Patents

Literature

95results about How to "Reduce unplanned downtime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

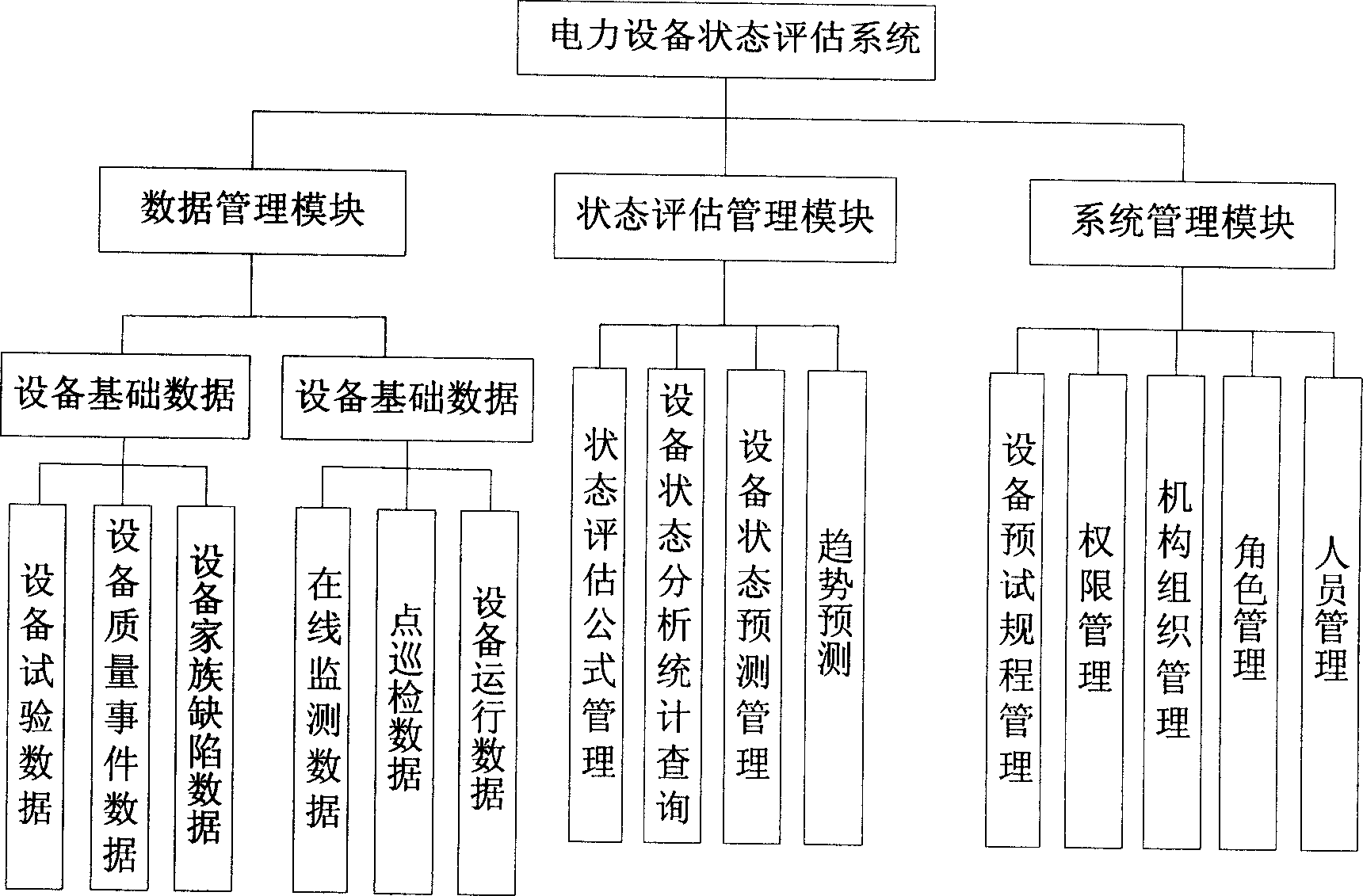

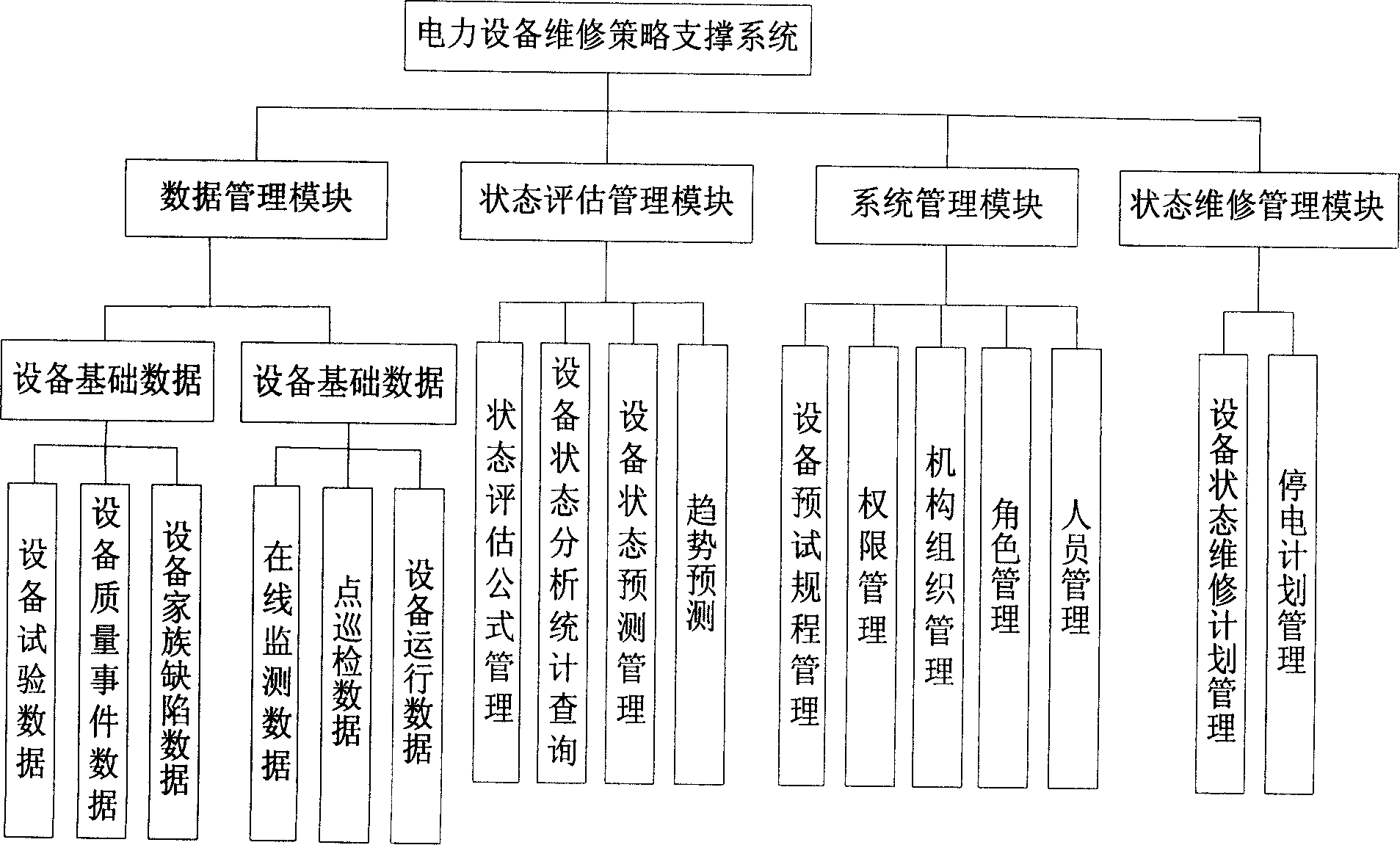

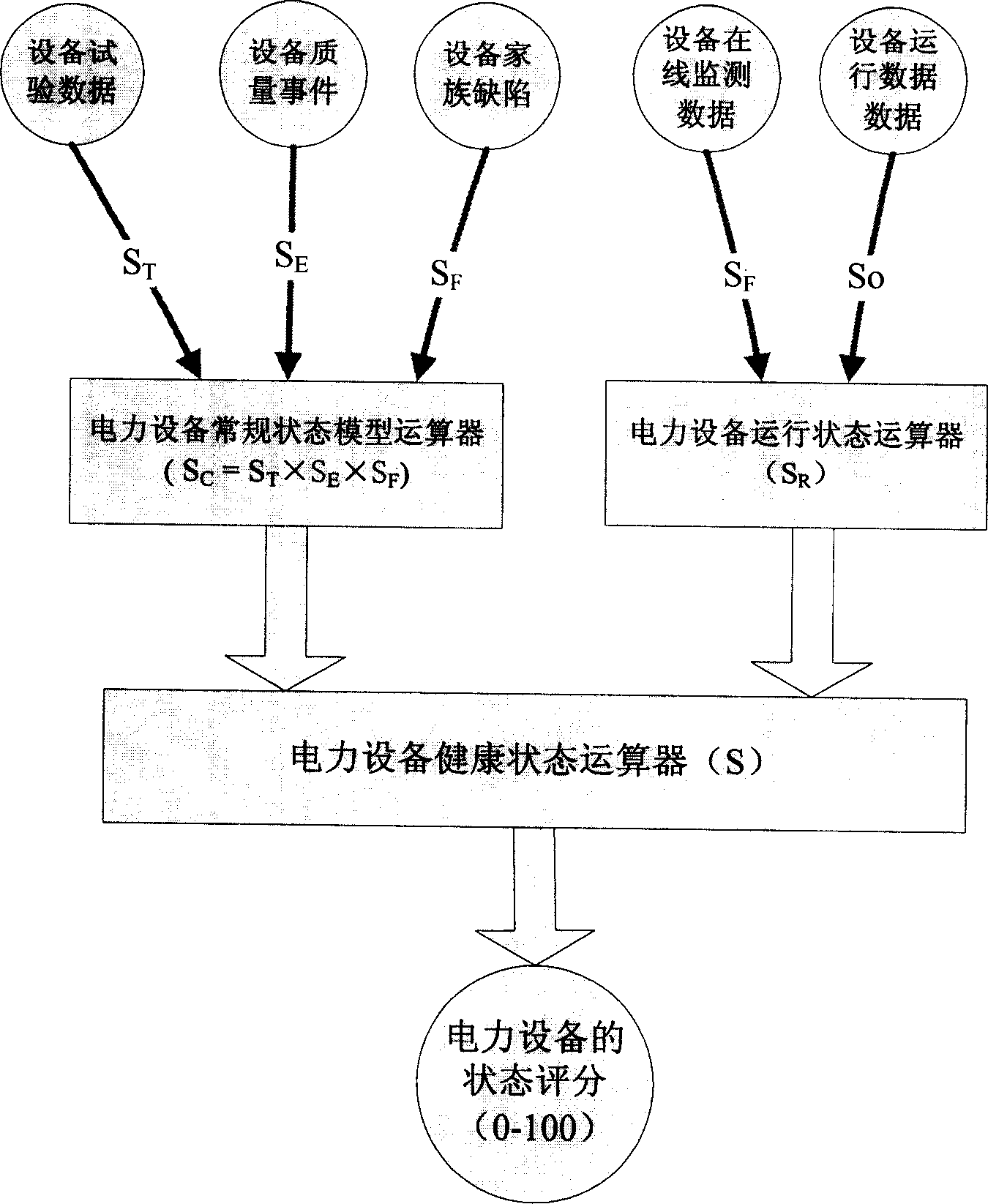

Support system for evaluating status of electric power equipments, and maintaining strategy

InactiveCN1916949AMeet more sub-level requirementsEasy to manage digitallyResourcesSystems managementElectric power equipment

An evaluation and support system of electric power device state comprises system management module for managing test process, authority, organization and personnel; data management module for classifying and managing device data such as device type, device parts, device parameter, weight ant test parameter; state evaluation management module for obtaining healthy state result of electric power device by calculating and analyzing means.

Owner:四川赛康智能科技股份有限公司

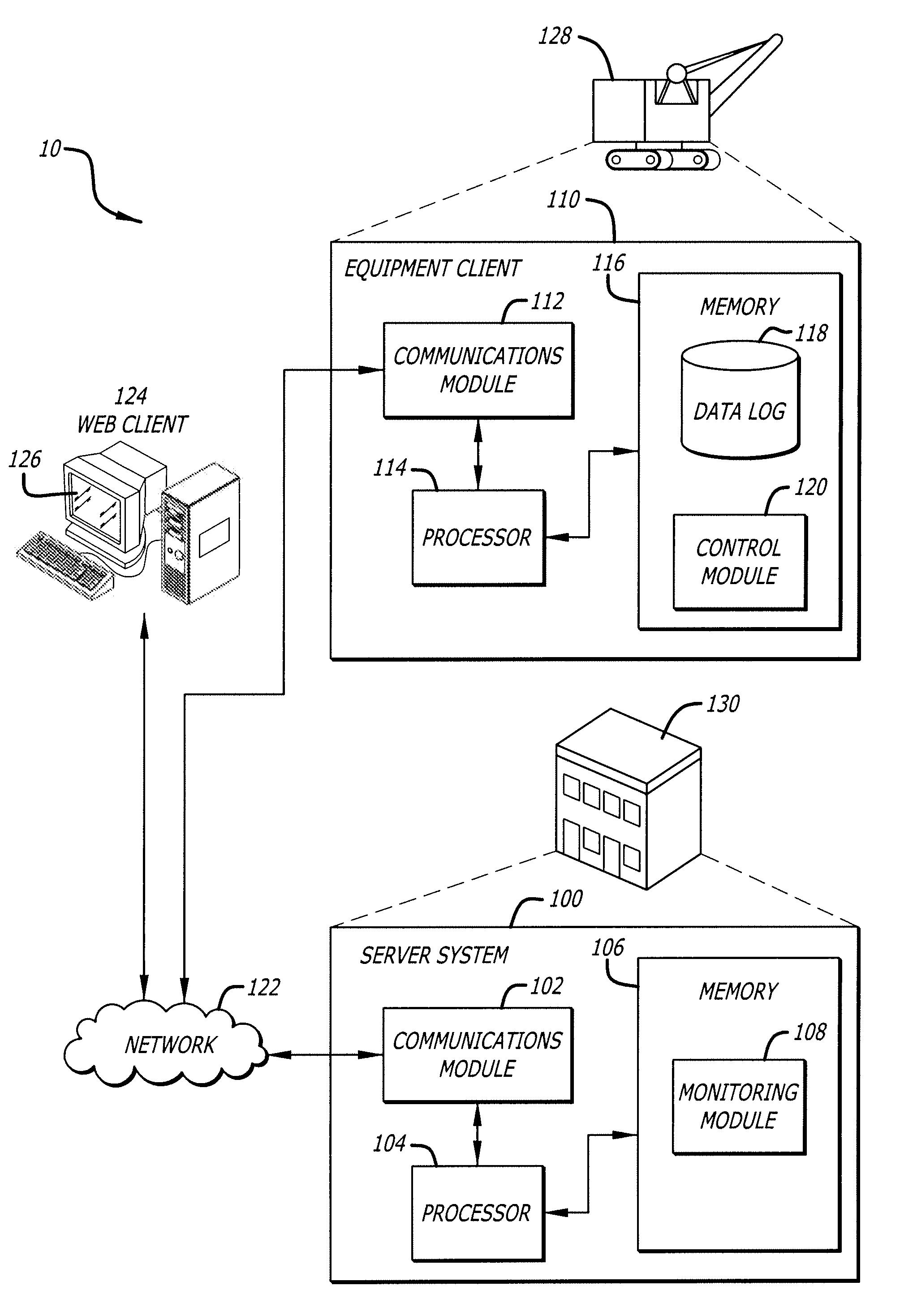

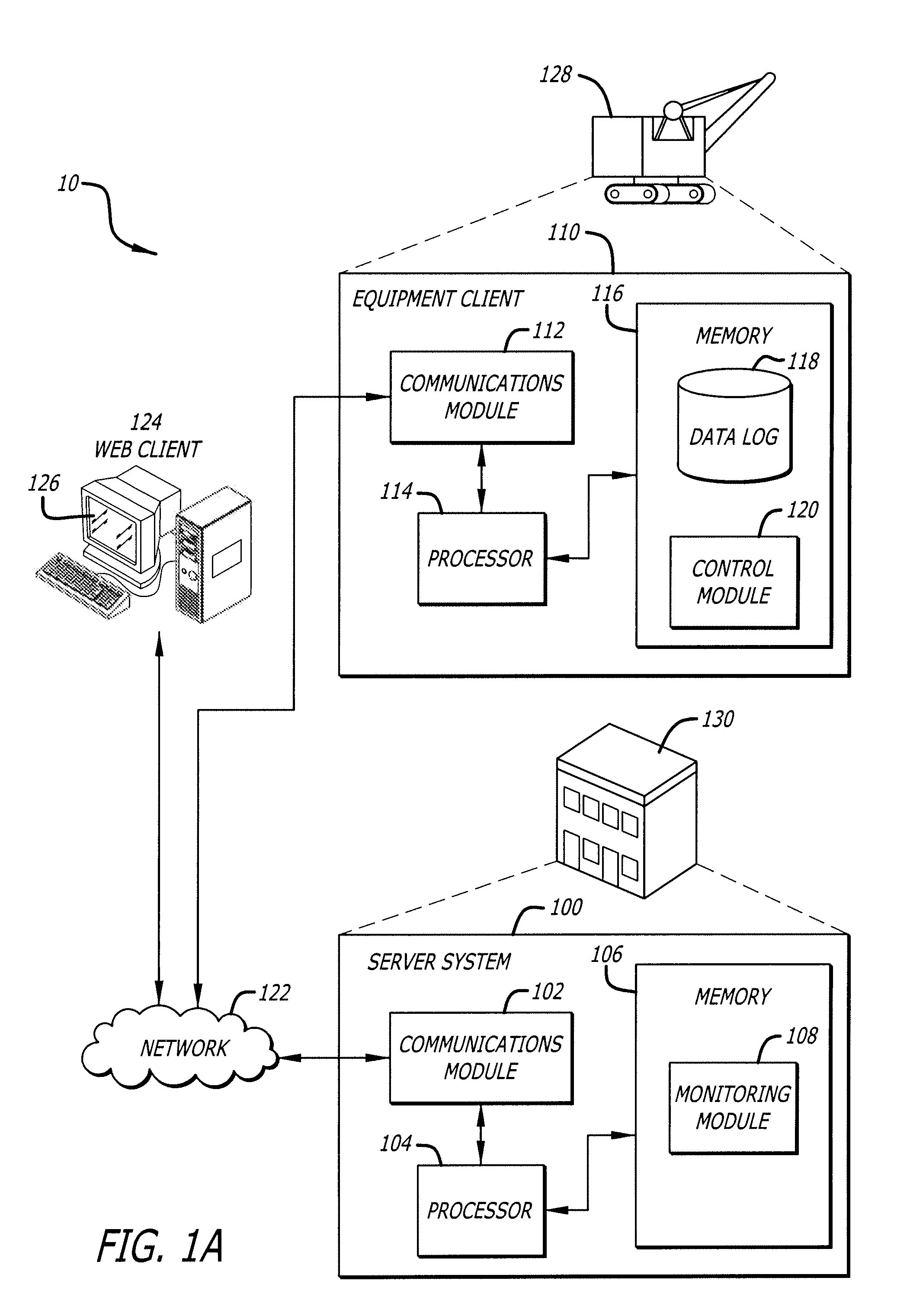

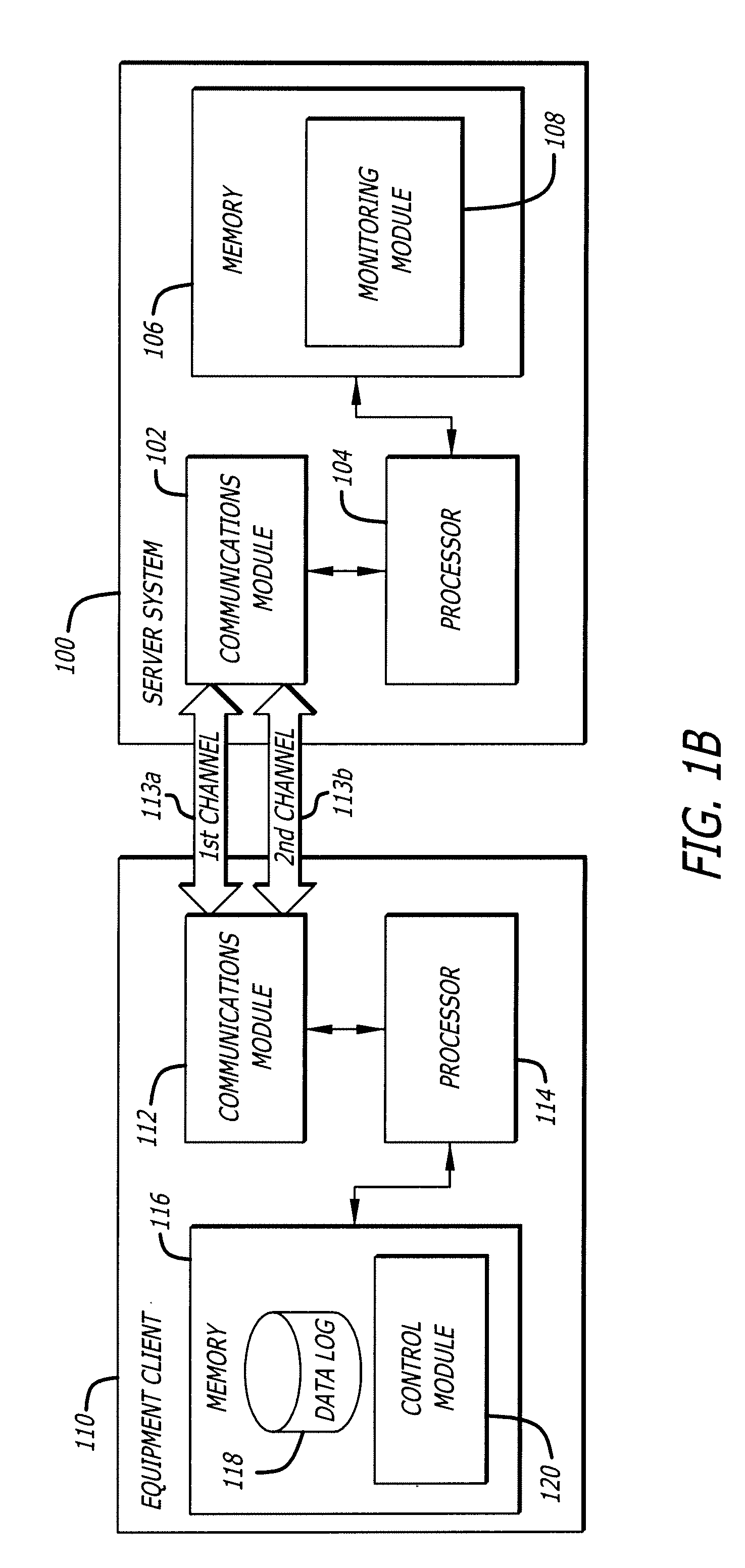

Predictive analysis for remote machine monitoring

ActiveUS20120092180A1Reduce unplanned downtimeReduce downtimeElectric testing/monitoringCharacter and pattern recognitionPredictive analyticsMachine-readable medium

Methods for predicting a machine event are described. In one aspect, a method includes receiving data for current events for the machine, and determining whether the data for the current events is within operational limits. The method also includes, when the data for the current events is within operational limits, determining, using a predetermined model, whether an anomaly exists, and generating an alert including information on the anomaly when the anomaly exists. Systems and machine-readable media are also described.

