Patents

Literature

74 results about "Sonic soot blowers" patented technology

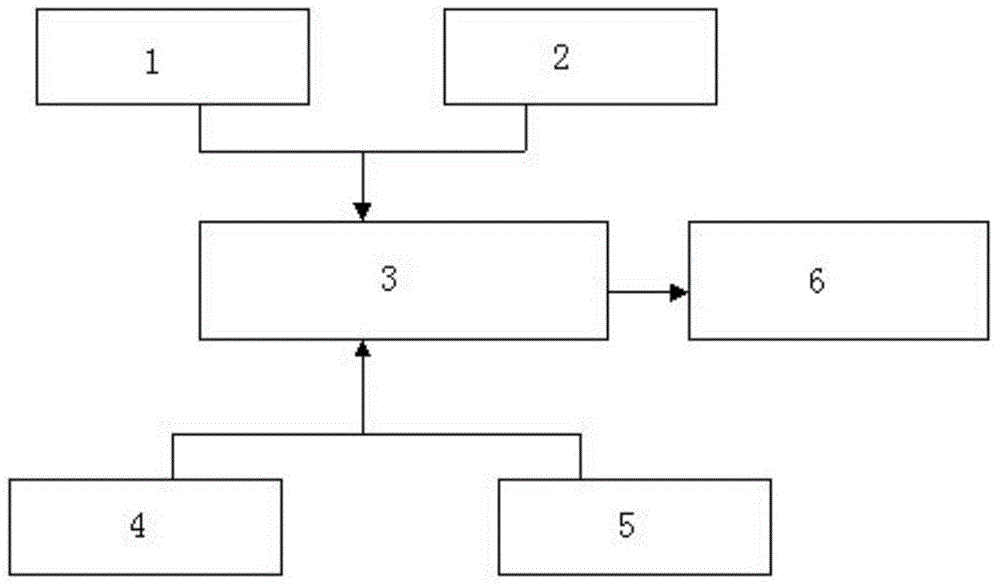

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sonic soot blowers offer a cost-effective and non-destructive means of preventing ash and particulate build-up within the power generation industry. They use high energy – low frequency sound waves that provide 360° particulate de-bonding and at a speed in excess of 344 metres per second. Because they employ non-destructive sound waves, unlike steam soot blowers they eliminate any concerns over corrosion, erosion or mechanical damage and do not produce an effluent stream.

SCR (silicon controlled rectifier) denitration system of cement kiln gas

InactiveCN103120899AReduce dust concentrationPromote denitrification reactionCombination devicesElectricitySilicon-controlled rectifier

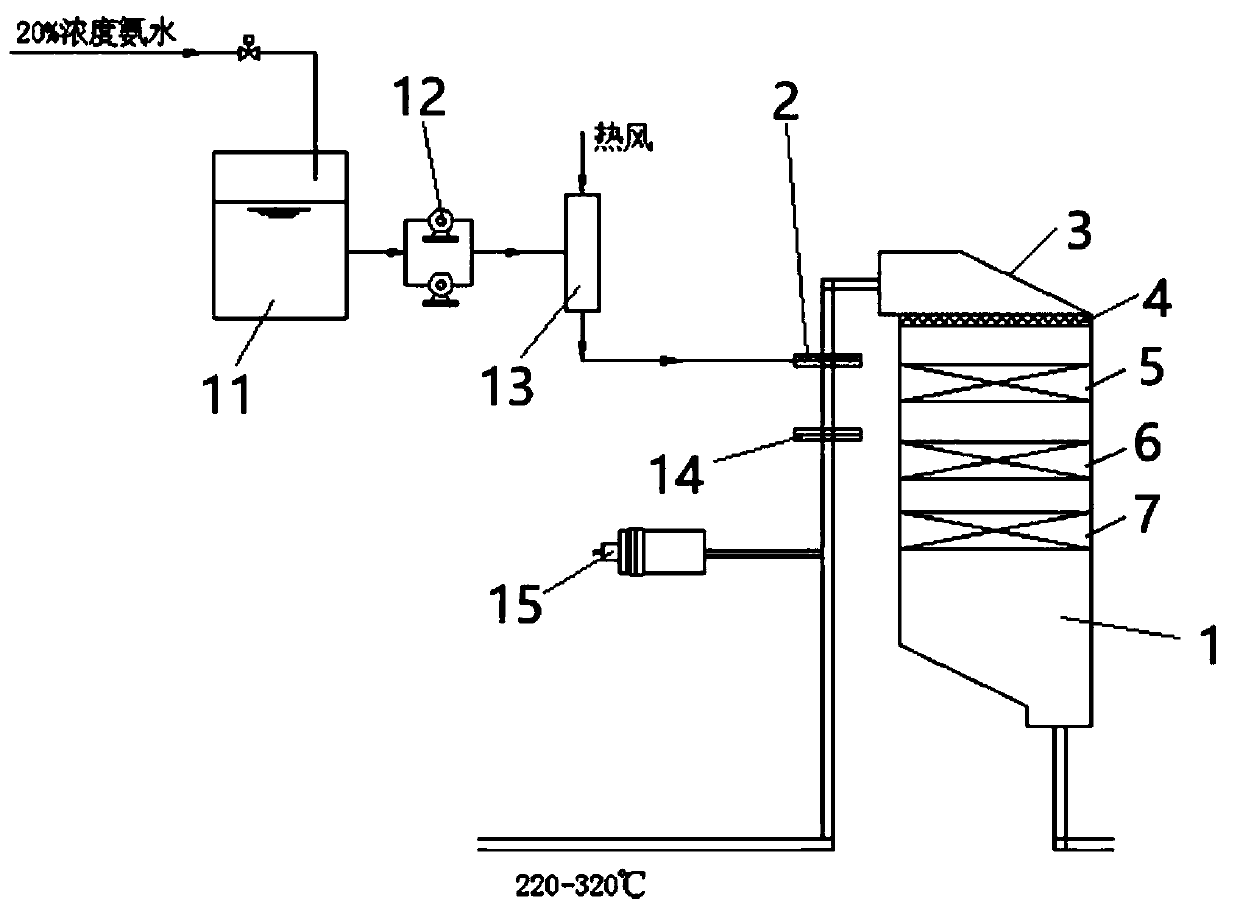

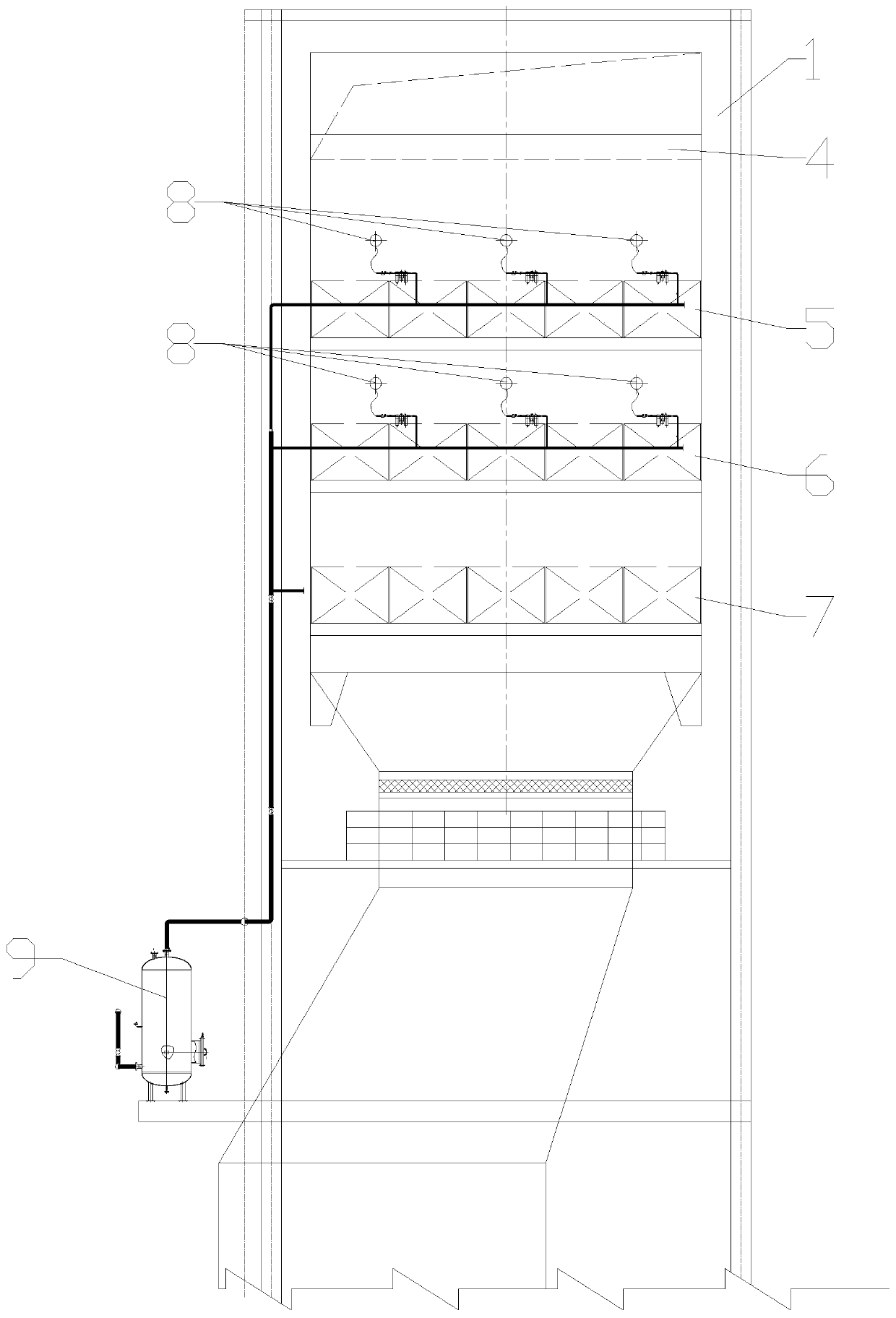

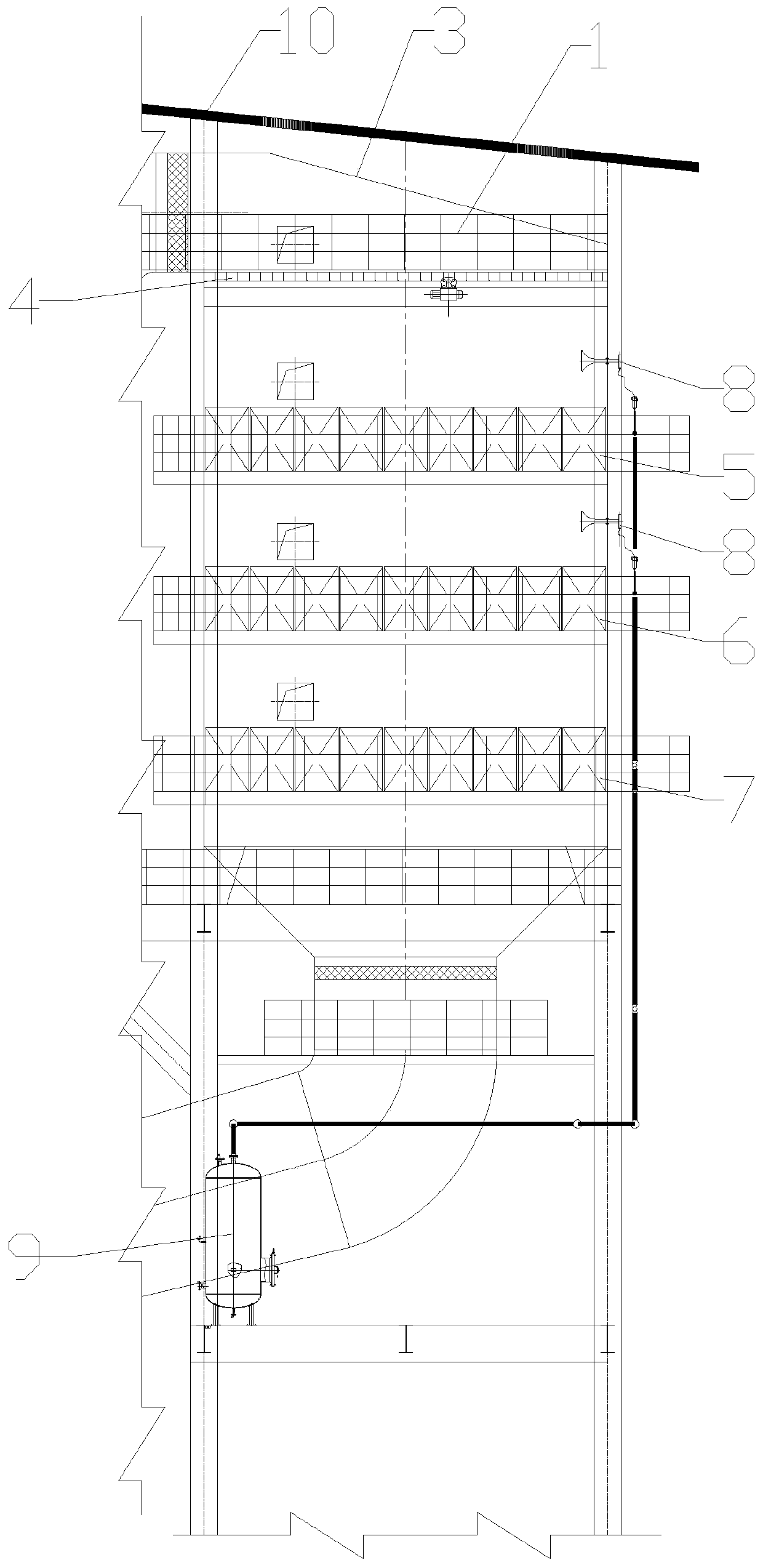

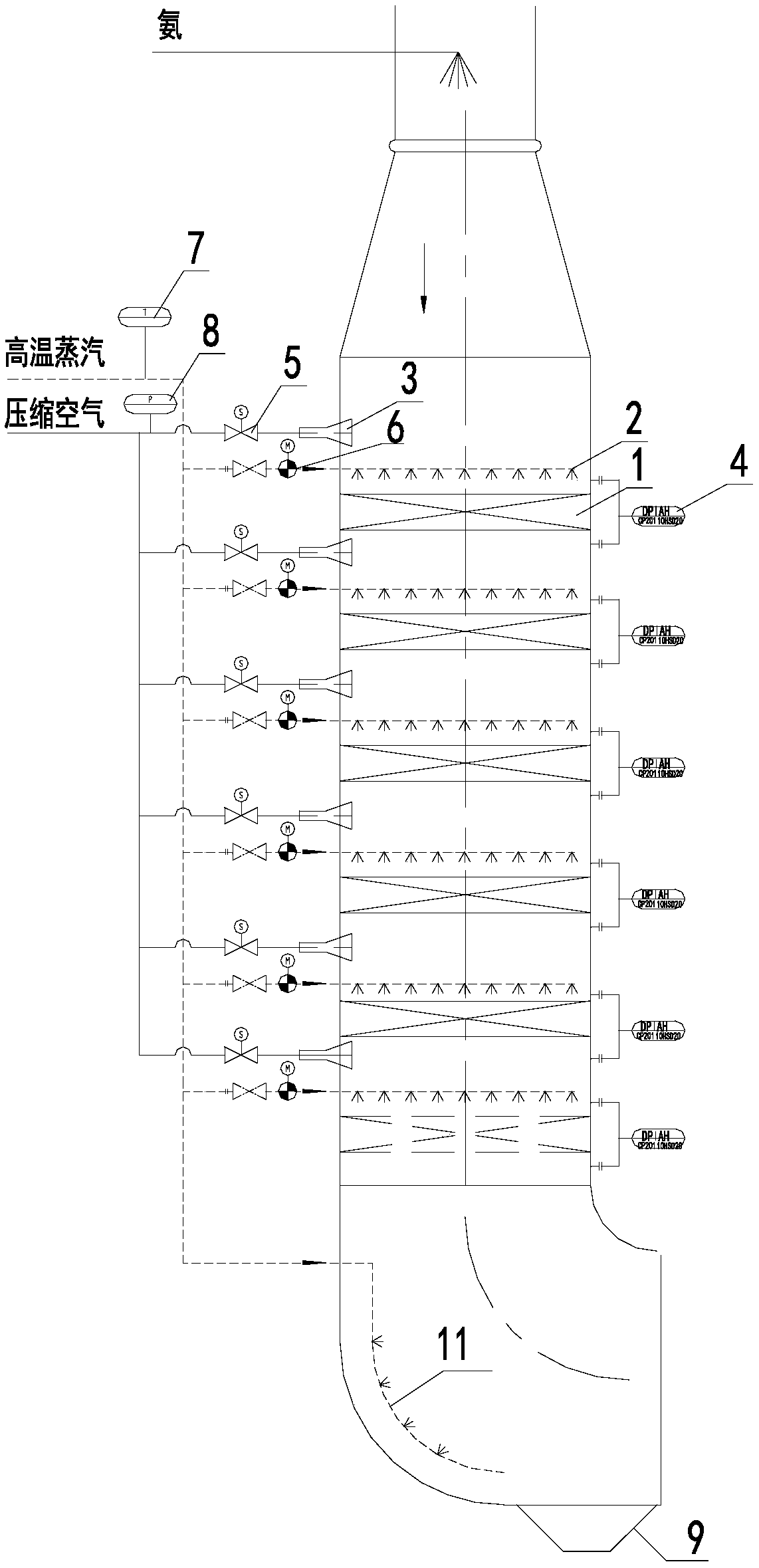

The invention discloses an SCR (silicon controlled rectifier) denitration system of cement kiln gas. The SCR denitration system comprise an ammonia spraying device, a reactor box body, a wind evening rectifying device, catalysts and sound wave soot blowers, wherein the wind evening rectifying device and the catalysts are respectively arranged on the upper part and the lower part in the reactor box body; and the sound wave soot blowers are arranged in the reactor box body. The SCR denitration system also comprises an electrofilter and a mixing device, wherein the electrofilter comprises a gas inlet and a gas outlet; and the gas inlet of the electrofilter is provided with a gas inlet pipeline. The ammonia spraying device and the mixing device are respectively arranged on the gas inlet pipeline, the mixing device is positioned on the down stream of the ammonia spraying device, an exit of the electrofilter is connected with the upper end of the reactor box body by a gas collection cover, the lower end of the reactor box body is provided with a lower cone bucket, and the lower cone bucket is connected with a gas outlet channel. The SCR denitration system of the cement kiln gas is long in service life and low in use cost.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

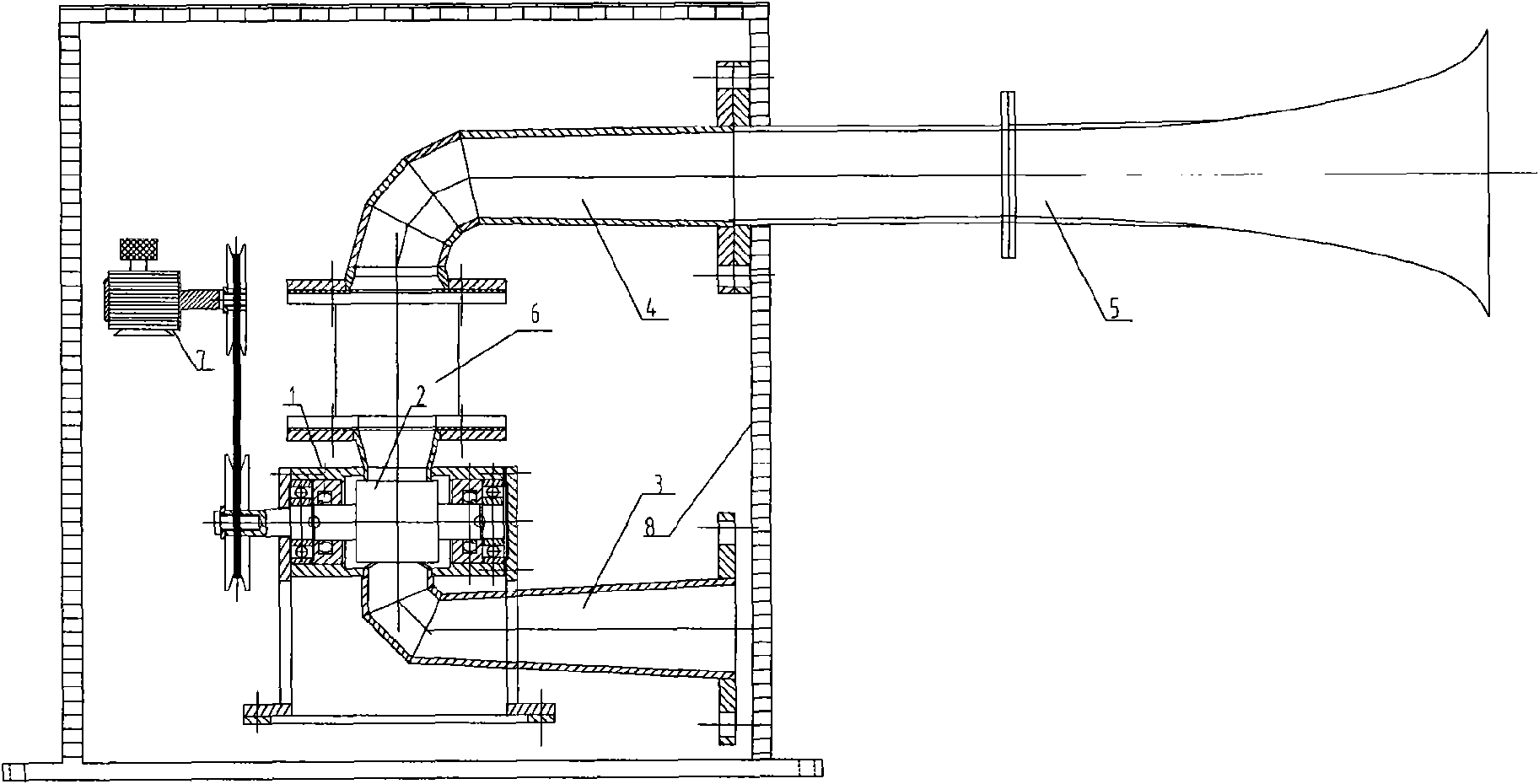

Rotary valve type sonic blowing ash device

InactiveCN1928434AAffect normal workGuaranteed high speed operationSound producing devicesSolid removalRotary valveEngineering

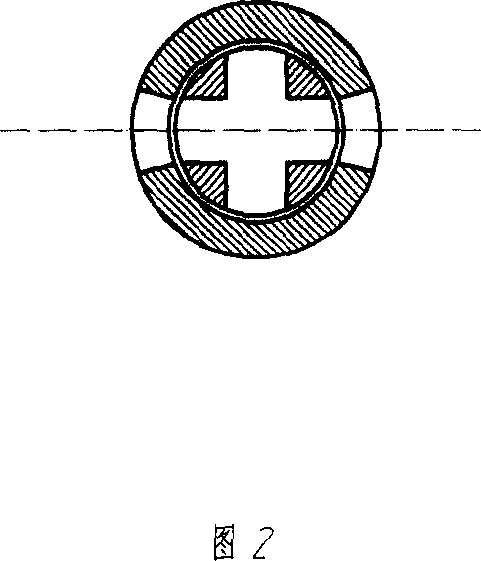

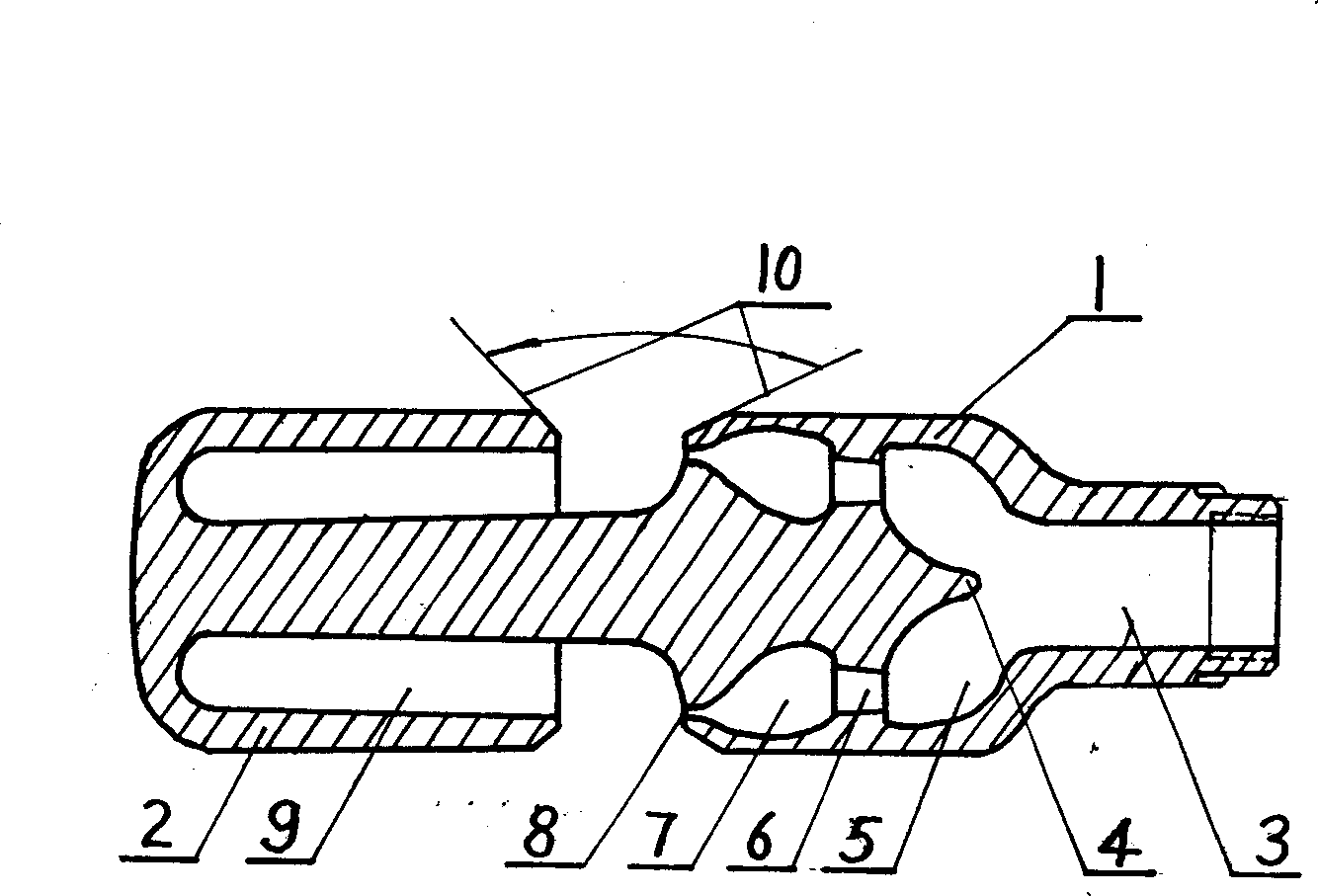

The invention discloses an acoustic soot blower with rotary valve, belonging soot-blowing equipment. By setting groove or hole on the rotor, rotor rotating in the stator and mounting with inlet pipe, air room, jet nozzle and acoustic-formed device, the blower can make air flow with high pressure converse sound wave with heavy power. By sound wave blowing soot, there is not easy to jam between every part; because of the structure without films, the film damage generated by high-frequency intense vibration is avoided, which affects the normal work of soot blower. It is provided with simple structure and long service life. It can be long run in hard circumstance such as boiler.

