Patents

Literature

41results about How to "No obvious crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

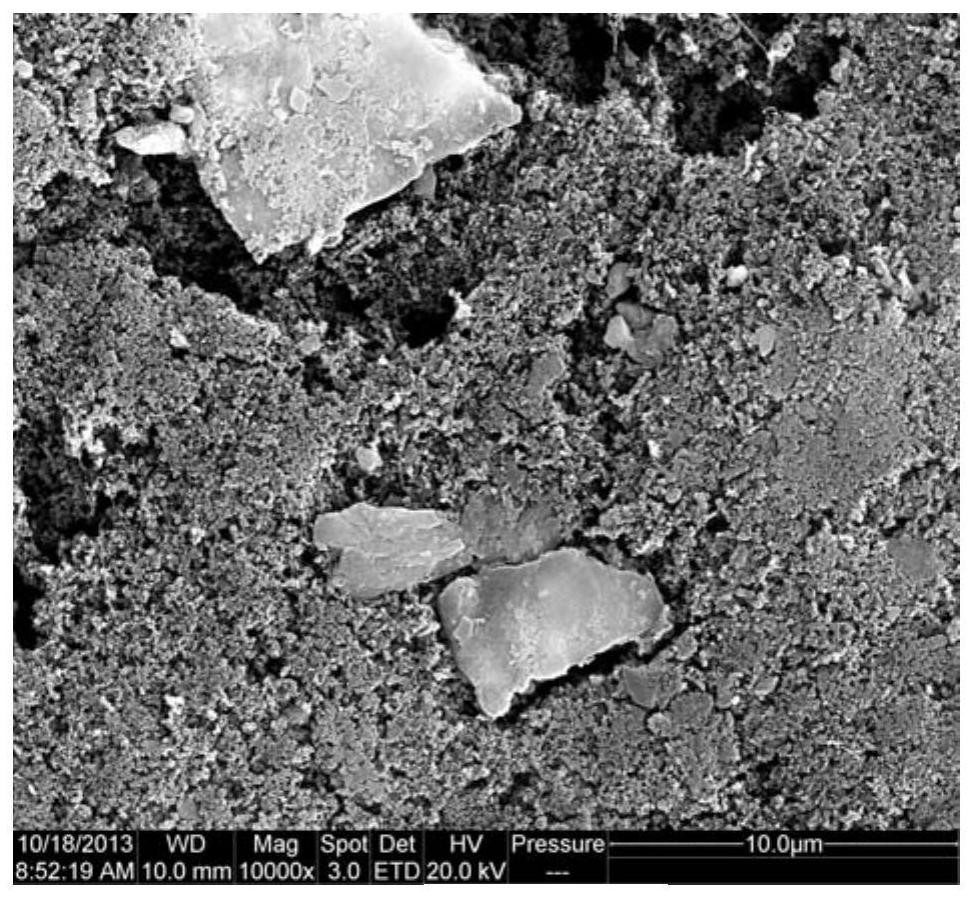

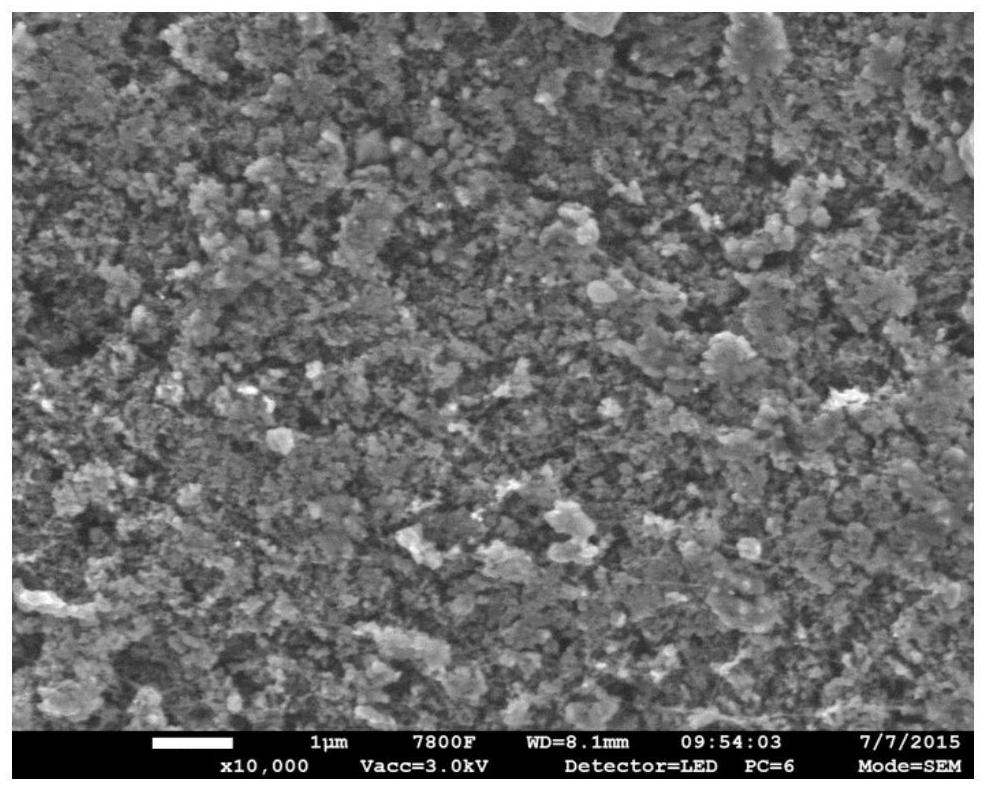

Preparation method of flexible silica aerogel

The invention discloses a preparation method of a flexible silica aerogel, relating to a silica aerogel. The invention provides the preparation method of the flexible silica aerogel, which takes methyl alkoxy-series silane as a silicon source precursor. The preparation method comprises the steps of mixing methyl trimethoxysilane or methyl trimethoxysilane, an anhydrous ethanol solution and water, further adding hydrochloric acid, regulating the pH value of the solution to 2-2.5, then adding ammonia water to obtain a sol, standing, then preparing a wet gel, further aging the wet gel, and then drying to prepare the flexible silica aerogel. The prepared flexible silica aerogel has the advantages of low density and high porosity, and simultaneously overcomes the shortcomings of poor integrity and great brittleness. According to the preparation method, the complicated steps of complex solvent exchange and gel modification are not required, so that the operation is simple and easy, the process is controllable, the cost is low, the period is short, and the continuous production can be realized.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

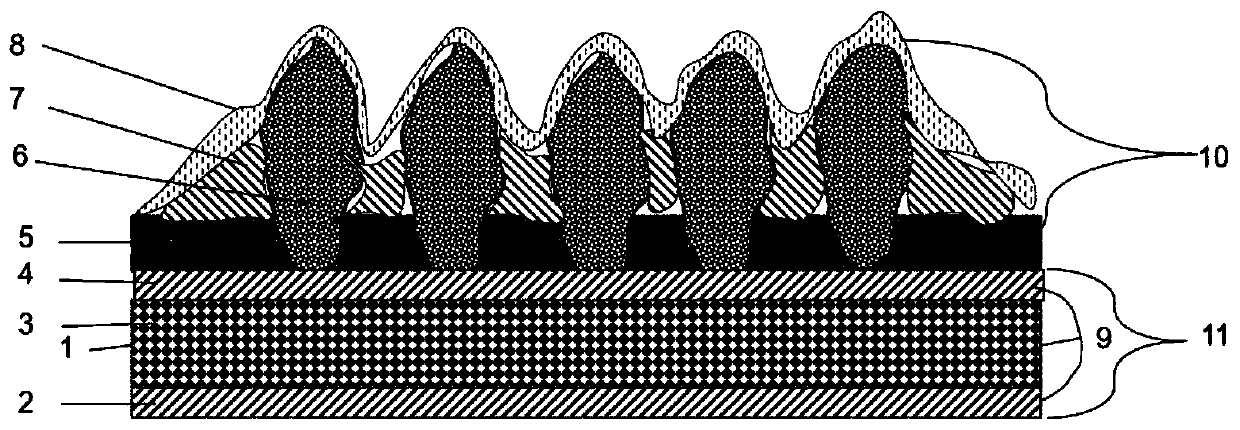

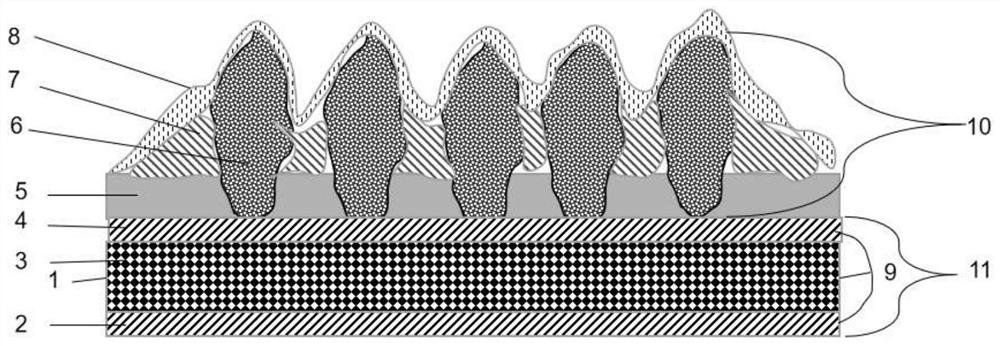

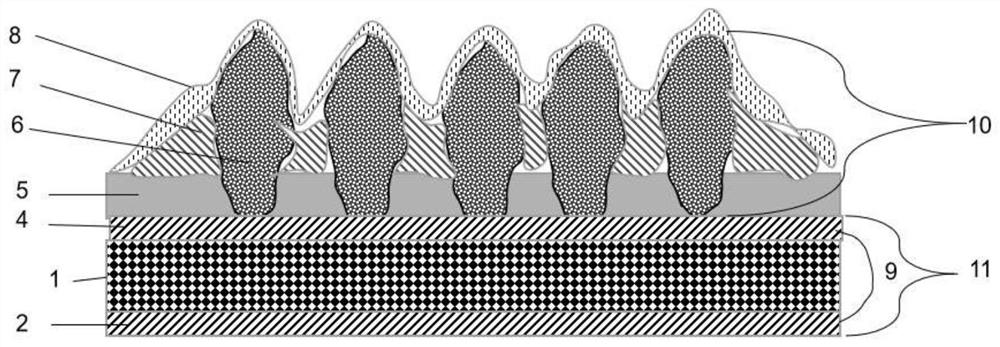

Ultra-flexible coated abrasive cloth and manufacturing method thereof

ActiveCN110405645ASmall bending radiusAchieve anti-cloggingAbrasion apparatusAdhesiveSurface grinding

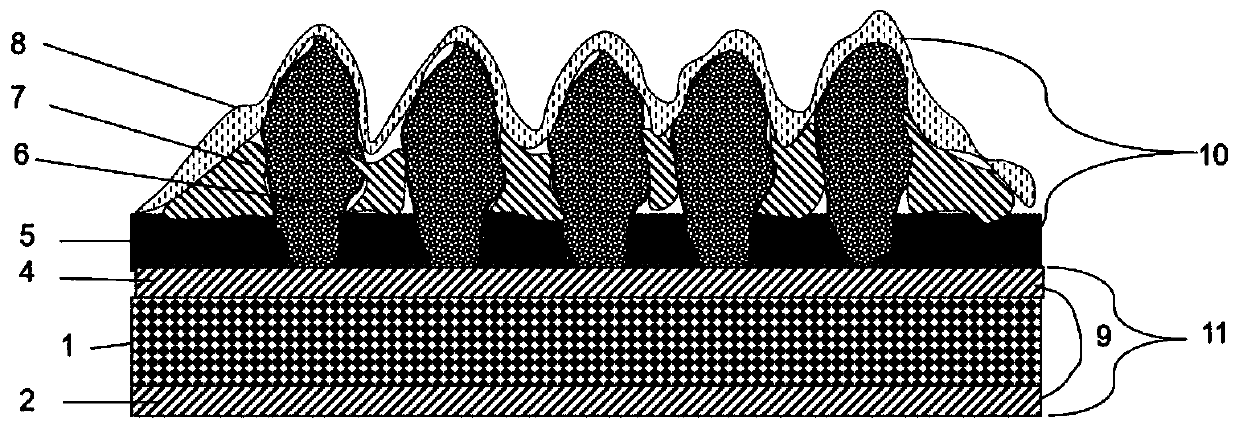

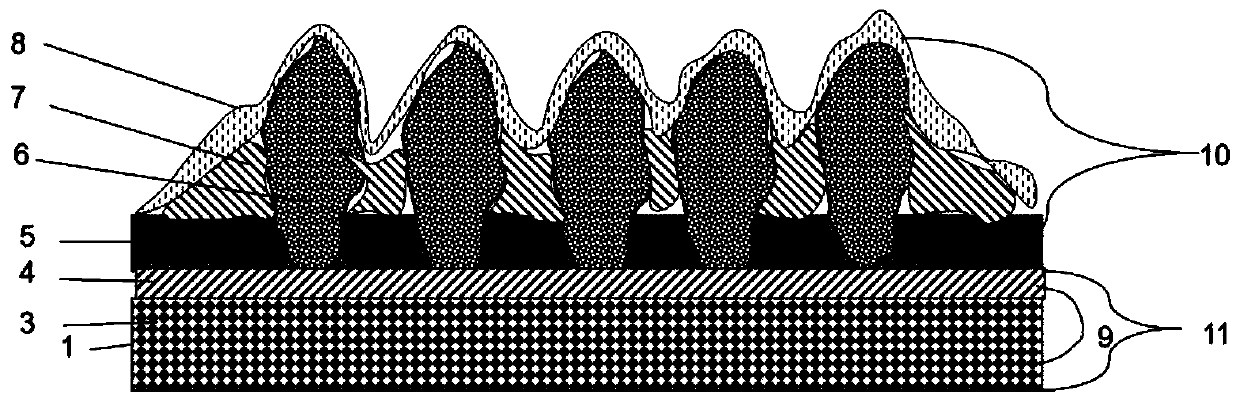

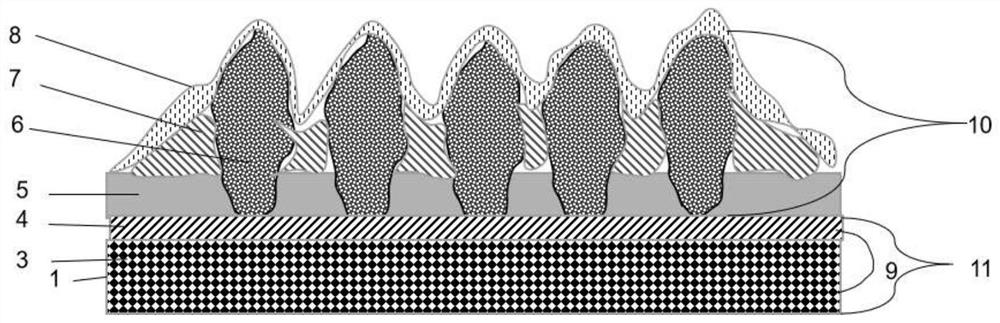

The invention discloses ultra-flexible coated abrasive cloth, and relates to the technical field of coated abrasive tool products. The ultra-flexible coated abrasive cloth comprises a substrate, an abrasive and a composite adhesive layer; the substrate and the abrasive are coated with the composite adhesive layer, and the abrasive is fixed to the substrate through the composite adhesive layer; thesubstrate comprises a base material and a flexible adhesive layer, and the composite adhesive layer comprises a bottom adhesive layer, a composite adhesive layer body and a coating layer which are distributed from bottom to top in sequence; the flexible adhesive layer comprises one layer of or combination of multiple layers of an upper adhesive layer, a lower adhesive layer and an inner adhesivelayer, the upper adhesive layer and the lower adhesive layer are arranged on the upper surface and the lower surface of the base material correspondingly, and the inner adhesive layer is distributed in the base material; and the base material adopts a cloth base of which the absolute dry weight is 25-180 g / m<2>. The good surface evenness of the coated abrasive cloth can be obtained, the flexible bending radius is 1-3 mm, the ultra-flexible coated abrasive cloth is suitable for grinding of light-load planes and curved surfaces, is resistant to breaking and blocking during grinding, and has thecharacteristics of being good in economical efficiency, light and thin.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

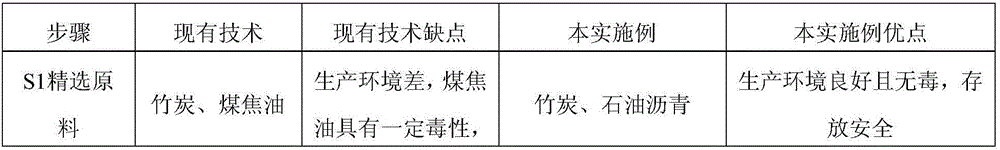

Preparation technology of bamboo columnar carbon with ultrahigh performance

InactiveCN106512938AHigh strengthImprove adsorption capacityGas treatmentCarbon compoundsActivated carbonDesorption

The invention discloses a preparation technology of a bamboo columnar carbon with ultrahigh performance. The preparation technology comprises steps as follows: S1), selection of a raw material: the raw material is a bamboo carbonized material; S2), grinding and sieving: the raw material is sieved with a 325-mesh sieve, and the bamboo carbonized material of 325 meshes or fewer than 325 meshes is taken as one raw material; S3), powder grinding and material mixing: a small amount of petroleum asphalt is added to the bamboo carbonized material powder of 325 meshes or fewer than 325 meshes for powder grinding and mixing treatment, and a first mixture is obtained; S4), stirring: water is added to the first mixture for stirring; S5), pre-extrusion; S6), pressing and extrusion molding; S7), segmented drying; S8), carbonizing; S9), gradient type activation: the carbonized material is put in an activating furnace to be activated for 1-2 h at the temperature of 750-850 DEG C and then is activated for 1-3 h after the temperature is increased to 850-950 DEG C, and the bamboo columnar activated carbon is obtained. The bamboo columnar activated carbon prepared with the technology has the characteristics that strength, adsorbability and adsorption capacity are high, the ash content is low, adsorption speed and desorption speed are high, obvious cracks on the outer surface are avoided, the yield of follow-up carbonized and activated products is high and the like.

