Patents

Literature

287 results about "Cutter location" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

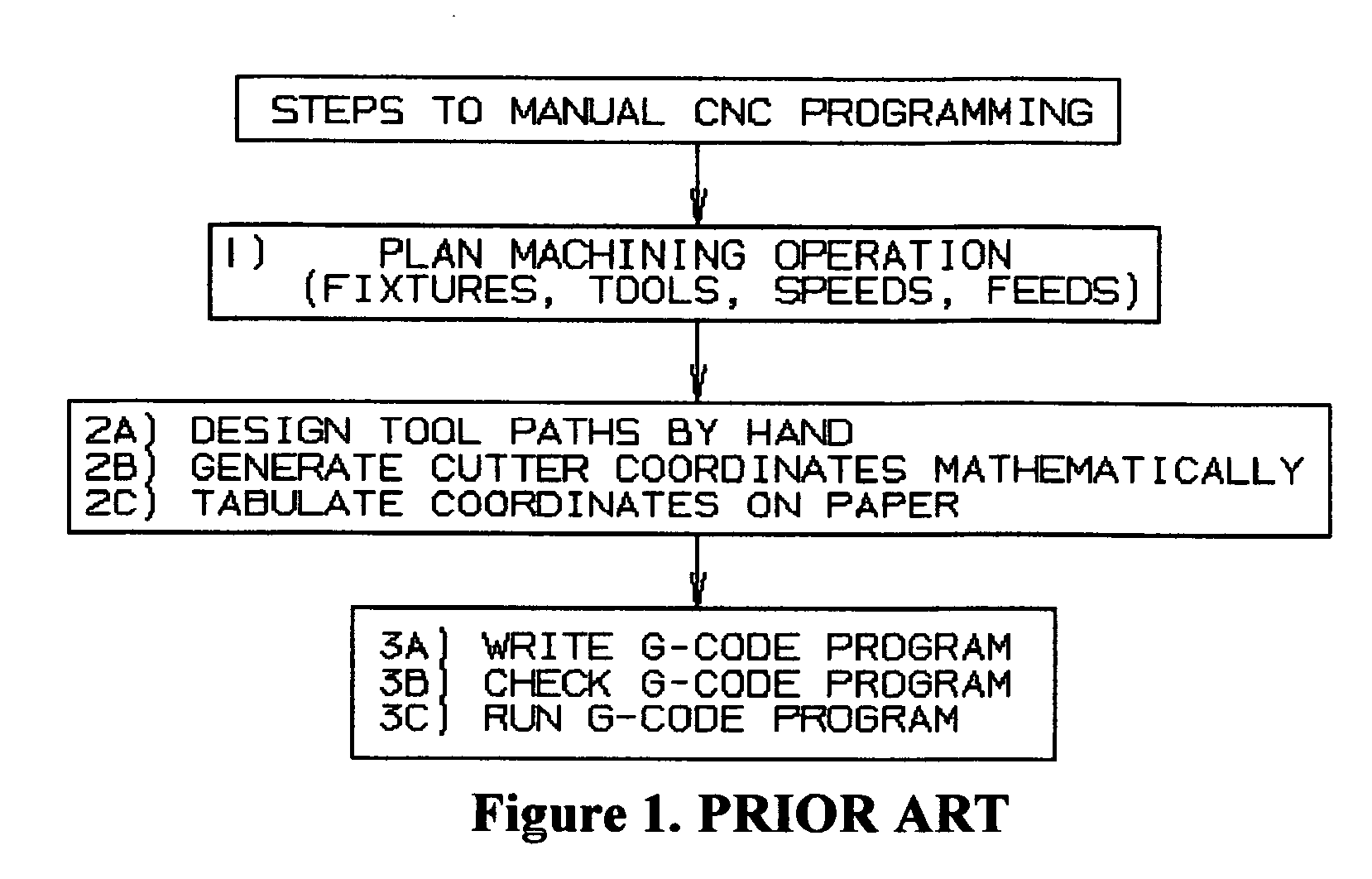

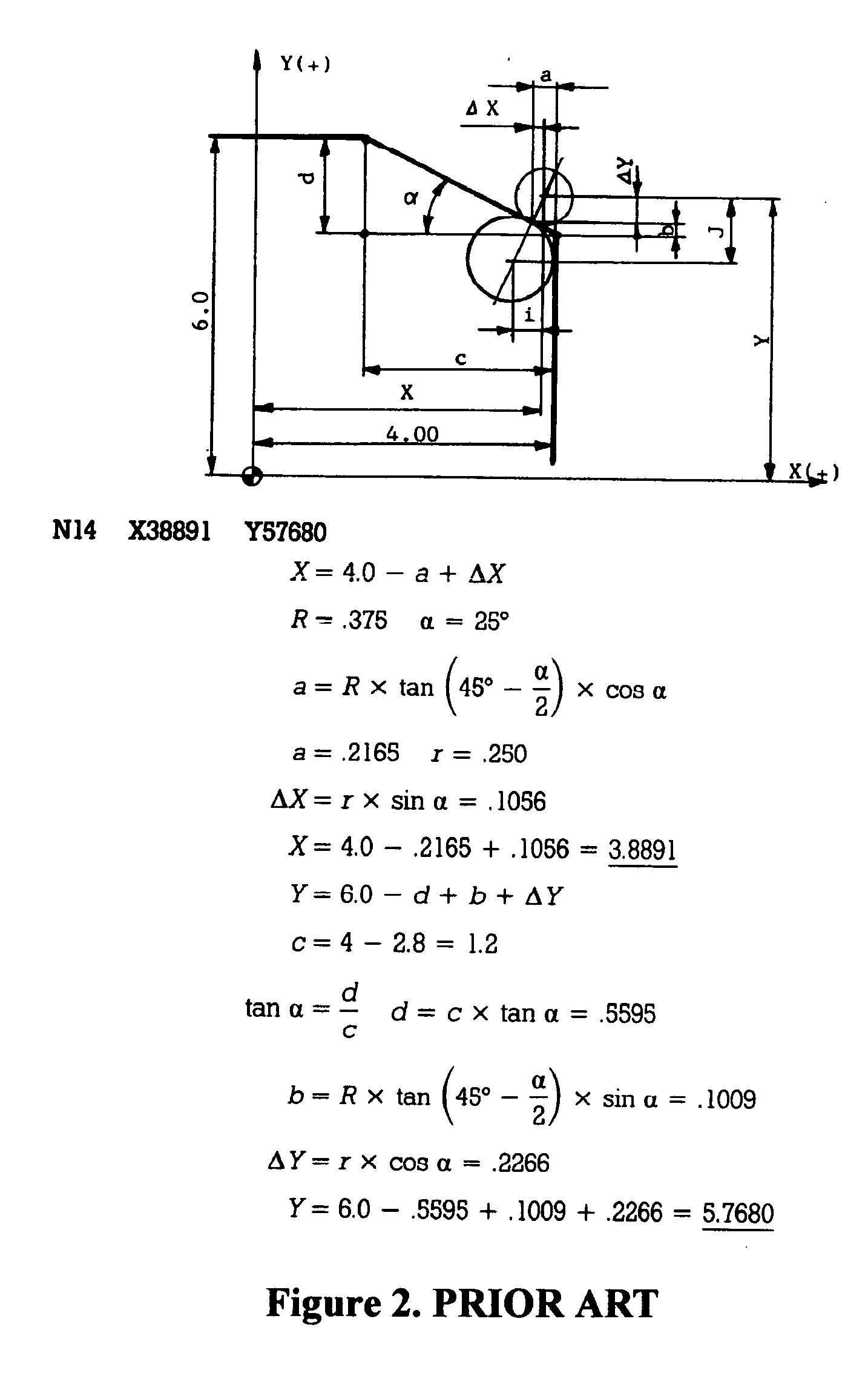

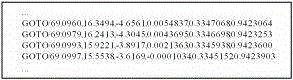

A cutter location (CLData) refers to the position which a CNC milling machine has been instructed to hold a milling cutter by the instructions in the program (typically G-code). Each line of motion controlling G-code consists of two parts: the type of motion from the last cutter location to the next cutter location (e.g. "G01" means linear, "G02" means circular), and the next cutter location itself (the cartesian point (20, 1.3, 4.409) in this example). "G01 X20Y1.3Z4.409"

Five-axis linkage numerical control (NC) machining post processor and processing method thereof

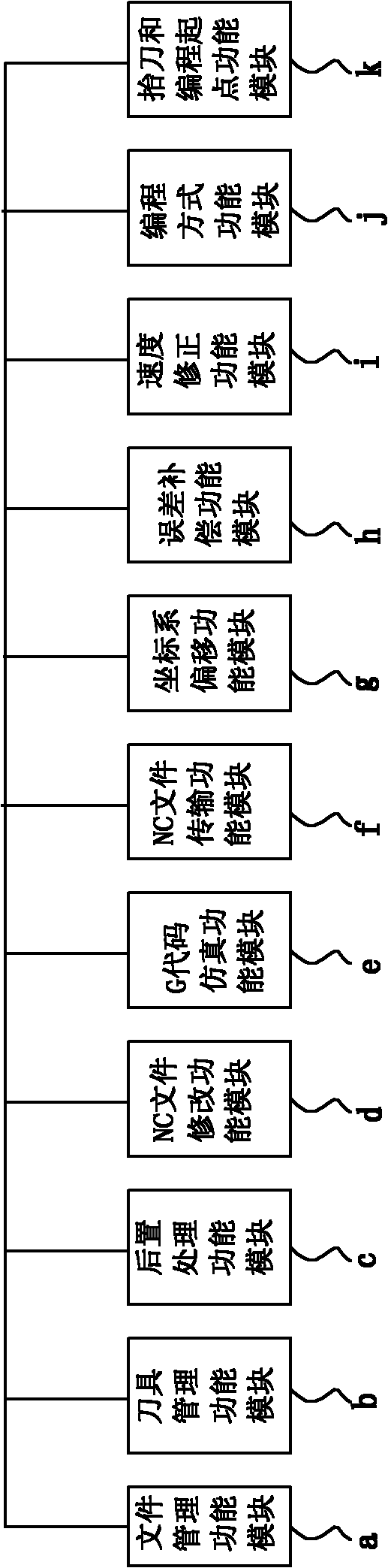

InactiveCN102023613ARealize simulationRealize serial communicationProgramme controlComputer controlPost processorManagement functions

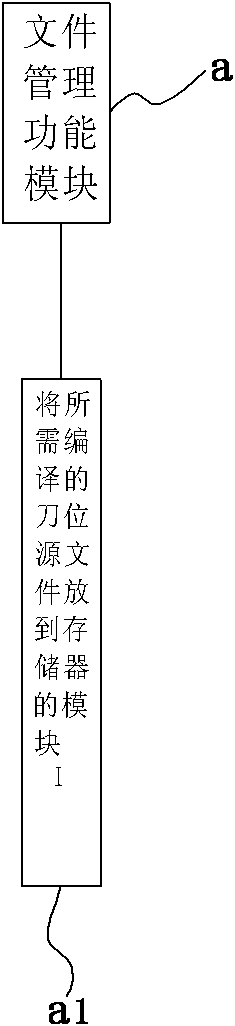

The invention discloses a five-axis linkage numerical control (NC) machining post processor and a processing method thereof, and relates to a post processor for an NC machining program and a processing method. The processor comprises computer program software which is used for processing a cutter location source file generated by a workpiece shape characteristic and a machining process, wherein the computer program software comprises a file management function module, a cutter management function module, a postprocessing function module, an NC file modification function module, a G code simulation function module, an NC file transmission function module, a coordinate system offset function module, an error compensation function module, a speed modification function module, a programming mode function module and a cutter-lifting and programming staring point function module. The processing method comprises the steps of setting a file, arranging a cutter, processing a programming mode, processing data of machine tool motion parameters, processing data of cutter dynamic cutting speed, outputting a G code file and the like. By the processor and the processing method, machining dynamic speed, speed compensation, non-linear error compensation and analog simulation of G code five-axis linkage can be realized.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

Manual CNC programming system and technique to use computer aided design systems to determine cutter location information

ActiveUS20070191982A1Simply carry-outComputer controlSimulator controlComputer Aided DesignCutter location

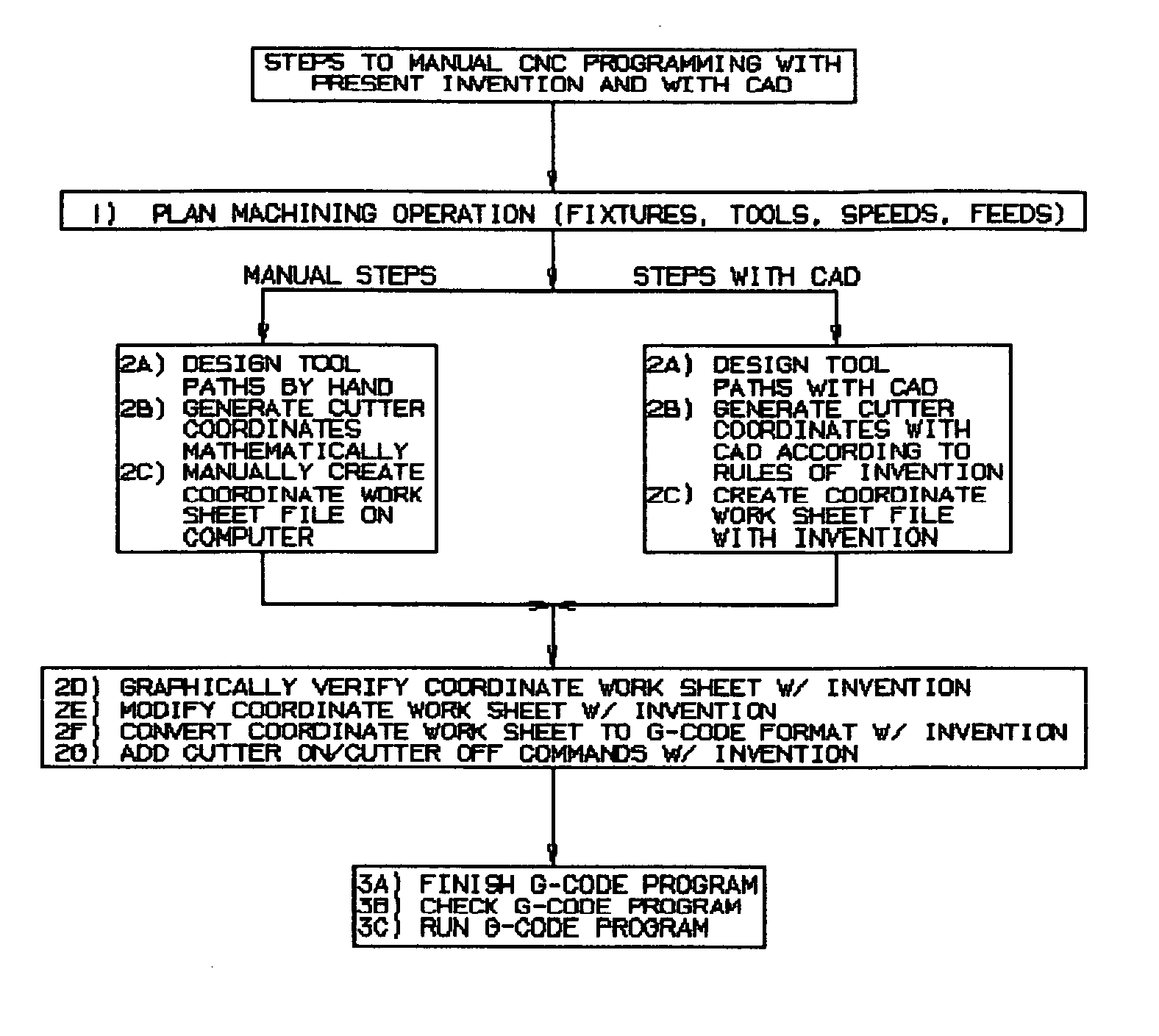

A manual computer numerical control (CNC) programming method and system (which may be embodied in whole or part in an article of manufacture or apparatus) in which coordinates may be manually entered into a text editor into a file format known as the coordinate work sheet (CWS) including verification, modification and conversion of the CWS to G-Code, the coordinate work sheet format being a comma delimited ASCII text file, and further including cutter on / off commands and using computer aided design (CAD) data to generate the coordinate work sheet (CWS).

Owner:SULLIVAN DOUGLAS G

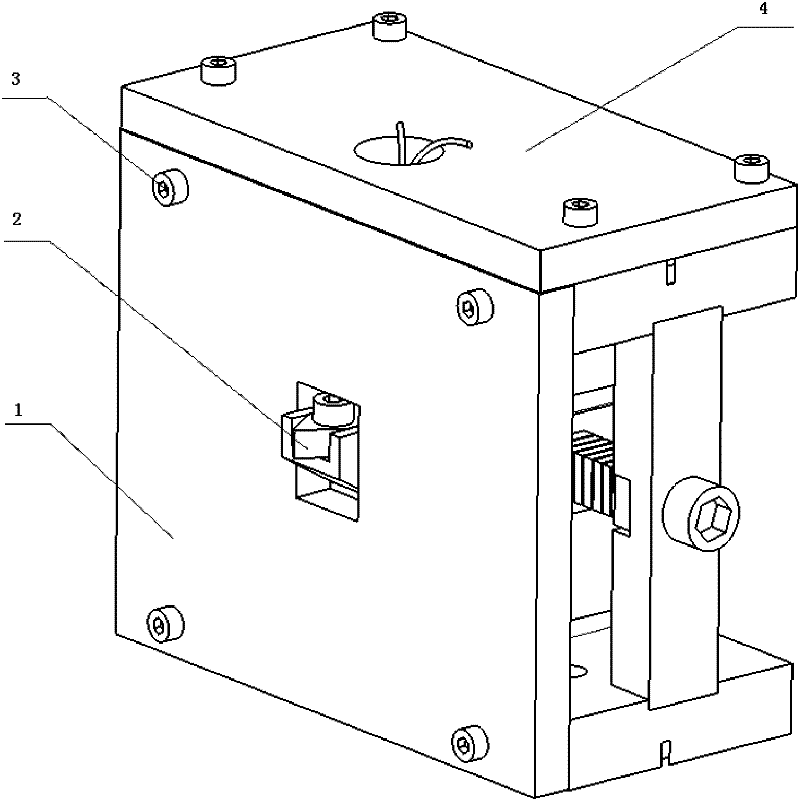

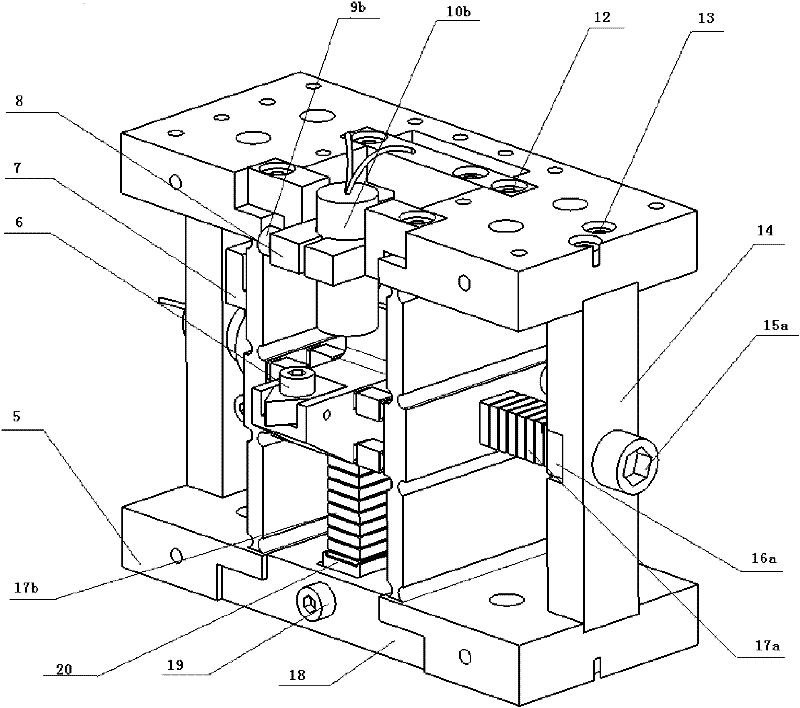

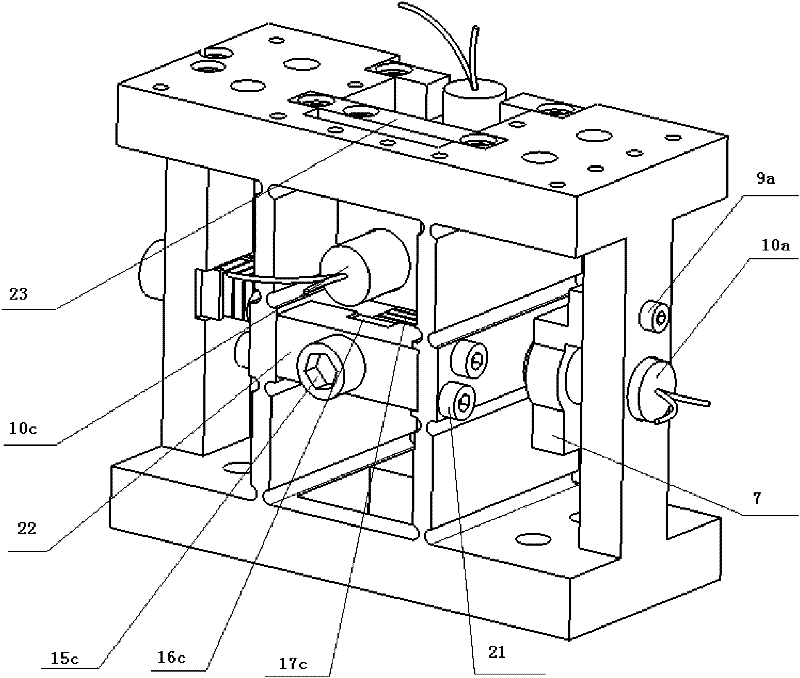

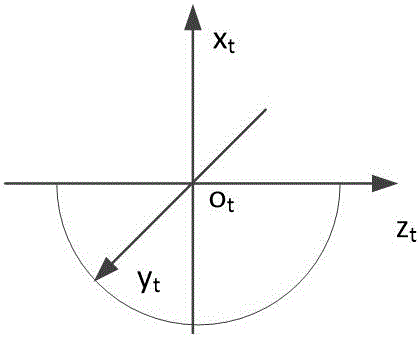

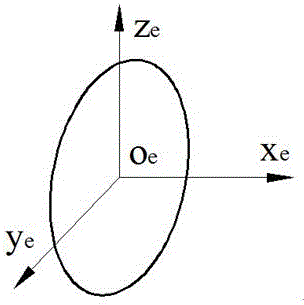

Three-dimensional elliptical vibration cutting device

ActiveCN102371359AImprove machinabilitySimplify the modeling processMeasurement/indication equipmentsTurning toolsLinear motionEllipse

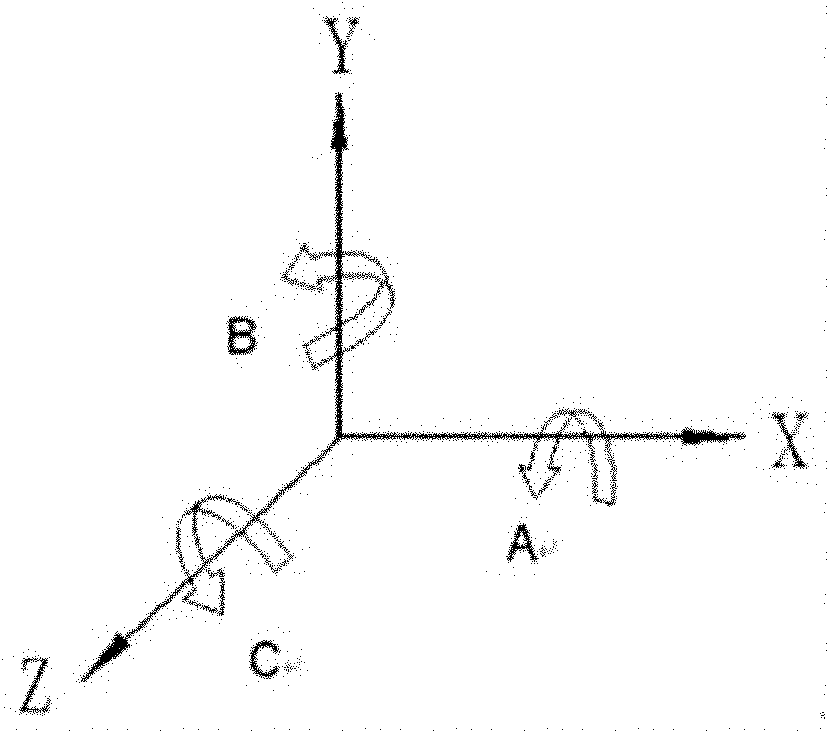

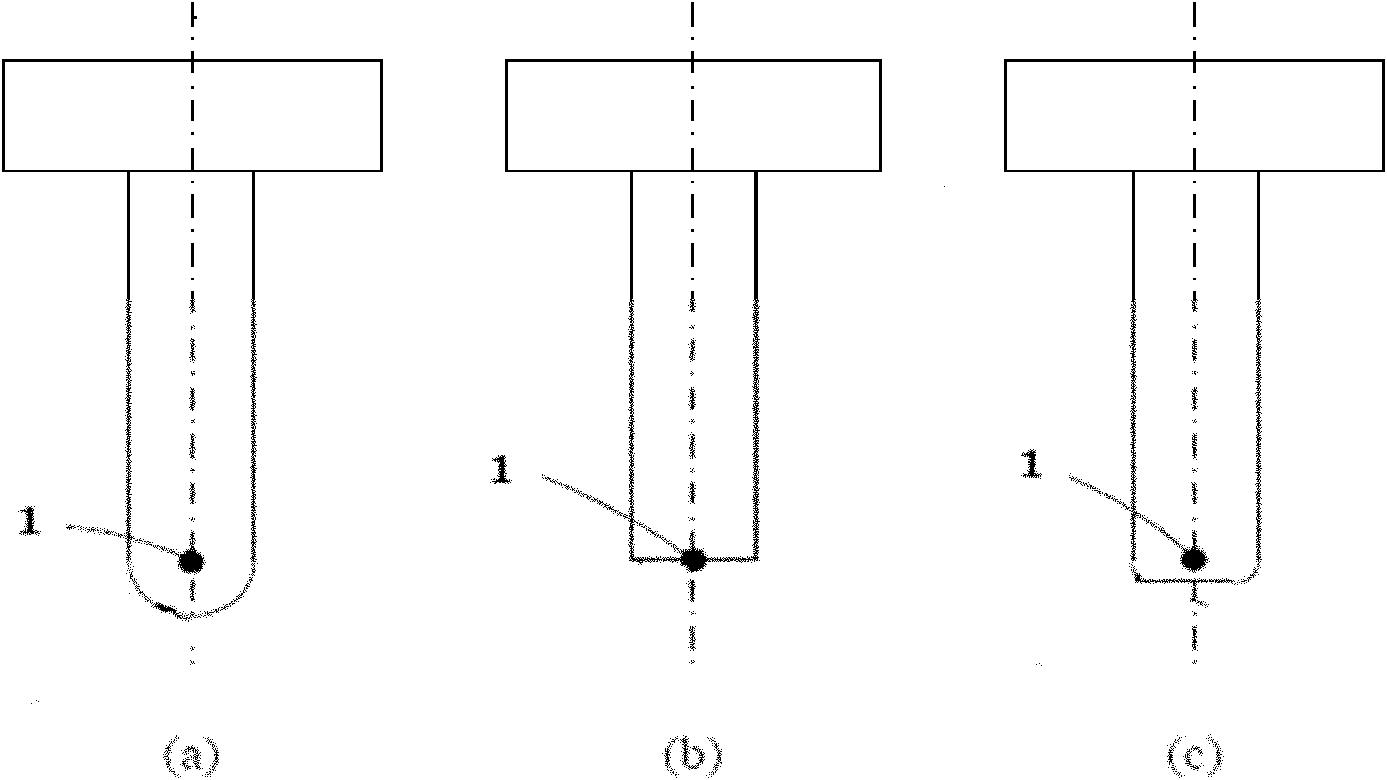

The invention relates to a three-dimensional elliptical vibration cutting device, belonging to the field of cutting and ultra-precision cutting machining of materials which are difficult to machine. A diamond cutter is guided through flexible hinge mechanisms respectively along an X direction, a Y direction and a Z direction, and further, is driven by three piezoelectric stacks respectively alongthe X direction, the Y direction and the Z direction; the piezoelectric stacks of the X direction and the Z direction are preloaded by preloading screw bolts along respective axial direction; the piezoelectric stack of the Y direction is preloaded through a screw bolt screwing wedge; the preloading processes of the three directions are mutually independent; through regulating and matching the initial phase position and the amplitude of a driving signal for each of the three piezoelectric stacks, the projections of the cutter location point movements of the diamond cutter in an X-Y plane and aY-Z plane are elliptical motions, and the projection of the cutter location point movements of the diamond cutter in an X-Z plane is reciprocating elliptical motion or linear motion. The three-dimensional elliptical vibration cutting device has a novel and simple structure, is easy to implement, and is beneficial to obtaining the best cutting machinability of the diamond cutter.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

