control submodules; the blade turnover clamping module is used for mounting and clamping blades to be ground; the two horizontal guide rails are arranged on the two sides of the blades in the long axis direction of the blades, and each horizontal guide rail is at least provided with one robot grinding unit; each robot grinding unit comprises a robot, a matched robot controller and a grinding device; each grinding device is mounted at the tail end of the robot corresponding to the grinding device, and each measuring module is mounted at the tail end of the corresponding robot; and the tool control submodules are connected with the blade turnover clamping module and control the turnover direction, turning angles and clamping operation of the blades. The large blade type workpiece robot collaborative grinding system can improve the grinding efficiency and quality of the blades.

Owner:无锡中车时代智能装备研究院有限公司

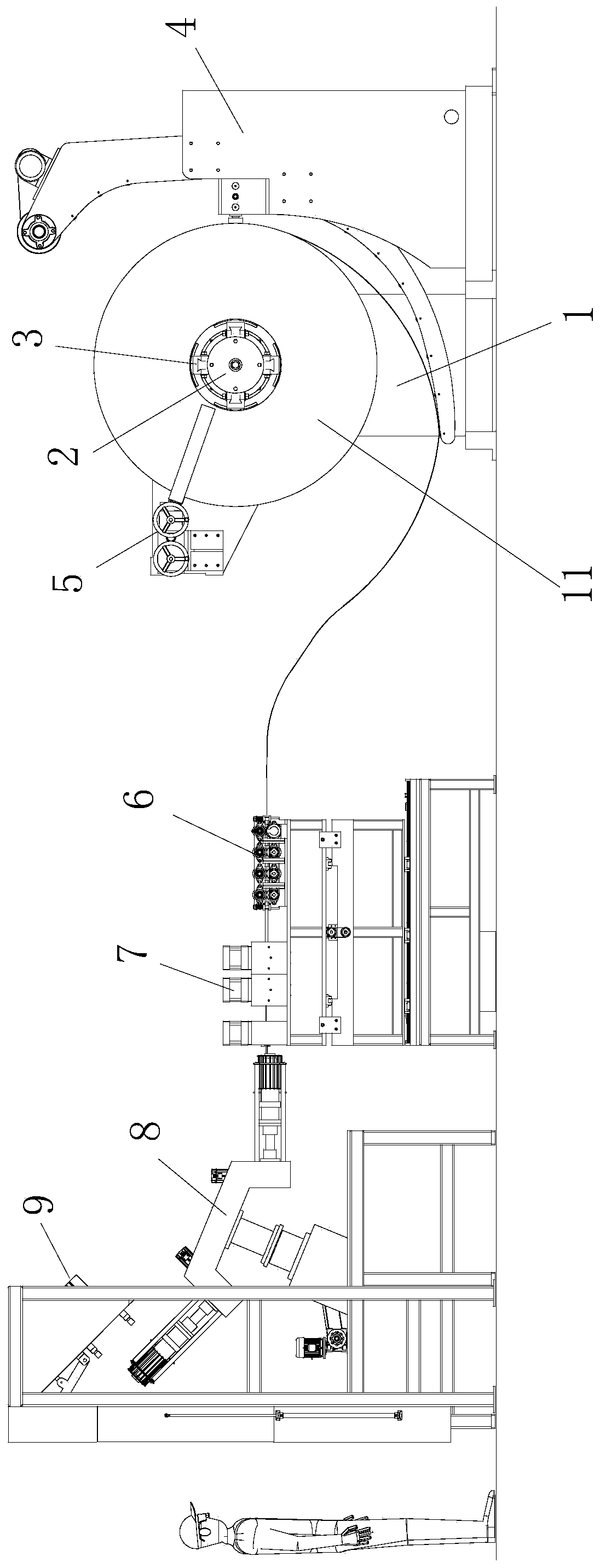

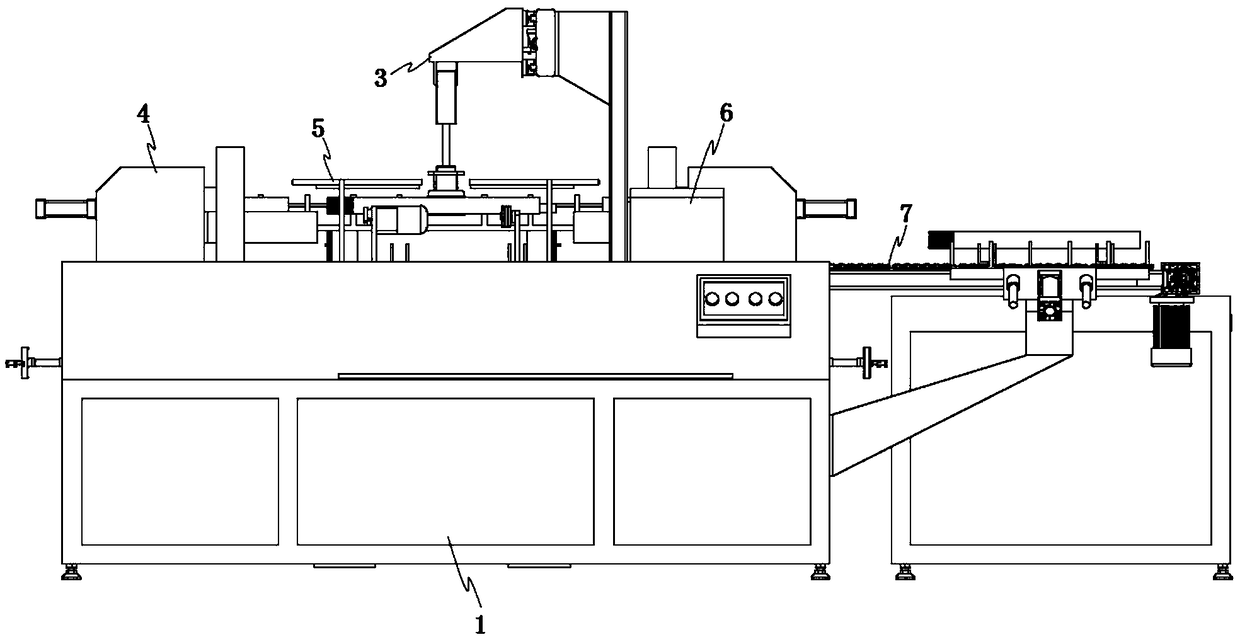

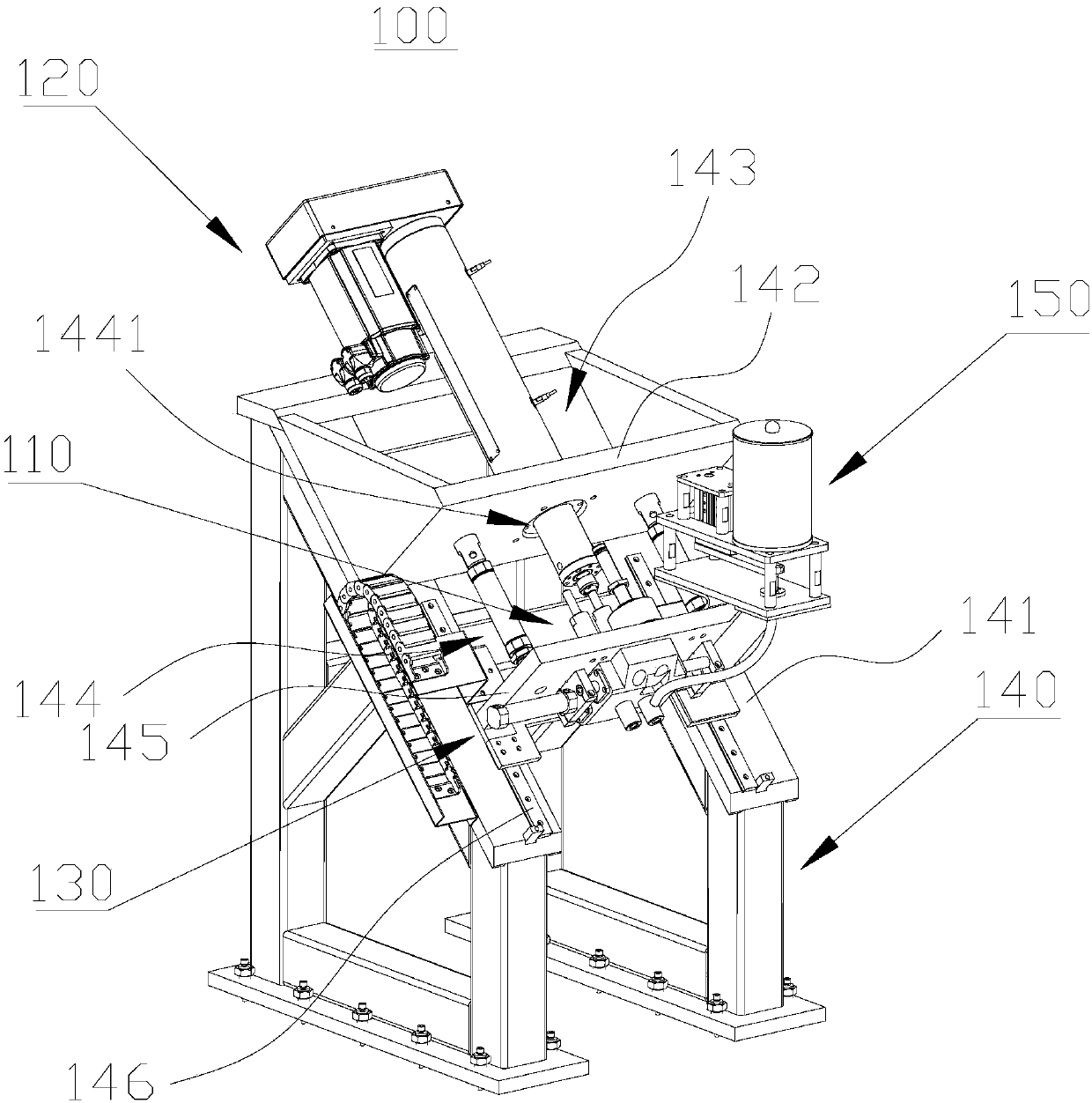

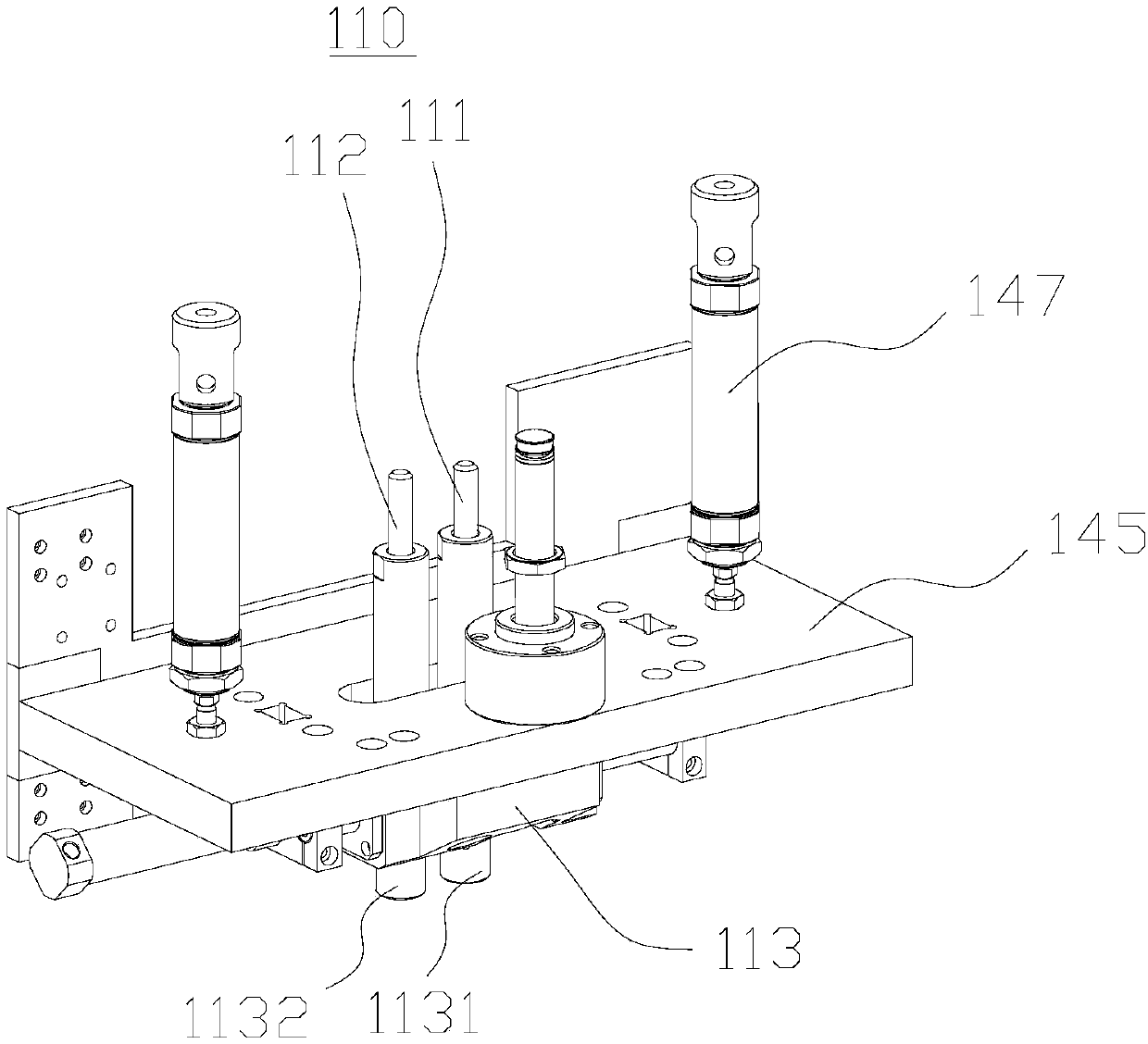

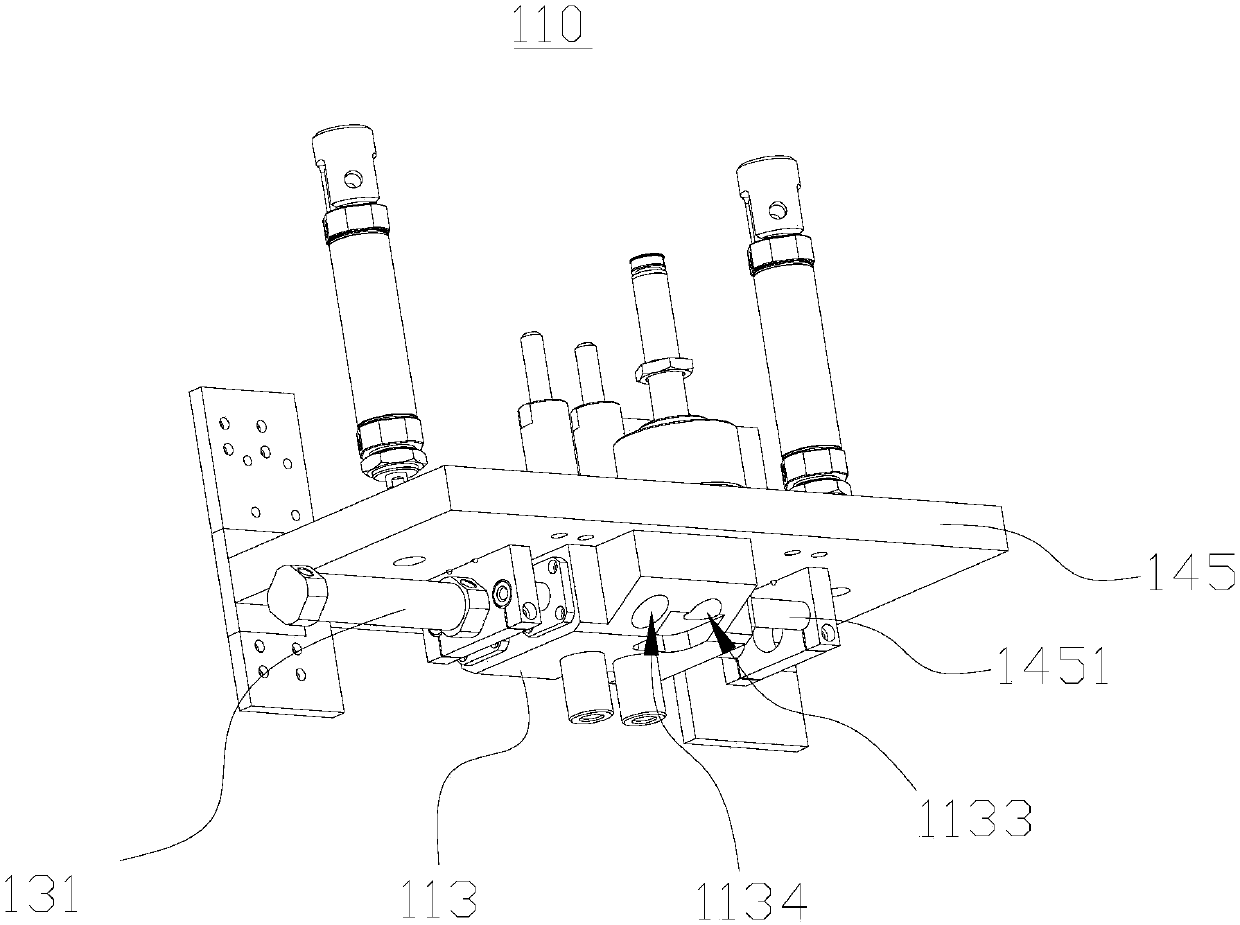

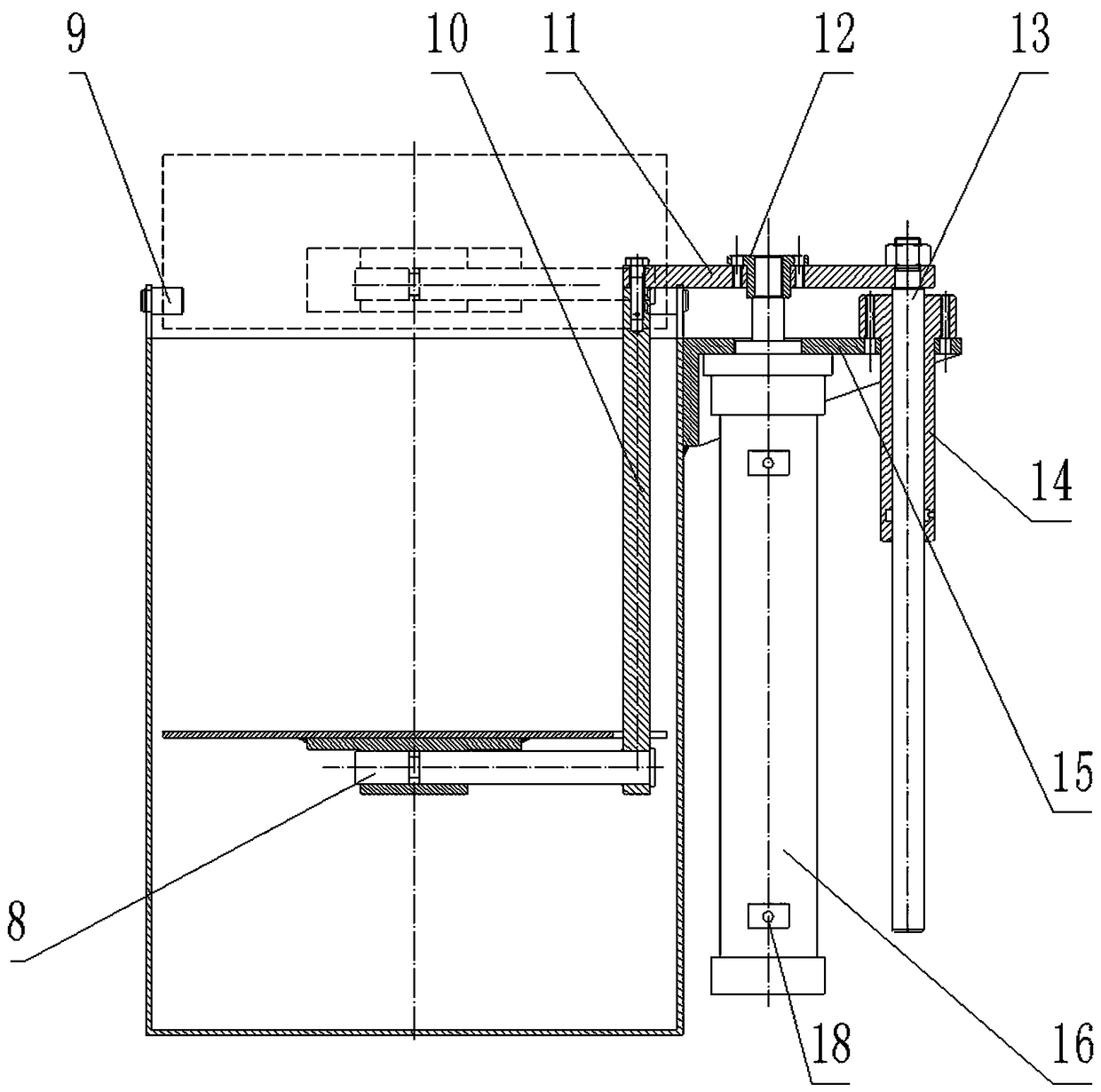

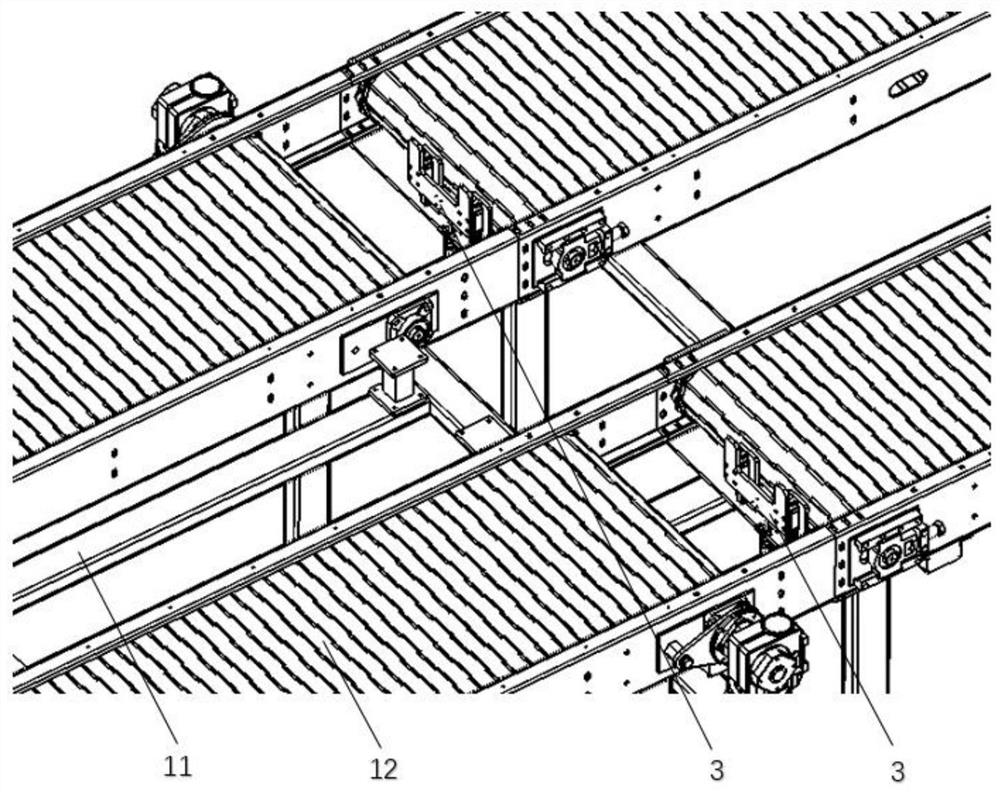

Automatic assembly production line for fan impellers

ActiveCN110394644ALabor savingIncrease productivityMetal-working feeding devicesAssembly machinesProduction lineImpeller

The invention discloses an automatic assembly production line for fan impellers. The automatic assembly production line for the fan impellers comprises a steel belt uncoiling mechanism, a blade roll forming feeding mechanism, a blade blanking mechanism, a double-station rotary assembly mechanism and a material pressing feeding and discharging mechanism sequentially arranged. During production, a lower end cover is manually fed from a material pressing feeding and discharging mechanism; a pneumatic safety door is closed, a double-station rotating assembly device rotates to rotate a machined finished product out, and the machined finished product is transferred to a de-stamping assembly blade; the steel belt uncoiling mechanism at the front end uncoils and feeds the machined finished product; a steel belt is pressed and formed through a straightening roller, then the steel belt is stamped and cut into a blade, and the blade is stamped and assembled into the lower end cover by matching with servo feeding and blanking cutting; the blade is transferred out by rotating through the double-station rotary assembly; the pneumatic safety door is opened, and an upper end cover is manually fed;the pneumatic safety door is closed, an open-close clamping pinch roller mechanism and a centering pressure head on a rotating pinch are matched with a shaft of the rotary assembly mechanism to rotate, and spinning fixation of the blade and the upper end cover and the lower end cover is completed; and the safety door is opened, finished products are manually discharged, and the lower end cover isfed.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