Owner:JIANGSU PURESTAR EP TECH CO LTD

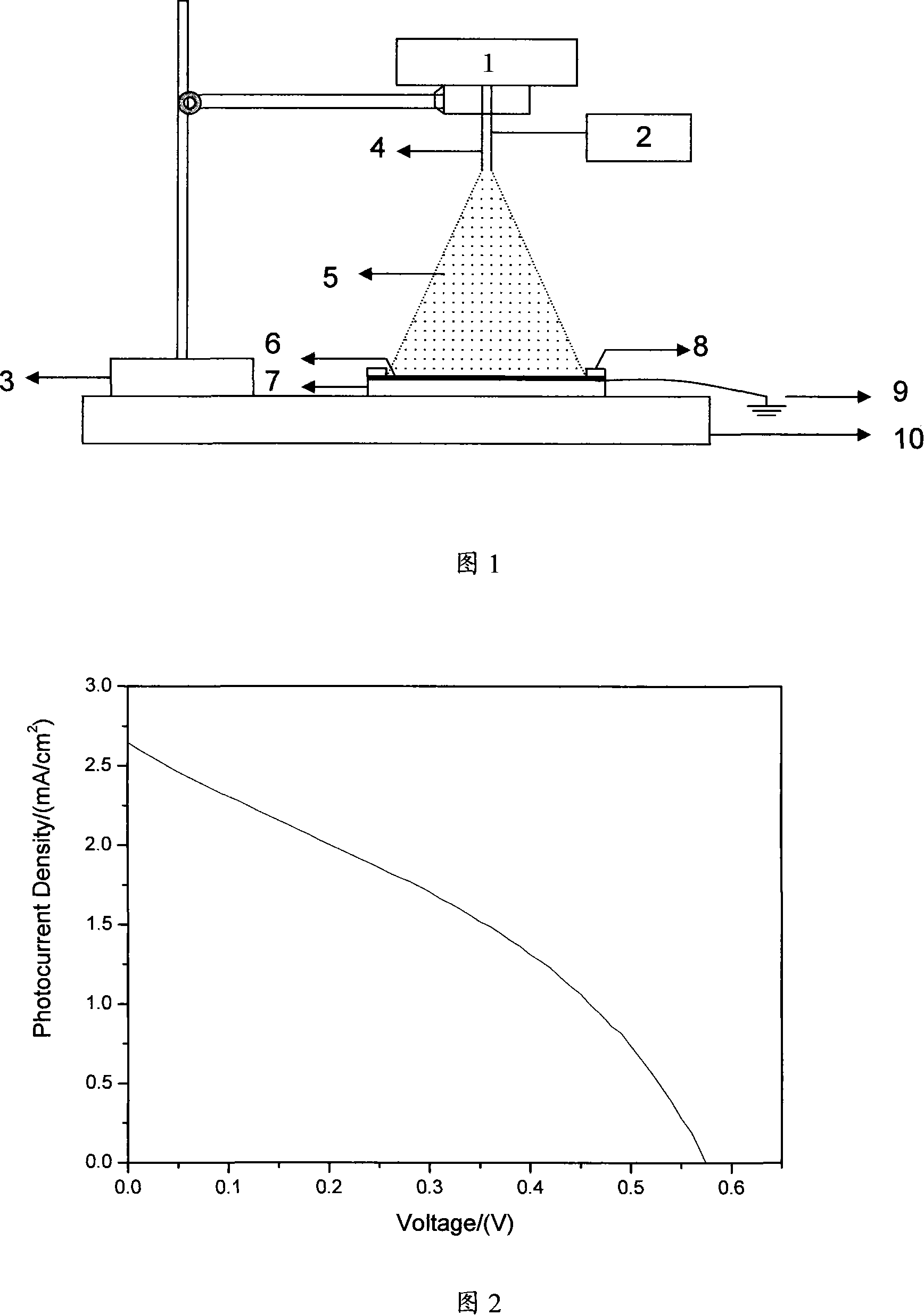

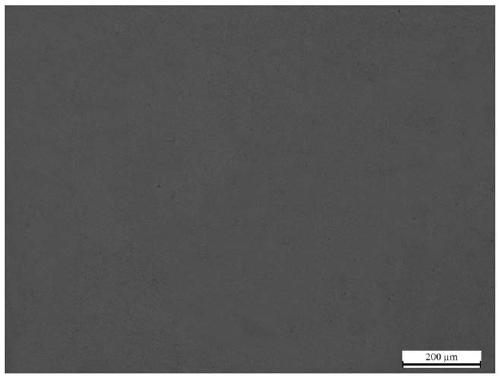

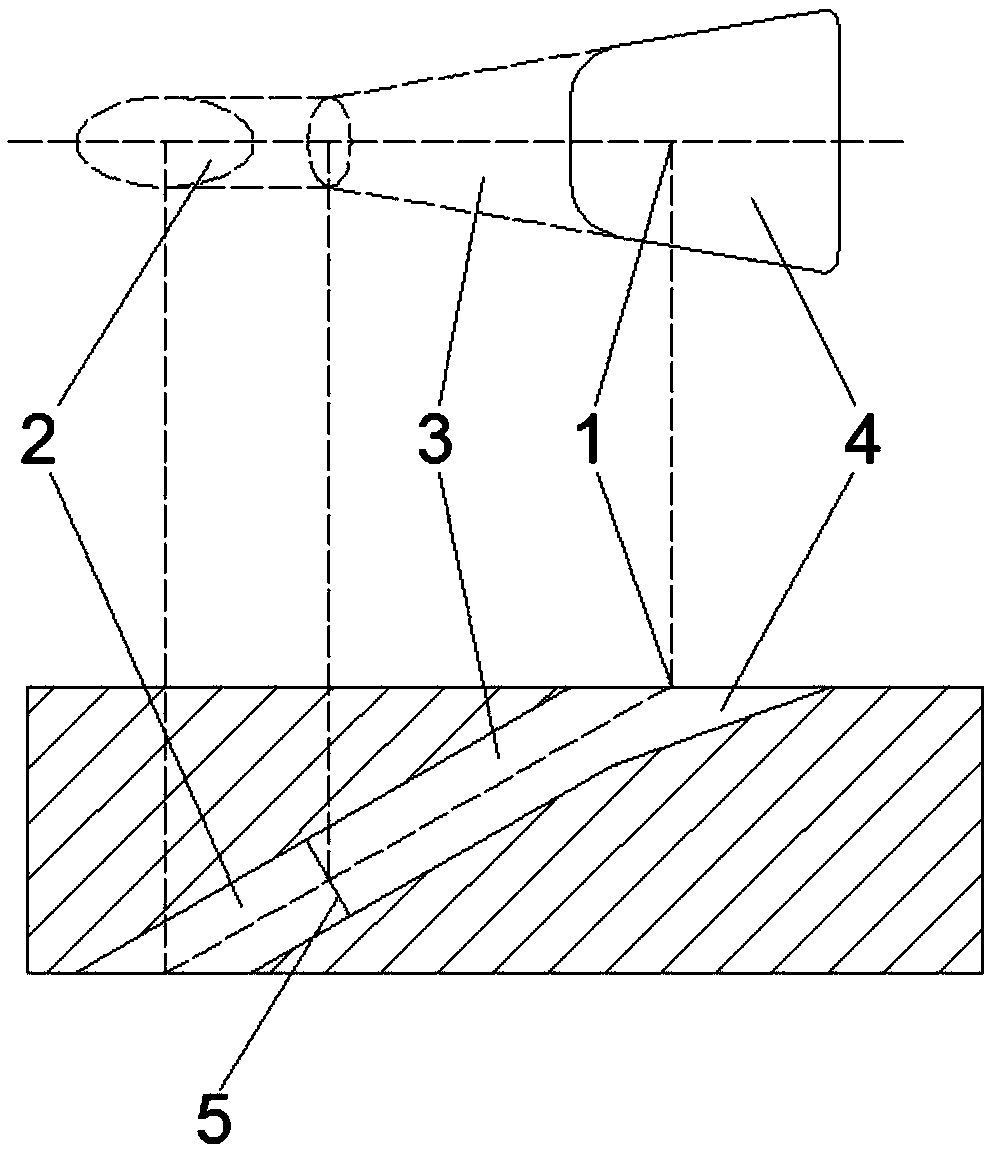

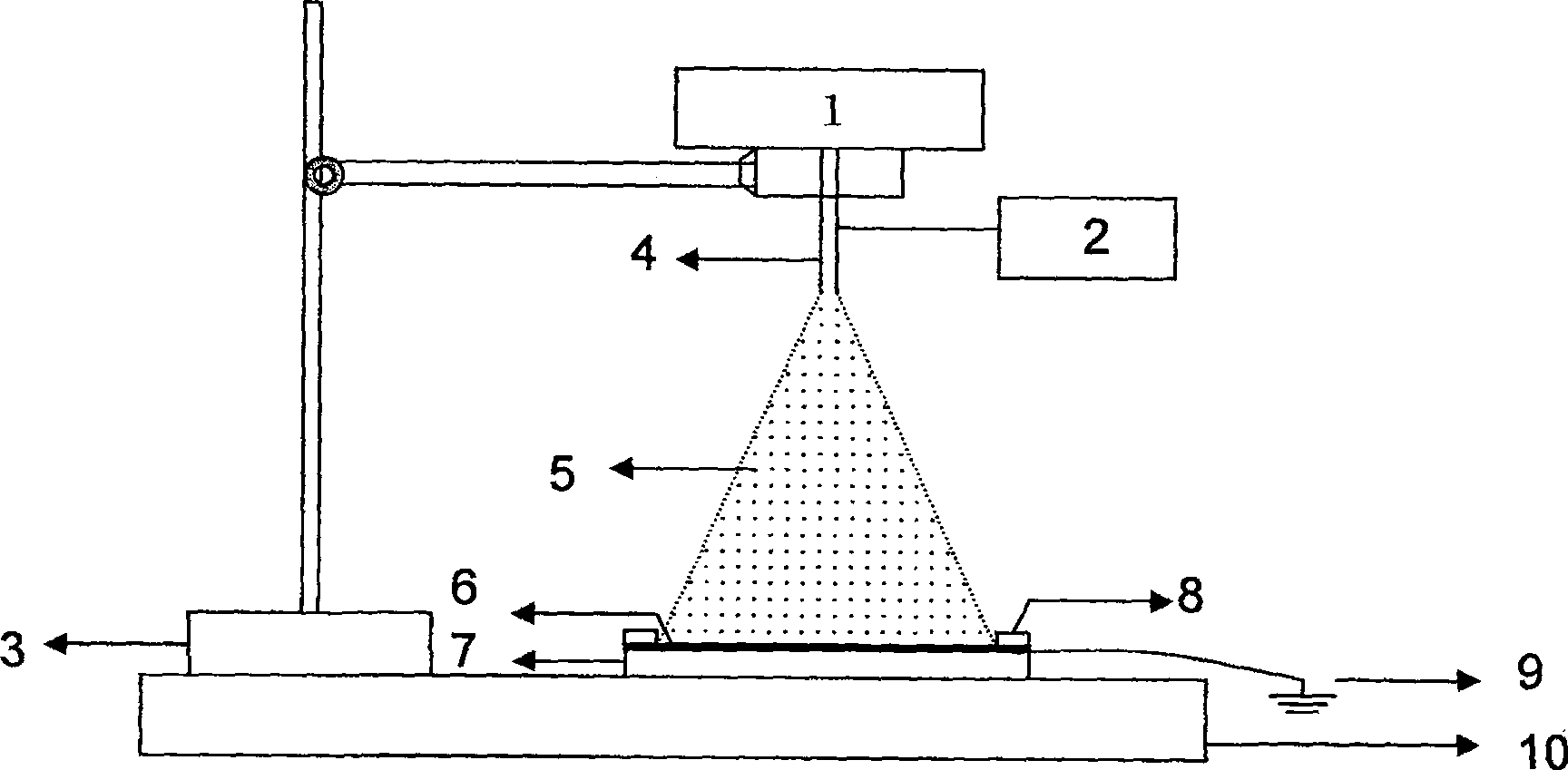

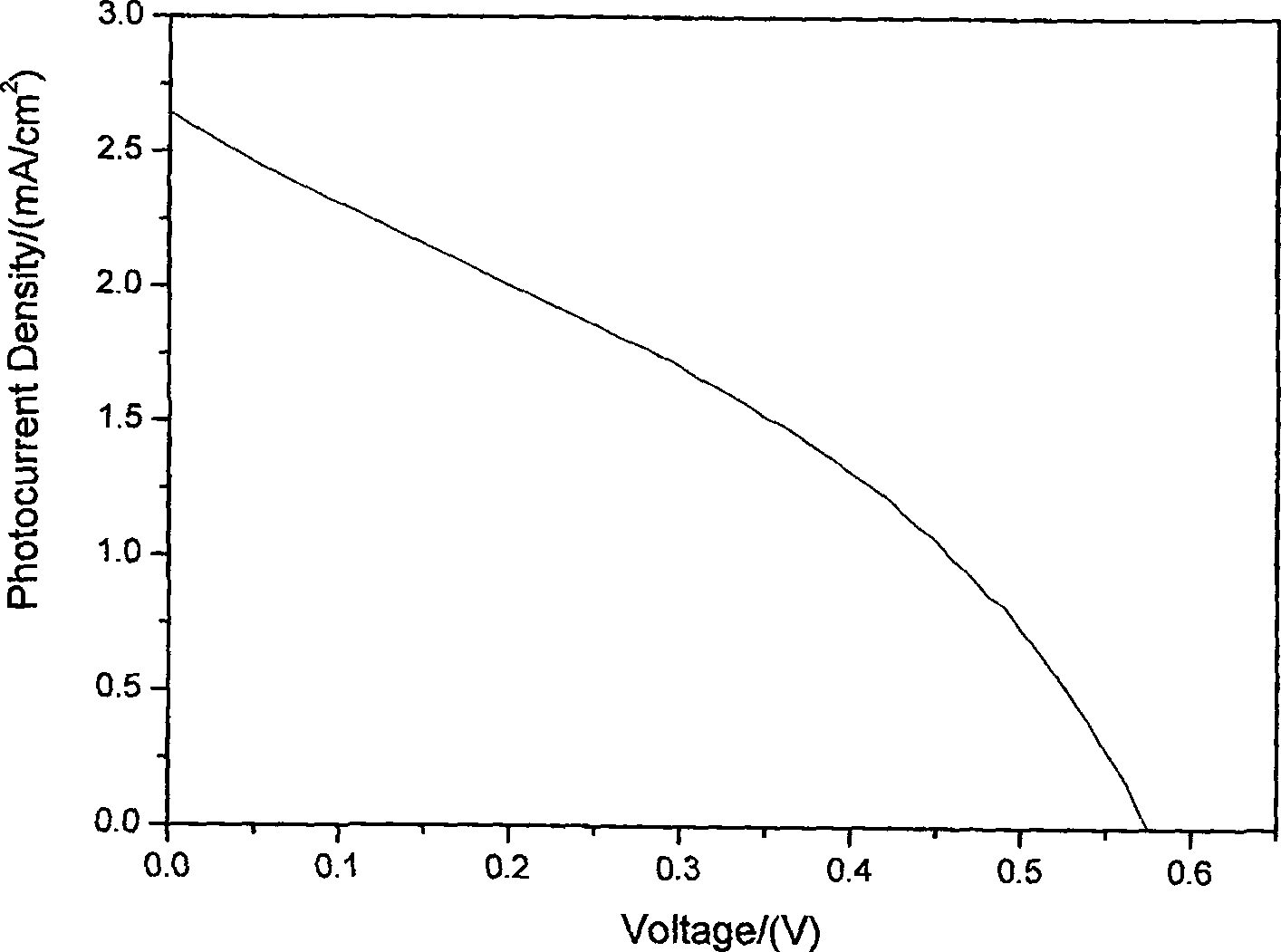

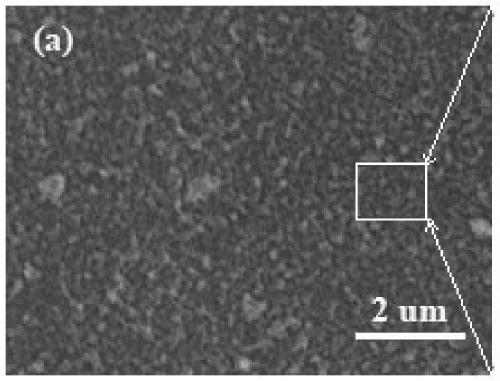

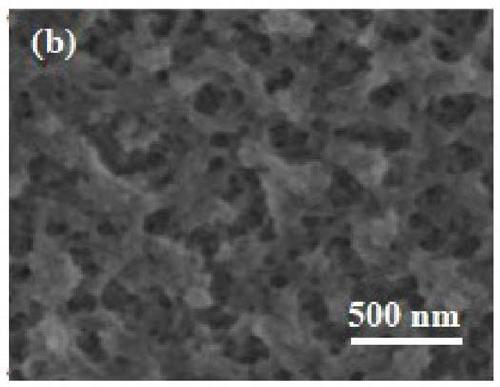

Flexible dye sensitized solar energy cell photoanode preparation method and apparatus

