Patents

Literature

155results about How to "Anti clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

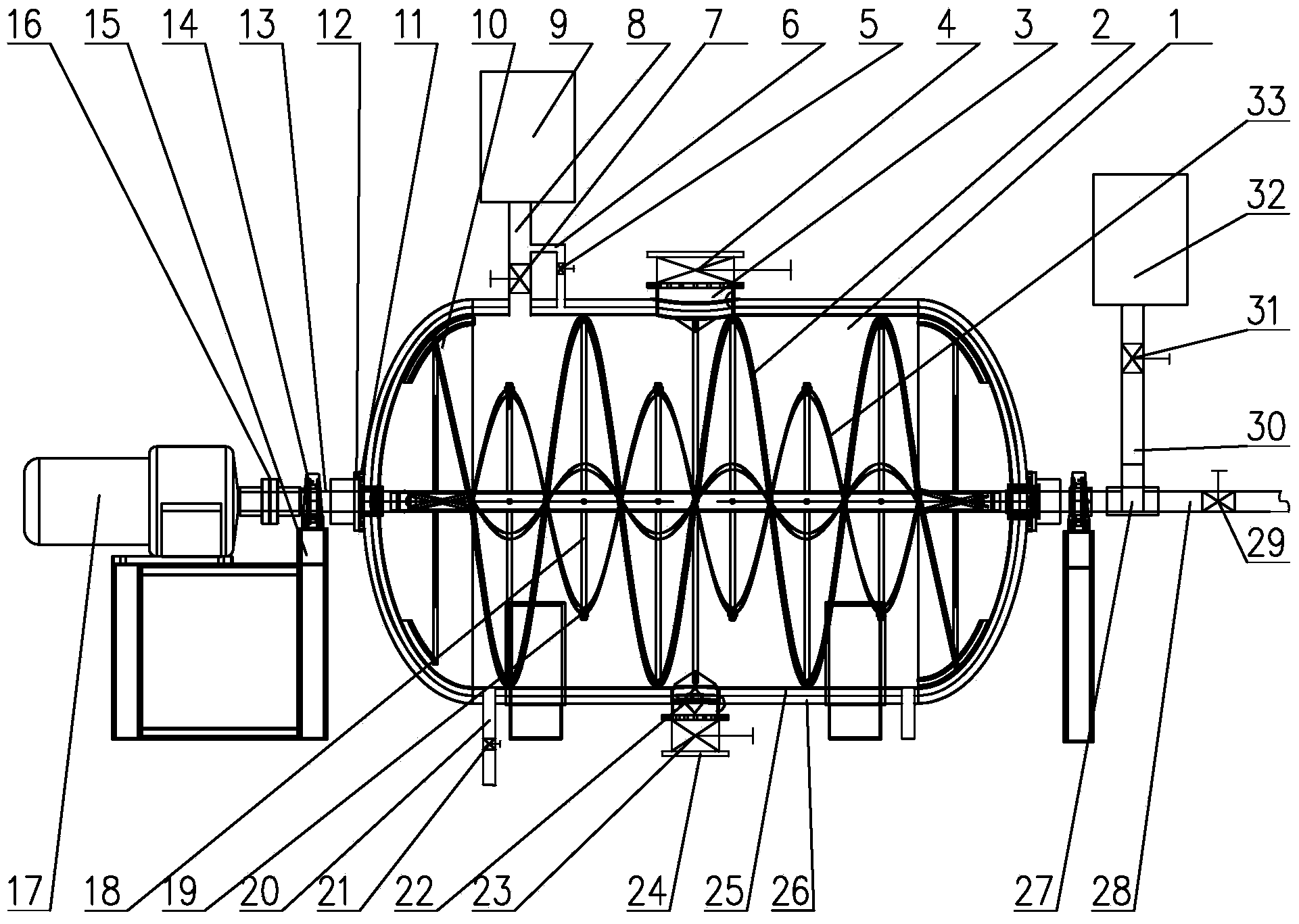

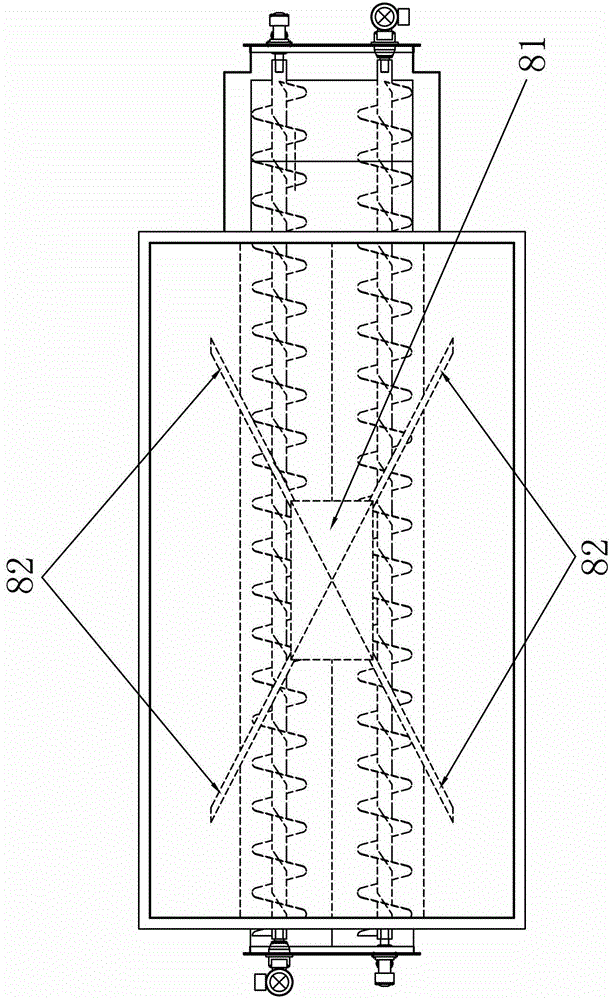

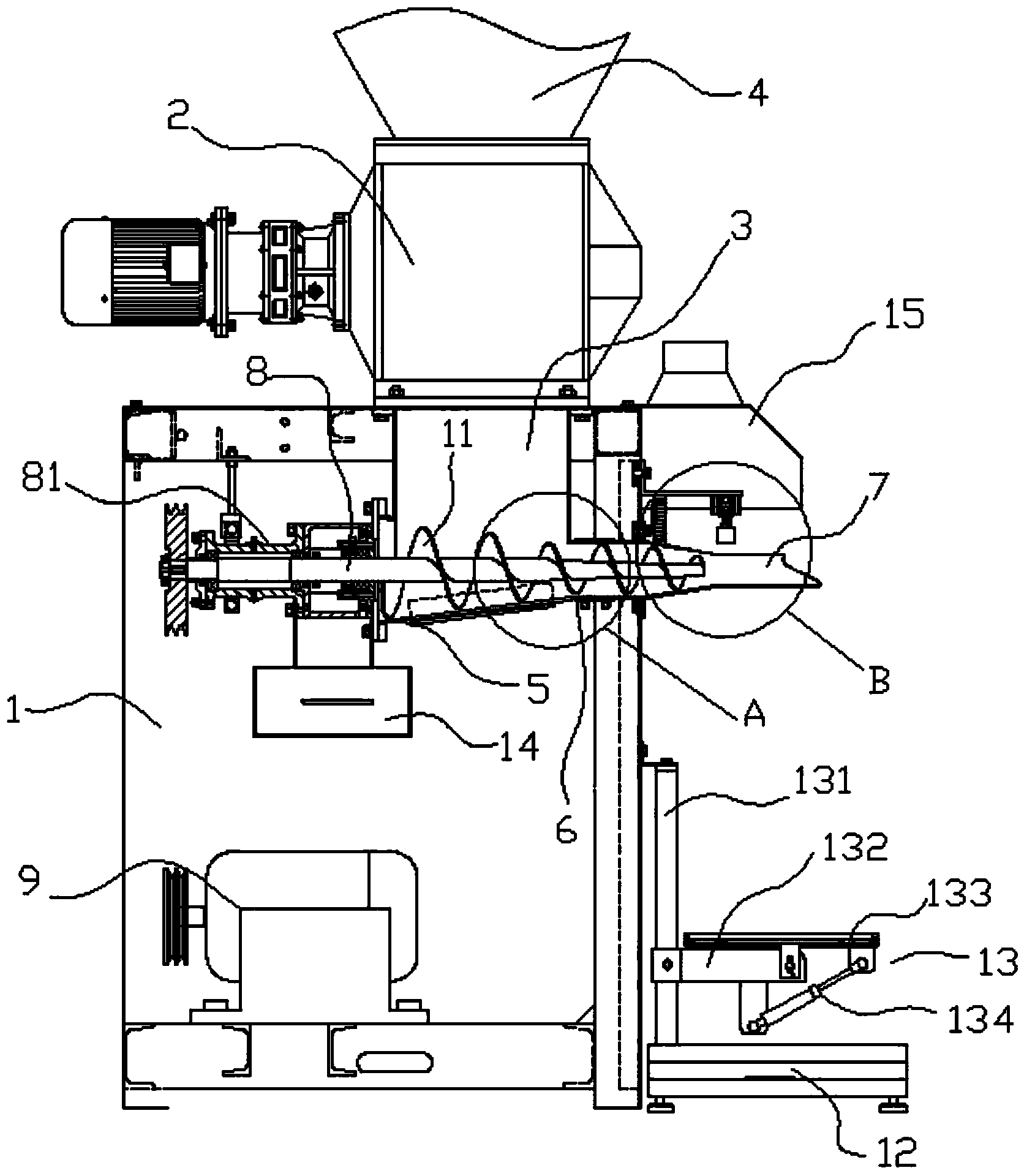

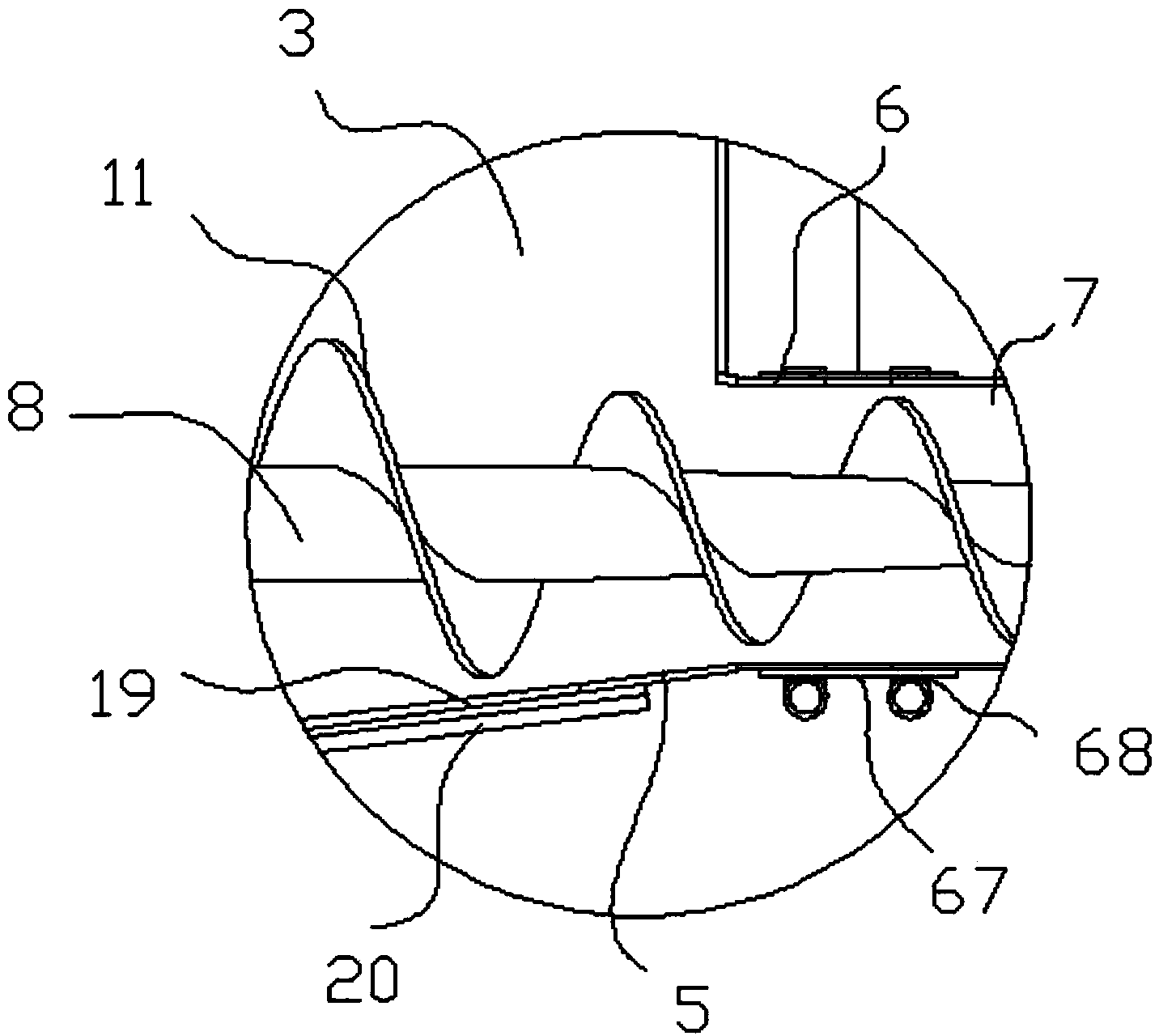

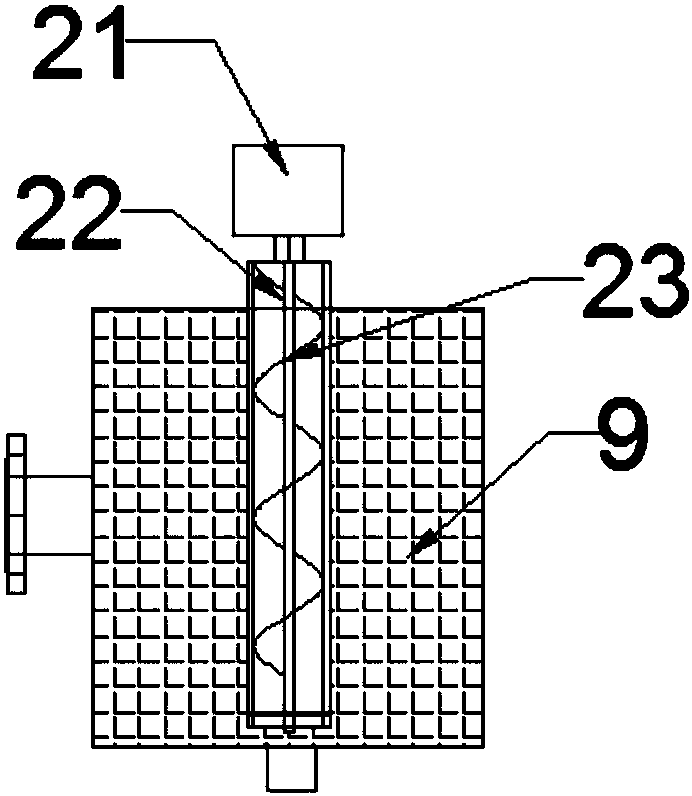

Automatic mixing type sterilization pot for edible fungi

ActiveCN103623439AGuaranteed sterilization qualityShort sterilization timeHeatHorticultureCold airSolenoid valve

The invention relates to an automatic mixing type sterilization pot for edible fungi. The sterilization pot comprises a sterilization pot barrel body, wherein a feeding assembly is arranged at the top of the sterilization pot barrel body; a discharging assembly is arranged at the bottom of the sterilization pot barrel body; a power mechanism is arranged at one end of the sterilization pot barrel body and is connected with a rotary shaft. The sterilization pot is characterized in that the rotary shaft is a hollow shaft pipe and is connected with a steam pipeline through a rotary connector after penetrating the sterilization pot barrel body; a solenoid valve is arranged between the rotary connector and the steam pipeline; the rotary connector is connected with aseptic cold air preparation equipment; multiple layers of spiral mixing blades are fixedly arranged on one section of the hollow shaft pipe in the sterilization pot barrel body through a plurality of fixing support pipes; one end of each fixing support pipe is communicated with the hollow shaft pipe, and the other end of the fixing support pipe is used for supporting each spiral mixing blade; a plurality of spray nozzles are formed in the periphery of the hollow shaft pipe and the fixing support pipes. Therefore, the sterilization quality is guaranteed; compared with conventional sterilization equipment, the sterilization time is greatly shortened and the production efficiency is improved.

Owner:淄博隆泰机械科技有限公司

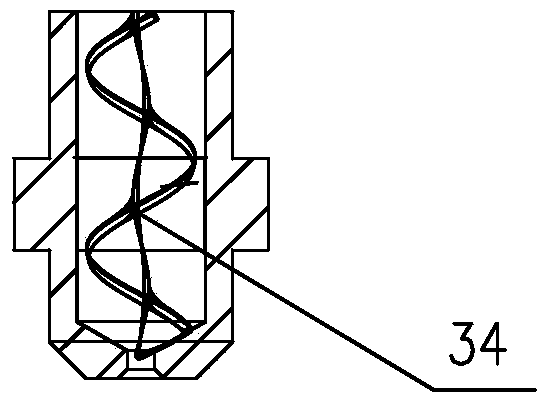

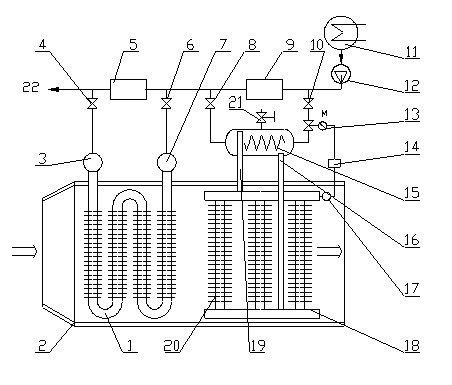

Composite phase-change heat exchange system

InactiveCN102607010ASafe operation of the economyAnti-cloggingEnergy industryIncreasing energy efficiencyEngineeringPhase change

The invention discloses a composite phase-change heat exchange system for afterheat recovery of exhaust gas at the tail part of a boiler. The composite phase-change heat exchange system comprises a single-phase heat exchanger and a vacuum phase-change heat exchanger, which are sequentially connected, and afterheat recovery of the exhaust gas is achieved by the exhaust gas at the tail part of the boiler through the single-phase heat exchanger and the vacuum phase-change heat exchanger. The composite phase-change heat exchange system disclosed by the invention not only has the advantages of being simple in structure, small in steel dosage and economic and safe in operation of the single-phase heat exchanger, but also has the advantages of being corrosion-resistant, anti-clogging, energy-saving and the like at the same time. The composite phase-change heat exchange system also has economic and practical significances and good popularization while being suitable for afterheat recovery of low-temperature exhaust gas under the current situations of saving energy and reducing emission.