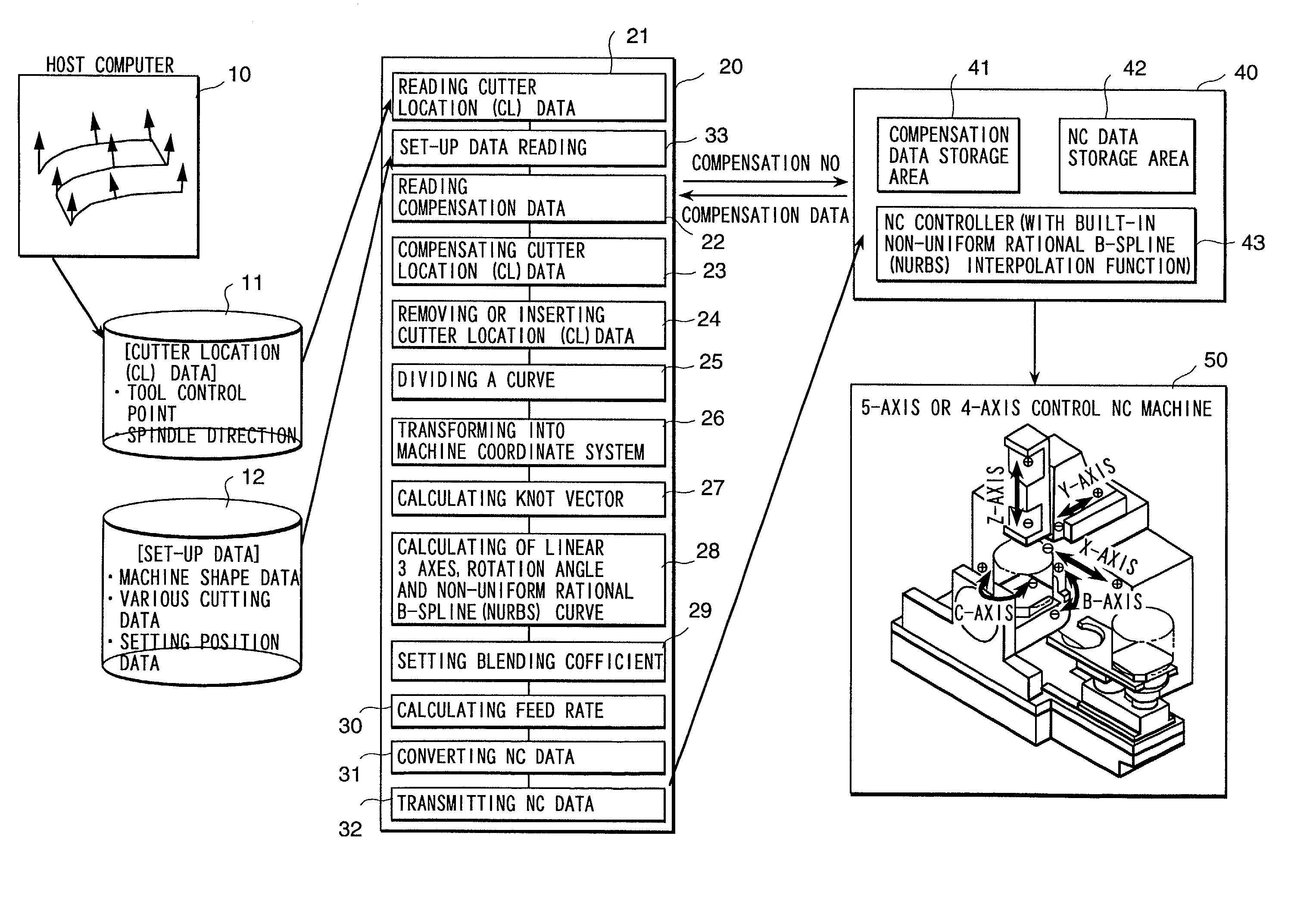

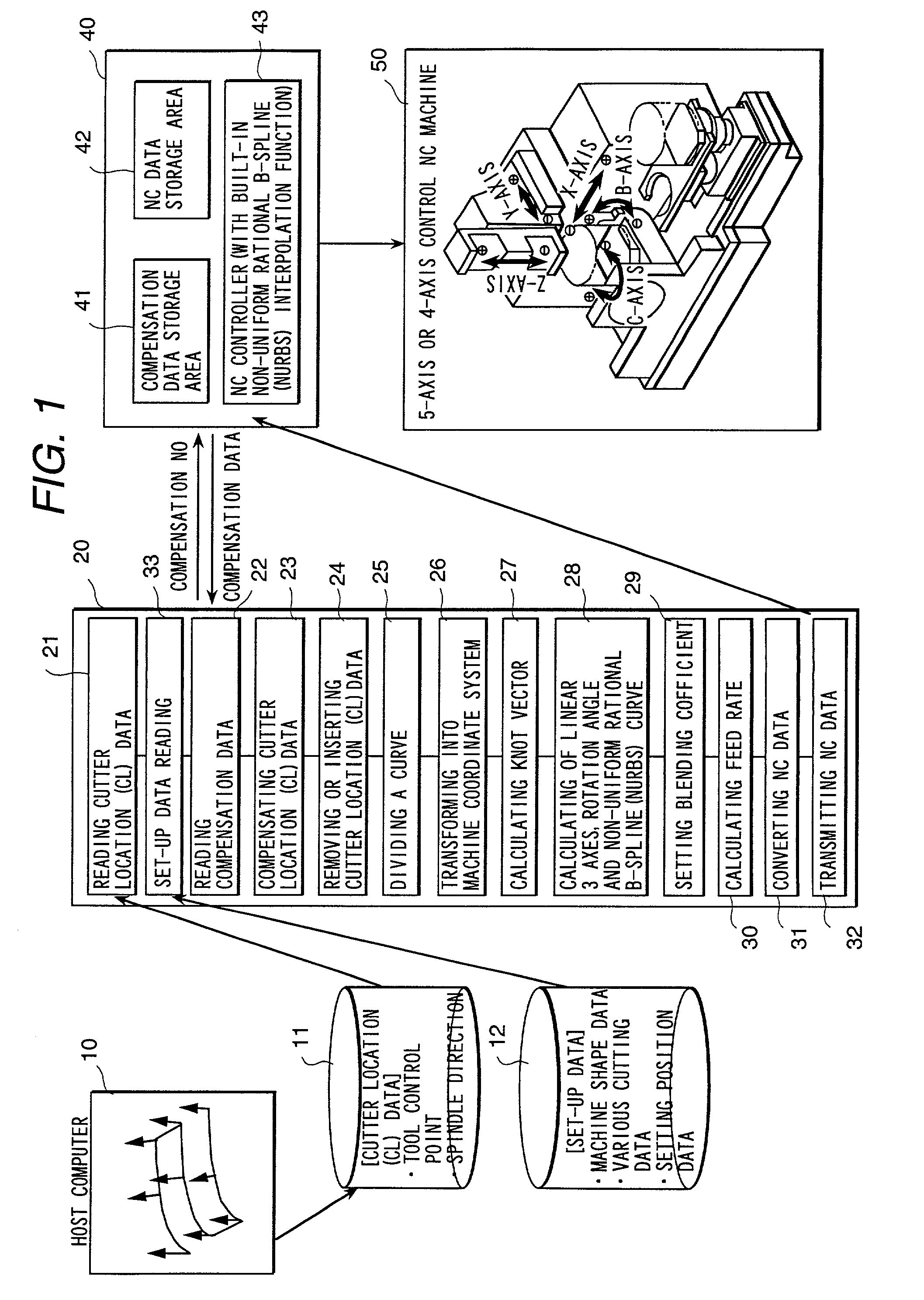

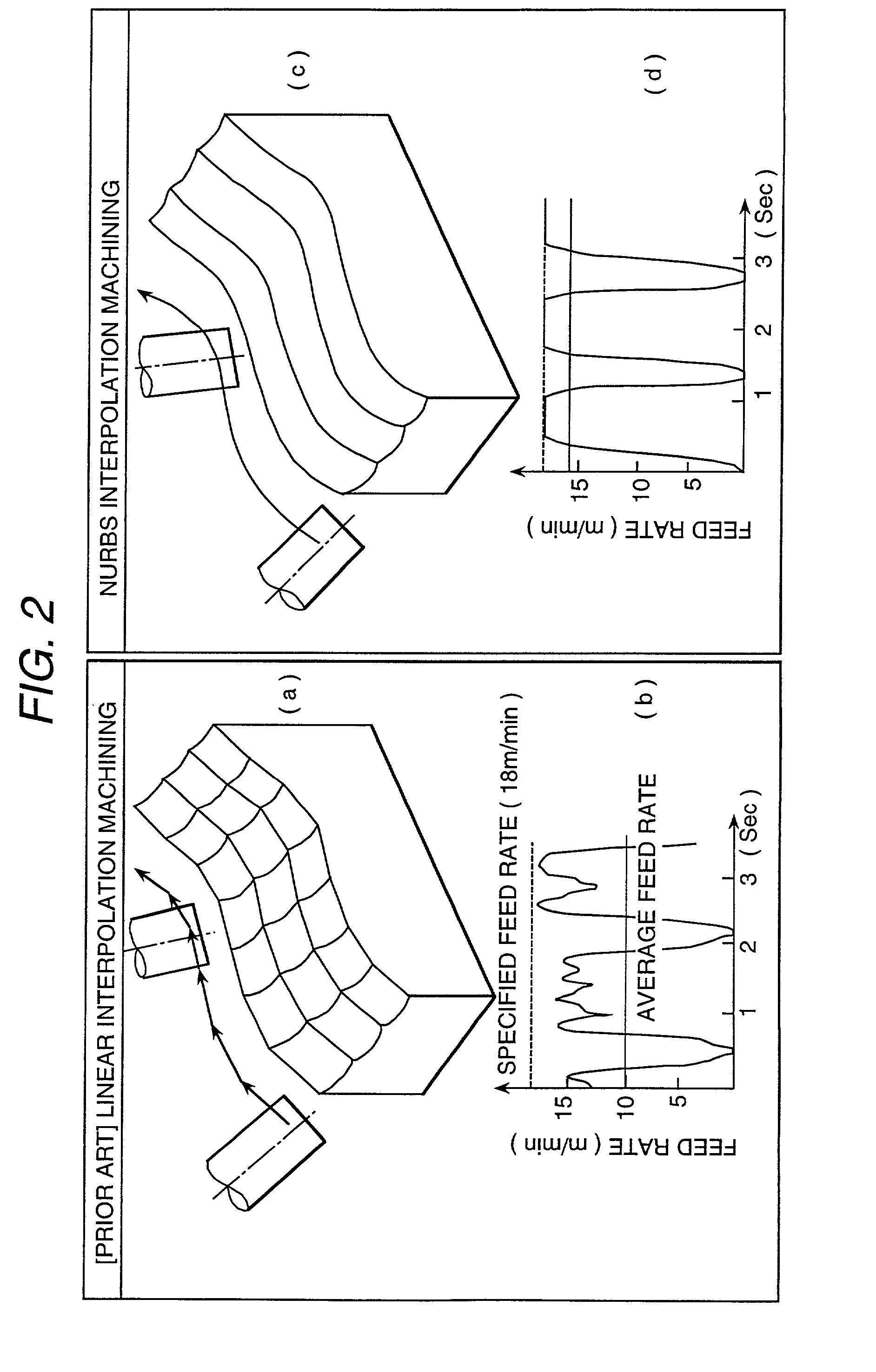

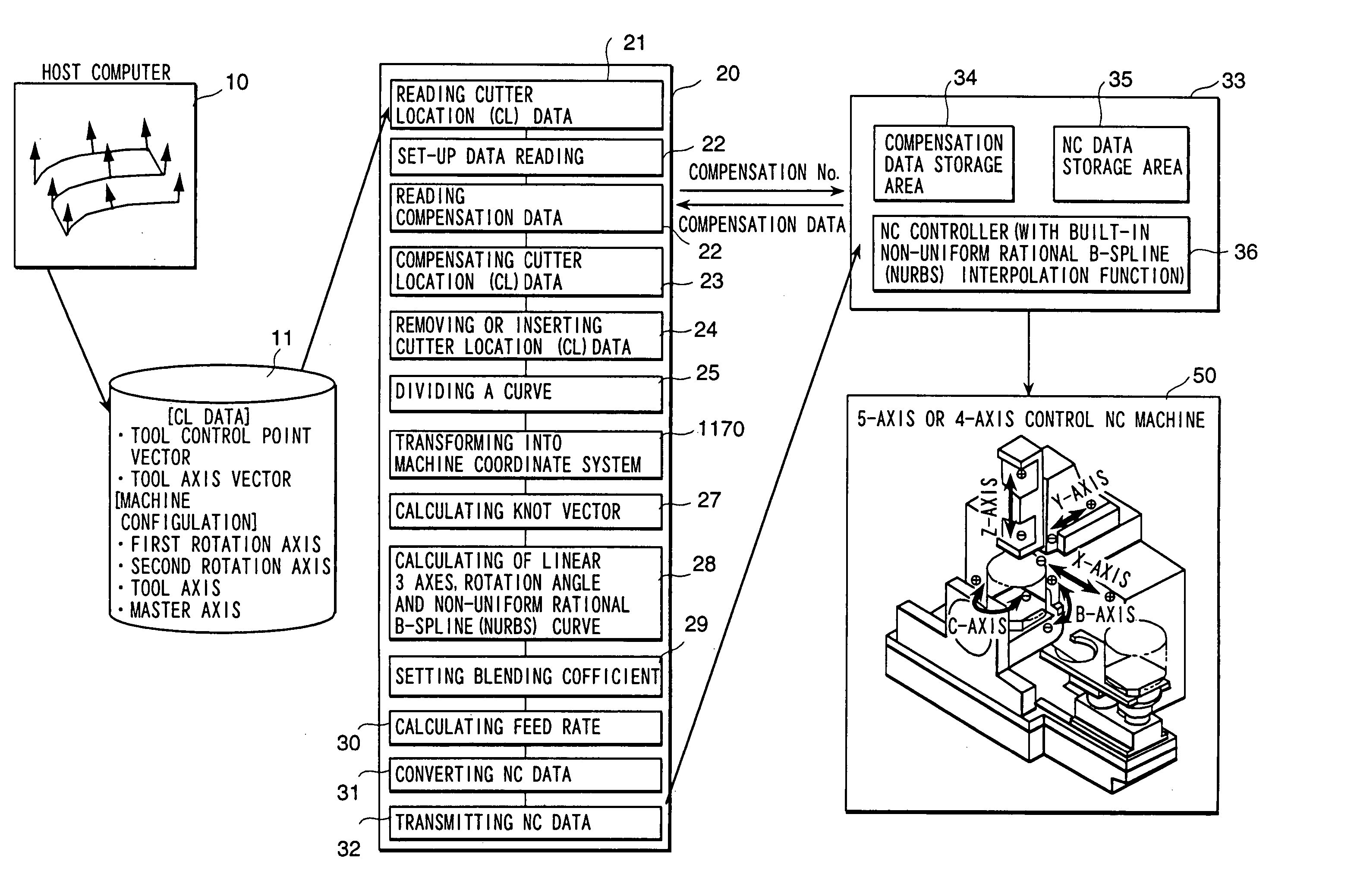

Numerically controlled curved surface machining unit

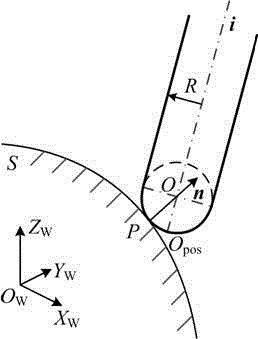

InactiveUS20020002420A1Automatic control devicesDrawing from basic elementsCutter locationSurface roughness

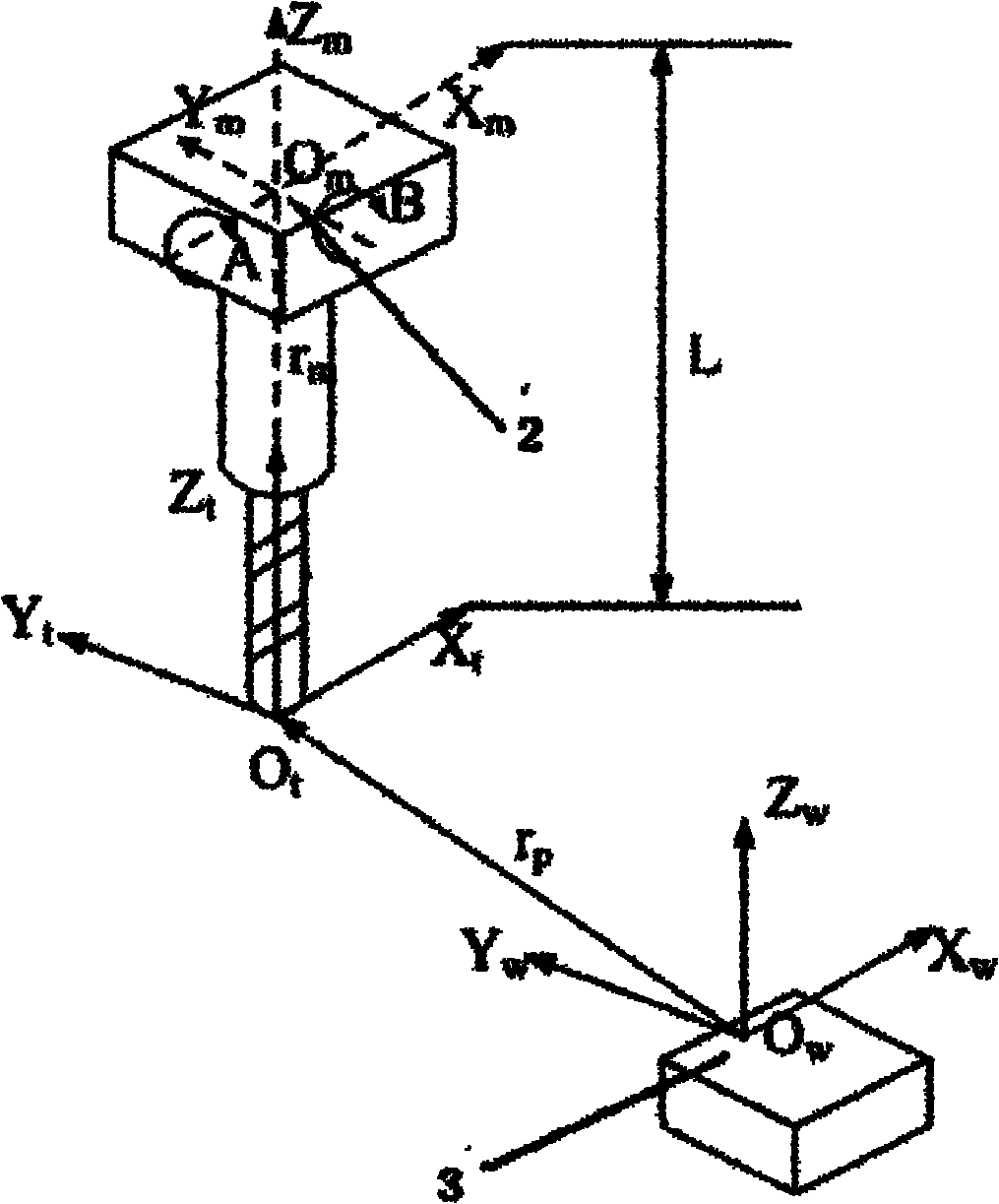

To provide a numerically controlled curved surface machining unit, and a method or program thereof, which, by moving a tool smoothly along a NURBS (non-uniform rational B-spline) curve, enables not only to improve the machining surface roughness and machining surface accuracy but to achieve high-speed machining so as to be able to eliminate hand finishing and reduce machining steps drastically. Performing NURBS (non-uniform rational B-spline) interpolation machining by a machine equipped with a means for reading cutter location (CL) data consisting of a tool control point vector and a tool axis vector on a workpiece coordinate system, a means for converting the CL data into a position vector of three linear axes and a rotation angle on a machine coordinate system in accordance with the machine configuration of a simultaneous multiple-axis NC machine, a means for calculating knot vectors of a NURBS curve with the most suitable chord length on the basis of a position vector of the three linear axes and a rotation angle, a means for calculating NURBS curve of the three linear axes and one rotary axis using the knot vectors, a means for converting the NURBS curve into NURBS interpolation NC data, a means for converting the feed rate on a workpiece coordinate system into the feed rate per minute on a machine coordinate system, and a means for transmitting NC data to a NC machine.