InactiveCN101145588AImprove uniformityNo obvious crackElectrode manufacturing processesLight-sensitive devicesCrazingSemiconductor materials

The invention provides a method and equipment of preparing flexible photo-anodes for dye-sensitized solar cells, and ensures an obtained semiconductor film free of cracks and superior in good uniformity and controllable thickness. The invention solves the problems of the prior art, such as long preparation time, poor repeatability, random distribution of local surface density of the semiconductor film, and high cracking risk. The flexible photo-anode is obtained by spray-coating of a conductive substrate by using a high-voltage electrostatic method and has good surface uniformity, and the surface semiconductor film doesn't produce cracks after random bending, thereby substantially realizing the flexibility. The preparation method is performed at normal temperature and pressure, without needing sinter process, thereby saving production energy and making it possible for nano-sized semiconductor materials with poor heat resistance to be applied in the field. The invention provides a new approach to improve the quality of the dye-sensitized solar cells.

Owner:SOUTHEAST UNIV

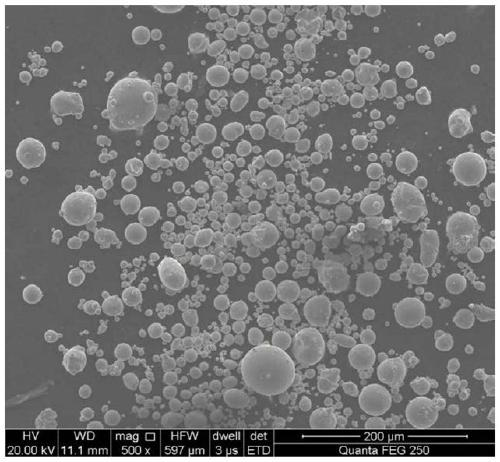

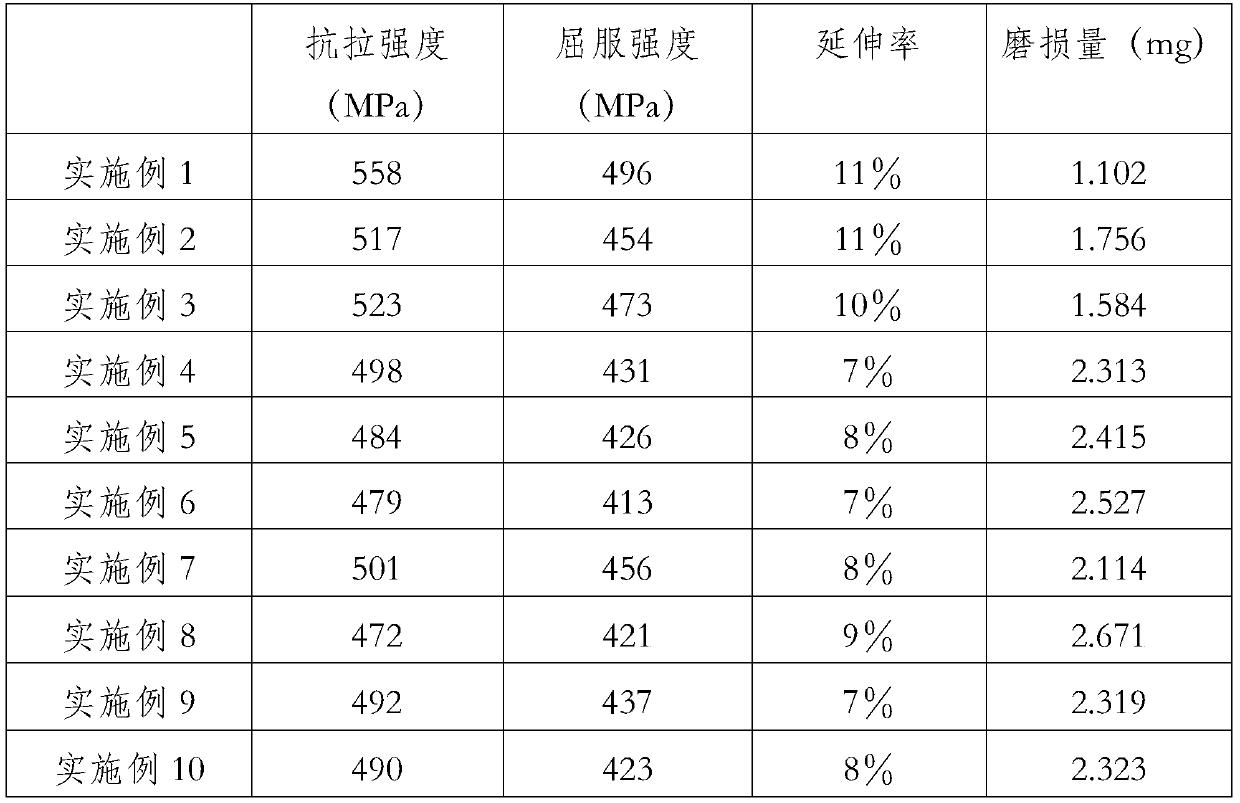

3D printing aluminum lithium alloy, preparing method of 3D printing aluminum lithium alloy and part printing method of 3D printing aluminum lithium alloy

ActiveCN110144502AImprove microstructureSimple structureAdditive manufacturing apparatusLithiumAlloy

The invention discloses a 3D printing aluminum lithium alloy, a preparing method of the 3D printing aluminum lithium alloy and a part printing method of the 3D printing aluminum lithium alloy. The 3Dprinting aluminum lithium alloy comprises, by mass percent, 0.5 to 2.0% of Li, 2.5 to 5.0% of Cu, 0.3 to 1.2% of Mg, 0.2 to 0.8% of Ag, 0.06 to 0.1% of Cr, 0.1 to 0.5% of Zr, 0.08 to 0.14% of Y, 0.02to 0.08% of Er, 0.1 to 0.5% of Sc, 0.02 to 0.08% of Ru, 0.1 to 1.5% of Ti and the balance Al. The obtained alloy sample is smooth in surface, free of obvious cracks, and high in compactness, the tensile strength is 558 MPa, the yield strength is 496 MPa, and the ductility is 11%.

Owner:CENT SOUTH UNIV +1

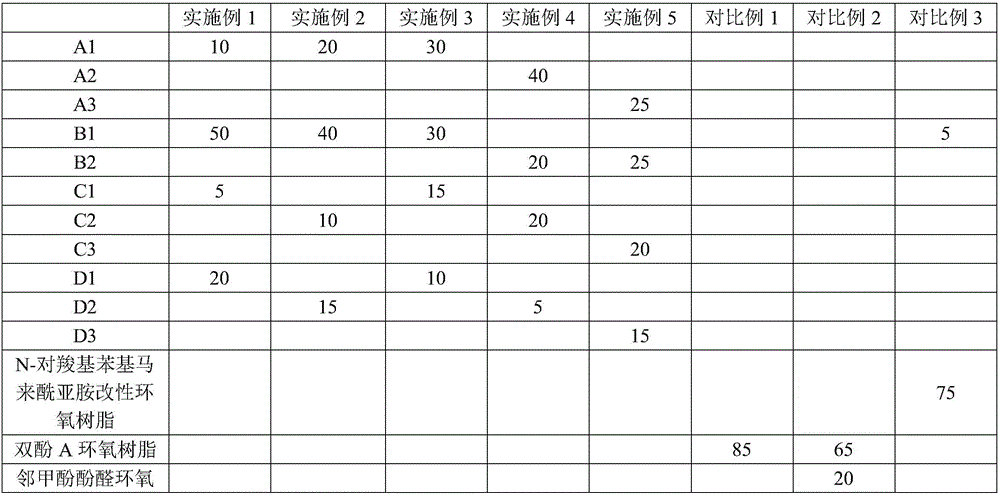

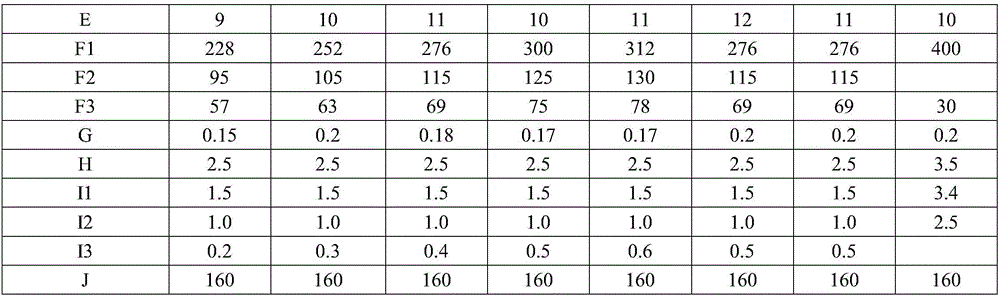

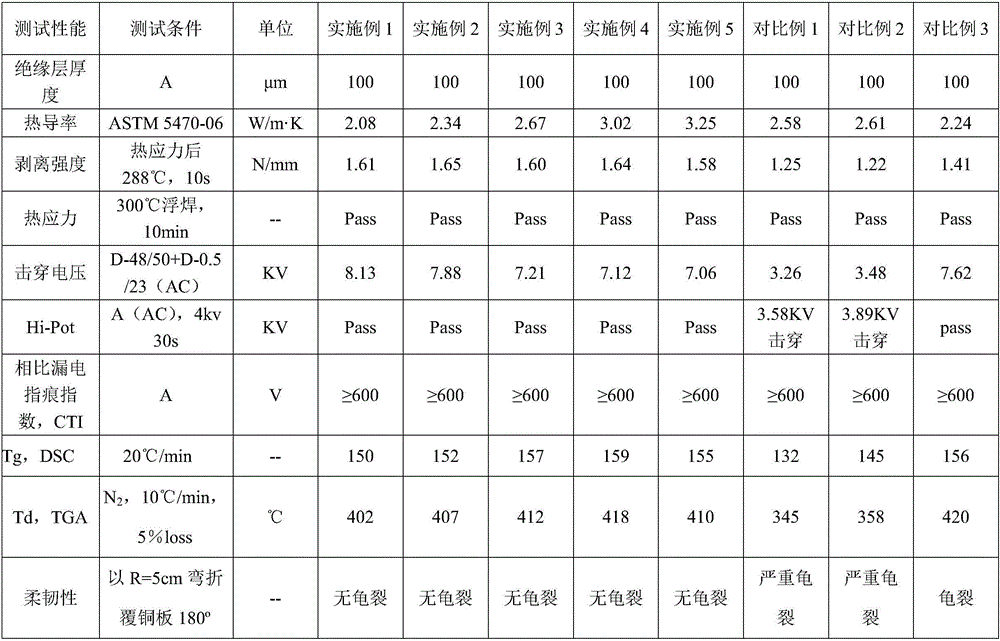

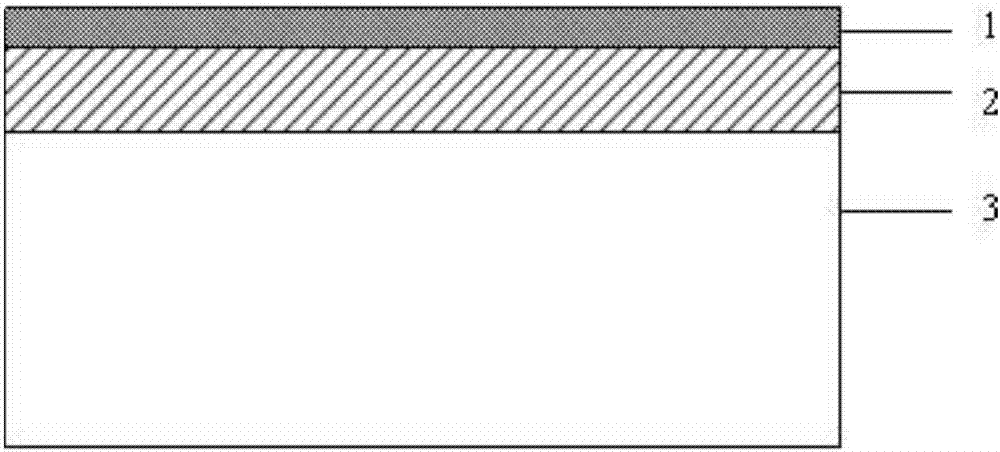

Resin compositionc and application thereof

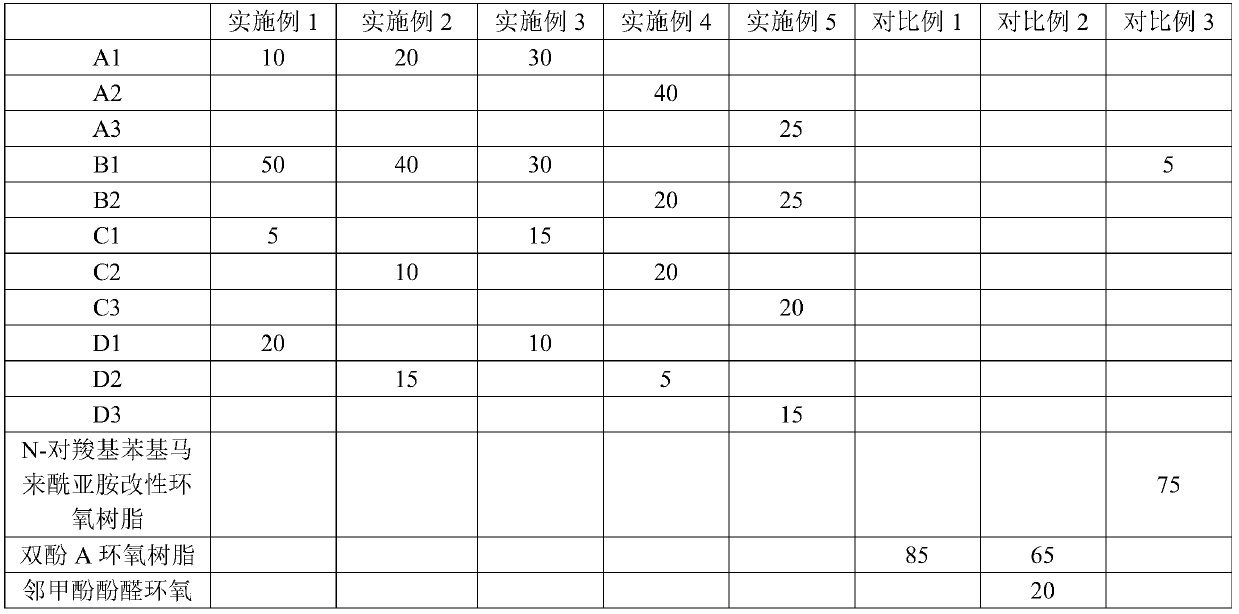

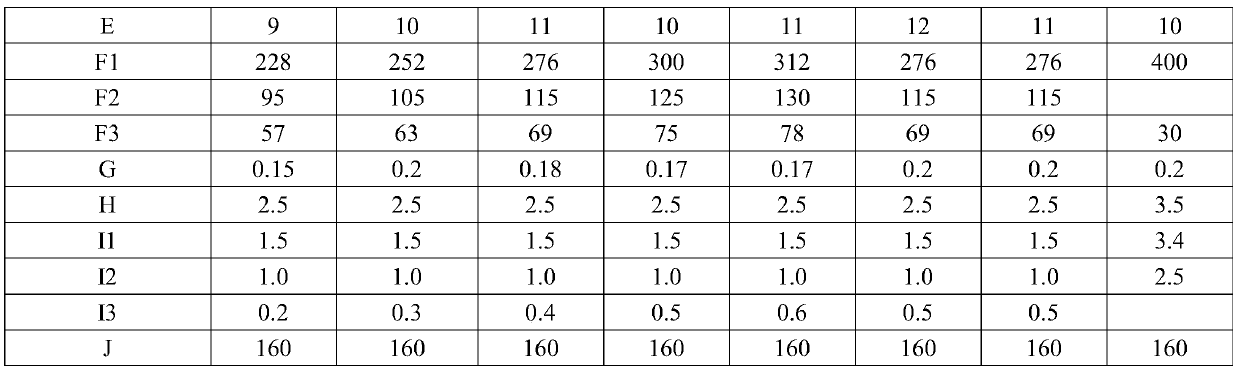

ActiveCN106633646AHigh filler loadingHigh thermal conductivityLamination ancillary operationsLaminationEpoxyPolyvinyl alcohol

