Patents

Literature

78 results about "Bi element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Al-Zn-Mg-Si alloy for hot dipping steel

InactiveCN101457320AAvoid gatheringDeterioration of surface propertiesHot-dipping/immersion processesRare earthZinc alloys

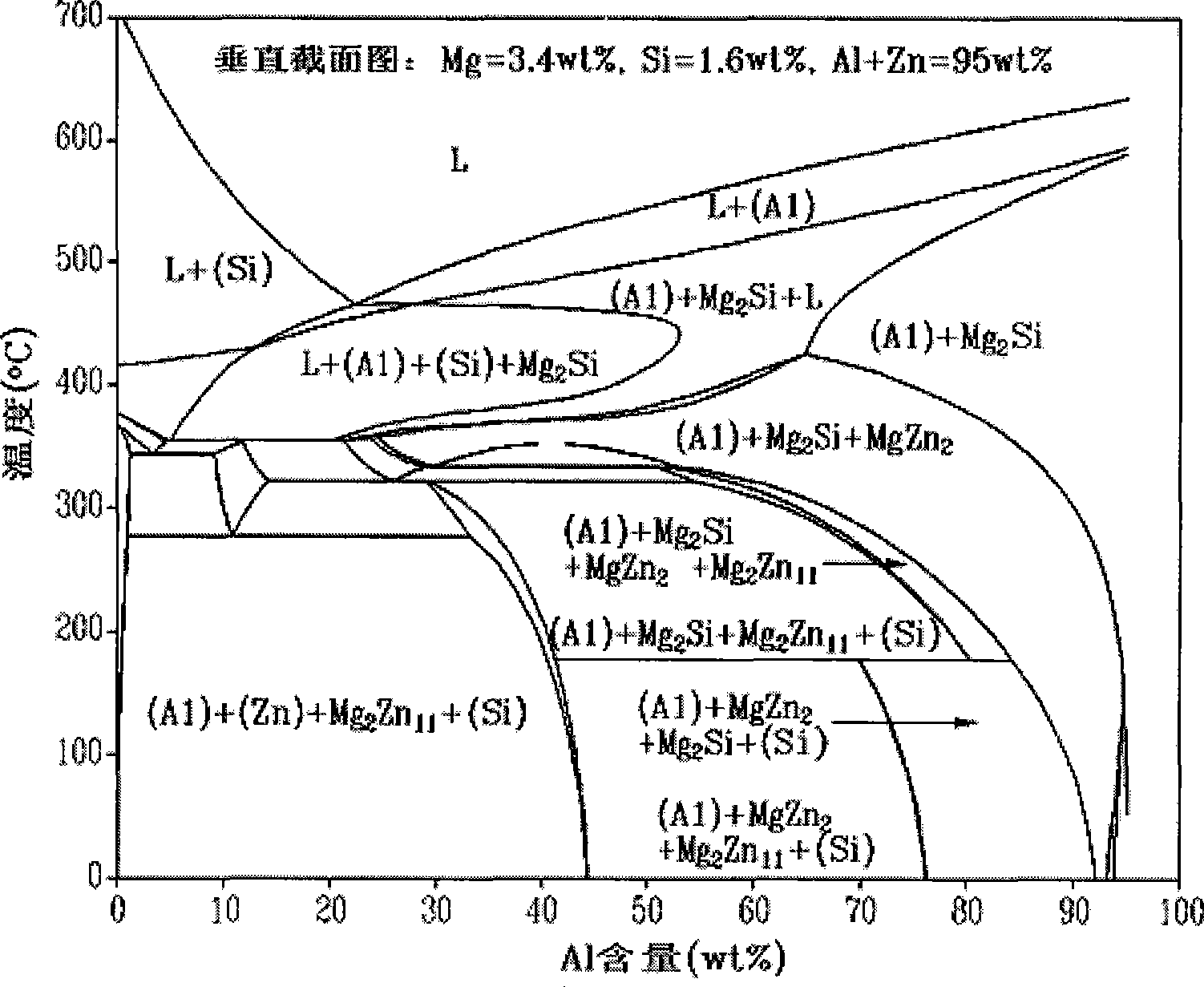

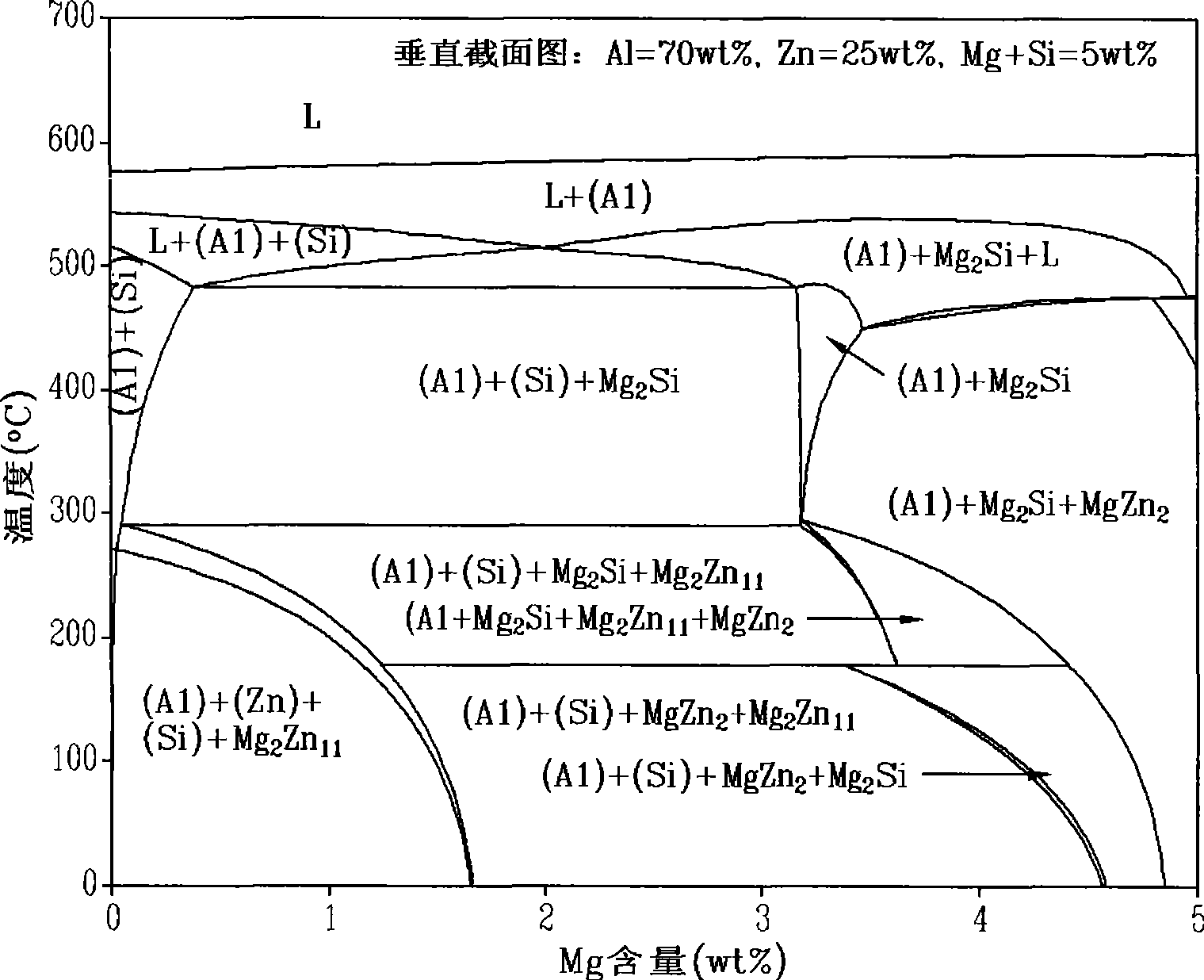

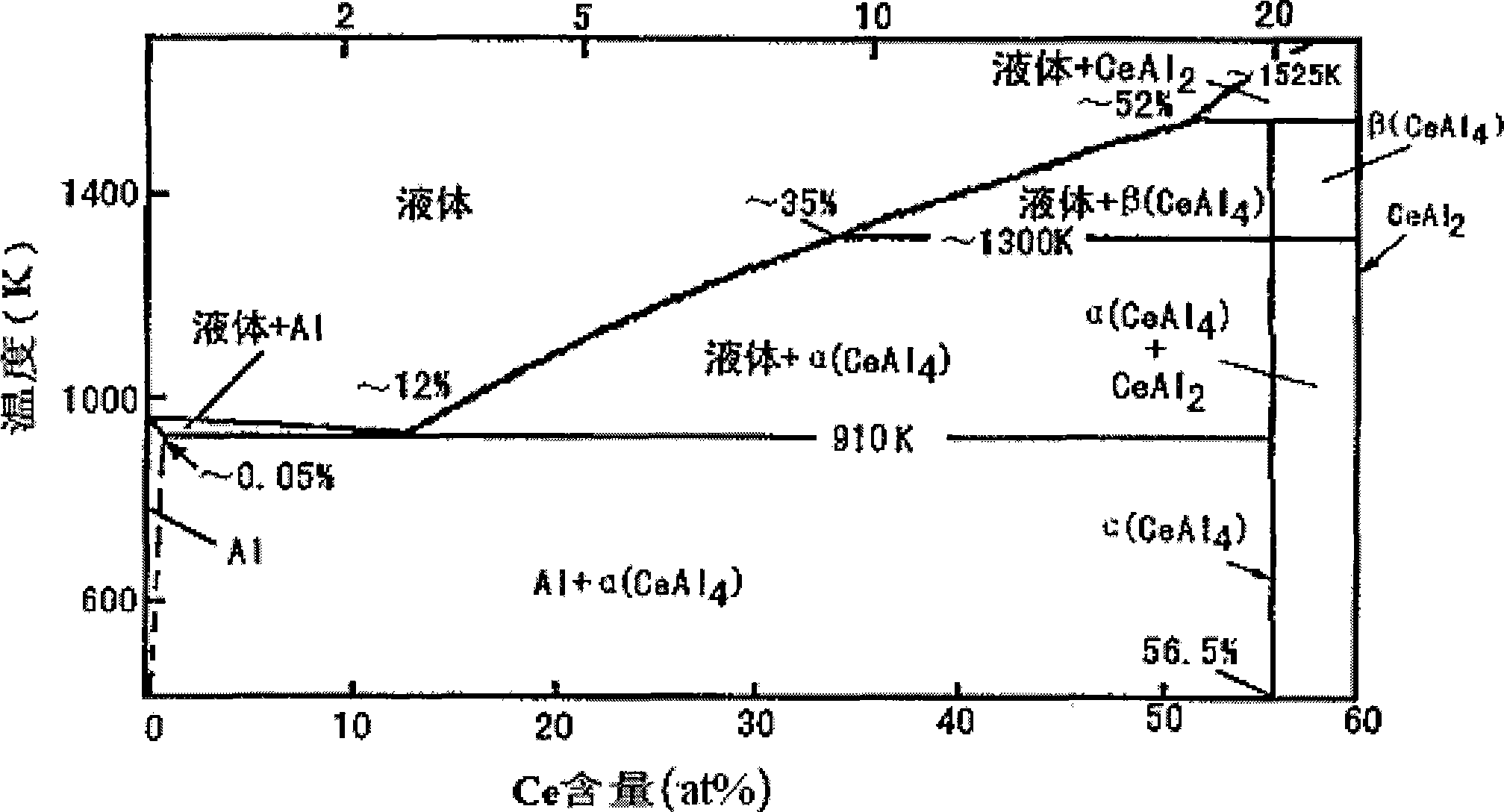

The invention provides a rare earth-containing Al-Zn-Mg-Si alloy with high aluminum content for hot-dipping steel products, comprising the following compositions by weight percent as follows; Al: 50-75%, Mg: 1-5%, Si: 0.5-2.5%, the addition of 0.002-0.1% of Ti, 0.001-0.045% of B and 0.05-1% of rare earth (La or Ce), and the balance of Zn and unavoidable impurities. The invention utilizes corrosion resistance of Mg2Si and grain-refining effect of the rare earth, the Ti and the Bi elements to improve quality of plating solution and obtain a high aluminum content aluminum-zinc alloy cladding with ,a bright and smooth surface and great corrosion resistance property. In addition, the content of aluminum in the alloy is up to 50-75%, thereby lowering production cost.

