Fixing device for electrode processing

The technology of fixing device and electrode is applied in the field of latent gate electric spark of injection mold and fixing device of processing electrode, which can solve the problems of difficulty in ensuring size and position accuracy, the electrode cannot be reused, and it takes a long time, and achieves a compact structure. , The effect of ingenious design and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

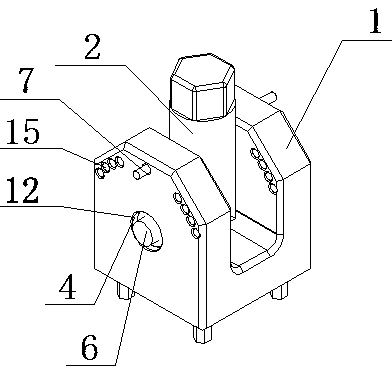

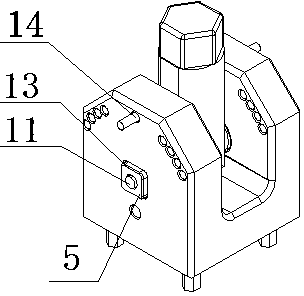

[0015] As shown in the figure, a fixing device for processing electrodes includes base 1, locking rod 2, EROWA positioning piece 3, bearing 4, square nut 5, shoulder bolt 6, pin 7, and EROWA positioning piece 3 through four positioning screws It is fixed under the base 1. A small round hole 11 and a large round hole 12 are respectively provided at the central symmetrical positions of the two U-shaped sides of the base 1. The small round hole 11 is also provided with a square groove 13 outside the center of the upper part of the two U-shaped sides. There is a pin hole 14, with the pin hole 14 and the vertical side of the base 1 as the axis, a plurality of angle holes 15 are arranged symmetrically along both sides of the pin hole 14, the bearing 4 is installed in the large round hole 12, and the square nut 5 is installed in the square groove 13. The upper part of the loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com