Owner:JOY GLOBAL SURFACE MINING INC

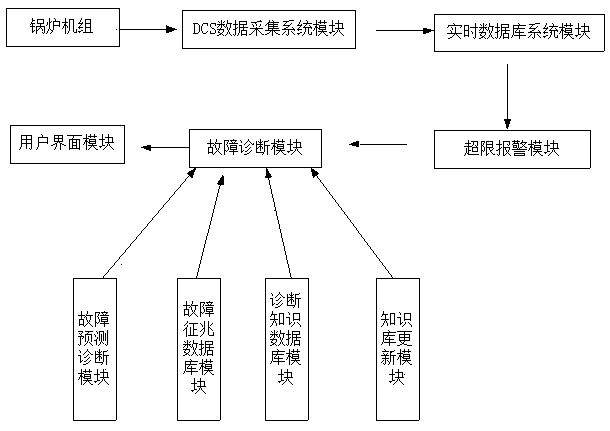

Power station boiler diagnosis expert system and fault diagnosis method thereof

InactiveCN108803569AReduce the probability of failureImprove reliability/availabilityElectric testing/monitoringDiagnosis methodsFailure diagnosis

The invention relates to a power station boiler diagnosis expert system and a fault diagnosis method thereof and aims to solve the problems that currently the operation fault causes of a thermal powerplant are not visual, the number of the parameters and state variables monitored by the system of the thermal power plant can reach hundreds and thousands, and fault position finding from the thousands of measuring parameters, state variables and alarm information is quite difficult. The power station boiler diagnosis expert system comprises a DCS data collecting system module which is mounted ona boiler unit and used for collecting boiler parameters and is characterized in that the DCS data collecting system module is connected with a real-time database system module, the real-time databasesystem module is connected with an overlimit alarm module, the overlimit alarm module is connected with a fault diagnosis module, and the fault diagnosis module is connected with a diagnosis knowledge database module, a fault symptom database module, a knowledge database updating module, a fault predicting diagnosis module and a user interface module. The power station boiler diagnosis expert system is applicable to power station boiler diagnosis.

Owner:HARBIN BOILER

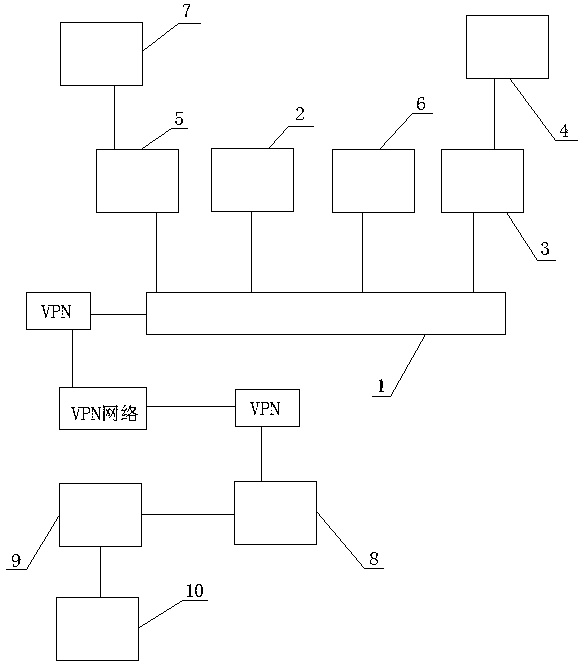

Power station boiler remote on-line diagnosis system and on-line diagnosis method thereof

InactiveCN108663980AReal-time analysis of running statusRun efficient security optimizationProgramme controlComputer controlWeb serviceElectric power system

The invention relates to a power station boiler remote on-line diagnosis system and an on-line diagnosis method thereof. The application of the computer and the artificial intelligence technology havegreat development, and the fault diagnosis of the power station boiler tends to develop intellectually, and the traditional way of relying on the manual detection has not met the requirements of theoperation of the power system equipment. The power station boiler remote on-line diagnosis system comprises a field measurement and control local area network and a remote diagnosis center, the remotediagnosis center comprises a remote diagnosis central local area network (1), a database server (2) and a diagnosis server (3), a Web server (4) and a data storage server (5) which are connected witheach other through a remote diagnosis central local area network, the diagnosis server is connected with a group of diagnosis modules (6), and the data storage server is connected with the central storage disk array (7), and the remote diagnosis center local area network and the data forwarding server (8) of the field measurement and control local area network is connected with the Internet through a firewall and a VPN router. The method is applied to remote on-line diagnosis of a power station boiler.

Owner:HARBIN BOILER

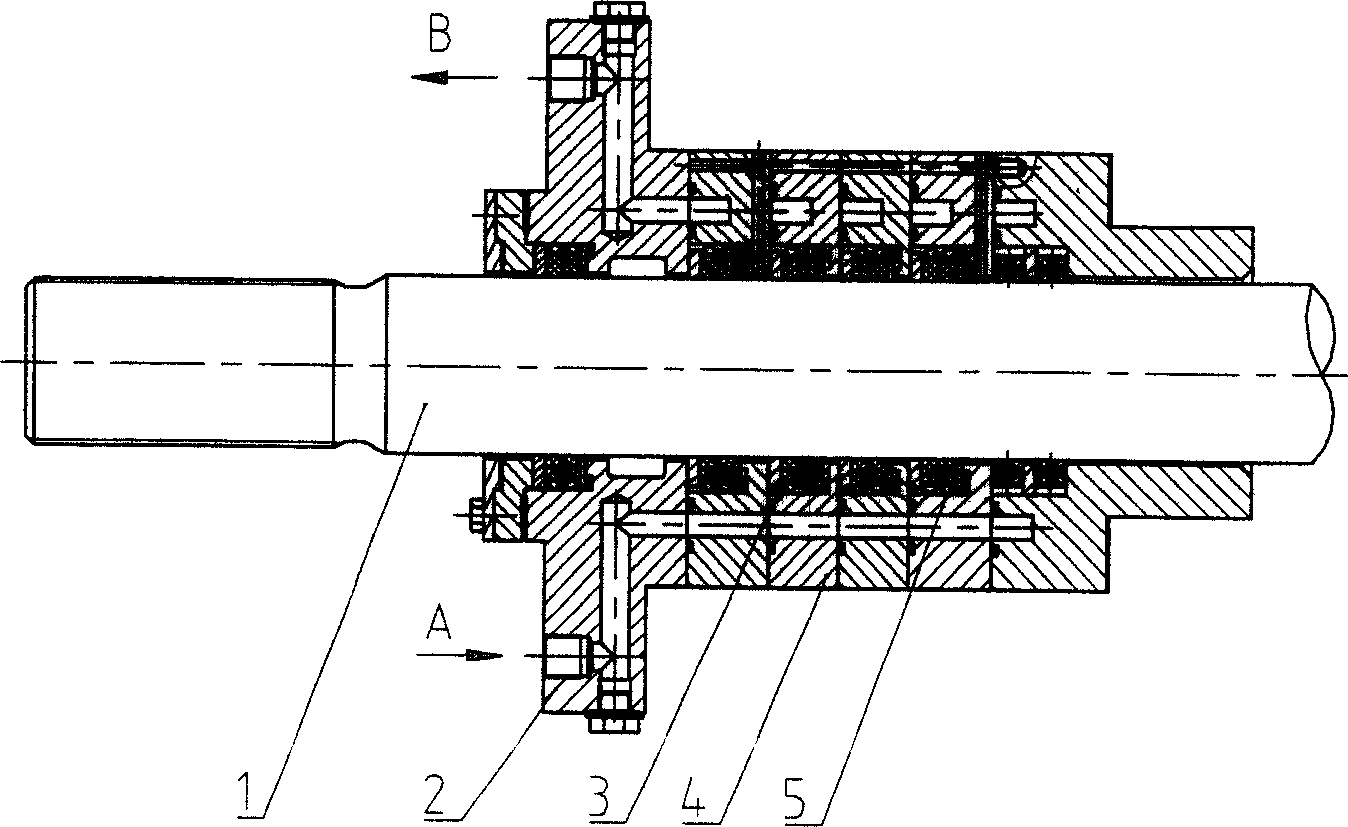

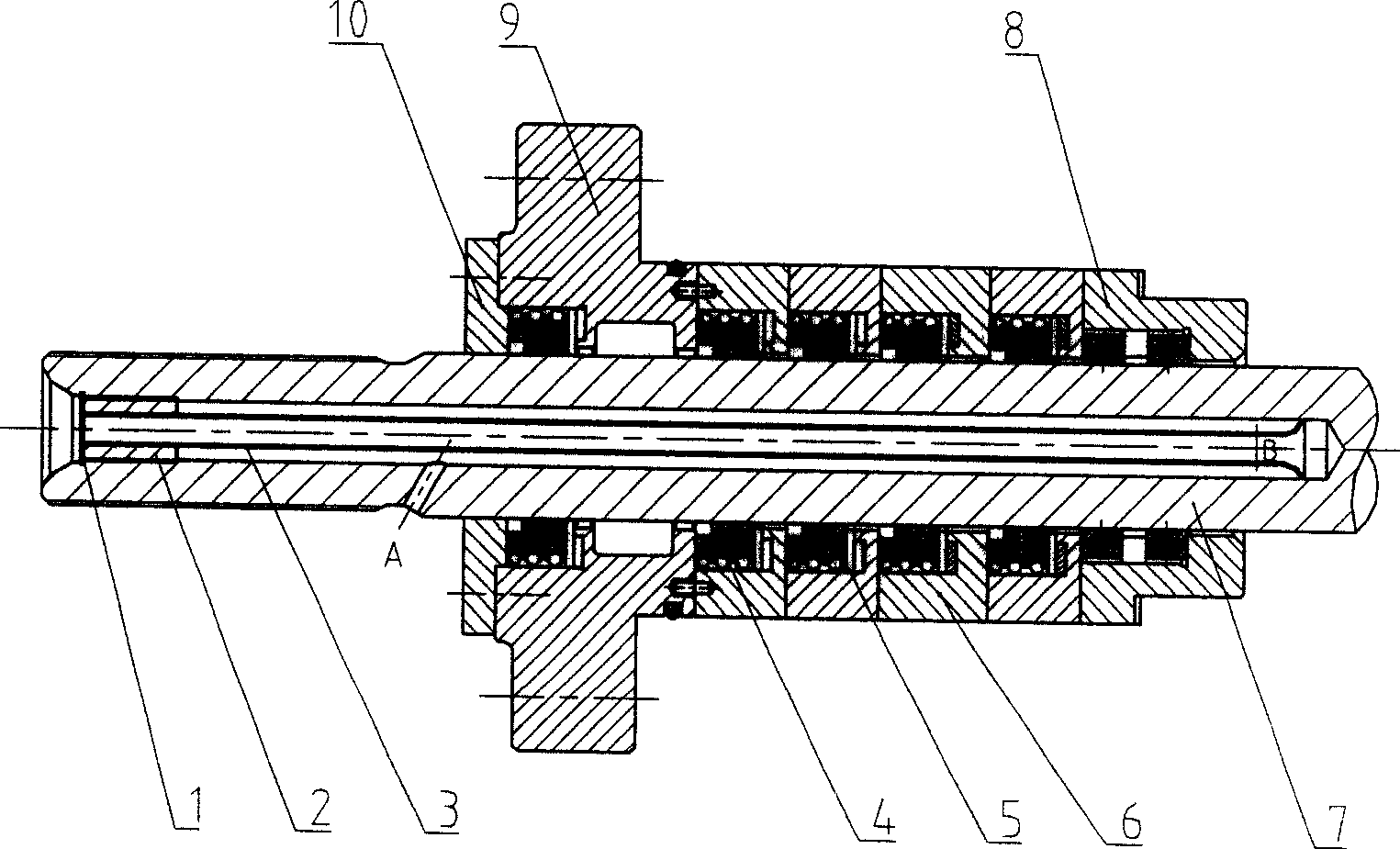

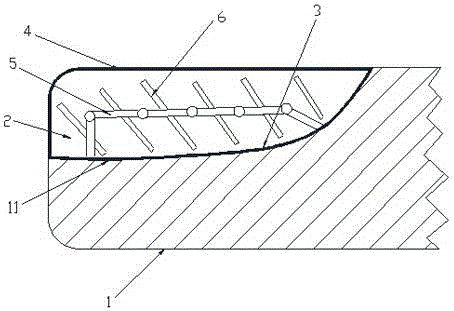

Oil cooling structure for piston rod of piston compressor

InactiveCN1766330AExtended service lifeGuaranteed to workPositive displacement pump componentsPositive-displacement liquid enginesCoolant flowOil cooling

The invention discloses a piston rod connection oil cooling structure of piston type compressor in the cooling device technique domain, which comprises the following parts: sealing ring, locking ring, filling box and piston rod, wherein the cooling hole is open on the rear of piston rod with an oil guiding pipe in the cooling hole to do circulating cooling through the cooling oil; the oil guiding pipe is pressed on the end of piston rod through the connector, which is pressed on the filling box and throttle case through gland and clamp plate. The invention guarantees the normal operation, which avoids the ineffective phenomenon of coolant flow and sealing due to friction and high temperature.

Owner:WUXI COMPRESSOR CO LTD

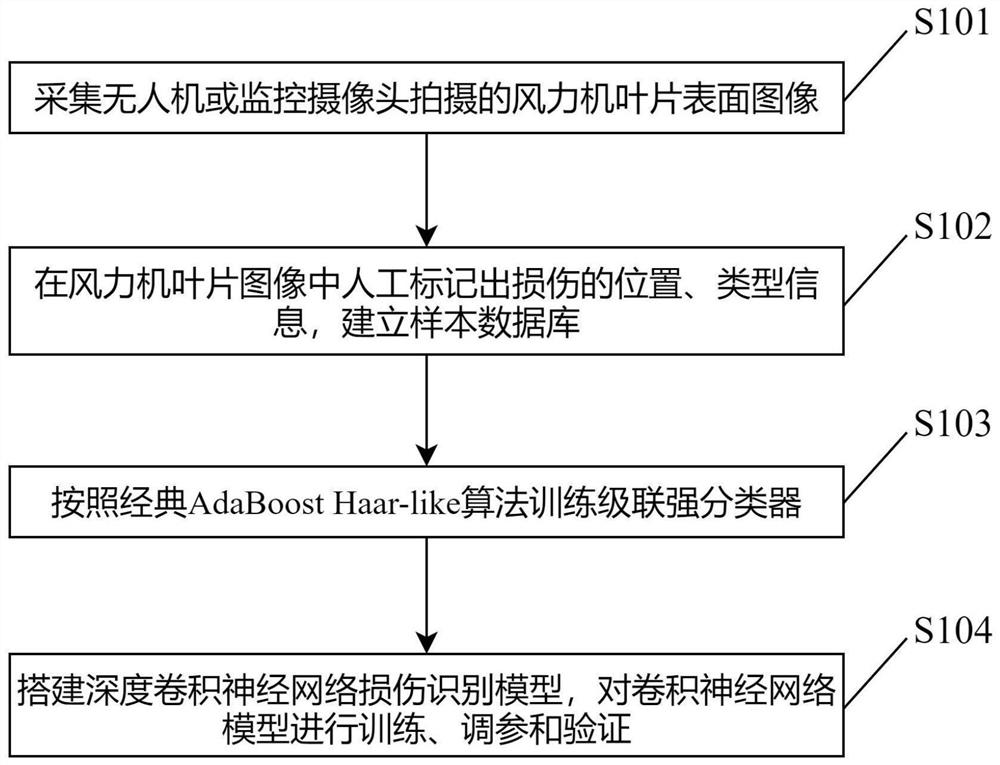

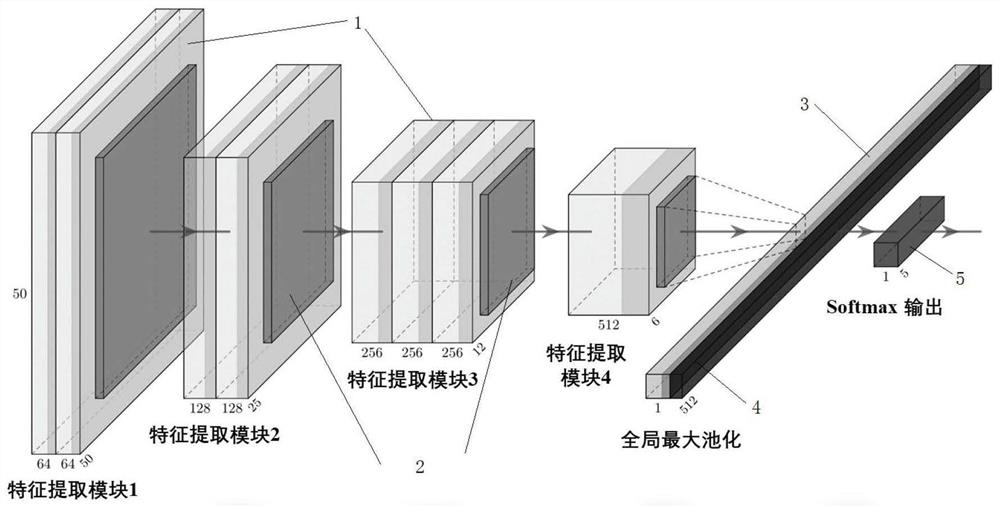

Wind turbine blade image damage detection and positioning method

ActiveCN112233091AReduce unplanned downtimeLow operating and maintenance costsData processing applicationsImage analysisNerve networkTurbine blade

The invention belongs to the technical field of fault detection, and particularly relates to a wind turbine blade image damage detection and positioning method. Based on a deep convolutional neural network, the method comprises two processes of model training and damage detection and positioning. According to the invention, the wind turbine blade images shot by the unmanned aerial vehicle and themonitoring camera can be automatically interpreted, and multiple types of wind turbine blade damage can be efficiently and accurately recognized and positioned. Blade damage evaluation and early warning are achieved, the frequency of accidental shutdown of the wind turbine caused by blade faults of the wind turbine is reduced, and the operation and maintenance cost of the wind turbine is reduced.The invention has the advantages of high recognition speed, high precision, full-automatic process, low operation threshold and the like, and makes up the defects of low efficiency, high misjudgment rate, time and labor waste and the like caused by manual operation in the traditional method.

Owner:青岛科多帮信息技术有限公司 +1

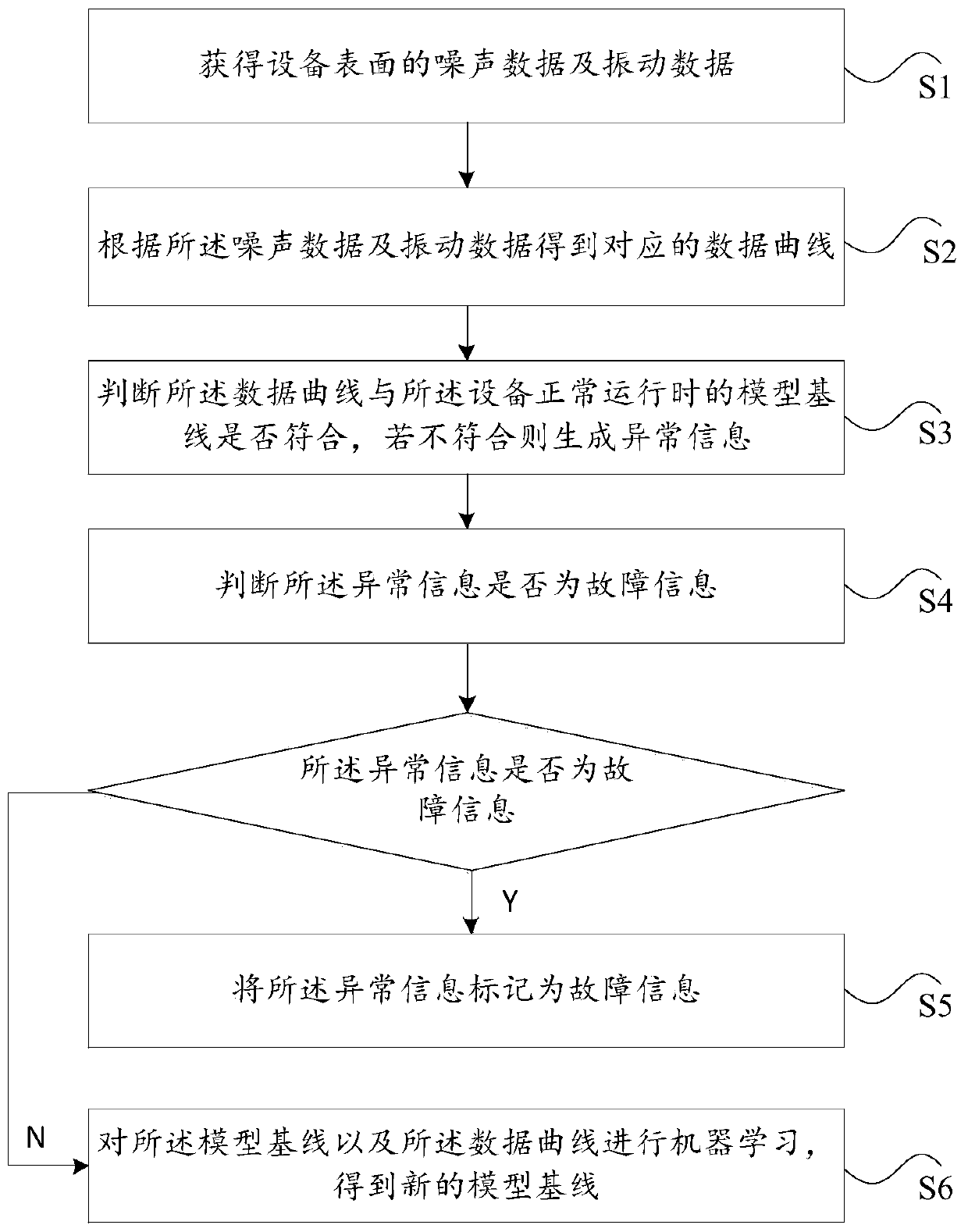

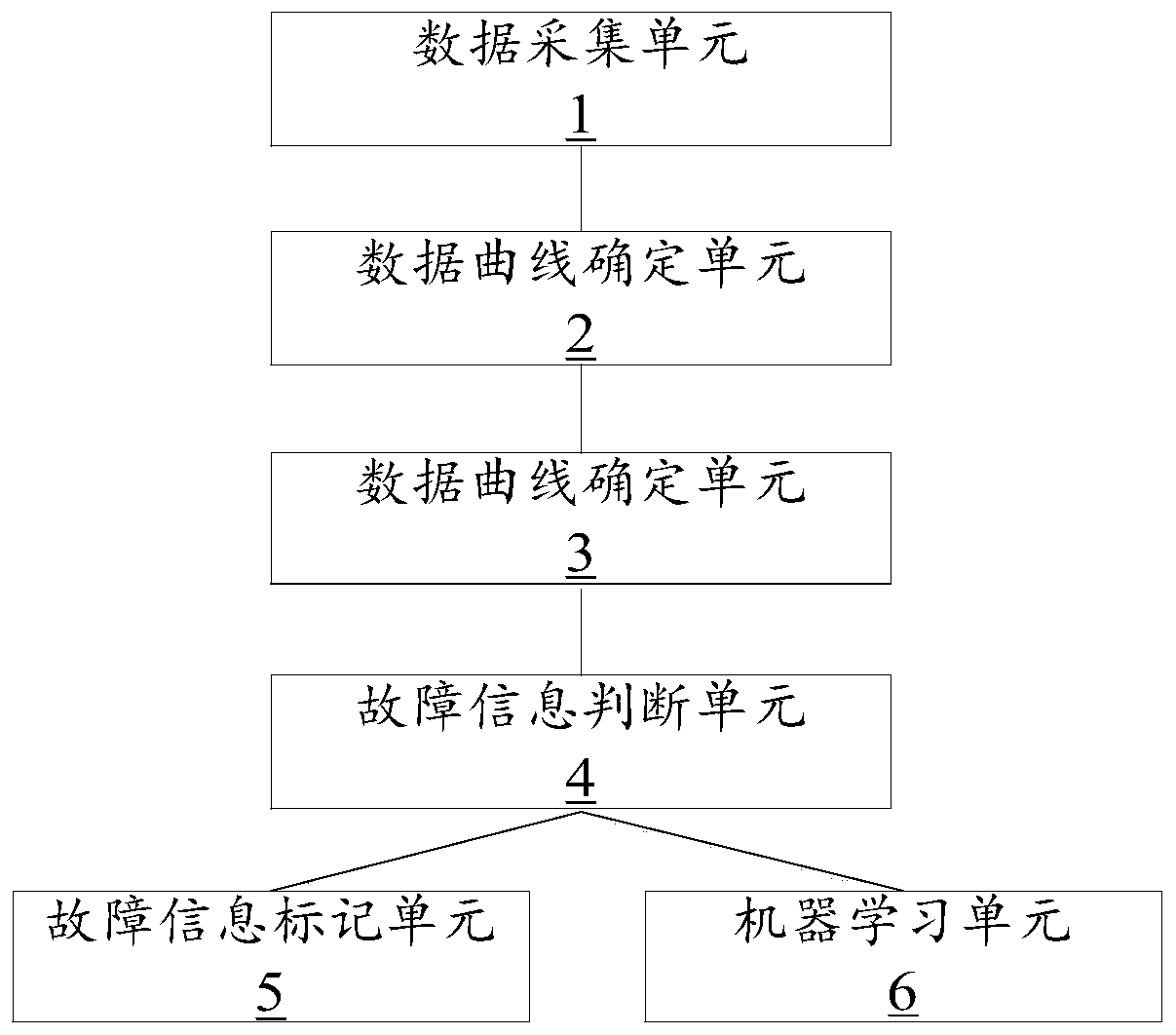

Equipment fault diagnosis method and device

PendingCN109885951AReduce unplanned downtimeLow cost of industrializationSubsonic/sonic/ultrasonic wave measurementSpecial data processing applicationsDiagnosis methodsDevice failure

The invention discloses an equipment fault diagnosis method and device. The method comprises the steps that acquiring noise data and vibration data of the surface of equipment; obtaining a corresponding data curve according to the noise data and the vibration data; judging whether the data curve is consistent with a model base line when the equipment runs normally or not, and if not, generating abnormal information; judging whether the abnormal information is fault information or not; if the abnormal information is fault information, marking the abnormal information as the fault information; and if the model base line is not the fault information, performing machine learning on the model base line and the data curve to obtain a new model base line. A fault diagnosis and prediction solutionbased on a local edge side system and through noise and vibration is constructed; continuous monitoring of equipment faults can be achieved only by detecting equipment noise and vibration data, and therefore accidental shutdown in the industrial production process is further reduced, the product yield is increased, and the industrial production cost is reduced.