Owner:SHANGHAI UNIV

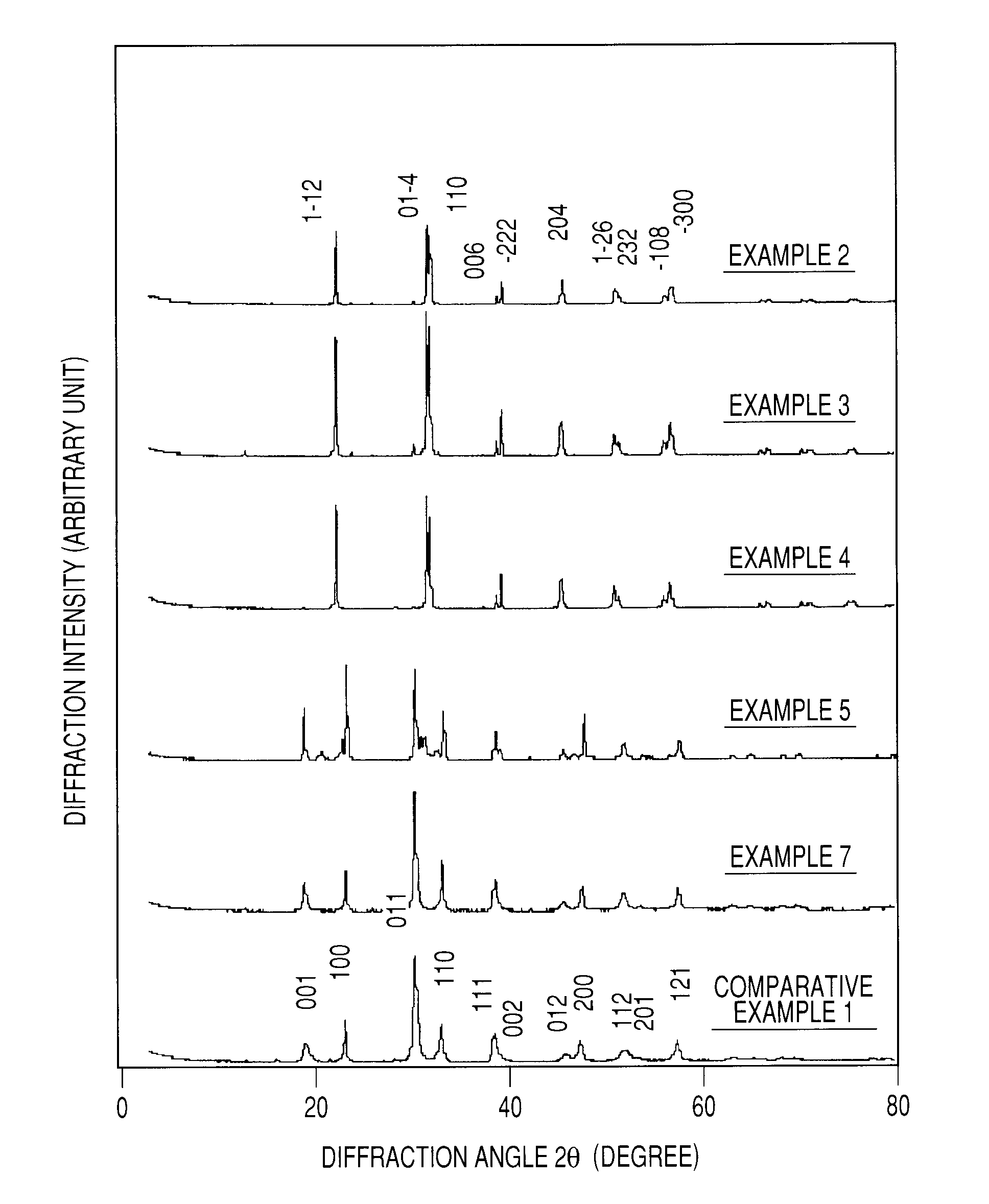

Magnetic material, magnet, and rotating machine

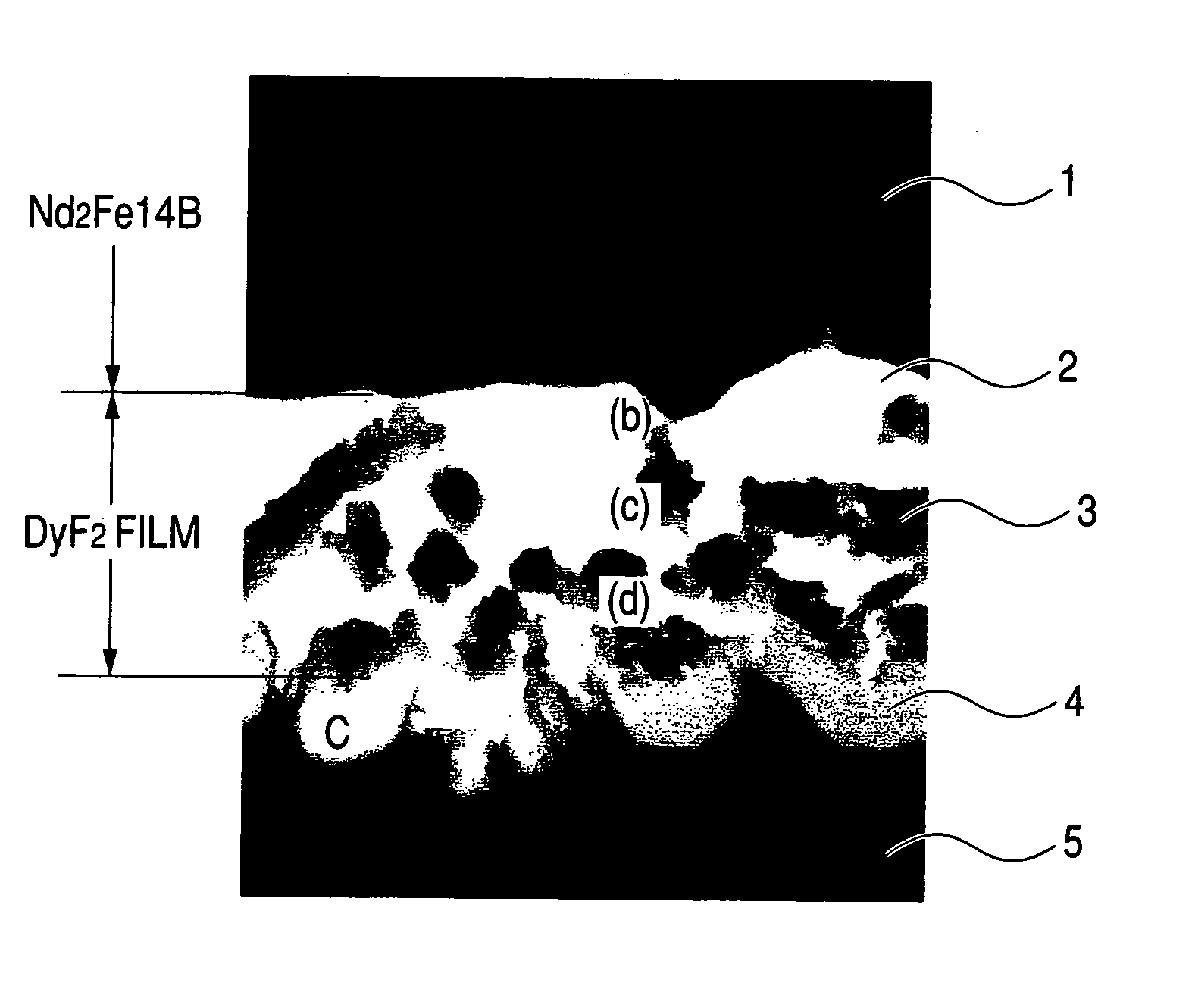

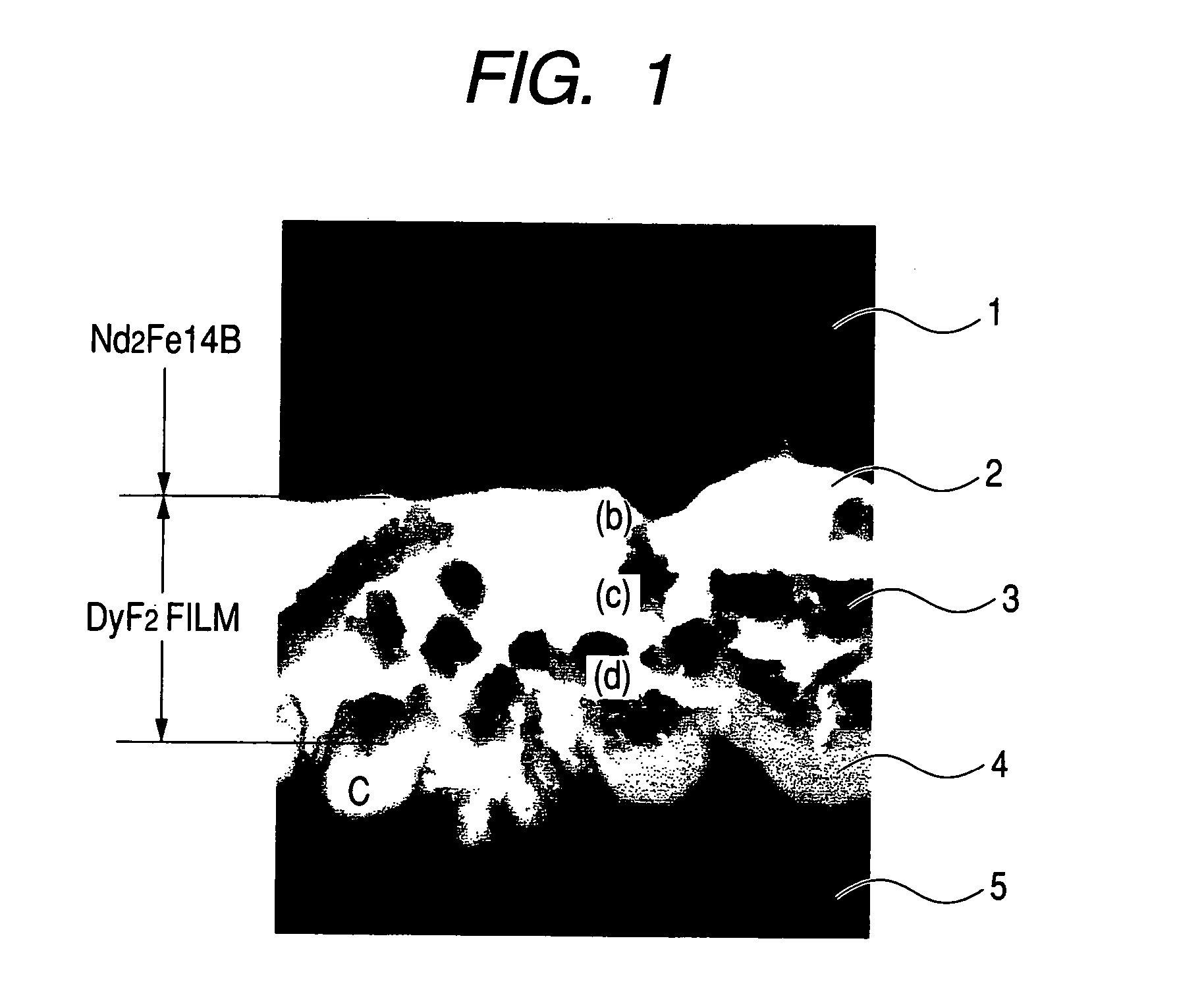

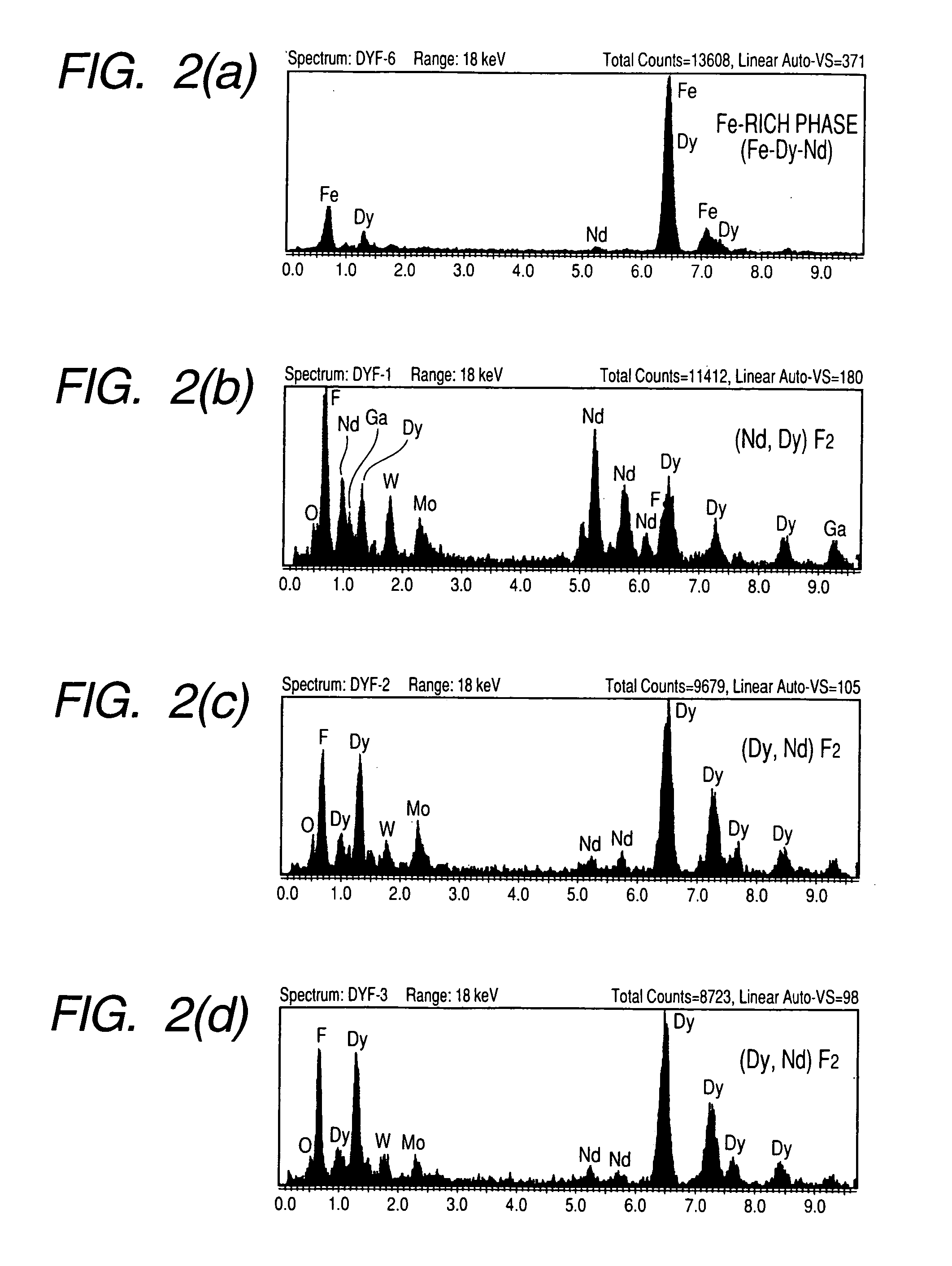

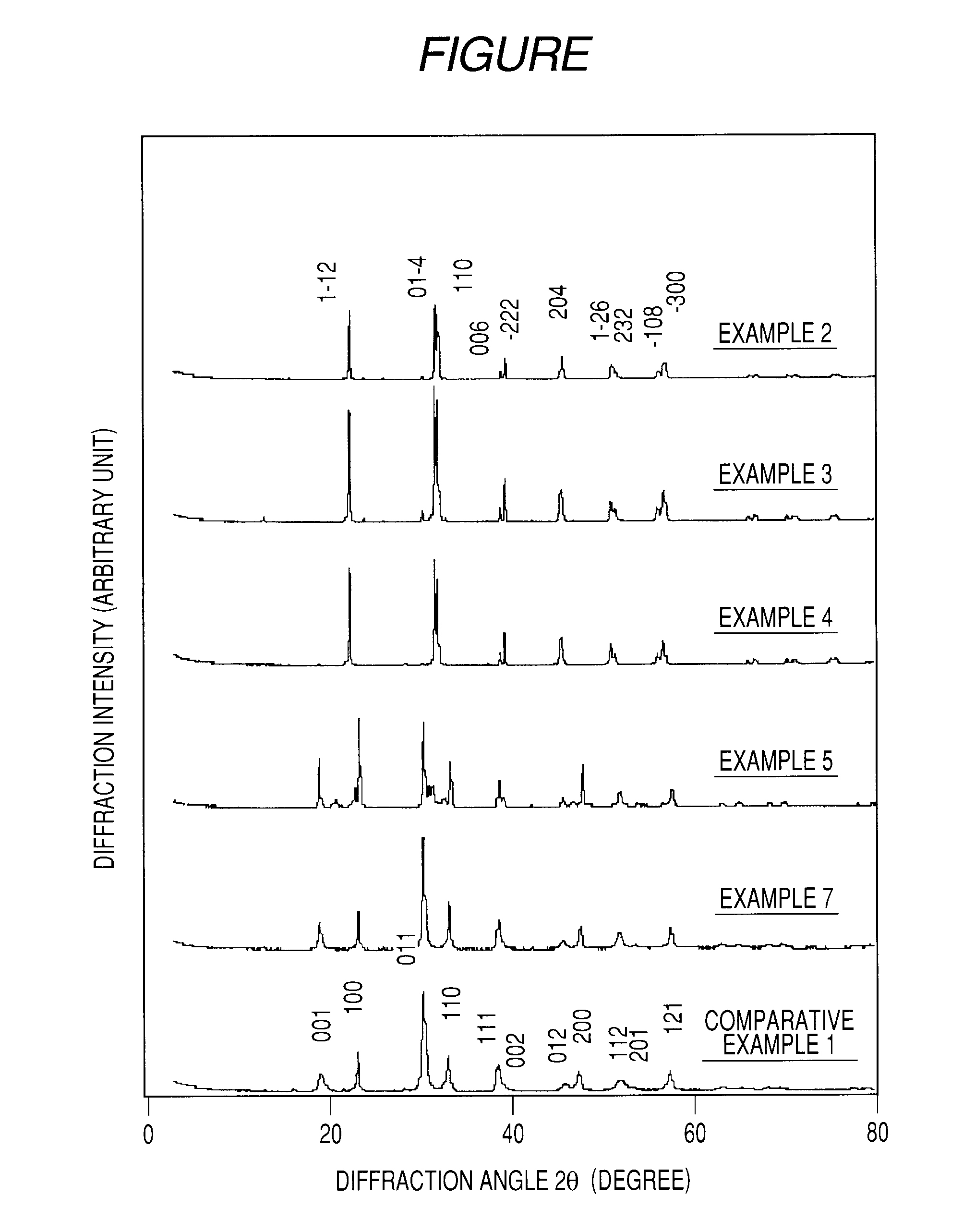

InactiveUS20070071979A1Residual magnetic flux density decreaseHigh energySynthetic resin layered productsMetal-working apparatusRare-earth elementBi element

A magnetic material is including magnetic particles including a rare earth element, wherein a fluorine compound including an alkaline earth element or a rare earth element is formed on a surface of the magnetic particles, an oxygen concentration of the fluorine compound is higher than an oxygen concentration of the magnetic particle and the fluorine compound includes at least one type of element selected from the group consisting of the Li, Mg, Ca, Sc, V, Cr, Mn, Fe, Co, Ni, Zn, Al, Ga, Sr, Y, Zr, Nb, Ag, In, Sn, Ba, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Pb, and Bi elements.