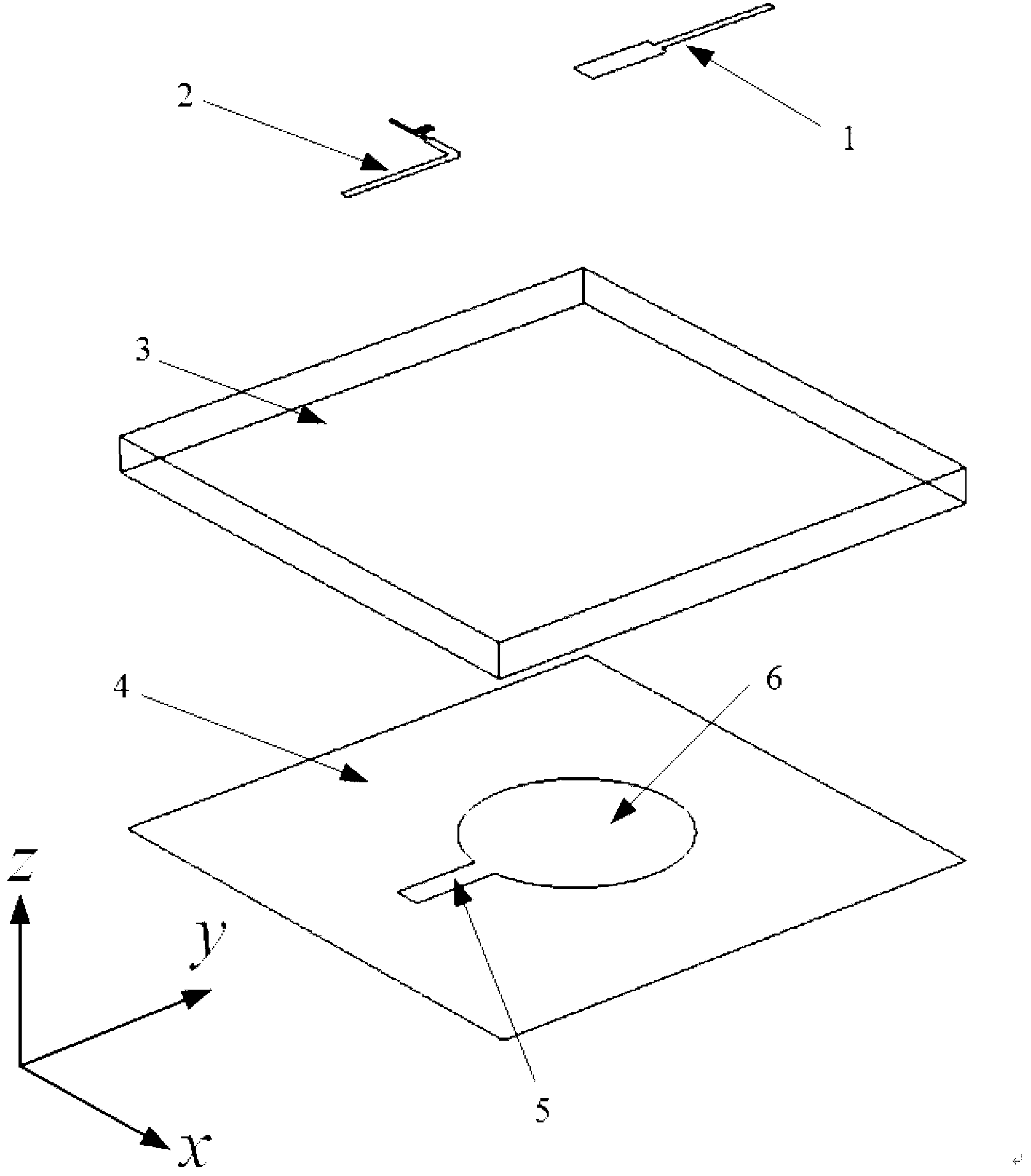

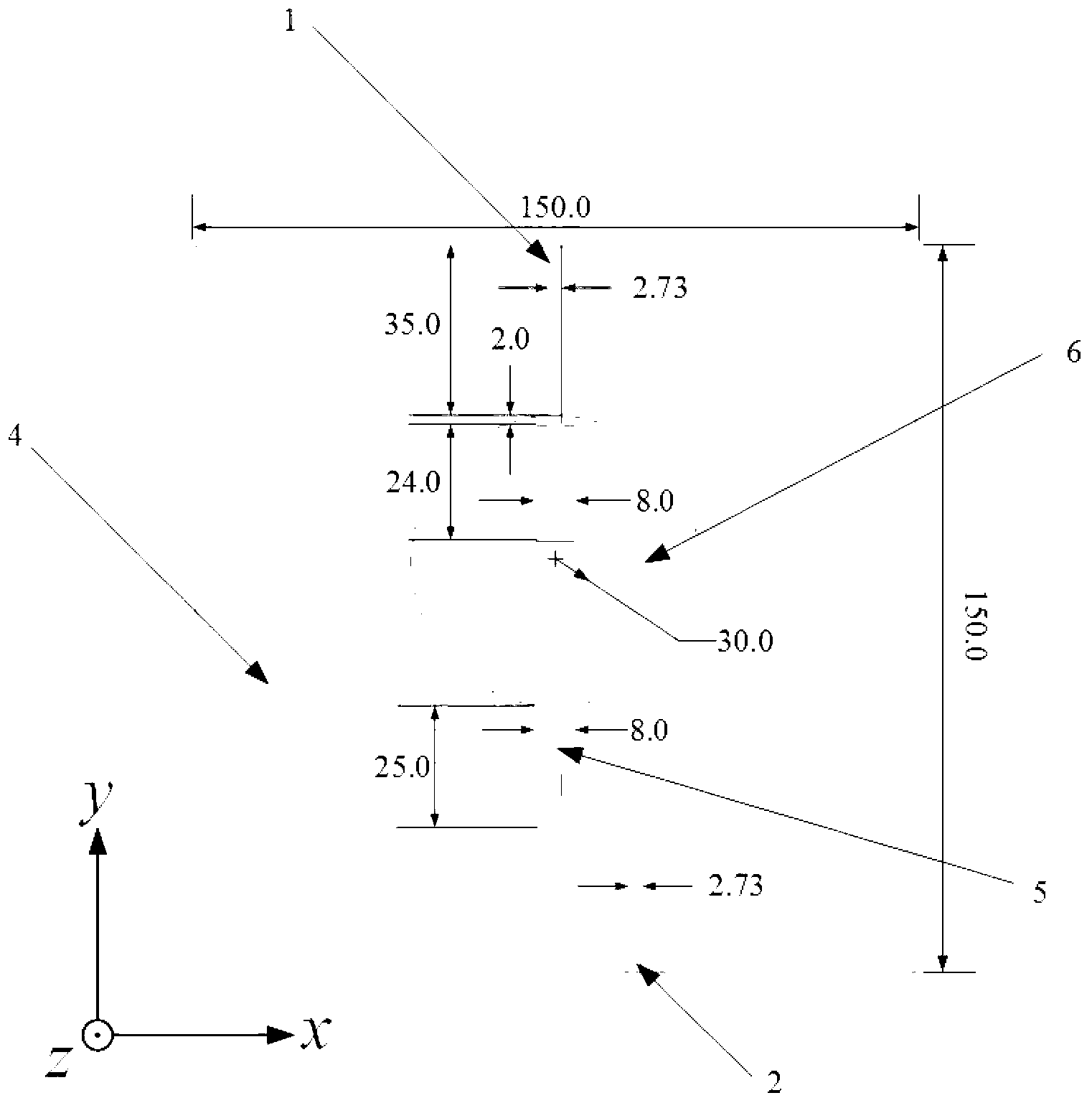

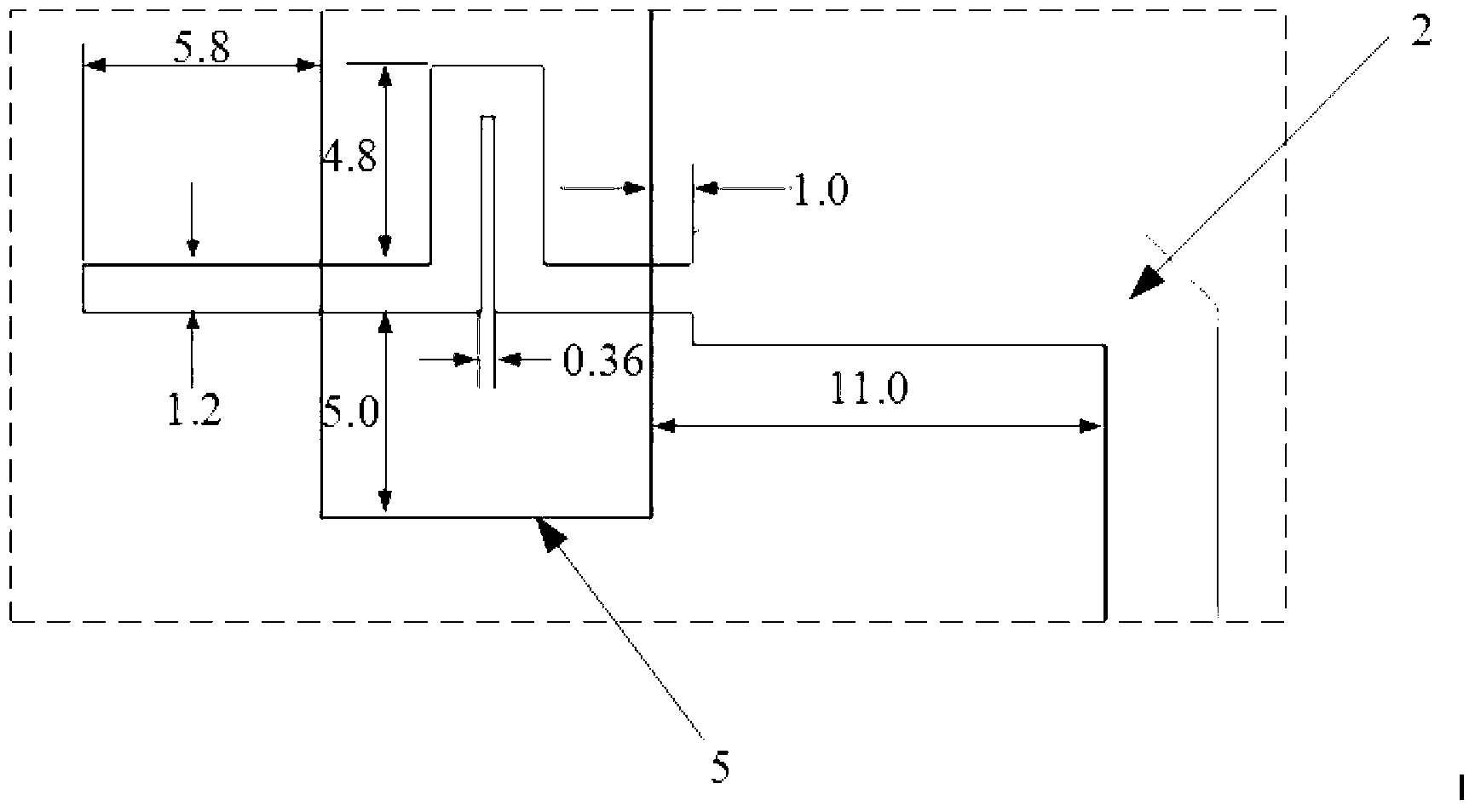

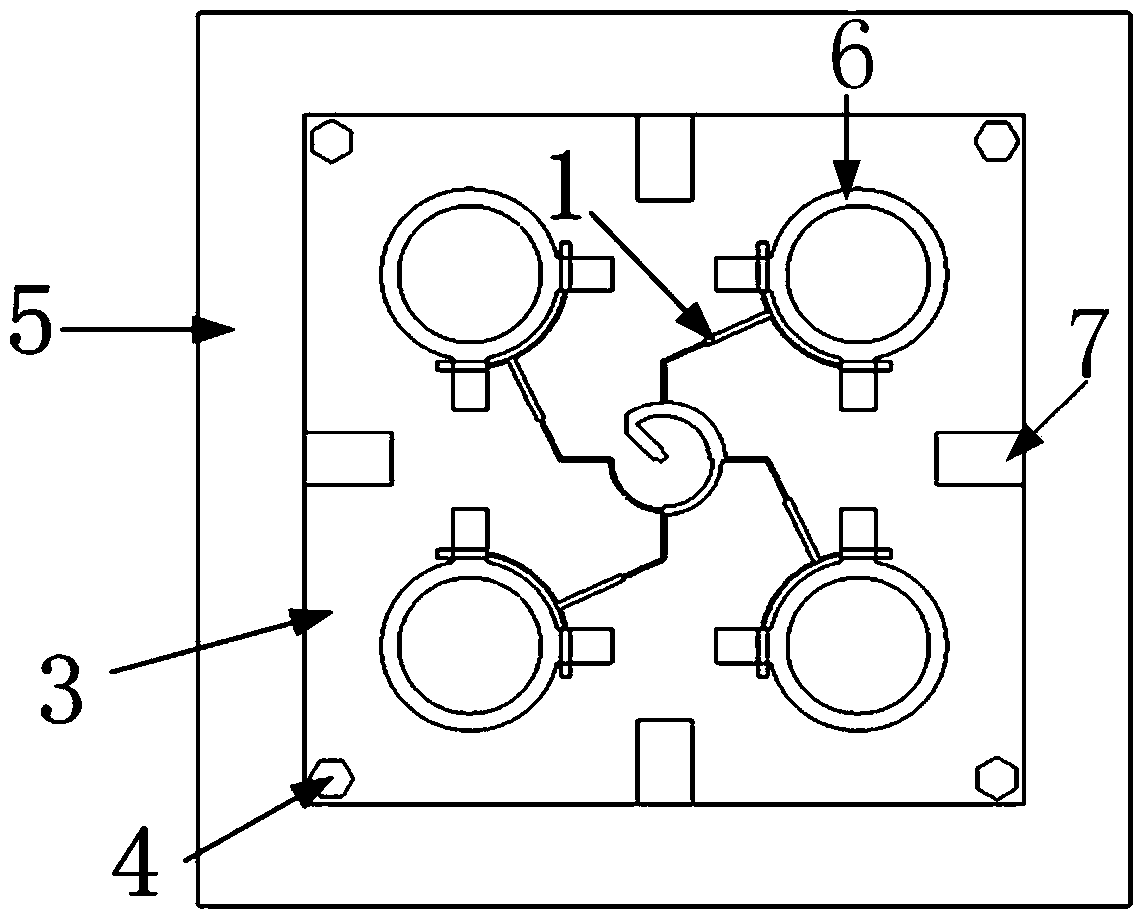

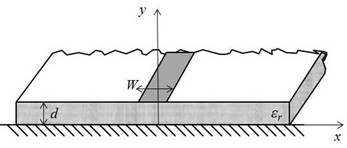

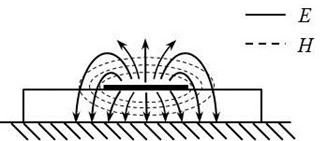

Broadband dual polarized antenna based on single-chip double-sided printed-circuit board

InactiveCN103296424ASimple structureImprove isolationRadiating elements structural formsAntenna earthingsDielectric substrateCross polarization

A broadband dual polarized antenna based on a single-chip double-sided printed-circuit board comprises a dielectric substrate, an earth plate, a monopole feeder line and a buckling feeder line, wherein the earth plate is located on the reverse side of the dielectric substrate, and the monopole feeder line and the buckling feeder line are located on the front side of the dielectric substrate. A circular groove with a thorough crevice is formed in the center of the earth plate, the projection of the monopole feeder line on the earth plate extends from the edge of the circular groove to the inside of the circuit groove, the projection of one side of the buckling feeder line on the earth plate crosses with the crevice perpendicularly, and the side is provided with a buckling structure on the crevice. According to the broadband dual polarized antenna based on the single-chip double-sided printed-circuit board, two cross polarizations are formed through two degenerated TE modes of a circular groove antenna, one polarization is generated theough microstrip line stimulation of a similar monopole, the other polarization is generated through the following steps: firstly, a narrow rectangular crevice forms an electric field on the circular groove antenna through microstrip line stimulation, and then the electric field is coupled on the circular groove antenna. The broadband dual polarized antenna based on the single-chip double-sided printed-circuit board can cover a broader frequency band, and high isolation exists between the two polarizations in all working bands. Further, the polarizations is simple in structure, low in cost, capable of being formed in one time, and good in craft uniformity.

Owner:TSINGHUA UNIV

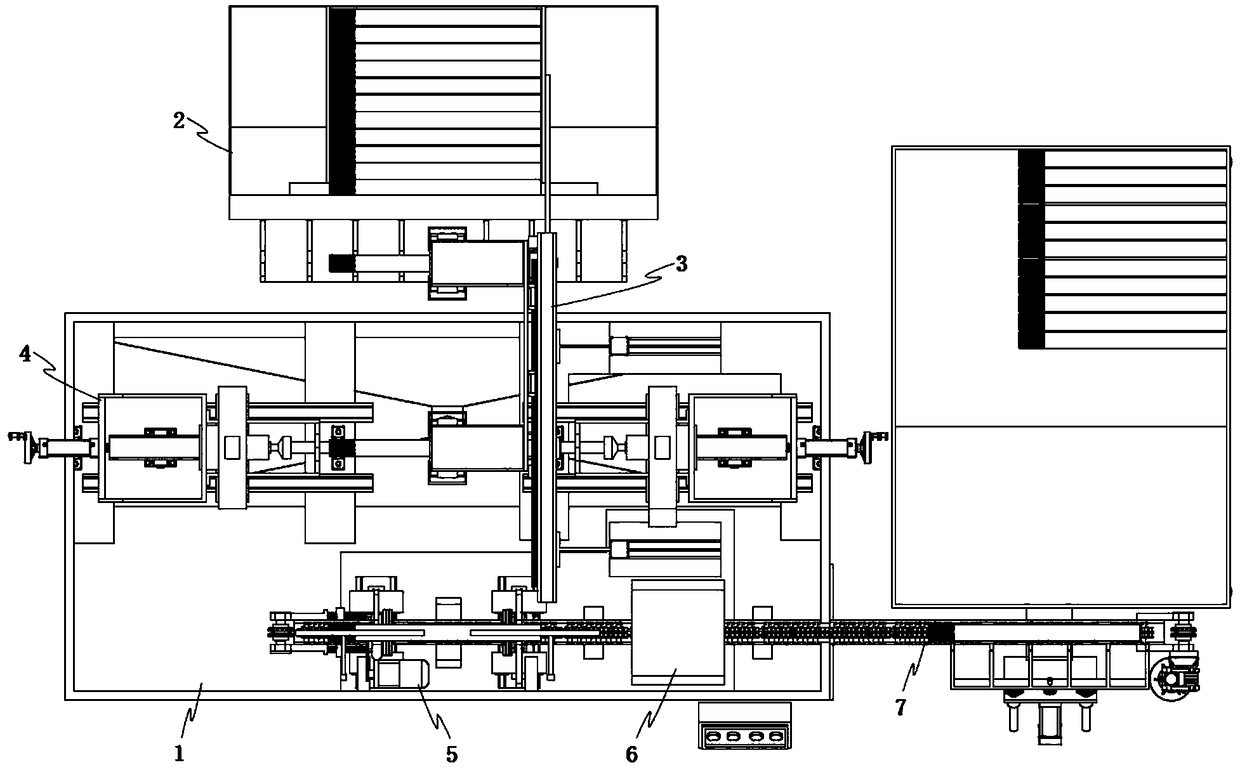

Drilling, grinding and spraying all-in-one machine for transmission shaft machining

InactiveCN108972007AImprove processing efficiencyEnsure processing consistencyOther manufacturing equipments/toolsDrive shaftEngineering

The invention relates to a drilling, grinding and spraying all-in-one machine for transmission shaft machining. The drilling, grinding and spraying all-in-one machine for transmission shaft machiningcomprises a mounting table body, wherein a transmission shaft carrying mechanism, a grinding and drilling mechanism, a spraying mechanism and a baking chamber are arranged on the mounting table body;a transmission shaft input mechanism is arranged on the side, close to the transmission shaft carrying mechanism, of the mounting table body; and a transmission shaft output mechanism is arranged onthe side, close to the spraying mechanism, of the mounting table body. Integrated machining of end face grinding, side wall surface drilling and surface rustproof paint spraying of a transmission shaft is realized, the machining method of grinding and drilling the transmission shaft by operating equipment manually in the past is replaced, not only is the machining efficiency of the transmission shaft improved, but also the machining consistency of the transmission shaft is guaranteed, the accuracy is ensured, meanwhile, rustproof paint is also sprayed on the surface of the transmission shaft,the corrosion protection effect of the transmission shaft is improved, and the service life of the transmission shaft is long.

