Spark fire resistant device for bag-type dust removers in biomass boilers

A technology of bag dust collector and biomass boiler, which is applied in the directions of transportation and packaging, chemical instruments and methods, and separation of dispersed particles, and can solve the problems of inability to completely eliminate tiny particle sparks and poor capture effect of sparks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

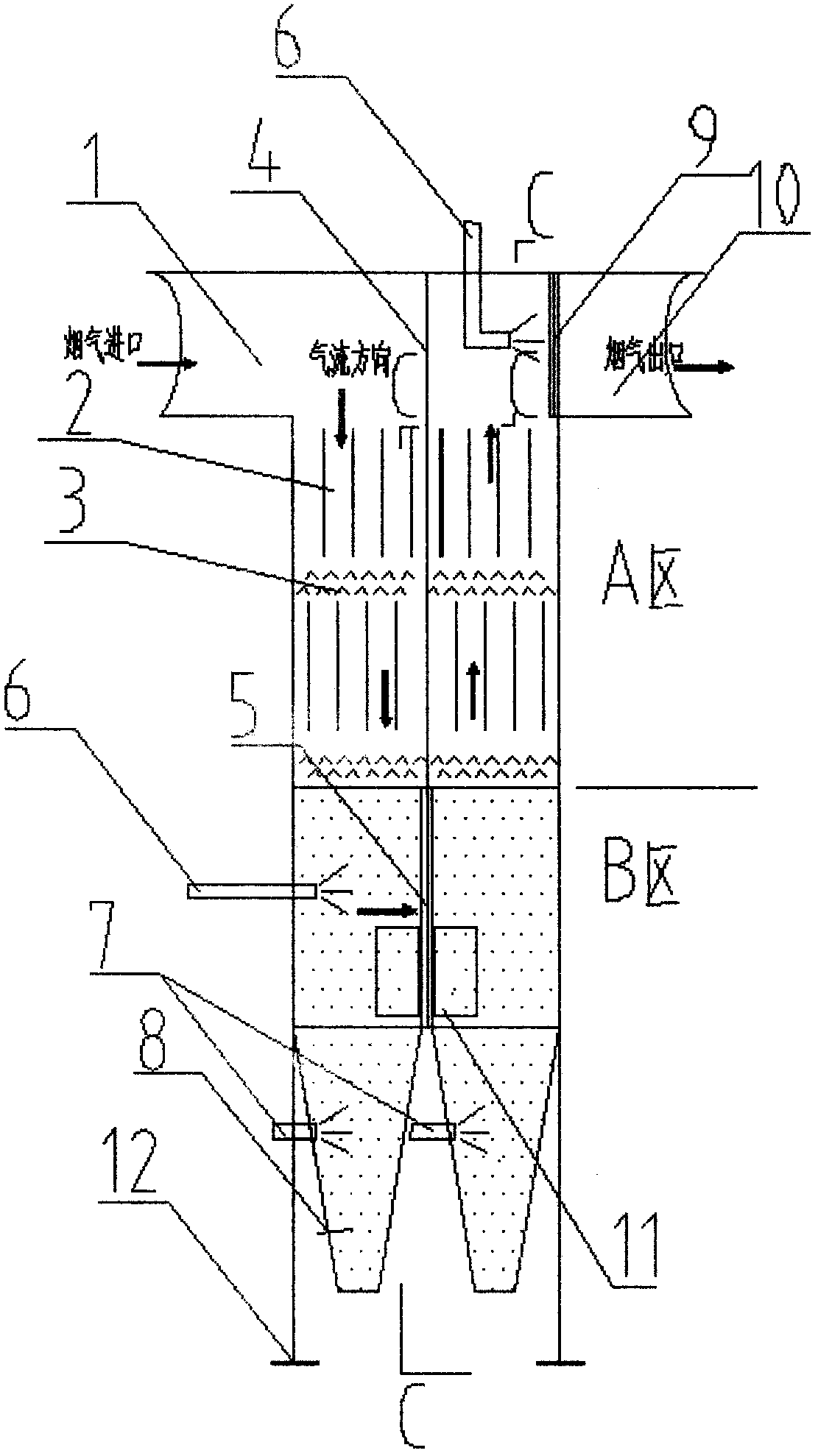

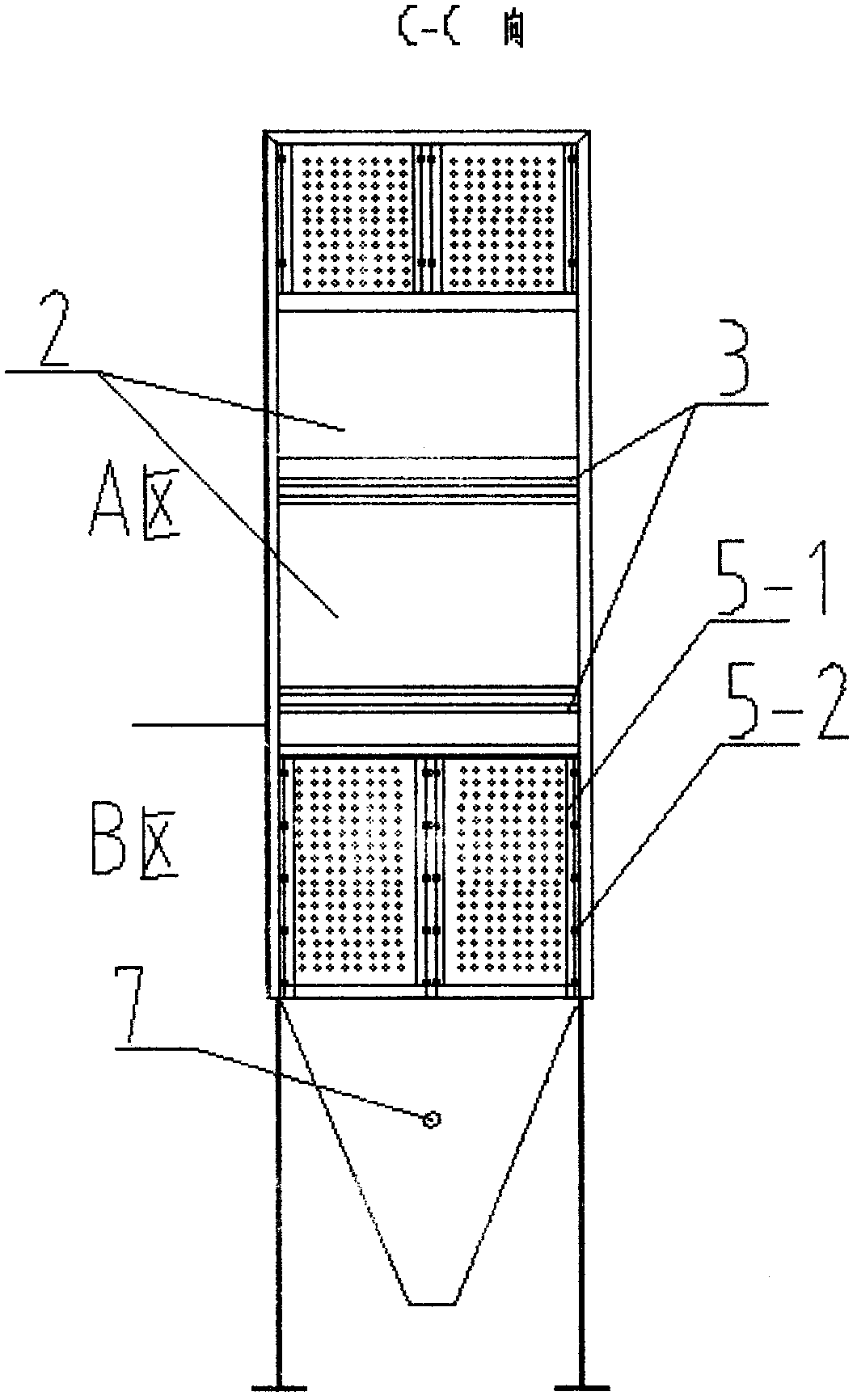

[0015] A kind of spark arresting device of bag filter such as figure 1 As shown, it includes the flue gas inlet 1, the flue gas cooling plate 2, the baffle plate 3, the middle partition plate 4 and the first metal microporous filter plate 5, and the corresponding metal microporous filter plate is equipped with sonic blowing Air blower or pneumatic soot blower 6, two ash hoppers 8 are provided at the bottom of the left and right boxes, and a pneumatic arch breaker 7 is arranged on the ash hopper, and the second metal microporous filter screen 9 is connected with the flue gas outlet 10 , the left and right boxes are respectively provided with access doors 11, and the whole device is supported by brackets 12.

[0016] The whole fire arresting device is divided into two boxes on the left and right by the dividing line of the middle partition 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com