Owner:HITACHI LTD

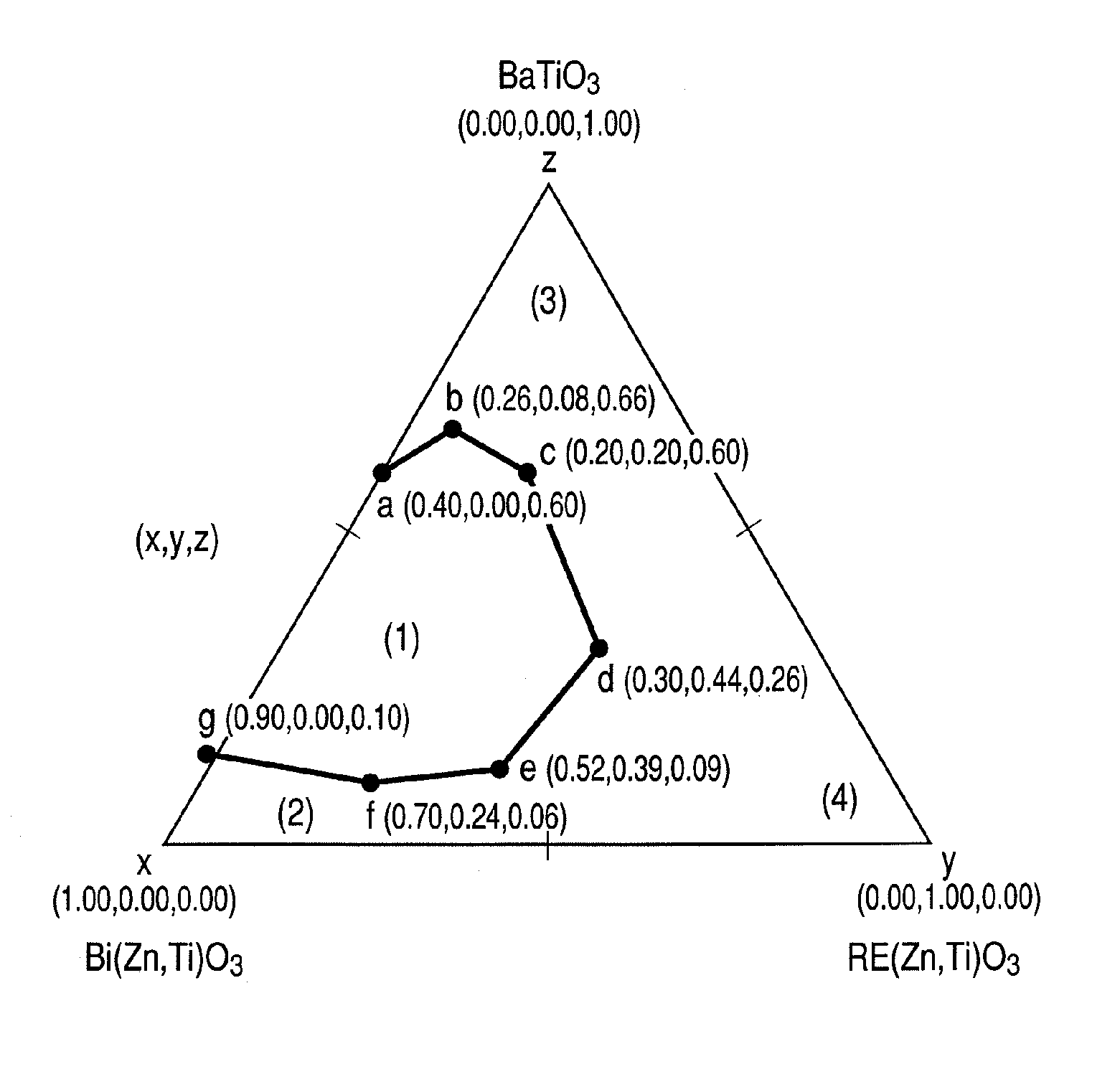

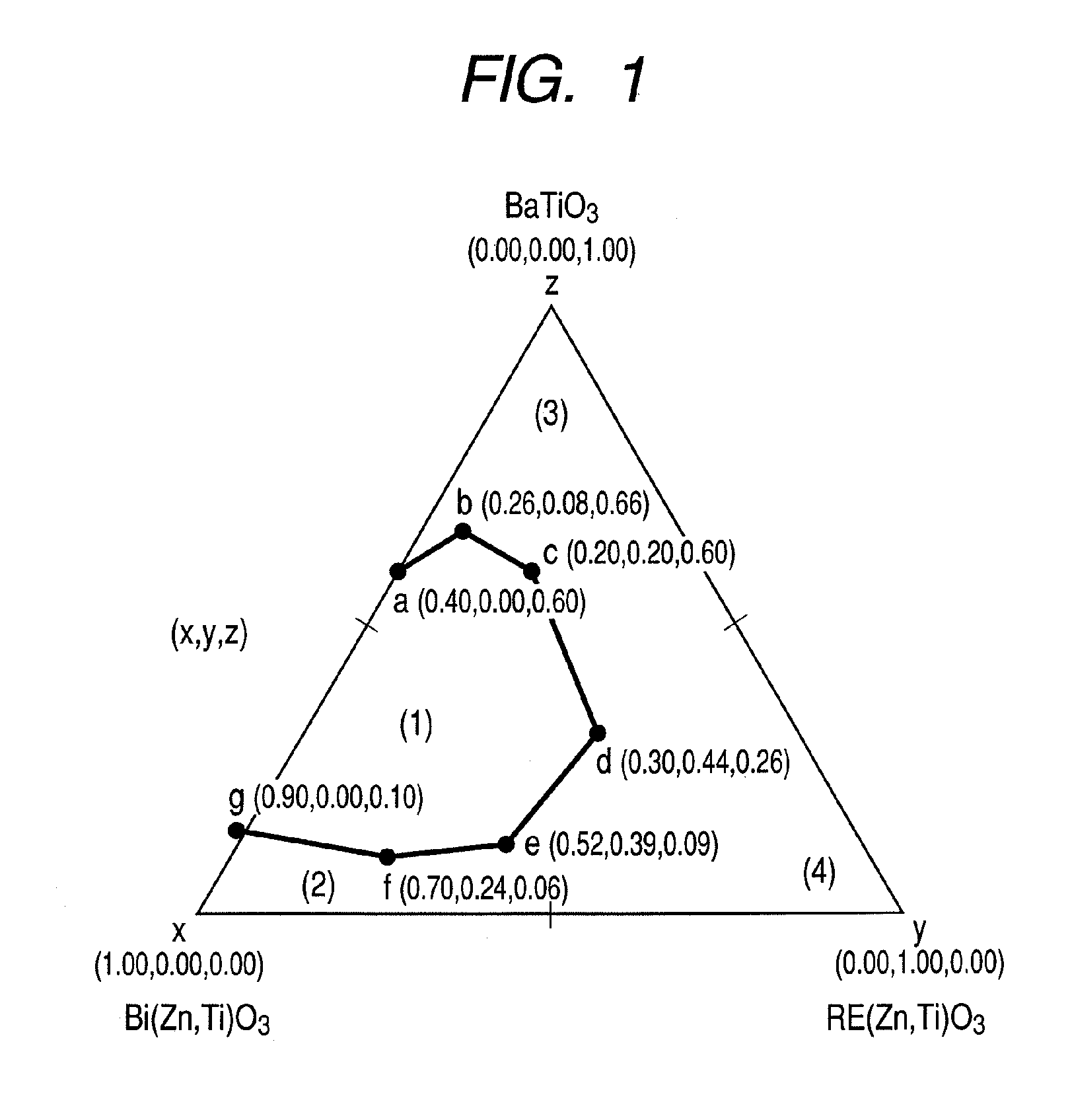

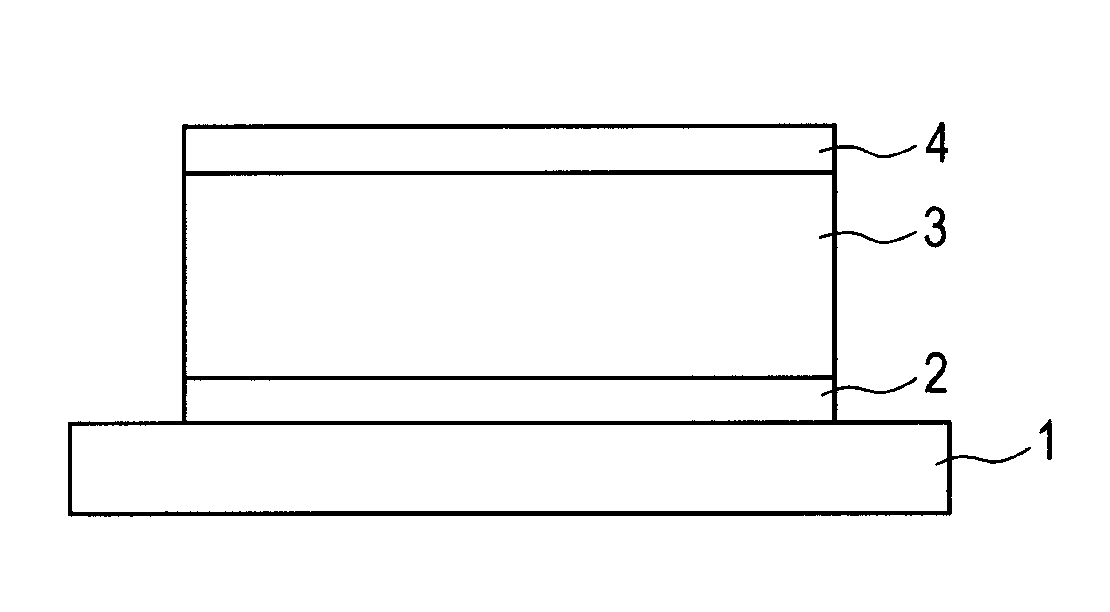

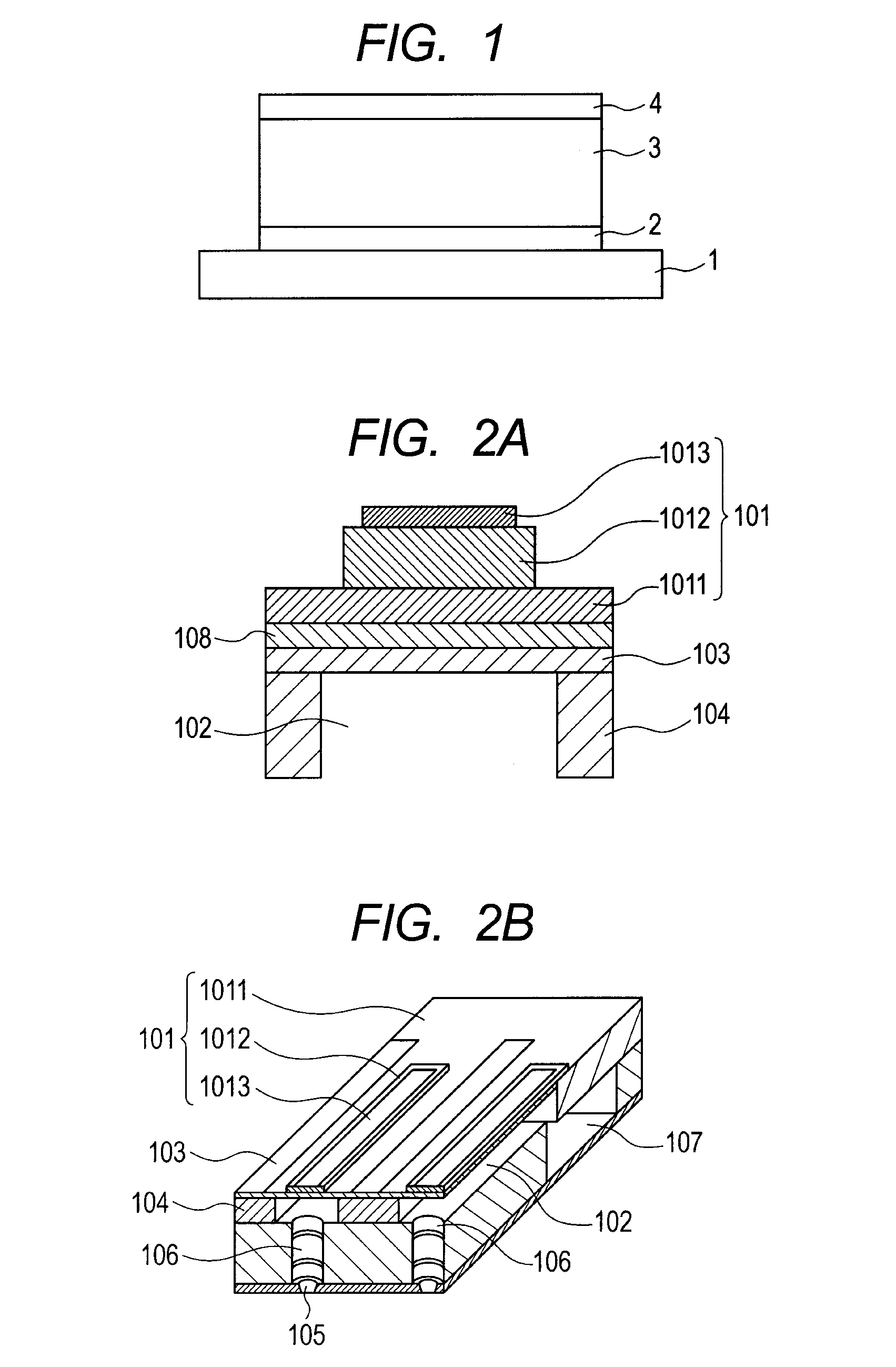

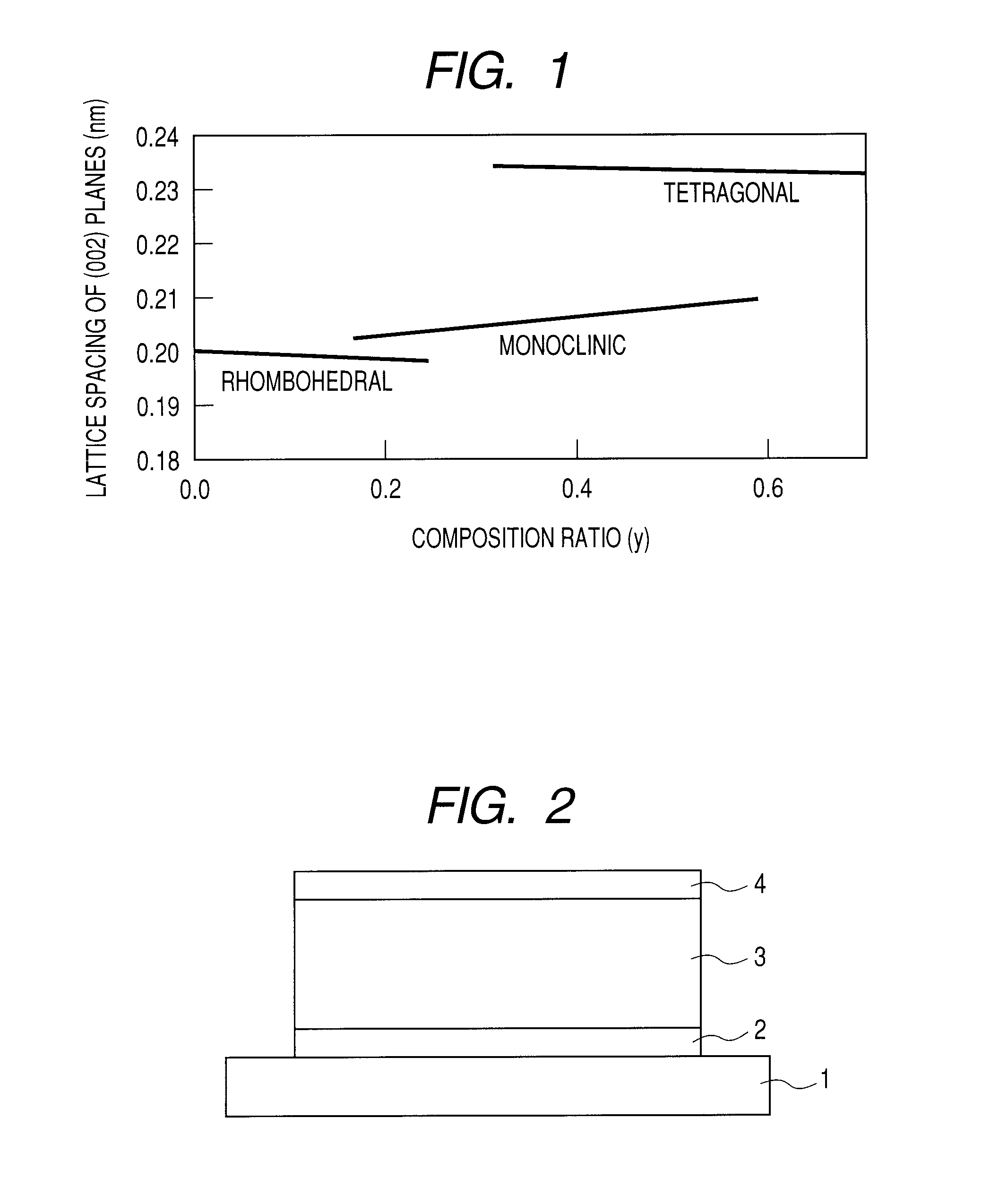

Metal oxide

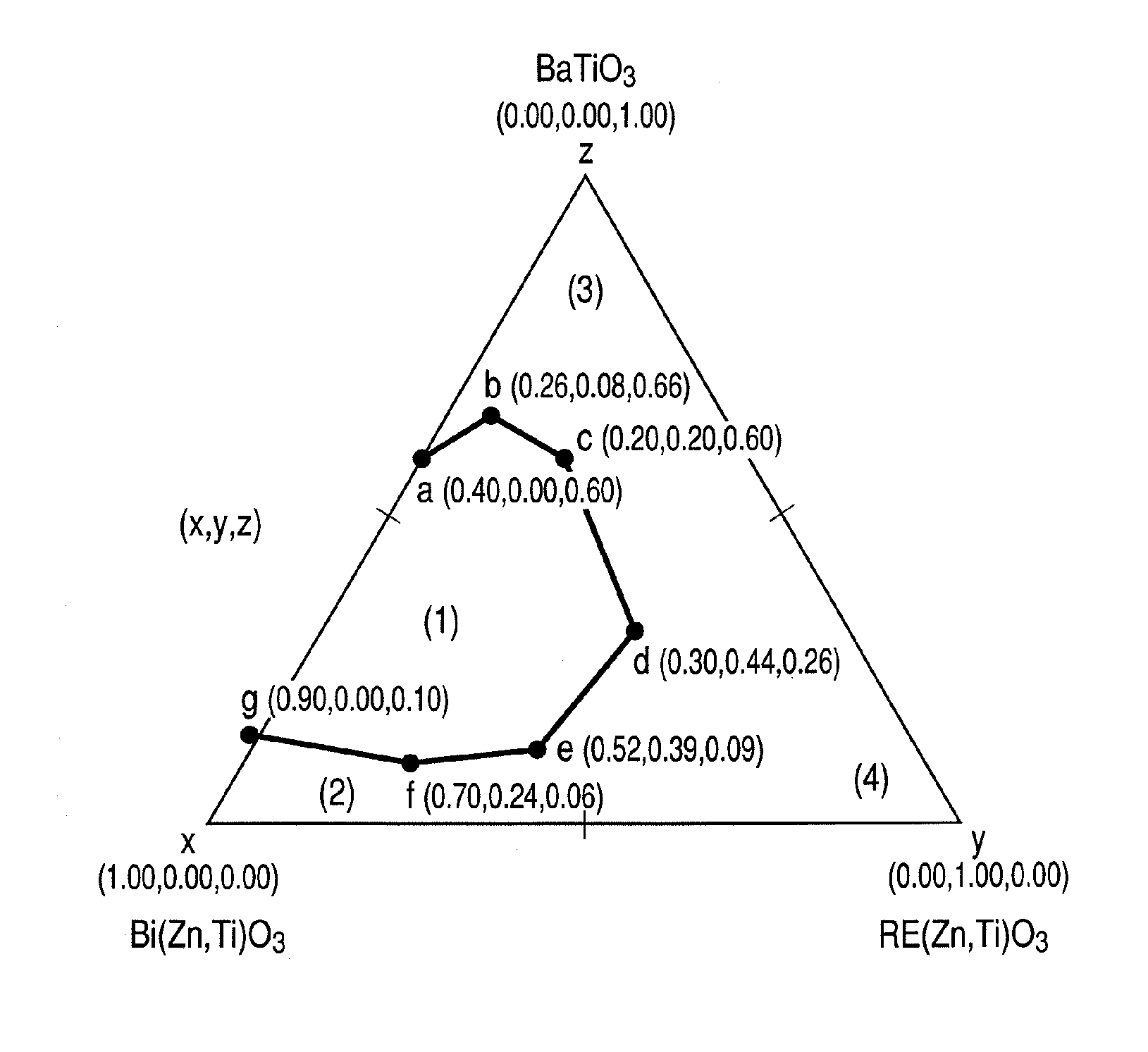

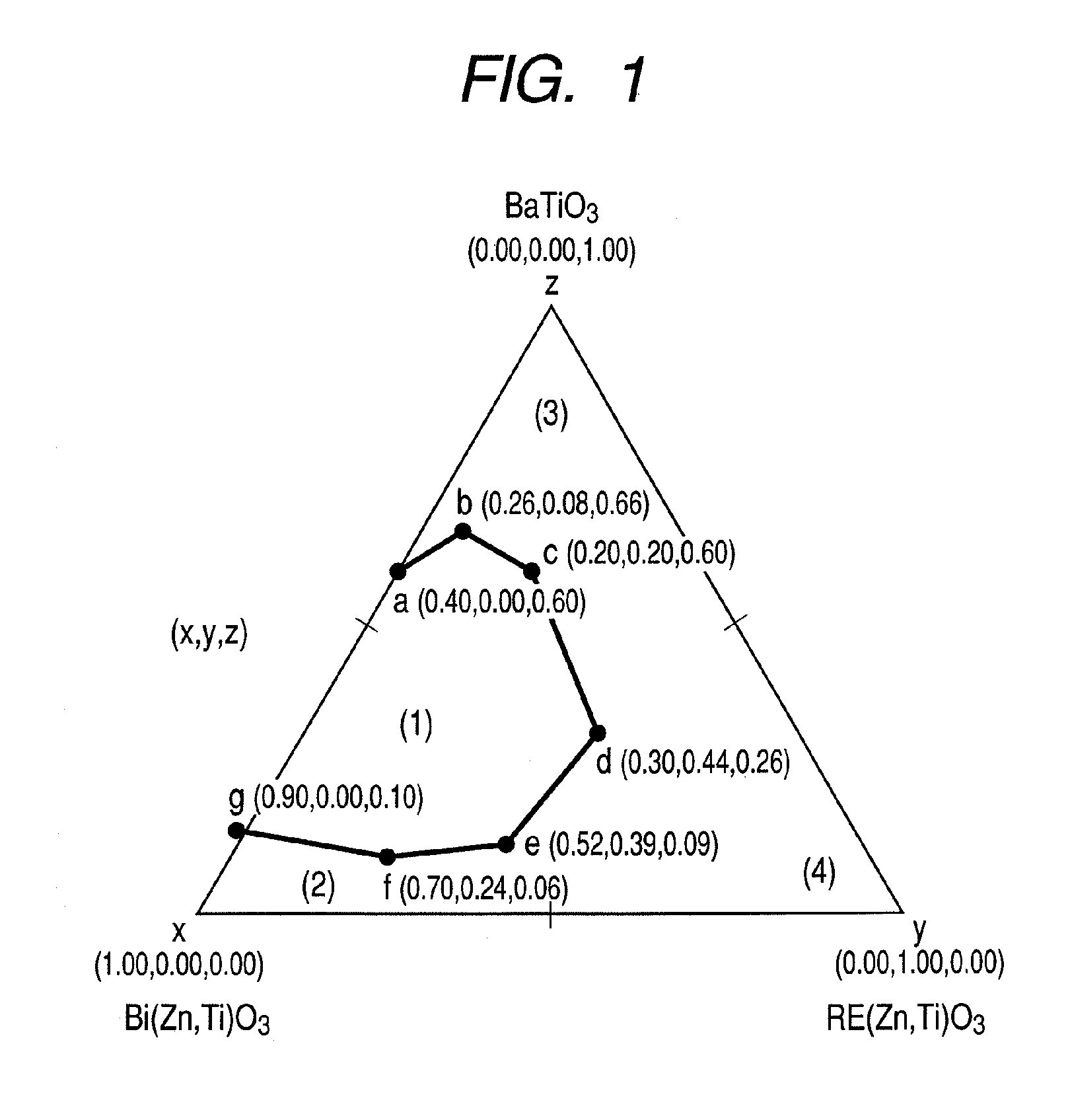

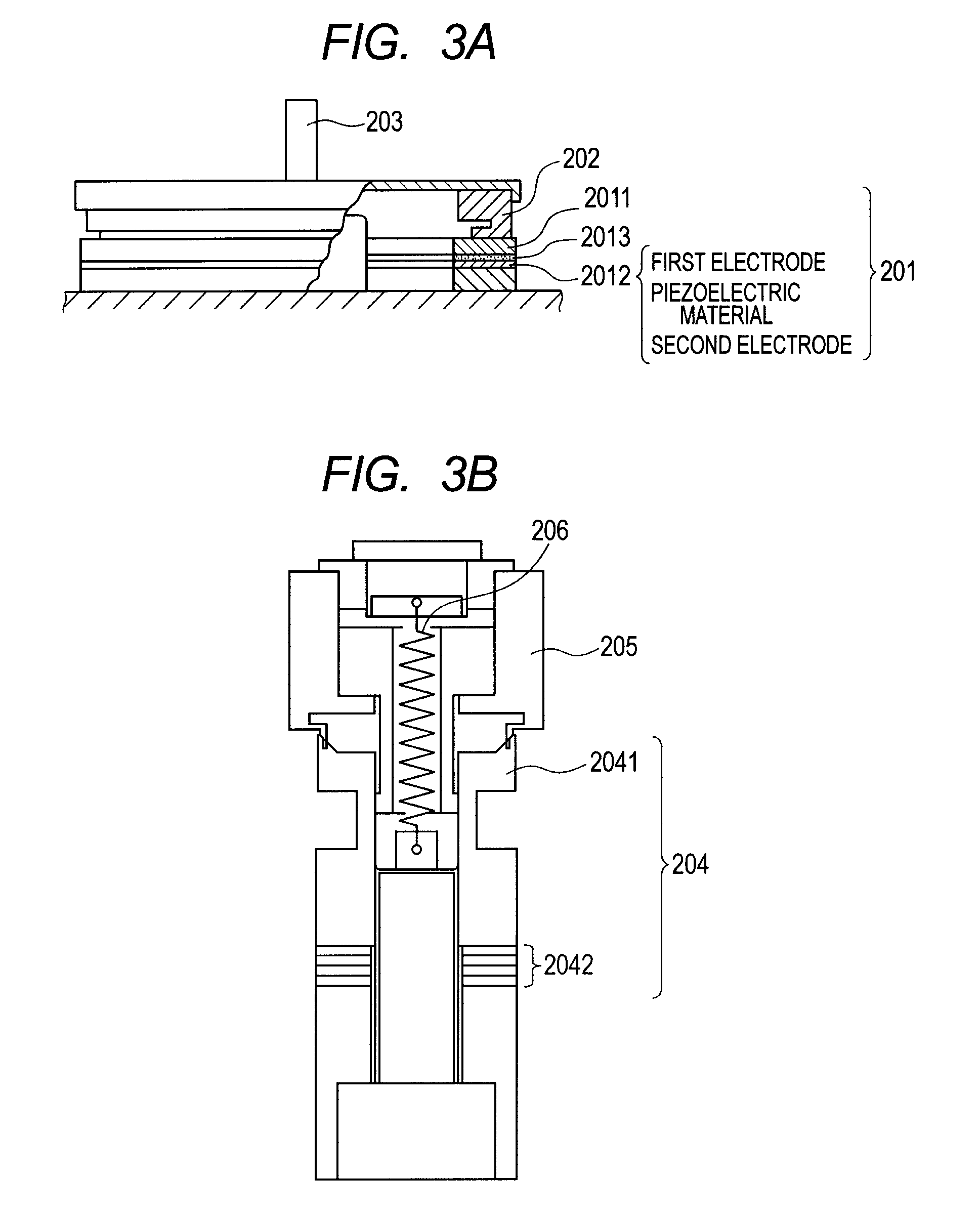

ActiveUS20100025617A1Satisfactory piezoelectricityIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyThin material handlingBi elementPiezoelectricity

Provided is a piezoelectric material excellent in piezoelectricity. The piezoelectric material includes a perovskite-type complex oxide represented by the following General Formula (1).A (ZnxTi1-x))yM(1-y)O3 (1)wherein A represents at least one kind of element containing at least a Bi element and selected from a trivalent metal element; M represents at least one kind of element of Fe, Al, Sc, Mn, Y, Ga, and Yb; x represents a numerical value satisfying 0.4≦x≦0.6; and y represents a numerical value satisfying 0.1≦y≦0.9.

Owner:CANON KK +6

Transparent conducting thin film with enhanced thermal stability and preparation method and application thereof

ActiveCN104979037ASuppresses the weak point that is easy to condense when heatedGood energy level matchingConductive layers on insulating-supportsSolid-state devicesOrganic solar cellRare-earth element

