Patents

Literature

54 results about "Ultrasonic lamb waves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microfabricated reactor, process for manufacturing the reactor, and method of amplification

ActiveUS7297313B1Faster cycle timeHeating or cooling apparatusFlow propertiesUltrasonic lamb wavesEngineering

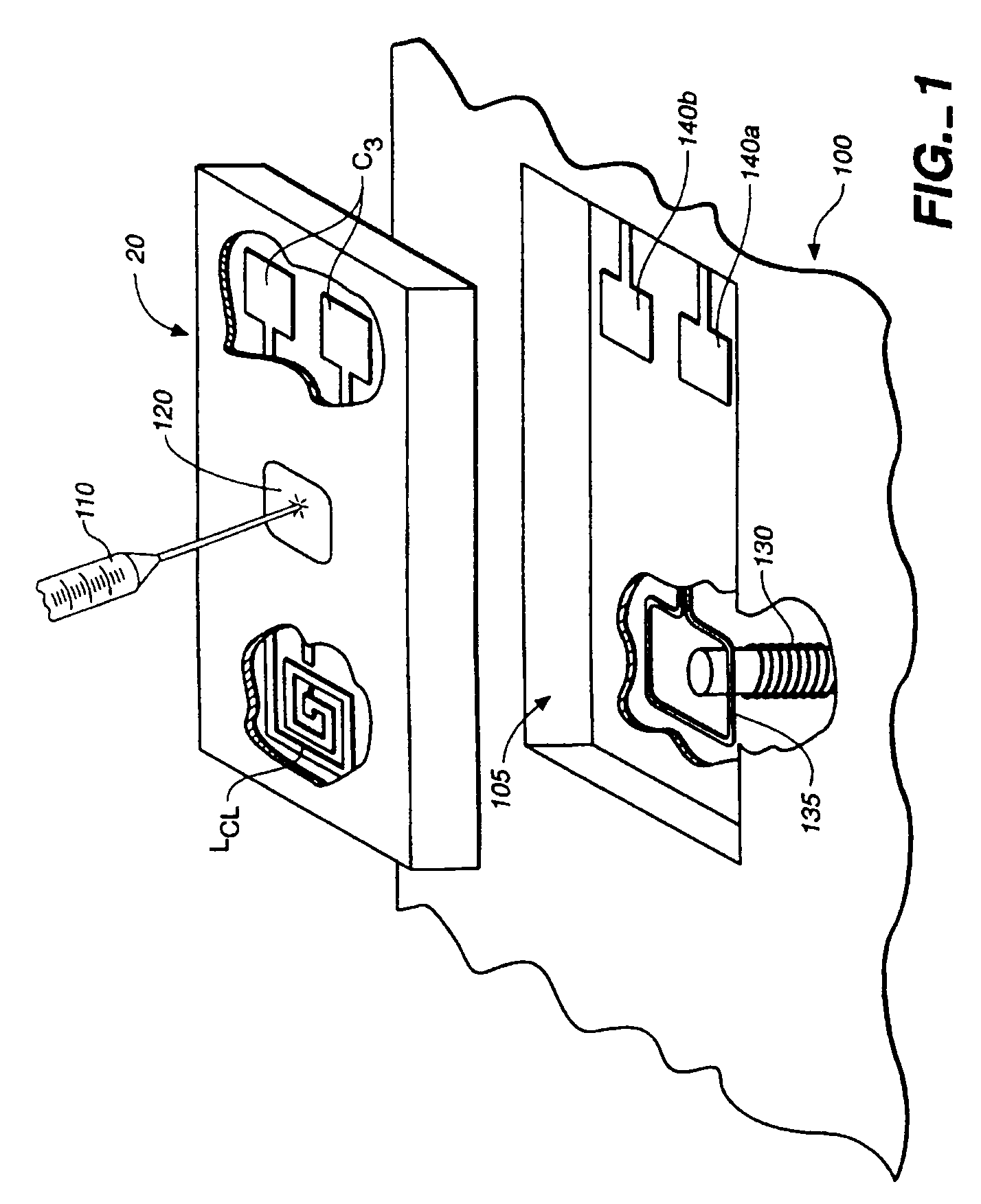

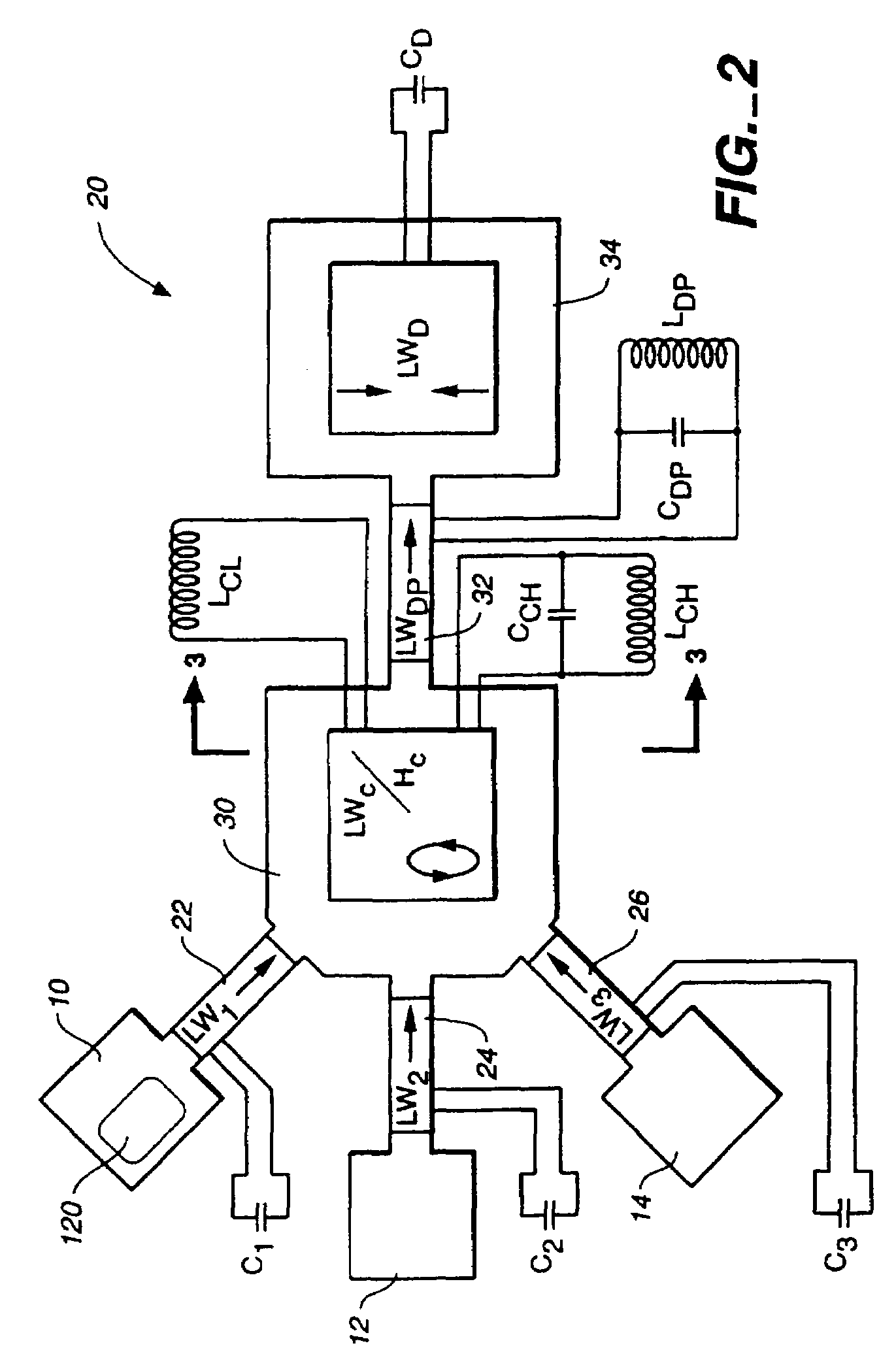

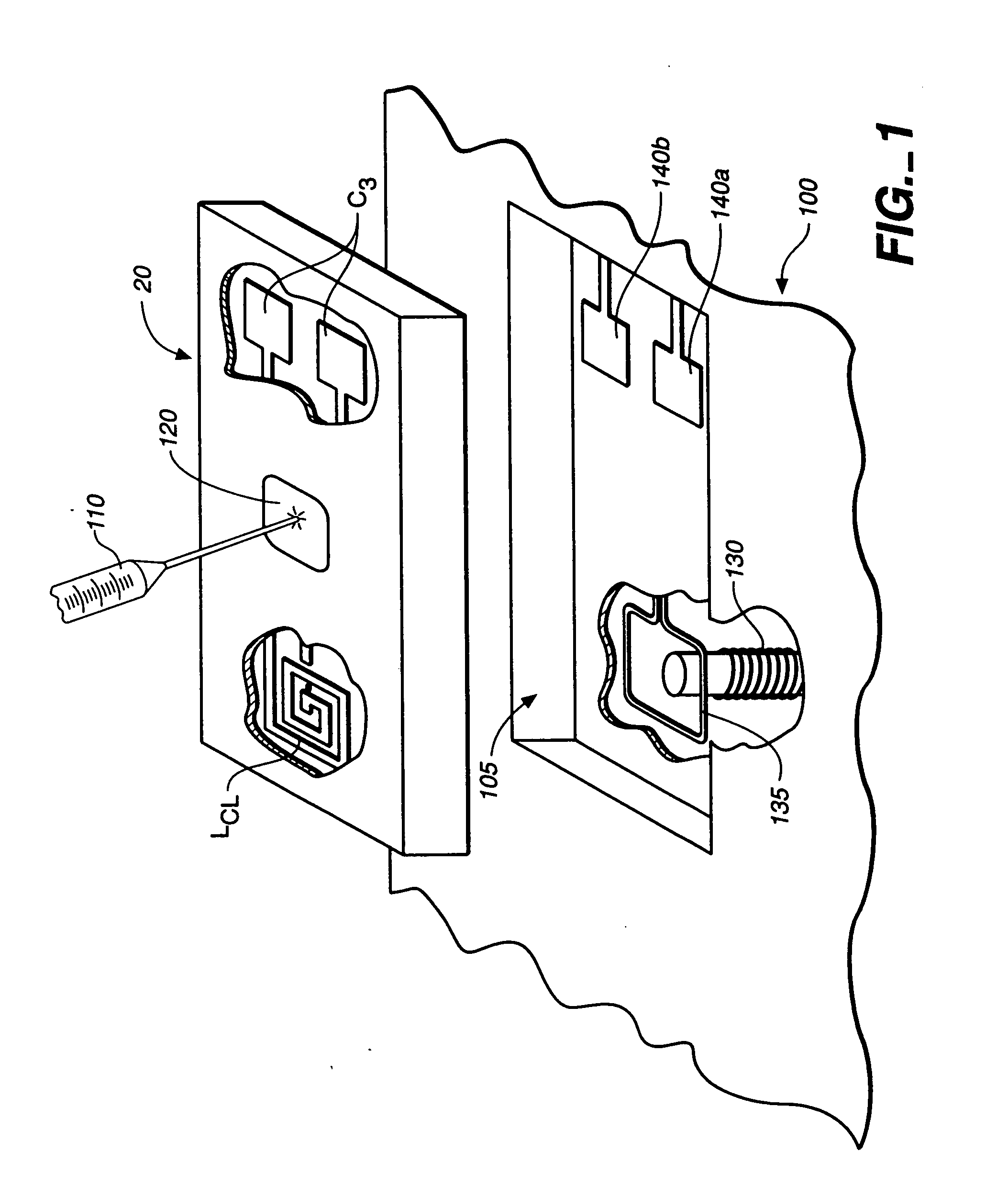

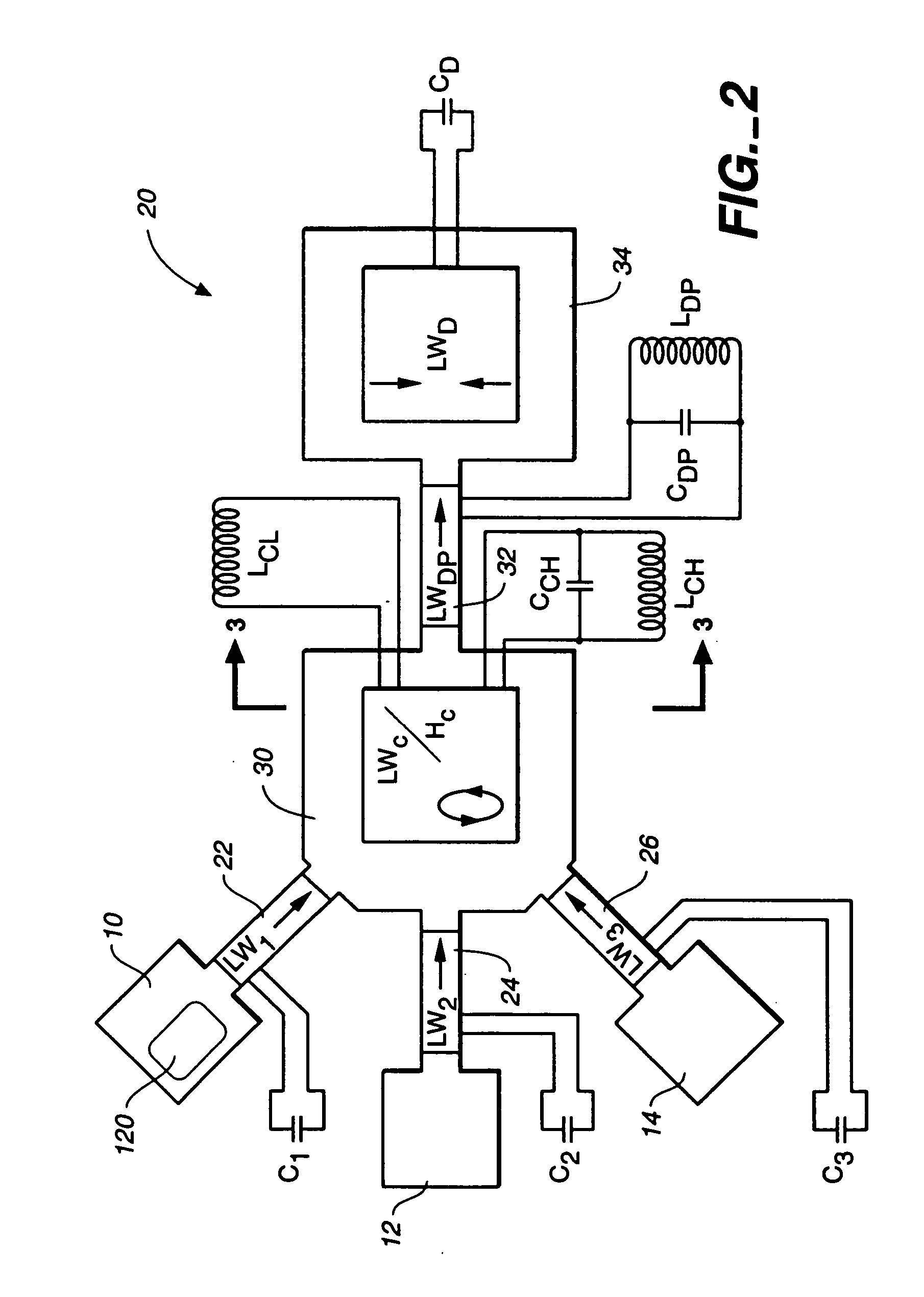

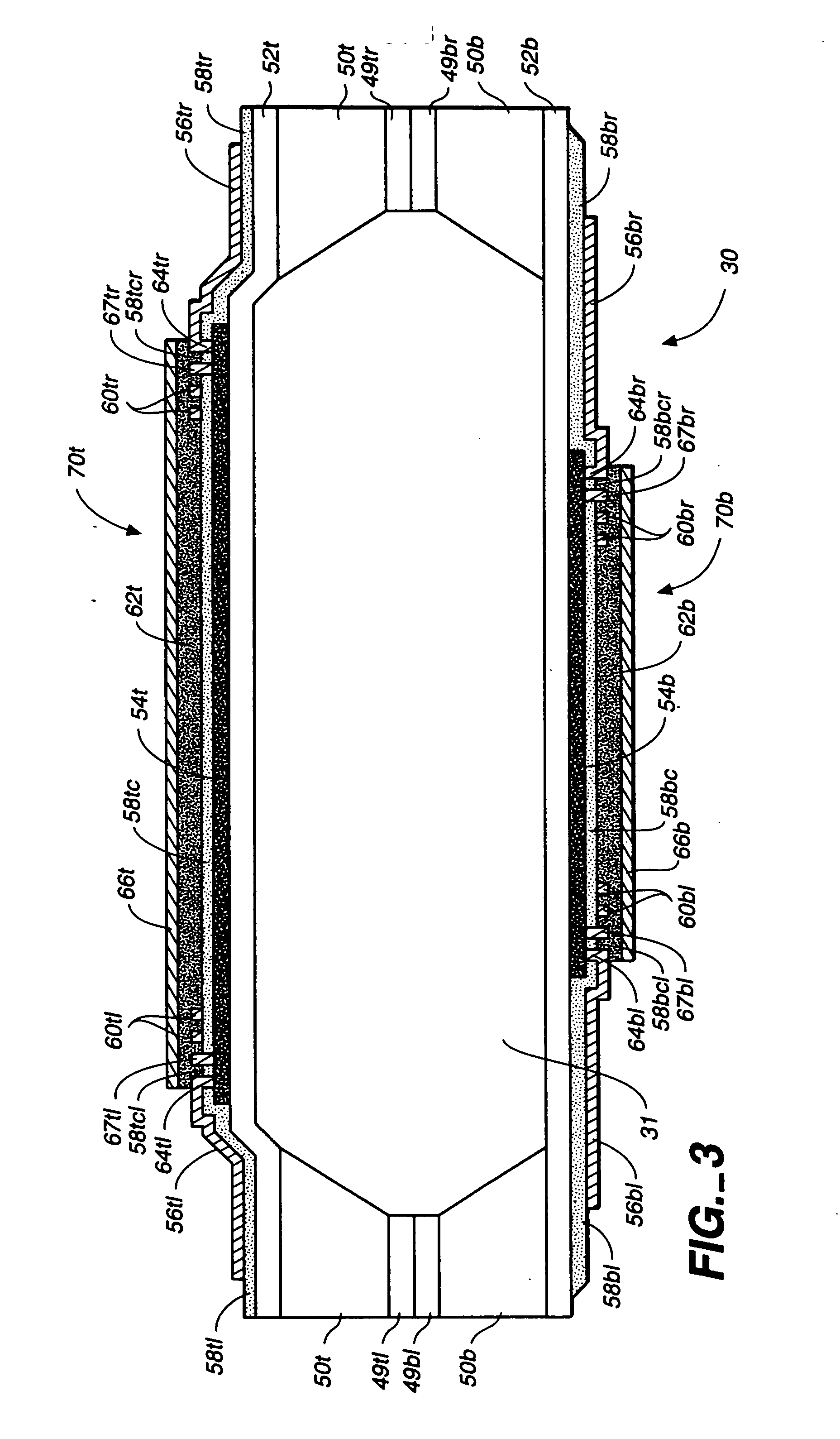

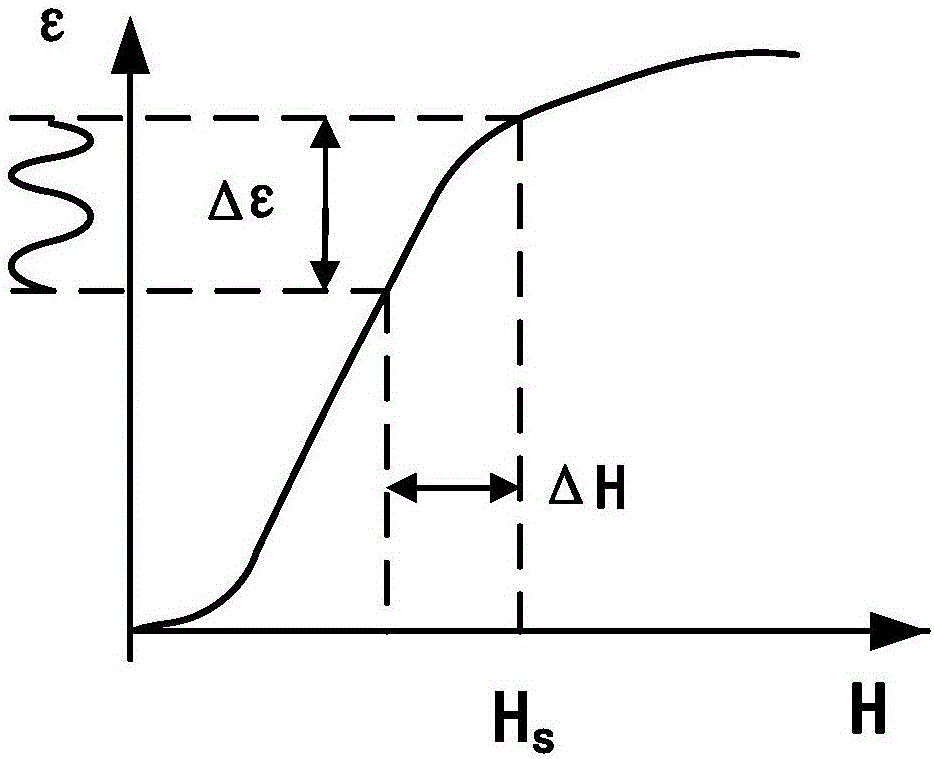

An integrated microfabricated instrument for manipulation, reaction and detection of microliter to picoliter samples. The instrument is suited for biochemical reactions, particularly DNA-based reactions such as the polymerase chain reaction, that require thermal cycling since the inherently small size of the instrument facilitates rapid cycle times. The integrated nature of the instrument provides accurate, contamination-free processing. The instrument may include reagent reservoirs, agitators and mixers, heaters, pumps, and optical or electromechanical sensors. Ultrasonic Lamb-wave devices may be used as sensors, pumps and agitators.