Owner:聂道静 +1

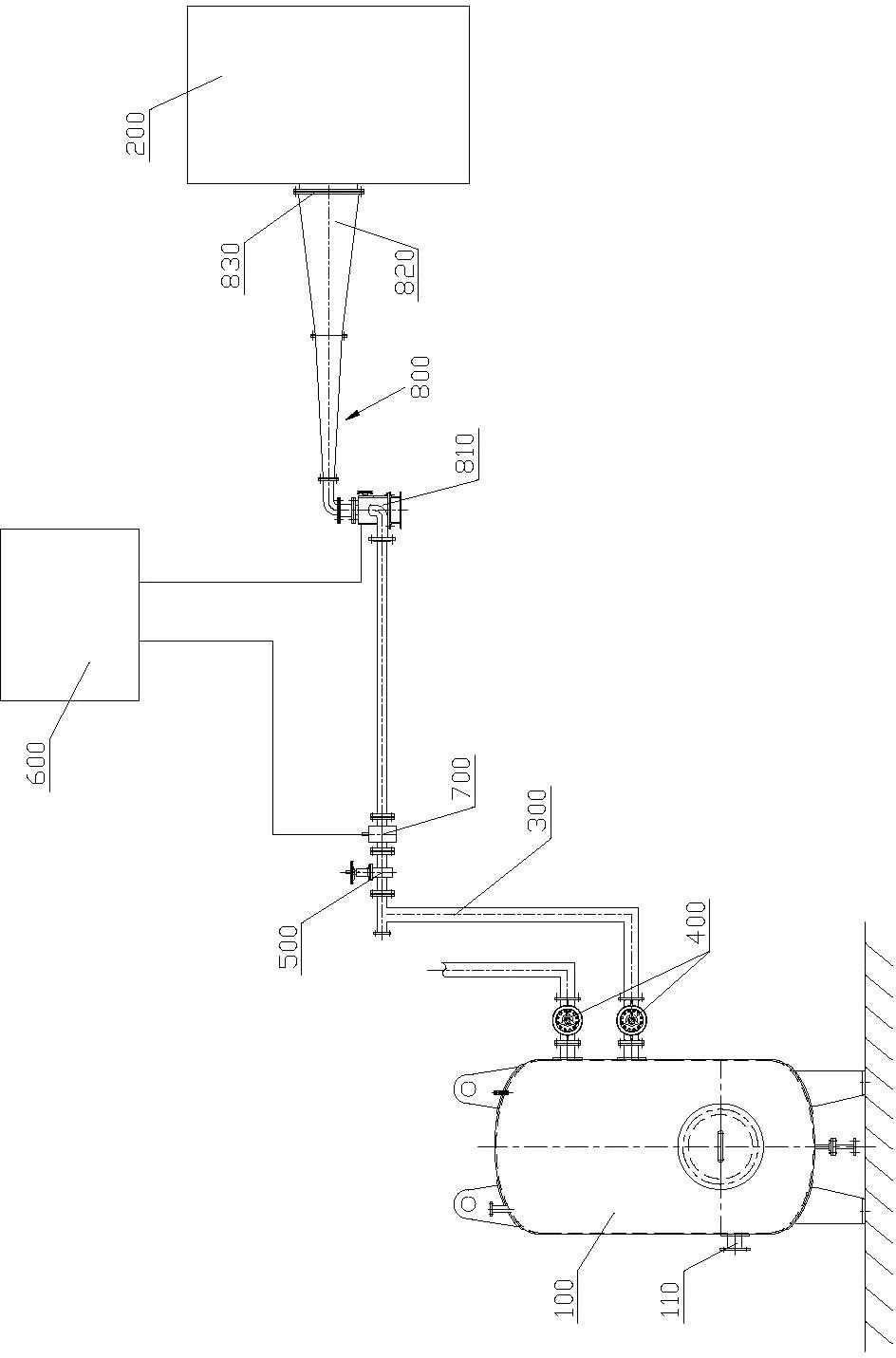

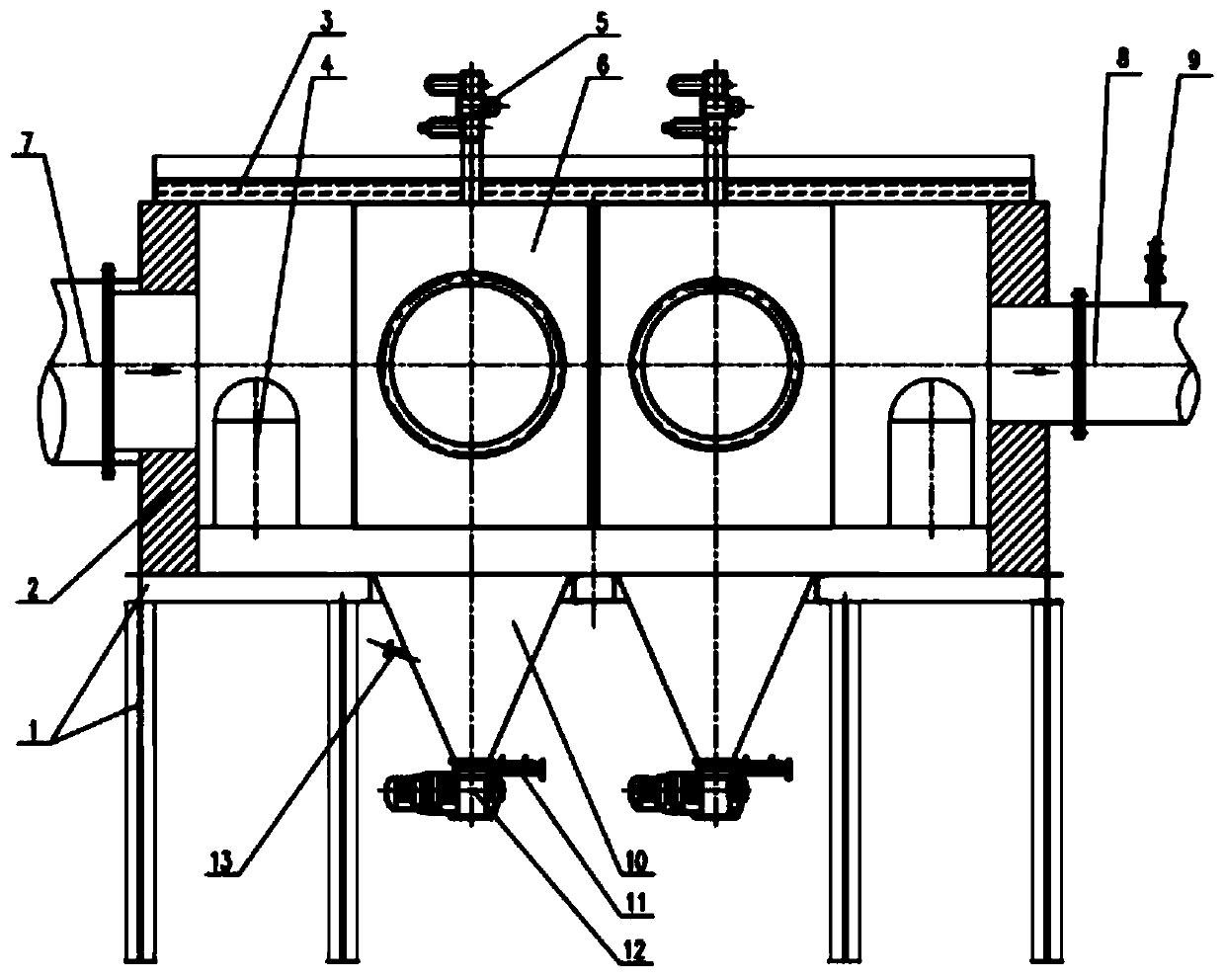

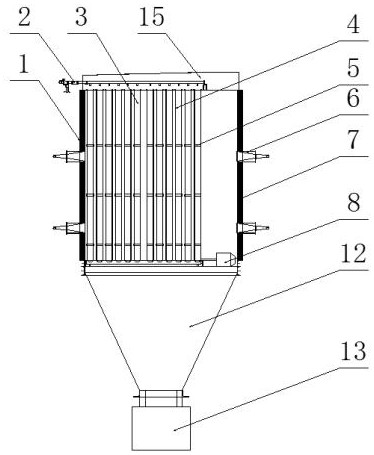

Hydrolysis reaction device for organic sulfur in blast furnace gas

PendingCN111500325ASolve the difficult problem of organic sulfurSolve the problem of excessive emissionsBlast furnace componentsGas purification by catalytic conversionPtru catalystEngineering

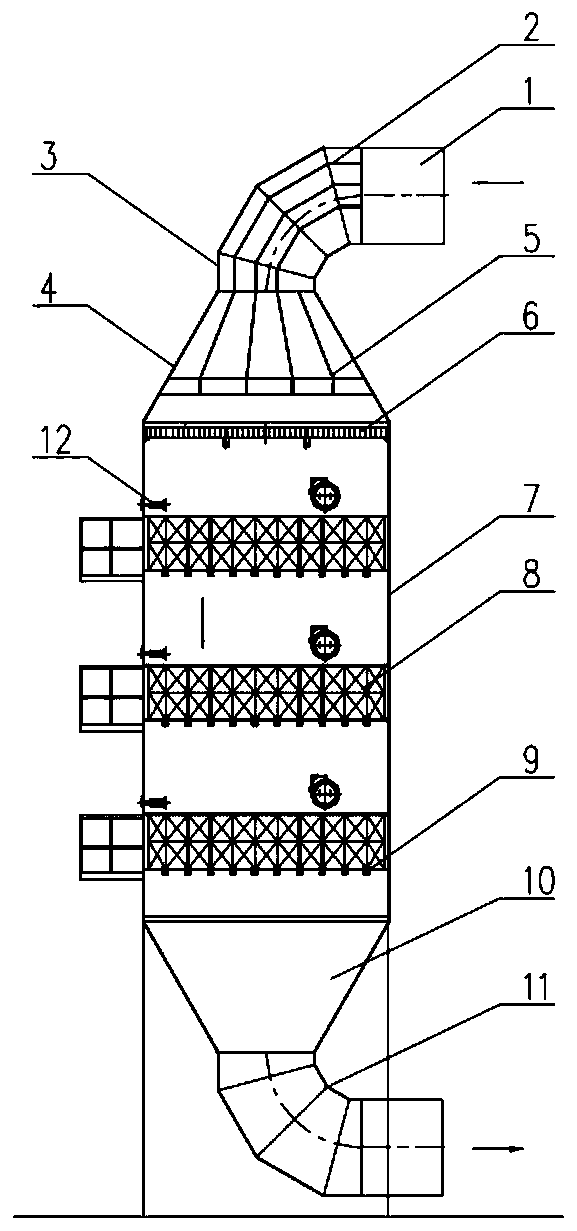

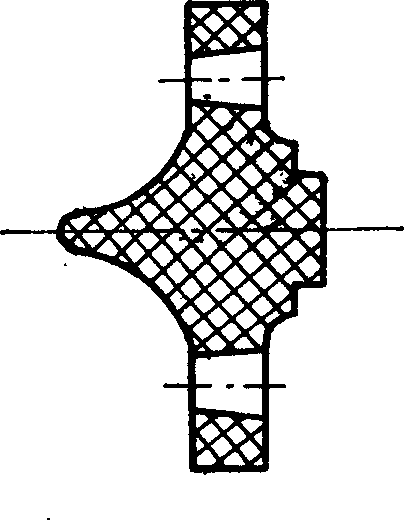

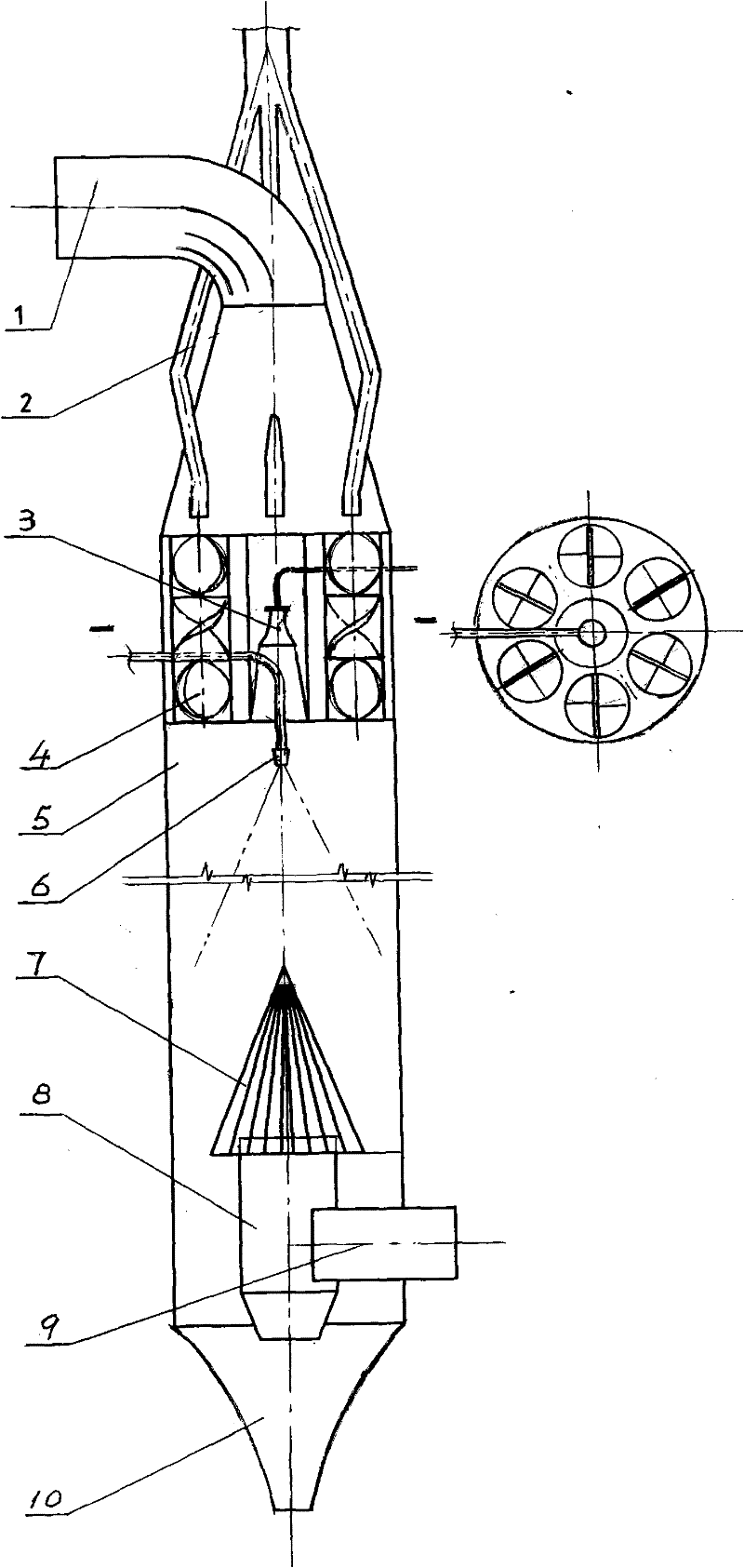

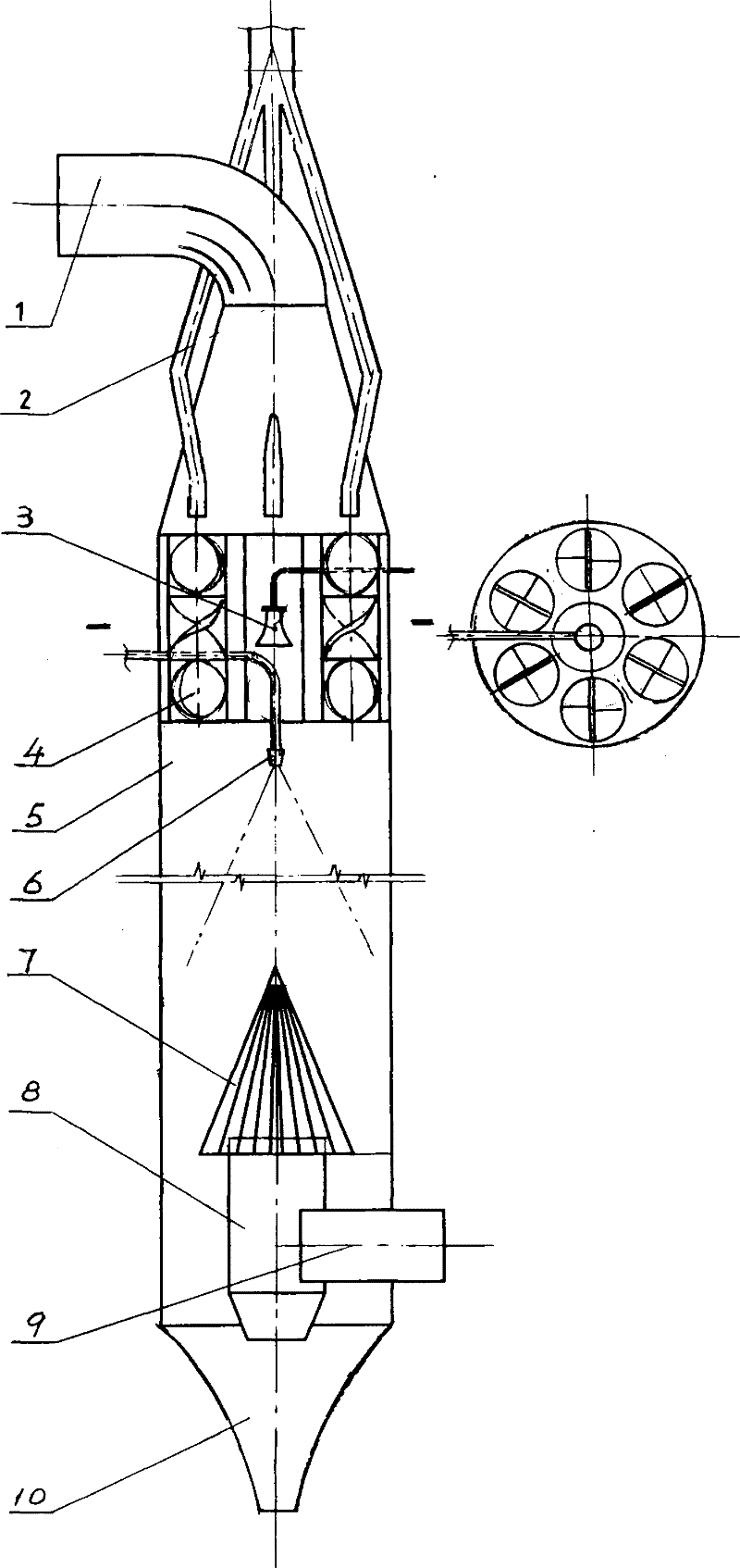

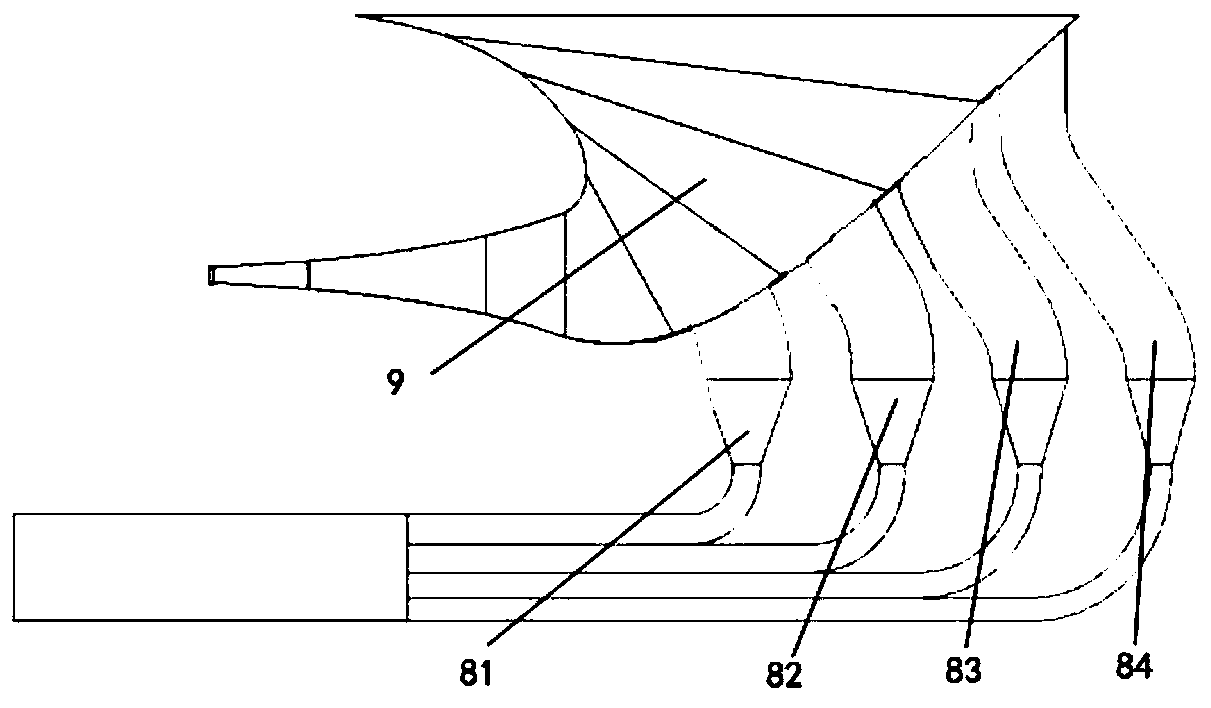

The invention provides a hydrolysis reaction device for organic sulfur in blast furnace gas, belonging to the technical field of fine desulfurization of blast furnace gas. The device comprises a middle flue, a flow baffle, an inlet elbow, an inlet reducing cone, an airflow uniform-distribution plate, a rectification grid, a reactor, a hydrolysis catalyst, an internal support beam, an outlet reducing cone, an outlet elbow and a sound wave soot blower, wherein the middle flue is connected with the inlet elbow of the device; the flow baffle is arranged in the inlet elbow; the inlet elbow is connected with the inlet reducing cone; the airflow uniform-distribution plate is positioned in the inlet reducing cone; the reactor is connected with the inlet reducing cone; the rectification grid is mounted at the uppermost part of the reactor; the internal support beam is arranged in the reactor; a catalyst is placed on the upper portion of the internal support beam and arranged in the reactor; theplacing intervals of all layers of the catalyst are equal; the sound wave soot blower is placed on the upper portion of the catalyst; and the reactor is connected with an external pipeline through the outlet reducing cone and the outlet elbow of the device. The device guarantees that a rear-end coal gas user finally discharges flue gas to achieve ultralow emission of sulfur dioxide.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

Integrated high temperature high efficiency soundwave and blower and its producing method

InactiveCN1749644AWarranty requirementsImprove utilityCeramic shaping apparatusSolid removalHearthMaterials science

The present invention relates to integrated high temperature high efficiency sound wave ash blower for boiler ash blowing job and its production process. The ash blower is cast with cobalt base alloy material and has smooth surface. The ash blower cavity includes the primary airflow distributing chamber and the secondary airflow distributing chamber communicated via shunting hole, as well as back flow cavity with annular back flow passage. The passage port is corresponding to the jetting hole of the secondary airflow distributing chamber, and jets are formed to have different jetting angles. The ash blower may be used directly inside the high temperature area of boiler and ash blower with proper jetting angle may be selected based on the ash accumulation to eliminate ash, scale and coke inside hearth effectively.

