U-shaped low speed anaerobic reactor

A reactor, U-shaped technology, applied in the field of anaerobic reactors, can solve the problems of poor sewage, easy loss of anaerobic sludge, inability to apply high-concentration water quality and biodegradability, etc., to achieve high treatment efficiency and easy automation Controlled, structured and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

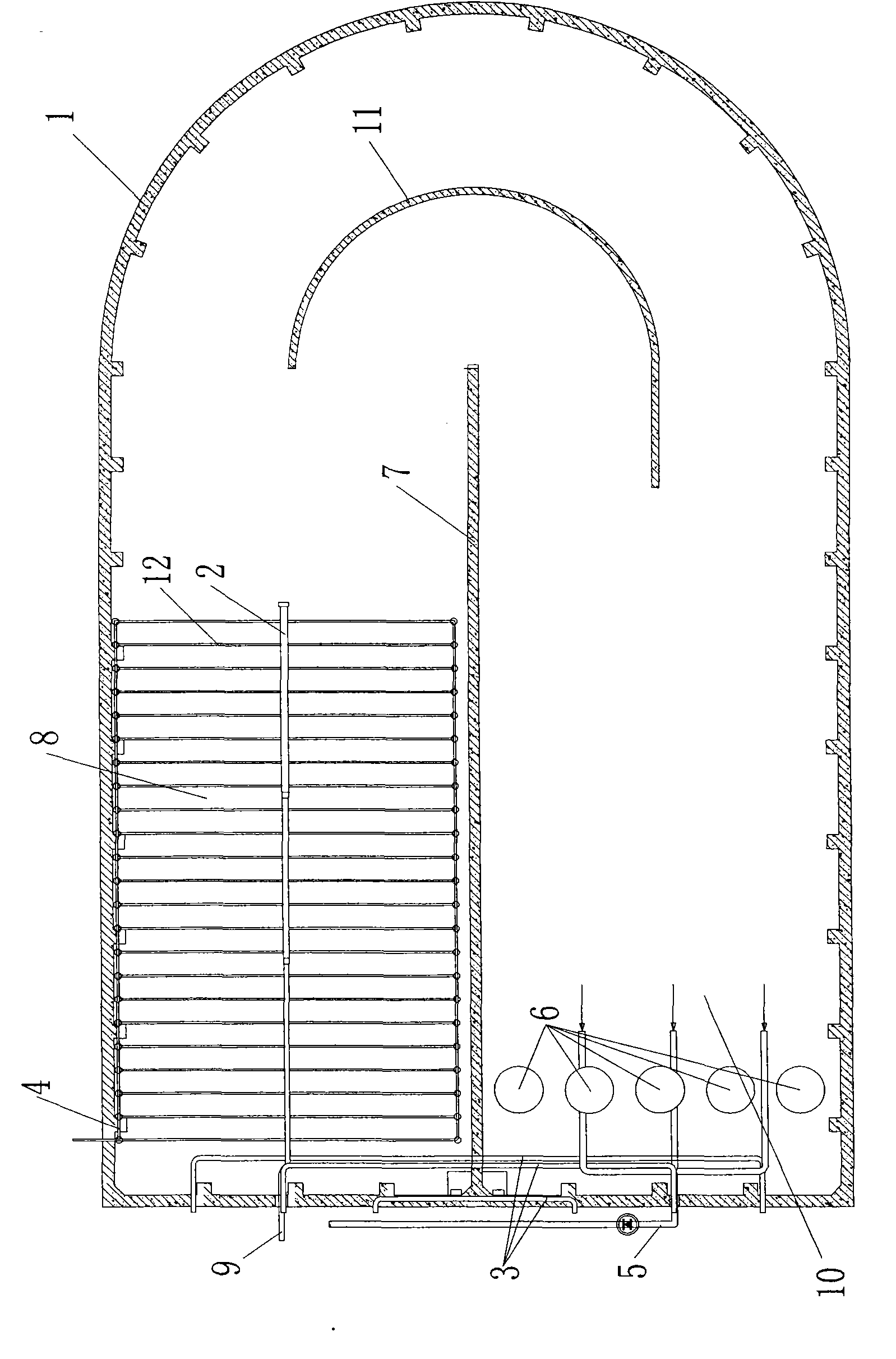

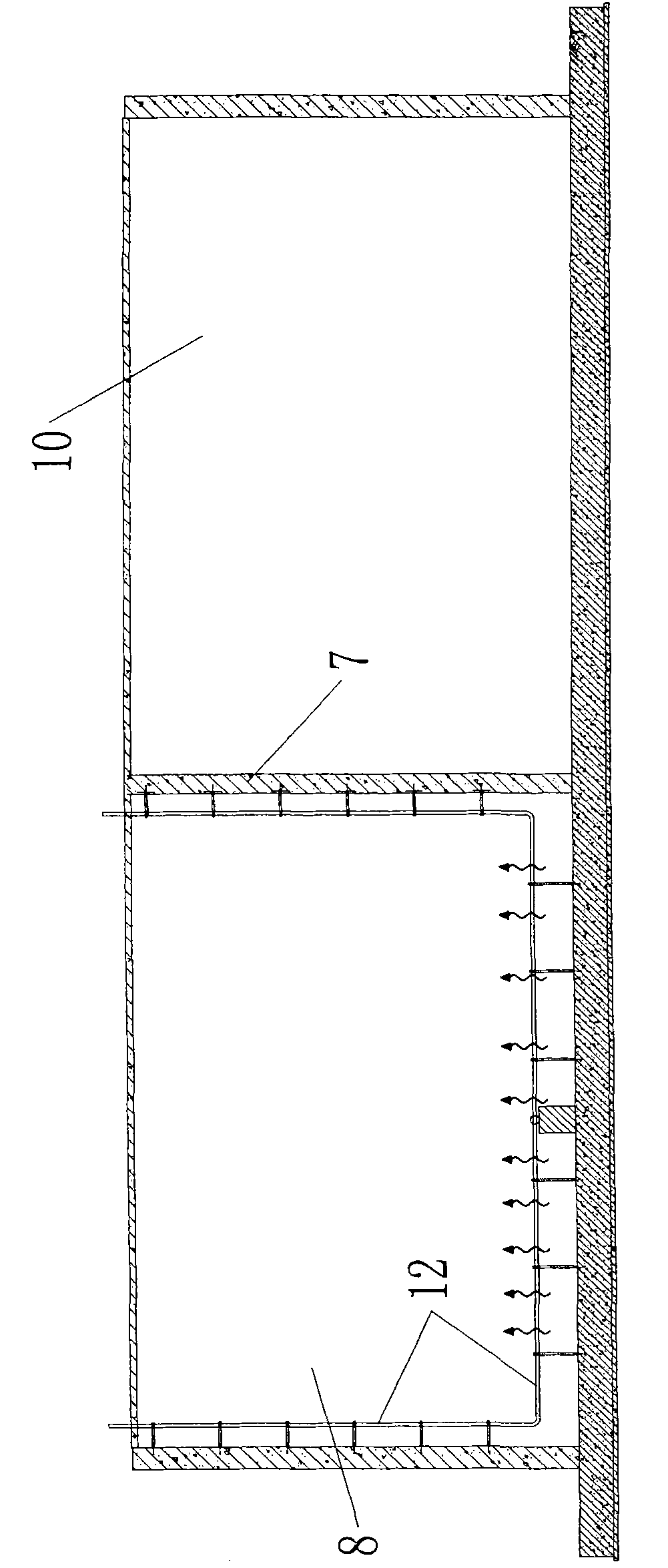

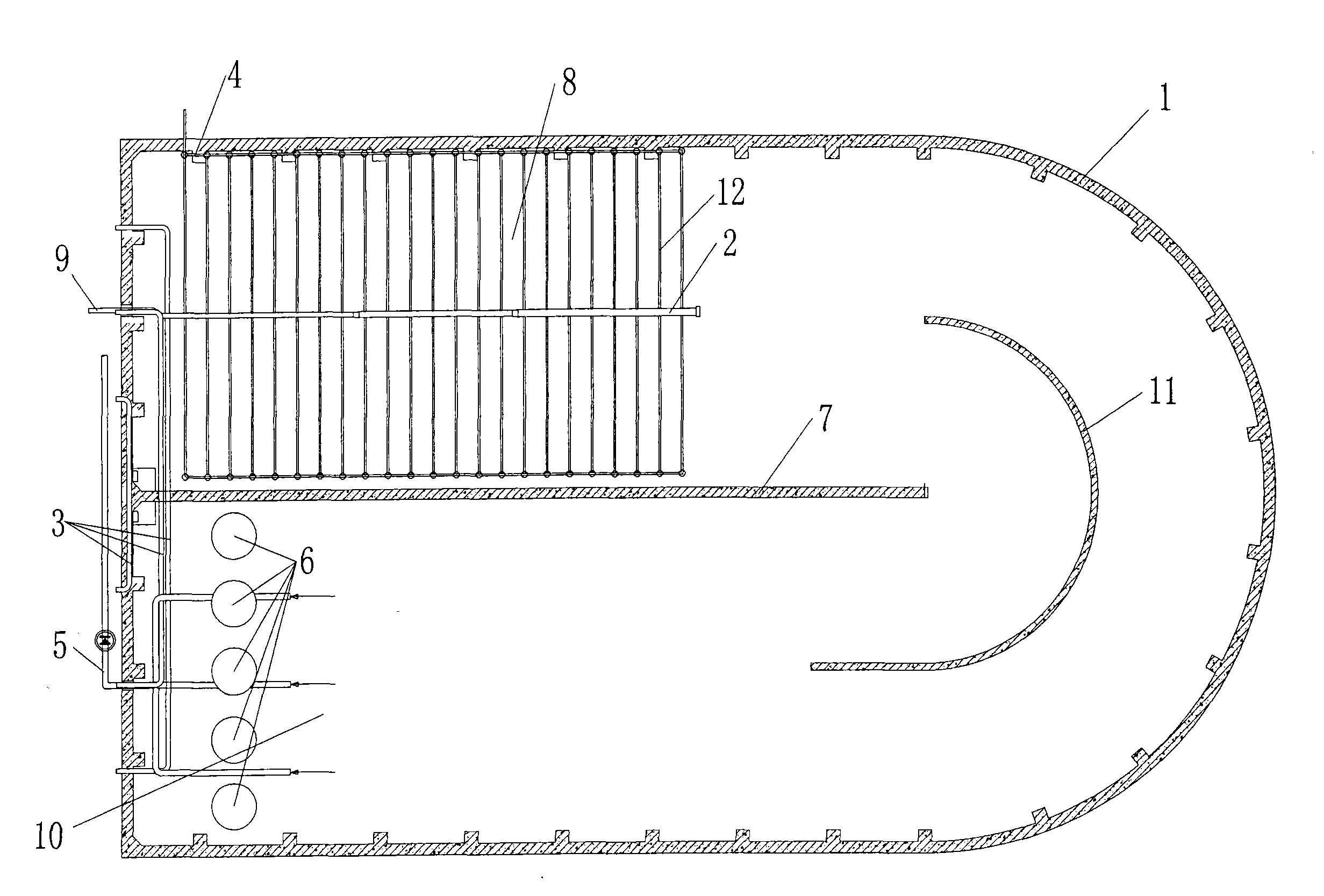

[0015] Such as figure 1 As shown, the U-shaped anaerobic bioreactor of the present invention mainly includes a tank body 1, a water distribution system 2, a backflow system 3, a backwash system 4, a sludge discharge system 5 and a water outlet system 6. The pool body 1 adopts a reinforced concrete structure, and the whole structure is a U-shaped structure, which is a combination of a square area at the front and a semicircular area at the rear. The U-shaped structure solves the construction difficulties caused by the large pool capacity and long pool shape in civil construction. There is a partition wall 7 in the middle of the pool body 1, which divides the square area at the front of the U-shaped pool body 1 into two areas: a water distribution area 8 and a water outlet area 10. Water outlet system 6 and mud discharge system 5 are arranged. In the water distribution area 8, the sludge and sewage are fully mixed, and the water intake area is where the most gas is produced. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com