Workpiece three-dimensional surface topography simulating method based on ball head milling

A technology of three-dimensional surface and simulation method, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of low calculation accuracy and high calculation efficiency, and achieve the effect of optimizing processing parameters and tool movement strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The specific implementation steps of the present invention are as follows:

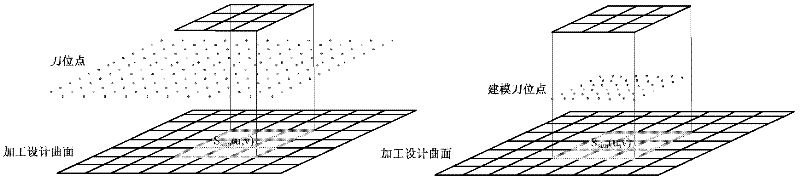

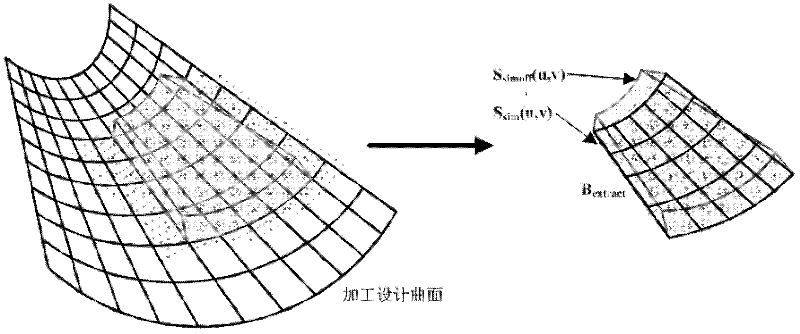

[0025] (1) Set the simulation area and extract the tool points that affect the three-dimensional surface topography of the simulation area. In order to reduce the amount of calculation, it is only necessary to affect the selected simulation area S sim The tool position points of (u, v) can be extracted and modeled, which can reduce unnecessary calculations and satisfy the characteristics of the three-dimensional surface topography of the machined surface.

[0026] Such as figure 1 As shown, under the three-axis machining conditions, in order not to lose generality, any area on the workpiece surface is selected as the simulation area S sim (u, v), and record its bounds:

[0027] E 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com