Owner:杭州佰牛科技有限公司

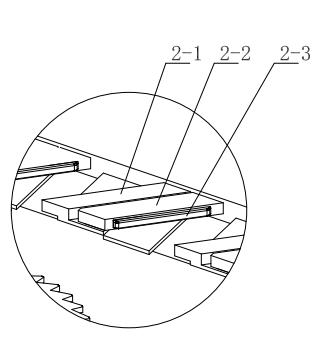

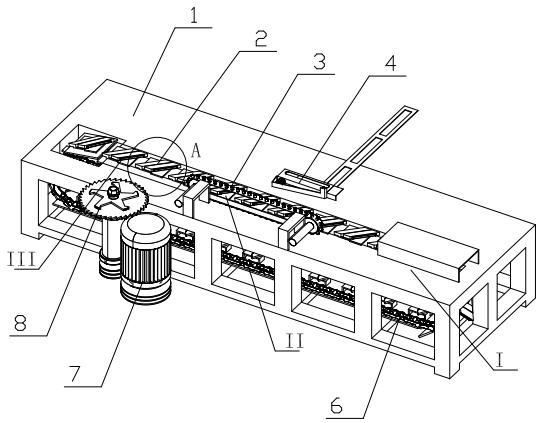

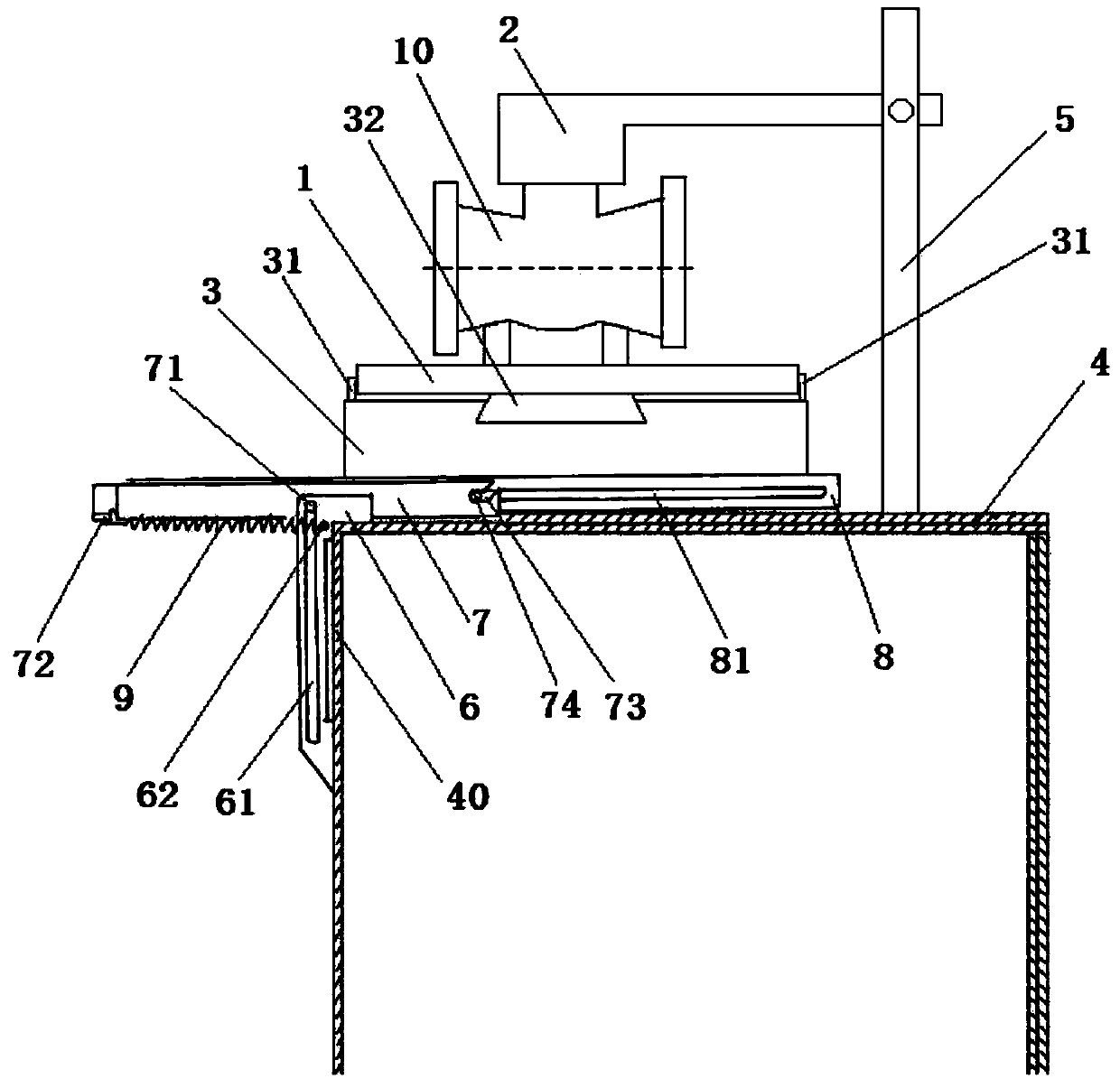

Rotary clamping block caterpillar track for wooden tenon automatic processing machine

ActiveCN102490222ACompact structureImprove clamping effectMitre joint working devicesRelative motionDrive motor

The invention discloses a rotary clamping block caterpillar track for a wooden tenon automatic processing machine. The rotary clamping block caterpillar track is arranged on a machine frame, is driven by a drive motor and a chain, and consists of a plurality groups of moving blocks and fixed blocks which are distributed at an included angle of 45 DEG to a delivering direction; the lateral parts of the fixed blocks are provided with chains; and the moving blocks are arranged on the fixed blocks in a slippage manner. Wooden materials are clamped and loosened by means of the relative motion of the moving blocks and the fixed blocks, and are accurately positioned and limited before being clamped by arranging vertical pressing belts and push-on elastic frames before clamping points. The rotary clamping block caterpillar track has a simple and compact structure and an extremely stable clamping effect, and reliably ensures the processing accuracy and consistency of products.

Owner:WUXI PHOENIX ARTIST MATERIALS

Wideband circular polarization directional antenna array based on single double-face printing circuit plate

ActiveCN103996900AAspect Ratio BandwidthAntenna structure is simpleAntenna arraysRadiating elements structural formsFrequency bandDielectric substrate

A wideband circular polarization directional antenna array based on a single double-face printing circuit plate comprises a dielectric substrate, a crossfeed network located on the front surface of the dielectric substrate, a grooved floor located on the reverse surface of the dielectric substrate, a reflecting plate located under the dielectric substrate and a nylon pillar connecting the dielectric substrate and the reflecting plate. Four unit groove antennas are etched in the grooved floor, each unit groove antenna is composed of an annular groove and two square grooves separately by 90 degrees, and four square grooves are further etched in the edges of the grooved floor to improve the gain characteristic of the array. A microstrip line of the tail end of the crossfeed network crosses the two square grooves of each unit groove antenna on the grooved floor, thereby exciting the unit groove antennas. Unit circular polarization is achieved through two orthogonal modes of the annular groove antennas and a feed method with the phase difference of 90 degrees, and a 2*2 antenna array is achieved through the crossfeed network. The wideband circular polarization directional antenna array based on the single double-face printing circuit plate can cover a wider frequency band, and meanwhile is simple in structure, low in cost, capable of being formed at one time and good in process consistency.