Owner:薛铁山

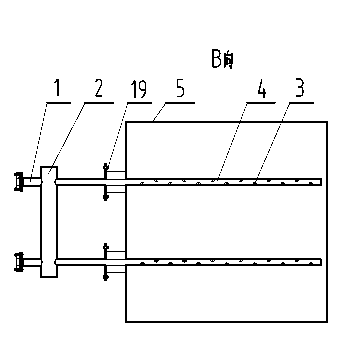

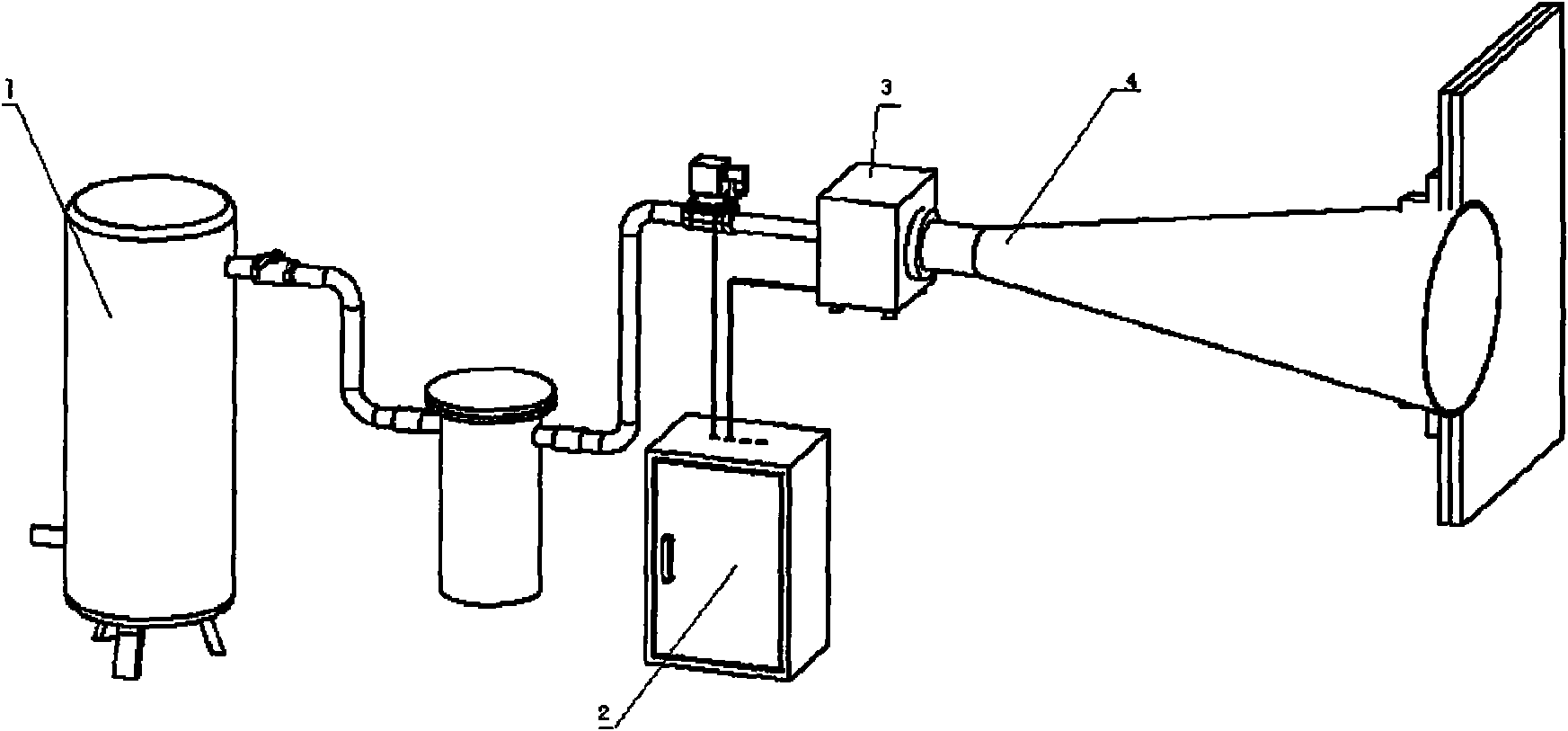

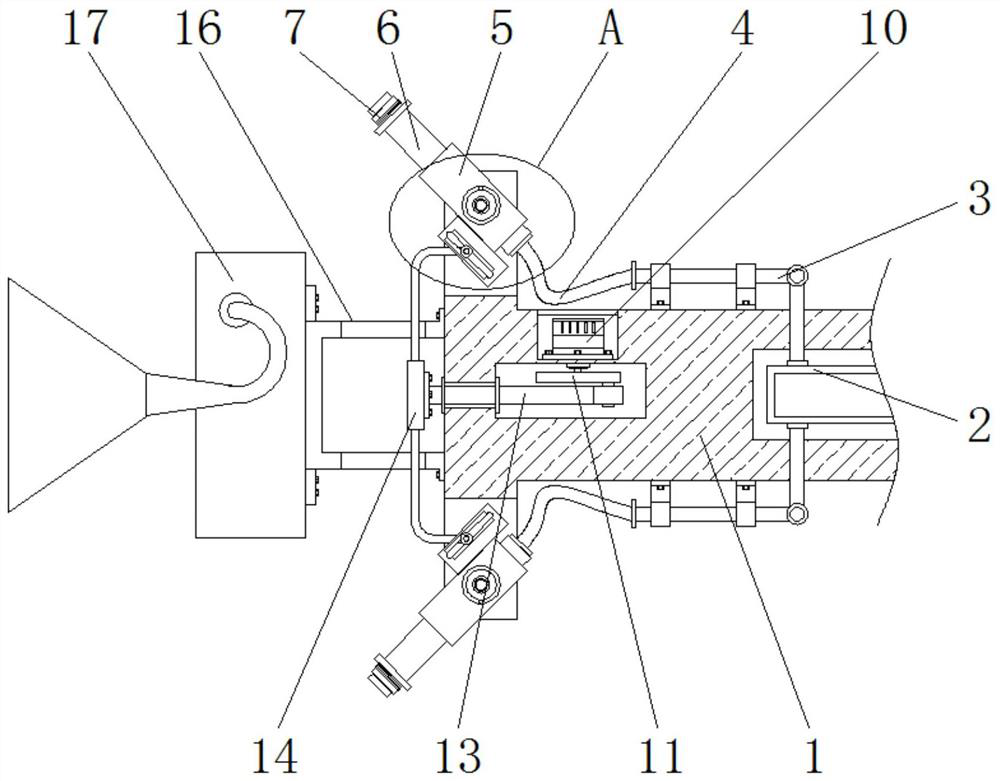

Multifunctional acoustic wave sootblower with ample power

InactiveCN101551109ASolve power problemsSolve the adjustmentSolid removalAudio power amplifierElectric machine

The present invention discloses a multifunctional acoustic wave sootblower with ample power. A sound wave generator connects with a sound wave transfers magnifying apparatus through an air outlet duct, air source connects with the sound wave generator through the air inlet duct, the sound wave generator includes a stator and a rotor, the rotor is opened with some holes or grooves with various size, the rotor connects with a variable-frequency control motor through a transmission device. The sound wave generator uses a rotary valve type structure by cooperating with the motor which solves problem of ample power and adjustable problem of the sound wave sootblower, an efficient blowing action radius reaches above 12m.

Owner:YICHANG JIUTIAN ENVIRONMENTAL SCI & TECH

Combined soot-blowing system

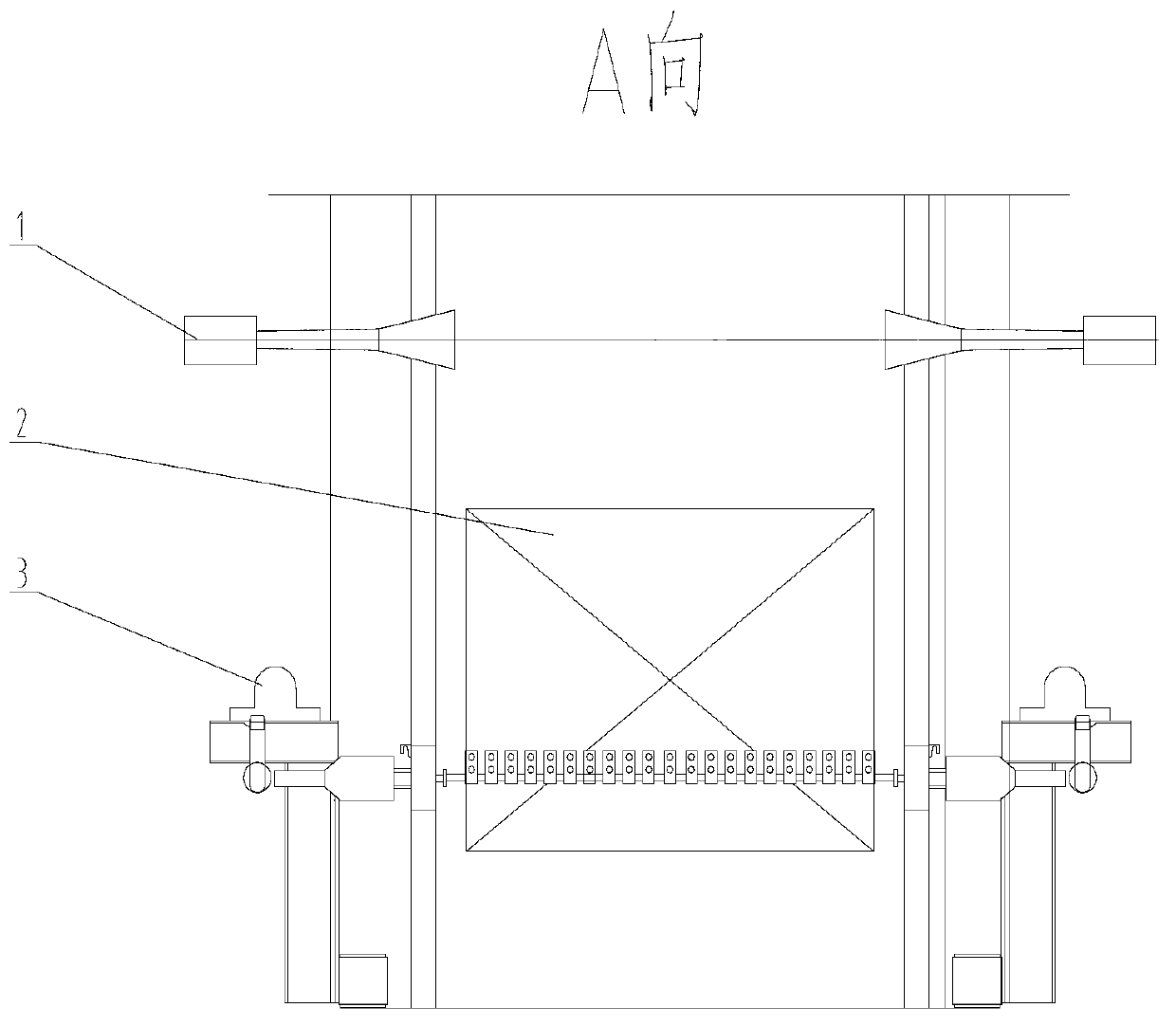

The invention relates to a combined soot-blowing system and relates to a soot-blowing system applied to a heating furnace. The combined soot-blowing system comprises a sonic soot blower, a pneumatic rotary soot blower and a heating furnace. The heating furnace is provided with a convection chamber. The sonic soot blower is disposed on the side of the convection chamber, and the pneumatic rotary soot blower is disposed on the front side of the convection chamber. Coke on a furnace tube is crushed by the sonic soot blower, broken powder is discharged out of the heating furnace with hearth smoke by the pneumatic rotary soot blower, and the convection chamber furnace tube is cleaned well. Therefore, coke sag and soot are avoided, and furnace efficiency is improved.

Owner:SHAANXI QIYUAN TECH DEV

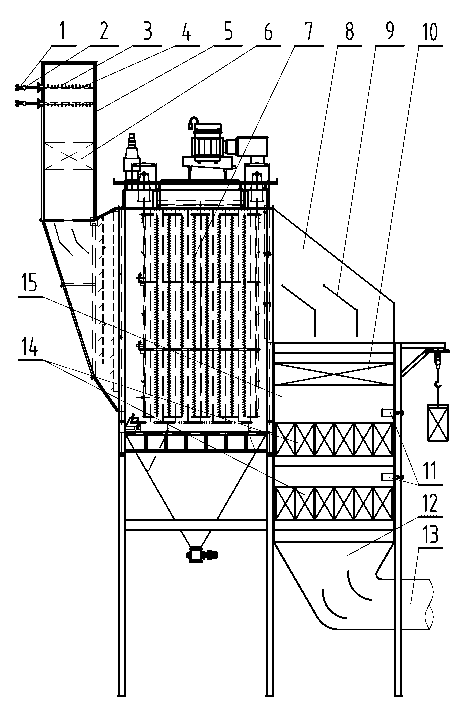

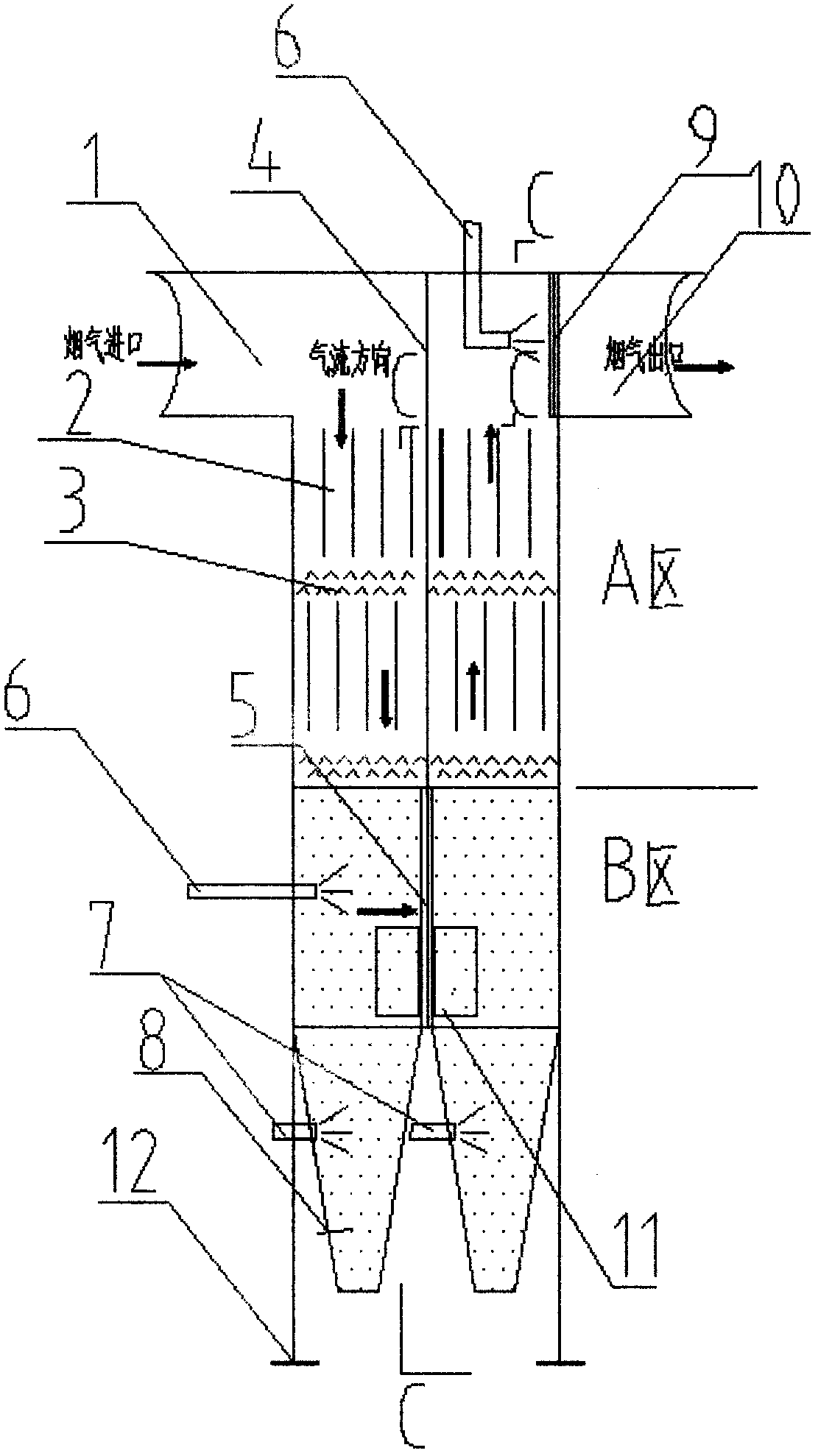

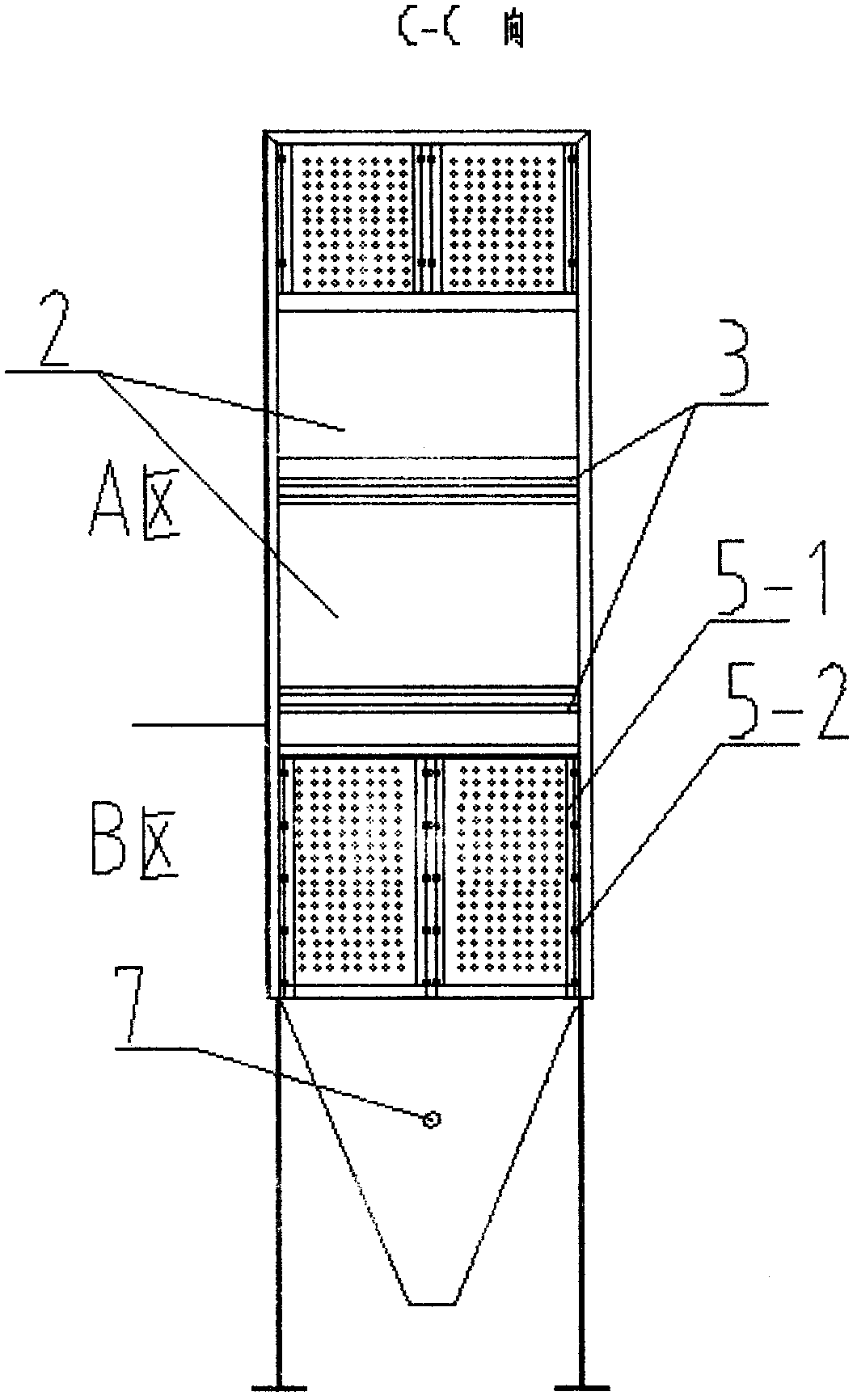

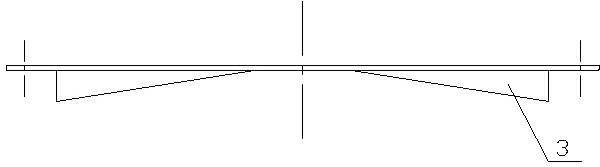

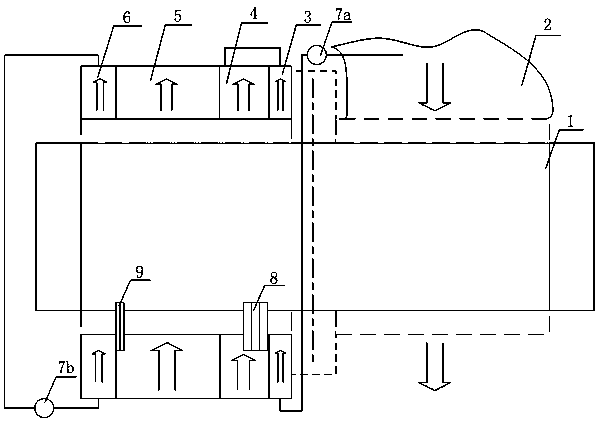

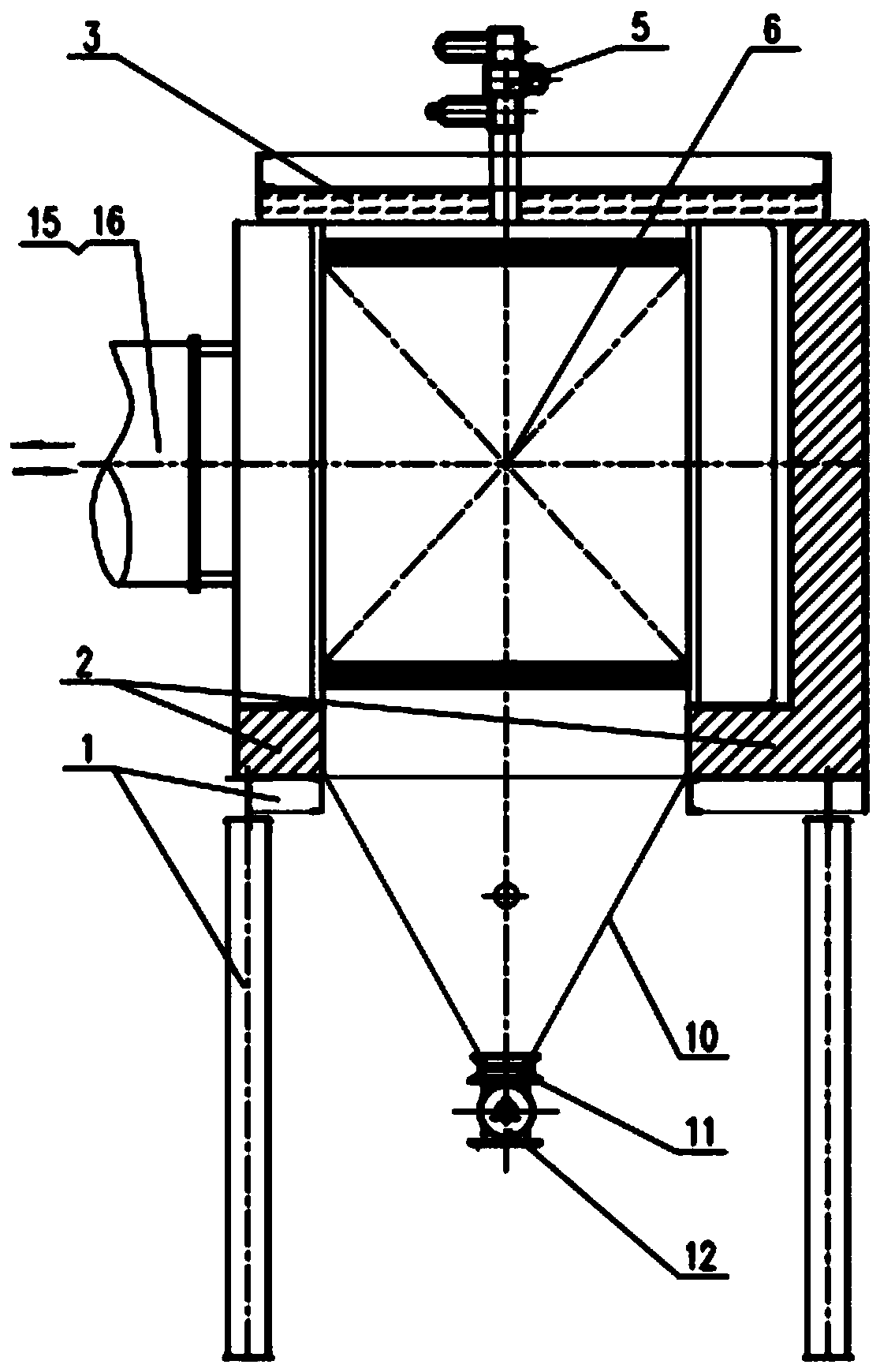

Flue gas desulfurization reactor for descending circulating fluidized bed

InactiveCN102441324AGood effectFull collisionGas treatmentDispersed particle separationNuclear engineeringFlue gas