The invention relates to a transparent conducting thin film with enhanced thermal stability and a preparation method and application thereof. The transparent conducting thin film consists of a substrate, a first semiconductor layer, a silver alloy layer and a second semiconductor layer sequentially from bottom to top; according to the silver alloy layer, metal silver is combined with aluminum, zinc, titanium, copper, magnesium, nickel, rare earth elements or chromium to form a bi-element silver alloy layer or a multi-element silver alloy layer. The transparent conducting thin film provided by the invention can be used for photoelectric devices, such as organic light-emitting devices (OLEDs), organic solar cells and perovskite batteries; furthermore, on the basis of improving the thermal stability of the photoelectric devices, the dose of the photoelectric devices on a silver material per unit area can be reduced, device cost can be beneficially controlled, resources are saved; and the transparent conducting thin film also can be applied to magnetic shielding, special functional window coatings, transparent heat preservation building glass and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

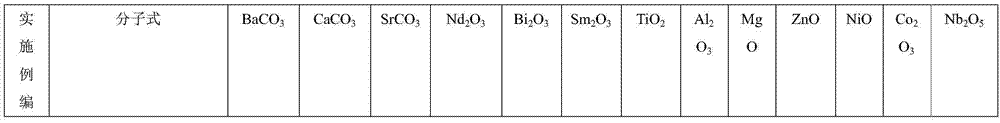

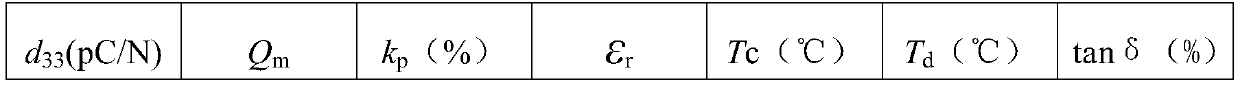

A-B site simultaneously substituting microwave dielectric ceramic material and preparation method thereof