Owner:中科云创(厦门)科技有限公司

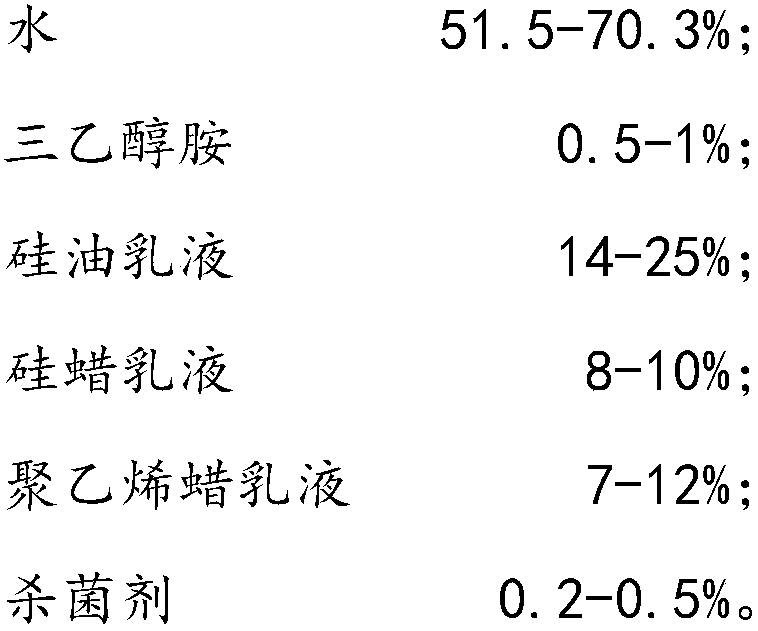

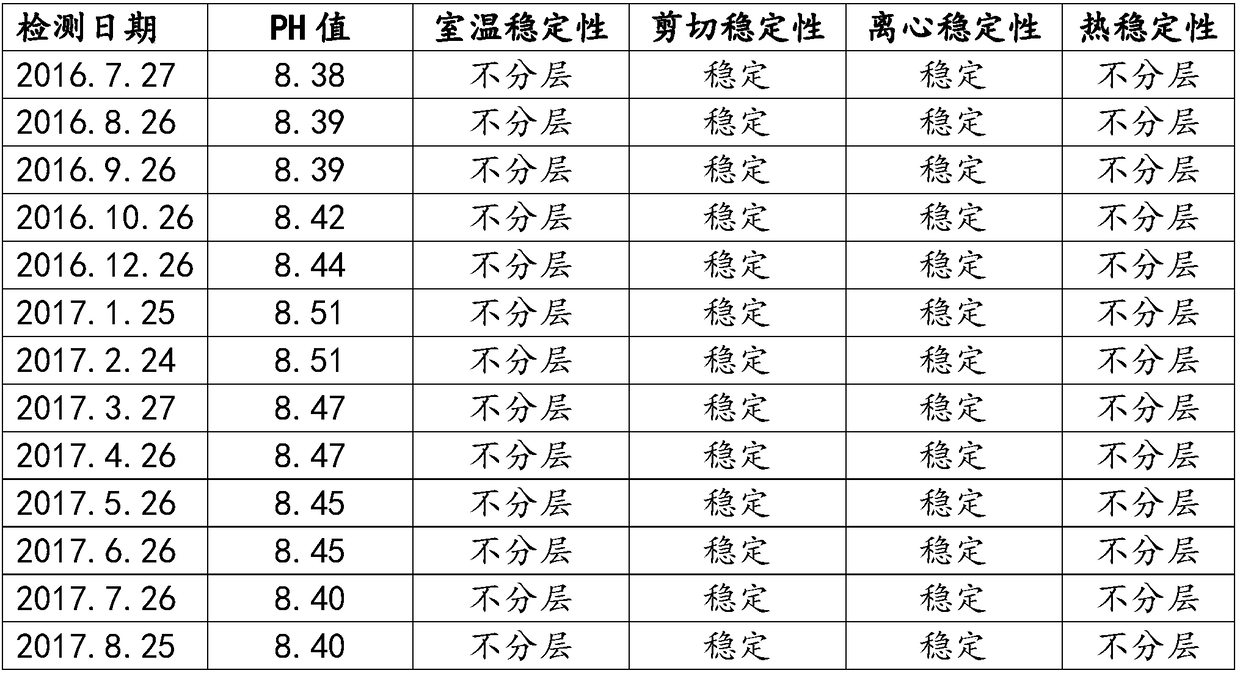

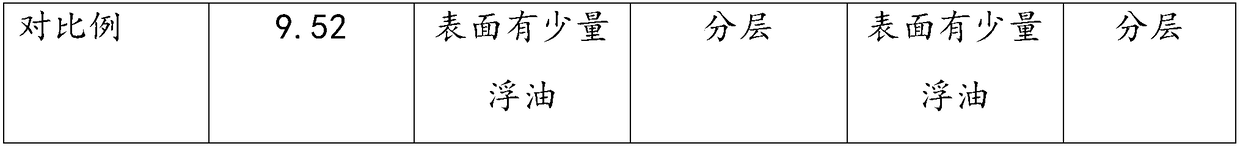

Water-based mold release agent applied to aluminum alloy die casting and preparation method of water-based mold release agent

ActiveCN108339930AImprove yieldReduce the burden onFoundry mouldsFoundry coresWater basedAdditive ingredient

The invention provides a water-based mold release agent applied to an aluminum alloy die casting. The water-based mold release agent comprises the following components of, by weight percentage, 51.5%to 70.3% of water, 0.5% to 1% of triethanolamine, 14% to 25% of silicone oil emulsion, 8% to 10% of silicon wax emulsion, 7% to 12% of polyethylene wax emulsion and 0.2% to 0.5% of a sterilizing agent. The invention also provides a preparation method of the water-based mold release agent applied to the aluminum alloy die casting. The preparation method provided by the invention can greatly increases the rate of finished products in a surface after-treatment process, alleviates the burthen of a washing procedure, effectively increases the rate of finished products of surface treatment, shortensthe unplanned shutdown time, remarkably lowers the cost and maintains the stability of the water-based mold release agent, and the water-based mold release agent has quite good compatibility and affinity to other ingredients in a system.

Owner:富兰克润滑科技(太仓)有限公司

Optimization method based on multipath technology

InactiveCN105141459AGood application effectReduce unplanned downtimeData switching networksOperational systemWeb cluster

The invention discloses an optimization method based on a multipath technology, and belongs to the field of multipath optimization. The technical problem to be solved is that a traditional storage system architecture scheme does not or lacks of integrating a virtualization technology, a network clustering technology and a host multipath technology to a large extent. The technical scheme is as follows: the method comprises the following steps of step (1) of providing efficient and reliable services to external customers through a virtual machine on a failover cluster and a cluster node and the host multipath technology, and deploying all these services to the virtual machine, wherein the virtual machine running on the cluster node is equivalent to one application or service resource of a cluster system, so that the virtual machine can seamlessly transfer on the cluster node manually or automatically; step (2) of using a sole IP (Internet Protocol) or a computer name of a microkernel operating system to access the microkernel operating system to a management server of the virtual machine in step (1).

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

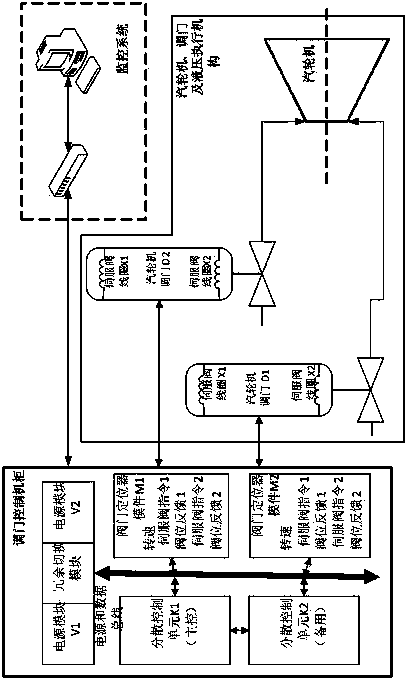

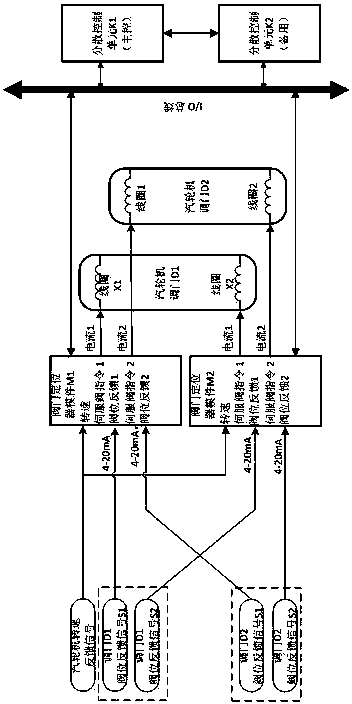

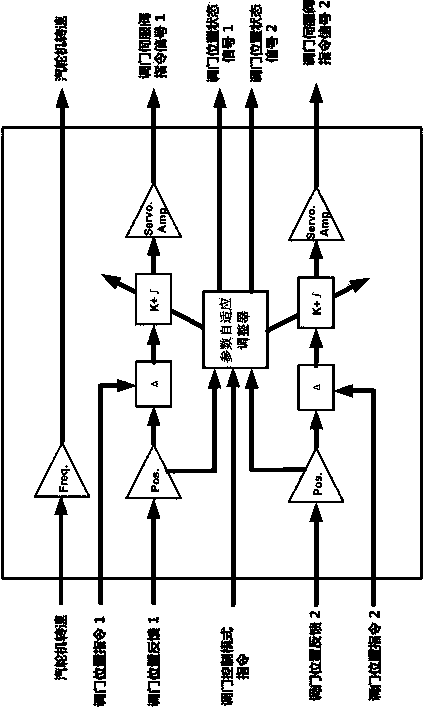

Steam turbine governing valve redundancy control system and control method thereof

ActiveCN103939154AImprove securityReduce unplanned downtimeMachines/enginesEngine componentsControl systemControl cell

The invention discloses a steam turbine governing valve redundancy control system and a control method thereof. Redundant distributed control units and redundant valve positioner modules are combined to control steam turbine governing valves. The distributed control units are arranged in pairs, the current valve position instruction signals of the steam turbine governing valves are calculated in real time to be sent to the valve positioner modules. The valve positioner modules are arranged in pairs, feedback signals of two different steam turbine governing valves are collected at the same time, the valve position instruction signals sent by the distributed control units are combined with the feedback signals, the instruction signals of a current governing valve servo valve are calculated and output to drive two coils of hydraulic servo-motor servo valves corresponding to the two governing valves, closed loop control over the steam turbine governing valves is achieved, the two coils of the hydraulic servo-motor servo valves corresponding to each steam turbine governing valve are respectively controlled by adopting the two valve positioner modules which are arranged in pairs, safety of valve control of a steam turbine is improved greatly, and on-line non-stop and interference-free renewing of the valve positioner modules can be achieved.

Owner:NANJING GUODIAN NANZI WEIMEIDE AUTOMATION CO LTD

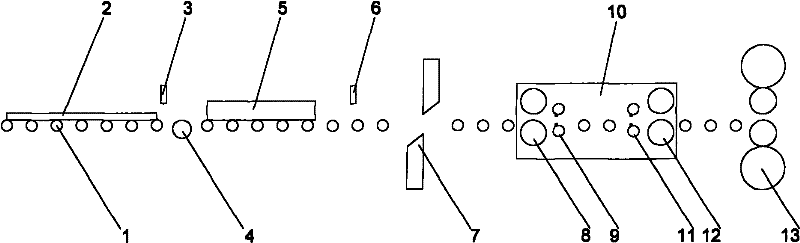

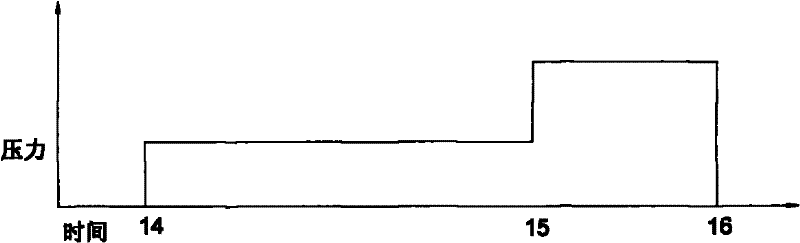

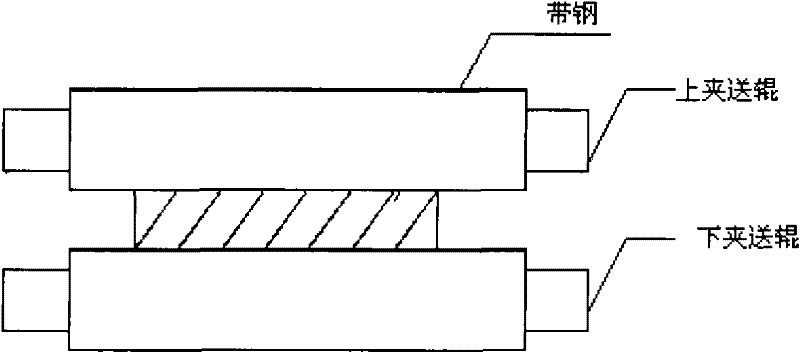

Controlling method of delaying water leakage of pinch roll

ActiveCN102161053AExtended service lifeReduce use costRoll mill control devicesWork treatment devicesShear zoneEngineering

The invention relates to a controlling method of delaying water leakage of a pinch roll, comprising the steps as follows: (1) when an intermediate blank head of rough rolling incoming materials arrives at a flying shear zone, a photoelectric tube in front of the flying shears is triggered and turned on to transmit the detected signal to BA basic automation, and the flying shears carry out the head cutting according to the shape of the detected intermediate blank head; (2) the pinch roll is controlled by low pressure: after the head of the intermediate blank is cut, the intermediate blank goesinto a de-scaling box 1#pinch roll at a de-scaling roller-way speed; and based on the days of the pinch roll using the computer and low pressure control pressure setting, a BA computer calculates thehead setting pressure according to the formula 1 and then roll gap is pressed until the pressure reaches the set value; (3) the pinch roll is controlled by high pressure: when the tail of the intermediate blank reaches the number 1 photoelectric tube, the pinch roll is controlled by high pressure; and based on the days of the pinch roll using the computer and high pressure control pressure setting, a BA computer calculates the tail setting pressure of the pinch roll according to the formula 2 and then the roller gap is further pressed until the pressure reaches the set value. The invention has the advantages of increased production operation efficiency, reduced fault time, and prolonged using periods of various pinch rolls.

Owner:BAOSHAN IRON & STEEL CO LTD

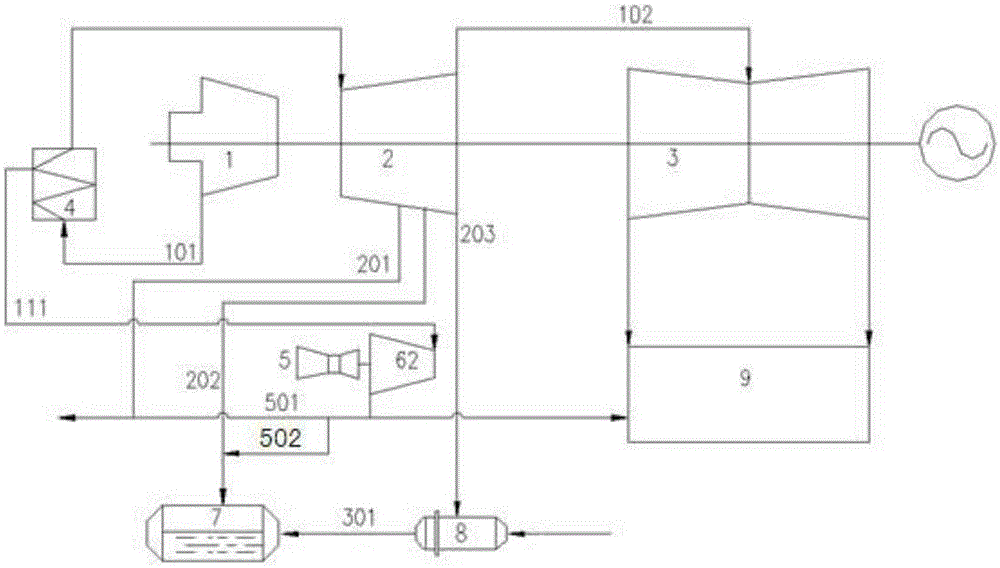

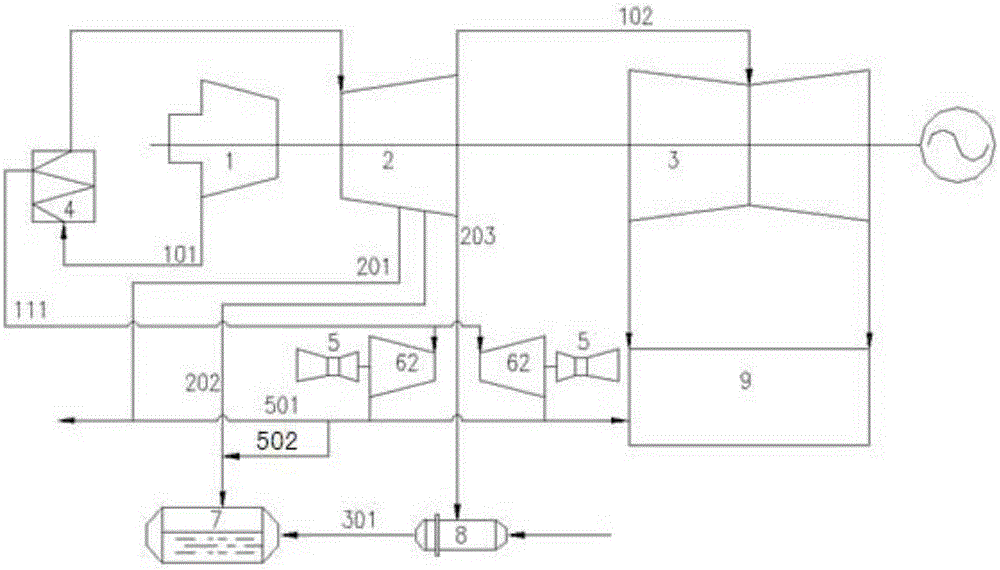

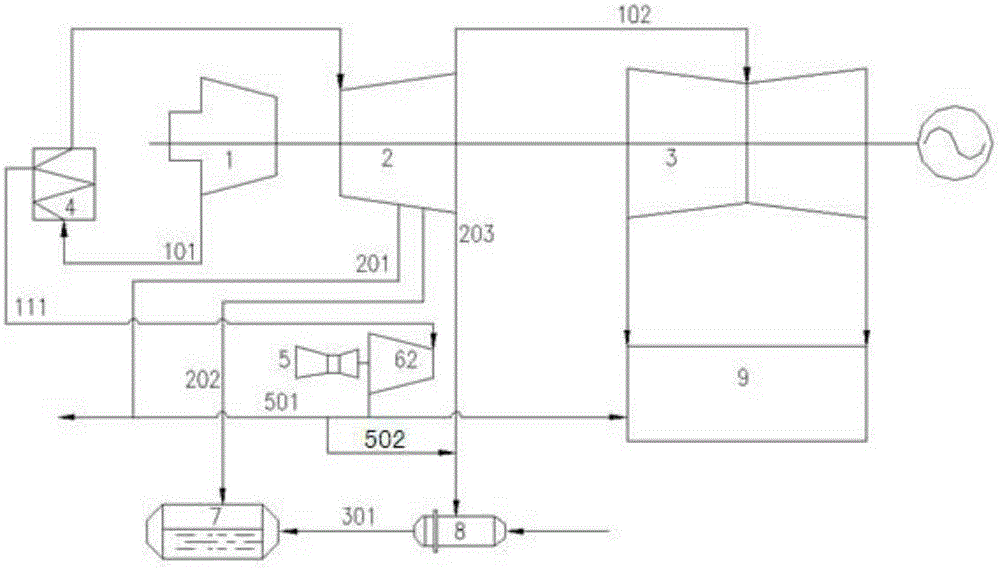

Wide-load heat supply energy saving system of back pressure type small turbine driving induced draft fan

ActiveCN105042666AEnsure safetyGuaranteed functionSteam generation plantsHot-water central heatingEngineeringDeaerator