The invention discloses a resin compositionc which comprises the following components in parts by weight: 10-40 parts of bismaleimide modified epoxy, 20-50 parts of flexible epoxy resin, 5-20 parts of polyvinyl butyral, 5-20 parts of phenoxy resin, 380-520 parts of heat-conductive padding, 5-12 parts of curing agent, 2-5 parts of coupling reagent, 0.05-0.85 part of curing accelerator and 2-6 parts of additives. According to the resin compositionc disclosed by the invention, the bismaleimide modified epoxy is introduced, so that the resin compositionc has excellent heat resistance and voltage resistance, and meanwhile, the flexible epoxy resin, the phenoxy resin, the polyvinyl butyral and the heat-conductive padding are added, so that the novel resin compositionc has excellent flexibility, heat dissipation, insulation, adhesion and heat resistance. A metal copper-clad plate prepared from the resin compositionc disclosed by the invention has the characteristics of high heat conductivity coefficient, high breakdown voltage, high peel strength, high heat resistance, halogen-free flame retardant and excellent flexibility.

Owner:SHAANXI SHENGYI TECH

Special-shaped hole machining method and special-shaped hole

InactiveCN109175732AHigh shape accuracyHigh dimensional accuracyLaser beam welding apparatusGalvanometerNanosecond pulse

The invention discloses a special-shaped hole machining method and a special-shaped hole and relates to the technical field of laser machining. According to the method, femtosecond or picosecond or nanosecond pulse laser is adopted, and a mode completely based on scanning galvanometer filling machining is provided. The method comprises the steps that firstly, a through hole smaller than the hole diameter requirement is machined so that gasification objects and fusion objects formed in the machining process can be discharged and re-coagulation objects are prevented from depositing; then, roughmachining of a special-shaped hole diffusion section is conducted; then, the laser focusing position is adjusted, broaching is conducted on the basis of a dust discharge through hole, and a cylindrical through hole meeting the hole diameter requirement is machined; and finally, the focus position is precisely adjusted, and the diffusion section is machined layer by layer. By means of the special-shaped hole machining method and the special-shaped hole, heat-induced defects such as recasting layers, microcracks, coating collapse and the like generated in the process that in the prior art, a special-shaped hole is machined, and in particular, the special-shaped hole is machined in a workpiece with the surface coated with a thermal barrier coating are avoided; and in addition, the shape and dimension precision of the special-shaped hole are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

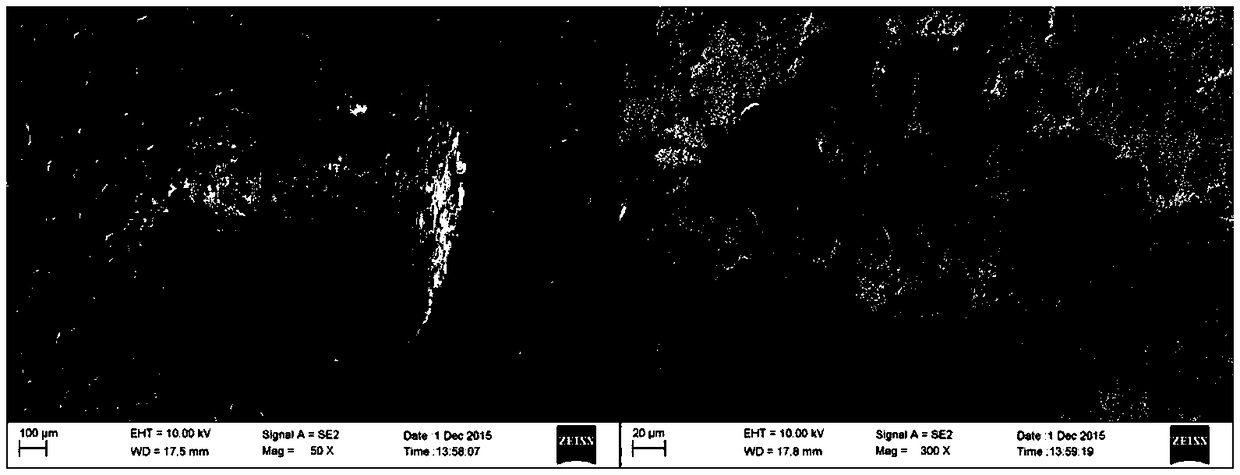

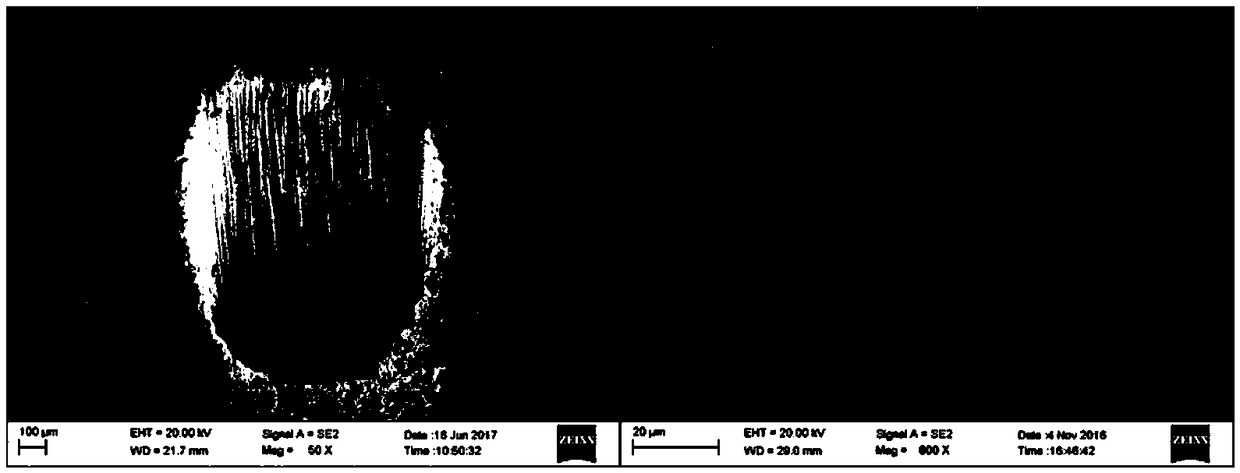

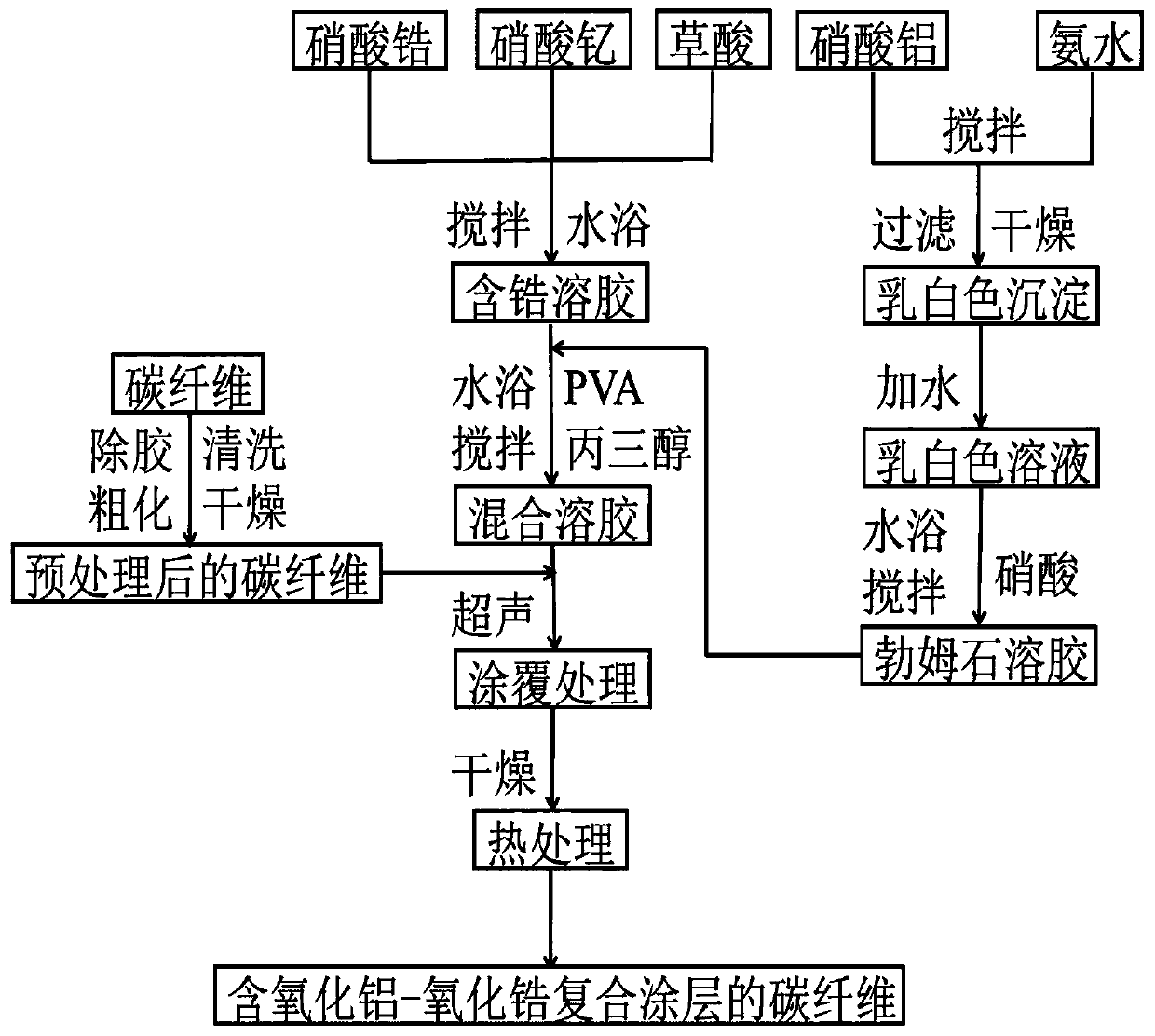

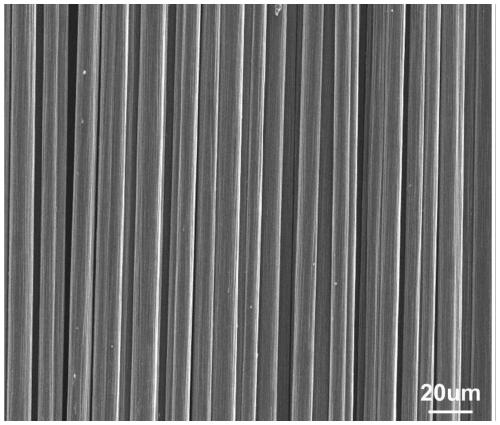

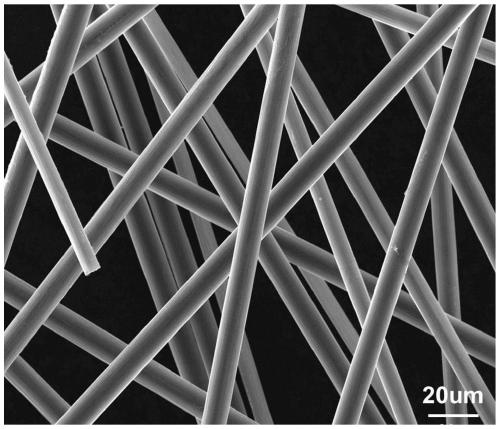

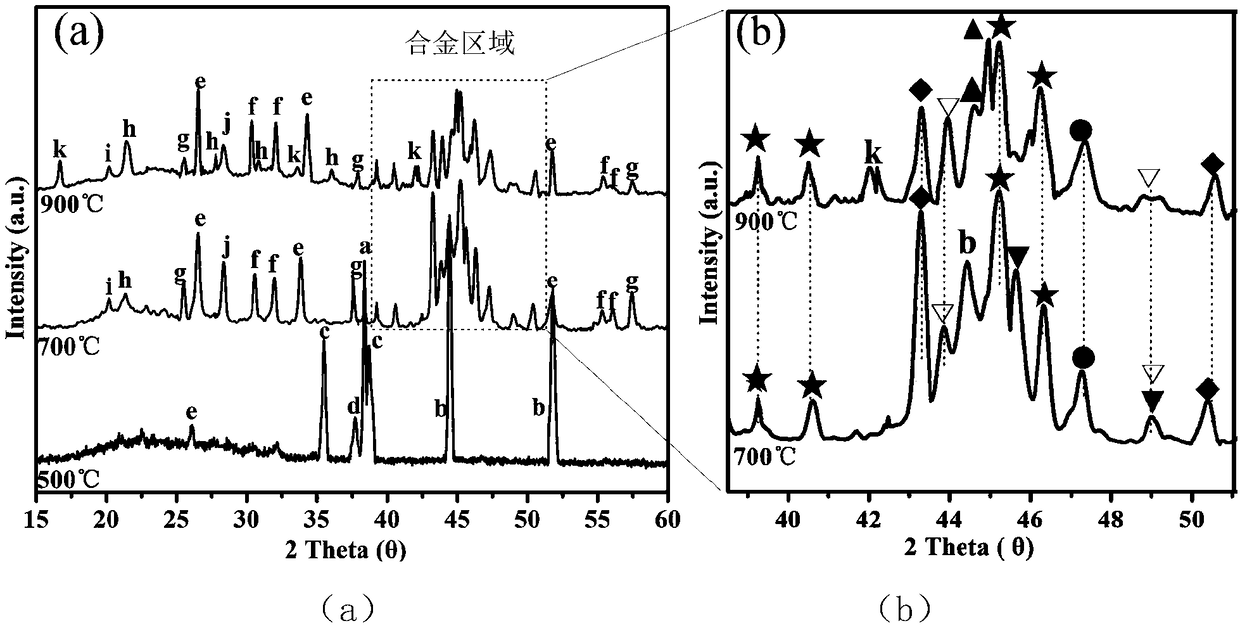

Preparation method of alumina-zirconia composite coating on surface of high-thermal-conductivity carbon fiber

The invention discloses a preparation method of an alumina-zirconia composite coating on the surface of a high-thermal-conductivity carbon fiber. The preparation method is a sol-gel method, and comprises the processes of pretreatment of the surface of the carbon fiber; preparation of composite sol; coating and drying treatments of the pretreated carbon fiber after the pretreatment; and low temperature heat treatment of the carbon fiber coated with the composite sol. The carbon fiber coated with the alumina-zirconia composite coating was obtained through the processes. The crystal form of the composite coating prepared by the preparation method is the composite coating of gamma-Al2O3.t-ZrO2. According to the preparation method, the process is simple, the requirements on equipment and operating environment are low, the implementability is strong, raw materials are low in price and easy to obtain, the method is easy to realize and energy-saving and environmentally friendly, the compositecoating with complete coating and adjustable thickness can be prepared on the surface of the high-thermal-conductivity carbon fiber, and the oxidation resistance of the carbon fiber and the thermal conductivity of a carbon fiber reinforced aluminum-based composite material are improved.