Owner:RGT UNIV OF CALIFORNIA

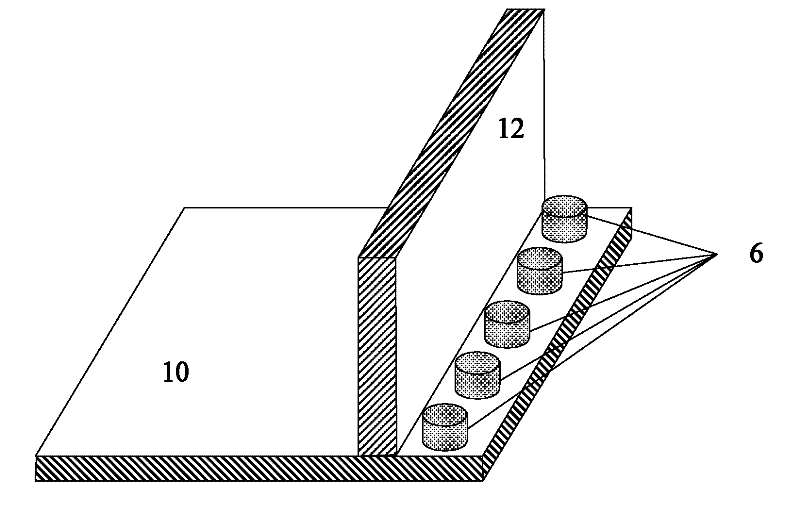

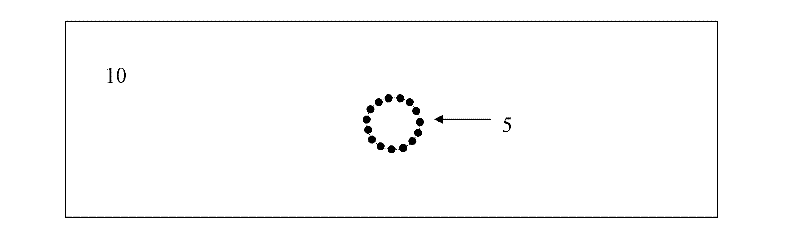

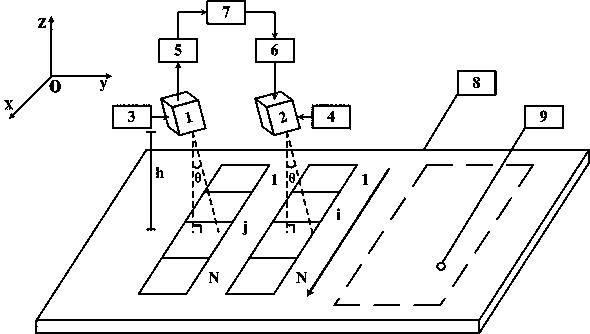

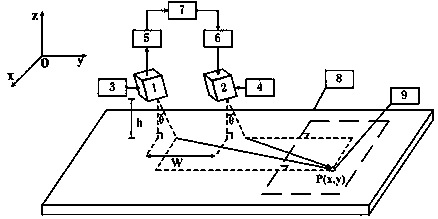

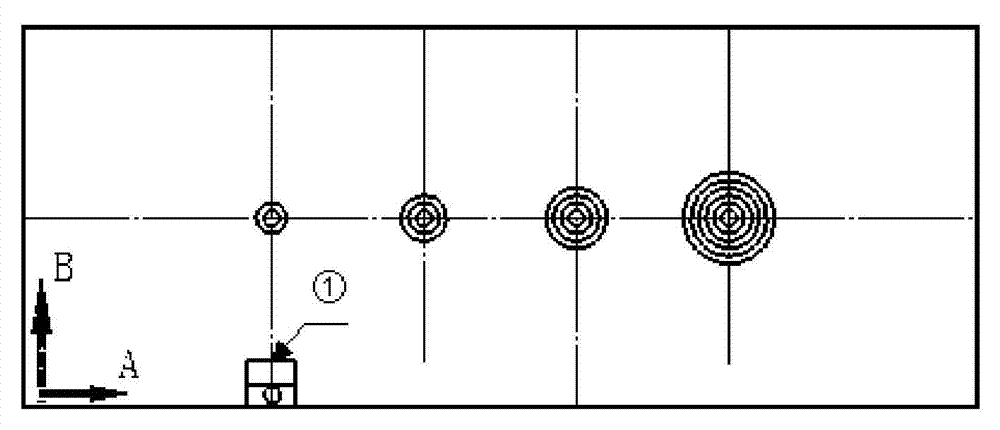

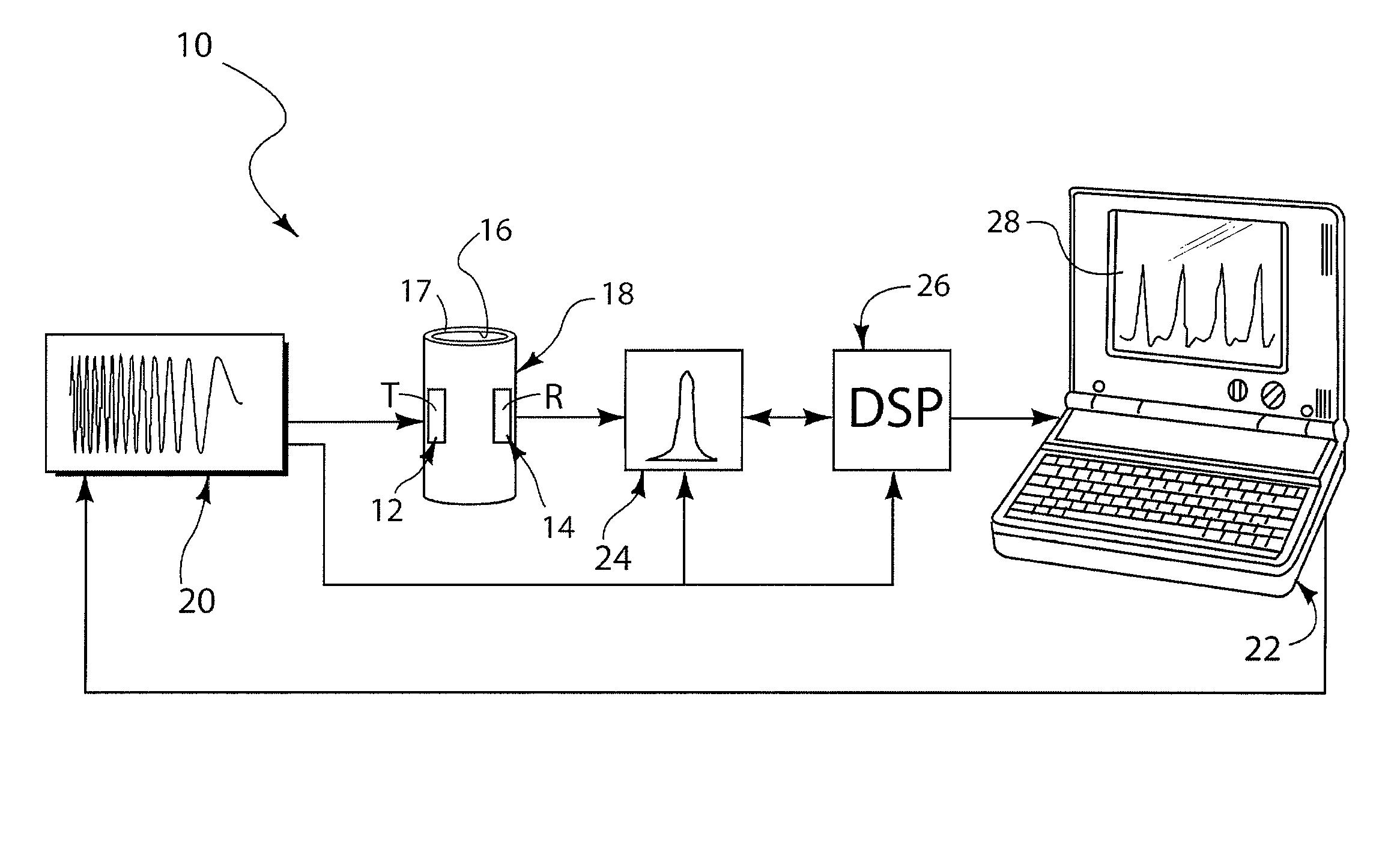

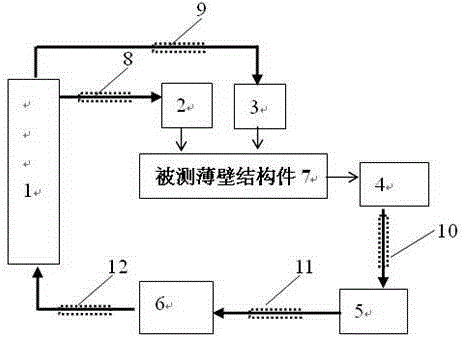

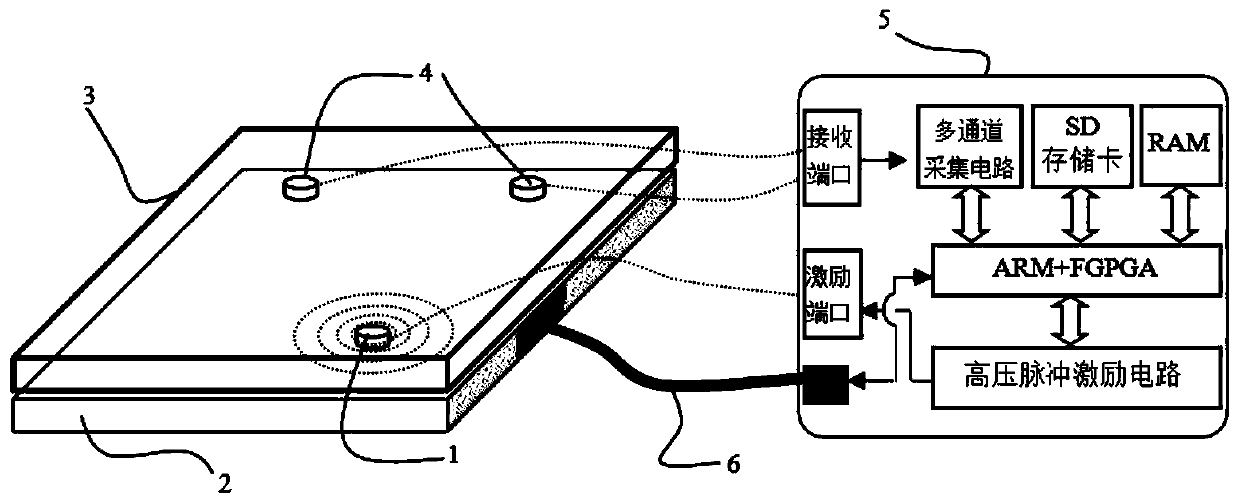

System and method for detecting corrosion of storage tank base plate based on ultrasonic Lamb wave

InactiveCN102539528AReduce the impact of noiseAnalysing solids using sonic/ultrasonic/infrasonic wavesSensor arrayAudio power amplifier

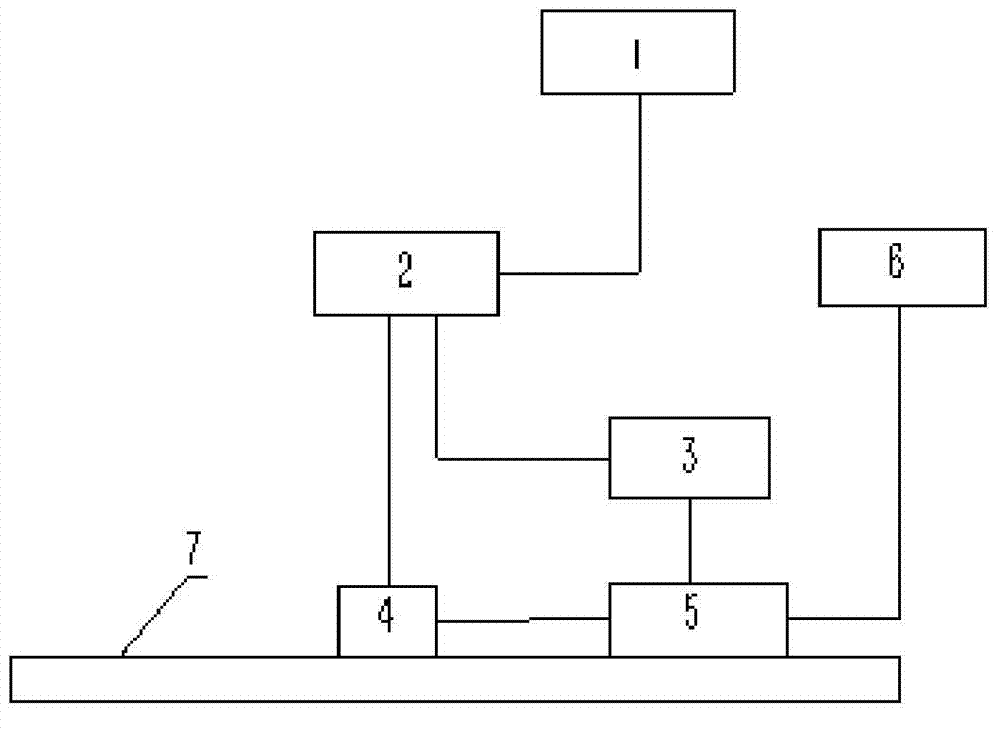

A system and a method for detecting corrosion of a storage tank base plate based on an ultrasonic Lamb wave belong to the technical field of nondestructive detection for pressure containers. An upper computer (1) is connected with an arbitrary function generation board (2) connected with a power amplifier (3), the power amplifier (3) is connected with a multi-channel selector switch (4) connected with a signal separator, the signal separator (7) is connected with a detecting sensor array and a multi-channel data collection board (9) connected into the upper computer (1), and the multi-channel data collection board (9) transmits a collected signal to the upper computer. The system and method for detecting the corrosion of the storage tank base plate based on the ultrasonic Lamb wave do not need to empty the storage tank or perform liquid surface lifting and can perform on-line detection on an edge board. For the off-line detection of a center board, compared with other detection methods, the system and the method can finish detection of a whole steel plate through one-step excitation receiving so as to be fast and efficient.

Owner:BEIJING UNIV OF TECH

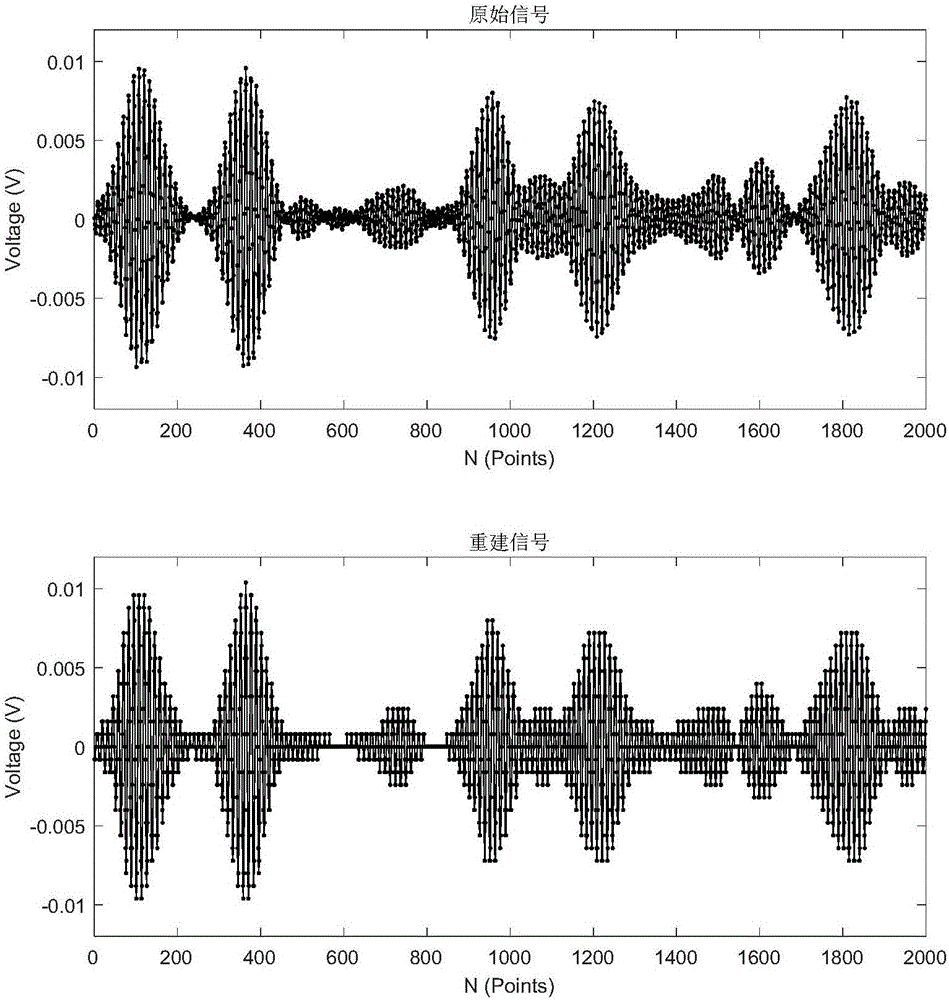

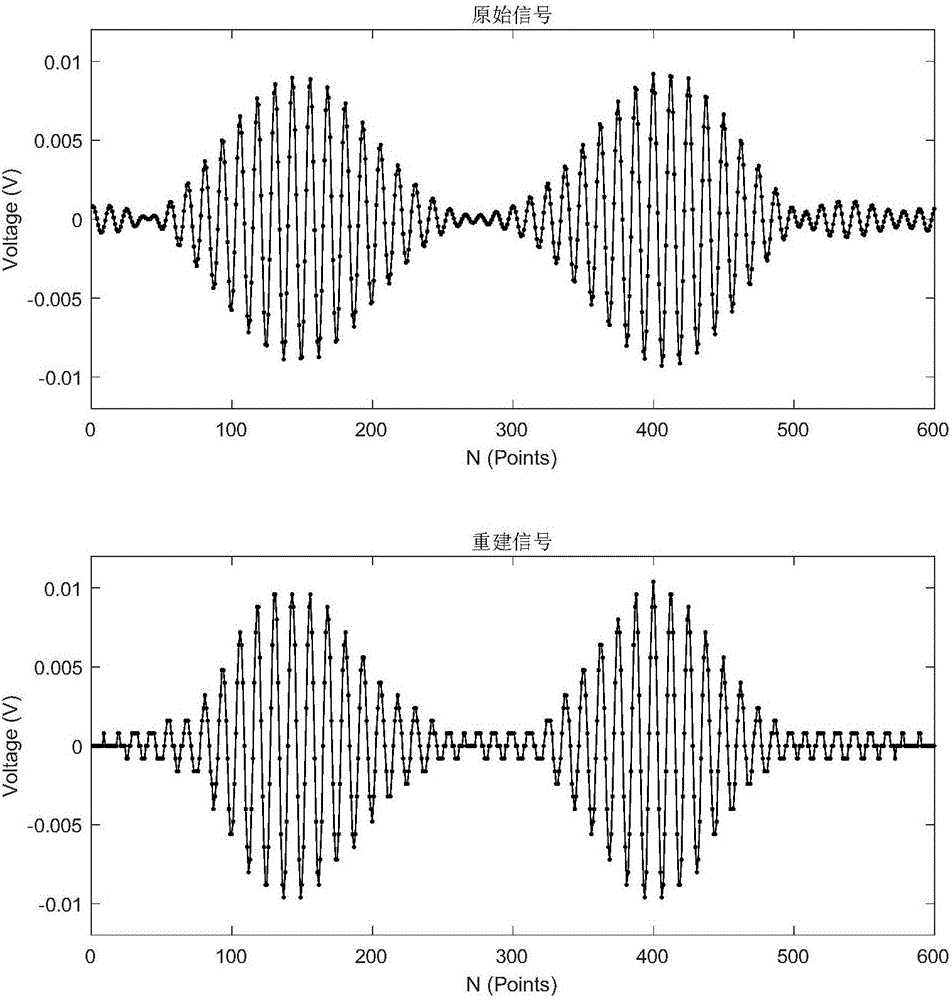

Method for analyzing depth of crack of thin plate based on ultrasonic lamb waves and time-reversal theory

ActiveCN107045017ASolve multimodal problemsEasy to detectAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalTime domainSonification

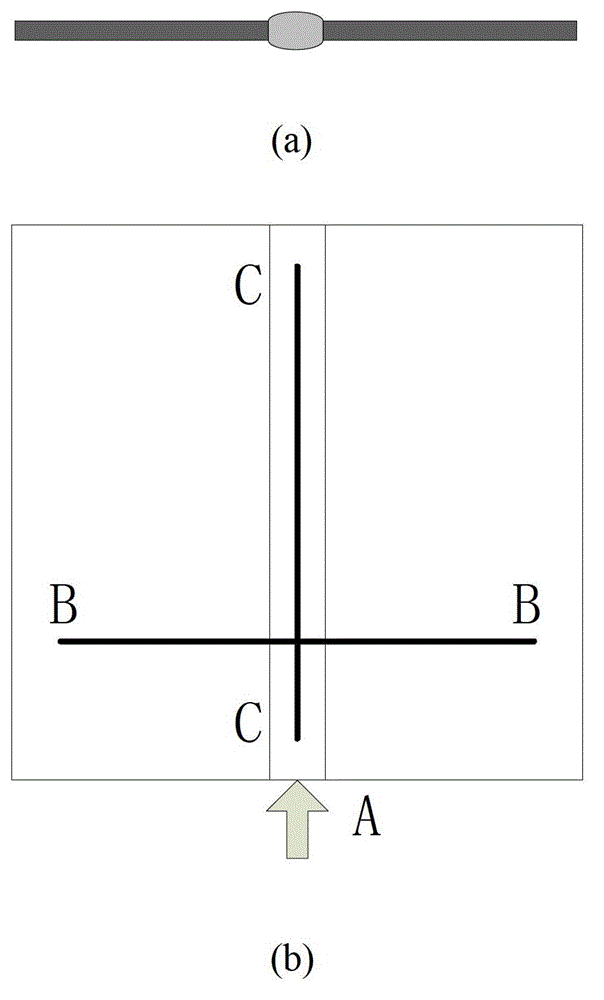

The invention discloses a method for analyzing the depth of the crack of a thin plate based on ultrasonic lamb waves and a time-reversal theory. The method comprises the following steps: selecting a thin plate with a crack, and stimulating single-mode Lamb waves IA(t) in the excitation point A of the thin plate; carrying out a sectioning technology to obtain a multi-mode domain signal received by a reception point B, carrying out the time-reversal technology to obtain a reconstructed signal I'A(t) at the point A, and calculating the waveform damage index DI of the reconstructed signal I'A(t) and an excitation signal IA(t); selecting thin plates having different crack depths L, repeating above steps to obtain corresponding waveform damage indexes DI, and carrying out data fitting through a least square technology to obtain a relation between the crack depth L and the waveform damage index DI; and detecting a thin plate with the crack having an unknown depth to obtain the DI value in order to determine the crack depth L. The sectional calculation technology is adopted to effectively solve the problem of propagation of the Lamb waves in a sheet having defects; and the r time-reversal theory is adopted to reconstruct the signal waveform in order to solve the multi-mode problem and the unable identification problem of the reception point, caused by long distance transmission.

Owner:中兴海陆工程有限公司

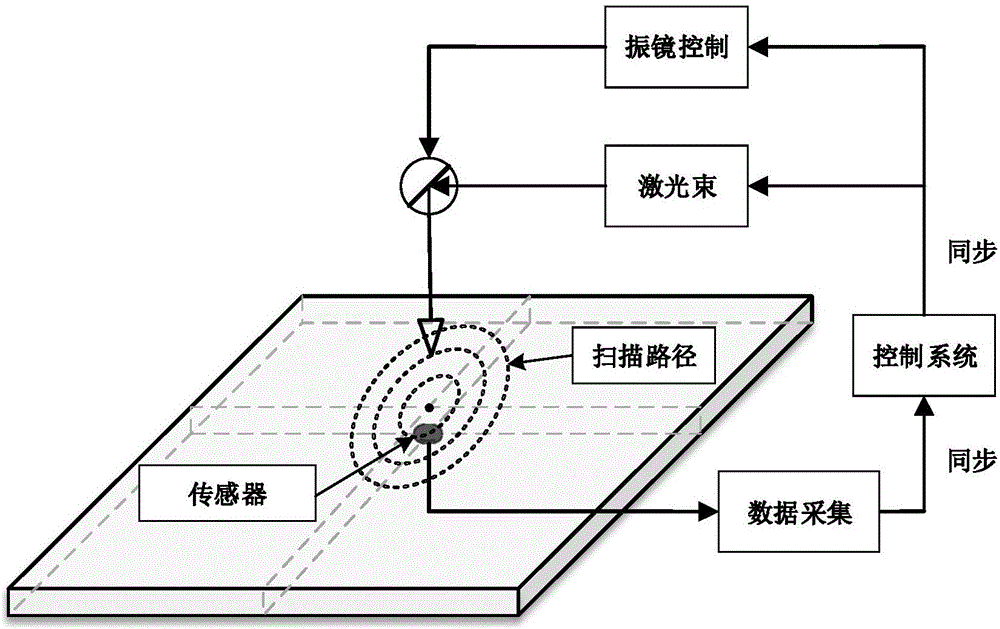

Sheet air coupled ultrasonic Lamb wave total-focusing imaging detection method

ActiveCN110045019AWill not cause secondary pollutionImprove detection signal-to-noise ratioAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationImage detection

The invention discloses a sheet air coupled ultrasonic Lamb wave total-focusing imaging detection method. Different from traditional ultrasonic array signal acquisition, only aiming at a single soundvelocity medium, propagation time of sound waves in air needs to be taken into consideration for acquisition of air coupled array signals. Therefore, the sound velocity ca in the air and the propagation speed cg of the Lamb wave in a plate are measured by using a standing wave method and a wave velocity method respectively. The acquired air coupled ultrasonic Lamb wave array signals exist in the form of a three-dimensional matrix Nti x Ntj x A, the acquired air coupled ultrasonic Lamb wave array signals are subjected to division of an imaging grid region, according to the arrangement positionof a probe, the defect position, and the sound wave propagation speed, the delay time of each scanning path is calculated, and delay superposition total-focusing imaging of the signals is realized according to a delay rule of the sound waves. According to the method, the high-quality ultrasonic total-focusing technology is expected to be expanded to the sheet air coupled ultrasonic Lamb wave imaging detection, so that the defect detection capability is effectively improved.

Owner:NANCHANG HANGKONG UNIVERSITY

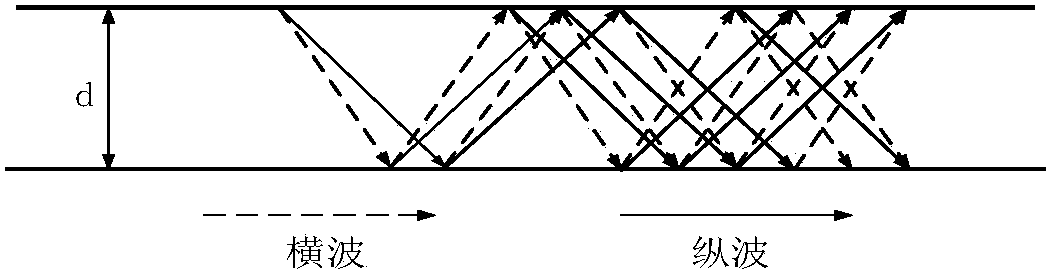

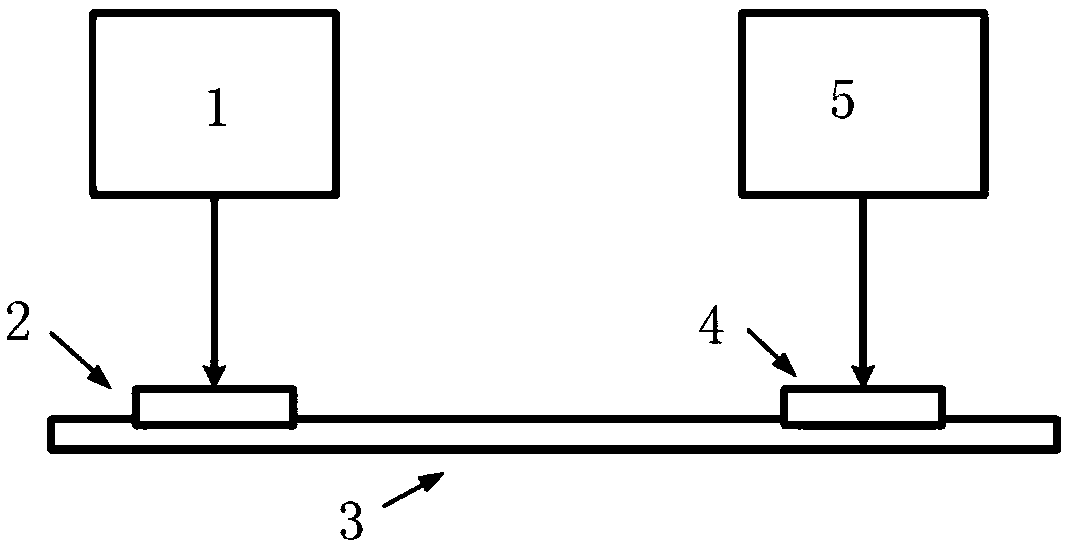

Ultrasonic Lamb wave-based butt weld nondestructive testing method

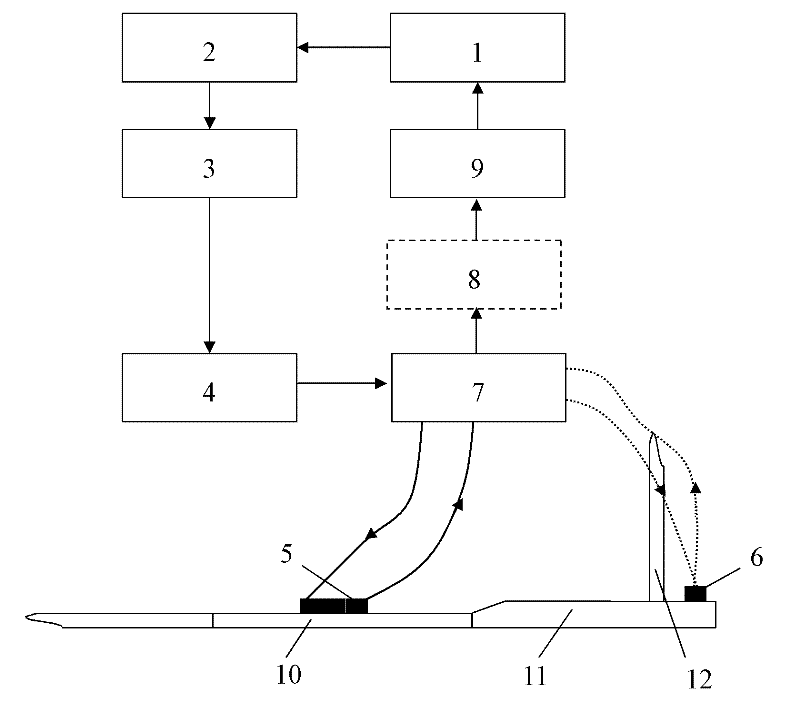

ActiveCN103336054AHigh energyEasy to detectAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalHigh energyFunction generator