The invention relates to a wide-load heat supply energy saving system of a back pressure type small turbine driving induced draft fan. The system comprises a main turbine, a back pressure type small turbine, an induced draft fan, a boiler reheater, a deaerator and a low-pressure heater, wherein a steam discharge end of a high-pressure cylinder in the main turbine is connected with a steam inlet end of the boiler reheater; one of steam outlet ends of the boiler reheater is connected with a steam inlet end of a medium-pressure cylinder to form a reheating loop; the other one of the steam outlet ends of the boiler reheater is connected with a steam inlet end of the back pressure type small turbine to form a heat supply loop; a power output end of the back pressure type small turbine is connected with a driving input end of the induced draft fan to form an induced draft fan driving loop; one of steam discharge ports of the medium-pressure cylinder is connected with a steam inlet end of the deaerator through a heat return steam extracting pipe; the other one of the steam discharge ports of the medium-pressure cylinder is connected with a steam inlet end of the low-pressure heater through a steam extracting pipe to form a heat returning loop; and a steam extracting and replenishing structure of the heat supply loop is formed between all connecting pipelines of the low-pressure heater, a condensed water pipe, the deaerator and the medium-pressure cylinder and a heat supply pipe network. The system improves the heat supply operation economy, and has the advantages of higher operation adjusting flexibility and better heat supply economy.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

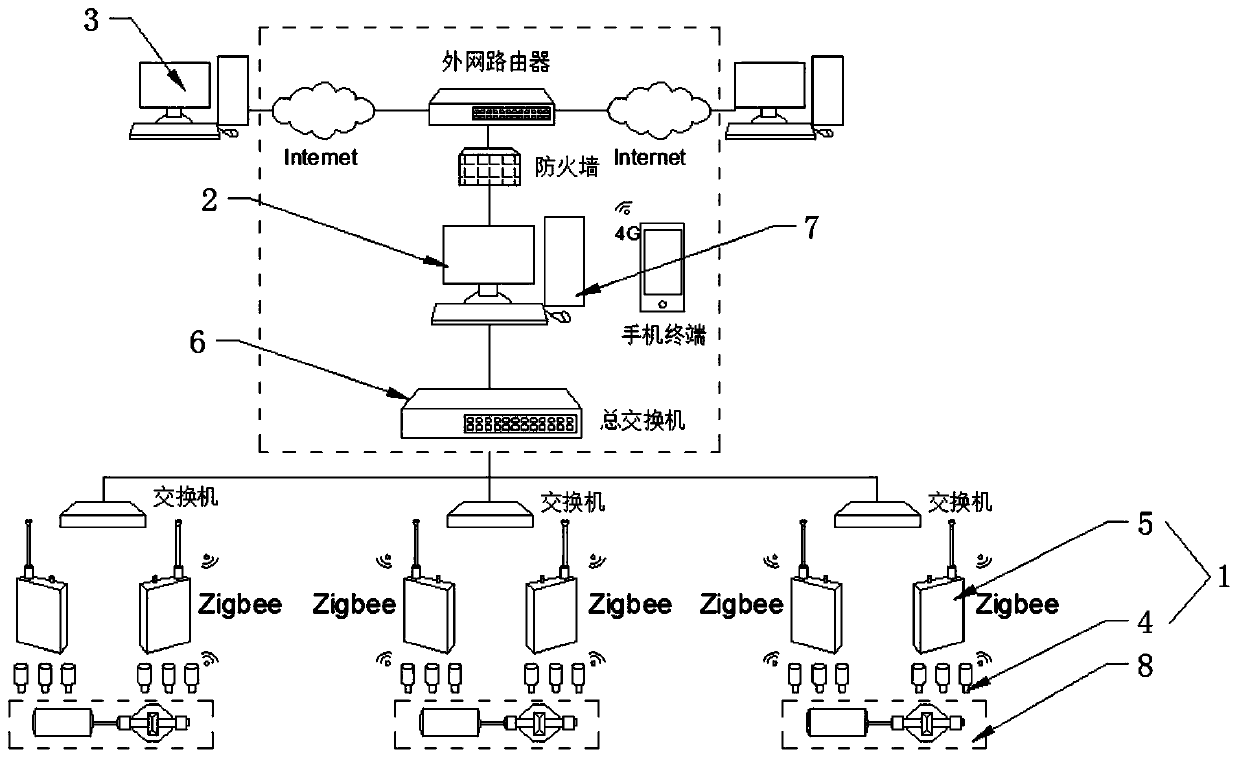

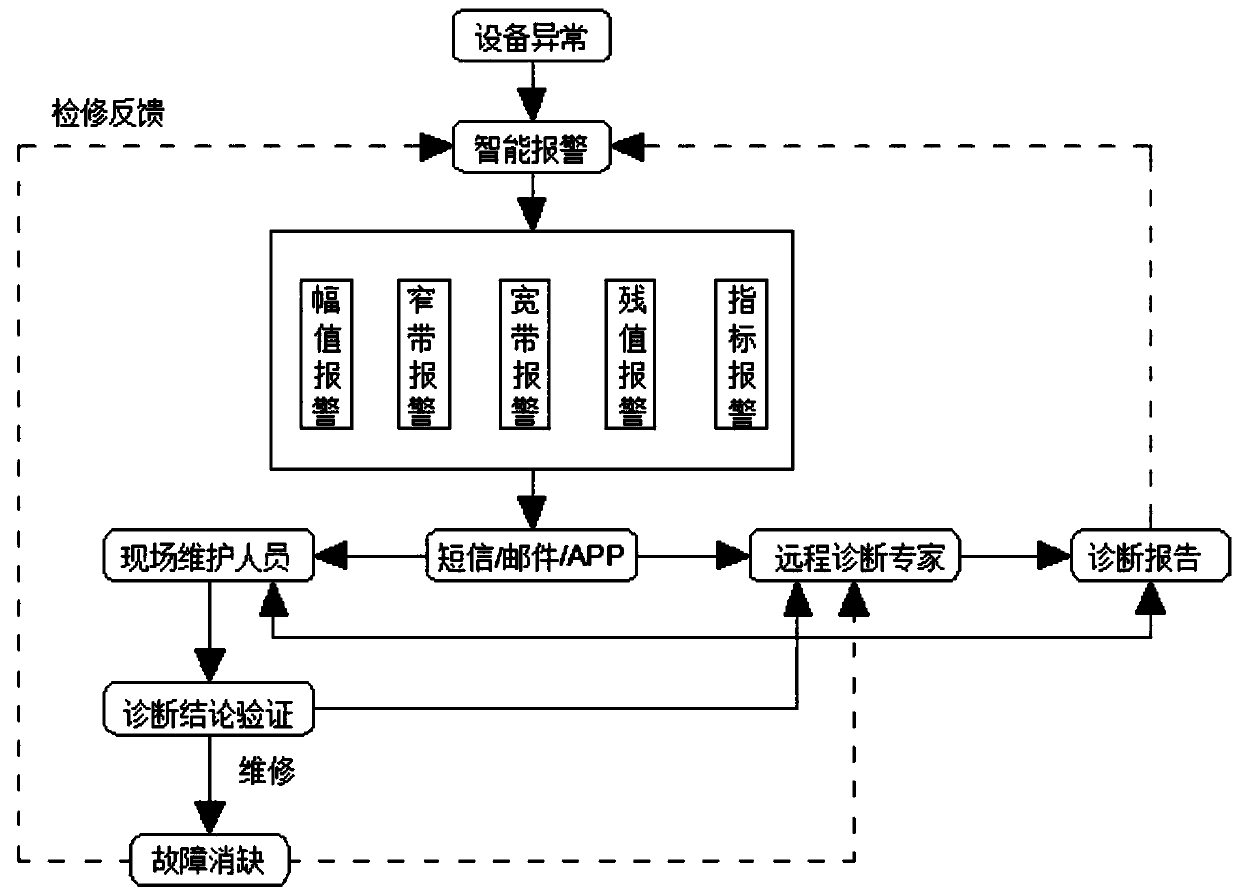

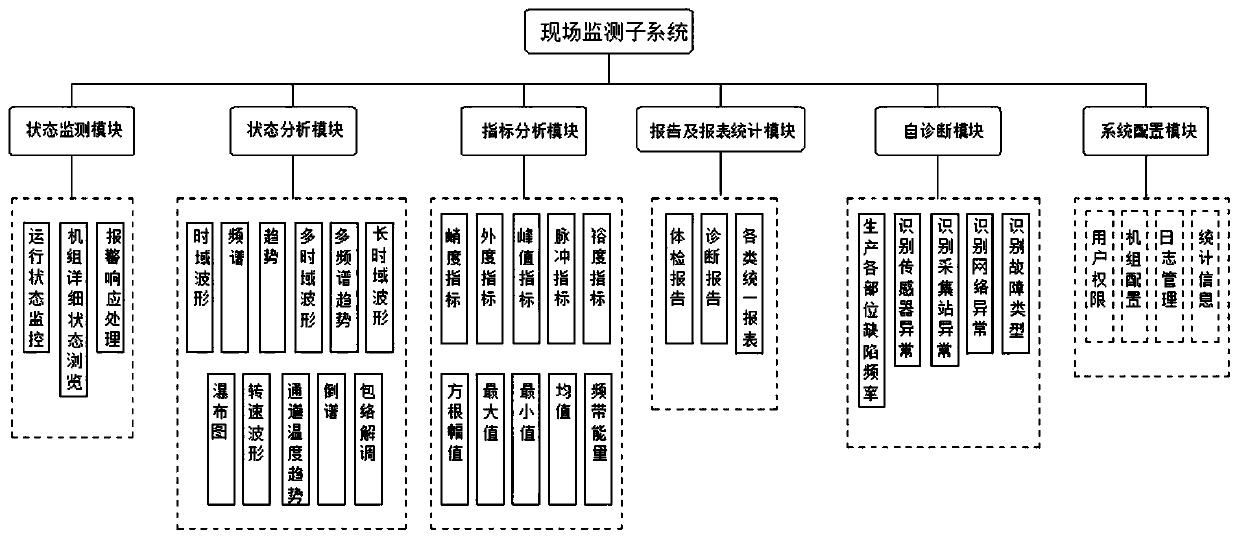

Remote intelligent monitoring system for petrochemical key unit equipment

PendingCN110445830AImprove availabilityEfficient managementMeasurement devicesTransmission systemsOriginal dataData acquisition

The invention discloses a remote intelligent monitoring system for petrochemical key unit equipment in the technical field of petrochemical engineering. The system comprises a data collection subsystem which is used for collecting original data and transmitting the original data to an on-site monitoring subsystem; the field monitoring subsystem is used for integrating the existing monitoring data,configuring a targeted data acquisition method according to the operation characteristics of the equipment unit, capturing, analyzing and positioning effective vibration and temperature data of the equipment unit fault through the data acquisition subsystem, and giving an intelligent alarm according to an output instruction of the remote diagnosis subsystem; remote diagnostic subsystem, the system is used for carrying out remote data analysis and fault diagnosis on an equipment unit monitored by an on-site monitoring subsystem. The problem of data acquisition is solved by setting up the Internet of Things through arrangement of sensors, and data sharing and analysis are performed by applying a large number of intelligent algorithms, so that the risks of equipment loss and repair loss areeffectively reduced. The unplanned shutdown is reduced. The availability of parts is improved. The spare part management is efficient, and the operation efficiency is improved.

Owner:SINOCHEM XINGZHONG OIL STAGING ZHOUSHAN

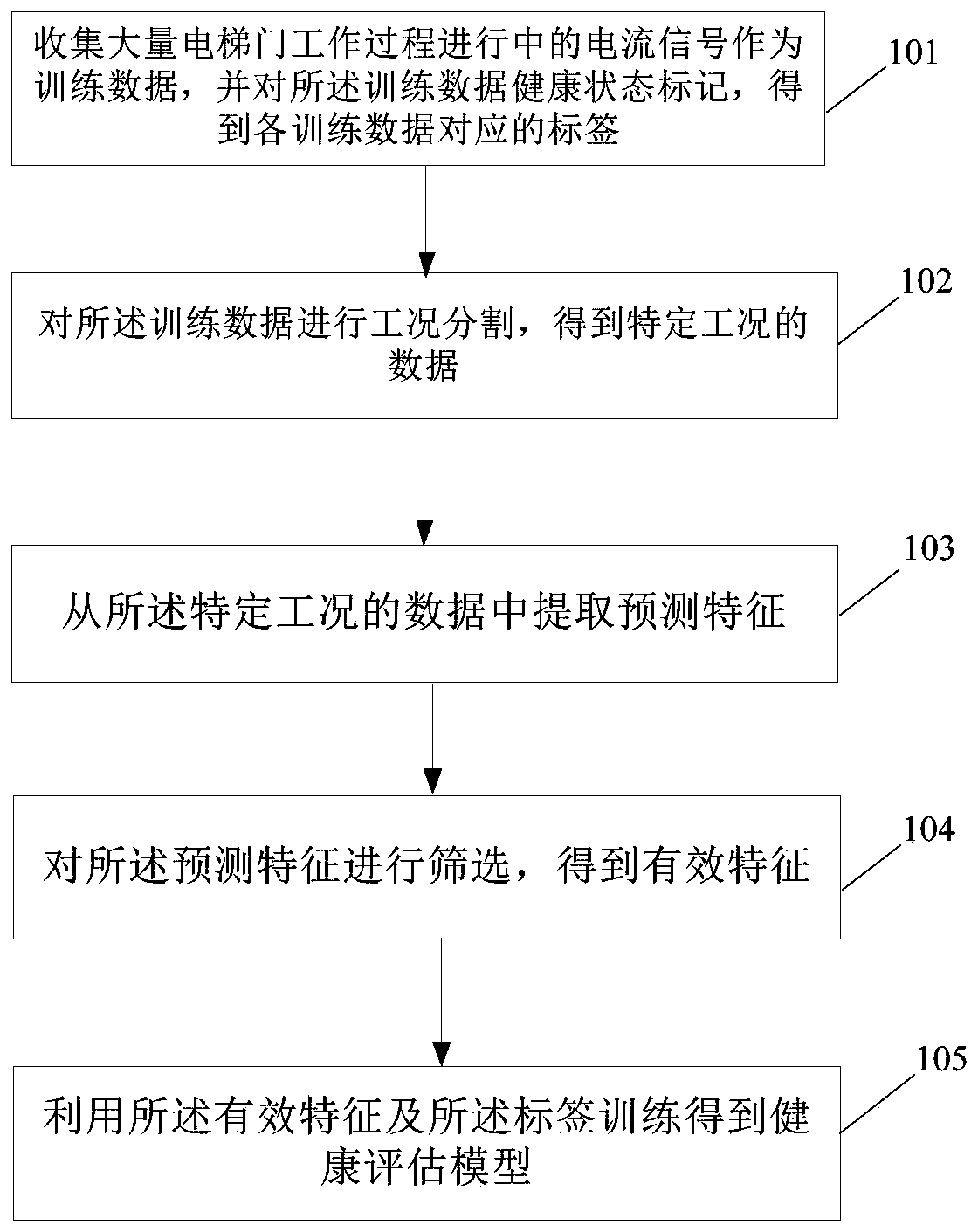

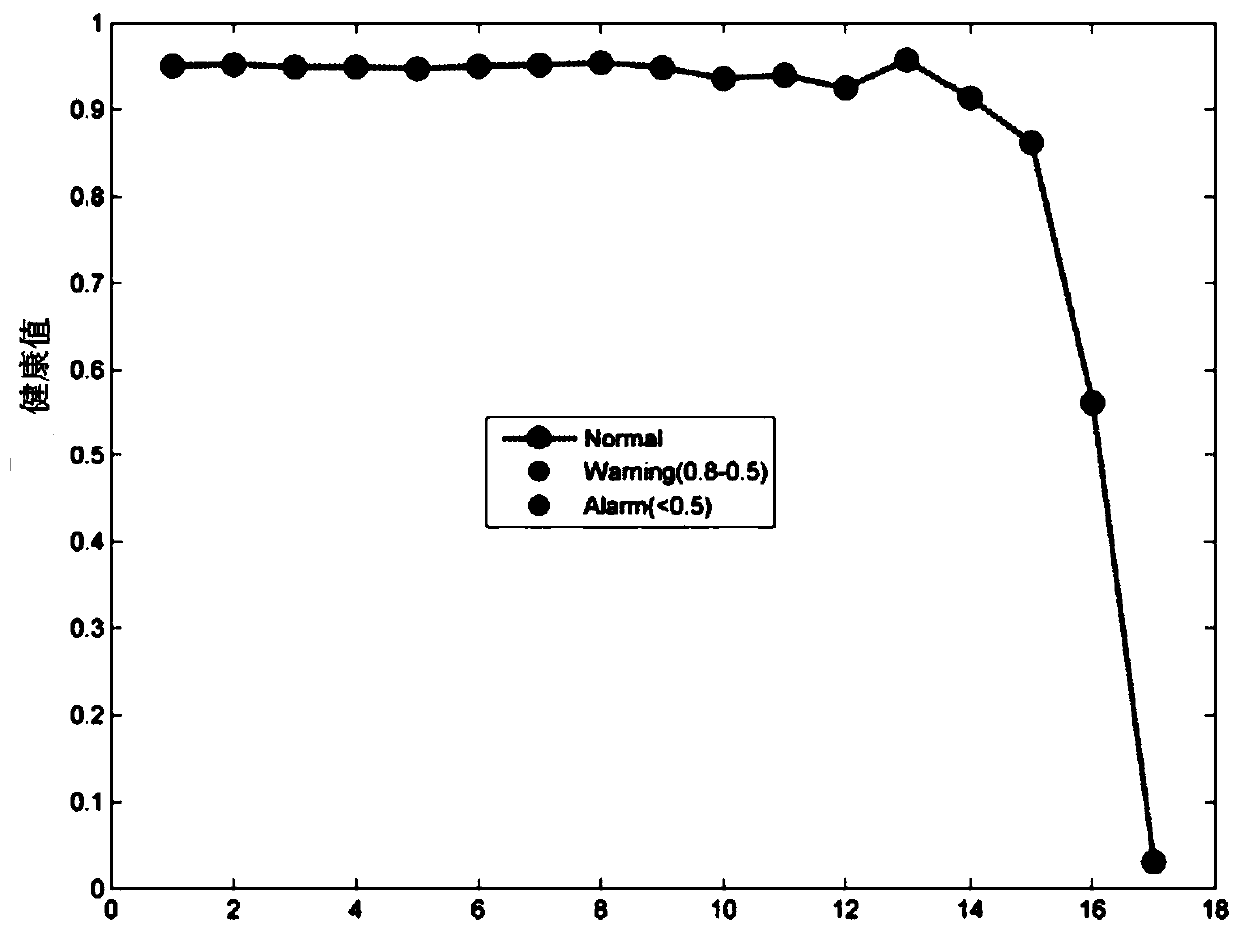

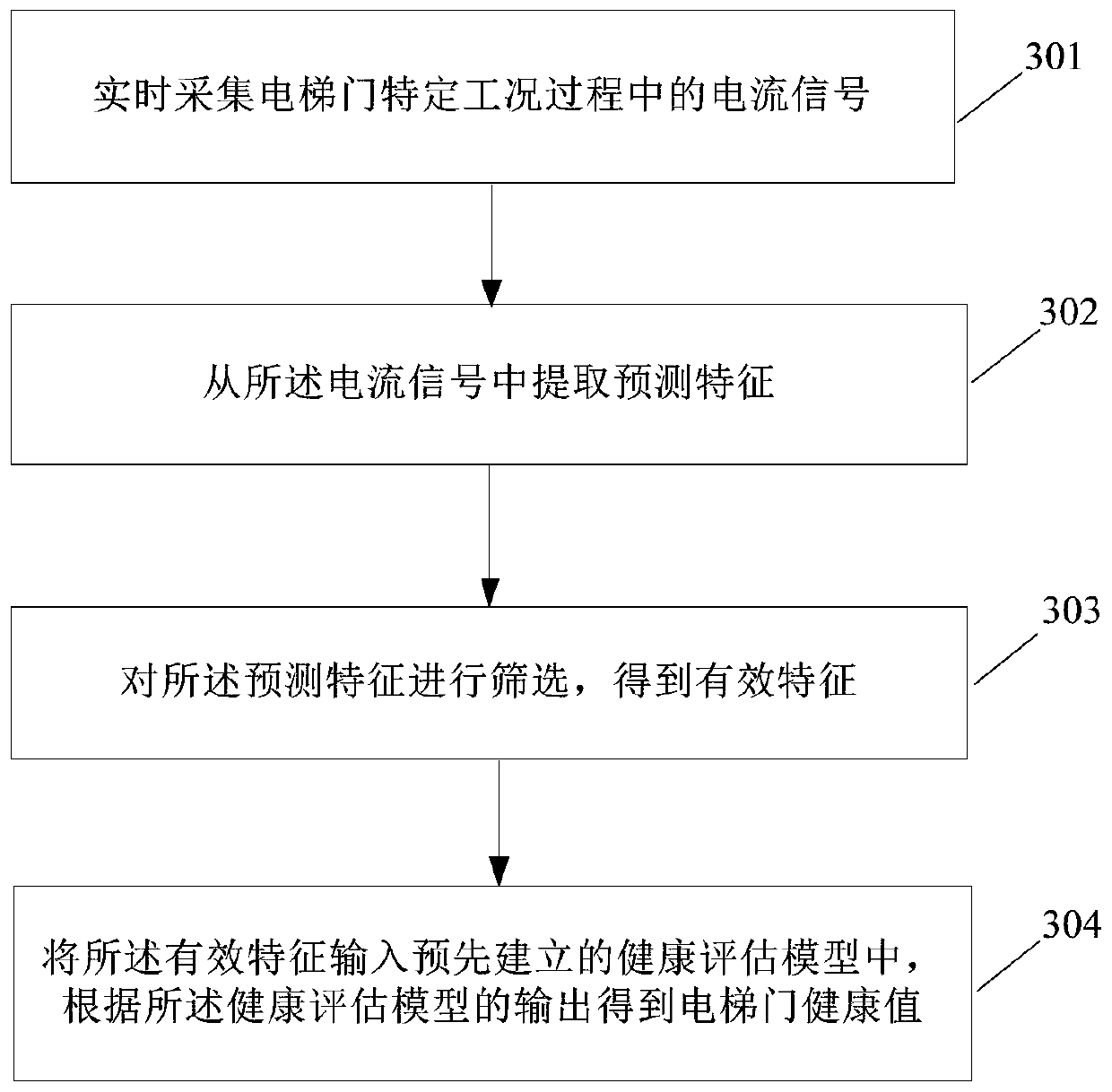

Method and device for maintaining health of elevator door system

ActiveCN111186741AAchieve initiativeRealize online monitoringElevatorsComputer scienceReliability engineering

The invention discloses a method and device for maintaining health of an elevator door system. The method comprises the following steps: collecting current signals in the working process of an elevator door in real time; extracting prediction features from the current signals; screening the prediction features to obtain effective features; and inputting the effective features into a pre-established health evaluation model, and obtaining a health value of the elevator door according to the output of the health evaluation model. According to the method and the device, accidental fault shutdown of the elevator door can be reduced, and the running safety of an elevator is guaranteed.