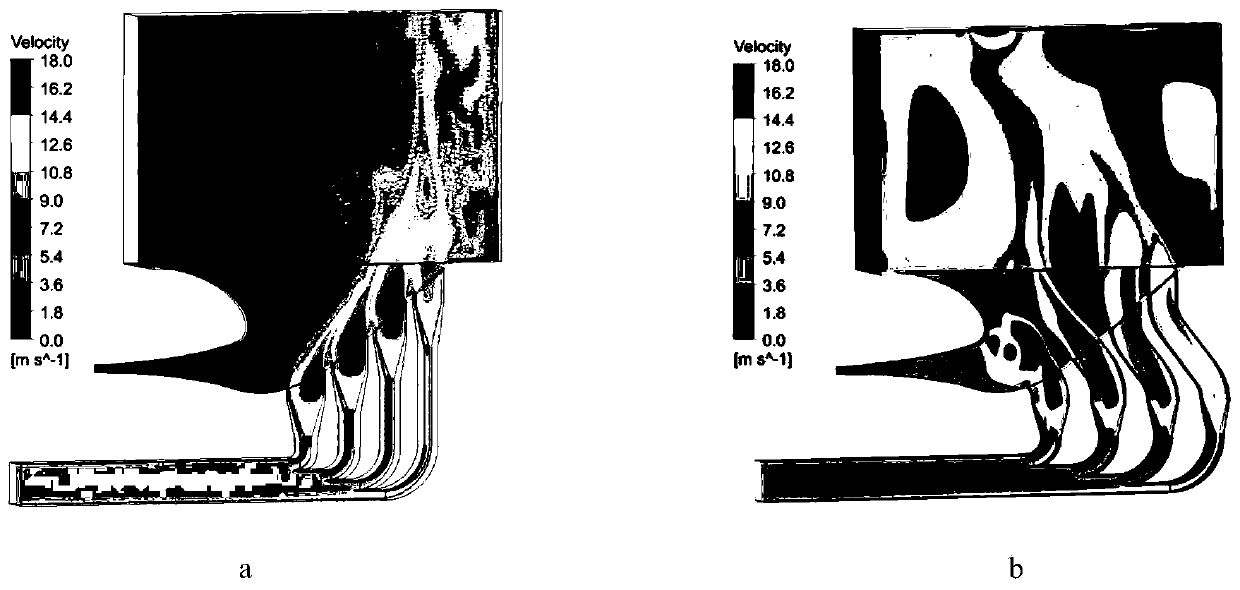

The invention relates to a flue gas desulfurization technique for a descending circulating fluidized bed. The core equipment of the reactor is a reactor structure, which comprises a straight-flow streamline inlet flue, an absorbent distributor, a sound-wave soot blower, a static mixer, a reaction shell, a humidifying and activating nozzle, a tapered swirl-board gas-solid separator, a gas-solid separation guide cylinder, a desulphurized-gas outlet flue and a hyperbolic ash hopper. The reactor has a rational configuration which enables the smoke in the reactor to be fully collided and mixed with the absorbent so as to obtain a stable and even flow field, a temperature field and a pressure field. Besides, the reactor enables the absorbent to obtain with higher circulation ratio and use ratio. The invention is out of any problems such as sticking wall, scaling and bed collapsing; meanwhile, the reactor reduces the dust load of the exit flue gas obviously and also lowers the load of the bag-type dust remover at the back part greatly, thereby guaranteeing the safe, reliable and long-term operation and solving the technical problem in the semidry method flue gas desulfurization effectively.

Owner:北京博朗环境工程技术股份有限公司 +2

Compound soot blower system for low-temperature flue gas waste heat recovery system

ActiveCN103104926AImprove efficiencyStrong ability to remove dense dust accumulationSolid removalFlue gasProcess engineering

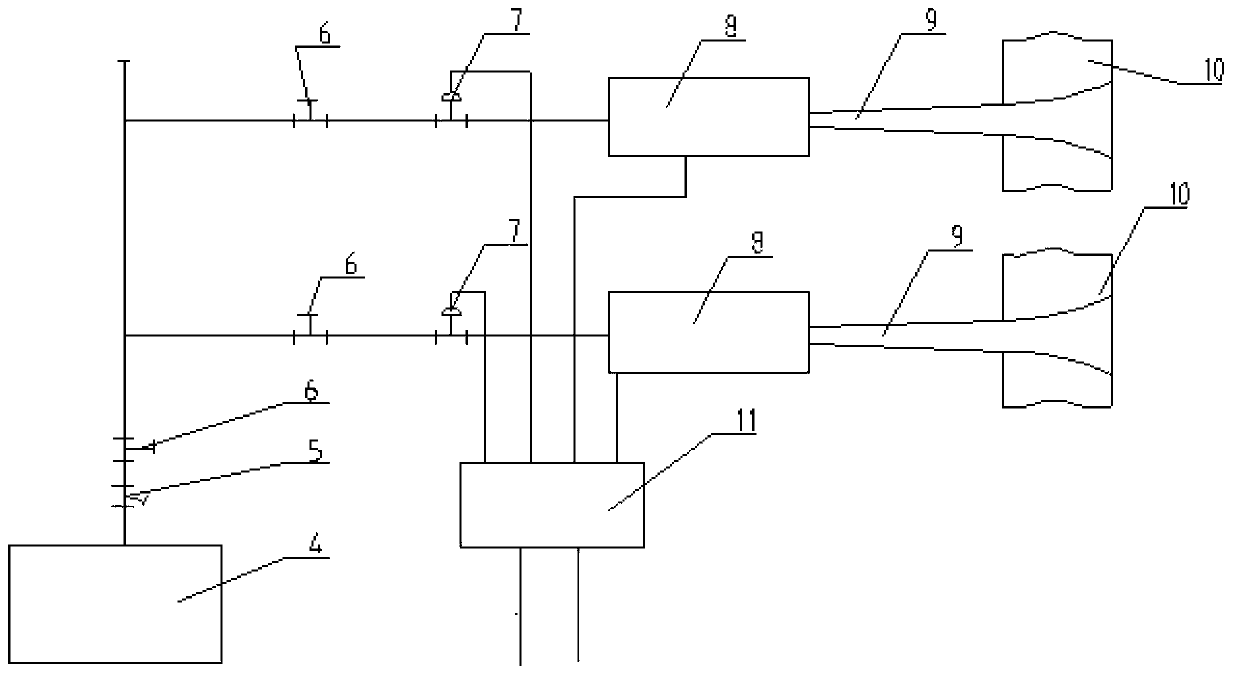

The invention relates to a compound soot blower system for a low-temperature flue gas waste heat recovery system. The compound soot blower system comprises a flue gas waste heat recovery device, wherein an acoustic-wave soot blowing system is arranged at the inlet of the flue gas waste heat recovery device, and a mechanically-vibrating soot removing system is arranged at the outlet of the flue gas waste heat recovery device. According to the invention, the acoustic-wave soot blowing system and the mechanically-vibrating soot removing system are mutually matched, so that the advantage of comprehensive soot blowing of an acoustic-wave soot blower is given a full play, and the advantages of a mechanically-vibrating soot removing device, such as low power consumption and high compact soot deposit removing capacity, are reflected; the soot deposit of a pipe bundle positioned on a heated surface is effectively removed under the action of the compound soot blower system disclosed by the invention, and the heat exchange coefficient is greatly enhanced, so that the efficiency of a waste heat recovery device is increased.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

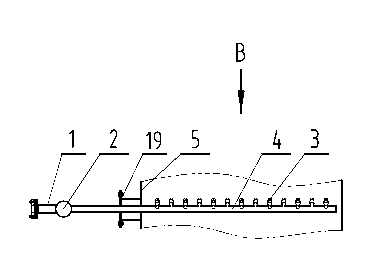

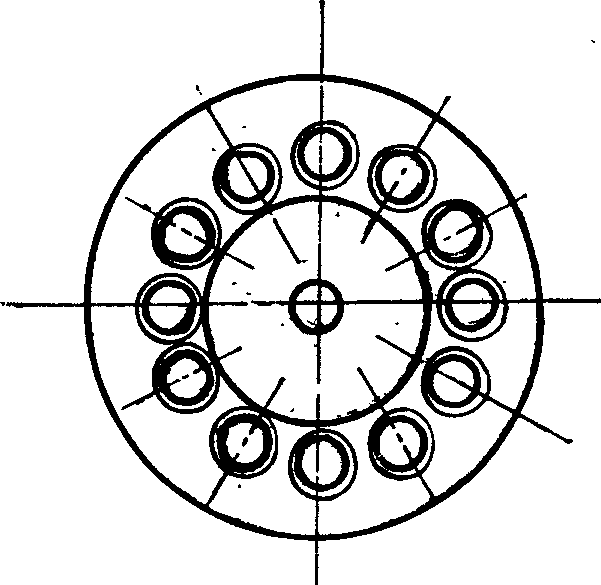

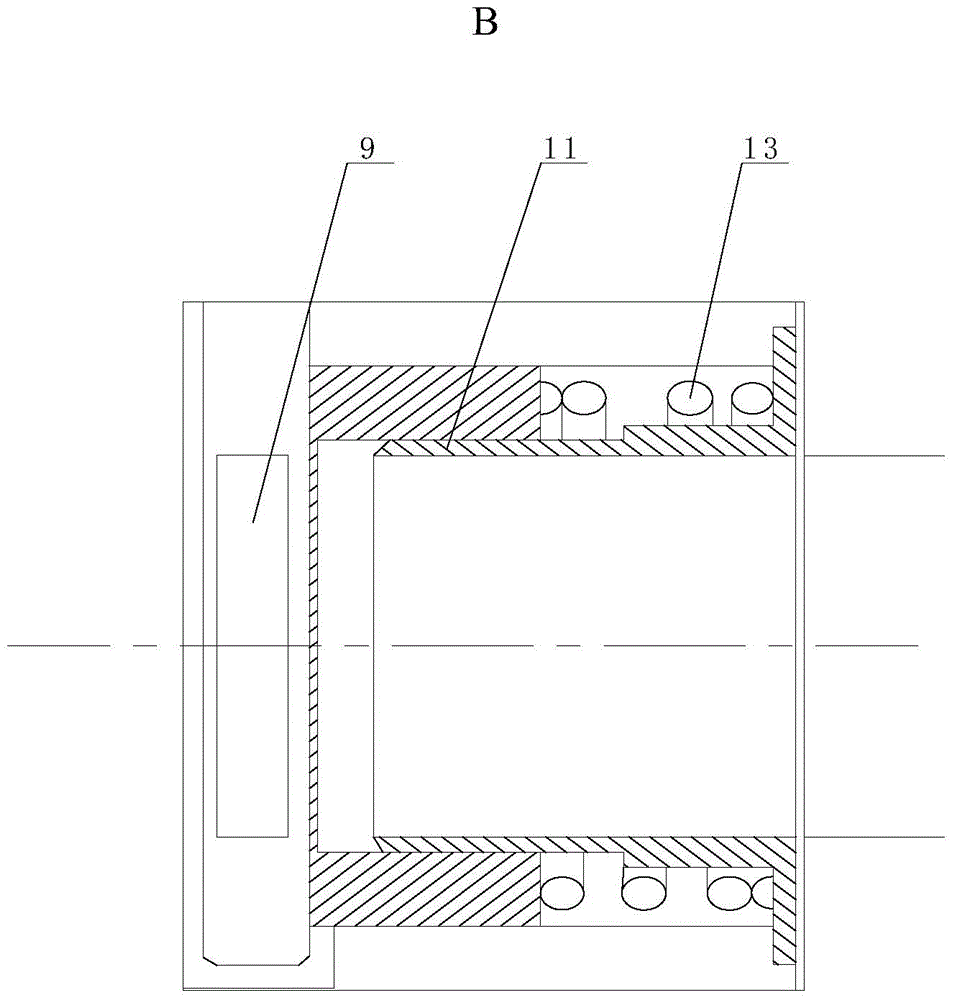

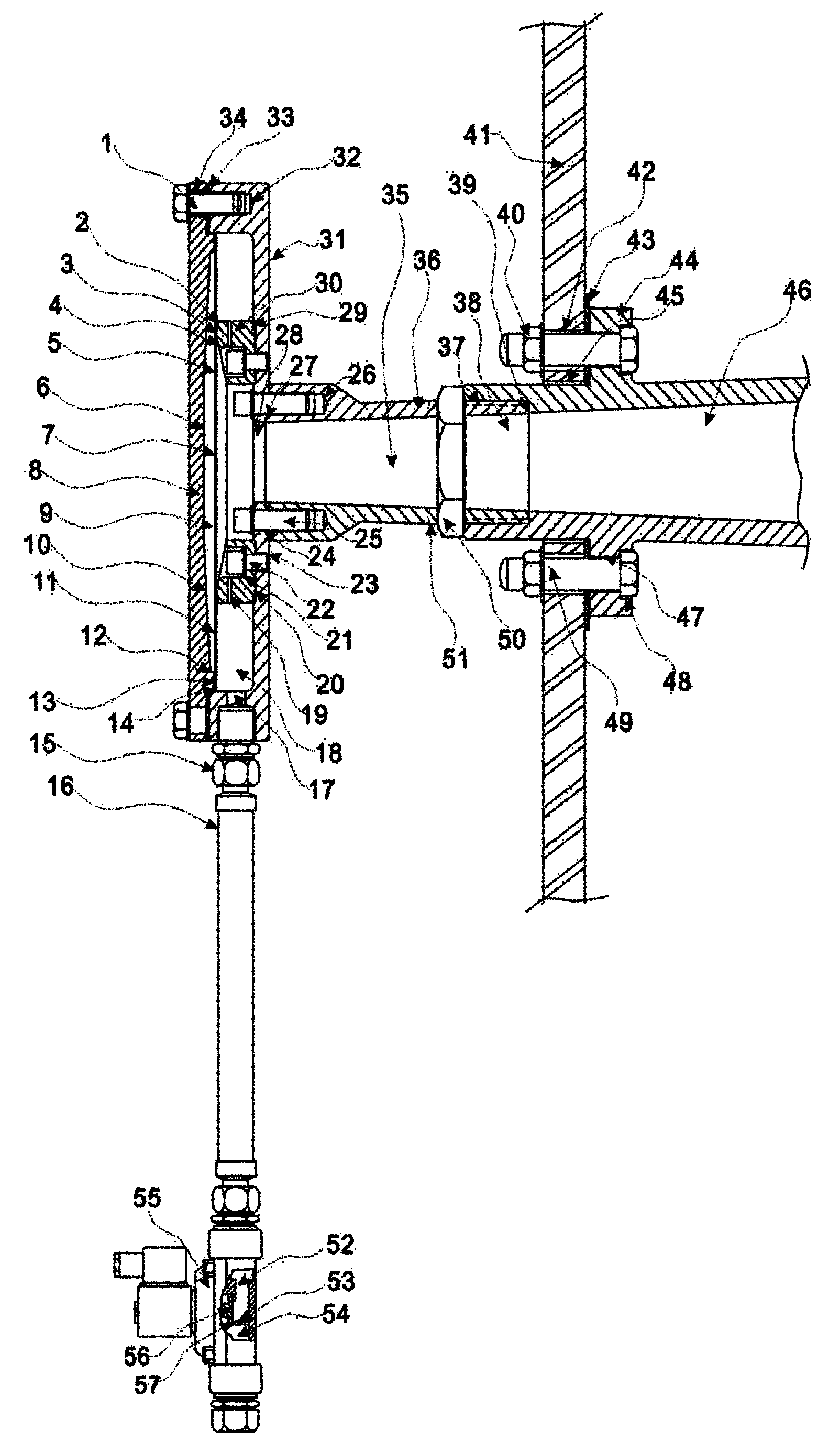

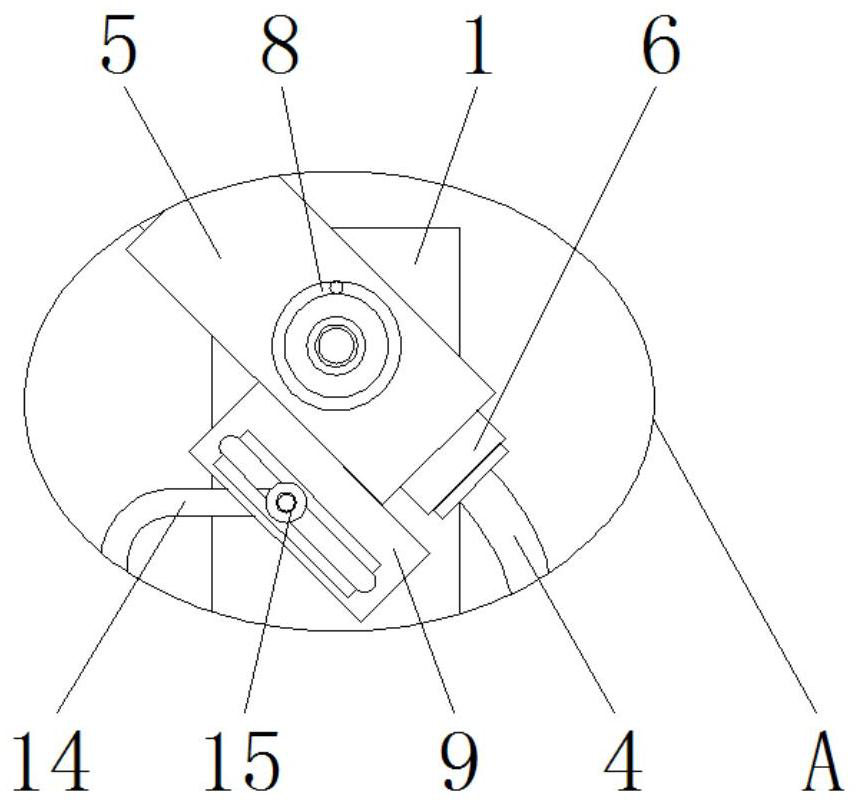

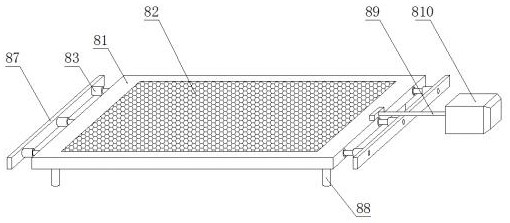

Sound-wave dust-blowing device

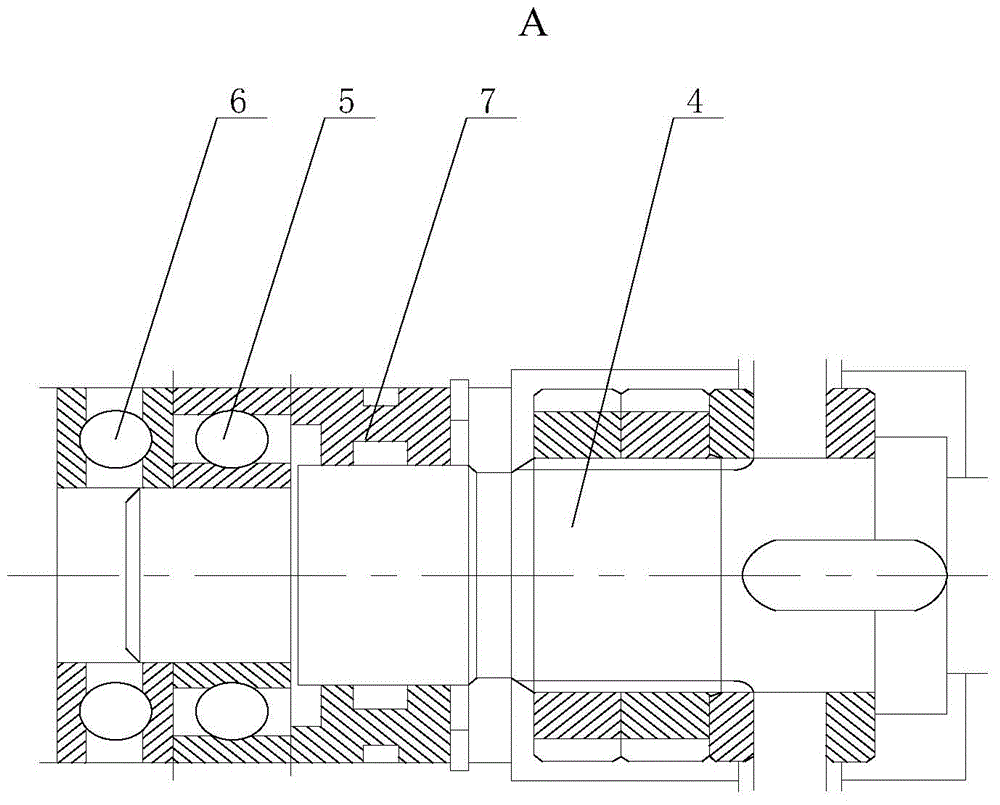

The invention relates to a dust-blowing device, in particular to a sound-wave dust-blowing device, and aims to solve the problem of instable wind shear, which is caused by the fact that when a rotating disc of the existing sound-wave dust blower rotates, due to change of airflow pressure, a bearing of a rotating shaft bears a relatively high load, is easily abraded and generates rotary swing of the rotating disc. The sound-wave dust-blowing device comprises a driving mechanism, a transmission shaft, a rotating bearing, a thrust bearing, a rotating disc, a housing and a blowing mechanism, wherein the driving mechanism is mounted at the upper part inside the housing; one end of the transmission shaft is connected with the driving mechanism; the rotating disc, the rotating bearing and the thrust bearing sequentially sleeve the transmission shaft from one end to the other end of the transmission shaft; a plurality of air holes are uniformly formed in the rotating disc; the blowing mechanism is mounted inside the housing; the air holes in the rotating disc are tangent to an airflow generated by the blowing mechanism. The sound-wave dust-blowing device is used for cleaning dust, rust, oxide skin and the like on a furnace wall.

