Deep-etched SiO2 ridge waveguide and its preparing process

A technology of silica and ridge waveguide, which is applied in light guides, optics, instruments, etc., can solve the problems of complex structure or process of mode matchers, increased fiber coupling loss, and reduced bending radius, so as to improve optical integration, Effects of improving film quality and reducing bending radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

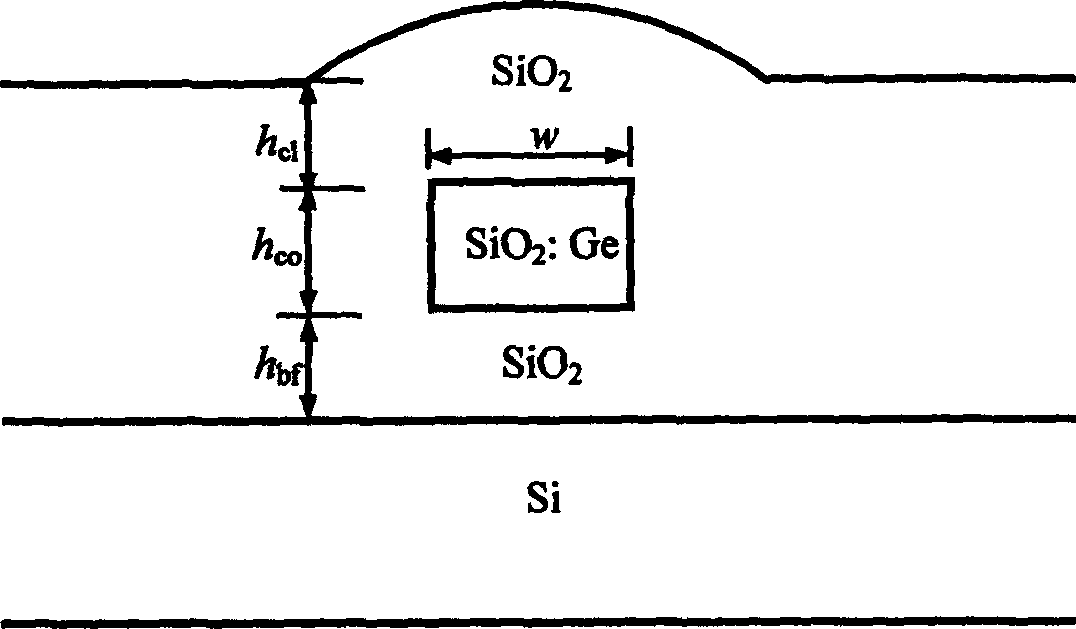

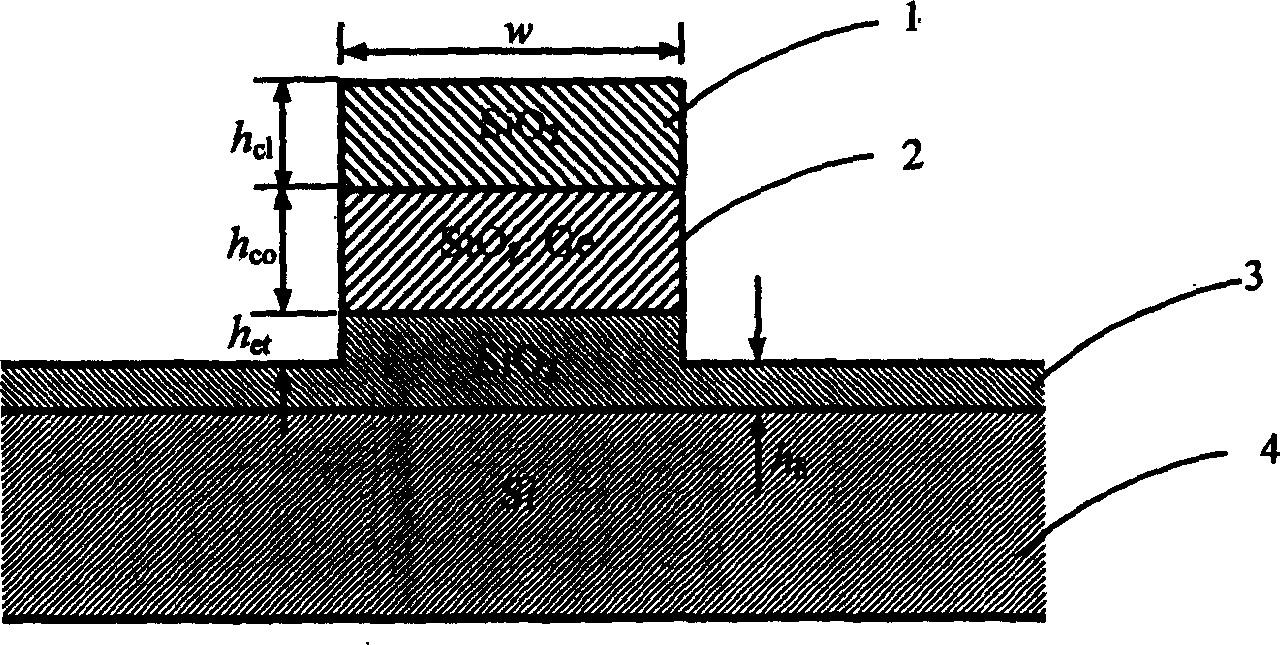

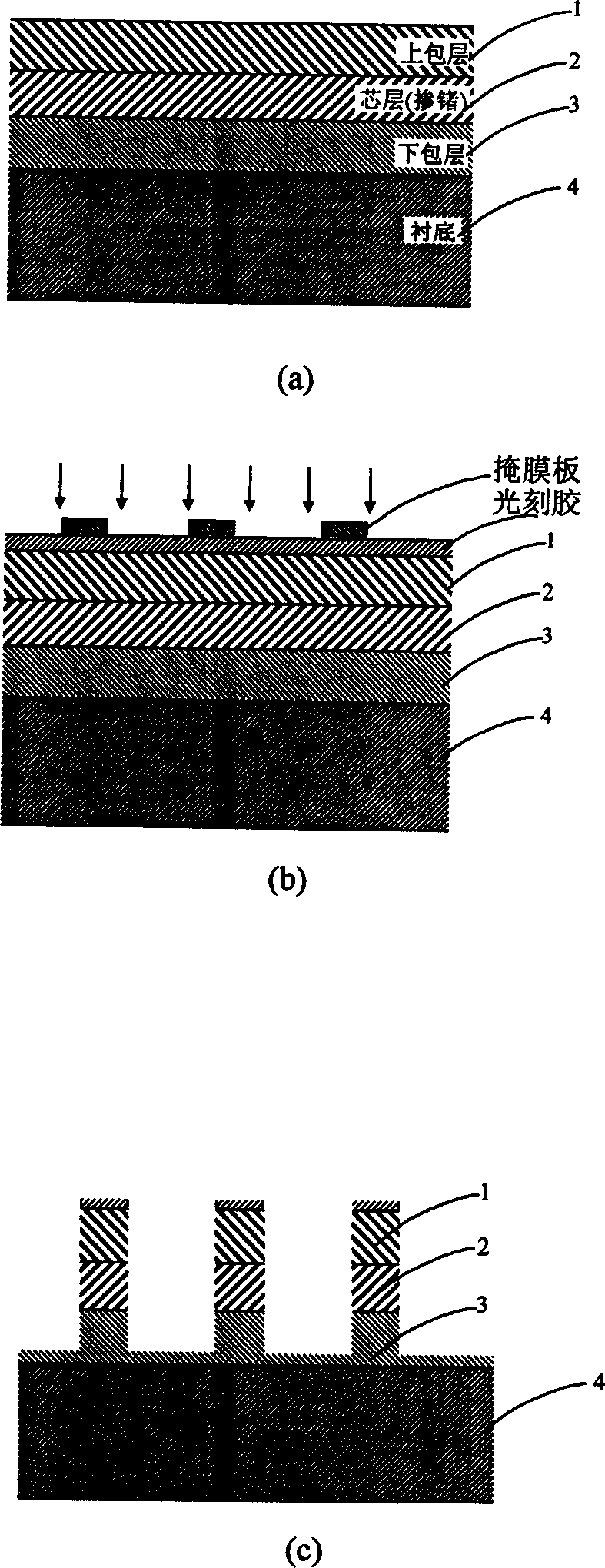

[0022] Such as figure 2 As shown, a deep-etched silica ridge waveguide includes an upper cladding layer 1, a core layer 2, a lower cladding layer 3, and a substrate 4 in sequence, and the lower cladding layer 3, core layer 2, and upper cladding layer 3 are sequentially deposited on On the substrate 4; it is characterized in that the etching depth is greater than the total thickness of the upper cladding layer 1 and the core layer 2, that is, the upper cladding layer 1, the core layer 2 and part or all of the lower cladding layer 3 are etched through.

[0023] The refractive index of the core layer 2 is slightly larger than the refractive index difference between the upper cladding layer 1 and the lower cladding layer 3, so the light field can be effectively confined in the vertical direction. Since the etching depth is sufficiently deep, the large refractive index difference between the core layer and the air in the horizontal direction can form a strong confinement, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com