Stator blade finish forging automatic machining method

A stator blade and processing method technology, applied in the field of automatic processing of precision forging stator blades, can solve the problems of complex process, low processing efficiency, low qualified rate of blade surface profile, etc. unhindered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in further detail below in conjunction with accompanying drawing:

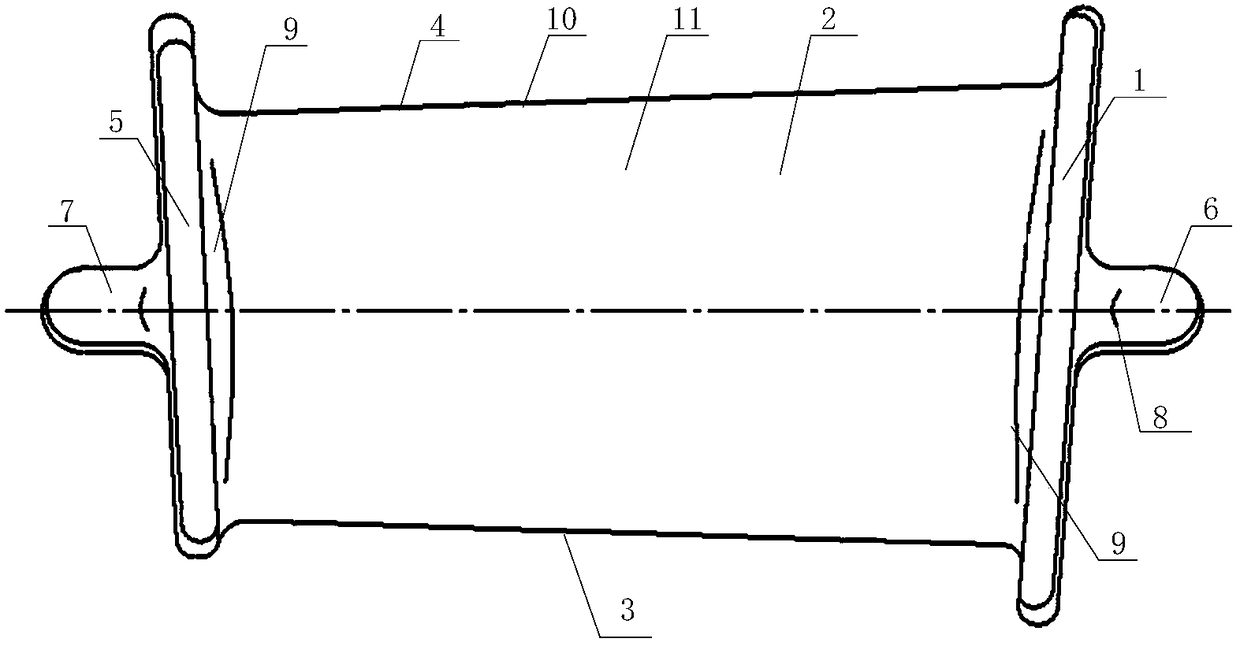

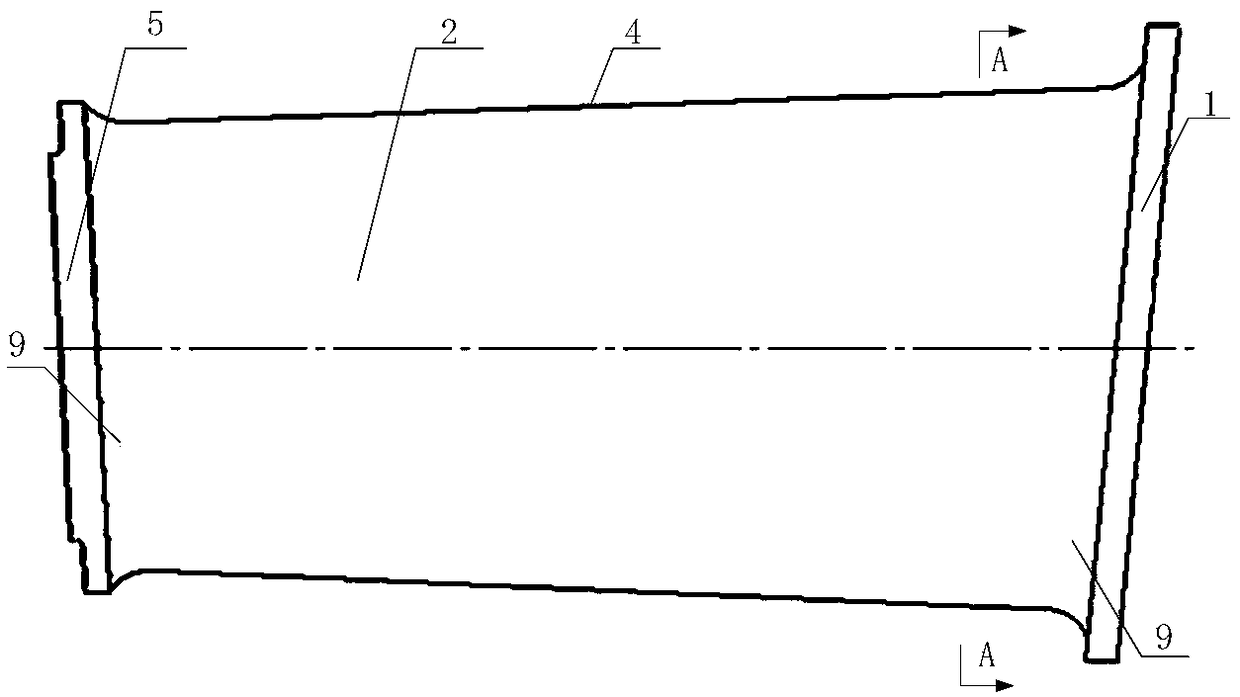

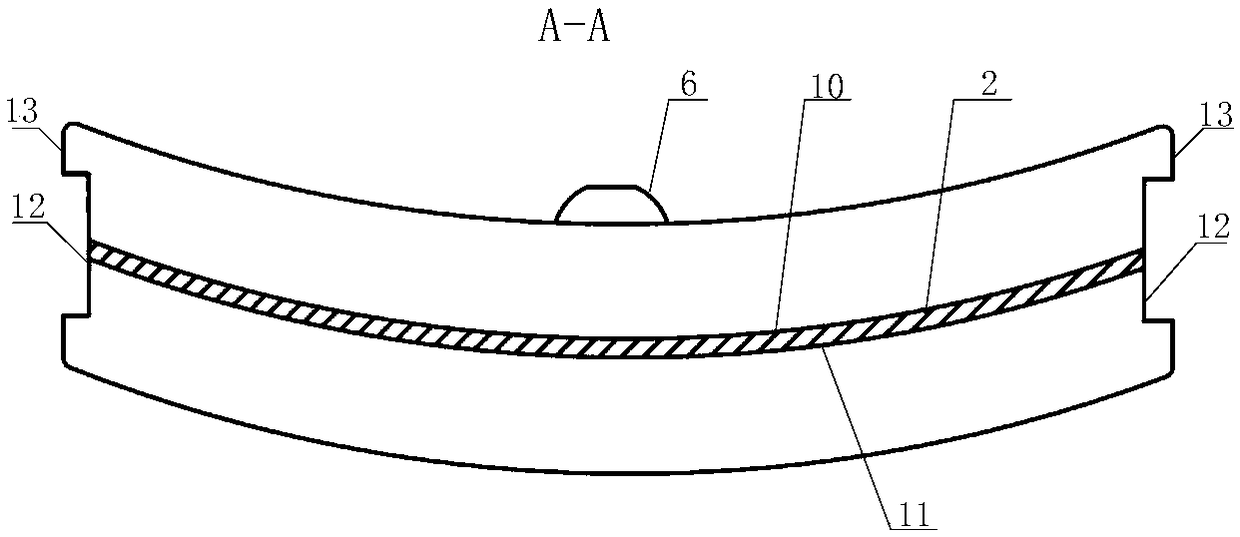

[0041] see figure 1 and image 3 , the engine stator blank blade of the present invention is a precision forging, and the blank blade includes an upper edge plate 1, a blade body 2, an exhaust edge 3, an air intake edge 4, a lower edge plate 5, a process upper boss 6, and a process lower boss 7 , transfer arc surface 9; the concave surface of the blade body 2 is the blade basin 10, and the convex surface of the blade body 2 is the blade back 11; one side of the blade body 2 is the exhaust edge 3, and the other side is the air intake edge 4; One end of 2 is the upper edge plate 1, and the other end is the lower edge plate 5; the outer surface of the upper edge plate 1 is fixedly connected with the upper boss 6 of the process, and the outer side of the lower edge plate 5 is fixedly connected with the lower boss 7 of the process. The fixed surface of the lower edge plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com