Owner:TIANJIN HANGWOTE MACHINERY MFG

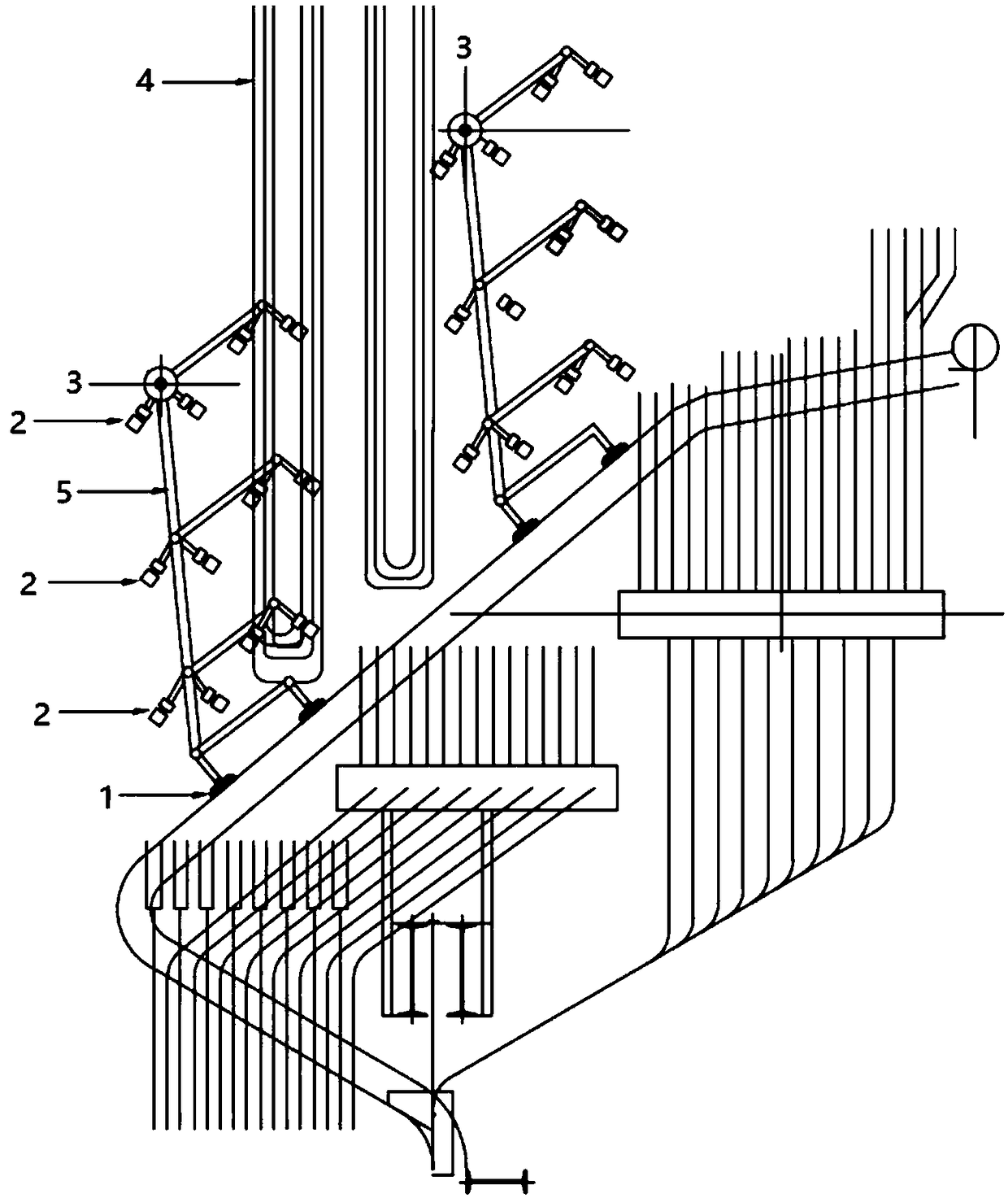

Furnace arch soot blowing system of boiler

The invention relates to a furnace arch soot blowing system of a boiler. The system comprises multiple soot blowing units and soot blowing pipes extending into the boiler from soot blowing holes. Thesystem is characterized in that the soot blowing units are arranged on the soot blowing pipes, each first soot blowing unit comprises multiple coke dust collection soot blowers, each second soot blowing unit comprises high-strength sonic wave soot blowers, and the soot blowing units cooperate with one another for use. The soot blowers cooperate with one another for use, advantages of the soot blowers are fully utilized, and disadvantages of the soot blowers are avoided; at the same time, the structures of the coke dust collection soot blowers and the structures of the high-strength sonic wavesoot blowers are improved, the coke dust collection soot blowers change a direct-flow blowing mode into a vortex blowing mode, and blowing damage caused to high-temperature superheaters, final-stage reheaters and furnace arches is avoided; dry saturated steam or compressed air is pressurized and accelerated twice through spiral guide bodies and annular slits of the high-strength sonic wave soot blowers and then ejected out, so that the speed of air flow is higher, the sound intensity of formed sonic waves is higher, and the effect of removing dust on a boiler pipe can be further improved.

Owner:伊思特(北京)能源科技有限公司

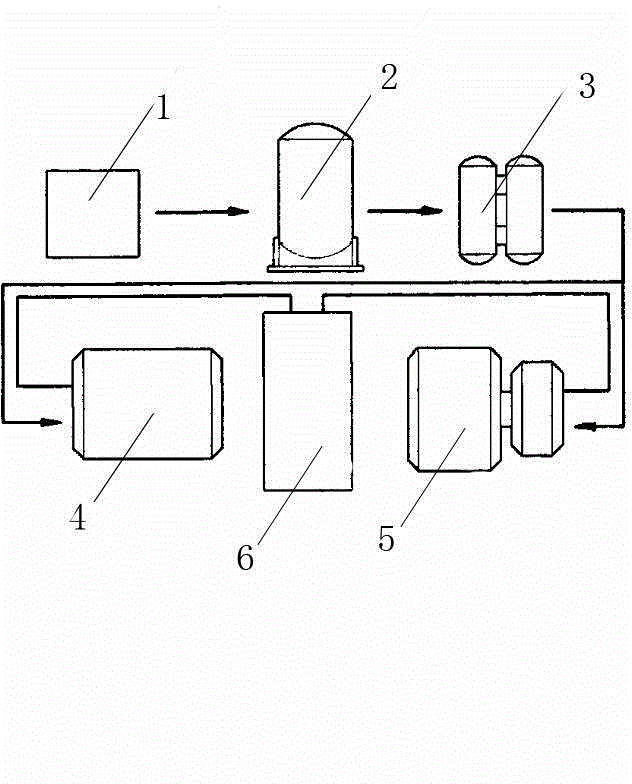

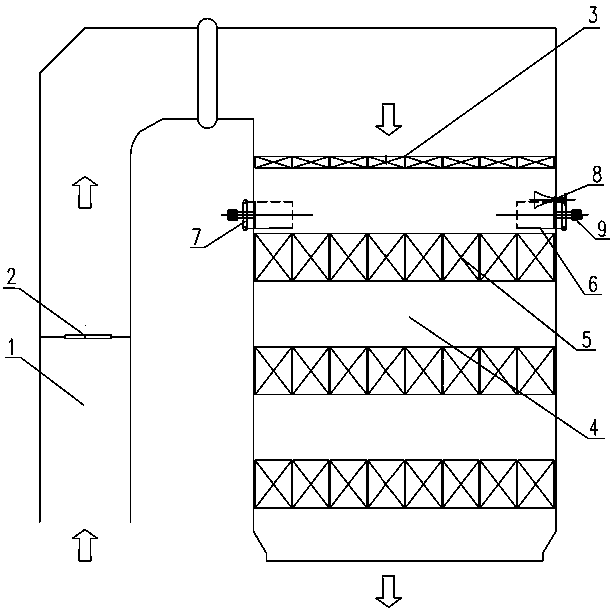

Flue gas denitration system

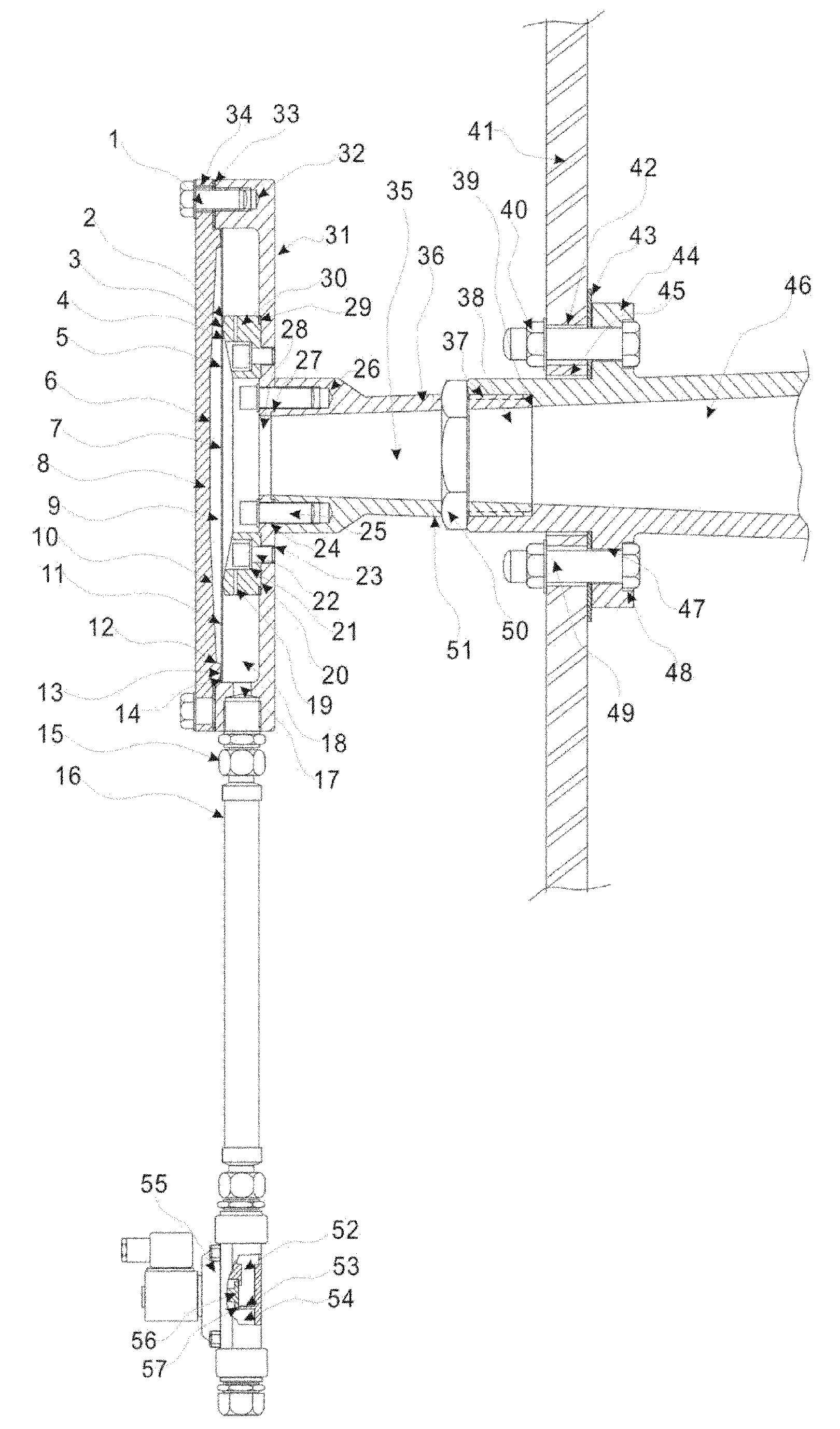

InactiveCN110152486ASmall temperature difference between inside and outsideGuaranteed service lifeDispersed particle separationWater storage tankEvaporation

The invention relates to a flue gas denitration system. The system comprises an ammonia water storage tank, an ammonia water transfer pump, an ammonia water evaporation tank, a tar adsorption device,a hot-blast stove, an ammonia spray grille, a reactor body, a flow guiding plate, a rectifying grille, a first catalyst module, a second catalyst module, a spare catalyst module, a sonic soot blower and a compressor tank. The hot-blast stove provides hot air for the reactor body to preheat the catalyst modules, so the service life of the catalyst modules is ensured, a temperature difference between the inside and the outside of the reactor body is small, and deformation of a steel structure is prevented; the heating rate of the catalyst modules, the temperature difference between flue gas andthe catalyst modules and the heating rate of the flue gas are controlled to prevent the catalyst structure from being damaged; and ammonia gas and the flue gas are sufficiently and uniformly mixed bythe ammonia spray grille, and the catalyst modules are periodically purged and cleaned by the sonic soot blower, so the efficiency of a denitration reaction is ensured.

Owner:无锡西江悦环境科技工程有限公司

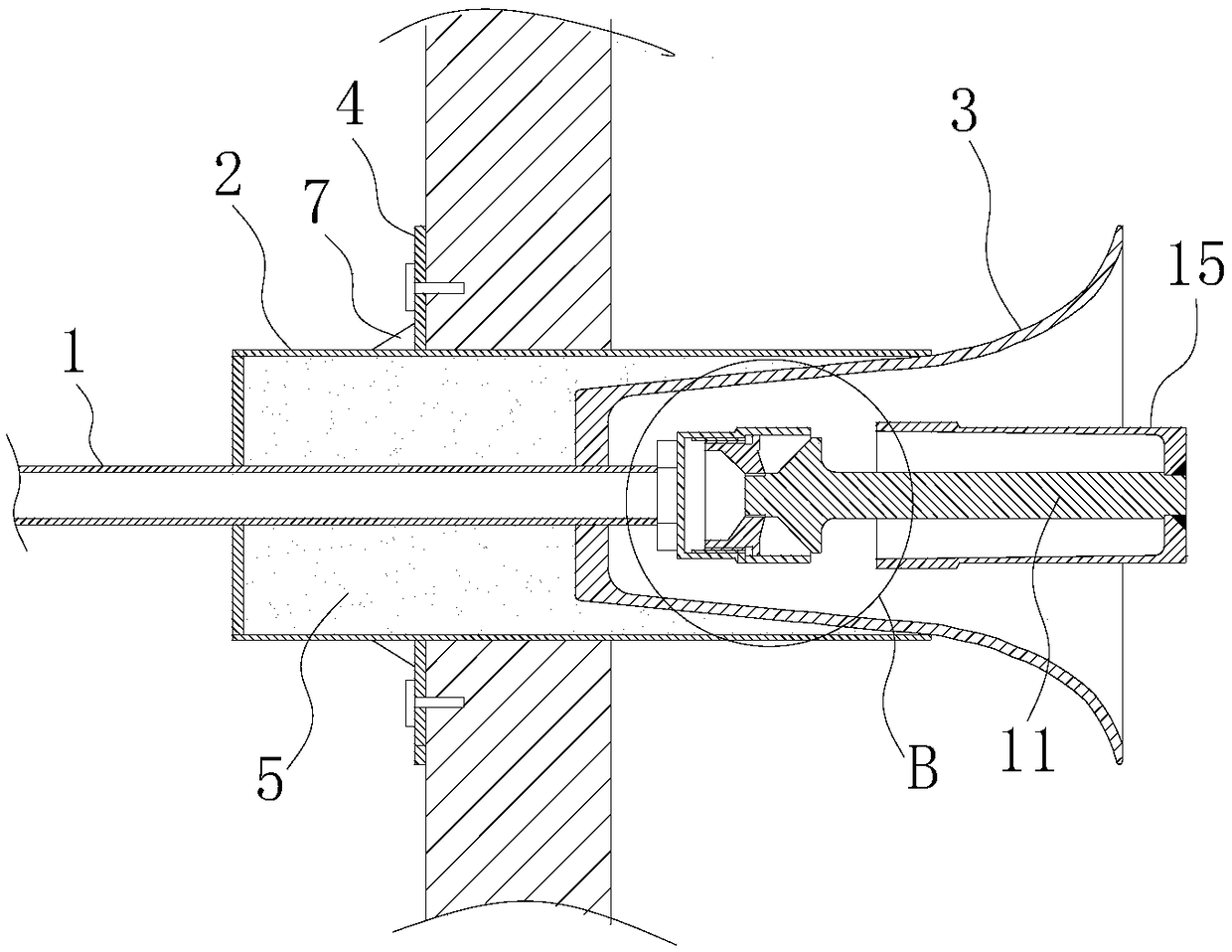

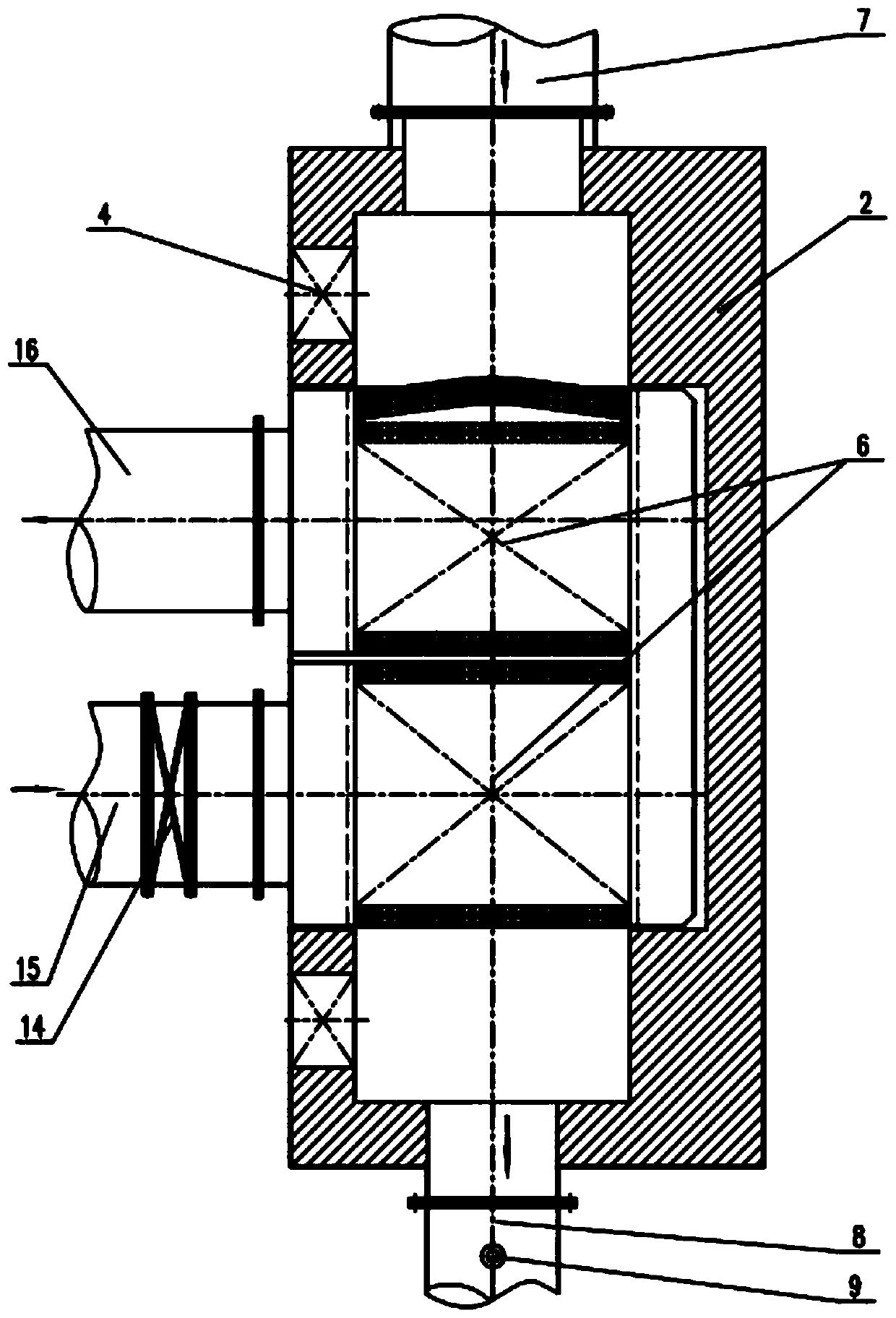

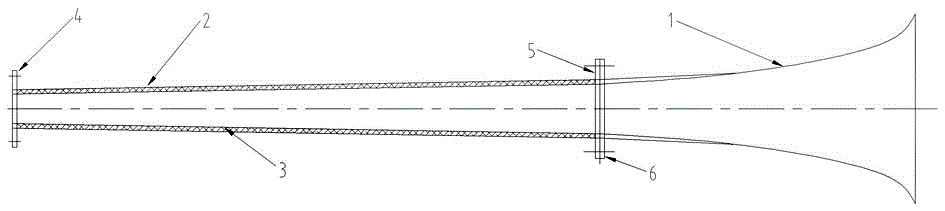

Suspended diaphragm type sound wave soot blower

InactiveCN102384478AAvoid deformationImprove sealingSolid removalCleaning processes and apparatusLow noiseSolenoid valve

The invention relates to a sound wave soot blower which comprises a sound wave generator and a sound wave conveying channel, wherein the sound wave generator comprises a U-shaped diaphragm support, an annular support body, a diaphragm and a pressing cover; the sound wave conveying channel comprises a sound wave output pipe and a horn mouth which are connected with each other through threads; the U-shaped diaphragm support is provided with a bottom part and two vertical side walls; a gas inlet is arranged on each side wall; a central through hole is formed on the bottom part and is communicated with the sound wave conveying channel; the annular support body is concentrically fastened at the inner side of the bottom part of the diaphragm support; the diaphragm is freely placed on the support body; the pressing cover is locked on the top surface of the diaphragm support by a fastening part and is provided with an annular flange matched with the diaphragm support in internal diameter and pressed against a diaphragm outer edge; and when compressed gas enters the diaphragm support through a solenoid valve via the gas inlet, the diaphragm is suspended on the support body to continuously and slightly bend and recover so as to generate sound wave to be sent out from the sound wave conveying channel. With the adoption of the suspended diaphragm, the sound wave soot blower is not easy to fail in advance and has the advantages of simple structure, low noise, convenience in disassembly and replacement and strong applicability.

Owner:K M TAM INT

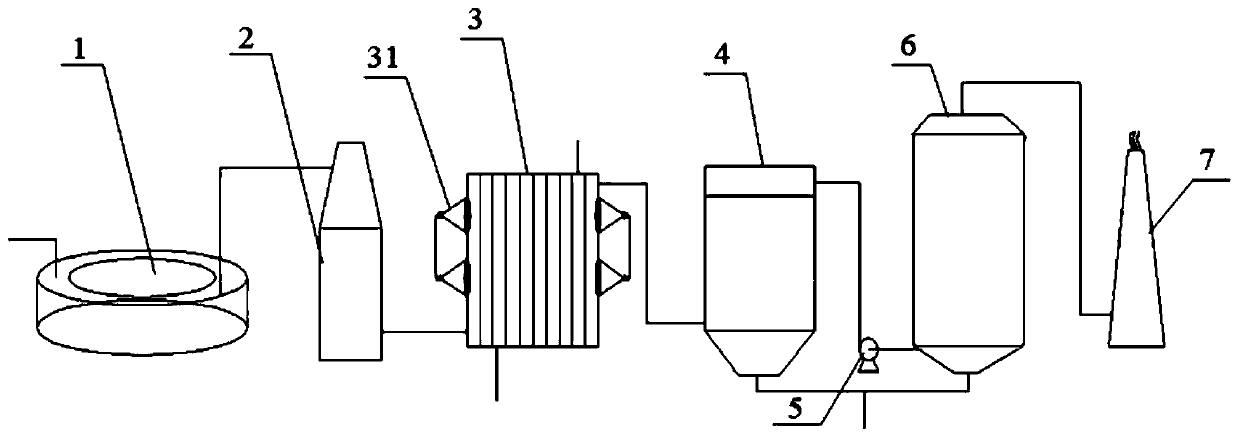

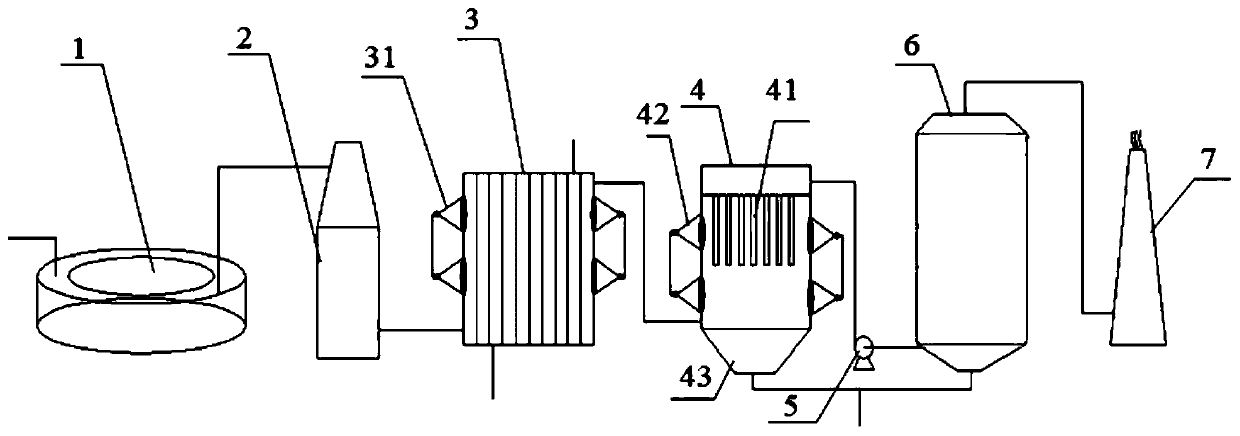

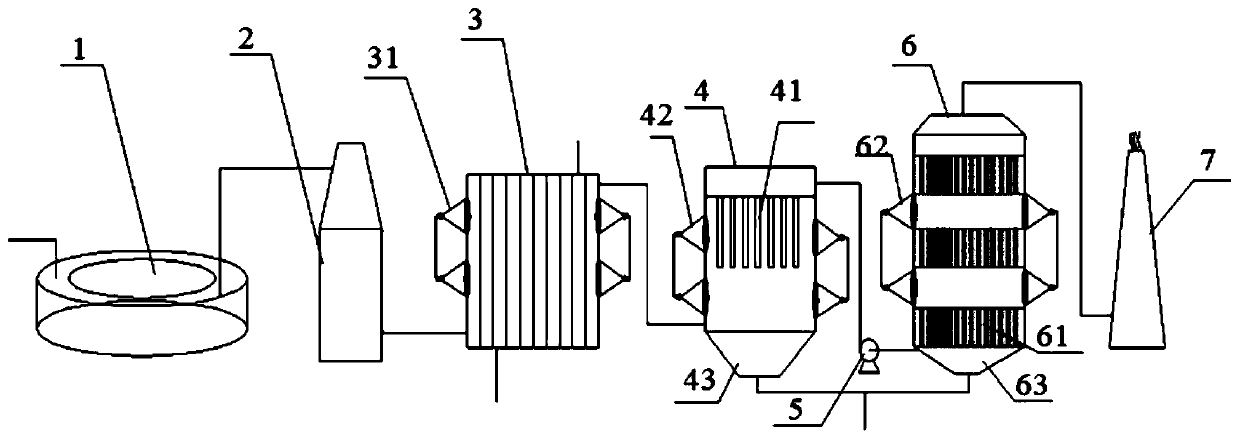

Rotary hearth furnace smoke comprehensive treatment system and method

PendingCN110986605AEffective interceptionGuaranteed uptimeCombustion processIncreasing energy efficiencyDust controlEngineering

The invention relates to a rotary hearth furnace smoke comprehensive treatment system and method. The treatment system comprises a rotary hearth furnace, a high-temperature smoke outlet of the rotaryhearth furnace is connected with a waste heat boiler, an outlet of the waste heat boiler is connected with an air heat exchanger, the air heat exchanger is connected with a bag type dust collector, anoutlet of the bag type dust collector is connected with a cyclone dust collector through a pipeline, and the cyclone dust collector is connected with a chimney. A frequency-adjustable high-sound-intensity acoustic wave soot blower located on the air heat exchanger can conduct effective blockage removing and descaling on the air heat exchanger; after zinc-containing metal dust and other metal dustenter the bag type dust collector, ultrafine particles are aggregated into large particles through a first acoustic wave aggregation device, and the metal dust recovery efficiency of the bag type dust collector is improved; the bag type dust collector is further subjected to real-time blockage removing, the service life of the bag type dust collector is prolonged, the cost is reduced, and high-sound-intensity acoustic waves conduct collaborative efficiency improving and descaling on the bag type dust collector in the rotary hearth furnace smoke system; and the ultralow emission requirement for smoke of the rotary hearth furnace is met on the front section of the chimney through an acoustic wave aggregation dedusting device.