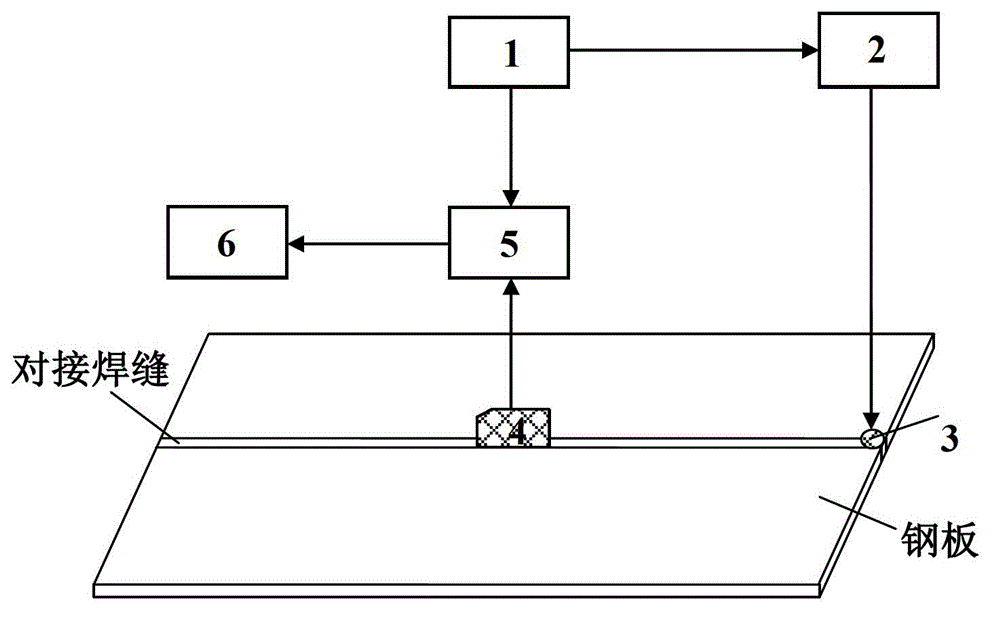

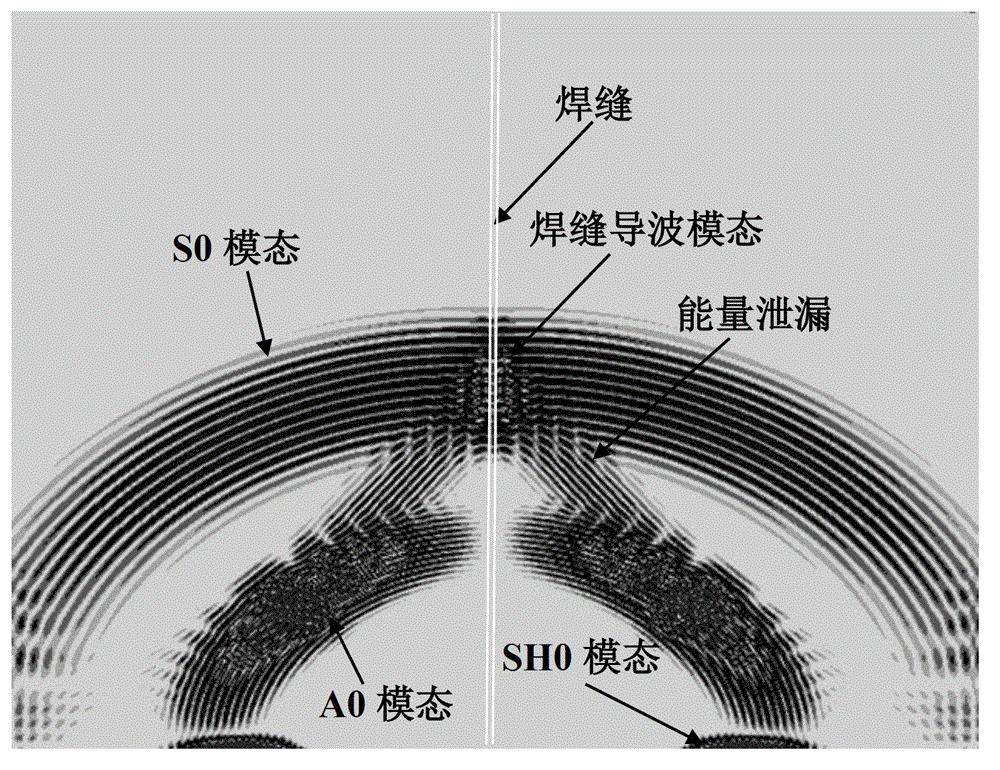

The invention concretely relates to an ultrasonic Lamb wave-based butt weld nondestructive testing method and belongs to the ultrasonic guided-wave nondestructive testing field. An excitation source is loaded at the end of a weld joint. Two piezoelectric patches are pasted on the upper surface and the lower surface of a plate symmetrically and excited. The generated weld joint guided-wave mode propagating along the weld joint has high energy and slow attenuation, and the long-distance testing problem can be solved. The testing system is shown in the figure, and composed of a function generator (1), a power amplifier (2), piezoelectric patches (3), an oblique incidence-type piezoelectric ultrasonic sensor (4), an oscilloscope (5) and a computer (6). By utilizing the testing system, when the ultrasonic Lamb wave encounters flaws of the weld joint, flaw echoes are generated. According to the time difference between the excitation waveforms and the waveforms of flaw echoes and the group velocity of the weld joint guided-wave mode, the distance from the flaws to the excitation source can be obtained, and therefore the effective locating of weld joint flaws can be achieved.

Owner:BEIJING UNIV OF TECH

Nondestructive detection system of sheet metal by ultrasonic planar guided-wave and detection method thereof

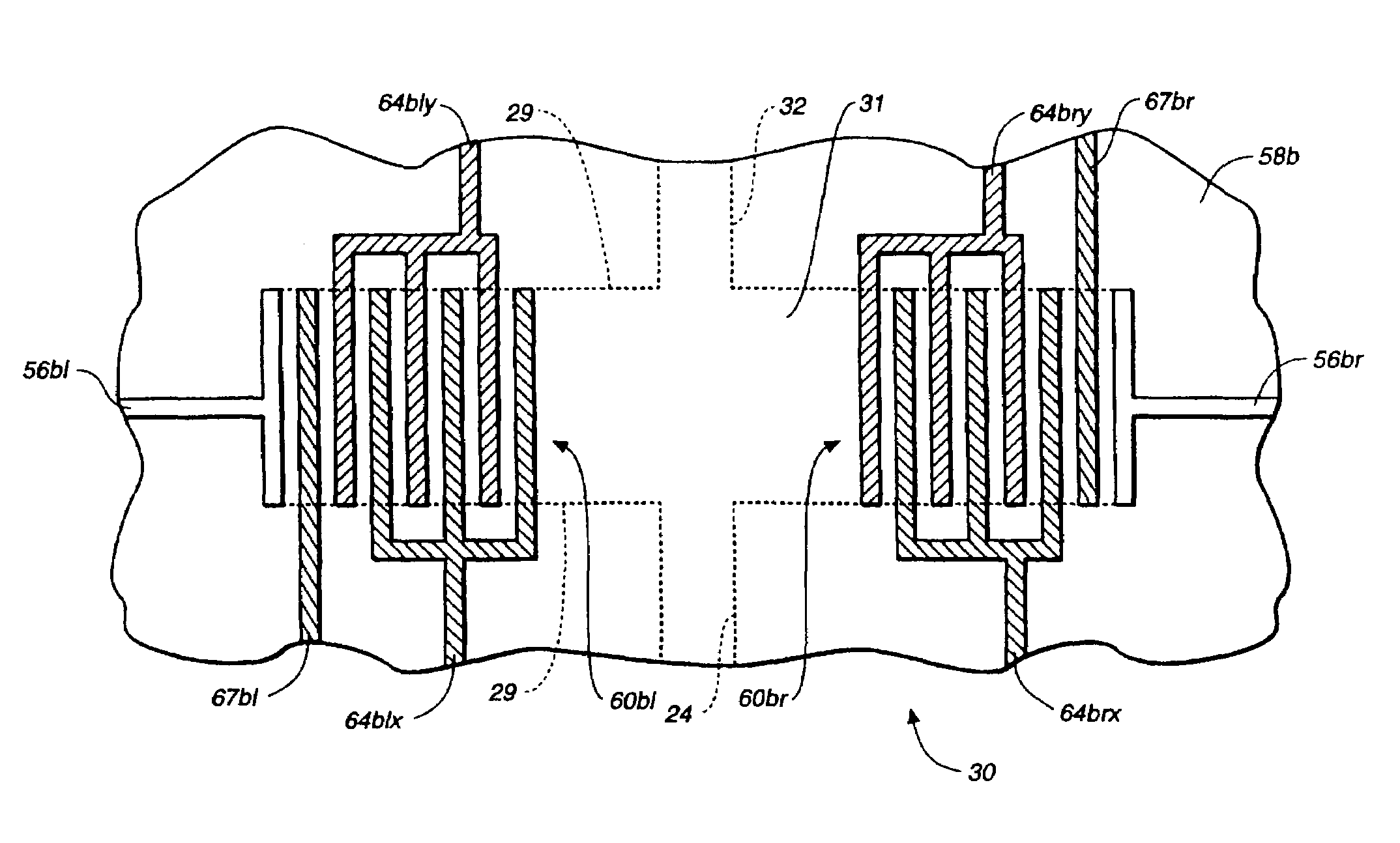

InactiveCN104297346AThe detection process is flexible and convenientImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesTransceiverDistance detection

The invention provides a nondestructive detection system of sheet metal by ultrasonic planar guided-wave. An ultrasonic transceiver of the system is connected with an encoder and a sensor. The encoder and the sensor are connected with a controller. The sensor is coupled to a steel plate to be detected through machine oil used as a couplant. Electrical signal transmission process of the system is as follows: a computer inputs excitation parameters to control the ultrasonic transceiver to apply an excitation signal onto the sensor while positional information acquired by the encoder and an echo signal acquired by the sensor are transmitted to the computer through the ultrasonic transceiver. Meanwhile, the invention provides a nondestructive detection system of sheet metal by ultrasonic planar guided-wave and a detection method thereof. The invention has the following beneficial effect: by the characteristic that propagation distance of ultrasonic Lamb wave is long, detection range is large and large-area long-distance detection of a plate can be realized only from one detecting point, continuous acquisition of test data can be carried out, and fast effective large-area detection of a sheet metal structure can be achieved. The ultrasonic Lamb wave detection process is flexible and convenient. Quantitative assessment is achieved; detection efficiency is high; and it is easy to achieve automation.

Owner:TIANJIN UNIV

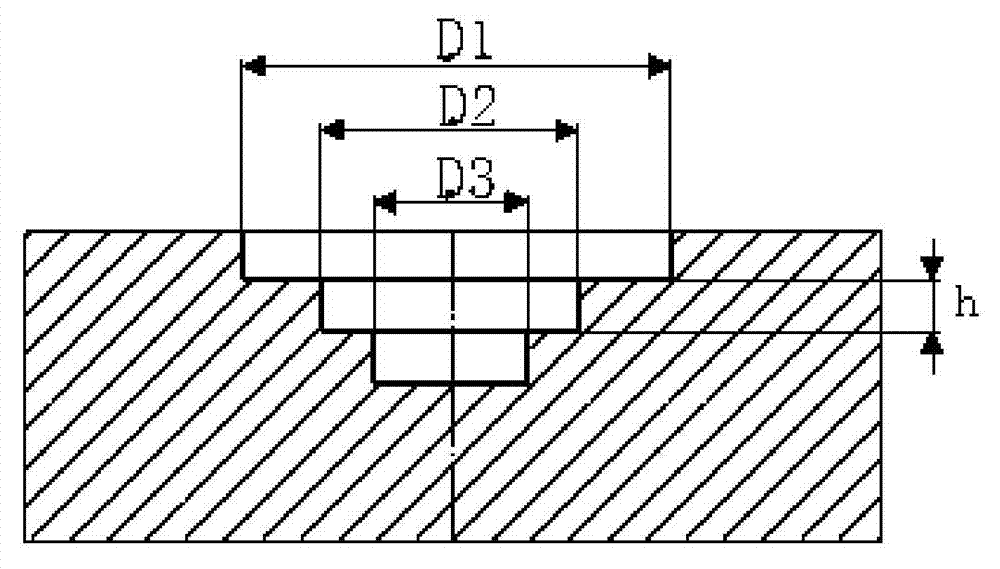

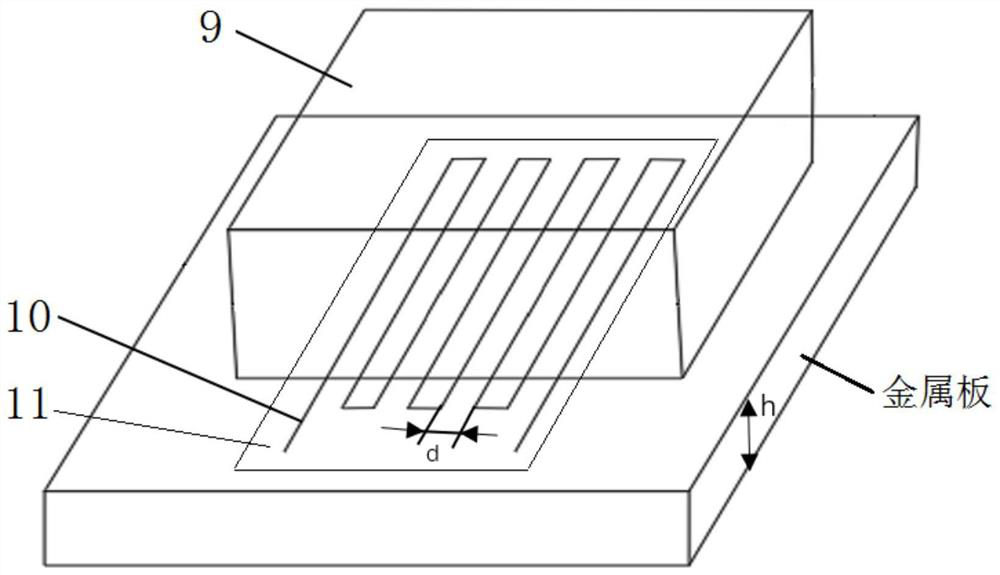

Electromagnetic ultrasonic Lamb wave transducer for guided wave tomography

InactiveCN104090034AMeet the needs of large directivity angleReduce volumeUltrasonic/sonic/infrasonic wave generationUltrasonic lamb wavesTransducer

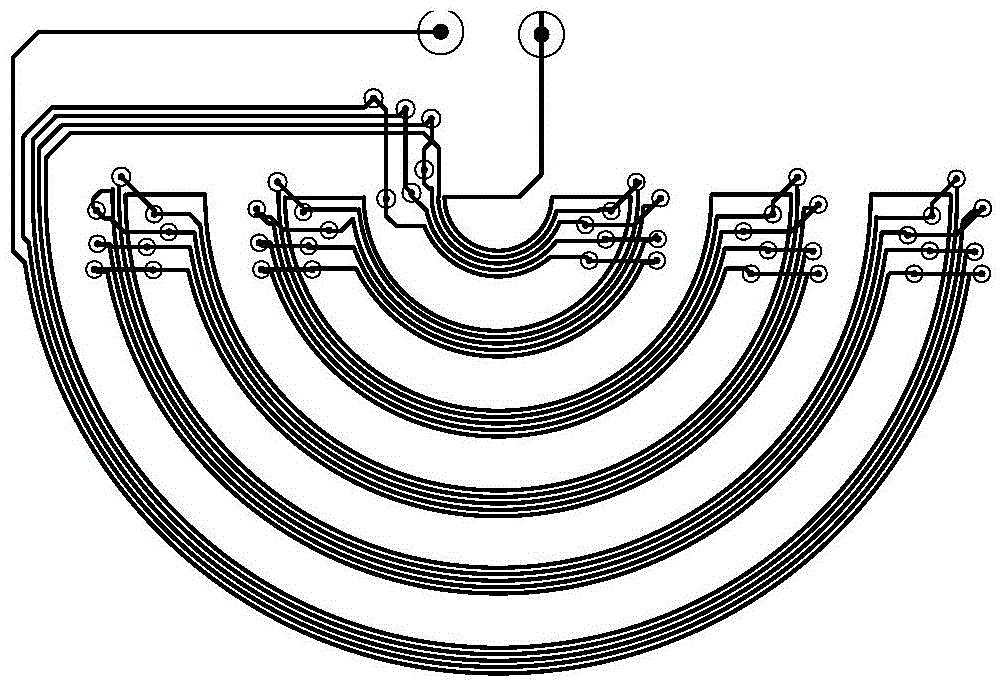

The invention discloses an electromagnetic ultrasonic Lamb wave transducer for guided wave tomography, belongs to the technical field of the guided wave tomography of metal panels, in particular relates to an single-mode electromagnetic ultrasonic Lamb wave transducer with a 180-degree directional angle, and solves the problems that the directional angle of an existing electromagnetic ultrasonic Lamb wave transducer is small and excitation guided wave modes are mixed. According to the electromagnetic ultrasonic Lamb wave transducer, a permanent magnet is a rectangular permanent magnet of which the length and the width are greater than the diameter of a coil, and the magnetic induction intensity of a static magnetic field of the permanent magnet is not smaller than 0.15T; each turn of semicircular zigzag coil comprises m wires, and the center distance d between two adjacent turns of wires in the radial direction is equal to lambda / 2; and n turns of semicircular zigzag coils are manufactured into a double-face PCB (printed circuit board) which is arranged right below the permanent magnet. The electromagnetic ultrasonic Lamb wave transducer is applicable to the tomography of various metal panel structures with uniform material properties.

Owner:HARBIN INST OF TECH

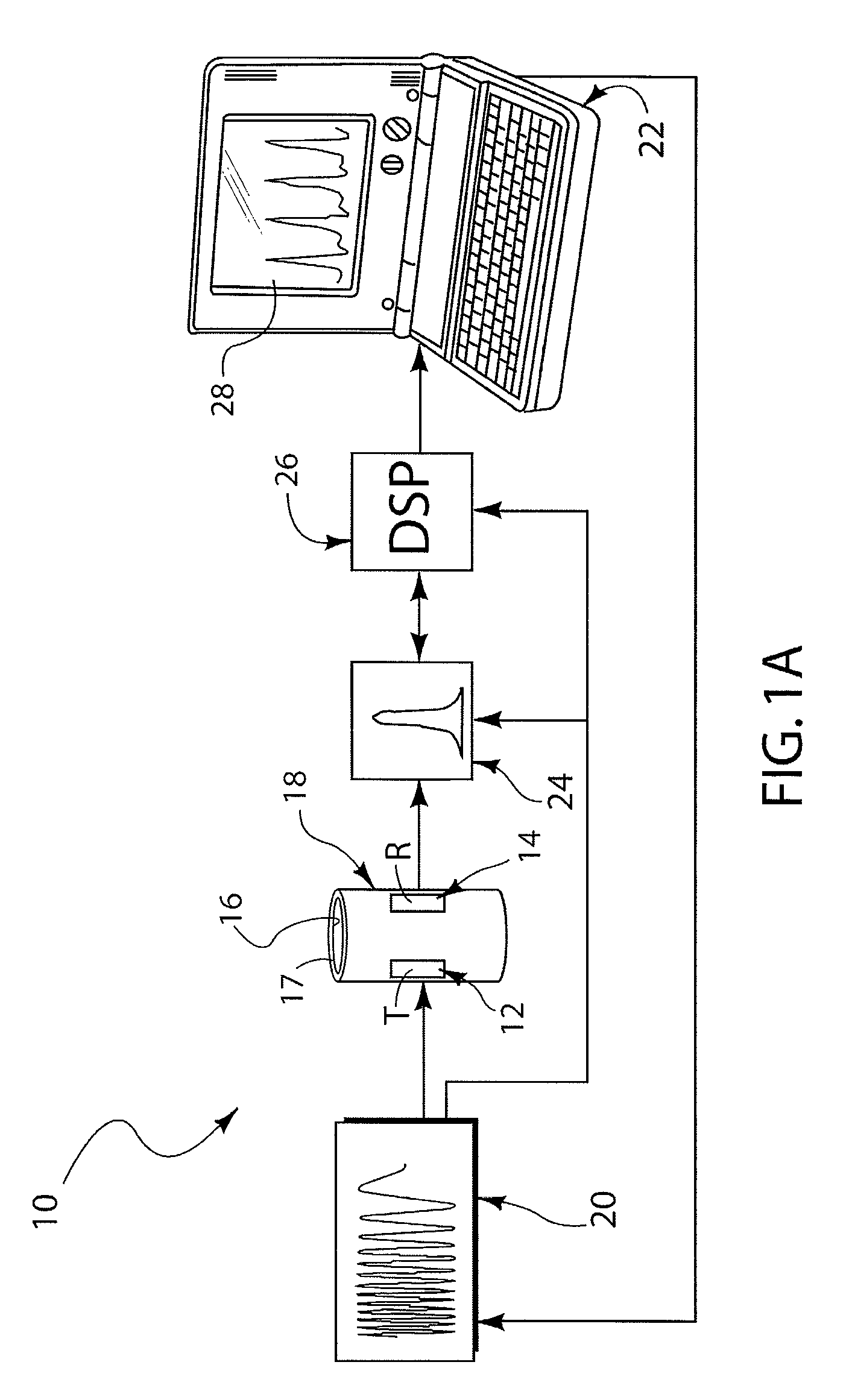

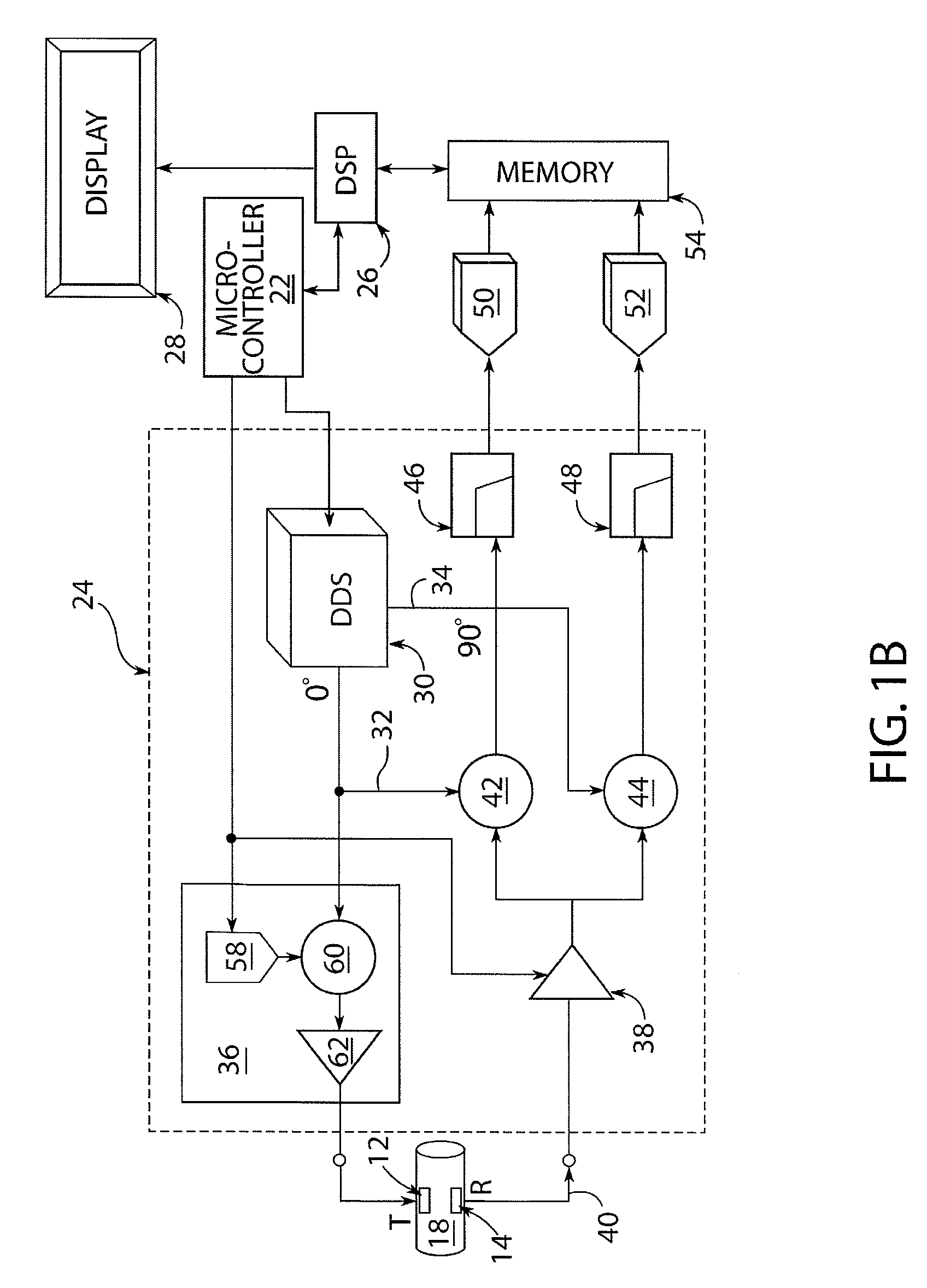

Non-contact feature detection using ultrasonic Lamb waves

ActiveUS7963165B2Reduce power consumptionVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTime domainNon-contact ultrasound

Apparatus and method for non-contact ultrasonic detection of features on or within the walls of hollow pipes are described. An air-coupled, high-power ultrasonic transducer for generating guided waves in the pipe wall, and a high-sensitivity, air-coupled transducer for detecting these waves, are disposed at a distance apart and at chosen angle with respect to the surface of the pipe, either inside of or outside of the pipe. Measurements may be made in reflection or transmission modes depending on the relative position of the transducers and the pipe. Data are taken by sweeping the frequency of the incident ultrasonic waves, using a tracking narrow-band filter to reduce detected noise, and transforming the frequency domain data into the time domain using fast Fourier transformation, if required.

Owner:TRIAD NAT SECURITY LLC

Ultrasonic nondestructive detection method of material mico-crack expanded size

InactiveCN109283247AAvoid Serious Impact on SecurityThe detection process is fastAnalysing solids using sonic/ultrasonic/infrasonic wavesReference sampleFatigue damage

The invention provides an ultrasonic nondestructive detection method of material micro-crack expanded size. The method comprises the following steps: constructing a measurement system; manufacturing multiple reference samples, and performing repeated fatigue test on each reference sample; performing metallographic observation after each fatigue test so as to obtain a micro-crack length of each reference sample, and performing ultrasonic nonlinear Lamb wave measurement to compute a nonlinear parameter beta0 of each reference sample; obtaining a nonlinear parameter-fatigue life curve, marking micro-crack sizes corresponding to various points on the curve; performing nonlinear ultrasonic Lamb wave measurement on the to-be-tested sample to obtain the nonlinear parameter beta0, and finding outthe point corresponding to the nonlinear parameter beta0 in the above curve, and finding the length of the micro-crack corresponding to the point. A relationship of the micro-crack size and the nonlinear parameter is used for judging the micro-crack length and representing the fatigue damage, in-service equipment cannot be damaged, and the micro-crack state of the material on active can be quicklydetected at low cost.

