Automatic machining and detecting device of energy-containing columnar material for aerospace fire work device

A pyrotechnic device and automatic processing technology, applied in the direction of manufacturing tools, manipulators, etc., can solve problems such as low intrinsic safety, prone to deformation out of tolerance, backward detection methods, etc., to eliminate operational safety risks and ensure processing consistency , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

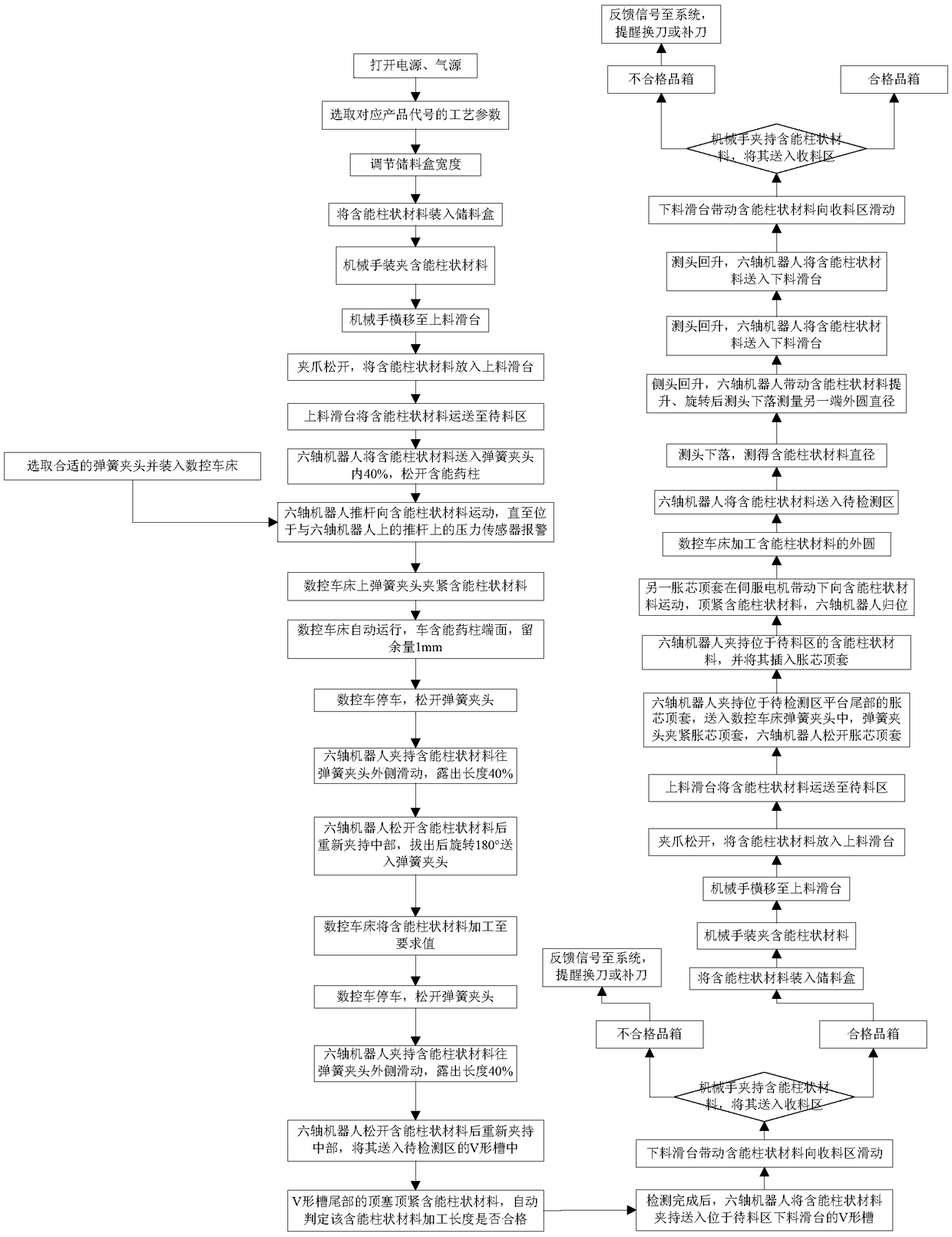

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0050] An automatic processing and detection device for energetic columnar materials used in aerospace pyrotechnic devices. The energetic columnar materials are shaped like Figure 10 as shown,

[0051] Including detection module, robot module and loading and unloading module,

