Composite material plate layering defect air coupling ultrasonic detection method based on HHT and neural network

A composite material board, ultrasonic detection technology, applied in neural learning methods, biological neural network models, neural architectures, etc. Effects of secondary pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

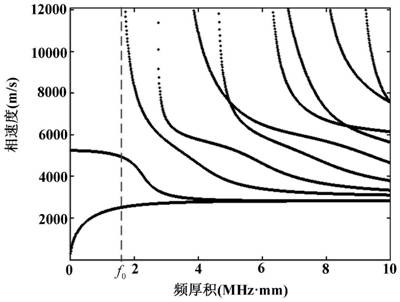

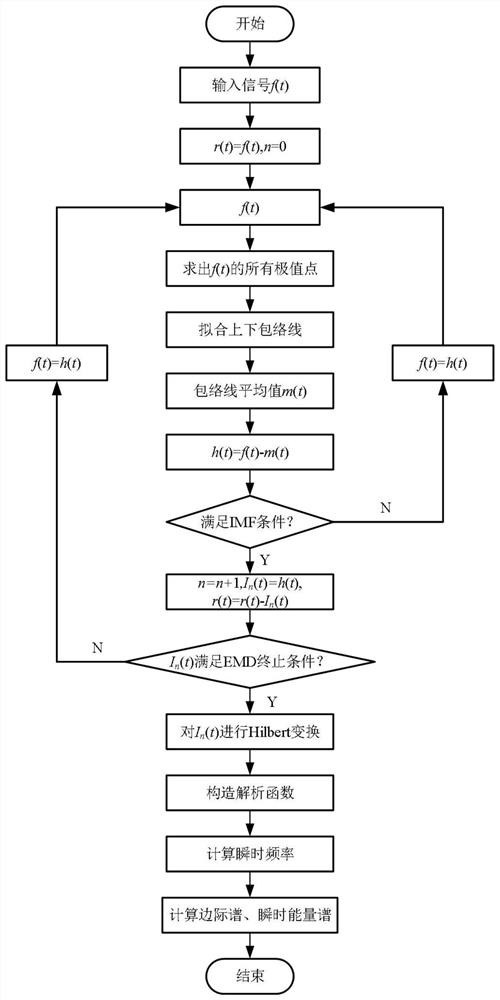

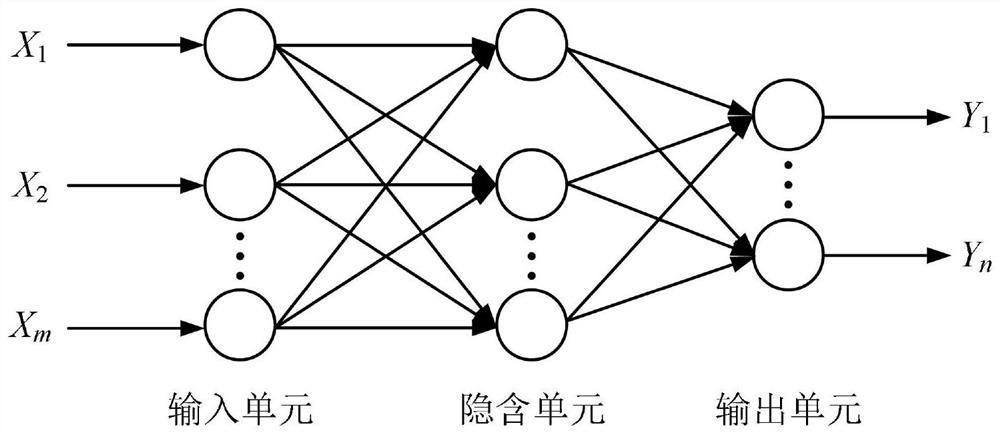

[0070] according to Figure 1 to Figure 4 As shown, the present invention determines the center frequency of the air-coupled transducer as f and the inclination angle as θ according to the Lamb dispersion curve and Snell's law. On one side of the composite material plate, the air-coupled transducer is placed according to the requirement of the inclination angle, and the distance between the exciting and receiving air-coupled transducer is set as L. The same-side-to-face detection method is adopted, and the A0 mode is used to detect the delamination defect of the composite material plate. The received signals obtained by air-coupled ultrasonic Lamb wave detection on artificially set composite plates with layered defects of different depths, widths, and lengths are subjected to HHT to obtain Hilbert spectrum, HHT marginal spectrum, and instantaneous energy spectrum, etc., and then the damage Features such as time delay and energy loss in detection. The above eigenvalues are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com