Owner:HITACHI SOFTWARE ENG +1

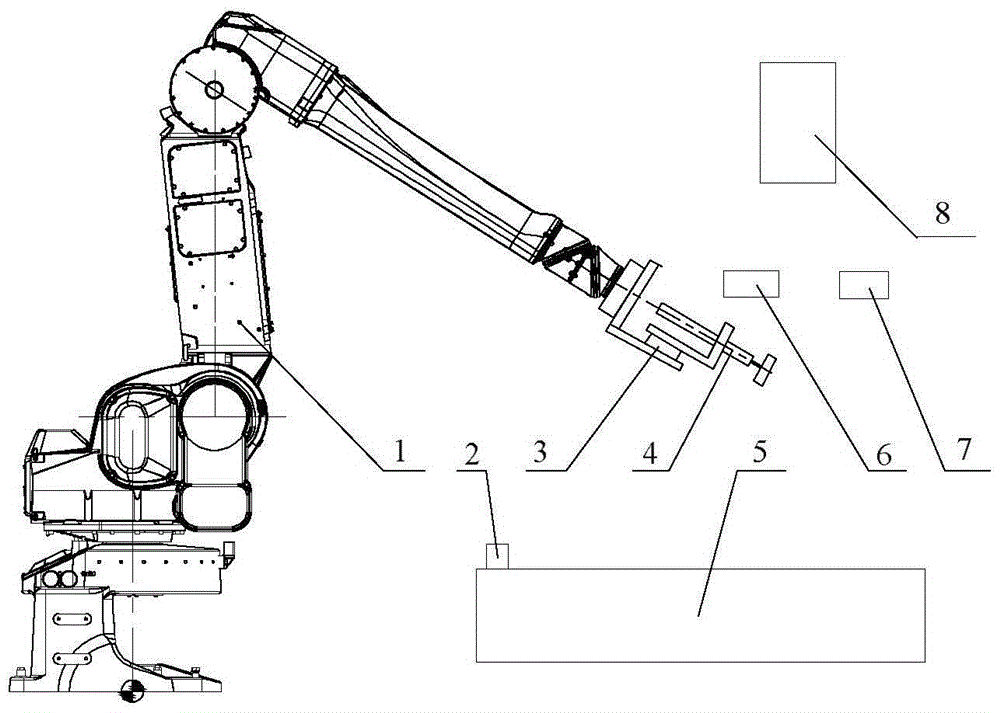

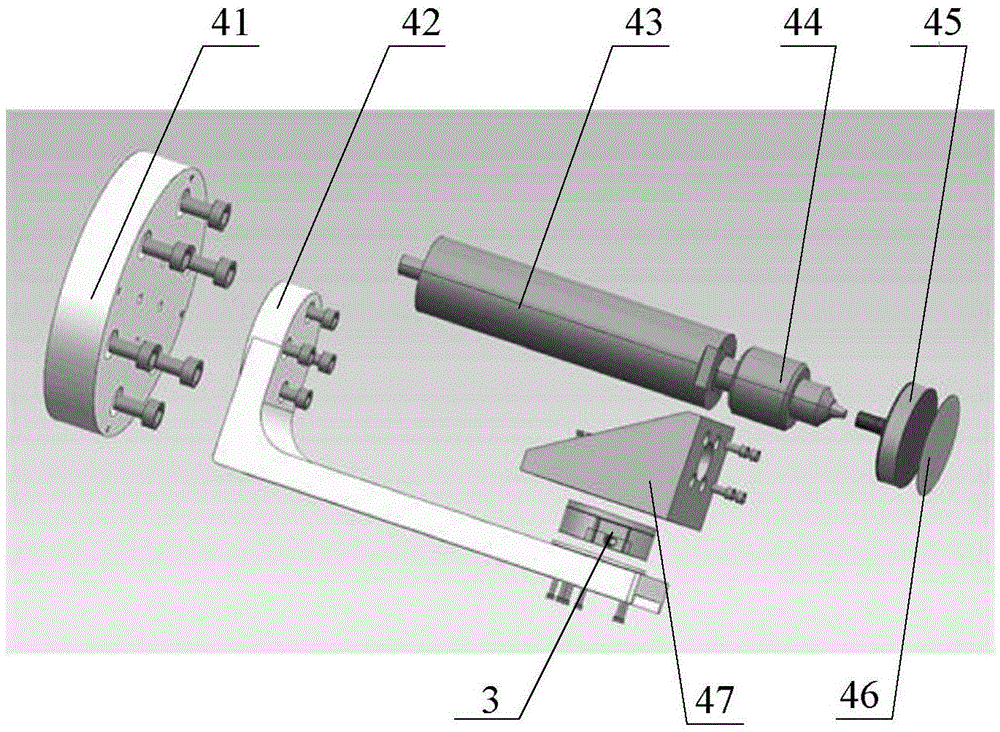

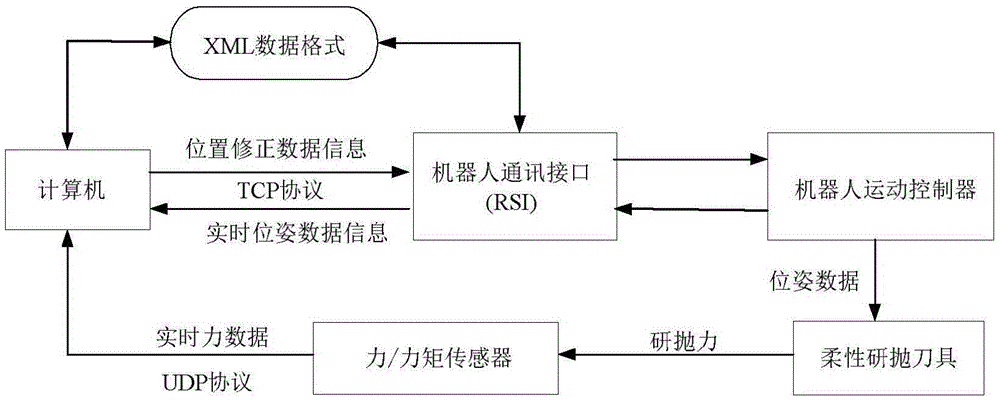

Automatic lapping and polishing system for complex surface of compliant control-based robot and machining method

InactiveCN105643399AReduce manual labor intensityReduce processing costsGrinding wheel securing apparatusGrinding drivesProcess systemsAudio power amplifier

The invention relates to an automatic lapping and polishing system for a complex surface of a compliant control-based robot and a machining method. The automatic lapping and polishing system comprises an industrial robot, a worktable, a force sensor, a flexible lapping and polishing cutter, a signal conversion amplifier, a computer and a robot controller; the method comprises the following steps: performing machining trace planning before lapping and polishing a complex surface workpiece to obtain cutter contact point trace of the lapping and polishing cutter to obtain a surface machining cutter location point trace; converting the surface machining cutter location point trace into a code format program file which can be identified by the robot controller, and inputting the code format program file into the robot controller; positioning and clamping the workpiece to complete coordinate labeling and unification of a process system; and driving the robot to move according to a machining trace planning program file to drive the lapping and polishing cutter arranged on an end executor of the robot to perform contact machining on a machined surface. According to the automatic lapping and polishing system and the machining method disclosed by the invention, manual operation at a finish machining stage of the complex surface workpiece, especially a large-sized complex surface workpiece, can be replaced; labor strength and machining cost are reduced; and quality stability and quality consistency of a machined molded surface are increased.

Owner:SHENYANG LIGONG UNIV

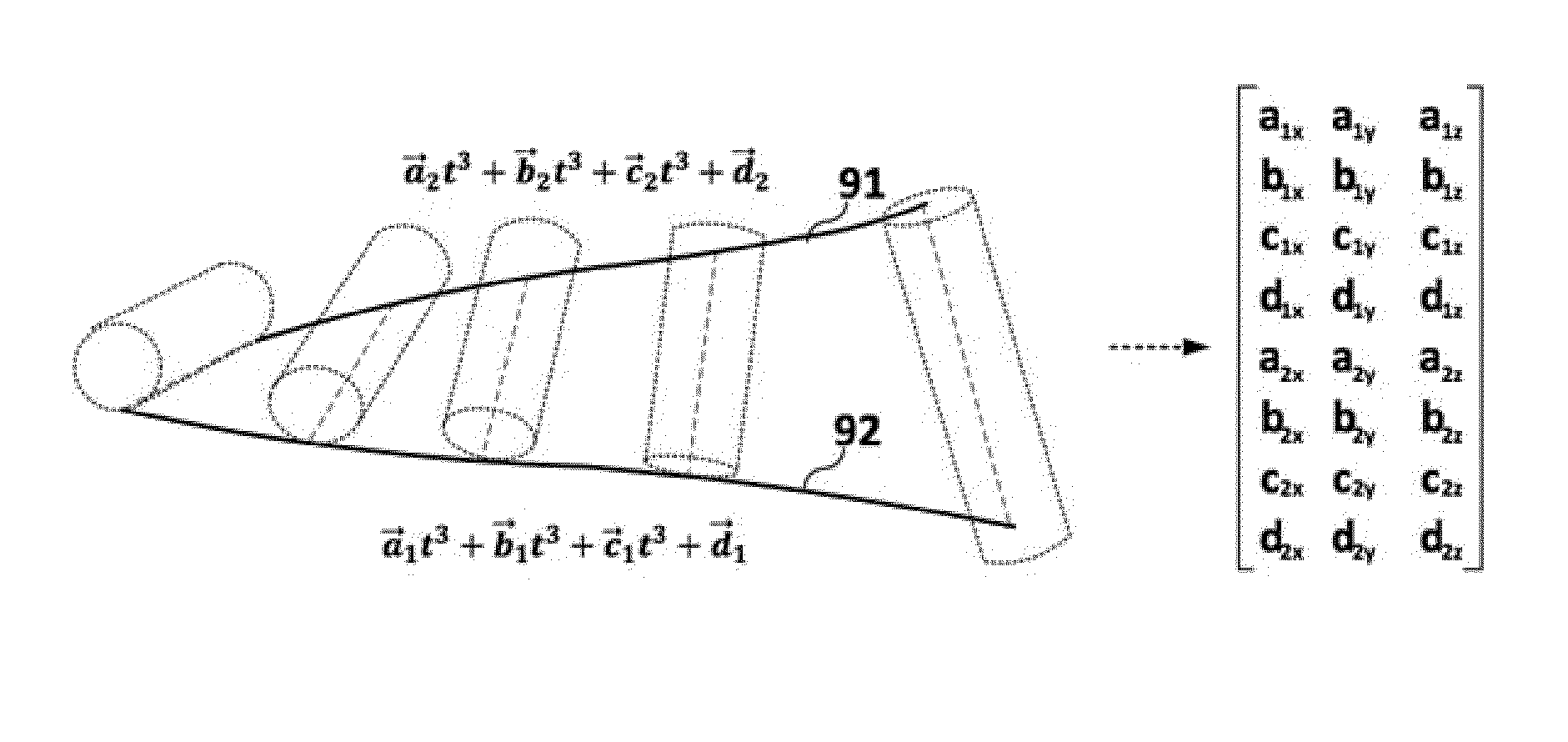

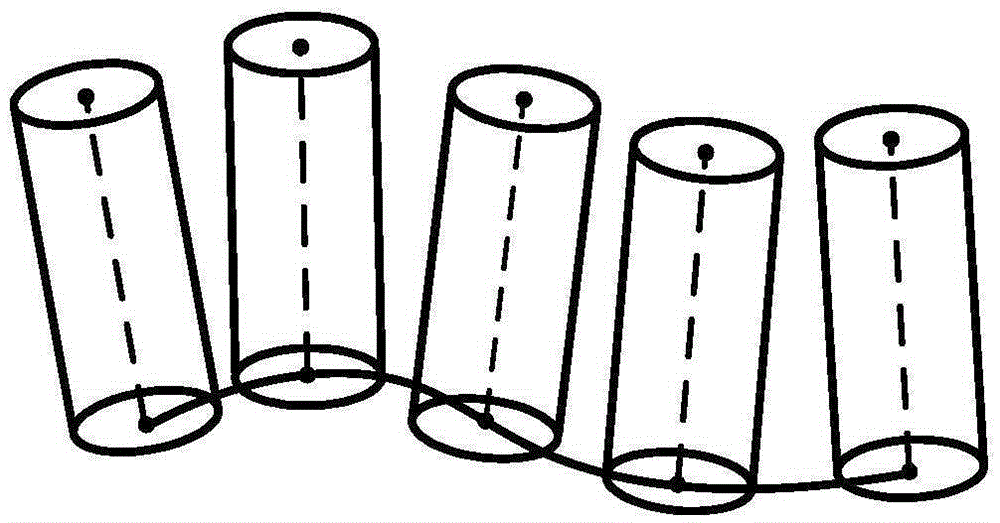

Five-axis flank milling system for machining curved surface and toolpath planning method thereof

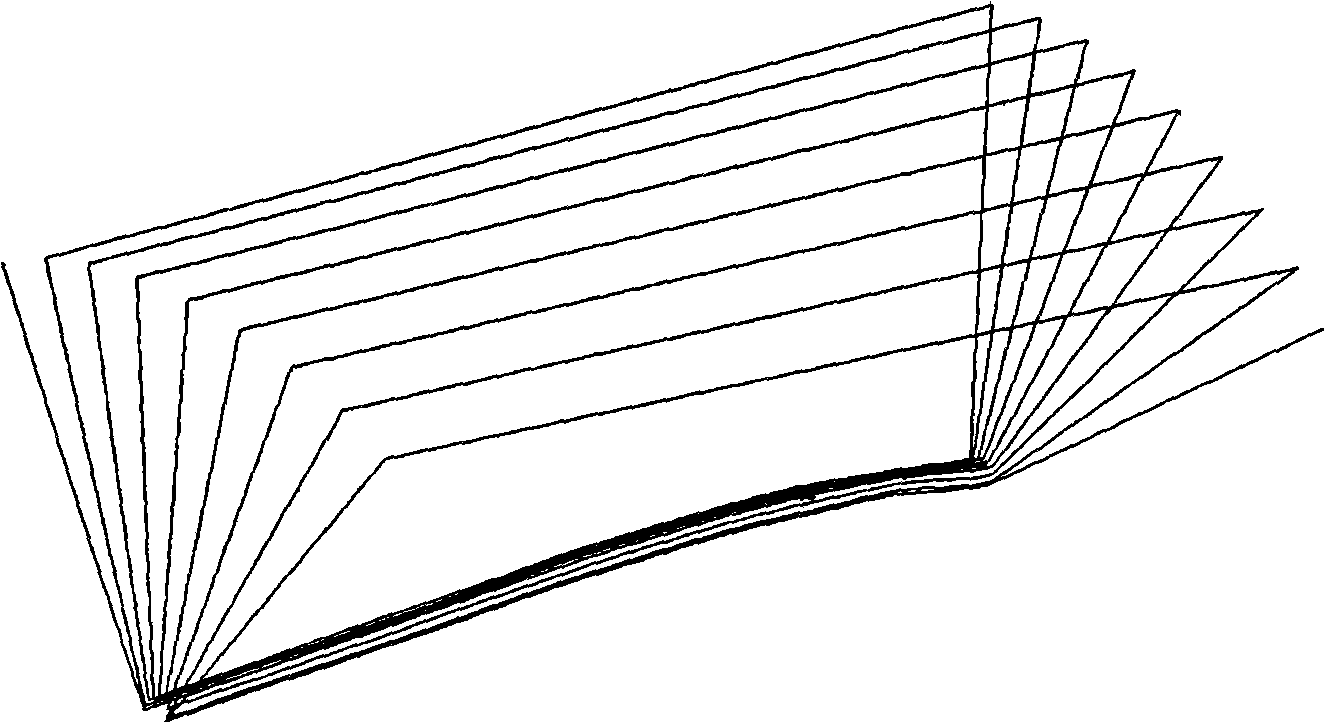

ActiveUS20150032250A1Reduces uneven modificationQuality improvementSpecial data processing applicationsNumerical controlCutter locationMachined surface

This invention provides a novel tool path planning method for five-axis flank milling by imposing the constraints of curve interpolation on the tool path. The tool motion is described in the form of spline curves during its optimization-driven calculation process, instead of discrete cutter locations in CNC linear interpolation. The coefficients of the curve equations are generated by minimizing accumulated geometrical errors on the machined surface using optimization algorithms. The continuity imposed by the spline motion reduces uneven modifications of cutter locations during the optimization process. The resultant tool path yields superior.

Owner:NATIONAL TSING HUA UNIVERSITY

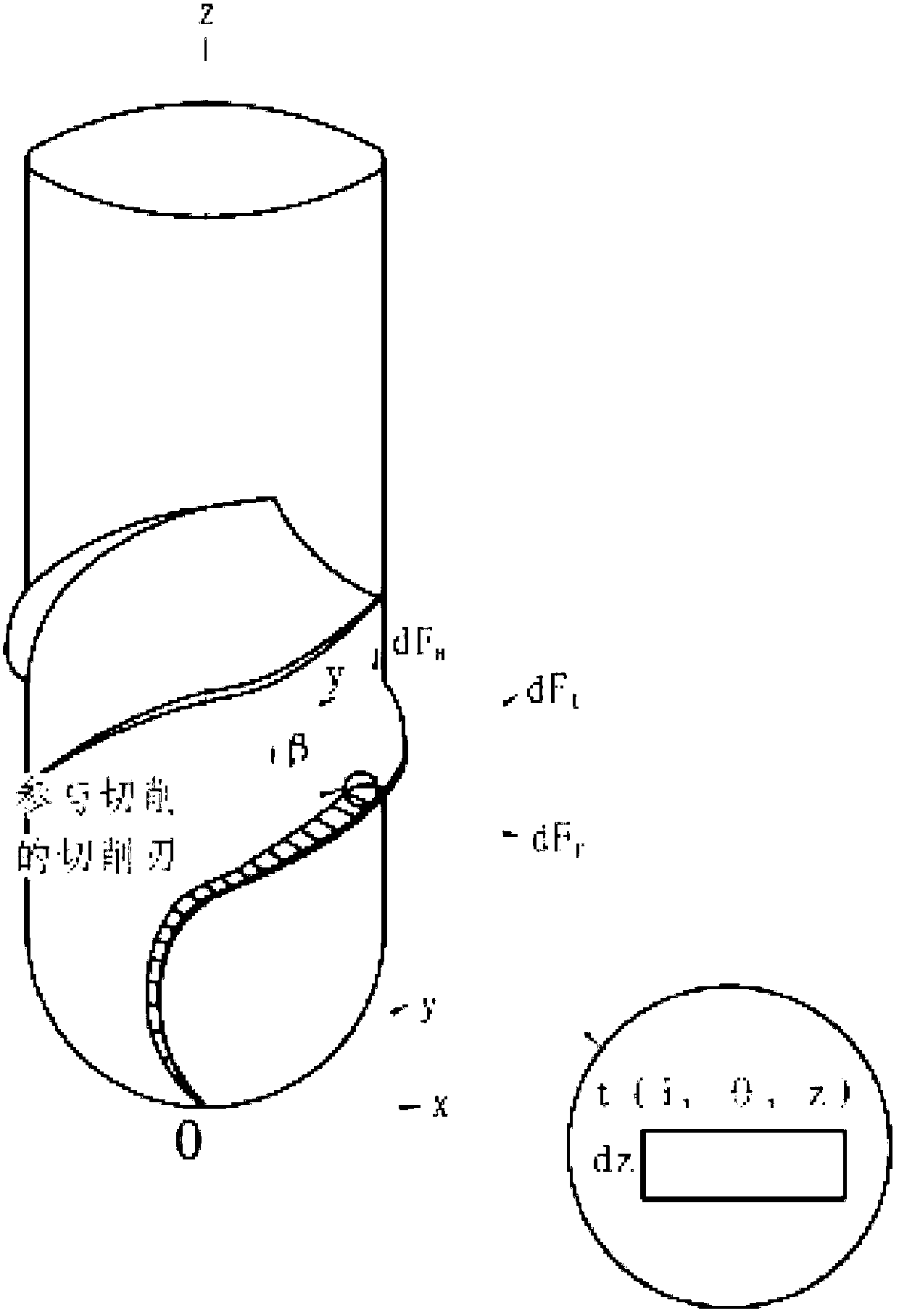

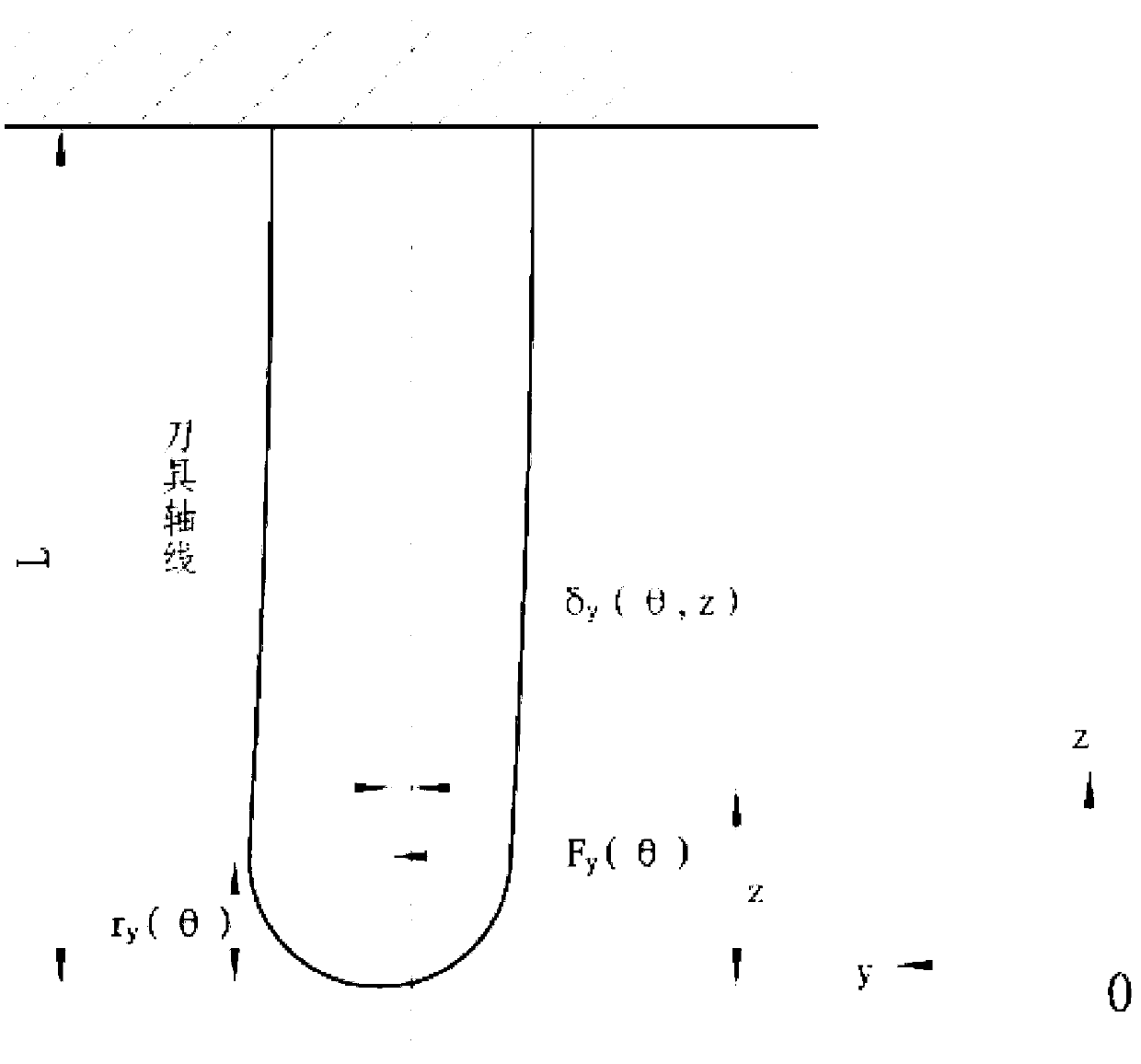

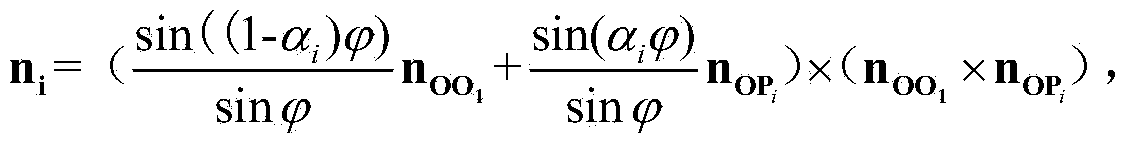

Ball-end cutter multi-axis machining cutter axis vector optimization method

ActiveCN104102171AImprove processing efficiencyImprove processing qualityNumerical controlCutter locationStructural engineering

The invention discloses a ball-end cutter multi-axis machining cutter axis vector optimization method. The method includes the following steps that: at first, a relationship equation between cutter location optimization variables and cutter location data is constructed, and at the same time, a movement transformation equation between the cutter location data and machine tool rotation axis angles is constructed, and therefore a relationship equation between the cutter location optimization variables and the machine tool rotation axis angles can be derived; then, a cutter axis vector computational formula of ball-end cutter multi-axis machining complex curved surfaces can be obtained through solving the above equations; and finally, the ball-end cutter multi-axis machining cutter axis vector optimization method is rendered based on the above steps. With the ball-end cutter multi-axis machining cutter axis vector optimization method adopted, large fluctuation of machine tool rotation axes in a machining process can be avoided, and the movement of the machine tool axes is more stable and smooth, and therefore, machining quality and machining efficiency of the curved surfaces can be improved. The ball-end cutter multi-axis machining cutter axis vector optimization method has a certain practical application value.

