Method for uniform distribution of PTFE (polytetrafluoroethylene) binder and electrode key component materials and application in battery industry

A PTFE, PTFE-based technology, applied in the uniform distribution of PTFE binder and electrode key component materials and the application field in the battery industry, can solve the problems of affecting the electrode coating quality, uneven mixing distribution, poor dispersion effect, etc. , to achieve the effects of improving discharge performance and operation stability, improving dispersion effect, and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

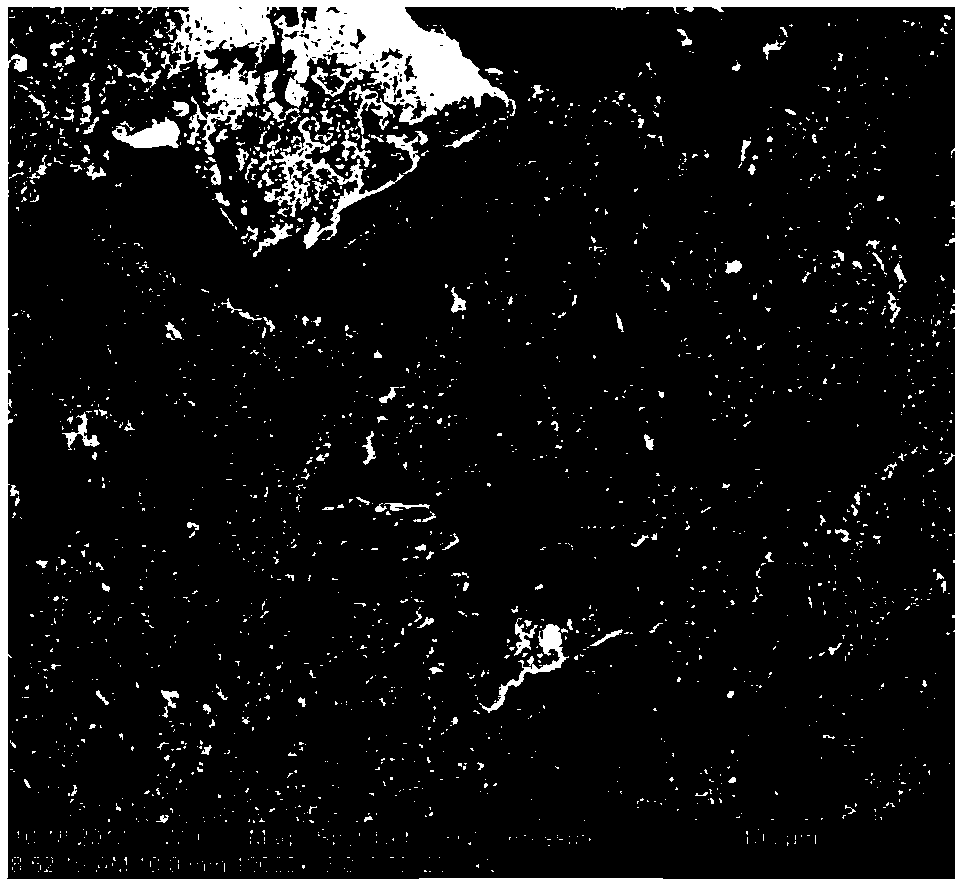

Embodiment 1

[0042] Take by weighing PTFE emulsion (mass concentration is 60wt%), MnO respectively by 2:4:4 mass ratio 2 A total of 20 grams of powder and conductive carbon black, then put 60wt% PTFE emulsion in a 1L beaker, add 0.7L deionized water to make the mass concentration of PTFE 1%, fully stir and disperse evenly, then heat up to 50°C for later use. This is solution 1; the MnO 2 The powder and conductive carbon black are fully ground (it can be ground into powder, and the particle size of the powder is not particularly limited), after mixing evenly, add 0.7L aqueous solution containing 10mM / L sodium dodecylsulfonate, fully stir and disperse After uniformity, heat up to 50°C for later use. This is solution 2; while maintaining high-speed stirring, quickly add solution 1 to solution 2 within 1 minute, keep the reaction temperature constant, and stir at 600 rpm. After reacting for 2 hours, let it stand to cool down, remove the supernatant, filter the ternary compound at the bottom t...