Owner:EAST CHINA UNIV OF SCI & TECH

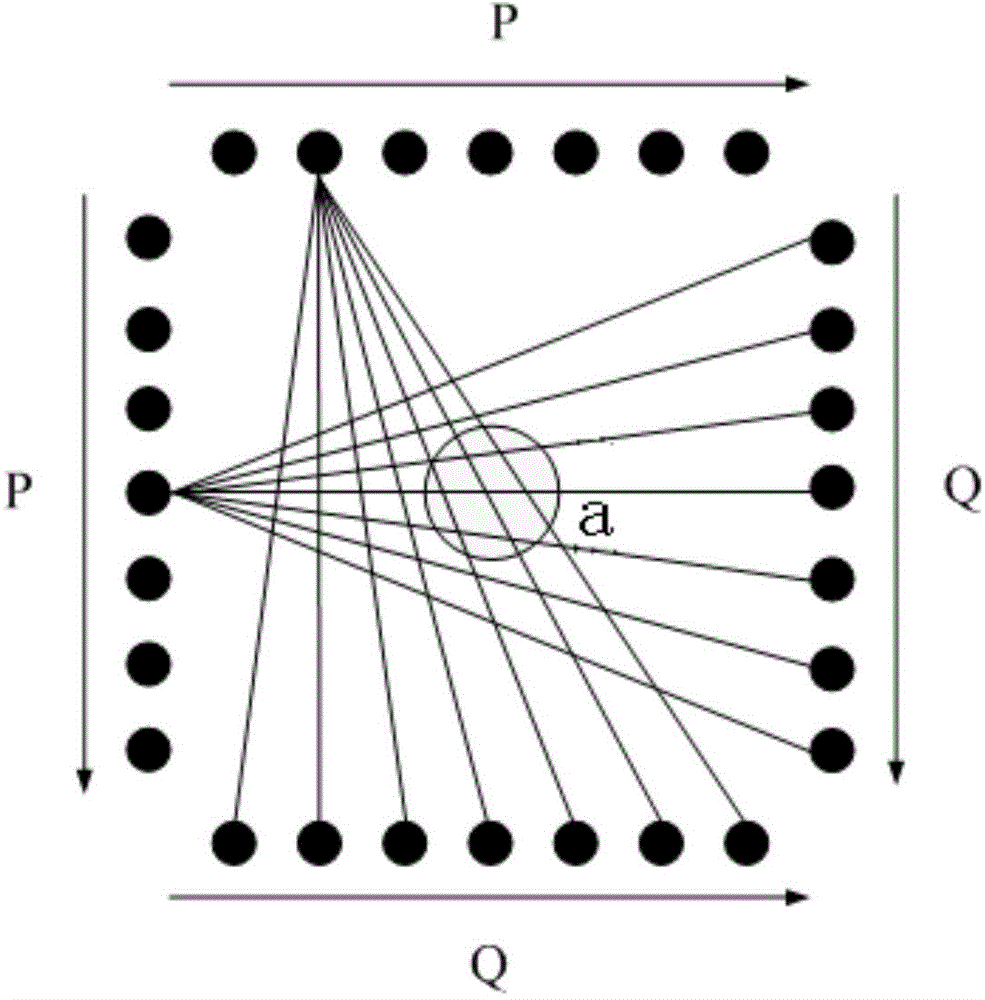

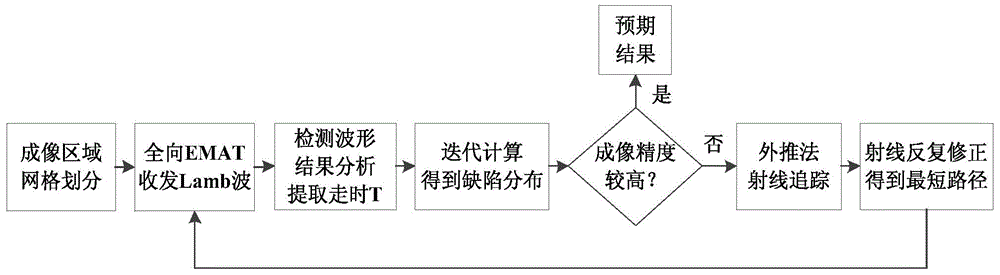

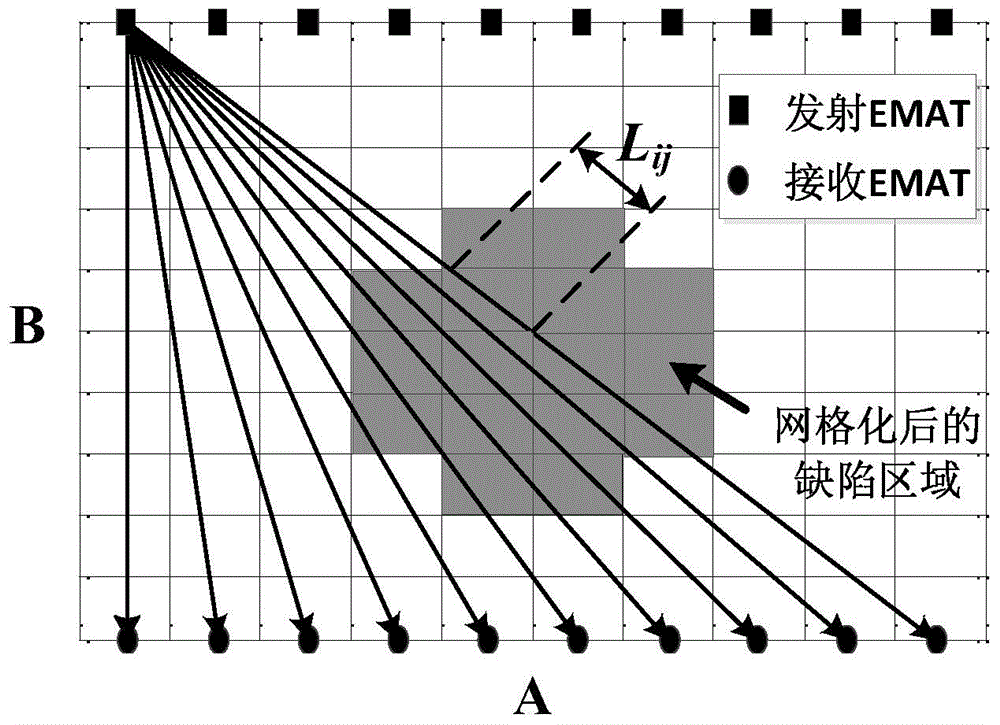

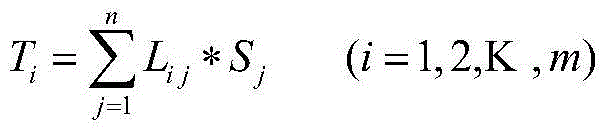

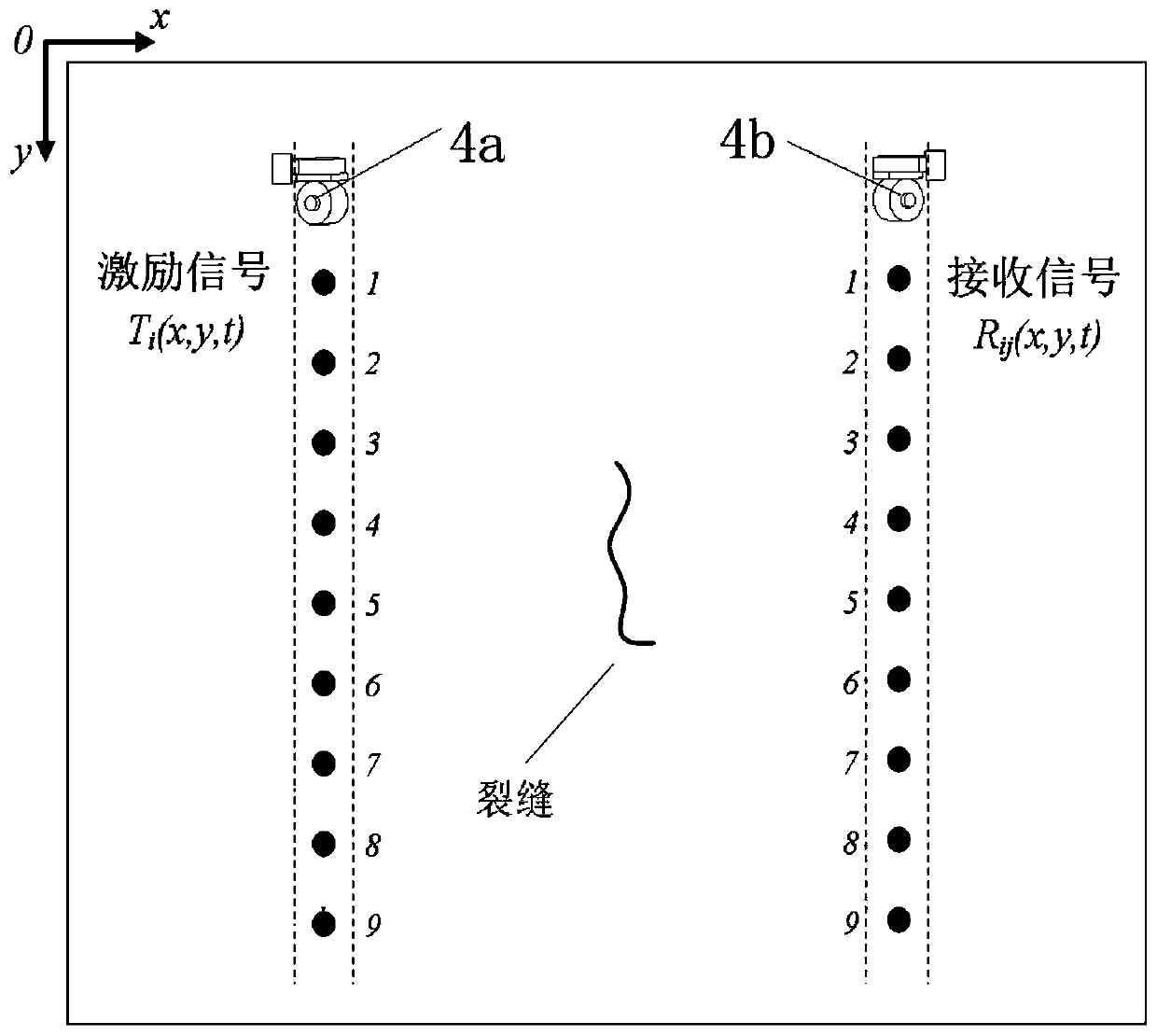

Ray tracing type ultrasonic Lamb wave defect tomographic imaging method

ActiveCN104535655ASolve the problem of low imaging accuracyAccurate calculationAnalysing solids using sonic/ultrasonic/infrasonic wavesSpecial data processing applicationsDiagnostic Radiology ModalitySonification

The invention belongs to the field of nondestructive testing, and relates to a ray tracing type ultrasonic Lamb wave defect tomographic imaging method, first, a to-be-measured material imaging area is divided into a plurality of small grids, and the same amount of emission EMAT (electro-magnetic acoustic transducer) and receiving EMAT are arranged on both sides of the area, then all emission ends are allowed to excite A0 mode Lamb wave, all receiving ends at the opposite side receive meanwhile, analysis results of all tested waveforms are extracted, the corresponding time is recorded, the slowness and defect distribution of every grids are determined by use of combined iterative reconstruction algorithm, the obtained defect distribution is used as a known condition for establishment of a RT extrapolation formula, by use of the extrapolation method, a ray path is gradually traced and corrected, and the ray path is gradually traced and corrected repeatedly until high imaging precision is obtained by calculation. The a ray tracing type ultrasonic Lamb wave defect tomographic imaging method avoids the problem of low imaging precision of a traditional TOF cross hole tomographic imaging method based on straight ray theory, is accurate, efficient and fast to calculate, provides an important basis for improving the defect imaging precision, and has broad application prospects.

Owner:TSINGHUA UNIV

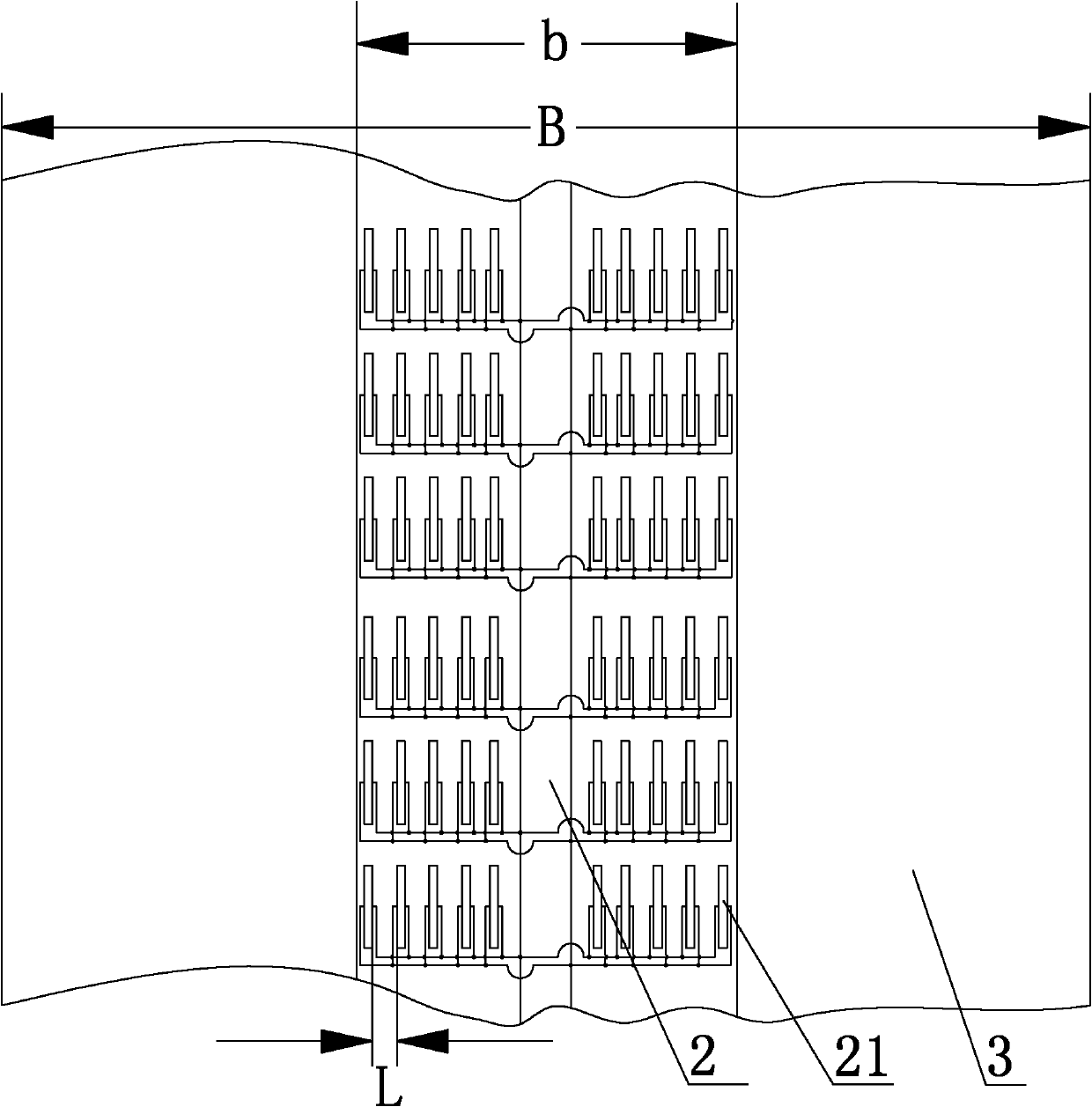

Online anti-icing and de-icing device for wind turbine

ActiveCN101907071AReduce unplanned downtimeImprove wind energy utilization efficiencyMachines/enginesWind energy generationUltrasonic lamb wavesTransducer

The invention discloses an online anti-icing and de-icing device for a wind turbine, comprising an ultrasonic generator (1) and a de-icing unit (2) which is used for generating ultrasonic Lamb waves and horizontal shear waves on the surface of a wind turbine vane (3), wherein the de-icing unit (2) comprises a plurality of piezoelectric transducers (21) arranged on the inner surface of the wind turbine vane (3), and the input end of each piezoelectric transducer (21) is respectively connected with the output end of the ultrasonic generator (1). The invention can realize online anti-icing and de-icing of the wind turbine vane without damaging wind turbine vane materials and has the advantages of low energy consumption, low cost and simple maintenance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

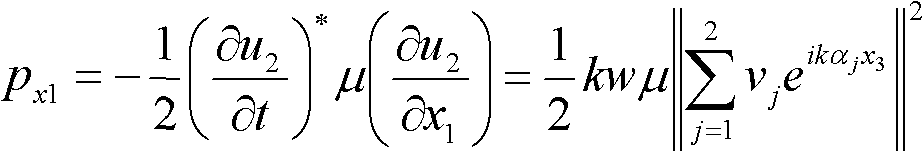

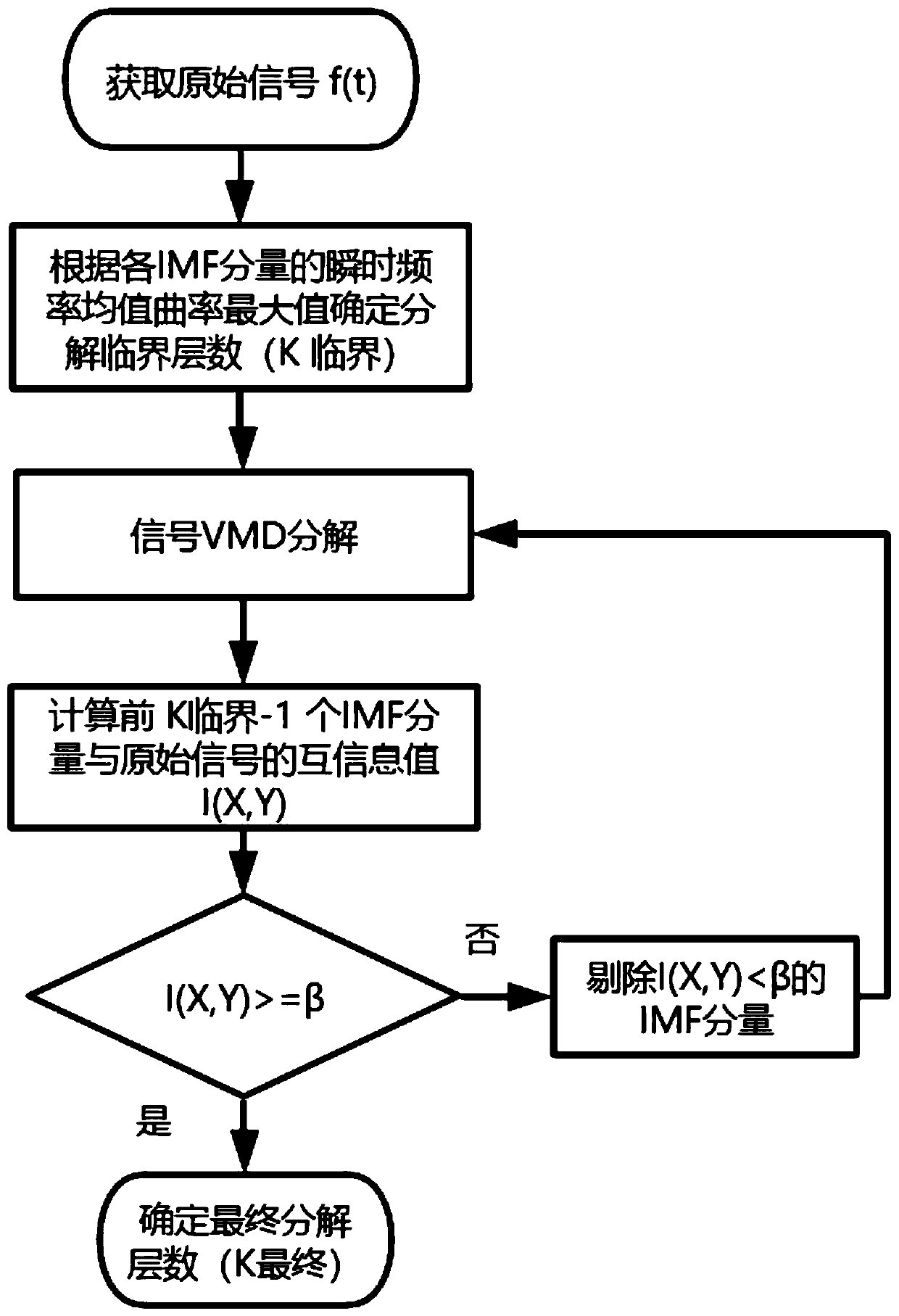

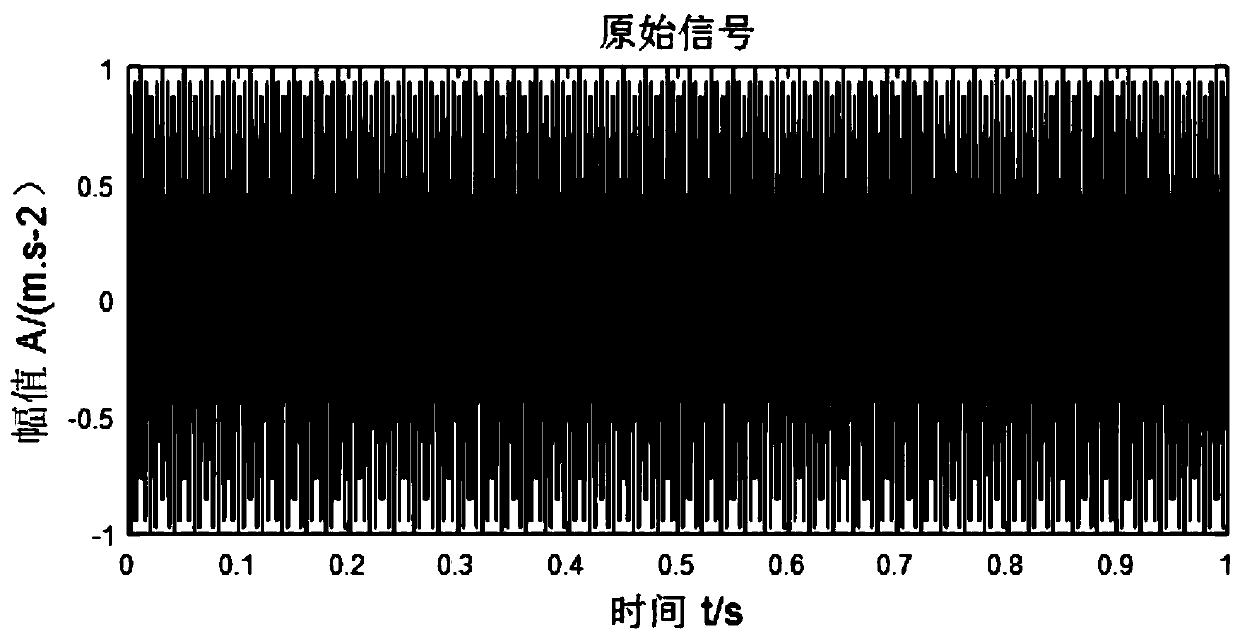

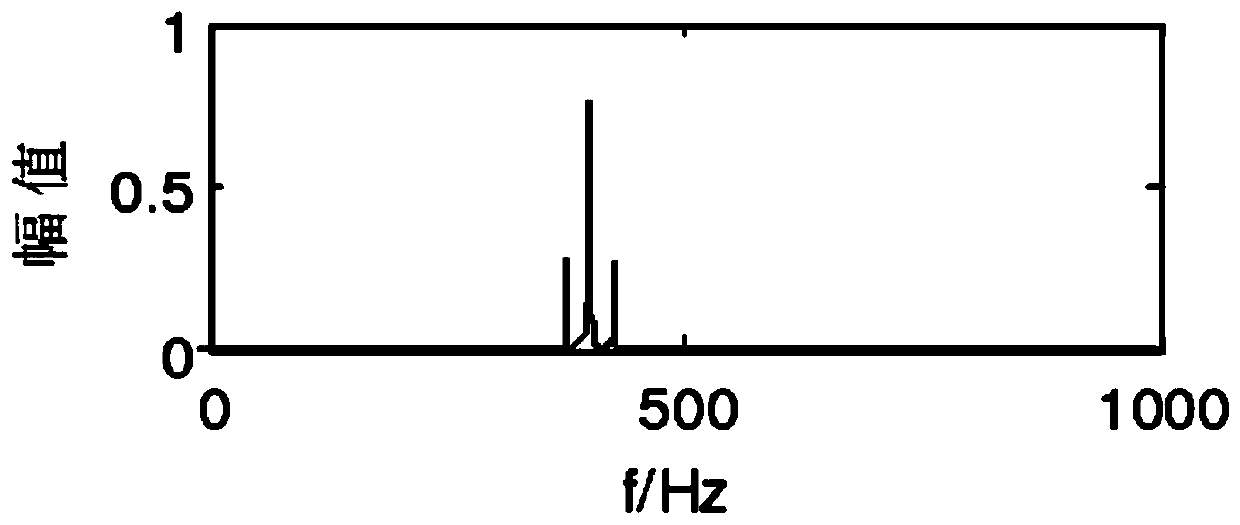

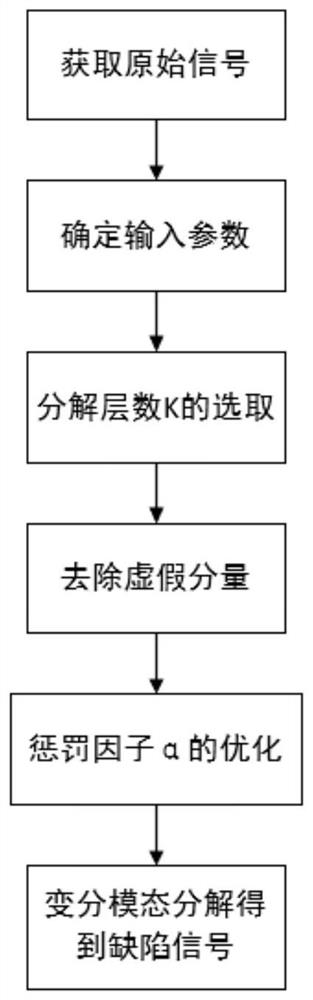

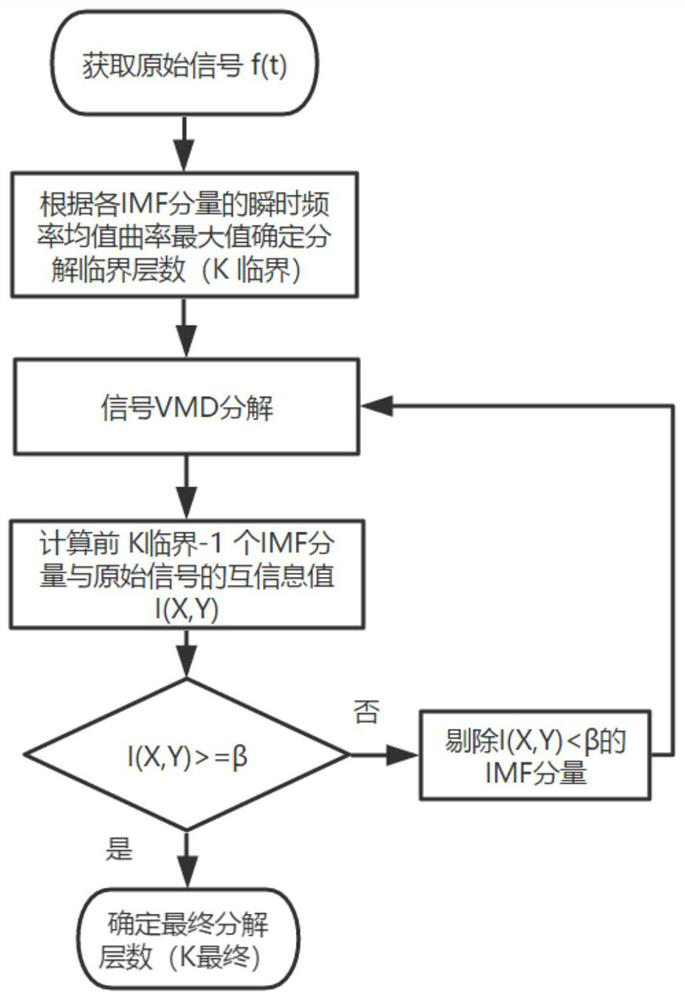

Ultrasonic Lamb wave defect signal recognition method based on variational mode decomposition

ActiveCN110333285AImprove accuracyEasy to identifyProcessing detected response signalSonificationDecomposition

The present invention relates to the technical field of signal processing, and provides an ultrasonic Lamb wave defect signal recognition method based on variational mode decomposition, including: step 1, exciting a to-be-detected aluminum plate by using an excitation signal to obtain a raw signal of an ultrasonic Lamb wave; step 2, determining an input parameter for variational mode decompositionaccording to the obtained raw signal of the ultrasonic Lamb wave; step 3, performing variational mode decomposition according to the determined input parameter for variational mode decomposition; step 4, calculating mutual information values between K<critical>-1 IMF components and the raw signal, comparing the mutual information values with a mutual information threshold, considering the IMF components for which the mutual information value is less than the mutual information threshold as false components and removing the false components, determining a final K value and in turn determiningthe number of final decomposition layers; and step 5, after determining the final number of decomposition layers, performing defect identification by using the obtained defect signal of a center frequency. The method enables accurate identification of a defect signal of the ultrasonic lamb wave.