Owner:TSINGHUA UNIV

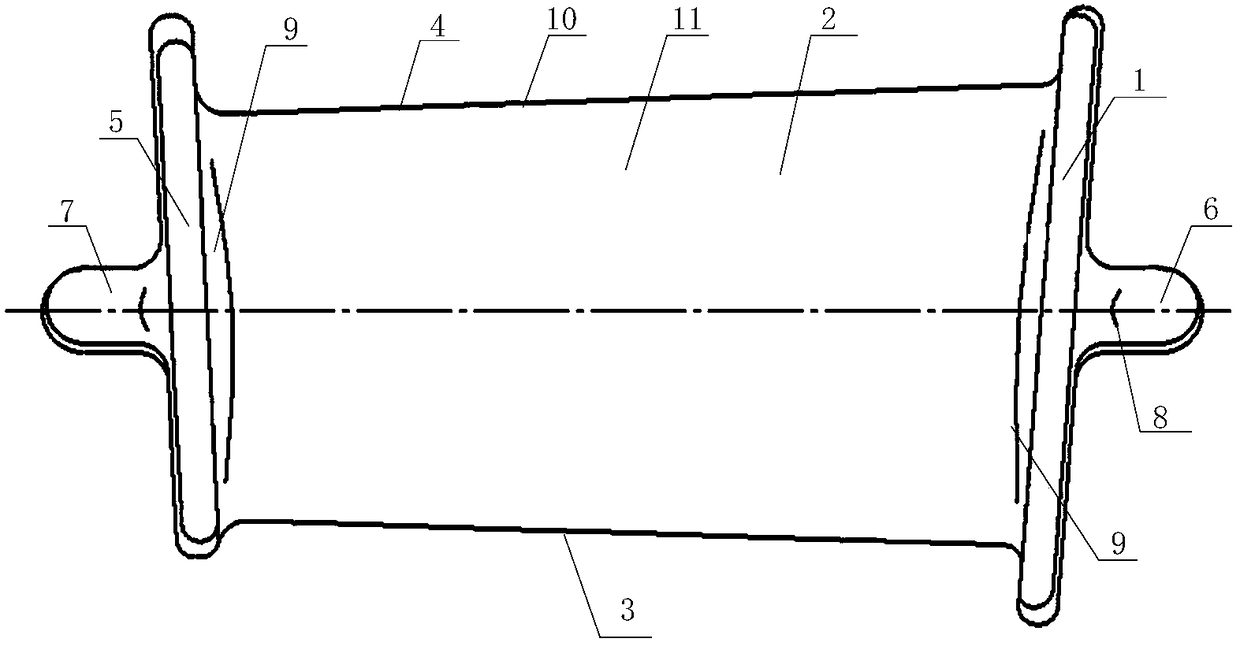

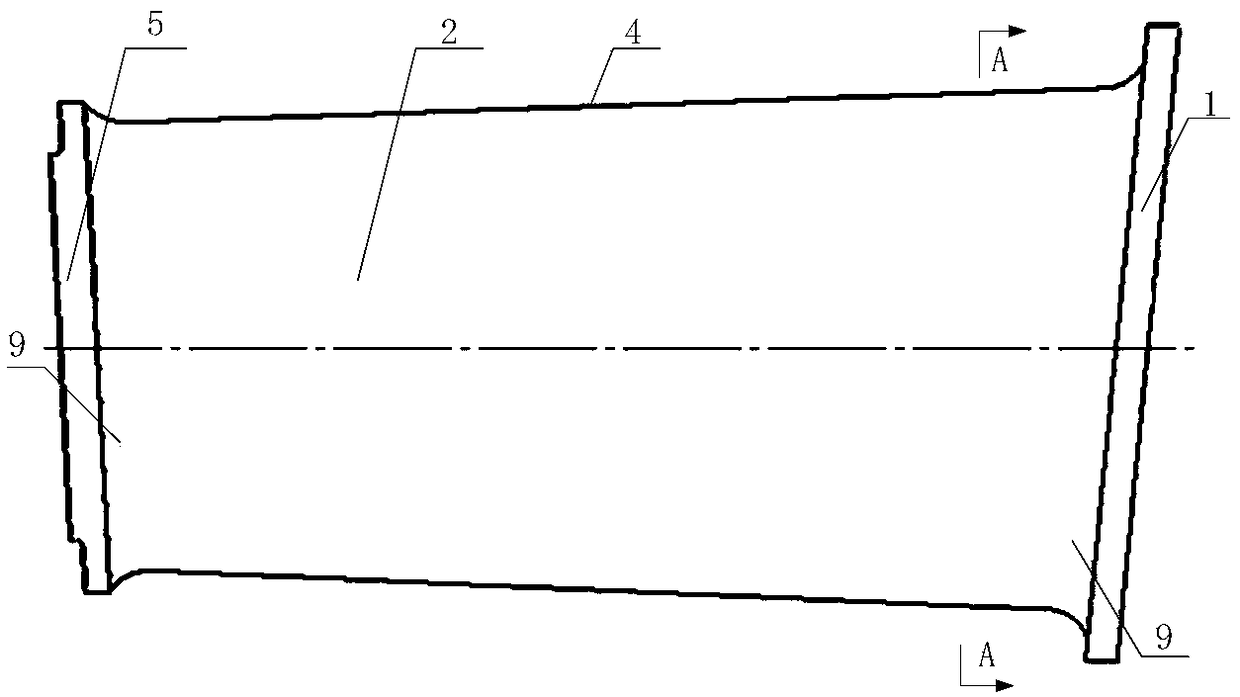

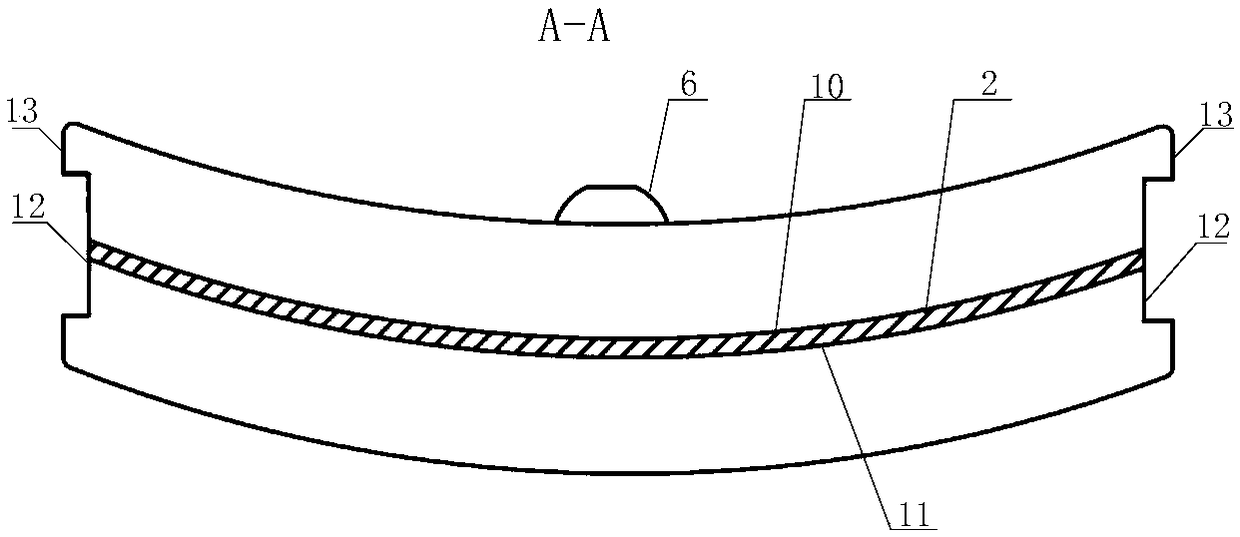

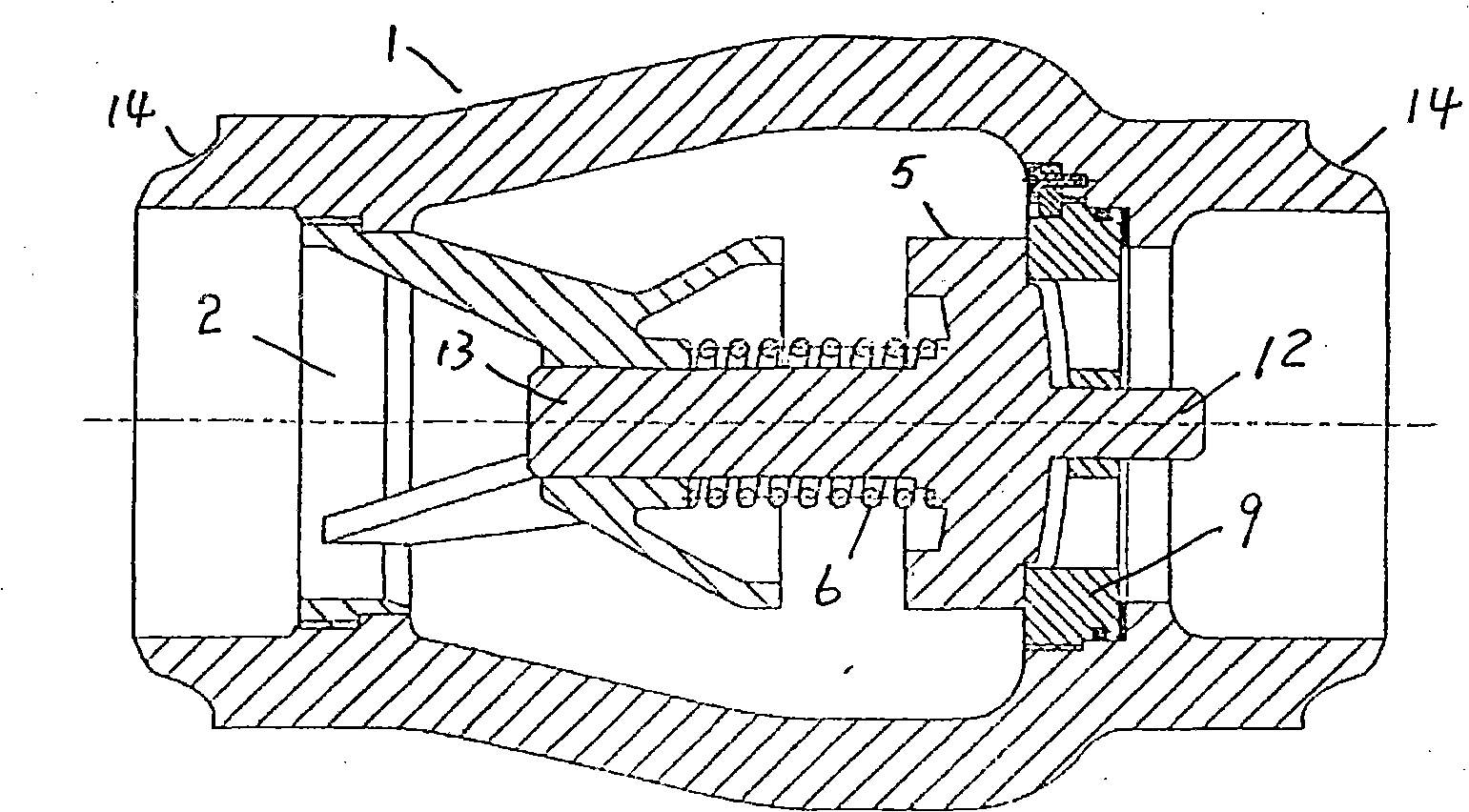

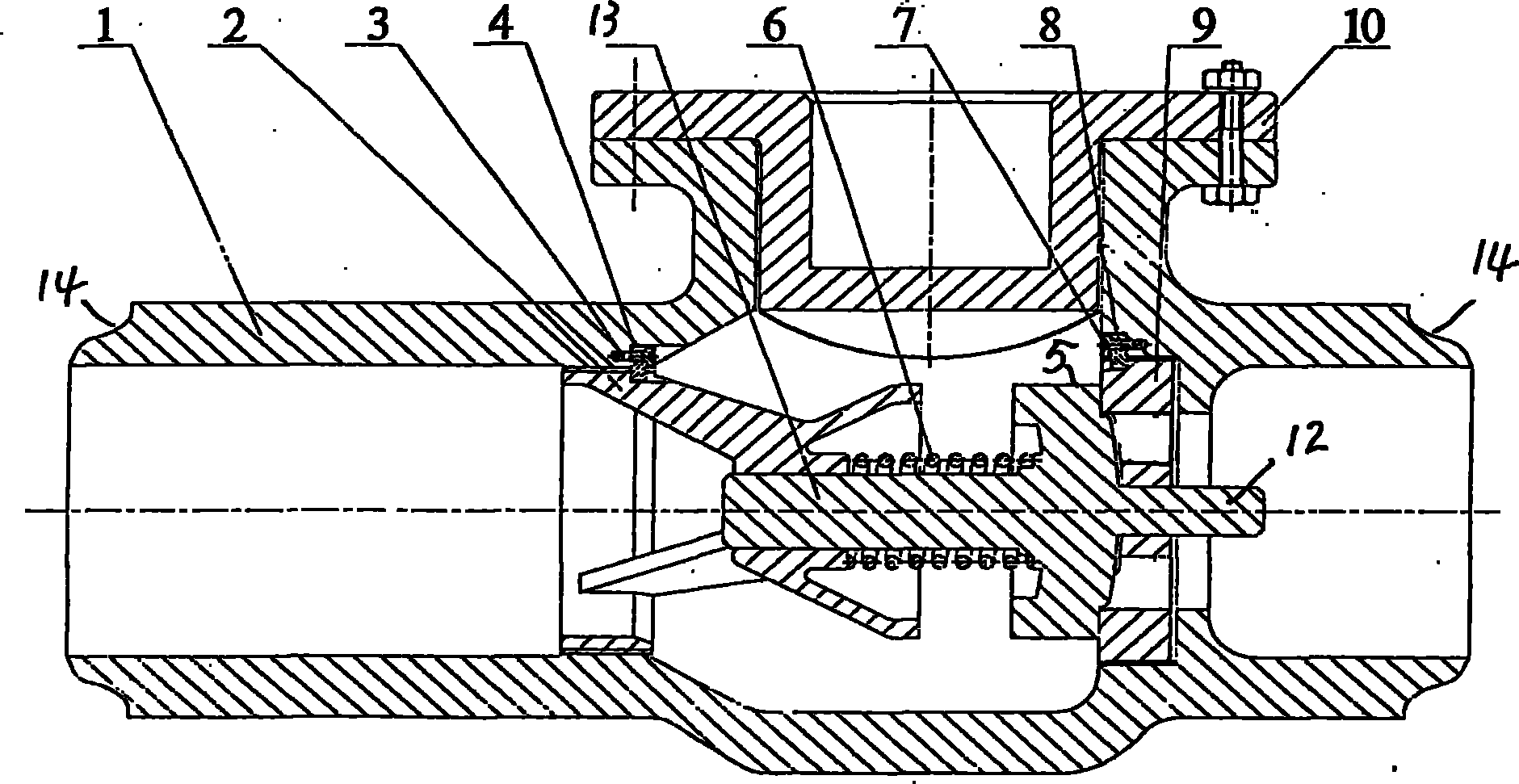

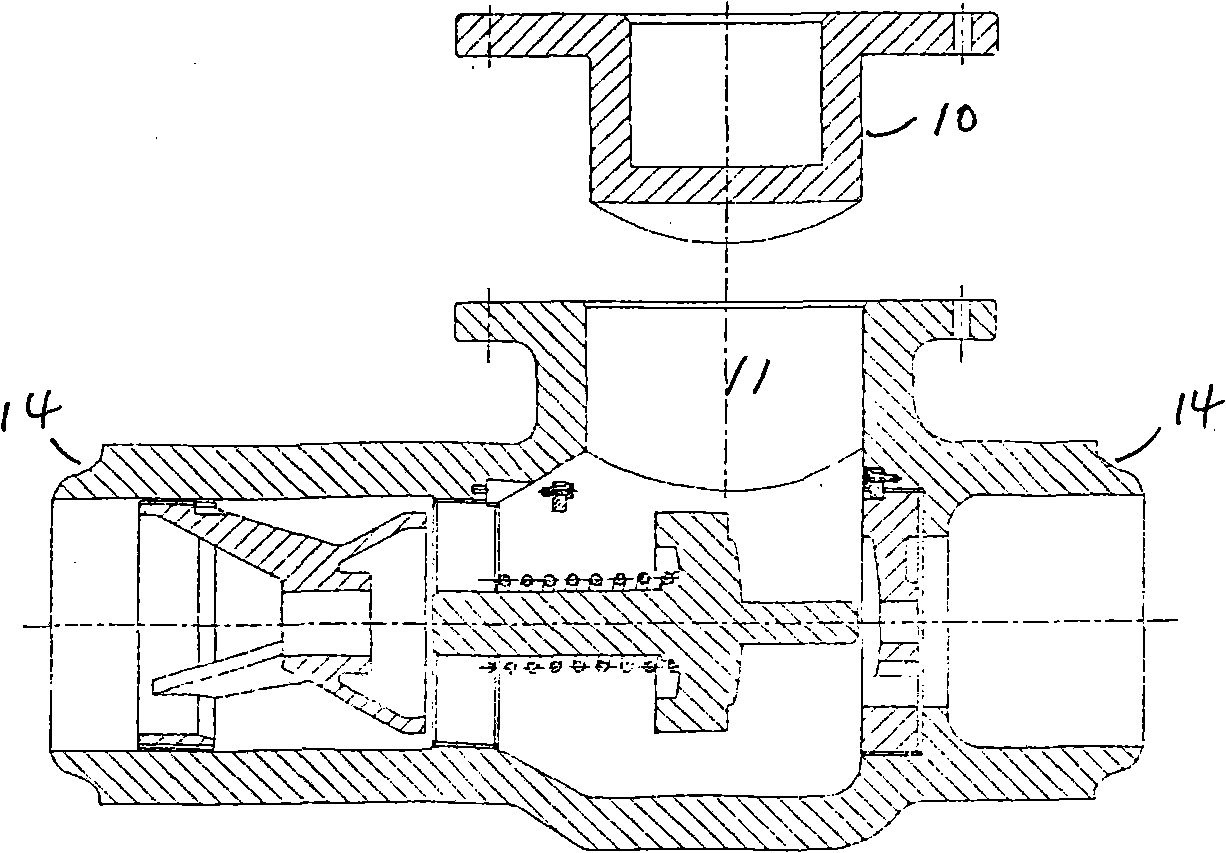

Shuttle-type high-temperature and high-pressure welding check valve

InactiveCN101776168ASimple structureSmall opening and closing resistanceCheck valvesValve housingsCouplingEngineering

The invention relates to a shuttle-type high-temperature and high-pressure welding check valve and solves the problems that the welded check valve cannot be installed at any angle and leakage happens easily. In the shuttle-type high-temperature and high-pressure welding check valve, a middle cavity of a valve body (1) is connected with a coupling at two axial ends, and an outer wall of a port of the coupling is provided with a welding groove (14); the two axial ends of the middle cavity and a connecting passage of the coupling are fixedly connected with a valve bush (2) and a front bearing (9) respectively; a valve flap (5) is in rigid connection with a front shaft (12) and a back shaft (13) which are coaxial; and the front shaft (12) is in movable fit with an axial central hole of the front bearing (9), the back shaft (13) is in movable fit with an axial central hole of the valve bush (2), and the back shaft (13) is sleeved with a spring (6).