The invention provides an A-B site simultaneously substituting microwave dielectric ceramic material and a preparation method thereof. The general chemical formula of the material is (Ba1-aAa)6-3x(Nd1-bBb)8+2x(Ti1-cCc)18O54, C=MN, wherein x=3 / 4, a is greater than or equal to 0.05 and smaller than or equal to 0.2, b is greater than or equal to 0.05 and smaller than or equal to 0.15, c is greater than or equal to 0.02 and smaller than or equal to 0.08, A represents divalent Ca and Sr elements substituting A1 sites, B represents trivalent Sm and Bi elements substituting A2 sites, M represents Nb with the valence state higher than tetravalency, N represents other one or more elements with a valence state lower than tetravalency and an ionic radius similar to Ti, and M and N substitute simultaneously or individually. The preparation method includes: determining the respective mass percentage content according to the general chemical formula, conducting ball mill mixing, performing presintering under 1000-1150DEG C, and then conducting sintering at 1250-1450DEG C. The prepared material has adjustable dielectric constant and frequency-temperature coefficient and at the same time maintains a high Q*f value. The formula does not contain Pb, Cd and other volatile or heavy metals, the performance is greatly enhanced, the raw materials are in abundant supply, and the price is low, so that low cost of high performance microwave ceramics becomes possible.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

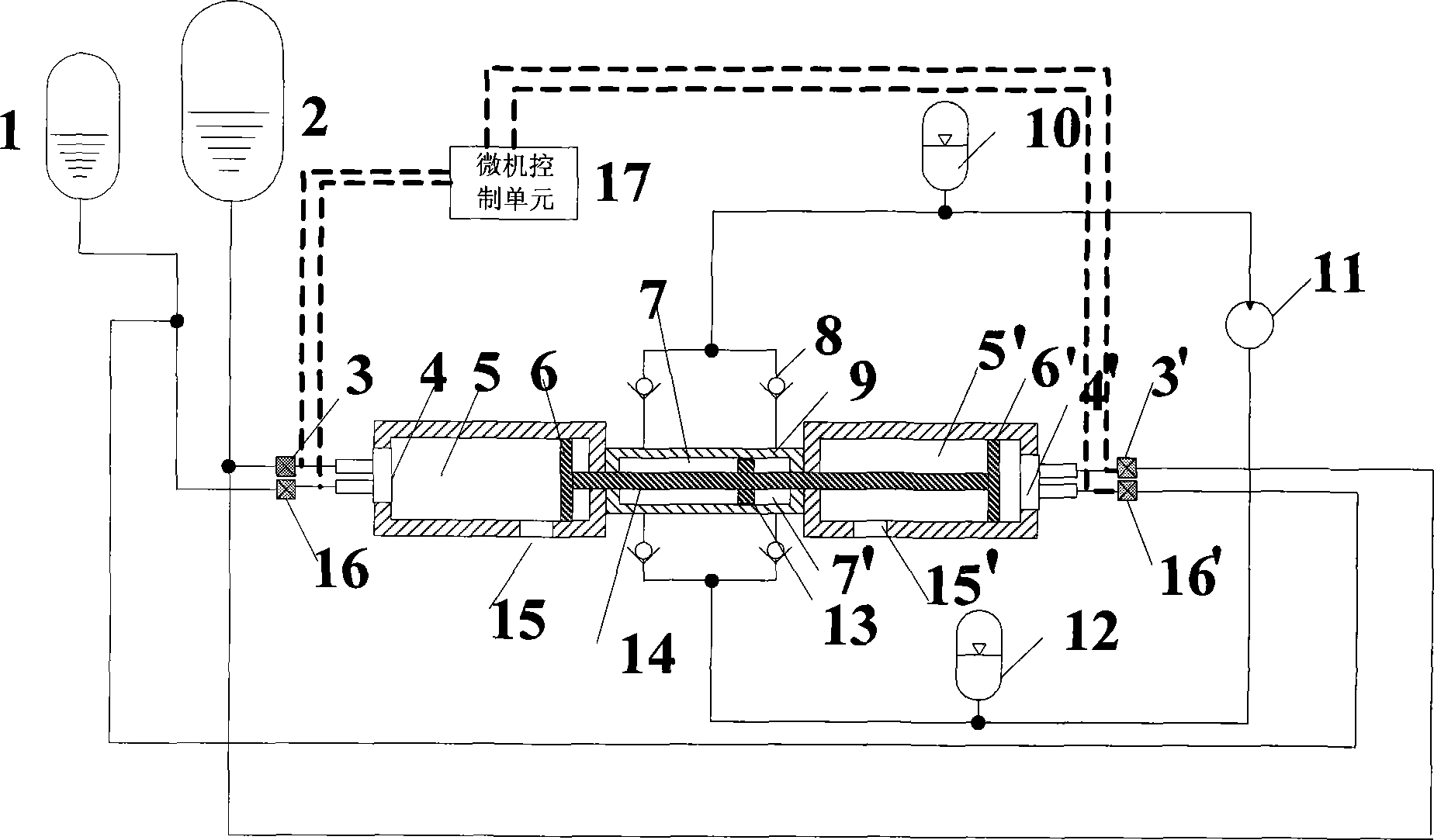

Double group component sydraulic free-piston engine

InactiveCN101082312ASimple structureAdapt to variable load occasionsRocket engine plantsFree-piston engineAviation