Owner:长春当代信息产业集团有限公司

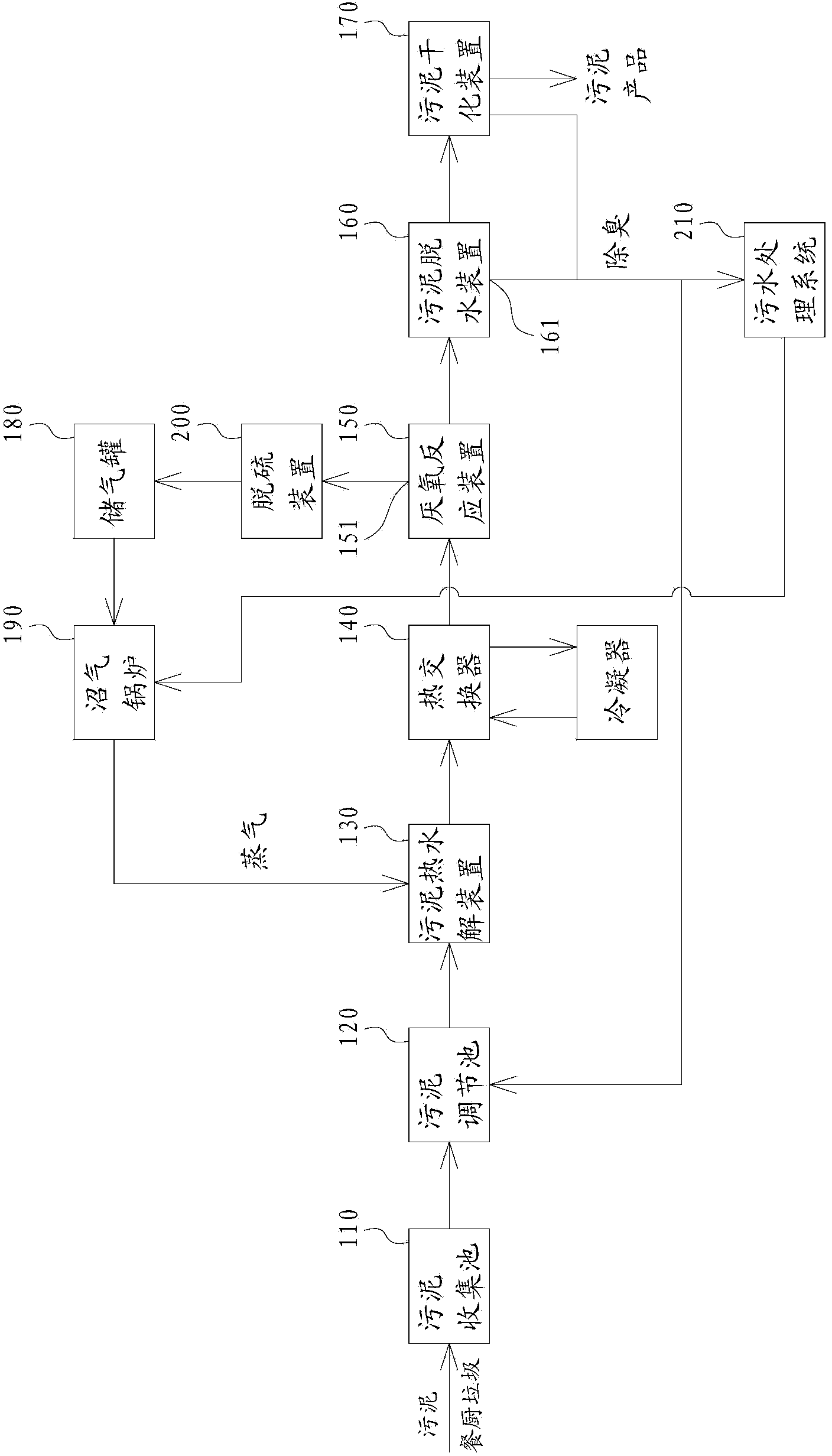

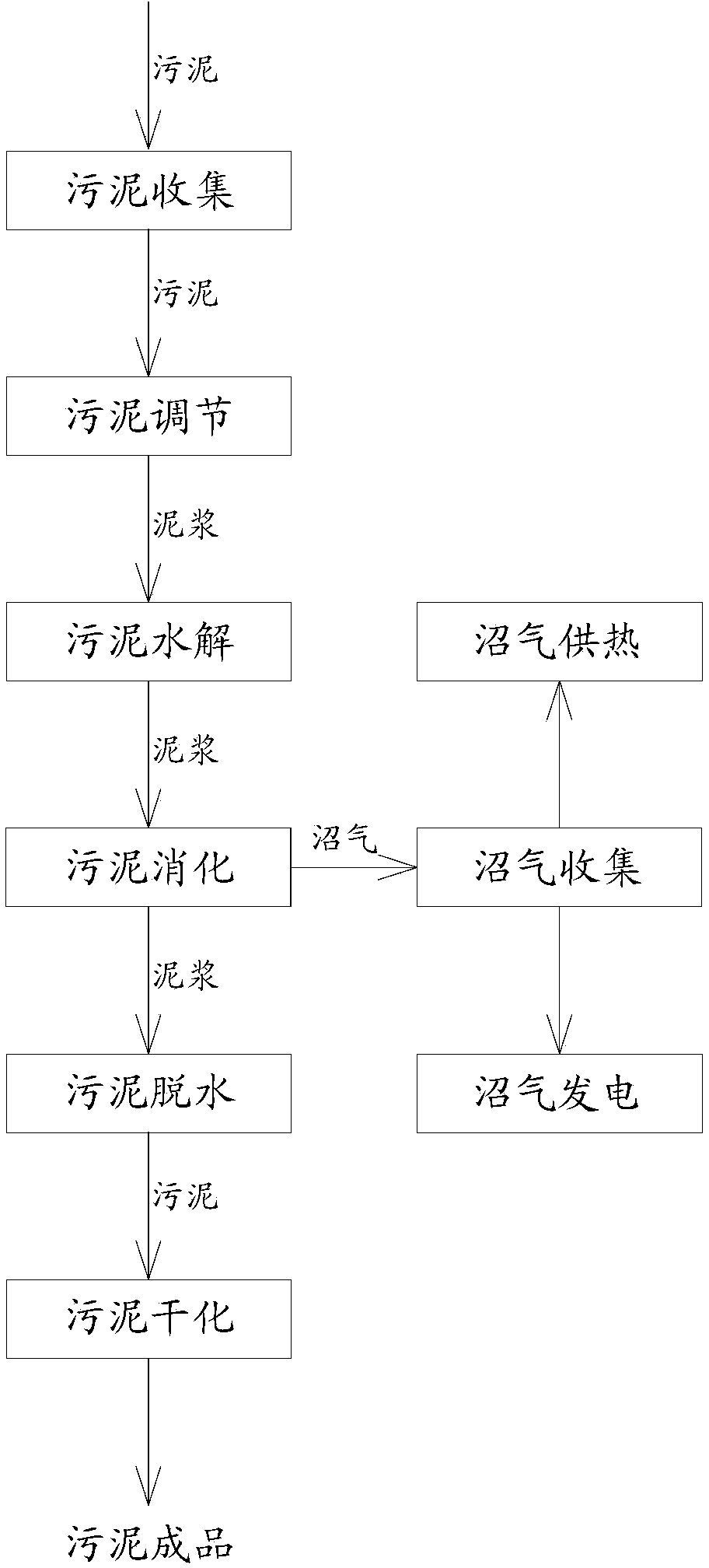

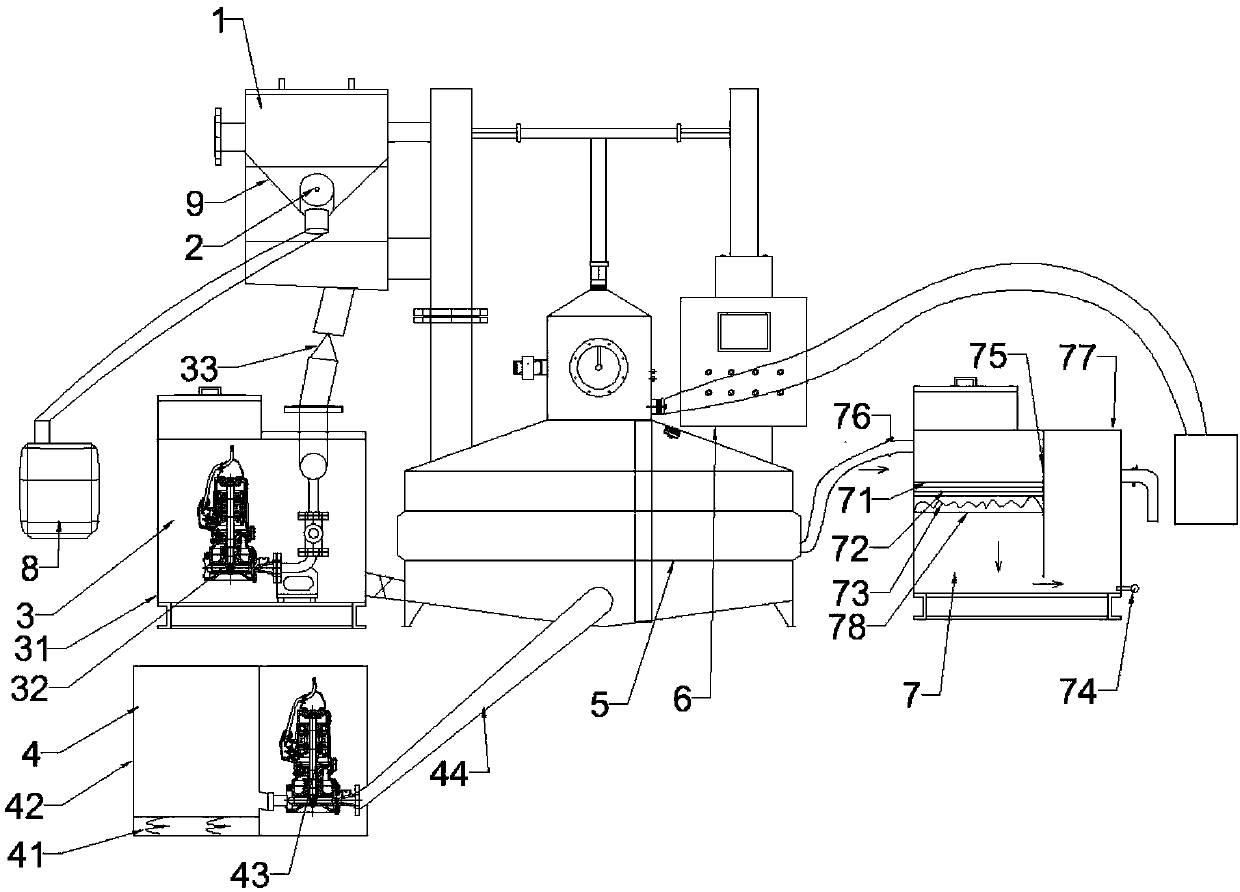

Sludge treatment system and sludge treatment method

InactiveCN104030537AIncrease in sizeSmall particlesSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisEngineeringThermal water

The invention discloses a sludge treatment system, comprising a sludge collecting tank, a sludge regulating pool, a sludge thermal hydrolysis device, a heat exchanger, an anaerobic reaction device, a sludge dewatering device and a sludge drying device, which are sequentially connected. The sludge treatment system also comprises a gas storage tank and a biogas boiler, wherein the input end of the gas storage tank is connected with the exhaust end of the anaerobic reaction device; the fuel input end of the biogas boiler is connected with the output end of the gas storage tank; the output end of the biogas boiler is connected with the sludge thermal hydrolysis device; the discharge end of the sludge dewatering device is connected with the input end of the sludge regulating pool. The invention also discloses a sludge treatment method. The sludge treatment method comprises the following steps: 1) collecting a sludge material and diluting by water; 2) hydrolyzing the diluted sludge material at high temperature; 3) carrying out anaerobic digestion on the sludge subjected to thermal hydrolysis to obtain biogas and digested sludge; 4) collecting the biogas; 5) dewatering and drying the digested sludge to obtain a sludge product. Reclamation, harmlessness, minimization and stabilization of sludge treatment are achieved by the steps and method.

Owner:王胜初

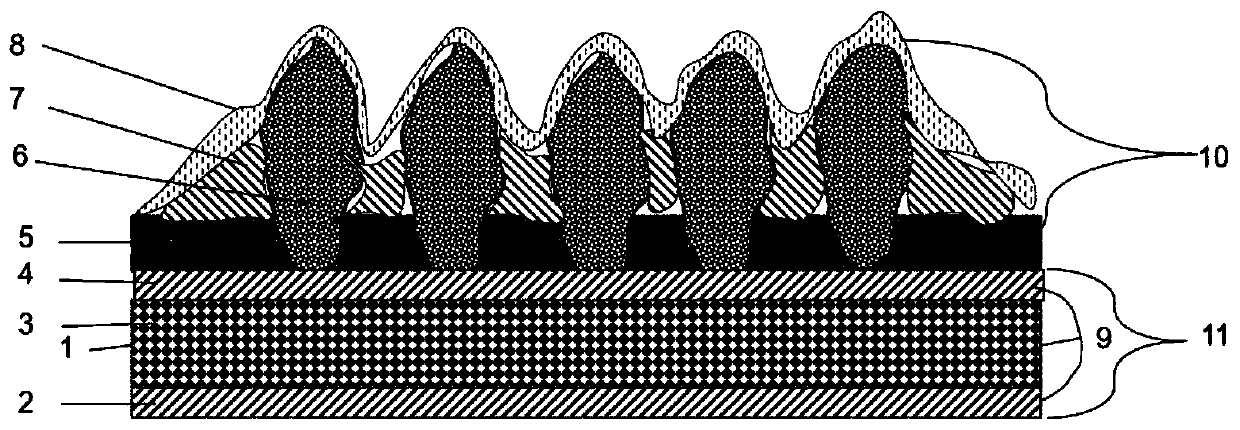

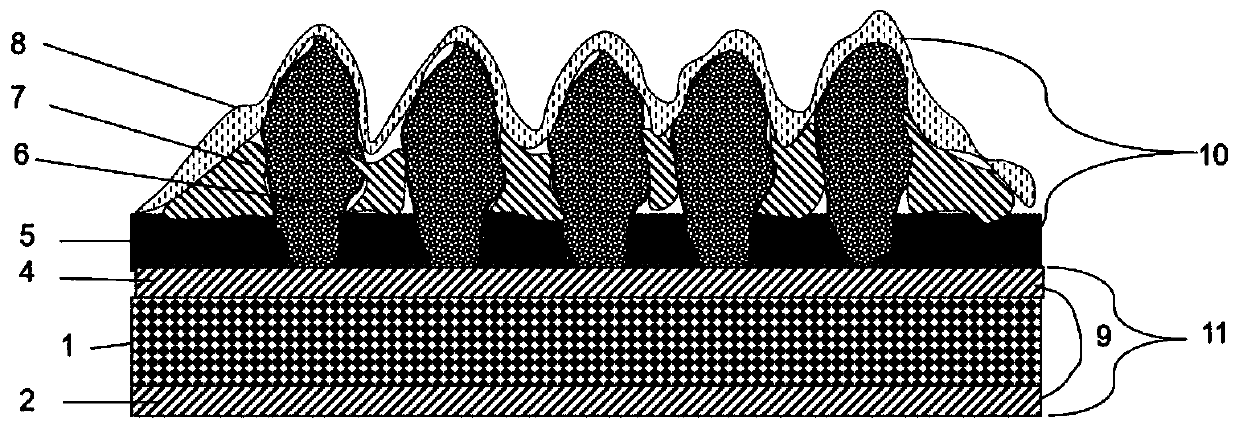

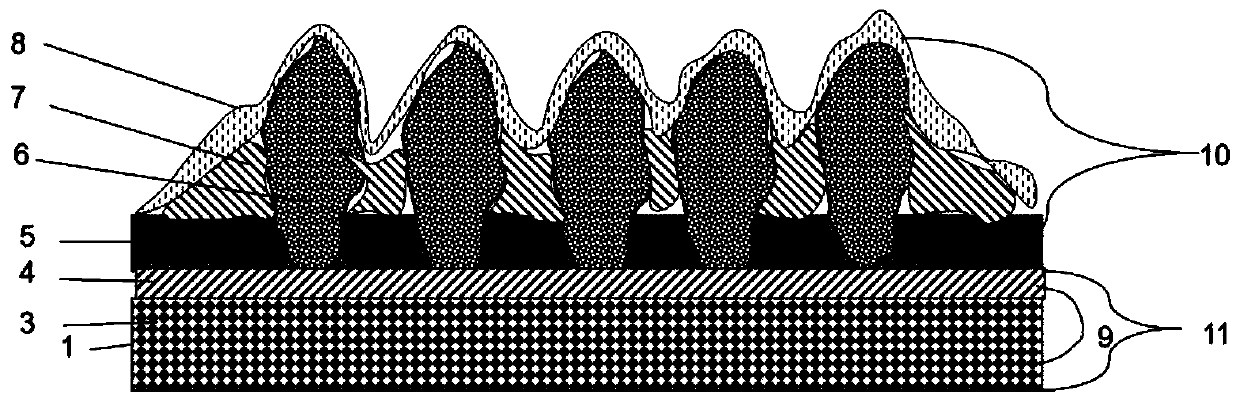

Ultra-flexible coated abrasive cloth and manufacturing method thereof

ActiveCN110405645ASmall bending radiusAchieve anti-cloggingAbrasion apparatusAdhesiveSurface grinding

The invention discloses ultra-flexible coated abrasive cloth, and relates to the technical field of coated abrasive tool products. The ultra-flexible coated abrasive cloth comprises a substrate, an abrasive and a composite adhesive layer; the substrate and the abrasive are coated with the composite adhesive layer, and the abrasive is fixed to the substrate through the composite adhesive layer; thesubstrate comprises a base material and a flexible adhesive layer, and the composite adhesive layer comprises a bottom adhesive layer, a composite adhesive layer body and a coating layer which are distributed from bottom to top in sequence; the flexible adhesive layer comprises one layer of or combination of multiple layers of an upper adhesive layer, a lower adhesive layer and an inner adhesivelayer, the upper adhesive layer and the lower adhesive layer are arranged on the upper surface and the lower surface of the base material correspondingly, and the inner adhesive layer is distributed in the base material; and the base material adopts a cloth base of which the absolute dry weight is 25-180 g / m<2>. The good surface evenness of the coated abrasive cloth can be obtained, the flexible bending radius is 1-3 mm, the ultra-flexible coated abrasive cloth is suitable for grinding of light-load planes and curved surfaces, is resistant to breaking and blocking during grinding, and has thecharacteristics of being good in economical efficiency, light and thin.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