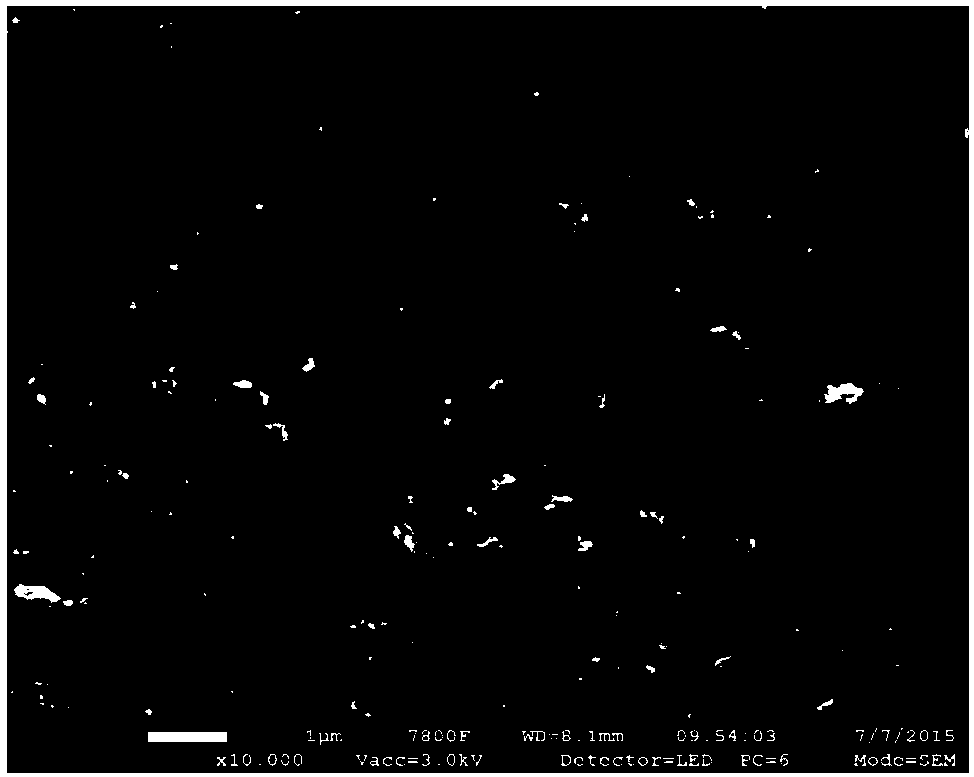

Embodiment 2

[0044] Take by weighing PTFE emulsion (mass concentration is 60wt%), MnO 2 A total of 20 grams of powder and conductive carbon black, then put 60wt% PTFE emulsion in a 1L beaker, add 0.7L deionized water to make the mass concentration of PTFE 0.5%, fully stir and disperse evenly, then heat up to 80°C for later use. This is solution 1; the MnO 2 After the powder and conductive carbon black are fully ground and mixed evenly, add 0.7L aqueous solution containing 10mM / L sorbitan laurate, fully stir and disperse evenly, then heat up to 80°C for later use, this is solution 2; keep stirring at a high speed Next, solution 1 was quickly added to solution 2 within 10 minutes, keeping the reaction temperature constant, and the stirring speed was 600 rpm. After reacting for 2 hours, let it stand to cool down, remove the supernatant, filter the ternary compound at the bottom to remove excess liquid, then add a mixed solvent of 5mL water and 15mL ethanol, and after ultrasonic dispersion is...

Embodiment 3

[0046] Take by weighing 20 grams of PTFE emulsion (mass concentration is 60wt%), Pt black and conductive carbon black respectively by 2:4:4 mass ratio, then the PTFE emulsion of 60wt% is placed in the beaker of 1L, add 0.7L to Ionized water makes the mass concentration of PTFE 0.5%. After fully stirring and dispersing, heat up to 70°C for later use. This is solution 1; after fully grinding and mixing Pt black and conductive carbon black, add 0.7L containing 10mM / L lauric acid For the aqueous solution of sorbitan ester, stir well and disperse evenly, then heat up to 70°C for later use. This is solution 2; while maintaining high-speed stirring, quickly add solution 1 to solution 2 within 10 minutes, keep the reaction temperature unchanged, and stir The speed is 700 rpm. After reacting for 2 hours, let it stand to cool down, remove the supernatant, filter the ternary compound at the bottom to remove excess liquid, then add a mixed solvent of 100mL water and 100mL ethanol, and aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com