Method for analyzing depth of crack of thin plate based on ultrasonic lamb waves and time-reversal theory

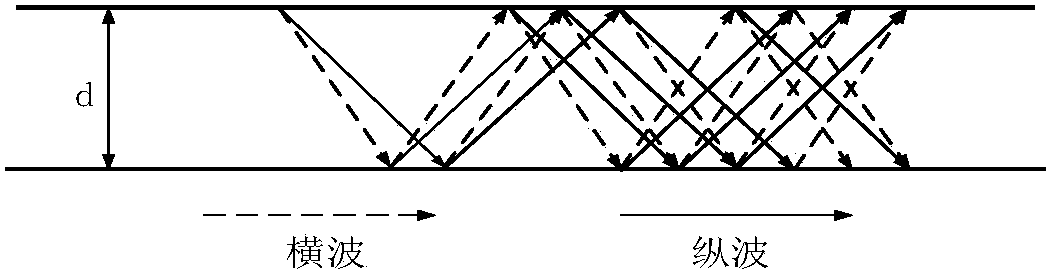

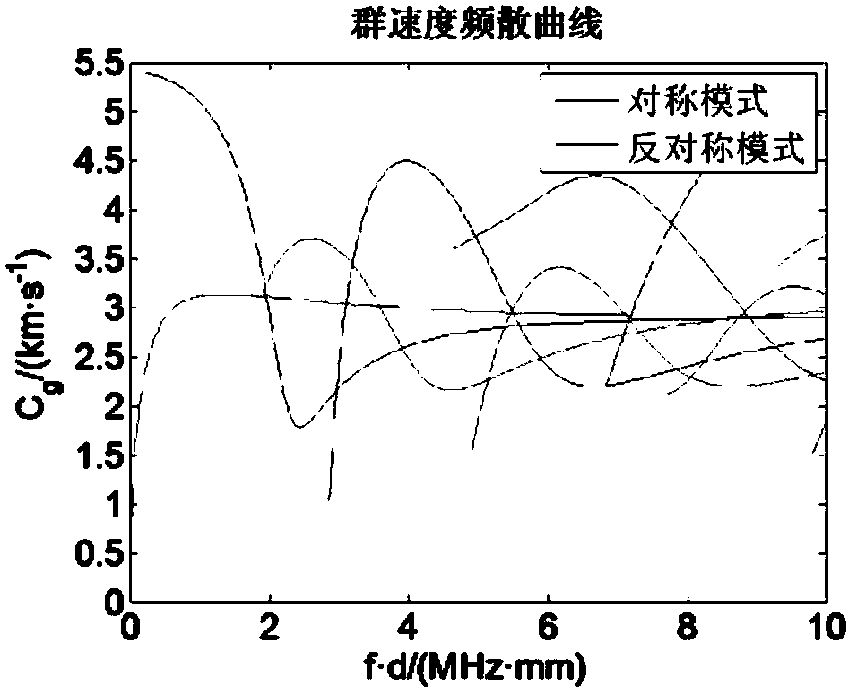

An ultrasonic Lamb wave and time reversal technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and material analysis, etc. Lamb waves cannot propagate and other problems, to achieve the effect of simple calculation method, improve detection ability and accuracy, achieve signal focusing and effective reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

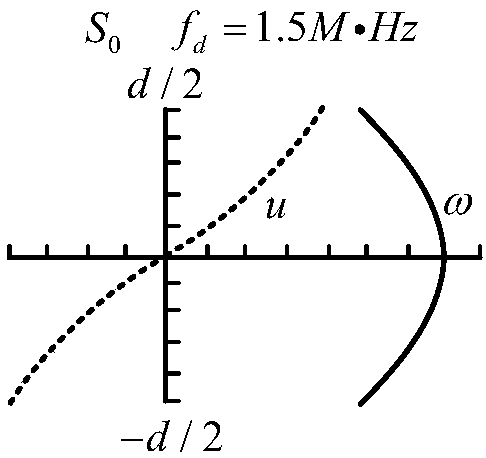

[0084] In the embodiments of the present invention, the crack depth is analyzed by taking an aluminum thin plate as an example. First, the longitudinal position X of the crack can be obtained by detecting the product of the time required to receive the reflected wave and the propagation velocity 1 ; Secondly, the size P of the crack can be obtained through the reflection coefficient or transmission coefficient, and the thickness of the crack can be regarded as very thin. Again, the depth of the crack is represented by the distance L between the center of the crack and the mid-plane, such as Figure 5 shown. It should be noted that the depth of the crack is of vital reference value for the evaluation of the advantages and disadvantages of the plate and the evaluation of the cause of the crack, and from the analysis of mechanics, it can be known that if the crack is sustained near the plate surface The pressure will break more easily than the thin plate near the midplane.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com