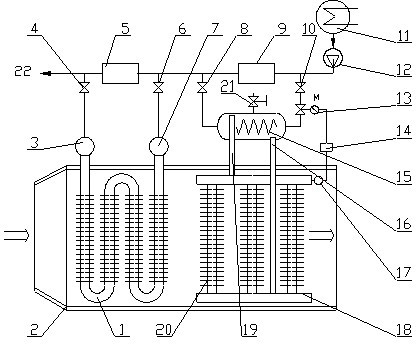

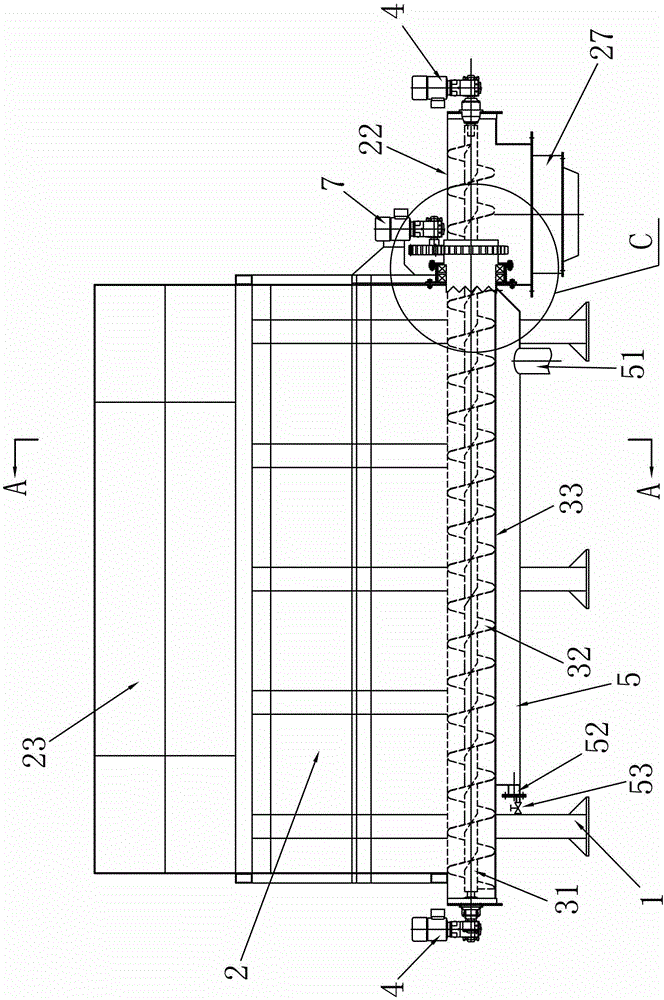

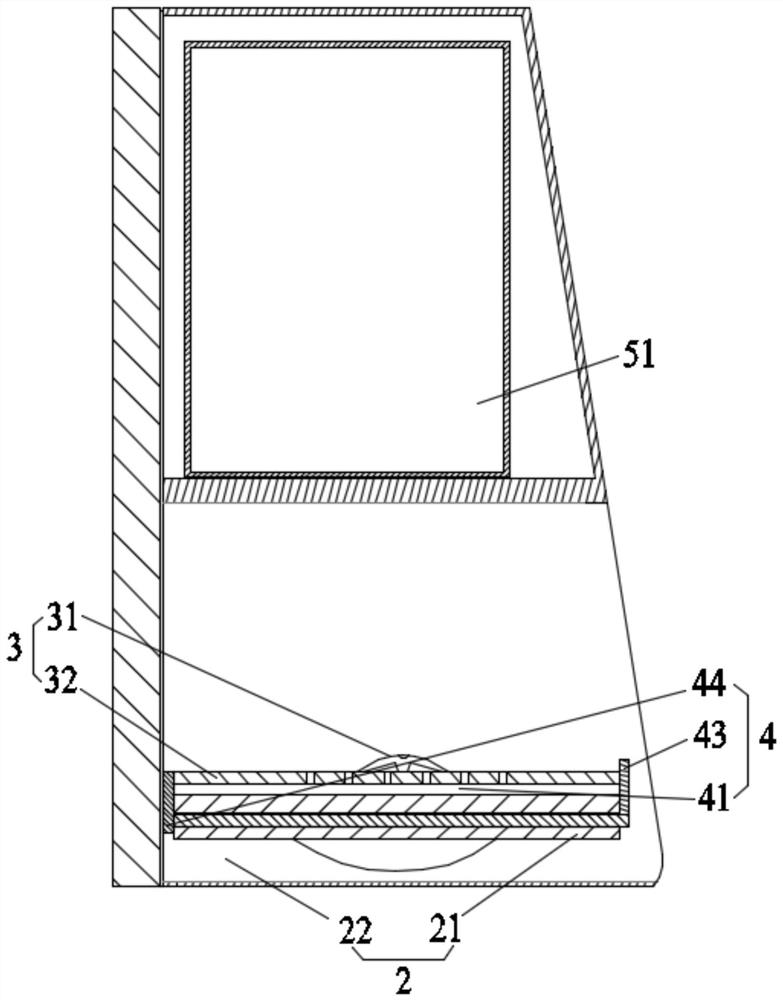

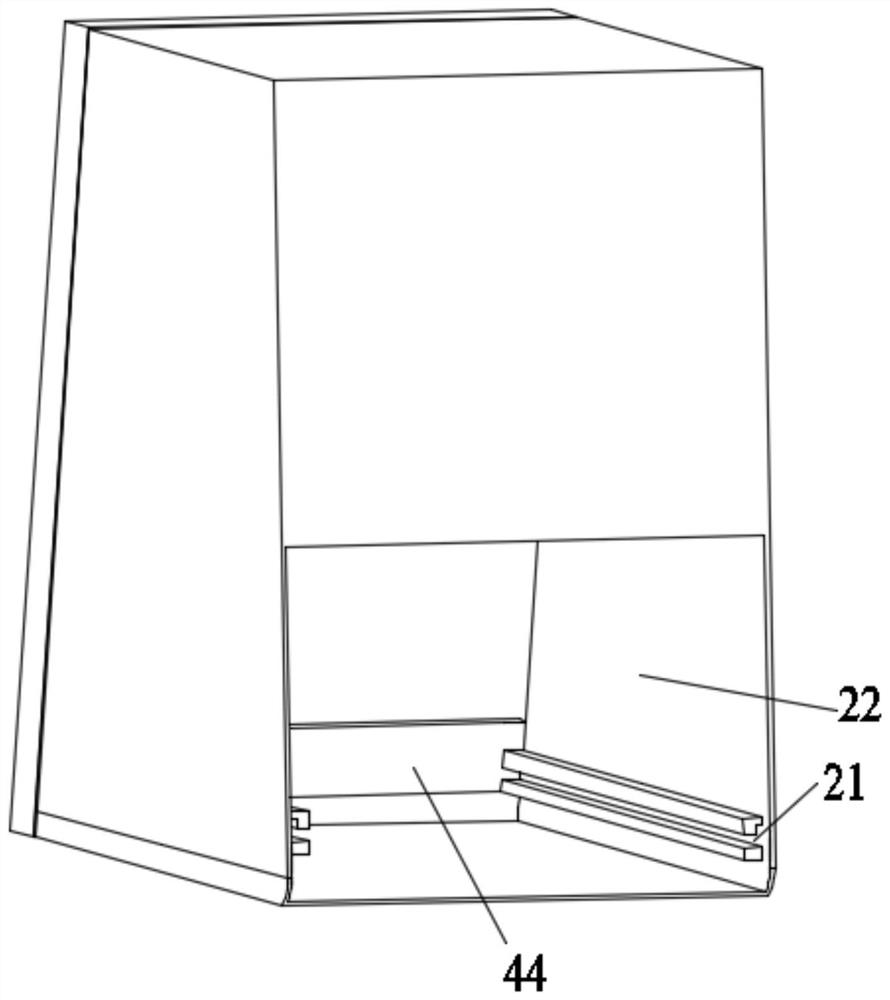

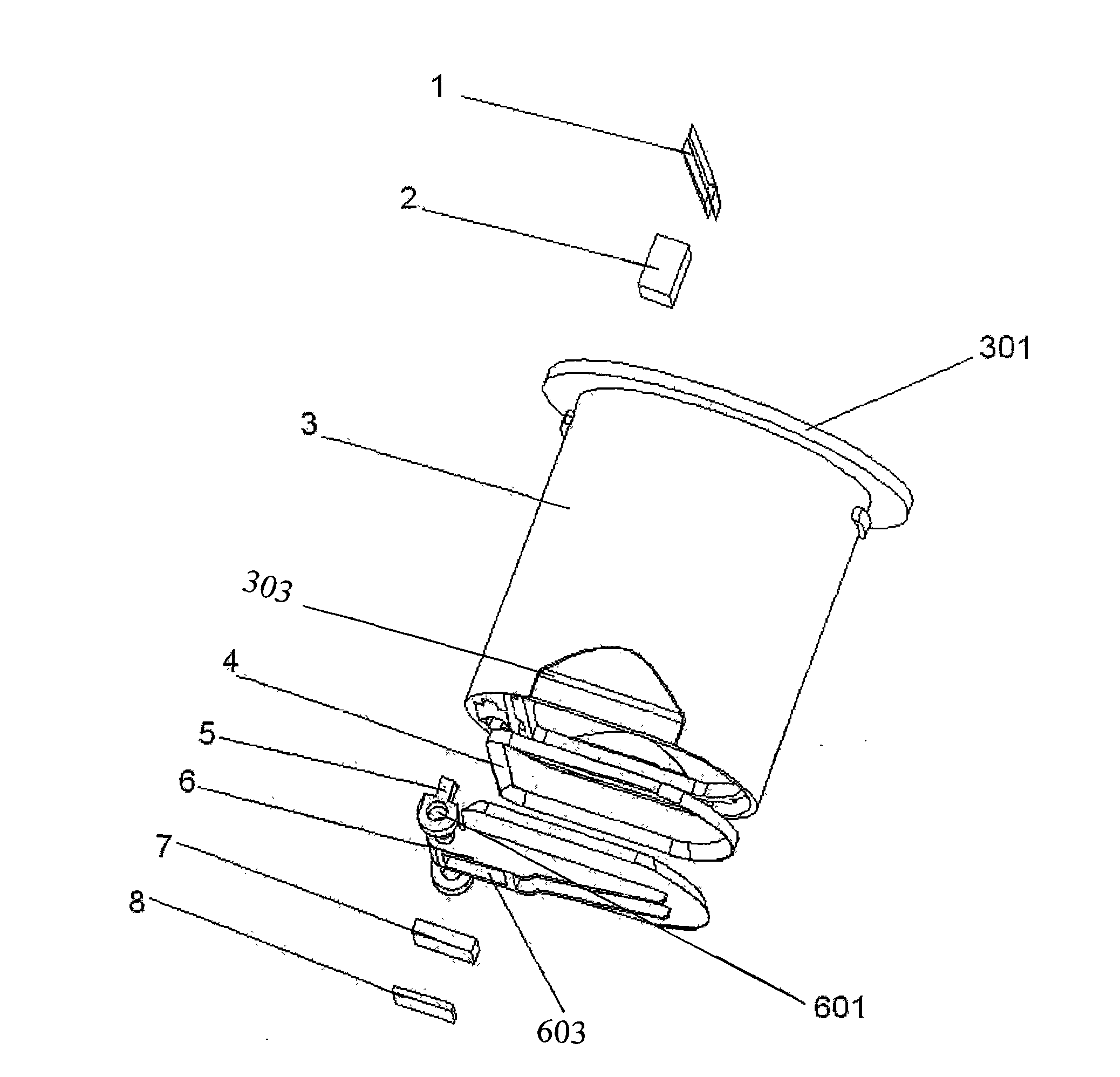

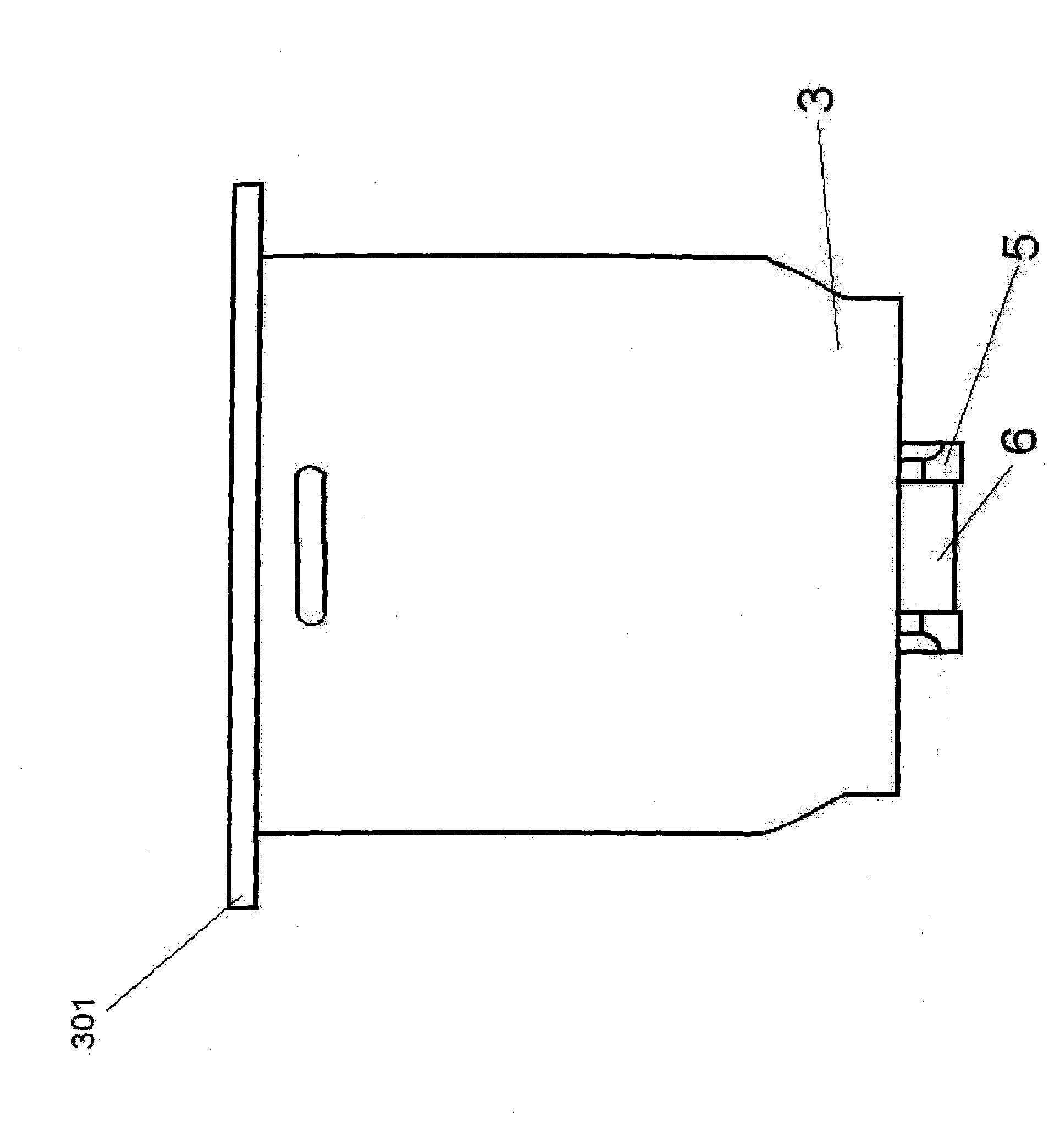

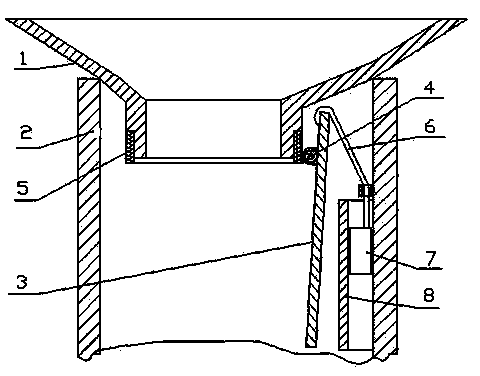

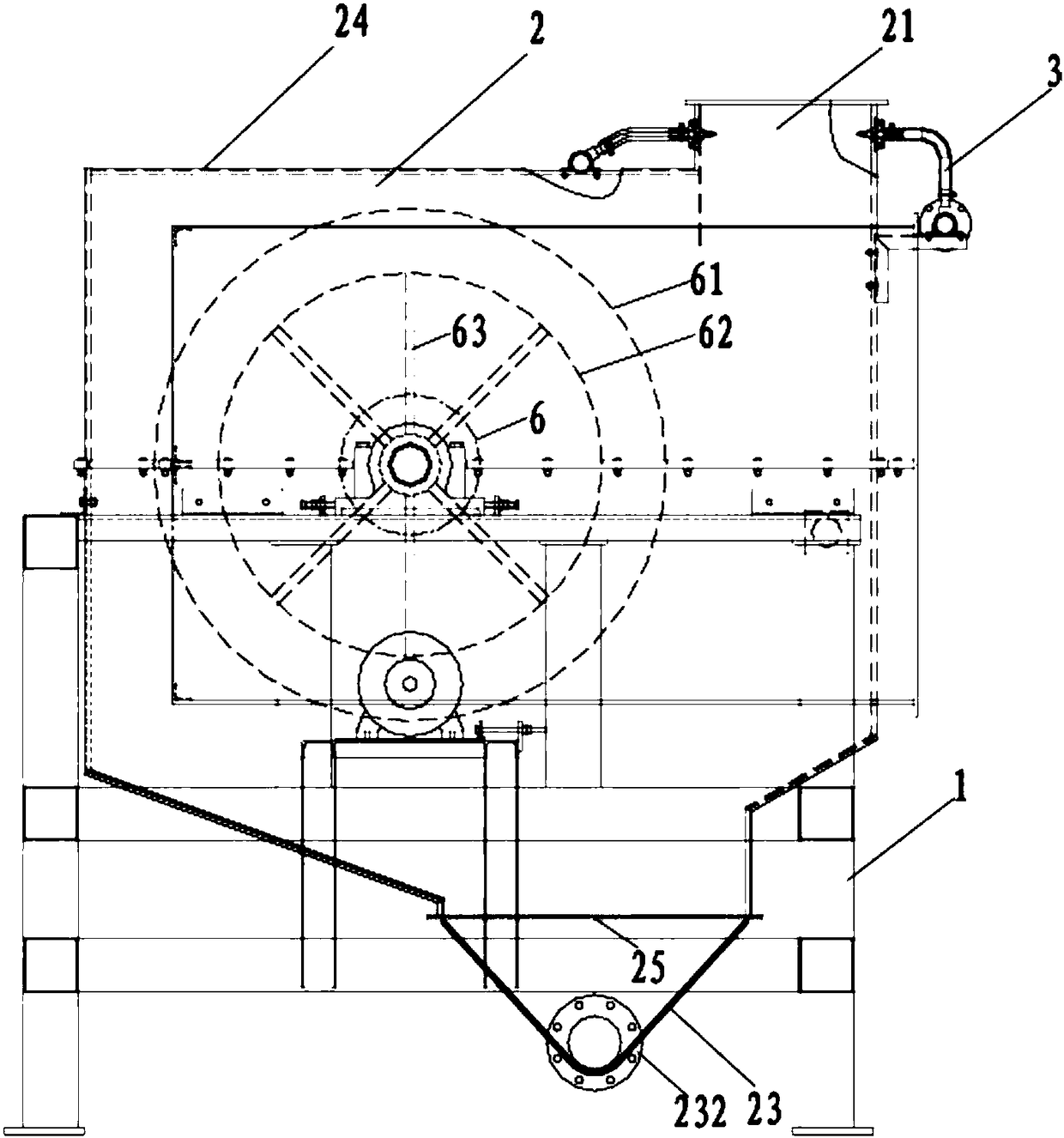

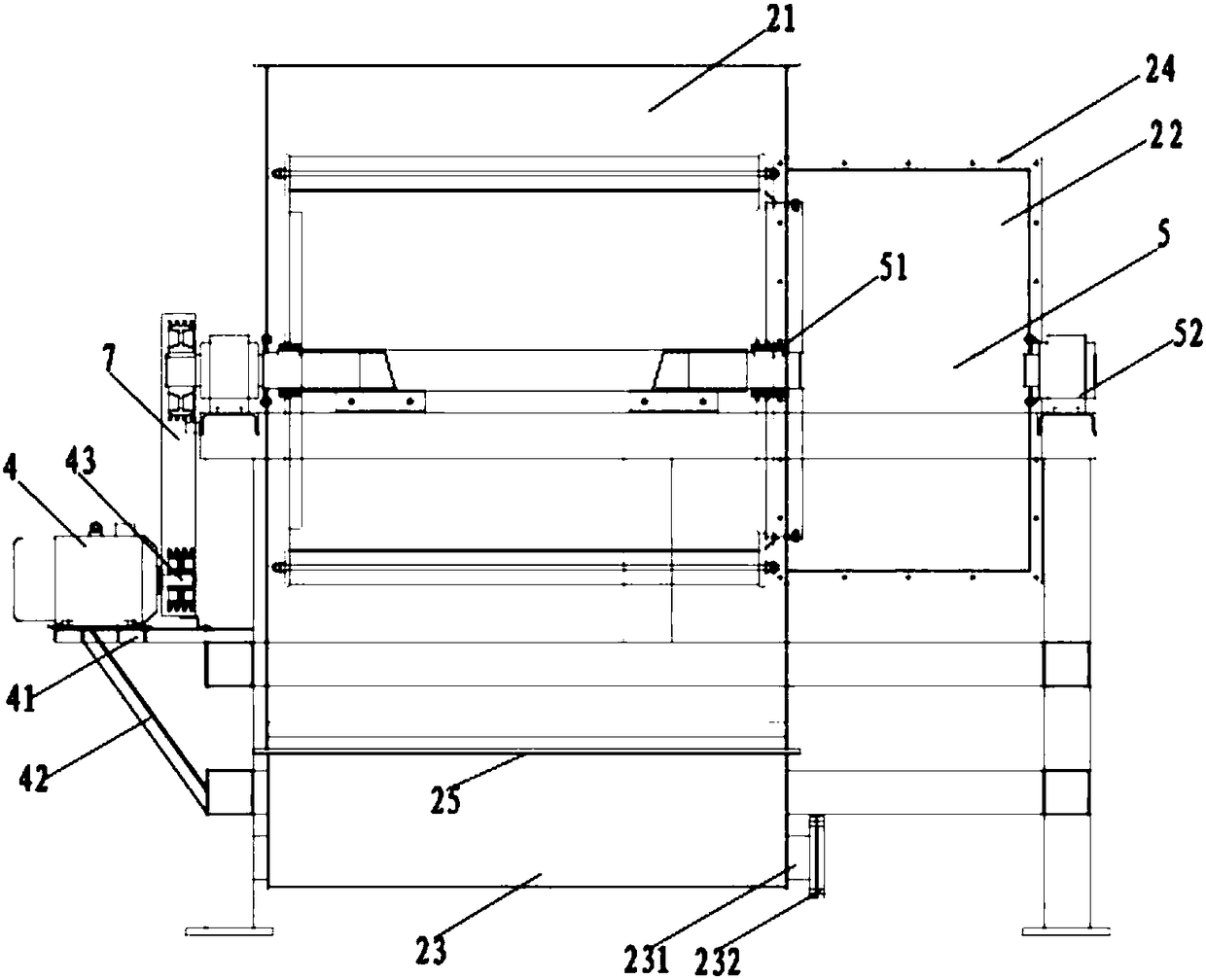

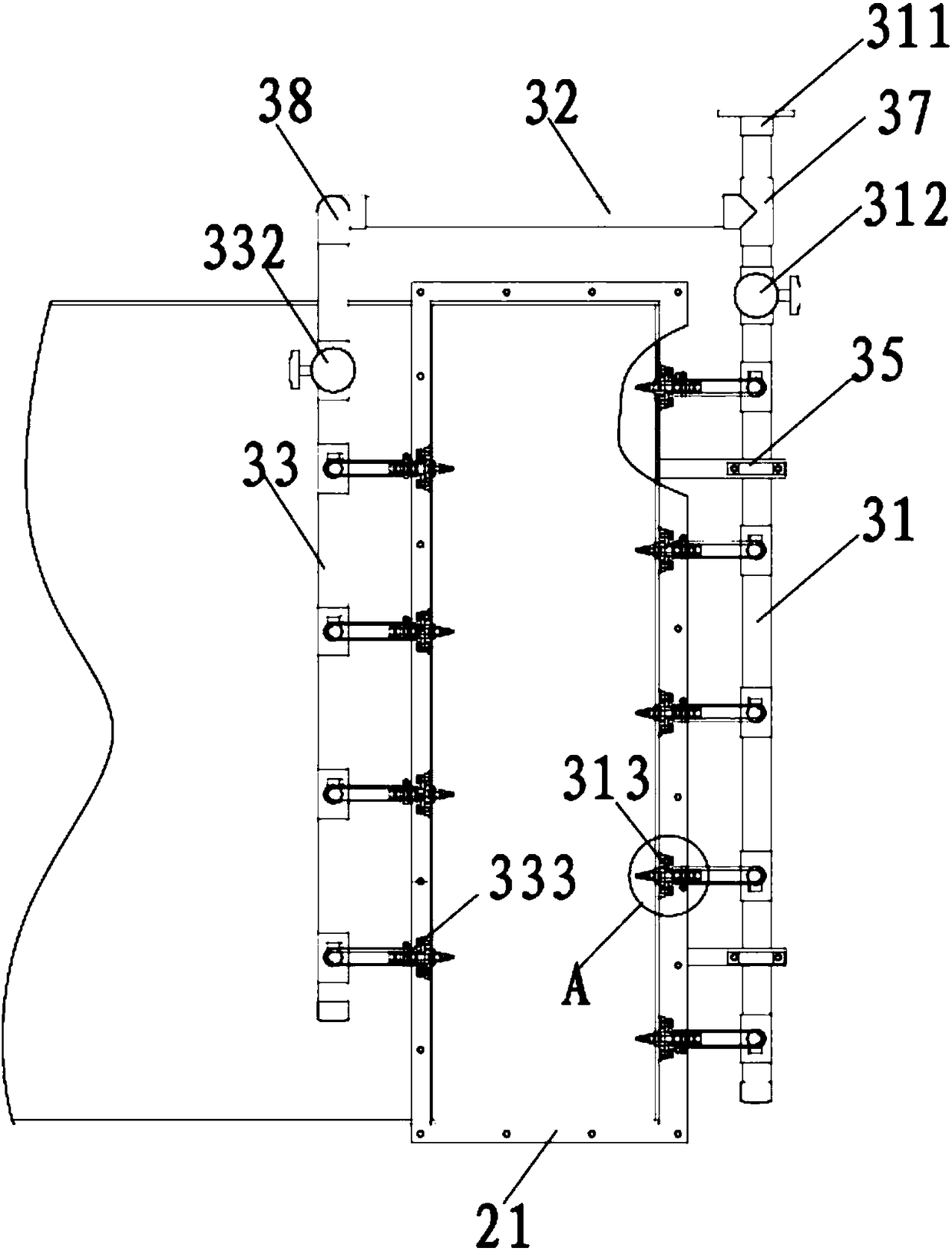

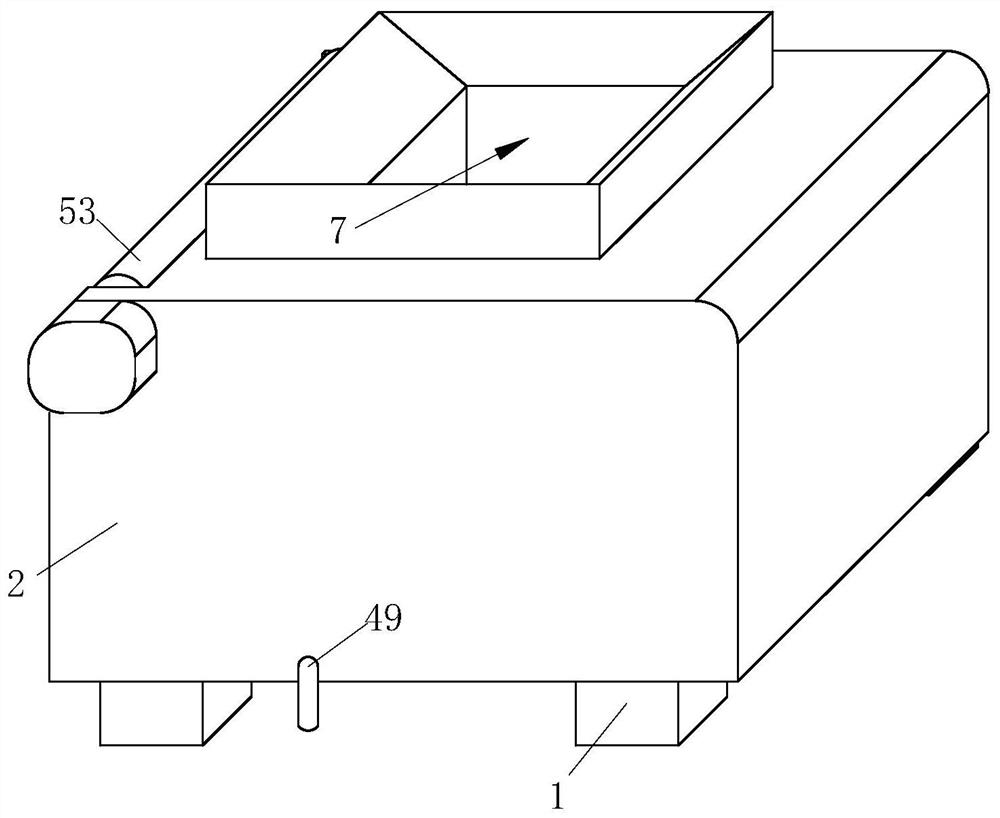

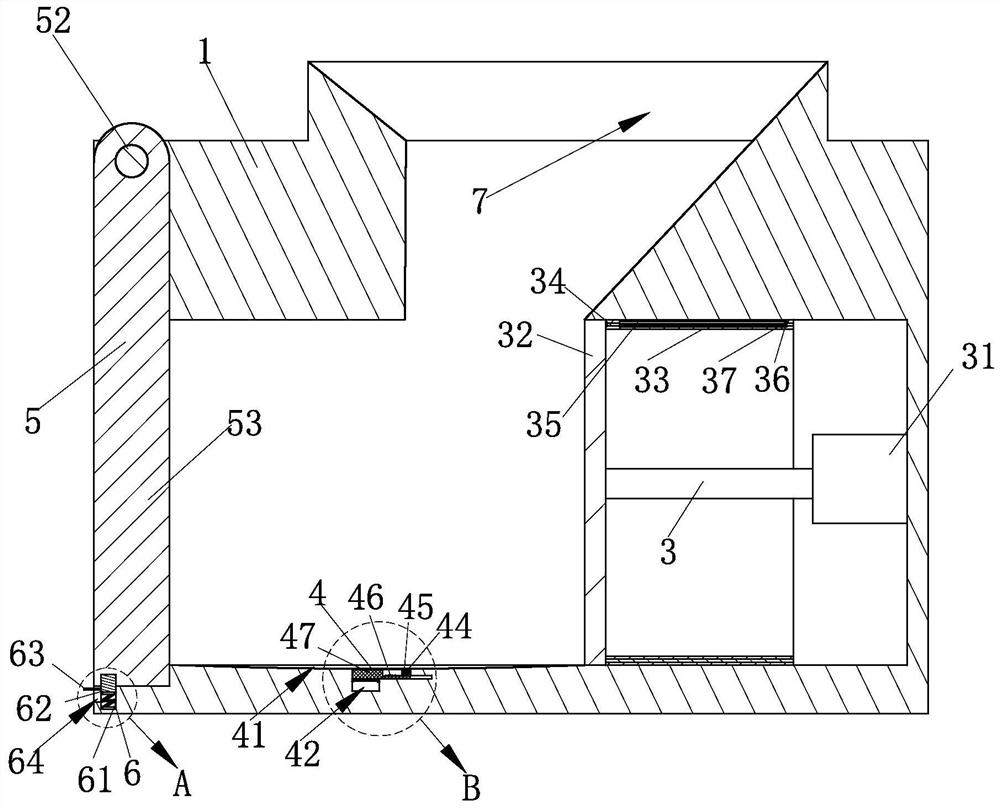

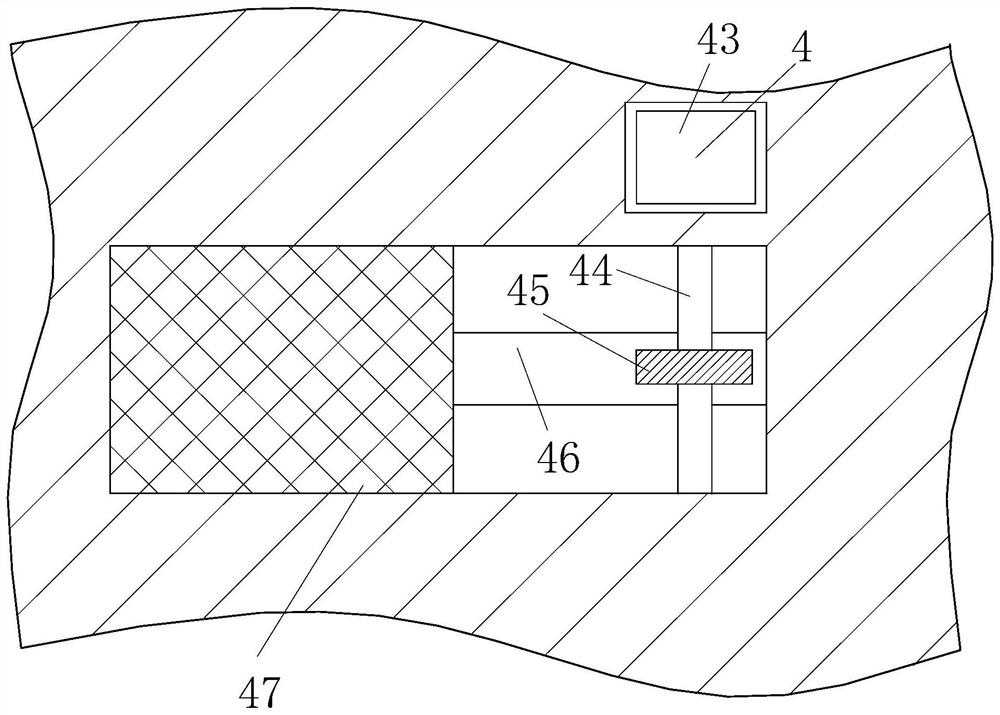

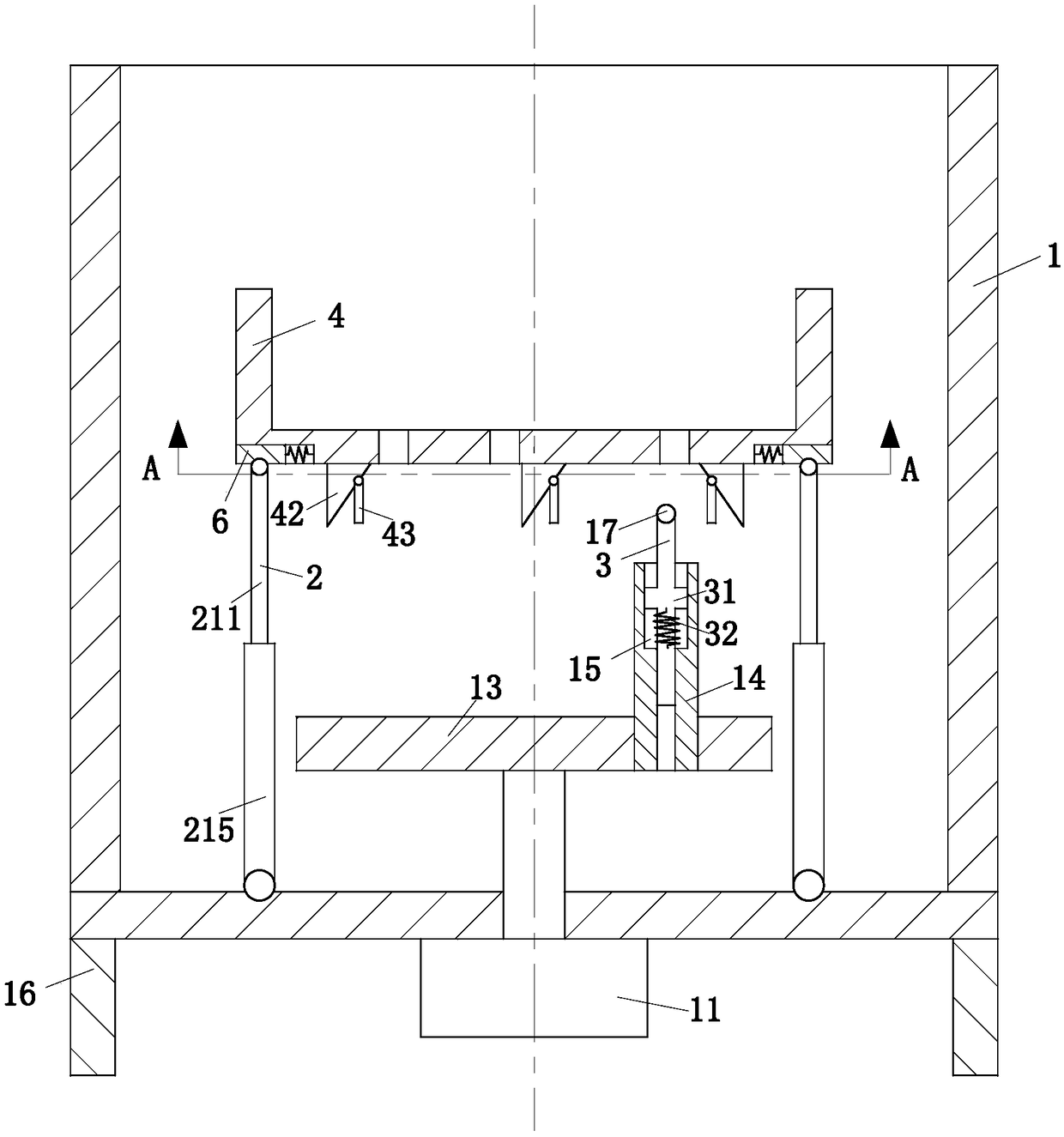

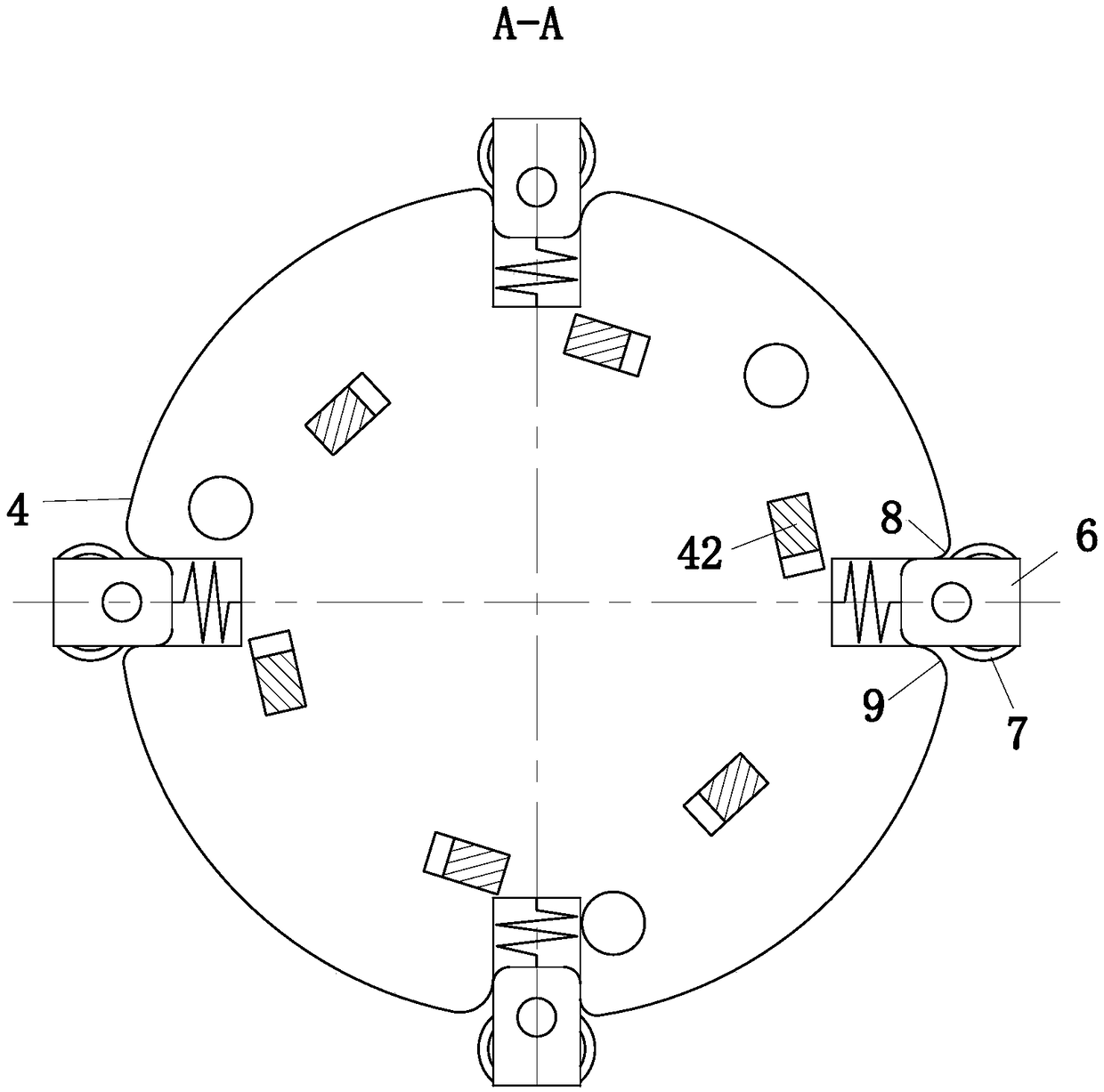

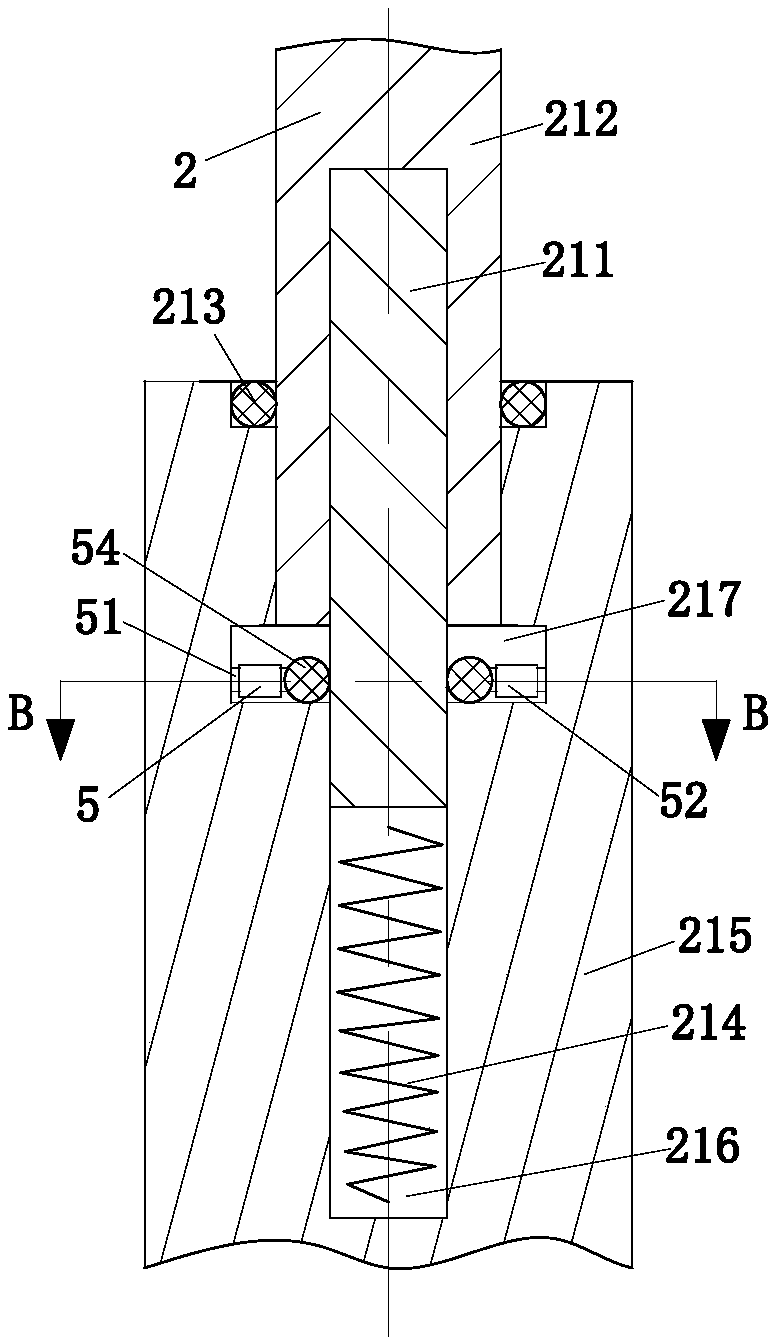

Food waste raw material receiving comprehensive treatment apparatus

InactiveCN102941208ASmooth dischargeReduce the numberSolid waste disposalPackagingFailure rateHelical blade

The present invention provides a food waste raw material receiving comprehensive treatment apparatus, and relates to a solid waste treatment apparatus, particularly to a waste treatment apparatus for food waste solid-liquid separation. A purpose of the present invention is to provide a food waste raw material receiving comprehensive treatment apparatus having functions of bag breaking, clogging resistance and failure rate reduction. The apparatus mainly comprises a rack 1, a receiving bin body 2 and at least a screw conveying separation mechanism, wherein the apparatus is characterized in that an arc pocket groove 33 in the screw conveying separation mechanism is provided with a plurality of liquid draining holes 331, a liquid draining guide sleeve 5 is arranged below the liquid draining holes, and is communicated with a liquid guide pipeline 51, at least an anti-winding steel belt 34 is fixed on the inner wall of the arc pocket groove and between a gap of the inner wall of the arc pocket groove and a helical blades 32, a bearing 6 is fixed on the receiving bin body, a bearing 6 is fixed on the receiving bin body, a bag breaking bush 61 is inserted and arranged inside the bearing, the bag breaking bush is sleeved outside the helical blades, one end of the bag breaking bush extends into the receiving bin body 2, the extending end is provided with saw-shaped cutter teeth, and the bag breaking bush is driven by a bag breaking driving motor 7.

Owner:北京弗瑞格林环境科技有限公司

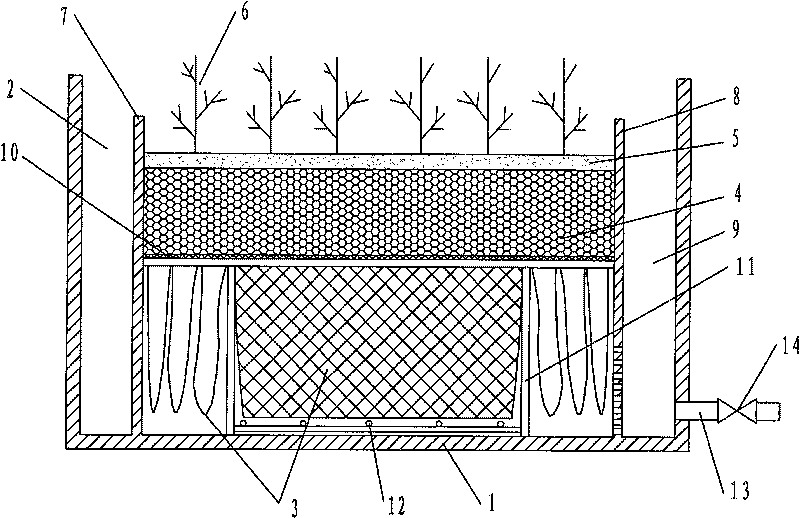

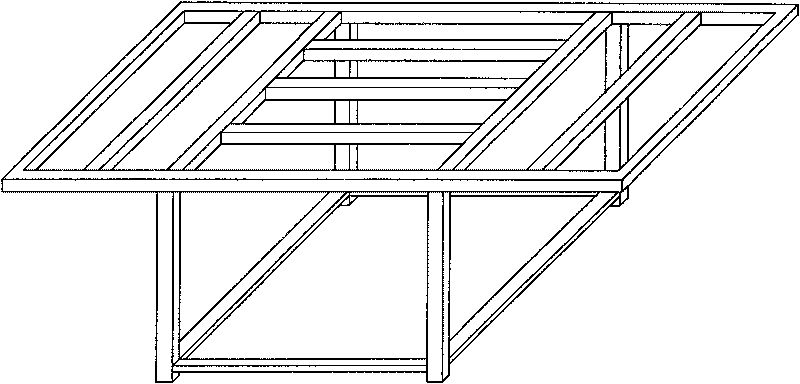

Quasi-undercurrent aeration constructed wetlands

ActiveCN101708898AAnti-cloggingNo cloggingTreatment using aerobic processesSustainable biological treatmentConstructed wetlandWater flow

The invention provides quasi-undercurrent aeration constructed wetlands, which comprise a wetland main body, a water distribution board, a watertight shutter, a rheid meshed packing layer, a vermiculite packing layer, a soil packing layer, a packing frame and an aeration tube, wherein the inside of the wetland main body is provided with the water distribution board and the watertight shutter; the meshed packing layer, the vermiculite packing layer and the soil packing layer are sequentially arranged between a space between the water distribution board and the watertight shutter from the bottom to the top; the meshed packing layer adopts an arrangement structure that meshed packing is longitudinally arranged near both sides of the water distribution board and the watertight shutter, the meshed packing is tangential to a water flow direction, and the meshed packing of the middle part is arranged horizontally; the mesh bottom of the meshed packing layer is 4 to 8 centimeters away from the bottom of the wetland main body; the meshed packing is hung on the packing frame; wetland plants are planted on the soil packing layer; and the aeration tube is arranged on the bottom between the water distribution board and the watertight shutter. The quasi-undercurrent aeration constructed wetlands have the characteristics of multiple designs and multiple guarantees so as to prevent the wetlands from being blocked and effectively process sewage in high quality.