Owner:CYBERINSIGHT TECH CO LTD

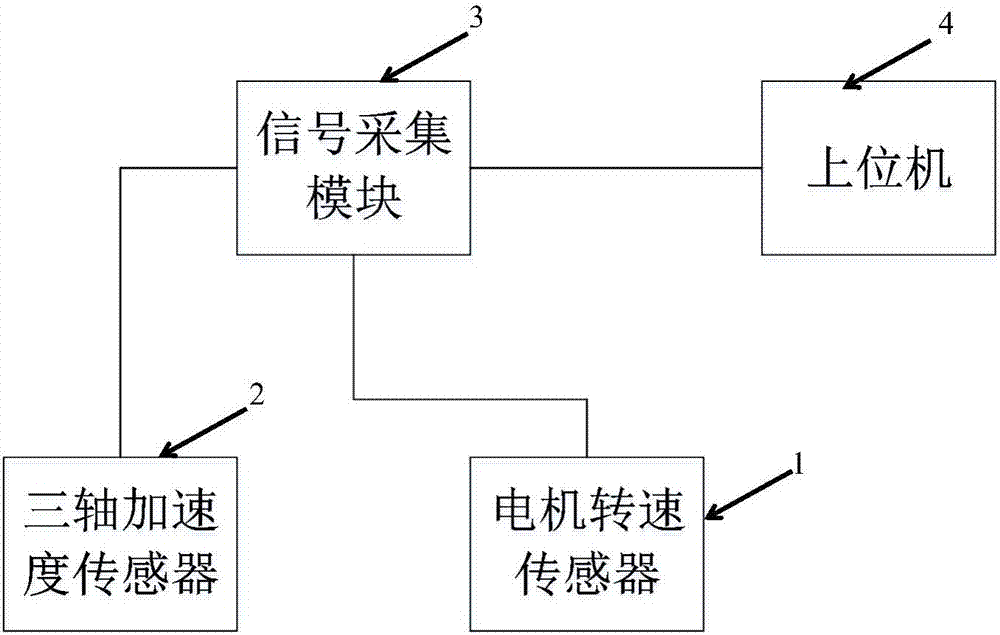

Ship propulsion motor online vibration monitoring system

InactiveCN107340052AImprove securityImprove economySubsonic/sonic/ultrasonic wave measurementDynamo-electric machine testingFault coverageVibration acceleration

The invention discloses a ship propulsion motor online vibration monitoring system. The ship propulsion motor online vibration monitoring system is characterized by comprising a motor rotation speed sensor, a three-shaft acceleration sensor, a signal collection module and an upper computer; the motor rotation speed sensor is installed on an end cover of the motor for detecting the rotation speed of the motor in real time; the three-shaft acceleration sensor is directly installed on a motor seat of the motor for detecting vibration accelerated speeds in an axial direction (X), a radial direction (Y) and a vertical direction (Y) and converting a vibration accelerated signal to an accelerated speed electric signal; the signal collection module is connected to a motor rotation speed sensor and a three-shaft acceleration sensor and is used for collecting and transmitting the rotation speed electric signal and the accelerated speed electric signal; a database is installed on the upper computer and the upper computer is used for comparing the rotation speed electric signal and the accelerated speed electric signal with information in the database through operation after receiving the rotation speed electric signal and the accelerated speed electric signal, and diagnosing that whether the motor is currently in a fault coverage.

Owner:CNR SHIP & MARINE ENG DEV CO LTD

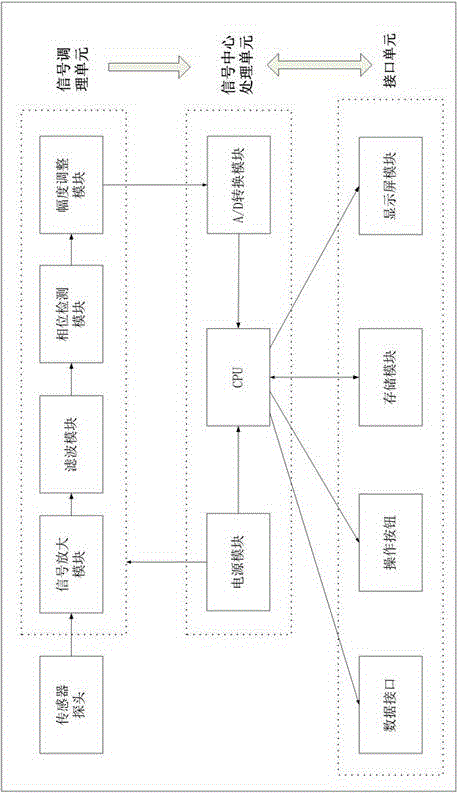

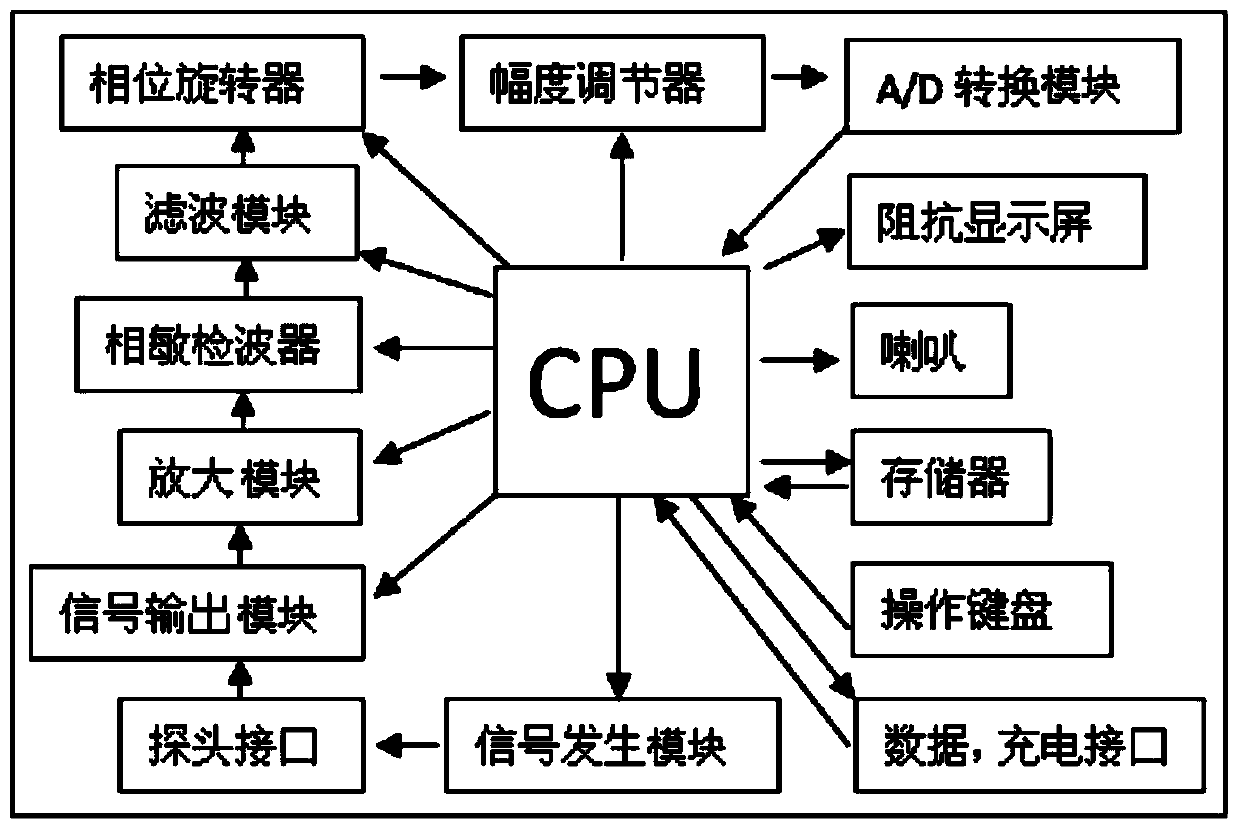

Vibration signal detection and fault diagnosis system in shield tunneling process

InactiveCN104457973AAccurate removalFast detection responseSubsonic/sonic/ultrasonic wave measurementSignal conditioningShield tunneling

The invention discloses a vibration signal detection and fault diagnosis system in the shield tunneling process. The vibration signal detection and fault diagnosis system comprises a signal processing center host module which comprises a power module, a CPU module unit connected with the power module, an A / D conversion module, a probe interface module, a display screen module, a signal conditioning unit module, an operating keyboard, a storage module and a power interface module, wherein A / D conversion module, the probe interface module, the display screen module and the signal conditioning unit module are connected with the CPU module unit, and the operating keyboard, the storage module and the power interface module are connected. Clutter signals in the underground tunneling process of a shield can be effectively removed, shield vibration signals which are truer and cleaner can be collected and analyzed, the vibration state of shield tunneling can be reflected truly, and therefore fault signals can be analyzed and evaluated. The system is fast in detection response, good in ration, low in cost, convenient to operate, capable of carrying out early warning and detecting on faults in the underground tunneling process of a shield assembly, reduces unplanned shut-down caused by the faults, reduces economic loss, and has great economic benefits and social benefits.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

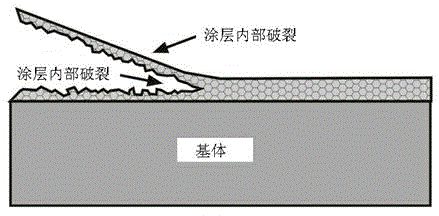

Preparation process for composite wear-resistant coating

InactiveCN104549948AFlexible designLow costPretreated surfacesCoatingsMaterials scienceMacromolecule

The invention discloses a preparation process for a composite wear-resistant coating which can be used for repairing and reconstructing all local defects, caused by conveying fluid materials, of associated metal parts. The preparation process comprises the following steps: by taking a processed metal surface as a base and taking a molded metal or nonmetal structure frame as an insert, painting a high polymer composite material layer on the scene to form an integer, wherein the high polymer composite material layer consists of three coatings with different properties, which are respectively a composite material bottom layer, a wear-resistant corrosion-resistant functional layer and a surface coating. The preparation process disclosed by the invention adopts a coating process, is not limited by a shape of a mould, is widely suitable for various complex mould surfaces and relatively low in total cost, and can be used for flexibly designing out composite wear-resistant coating structures of various shapes for different working conditions.

Owner:SHANGHAI HANLE ANTICORROSION ENG SERVICESCO

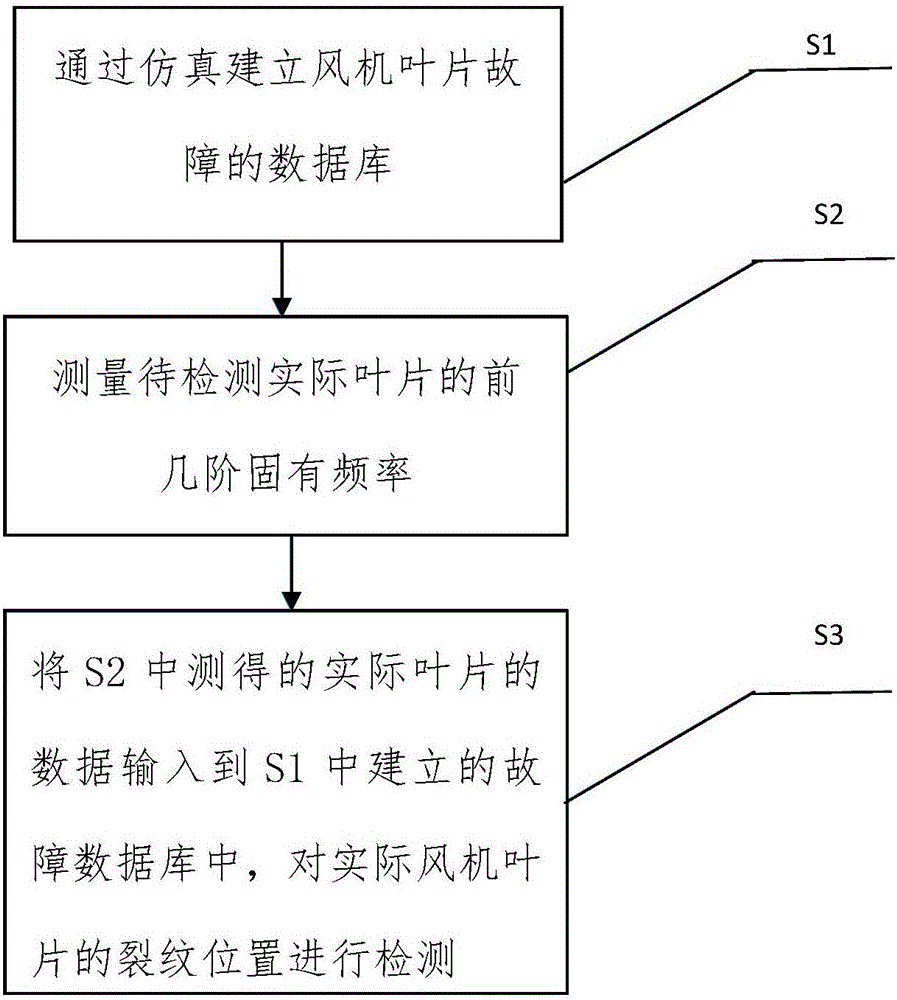

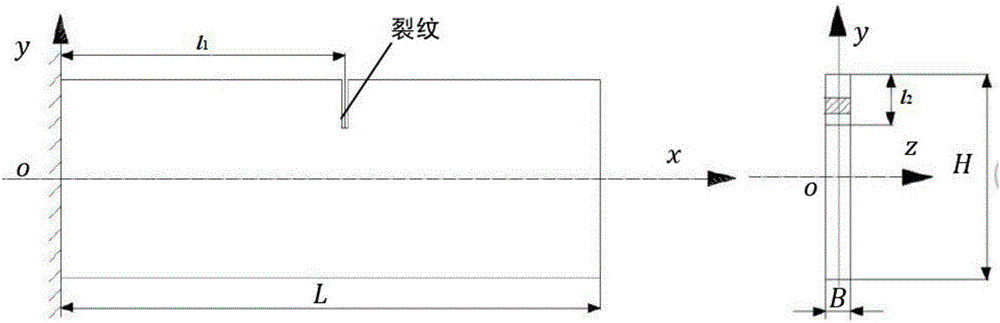

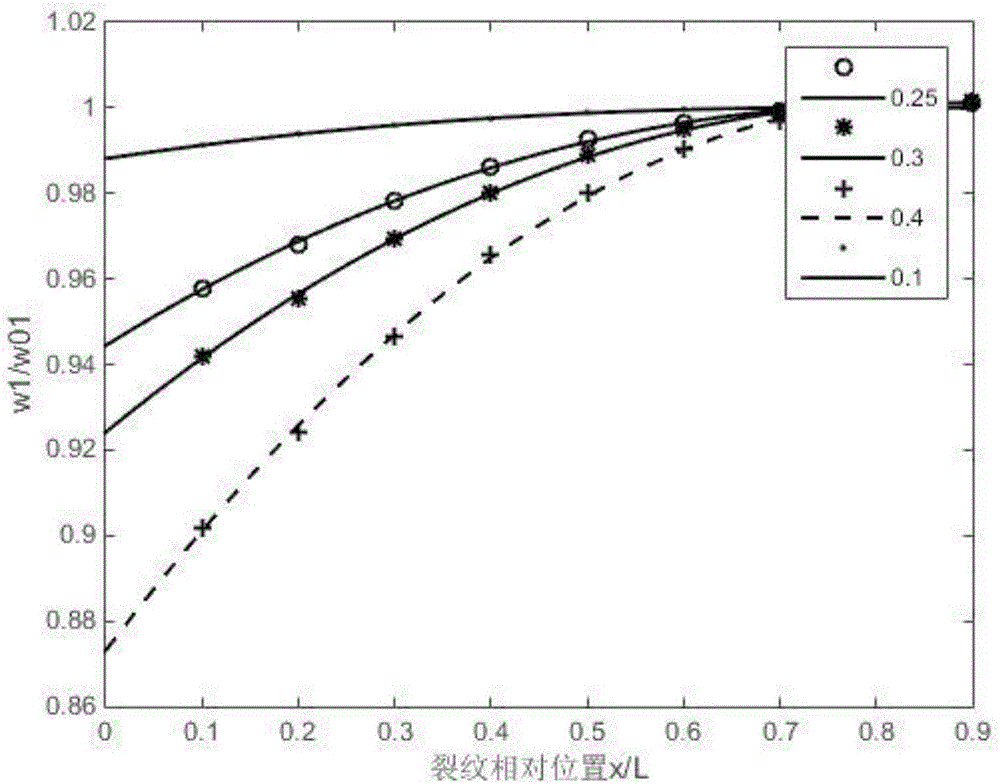

Method for determining position of crack of fan blade

InactiveCN106501369ATimely diagnosisRealize quantitative analysisAnalysing solids using sonic/ultrasonic/infrasonic wavesSimulationFan blade

The invention discloses a method for determining a position of a crack of a fan blade. The method comprises S1, establishing a database of fan blade failure by simulation, S2, measuring first few order natural frequencies of an actual blade to be detected, and S3, inputting the actual blade data measured in the step S2 into the fault database established in the step S1, and detecting the crack position of the actual fan blade. The method uses a simulation method to compute the position of the blade crack, not only realize timely diagnosis of the fan blade crack, but also realize quantitative analysis of the crack position of the fan blade, has a fast diagnosis speed, produces a reliable result and provides a strong guarantee for the equipment maintenance.

Owner:BEIJING UNIV OF TECH

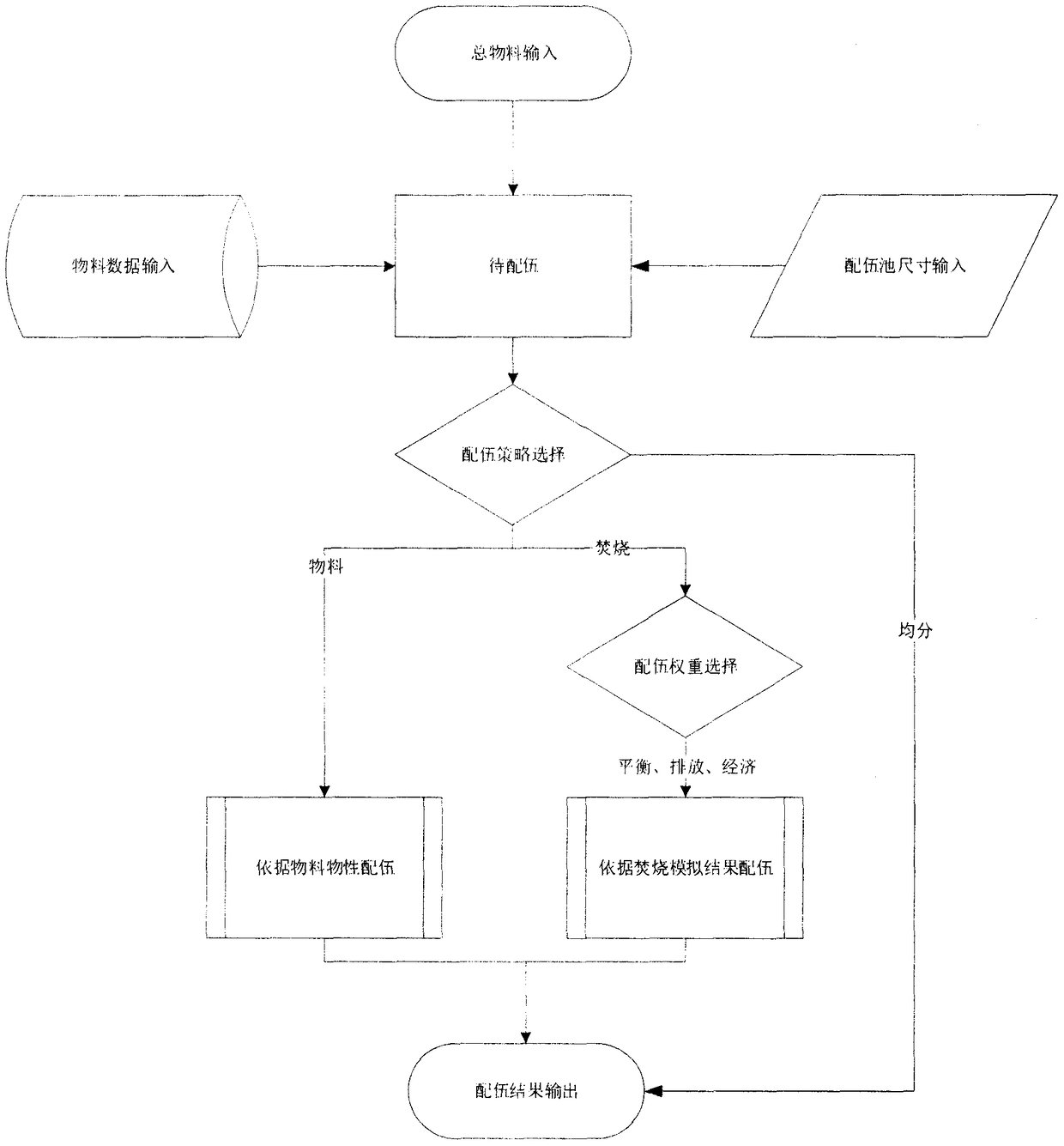

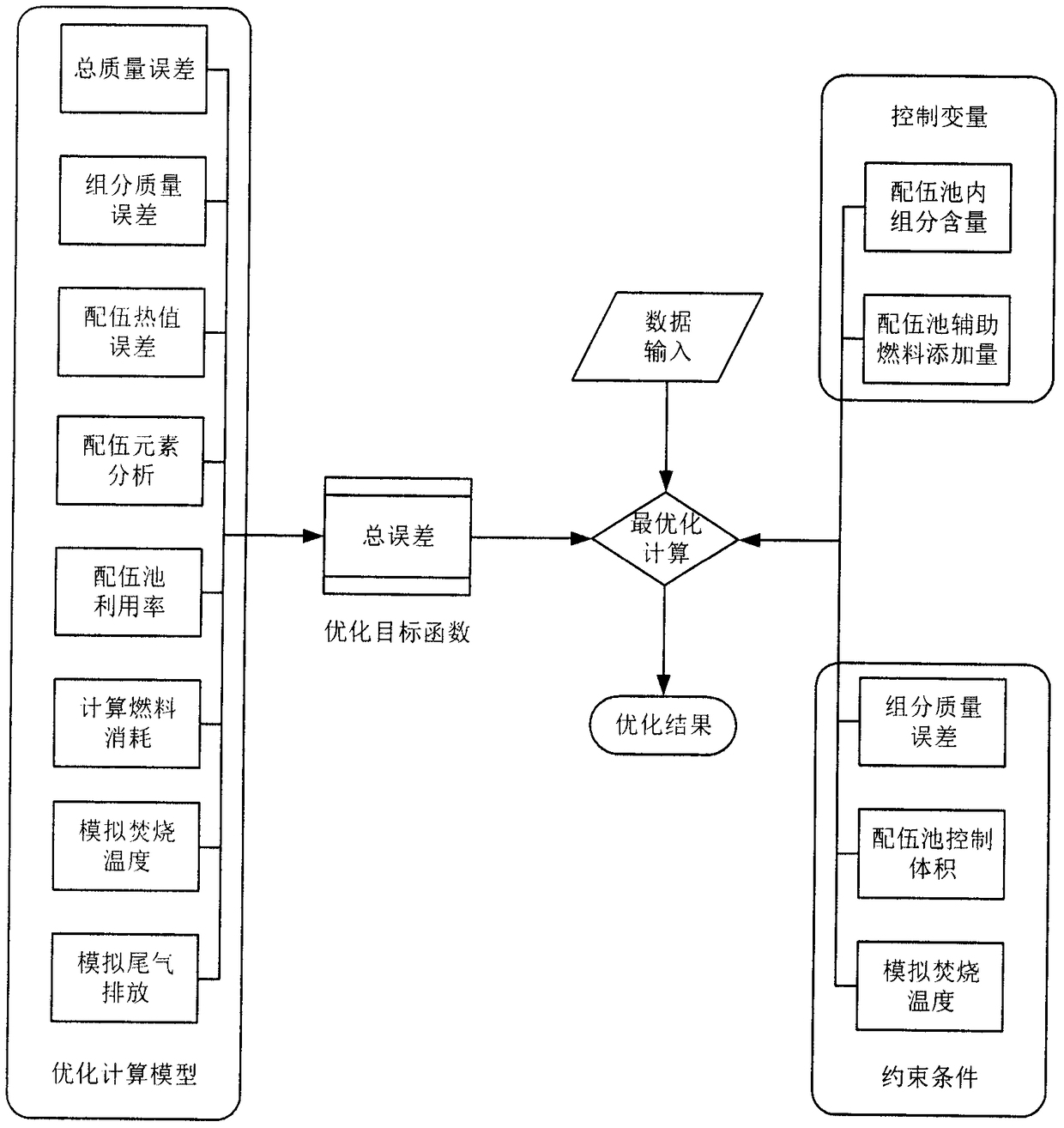

A hazardous waste incineration compatibility system based on off-line operation optimization

PendingCN109359387ACompatibility is simpleEffective compatibilityDesign optimisation/simulationSpecial data processing applicationsEconomic benefitsUser Friendly

The invention relates to a hazardous waste incineration compatibility system based on off-line operation optimization, including a hazardous waste databases, a module to be compatible, a compatibilitystrategy selection module and a compatibility module; by using the mixed integer nonlinear optimization method, the optimal compatibility scheme is calculated under the given limited conditions, Theresulting compatibility scheme can be exported as a user-friendly document for practical reference, The system can assist operators to quickly and simply carry out effective compatibility of various materials, thereby improving equipment operation efficiency, reducing temperature fluctuation caused by improper feed compatibility and equipment unplanned shutdown, and effectively improving the economic benefits of hazardous waste incineration.