Owner:NANJING CHANGRONG ACOUSTIC INC +2

Spark fire resistant device for bag-type dust removers in biomass boilers

PendingCN108671642AAvoid enteringAnti-cloggingDispersed particle filtrationTransportation and packagingBaghouseAcoustic wave

The invention discloses a spark fire resistant device for bag-type dust removers in biomass boilers. The device includes a flue gas inlet, flue gas cooling plates, baffling fire resistant plates, a middle partition plate and a first metal microporous mesh plate; the metal microporous mesh plates are provided with sonic soot blowers; two ash buckets are arranged at the bottoms of the left and rightcase bodies, and are provided with pneumatic arch breakers; a second microporous filtering mesh plate is connected to a flue gas outlet; the left and right case bodies are provided with access doors;and the whole device is supported by a support. Flue gas can be cooled by the cooling plates, and hit by the baffling fire resistant plates to make large particle sparks smaller or even quench afterimpact. The whole boiling zone is filled with boiling fluidized state ash, so that most tiny particles having sparks can be wrapped and quenched; and part of tiny particles having sparks which are notbeing eliminated can be blocked by the first metal microporous filtering mesh plate and the second microporous filtering mesh plate, and therefore, sparks can be completely stopped to enter bag-typedust removers.

Owner:王脯胜

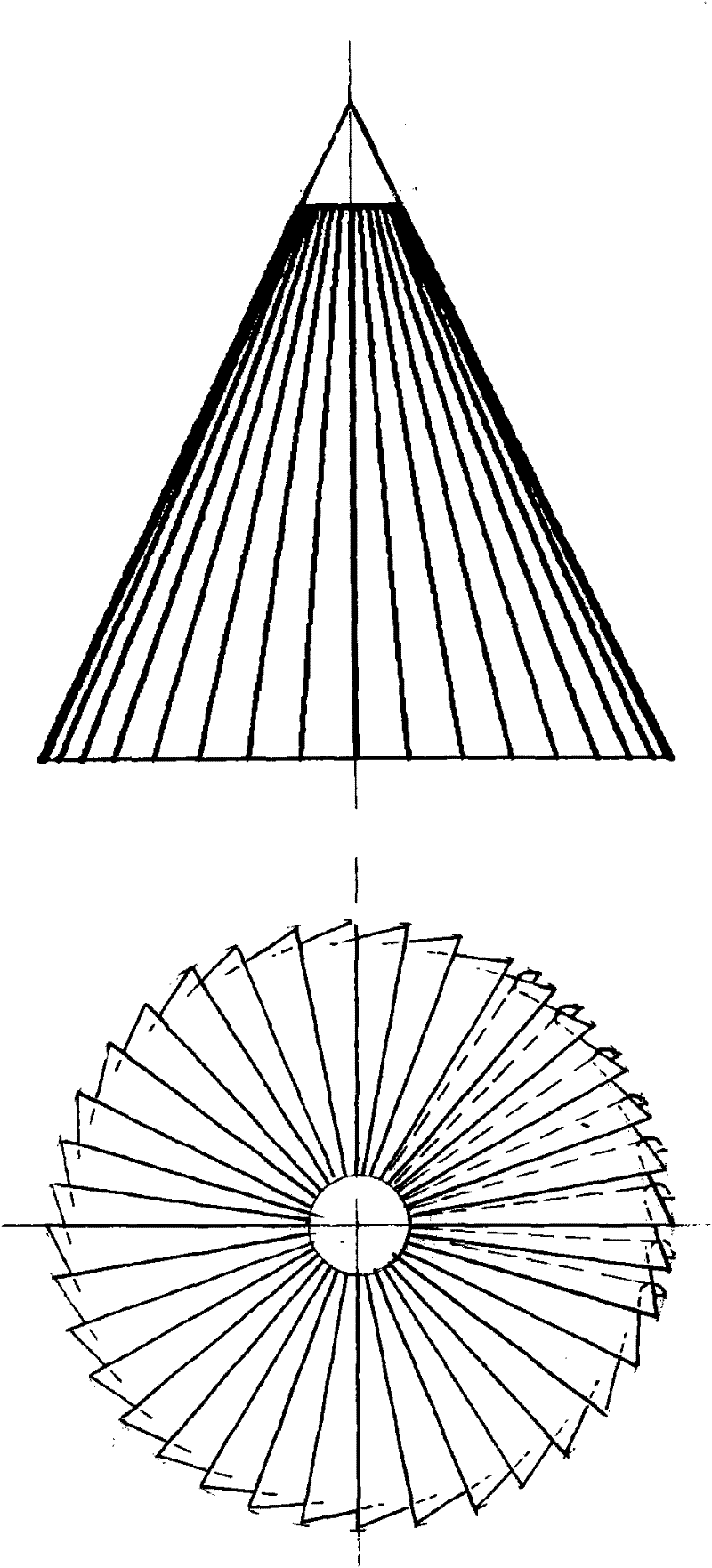

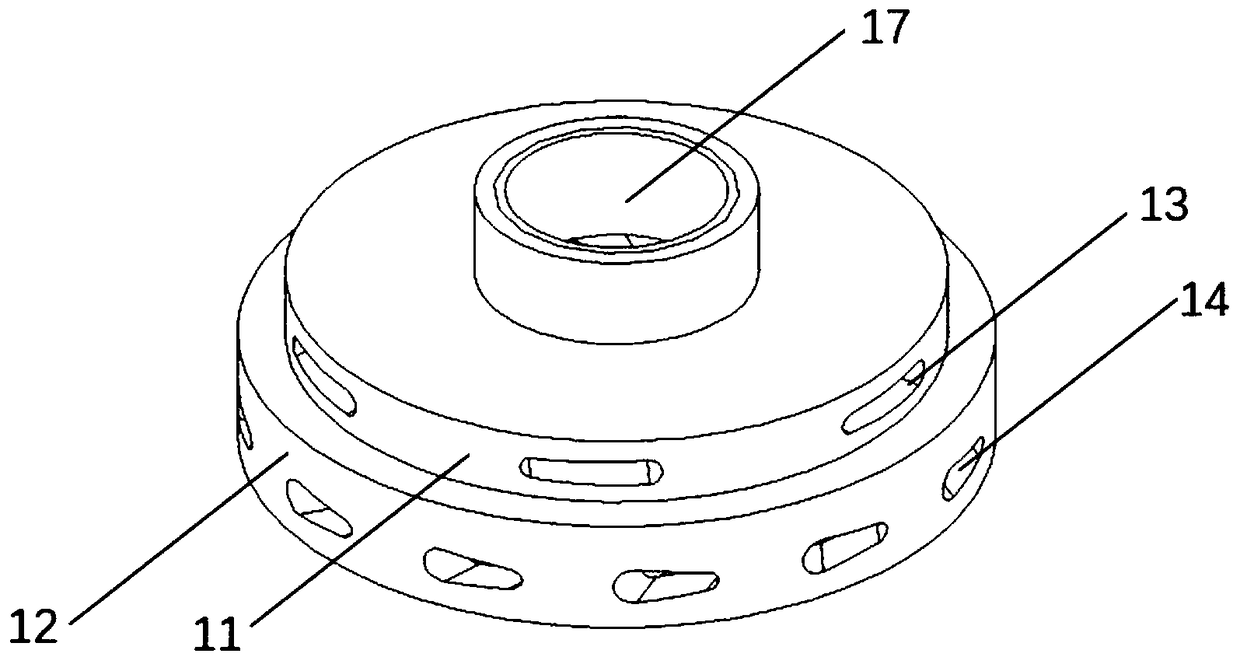

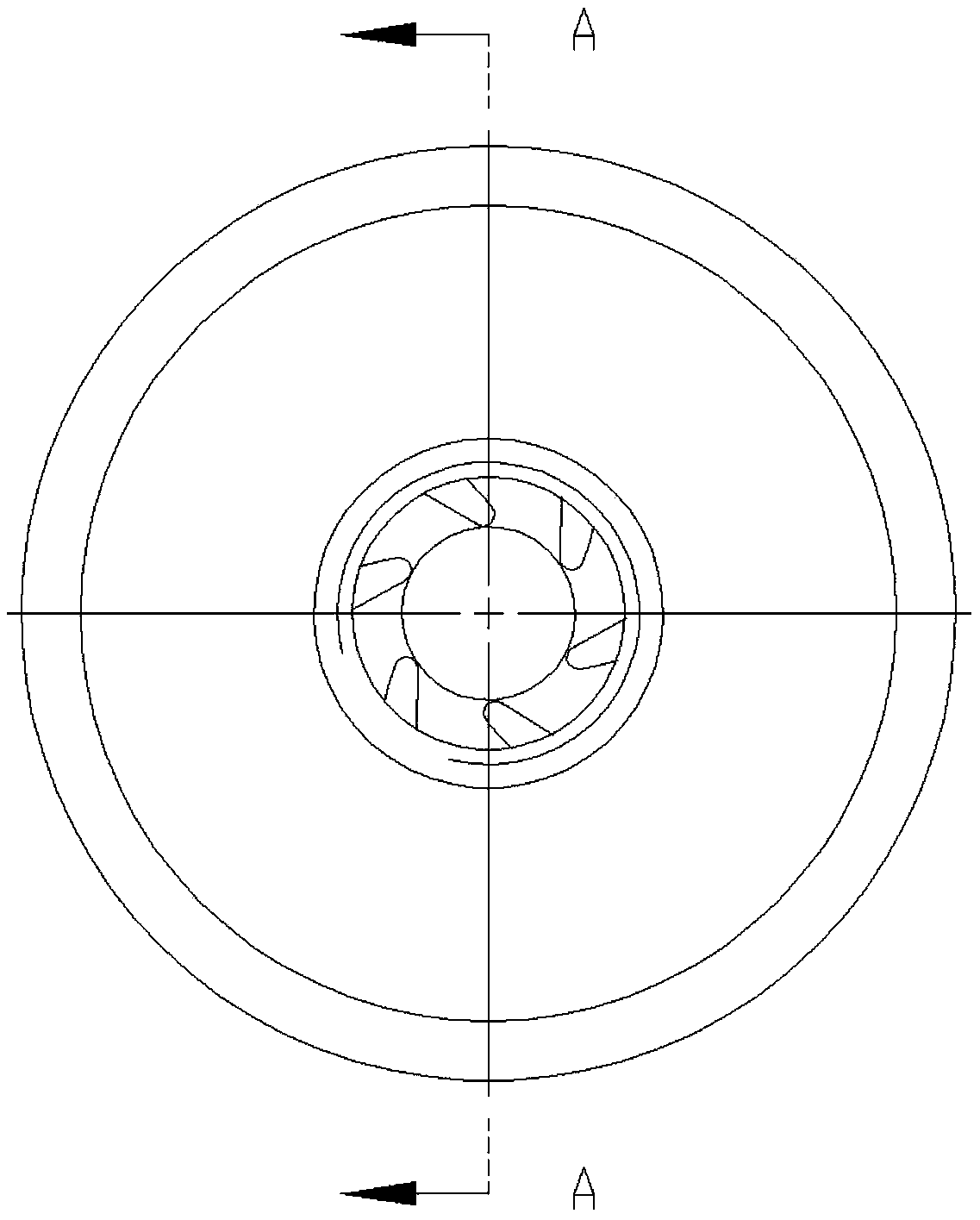

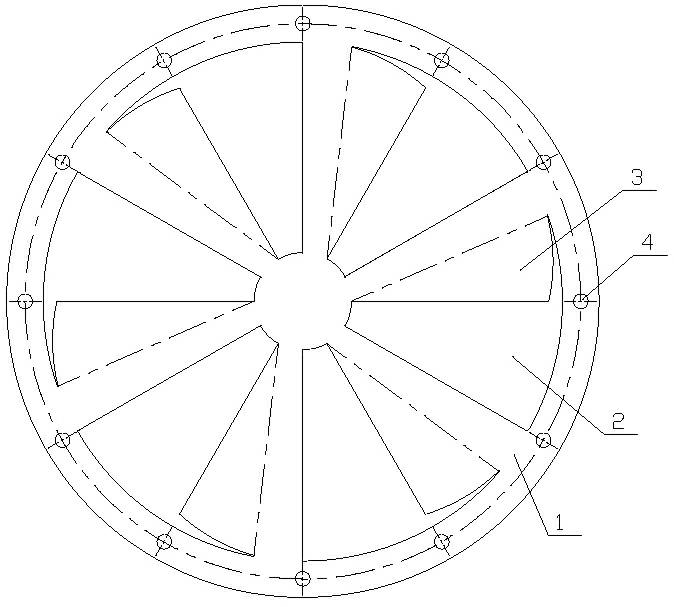

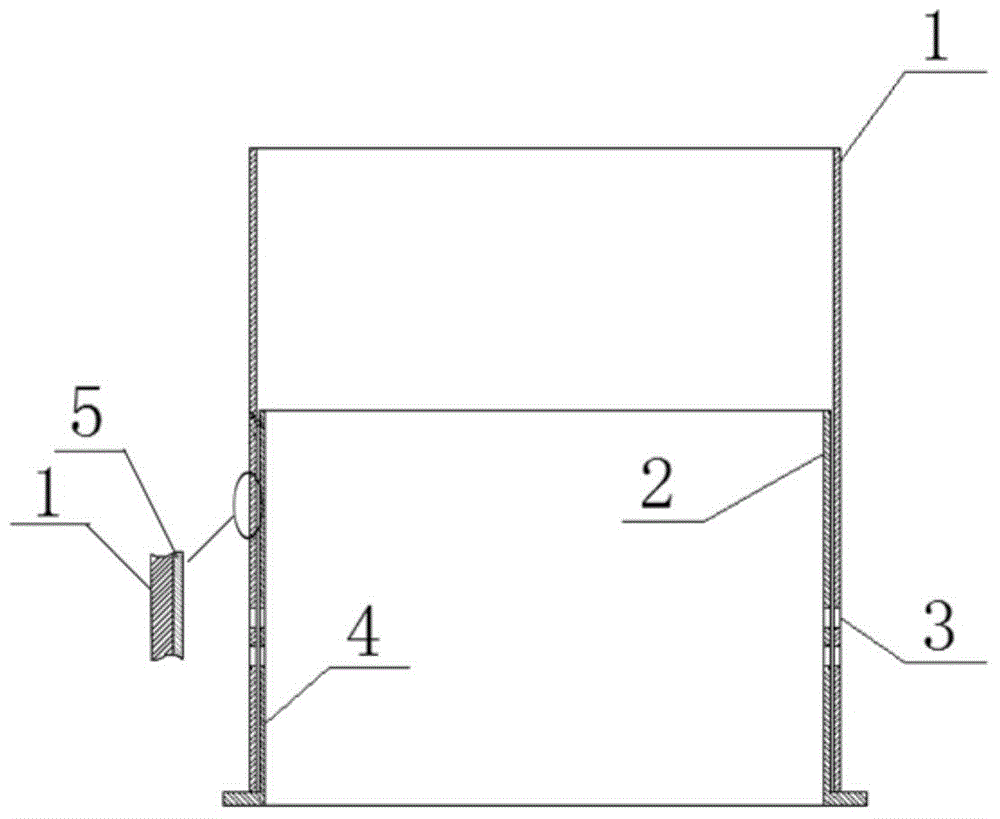

Diversion plate used for acoustic wave soot blower

The present invention discloses a diversion plate used for an acoustic wave soot blower. The guide plate is characterized in that a circular guide plate is included, fan-shaped diversion holes are arranged on the upper circumference of the circular guide plate, diversion blades are arranged on the same side of every fan-shaped diversion hole, and the included angle between the diversion surface of the diversion blade and the through-flow surface of a fan-shaped diversion hole is more than 10 degrees and less than 60 degrees. The diversion plate has the advantages that, after being diverted by the diversion blades arranged on the side of every fan-shaped diversion hole, compressed air and acoustic wave are blown out in the tangential direction of the fan-shaped diversion hole to form a whirlpool shape, thus the effective soot blowing area is greatly increased and the use effect of the acoustic wave soot blower is consequently increased.

Owner:上海恒纽科技发展有限公司

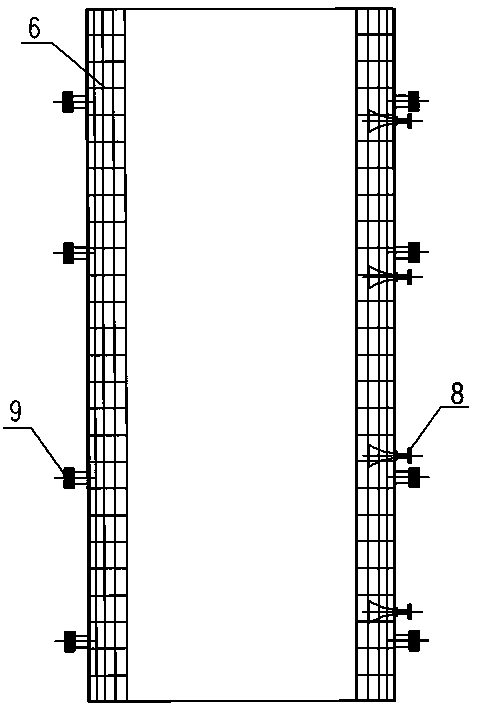

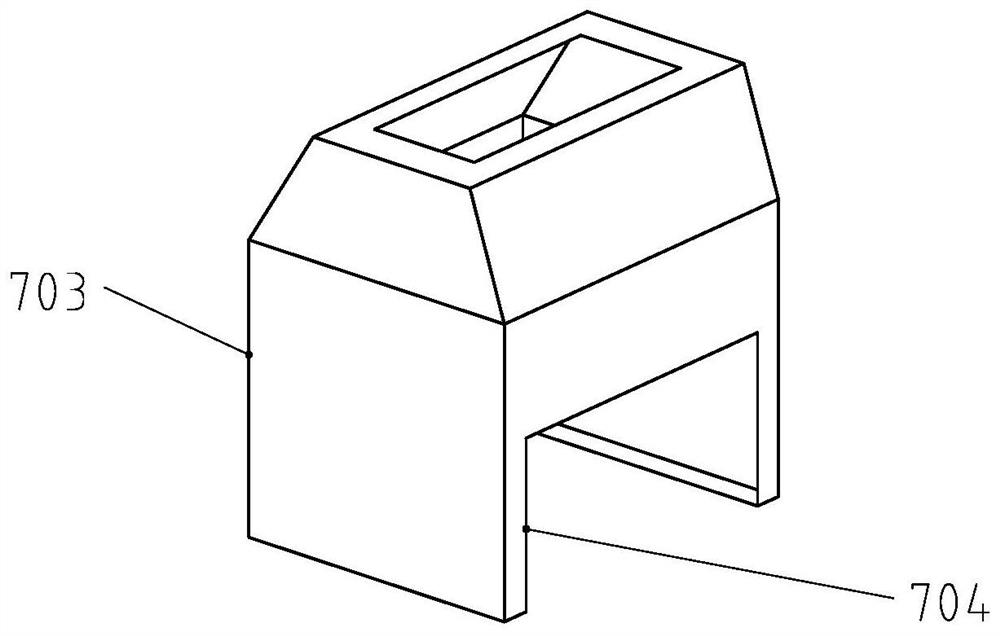

Reciprocating type vibration device for reducing soot formation blockage of SCR denitration catalyst, and working method thereof

PendingCN111013379ALittle impact on the flow fieldImprove the serious problem of dust accumulation and blockageDispersed particle separationPtru catalystEconomic benefits

The invention discloses a reciprocating type vibration device for reducing soot formation blockage of an SCR denitration catalyst, and a working method thereof, and belongs to the technical field of SCR denitration. In the long-term operation process of the SCR denitration catalyst, the change of a flow field and the existence of a purging blind area in a soot blower easily cause the problem of soot accumulation and blockage on the surface of the catalyst around a reactor and seriously affects the safe and stable operation of a denitration system and a unit. Movable dust-proof nets are arranged in the areas, prone to soot accumulation blockage, of the front wall and the rear wall of the SCR reactor on the upper portion of the catalyst, a driving device is arranged to move up and down, andthe purpose of reducing catalyst soot formation is achieved in combination with dust blowing of the vibration device and the sound wave dust blower. The device is simple in structure, small in influence on the flow field of an existing denitration device, low in investment and operation cost and high in operability, has applicability to the SCR denitration device, can effectively solve the problemthat a catalyst is seriously blocked by accumulated dusts, has good environmental protection benefits and economic benefits and is wide in application prospect.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Ammonium bisulfate deposition prevention five-chamber rotary preheater and operation method thereof

PendingCN110118361ALow costRelieve blockageCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention belongs to the technical field of thermal power plant boiler auxiliary equipment and relates to an ammonium bisulfate deposition prevention five-chamber rotary preheater and an operationmethod thereof in order to solve the technical problem that an existing air preheater is blocked by ammonium bisulfate easily. The air preheater is internally provided with an air preheater rotor. Aheat exchange element is arranged on the air preheater rotor. The air preheater internally comprises an exhaust gas side and air sides. The air sides include the air side I, the air side II, the air side II and the air side IV. An inlet of the air side I is connected with an inlet of the exhaust gas side through a pipeline. A high-temperature fan I is arranged between the inlet of the air side I and the inlet of the exhaust gas side. An outlet of the air side IV is connected with an inlet of the air side IV through a pipeline. A high-temperature fan II is arranged between the outlet of the airside IV and the inlet of the air side IV. A steam soot blower is arranged at the cold end of the air side II. An acoustic soot blower is arranged at the cold end of the air side III. Under the full-load working condition, the phenomenon of blockage of the ammonium bisulfate deposition prevention five-chamber rotary preheater can be effectively relieved on line, and the frequency of non-planned shutdown of the air preheater can be reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