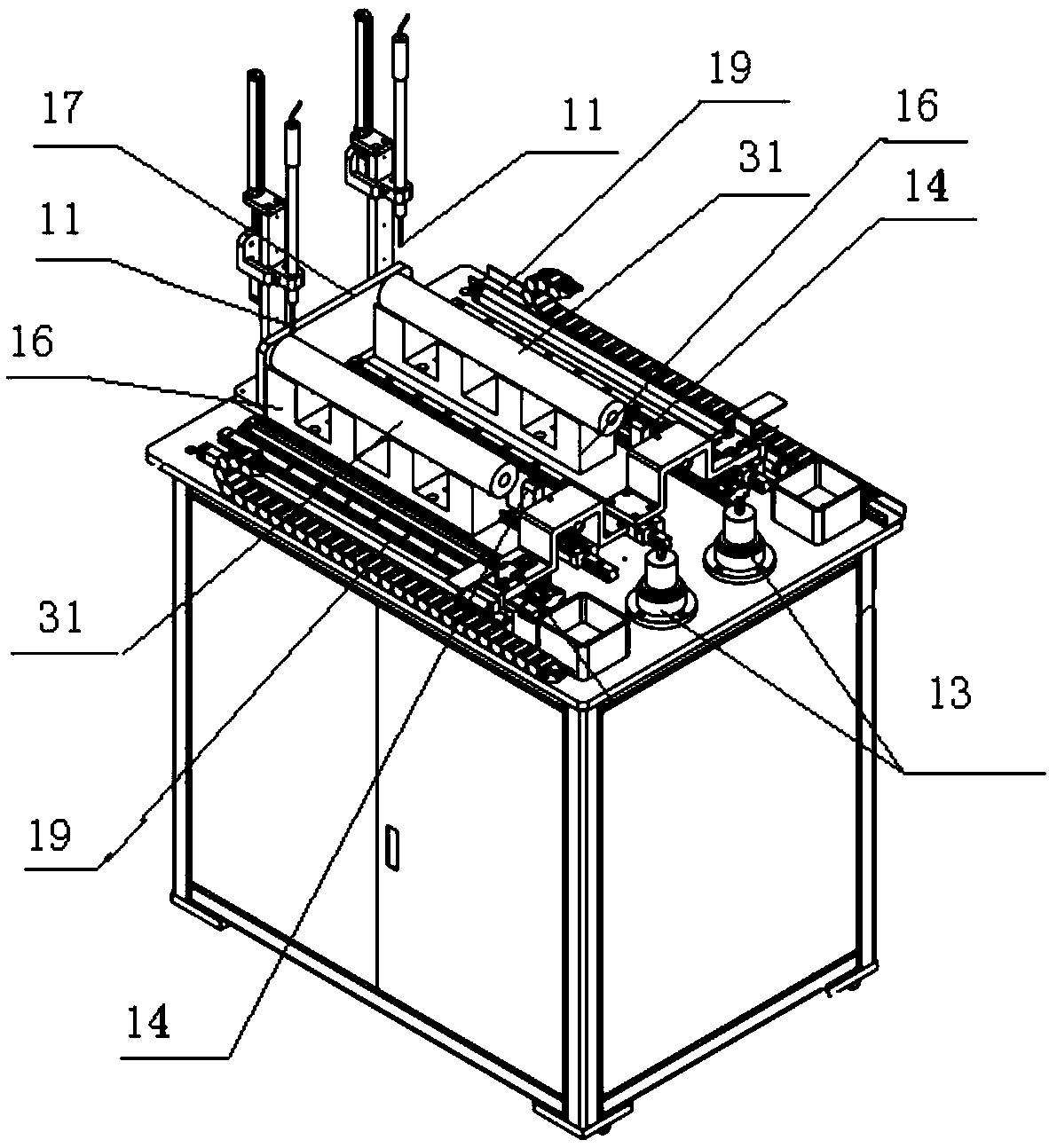

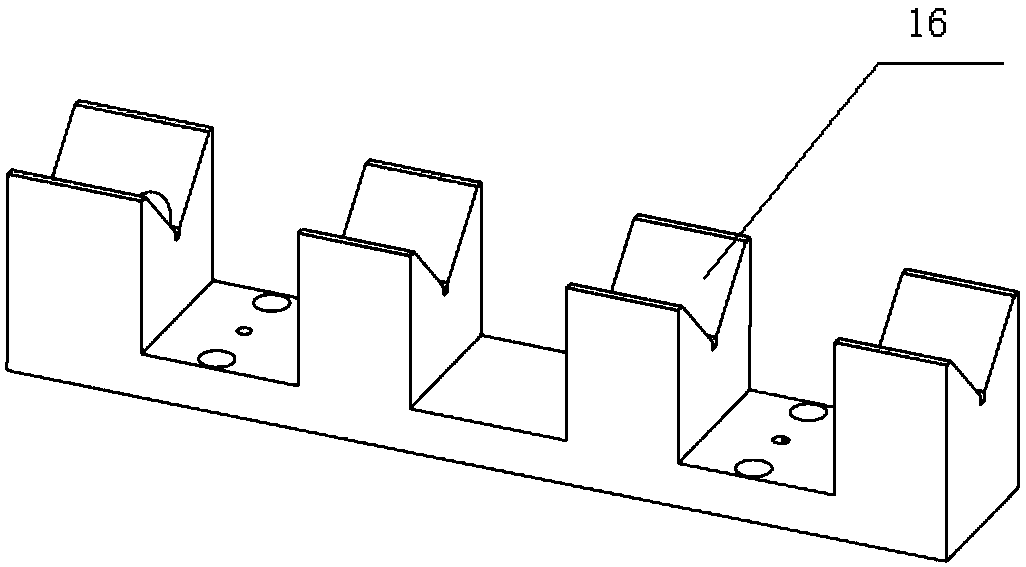

[0052] Such as figure 2As shown, the detection module includes a probe 11, a top plug 14, a V-shaped block 16, a baffle plate 17 and a first slide rail 19 located on the detection platform, and the V-shaped surface of the V-shaped block 16 is perpendicular to the baffle plate 17, and the verticality No more than 0.01mm. It also includes the expansion core top sleeve 13, the expansion core top sleeve 13 is located at the tail of the top plug 14, when processing the outer circle of the energetic columnar material, use two expansion core top sleeves 13 to insert the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com