Method for measuring photoresist mask slot-shaped structure parameter

A technique for measuring structural parameters and measuring light, which is applied in the direction of measuring devices, optical devices, instruments, etc., and can solve the problems of inapplicability of large-area samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

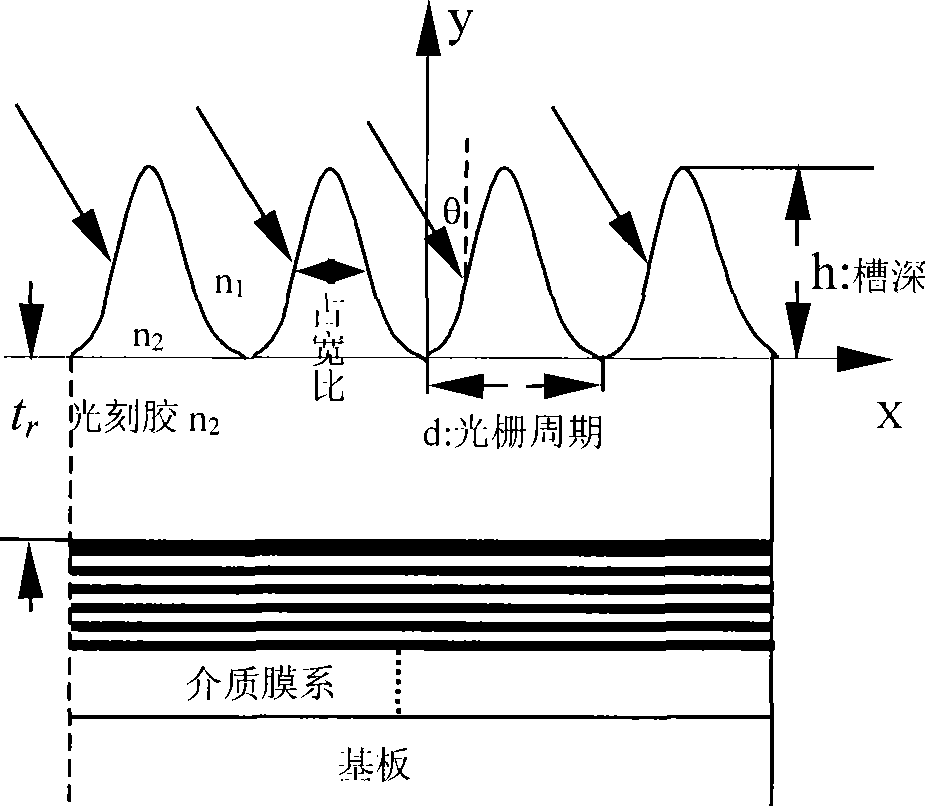

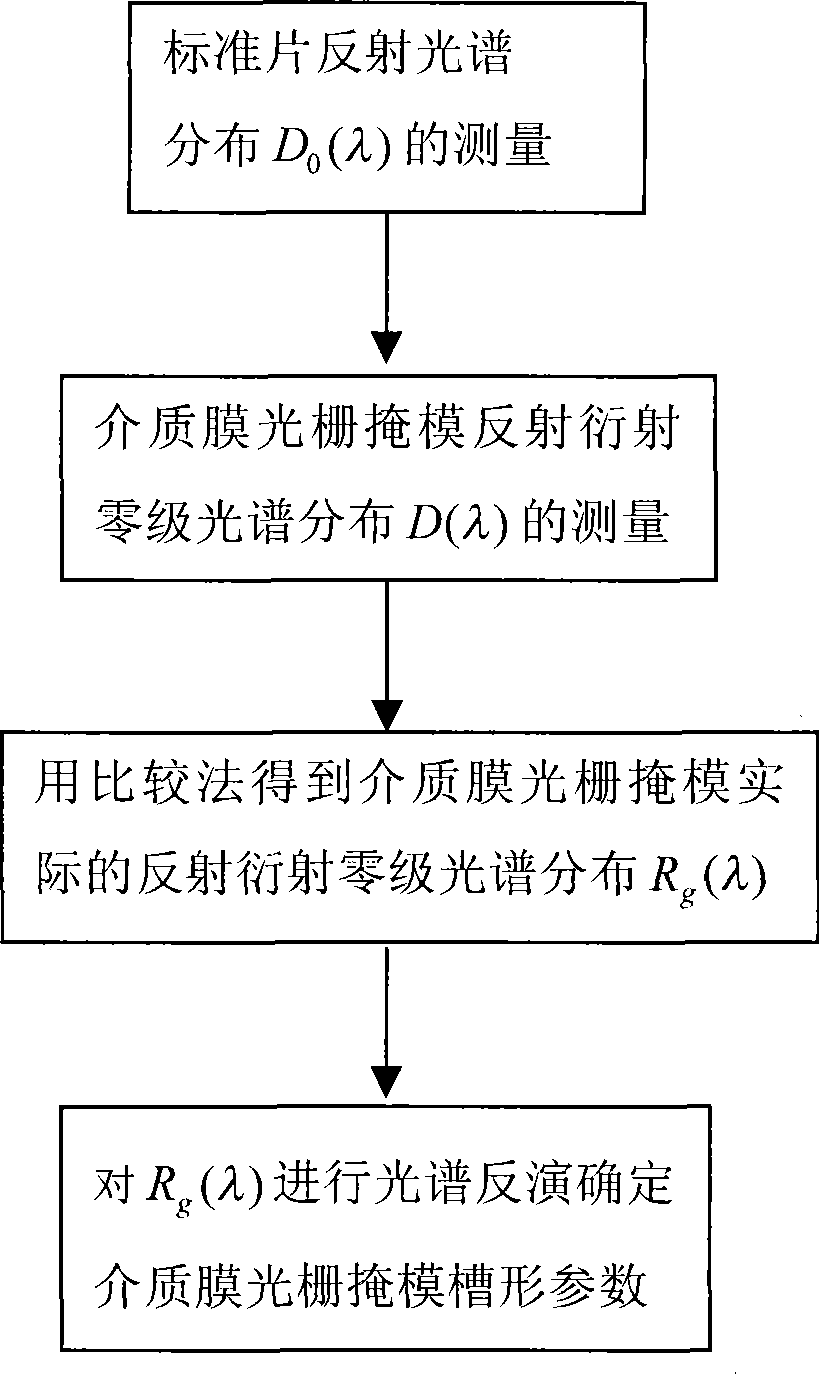

[0054] Embodiment one: see attached figure 1 to attach Figure 4 As shown, a method for measuring the groove structure parameters of a photoresist mask, the specific process of measurement is as follows:

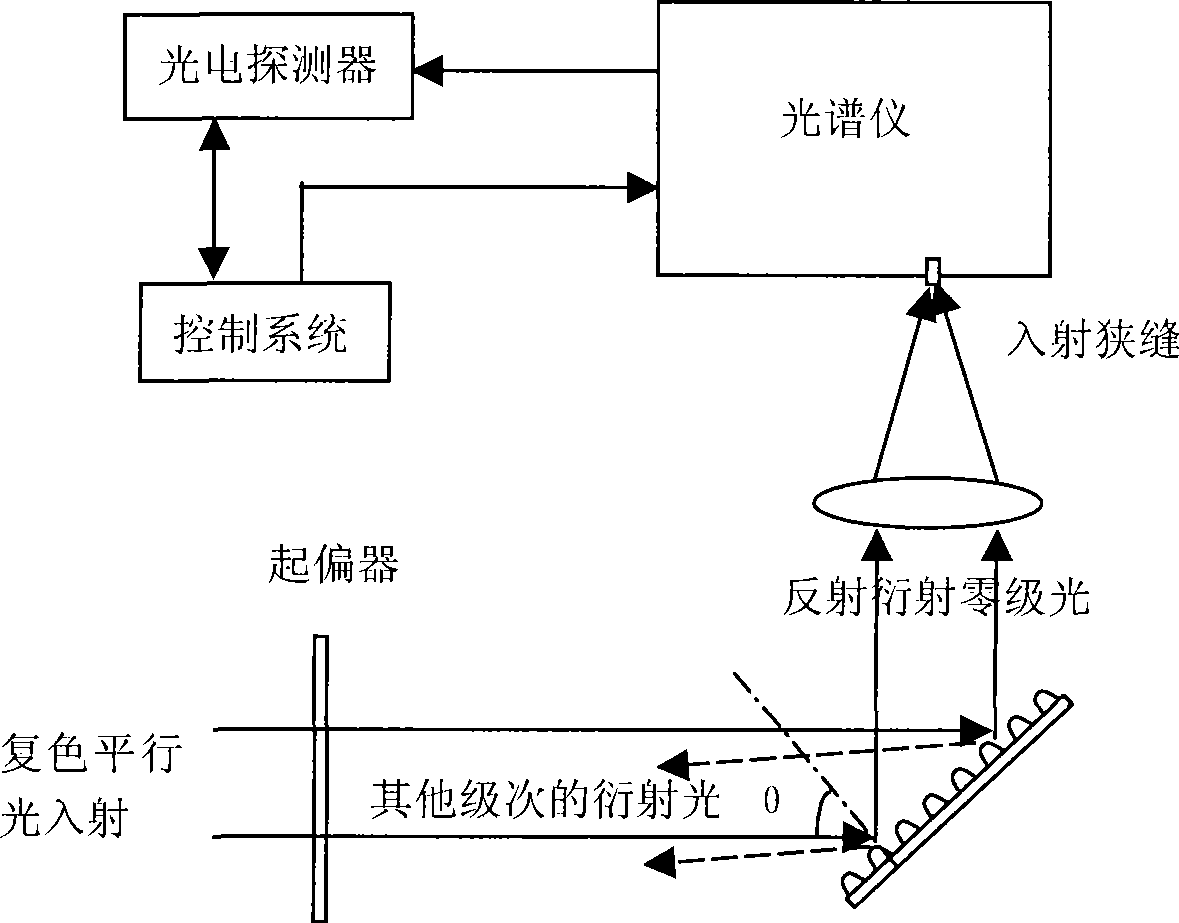

[0055] (1) According to image 3 The measurement optical path is established as shown, and the polarizer is adjusted so that the incident polychromatic parallel light incident on the mask under test is TE / TM linearly polarized light;

[0056] (2) Adjust the angle of the sample holder so that the incident angle is the Littrow angle (that is, θ angle) of the measured grating, and fix the sample holder;

[0057] (3) First place the standard reflector on the sample holder, use the lens to focus the reflected light of the standard reflector to the incident slit of the spectrometer, and use the spectrometer to measure the spectrum D of the reflected light of the standard reflector 0 (λ);

[0058] (4) After completing the measurement of the reflection spectrum of the standard r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com