Owner:TIANJIN UNIV OF SCI & TECH

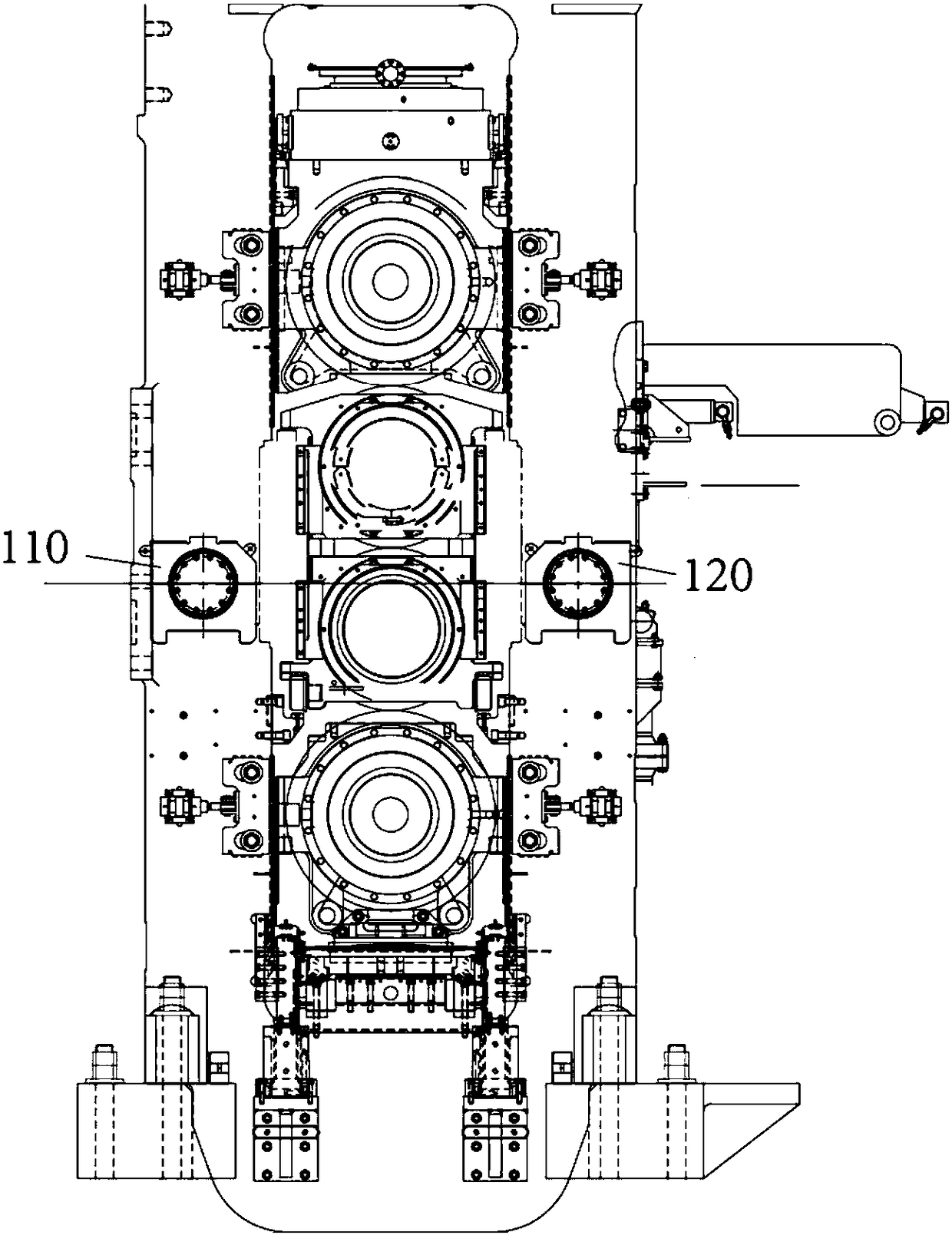

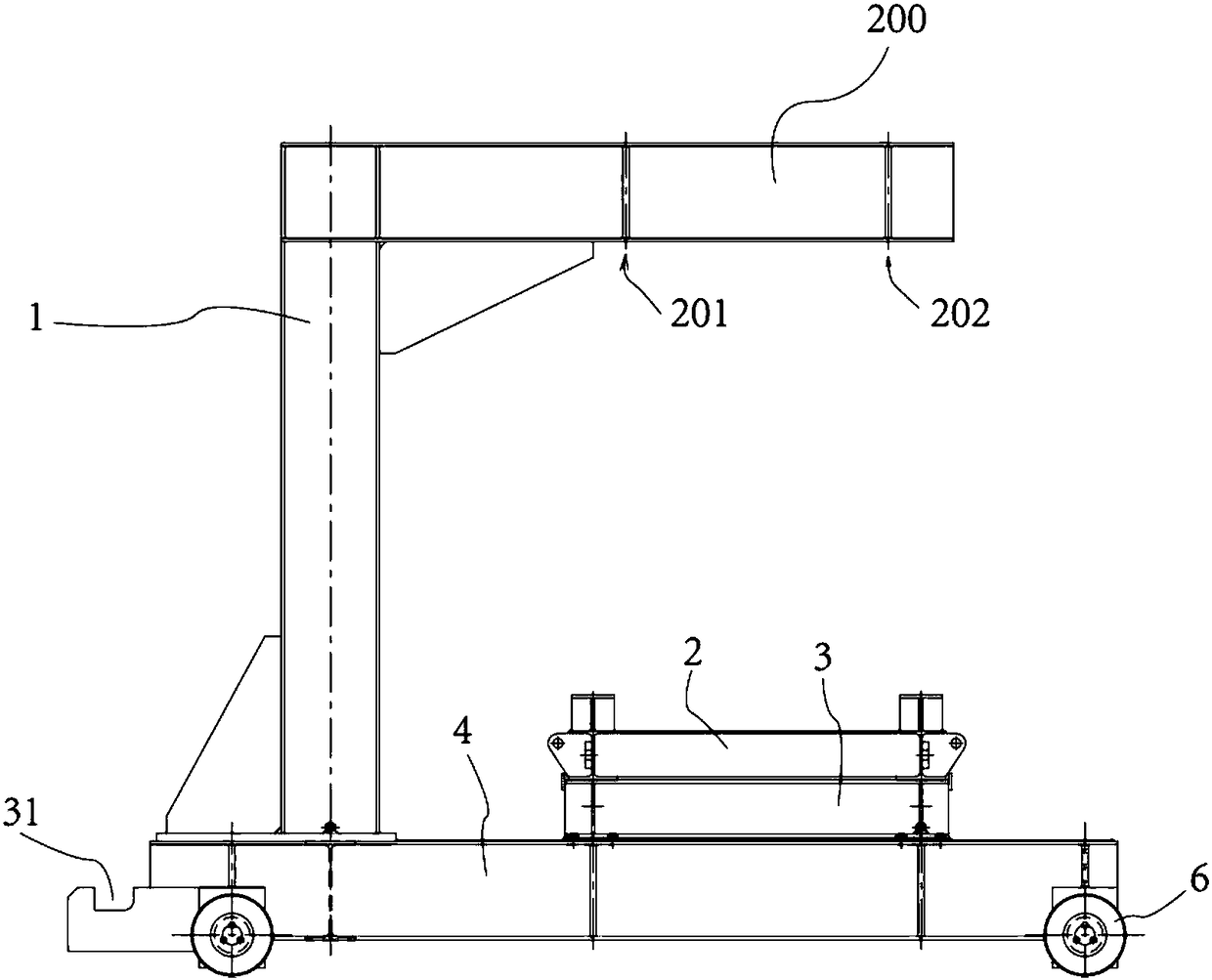

Rolling mill stand roller replacing device

ActiveCN108114988AEasy to installAvoid failureMetal rolling stand detailsPortable liftingJoistEngineering

The invention provides a rolling mill stand roller replacing device. The device comprises a crane capable of going into and out of a rolling mill, and the traveling track of the crane is parallel to aroller shaft of a stand roller to be replaced; a supporting beam is arranged on a base of the crane, and is provided with a sliding rail which allows a supporting frame to horizontally slide along the sliding rail, the sliding rail is perpendicular to the traveling track of the crane, and a suspension beam is arranged at the top of the crane; and the device further comprises the supporting framewhich can be placed in the rolling mill and is supported by the supporting beam of the crane entering the rolling mill, lifting lugs or hanging holes are formed in the peripheral ends of the supporting frame; and a supporting rotating shaft with changeable rotating positions is arranged at the position, opposite to the supporting frame, of the supporting beam, and an avoiding space capable of preventing interference with guide and guard plates in the rolling mill is formed in a frame body of the supporting frame.

Owner:BAOSHAN IRON & STEEL CO LTD

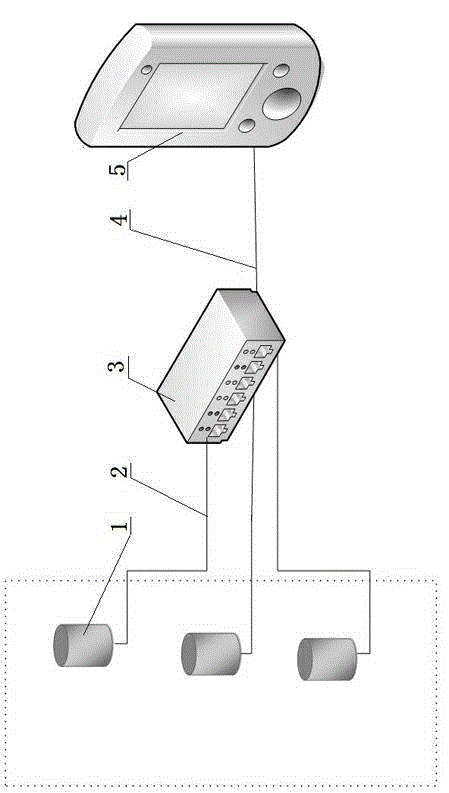

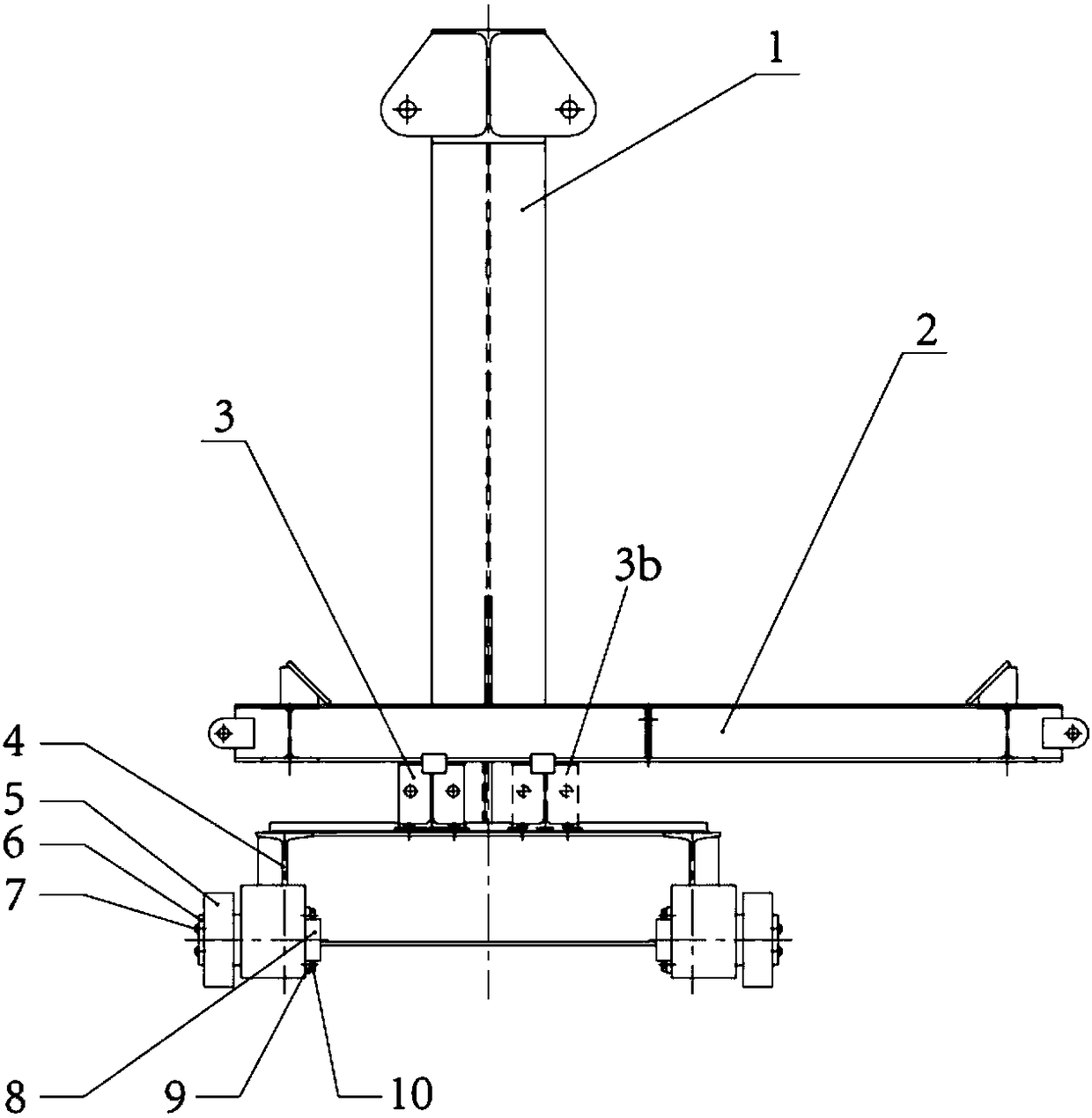

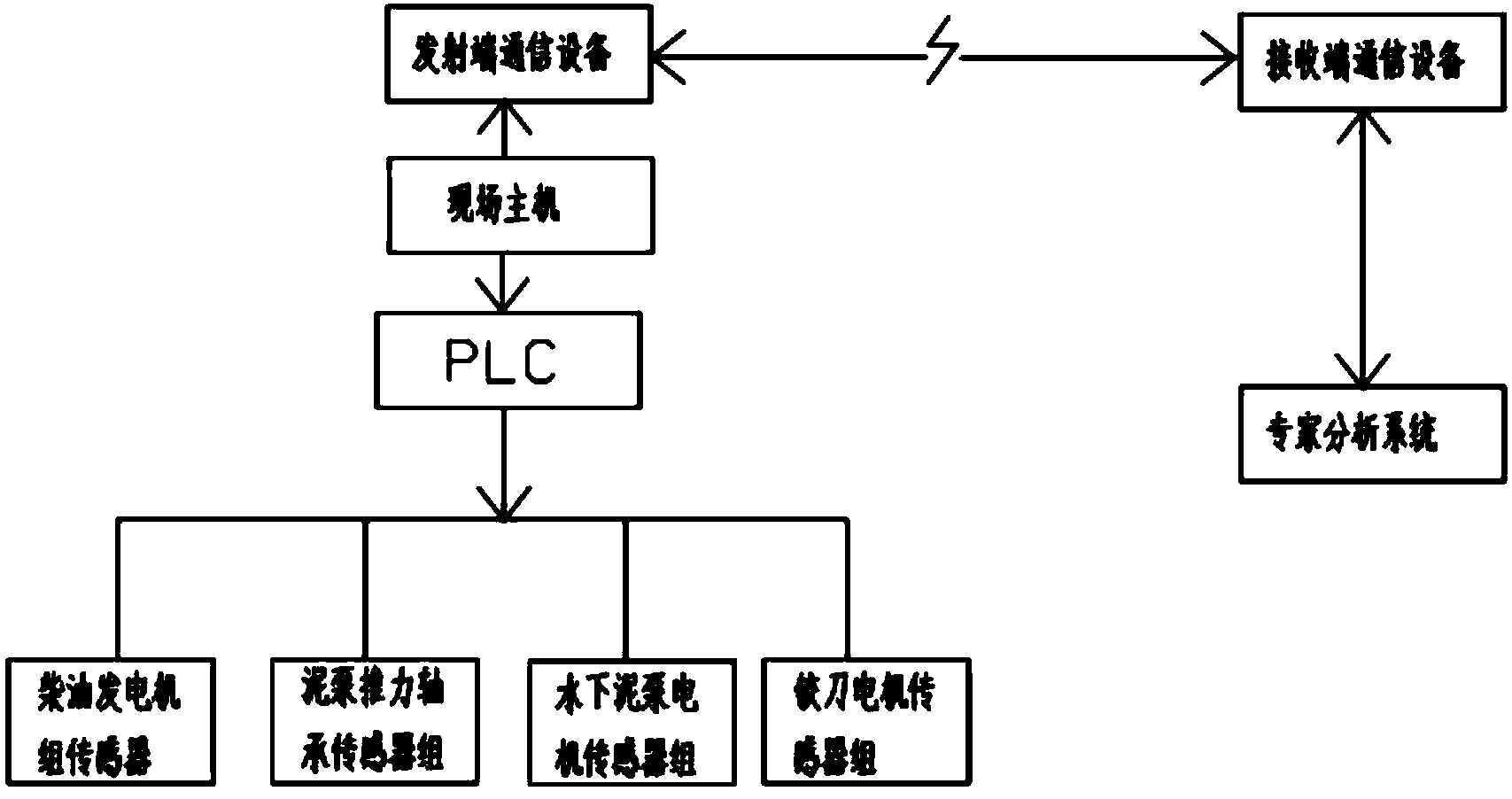

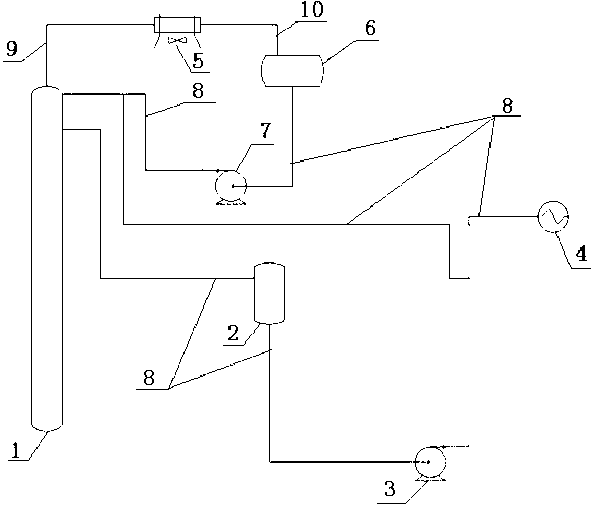

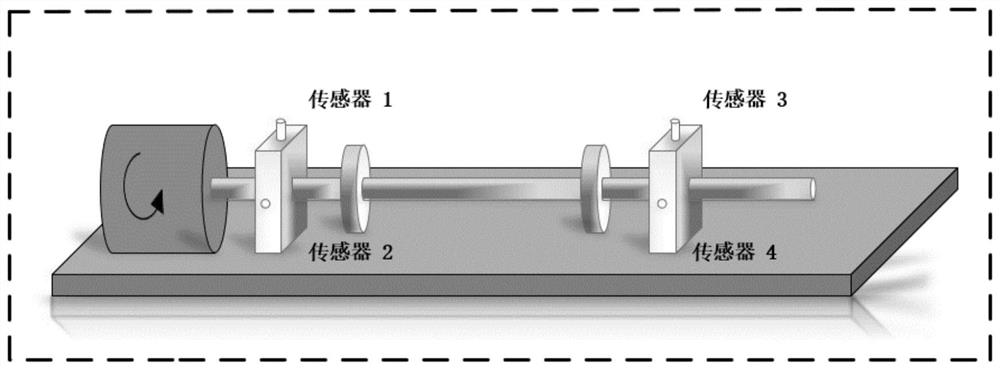

Ship mechanical fault remote detecting device and method

InactiveCN103728948AGuaranteed to workShorten the timeProgramme total factory controlFrequency spectrumProgrammable logic controller

The invention relates to a ship mechanical fault remote detecting device and method. The device comprises multiple sensor sets mounted on a ship, a PLC connected with all the sensor sets and a site host computer. The site host computer sends out information through communication devices of a transmitting terminal, and communication devices of a receiving terminal receive the information and send the information to a base station host computer. The method comprises the steps of collection of sensor set information, analog-digital conversion, packaging sending and receiving, storage and display of the sensor set information, comparative analysis in a specialist analysis system of the base station host computer, establishment and providing of alarm modes and alarm values, fault character frequency labeling, providing of spectrum characteristic conclusions and feedback of analysis conclusions. According to the ship mechanical fault remote detecting device and method, the specialist analysis system of a base station is extended to the site of the ship, the fault points of equipment can be searched and controlled remotely on line, and normal work of a ship can be further guaranteed.