Owner:SHANDONG UNIV

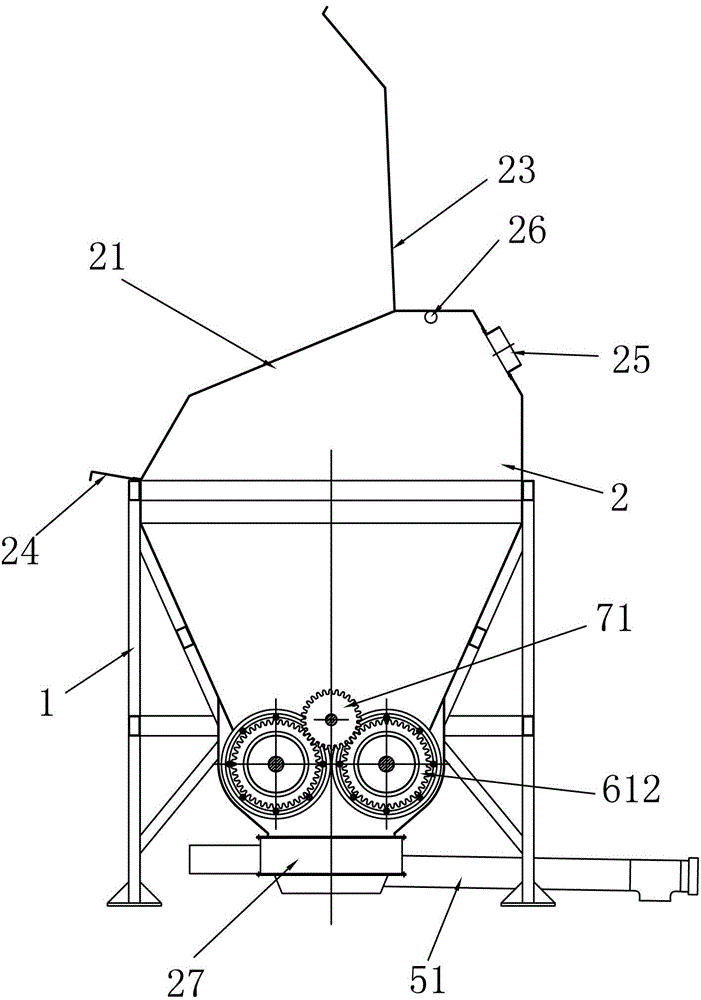

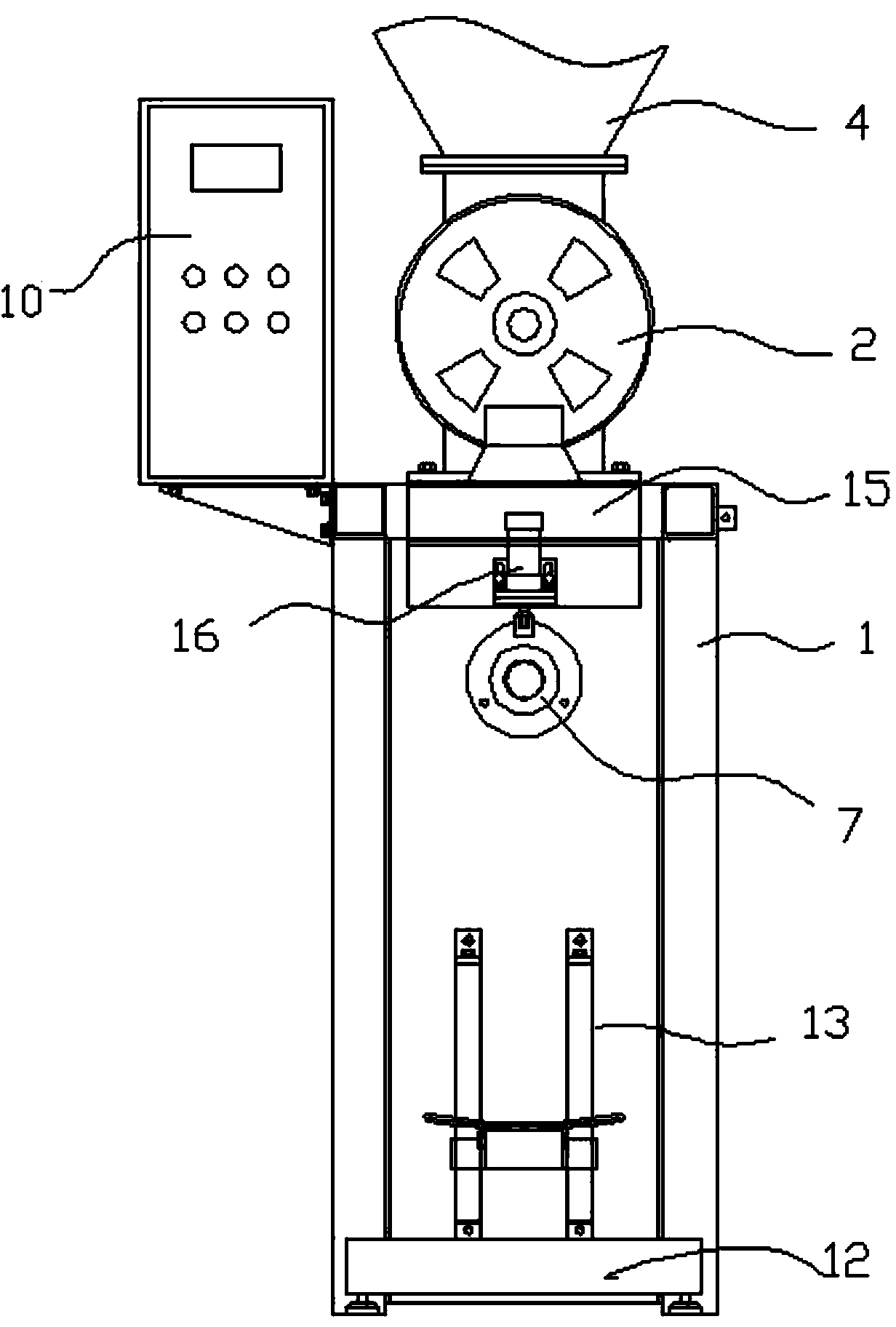

Dry mortar packing machine

InactiveCN103863590AUniform dischargeImprove feeding efficiencySolid materialAgricultural engineeringDischarge efficiency

The invention relates to the technical field of packing, and particularly discloses a dry mortar packing machine. The dry mortar packing machine comprises a machine frame and a discharging device. A feeding channel is arranged in the machine frame, a closed baffle is arranged at the lower end of the feeding channel, a discharging pipe is arranged on the side face of the lower end of the feeding channel, the outer end of the discharging pipe is provided with a discharging nozzle, a transverse rotating shaft is arranged at the lower end of the feeding channel, one end of the rotating shaft stretches out of the feeding channel and is connected with a rotating shaft fixing base, the other end of the rotating shaft is stretches into the discharging pipe, the rotating shaft and the discharging pipe are coaxially distributed, a motor is arranged at the bottom of the machine frame, a motor controller is connected to the motor, a control cabinet is further arranged on the side face of the upper end of the machine frame, the motor is connected with the rotating shaft through a belt, the rotating shaft is further provided with a spiral belt, an electronic scale and a material bag supporting frame arranged on the electronic scale are further arranged at the positions, located below the discharging nozzle, of the outer side of the machine frame, and the electronic scale, the motor controller and the control cabinet are connected. Therefore, the dry mortar packing machine has the advantages of being high in discharging efficiency and capable of preventing blocking and further improving the mixing uniformity of dry mortar.

Owner:SHANGHAI CONLY IND

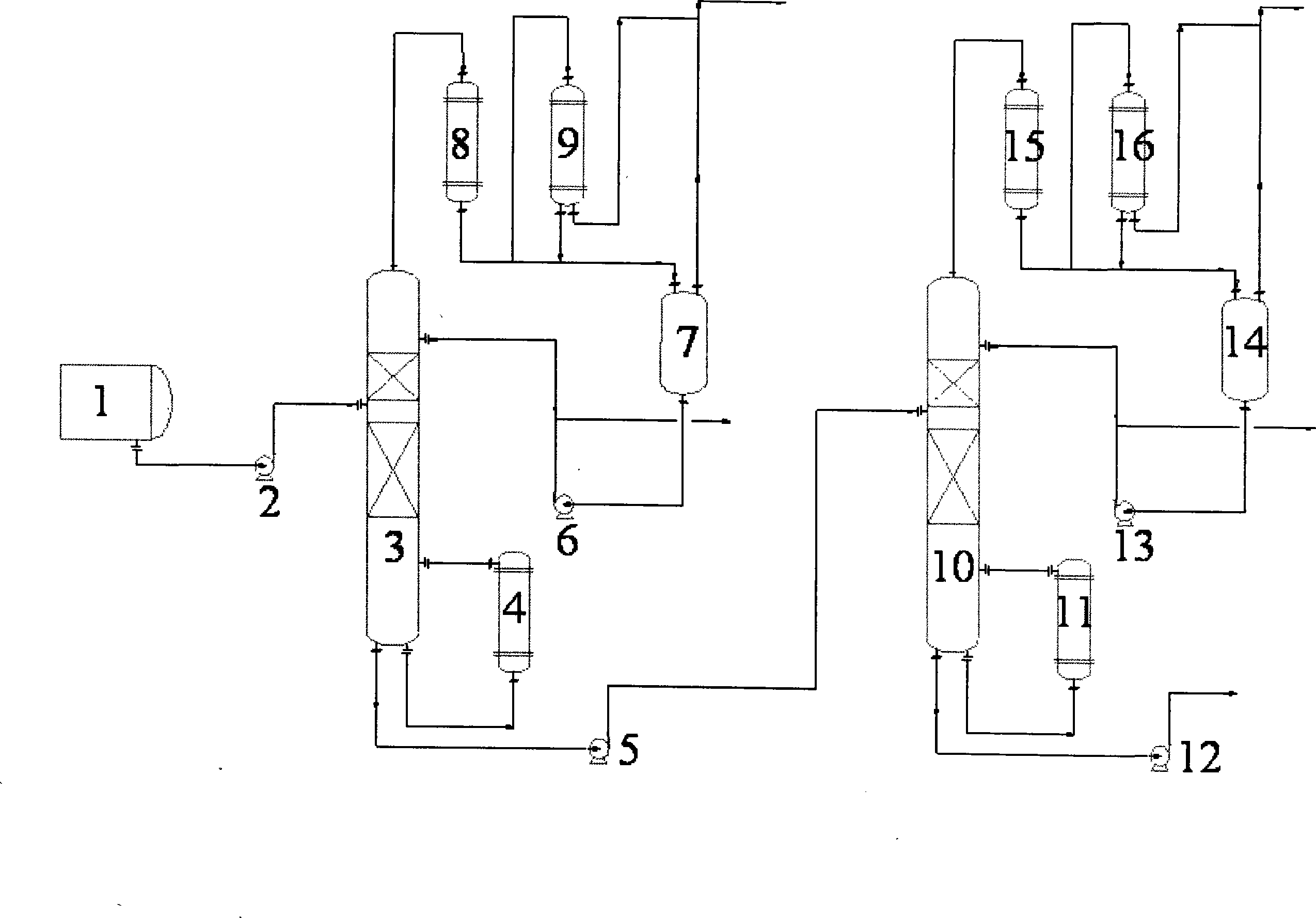

Continuous process and device for the separation of benzyl chloride regular packing column

InactiveCN101219927AAnti-cloggingSmall pressure dropDistillation purification/separationChemical/physical/physico-chemical processesTheoretical plateReboiler

The invention relates to a refining separation device for benzyl chloride serial, comprising a toluene distillation column and a benzyl chloride distillation column; the invention is characterized in that the toluene distillation column and the benzyl chloride distillation column are both structured packing columns. The two columns are both provided with a secondary condenser; one end of the secondary condenser is connected with an outlet at the top column after connected in series and the other end of the secondary condenser is connected with a reflux tank. The reflux tank is connected with a vacuum device and the bottom of the tower is provided with a reboiler. The device adopts the serial technique of two structured packing columns and negative pressure operation. Simultaneously when the highly purified benzyl chloride is produced, the toluene which is not completely reacted can be fully recycled. The continuous technique adopted by the invention has the advantages of stable material discharging, short staying time of material in the column, stable product quality, low unit energy consumption, operation time reducing and great production capacity. The theoretical plate number of the structured packing columns is high; the material discharging needs a smaller reflux ratio; the needed energy consumption is low and the production cost is reduced greatly.

