Flexible dye sensitized solar energy cell photoanode preparation method and apparatus

A technology of solar cells and dye sensitization, which is applied in the field of photoanode preparation of dye-sensitized solar cells, can solve the problems of random distribution of surface density, poor reproducibility, and easy cracking of semiconductor thin films, and achieve universal applicability and good uniformity , The effect of saving production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

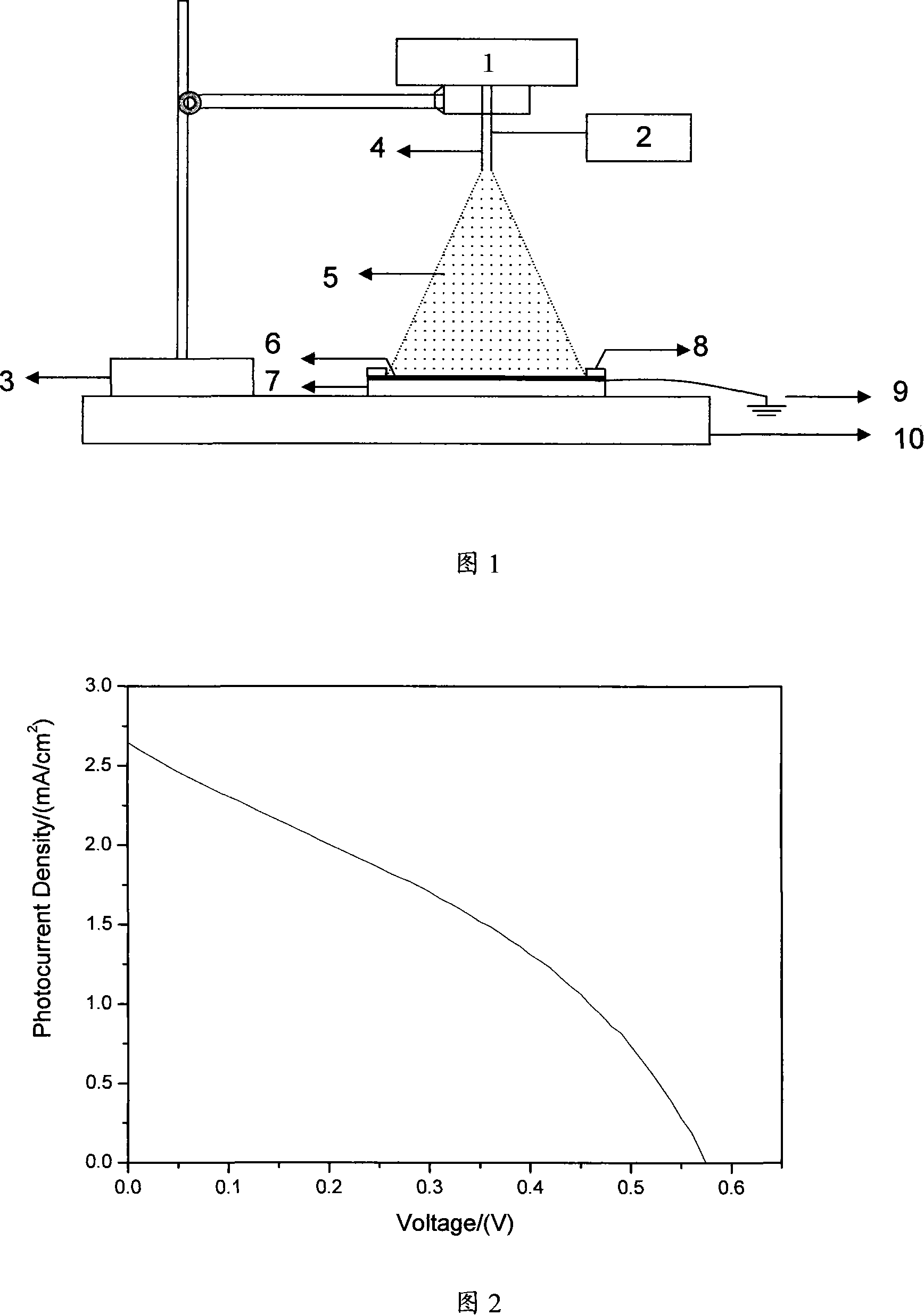

Image

Examples

Embodiment 1

[0037] Embodiment 1: a. Use flexible conductive polymer film ITO / PET as the photoanode electrode material, the substrate thickness is 100um, the visible light transmittance is 75%, and the surface sheet resistance is 14Ω / μm.

[0038] b. Clean the substrate. Drop a few drops of detergent in deionized water, rinse the substrate in it for a few minutes, rinse with deionized water, then soak in KOH isopropanol saturated solution for 2 hours, rinse with deionized water, and then rinse in deionized water Clean with ultrasonic vibration in water and absolute ethanol for 10 minutes, rinse with absolute ethanol and blow dry with nitrogen.

[0039] c. According to actual needs, the place on the substrate that does not need to be sprayed is encapsulated with insulating tape, and the shape of the photoanode is controlled by adjusting the geometry and size of the encapsulation area to manufacture photoanodes that meet the needs of different places, even on non-planar surfaces Photoanodes ...

Embodiment 2

[0044] Example 2: a. Use flexible conductive polymer film ITO / PET as the photoanode electrode material, the substrate thickness is 125um, the visible light transmittance is 80%, and the surface sheet resistance is 100Ω / □.

[0045] b. Clean the substrate. Drop a few drops of detergent in deionized water, rinse the substrate in it for a few minutes, rinse with deionized water, then soak in KOH isopropanol saturated solution for 2 hours, rinse with deionized water, and then rinse in deionized water Clean with ultrasonic vibration in water and absolute ethanol for 10 minutes, rinse with absolute ethanol and blow dry with nitrogen.

[0046] c. According to actual needs, the place on the substrate that does not need to be sprayed is encapsulated with insulating tape, and the shape of the photoanode is controlled by adjusting the geometry and size of the encapsulation area to manufacture photoanodes that meet the needs of different places, even on non-planar surfaces Photoanodes wit...

Embodiment 3

[0051] Example 3: a. Use flexible conductive polymer film ITO / PET as the photoanode electrode material, the substrate thickness is 200um, the visible light transmittance is 85%, and the surface sheet resistance is 14Ω / □.

[0052] b. Clean the substrate. Drop a few drops of detergent in deionized water, rinse the substrate in it for a few minutes, rinse with deionized water, then soak in KOH isopropanol saturated solution for 2 hours, rinse with deionized water, and then rinse in deionized water Clean with ultrasonic vibration in water and absolute ethanol for 10 minutes, rinse with absolute ethanol and blow dry with nitrogen.

[0053] c. According to actual needs, the place on the substrate that does not need to be sprayed is encapsulated with insulating tape, and the shape of the photoanode is controlled by adjusting the geometry and size of the encapsulation area to manufacture photoanodes that meet the needs of different places, even on non-planar surfaces Photoanodes with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com