Ultra-flexible coated abrasive cloth and manufacturing method thereof

An ultra-soft, coating technology, used in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problems of inability to meet grinding requirements, too hard, poor economy, etc., and achieve the effect of economical and thin characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

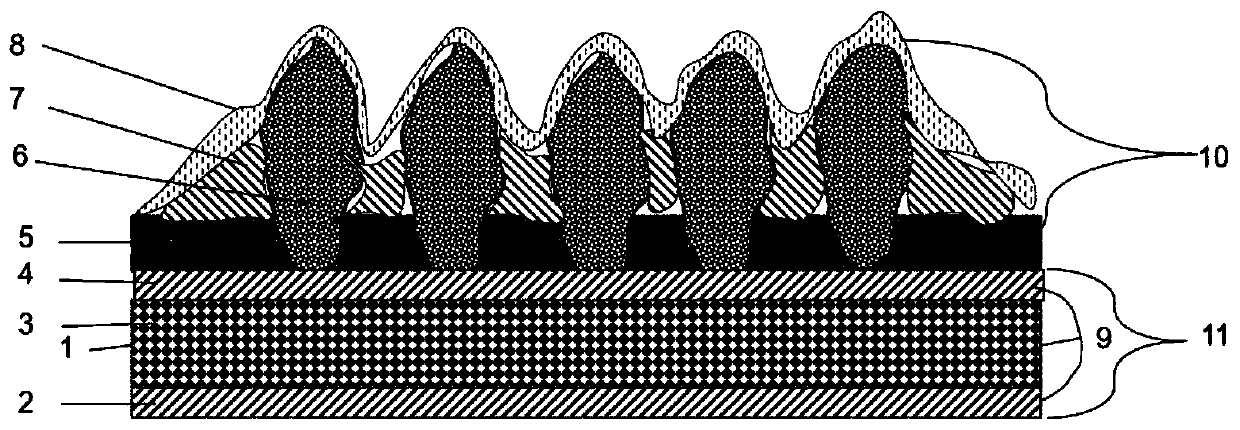

[0028] A kind of ultra-soft coated emery cloth provided by this embodiment has a structure such as figure 1 As shown, it includes a substrate 11 , an abrasive layer 6 and a composite adhesive layer 10 , the composite adhesive layer 10 covers the substrate 11 and the abrasive layer 6 , and the abrasive layer 6 is fixed on the substrate 11 through the composite adhesive layer 10 .

[0029] The substrate 11 includes a base material 1 and a flexible adhesive layer 9, and the base material 1 adopts a dry weight of 100g / m 2 A pure cotton cloth base with a flat surface. The base material 1 has double-sided uniform fluff layers, and the fluff layers are formed by mechanical brushing.

[0030] The flexible adhesive layer 9 includes an upper adhesive layer 4, a lower adhesive layer 2 and an inner adhesive layer 3, wherein the upper adhesive layer 4 and the lower adhesive layer 2 are respectively covered on the upper and lower surfaces of the substrate 1, and the inner adhesive layer 3 ...