Owner:WINJET HIGH TECH INVESTMENT BEIJING

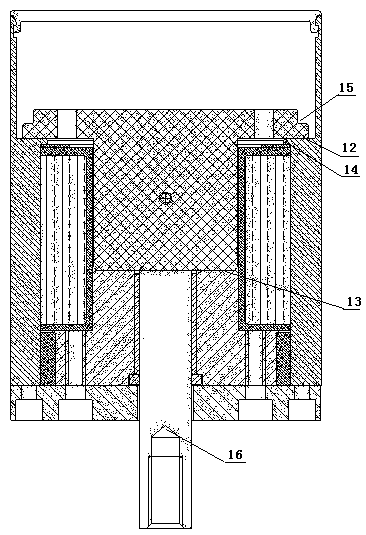

Steel ball pressing device and crankshaft production equipment

The invention provides a steel ball pressing device and crankshaft production equipment and relates to the field of engines. The steel ball pressing device comprises a pressing head assembly and a power device, wherein the pressing head assembly comprises a pressing rod used for pressing a steel ball into a crankshaft oil hole and a riveting rod used for pressing a rivet into the crankshaft oil hole, wherein the pressing rod and the riveting rod are arranged side by side; and the power device comprises a piston rod used for pushing the pressing rod or the riveting rod, and the piston rod can be driven by a switching mechanism to selectively act on the pressing rod or the riveting rod so as to realize the accurate and rapid switching of a steel ball pressing procedure and an oil hole blocking procedure. Besides, the steel ball pressing device well avoids the problems of low processing precision, poor technical reproducibility and the like, occurring in the manual processing process by using the power device to provide pressing power. The crankshaft production equipment comprising the steel ball pressing device can well keep technical consistency and can produce high-quality crankshafts in a high-reproductive manner.

Owner:银川合宜科技有限公司

Work fixture for processing brake valve body

InactiveCN104209787AEasy and fast rotation operationReduce machining errorsLarge fixed membersPositioning apparatusGate valveFlange

The invention discloses a work fixture for processing a brake valve body. The work fixture comprises a rotary tray for fixing a base of the valve body, a cover plate for pressing and giving the clamping force to a flange in the valve body, and a transform component arranged on the bottom part of a chassis and the right-angle sides of a fixed platform, wherein the rotary tray is arranged on the chassis; the chassis is arranged on the fixed platform with corners being right angle; a stop pin for fixing the rotary tray is arranged on the chassis; a stand column for supporting the cover plate is arranged on the fixed platform; the cover plate is detachably connected with the stand column; the transform component is used for transforming the chassis to be in the vertical state from the horizontal state along the right-angle sides of the fixed platform. The work fixture for the processing brake valve body is compact in structure, convenient to disassemble and assemble, simple and convenient to operate, safe and reliable, and strong in universality; the processing of multiple parts of the valve body can be finished through one-time clamping, and the processing efficiency can be greatly improved; the processing error can be reduced, the consistency of processing is ensured, and the processing quality is ensured; mass processing production can be carried out favorably.

Owner:SUZHOU FURUN MACHINERY

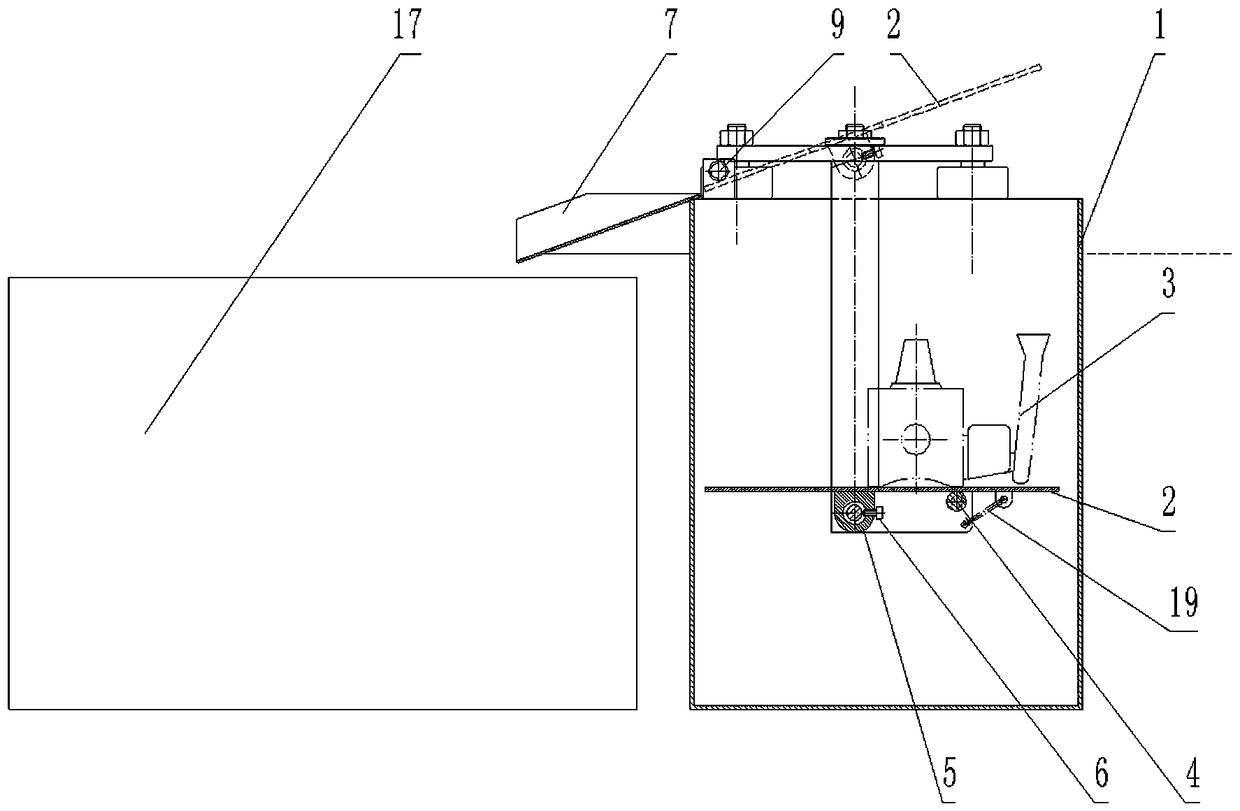

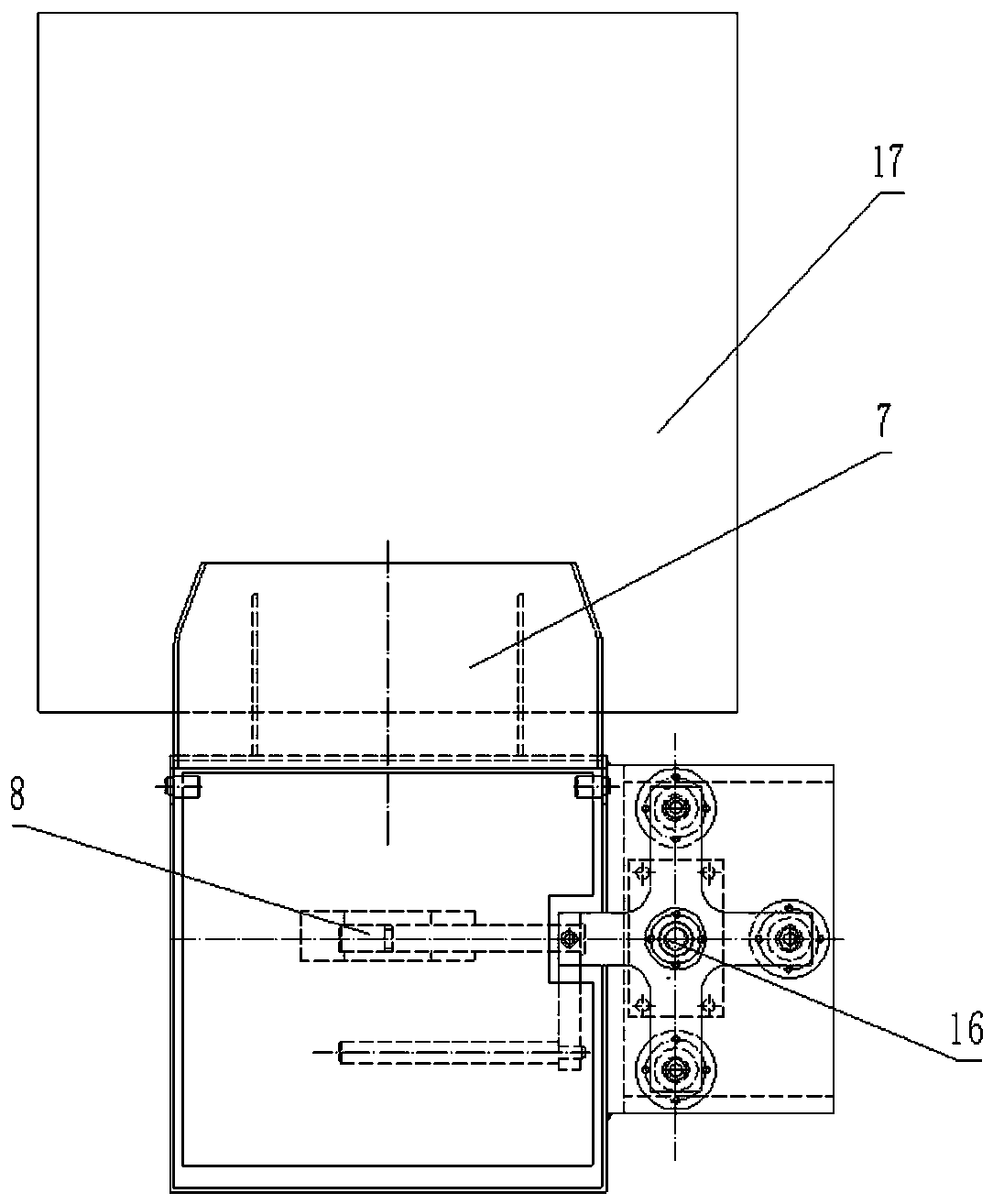

Piston automatic quenching device and method based on incomplete solution treatment technology

InactiveCN108103281ASave energy and man hoursIncrease productivityFurnace typesHeat treatment process controlQuenchingPiston

The invention discloses a piston automatic quenching device based on an incomplete solution treatment technology. The piston automatic quenching device comprises a quenching water tank, wherein a lifting mechanism is arranged outside the quenching water tank; a material receiving plate bracket is arranged along the vertical direction in the quenching water tank; a material receiving plate supportis arranged along the horizontal direction at the lower end of the material receiving plate bracket; the material receiving plate support is connected with a material receiving plate; the lifting mechanism is connected with the material receiving plate bracket; the piston automatic quenching device also comprises a material receiving plate tilting device for driving the material receiving plate totilt for material discharge; the piston automatic quenching device further comprises a material discharge device. The device can work independently or in combination, realizes automation and programcontrol of the quenching process, and can guarantee the quenching quality and process stability and reduce the labor intensity of workers.

Owner:ANHUI WHITE RABBIT POWER

Fixing device for electrode processing

InactiveCN103381514AGuaranteed machining accuracyEnsure processing consistencyEngineeringProcessing cost

The invention relates to a fixing device for electrode processing by adopting the injection mold submarine gate electric spark. The EROWA locating plate of the fixing device is fixed at the lower part of a base, a small circular hole and a big circular hole are formed in the central symmetry positions of two U-shaped side surfaces of the base respectively, pin holes are formed in the central positions of the upper parts of the U-shaped side surfaces of the base, by taking the perpendicular edges of the base and the pin holes as the axis, a plurality of angle holes are symmetrically formed along the two edges of each pin hole, a bearing is mounted in the big circular hole, square nuts are mounted in square grooves, an upper through hole and a lower through hole are formed in the upper part of a locking lever, a shoulder bolt is matched with the bearing and the square nuts through the lower through hole to tightly fix a locking rod on the base, side plane surfaces of the locking rod are oppositely fitted with the U-shaped inner side surfaces for positioning, and a pin fixes the locking rod in the different positions in different angles through the upper through hole. The device has the advantages that the design is artistic, the operation is stable, the structure is compact, the processing operation is convenient, and the adjustable angle of the electrode is enlarged, so that the processing accuracy and consistency of the submarine gate are ensured, the work difficulty of operators is reduced, the processing cost of a die is reduced, and the application scope is wide.

Owner:TIANJIN ZHONGHUAN SANFENG ELECTRONICS

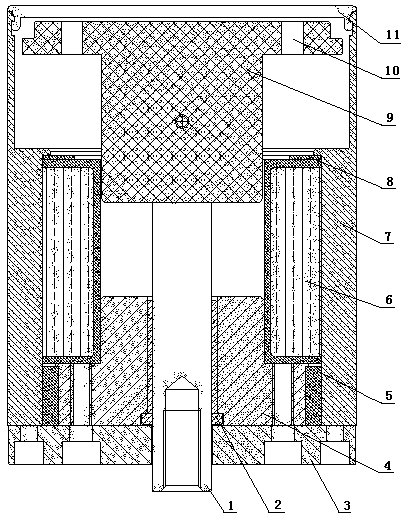

Magnetic latching operating mechanism capable of being directly opened by microcomputer protection device

PendingCN111477501AEnsure processing consistencyElectromagnetic relay detailsNon-polarised relaysMagnetic reluctanceEngineering

The invention discloses a magnetic latching operating mechanism capable of being directly driven to be opened by a microcomputer protection device. The magnetic latching operating mechanism is composed of a driving shaft, a guide sleeve, a lower magnetic insulation plate, a cylindrical inner magnet yoke, a permanent magnet, a magnet exciting coil, a cylindrical outer magnet yoke, a gasket, a cylindrical movable iron core armature and an upper magnetic insulation plate. According to the invention, by improving the working voltage of the magnet exciting coil, reducing the size of the magnet exciting coil, improving the magnet yoke structure, reducing the magnetic conduction magnetic resistance and winding the magnet exciting coil according to specific working parameters, the microcomputer protection device can protect output driving parameters, direct driving opening of the microcomputer protection device is achieved, and the protection tripping time of a middle-high voltage circuit breaker is shortened; and the line resistance of the magnet exciting coil can be improved, the closing driving current and the saturated conduction current are reduced, and the heating damage risk of themagnet exciting coil is reduced.

Owner:胡春生

Fixture for roof prism gluing part production

The invention discloses a fixture for roof prism gluing part production, and belongs to the technical field of optical component production. The fixture for roof prism gluing part production comprises a base, two limit blocks, three square flat plates, a 45-degree rest and a square brick. Glue grooves are formed in the middles of the limit blocks, a glue groove is formed in the middle of a large surface of the 45-degree rest, the square brick has a 90-degree angle, angular accuracy is within 1', the two limit blocks are vertically used, the three square flat plates are placed among the two limit blocks and the base and between a semi-finished product and the base, the surface evenness of the base is lambda / 4, the finish degree of the base is second level, accuracy of the 90-degree angle of the limit blocks is within 30', and the tolerance of the square flat plates is + / -0.01mm. Processing accuracy of a roof ridge surface is ensured, processing cycle is shortened, working efficiency and angular accuracy are improved, dimensional errors are decreased, and product qualification ratio is increased.