Owner:TIANJIN UNIV +1

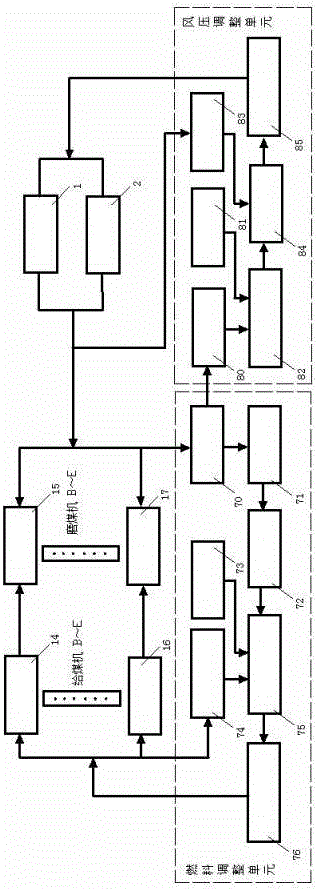

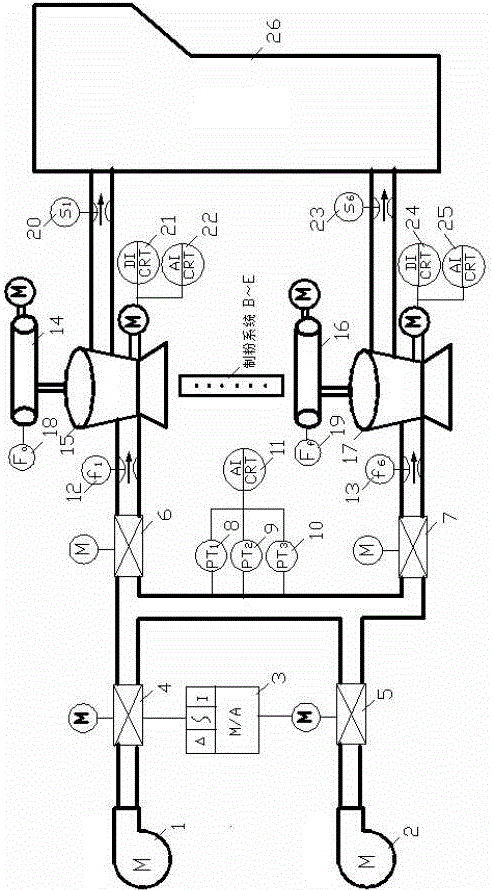

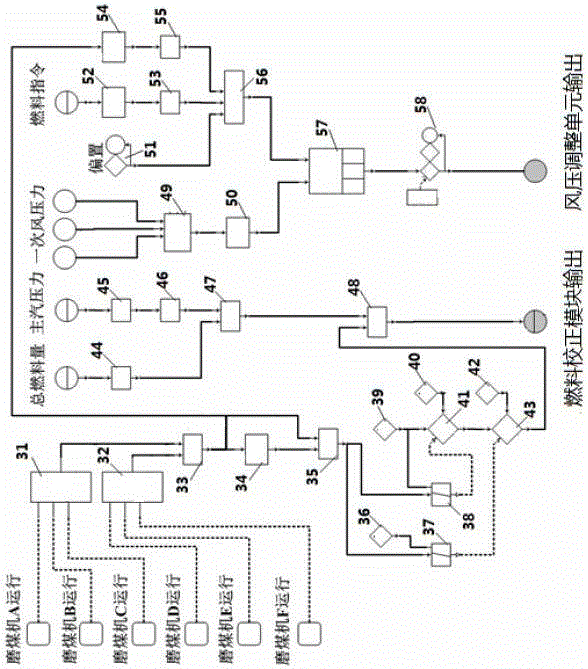

Anti-interference and energy-saving type thermal power generating unit powder making control system

PendingCN106801887AAnti-cloggingImprove anti-interference abilityFuel supply regulationFuel feeding arrangementsSteam pressureControl system

The invention provides an anti-interference and energy-saving type thermal power generating unit powder making control system. The anti-interference and energy-saving type thermal power generating unit powder making control system comprises a plurality of coal feeders, a plurality of coal mills, two primary air fans, a fuel adjusting unit and an air pressure adjusting unit. A counting module and a judgment module in the fuel adjusting unit are used for monitoring the running state of the coal mills, and once start or stop signals of the coal mills are monitored, the control system is immediately started. A fuel measuring module, a main steam pressure and fuel correcting module and a fuel output module conduct operation, then a fuel instruction is rapidly adjusted, and the stability of the fuel amount of a hearth is maintained. Meanwhile, the primary air pressure is rapidly adjusted through an air pressure correcting module, an instruction module and an adjusting module in the air pressure adjusting unit, and the dynamic matching relation between the average output of the coal mills and the primary air pressure is kept. The anti-interference and energy-saving type thermal power generating unit powder making control system solves the technical problem that in the coal mill start and stop processes, main parameters of the unit greatly fluctuate; the energy consumption of the primary air fans is reduced, blockage of the powder making control system can be prevented, and the safety performance, the stability performance and energy saving indexes of the unit are comprehensively improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

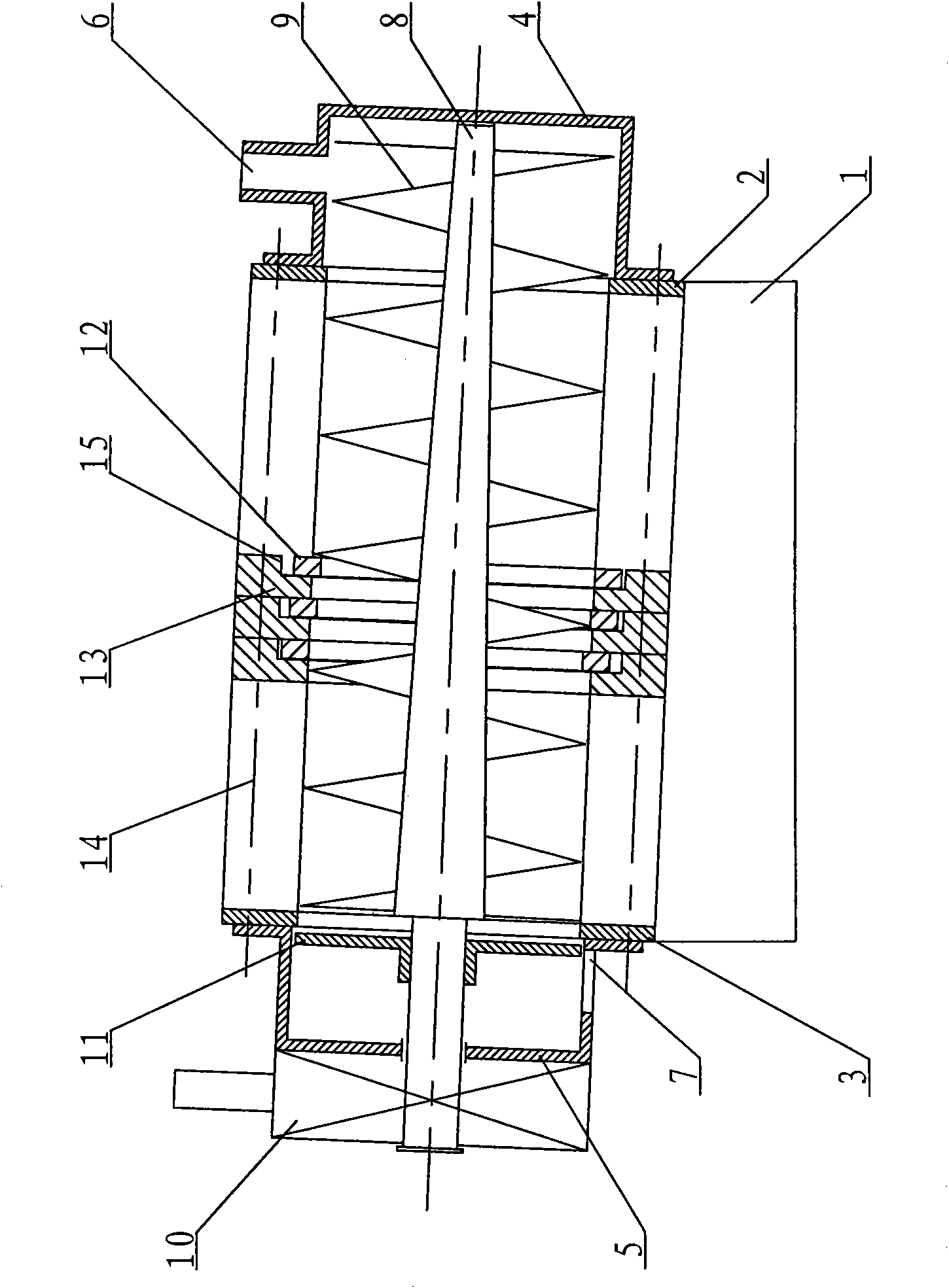

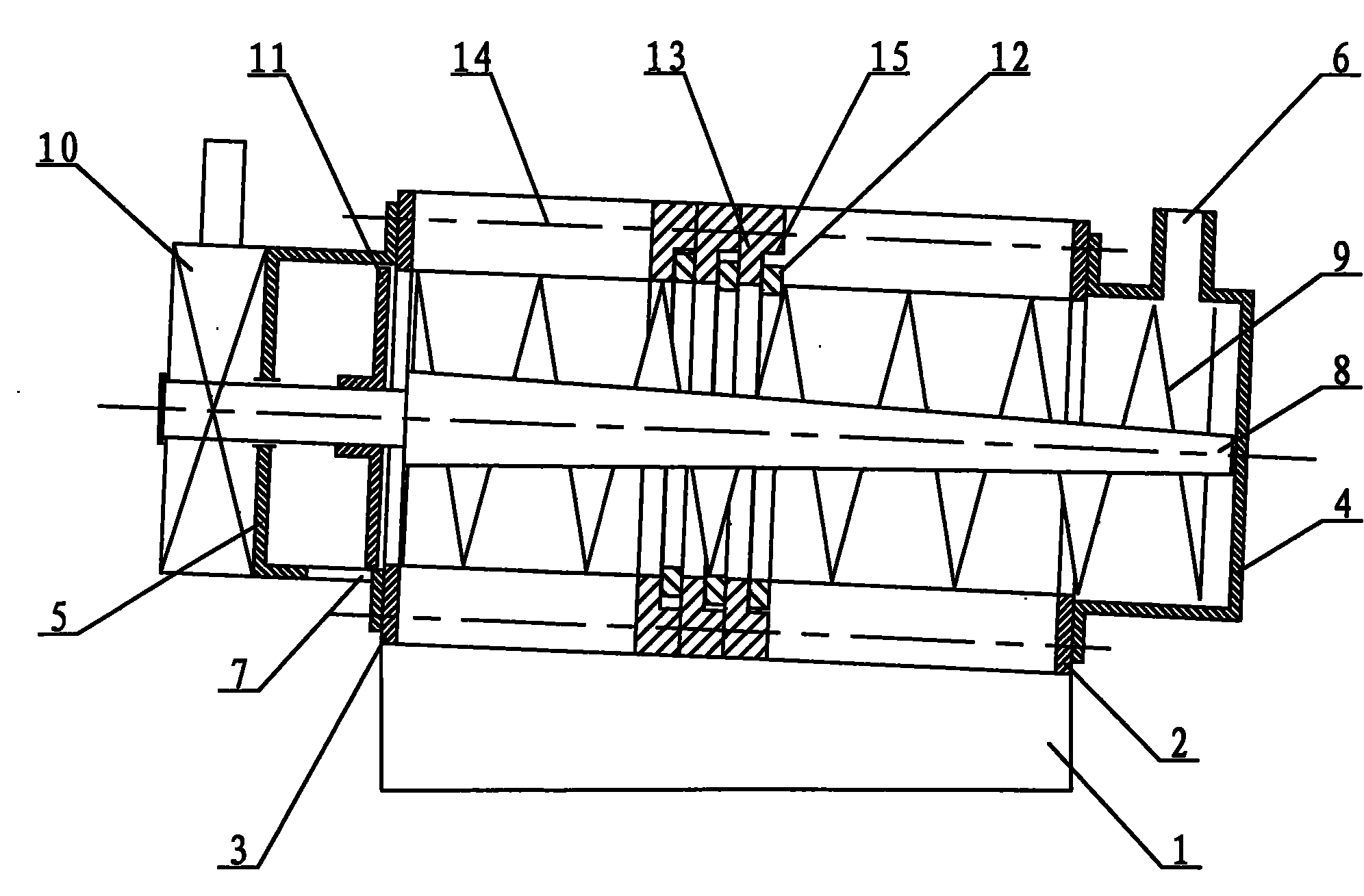

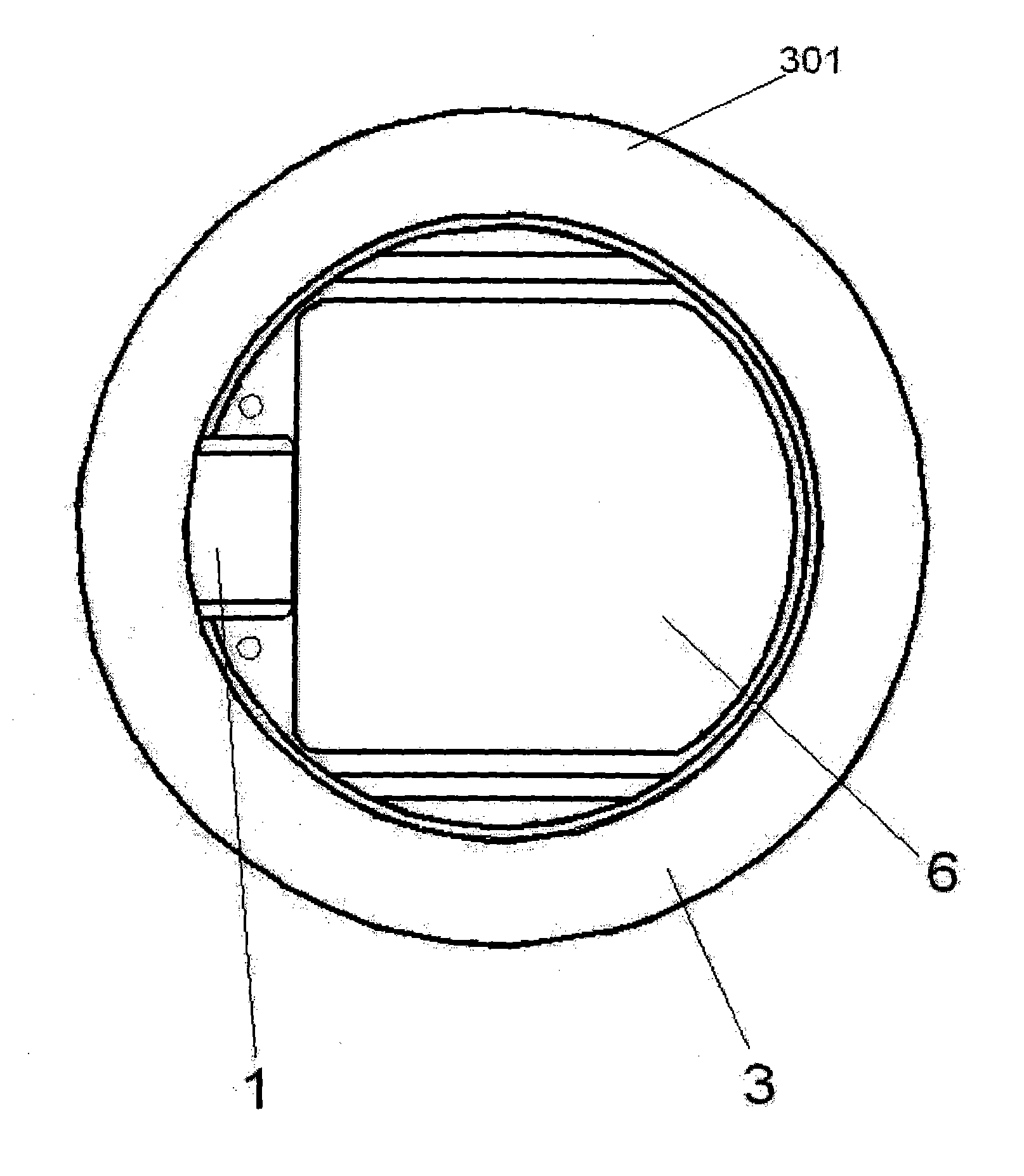

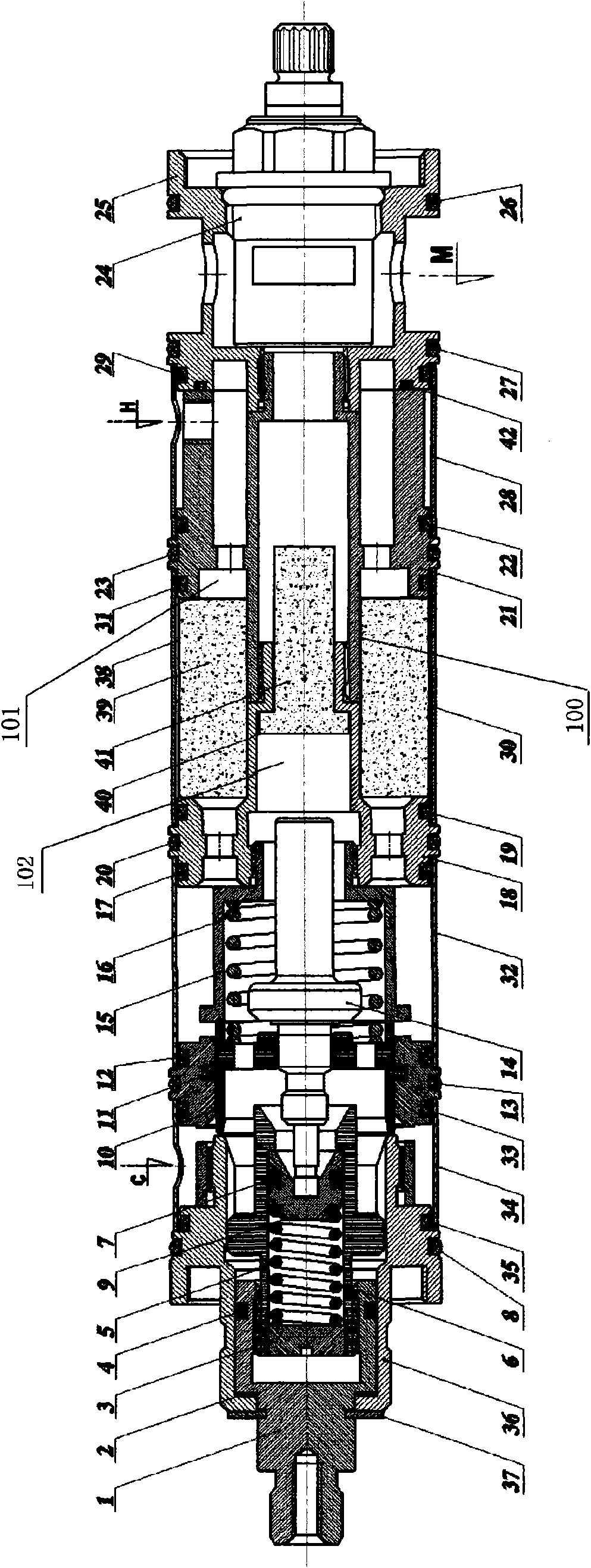

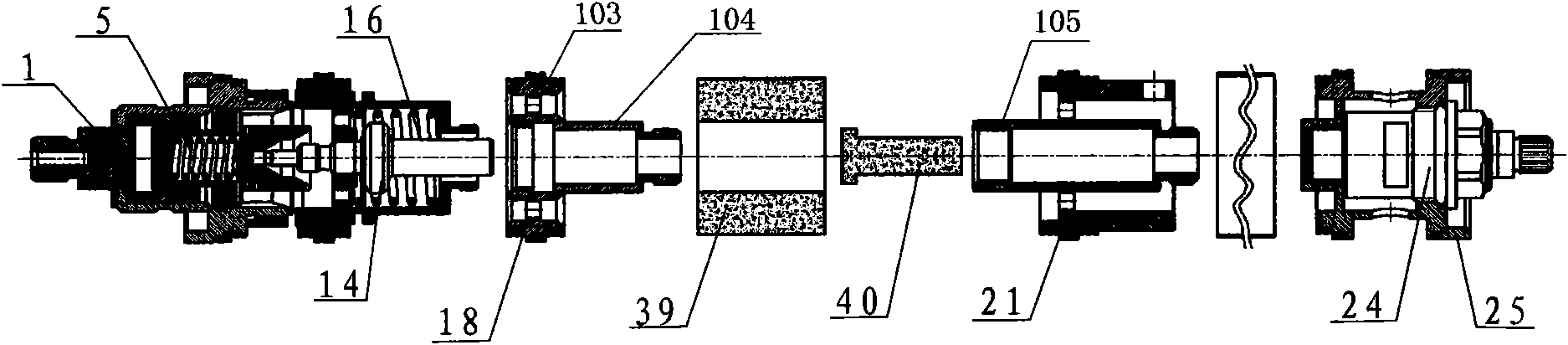

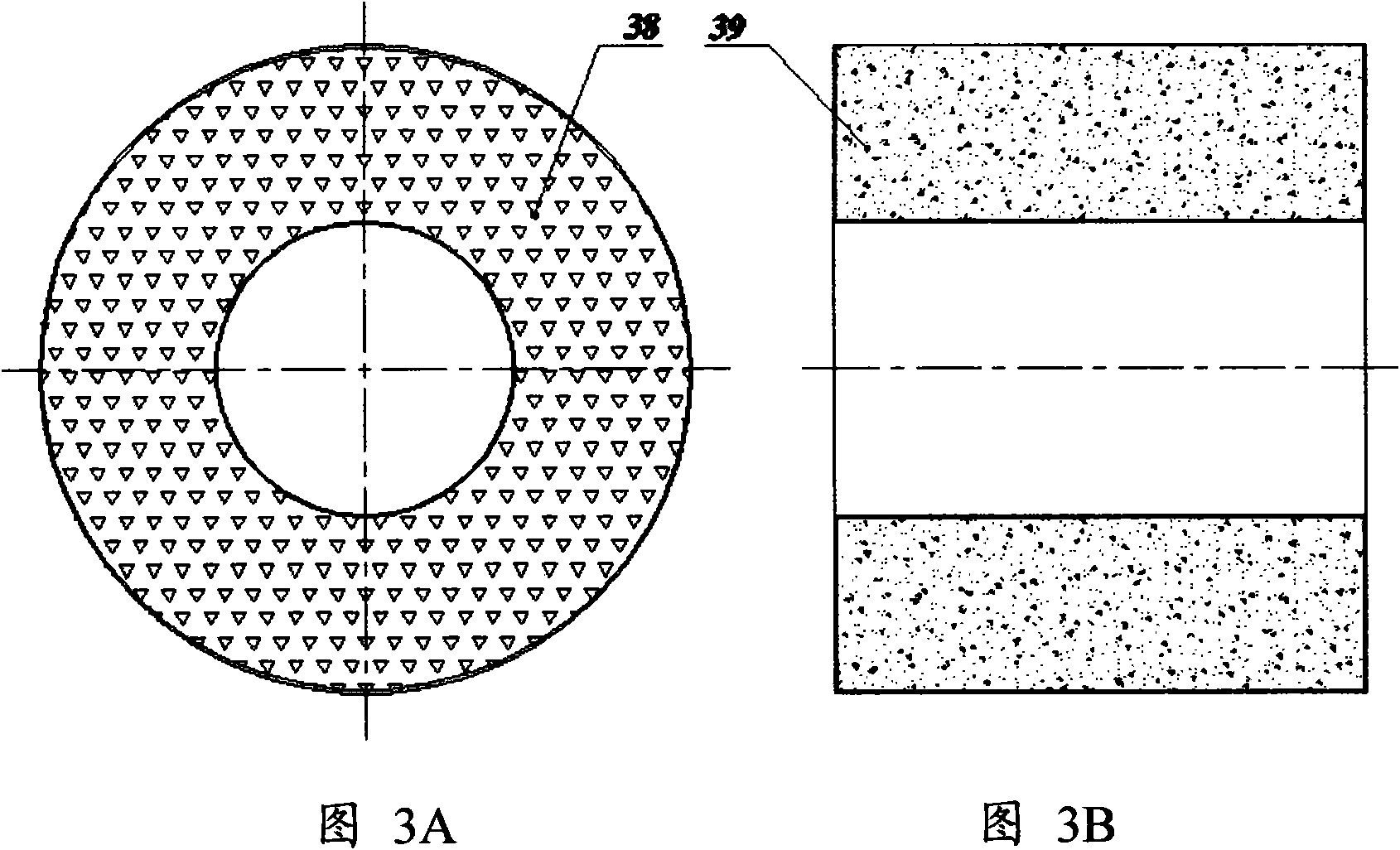

Dynamic gap type screw press

The invention relates to a dynamic gap type screw press comprising a spiral auger driven by a speed reducer and front and rear flange sleeves for supporting the spiral auger, wherein moving and static sheet groups matched with the spiral auger are arranged between the front flange sleeve and the rear flange sleeve; the front flange sleeve is provided with a feed opening; the rear flange sleeve is provided with a discharge opening; the spiral auger consists of a tapered shaft and blades; the outside diameters of the blades are equal; the screw pitches of the blades are equal; the inside diameters of the moving and the static sheet groups are greater than the outside diameter of the blades of the spiral auger; and the inside diameters of moving blades of the moving and the static sheet groups are smaller than the outside diameter of the blades of the spiral auger. According to the invention, sludge is propelled and extruded in the moving and the static sheet groups by the spiral auger consisting of the tapered shaft and the equidistant blades so as to realize the solid-liquid separation. The dynamic gap type screw press has simple structure and is convenient to process and stable for dehydration and has long service life; the equidistant blades have high rigidity; and the moving and the static sheet groups have the functions of draining, automatically cleaning, preventing blockage and the like.

