Nondestructive plate testing method with Lamb wave mode control based on electromagnetic ultrasonic receiving transducer

An electromagnetic ultrasonic and non-destructive testing technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, etc. The effect of weakening the influence of the Lamb wave multi-mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

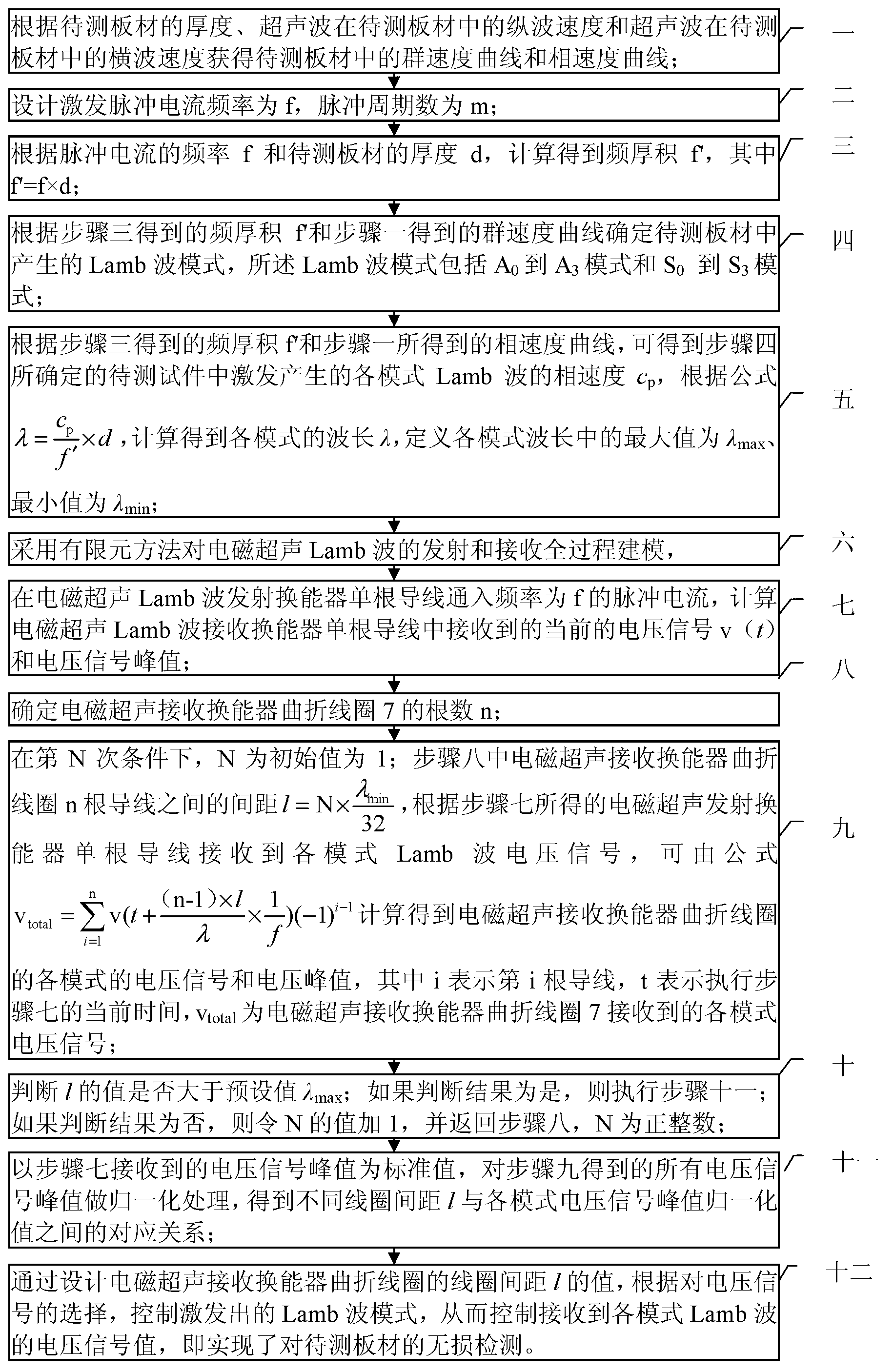

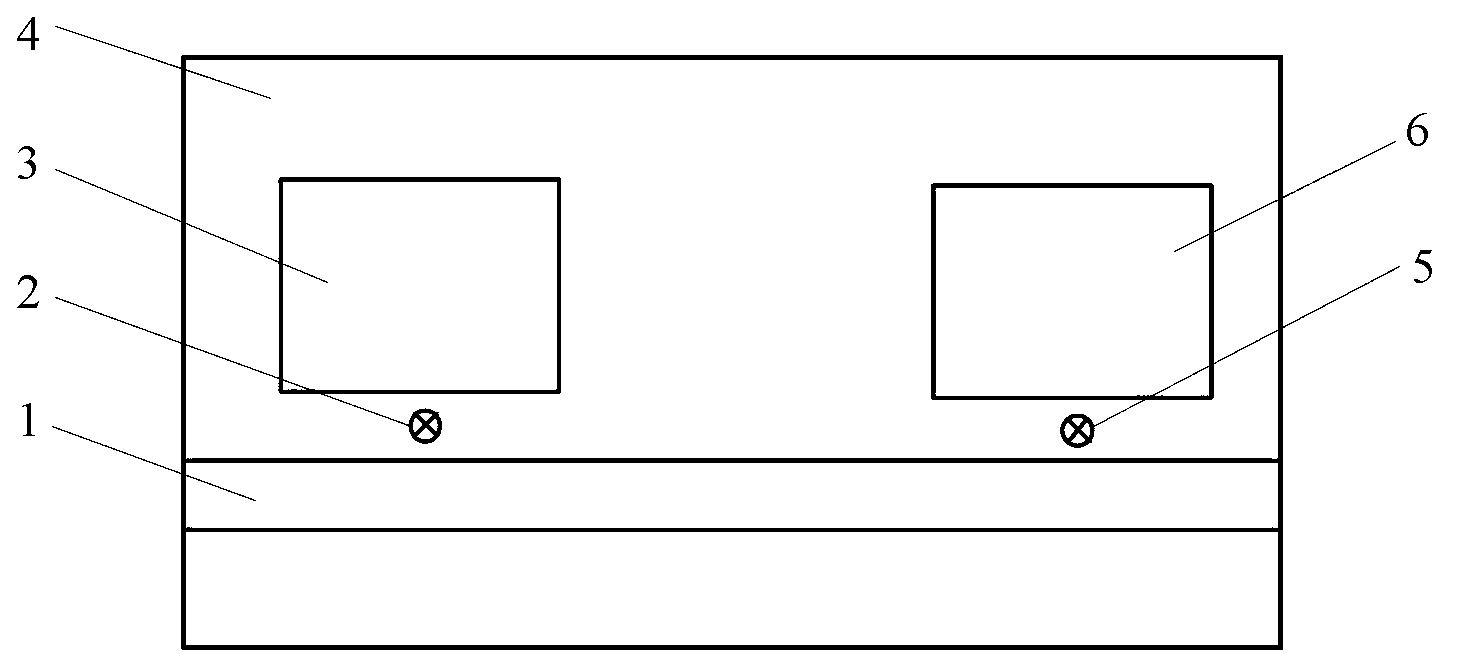

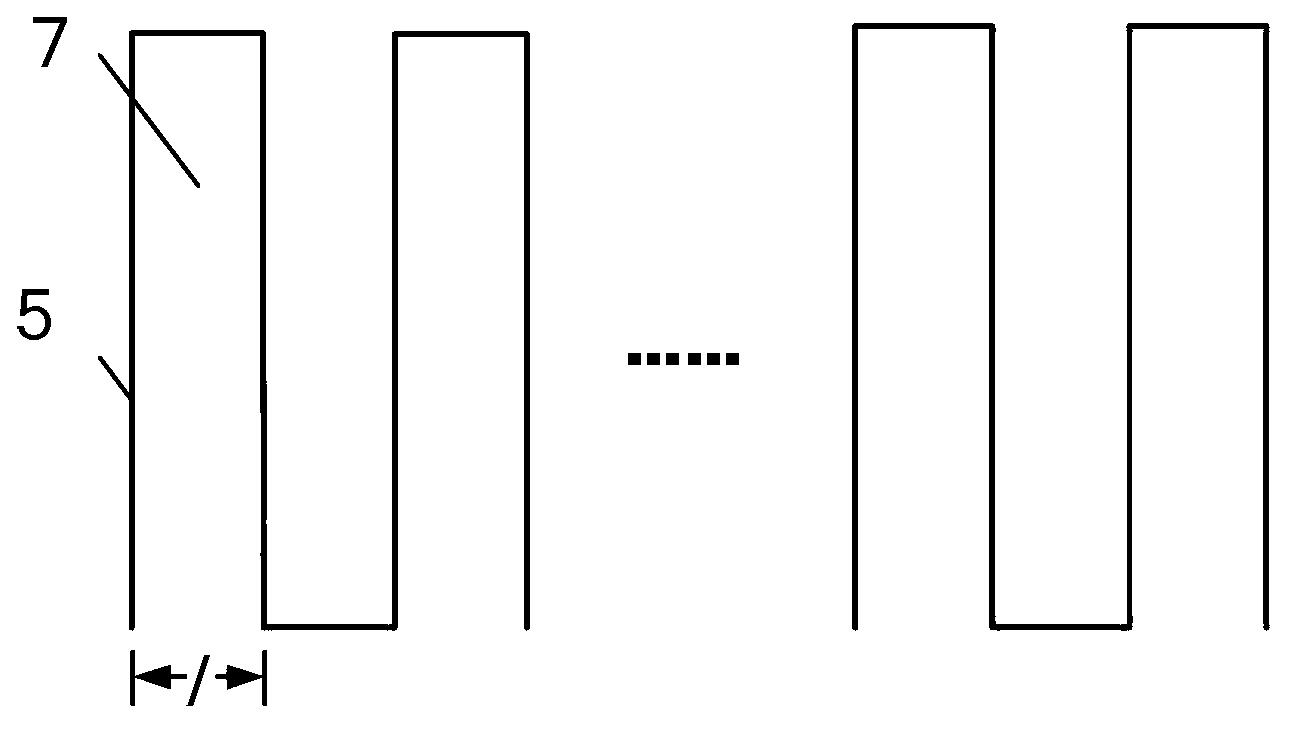

[0030] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment mode, a kind of plate material non-destructive testing method based on the Lamb wave mode control of the electromagnetic ultrasonic receiving transducer described in this embodiment mode, it is realized by the following steps:

[0031] Step 1: Obtain the group velocity curve and the phase velocity curve in the plate to be tested according to the thickness of the plate to be tested, the longitudinal wave velocity of the ultrasonic wave in the plate to be tested, and the transverse wave velocity of the ultrasonic wave in the plate to be tested;

[0032] Step 2: Design the excitation pulse current frequency as f and the number of pulse cycles as m;

[0033] Step 3: Calculate the frequency-thickness product f′ according to the frequency f of the pulse current and the thickness d of the plate to be measured, where f′=f×d;

[0034] Step 4: Determine the Lamb wave mode gener...

specific Embodiment approach 2

[0048] Specific embodiment 2: This embodiment is a further limitation of the plate non-destructive testing method based on the Lamb wave mode control of the electromagnetic ultrasonic receiving transducer described in the specific embodiment 1: when the plate to be tested in the step 1 Aluminum alloy plate with a thickness of 2mm.

specific Embodiment approach 3

[0049] Specific embodiment 3: This embodiment is a further limitation of the plate non-destructive testing method based on the Lamb wave mode control of the electromagnetic ultrasonic receiving transducer described in the specific embodiment 1: the frequency f of the pulse current in the step 7 500kHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com