Owner:SHANDONG UNIV OF TECH

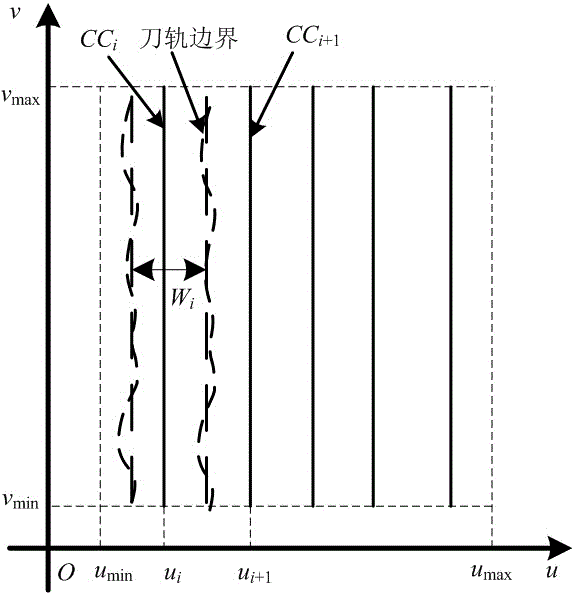

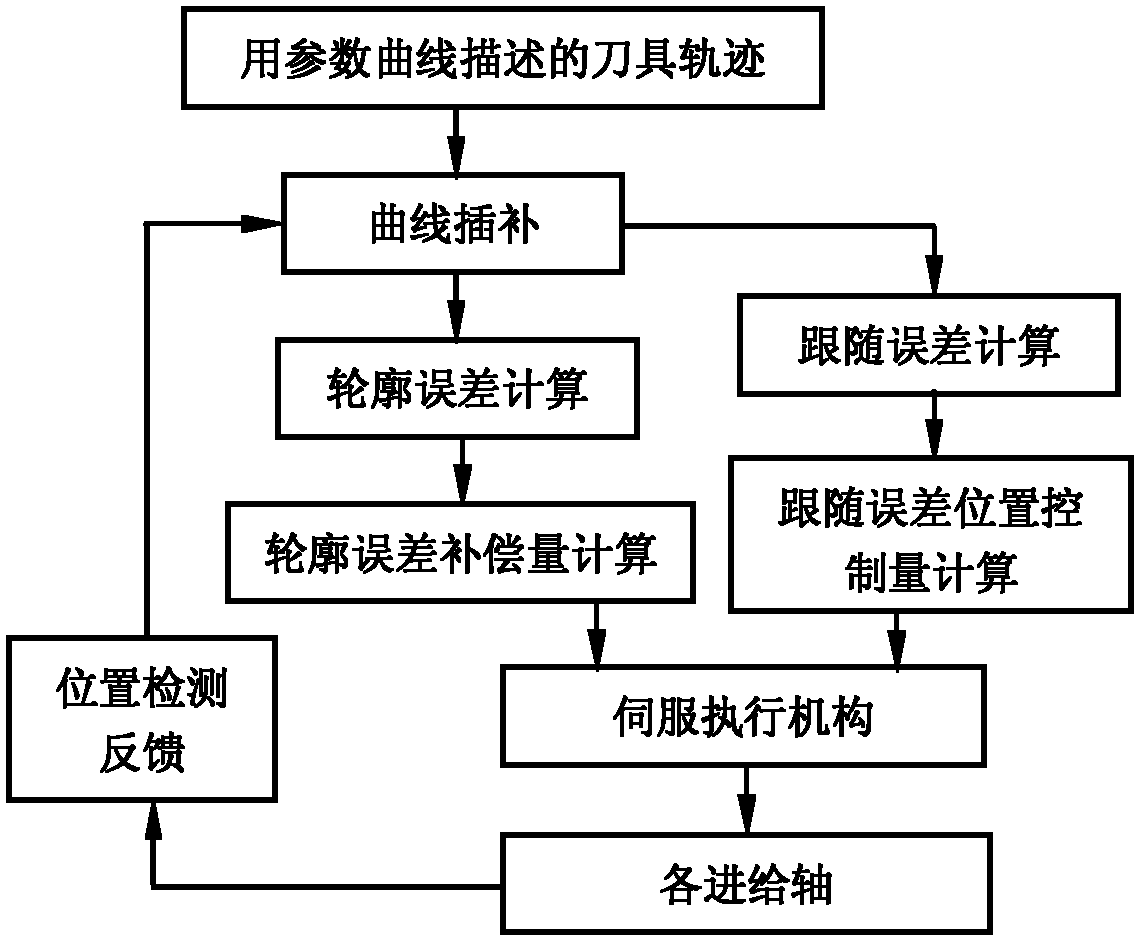

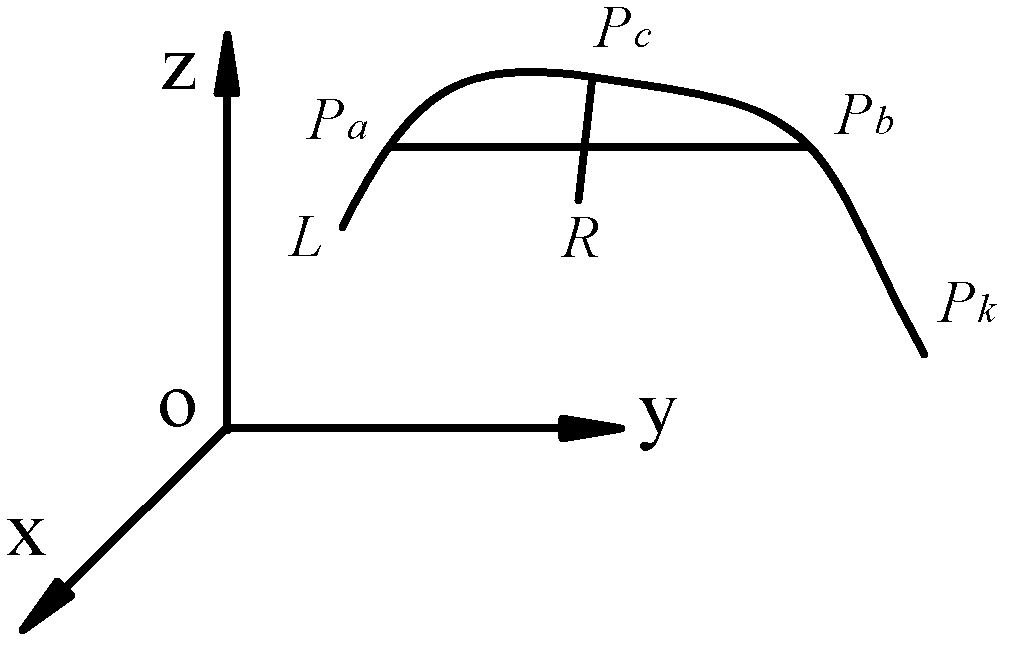

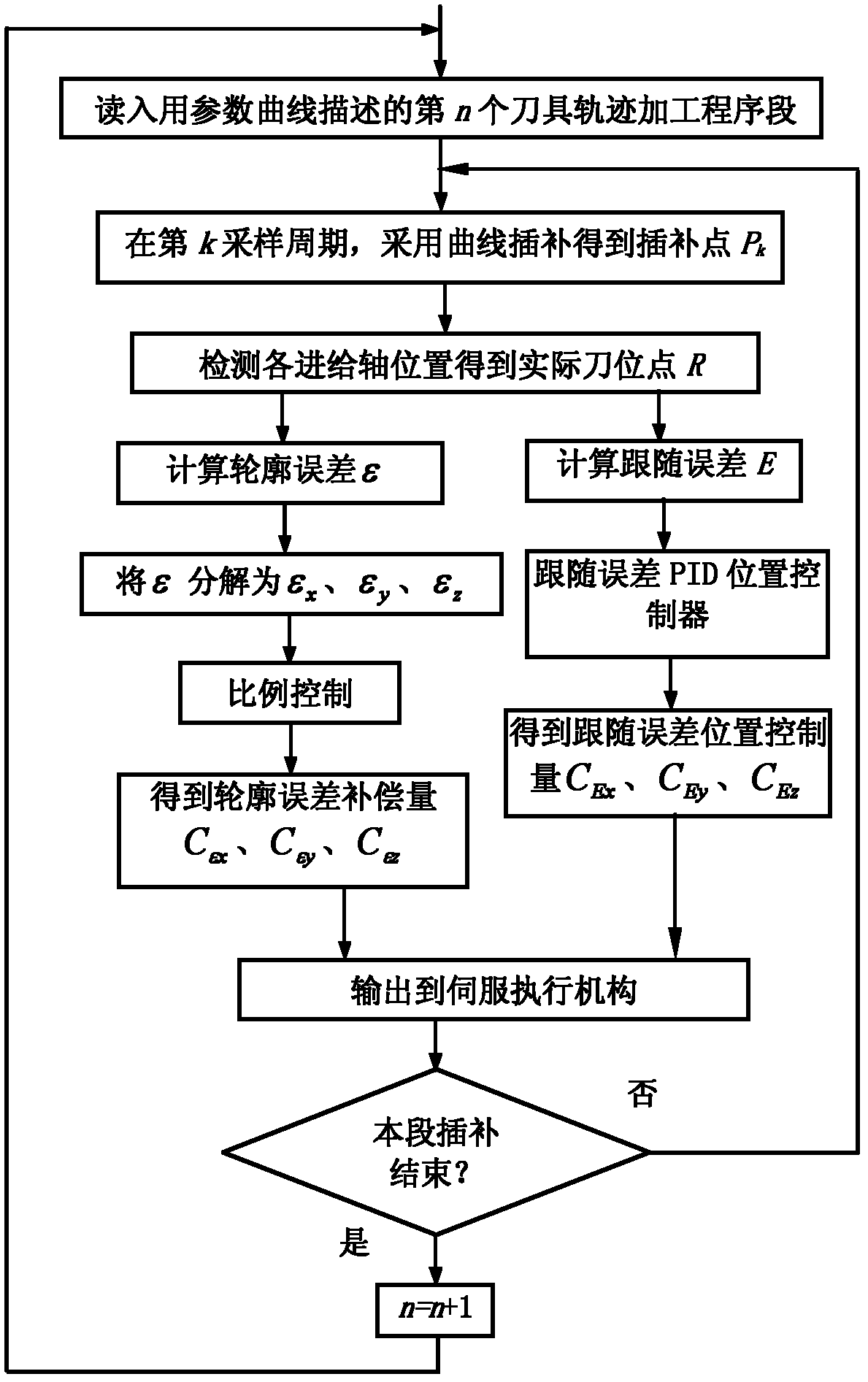

Parameter curve cutter path oriented numerical control system contour error control method

InactiveCN102591257ACalculation method is simpleImprove calculation accuracyProgramme controlComputer controlProportional controlCutter location

The invention provides a parameter curve cutter path oriented numerical control system contour error control method which comprises the following steps of: 1) calculation of the contour error; 2) calculation and control of the contour error compensation quantity, and is characterized in that: in the step 1), in each sampling period for performing curve interpolation on the parameter curve cutter path, the contour error epsilon is calculated according to the current actual cutter location point and the interpolation point on the tracked parameter curve cutter path, namely the shortest distancefrom the current actual cutter location point to the tracked parameter curve cutter path is calculated; in the step 2), the components of the contour error epsilon along the X axis, Y axis and Z axisare calculated, and the contour error compensation quantities are obtained by proportional control and superposed with the location control quantities for the following error on the X axis, Y axis and Z axis respectively; and then the result is output to a servo execution mechanism to perform contour error compensation control. The method provided by the invention has the advantages that: the contour error calculation precision is high, the contour error compensation method is simple and effective, and the contour precision can be obviously improved.

Owner:SHANDONG UNIV OF TECH

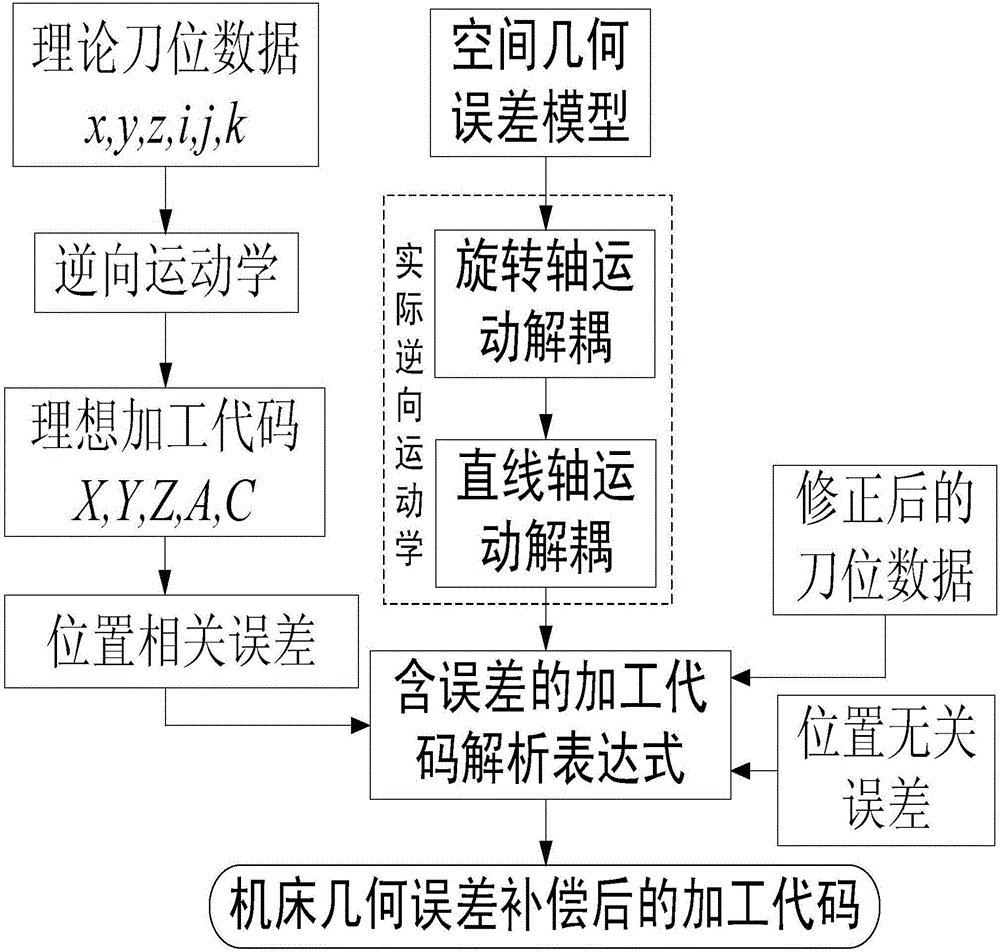

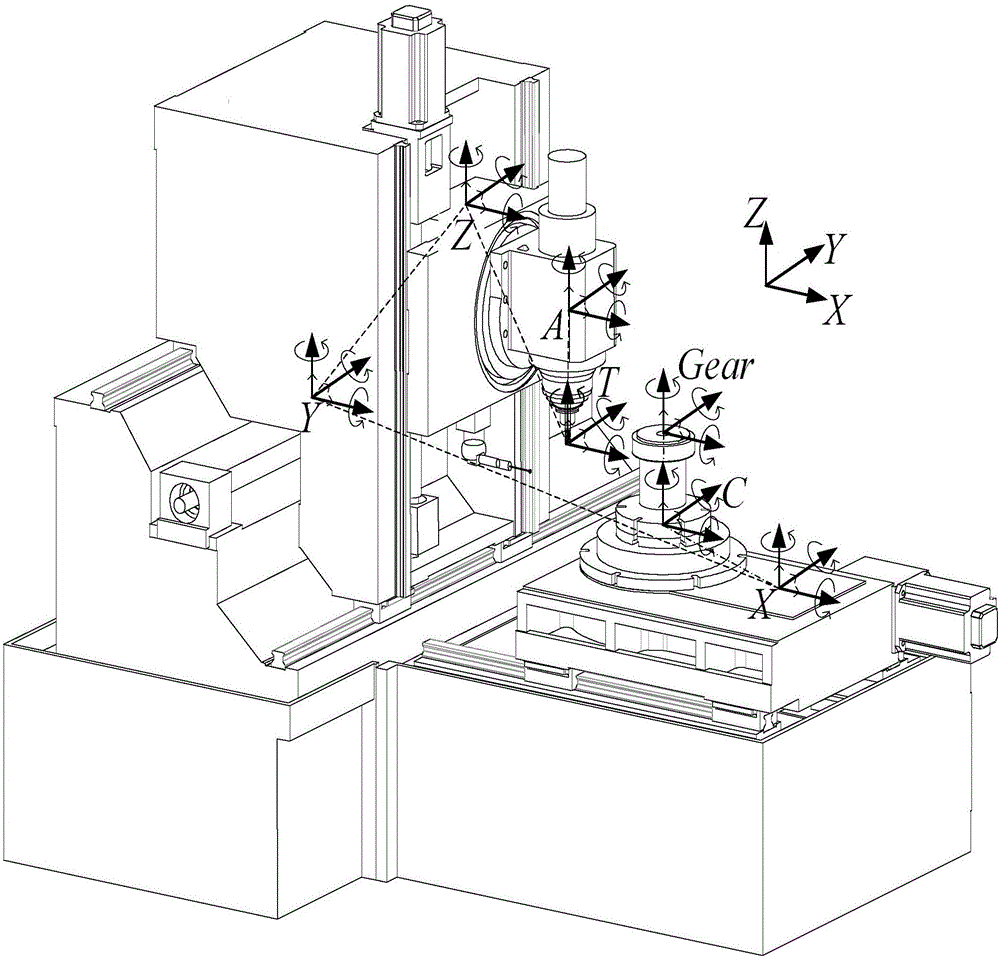

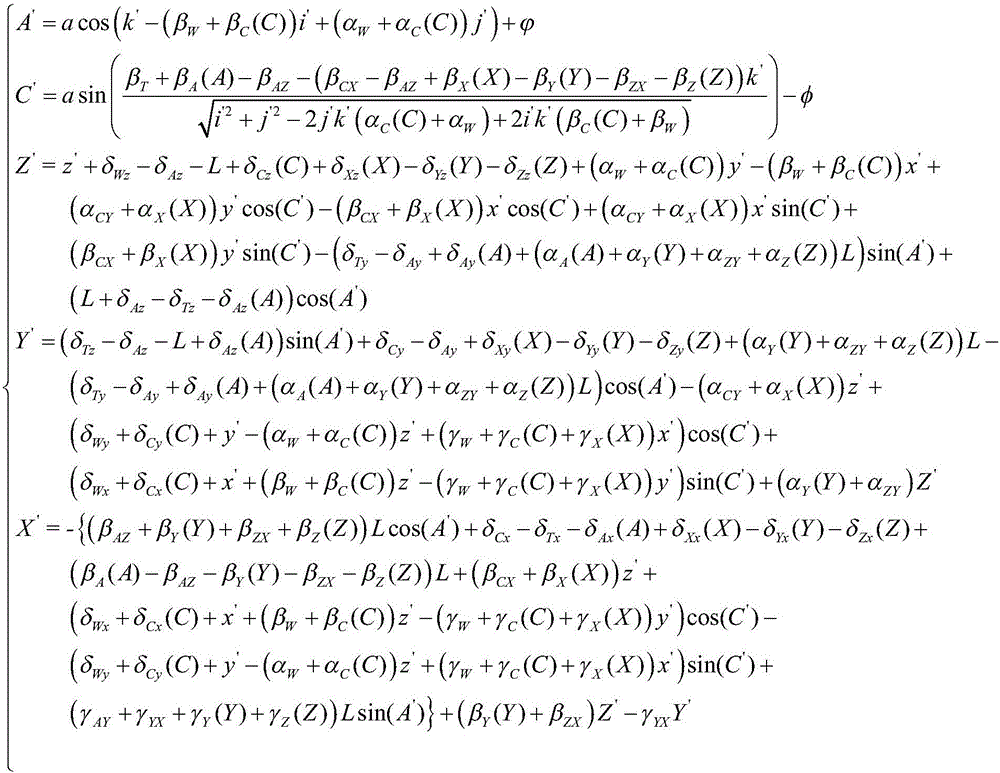

Method for actually compensating for geometrical errors of five-axis numerical control tooth manufacturing machine tool through inverse kinematics

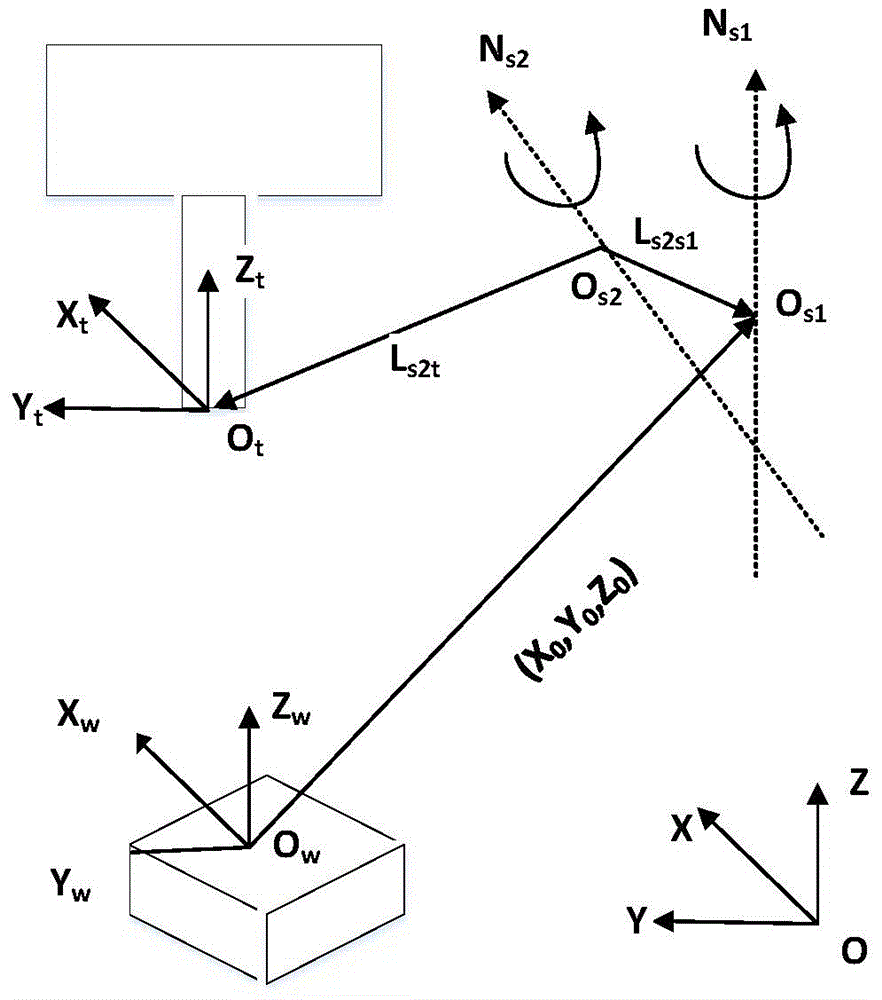

ActiveCN106325207AImprove computing efficiencyProgramme controlComputer controlCutter locationAnalytical expressions

The invention provides a method for actually compensating for geometrical errors of a five-axis numerical control tooth manufacturing machine tool through the inverse kinematics. The method includes the steps of building a space geometrical error model containing position unrelated errors and position related errors on the basis of a homogeneous coordinate transformational matrix, and deducing a processing code analytical expression containing the geometrical errors from the space geometrical error model according to the characteristics of the homogeneous coordinate transformational matrix. Theoretical cutter location data is modified by 12 pose deviations (6 static pose deviations and 6 movement pose deviations) of a cutter relative to a workpiece. The geometrical errors of the machine tool can be compensated for by substituting the position unrelated errors, the position related errors and the modified cutter location data into the processing code analytical expression for compensating for the geometrical errors of the machine tool, and meanwhile the12 pose deviations of the cutter relative to the workpiece are modified. The error compensation method is simple in compensation process, easy to understand, small in calculation amount, high in compensation efficiency and wide in application range, and the basic compensation concept of the method is suitable for numerical control machine tools of various types.

Owner:NANJING GONGDA CNC TECH

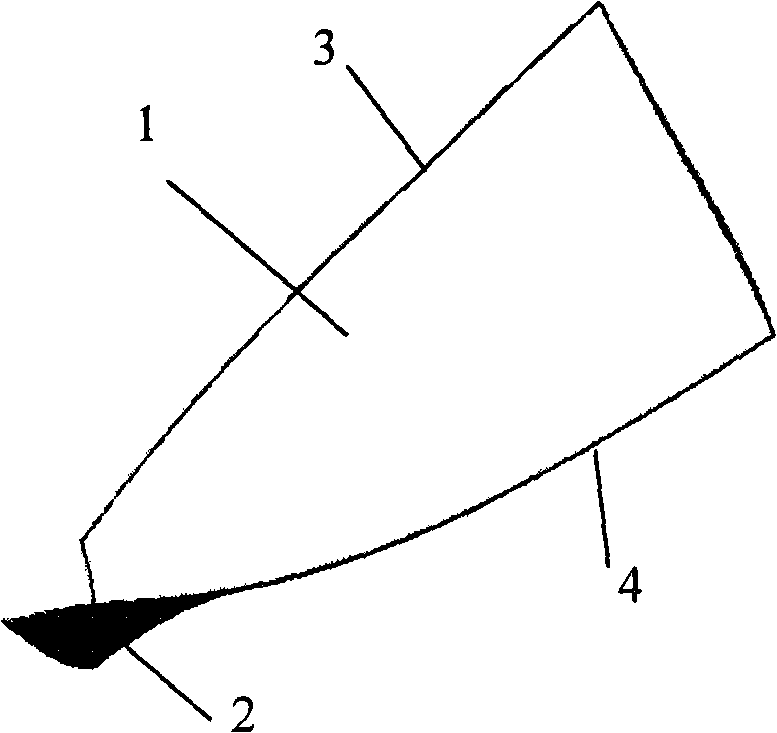

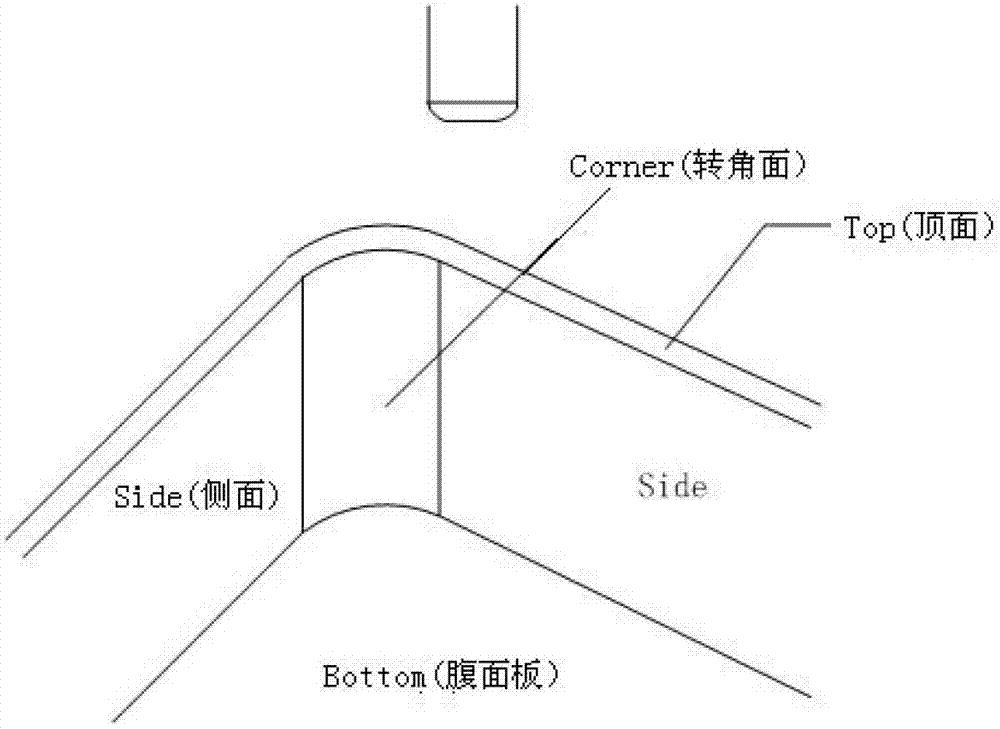

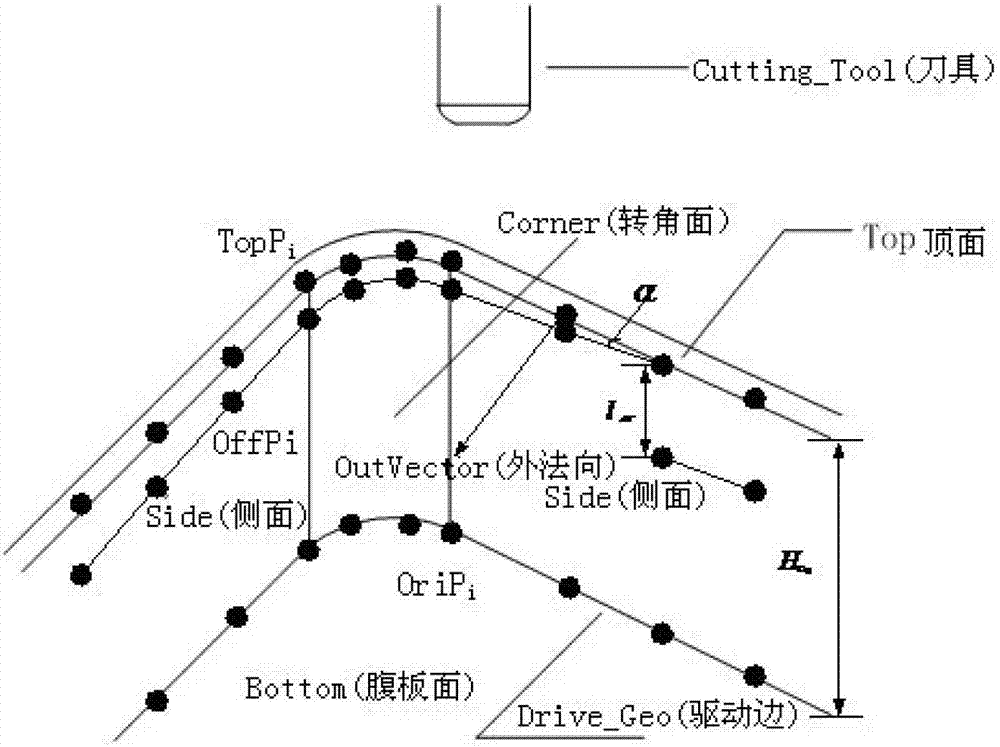

Radial direction milling method of thin wall blade edge head curved face

InactiveCN101323030APrevent overcutImprove machining accuracyMilling equipment detailsCutter locationDimensional modeling