Owner:周明泉

Biomolecular detection test strip design

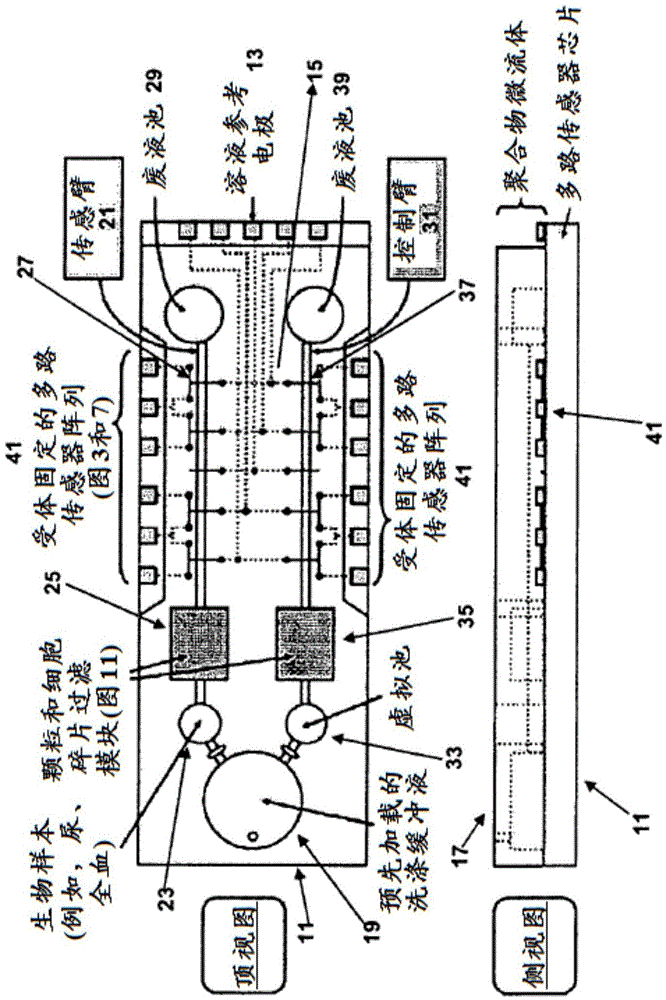

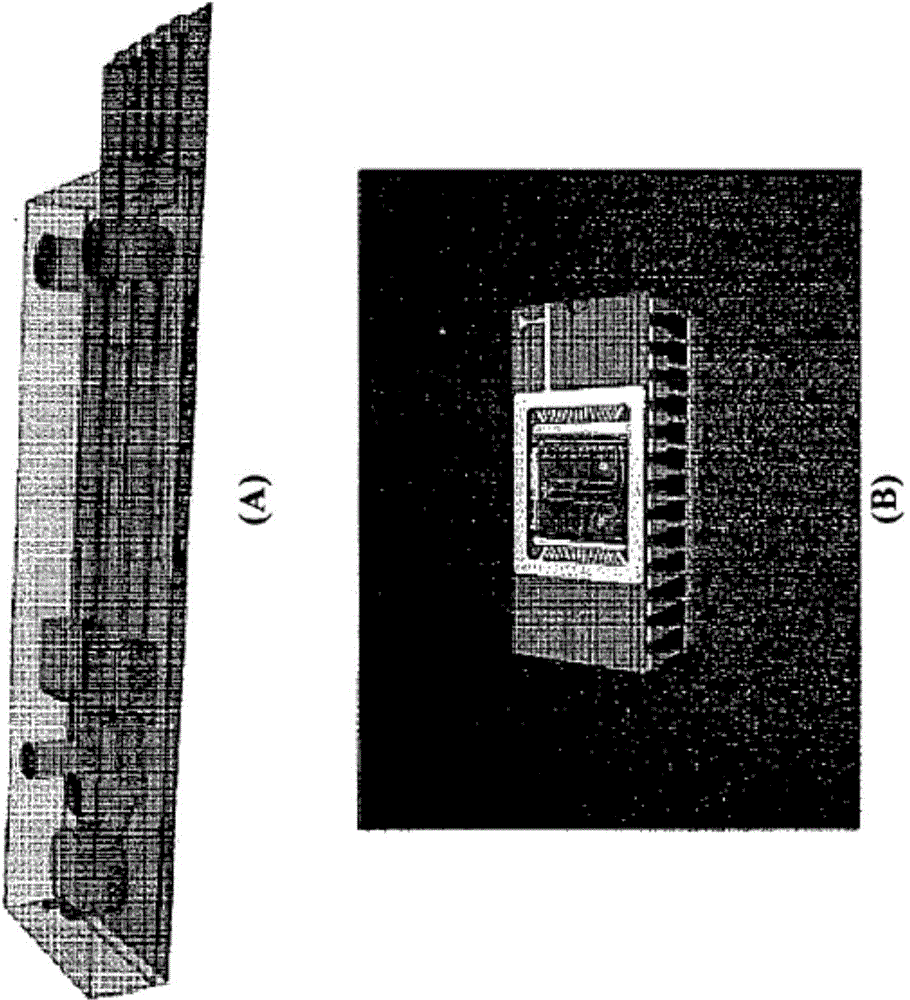

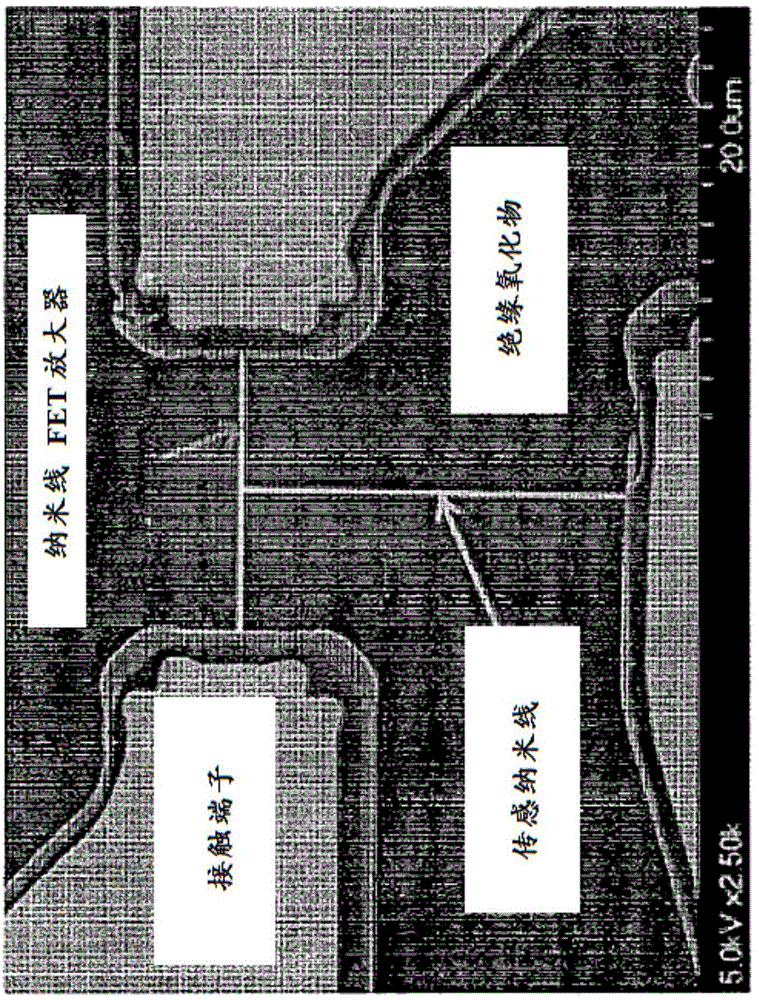

PendingCN104704357AEliminate needShort turnaround timeLaboratory glasswaresMaterial electrochemical variablesNanowireEngineering

Described here are a device and a method for detecting the presence of a biomarker using the device, wherein the device comprises (a) a substrate comprising a plurality of electrodes; (b) a plurality of nanowire field-effect transistor sensors integrated or assembled on the substrate and connected to the electrodes; and (c) a microfluidic component disposed on the substrate and adapted to communicate fluidically with the nwFET sensors.

Owner:RGT UNIV OF CALIFORNIA

Maintenance station capable of automatically washing mop

PendingCN111759240ASolve the inconvenience of cleaningEasy to clean and maintainCarpet cleanersFloor cleanersSewageWater resource management

The invention relates to the field of cleaning equipment. The invention particularly relates to a maintenance station capable of automatically washing a mop. By setting a base, a cleaning groove usedfor cleaning a mopping piece of a cleaning robot is formed in the base. A dirt deposition part with a sewage collection cavity is arranged below the cleaning tank; when the mopping piece is cleaned inthe cleaning groove, generated sewage automatically flows into the sewage collection cavity downwards under the action of gravity; the dirt deposition part is arranged in a detachable connection manner; therefore, the dirt deposition part can be detached at any time to clean dirt accumulated in sewage; compared with the structure that sewage in the cleaning tank directly flows into the bottom ofthe base, the structure of the invention has the advantages that stain deposits to the bottom of the base and is transferred to the dirt deposition part, the problem that dirt on the mop easily staysat the bottom of the base and accordingly cleaning is inconvenient is solved, the sewage collection cavity can be cleaned without squatting down or lifting up the whole automatic mop cleaning maintenance station, and the cleaning and maintenance are quite convenient.

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

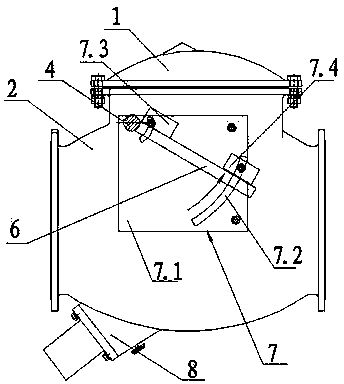

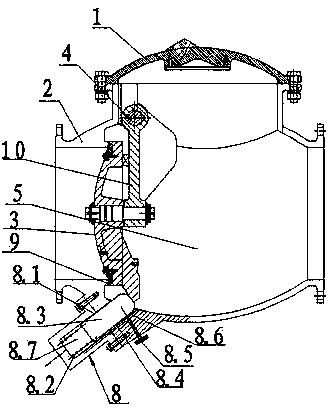

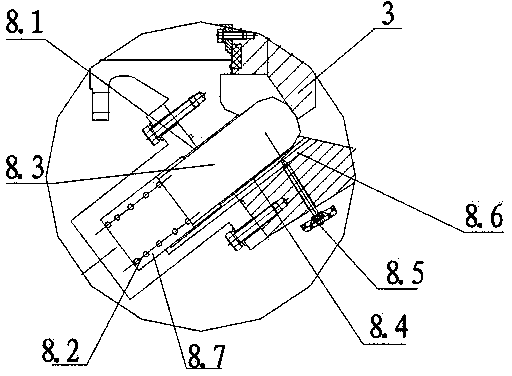

Automatic magnetic check valve

The invention relates to an automatic magnetic check valve, which comprises a cover body, an upper magnet, a valve body, a shaft seat, a valve, a lower magnet and a sealing ring, wherein the shaft seat is arranged on one side of the bottom of the valve body; the valve is hinged on the shaft seat; the upper magnet is arranged on the valve body; the lower magnet is arranged on the valve; the sealing ring is arranged between the valve and the valve body; and the upper magnet and the lower magnet are in a Z-plane asymmetric structure. When asymmetric magnets attract each other, an Fx component force not equal to zero is generated, the consistency of the repeated opening / closing action of the valve is greatly improved under the action of the Fx, and the valve is closed to be accurately attracted and sealed; the valve body has a high flow structure, so that an effective area of fluid flowing through the valve body is greatly improved; the valve body is hardly wound with hair and cotton and is cleaning-free; the valve can realize 90-degree opening in a circular pipeline, the drainage is not hindered and the flow velocity is high; and the overflow of sewage is prevented, polluted air, insects and cockroaches are prevented. The check valve is conveniently arranged at a sewage pipeline to replace the conventional water return bend, is suitable for sewage drainage, and is also suitable for other fluid pipelines with one-way flow requirement.

Owner:张成

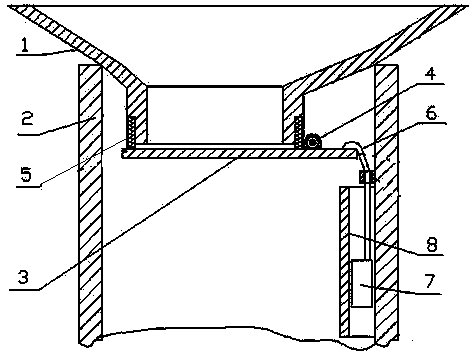

Constant-temperature valve core

ActiveCN102042425ADeodorantAnti-cloggingOperating means/releasing devices for valvesMultiple way valvesEngineeringThermal water

The invention discloses a constant-temperature valve core, which comprises a valve core body, a first waterway director, a second waterway director and a regulating switch which are connected sequentially, wherein a plurality of heat-insulating sleeves are arranged outside the valve core body, the first waterway director and the second waterway director respectively; the first waterway director is matched with the second waterway director; the first waterway director and the second waterway director protrude oppositely and are connected to form a combined part with a communicated hollow cavity; hot-water channel is formed between the combined part and the heat-insulating sleeves, and is communicated with a hot-water inlet; a hollow water mixing channel is formed in the hollow cavity of the combined part; and a first filter is arranged in the hot-water channel, and a second filter is arranged in the water mixing channel. The constant-temperature valve core has the functions of scald prevention, deodorization, blocking prevention, sterilization, disinfection and environmental protection.

Owner:TAIZHOU XUSHENG SANITARY WARE CO LTD

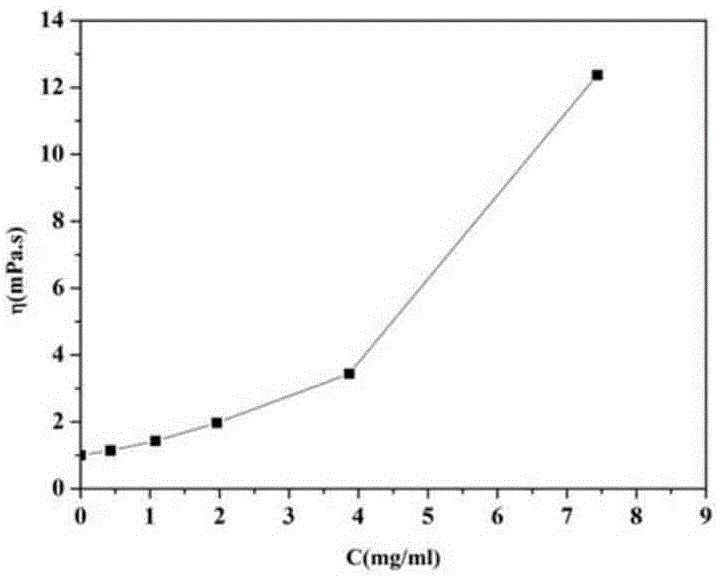

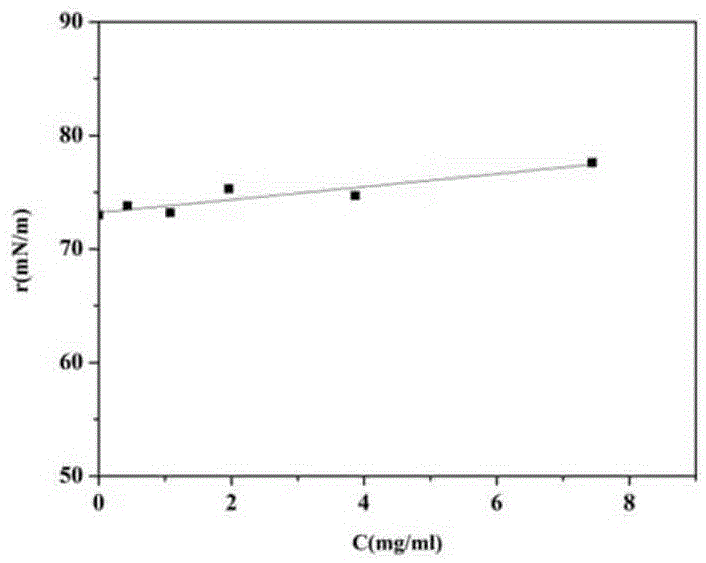

Graphene oxide ink as well as preparation method and application thereof

ActiveCN105860667AProcess stabilityUniform processSingle layer grapheneInksComputer printingMicrofiltration membrane

The invention discloses graphene oxide ink as well as a preparation method and application thereof. The graphene oxide ink is prepared from graphene oxide, surfactant and solvent as raw materials, and counted by mass fraction, the graphene oxide accounts for 0.1%-0.5%, the surfactant accounts for 0.05%-0.5% and the rest is solvent. The preparation method comprises steps of dispersing the graphene oxide in the solvent, adding the surfactant to obtain a mixed solution, and carrying out filtering with a micro-filtration membrane to obtain the graphene oxide ink. The graphene oxide ink can be applied to an inkjet printer, and particularly can be used for preparing a graphene flexible circuit through an inkjet printer. The graphene oxide ink and the preparation method thereof disclosed by the invention have the advantages of greenness, environment protection, low cost, simple preparation and the like, and the graphene oxide ink applied to a common home inkjet printer can meet the market requirement.

Owner:NAT UNIV OF DEFENSE TECH

Deodorant water floor drain capable of being automatically opened and closed

InactiveCN104294907ARealize automatic opening and closingHas spreadSewerage structuresEngineeringSelf weight

The invention relates to a deodorant water floor drain capable of being automatically opened and closed. The water floor drain comprises a water collecting baffle, a cylinder main body, a sealing plate, and a counter weight hammer, wherein the water collecting baffle is fixedly mounted at an upper end opening of the cylinder main body, and a circular or elliptic water outlet pipe opening formed in the lower part of the water collecting baffle is positioned in the cylinder main body; the sealing plate which rotates around a rotating shaft is arranged at the lower part of the water outlet pipe opening of the water collecting baffle; the rotating shaft is mounted on a supporting seat arranged on the outer wall of the water outlet pipe opening or a supporting seat arranged on the inner wall of the cylinder main body through a shaft sleeve; the counter weight hammer is mounted in the cylinder main body, and is connected with one end of the sealing plate through a driving member. Through the self-weight traction of the counter weight hammer, the driving member drives the sealing plate to rotate around the rotating shaft to a horizontal position so as to block the water outlet pipe opening and realize the purpose that the floor drain is sealed for deodorization; when water is collected in the water collecting baffler, the sealing plate is automatically opened, so that drainage is realized. The deodorant water floor drain has the advantages of reasonable structure, low building cost and convenience in maintenance, and has the functions of quick deodorization, blocking prevention and backwater prevention.

Owner:HARBIN INST OF TECH AT WEIHAI

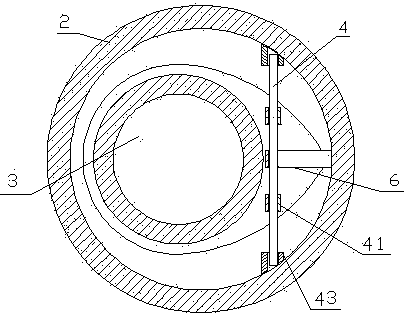

Device and process for recycling trimethylamine

ActiveCN104725238AIncrease recovery concentrationHigh recovery rateAmino compound purification/separationAutomatic controlChemistry

The invention discloses a device for recycling trimethylamine. The device comprises a reactive evaporation kettle, a rectifying column, a condenser, a gas-liquid separator, an absorption liquid intermediate tank, an absorption liquid intermediate pump and a clear water intermediate tank. Trimethylamine wastewater and liquid caustic soda react with each other in the reactive evaporation kettle, the trimethylamine flows into the rectifying column and flows into a cooler to be condensed after mass and heat are transferred by the aid of absorption liquid in the absorption liquid intermediate tank, the clear water intermediate tank and the absorption liquid intermediate pump, finished products are fed into the absorption liquid intermediate tank, and tail gas flows into the gas-liquid separator. The device has the advantages that the trimethylamine is recycled and absorbed by the aid of the absorption liquid intermediate tank, accordingly, the device is favorable for increasing the trimethylamine recycling concentration and high in trimethylamine recycling rate, is high in wastewater treatment capacity owing to separation effects of the rectifying column and the reactive evaporation kettle, is high in theoretical plate number, low in resistance loss and stable and reliable in performance, can run continuously or intermittently, has an automatic control function, can be cleaned in an online manner and is free of blockage, small in occupied area and simple in arrangement, reaction can be carried out in an online manner without device shutdown, and aeration energy consumption can be reduced.