Owner:JIANGNAN OPTICS CO LTD

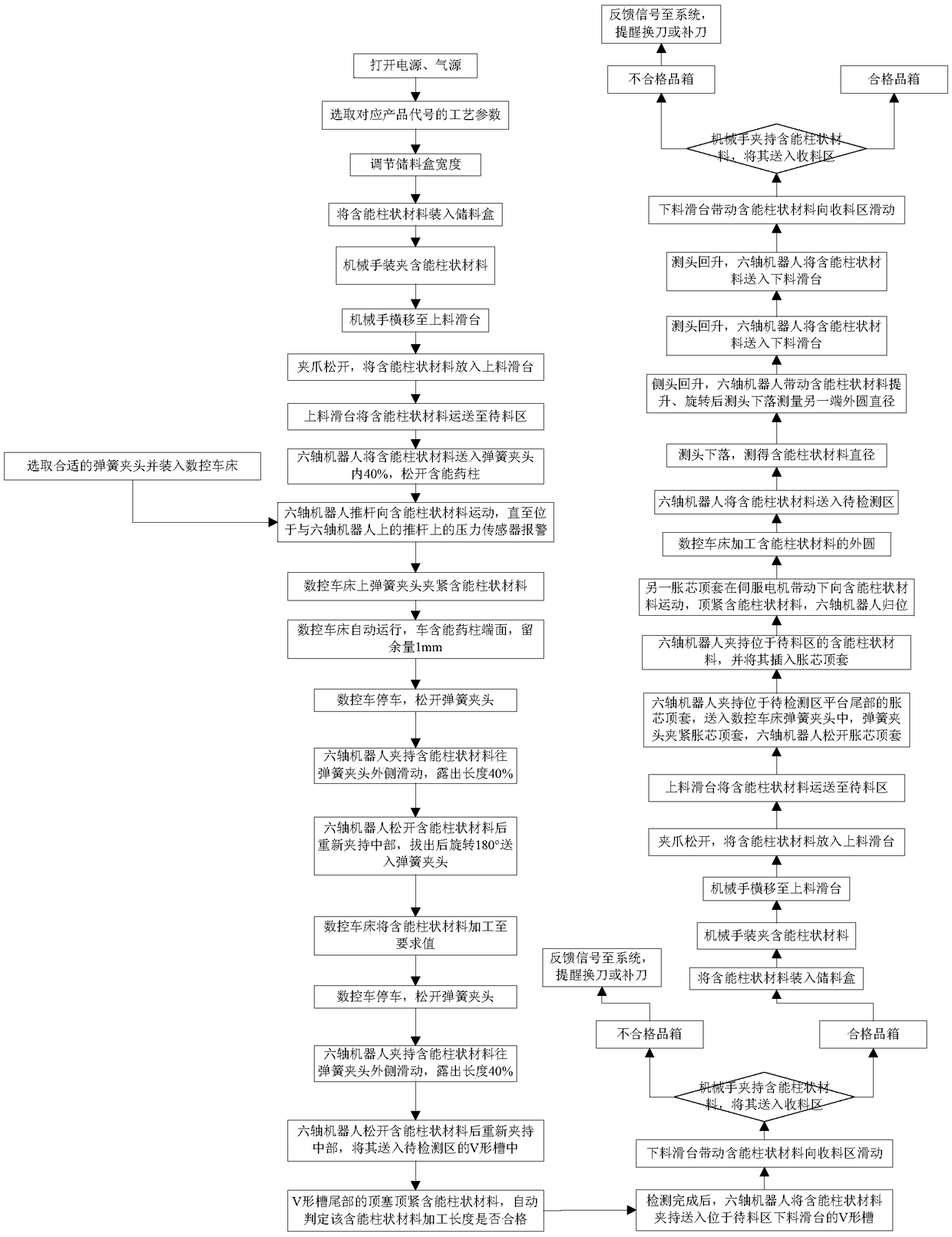

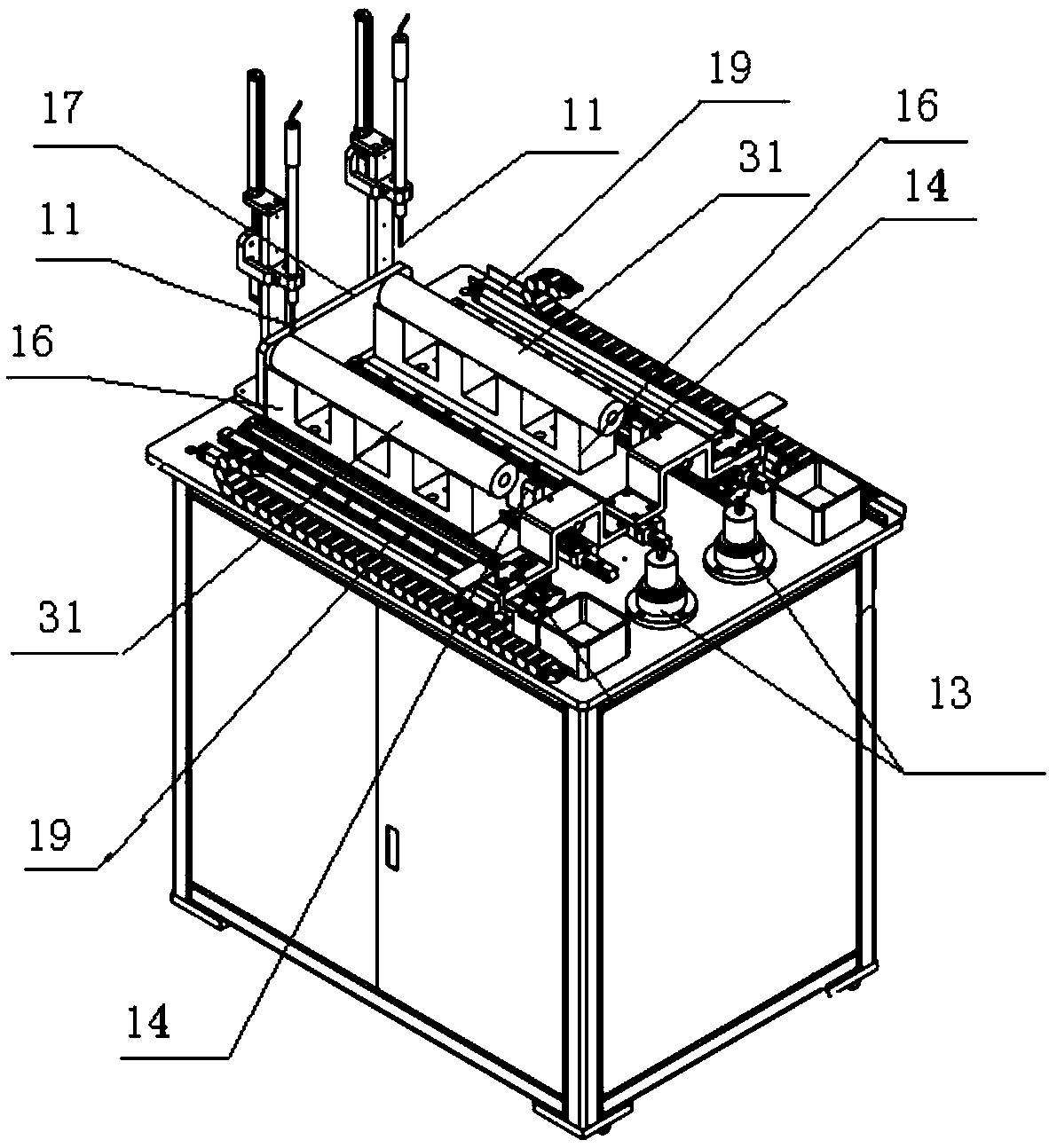

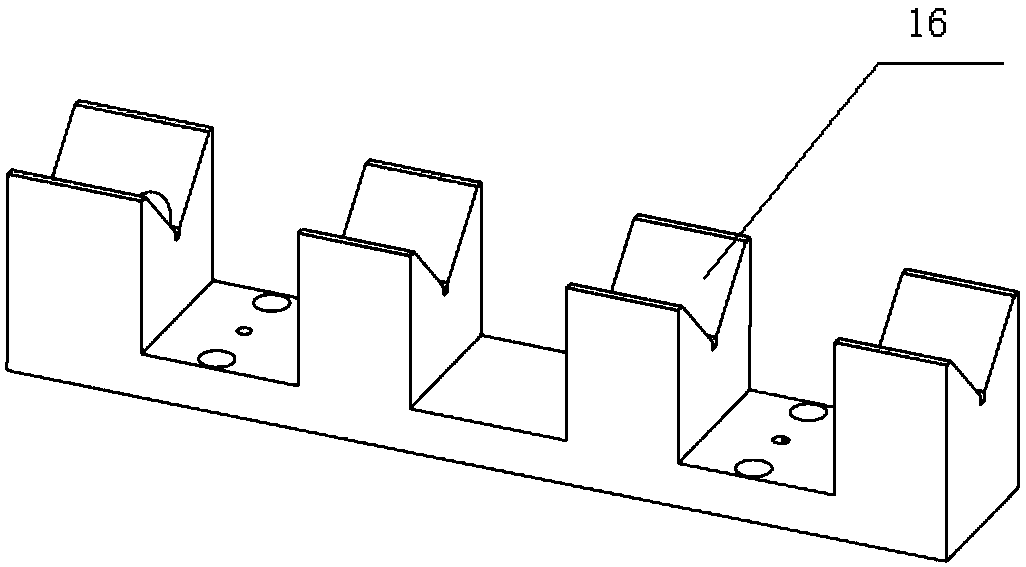

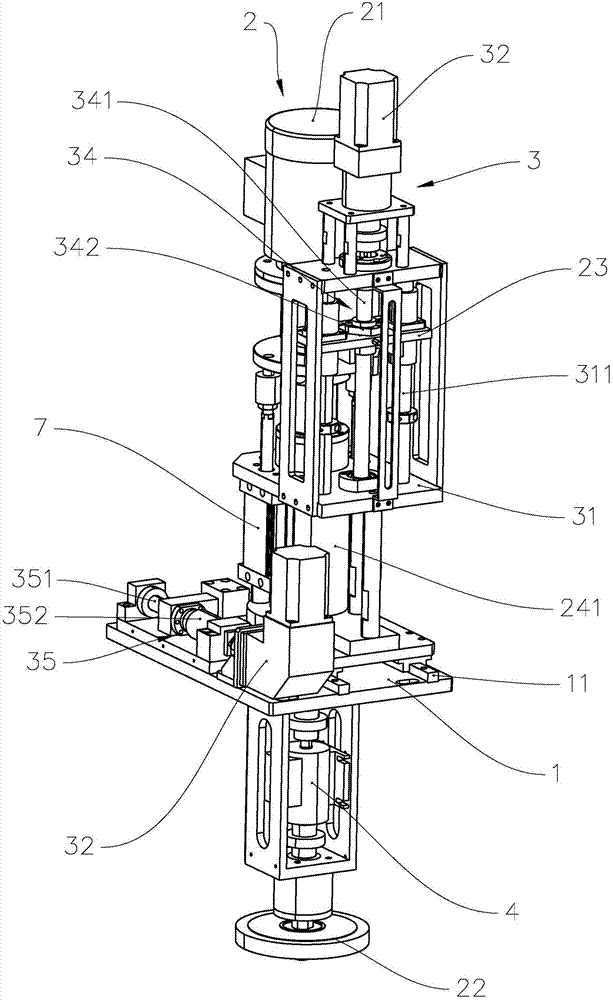

Automatic machining and detecting device of energy-containing columnar material for aerospace fire work device

The invention discloses an automatic machining and detecting device of an energy-containing columnar material for an aerospace fire work device. The automatic machining and detecting device comprisesa detecting module, a robot module and a feed and discharge module. The detecting module comprises a detecting head, a top plug, a V-shaped block, a baffle and a first slide rail which are located ona detecting platform. The energy-containing columnar material is placed on the V-shaped block. The V-shaped block is composed of at least two V-shaped structures. The detecting head above the V-shapedblock is of a bulb structure. The detecting head is connected with a displacement sensor, the displacement of the detecting head moving in the direction perpendicular to the detecting platform is measured, and the diameter of the energy-containing columnar material is obtained. The top plug is placed on the first slide rail and connected with the displacement sensor and moves along the first slide rail, and the length of the energy-containing columnar material is obtained. The robot module is used for clamping the energy-containing columnar material. The feed and discharge module comprises arejected product collecting box, a qualified product collecting box, a feed slide table, a mechanical hand, a discharge slide table, a material storage box, a second slide rail and a third slide rail.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

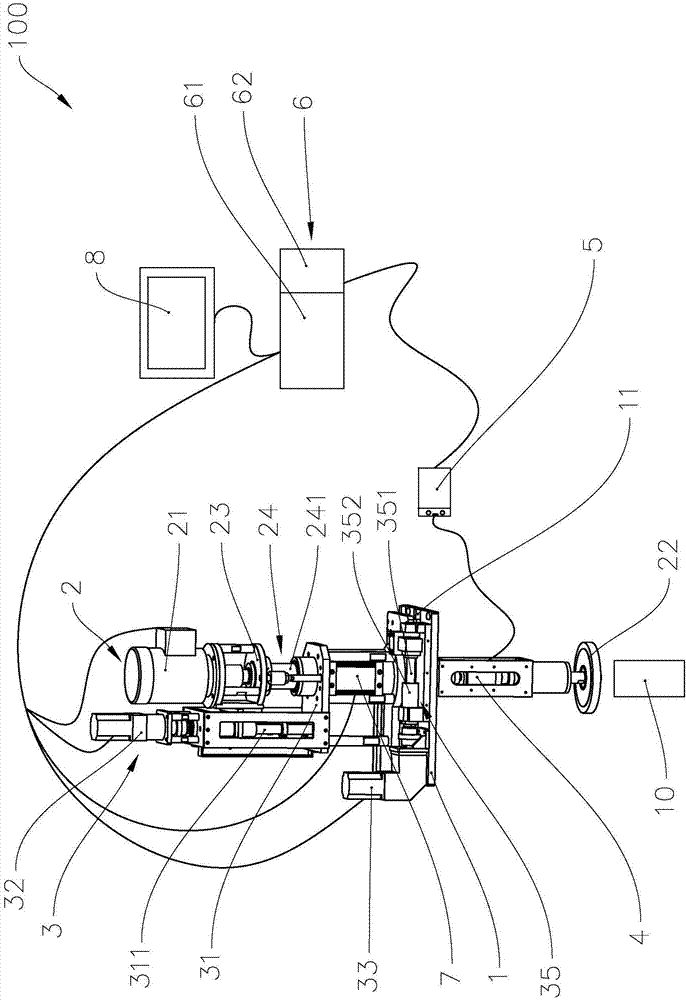

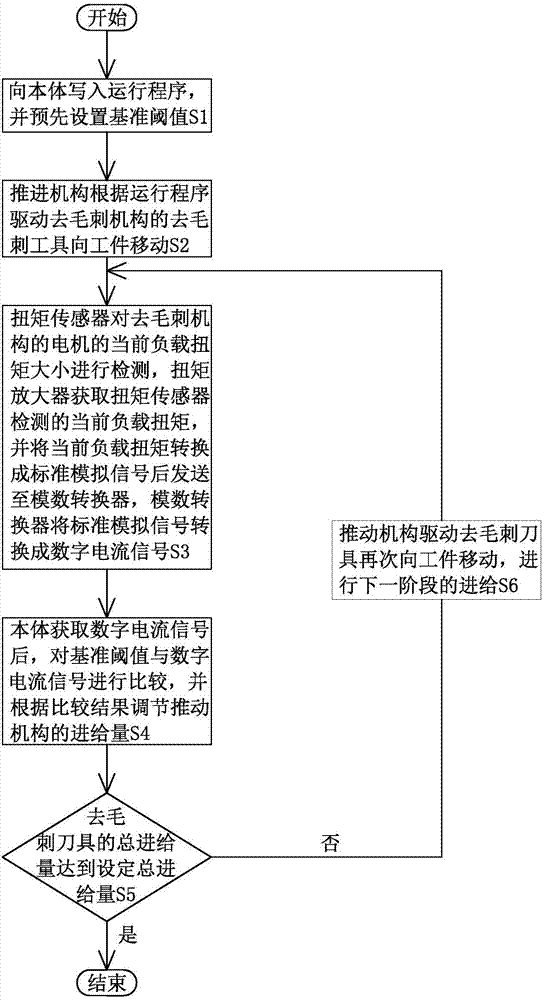

Burr removing machining method based on torque control and burr removing system

PendingCN107971858AGuarantee processing qualityEnsure processing consistencyEdge grinding machinesGrinding drivesCurrent loadLoad torque

The invention provides a burr removing machining method based on torque control and a burr removing system. The burr removing system comprises a pushing mechanism, a burr removing mechanism with a motor, a torque sensor, a torque amplifier and a controller with a body and an analog-digital converter. The burr removing machining method comprises the steps that a run program is written into the body, and a standard threshold value is set in advance; a burr removing tool is driven by the pushing mechanism according to the run program to move to a workpiece; the current load torque of the motor isdetected through the torque sensor, the current load torque is converted into standard analog signals through the torque amplifier, and the standard analog signals are converted into digital currentsignals through the analog-digital converter; and the digital current signals are obtained by the body, the standard threshold value is compared with the digital current signals, and the feeding amount of the pushing mechanism is adjusted according to the comparative result. By means of the burr removing device and the burr removing machining method, the burr removing tool feeding amount can be adjusted according to friction force borne by the burr removing tool, and the beneficial effects of being high in machining accuracy and good in machining quality are achieved.