The invention discloses a radial milling method for an edge head curved surface of a thin walled vane. At first, three-dimensional modeling is carried out on the thin walled vane to be processed, the processing coordinate system of the three-dimensional model of the thin walled vane is adjusted, a vane basin curved surface, a vane back curved surface, a front edge curved surface and a back edge curved surface are respectively extracted, effective processing regions are divided on the vane curved surface and contact point track is designed on the vane basin curved surface and the vane back curved surface, thus obtaining a contact point trajectory covering the whole processing region. Then a non-uniform B sampling curve that connects the trajectory of the vane basin cutter location and the trajectory of the vane back cutter location is constructed on the front edge and the back edge of the vane, and the corresponding cutter-axis vector and the cutter location are calculated. As only the vane basin curved surface and the vane back curved surface are involved in the cutting in the processing process, the front edge curved surface and the back edge curved surface are processed separately, thus avoiding over-cutting caused by intensive cutter locations on the front edge and the back edge and violent change of the cutter-axis vector. The processing precision can be improved to 0.05 to 0.10mm from 0.24 to 0.60mm of the prior art, and the processing efficiency can be improved at the same time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

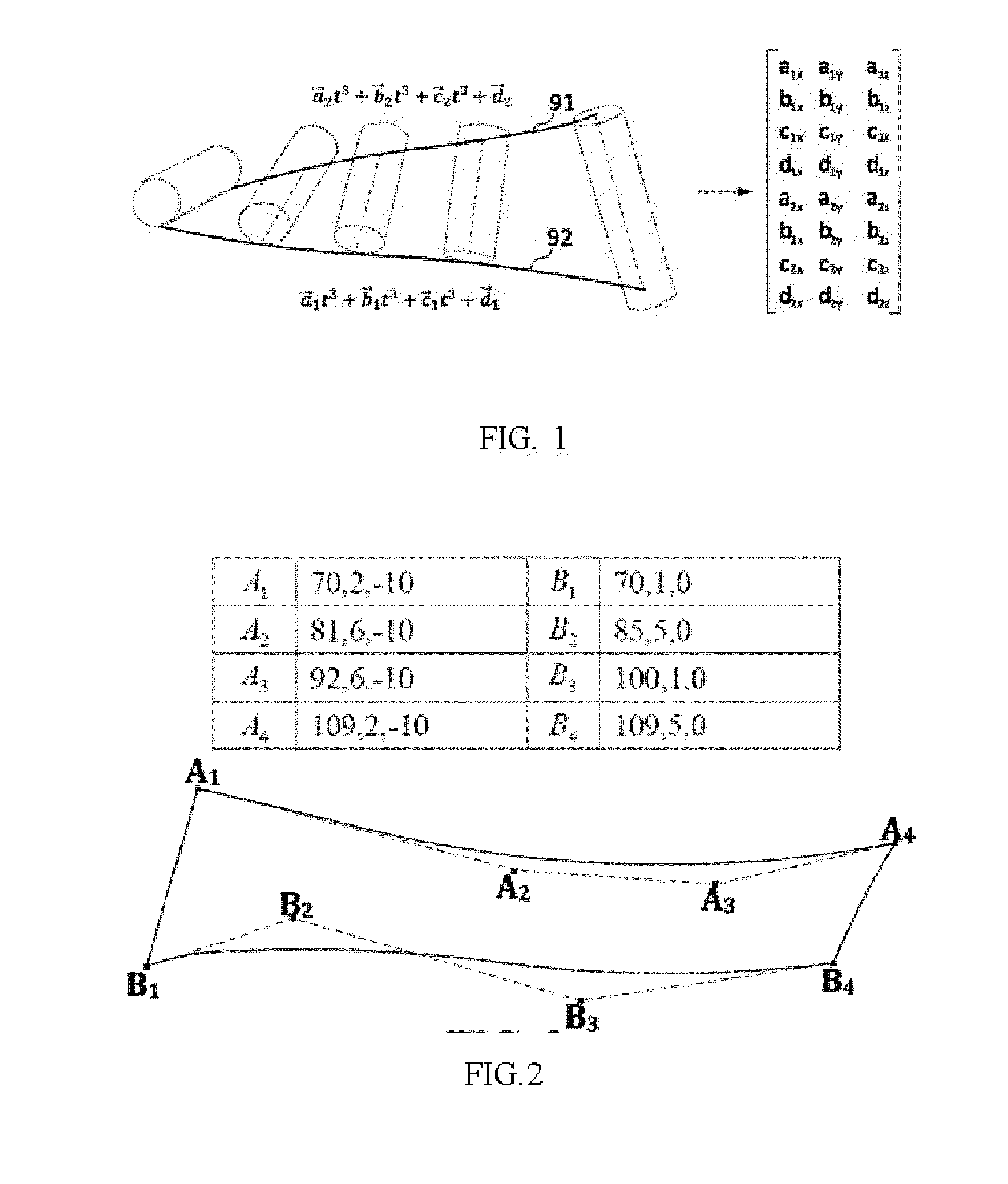

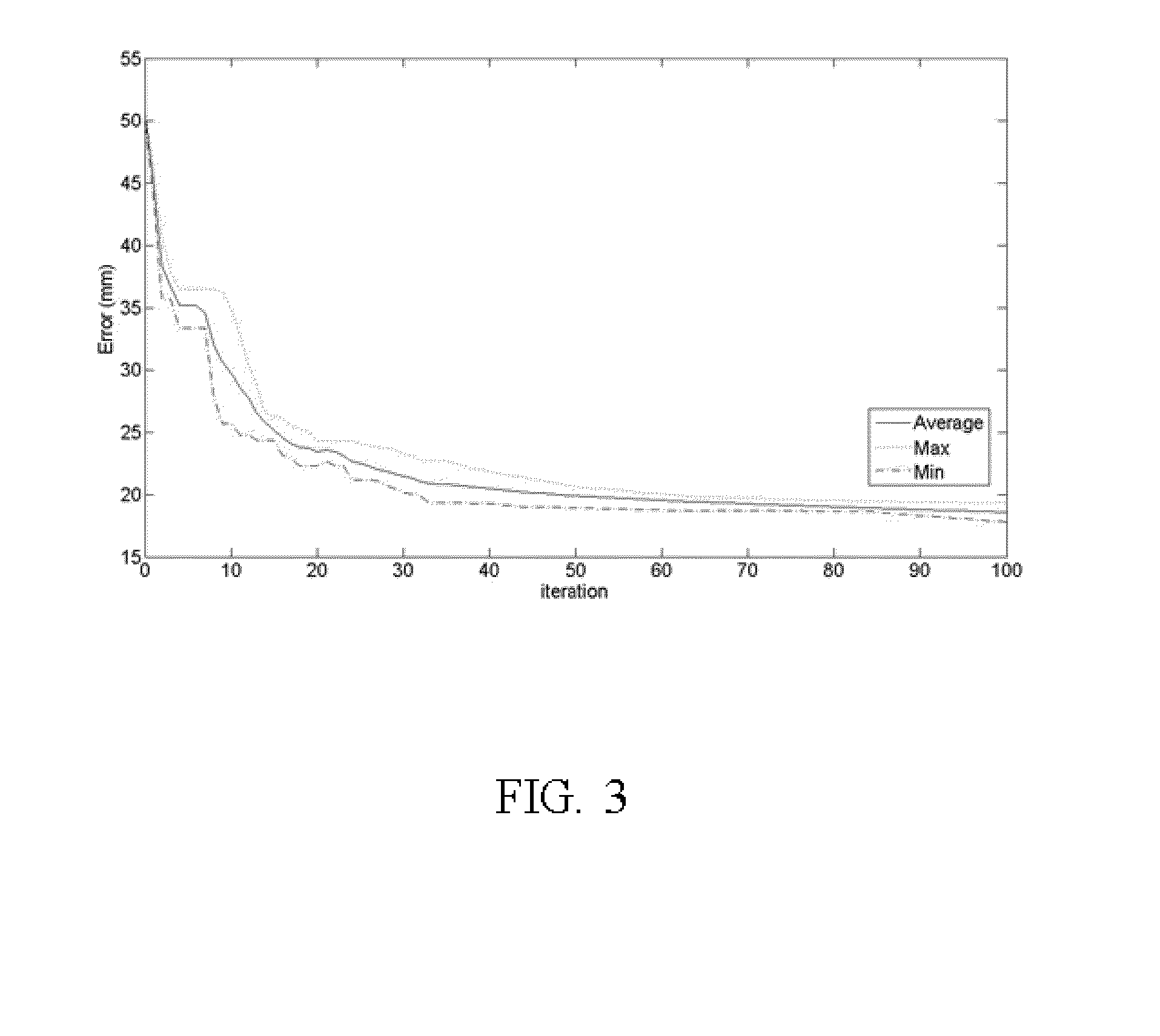

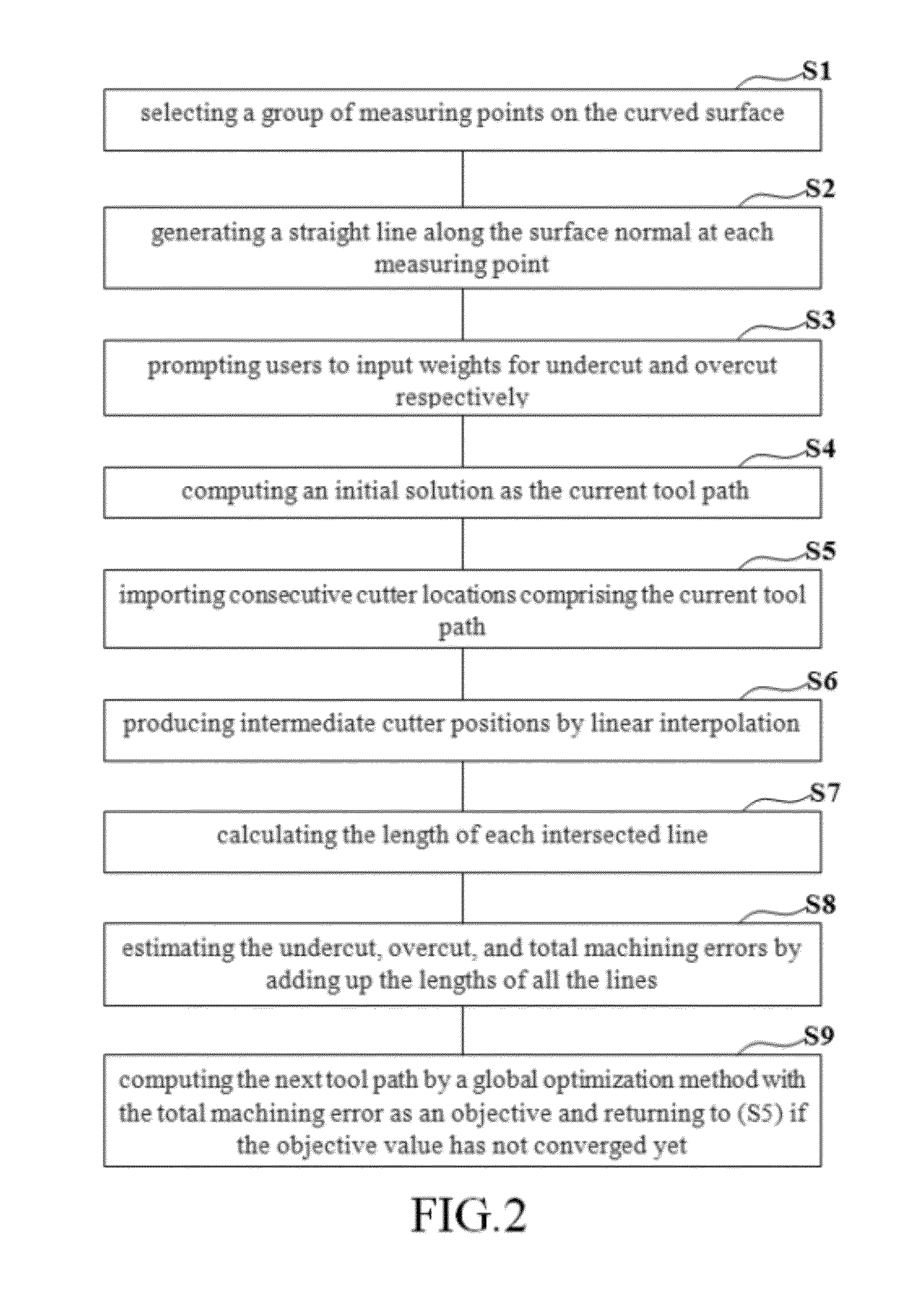

Five-axis flank milling system for machining curved surface and the tool-path planning method thereof

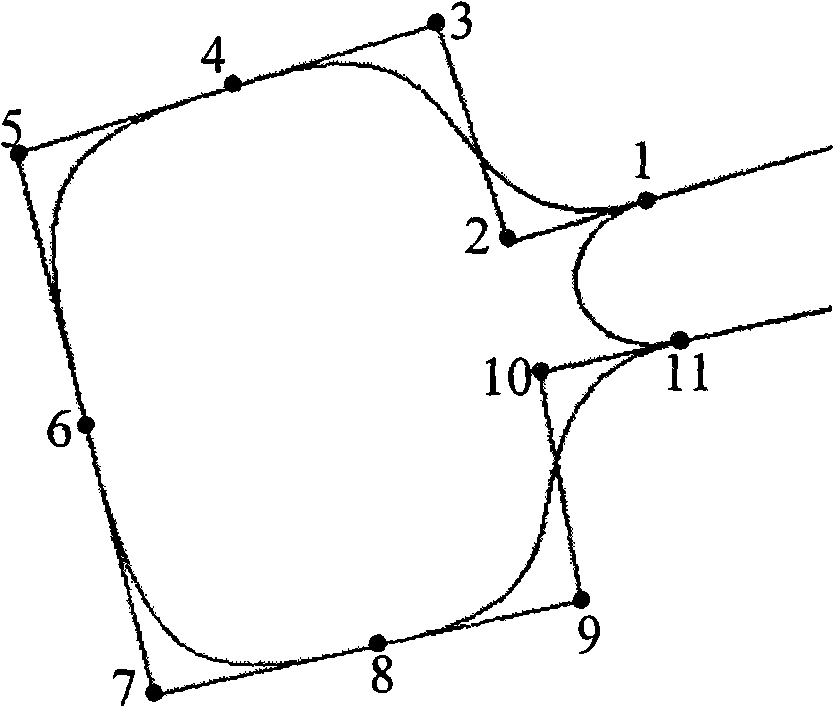

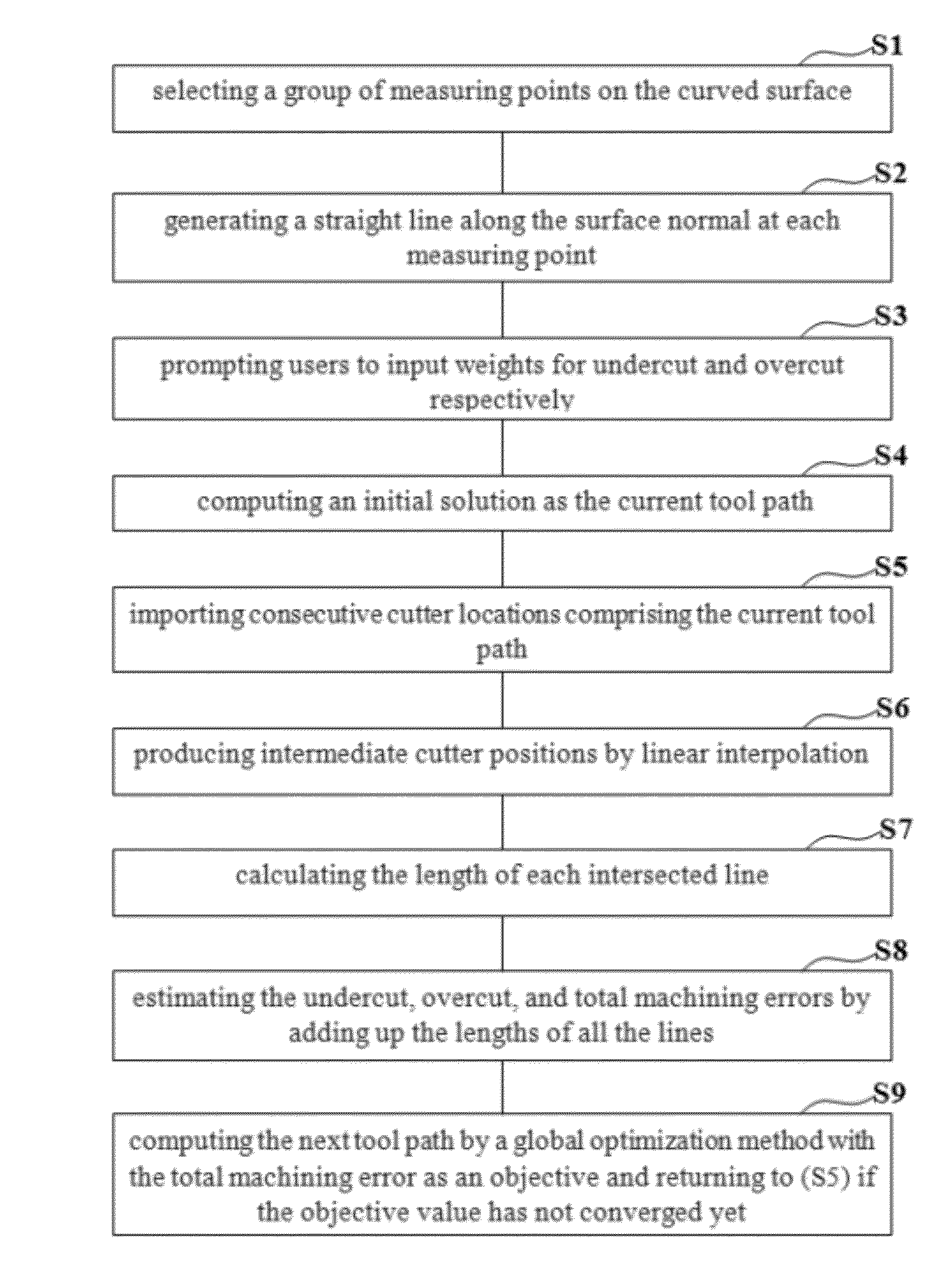

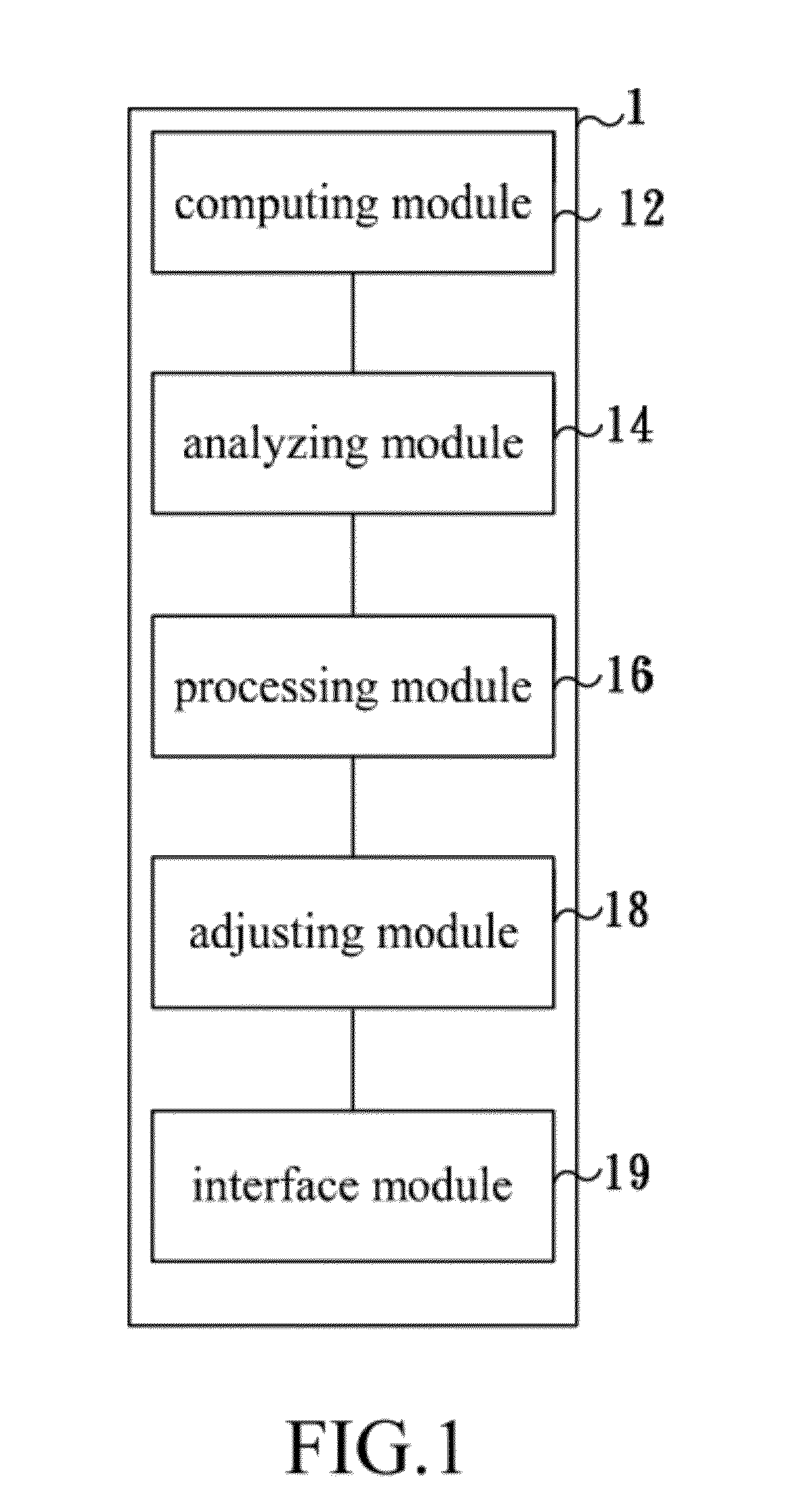

InactiveUS20120265331A1Error minimizationProgramme controlComputer aided designCutter locationPlanning method

The invention discloses a five-axis flank milling system for machining curved surface and the method thereof, the system is capable of generating a tool path that minimizes the undercut error, overcut error, or the total machining error. The amount of the overcut, undercut, or total machining errors can be precisely controlled by adjustment of the cutter locations contained in a tool path. This invention is to transform tool path planning in five-axis flank milling into an optimal matching problem. The proposed mechanism of the invention significantly improves the manufacturing capability of five-axis flank milling. It enhances the machining quality by reducing various machining errors and provides a systematic approach to precise control of machining error in five-axis flank milling.