The invention discloses a bi-element hydraulic free-piston engine which flats to the hydraulic pump by using the one-way valve. The device takes the aviation single-element propellant as the oxidizer and the high-energy mineral fuel as the incendiary agent to form the bi-element driving energy. The mineral fuel is ignited by the high-temperature and the oxygen generating from the oxidizer catalytic decomposition to release the huge energy, which propels the hydraulic free-piston engine running and outputs high-pressure oil driving the load running. The fuel self-ignition utilizes the oxygen and heat provided by the oxidizer directly without controlling the compression ratio and the firing of the engine. So the positional requirement of the piston components is not strict, the phenomenon of losing fire can not happen and the reliability is very high. It cancels the firing and starting devices to have simple structure and higher energy density.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

Preparation method of high-silicon non-oriented electrical steel for motor

The invention discloses a preparation method of high-silicon non-oriented electrical steel for motors; Sn, Cu, B, Bi elements are added into electrical steel, and the contents are controlled reasonably, which bring into play the functions of each element and generate synergistic effect; wherein Sn and Cu facilitate the control of the morphology and distribution of precipitates and thus influence the texture; the added B and Bi elements can greatly reduce the annealing temperature of the electrical steel with high silicon content; only an annealing temperature of 870-890 DEG C is required to obtain magnetic performance with magnetic induction intensity B50 of more than 1.7 T, and iron loss P1.5 of less than 2.7 W / kg; with the combined action of the four elements and other routine alloying elements, the microstructure of the electrical steel is improved, and thus the mechanical properties of the steel are improved. Because the annealing temperature is decreased, furnace roller nodulation is completely avoided, and the scratch of strip steel is completely avoided; the production energy consumption is reduced, and thus the production cost is reduced.

Owner:JIANGSU HAODA

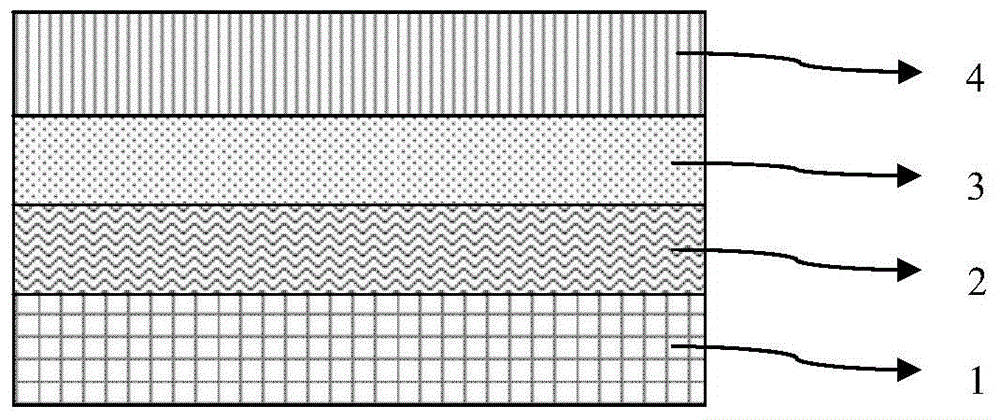

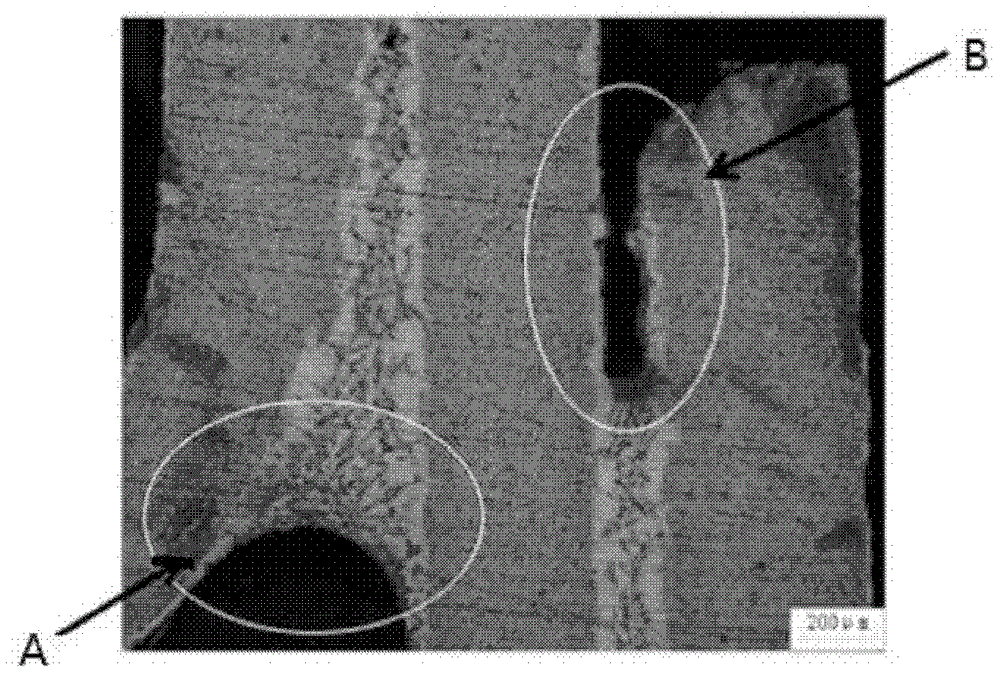

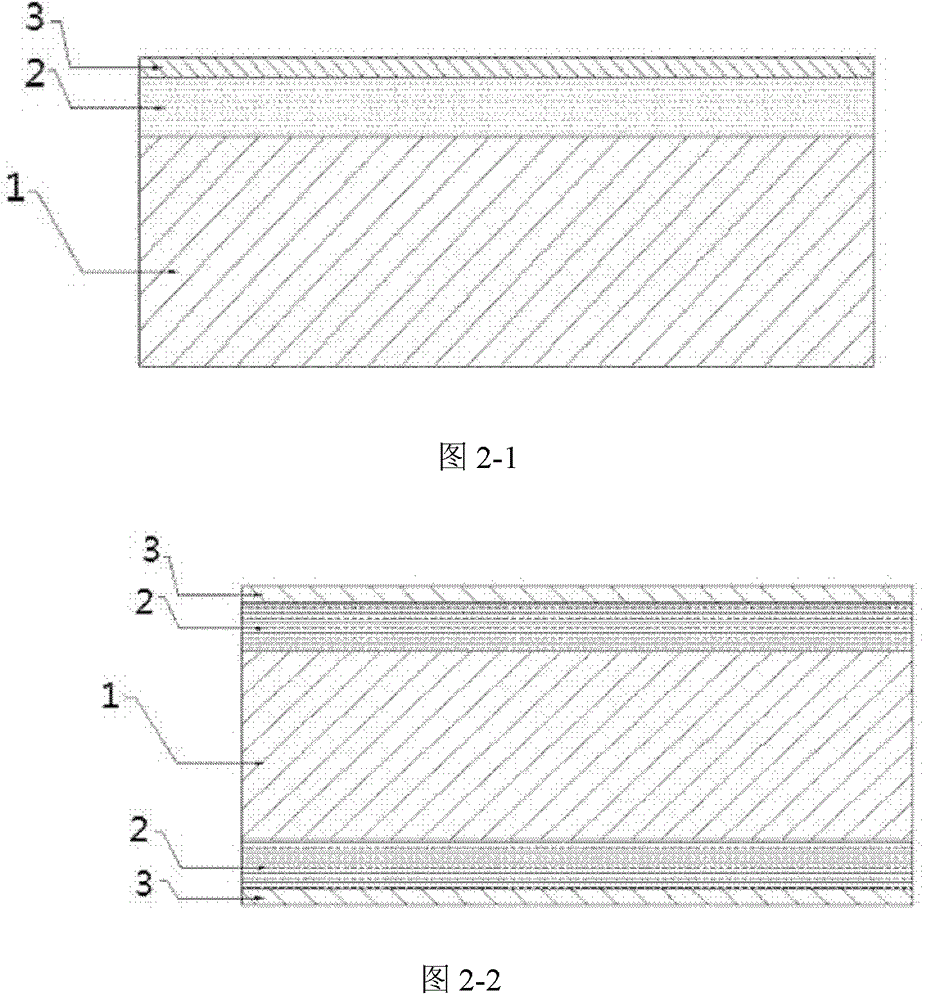

Multilayer fluxless material with stepped silicon content and preparation method and application thereof

ActiveCN106476359AEffective breakthroughBreak through benefitMetal layered productsHigh concentrationHigh density

The invention discloses a multilayer fluxless material with stepped silicon content and a preparation method and an application thereof. The multilayer fluxless material comprises a core layer, a soldering layer and a cover layer which are composited in order, and the silicon mass content of the soldering layer and cover layer are different. The cover layer and the soldering layer contains a silicon material, by using the different differential concentrations of the silicon content of the soldering layer and the cover layer, the soldering liquid flows from high density to low concentration direction, and an oxide-film is effectively broken through. at the same time, Mg with high concentration flows with the silicon material, then is diffused next to the oxide-film, under condition that oxygen content is low, the diffused magnesium and the aluminium alloy oxide-film are subjected to spinel, the generated spinel is easily coiled into the liquid by the soldering liquid (the silicon material), the soldering liquid is fully contacted, capillary and infiltration effects are employed, so that the welding quality of a soldered joint is saturated. a Bi element is added in the cover layer or the soldering layer, and the oxide-film can be firstly broken through.

Owner:HUAFON NIKKEI ALUMINUM

Metal oxide

ActiveUS8529785B2Satisfactory piezoelectricityIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionBi elementPiezoelectricity