Owner:TIANJIN OCEAN DIGITAL TECH

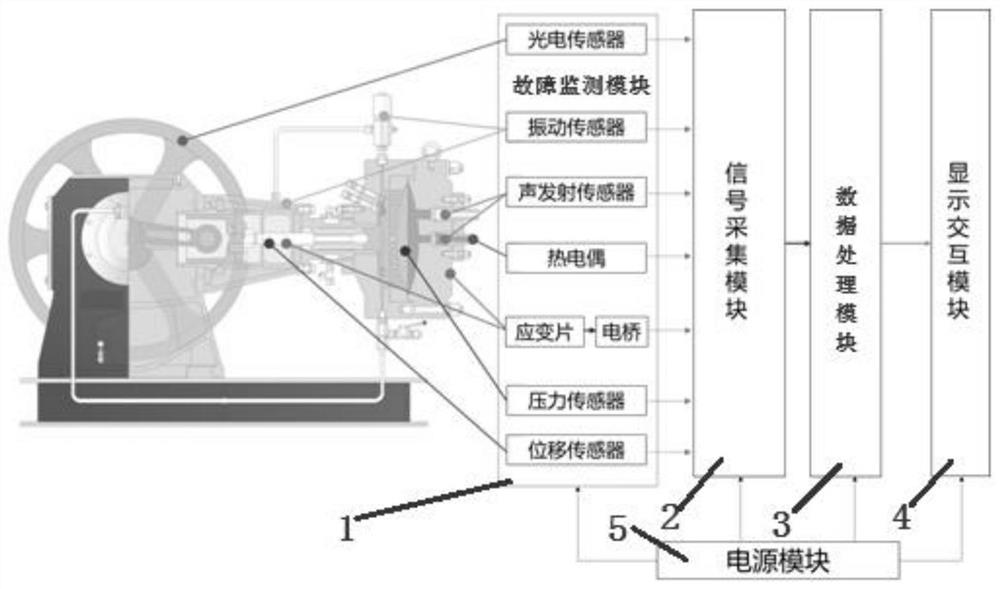

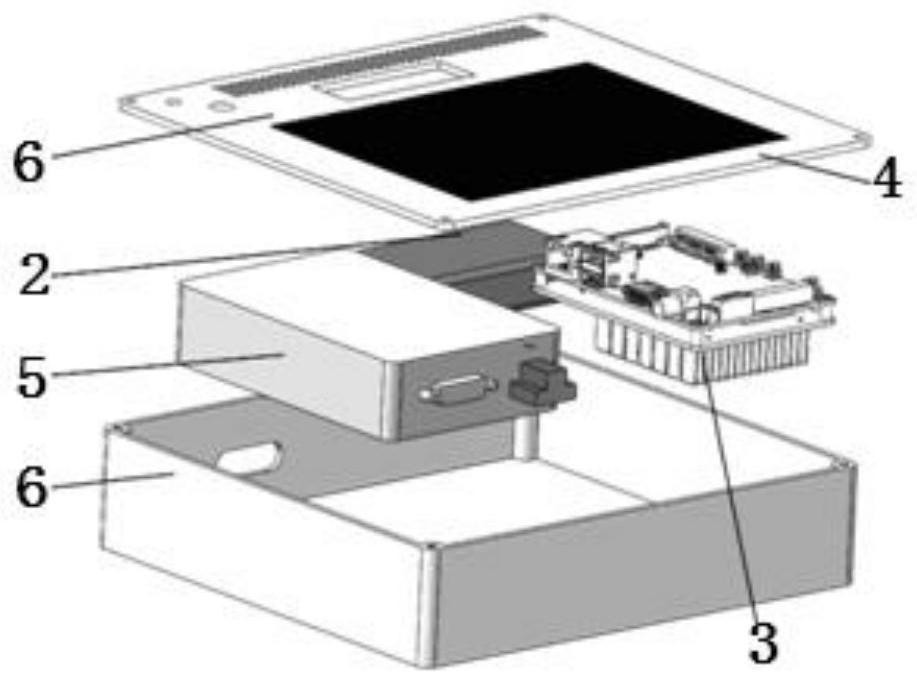

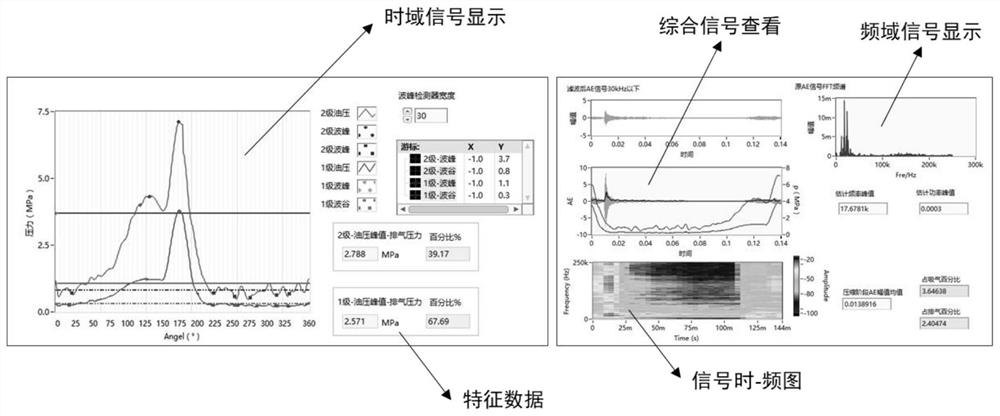

Fault diagnosis instrument for diaphragm compressor

ActiveCN111927752AImprove reliabilityImprove maintainabilityPump testingMeasurement devicesControl engineeringDiaphragm compressor

The invention belongs to the technical field of compressors, and particularly relates to a fault diagnosis instrument for a diaphragm compressor. An existing compressor fault monitoring device cannotcomprehensively monitor a diaphragm compressor and cannot timely obtain the operating parameters of the diaphragm compressor to perform health monitoring and fault diagnosis on the diaphragm compressor. The fault diagnosis instrument for the diaphragm compressor comprises a fault monitoring module, a signal acquisition module, a data processing module, a display interaction module and a power supply module which are sequentially connected. The fault monitoring module is connected with the power supply module, the signal acquisition module is connected with the power supply module, the data processing module is connected with the power supply module, and the display interaction module is connected with the power supply module. Operation state monitoring and fault diagnosis of the diaphragmcompressor are achieved.

Owner:XI AN JIAOTONG UNIV +1

Arene device with improved structure, and arene technology

ActiveCN103240044AImprove efficiencyAvoid Downtime CostsHydrocarbon by isomerisationChemical/physical/physico-chemical processesChemical industryEngineering

The invention relates to the technical field of chemical industry, and specifically relates to an arene device with improved structure, and an arene technology. The device is provided with a tee joint between an isomerization charge pump outlet pipeline and an isomerization feeding / separation tank bottom heat exchange tube stream inlet, wherein the tee joint is connected with a reflux pump outlet pipeline through a pipeline. Tower reflux is realized by change of the device structure, meanwhile, the emergency repair time for the faulted pump is obtained, and the device can be in normal operation all the time without stopping; and surcharge and energy consumption caused by shut down are lowered, times of unscheduled shut down is reduced, energy consumption increased in the starting up and shutting down process is lowered, increase of downtime cost of enterprises is avoided, and sequentially, the enterprise revenue is increased.

Owner:DALIAN FUJIA DAHUA GASOLINEEUM CHEM

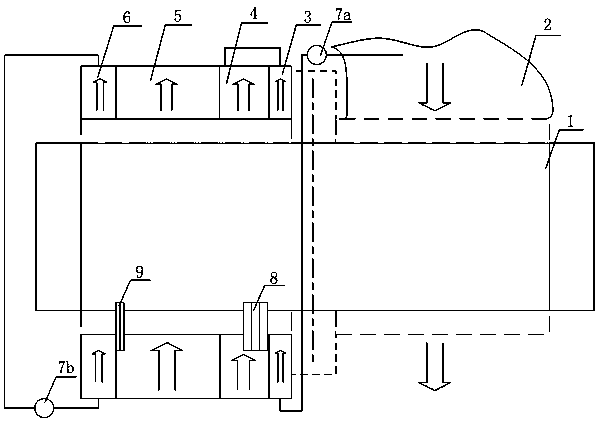

Ammonium bisulfate deposition prevention five-chamber rotary preheater and operation method thereof

PendingCN110118361ALow costRelieve blockageCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention belongs to the technical field of thermal power plant boiler auxiliary equipment and relates to an ammonium bisulfate deposition prevention five-chamber rotary preheater and an operationmethod thereof in order to solve the technical problem that an existing air preheater is blocked by ammonium bisulfate easily. The air preheater is internally provided with an air preheater rotor. Aheat exchange element is arranged on the air preheater rotor. The air preheater internally comprises an exhaust gas side and air sides. The air sides include the air side I, the air side II, the air side II and the air side IV. An inlet of the air side I is connected with an inlet of the exhaust gas side through a pipeline. A high-temperature fan I is arranged between the inlet of the air side I and the inlet of the exhaust gas side. An outlet of the air side IV is connected with an inlet of the air side IV through a pipeline. A high-temperature fan II is arranged between the outlet of the airside IV and the inlet of the air side IV. A steam soot blower is arranged at the cold end of the air side II. An acoustic soot blower is arranged at the cold end of the air side III. Under the full-load working condition, the phenomenon of blockage of the ammonium bisulfate deposition prevention five-chamber rotary preheater can be effectively relieved on line, and the frequency of non-planned shutdown of the air preheater can be reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

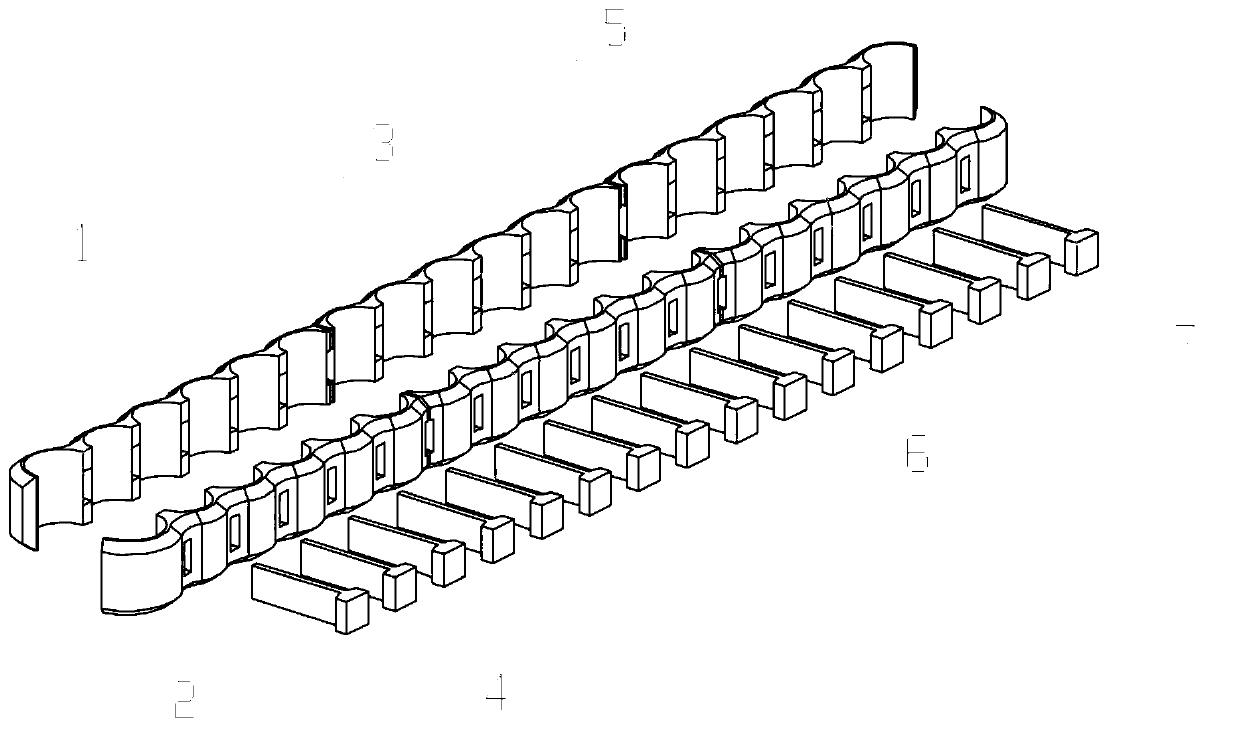

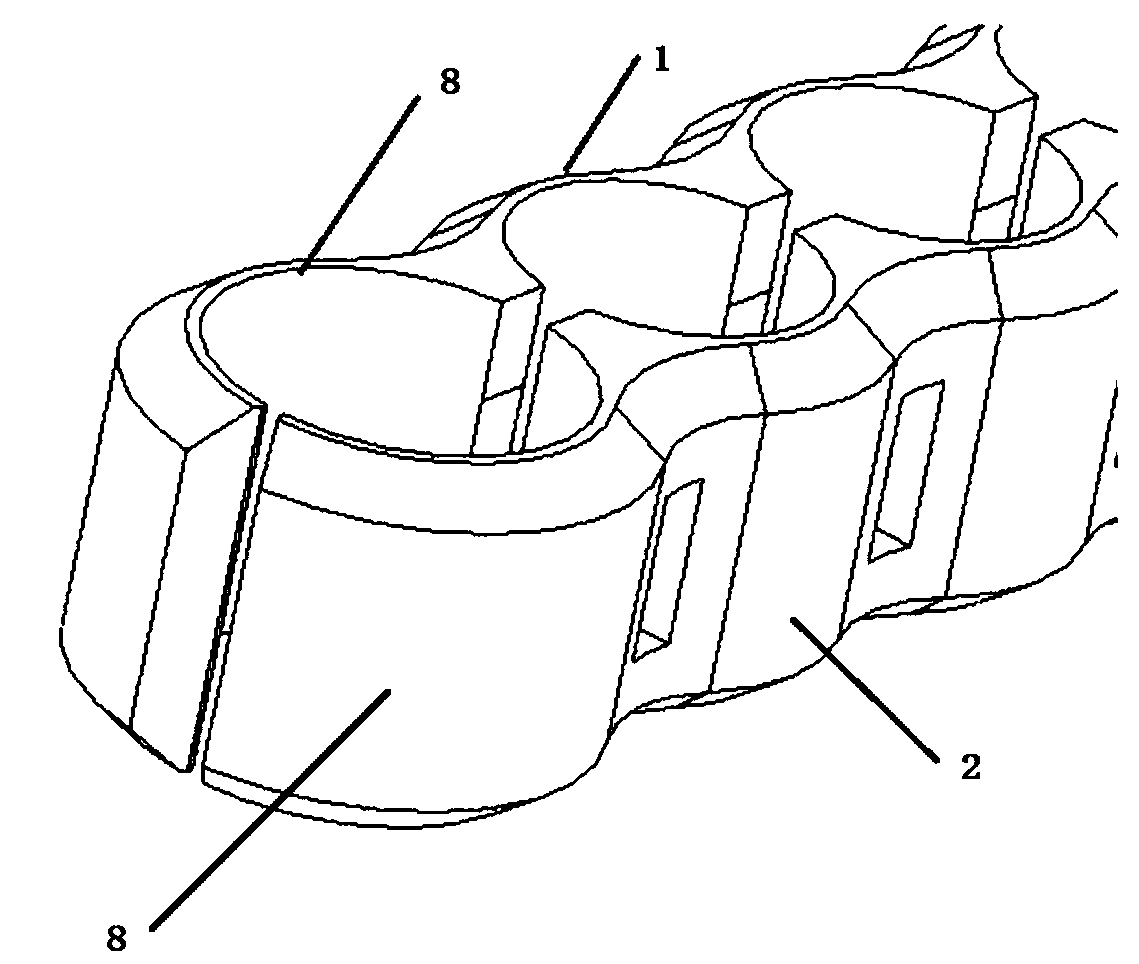

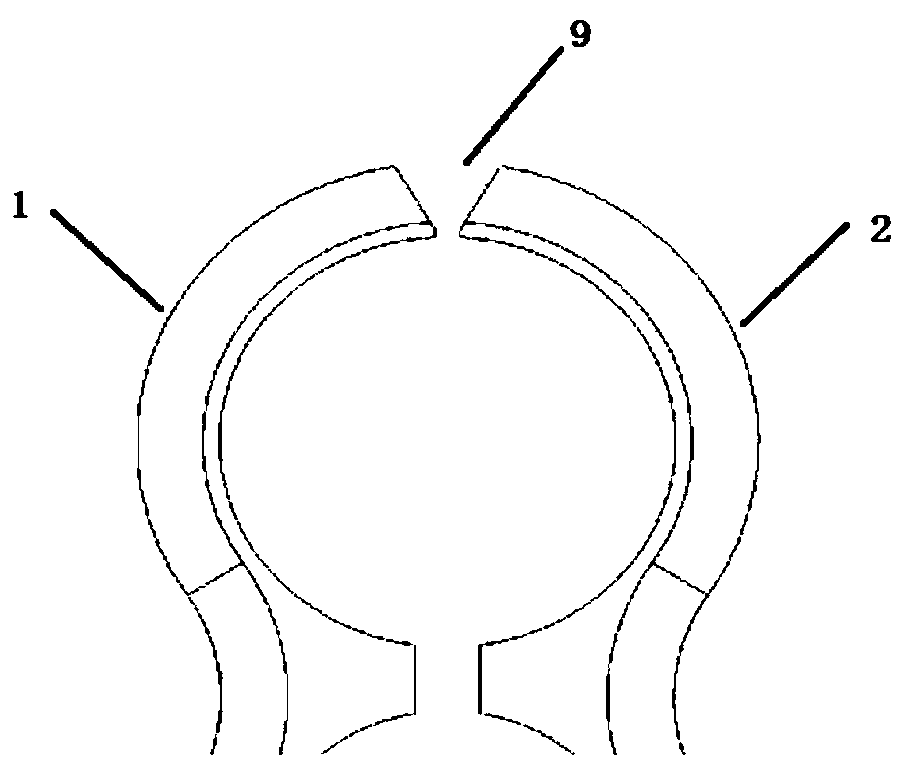

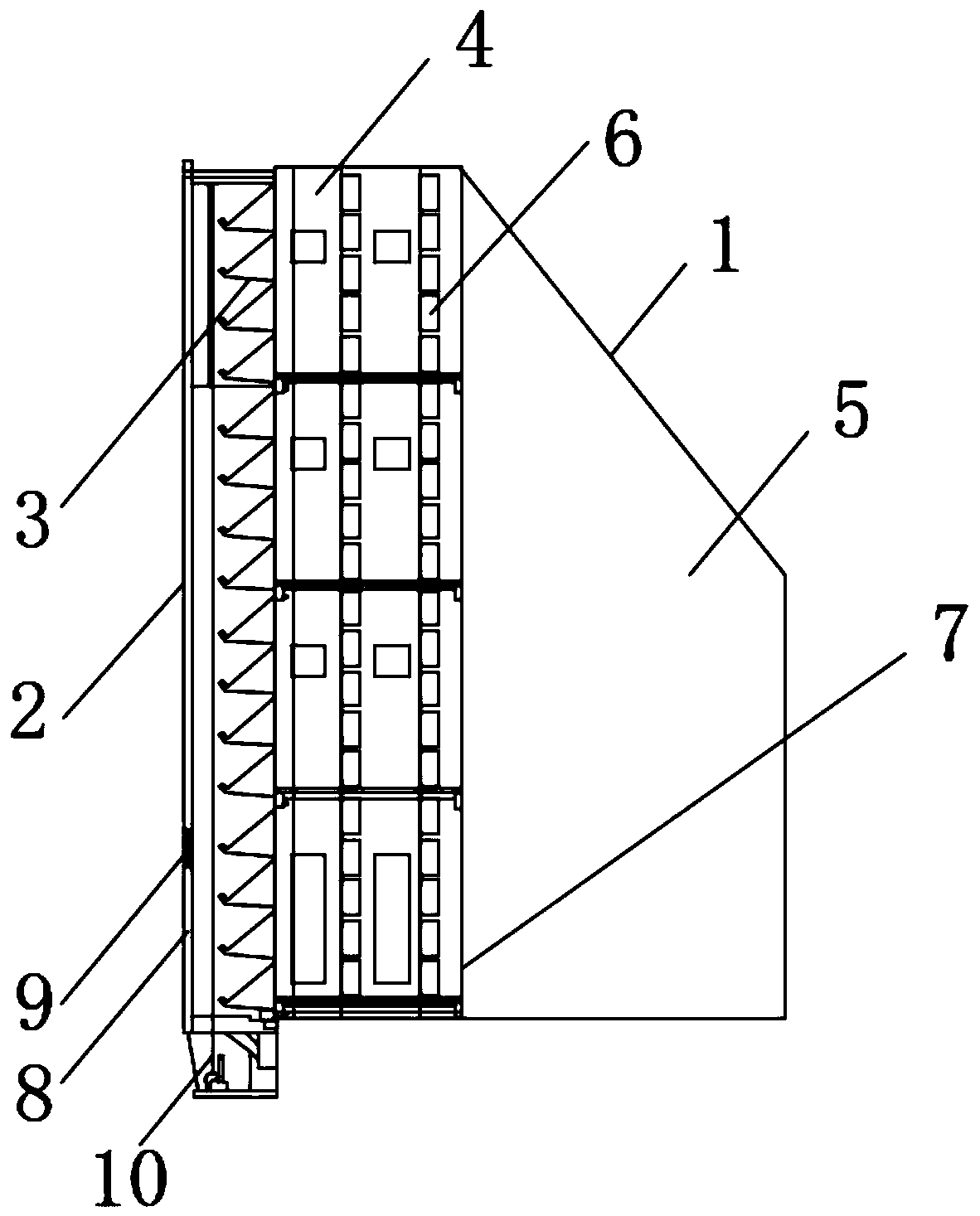

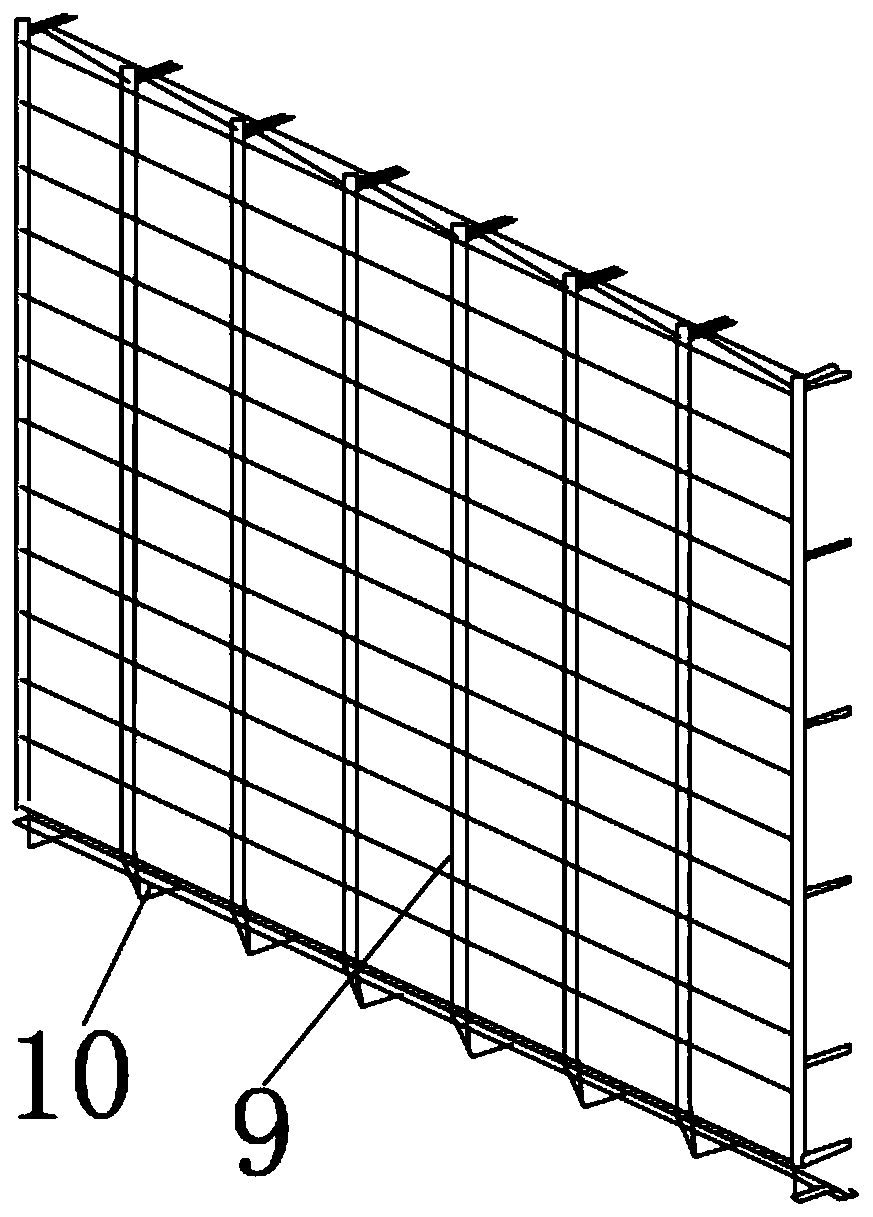

Boiler pipe bundle deformation preventing device and using method and application thereof

PendingCN110160031AReasonable structural designImprove applicabilityBoiler water tubesSteam boilersEngineeringMechanical engineering

The invention relates to a boiler pipe bundle deformation preventing device and a using method and application thereof. The boiler pipe bundle deformation preventing device comprises a left side clamping plate assembly and a right side clamping plate assembly which are parallel to each other. The left side clamping plate assembly comprises a left outer side clamping plate, a right outer side clamping plate and a left middle side clamping plate. The right side clamping plate assembly comprises a right middle side clamping plate, a left inner side clamping plate and a right inner side clamping plate. Centers of plate bodies of the left outer side clamping plate, the right outer side clamping plate, the left middle side clamping plate, the right middle side clamping plate, the left inner sideclamping plate and the right inner side clamping plate are provided with a plurality of arc portions correspondingly, wherein the arc portions are parallel and are used for storing pipe bundles. Thedevice further comprises a series-connection pin plate. The left side clamping plate assembly is fixedly connected with the right side clamping plate assembly through the series-connection pin plate.The boiler pipe bundle deformation preventing device has the advantages of being reasonable in structural design, stable and reliable in performance and the like, displacement of single pipes of the pipe bundles can be controlled effectively, and the situation that due to mutual friction between the pipe bundles, the pipe wall is thinned, pipe burst is generated, and safety operation of a boiler is influenced can be avoided.