Owner:NATIONAL TSING HUA UNIVERSITY

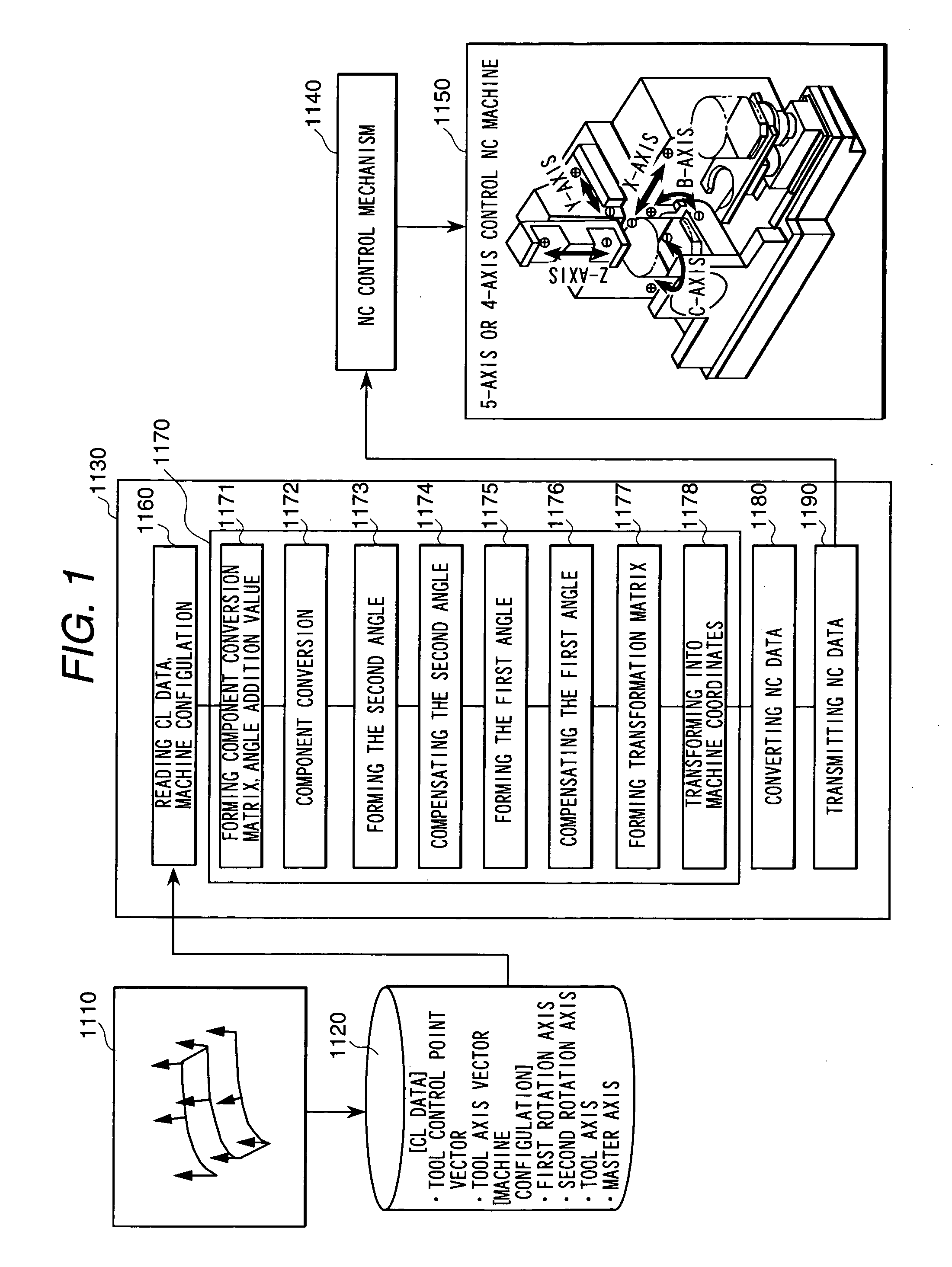

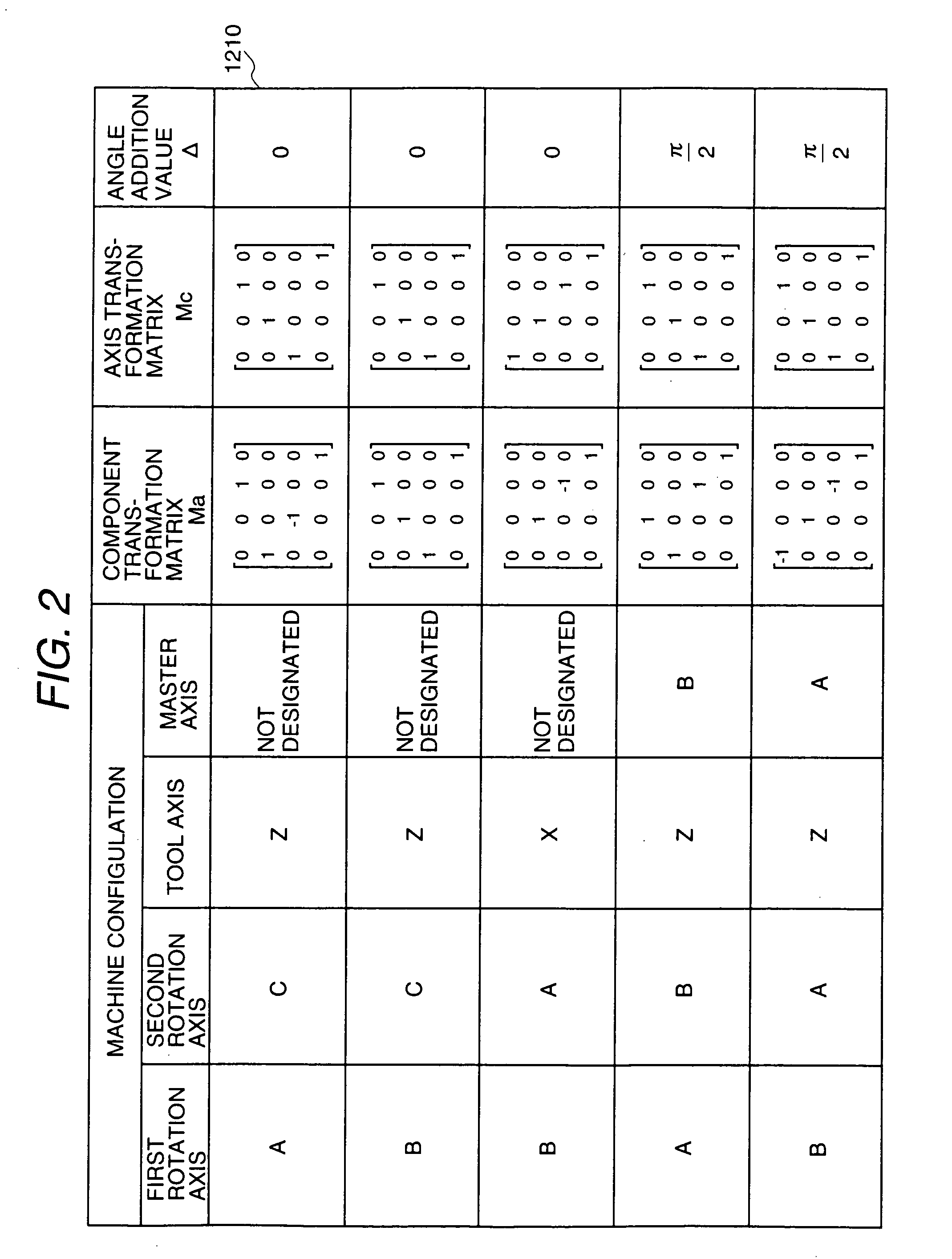

Numerically controlled curved surface machining unit

A numerically controlled curved-surface machining unit comprises a component converting matrix.angle-addition value forming function of converting CL (cutter location) data into components on a normal coordinate system on the basis of the machine configuration of the simultaneous multiple-axis control NC machine, a component converting function of converting from the workpiece coordinate system to the normal coordinate system, a function of forming second angles of a second rotary axis on the normal coordinate system, a compensating function of forming a continuous angle distribution from a distribution of the second angles, a function of forming first angles of a first rotary axis on a coordinate system rotated by the second angles at the second rotary axis, a compensating function of forming a continuous angle distribution from a distribution of the first angles, a machine coordinate transformation matrix forming function of obtaining a matrix for converting the tool control point vectors on the workpiece coordinate system into a machine coordinate system by using the first angles and the second angles, and a machine coordinate converting function of converting the tool control point vectors into the machine coordinate system by using the machine coordinate transforming matrix.

Owner:HITACHI LTD +1

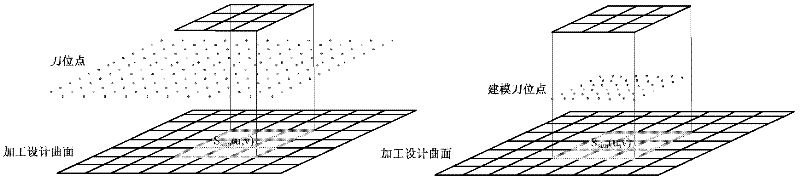

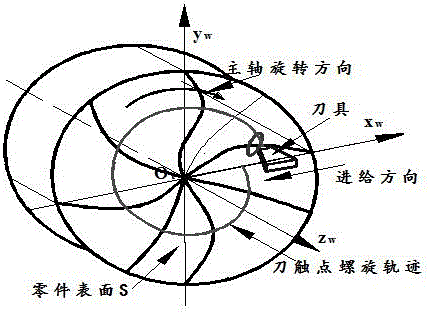

Workpiece three-dimensional surface topography simulating method based on ball head milling

ActiveCN102490081ACharacterize 3D surface topographyAutomatic control devicesFeeding apparatusPoint cloudCutter location

The invention provides a workpiece three-dimensional surface topography modeling and simulating method based on the ball head milling. Firstly, a cutter location point influencing the generation of the three-dimensional surface topography in a simulation area is extracted, and a cutting edge sweeping point cloud model is established according to the combination of the extracted cutter location point with a kinematics model of a cutter in the processing process, then a three-dimensional surface topography sampling point within the range of the simulating area is set, and finally, the workpiecethree-dimensional surface topography in the simulation area is formed. In the invention, the relation among the cutter parameters, the machining parameters and the workpiece three-dimensional surfacetopography is established, so that the three-dimensional surface topography under the condition of ultraprecision machining can be clearly represented, and the technological parameter optimization ofthe workpiece three-dimensional surface topography can be further realized.

Owner:HUAZHONG UNIV OF SCI & TECH

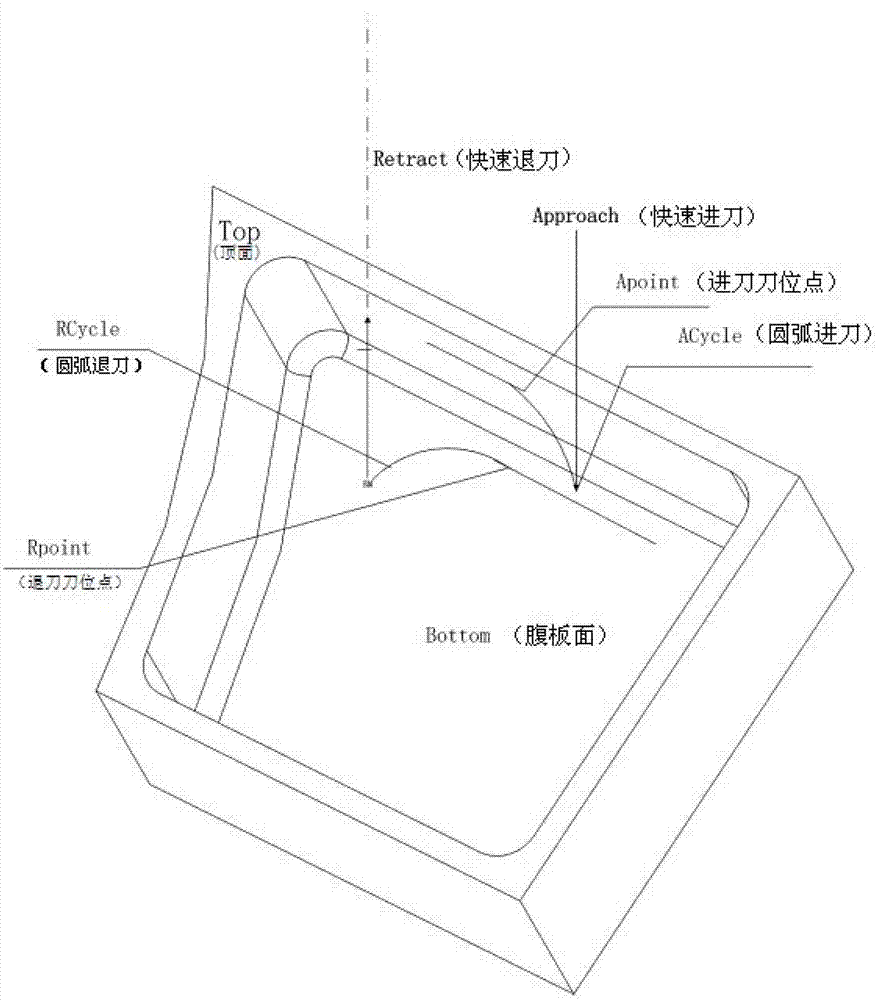

In-groove type helical milling method

ActiveCN102825315AImprove surface qualityExtend your lifeMilling equipment detailsCutter locationEngineering

The invention discloses an in-groove type helical milling method. The in-groove type helical milling method comprises the following steps of 1, extracting an in-groove type drive wire, dispersing the drive wire into base discrete points, axially offsetting the base discrete points to a top surface of a groove along a cutter so that top discrete points are formed, selecting a cutting feed point, setting an arc-shape cutting feed mode, and carrying out axial and reverse offsetting along the cutter based on the top discrete points according to a helical angle and an axial cutting depth so that a first layer of the discrete points are formed and a first layer of cutter location points are formed further, 2, axially, reversely and orderly offsetting the first layer of cutter location points layer by layer to a penultimate layer along the cutter according to the axial cutting depth so that a middle layer of cutter location points are formed, and 3, setting a helical angle of a last layer of cutter location points to zero degree so that the last layer of cutter location points are formed, setting an arc-shape cutter retracting mode, setting a cutter-axis vector of each one of the cutter location points, and connecting the all cutter location points to obtain an integral milling track of in-groove type helical milling. The in-groove type helical milling method can reduce frequency of cutter retracting, improve cutting stability and improve surface processing quality and processing efficiency.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

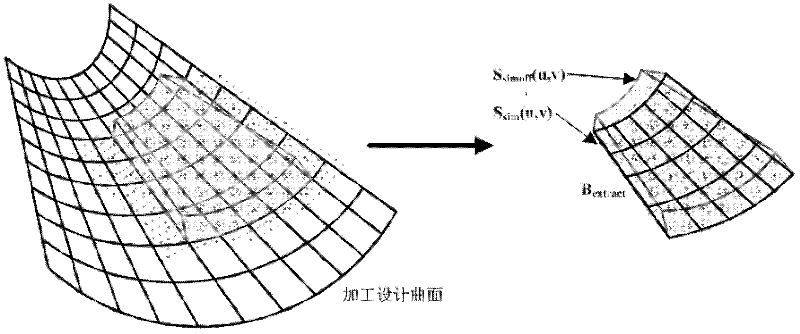

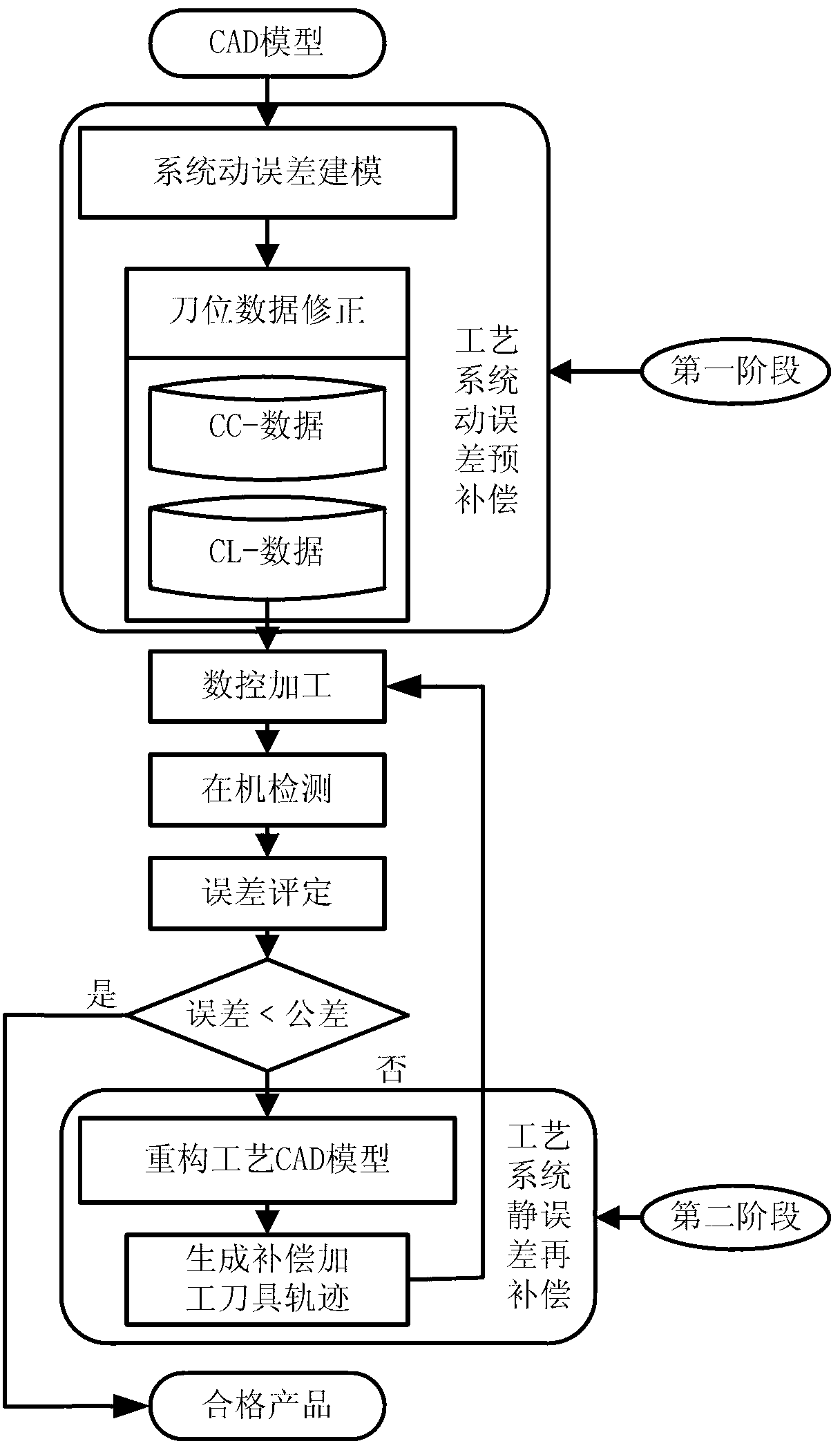

In-process evaluation based complex spatial surface error feedback compensating method

ActiveCN103218475AAvoid repeated positioning errorsReduce handlingSpecial data processing applicationsComputer Aided DesignCutter location

The invention discloses an in-process evaluation based complex spatial surface error feedback compensating method. The method comprises the following steps of processing a complex surface cutting force module through a ball-end cutter, performing dynamic compensation for a target cutter location point for workpiece pre-processing; performing in-process detection for the pre-processed workpiece to obtain geometrical information of an actual contour; evaluating error for the pre-processed workpiece through a contour degree error evaluation model; when the contour error is greater than tolerance, determining a compensation point position U1 corresponding to each contact point; guiding the compensation point position corresponding to each contact point to three-dimensional CAD (Computer-Aided Design) to obtain a compensating process contour to generate a compensating processing tool track; and performing static compensation and processing for the pre-processed workpiece and finishing the flow. Under the premise of ensuring the processing precision of part surface, the processing precision of the part is detected in process without investing fund to purchase more detection devices, so that the conveying and loading time of workpieces is shortened.

Owner:TIANJIN SAIXIANG TECH

Impeller machining cutter-axis vector control method based on five-axis interference-free cutter axis control line

ActiveCN103433804AAvoid global interferenceQuality improvementAutomatic control devicesFeeding apparatusImpellerRotational axis

The invention discloses an impeller machining cutter-axis vector control method based on a five-axis interference-free cutter axis control line. The method is used for solving the technical problem that a machined impeller machined through an existing impeller machining cutter-axis vector control method is poor in quality. According to the technical scheme, the method comprises the steps that a cutter axis selection border is generated, a curve projection surface where the cutter axis control line is located is determined, the offset surface of an impeller to be machined is expanded along the tangential direction of an air inlet edge and the tangential direction of an air exhaust edge, and an five-axis interference-free cutter axis control line is constructed to determine the cutter axis vector of any cutter location point. Because the angle between the cutter axis and the rotating shaft of the impeller is singly and evenly changed from the air inlet edge to the air exhaust edge, minimal swinging changes of the cutter axis surrounding the rotating shaft are achieved, minimal angle changes of the cutter axis surrounding the rotating shaft of the impeller are achieved, and two rotating shafts of a machine tool evenly and slowly rotate in the five-axis machining process; the whole blade-type surface multi-axis machining can be achieved through the cutter axis control line, the interference-free cutter axis vector determination of the whole impeller curved blade surface is achieved, and the method is simple; meanwhile, overall interference of the cutter axis is avoided, and the quality of the machined impeller is improved.

Owner:西安三航动力科技有限公司

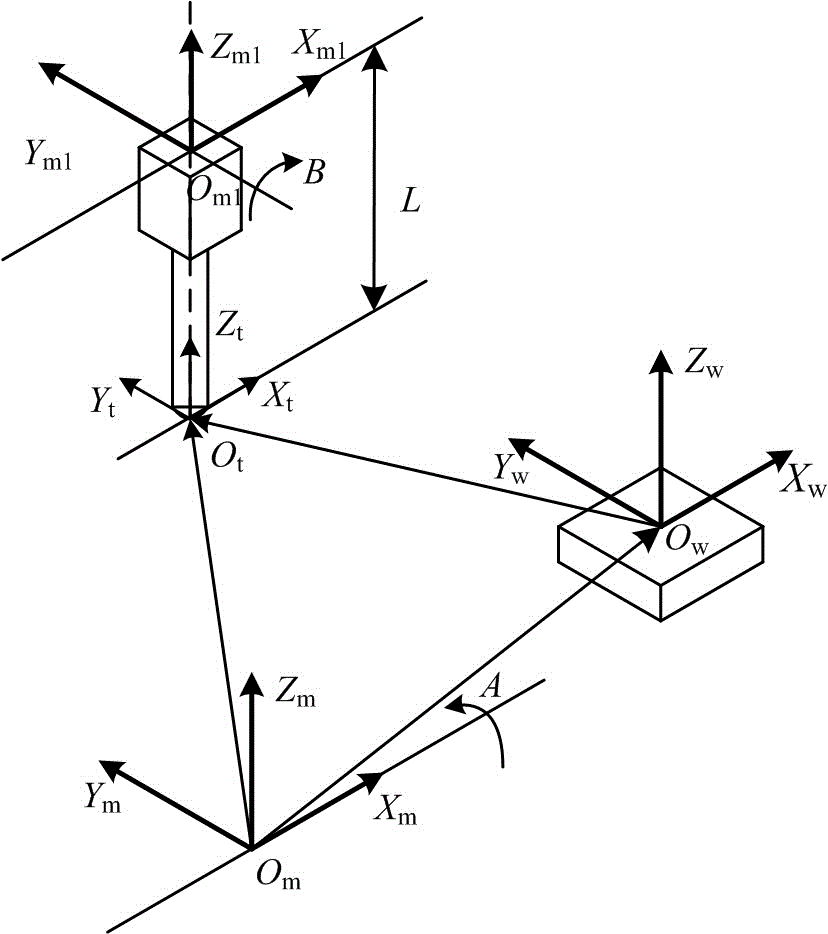

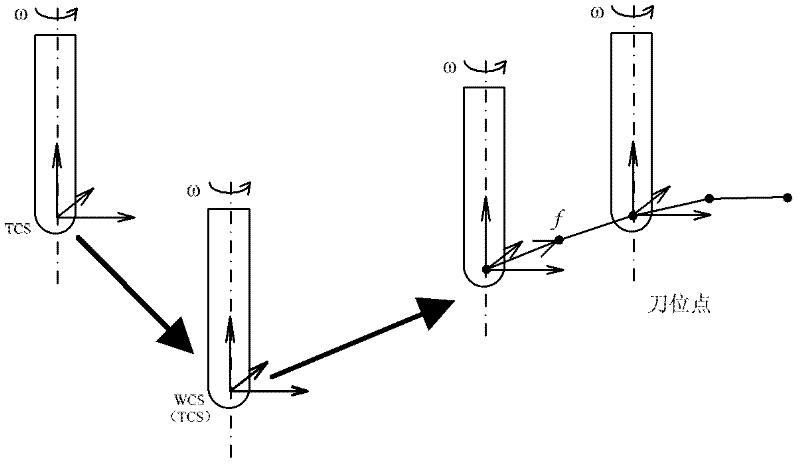

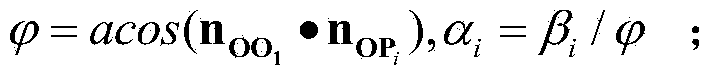

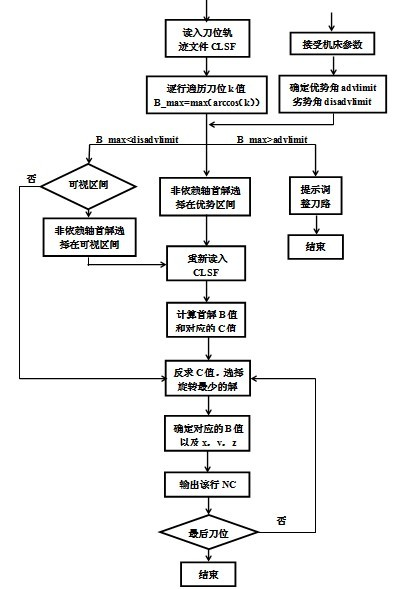

Post-processing method of five-axis linkage NC machining

ActiveCN102269984AAvoid interferenceAvoid knife collisionNumerical controlCutter locationAngular degrees

The invention discloses a post-processing method for five-axis linked numerical control processing. The method provided by the invention comprises the following steps of: (1) separating a planned feeding amount and six parameters in a cutter location sentence from a cutter location file; (2) defining an advantage region and a disadvantage region of a non-dependent rotary axis F in a five-axis linked numerical control machine and defining corresponding advantage angle thetaFa and disadvantage angle thetaFd; (3) obtaining solutions of thetaF=arccos (k) of the axis F corresponding to each cutterlocation point and obtaining the maximum angle thetaFmax of the axis F, which rotates in the cutter location file, corresponding to the non-dependent rotary axis; (4) determining the angle value of the axis F of the cutter location data in the first row and the angle value of a dependent axis E of the axis F; and (5) obtaining angle values thetaE and thetaF of the axis E and the axis F on each cutter location point; obtaining solutions of each row of translation axis according to the angle value corresponding to each row of cutter location data so that the transformation of the cutter location data is completed and the post-processing is realized. According to the method provided by the invention, the cutter location file and the rotary limit of the non-dependent rotary axis can be considered, and the solution-selecting problem of the inverse kinetics of the five-axis linked numerical control processing is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

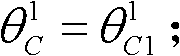

Five-axis side milling machining cutter path smoothing method

ActiveCN105425727AAddressing drastic changesConsider geometric accuracy requirementsProgramme controlComputer controlFree formCutter location

The invention provides a five-axis side milling machining cutter path smoothing method. The method comprises calculating the initial cutter location, and calculating the machine tool turning axle angle corresponding to the direction of a cutter axis through a dynamitic model of a specific machine tool; performing interpolation for the machine tool turning axle angle of the initial cutter location and the cutter nose point location, and obtaining a cutter nose point location trajectory and a machine tool rotation angle change curve; according to the cutter nose point location trajectory and the cutter axis vector, showing a side milling machining cutter path; calculating the rigidity matrix, corresponding to the cutter path, of the machine tool rotation angle curve; according to a differential evolution algorithm, calculating the point that the distance between the point to the cutter enveloping surface is shortest among the points on the design surface; and according to a weighted least square method, establishing a five-axis side milling machining cutter path smoothing model, and obtaining an optimized the initial cutter location and the cutter nose point location curve and a smooth machine tool rotation angle curve after solution. The five-axis side milling machining cutter path smoothing method solves the problem about smoothing and geometric deviation control of the five-axis side milling machining cutter path, and is suitable for five-axis side milling machining on a free form surface, a ruled surface or a curved surface similar to the ruled surface.

Owner:SHANGHAI JIAO TONG UNIV

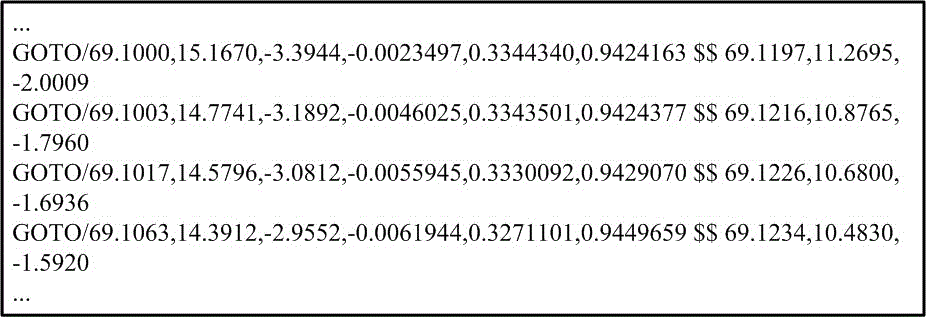

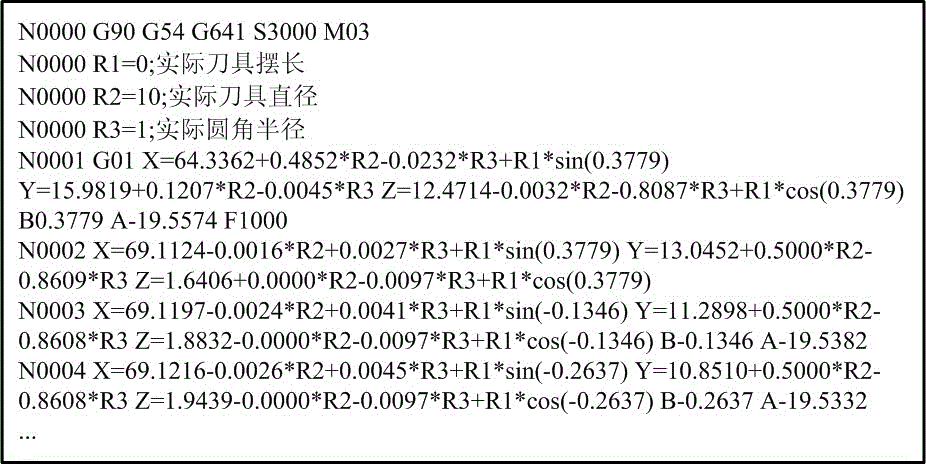

Five-axis cutter radius compensation method based on post-processing

ActiveCN104460516AEasy to realize compensationSolve the length compensation problemProgramme controlComputer controlMilling cutterCutter location

The invention discloses a five-axis cutter radius compensation method based on post-processing. The five-axis cutter radius compensation method comprises the steps that firstly, the basic principle of five-axis cutter radius compensation is studied, and the radius compensation direction and vectors of cutter location points obtained after compensation is conducted of three types of common face milling cutters are derived respectively for the three types of common face milling cutters; secondly, a relation equation between preposition cutter location data and the movement data of all axes of a machine tool is established, and a relation equation between cutter location data obtained after compensation is conducted and all the coordinate axes of the machine tool is derived; finally, prost-processing software having a cutter radius compensation function is developed through VisualC++6.0. The five-axis cutter radius compensation method solves the problem of cutter radius compensation of machine tools which do not having the five-axis radius compensation function, the complex process that after the radius size of the cutter is changed, the cutter needs to return a CAM system, a cutter track needs to the regenerated, and post processing needs to be conducted again is avoided, so that the total processing time of parts is shortened, the reusability of a numerical control program is improved, and high engineering application value is achieved.

