Ammonium bisulfate deposition prevention five-chamber rotary preheater and operation method thereof

A technology of air preheater and ammonium bisulfate, applied in combustion methods, heat exchange equipment, cleaning heat transfer devices, etc., can solve problems such as ammonium bisulfate blockage, achieve blockage relief, reduce the number of unplanned shutdowns, and reduce related The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0025] Example.

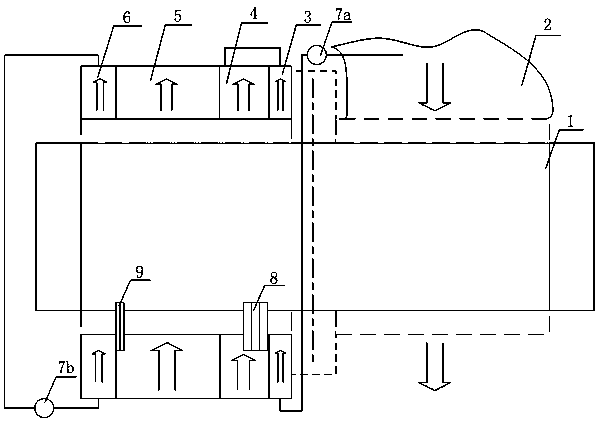

[0026] see figure 1 , the anti-ammonium bisulfate deposition five-compartment rotary air preheater in this embodiment includes an air preheater 1, an air preheater rotor is arranged in the air preheater 1, and a heat exchange element is arranged on the air preheater rotor The air preheater 1 includes a flue gas side and an air side, and the air side includes a wind side 3, a wind side 2 4, a wind side 3 5 and a wind side 4 6; the inlet of the wind side 3 passes through the pipe and the flue gas side inlet 2 connected, and a high-temperature fan 7a is set on the pipeline between the inlet of wind side 3 and the flue gas side inlet 2; the outlet of wind side 4 6 is connected with the inlet of wind s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com