Owner:DALIAN OCEAN UNIV

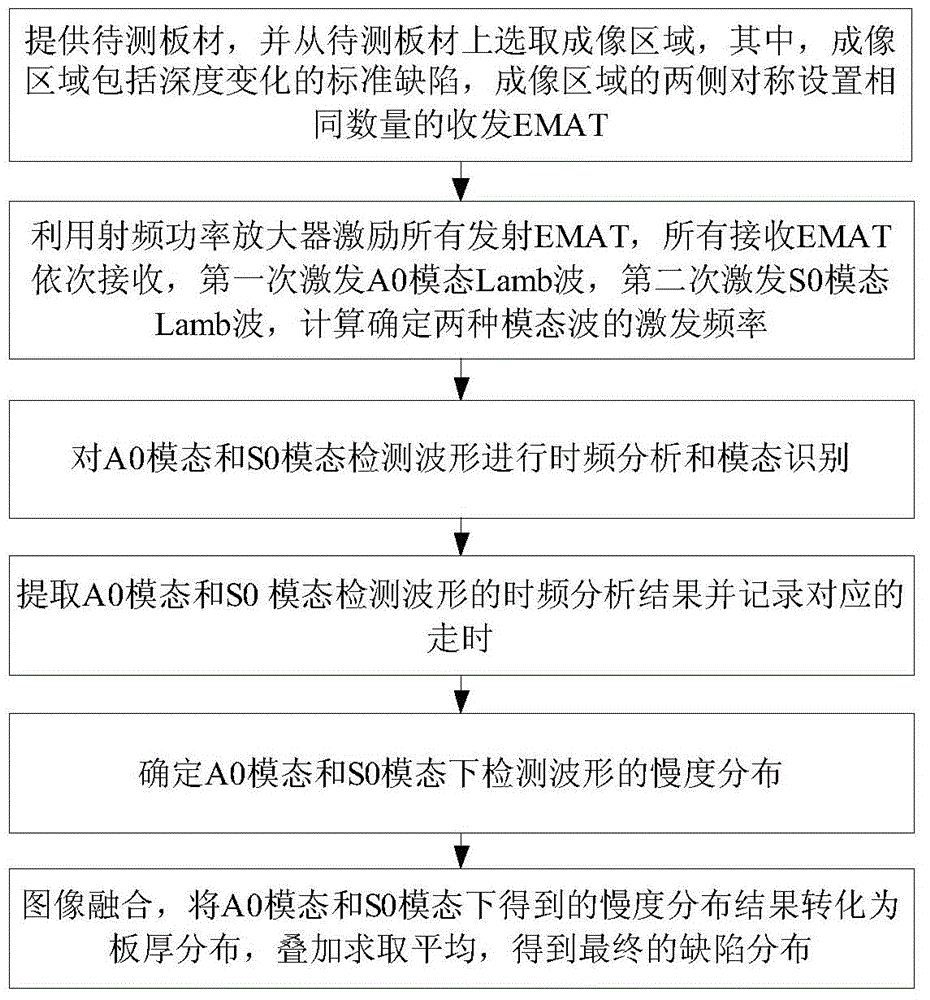

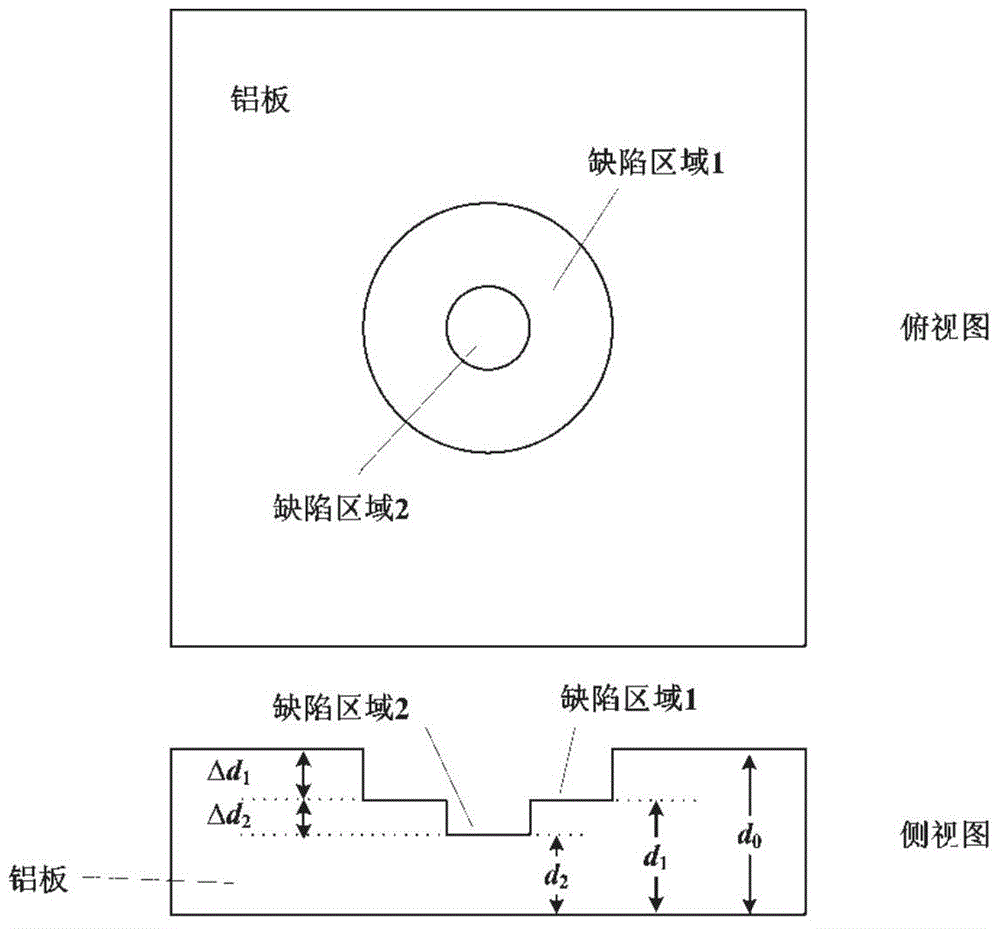

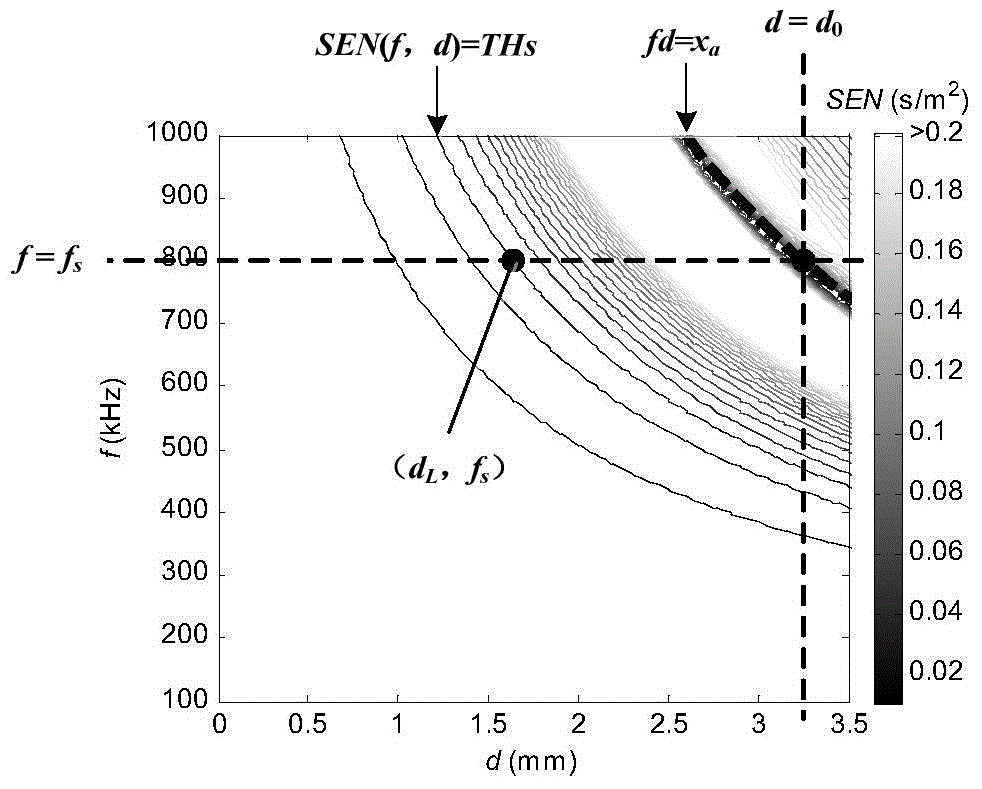

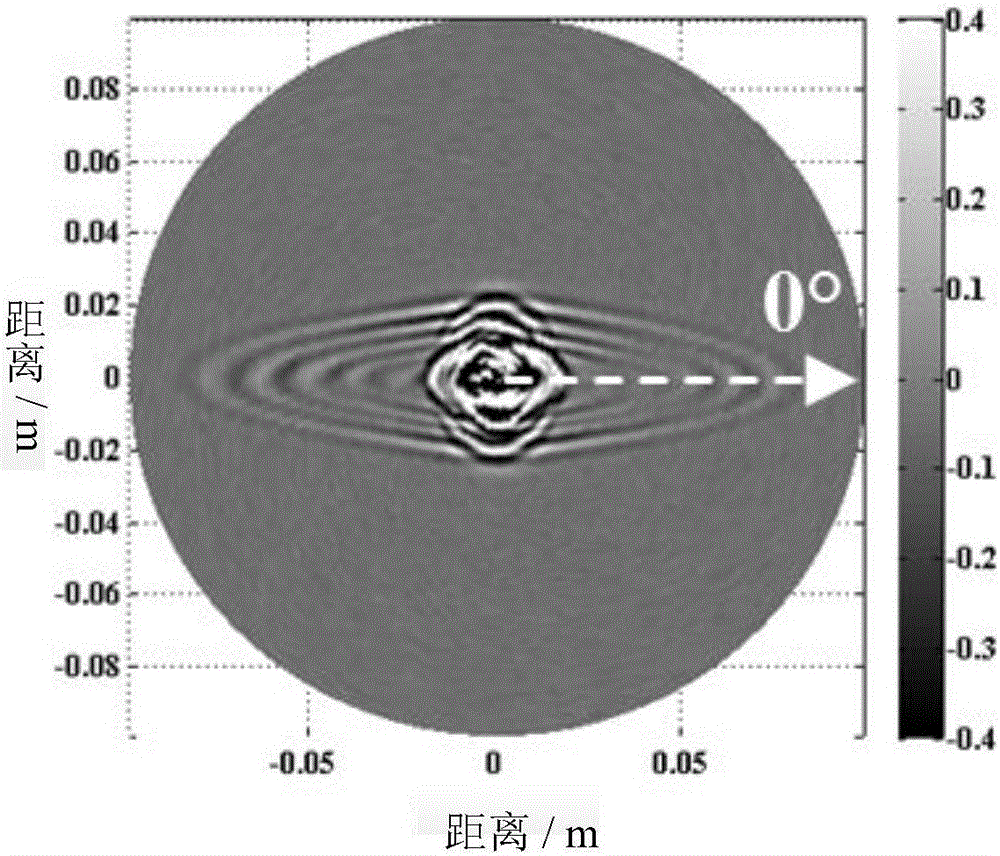

Multimodal ultrasonic Lamb wave complex defect tomography method

InactiveCN105044212AImprove recognition efficiencyImproving Imaging AccuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationUltrasonic lamb waves

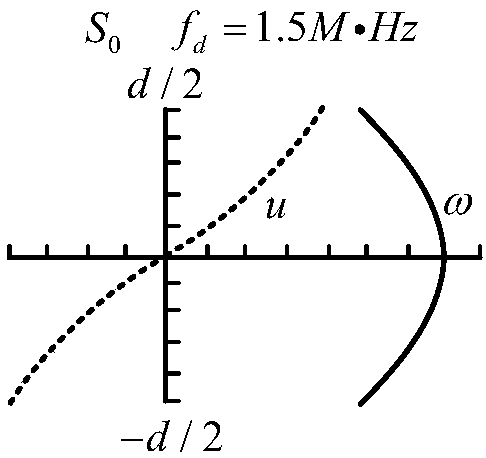

The invention provides a multimodal ultrasonic Lamb wave complex defect tomography method. The method comprises the following steps: presetting a sensitivity threshold THs and a sensitivity dead zone dz, and calculating to obtain the appropriate working frequencies of Lamb waves with A0 and S0 modals; carrying out A0 wave cross-hole tomography and S0 wave cross-hole tomography under respective working frequency conditions by respectively using A0 wave EMAT array and S0 wave EMAT array; and carrying out image fusion, and organically combining two results to obtain a final defect image reconstruction result. The method fully uses different sensitive areas of the Lamb waves with different modals to carry out complementation of the sensitive areas, so the method has the advantages of enlargement of the integral sensitive area of tomography, reduction of influences of noises, effective reduction of the difficulty of extraction of defect characteristic information from a slowness distribution map, improvement of the identification efficiency and imaging precision of complex defects, and wide application prospect.

Owner:TSINGHUA UNIV

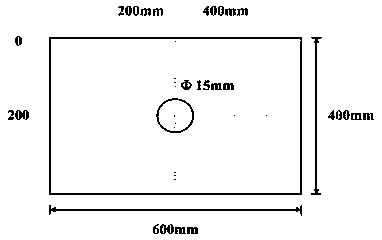

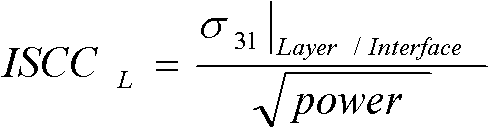

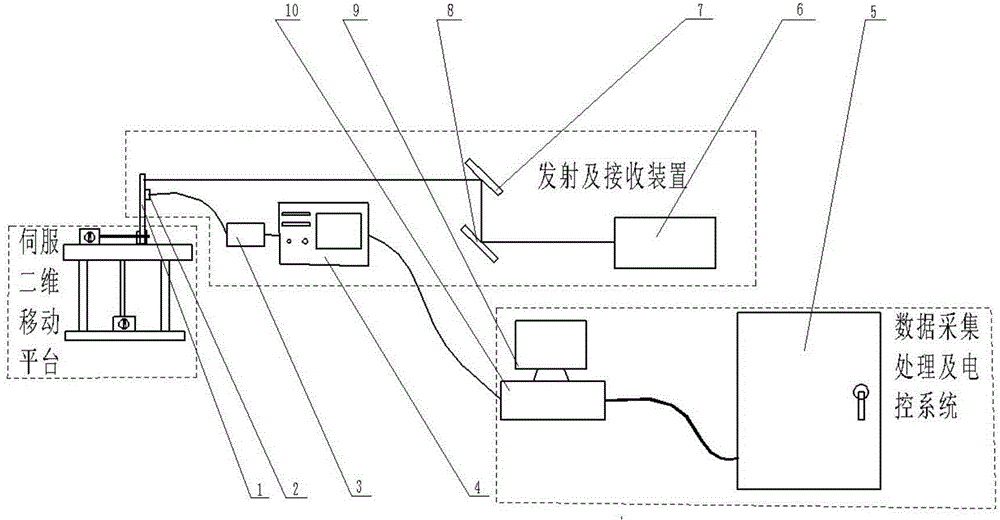

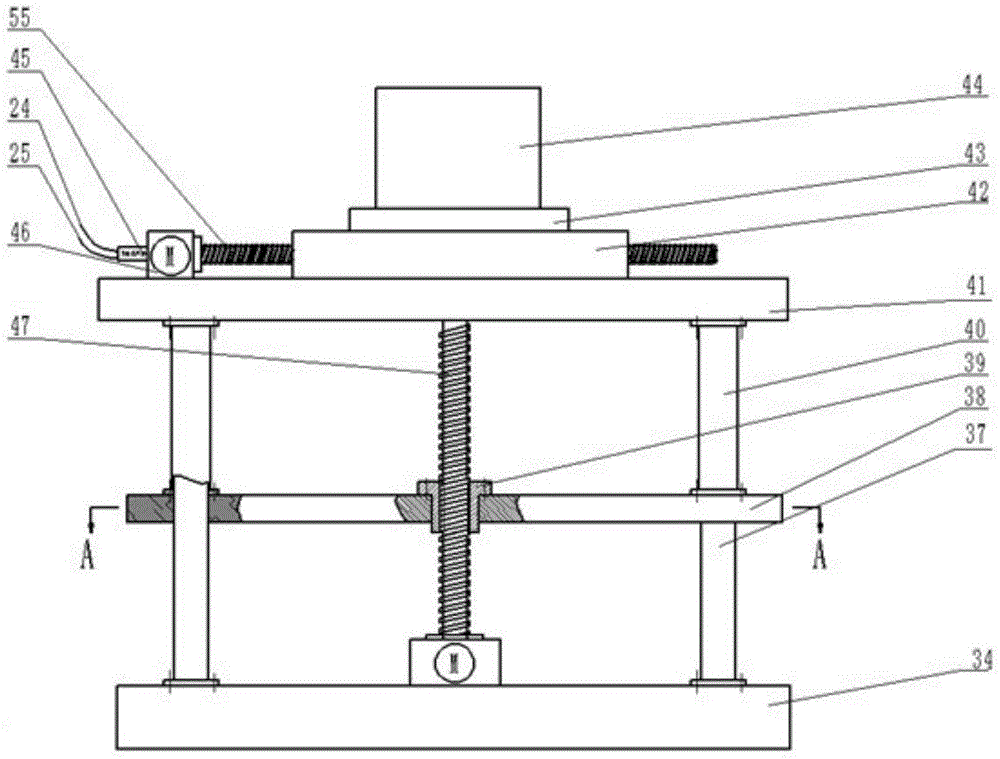

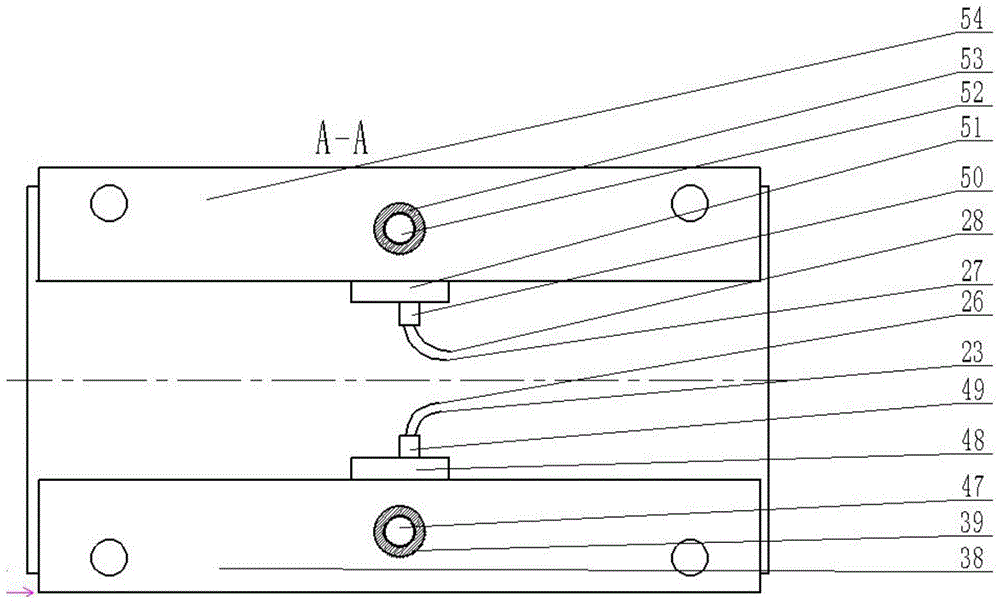

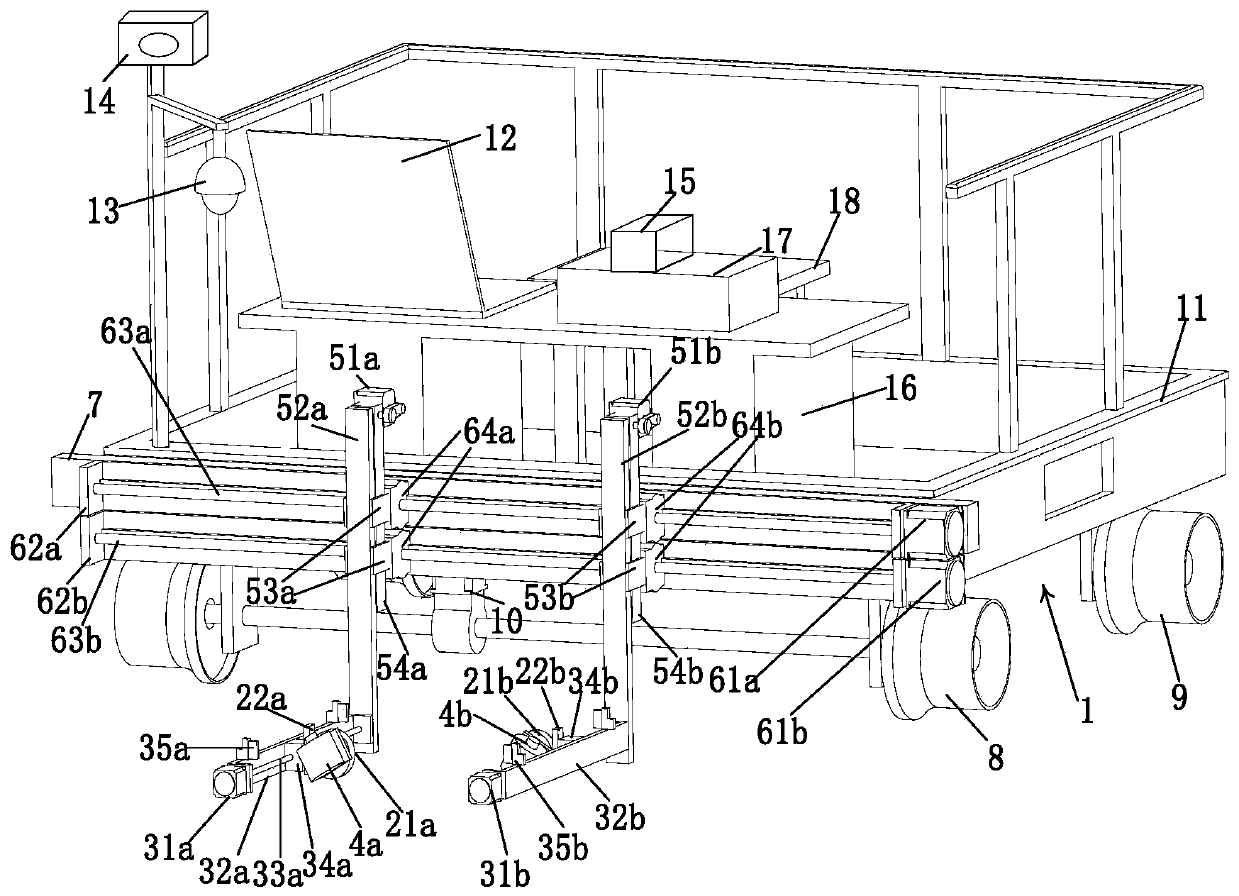

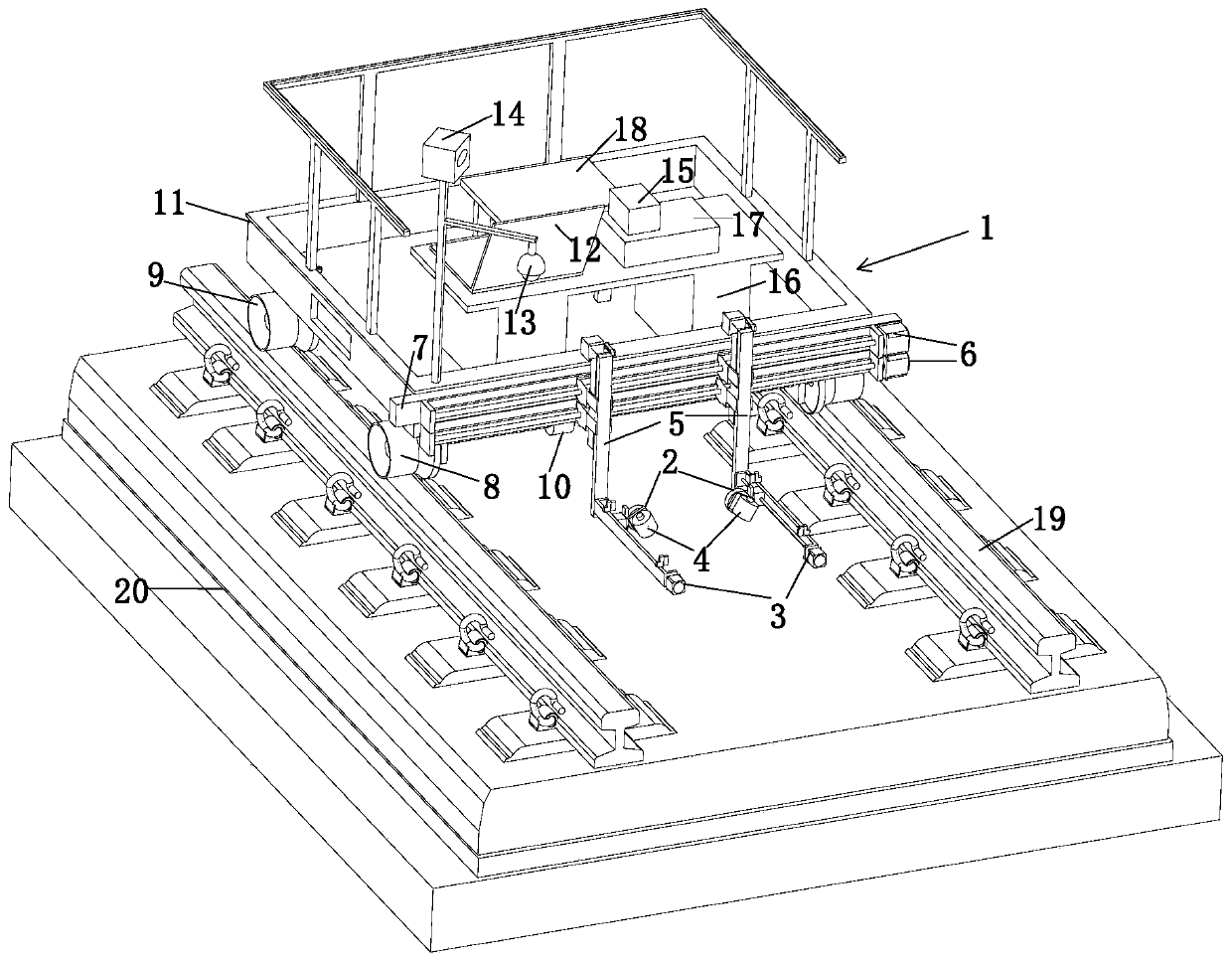

Device and method for measuring internal stress of plastic sheet products on basis of ultrasonic lamb waves

ActiveCN104807570AImprove measurement accuracyAvoid errorsForce measurementSignal onData acquisition

The invention discloses a device and method for measuring internal stress of plastic sheet products on the basis of ultrasonic lamp waves and belongs to the field of material performance detection. The device mechanically comprises a base, a longitudinal double-servo synchronous-drive moving component, a horizontal servo moving component and a test-piece clamping device; data collection processing and electric controlling systems transmit lamb wave signals on a digital oscilloscope to a computer processing system via a USB (universal serial bus), amplitude signals are processed to acquire stress distribution on different areas, and the electric controlling system controls a servo two-dimensional mobile platform to realize measurement of the different areas. The device and method is high in integration degree and simple in operation, standard splines are calibrated with the lamb wave amplitude signals under different stresses, and quantitative measurement of the internal stress distribution of the plastic sheet products can be realized by detection of lamb wave amplitudes.