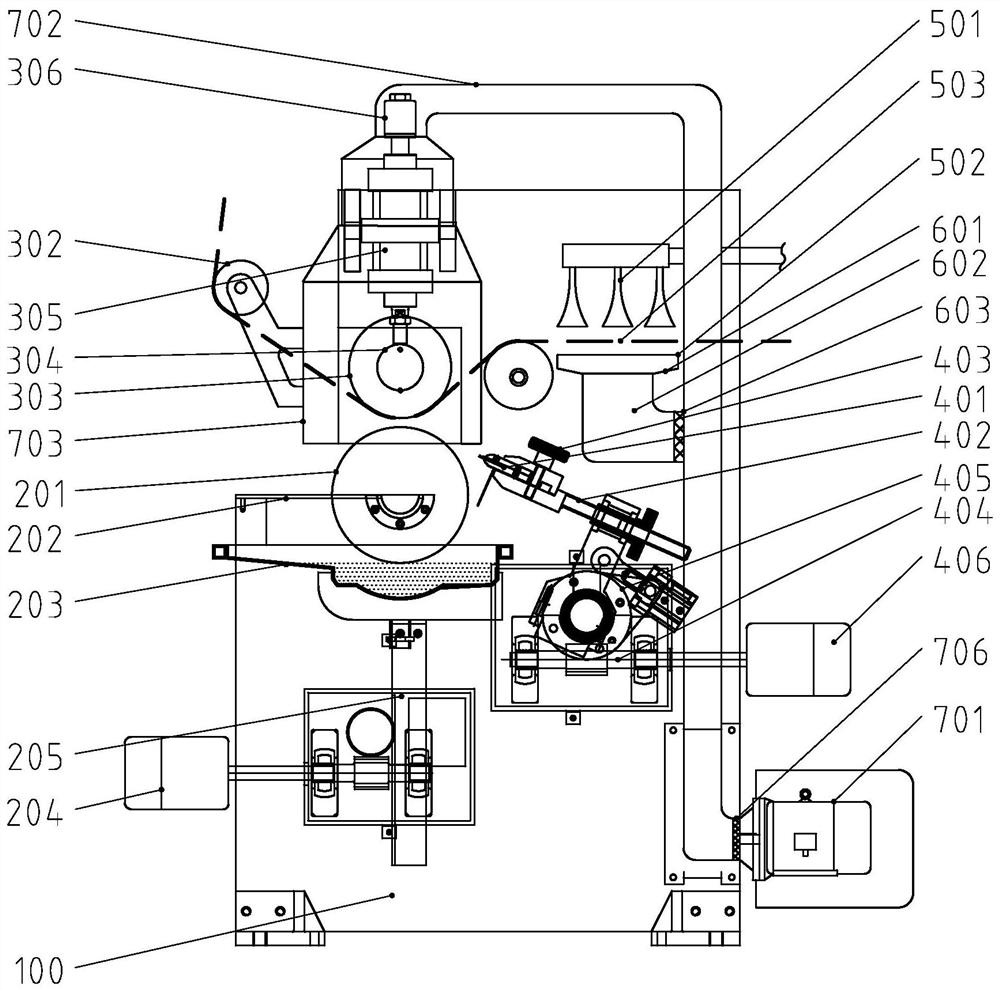

Industrial glass fiber fabric coating device

InactiveCN112058583AGood adhesionPenetrate fastMechanical cleaningPressure cleaningGlass fiberPolymer solution

The invention provides an industrial glass fiber fabric coating device capable of effectively eliminating bubbles in the coating process. The industrial glass fiber fabric coating device comprises a rack, a coating roller assembly, a conveying roller assembly, a fixed-thickness scraper assembly, a front ash removal assembly and a negative pressure assembly, wherein the coating roller assembly, theconveying roller assembly, the fixed-thickness scraper assembly, the front ash removal assembly and the negative pressure assembly are arranged on the rack, the front ash removal assembly comprises asonic ash blower and a negative pressure dust removal pipeline which are arranged oppositely, a feeding channel is arranged between the sonic ash blower and the negative pressure dust removal pipeline, and one end of the negative pressure dust removal pipeline communicates with the negative pressure assembly; and the negative pressure assembly comprises a vacuum pump, an air suction main pipe anda negative pressure cover, the vacuum pump communicate with the negative pressure cover through the air suction main pipe, the negative pressure cover is arranged above the coating roller assembly and a back roller in a covering mode, and the middle of the air suction main pipe communicates with the negative pressure dust removal pipeline. According to the device, the negative pressure assembly enables the coating working portion of a glass fiber fabric to generate negative pressure, the residual bubbles in a polymer solution at the coating position are rapidly separated out, and the qualityof the finally formed coating is better.

Owner:嘉兴杰特新材料股份有限公司

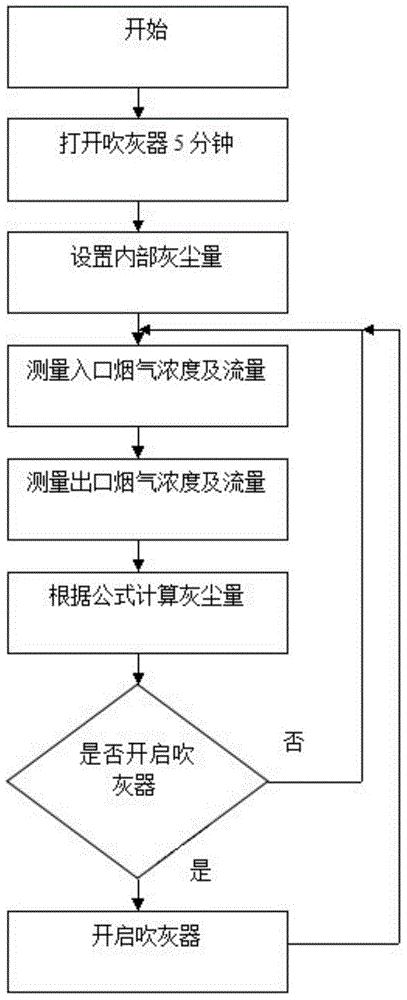

Automatic control device for soot blower in SCR denitration process, and control method of control device

InactiveCN104407563AControl the amount of dustAutomatic and precise soot blowingProgramme control in sequence/logic controllersAutomatic controlEngineering

The invention discloses an automatic control device for a soot blower in an SCR denitration process and a control method of the control device. The control method comprises the following steps: controlling the ultrasonic wave soot blower to blow soot for 5 minutes by a PLC processor; presetting a value of soot content inside a reactor in the PLC processor; according to a time interval with the cycle of 1 second, respectively detecting the particle concentration and the gas flow of inlet gas through an inlet particle concentration sensor and an inlet gas flow sensor; according to the time interval with the cycle of 1 second, respectively detecting the particle concentration and the gas flow of outlet gas through an outlet particle concentration sensor and an outlet gas flow sensor; calculating the soot content inside the reactor by a formula, judging whether the internal soot content is larger than the set value or not, opening the ultrasonic wave soot blower and delaying for 1-3 minutes when the internal soot content is larger than the set value, and continuing to measure when the internal soot capacity is smaller than the set value. The device and the method have the benefits that the soot content in a reactor can be effectively controlled, and soot can be automatically and precisely blown.

Owner:YANCHENG INST OF TECH

High energy environment-friendly sonic soot blower

InactiveCN108895476AReduce noiseImprove working environmentSolid removalHigh energyWorking environment

The invention relates to the technical field of sonic soot blowers. The purpose is to provide a high energy environment-friendly sonic soot blower which can effectively prevent noise pollution. According to the technical scheme, the high energy environment-friendly sonic soot blower comprises a soot blower body, an intake pipe and a cylindrical mounting sleeve of which one end is closed and the other end is opened; the soot blower body comprises a heat-resistant steel horn and a sounding assembly arranged in the heat-resistant steel horn; the smaller end of the heat-resistant steel horn is inserted from the opened end of the mounting sleeve, and the middle of the heat-resistant steel horn abuts against the edge of the opened end of the mounting sleeve and is fixedly connected with the mounting sleeve; a fixing flange is arranged on the outer surface of the middle of the mounting sleeve in the circumferential direction. The blower can greatly reduce the noise outside a furnace chamber,improve the working environment of staff, and be more environmentally friendly.

Owner:上海能靖机电科技有限公司

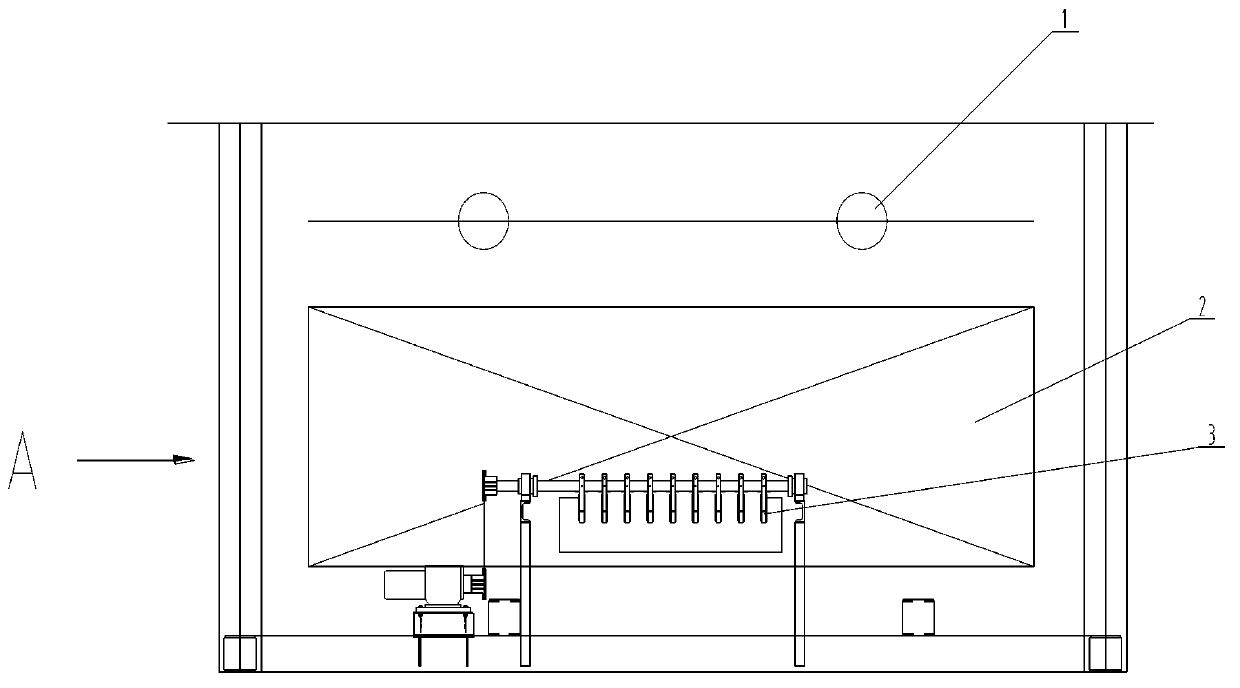

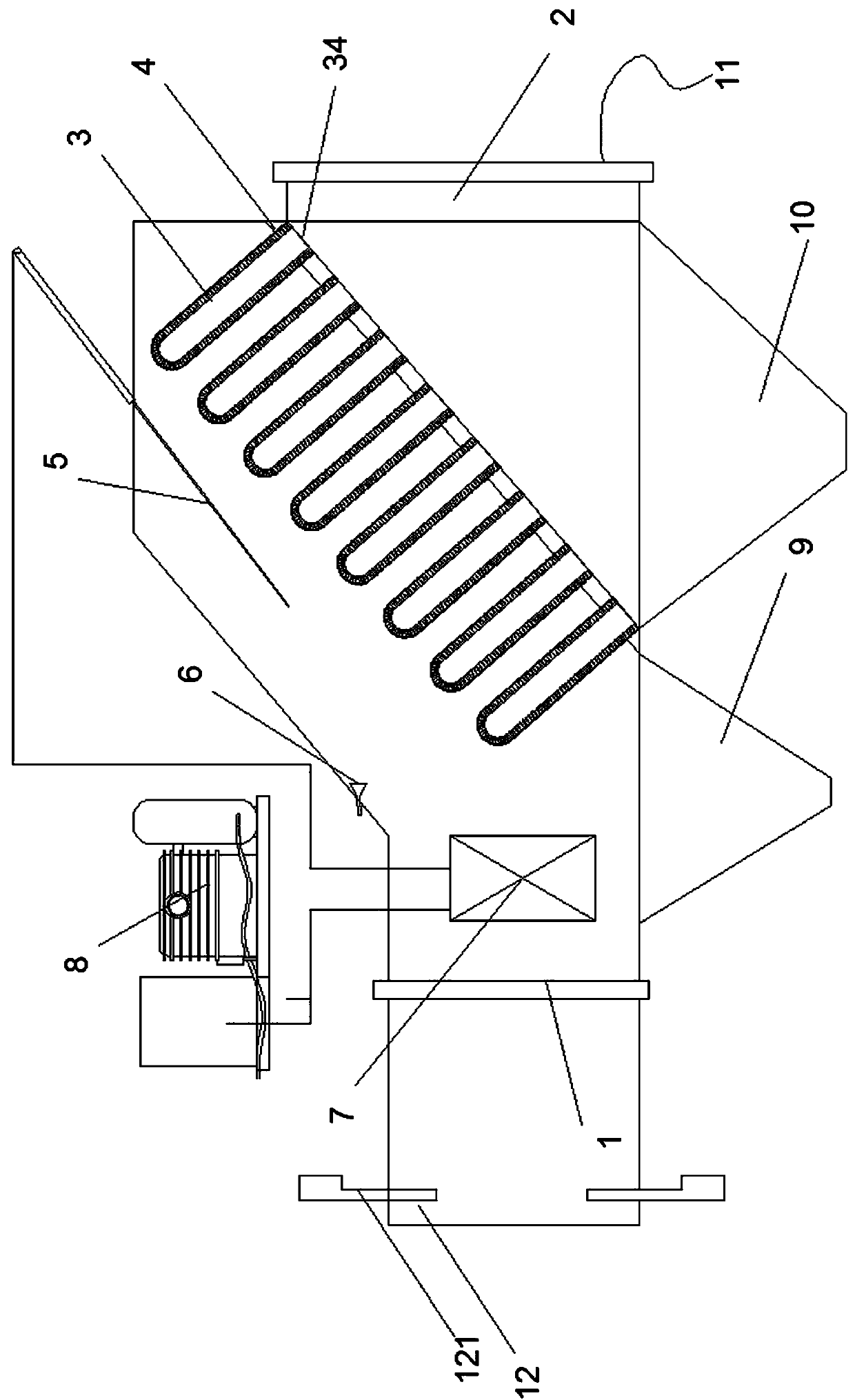

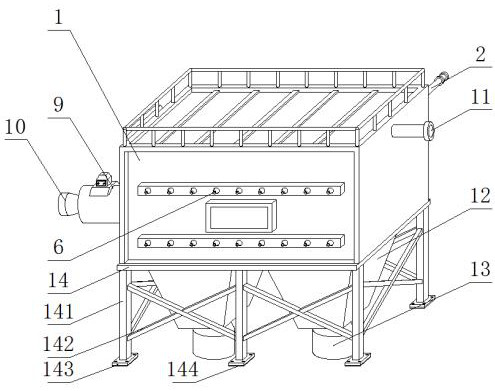

Energy-saving system with automatic ash removal function of horizontal type gas heat exchanger

PendingCN111397385AExtended service lifeImprove heat transfer efficiencyFurnace safety devicesControl devices for furnacesInsulation layerSound wave

The invention discloses an energy-saving system with an automatic ash removal function of a horizontal type gas heat exchanger, and belongs to the technical field of energy conservation and emission reduction. The energy-saving system comprises a steel structure supporting frame, the horizontal type energy-saving heat exchanger is borne on the upper part of the steel structure supporting frame, aninner masonry heat preservation layer is built on the inner wall of the horizontal type energy-saving heat exchanger, a sound wave ash blower is installed on the upper part of the horizontal type energy-saving heat exchanger, the input end of the horizontal type energy-saving heat exchanger is connected with a smoke inlet pipeline, the output end of the horizontal energy-saving heat exchanger isconnected with a smoke outlet pipeline, and a coal gas monitoring instrument is installed on the smoke outlet pipeline; and ash deposition bins are arranged at the bottom of the horizontal type energy-saving heat exchanger at intervals. According to the energy-saving system with the automatic ash removal function of the horizontal type gas heat exchanger, high-pressure blowing is carried out through the sound wave ash blower at the top, ash on the pipe wall of the heat exchanger can be blown off at any time and collected in a centralized mode, thus the service life of the horizontal type energy-saving heat exchanger is prolonged, the heat exchange efficiency is greatly improved due to the fact that ash does not exist on the pipe wall, and meanwhile dust particles in smoke are reduced.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

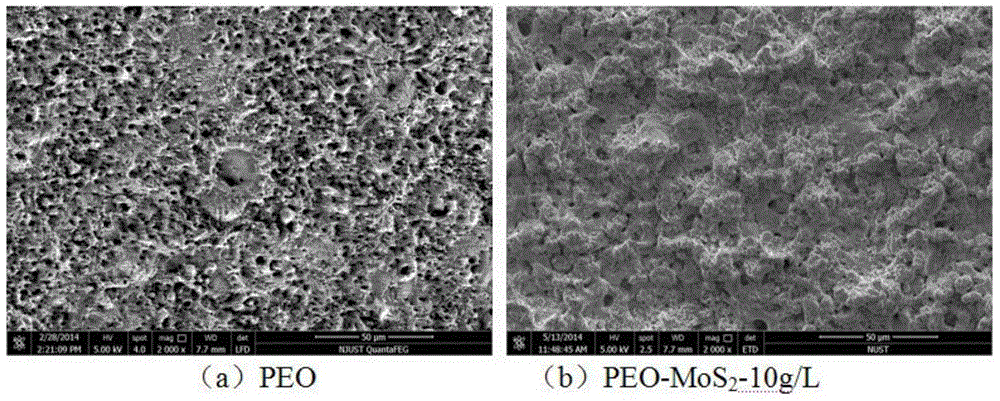

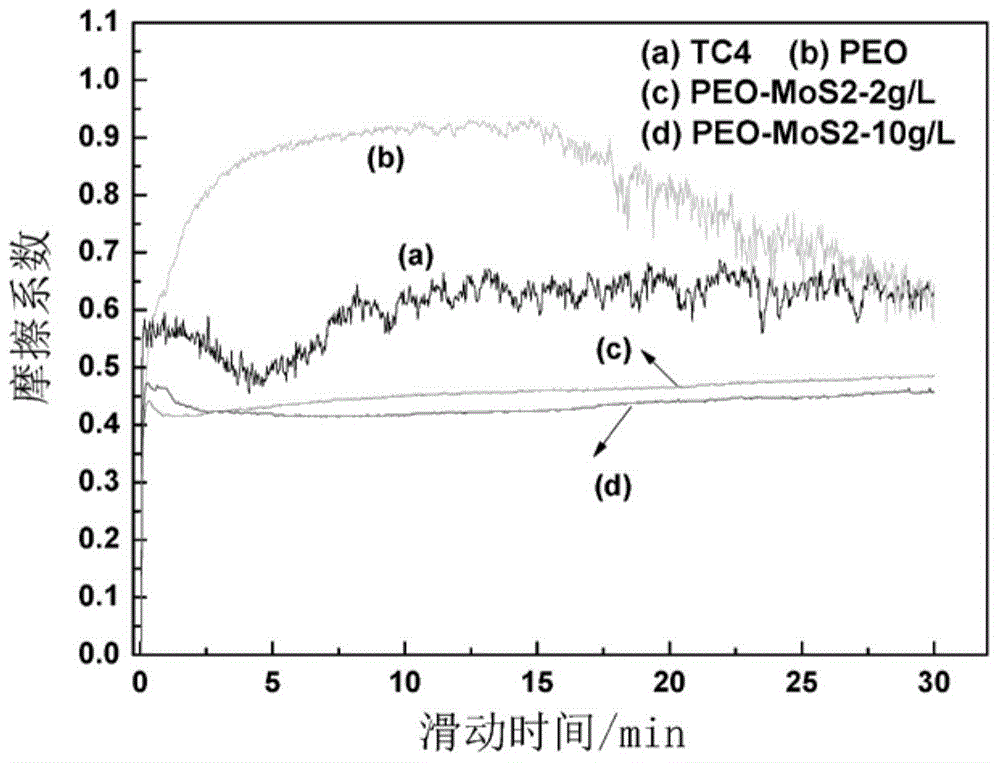

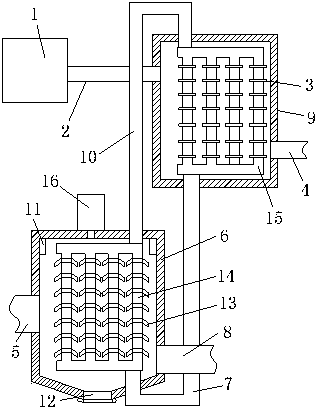

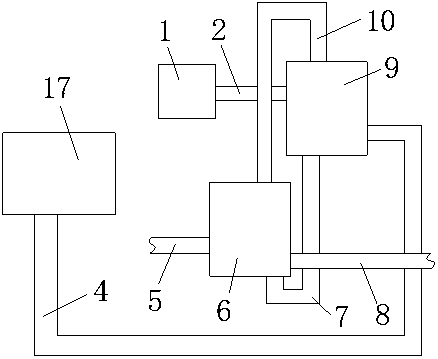

Coating for frequency-adjustable high-sound-intensity soot blower sound production assembly, and preparation method for coating

InactiveCN104404600AReduce repeated toolingAvoid mismatchSurface reaction electrolytic coatingAnodizingSound production

The invention discloses a coating for a frequency-adjustable high-sound-intensity soot blower sound production assembly and a preparation method for the coating. The coating is arranged on the soot blower sound production assembly, and comprises an oxidation ceramic layer and nano solid lubricant particles, wherein the interior of the oxidation ceramic layer is filled with the nano solid lubricant particles; the oxidation ceramic layer is a hard anodizing coating; the nano solid lubricant particles comprise nano MoS2 particles or nano graphite particles. According to the coating, the nano solid lubricant particles are uniformly dispersed in an electrolyte solution, and a continuous oxidation ceramic layer / solid lubricant composite coating can be formed on the inner surface of an outer cylindrical thin-walled part in one time, repeated tooling times of the outer cylindrical thin-walled part are reduced, so that mismatching of a sound production assembly due to the deformation of the thin-walled part is avoided.

Owner:NANJING UNIV OF SCI & TECH +1

Heat pipe heat exchange device for waste heat recovery, and working method thereof

PendingCN110793364ARealize heat absorption utilizationIncrease profitIndirect heat exchangersCombustion technology mitigationAir compressionProcess engineering

The invention discloses a heat pipe heat exchange device for waste heat recovery, and a working method thereof. The heat exchange device comprises a hot air duct, and the hot air duct is fixedly installed on and communicates with a heat exchanger evaporation shell; the heat exchanger evaporation shell is fixedly provided with and communicates with an air outlet pipe, and an evaporation pipe is fixedly installed in the heat exchanger evaporation shell; the inner top end of the heat exchanger evaporation shell is fixedly provided with a plurality of acoustic soot blowers, and the middle part ofthe top end of the heat exchanger evaporation shell is fixedly connected with an air compression soot blower; the upper end of the evaporation pipe is fixedly provided with and communicates with a steam riser, and the other end of the steam riser is fixedly installed on and communicates with the top end of a heat exchanger condensation shell; a condensation pipe is fixedly installed in the heat exchanger condensation shell, and the other end of the steam riser penetrates through the heat exchanger condensation shell, and communicates with the top end of the condensation pipe; and the bottom end of the condensation pipe is fixedly provided with and communicates with a return pipe. The heat exchange device is scientific and reasonable and environmentally friendly, has the good effects of waste heat absorption and utilization, and is, and is suitable for promotion and application.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Novel denitration and dust removal device for cement kilns

InactiveCN110052163AImprove denitrification efficiencyStable and efficient denitrification efficiencyDispersed particle filtrationTransportation and packagingShock waveFlue gas

The invention provides a novel denitration and dust removal device for cement kilns. The novel denitration and dust removal device for cement kilns comprises a flue gas inlet and a flue gas outlet. The flue gas inlet is connected to an air inlet flue, two-fluid spray guns are annularly arranged on the air inlet flue, an airflow partition plate inclining by 30-60 degrees is arranged in a denitration dust remover shell, a plurality of groups of end-closed ceramic membrane tubes are arranged on the airflow partition plate, a compressed air shock wave soot blower and an acoustic soot blower are arranged on two sides above the end-sealed ceramic membrane pipes respectively, and a first soot pit and a second soot pit are arranged on the left side and the right side of the airflow partition platerespectively and at the bottom of the shell. The novel denitration and dust removal device for cement kilns can achieve denitration and dust removal simultaneously and is higher in denitration and dust removal efficiency, smaller in size and convenient to maintain and repair.

Owner:XIAN XIKUANG ENVIRONMENTAL PROTECTION

Device for protecting air preheater against blockage by combining sound wave and hot air

InactiveCN110454807AAdaptableWide applicabilityVibration cleaningIndirect carbon-dioxide mitigationAir preheaterFlue gas

The invention discloses a device for protecting an air preheater against blockage by combining sound wave and hot air. The device comprises a three-branch-bin rotary air preheater, wherein a first sound wave soot blower is arranged on one side of the top of the three-branch-bin rotary air preheater, an air leakage side collecting cover is arranged on the other side of the top of the three-branch-bin rotary air preheater, an air inlet air collecting cover is arranged at the bottom of the three-branch-bin rotary air preheater, a second sound wave soot blower is arranged on the air inlet air collecting cover, the air leakage side collecting cover is connected with the input end of a circulating fan through an air leakage side collecting pipeline, the output end of the circulating fan is connected with a circulating flue gas spraying pipe through a circulating flue gas pipeline, and the circulating flue gas spraying pipe is connected with the air inlet air collecting cover. According to the device, the NH4HSO4 and the fly ash scale layer which are condensed in the flue gas are released through the combination of high intensity sound wave and hot air circulation, the temperature of thecold end of the air preheater is further increased through the hot air recirculation, so that the problems that the pressure difference between the inlet and outlet of the air preheater is gradually increased and the blockage is serious are solved.