Owner:SHANDONG UNIV OF TECH

Feed rate control system for five-axis digital control processing

ActiveCN101976055AAvoid the disadvantages of constraintsImprove computing efficiencyNumerical controlControl systemCutter location

The invention relates to a feed rate control system for five-axis digital control processing, which belongs to the technical field of mechanical digital control processing. The system comprises a processing code reading module, a coordinate transformation module and a feed rate optimization control module, wherein the processing code reading module is connected with the coordinate transformation module and the feed rate optimization control module and transmits the information of a coordinate position in a machine tool coordinate system; and the coordinate transformation module is connected with the feed rate optimization control module and transmits the information of a cutter location in a workpiece coordinate system. The system has high computational efficiency and is suitable for controlling the feed rates of five-axis linkage digital control processing codes of various structural types.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD

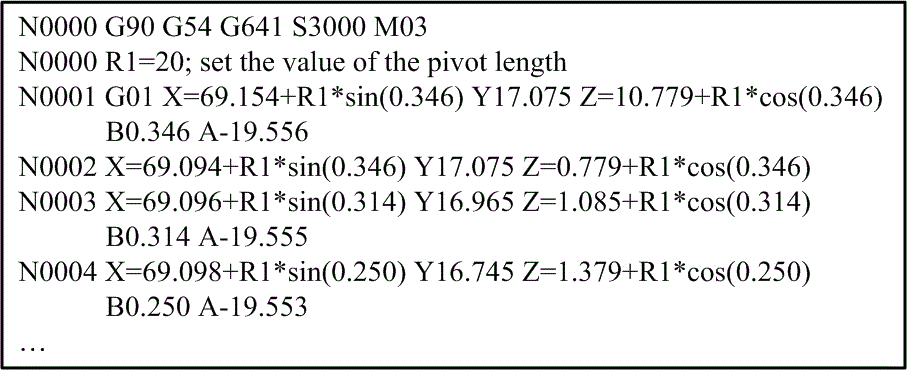

Five-axis cutter length compensation method based on post-processing

The invention discloses a five-axis cutter length compensation method based on post-processing. Firstly, the structure of a given five-axis numerical control machine tool is analyzed, and thus a kinetic model of the machine tool is established and solved; secondly, post-processing software having a five-axis cutter compensation function is developed based on a VisualC++ platform by using the macro-variable and the numerical operation function provided by a numerical control system; finally, the pendulum length of a cutter is regarded as a macro-variable and written into a numerical control program obtained after post-processing is conducted through the software, and thus the compensation for the length of the five-axis cutter can be conveniently achieved by modifying the macro-variable of the pendulum length in the numerical control program. By means of the five-axis cutter length compensation method, the problem of cutter compensation of machine tools which do not having the five-axis radius compensation function can be solved, the phenomenon that post-processing is conducted again on preposition cutter location data is avoided, and thus the reusability of the numerical control program is improved. It is proved through practice that by means of the method, the five-axis cutter compensation function can be conveniently achieved, cost is low, and high engineering application value is achieved.

Owner:SHANDONG UNIV OF TECH

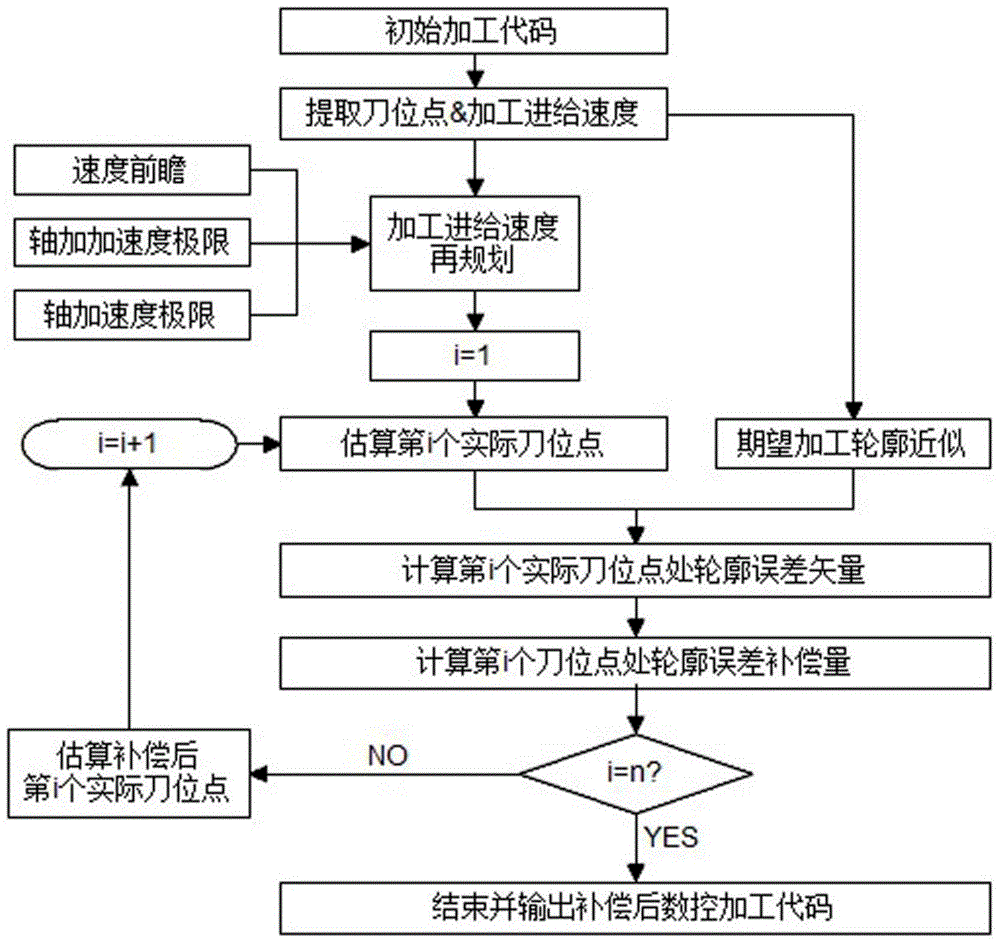

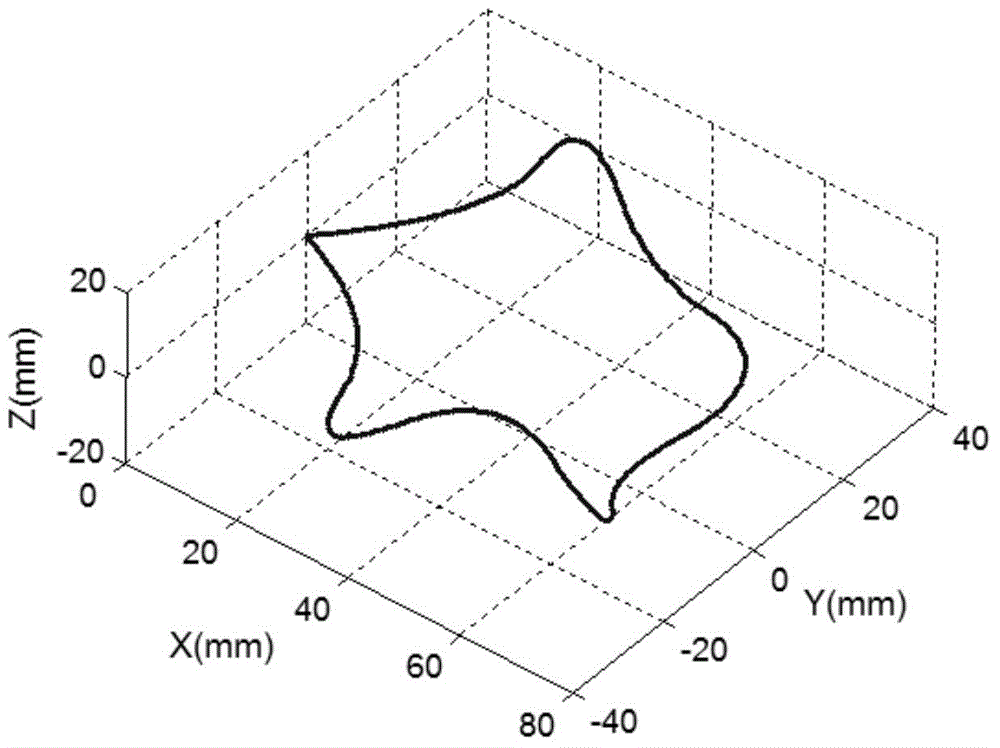

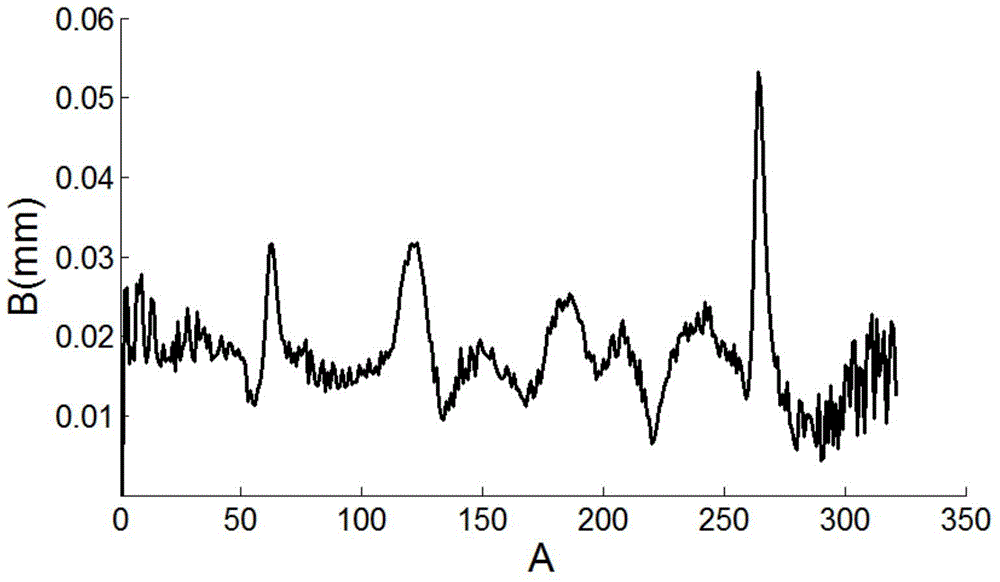

Method for reducing three-shaft linkage contour error

ActiveCN104898564AImprove performanceImprove general performanceProgramme controlComputer controlProgram segmentCutter location

The invention discloses a method for reducing a three-shaft linkage contour error, belongs to the field of precision efficient machining of complex curved parts, and relates to a method for reducing the three-shaft linkage contour error of a numerical control machine tool in combination with machining feed speed re-planning and contour error pre-compensation. The method comprises the steps of firstly extracting machining feed speed and ideal cutter location information from numerical control codes, and re-planning the machining feed speed of each program section in a numerical control program by using the accelerated acceleration limit and the acceleration limit of each machining feed shaft as restraint conditions; estimating a contour error value by using an accumulated chord length parametric spatial cubic spline similar desired contour method; calculating the contour error compensation quantity of each feed shaft by using a Taylor series expansion method to obtain a pre-compensated cutter location; and iteratively cycling the above processes to obtain a pre-compensated machining code, thus realizing high-quality and high-efficiency machining of complex curved parts. The method is simple and practical, and can sufficiently exert the performance of the numerical control machine tool and improve the multi-shaft linkage contour precision.

Owner:DALIAN UNIV OF TECH

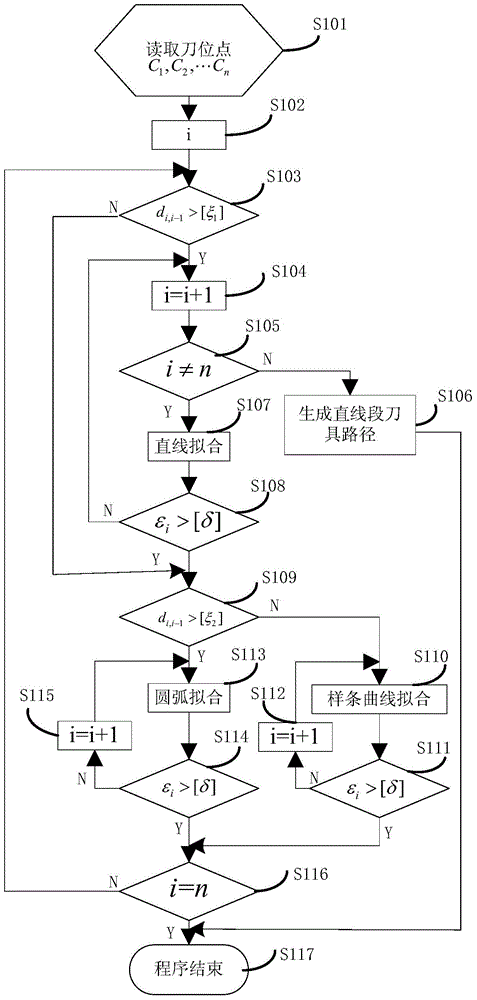

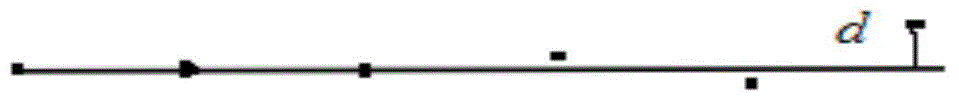

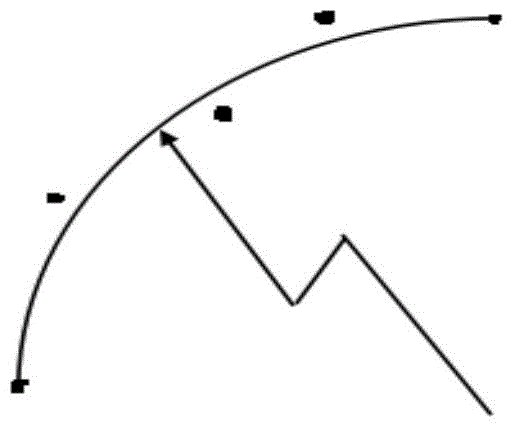

Composite cutter path generation method based on discrete cutter location point

InactiveCN104898554AAdapt to Curved Surface ProfilesReduce computationNumerical controlCutter locationPath generation

The invention provides a composite cutter path generation method based on a discrete cutter location point. A composite cutter path is a cutter patch which comprises multiple interpolation modes such as a line, an arc, a spline curve and the like and optimization combinations thereof. The combination form changes with the shape characteristics of a processed workpiece and a processing trajectory. According to the invention, for cutter location point information on an already known processing trajectory, the composite cutter path formed by reasonable combination of the three interpolation modes as the line, the arc and the B spline curve is studied through such means as interpolation priority arrangement, error analysis, optimization segmentation, fitting calculation and the like, under the condition that allowed processing errors are satisfied, smoothing processing on the cutter path is realized, at the same time, a numerical control program is simplified, and the processing quality and efficiency are improved.

Owner:柳州宏开汽车科技有限公司

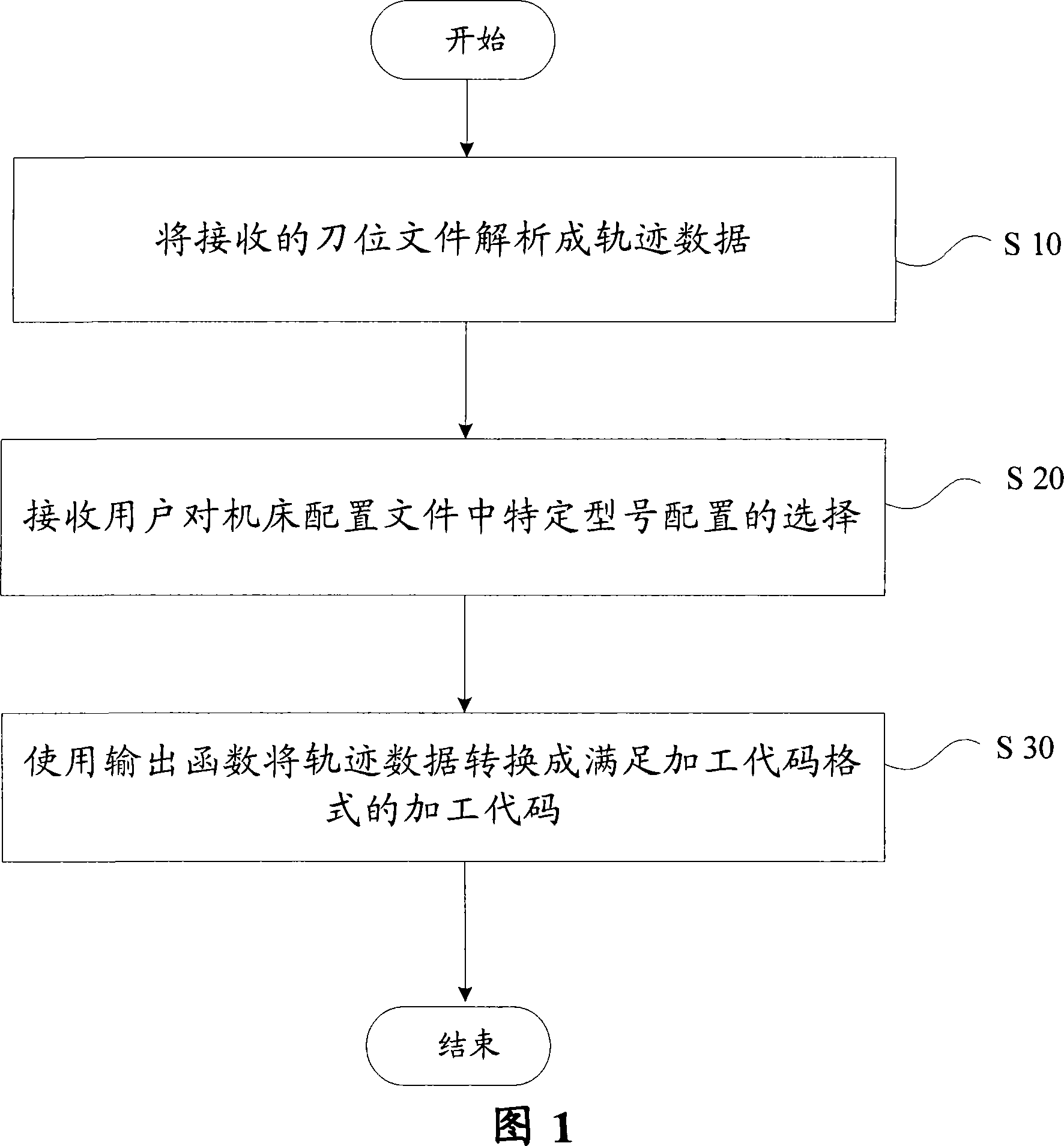

Digital control system machining code general generation method and device

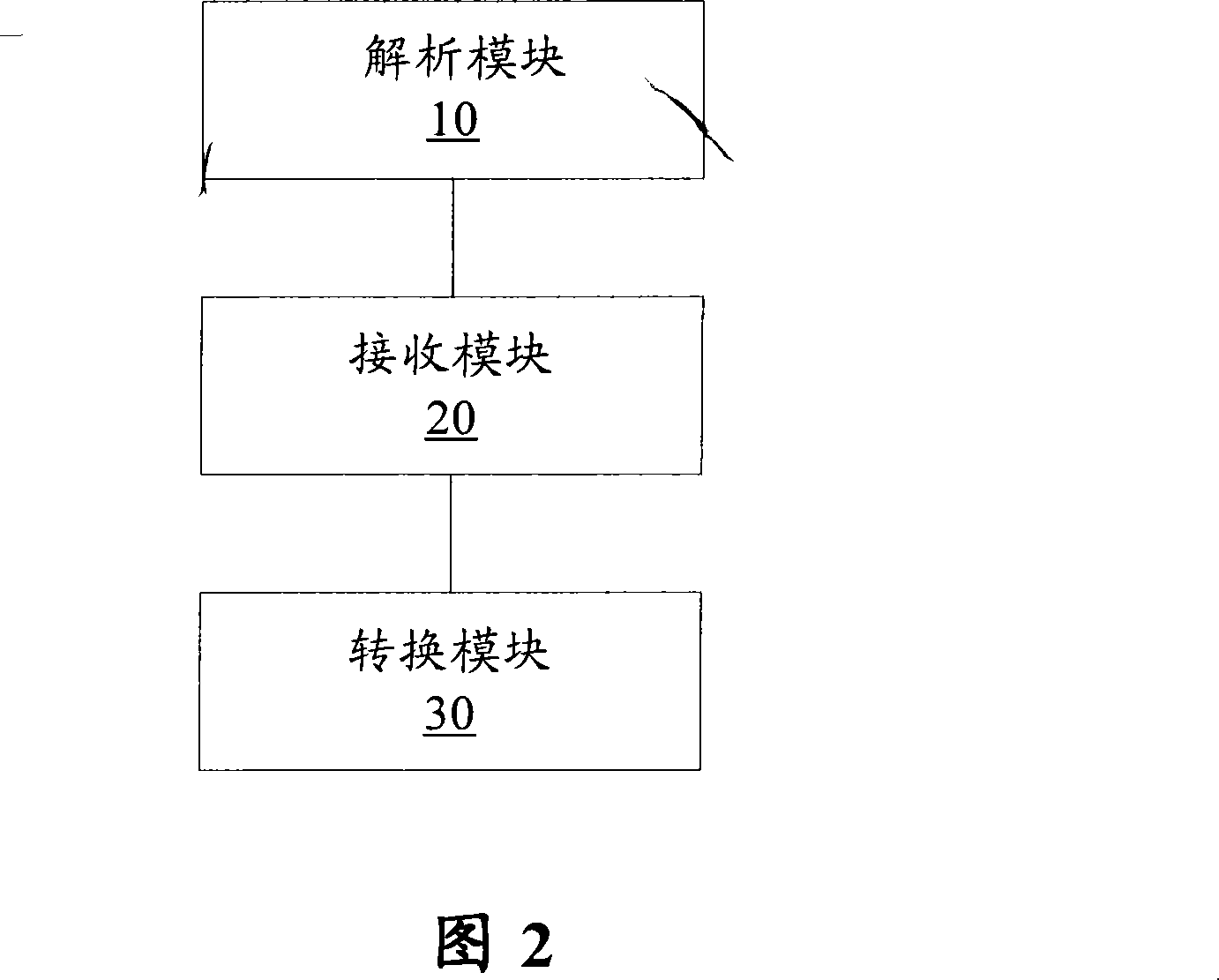

The invention provides a common generating method and a device for a numerical control system to process codes. The method comprises the following steps that: received cutter location files can be analyzed into orbit data; the selection of specific-model configurations made by users among machine configuration files can be received, wherein, the specific model-configurations include the output functions of the processing code forms about specific-model configurations; the output function can be used to convert orbit data into the processing codes satisfying the form of the processing codes. The invention can convert the cutter location files into processing codes which can meet the needs of numerical control machines in different models.

Owner:CAXA TECH

Registration and alignment-based lineation-free forging-casting part machining positioning method

ActiveCN105467927AAccurately determineAutomatically determinedTotal factory controlNumerical controlAviationCutter location

The invention relates to a registration and alignment-based lineation-free forging-casting part machining positioning method. Since an aviation forging-casting part is complex in structure, smaller in machining margin and poor in blank consistency, if a traditional mode in which lineation is adopt to find machining references is used, problems such as poor positioning accuracy, low alignment efficiency and high rejection rate can be brought about, and those problems are the bottleneck of the machining of forging-casting piece blanks, and seriously hinder the intelligent, automated and numerical control development of the machining modes of forging-casting pieces. In order to solve the above problems, a measurement coordinate system and a machining coordinate system are unified; registration and alignment are performed on the digital model of the blanks and the CAD model of the blanks under residual constraint; a cutter location file is corrected through using a registration and alignment result; machining references can be determined accurately and automatically; after the accurate references are prepared, a lineation alignment auxiliary preparation process at a later stage is not required, and the prepared accurate references can be directly utilized to carry out quick and accurate positioning; and therefore, the automation degree and numerical control rate of the machining of the forging-casting piece blanks can be improved.