Owner:苏州优越新材料有限公司

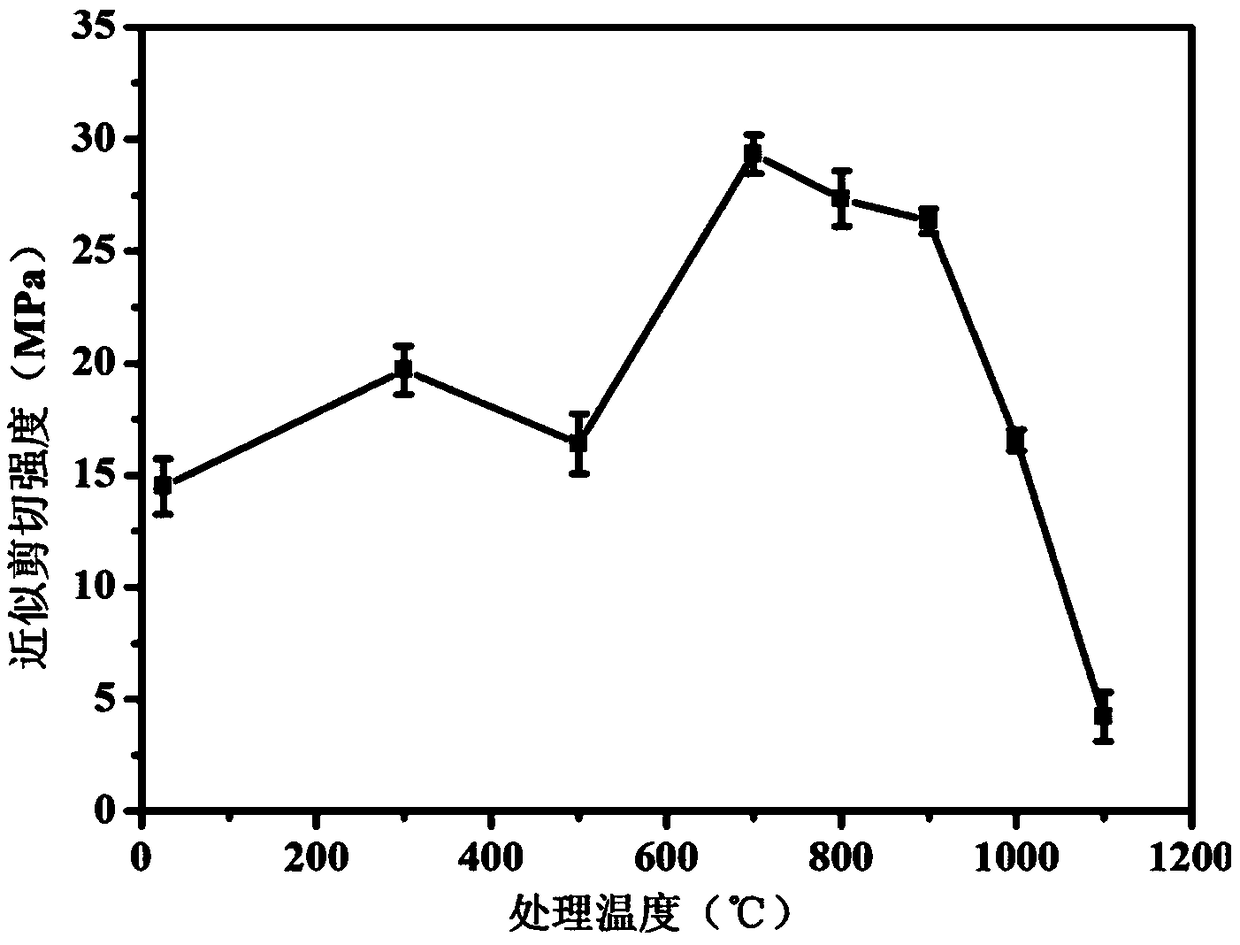

Preparation method of high temperature adhesive for nickel based alloy

ActiveCN108822792AGood thermal expansionLow decomposition shrinkageNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilanesAdhesive

The invention discloses a preparation method of a high temperature adhesive for a nickel based alloy. The preparation method comprises following steps: mixing following raw materials: ultrafine nickelpowder, ultrafine aluminum powder, ultrafine boron carbide powder, ultrafine low temperature molten glass powder, and high activity copper oxide powder to prepare a raw material mixture; subjecting the raw material mixture to ball milling; preparing a resin solution from silane MK resin and isopropanol; and finally mixing the raw material mixture with the resin solution to prepare a gel solution.The prepared high temperature adhesive can realize partial alloying, can tolerate a high temperature as high as 1000 DEG C, and has the advantages of high thermal expansion, low decomposition rate and low shrinking percentage; high temperature resistant metal compounds and ceramic dually enhance the performance, the high temperature mechanical properties are excellent; the high temperature adhesive has the prominent characteristics that after curing the adhesive does not need any post treatment, can be used at a temperature of 1000 DEG C, and is especially suitable for a high temperature nickel based alloy (GH2132) at a temperature of 600 to 1000 DEG C.

Owner:天津航大翼安科技发展有限公司

A kind of preparation method of flexible silica airgel

ActiveCN103708476BNo obvious crackOvercome the disadvantage of single shapeSilicaPorosityAnhydrous ethanol

The invention discloses a preparation method of a flexible silica aerogel, relating to a silica aerogel. The invention provides the preparation method of the flexible silica aerogel, which takes methyl alkoxy-series silane as a silicon source precursor. The preparation method comprises the steps of mixing methyl trimethoxysilane or methyl trimethoxysilane, an anhydrous ethanol solution and water, further adding hydrochloric acid, regulating the pH value of the solution to 2-2.5, then adding ammonia water to obtain a sol, standing, then preparing a wet gel, further aging the wet gel, and then drying to prepare the flexible silica aerogel. The prepared flexible silica aerogel has the advantages of low density and high porosity, and simultaneously overcomes the shortcomings of poor integrity and great brittleness. According to the preparation method, the complicated steps of complex solvent exchange and gel modification are not required, so that the operation is simple and easy, the process is controllable, the cost is low, the period is short, and the continuous production can be realized.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

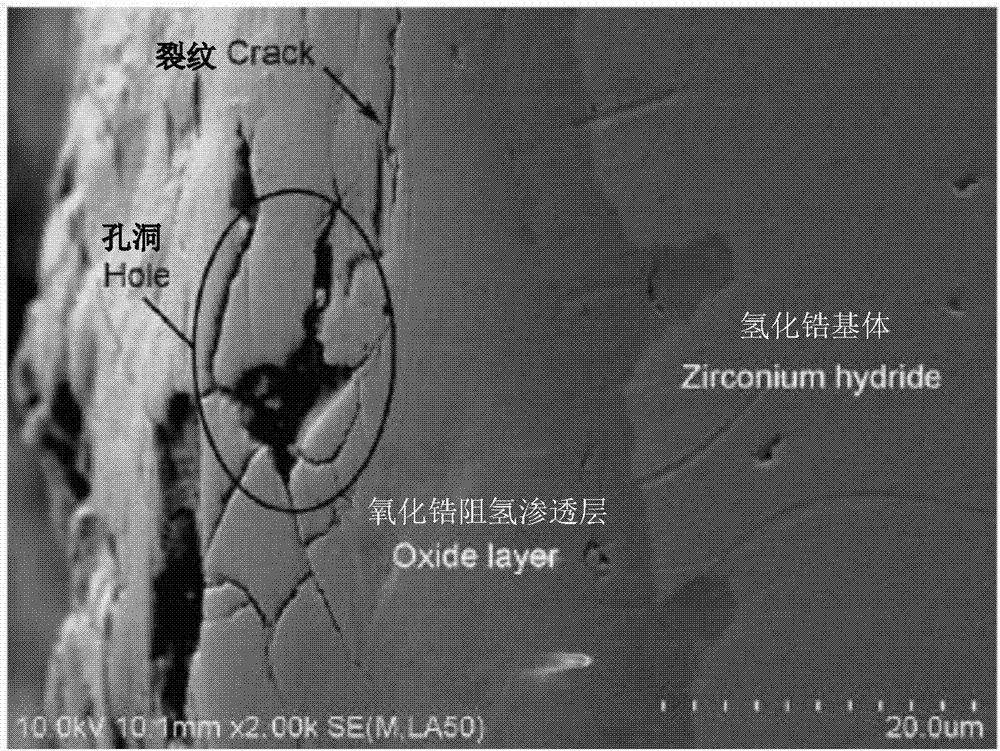

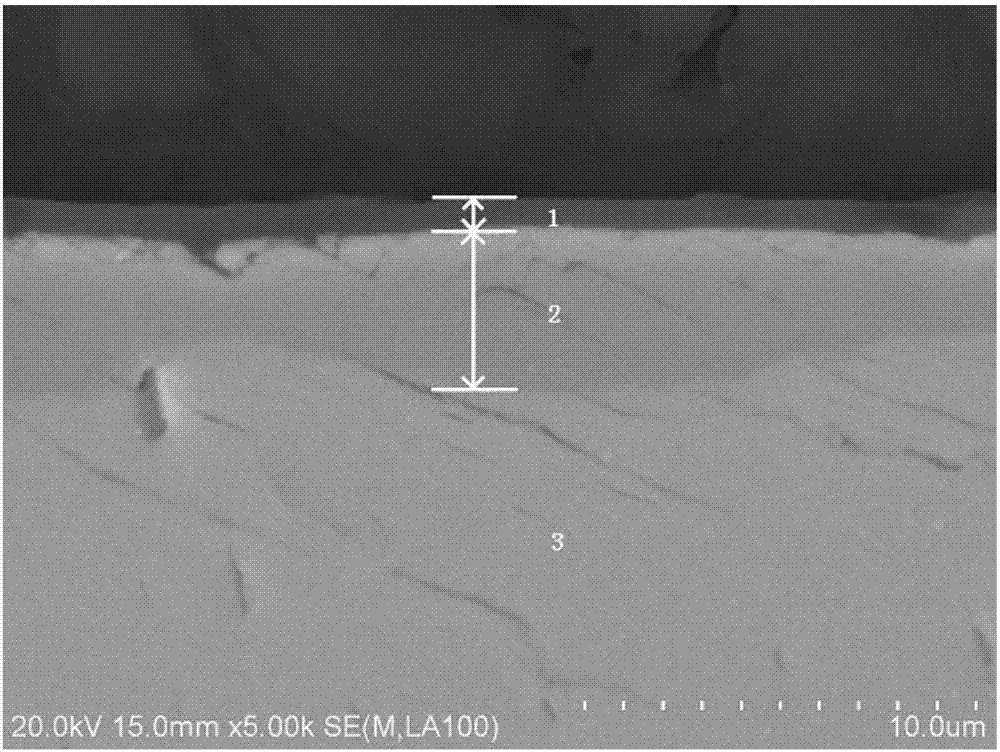

Composite hydrogen resisting permeating layer on surface of metal hydride and preparation method thereof

ActiveCN107043905AEnhanced hydrogen permeation resistanceNo obvious crackSolid state diffusion coatingLiquid/solution decomposition chemical coatingHydrideCarbon nitrogen

Owner:有研资源环境技术研究院(北京)有限公司

Straw utilization method

The invention discloses a straw utilization method. The utilization method comprises the following steps that firstly, straw is pretreated, wherein straw raw materials are cut up, the cut straw, a mixed bacteria solution and a synergist are mixed, clear water is added, and a ferment mixture is obtained after uniform stirring; secondly, the ferment straw is stacked; thirdly, the straw is fermented; fourthly, drying and crushing are conducted; fifthly, granulation is conducted, wherein straw fibers are conveyed into a hoop standard granulator, compression formation is conducted by means of circular dies and compression rollers, and rod-like straw particles are obtained; sixthly, cooling formation is conducted, wherein the compressed straw particles are fed into a cooling machine, and smoothly formed particles are obtained. According to the straw utilization method, the fermented straw can be directly used for production of fodder, methane fermentation, organic fertilizers and poultry feed, through the processes of drying and crushing, granulation and cooling formation, the surfaces of the straw particles are smooth and free of obvious cracks, the straw particles can be used as clean biomass combustion energy, and the utilization method is suitable for large-scale application and popularization.