Embodiment 2

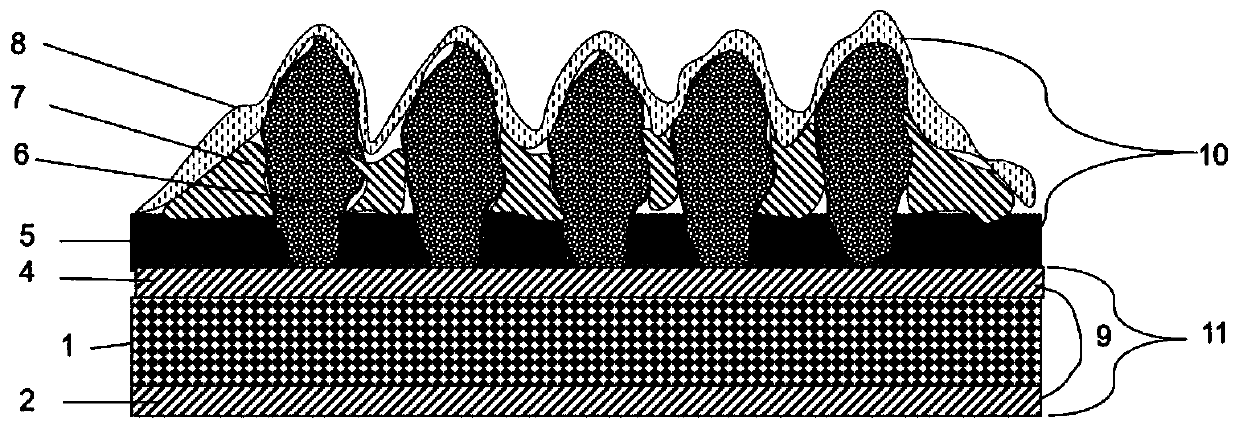

[0034] A kind of ultra-soft coated emery cloth provided by this embodiment has a structure such as figure 2 As shown, it includes a substrate 11 , an abrasive layer 6 and a composite adhesive layer 10 , the composite adhesive layer 10 covers the substrate 11 and the abrasive layer 6 , and the abrasive layer 6 is fixed on the substrate 11 through the composite adhesive layer 10 .

[0035] The substrate 11 includes a base material 1 and a flexible adhesive layer 9, and the base material 1 adopts a dry weight of 80g / m 2 Polyester cloth base with a flat surface. The base material 1 has a uniform fluff layer on one side, and the fluff layer is formed by mechanical brushing.

[0036] The flexible adhesive layer 9 includes an upper adhesive layer 4 and a lower adhesive layer 2 , wherein the upper adhesive layer 4 and the lower adhesive layer 2 cover the upper and lower surfaces of the substrate 1 respectively. The upper adhesive layer 4 and the lower adhesive layer 2 are formed by...

Embodiment 3

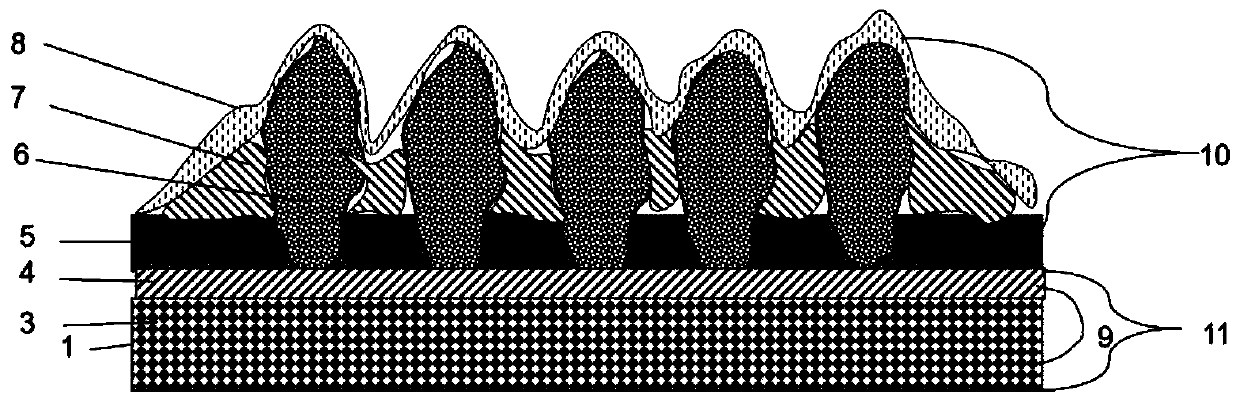

[0039] A kind of ultra-soft coated emery cloth provided by this embodiment has a structure such as image 3 As shown, it includes a substrate 11 , an abrasive layer 6 and a composite adhesive layer 10 , the composite adhesive layer 10 covers the substrate 11 and the abrasive layer 6 , and the abrasive layer 6 is fixed on the substrate 11 through the composite adhesive layer 10 .

[0040] The substrate 11 includes a base material 1 and a flexible adhesive layer 9, and the base material 1 adopts a dry weight of 120g / m 2Polyester cloth base with a flat surface. The base material 1 has double-sided uniform fluff layers, and the fluff layers are formed by mechanical brushing.

[0041] The flexible adhesive layer 9 includes an upper adhesive layer 4 and an inner adhesive layer 3 , wherein the upper adhesive layer 4 covers the upper surface of the base material 1 , and the inner adhesive layer 3 is distributed in the base material 1 . The upper adhesive layer 4 and the inner adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com