Owner:CANON KK +6

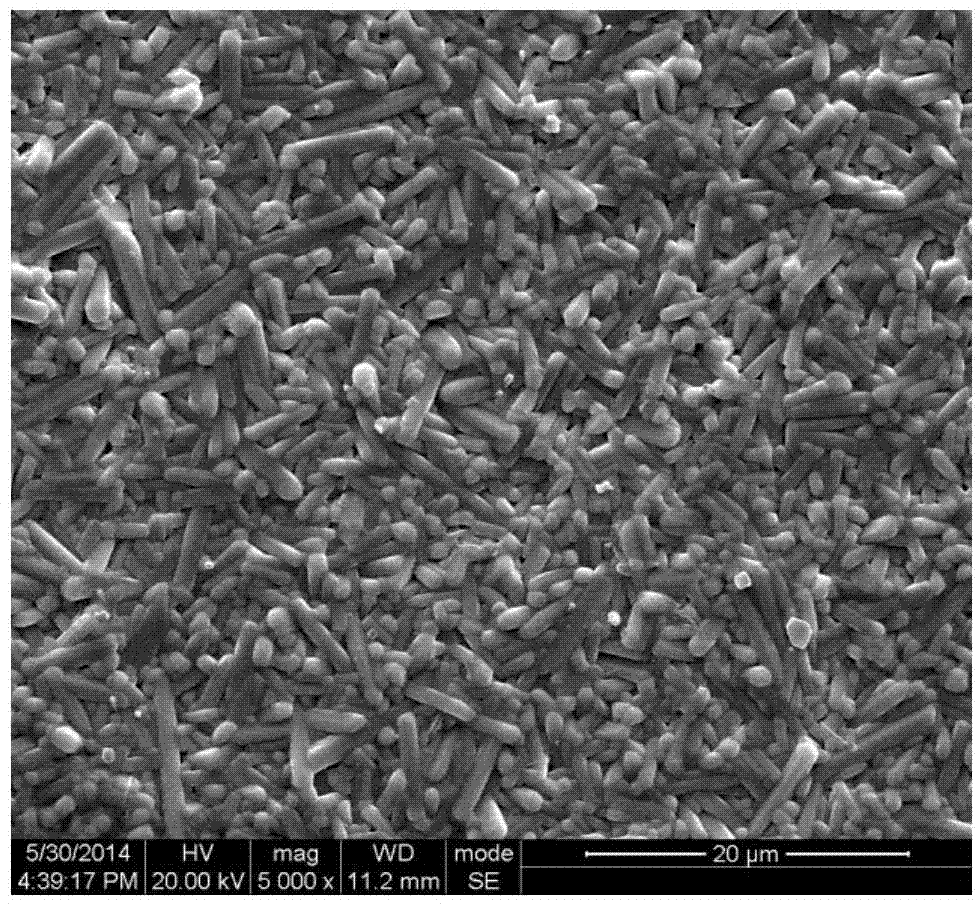

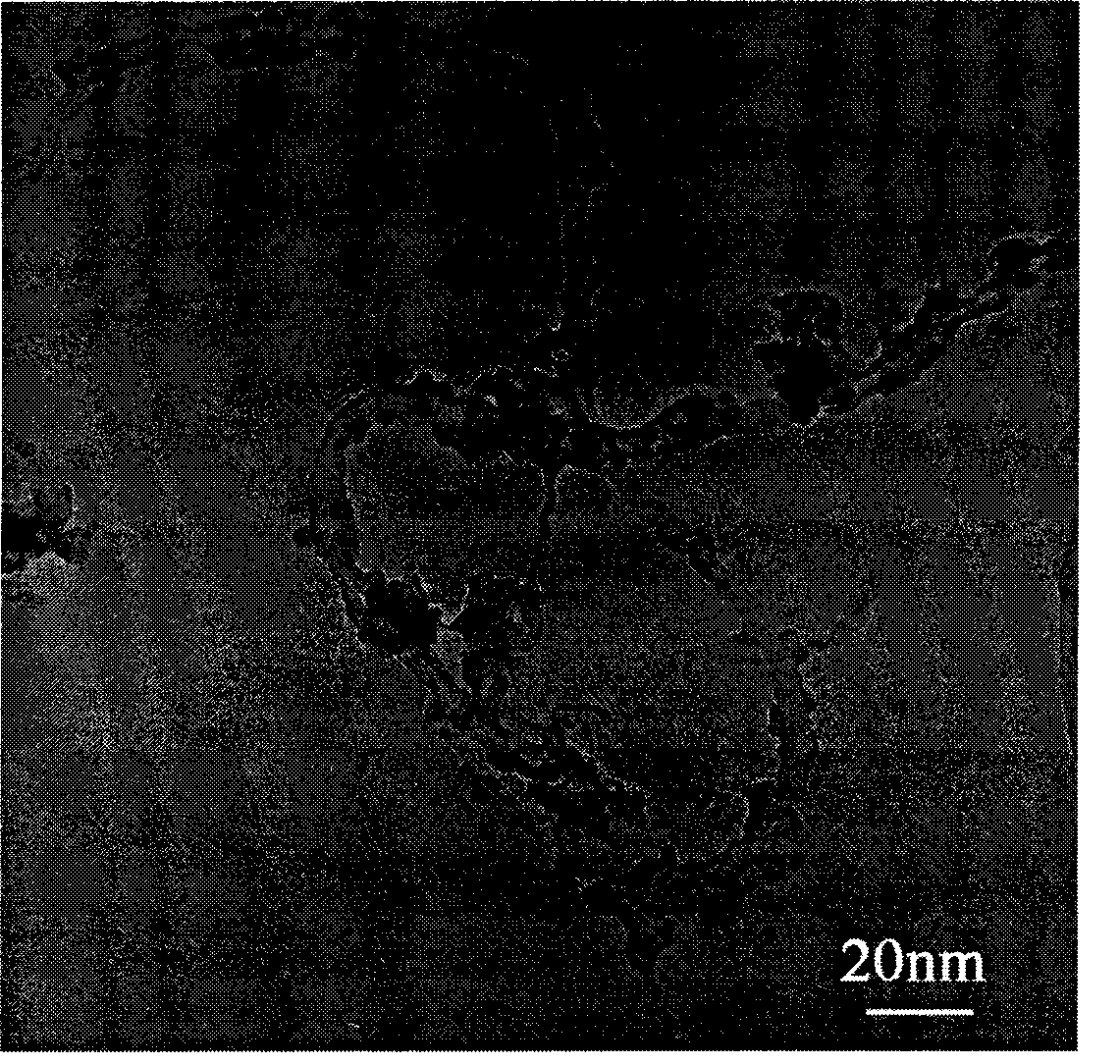

Method for preparing Bi2Te3 / carbon nano-tube composite material

InactiveCN101503176AImprove thermoelectric performanceSimple processNanostructure manufactureThermoelectric device manufacture/treatmentThermoelectric materialsPolyol synthesis

The invention discloses a method for preparing Bi2Te3 carbon nano tube composite material, which adopts microwave polyol synthesis technique: 1) Bi element compound and Te element compound or Te elementary substance are respectively dissolved in glycol according to the mol ratio of Bi: Te determined by the chemical composition of Bi2Te3 and then stirred and mixed together; 2) ultrasonic dispersion is carried out on the processed carbon nano tube in the glycol, and the pH value is adjusted to be 11-14; 3) according to the mass ratio of 0.1:1-2:1 between the carbon nano tube and the Bi2Te3, the mixed solution in the step 1) is titrated in the solution of the step 2) for reaction at the temperature of 140-190 DEG C in a state of microwave radiation; after the reaction, the products are separated centrifugally and washed, and the solid products are collected and dried. The technique is simple and rapid, and the prepared Bi2Te3 carbon nano tube composite material can be used for improving the thermoelectric property of Bi2Te3-based thermoelectric material. Furthermore, the method can be widely applied to the fields such as physics, chemistry, micro-electronics, material, etc.