Owner:合肥市风达农业有限责任公司

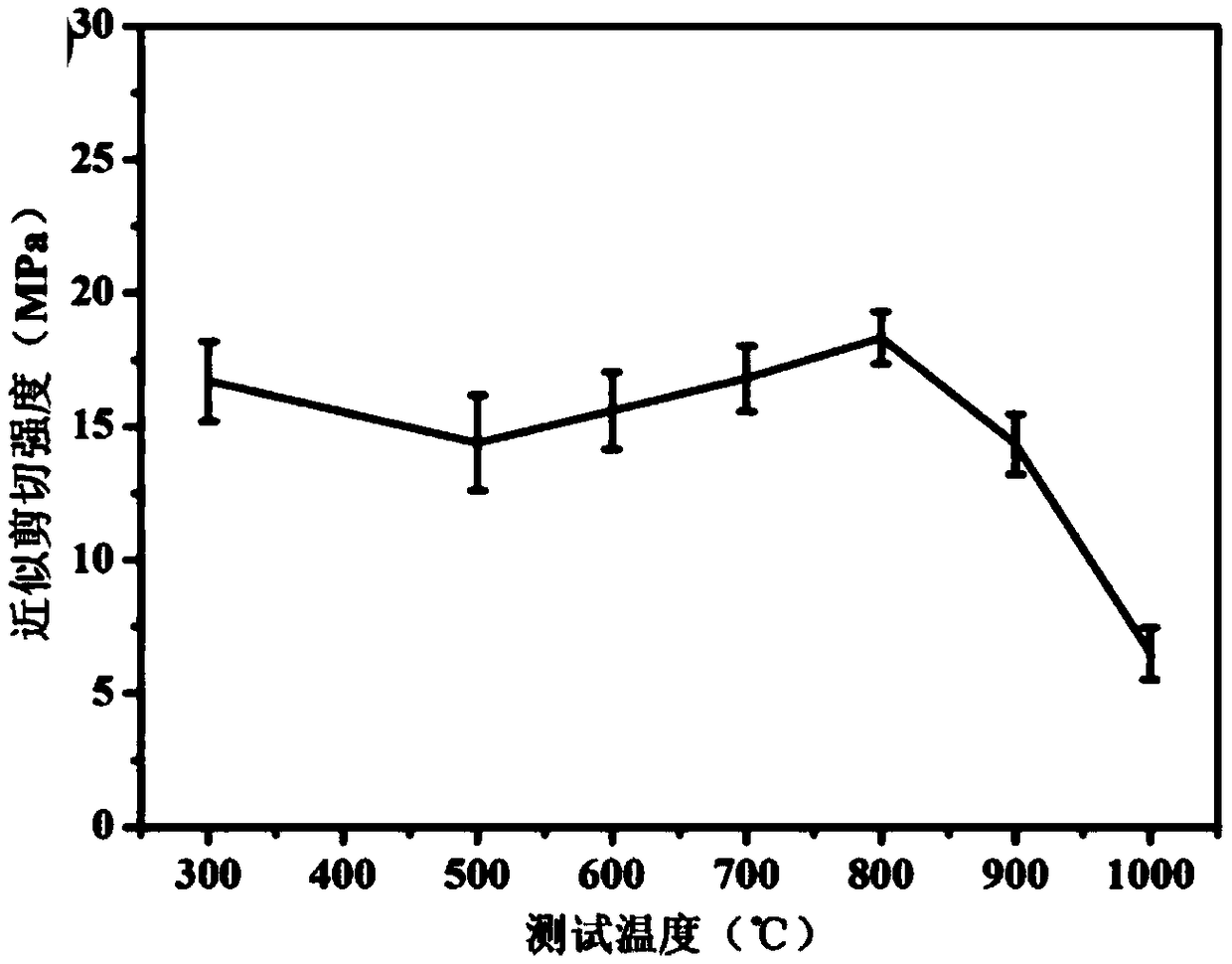

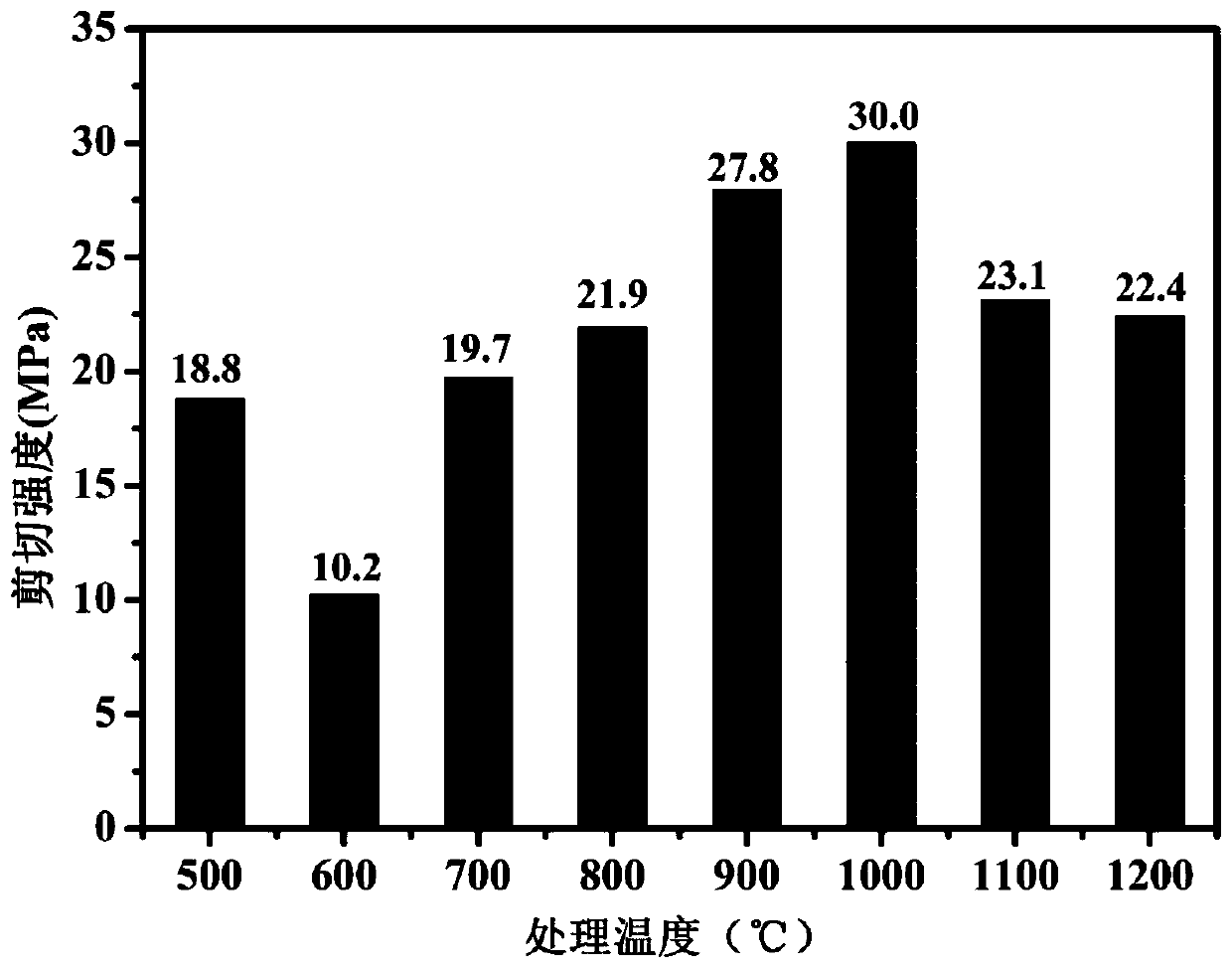

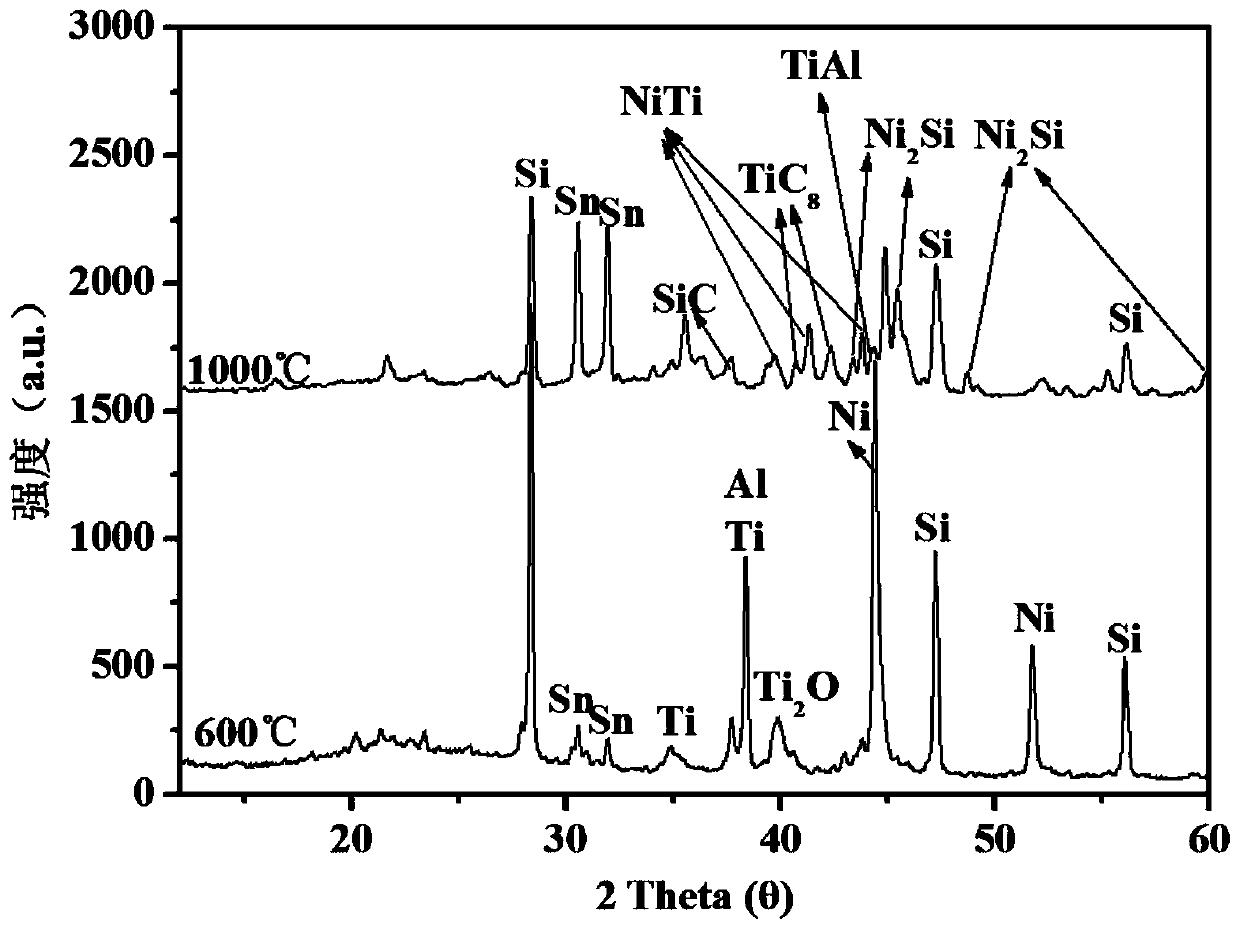

Preparation method of high-temperature adhesive suitable for TC4 titanium-base alloy

ActiveCN110591619AHigh bonding strengthLow decomposition shrinkageNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesBoron carbideSuperalloy

Disclosed is a preparation method of a high-temperature adhesive suitable for a TC4 titanium-base alloy. The method comprises the following steps of dissolving phenolic resin and MK siloxane resin inisopropanol to prepare resin solutions respectively; mixing the two resin solutions to prepare a glue solution; carrying out mixing on nickel powder, titanium powder, silicon powder, aluminum powder,boron carbide powder and glass powder and then performing ball milling to prepare a uniform filler; and mixing the filler and the glue solution and executing other steps to prepare the adhesive. The preparation method has the advantages that the prepared high-temperature adhesive has the characteristics of being high in temperature resistance, up to 1200 DEG C, high in intermetallic compound generation amount, low in decomposition shrinkage rate, tight in connection with a bonded part, high in bonding strength and the like; and in an anaerobic high-temperature environment of 700-1200 DEG C, the adhesive can provide bonding strength of not less than 20 MPa for the TC4 titanium-based alloy, so that the application of the adhesive technology in high-temperature alloy connection and repair isgreatly improved.

Owner:CIVIL AVIATION UNIV OF CHINA

Method for uniform distribution of PTFE (polytetrafluoroethylene) binder and electrode key component materials and application in battery industry

ActiveCN109935843AEvenly distributedIncrease profitElectrode manufacturing processesSlurryUltrasonic dispersion

The invention discloses a method for uniform distribution of a PTFE (polytetrafluoroethylene) binder and electrode key component materials and an application in the battery industry. The method comprises the steps of carrying out ultrasonic dispersion or high-speed mechanical stirring on a water diluent of PTFE emulsion to obtain a solution 1; mixing conductive carbon powder, an electrode active component, a surfactant and water, then carrying out ultrasonic dispersion or high-speed mechanical stirring on the mixed solution to obtain a solution 2; preheating and mixing the solution 1 and the solution 2 to obtain a solution 3; carrying out high-speed stirring on the solution 3 for 1-6 hours under a constant temperature condition, standing and cooling to the room temperature so as to obtaina layered solid-liquid mixture; and removing a supernatant of the solid-liquid mixture to obtain a PTFE-conductive carbon powder-electrode active material ternary compound. The method realizes the uniform distribution of the binder, the conductive carbon powder and the electrode active material in an electrode, avoids the agglomeration of single component, improves the utilization ratio of the electrode active material and improves the discharge performance and operation stability of the battery; and the uniform distribution of each component in the electrode structure is obtained through preparing electrode slurry, there is no obvious secondary agglomeration, and the surface of the electrode is smooth, flat and free of obvious cracks.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

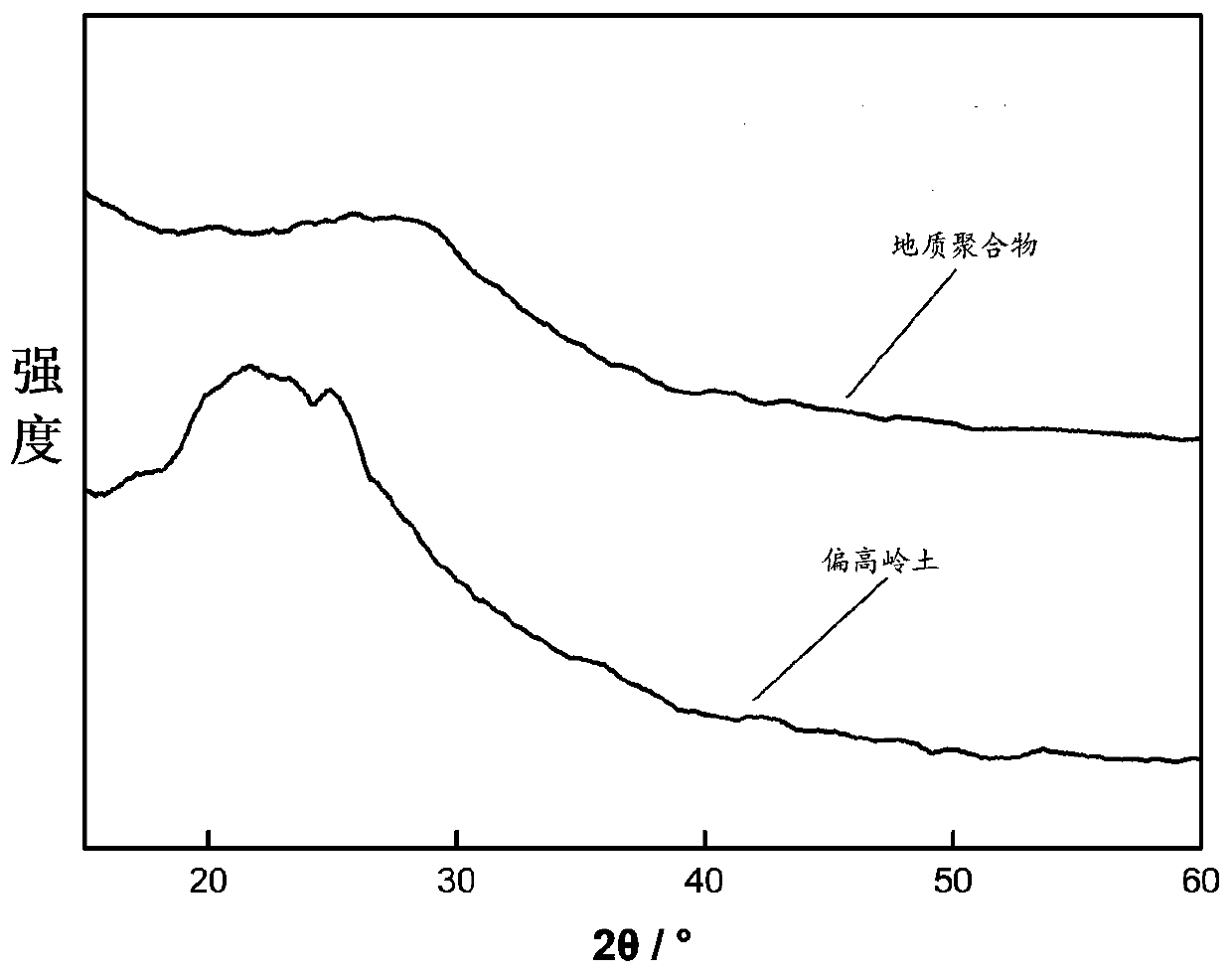

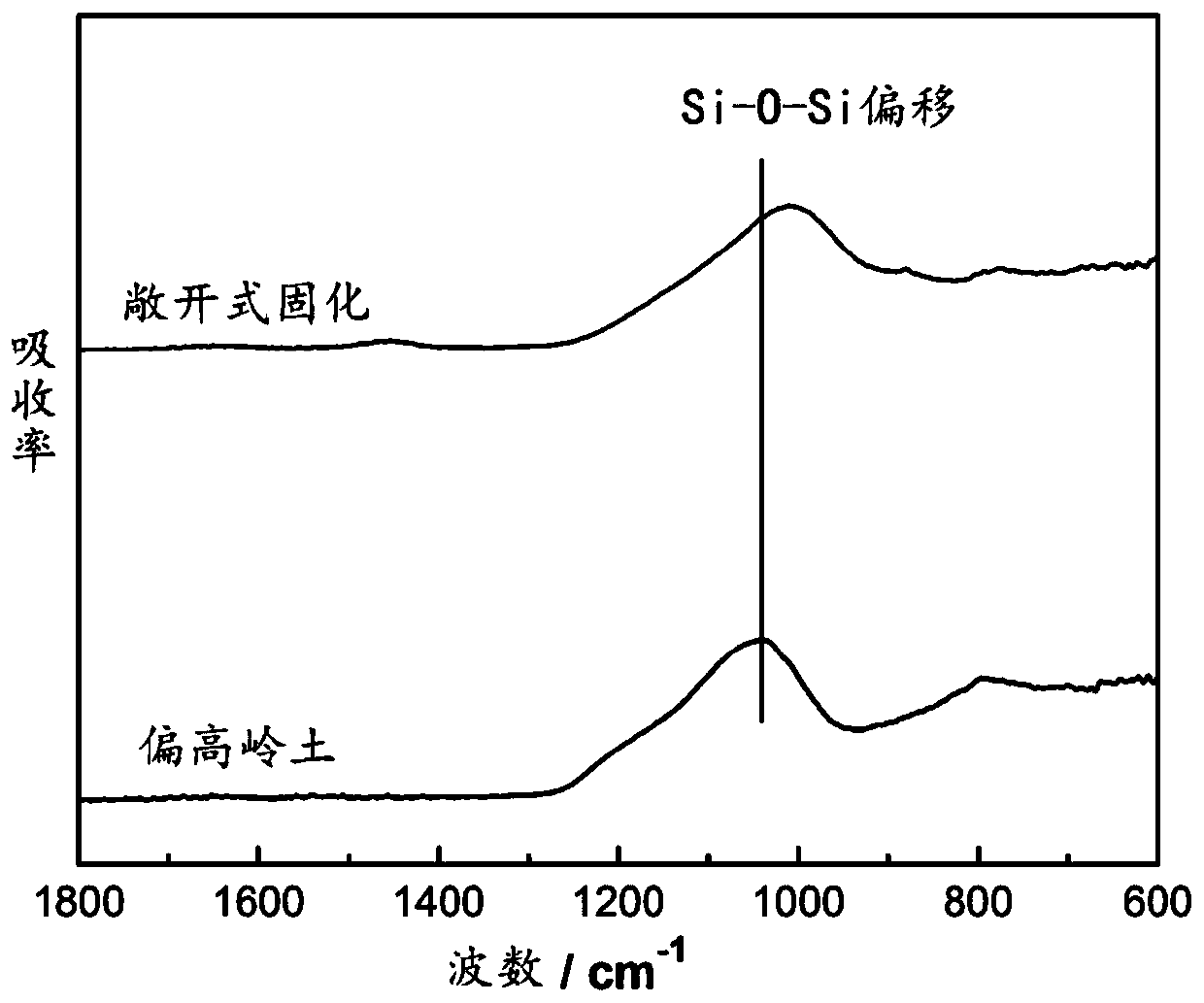

Preparation method of geopolymer precursor and product, application and connection method of geopolymer precursor