Owner:GUANGDONG HESHI AUTOMATION TECH CO LTD

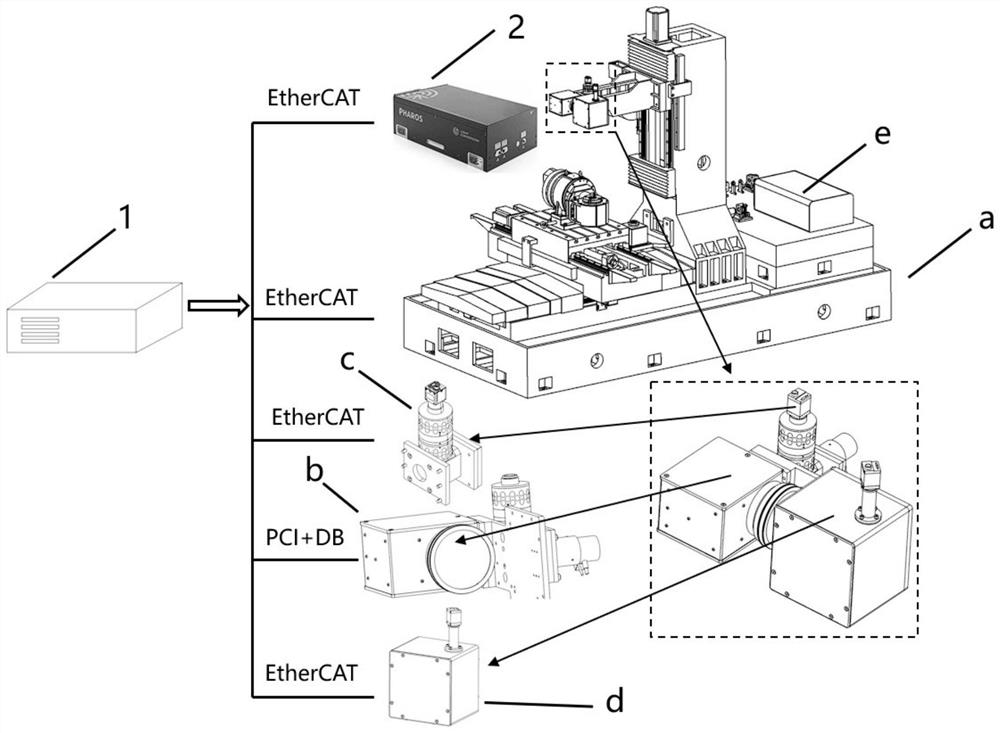

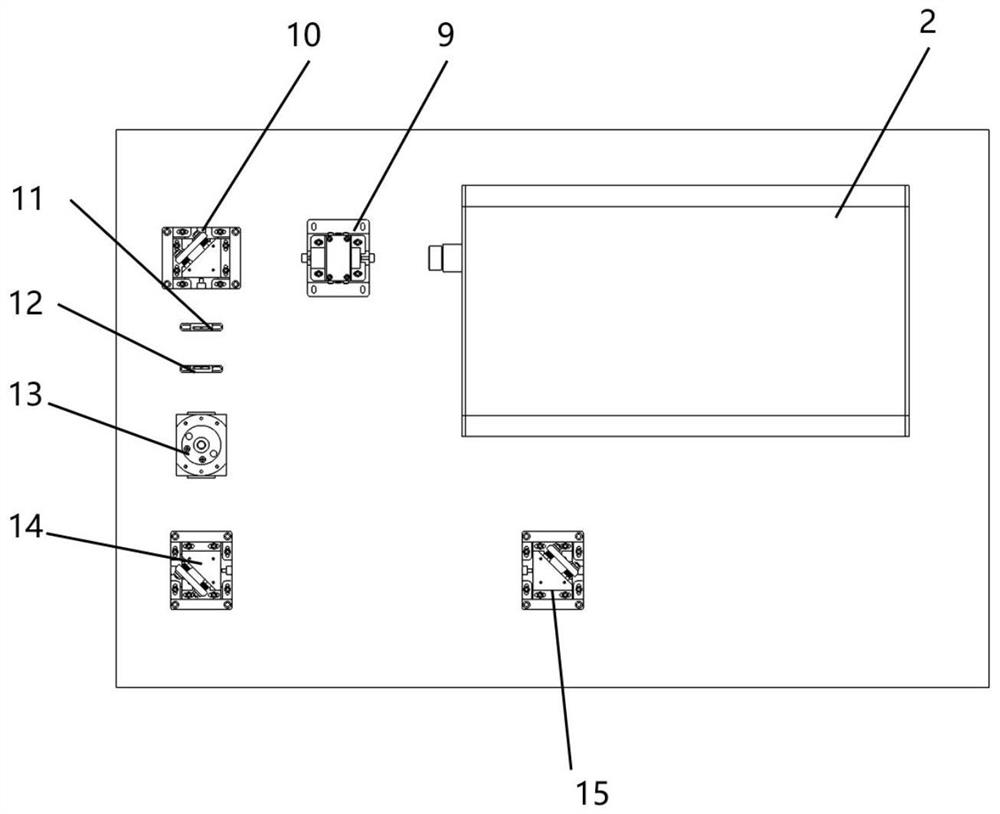

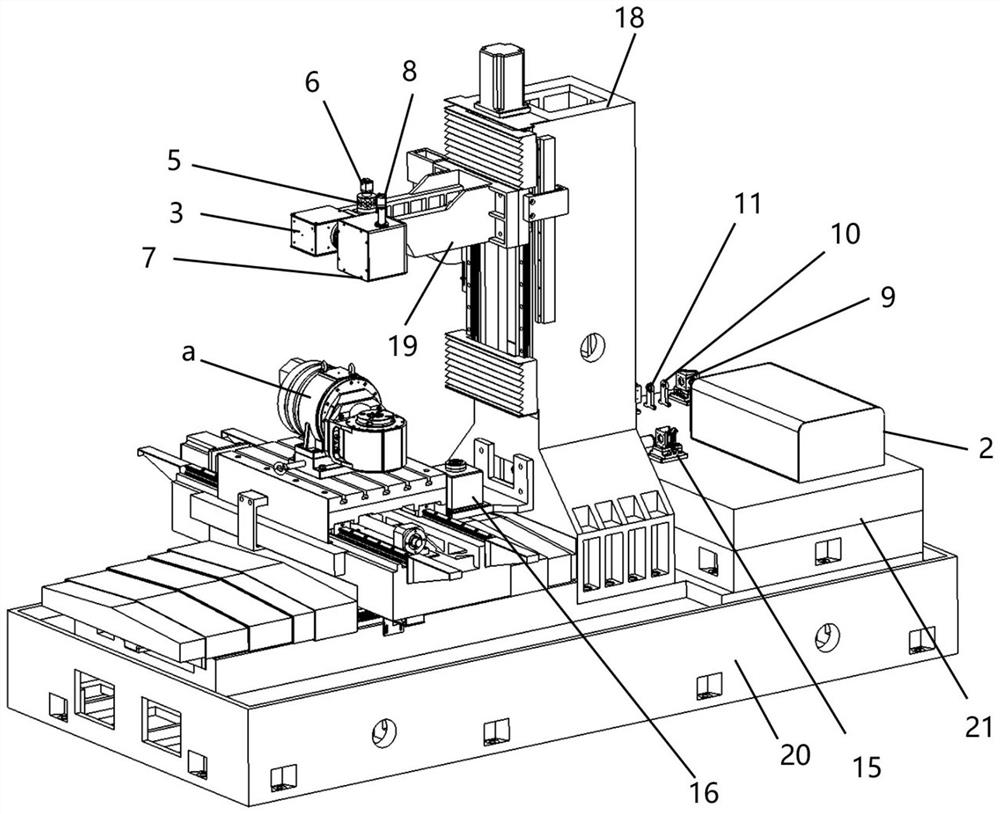

Multi-axis laser processing system for error on-machine detection and correction

PendingCN113427134AImprove processing qualityHigh precisionLaser beam welding apparatusNumerical controlLaser processing

The invention discloses a multi-axis laser processing system for error on-machine detection and correction. The system comprises a five-axis numerical control machine tool, a femtosecond laser system, a three-dimensional galvanometer scanning system, an in-situ visual detection system, a light beam stabilizing system and an industrial personal computer. The system has on-machine in-situ measurement capability and a light beam real-time automatic collimation function for complex components, the built pose error detection and correction can be realized, the laser focus position can be controlled in real time by the three-dimensional galvanometer only through one-time clamping without designing a special clamp, the surface etching capability is realized, the system is also suitable for deep hole machining, the machining flexibility is improved, the femtosecond laser machining precision is high, the machining quality is good, and the five-axis numerical control machine tool is large in stroke, high in load capacity, large in freedom degree and capable of achieving precise machining of large-breadth complex curved surface components.

Owner:XI AN JIAOTONG UNIV

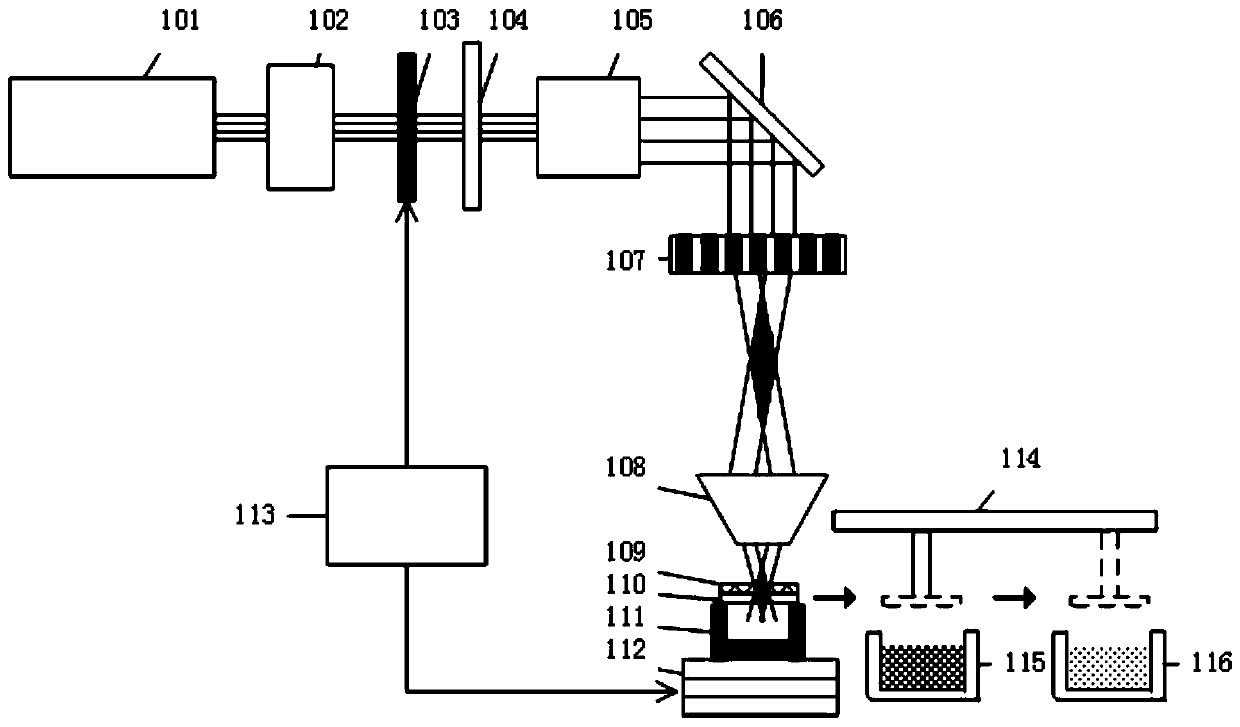

Hard and brittle material complex component femtosecond laser precision forming processing system

ActiveCN110788500AAvoid pollutionReduce thermal stressLaser beam welding apparatusFemto second laserElectric control

A hard and brittle material complex component femtosecond laser precision forming processing system comprises a femtosecond laser, a laser tuning module, a mechanical optical shutter, a laser polarization module, a variable-magnification beam expander, a plane reflector, an optical diffraction element, a filamentation modification module, a filamentation auxiliary piece, a special clamping tool, amulti-shaft linkage electric control displacement table, an industrial personal computer, a mechanical arm, a chemical corrosion pool and an alkaline neutralization pool. The femtosecond laser filamentation length and the diameter are regulated and controlled through the variable-magnification beam expander, the optical diffraction element and the filamentation modification module, and the largeratio of pit-depth to pit-diameter machining of the hard and brittle material is achieved; by means of the filamentation auxiliary piece, adverse effects of poor filamentation front end machining consistency are avoided; and through the mechanical optical shutter, the multi-shaft linkage electric control displacement table, the industrial personal computer and other optical electromechanical cooperation control, the complex component laser modification function is completed. The hard and brittle material complex component femtosecond laser precision forming processing system has the beneficialeffects that the ratio of pit-depth to pit-diameter machining is large, the machining quality is excellent, complex components can be formed, and fully automatic operation is achieved and has wide application prospects in the fields of aerospace, semiconductors, electronics industry and the like.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

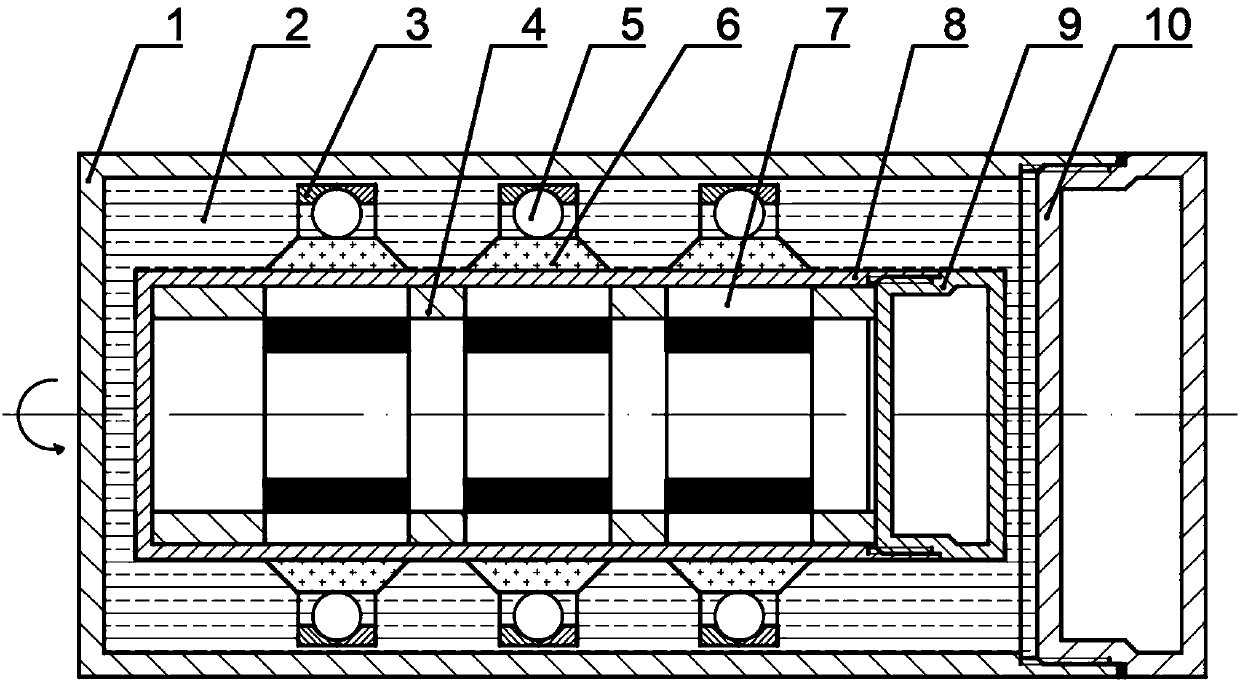

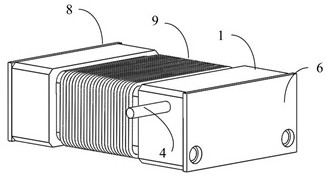

Rolling-bearing magneto-rheological polishing device for high-accuracy ceramic balls

ActiveCN107855834ASimple structureEasy clampingSpherical surface grinding machinesGrinding work supportsMagnetic currentMagneto rheological

The invention discloses a rolling-bearing magneto-rheological polishing device for high-accuracy ceramic balls. The rolling-bearing magneto-rheological polishing device comprises an inner-ring barrel(8), an outer-ring barrel (1) and a ceramic ball retainer (3) arranged between the inner-ring barrel and the outer-ring barrel (1), wherein a ceramic ball accommodating space (5) is formed in the ceramic ball retainer (3), a plurality of annular magnets (7) are arranged in the inner-ring barrel (8), location blocks (4) are arranged among the annular magnets (7), and the location blocks (4) are uniformly arranged in the inner-ring barrel (8); and the ceramic ball retainer (3) is connected with the inner-ring barrel (8) through a bolt, and concentrically arranged with the inner-ring barrel (8),and the space between the outer-ring barrel (1) and the inner-ring barrel (8) is filled with a magneto-rheological polishing liquid (2). In combination with magneto-rheological flexible polishing, thepolishing device disclosed by the invention is capable of efficiently obtaining high-quality smooth ceramic ball surfaces with both high dimension accuracy and shape accuracy.

