Medium pressurized thermal annealing mixed bonding method

A technology of thermal annealing and hybrid bonding, which is used in the manufacture of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

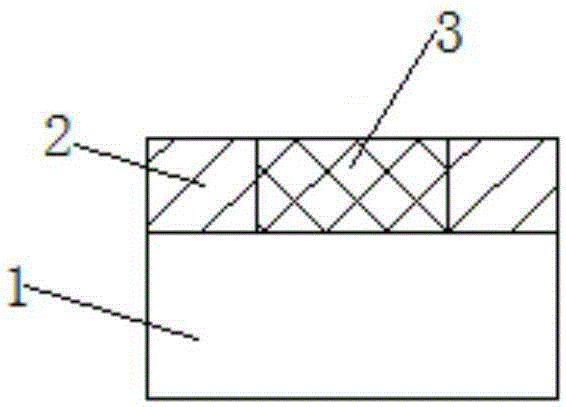

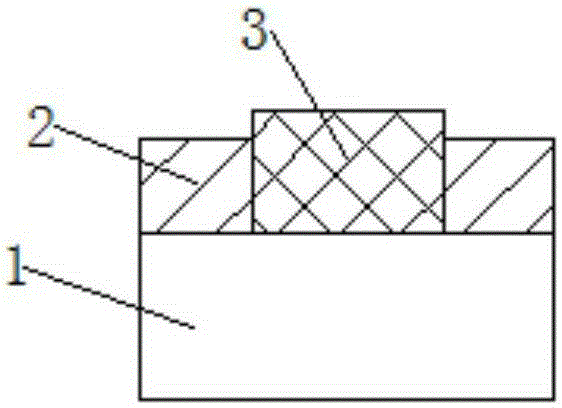

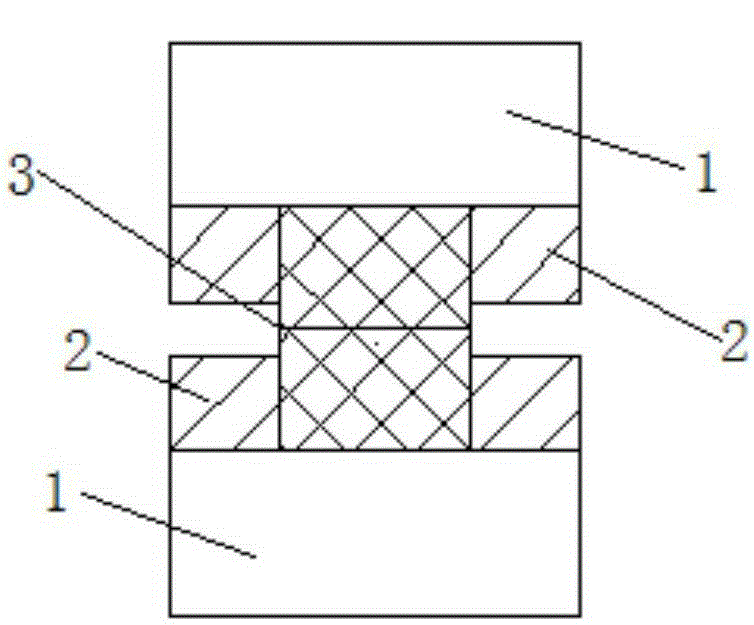

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0022] A medium pressurized mixed bonding method of the present invention, after the mixed bond is completed at normal temperature and pressure, special medium pressurized thermal annealing is carried out: in the thermal annealing environment, a medium with good thermal conductivity is used to bond the bonded The wafer exerts pressure, and at the same time as the thermal annealing is completed, the pressure is used to offset the internal pressure generated by the thermal expansion on the wafer interface; thus weakening the influence of the difference in the thermal expansion coefficient of different media on the wafer surface.

[0023] The specific embodiments of the present invention will be further described below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com