Owner:NANJING CHANGRONG ACOUSTIC INC +2

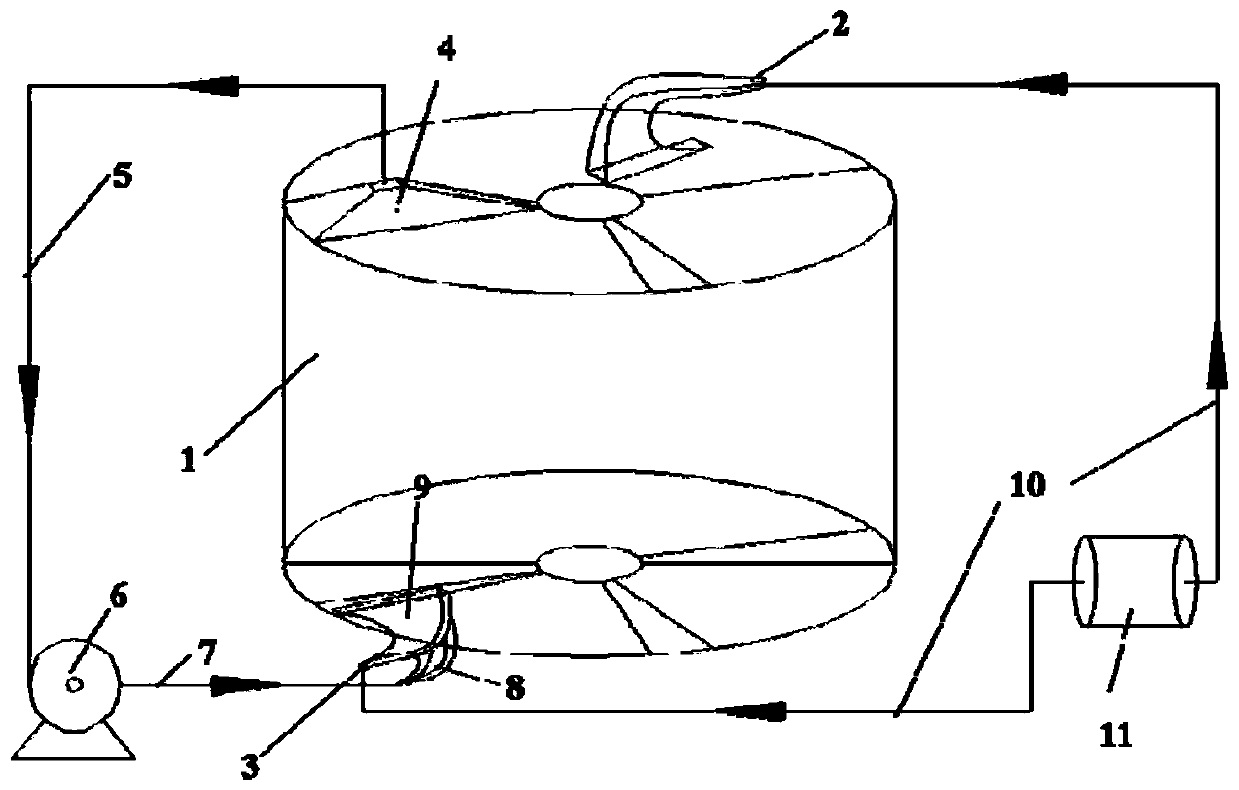

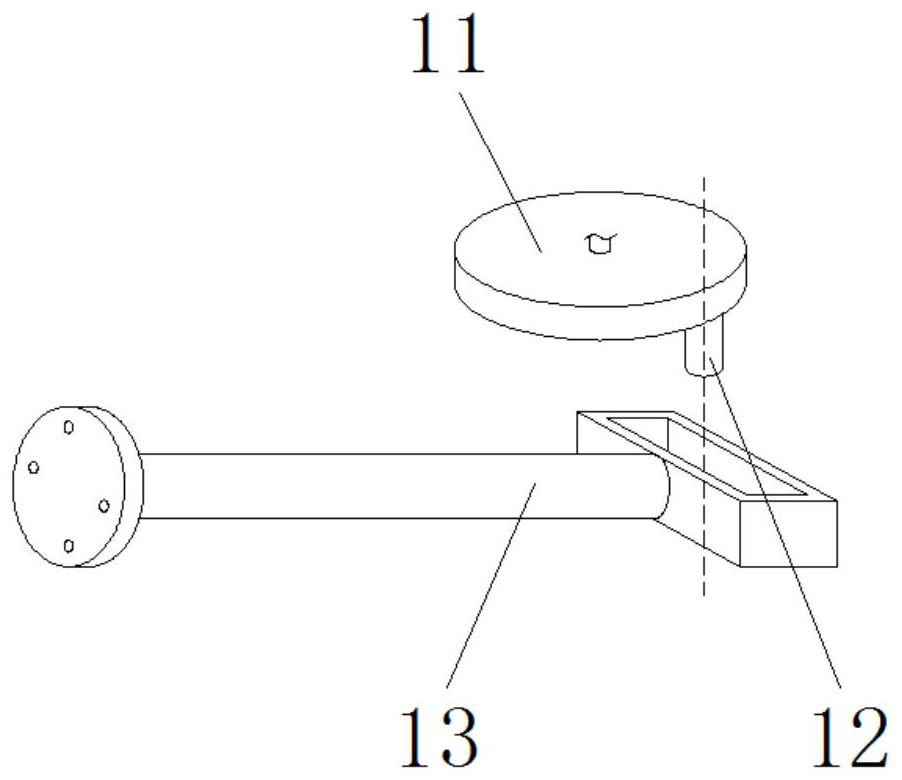

Sonic soot blower as well as manufacture method and application method thereof

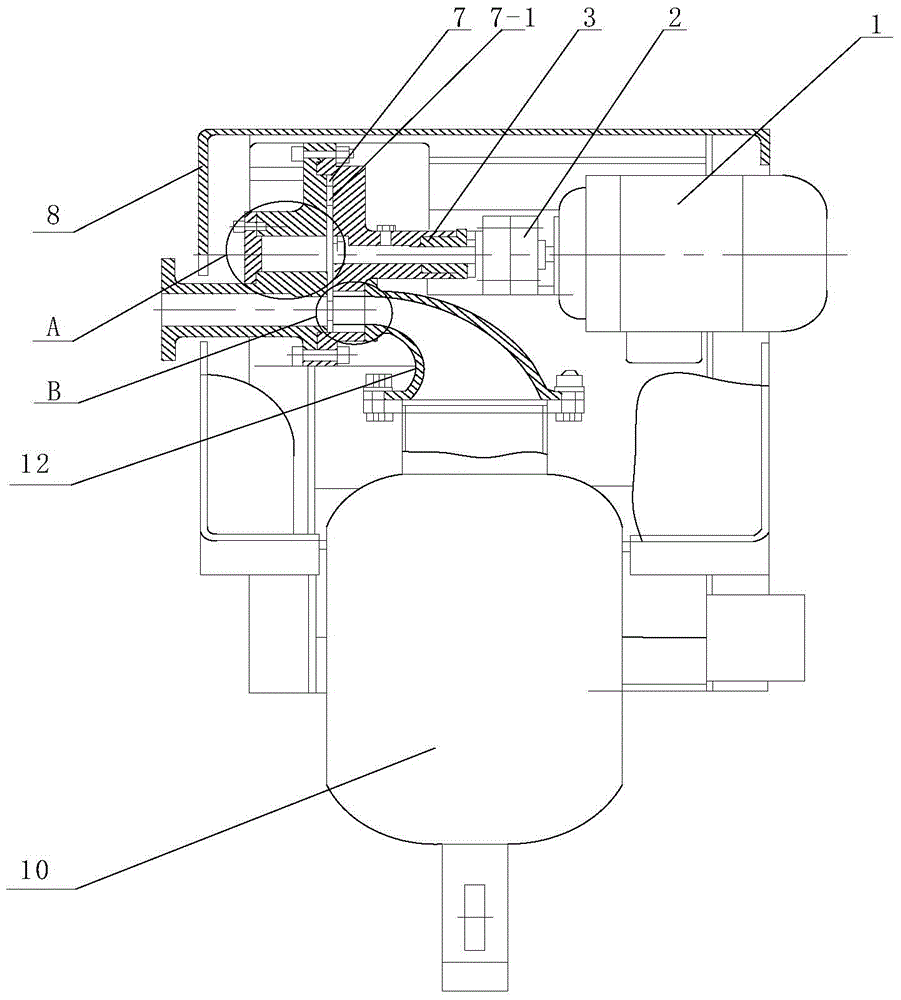

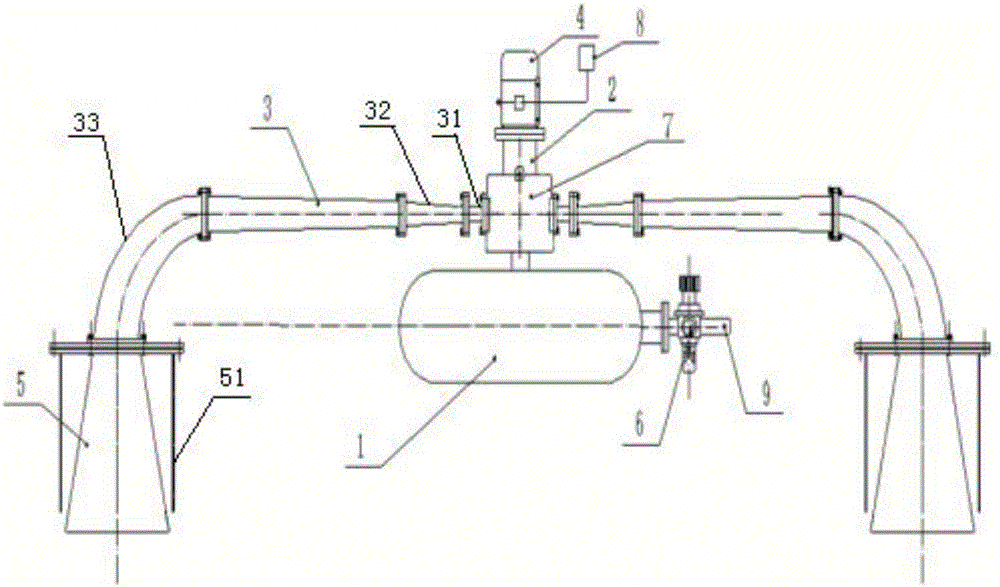

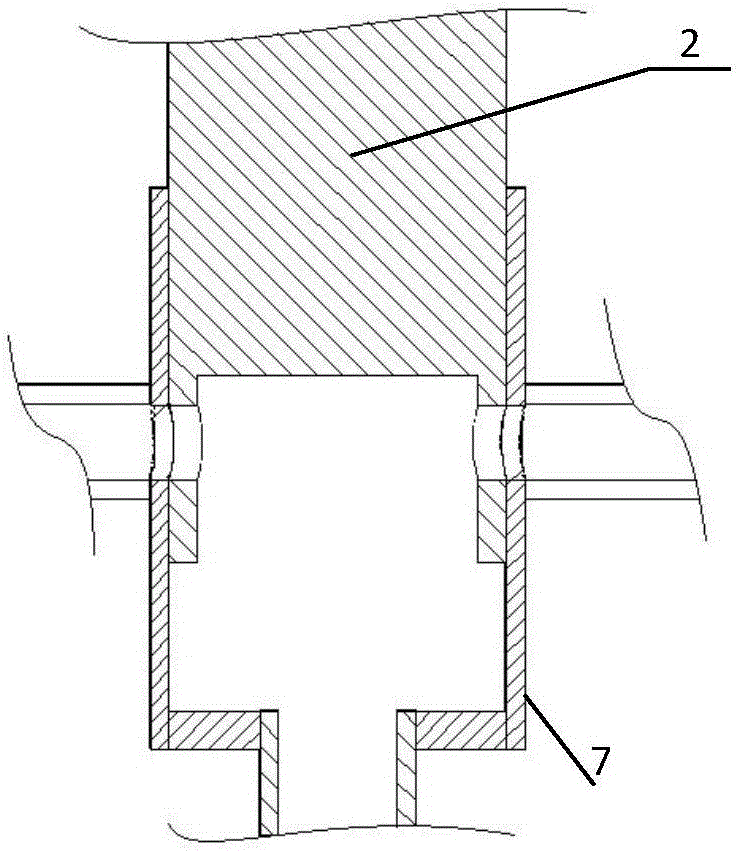

The invention relates to a sonic soot blower as well as a manufacture method and an application method thereof. The sonic soot blower comprises a sonic wave generator and sonic wave emitters, wherein the sonic wave generator comprises an air inlet, an air storage tank, an outer cylinder and a motor; each sonic wave emitter comprises a sonic wave emitter body and a sonic wave speaker, the air inlet is connected with the air storage tank through an air delivery pipe, an air outlet of the air storage tank is connected with one end of the outer cylinder, a rotary shaft of the motor is arranged in the outer cylinder and tightly connected with the outer cylinder, a hollow ring is arranged at the front end part of the rotary shaft and at least one through hole is formed in the ring wall, cylinder wall through holes are formed in corresponding positions of the through hole and the wall of the outer cylinder and connected with one end of each sonic wave guide pipe, and the other end of the sonic wave guide pipe is connected with the corresponding sonic wave speaker. The sonic soot blower is simple in structure, stable in operation, high in soot blowing energy and wide in range and effectively increases the working efficiency of equipment.

Owner:SUZHOU HUICHENG ZHIZAO IND DESIGN

SCR denitration method and device with combined soot blowing function

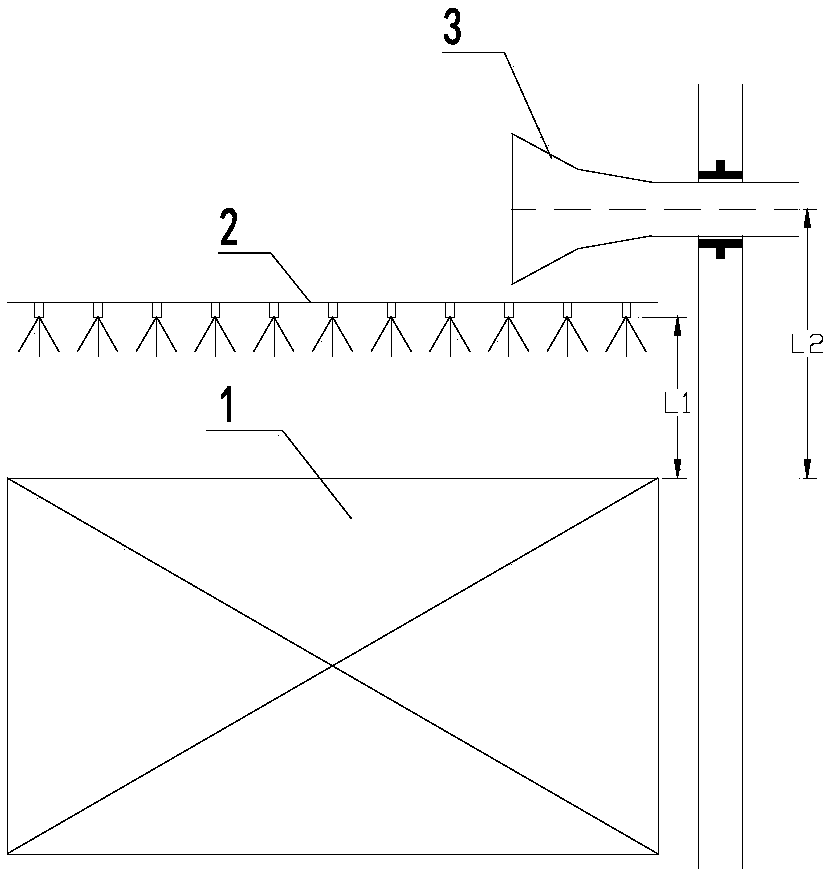

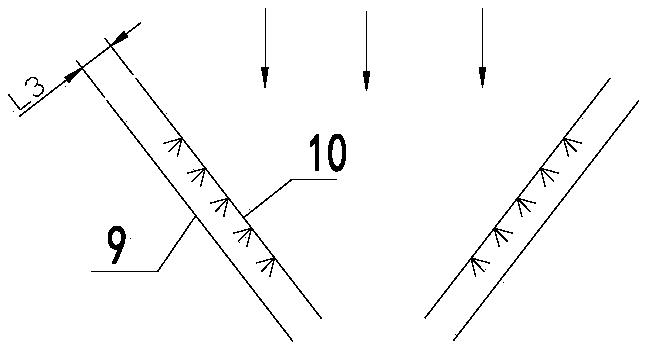

ActiveCN109603545AAvoid stickingAvoid problems such as dust and scalingGas treatmentDispersed particle separationParticulatesThermal energy

The invention discloses an SCR denitration method and device with a combined soot blowing function. The device comprises an SCR reactor, wherein steam soot blowers and sonic soot blowers are arrangedin sequence in the counter-smoke flow direction above each catalyst bed layer in the reactor; differential pressure transmitters are arranged between the upper and lower portions of the catalyst bed layers; all steam soot blowers are connected in parallel and then externally connected with an high-temperature steam source, each parallel pipeline is provided with a high-temperature steam electric valve respectively, and a main pipe is provided with a temperature sensor; all acoustic sensors are connected in parallel and then externally connected with a compressed air source, each parallel pipeline is provided with a compressed air electric valve respectively, and the main pipe is provided with a pressure transmitter; the device further comprises a controller, the temperature sensor, the pressure transmitter and all differential pressure transmitters are connected with the controller separately, and all high-temperature steam electric valves and compressed air electric valves are connected with the controller separately. The SCR denitration method and device with the combined soot blowing function solves the problems that the content of denitrated particulate matters of the SCR in acement kiln is large, large granular particles in soot cannot be removed, and the thermal energy loss is large due to the steam consumption of a pure steam scoot blower.

Owner:ZHEJIANG UNIV

Novel multi-medium sound wave soot blower

The invention discloses a novel multi-medium sound wave soot blower. The novel multi-medium sound wave soot blower comprises a mounting column, a servo motor and a sound wave soot blower body, whereina conveying pipe is arranged on the inner side of the right end of the mounting column; hoses are fixedly connected to the outer sides of the left ends of flow dividing pipes, carrying blocks are rotationally connected to the inner side of the left end of the mounting column, fan-shaped spray heads are arranged at the left ends of auxiliary pipes, and torsion springs are fixedly connected to theconnecting positions of the carrying blocks and the inner side wall of the mounting column; and the servo motor is arranged on the inner side of the mounting column through bolts, a movable frame is connected to the middle portion of the left side wall of the mounting column in a penetrating mode, rolling wheels are rotationally connected to the ends, close to connecting frames, of an auxiliary frame, and a mounting frame is fixedly connected to the left side wall of the mounting column through bolts. According to the novel multi-medium sound wave soot blower, the spraying angle can be adjusted conveniently, so that the application range is widened; and in addition, the spray heads can swing conveniently in the soot blowing process, so that the soot blowing efficiency is improved.

Owner:熊健

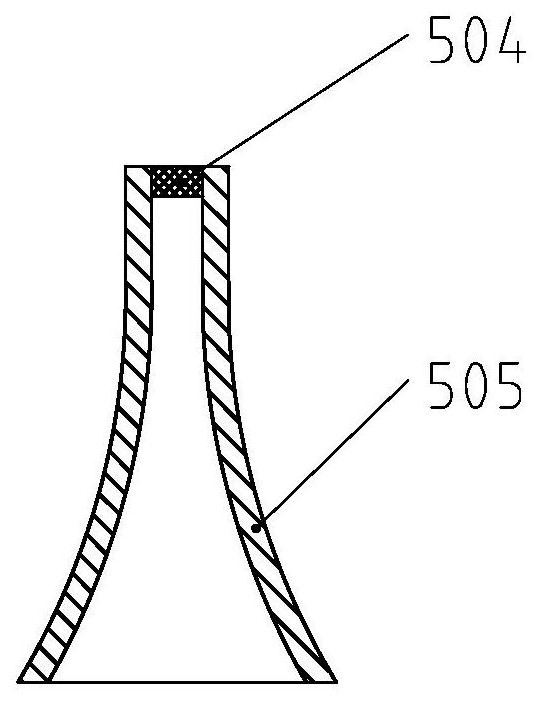

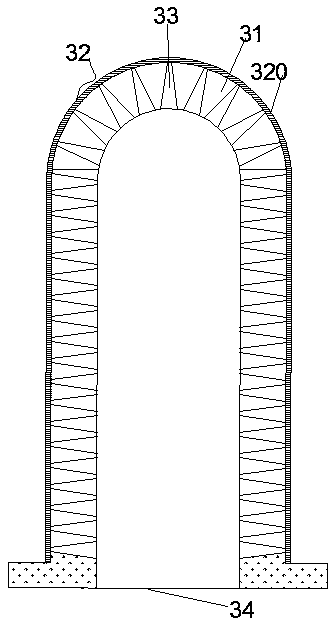

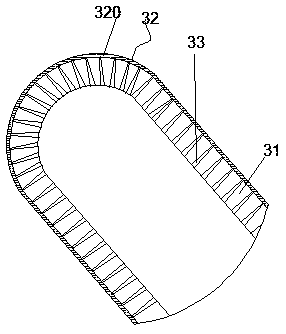

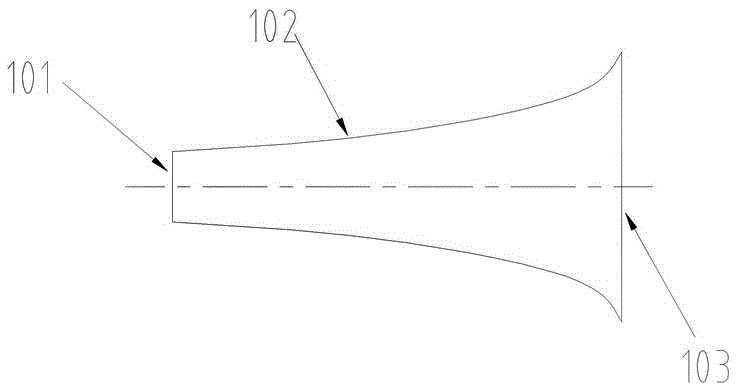

Trumpet for acoustic wave sootblower

The invention provides a trumpet for an acoustic wave sootblower, which enables acoustic waves to not only meet expected acoustical power and frequency response requirements but also avoid sudden change of acoustic impedance, enables acoustic waves to have relatively good response in medium and low frequency bands, completely meets the requirement of the acoustic wave sootblower on 50 to 300 HZ frequency, and is simple in structure, low in cost and convenient to construct. The trumpet comprises a trumpet opening, wherein the trumpet opening comprises a large end and a small end; the small end of the trumpet opening comprises a trumpet outer shell and a trumpet inner shell; a 10 mm clearance is arranged between the trumpet inner shell and the trumpet outer shell; the clearance is filled with river sand adopted as a damping and sound insulation material; a small end inlet flange is mounted at a small end inlet part of the trumpet opening; a small end outlet flange is mounted at a small end outlet part of the trumpet opening; and a large end inlet flange is mounted at a large end inlet part of the trumpet opening.

Owner:湖北省端胜实业有限公司

Cloth bag multi-mode combined ash and dust remover

InactiveCN111729426AExtended service lifeStable structureDispersed particle filtrationFlue gasDust control

The invention discloses a cloth bag multi-mode combined ash removal dust remover which comprises: a shell, a blowing system, a cage frame, a dust removing cloth bag, an anti-collision ring, a sound wave soot blower, a silencing plate, a soot removing assembly, a drying assembly, an air inlet pipe, an exhaust pipe, a soot hopper, a soot discharging barrel, a bearing assembly and an air purifying chamber. The air purification chamber is formed in the top of the inner side of the shell, the blowing system is inserted into the air purification chamber, a plurality of cage frames are installed in the center of the interior of the shell, the tops of the cage frames are located in the air purification chamber, and one side of each cage frame is connected with a dust removal cloth bag; sound wavesoot blowers are installed at the lower middle ends of the front end face and the rear end face of the shell. The cloth bag multi-mode combined ash removal dust remover is stable in structure and goodin supporting firmness; during use, flue gas can be dried, water in the gas is effectively prevented from influencing normal use of the cloth bag, and meanwhile, the bag type dust collector has a good dust removing and falling effect, and the service life of the cloth bag can be prolonged.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com