Nondestructive detection system of sheet metal by ultrasonic planar guided-wave and detection method thereof

A metal sheet, non-destructive testing technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of difficult extraction and analysis of conversion modes, inflexible detection process, complex mode conversion, etc., and achieve accurate evaluation results. and reliable, flexible and convenient detection process, easy to automate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The metal plate non-destructive testing system and testing method thereof of the present invention will be further described in conjunction with the accompanying drawings and embodiments.

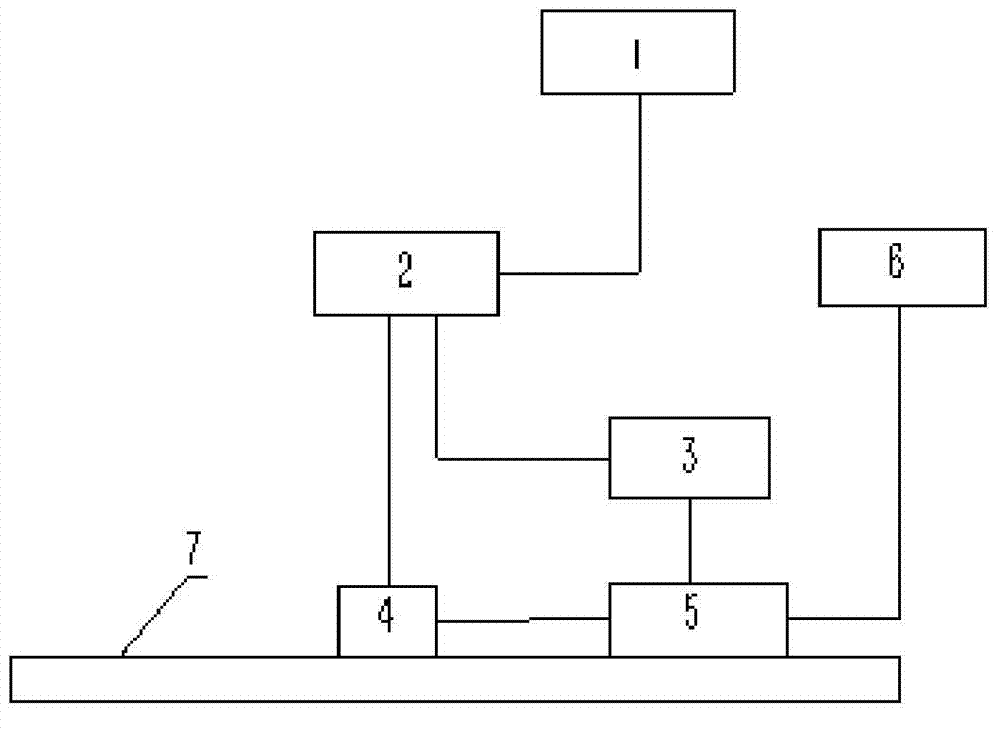

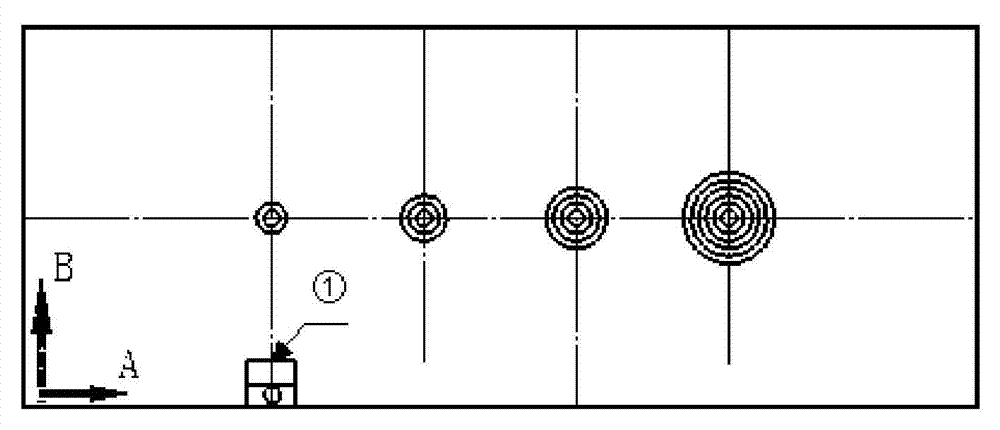

[0026] Such as figure 1 As shown, the detection system of the present invention includes: a computer 1 , an ultrasonic transceiver device 2 , an encoder 3 , a sensor 4 , an electric scanner 5 , a controller 6 and a steel plate 7 to be tested. The computer 1 is connected to the ultrasonic transceiver device 2 and controls the excitation and reception of its Lamb wave through the ultrasonic imaging software. The ultrasonic transceiver device 2 is connected to the encoder 3 and the sensor 4, and the encoder 3 and the sensor 4 are installed on the electric scanner 5. The sensor 4 is coupled to the steel plate 7 to be tested with engine oil as a coupling agent, and the scanner 5 is connected with the controller 6 to control the walking speed. Among them, the model of the ultrasonic trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com