Owner:江苏金杉新材料有限公司

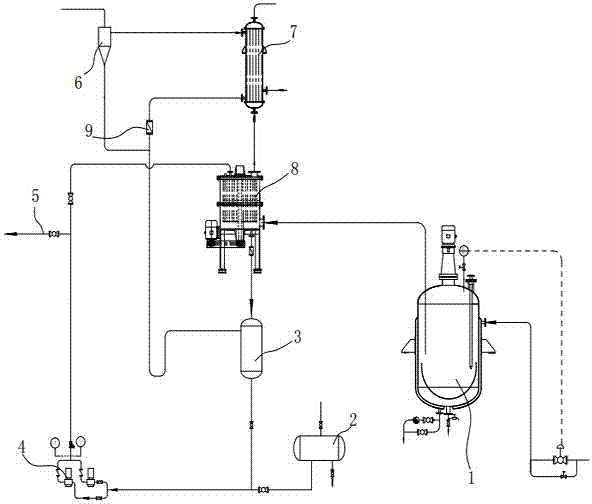

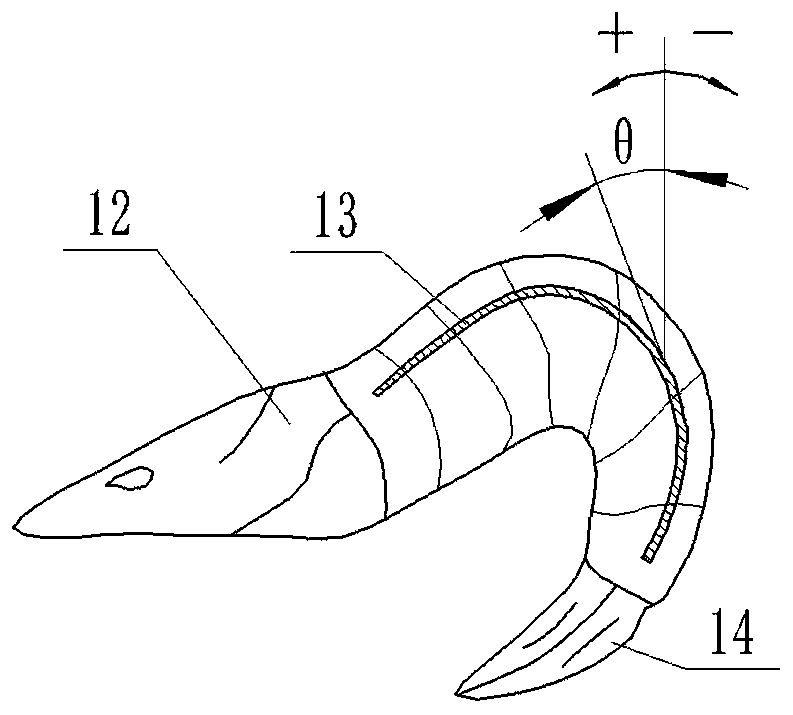

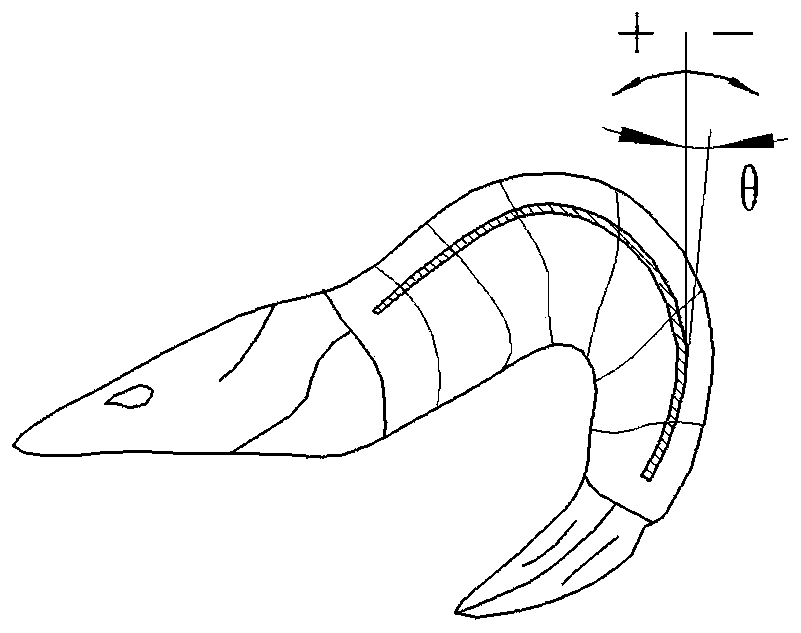

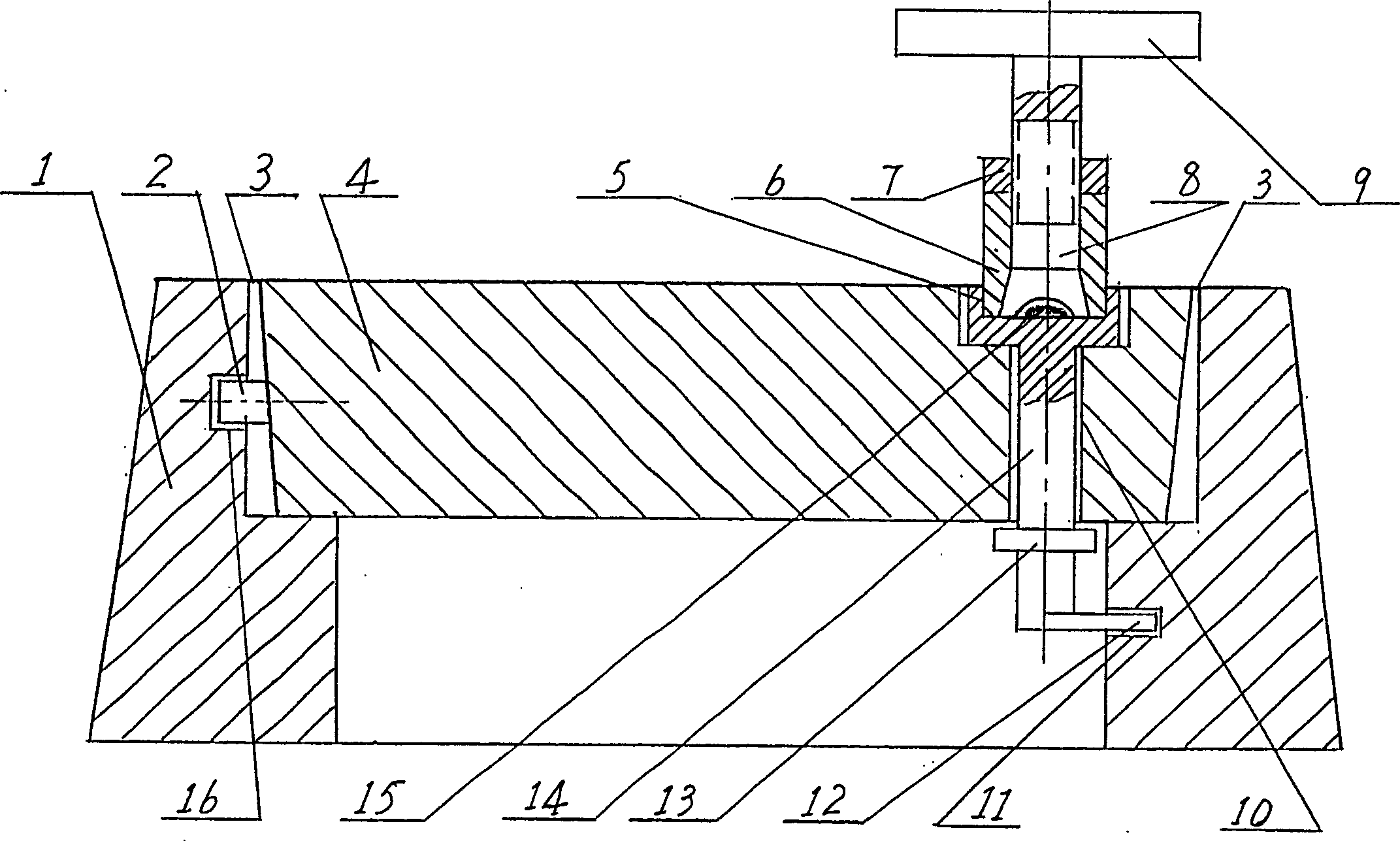

Shrimp line automatic removal device and use method thereof

The invention belongs to the field of mechanical design, and relates to a shrimp line automatic removal device and a use method thereof. Based on a detection device, a loading system and a feeding system, the device can automatically remove a shrimp line. The use method includes the following steps that first, a shrimp is positioned and clamped on the loading system, then under the strong light, amicro camera is used for taking photos to identify the position of the shrimp line, a combined tool opens the back according to a generated tool path, and at the same time, the shrimp line is automatically sucked out. According to the shrimp line automatic removal device and the use method thereof, the shrimp is positioned and clamped in a flexible clamping mode, and the device can adapt to shrimps of different shapes and sizes. The position of the shrimp line is easier to catch through strong light. The optimal design of the combined tool can improve the force direction of the suction process of the shrimp line, make the shrimp line easier to be sucked out, and have the anti-blocking function.

Owner:DALIAN UNIV OF TECH

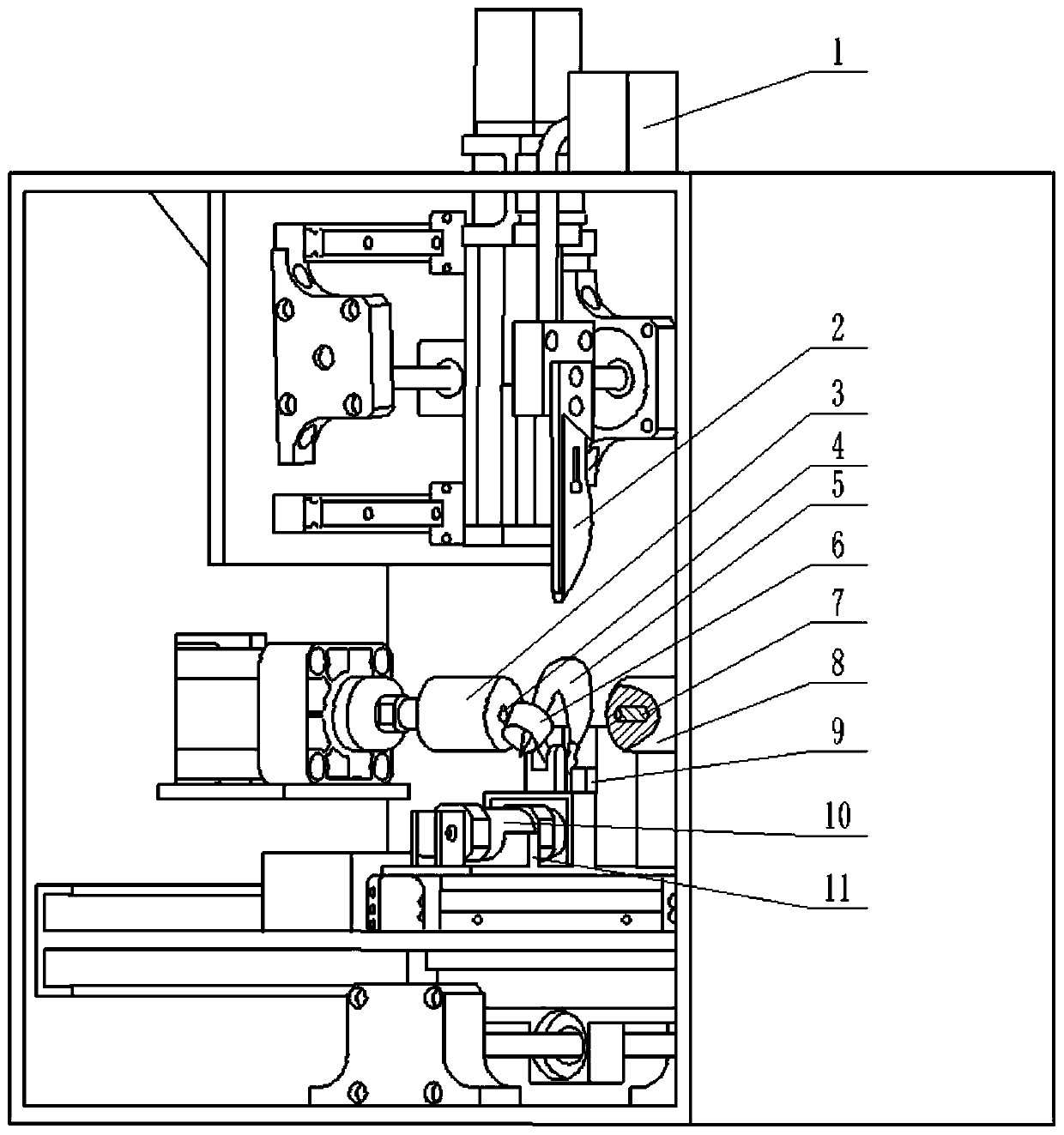

Antitheft manhole cover with special opening and locking device

InactiveCN1710216ASimple structureEasy to install and useArtificial islandsUnderwater structuresAnti theftCross pin

The invention discloses anti-theft manhole cover, which consists of maphole cover with lock device, support base and special key. The lock device consists of a T stand lock core with a key-hole, bolt, boss, cross-pin; the special key consists of expanding wall, expanding core and handle. The lock device is simple which prevents the silt jamming with a handily installation and application. Workers will not be interfered after the cover is open for maintenance construction. There is no open hole and gap on the cover and the base. The cover and base associate tightly and is strongly anti-picking, anti-corrosion, anti-foul-release, and anti-frostbite so that rain water, silt and waste will not easily enter the observer well. The cover can not be opened without the special key so to prevent the underground wire facility from damaging, stolen.

Owner:句容市科达技术开发有限公司

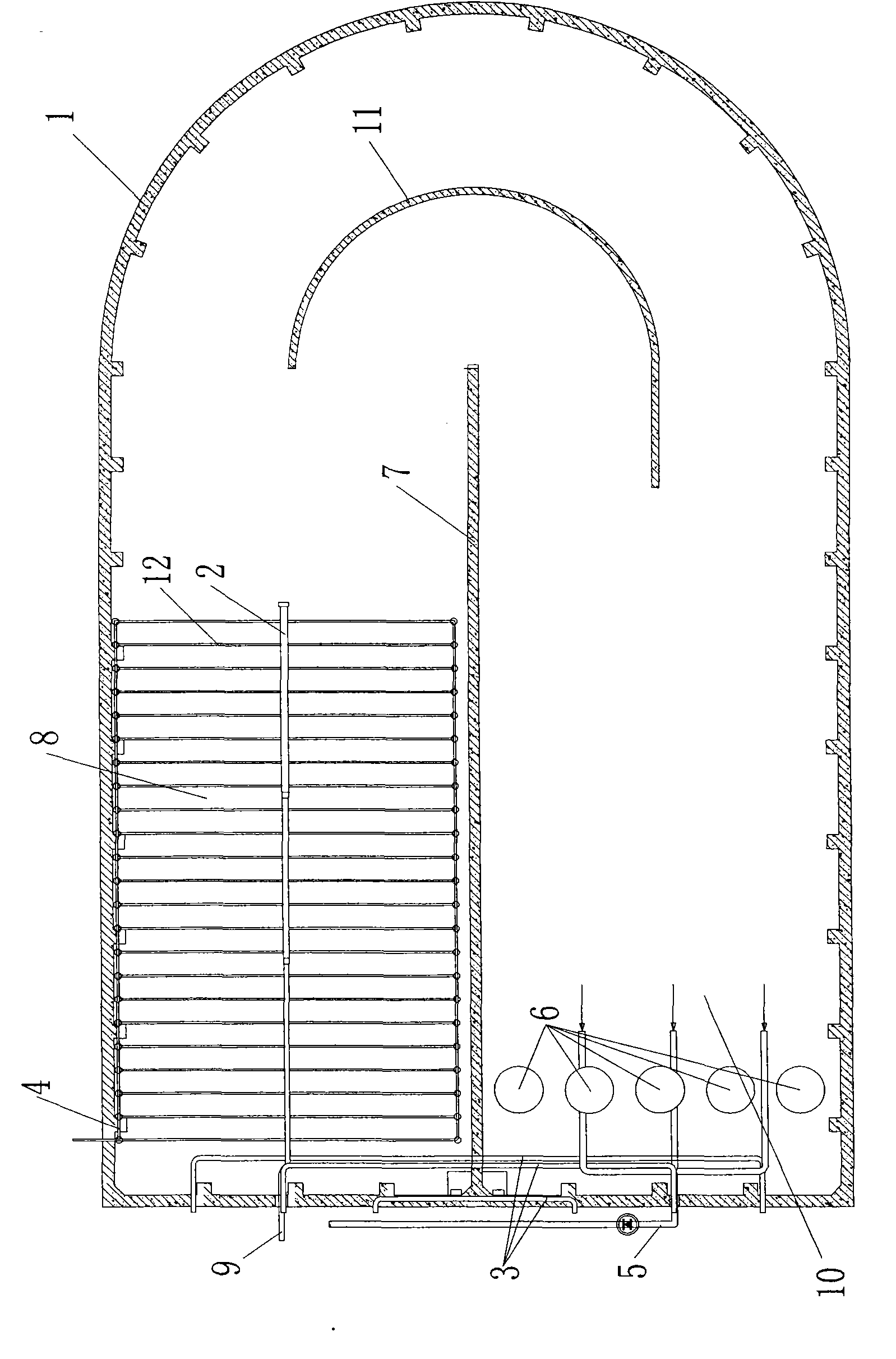

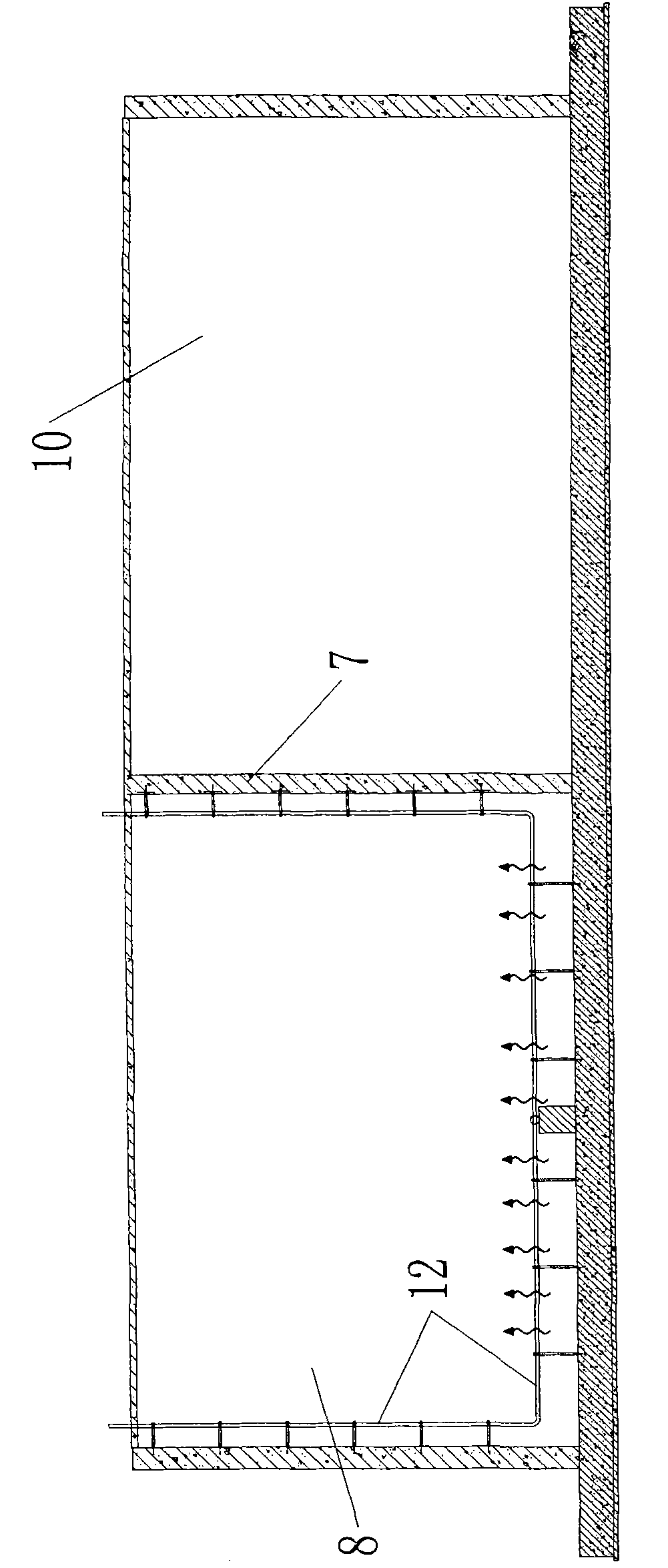

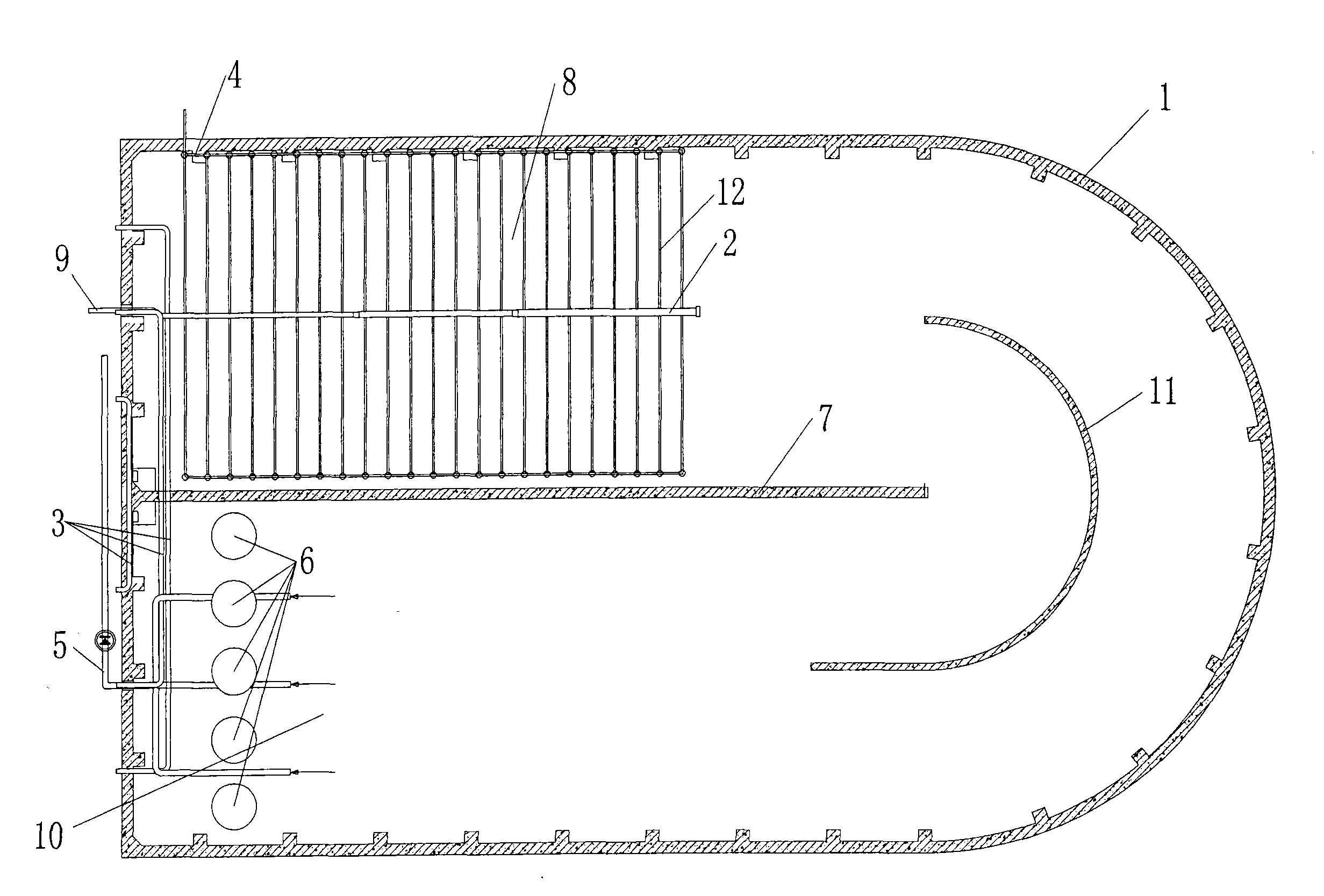

U-shaped low speed anaerobic reactor

ActiveCN102139954AAnti-cloggingImprove processing efficiencyWaste based fuelTreatment with anaerobic digestion processesHigh concentrationSEMI-CIRCLE

The invention provides a U-shaped low speed anaerobic reactor which comprises a tank body, a water distribution system, a reverse-flow system, a back-washing system, a sludge discharging system and a water outlet system, wherein the tank body is a U-shaped structure and is divided into a front square area and a rear semi-circle area; a partition wall is arranged in the middle of the front square area of the tank body and separates the front square area into a water distribution area and a water outlet area, wherein the water distribution area is internally provided with the water distribution system; the water outer area is internally provided with the water outlet system and the sludge discharging system; the rear semi-circle area of the tank body is also internally provided with a semi-circle partition wall; the back-washing system is connected with the water distribution system; the reverse-flow system is connected between the bottom of the water outlet area and the top of the water distribution area; the sludge discharging system is arranged at the bottom of the water outlet system; and a marsh gas separation system is arranged above the whole tank body. The U-shaped low speed anaerobic reactor has anti-blocking function, high processing efficiency and stable quality of treated water, can treat multiple high-concentration waste water, is stable in running, has long service life and is convenient to operate and run.

