Diversion plate used for acoustic wave soot blower

A technology of sonic sootblower and deflector, which is applied in the treatment of combustion products, combustion methods, and removal of solid residues, etc. problem, to achieve the effect of improving the use effect and increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

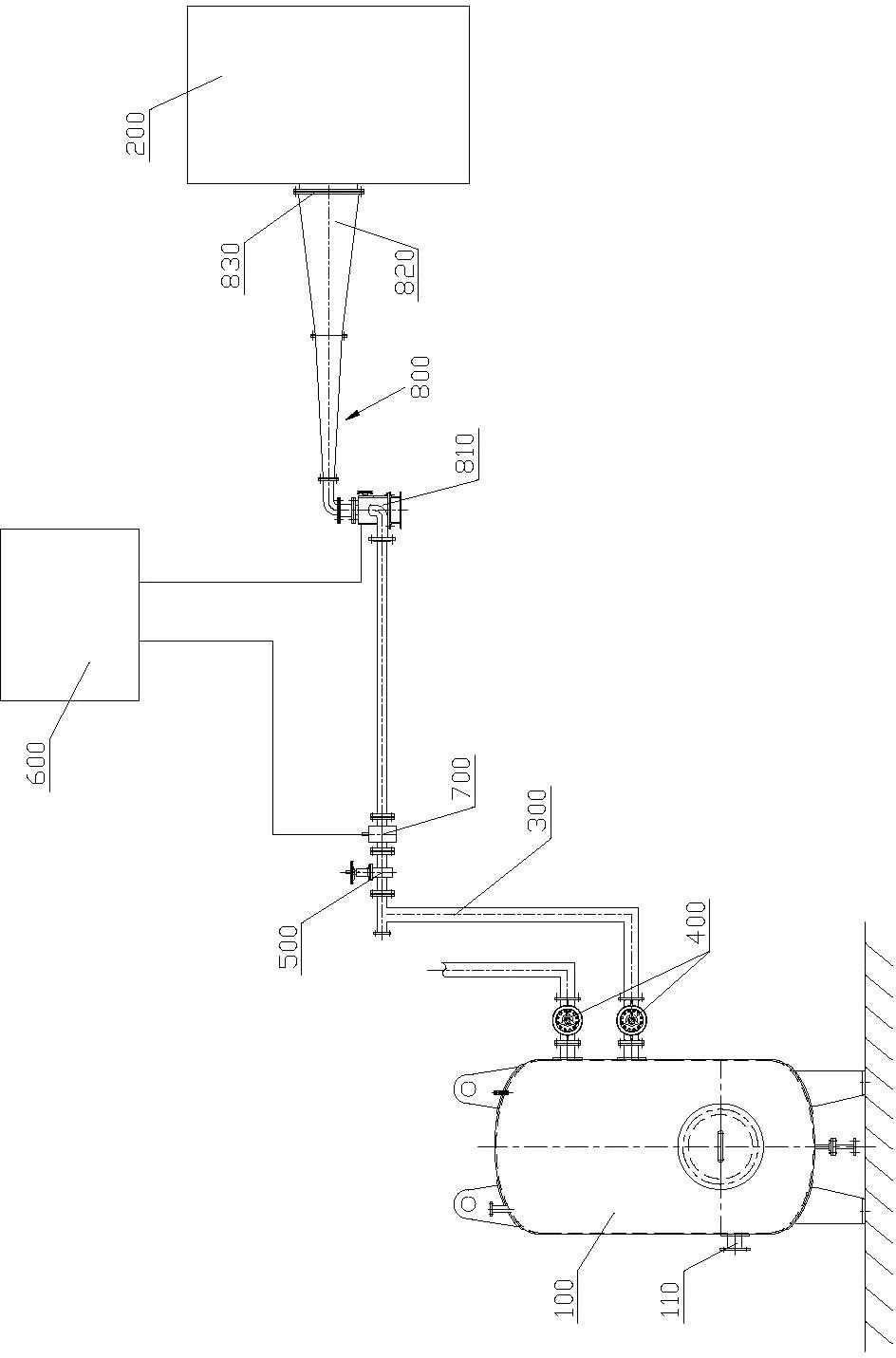

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

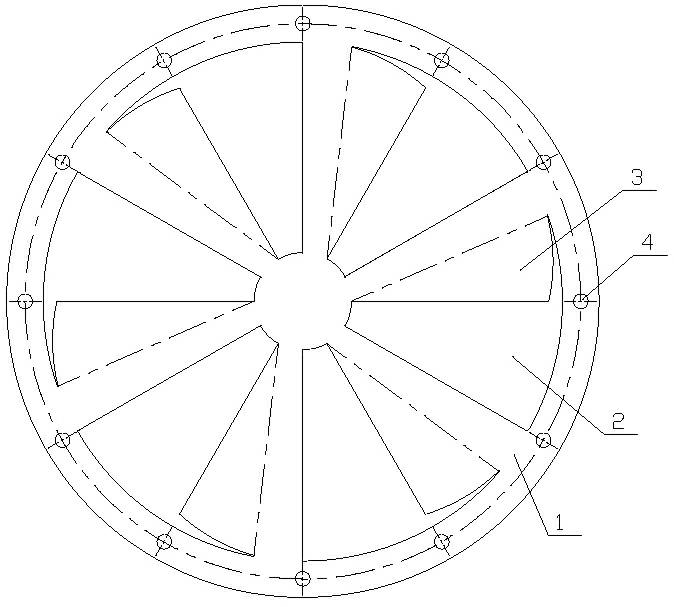

[0016] see figure 1 , a deflector for a sonic soot blower is a circular deflector 1, and the thickness of the circular deflector 1 is 2 mm to 4 mm. A plurality of fan-shaped guide holes 2 are evenly processed on the circular guide plate 1 along the circumference. Because the sonic soot blower is used in boilers, the circular guide plate 1 is made of high temperature resistant, wear-resistant, corrosion-resistant, Stainless steel. Of course, according to the size of the horn of the sonic soot blower, the present invention can also set the number of fan-shaped guide holes 2 to 5 or more than 6 according to the actual situation.

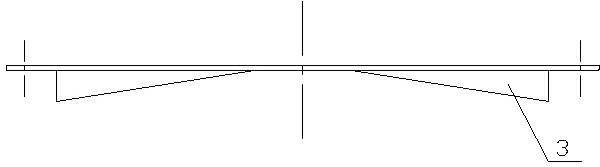

[0017] The sides of each fan-shaped flow guide hole 2 in the same direction are provided with guide vanes 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com