Parameter curve cutter path oriented numerical control system contour error control method

A contour error and tool path technology, applied in the field of error compensation control, can solve the problems of large amount of calculation, difficult to set PID controller control parameters, difficult to meet the real-time requirements of CNC system, etc., to achieve simple calculation method and high calculation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

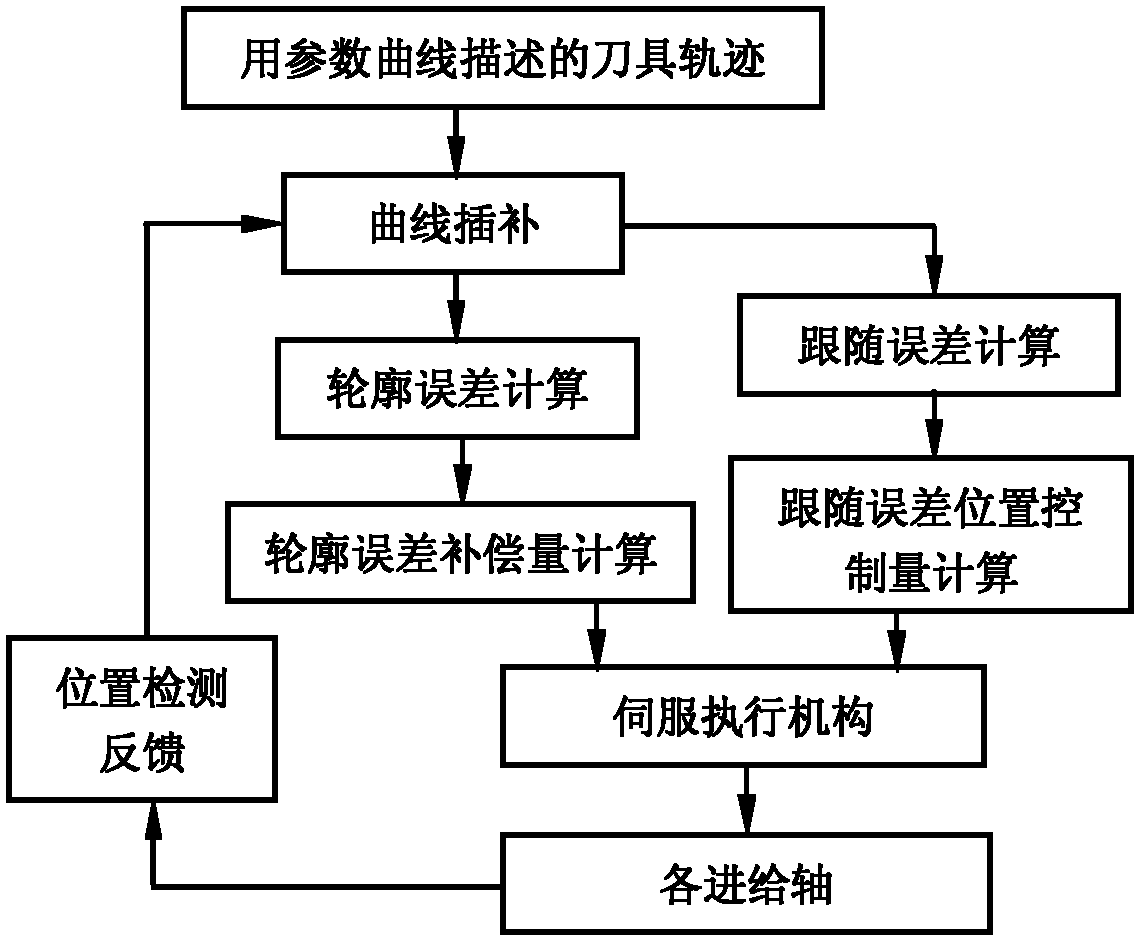

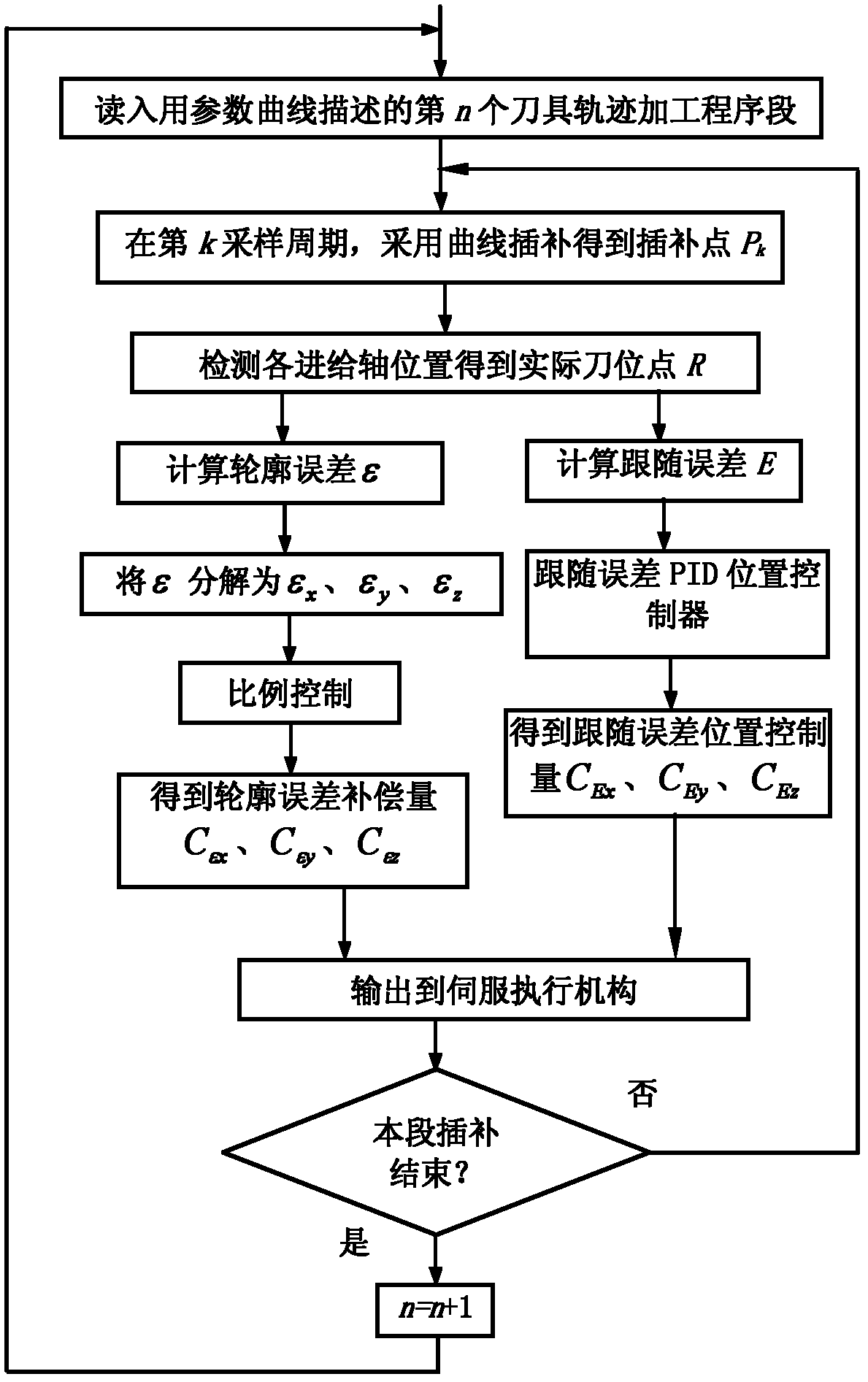

[0017] Combine below Figure 1~3 The present invention is described in further detail:

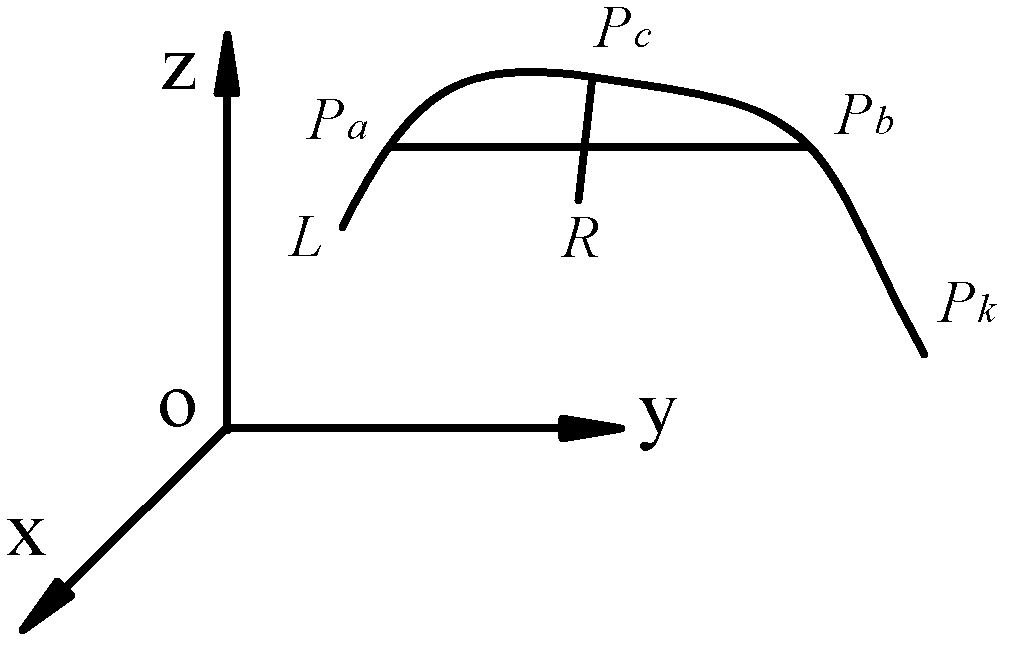

[0018] Step 1), in each sampling cycle of curve interpolation processing on the parameter curve tool trajectory, calculate the contour error according to the current actual tool position point and the interpolation point on the tracked parameter curve tool trajectory, that is, calculate the current actual tool position The shortest distance from the point to the tracked parametric curve toolpath. Specific as figure 2 As shown, suppose the tool path L is described by a NURBS parameter curve, and each point on the tool path L is

[0019] P ( u ) = Σ i = 0 n B i , k ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com