Owner:哈尔滨驰远电力设备工程有限公司

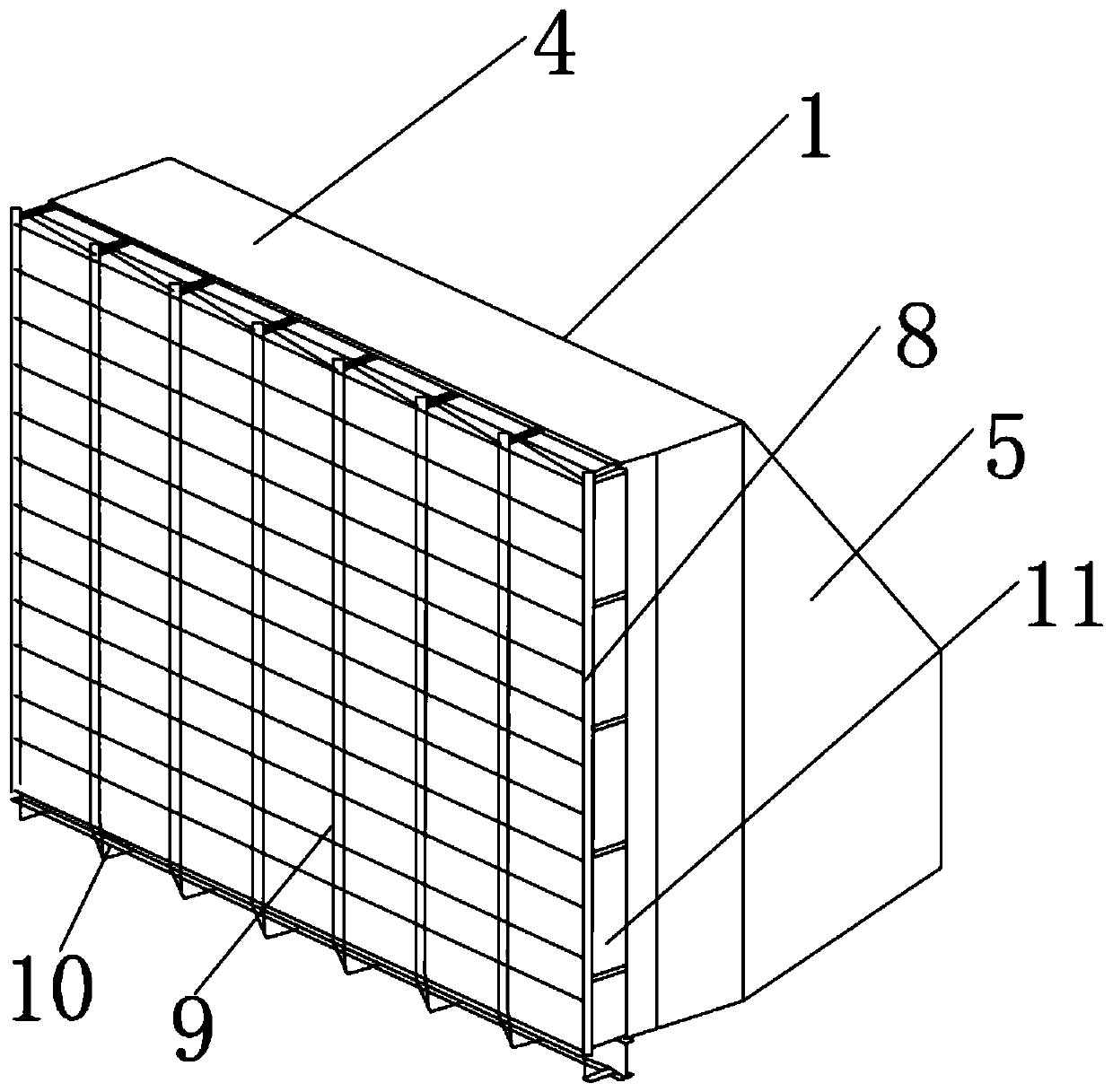

Rapid replacing system for air pre-filtering device

PendingCN109944702AQuick changeEasy to replaceDispersed particle filtrationPositive displacement pump componentsEngineeringGas turbines

The invention provides a rapid replacing system for an air pre-filtering device, and relates to the technical field of air inlet systems of gas turbines and industrial compressors. The rapid replacingsystem comprises a pre-filtering device, wherein a pre-filtering module is arranged on the surface of the pre-filtering device, a supporting component is embedded in the bottom of the side surface ofthe pre-filtering device, and a lifting mechanism is arranged at the bottom surface of the pre-filtering device. The pre-filtering element can be quickly replaced on line without stopping; the replacement is simple, the labor intensity is low, the operation environment is excellent, and no additional tool or fixture is needed; and the pre-filtering element shares the filtering burden of a downstream filter, prolongs the service life of the downstream filter with high purchase cost, reduces the frequency of unplanned stoppage, and improves the reliability and economical efficiency of machine operation.

Owner:南京国源电气有限公司

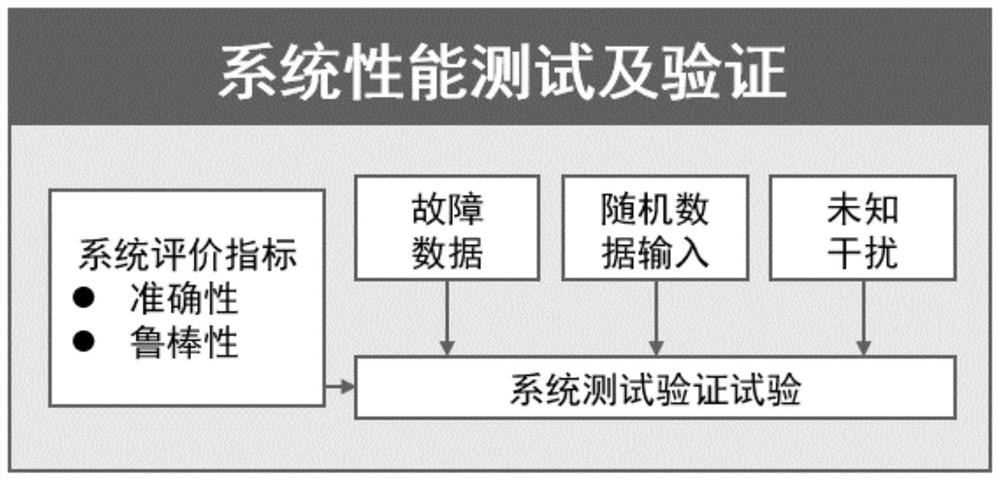

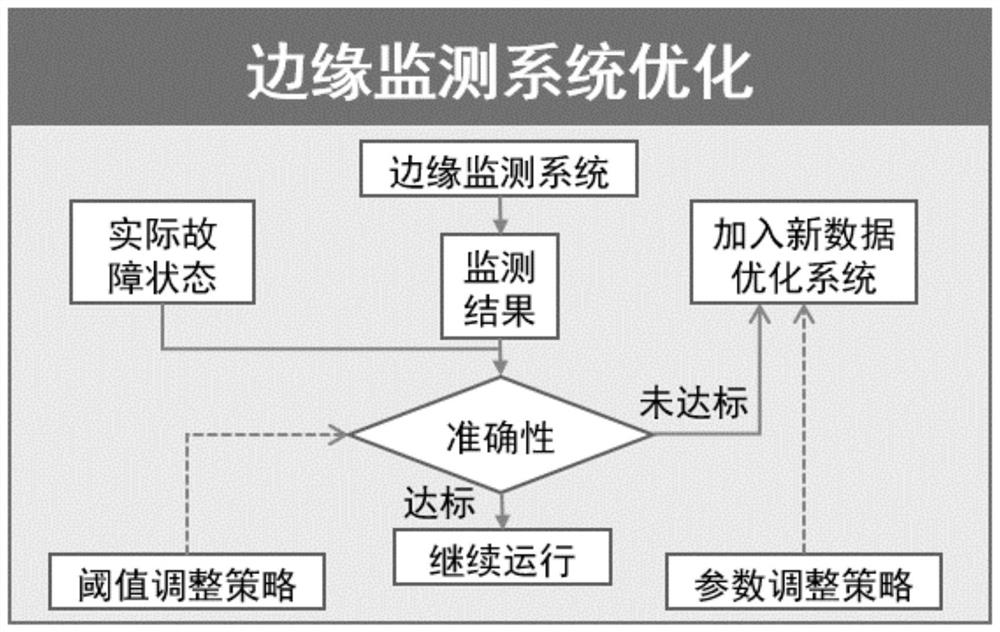

Bearing state monitoring and health management system performance test and optimization method and system

PendingCN114462820AAccurate performance descriptionOptimizing Edge Monitoring SystemsMachine bearings testingForecastingMonitoring systemComputer science

The invention discloses a bearing state monitoring and health management system performance test and optimization method and system, and the method specifically comprises the steps: firstly, giving an accuracy index and a robustness index of the bearing state monitoring and health management system performance as evaluation indexes; testing and verifying the performance of the bearing state monitoring and health management system based on the bearing fault data as input and the fault data added with the random interference data; in the edge monitoring system, the actual fault state of the bearing is compared with the monitoring result of the edge monitoring system, and if the accuracy reaches the standard, a threshold value adjusting strategy is used; if the accuracy does not reach the standard, adjusting the strategy by using parameters; in a remote cloud platform system, according to comparison between the actual health state of the bearing and the predicted health state of the model, a parameter adjustment strategy of the model is adopted if the actual health state and the predicted health state of the model are inconsistent, more accurate system performance description can be obtained, and meanwhile edge monitoring system optimization and cloud platform remote system optimization are carried out respectively by optimizing a feedback mechanism.

Owner:XI AN JIAOTONG UNIV

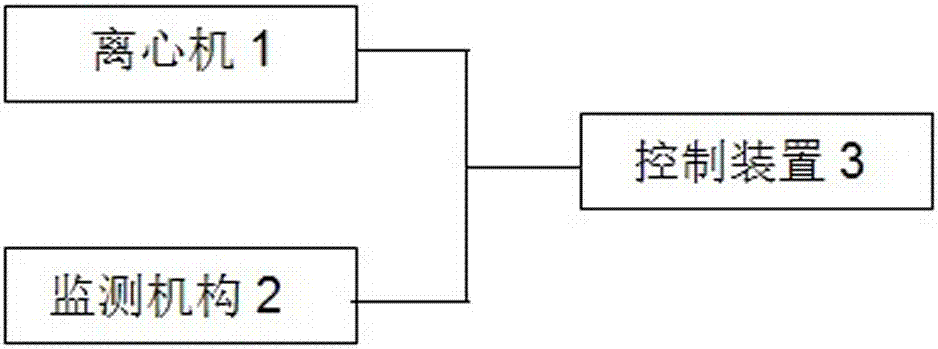

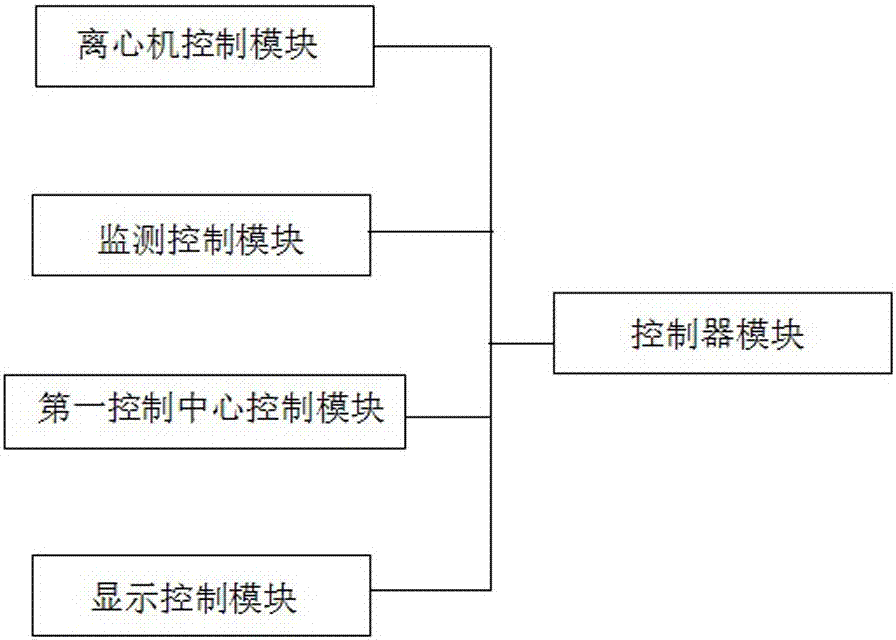

Intelligent centrifuge monitoring system

InactiveCN107350092AReal-time grasp of running statusSolve monitoring difficultiesCentrifugesComputer moduleMonitoring system

Disclosed is an intelligent centrifuge monitoring system. The intelligent centrifuge monitoring system comprises a centrifuge, a monitoring mechanism and a control device. A detection module and a conversion module are arranged in the monitoring mechanism, and are connected. The input end and the output end of the monitoring mechanism are connected with the centrifuge and the control device correspondingly. A first control center and a second control center are arranged in the control device, the monitoring mechanism is connected with the first control center, the first control center is connected with the second control center through the network, and the centrifuge, the monitoring mechanism and the first control center are connected with the second control center. According to the intelligent centrifuge monitoring system, due to the facts that the monitoring mechanism is arranged on the centrifuge and conducts monitoring on the operating condition and the operating environment of the centrifuge, and detection data are processed through the first control center and then are transmitted to the second control center through the network, a worker in a monitoring room can learn about the working state of the centrifuge at any time, the operating state of a facility is grasped in real time, and the situation that the facility can stably work is guaranteed.

Owner:南京新筛分科技实业有限公司

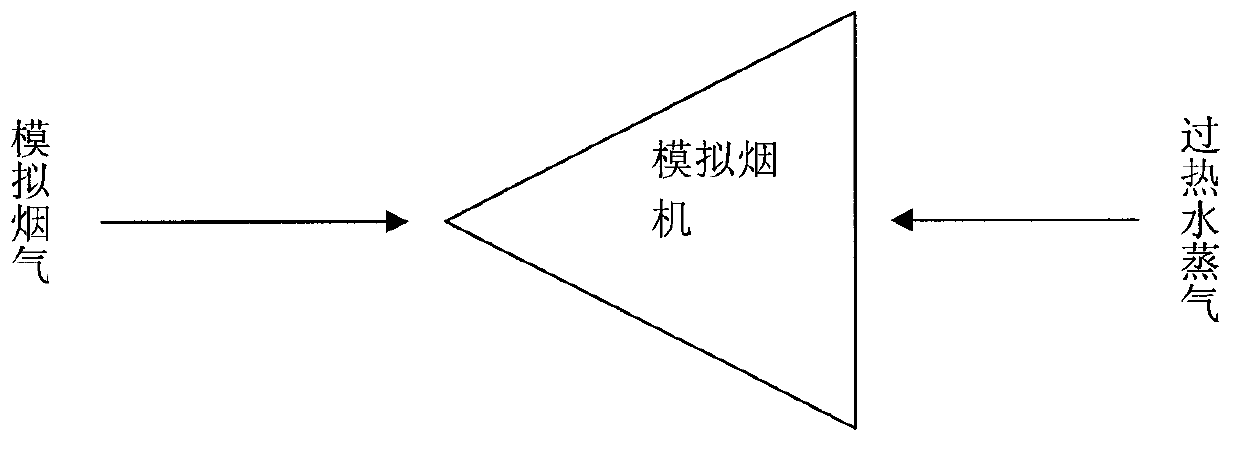

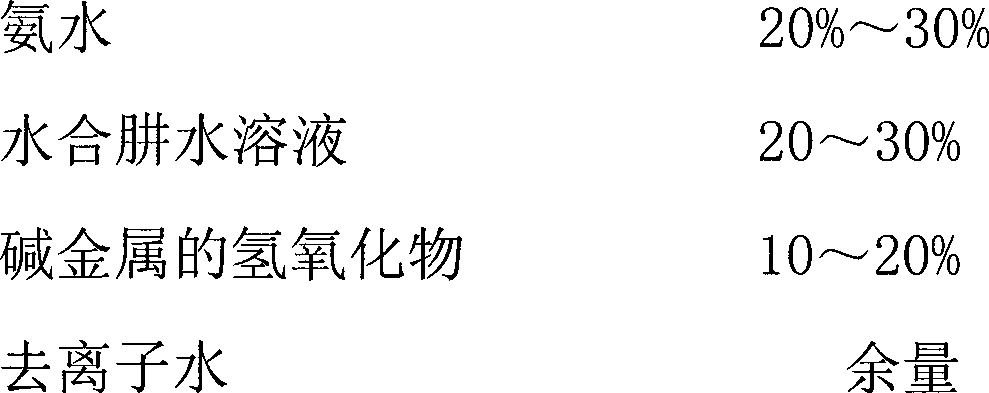

Scale inhibitor for inhibiting scale formation on flue gas turbine blade

ActiveCN103865581AIncreased solid dust contentIncreased operating lifeTreatment apparatus corrosion/fouling inhibitionSal ammoniacFlue gas

The invention provides a scale inhibitor for inhibiting scale formation on a flue gas turbine blade. The scale inhibitor comprises the following components by mass percentage: 20%-30% of aqua ammonia, 20-30% of a hydrazine hydrate aqueous solution, 10-20% of an alkali metal hydroxide, and the balance deionized water. The aqua ammonia concentration is 25-37%, the concentration of the hydrazine hydrate aqueous solution is 40-80%, and the alkali metal hydroxide can be sodium hydroxide or potassium hydroxide. With application of the scale inhibitor, the formation of scale in a flue gas turbine can be effectively reduced, a series of scale removal problems after the flue gas turbine is scaled are reduced or eliminated, and economic losses caused by equipment damage and non-scheduled work stopping are reduced.

Owner:CHINA PETROCHEMICAL CORP +1

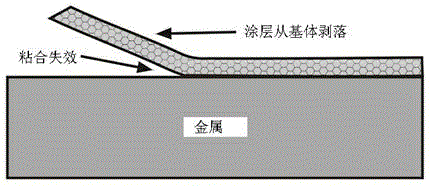

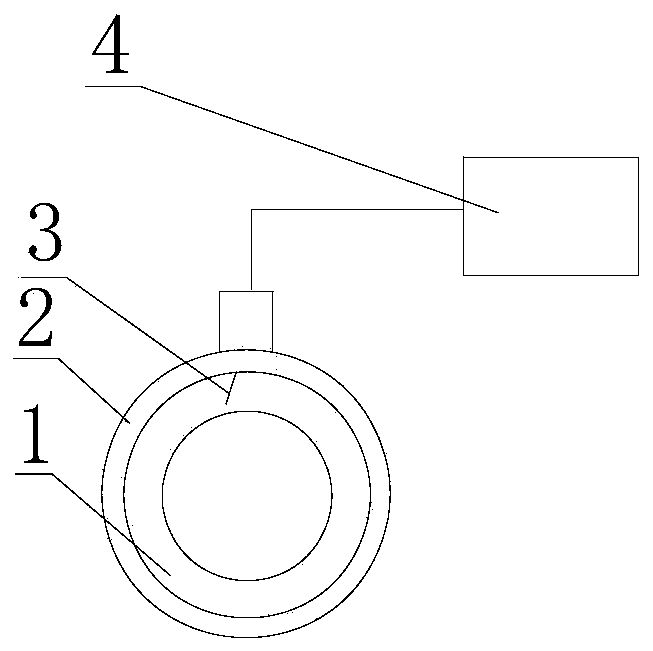

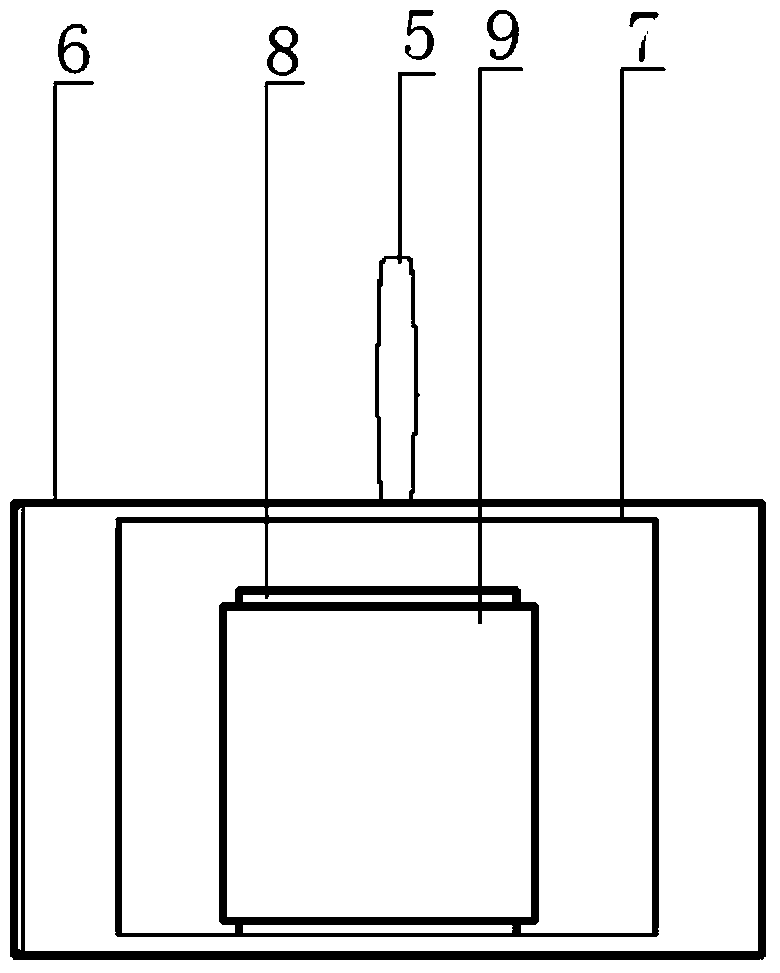

Vibrating screen crossbeam fault detection device and method

The invention relates to a vibrating screen crossbeam fault detection device and method. The device comprises a low-frequency eddy current testing host, wherein a CPU (Central Processing Unit) is arranged in the low-frequency eddy current testing host; the CPU is connected with a signal generation module, a probe interface, a signal output module, an amplifier module, a phase sensitive detector, a filtering module, a phase rotator, an amplitude regulator, an A / D (Analog / Digital) conversion module, an impedance display screen, a loudspeaker, a storage device, an operation keyboard and a data charging interface; a probe device is inserted into the probe interface. The device has the beneficial effects that a method for detecting vibrating screen crossbeam fatigue cracks by using low-frequency eddy current is different from conventional eddy current, the low-frequency eddy current can penetrate through a coating layer so as to detect the crossbeam cracks, the device is low in cost, high in speed, and good in quantification and is used for early warning and nondestructive quantitative detection on vibrating screen fatigue crack faults, the detection result is reliable, and unscheduled shutdown caused by the faults is reduced, so that the economic loss is reduced, and economic benefits and social benefits are huge.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com