Owner:BEIJING UNIV OF CHEM TECH

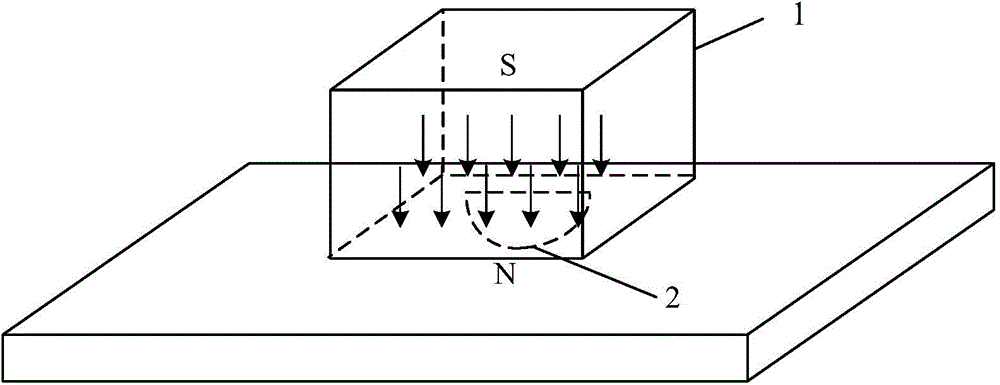

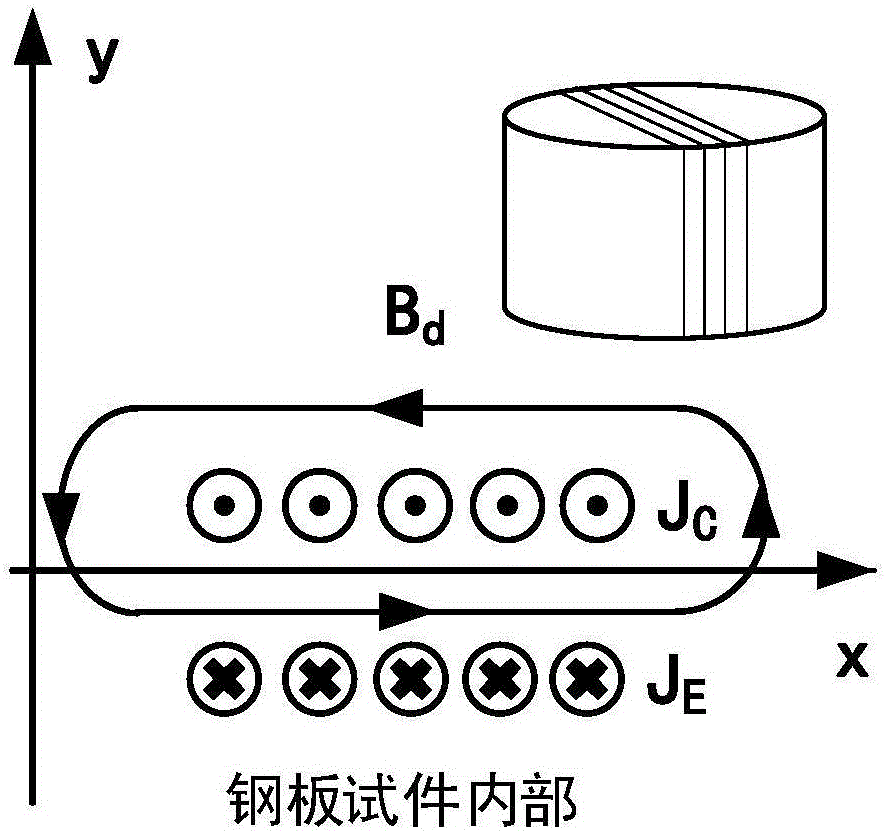

Coil autoexcitation electromagnetic ultrasonic lamb wave transducer

The invention relates to a novel electromagnetic ultrasonic transducer. Compared with traditional transducers, the largest difference in design is that the novel electromagnetic ultrasonic transducer can supply a static magnetic field without the need of a magnet, a strongly dynamic magnetic field is generated by a linearly wound coil through excitation of large current, and the dynamic magnetic field and a ferromagnetic plate achieve ultrasonic lamb wave excitation through magnetic coupling. Most of the traditional transducers are excited through lorentz force or magnetostrictive force under static magnetic fields, and the novel electromagnetic ultrasonic transducer achieves ultrasonic wave excitation through lorentz force and magnetostrictive force under the dynamic magnetic field. The newly designed transducer can achieve transduction in a lift-off distance range of 0-9 mm and is superior to the traditional electromagnetic ultrasonic transducers in lift-off performance.

Owner:UNIV OF SCI & TECH BEIJING

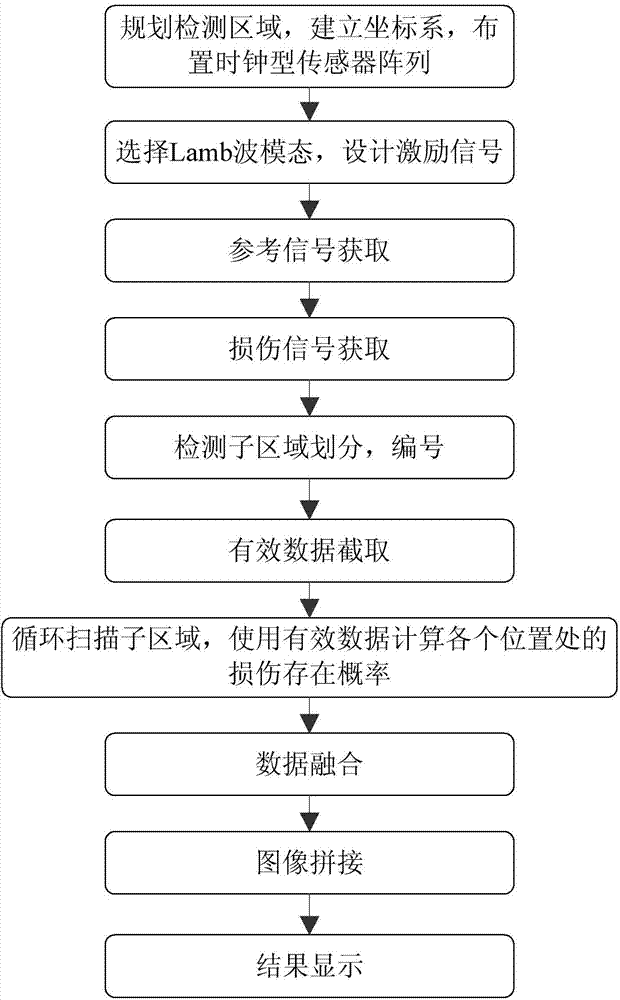

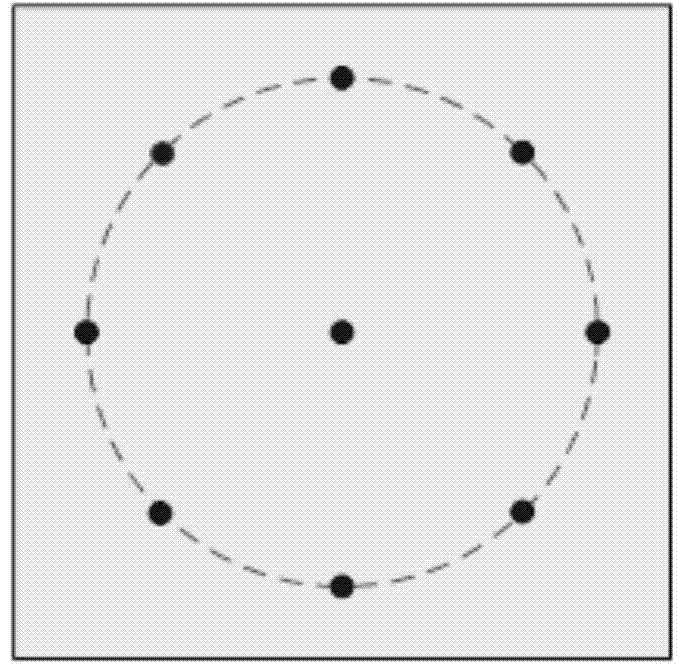

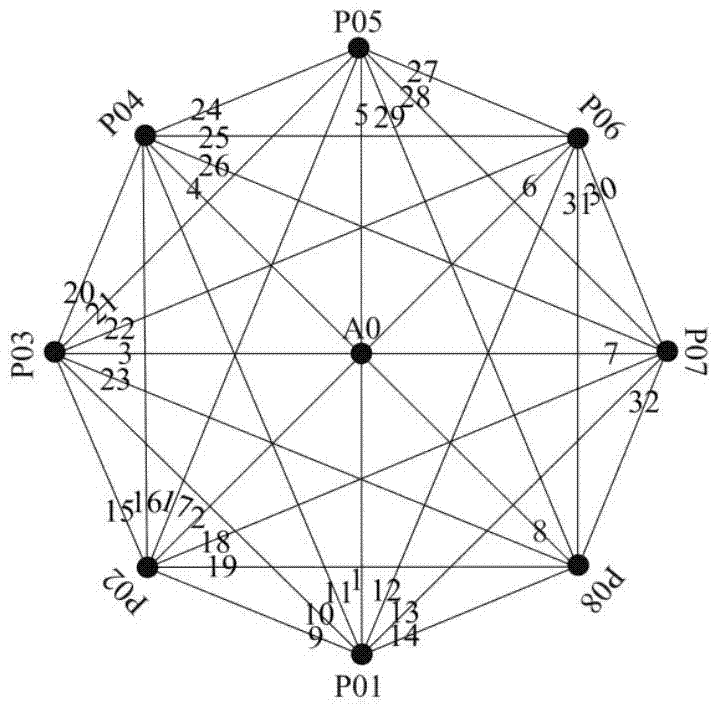

Ultrasonic Lamb wave local circulation scanning probability reconstruction tomography method

InactiveCN104764804AEliminate the effects ofImprove accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesSensor arraySonification

An ultrasonic Lamb wave local circulation scanning probability reconstruction tomography method includes following steps: (1) planning a detection zone and arranging a sensor array on a detection part; (2) selecting a Lamb wave modal and designing an excitation signal, and respectively collecting reference signals and damage signals relative to the sensor pairs; (3) dividing the detection zone to obtain a plurality of sectors, wherein several adjacent sectors are employed as a sub zone; (4) when detection in a sub zone is completed every time, clockwisely rotating the sub zone by a position of one sector to form a next cyclic detection sub zone; (5) performing data selection pre-processing, calculating an valid data length according to the distance among the sensor pairs and the modal speed of the selected Lamb wave; (6) performing local circulation probability reconstruction tomography calculation; and (7) finally performing data fusion and image splicing. The method is strong in anti-jamming capability, is high in precision, can effectively eliminate the influence of multiple faults and the like on the method, and can increase detection resolution rate in multi-fault damage.

Owner:XI AN JIAOTONG UNIV

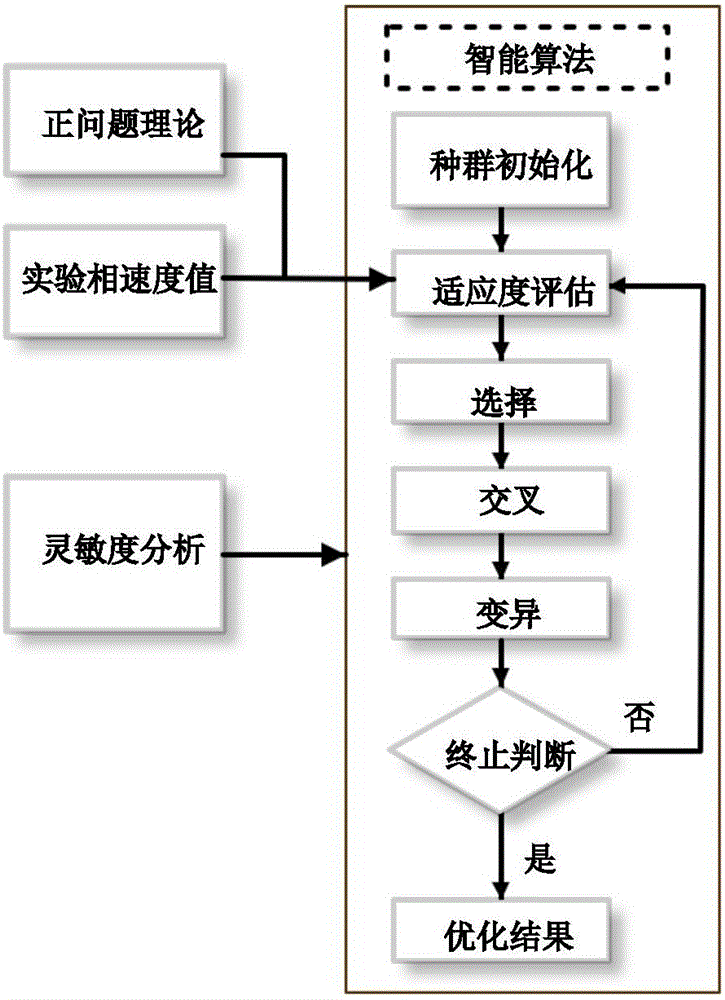

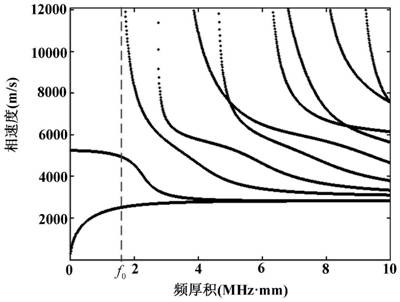

Composite material stiffness coefficient nondestructive measurement method

PendingCN106770648AInnovativeGood experimental stabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalStiffness coefficientPlate theory

The invention discloses a composite material stiffness coefficient non-destructive recognition method based on an ultrasonic Lamb wave technology. The method comprises the four parts including direct problem theoretical modeling, sensitivity analysis, measurement of phase velocity value by experiments and stiffness coefficient inverse problem solving; for a direct problem theoretical model, the self derived novel third-order plate theory is used for solving the spread theoretical phase velocity value of Lamb waves in a composite material plate; the theory considers the plate wave stress free boundary conditions; the complicated step of shearing correction factor calculation required by the ordinary plate theory is avoided; for the sensitivity analysis, the proper spreading angle and the Lamb wave mode are selected, and are the premise for complete reconstruction of nine stiffness coefficients; the experiment uses a non-contact type laser ultrasonic system, and an advanced signal processing method is combined, so that the multi-angle waveguide phase velocity value measurement is completed; finally, an intelligent optimization algorithm is combined; the optimal solution of the composite material stiffness coefficient is obtained through the minimum experimental measurement phase velocity value and the theoretical calculation phase velocity value.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

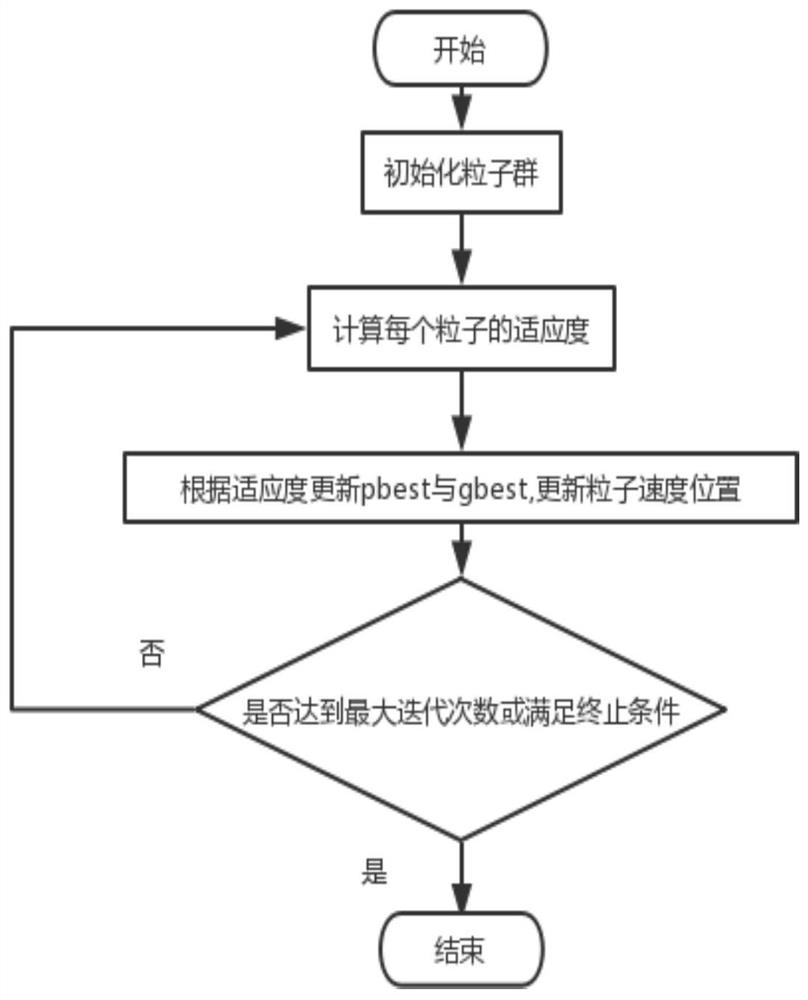

Ultrasonic lamb wave defect signal identification method based on variational mode decomposition

ActiveCN113049684AImprove accuracyEasy to identifySustainable transportationProcessing detected response signalInformation processingUltrasonic sensor

The invention relates to the technical field of information processing, and provides an ultrasonic lamb wave defect signal identification method based on variational mode decomposition, which comprises the following steps of: 1, generating an excitation signal by using an electromagnetic ultrasonic transducer to detect an aluminum plate, and receiving an original signal of an ultrasonic lamb wave by using a receiving transducer on the other side of the aluminum plate; 2, determining input parameters of variational mode decomposition, wherein the input parameters comprise a decomposition layer number, a secondary penalty factor and a termination condition; 3, carrying out variational mode decomposition; 4, determining a final decomposition layer number, and obtaining sub-signals at the center frequency after separation; 5, selecting and optimizing a variational mode decomposition input parameter-penalty factor by adopting a particle swarm algorithm; and 6, variational modal is carried out by using the final decomposition layer number and the optimized penalty factor, complete extraction of defect signals is ensured, and defect identification is carried out by obtaining the defect signals of the center frequency. According to the invention, the accuracy and the recognition rate of ultrasonic lamb wave defect signal detection can be improved.

Owner:DALIAN OCEAN UNIV

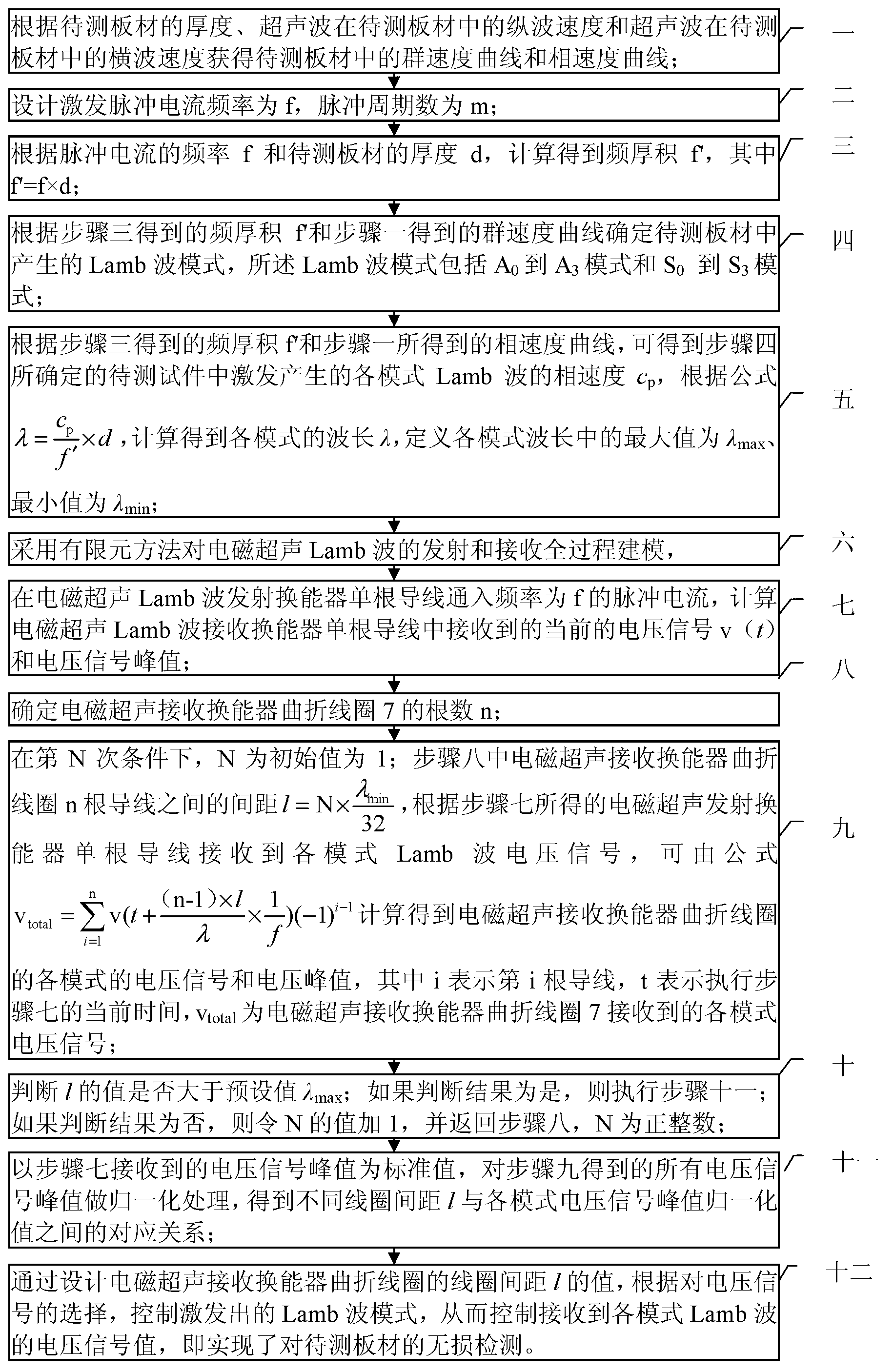

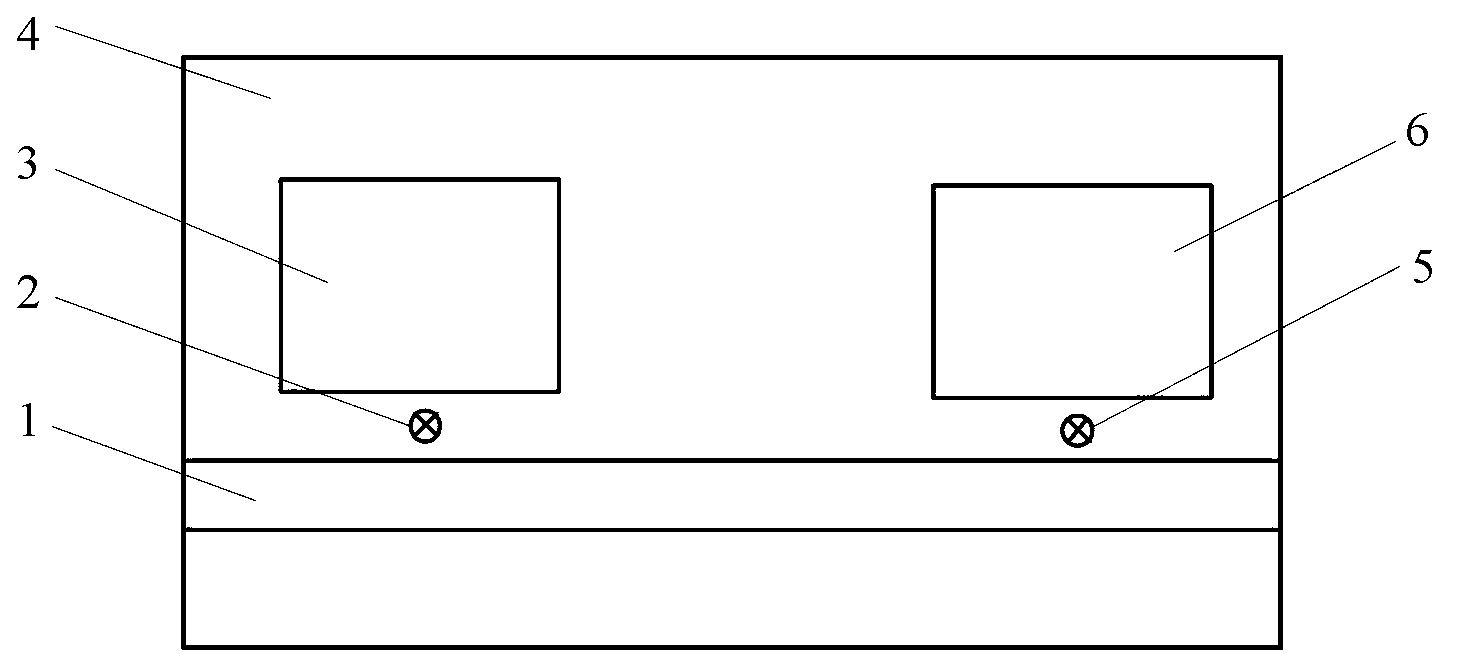

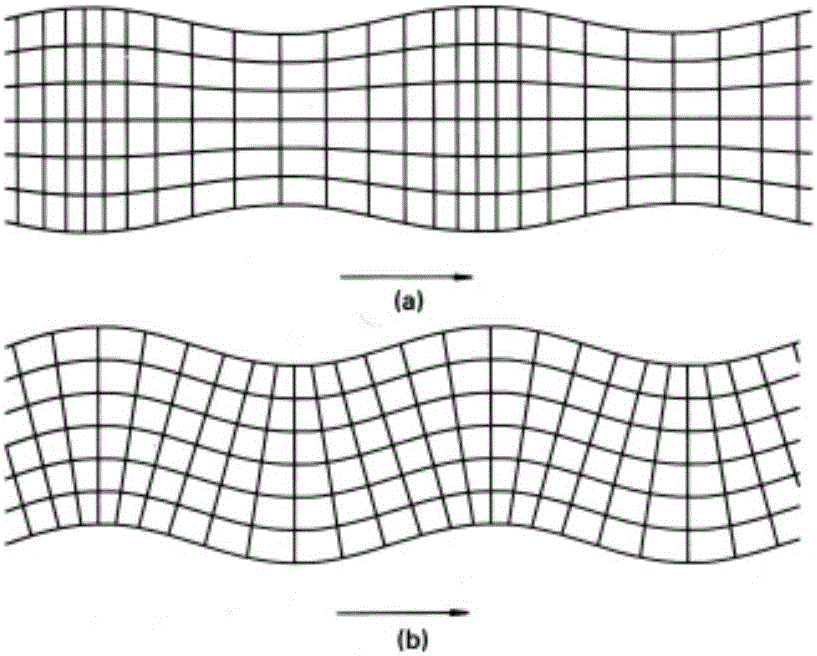

Nondestructive plate testing method with Lamb wave mode control based on electromagnetic ultrasonic receiving transducer