The invention provides a preparation method of a geopolymer precursor and a product, application and a connection method of the geopolymer precursor. The preparation method of the geopolymer precursorcomprises the following steps that a1, potassium silicate, KOH and deionized water are taken to be made into an alkali activator, and the mass ratio of potassium silicate to KOH to deionized water is100: 4.9-6.5: 90-115; and a2, metakaolin and the alkali activator prepared in the step a1 are mixed and stirred uniformly to prepare a geopolymer precursor, and the mass ratio of metakaolin to the alkali activator is 70-100: 195-222. The preparation method of the geopolymer precursor provided by the technical scheme of the invention is simple and easy to operate, and the synthetic raw materials are low in cost; connection can be successful at a low temperature by using a drying oven, the connection cost is low, energy is saved, and the environment is protected; and when a ceramic aluminum piece is connected by using the product, the combination is firm without no obvious cracks, and the connection strength of the joint is relatively high.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

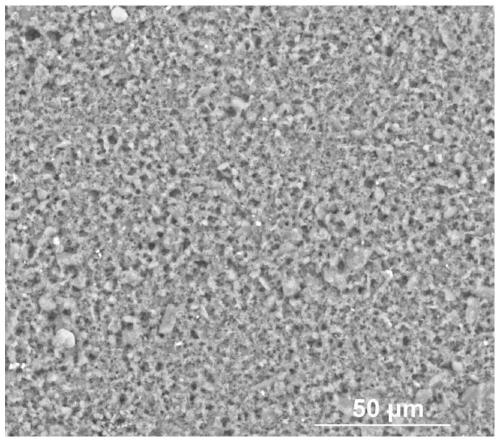

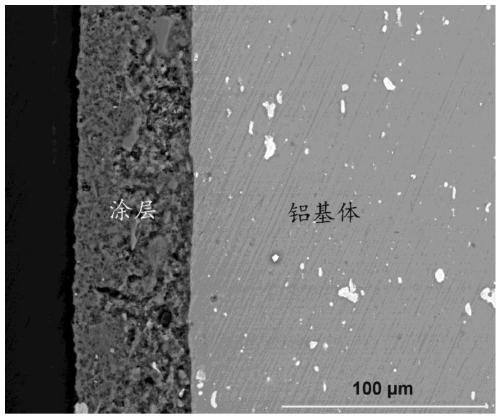

Geopolymer coating layer suitable for metal substrate and preparation method of geopolymer coating layer

The invention discloses a geopolymer coating layer suitable for a metal substrate and a preparation method of the geopolymer coating layer. The preparation method includes the steps of firstly, evenlymixing sodium silicate, NaOH and H2O, and drying to obtain a transparent alkali-activator; secondly, weighing geopolymer synthesizing raw materials and the alkali-activator, and mixing and stirring to obtain flowing-state geopolymer precursor; thirdly, spraying the geopolymer precursor to the surface of metal to obtain a geopolymer coating layer; thirdly, curing the obtained coating layer in theair to obtain the geopolymer coating layer. The preparation method has the advantages that the method is simple, easy to operate and cheap in raw materials; the real geopolymer coating layer uniform in thickness can be prepared, the geopolymer coating layer can be firmly combined with the metal substrate, and the cured coating layer is free of defects such as cracks; in addition, the geopolymer coating layer on the surface of the metal substrate can favorably improve the heat resistance and corrosion resistance of metal and is promising in industrial application prospect.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Flexible dye sensitized solar energy cell photoanode preparation method and apparatus

InactiveCN100533786CImprove uniformityNo obvious crackLight-sensitive devicesElectrode manufacturing processesCrazingSemiconductor materials

The invention provides a method and equipment of preparing flexible photo-anodes for dye-sensitized solar cells, and ensures an obtained semiconductor film free of cracks and superior in good uniformity and controllable thickness. The invention solves the problems of the prior art, such as long preparation time, poor repeatability, random distribution of local surface density of the semiconductor film, and high cracking risk. The flexible photo-anode is obtained by spray-coating of a conductive substrate by using a high-voltage electrostatic method and has good surface uniformity, and the surface semiconductor film doesn't produce cracks after random bending, thereby substantially realizing the flexibility. The preparation method is performed at normal temperature and pressure, without needing sinter process, thereby saving production energy and making it possible for nano-sized semiconductor materials with poor heat resistance to be applied in the field. The invention provides a new approach to improve the quality of the dye-sensitized solar cells.

Owner:SOUTHEAST UNIV

Multilayer structure pellet, preparation method thereof, and lightweight heat transfer coating containing multilayer structure pellet

ActiveCN110204943AGuaranteed StrengthGuaranteed compactnessFireproof paintsAntifouling/underwater paintsCoated surfacePolymer science

A multilayer structure pellet sequentially comprises a heat transfer layer, a transition layer, an anticorrosion layer and a high temperature-resistant layer from the inside to the outside; and all the layers are closely bonded. A preparation method of the multilayer structure pellet is characterized in that the multilayer structure pellet is prepared layer by layer from the inside to the outside.A heat transfer coating containing the multilayer structure pellet comprises 40-65 wt% of the multilayer structure pellet having a particle size of 6 mm or below, 10-30 wt% of fused white corundum having a particle size of 0.074-1 mm, 18-55 wt% of silicon carbide with a particle size of 0.074 mm or below, 0.1-0.5 wt% of aluminum powder with a particle size of 0.074 mm or below and 5-18 wt% of a boehmite sol. A preparation method of the coating comprises the following steps: mixing and stirring the multilayer structure pellet, fused white corundum, silicon carbide and aluminum powder to uniformity, adding the boehmite sol, and performing stirring to prepare the coating for later use. The lightweight heat transfer coating containing the multilayer structure pellet has can resist the high temperature of 1500 DEG C or above; and after the coating is used for 8 months, the surface corrosivity of a whole coating layer formed by the coating does not exceed 1%, the surface scaling rate does not exceed 2.6%, the surface has no obvious cracks, and the heat transfer performance is not less than 1.80 w / m.k.

Owner:武汉钢铁有限公司

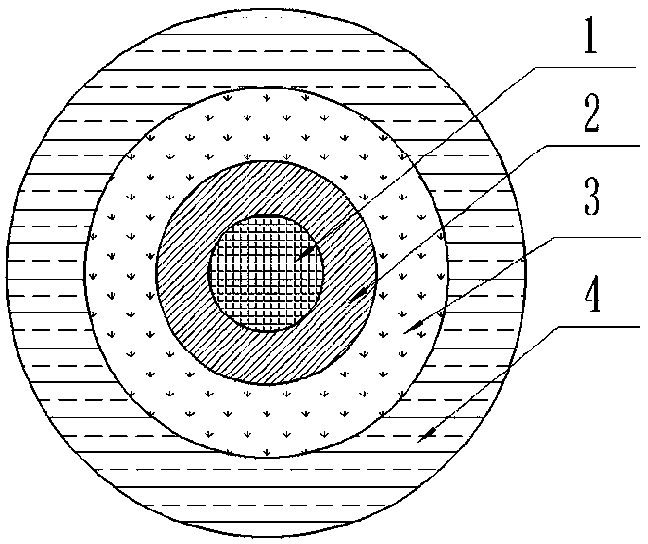

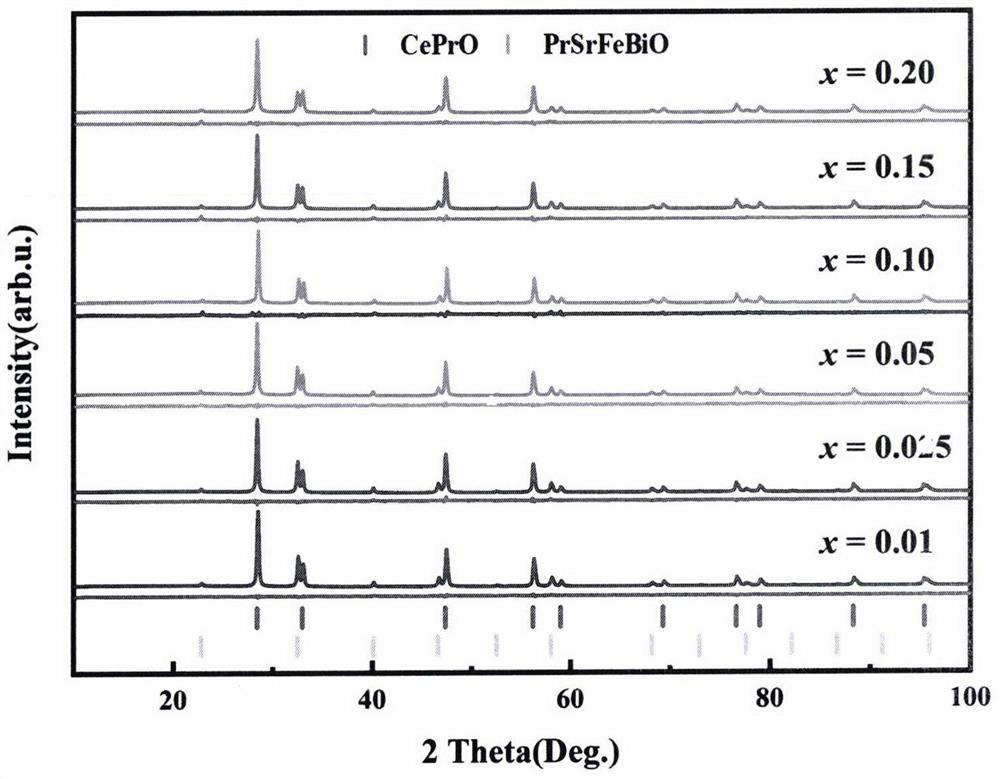

Bismuth-containing biphase mixed conductor oxygen permeation membrane material with carbon dioxide resistance and high stability and preparation method thereof

PendingCN113600024ADense surfaceNo obvious crackSemi-permeable membranesGas treatmentMuffle furnaceChemistry