Owner:JIANGXI CHANGHE AVIATION IND +1

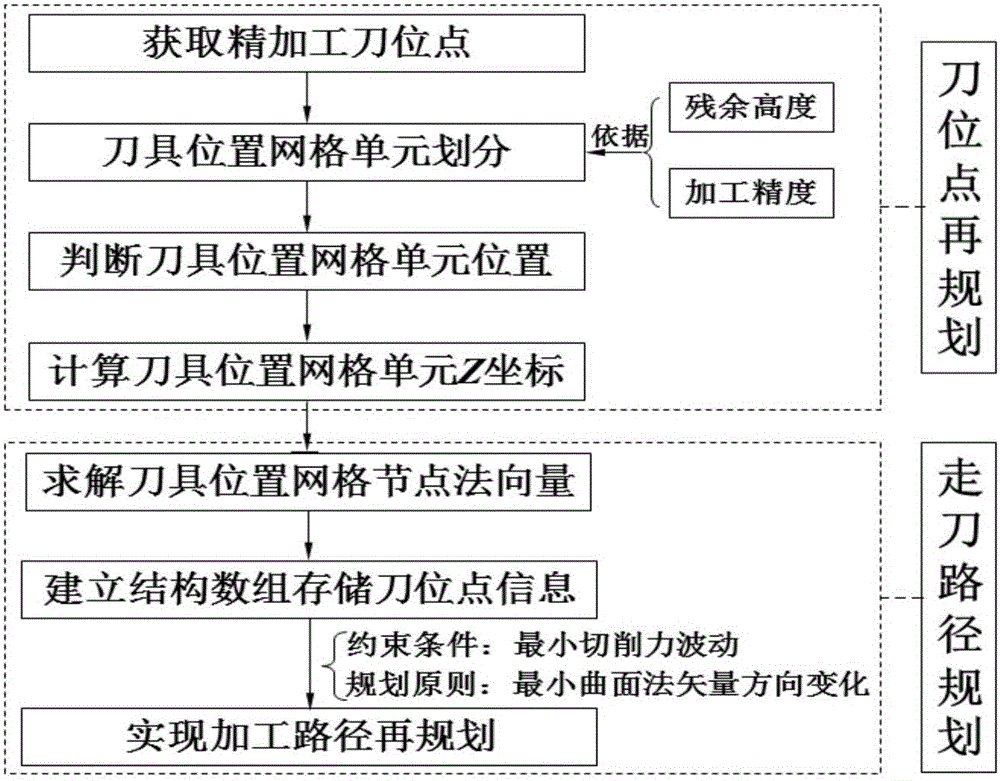

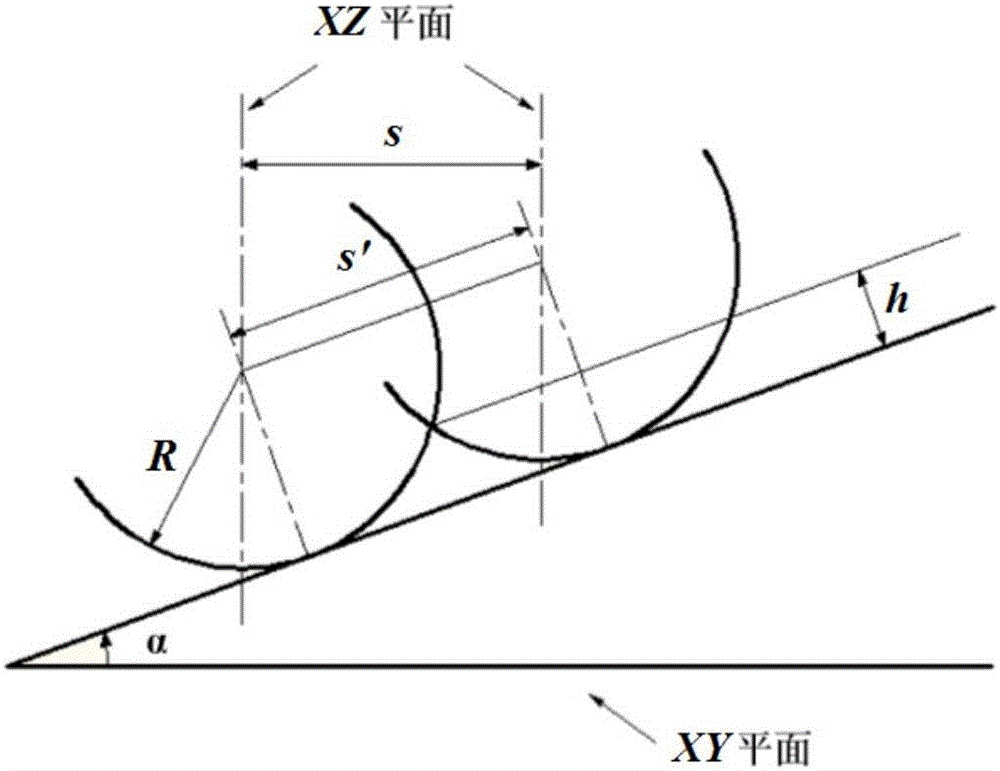

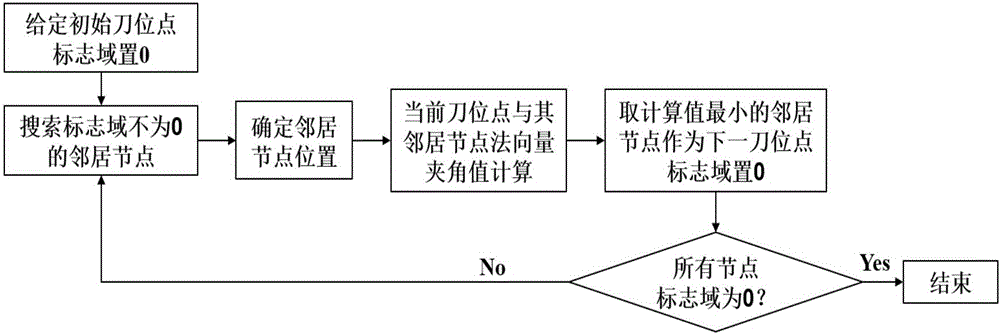

Curved-surface machining cutter track planning method using cutting force fluctuation as constraint

ActiveCN106125666AExcellent line spacingExcellent step sizeNumerical controlCutter locationEngineering

The invention relates to a curved-surface machining cutter track planning method using cutting force fluctuation as a constraint, which belongs to the technical field of the high-efficiency milling processing for complicated curved-surface parts. According to the method, on the basis of cutter location point data obtained by an equal-residual-height method, an optimal feeding ling spacing value and an optimal feeding step length are determined, thereby realizing a cutter location grid unit division based on a cutter location grid node. With fitting of a cutter location grid unit plane, a cutter location grid node Z coordinate is determined by combining an adjacent associated cutter location grid unit. And then a cutter location grid node normal vector is calculated; and with the cutting force fluctuation during the processing process as a constraint, a curved-surface processing cutter track is planned by using the cutter location grid node as a cutter location point according to a fundamental principle of normal vector included angle minimization between adjacent cutter location points, so that the high-quality and high-efficiency curved surface processing is realized. The method has the high adaptability to the local complicated geometrical features; and high-quality and high-efficiency curved surface processing is realized.

Owner:DALIAN UNIV OF TECH

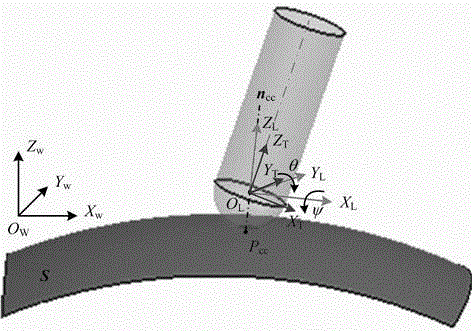

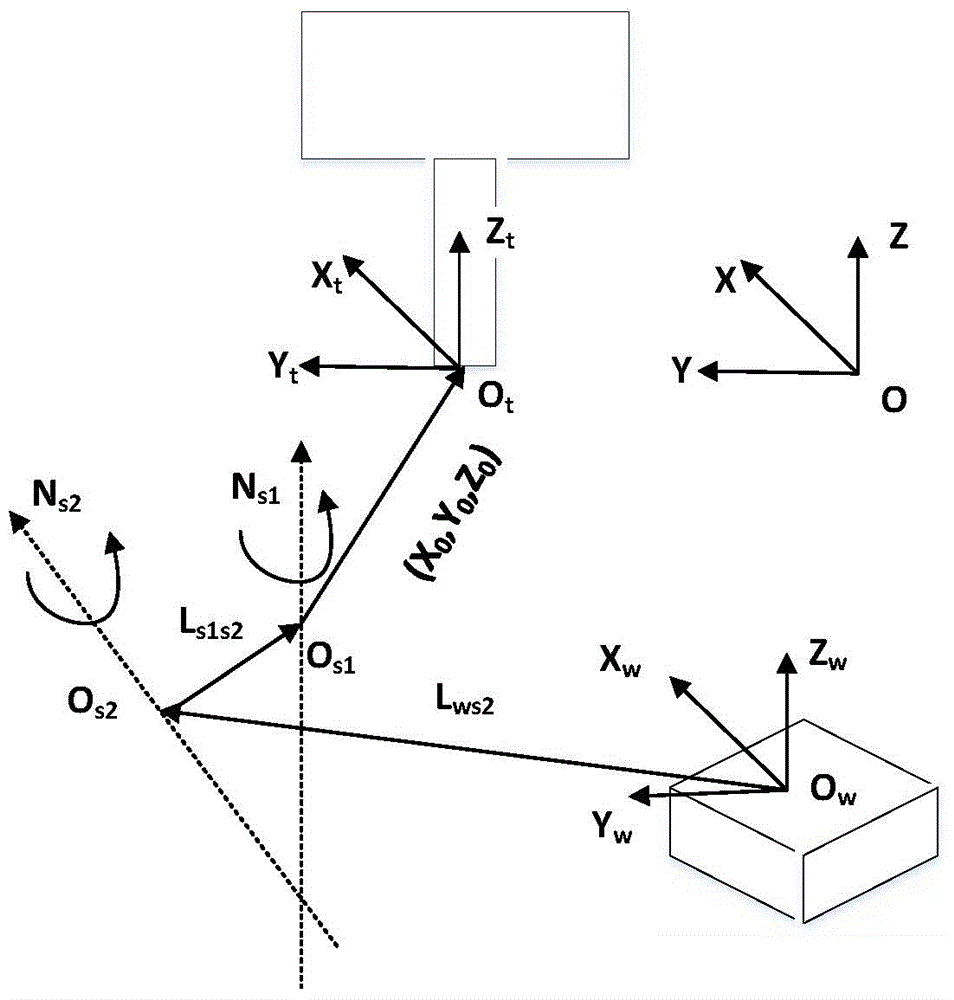

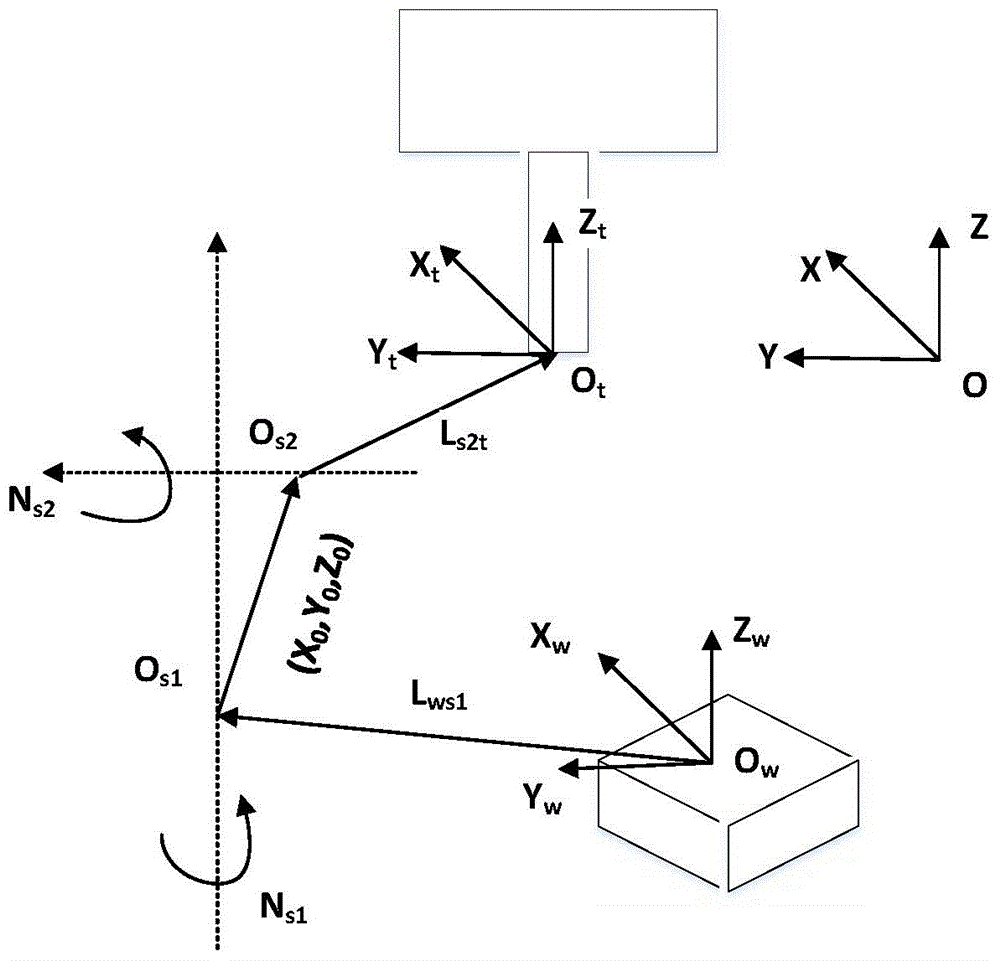

Three-dimensional ellipse vibration auxiliary cutting micro-texture morphology modeling method

The present invention discloses a three-dimensional ellipse vibration auxiliary cutting micro-texture morphology modeling method. A workpiece coordinate system, a cutter coordinate system and a local coordinate system of three-dimensional ellipse vibration auxiliary cutting are established. In the cutter coordinate system and the local coordinate system of three-dimensional ellipse vibration auxiliary cutting, a cutter point arc curvilinear equation and a three-dimensional ellipse vibration expression are established according to the processing parameters and the ellipse vibration parameters. In the workpiece coordinate system, workpiece parameters and machine tool parameters are set. In the process of processing surfaces S of parts, the cutter location point Pt locus of the surface S of a general turning part is calculated, on the basis of obtaining the cutter location point Pt locus of the general turning part, the three-dimensional ellipse vibration on the cutter location point Pt is applied, the cutter location point P2t2 of the three-dimensional ellipse vibration applied on the cutter location point is calculated, the cutter is interacted with the surface S of the parts along the cutter location point P2t2 locus, and a micro-texture morphology is generated on the surface S of the parts. The problem of generation of the surface morphology of the three-dimensional ellipse vibration auxiliary cutting microgroove can be solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

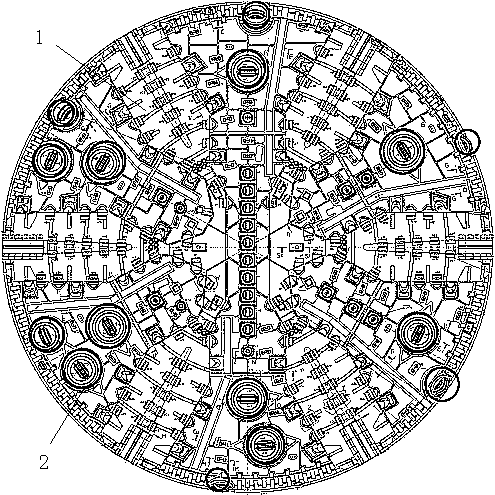

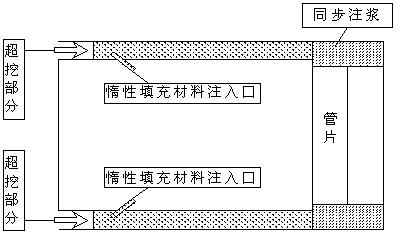

Large-diameter slurry shield comprehensive tunneling method for strong permeable soil and rock composite stratum

The invention provides a large-diameter slurry shield comprehensive tunneling method for a strong permeable soil and rock composite stratum, and relates to the field of shield construction. Accordingto the method, a combined type atmospheric pressure cutterhead is adopted, cutter locations are arranged on the cutterhead, and tools which can be changed at the atmospheric pressure are installed onthe cutter locations; the cutter locations include a Class I cutter location fixed in the form of the tool and a Class II cutter location which can realize hobbing interchange at the atmospheric pressure; fixed tools are installed on the Class I cutter location, interchangeable tools are installed on the Class II cutter location, and cutting trajectories of the interchangeable tools covers the cutterhead; tunneling process control includes control over the cutterhead rotating speed, control over the cutterhead thrust and torque, control over the cutting opening pressure, control over attitude,and control over synchronous grouting construction parameters; and rigid single-fluid slurry with water dispersion resistance is adopted during synchronous grouting construction. By adopting the combined type atmospheric pressure cutterhead, the two types of tools are sepatrately mounted on the cutterhead, the two types of cutter locations cover the cutting trajectory of the entire cutterhead, the fixed tools are used for cutting soil mass, the interchangeable tools are used for cutting rock mass, and therefore smooth tunneling of composite geology is ensured.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

Five-axis machine tool measuring method based on AxiSet

InactiveCN105643362ALow efficiencyAccurate measurementMeasurement devicesMeasurement/indication equipmentsCutter locationStructural error

The invention belongs to the technical field of numerical control, and particularly provides the design of a five-axis machine tool measuring method based on AxiSet. The method includes the steps that according to kinetic models of five-axis machine tools, the influence of structural errors of the five-axis machine tools on cutter location points is determined, and a five-axis machine tool kinetic error model is set up; the error model is analyzed, so that the sources of error terms of the machine tools are determined; the characteristics of the models of the three types of machine tools are analyzed, and measuring schemes for the machine tools are determined; according to hardware equipment adopting an AxiSet<TM> Check-up assembly, a touch trigger probe is used for collecting data of a master ball; and the collected data are substituted into the error models, and after the error terms are worked out, the kinetic models of the machine tools are corrected. By means of the five-axis machine tool measuring method, machining precision of an existing numerically controlled machine tool can be improved, and measurement bases are provided for measurement of multi-axis machine tools in the future.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

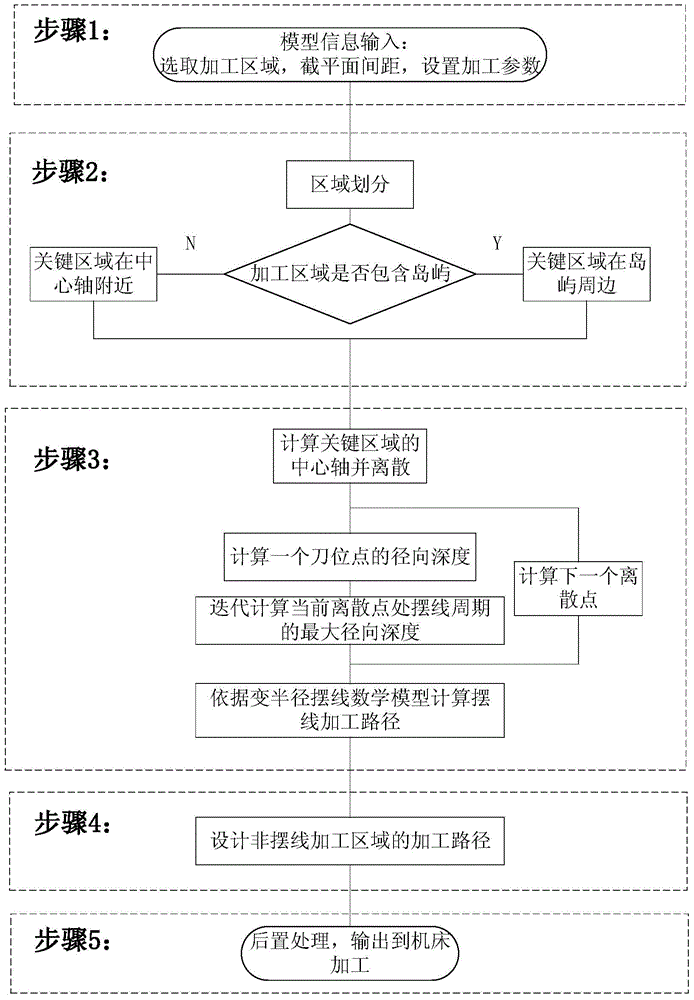

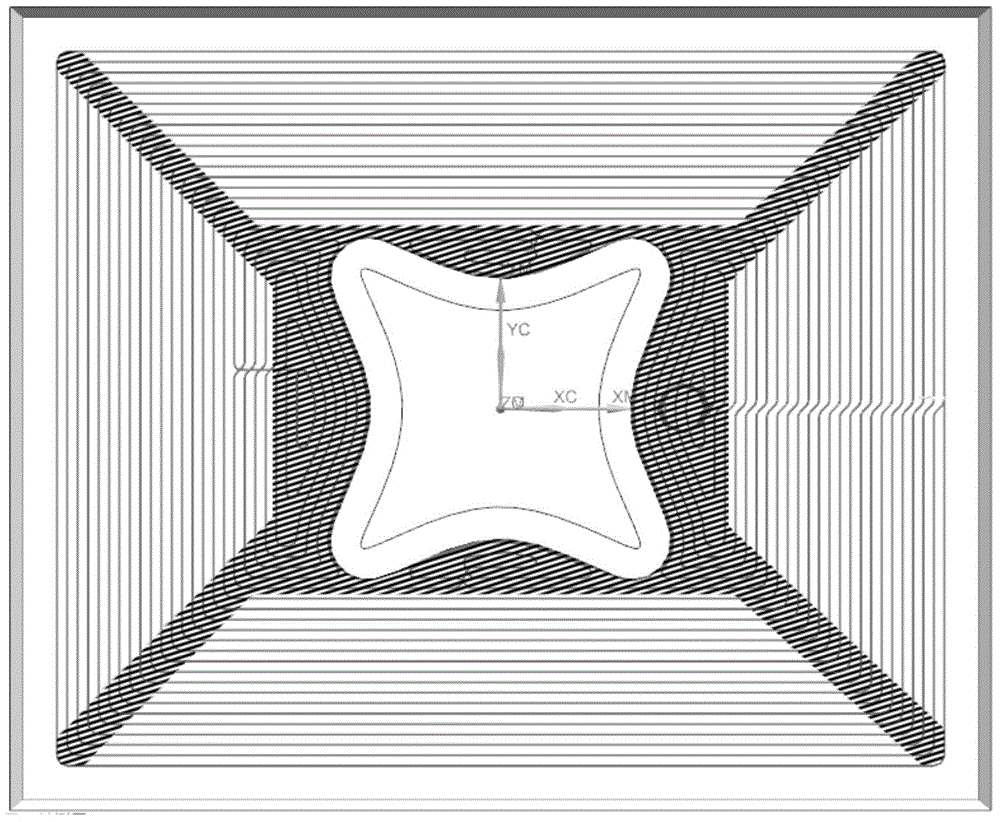

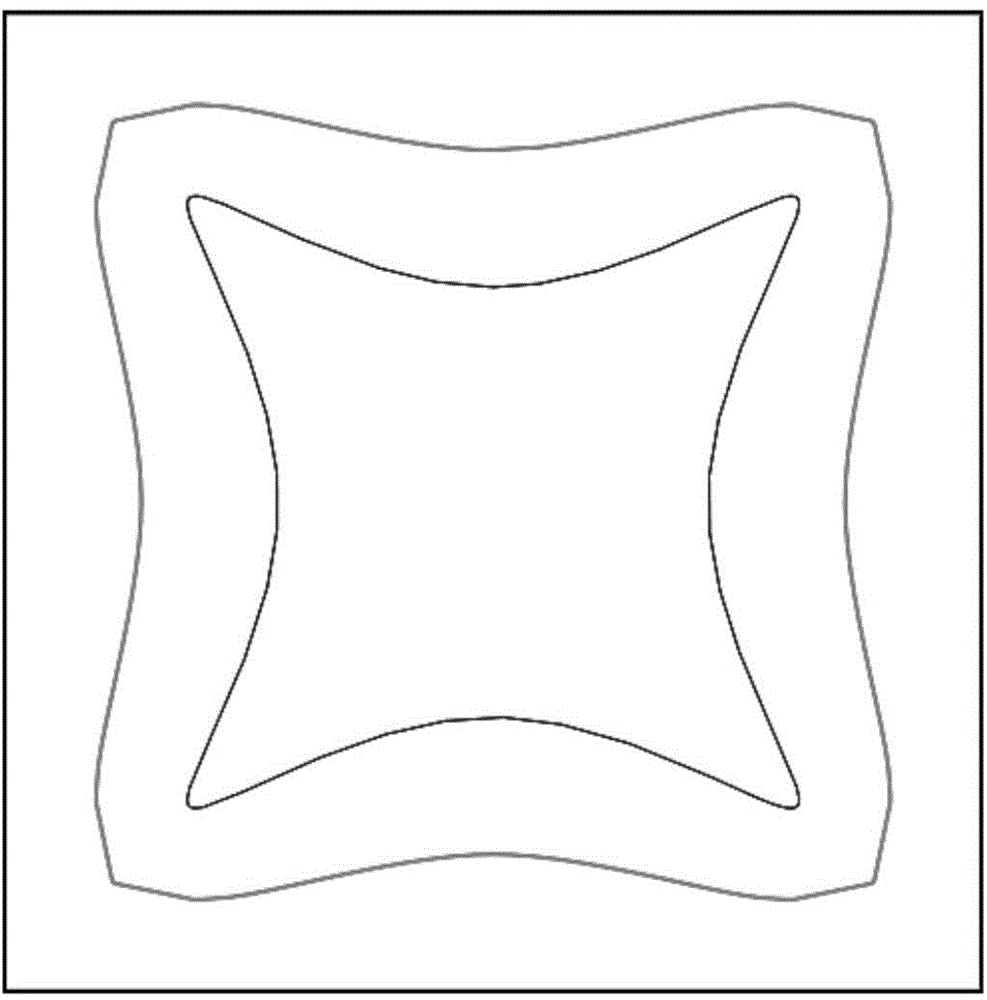

Method suitable for cycloid high-speed milling machining path

ActiveCN104090528AReduce redundancyShorten the lengthProgramme controlComputer controlMathematical modelCutter location

The invention discloses a method suitable for a cycloid high-speed milling machining path. The method includes the steps of firstly inputting part model information and part characteristic information, and automatically dividing a machined area to obtain a key cycloid machined area and a traditional cycloid machined area; according to boundary information of the key area, calculating a cycloid center path, carrying out dispersing, and iteratively calculating the cycloid single-cycle maximum radial depth of each discrete point with the simplex method; then, screening the discrete points of the variable-radius cycloid center axis according to the maximum radial cutting-in depth; after screening is completed, calculating the cycloid machining path of the key area according to a mathematic model of a variable-radius cycloid, and carrying out dispersing on cutter location points; finally, machining left areas with a traditional machining method. By means of the method, the cycloid path is short, the time for passing through an idle-cutting path is short, and the redundancy is low; the cutter contact angle and the radial cutting-in depth can be kept relatively stable, the problems that in the high-speed milling process, the cutter contact angle is prone to sudden change, and the idle-cutting path is long are solved, the machining path is stable, and the milling efficiency is improved.

Owner:ZWCAD SOFTWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com