InactiveCN103323531ARealize non-destructive testingWeaken the multi-mode influence of electromagnetic ultrasonic Lamb waveAnalysing solids using sonic/ultrasonic/infrasonic wavesMode controlUltrasonic lamb waves

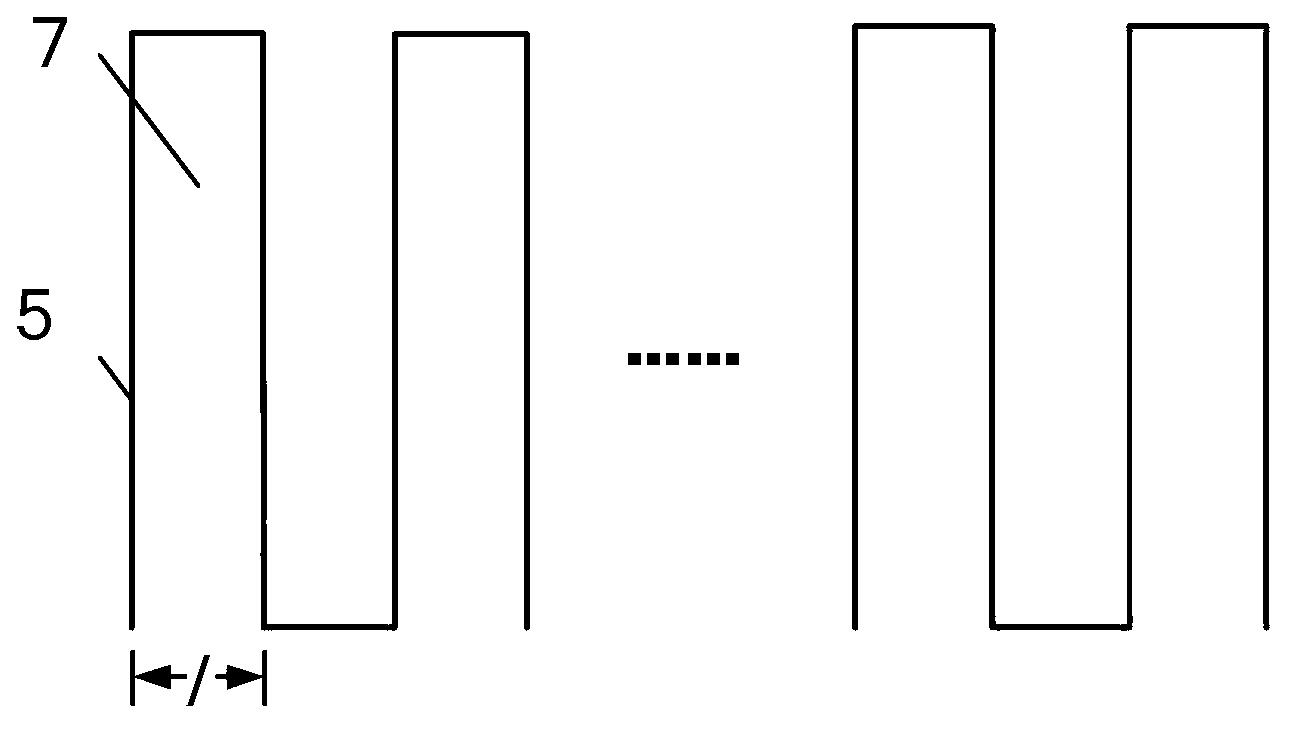

The invention discloses a nondestructive plate testing method with Lamb wave mode control based on an electromagnetic ultrasonic receiving transducer, which belongs to the technical field of converter control. The Lamb wave mode control method based on the electromagnetic ultrasonic receiving transducer aims to solve the problem that an echo signal is complex and cannot be detected due to the multi-mode characteristics of electromagnetic ultrasonic Lamb waves. The method comprises the following steps of: determining an excitation wave mode in a plate according to excitation parameters, modeling and solving the total process of transmitting and receiving electromagnetic ultrasonic Lamb waves by a finite element method, and analyzing a corresponding relationship between the coil distance l of rectangular-wave-shaped winding coils of the electromagnetic ultrasonic Lamb wave transducer and a voltage signal in each mode, wherein the voltage signal amplitude of the received Lamb wave in each mode can be controlled through the set value l, namely the aim of controlling the electromagnetic ultrasonic Lamb wave mode is fulfilled. The method is widely applied to control on the Lamb wave mode by the electromagnetic ultrasonic method.

Owner:HARBIN INST OF TECH

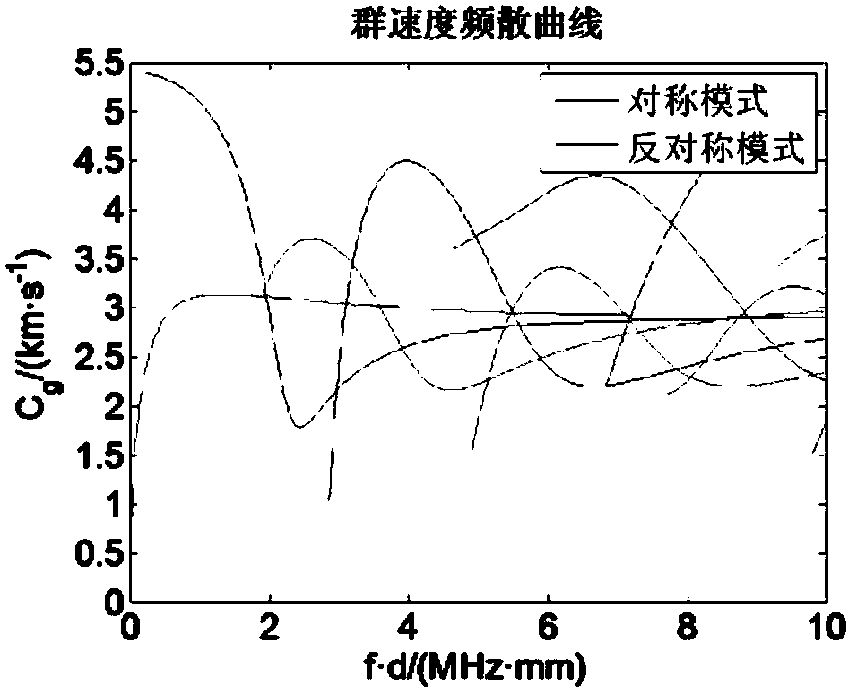

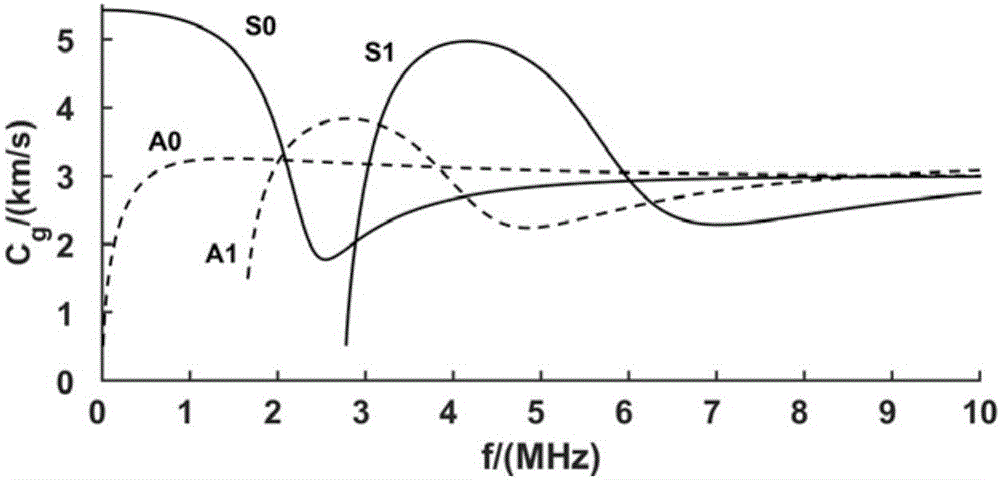

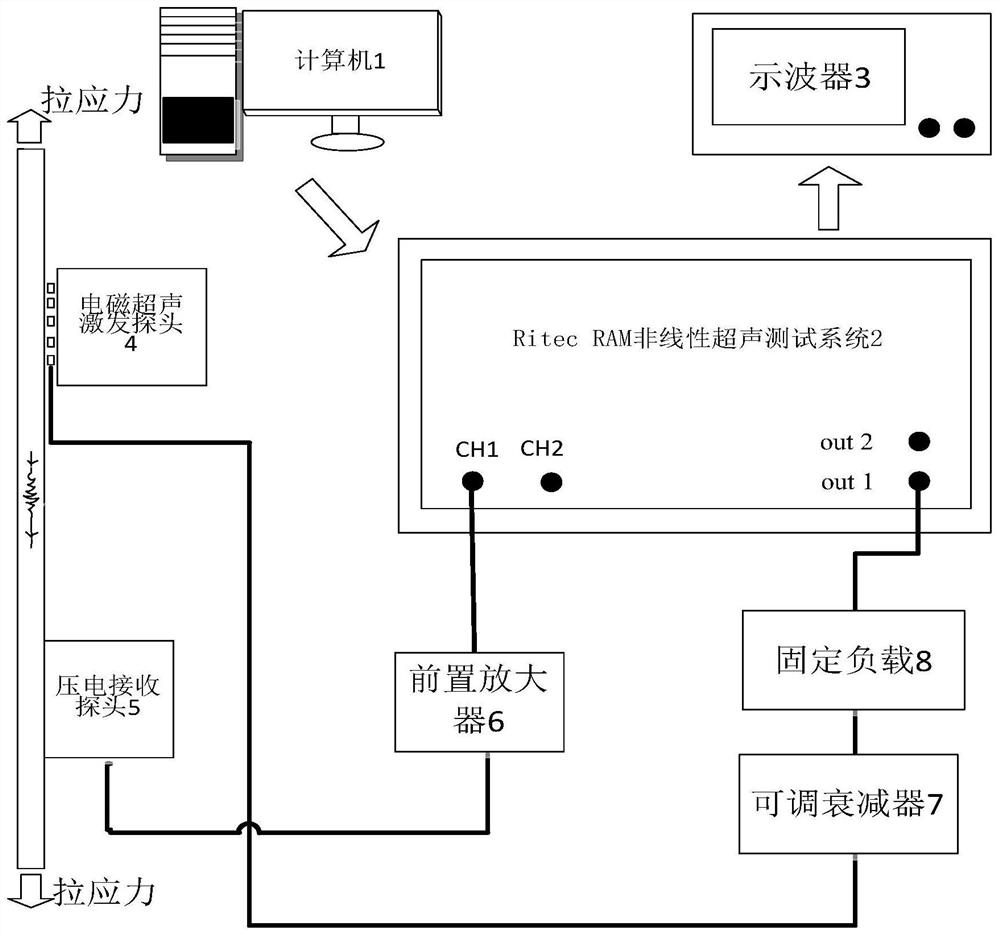

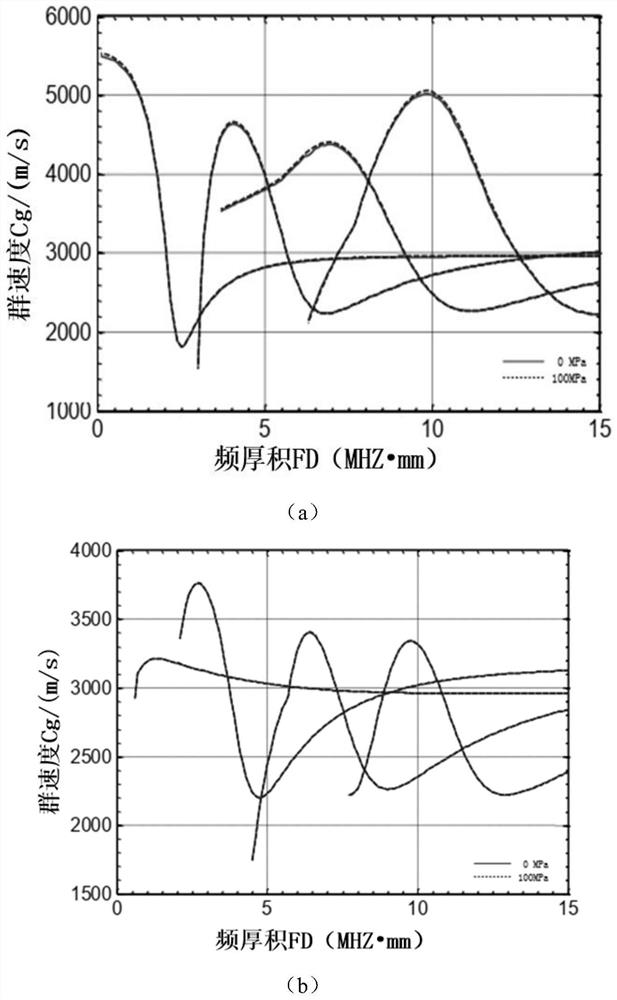

Metal plate stress detection method based on electromagnetic ultrasonic Lamb wave S1 modal group velocity

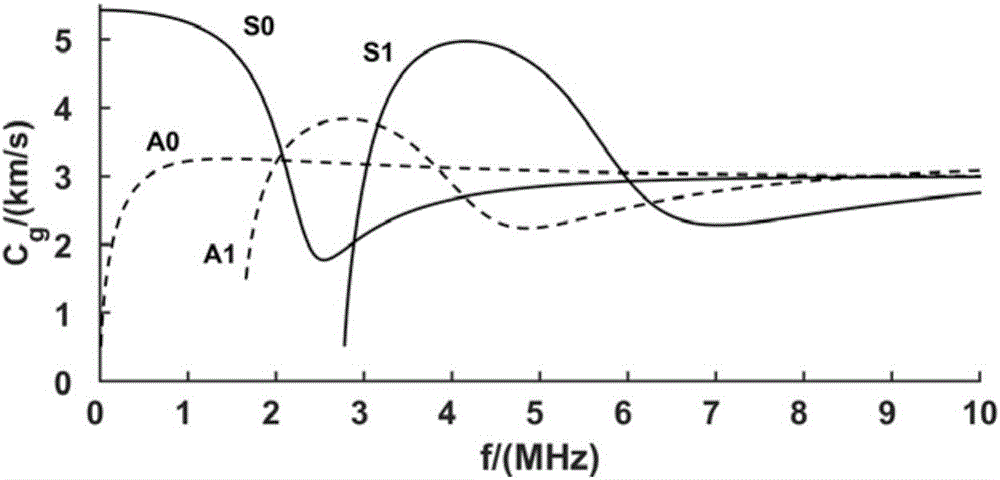

ActiveCN112326786AIncreased rate of change of speedImprove detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic lamb wavesAcoustics

The invention discloses a metal plate stress detection method based on electromagnetic ultrasonic Lamb wave S1 modal group velocity. According to the method, an electromagnetic ultrasonic excitation probe is adopted to excite Lamb waves, Lamb waves in a specific mode are excited according to specific intervals of excitation coils, the S1 mode of the Lamb waves is accurately recognized, and stressdetection is conducted on a metal plate through high sensitivity of the S1 mode group speed of the Lamb waves to stress changes. Compared with traditional body wave stress detection, the method has the advantages that the speed change rate is remarkably increased under the same loading stress, and the method can be used for measurement and research of sheet stress distribution in the field of nondestructive testing.

Owner:HEBEI UNIV OF TECH

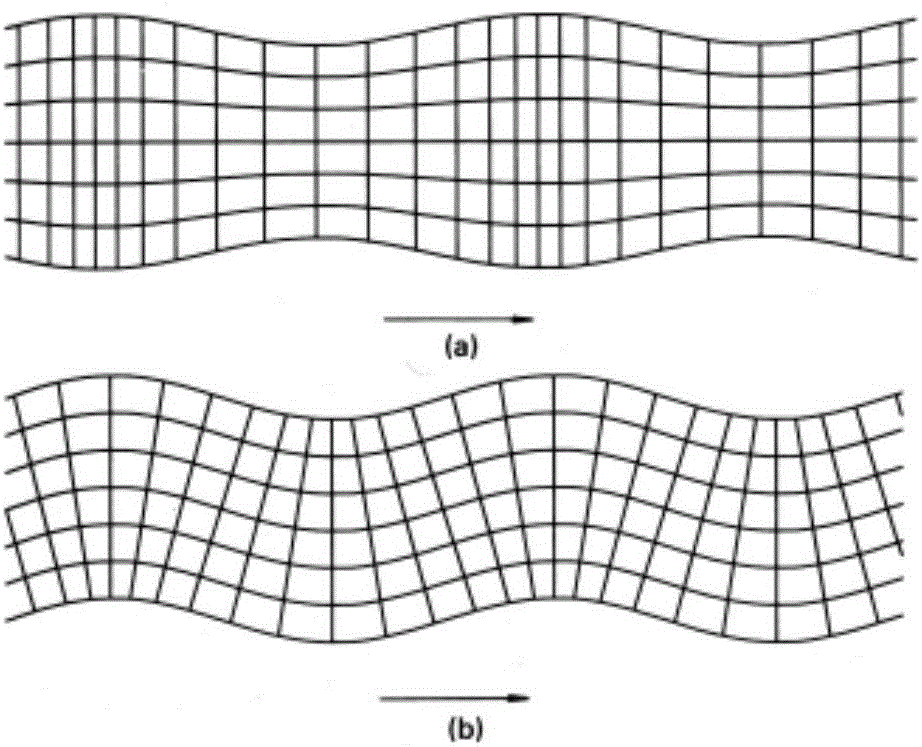

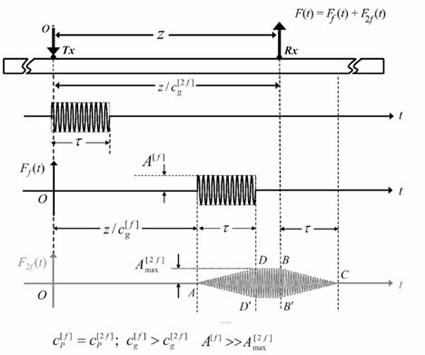

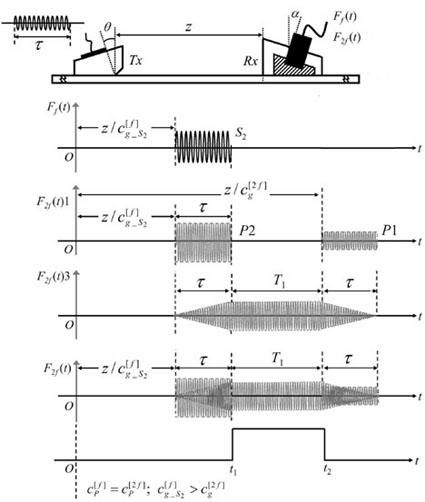

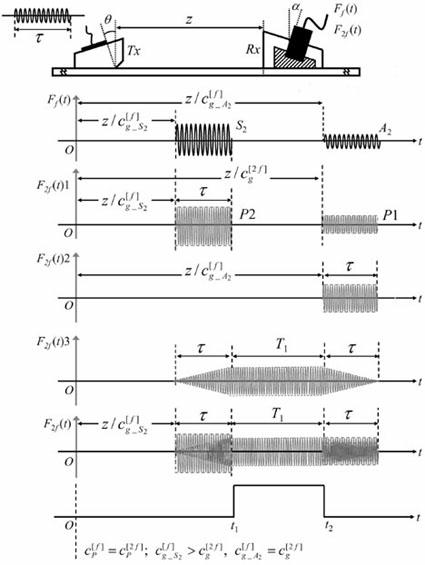

Ultrasonic lamb wave second harmonic time domain signal measuring method based on group-velocity mismatch

InactiveCN102243214ARelaxation of measurement conditionsResponse signal detectionProcessing detected response signalVibration amplitudeSonification

The invention provides an ultrasonic lamb wave second harmonic time domain signal measuring method based on group-velocity mismatch. When phase velocity of fundamental frequency matches phase velocity of frequency-doubled ultrasonic lamb wave and group-velocity is mismatched, a second harmonic signal generated in a fundamental frequency ultrasonic lamb wave propagation process can be fully separated from a second harmonic signal from a wedge ultrasonic transducer in time domain. According to propagation distance of ultrasonic lamb wave time domain pulse and group speed of frequency-doubled ultrasonic lamb wave, a time domain range of corresponding ultrasonic lamb wave second harmonic signal is determined. By adopting integration amplitude enveloped by second harmonic signal in the time domain range as characteristic parameter of measurement, second harmonic generation efficiency of the ultrasonic lamb wave is characterized. According to the invention, measuring condition of the ultrasonic lamb wave second harmonic signal is widened, and influence of the wedge ultrasonic transducer to the ultrasonic lamb wave second harmonic measurement can be fully deducted. The method of the invention can be used for accurate measurement of the ultrasonic lamb wave non-linear effect and lossless evaluation research of non-linear ultrasonic lamb wave of sheet materials.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

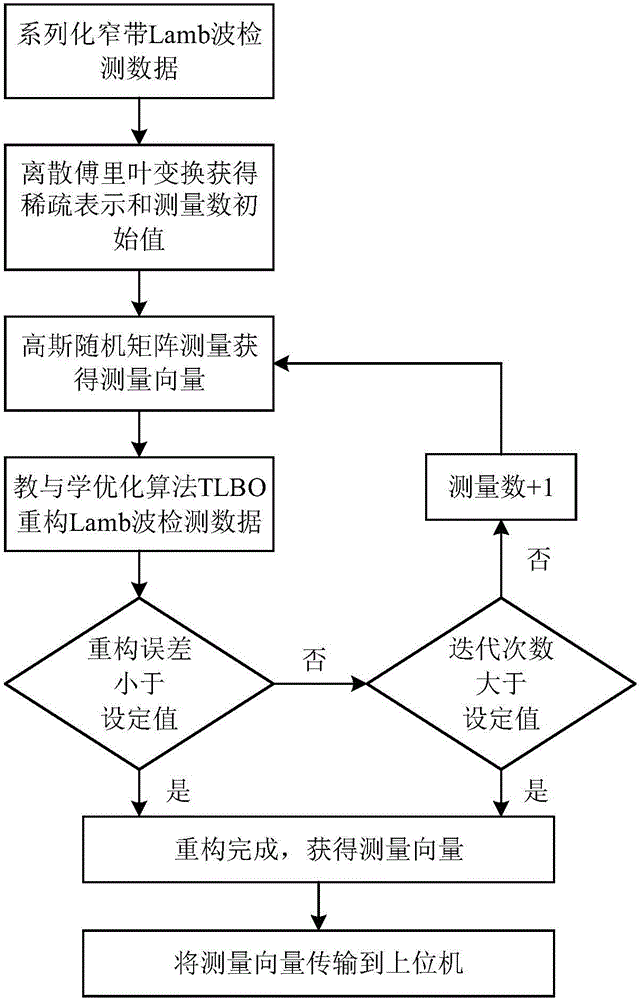

Method for sparse compression optimization reconstruction of narrowband Lamb wave detection data

ActiveCN106596724AReduce transfer timeReduce reconstruction errorAnalysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionData compressionSonification

The invention discloses a method for sparse compression optimization reconstruction of narrowband Lamb wave detection data. The method comprises the steps: an EMAT emitting array and an EMAT receiving array are arranged on two sides of a to-be-tested material detection area, EMATs in the emitting array excite required modal Lamb waves with narrowband frequency respectively according to a preset order, the Lamb waves are received by the opposite receiving array, received Lamb wave detection signals are subjected to narrowband filtering treatment, and narrowband Lamb wave detection data are formed; after the detection data are obtained, discrete Fourier transform is performed, original data are reconstructed by using a teaching and learning optimization algorithm TLBO, a measurement vector and a recovery matrix are optimized, and a low-dimension measurement vector is transmitted to an upper computer. The problem that low detection efficiency is caused because a large-area plate electromagnetic ultrasonic Lamb wave tomography data size is large and the transmission time is long is solved, rapid, large-scale and high-quality data compression and transmission are achieved, a solid foundation is laid for the large-area plate Lamb wave real-time tomography, and the method has broad application prospects.

Owner:TSINGHUA UNIV

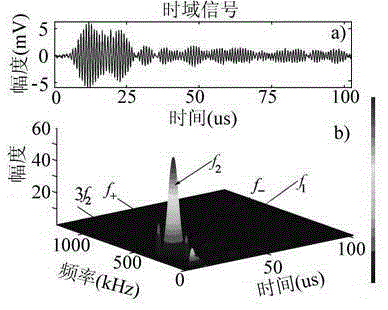

Method for actively detecting defects in metal thin-walled structure part

InactiveCN105424798ASimple extraction methodAvoid complexityAnalysing solids using sonic/ultrasonic/infrasonic wavesFrequency spectrumEngineering

The invention discloses a method for actively detecting defects in a metal thin-walled structure part, and relates to the field of thin-walled structure part nondestructive detecting. The thin-walled structure part is excited by two different lines of frequency ultrasonic Lamb waves at the same time; through time-frequency combined analysis, the modulation spectrum generated by the defects is rapidly found, the Lamb wave characteristic parameter extracting method is simplified, and the problem that the existing ultrasonic recognition accuracy for fine defects is not high is solved. A testing system comprises a random waveform generator, a transmitting transducer, a non-contact laser vibration measurement instrument, a digital signal oscilloscope, a computer, a tested medium and five coaxial data transmission lines. The random waveform generation is loaded with the two different lines of frequency ultrasonic Lamb waves through the computer, a transmitting transducer array is loaded with signals through the random waveform generator at the same time, and the signals are collected by the non-contact laser vibration measurement instrument, displayed and stored by the oscilloscope and then transmitted to the computer to be analyzed so that Lamb waves and defect related characteristic parameters can be found. The method is suitable for rapidly detecting the defects in the metal thin-walled structure part.