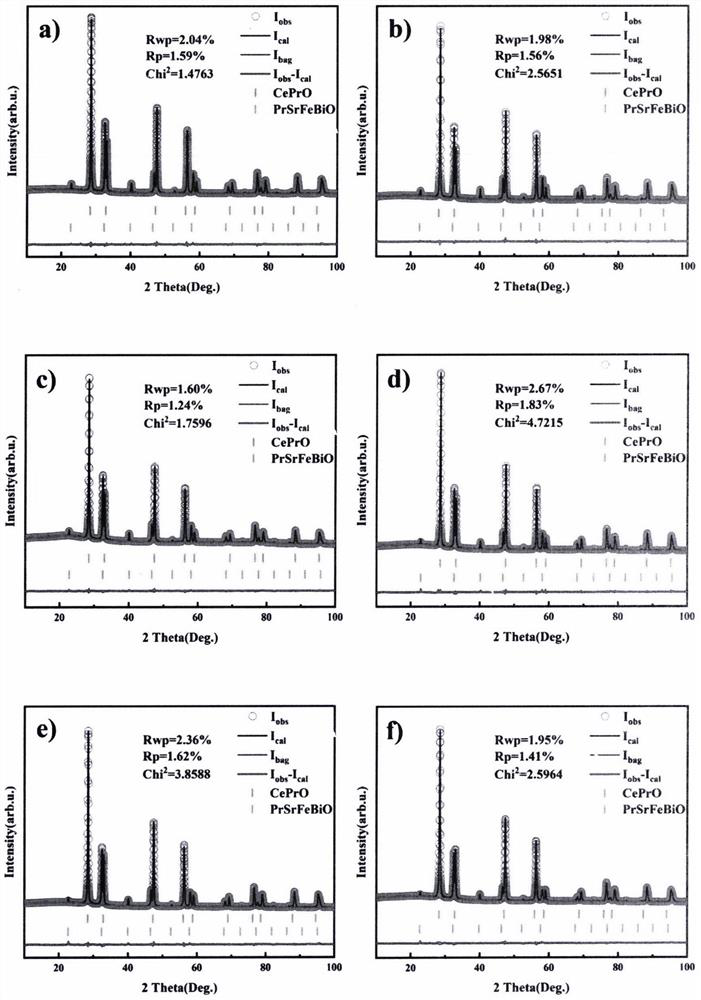

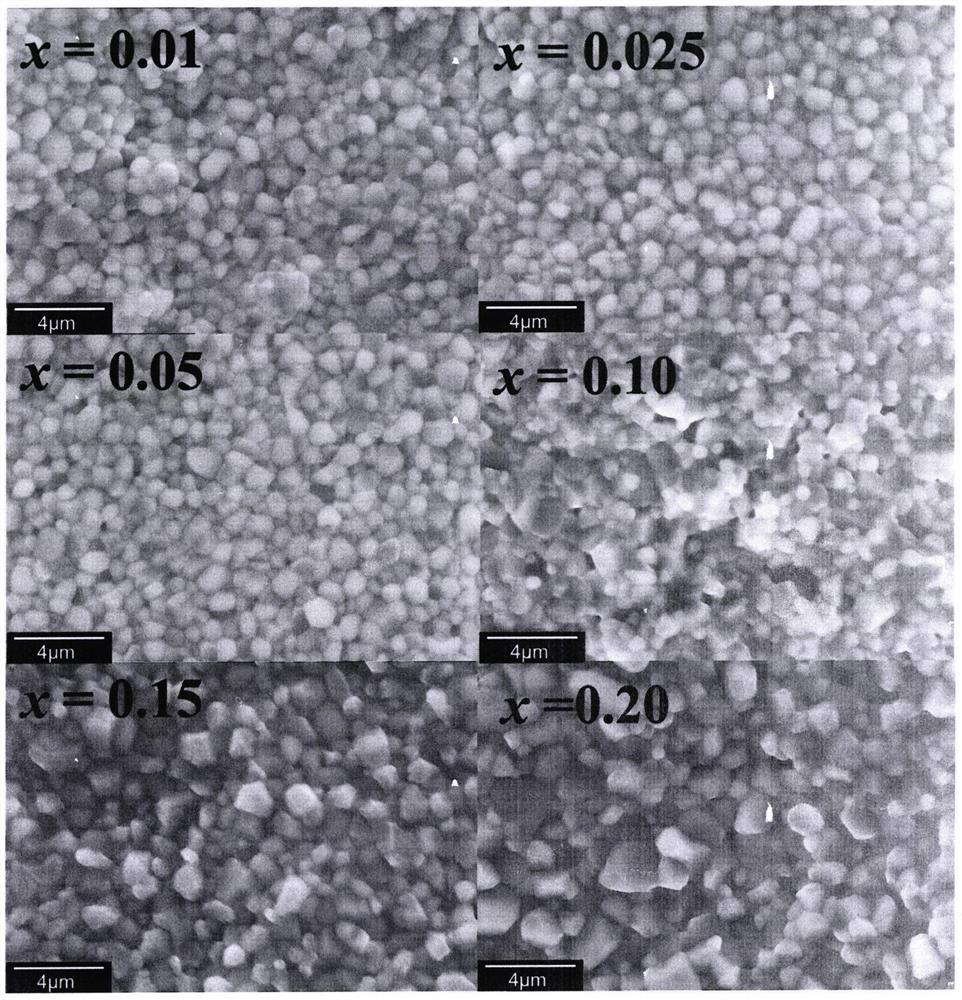

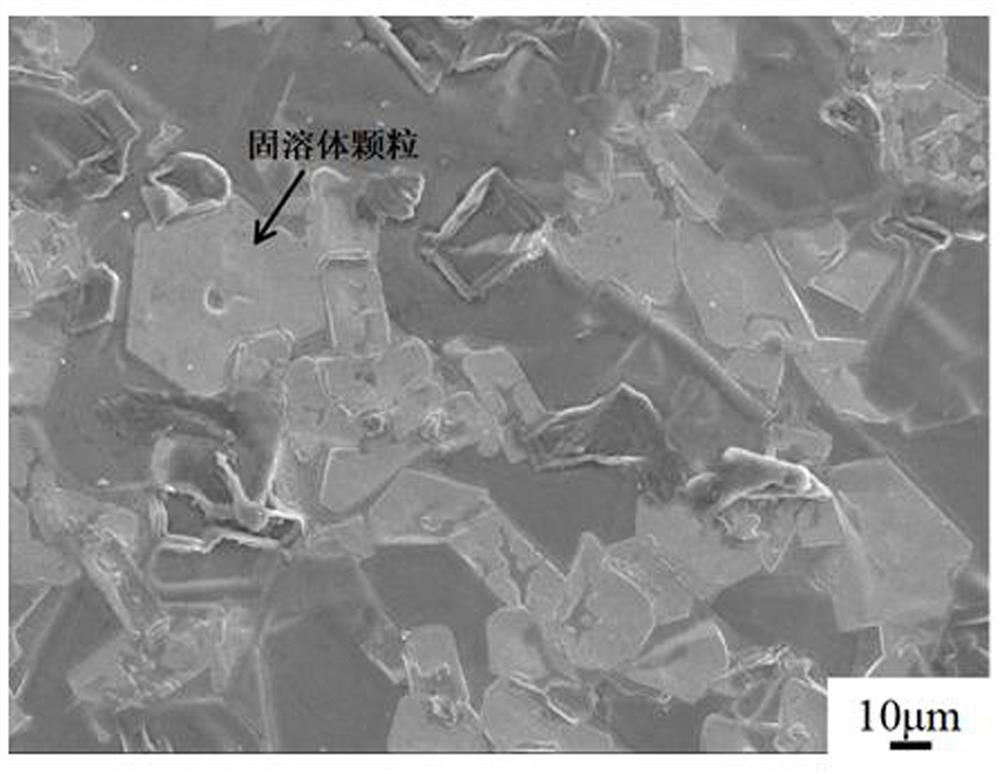

The invention designs and prepares a bismuth-containing biphase mixed conductor oxygen permeation membrane material with carbon dioxide resistance and high stability, and belongs to the technical field of inorganic functional ceramic manufacturing. The general formula of the bismuth-containing biphase mixed conductor oxygen permeation membrane material is Ce[0.9]Pr[0.1]O[2-delta]-Pr[0.6]Sr[0.4]Fe[1-x]Bi[x]O[3-delta] (CPO-PSF[1-x]B[x]O; x is equal to 0.01, 0.025, 0.05, 0.10, 0.15 or 0.20). The preparation method comprises the steps: firstly, preparing powder by a sol-gel one-pot method, calcining the powder in a muffle furnace at the temperature of 950 DEG C for 12 hours to obtain precursor powder, and then tabletting and sintering the precursor powder to obtain the required mixed conductor oxygen permeation membrane. The required bismuth-containing biphase mixed conductor oxygen permeation membrane material is obtained by regulating and controlling the ratio of the Bi element to the Fe element. The prepared oxygen permeation membrane material has good stability under purging of helium / carbon dioxide and other gases, and the oxygen permeation amount loss is small under the carbon dioxide corrosive atmosphere. The material can be used as a novel gas separation material and a carbon capture material to be applied to the high-temperature complex atmosphere oxygen industry, such as the fields of oxygen-enriched combustion, water decomposition, methane coupling and the like.

Owner:SUN YAT SEN UNIV

Carbon material wide-temperature-range anti-oxidation anti-scouring multiphase ceramic coating and preparation method thereof

ActiveCN113735629AAnti-oxidation and anti-scour performance in wide temperature rangeLarge area of protectionCrazingCeramic coating

The invention belongs to the technical field of material protection, and particularly relates to a carbon material wide-temperature-range anti-oxidation anti-scouring composite ceramic coating and a preparation method thereof. The (ZrxHf< 1-x-y >Tay) B2-SiC multiphase ceramic coating with wide-temperature-range anti-oxidation and anti-scouring performance is prepared by adopting a reaction sintering method for the first time, the wide-temperature-range protection range is large, oxidation protection which can reach the high temperature of 800 DEG C and can reach 3000 DEG C or above can be provided, and at present, coatings with the wide-temperature-range protection performance are not reported. The method is low in cost and easy to operate, and the coating is compact in structure, controllable in thickness, high in binding force and excellent in thermal shock resistance. A (ZrxHf < 1-x-y > Tay) B2-SiC coating sample can bear oxidation corrosion for more than 1000 hours at the temperature of 800-1200 DEG C, and no weight loss exists; oxidation protection for more than 1200 hours can be provided in an oxidation environment of 1500 DEG C; ablation protection can be provided for at least 300 seconds under plasma high-temperature flames of 3000 DEG C; and after 50 times of thermal shock cycles at the room temperature of 1500 DEG C, the coating has no obvious cracks.

Owner:沈阳先进涂层材料产业技术研究院有限公司

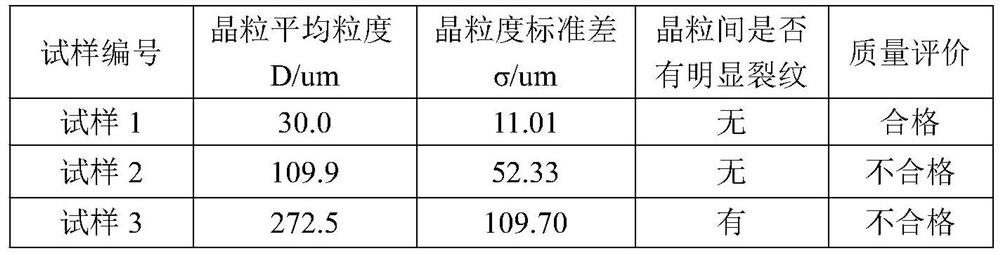

Method for detecting quality of steelmaking auxiliary material dolomite

PendingCN112903689ANot prone to crushing and pulverizationNo obvious crackPreparing sample for investigationOptically investigating flaws/contaminationSteelmakingPhysical chemistry

The invention discloses a method for detecting the quality of steelmaking auxiliary material dolomite. The method mainly solves the technical problem that the quality of existing dolomite cannot be accurately evaluated. The method for detecting the quality of steelmaking auxiliary material dolomite comprises the following steps: 1) preparing a sample, and crushing the weighed dolomite sample until the particle size of the crushed dolomite sample is 5-10mm; (2) taking a sample mineral phase structure picture; (3) detecting the ore phase structure of the sample; 4) judging the quality of the sample when the average grain size of the sample is <50[mu]m, the grain size standard deviation is <20 um, the sample is uniform in crystal grain distribution and free of obvious cracks among crystal grains, the sample being qualified, that is, the dolomite is not crushed or pulverized in the process of being calcined into the light-burned dolomite; otherwise, the sample quality being unqualified. The method is simple in process, easy and convenient to operate and convenient to implement; the detected quality of the limestone is accurate and reliable, and the detection cost is low.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Composite coating layer for eliminating heavy metal chromium and VOCs pollution from source, and preparation method thereof

ActiveCN111218172AEliminate emissionsCompatiblePretreated surfacesAnti-corrosive paintsOrganic compoundMaterials science

The invention discloses a composite coating layer for eliminating chromium and VOCs pollution from the source. The composite coating layer comprises a conversion film layer and a coating surface layer; the conversion film layer is prepared from a surface pretreatment solution, and the surface pretreatment solution comprises: an organic compound A with an aromatic ring and at least two phenolic hydroxyl groups in molecules, or a hydrate thereof; an ionic compound B containing zirconium and / or titanium and fluorine elements; a mixed solution C containing manganese fluoride; and an inorganic saltD containing potassium ions or sodium ions; and the coating surface layer is an FEVE type fluorocarbon powder coating layer. The composite coating layer has excellent impact resistance, weather resistance and chemical reagent resistance, the pollution problem of heavy metal chromium and VOCs is eliminated from the source at the same time, and the composite coating layer is green and environmentally friendly. The invention further discloses a preparation method of the composite coating layer.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

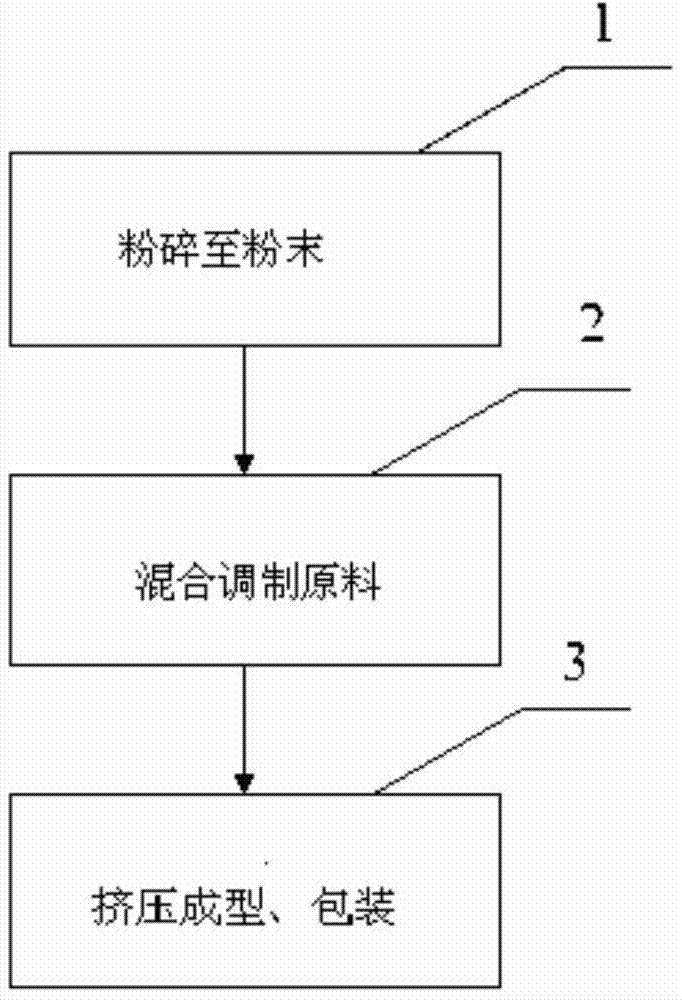

Rice hull fuel forming method

The invention discloses a rice hull fuel forming method. The method includes the steps of (1) pulverizing rice hull into powder; (2) mixing rice hull powder with other debris raw materials; (3) forming a mixture obtained in the last step through solidifying. The rice hull fuel formed through the rice hull fuel forming method can increase the combustion temperature and thermal utilization efficiency and reduce air pollution and is high in combustion speed and time-saving. The rice hull fuel forming method is simple in process, low in cost and easy to use and popularize in cities and towns for forming industrialization.

Owner:JILIN DEYA AGRI DEV GRP

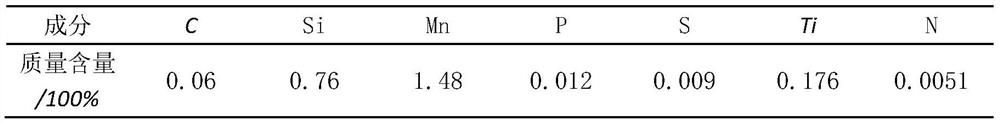

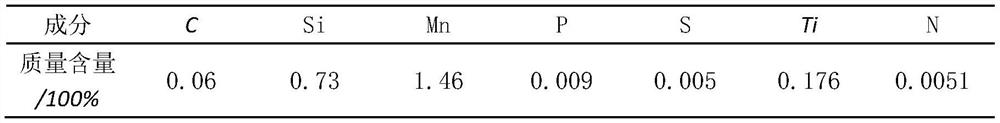

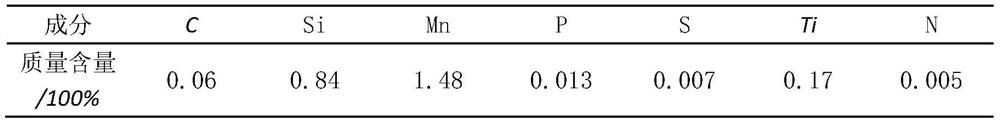

A method for controlling surface cracks of welding wire steel continuous casting slab

ActiveCN110438286BCrack controlPrevent flocculationManufacturing convertersFurnace temperatureRefining (metallurgy)

The invention relates to the technical field of iron and steel metallurgy, in particular to a method for controlling surface cracks of welding wire steel continuous casting slabs. It specifically includes the following key process steps: 1) Pretreatment of molten iron, 2) Converter treatment has two operation modes, 3) Special ferrosilicon 10kg / ton steel is used for the alloy, 8kg / ton steel of low-phosphorus manganese ferroalloy is used with metal manganese, 4) Refining Treatment process: The temperature of the LF furnace is required to be above 1560°C. The LF furnace adjusts the addition of lime and ferro-titanium according to the S and Ti content of the furnace, and raises the temperature to 1580-1600°C at one time, and the basicity of the top slag is controlled at 1.8-2.4 ;5) Ensure that the treatment period is ≥ 30min, and the stirring period is at least 2-3min; 6) After the refining treatment is completed, the machine is poured after weak blowing for 3‑5min; 7) The amount of secondary cooling water is optimized. The shell of the invention effectively controls TiN inclusions, avoids flocculation of molten steel, and controls microcracks on the surface of casting slabs.

Owner:ANGANG STEEL CO LTD

A kind of supersoft coated emery cloth and its manufacturing method

ActiveCN110405645BSmall bending radiusAchieve anti-cloggingAbrasion apparatusAdhesive cementEngineering

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Aluminum alloy powder and preparation method thereof

PendingCN114293078AImprove welding effectImprove mechanical propertiesAdditive manufacturing apparatusSelective laser meltingUltimate tensile strength

The invention provides aluminum alloy powder for selective laser melting forming. The aluminum alloy powder is prepared from, by mass, 3.7%-4.3% of Cu, 0.8%-1.2% of Li, 0.25%-0.8% of Mg, 0.25%-0.6% of Ag, 0.2%-1.0% of Sc, 0.1%-0.5% of Zr and the balance Al and unremovable impurity elements. Part of alloy samples obtained through the method are smooth in surface, free of obvious cracks and high in density, after heat treatment, the tensile strength is 580 MPa, the yield strength is 525 MPa, the ductility is 7%, and the satisfactory comprehensive performance of strength and toughness is achieved. The method has a wide application prospect in the field of aerospace.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

A kind of resin composition and its application

ActiveCN106633646BHigh filler loadingHigh thermal conductivityLamination ancillary operationsLaminationEpoxyPolyvinyl alcohol

Owner:SHAANXI SHENGYI TECH

Preparation Technology of Low Iron and Low Chlorine Activated Carbon

ActiveCN109574006BPromote continuous dissolutionReduce iron and chlorine levelsCarbon compoundsActivated carbonIron removal

The application discloses a preparation process of low-iron and low-chlorine activated carbon. The preparation process of the low-iron and low-chlorine activated carbon, its specific steps are as follows: (1), selection of raw materials; (2), pickling; (3), one-time rinsing; (4), removal of impurity ions; (5), two (6) drying; (7) secondary iron removal. The low-iron and low-chlorine activated carbon prepared by the low-iron and low-chlorine activated carbon has high strength, strong adsorption capacity, large adsorption capacity, less ash content, fast adsorption rate, no obvious cracks on the surface, and the manufactured products are extremely durable in water. Low iron and chlorine precipitation can be widely used in the field of electronics, as activated carbon for reuse water treatment.

Owner:JIANGSU PURESTAR EP TECH CO LTD

A method for uniform distribution of PTFE binder and electrode key component materials and its application in the battery industry

ActiveCN109935843BEvenly distributedIncrease profitElectrode manufacturing processesElectrical batteryActive agent

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Straw pelleting process

InactiveCN102764611BSimple granulation processHigh densityAnimal feeding stuffGranulation by pressingCompression moldingFiber

The invention belongs to the field of processing and application of straw and particularly relates to a straw pelleting process. The process mainly comprises the steps of 1), performing coarse grinding and feeding the ground straw into an ensiling pool to perform ensiling fermentation treatment; 2), drying to obtain ground straw with the water content of 9-15%; 3), performing fine grinding to obtain straw fiber with the particle size of 40-50 meshes per square inch and placing the straw fiber into a storage bin for storage through an air-assisted dust removal system; 4), pelleting, conveying the straw fiber to a ring die pelleting machine and performing compression molding by using a ring die and a compression roller to obtain rodlike straw particles with the density of 1-1.2g / cm3; and 5), performing cooling molding, placing the compressed straw particles into a cooler and cooling the straw particles to the room temperature through air cooling to obtain formed particles with smooth surfaces. According to the process, the straw is used fully, the pelleting effect is good, and the formed straw particles are smooth in surface and free from obvious cracks, are clean energy, can be used as base materials for culture of fungi or supplementary feed of livestocks and are convenient to popularize and apply in a large scale.

Owner:ZIBO SENYUAN STRAW ENERGY DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com