Preparation technology of bamboo columnar carbon with ultrahigh performance

A technology with ultra-high performance and preparation technology, which is applied in the fields of alkali metal oxides/hydroxides, inorganic chemistry, water/sludge/sewage treatment, etc. It can solve the problem that special adsorbents do not have adsorption capacity and the product quality is not very good. Good, limited adsorption capacity and other problems, to achieve the effect of fast desorption rate, fast adsorption rate and less ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

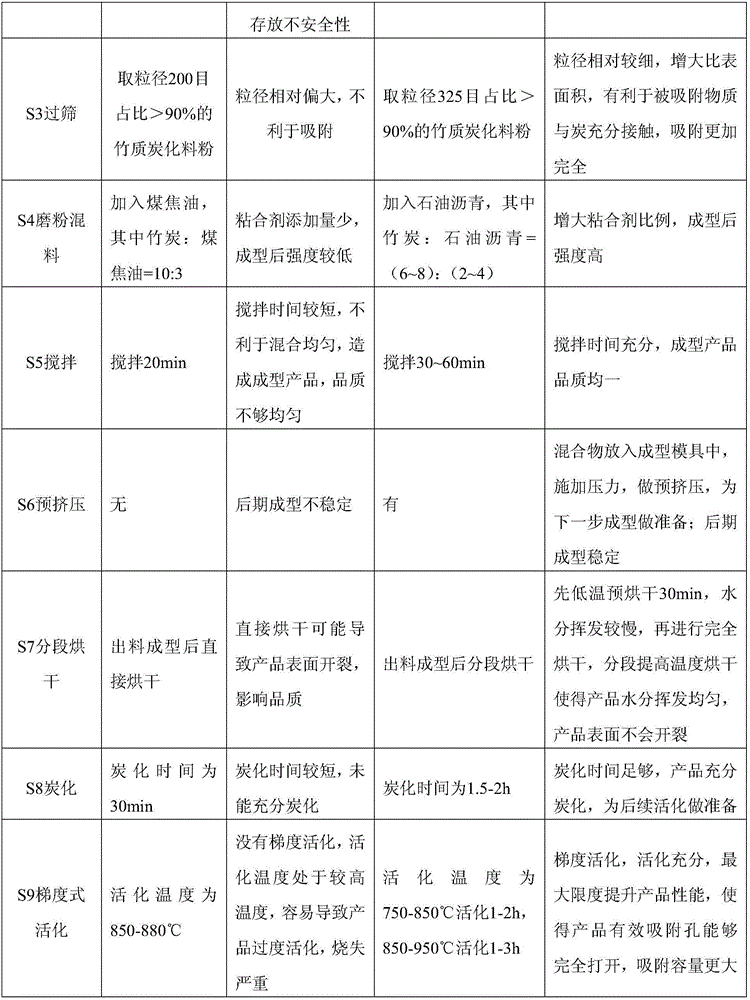

[0027] The preparation technology of a kind of ultra-high performance bamboo charcoal columnar charcoal of the present embodiment, its step comprises:

[0028] S1) Selection of raw materials: select high-quality bamboo carbonized materials as raw materials;

[0029] S2) Grinding: using a sealed sample preparation grinder to grind the bamboo carbonized material to obtain bamboo carbonized material powder;

[0030] S3) sieving: sieve the ground bamboo carbonized material through a 325-mesh sieve, and take bamboo carbonized material powder below 325 mesh as one of the raw materials;

[0031] S4) Grinding mix: get a small amount of petroleum asphalt and add it to the bamboo carbonized material powder below 325 meshes to carry out grinding and mixing treatment to obtain the first mixture, the ratio of petroleum pitch to the bamboo carbonized material powder below 325 meshes in the first mixture is ( 6~8): (2~4), the mixing time is 30~60min, and the temperature during mixing is 25~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com