Owner:山东亿龙环保股份有限公司

Improved oil-water separation device

PendingCN107892357AEasy to separateMaster the separation status in real timeFatty/oily/floating substances removal devicesSpecific water treatment objectivesSludgeSlag

The invention provides an improved oil-water separation device including a solid-liquid separation box, a backwashing device, a mud suction device, an oil-water separation box, a control cabinet and an oil-water secondary separation device, wherein the solid-liquid separation box is connected with the oil-water separation box; the oil-water separation box is connected with the oil-water secondaryseparation device; the control cabinet is arranged on the oil-water separation box; the solid-liquid separation box is internally provided with a spiral slag discharging device which is connected witha slag collecting barrel; the backwashing device is connected with the bottom of the solid-liquid separation box, and the side face of the backwashing device is connected with the oil-water separation box; the mud suction device is connected with the oil-water separation box; the oil-water secondary separation device includes a box body, a filter device and a monitoring device. The improved oil-water separation device has the beneficial effect of solving the problems that separation of oil and water is not thorough, a solid-liquid separation device is blocked and the discharge of silt is notthorough in the prior art.

Owner:SHANGHAI HUIYE MASCH TECH CO LTD

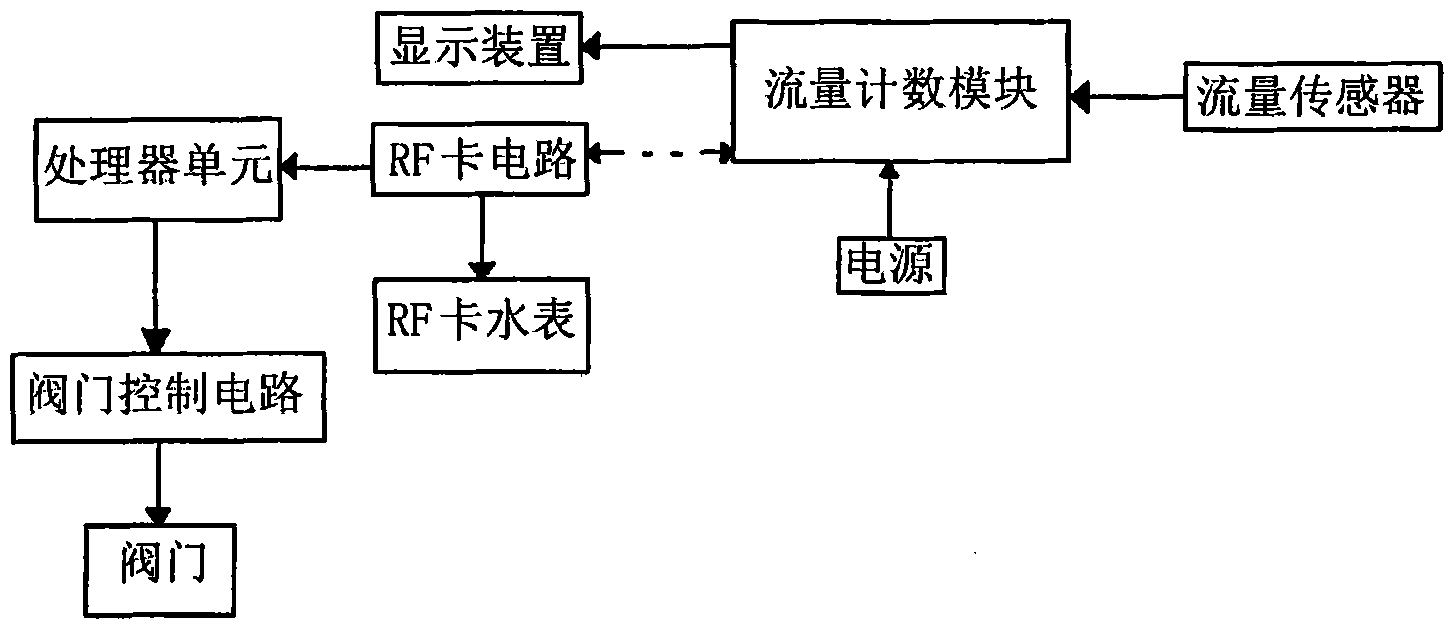

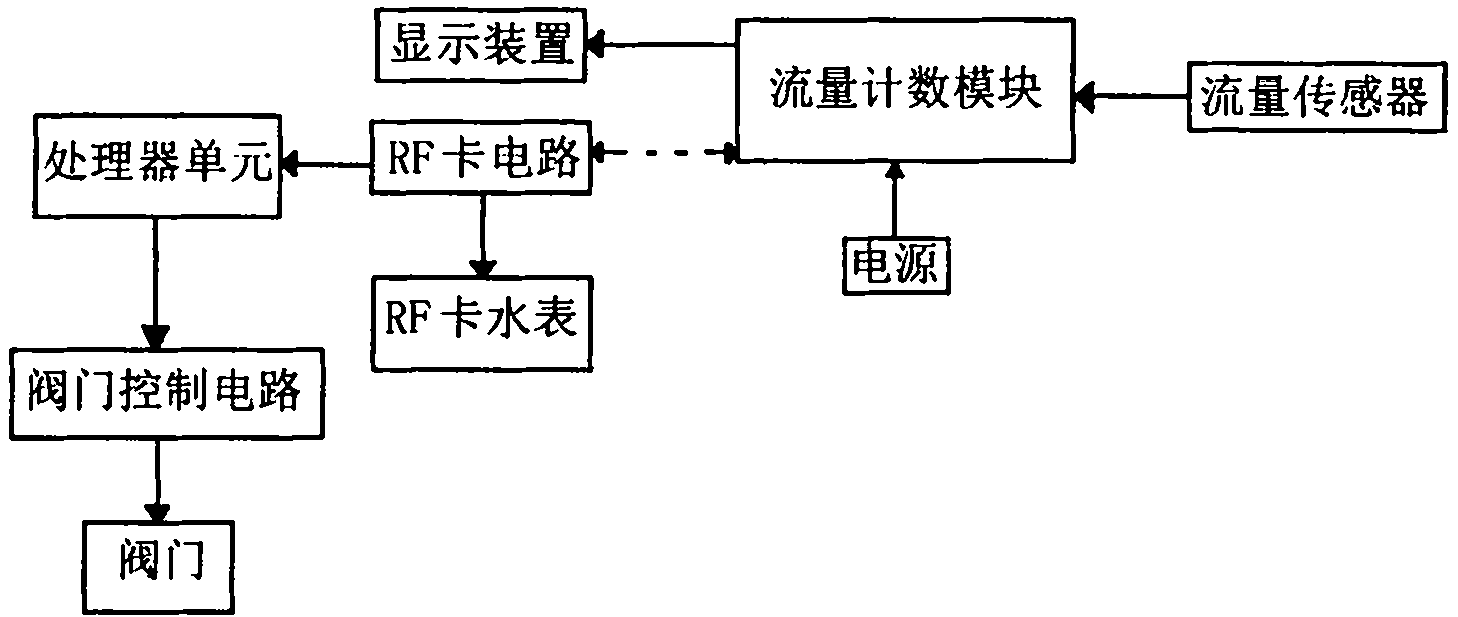

Water meter management system capable of realizing step water price

InactiveCN102063765AWith anti-lock brakeReduce power consumptionApparatus for hiring articlesWater savingWater volume

The invention discloses a water meter management system capable of realizing step water price, which comprises a processor unit, a display device, a flow counting module, a valve control circuit, a radio frequency (RF) card circuit, a power supply and an alarm circuit, wherein the flow counting module is connected with the power supply; the input port of the flow counting module is connected with a flow sensor; the output port of the flow counting module is connected with the display device and the RF card circuit respectively; the input end of the RF card circuit is connected with the flow counting module; the output end of the RF card circuit is connected with the processor unit; the RF card circuit is connected with an RF card water meter; the processor unit is connected with a valve control circuit; and the valve control circuit is connected with a valve. In the invention, a dividing point of two water volumes can be set to realize step charging, so the water volume consumed by a user can be limited reasonably; and thus, water is saved and waster resource waste is avoided.

Owner:孙建东

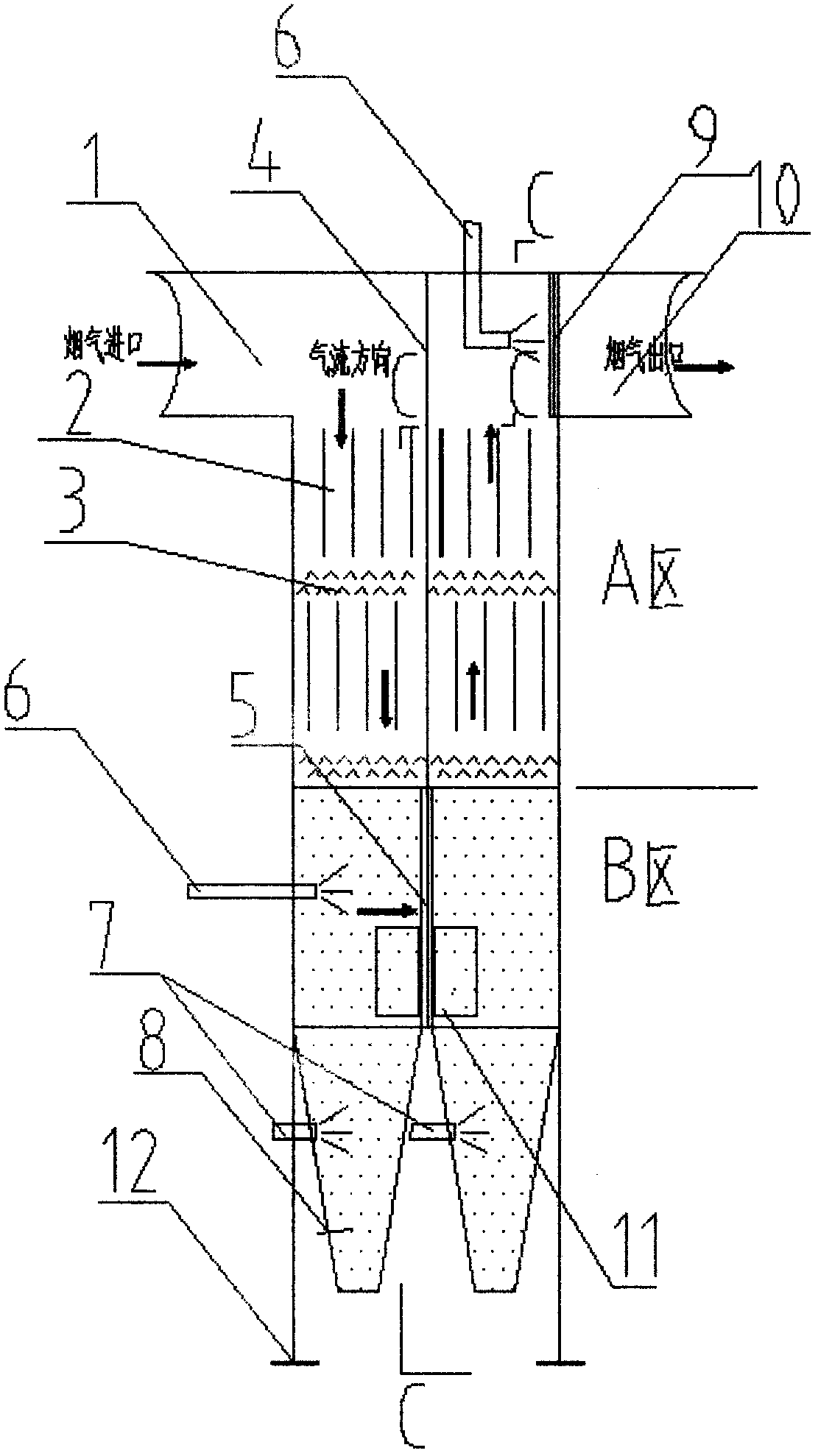

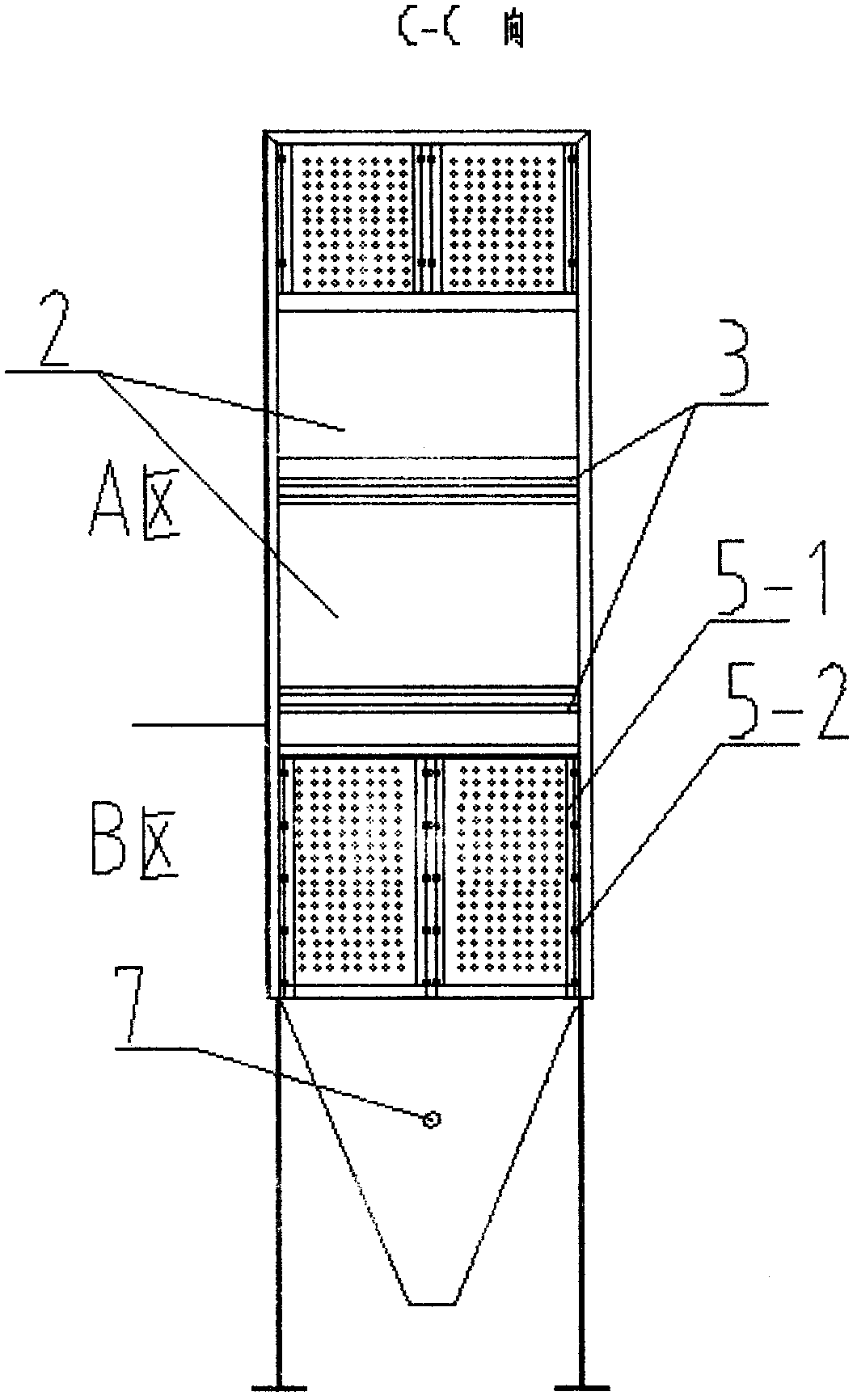

Spark fire resistant device for bag-type dust removers in biomass boilers

PendingCN108671642AAvoid enteringAnti-cloggingDispersed particle filtrationTransportation and packagingBaghouseAcoustic wave

The invention discloses a spark fire resistant device for bag-type dust removers in biomass boilers. The device includes a flue gas inlet, flue gas cooling plates, baffling fire resistant plates, a middle partition plate and a first metal microporous mesh plate; the metal microporous mesh plates are provided with sonic soot blowers; two ash buckets are arranged at the bottoms of the left and rightcase bodies, and are provided with pneumatic arch breakers; a second microporous filtering mesh plate is connected to a flue gas outlet; the left and right case bodies are provided with access doors;and the whole device is supported by a support. Flue gas can be cooled by the cooling plates, and hit by the baffling fire resistant plates to make large particle sparks smaller or even quench afterimpact. The whole boiling zone is filled with boiling fluidized state ash, so that most tiny particles having sparks can be wrapped and quenched; and part of tiny particles having sparks which are notbeing eliminated can be blocked by the first metal microporous filtering mesh plate and the second microporous filtering mesh plate, and therefore, sparks can be completely stopped to enter bag-typedust removers.

Owner:王脯胜

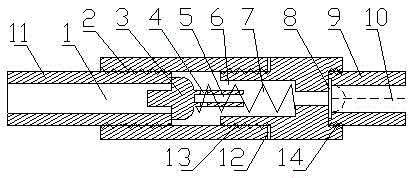

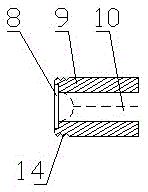

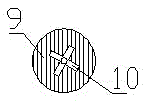

Single-hole cross-shaped jet slurry-making nozzle

A single-hole cross-shaped jet slurry-making nozzle comprises a casing, a non-return valve, a spring and a nozzle, wherein an air chamber and a pipe nipple are arranged in the casing, the pipe nipple is used for being connected with a main air pipe used for supplying air, and an air inlet hole is formed in the pipe nipple; the non-return valve and the spring are mounted in the air chamber, one end of the spring is connected with the casing, the other end of the spring is connected with the non-return valve, the non-return valve is connected with the pipe nipple mounted in the casing, and a tail rod is arranged on the non-return valve and located in the spring; when high-pressure air passes through the air inlet hole, the high-pressure air pushes the non-return valve open and then enters the air chamber; the open / closed state of the non-return valve is controlled by the spring; when no high-pressure air is supplied, the non-return valve is pushed by the spring to a closed state; and the nozzle is mounted on the casing and communicates with the air chamber, a notched rubber gasket is arranged in the nozzle, and a nozzle hole of the nozzle is cross-shaped. Through the single-hole cross-shaped jet slurry-making nozzle, uniform tailings slurry can be prepared fast and efficiently, and the effects of slurry making and blocky tailings hammering are remarkable.

Owner:邓代强 +2

Ultra-centrifugal dust remover adopting spraying device

InactiveCN108057304AEasy to collectLarge spray angle rangeCombination devicesMechanical engineeringEngineering

The invention relates to the technical field of dust removing equipment and discloses an ultra-centrifugal dust remover adopting a spraying device. The ultra-centrifugal dust remover comprises a rack,a box body, a spraying device and a motor, wherein the box body and the motor are mounted on the rack; the box body comprises a gas inlet, a gas outlet and a downspout funnel; the gas inlet is formedin the top of the box body; the spraying device is mounted on the gas inlet; the gas outlet is formed in a side face of the box body; the downspout funnel is located below the box body; the box bodyis internally provided with a rotary shaft and a rotor; two ends of the rotary shaft are fixed at two sides of the rack respectively; the rotor sleeves the rotary shaft; the rotor is provided with a first filtering screen, a second filtering screen and a plurality of blades; the motor is connected with one end of the rotary shaft through a transmission device. According to the ultra-centrifugal dust remover disclosed by the invention, the spraying device is mounted at the gas inlet of the centrifugal dust removing equipment and water mist adsorbs dust so that a plurality of dust with small grain diameters becomes dust with relatively large grain diameters and the dust removing efficiency is improved; meanwhile, an inclined plane structure is arranged at the bottom of the box body so that water with the dust is convenient to collect by the downspout funnel.

Owner:宁波江北峰尚环保设备有限公司

Self-washing damping and wear-resistant rotation type check valve

ActiveCN103775691ASimple structureReduce manufacturing costOperating means/releasing devices for valvesHollow article cleaningWear resistantEngineering

The invention relates to a self-washing damping and wear-resistant rotation type check valve, which belongs to the technical field of a control device on a medium pipeline. The self-washing damping and wear-resistant rotation type check valve comprises a valve body, a valve deck, a valve shaft, a tumbler and a valve clack, wherein the valve deck is arranged on the valve body; the valve shaft is arranged on the upper end in the valve body, which is near one end of a water inlet; the tumbler is fixedly connected to the valve shaft; the valve clack is fixedly connected to the outer side of the tumbler; the water inlet end of the valve body is provided with a valve seat used to be sealed with the valve clack; the valve shaft passes through the valve body to extend out of the valve body; the part of the valve shaft, which extends out of the valve body, is fixedly connected with a rotary arm; a rotary arm traction device is fixedly arranged out of the valve body. The automatic damping device in the self-washing damping and wear-resistant rotation type check valve disclosed by the invention has the characteristics of simple structure, low manufacture cost and blocking resistance, reliable adjustable damping can be realized without an externally-connected device, and the problem of the water hammer is solved. The valve clack mechanism is prevented from shaking under the hydraulic fluctuation via the rotary arm traction device so as to prevent the valve shaft from being abraded.

Owner:WUHAN DAYU VALVE

Horizontal pushing type garbage compression equipment

The invention discloses horizontal pushing type garbage compression equipment comprising a base, a box body, a compression structure, a hydraulic rod, a pushing plate, a filtering structure, a groove,a seepage hole, a first motor, a rotating shaft, a gear, a rack, a piston, a filter screen, a water pipe, a rotating structure, a fixing structure and a feeding port. According to the garbage compression equipment, through fixed connection of the hydraulic rod and the pushing plate, and connection of the filtering structure with the inner wall of the box body, when garbage is thrown into the boxbody through the feeding port, the pushing plate is driven by the hydraulic rod to extrude the garbage towards a rotating door fixed by the fixing structure, and fine garbage generated during extrusion is blocked outside the seepage hole by the piston; thus, the seepage hole and the filter screen are prevented from being blocked; and after garbage compression is finished, the first motor is driven, so that the piston is moved away from the seepage hole, thereby facilitating discharge of sewage and waste liquid generated during compression.

Owner:湖北贝利莱机械设备股份有限公司

Multifunctional PET (Polyethylene terephthalate) bright master batch

ActiveCN104177792AEasy to processPrevent impact on mechanical propertiesPolyethylene terephthalate glycolEngineering plastic

The invention relates to a multifunctional PET (Polyethylene terephthalate) bright master batch. The multifunctional PET bright master batch is characterized by comprising the following components in percentage by weight: 89.5% of PET powder, 10% of fine IPA (isopropylamine), and 0.5% of grafted modified polyfatty acid amide lubricant. The multifunctional PET bright master batch is applied to the PET glass fiber reinforced modified engineering plastics and PET spinning, so that the current and torque during pelletizing can be lowered, and the material melt index is improved. For a product which is injection-molded after being pelletized, a glass fiber exposing phenomenon on the product surface can be effectively prevented, the glossiness of the product surface can be improved, influences on the mechanical performances of the product are not great, and especially, the toughness of the material is improved to a certain extent. Moreover, the brightness, the vividness, the dyeing strength, the wear resistance, the moisture absorption, the antistatic property and the elongation at break for spinning are partially increased, so that the spinnability of the spinning is improved greatly.

Owner:苏州兴泰国光化学助剂有限公司

Novel spinning head washing technology

The invention belongs to the spinning detection field, and particularly relates to a novel spinning head washing technology. The novel spinning head washing technology includes the concrete steps of: 1, alkaline liquid spray washing; 2, hot water spray washing; 3, hot water spray washing; 4, air spray washing; 5, acid pickling; 6, alkaline liquid spray washing; 7, hot water spray washing; 8, hot water spray washing; 9, air spray washing; and 10, drying. The above technical processes realize automation except the beginning manual material-loading and the final manual material-discharging and assembling. At the same time, a process of supersonic wave washing is not needed. Two-stage filtration is adopted in a reservoir, so that clean washing is guaranteed and a nozzle is prevented from being blocked. The continuous washing is realized. Unclean matters on the outer surface of a spinning head are removed, and the spinning head is not damaged.

Owner:YIBIN GRACE

Semiconductor diode acid pickling system

ActiveCN108735634AImprove pickling efficiency and effectReduce corrosionSemiconductor/solid-state device manufacturingCorrosionSemiconductor

The invention belongs to the technical field of semiconductor diodes, and specifically discloses a semiconductor diode acid pickling system. The semiconductor diode acid pickling system comprises a barrel, a first guide rod, a telescopic rod and an acid pickling box; the first guide rod is mainly used for colliding with a first plate during rotating so that the acid pickling box shakes up and down, simultaneously, a first sliding telescopic rod shakes up and down inside the acid pickling box to carry out telescoping and reciprocating cooperatively, stirring is carried out inside the acid pickling box constantly, and semiconductor diodes inside the acid pickling box are in sufficient contact with an acid pickling solution, so that the acid pickling efficiency and effect of the semiconductordiodes are improved; simultaneously, a first seal ring on the outer layer of the first sliding telescopic rod and a sealing unit are used for sealing the first sliding telescopic rod, and the corrosion of the acid pickling solution on the first sliding telescopic rod is slowed down, so that the service life of the first sliding telescopic rod is prolonged, and then the service life of the semiconductor diode acid pickling system is prolonged.

Owner:朝阳微电子科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com