Owner:GUANGDONG UNIV OF TECH

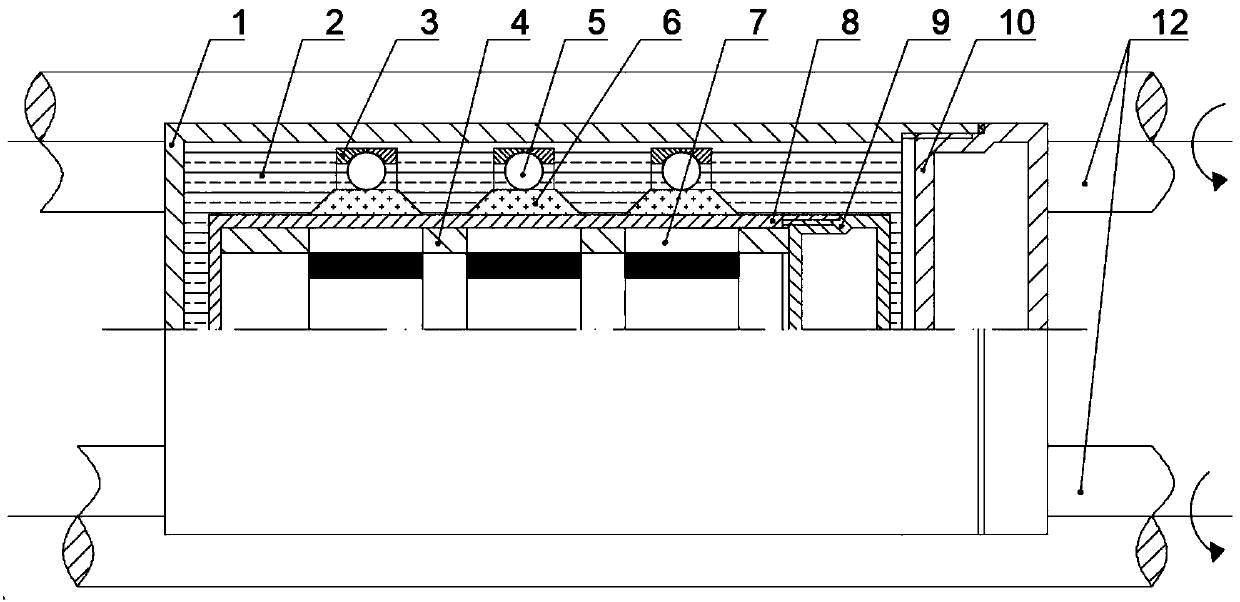

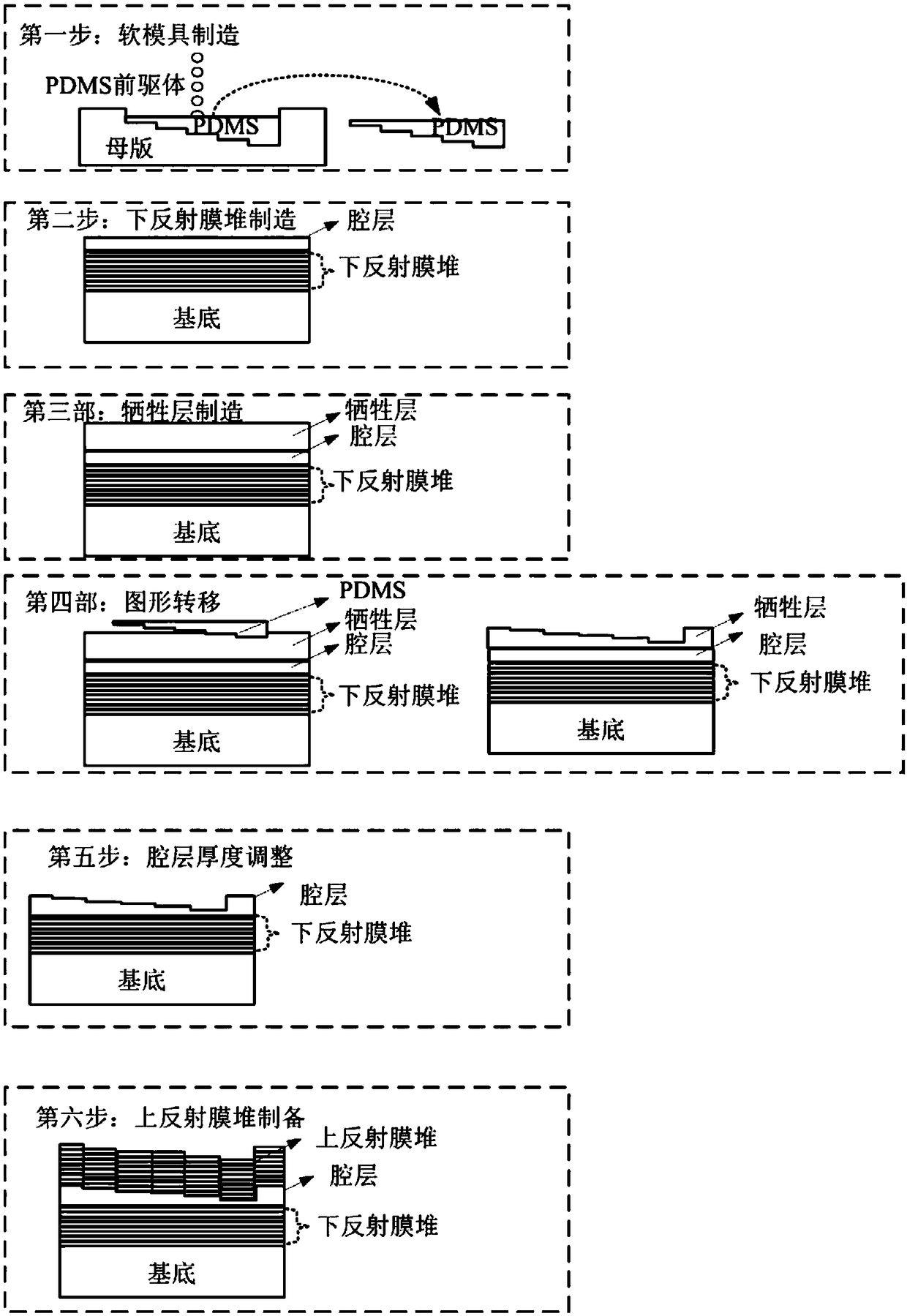

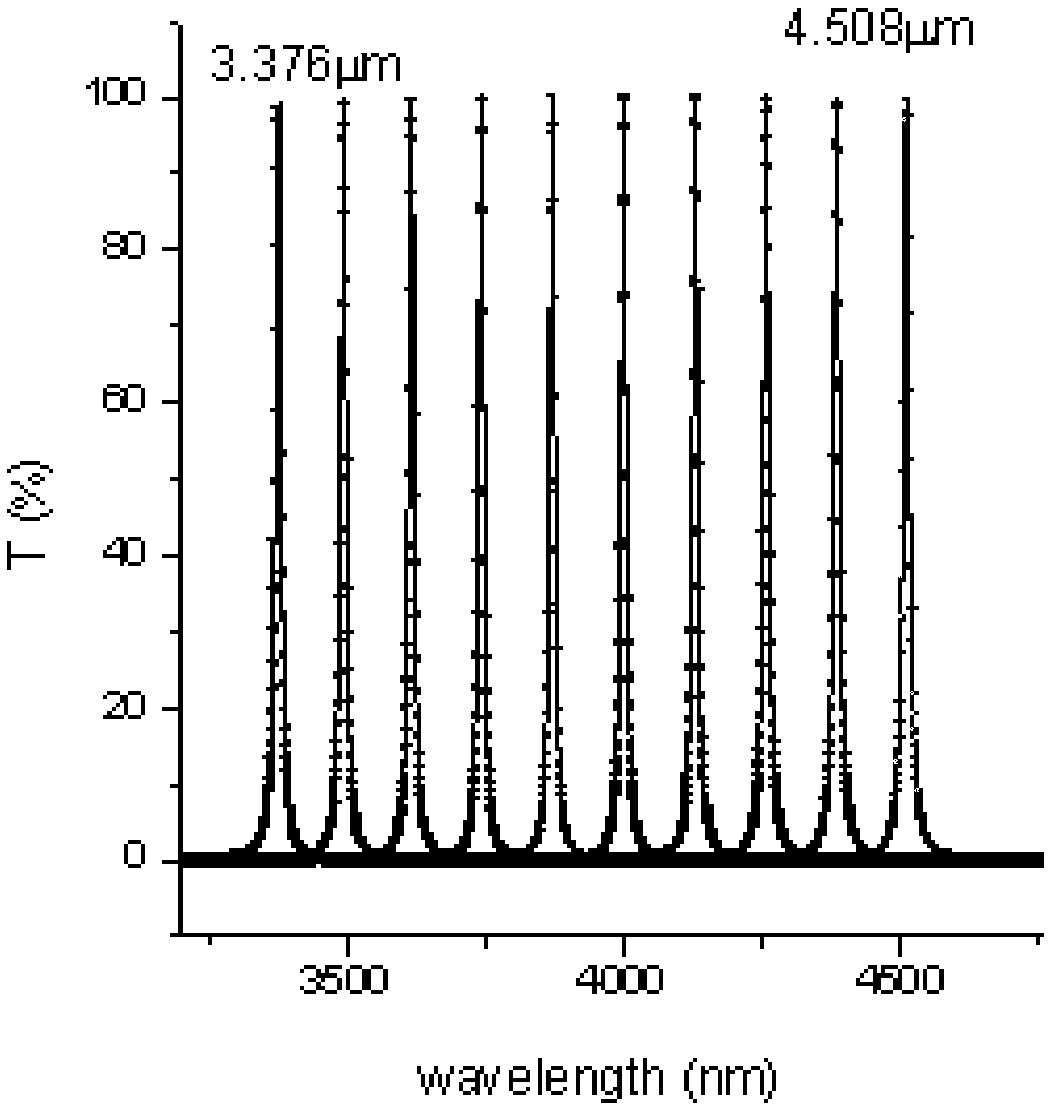

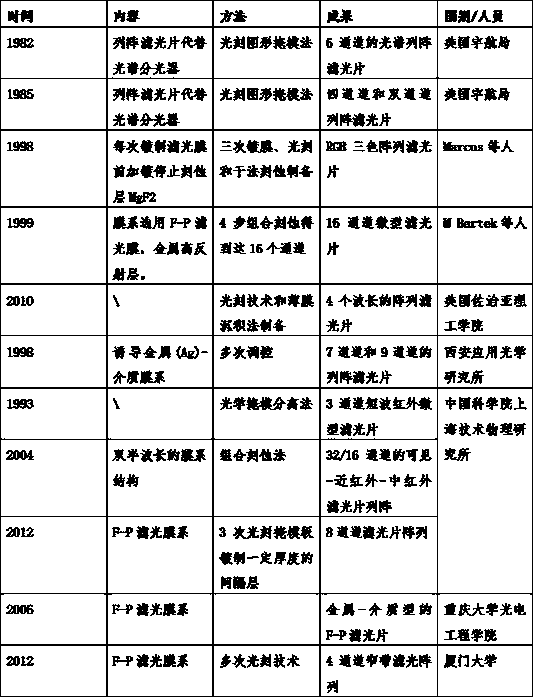

Preparation method for array F-P (Fabry-Perot) cavity optical filter

PendingCN109031491AEnsure Process ConsistencyAchieve precise controlOptical filtersTransmittanceIon beam etching

The invention relates to a preparation method for an array F-P (Fabry-Perot) cavity optical filter. The preparation method comprises the following steps that: (1) manufacturing a soft module; (2) manufacturing a lower reflecting film stack: on a substrate, adopting a thermal evaporation plating method to prepare the reflecting film stack and a cavity layer on one side of the F-P narrow band optical filter; (3) manufacturing a sacrificial layer: carrying out the spin coating of a sacrificial glue layer on the cavity layer; (4) carrying out pattern transfer: transferring the soft module patternprepared in (1) to the sacrificial layer prepared in (3) through a natural pressurization form; (5) regulating and controlling cavity layer thickness: adopting an ion beam etching technology to transfer the pattern of the sacrificial layer to the cavity layer to finish the regulation of multi-channel cavity layer thickness in one time; and (6) manufacturing an upper reflecting film stack: adoptinga thermal evaporation method to prepare the top reflecting film stack to finish manufacturing the optical filter. By use of the method, the problems of low transmittance and inaccurate position of the center wavelength of the optical filter in the prior art are overcome.

Owner:XIAN TECHNOLOGICAL UNIV

Pushing elastic frame for automatic wood rabbet processing machine

InactiveCN102441926ACompact structureStable tightening effectMitre joint working devicesRabbetEngineering

The invention discloses a pushing elastic frame for an automatic wood rabbet processing machine. A slide track is arranged on the top surface of a frame; a bracket is arranged on the slide track in a sliding way; one end of an inclined surface elastic sheet is pivoted at a revolving shaft on the side face of the bracket; and an elastic body is cushioned on the back part of the other end of the inclined surface elastic sheet. The pushing elastic frame is arranged in front of a wood clamping point, so that wood is accurately positioned and limited before clamping. The pushing elastic frame has a simple and compact structure and a stable pushing effect, and the processing accuracy and consistency of a product are ensured.

Owner:WUXI PHOENIX ARTIST MATERIALS

Microminiature atomic frequency standard microwave cavity based on microstrip line structure

ActiveCN112332840AReduce processing difficultyAccuracy controllablePulse automatic controlMicrowave cavityElectrical conductor

The invention discloses a microminiature atomic frequency standard microwave cavity based on a microstrip line structure, and the cavity comprises a cavity body, one end of the cavity body is a lightoutlet, the other end of the cavity body is a light inlet, the outer surface of the cavity body is circumferentially provided with a wire duct, a C field coil is wound in the wire duct, the light outlet of the cavity body is provided with an end cover, the light inlet of the cavity is provided with a bottom cover, a light inlet hole is arranged on the bottom cover, an atomic bubble is arranged inthe cavity, a microstrip line substrate is arranged in the cavity, the microstrip line substrate comprises a dielectric substrate and a metal conductor arranged on the dielectric substrate, the dielectric substrate is bonded with the inner wall of the cavity, and the metal conductor faces the atomic bubble. The microminiature atomic frequency standard microwave cavity has the advantages of easiness in processing, simplicity in assembly, good field pattern distribution, small size and low cost, and is suitable for mass production of high-performance ultra-small atomic frequency standards.

Owner:INNOVATION ACAD FOR PRECISION MEASUREMENT SCI & TECH CAS

Automatic cutting device compatible with various hinge door stop plates

PendingCN111716020AEnsure processing consistencyAchieve freedom of movementLaser beam welding apparatusEngineeringStructural engineering

The invention relates to the technical field of automatic laser cutting of non-standard hinge stop door plates, and discloses an automatic cutting device compatible with various hinge stop door plates. The automatic cutting device compatible with the various hinge stop door plates comprises a first section of chain transmission assembly, a second section of chain transmission assembly, a stop assembly, a side thrust servo assembly, a positioning and clamping assembly, a robot assembly, a first protection assembly and a second protection assembly. According to the automatic cutting device compatible with the various hinge stop door plates, completely positioning a to-be-machined product can be carried out through the side thrust servo assembly and the positioning and clamping assembly, so that the machining consistency of the to-be-machined product can be effectively guaranteed; meanwhile, a suction assembly can move in an X axis, a Y axis and a Z axis, so that free movement of the robot assembly in plane cutting can be achieved, and the cutting efficiency is improved; and compared with a 45-degree or 90-degree positioning to-be-machined product laser cutting mode or a manual machining mode in the prior art, the equipment safety performance and reliability are improved, the two hands of an operator are liberated, the workload is relieved, time and labor are saved, and thereforethe production cost is reduced, and the production efficiency is improved.

Owner:上海电气自动化集团有限公司

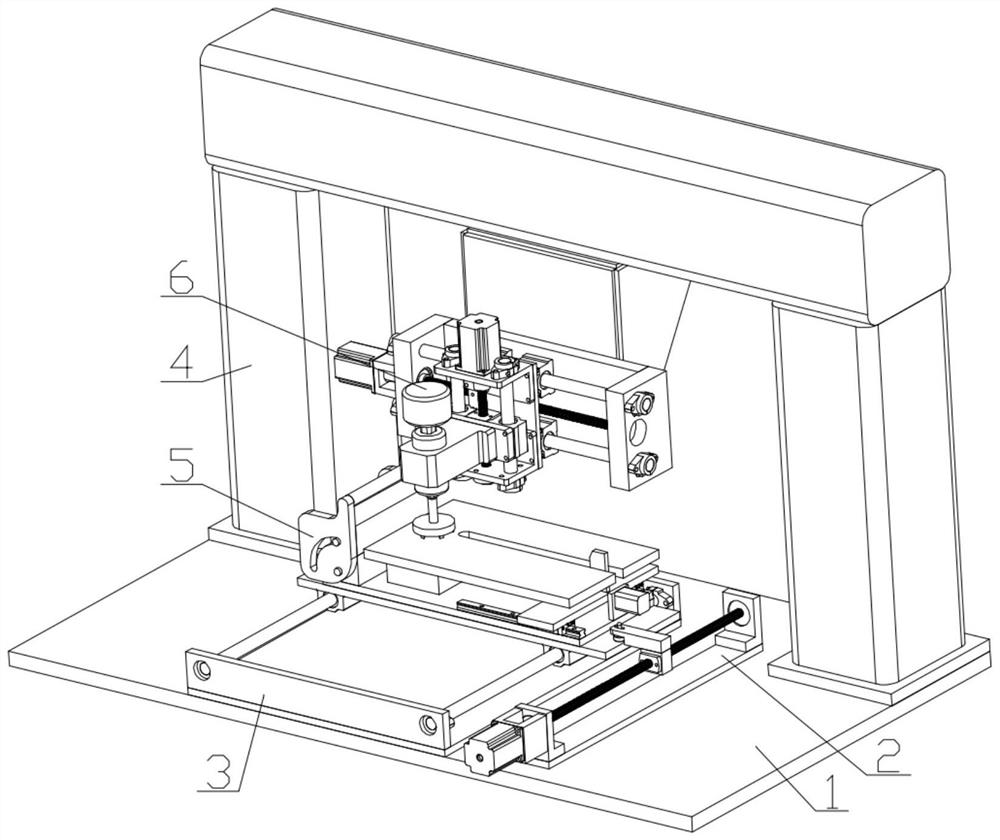

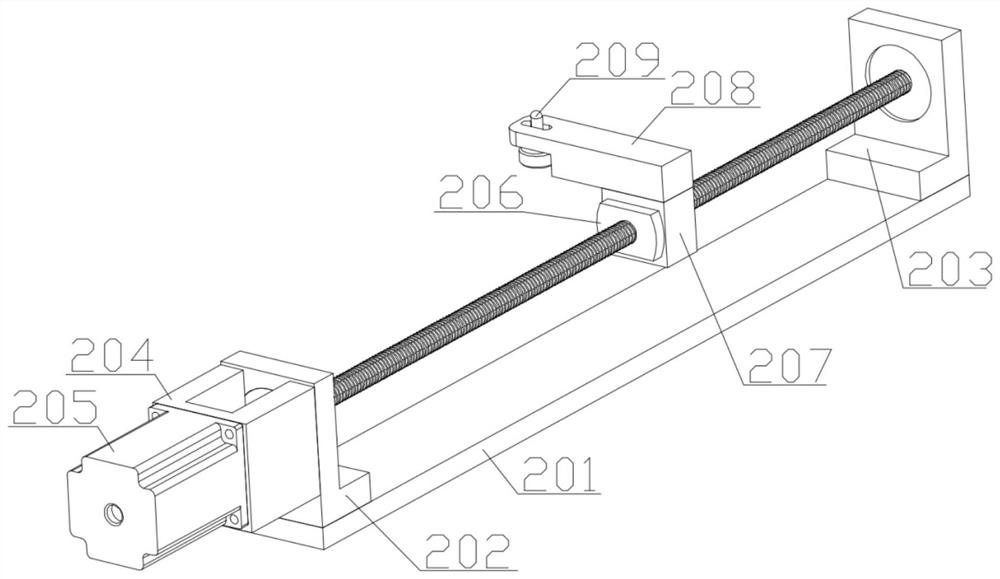

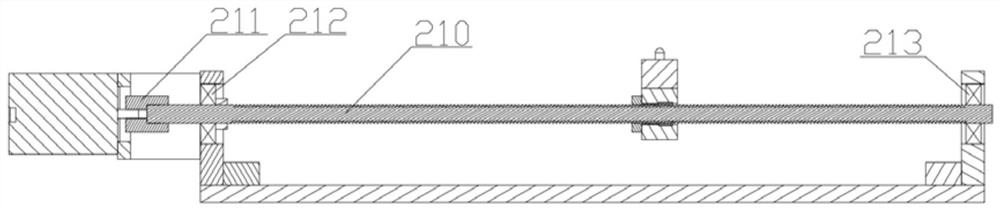

Multi-axis milling equipment for workpiece machining

PendingCN112338243ABig spaceGuaranteed machining accuracyMilling machinesFeeding apparatusPortal frameServo drive

The invention discloses multi-axis milling equipment for workpiece machining, and relates to the field of metal cutting machining. The multi-axis milling equipment comprises an equipment bottom plate,a servo driving device, a workpiece conveying device, a portal frame body device, a workpiece positioning clamp and a milling machining device, wherein the equipment bottom plate is a mounting substrate of other devices of the multi-axis milling equipment, the servo driving device is used for driving the workpiece conveying device to move back and forth, the portal frame body device is used for mounting and fixing the milling machining device, the workpiece positioning clamp is used for positioning a workpiece to be machined, and the milling machining device is used for machining and cuttingmetal. According to the multi-axis milling equipment, a portal frame structure is adopted, the structural rigidity is high, the cutting power is large, and parts are convenient to clamp and disassemble.

Owner:于建庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com