Owner:HARBIN UNIV OF SCI & TECH

Microfabricated reactor, process for manufacturing the reactor, and method of amplification

InactiveUS20070117111A1Faster cycle timeBioreactor/fermenter combinationsBiological substance pretreatmentsUltrasonic lamb wavesEngineering

An integrated microfabricated instrument for manipulation, reaction and detection of microliter to picoliter samples. The instrument is suited for biochemical reactions, particularly DNA-based reactions such as the polymerase chain reaction, that require thermal cycling since the inherently small size of the instrument facilitates rapid cycle times. The integrated nature of the instrument provides accurate, contamination-free processing. The instrument may include reagent reservoirs, agitators and mixers, heaters, pumps, and optical or electromechanical sensors. Ultrasonic Lamb-wave devices may be used as sensors, pumps and agitators.

Owner:RGT UNIV OF CALIFORNIA

Electromagnetic ultrasonic lamb wave transducer based on magnetostrictive mechanism

ActiveCN106824736ARealize Ultrasonic ExcitationMechanical vibrations separationUltrasonic sensorUltrasonic lamb waves

The invention relates to novel electromagnetic ultrasonic transducer design based on the magnetostrictive mechanism. Compared with traditional transducer design, the novel electromagnetic ultrasonic transducer design has the largest difference that a vertical linear coil and magnet separated structure is adopted. A magnet provides a horizontal static bias magnetic field for a system, and a linear winding coil is excited by large current to generate a strong dynamic magnetic field. Since a ferromagnetic material has the magnetostrictive performance, change of material strain is caused by change of a composite magnetic field composed of the static magnetic field and the dynamic magnetic field, and ultrasonic lamb wave excitation is achieved through high-frequency vibration caused by change of strain. Compared with a traditional linear electromagnetic ultrasonic transducer, a newly designed transducer can achieve transduction at a lift-off distance of 10 mm, and the lift-off performance index is superior to that of the traditional transducer.

Owner:UNIV OF SCI & TECH BEIJING

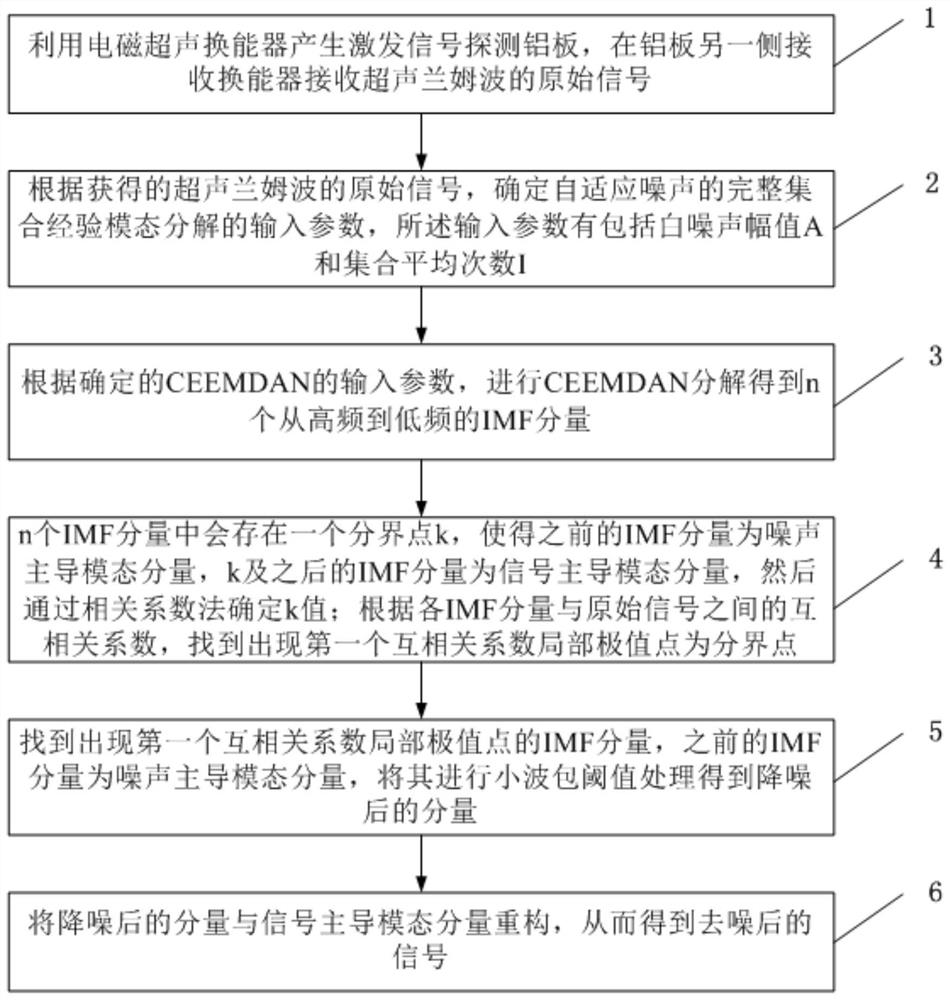

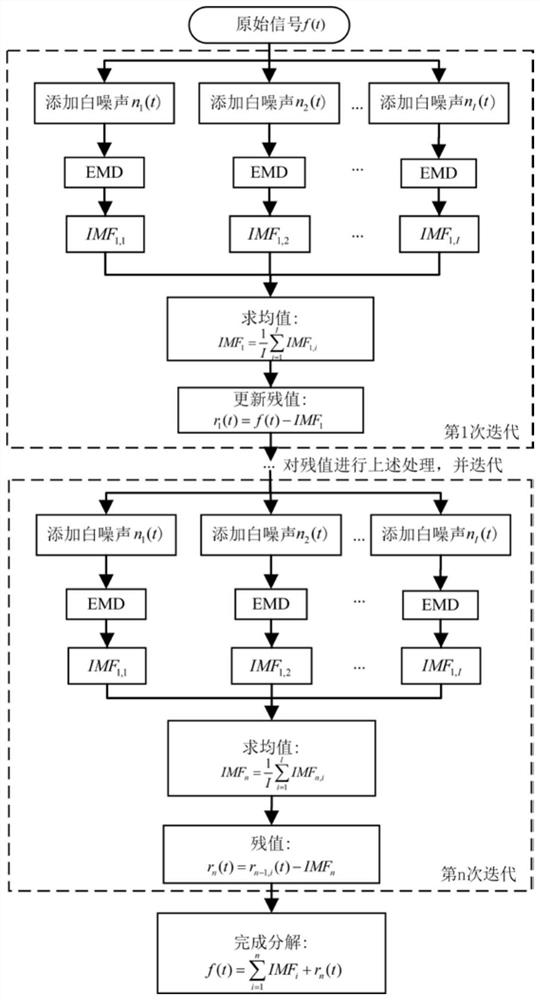

Ultrasonic signal processing method based on CEEMDAN combined wavelet packet threshold

PendingCN114264724AImprove efficiencyReduce decomposition timeAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalUltrasonic sensorUltrasonic lamb waves

The invention relates to the technical field of signal processing, and provides an ultrasonic signal processing method based on CEEMDAN combined wavelet packet threshold, which comprises the following steps of: 1, generating an excitation signal by using an electromagnetic ultrasonic transducer to detect an aluminum plate, and receiving an original signal of an ultrasonic lamb wave by using a receiving transducer on the other side of the aluminum plate; step 2, determining input parameters of complete set empirical mode decomposition of adaptive noise according to the obtained original signals of the ultrasonic lamb waves; step 3, according to the determined input parameters of the CEEMDAN, performing CEEMDAN decomposition to obtain n IMF components from high frequency to low frequency; 4, determining a k value through a correlation coefficient method; step 5, wavelet packet threshold processing is carried out on the first k-1 IMF components; and step 6, performing signal reconstruction on the IMF after threshold processing and the reserved IMF. The method can improve the signal processing efficiency and reduce the decomposition time.

Owner:DALIAN OCEAN UNIV

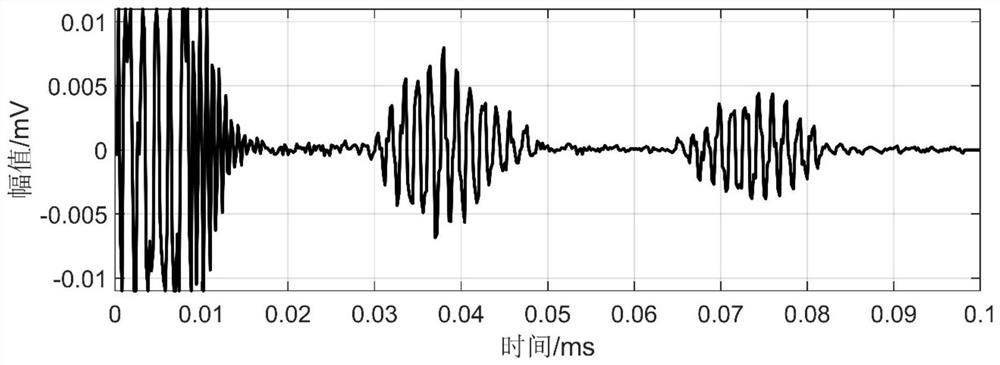

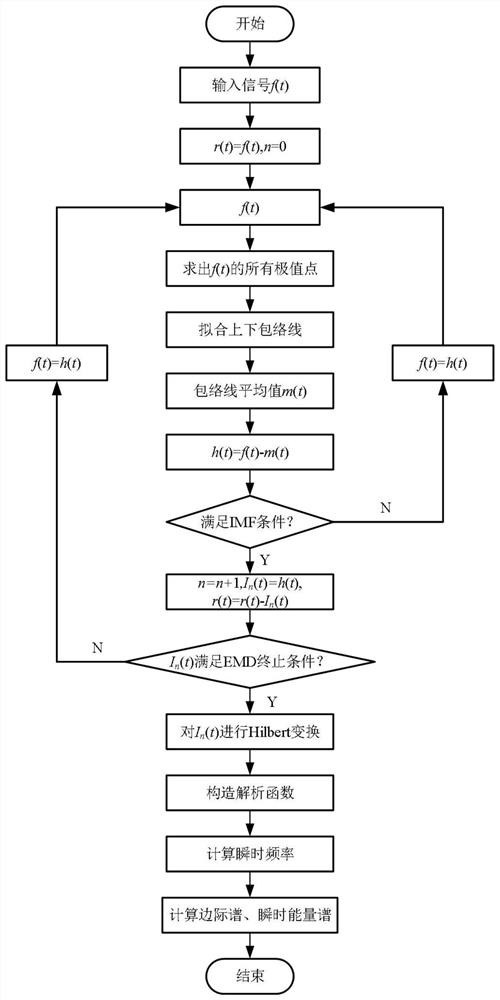

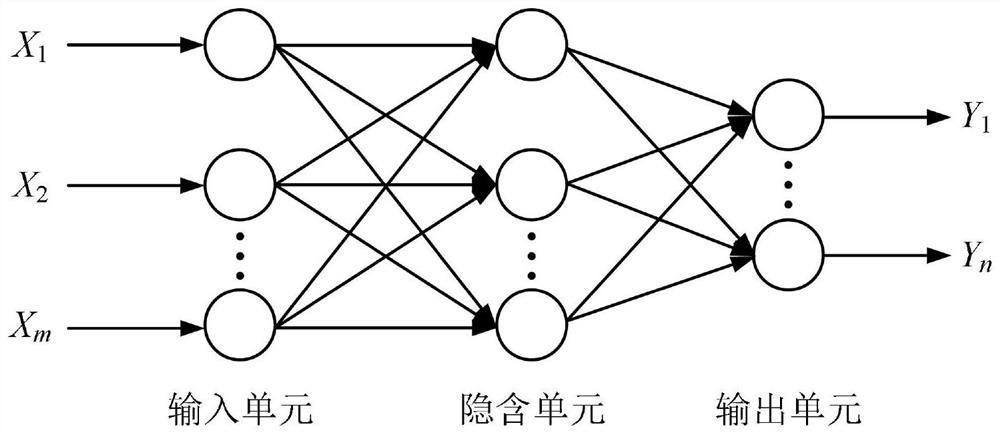

Composite material plate layering defect air coupling ultrasonic detection method based on HHT and neural network

PendingCN114324582AAvoid secondary pollutionExtended service lifeAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalMechanical engineeringMaterials science

The invention relates to a composite material plate layering defect air coupling ultrasonic detection method based on HHT and a neural network. The invention relates to the technical field of composite material defect detection. The method comprises the following steps: determining an excitation frequency and an inclination angle of an air coupling transducer; eMD decomposition is carried out, and an intrinsic mode function is extracted; a BP neural network is established, and network learning is carried out; and identifying the depth, width and length of the layered defect based on the established BP neural network. In the detection process, air is used as a transmission medium to replace a coupling agent in traditional ultrasonic nondestructive detection, so that the problem of secondary pollution of a coupling material to a to-be-detected piece can be fundamentally avoided, the air coupling ultrasonic transducer has the advantages of no contact, no invasion and no damage in the detection process, and the service life of the air coupling ultrasonic transducer is prolonged; therefore, the air-coupled ultrasonic Lamb wave detection realizes on-line rapid detection, and is suitable for ultrasonic detection of layering defects of composite material plates which cannot be subjected to contact detection by using a coupling agent.

Owner:HARBIN INST OF TECH

Topological imaging method and device based on ultrasonic Lamb wave plate type ballastless track cracks

ActiveCN111337574AEasy to receiveEasy to handleAnalysing solids using sonic/ultrasonic/infrasonic waves2D-image generationUltrasonic lamb wavesImaging algorithm

The invention discloses a topological imaging method and device based on ultrasonic Lamb wave plate type ballastless track cracks. The topological imaging method comprises the steps that air couplingultrasonic excitation transducers at different positions are used for exciting ultrasonic waves to enter a track plate to excite Lamb wave signals; then, air coupling ultrasonic receiving transducersarranged at different positions receive lamb wave echo signals; and then the Lamb wave echo signals are filtered by a computer through MATLAB software, and then crack imaging of the track is performedaccording to a topological imaging algorithm. According to the method, information such as the position and the shape of the crack of the track board can be clearly presented, and timely early warning and powerful evaluation means can be provided for daily track board damage detection of the high-speed rail.

Owner:SHANGHAI UNIV OF ENG SCI

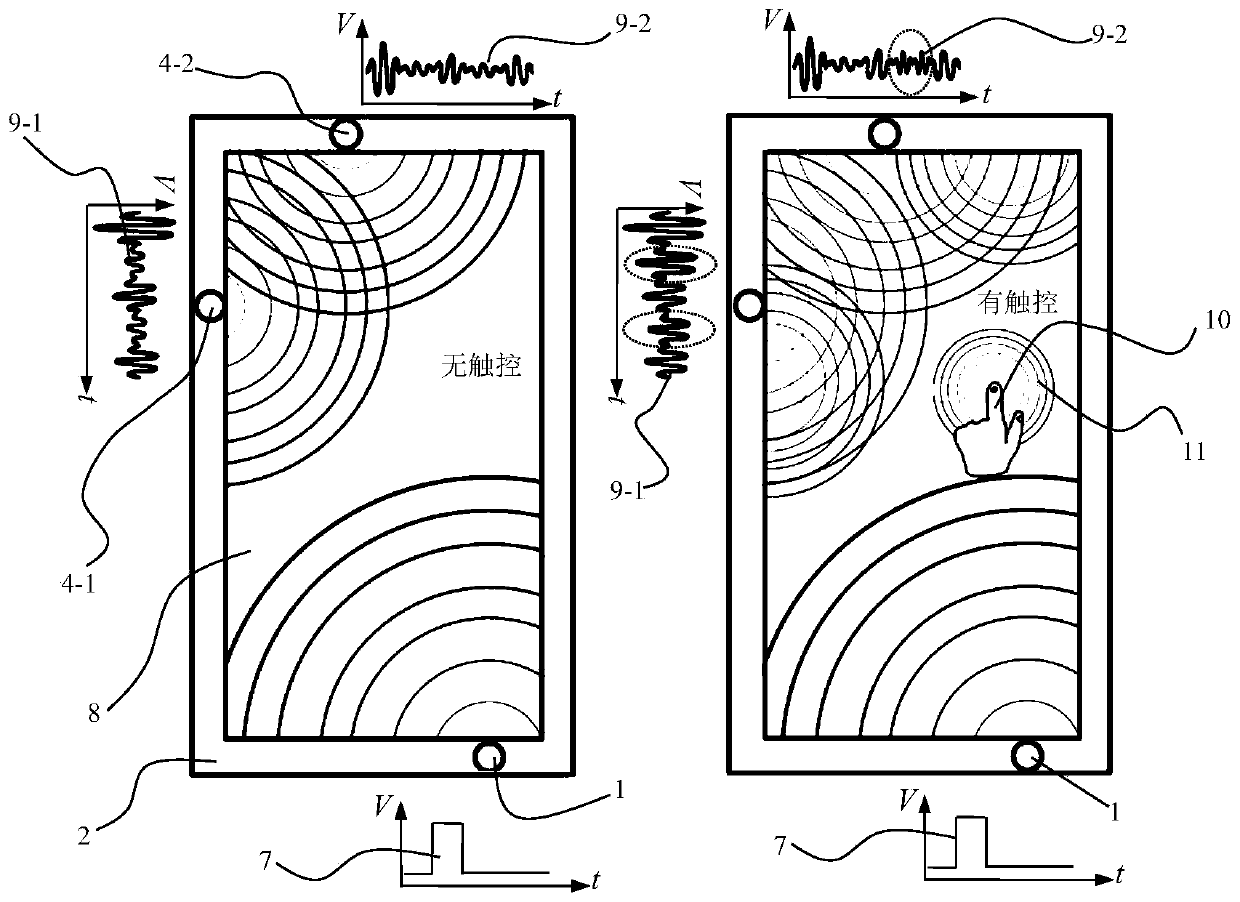

Ultrasonic lamb wave touch screen

ActiveCN111459324AAchieve positioningBiological neural network modelsInput/output processes for data processingUltrasonic lamb wavesControl system

The invention discloses an ultrasonic lamb wave touch screen. The disturbance effect of a touch medium on an ultrasonic Lamb wave sound field changes along with the position of the touch medium. An ultrasonic Lamb wave sound fingerprint library of the touch medium is calibrated in advance. In practical application, an intelligent algorithm is used for matching an actual measurement signal with a pre-calibrated sound fingerprint library, and positioning of the touch medium on a screen plate is achieved. The ultrasonic lamb wave touch screen is mainly composed of a main control system, an ultrasonic excitation receiving module, a sensing screen and a display screen module. An ARM is used for realizing acoustic fingerprint identification by a built-in algorithm program to determine the position coordinates of the touch medium on the sensing screen, converting the position coordinates into a control instruction to communicate with the display screen through the MIPI interface, and realizing program touch at the identified position coordinates. The ultrasonic lamb wave touch screen disclosed by the invention can be used for positioning and identifying a non-conductive touch medium, andcan be used for robot touch system design and the like for reference.

Owner:BEIJING UNIV OF TECH

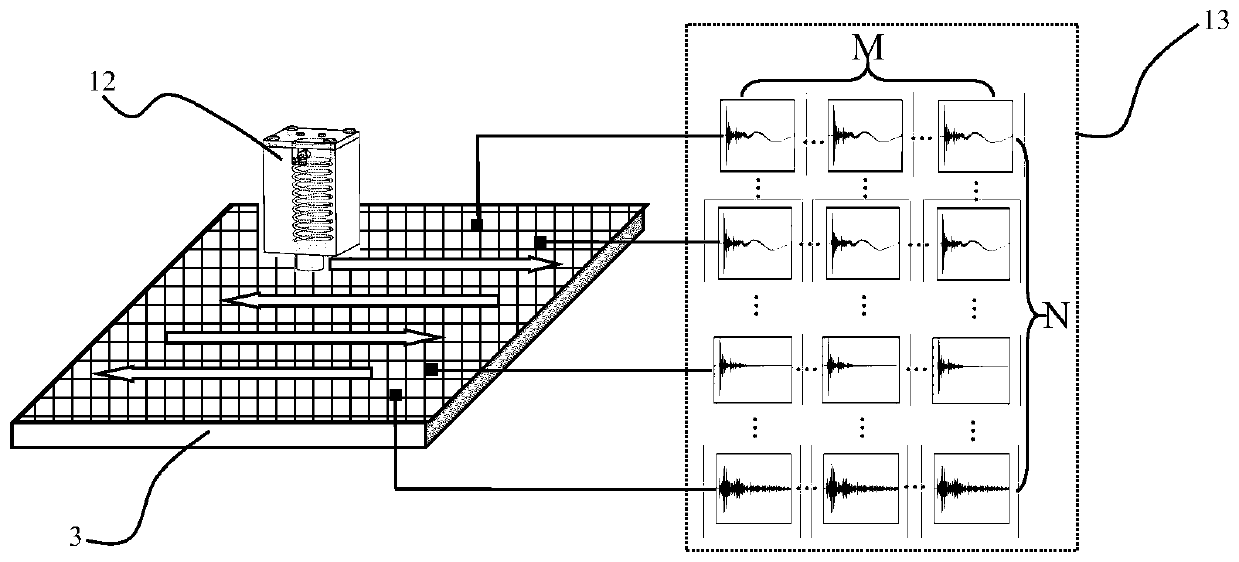

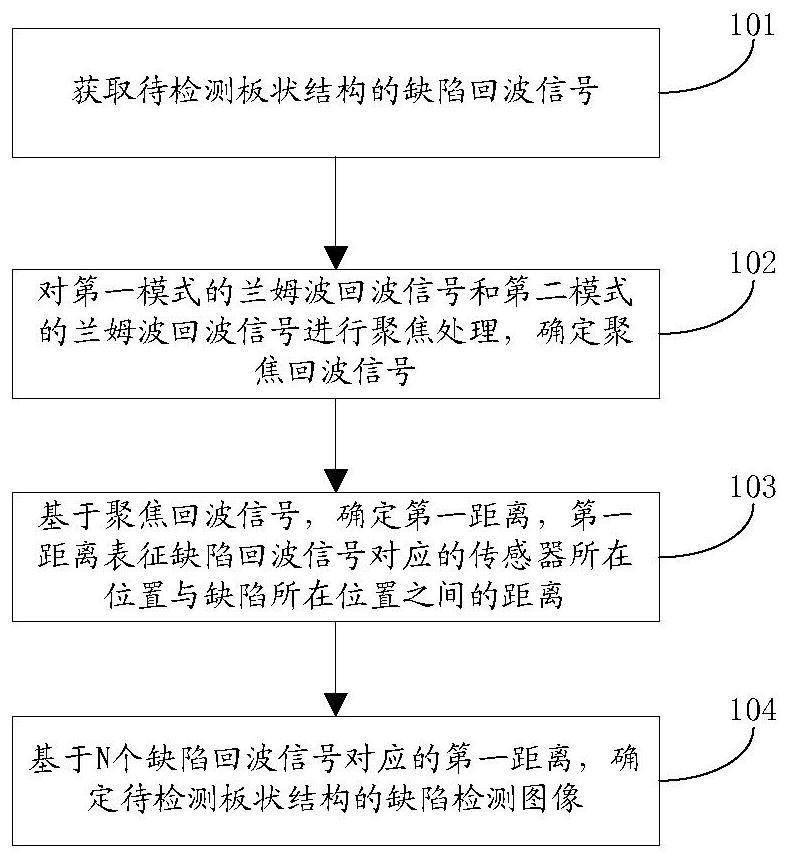

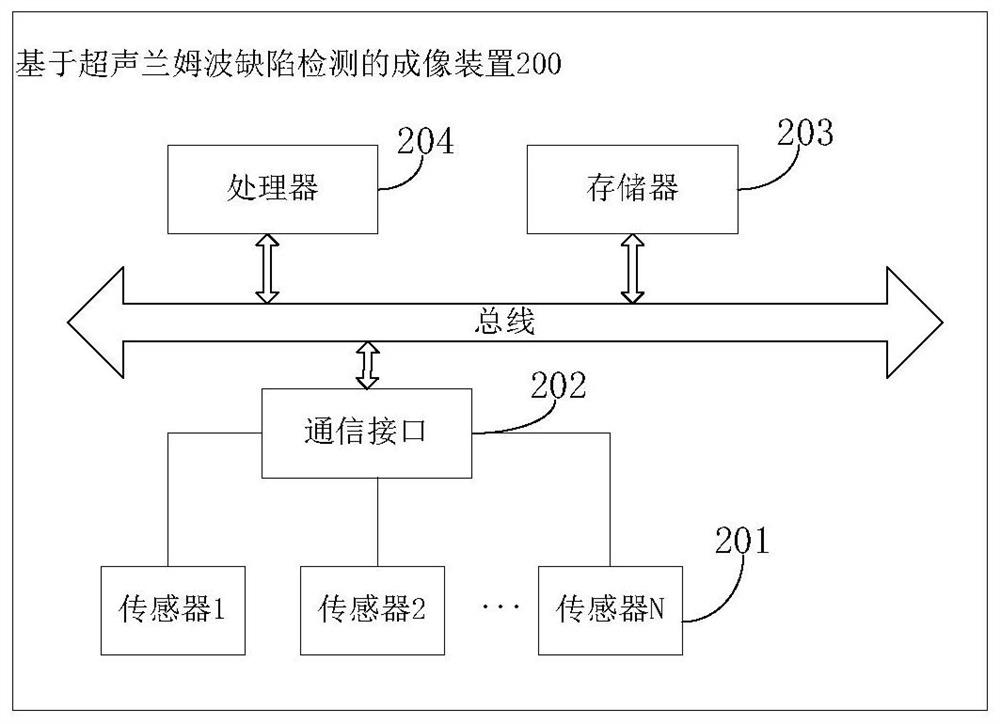

Imaging method and device based on ultrasonic Lamb wave defect detection

ActiveCN113686959AAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic lamb wavesAcoustics

The invention relates to an imaging method based on ultrasonic Lamb wave defect detection, the method comprises the following steps: acquiring defect echo signals of a to-be-detected plate-shaped structure, the defect echo signals at least comprising a first mode Lamb wave echo signal and a second mode Lamb wave echo signal; performing focusing processing on the Lamb wave echo signal of the first mode and the Lamb wave echo signal of the second mode, and determining a focused echo signal; based on the focusing echo signal, determining a first distance, wherein the first distance represents the distance between the position of the sensor corresponding to the defect echo signal and the position of the defect; and determining a defect detection image of the to-be-detected plate-shaped structure based on the first distance corresponding to the N defect echo signals. According to the imaging method based on ultrasonic Lamb wave defect detection, high-precision imaging of defects in the two-dimensional plate-shaped structure can be achieved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com