Owner:ZHEJIANG UNIV

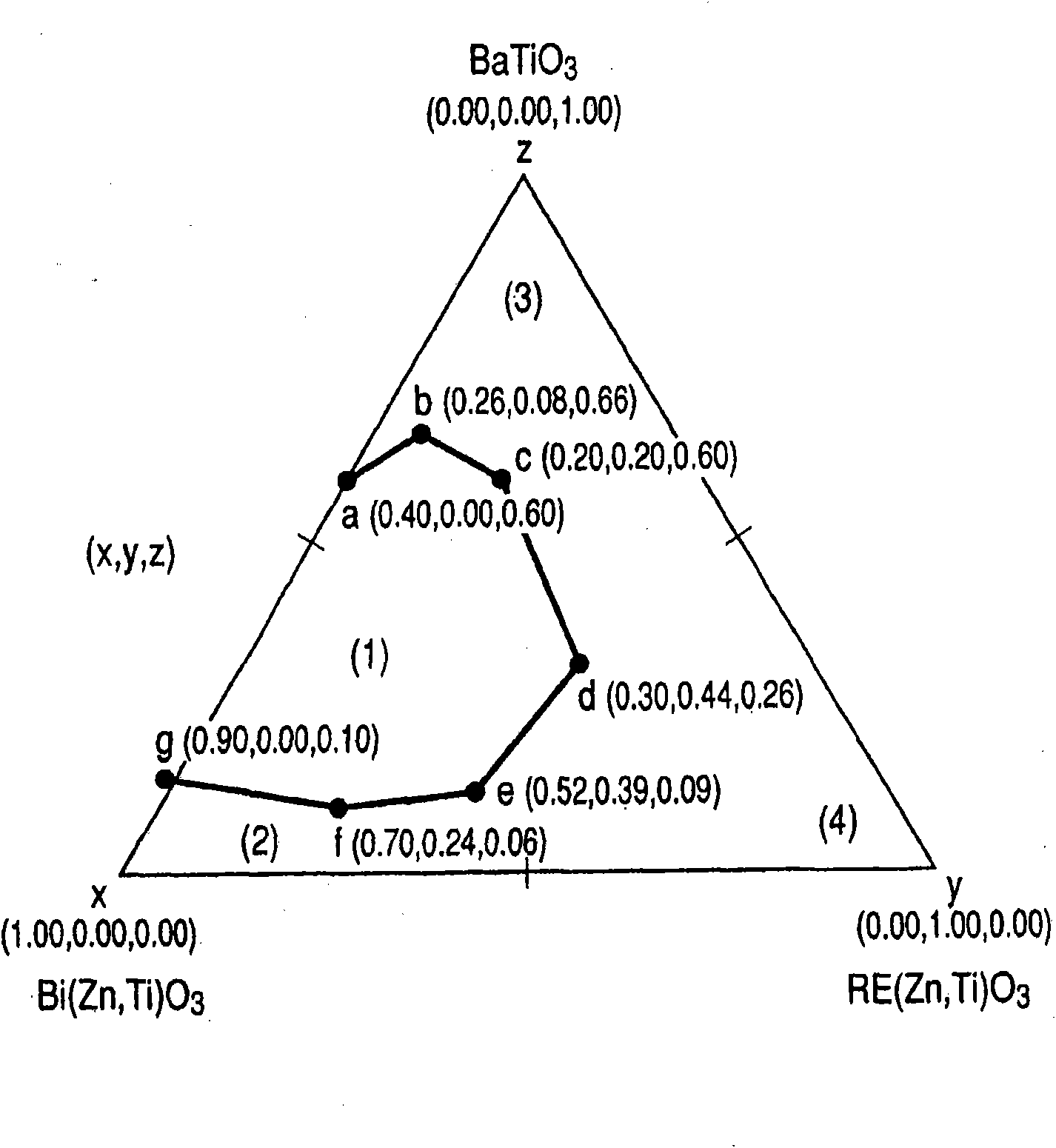

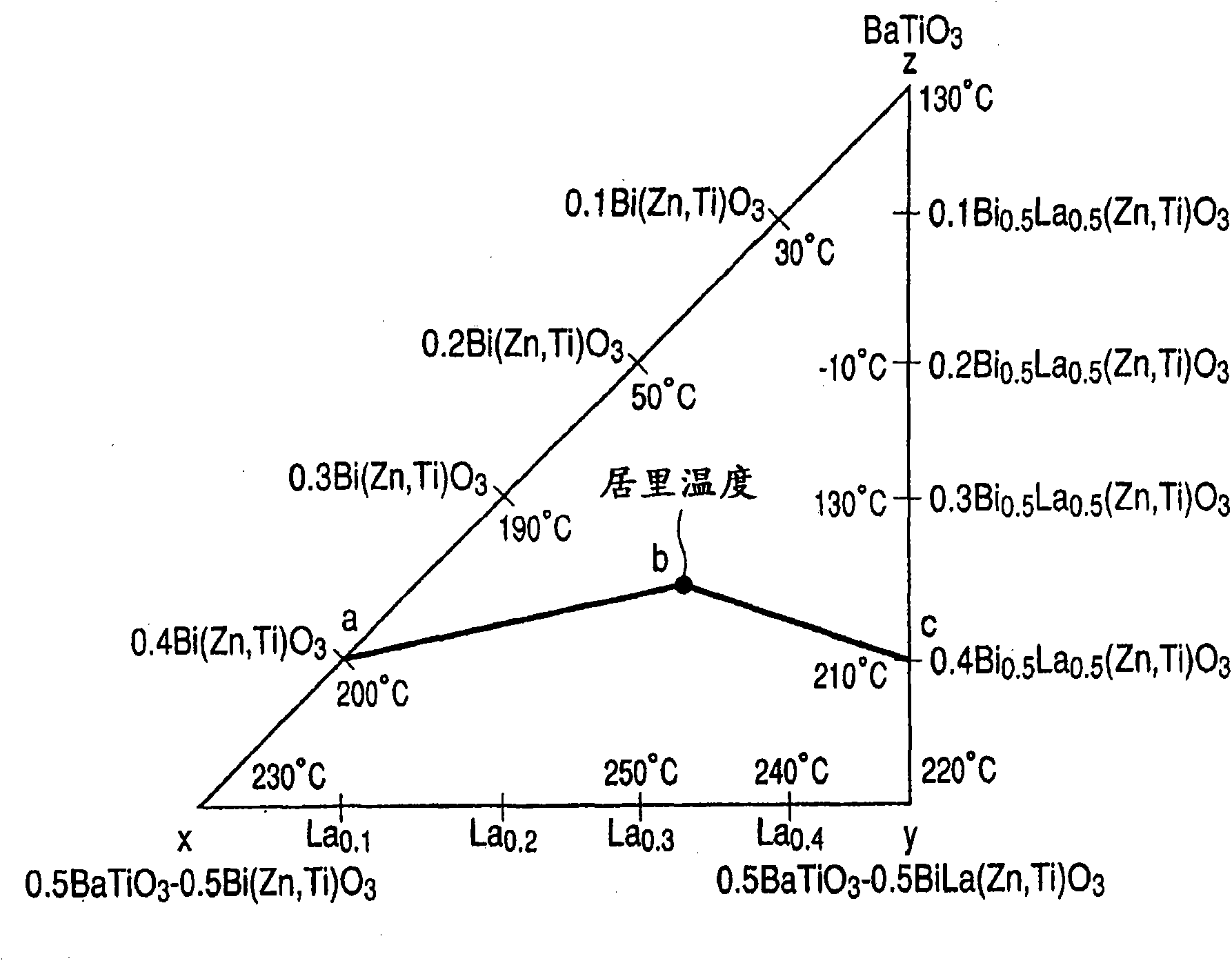

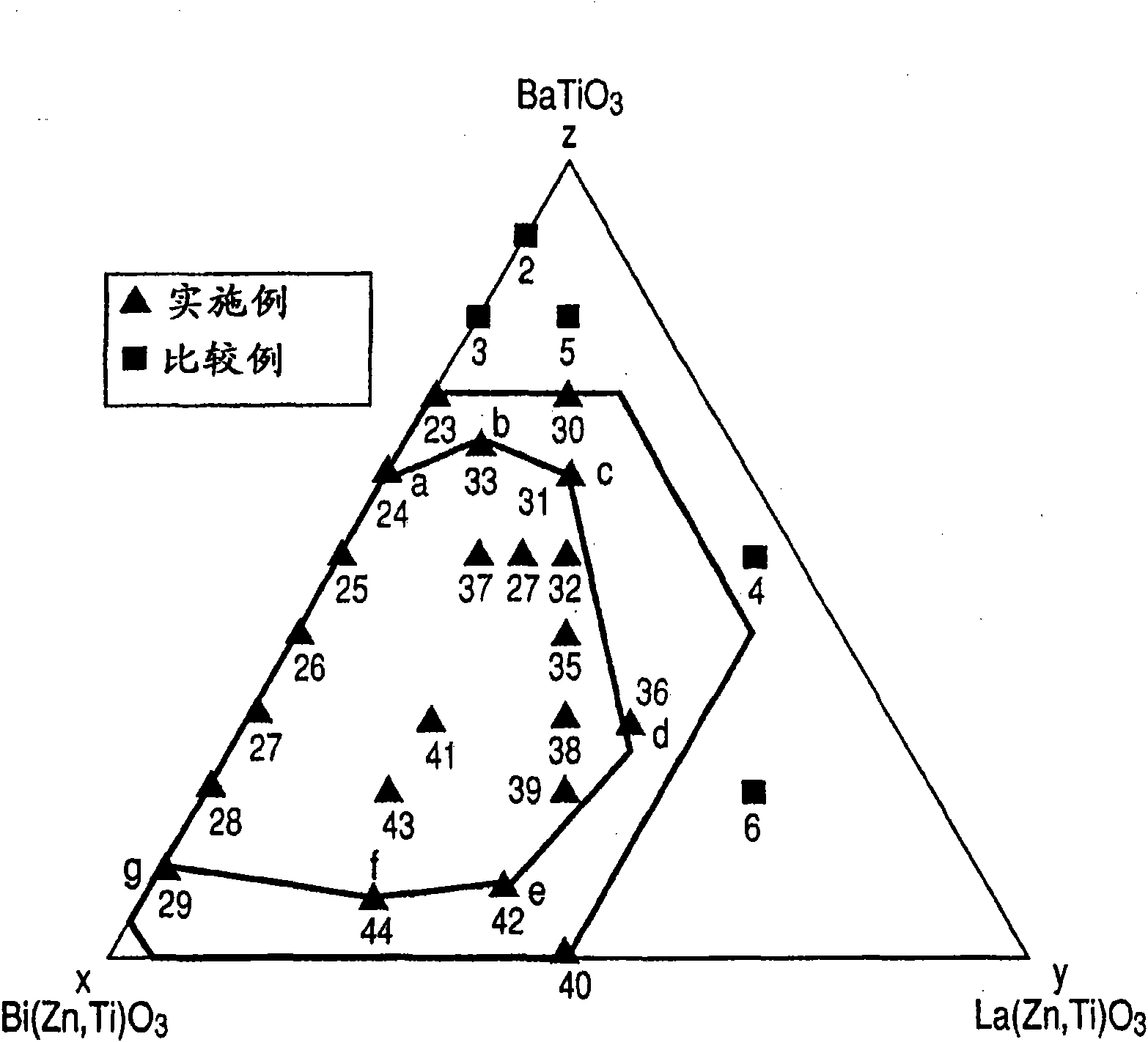

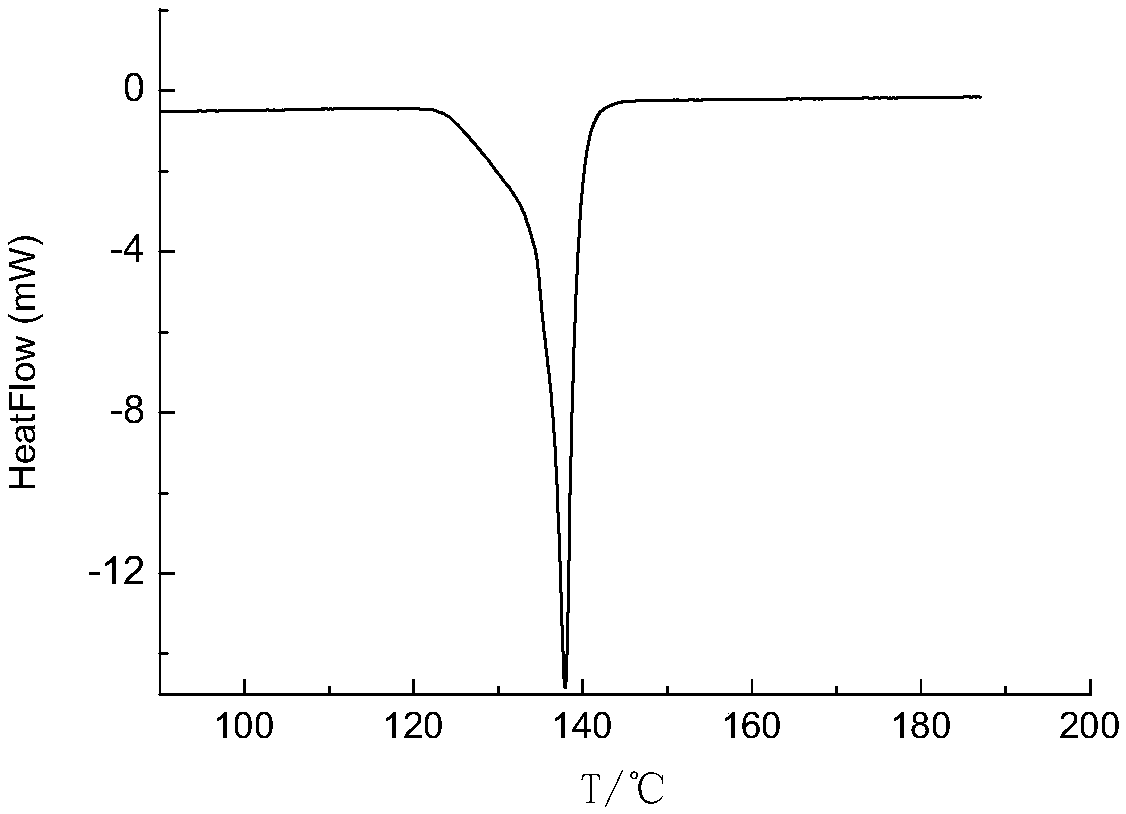

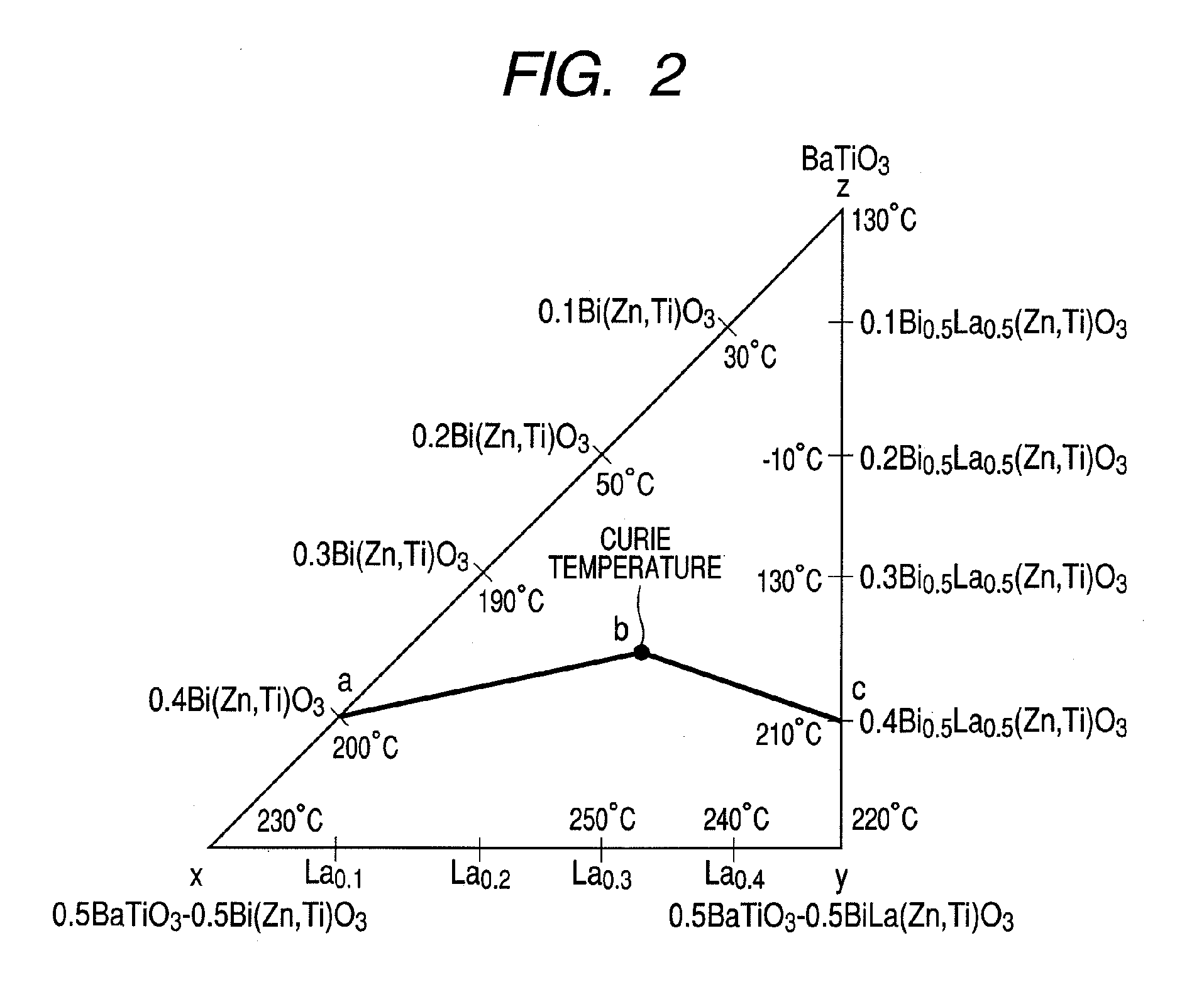

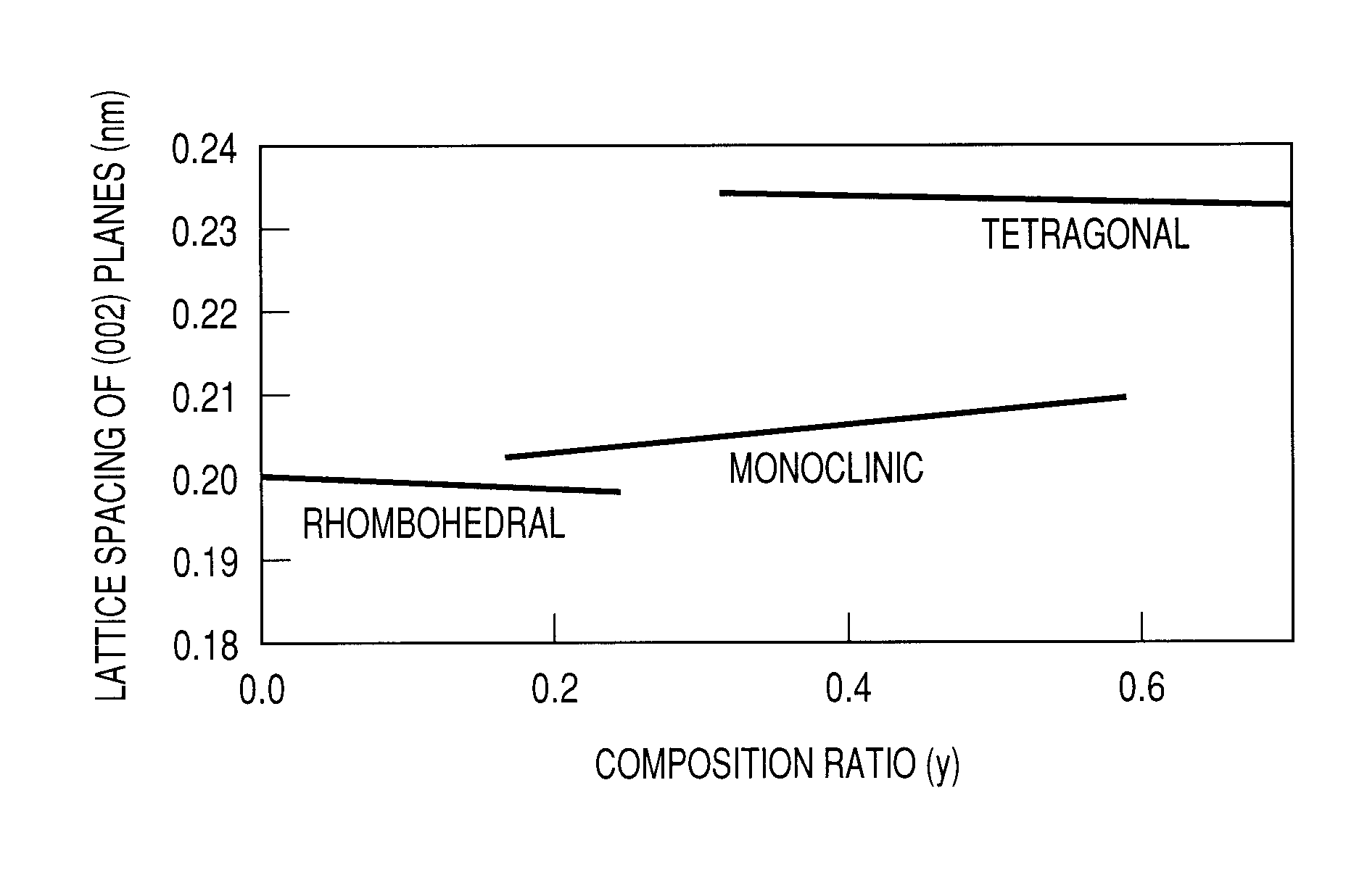

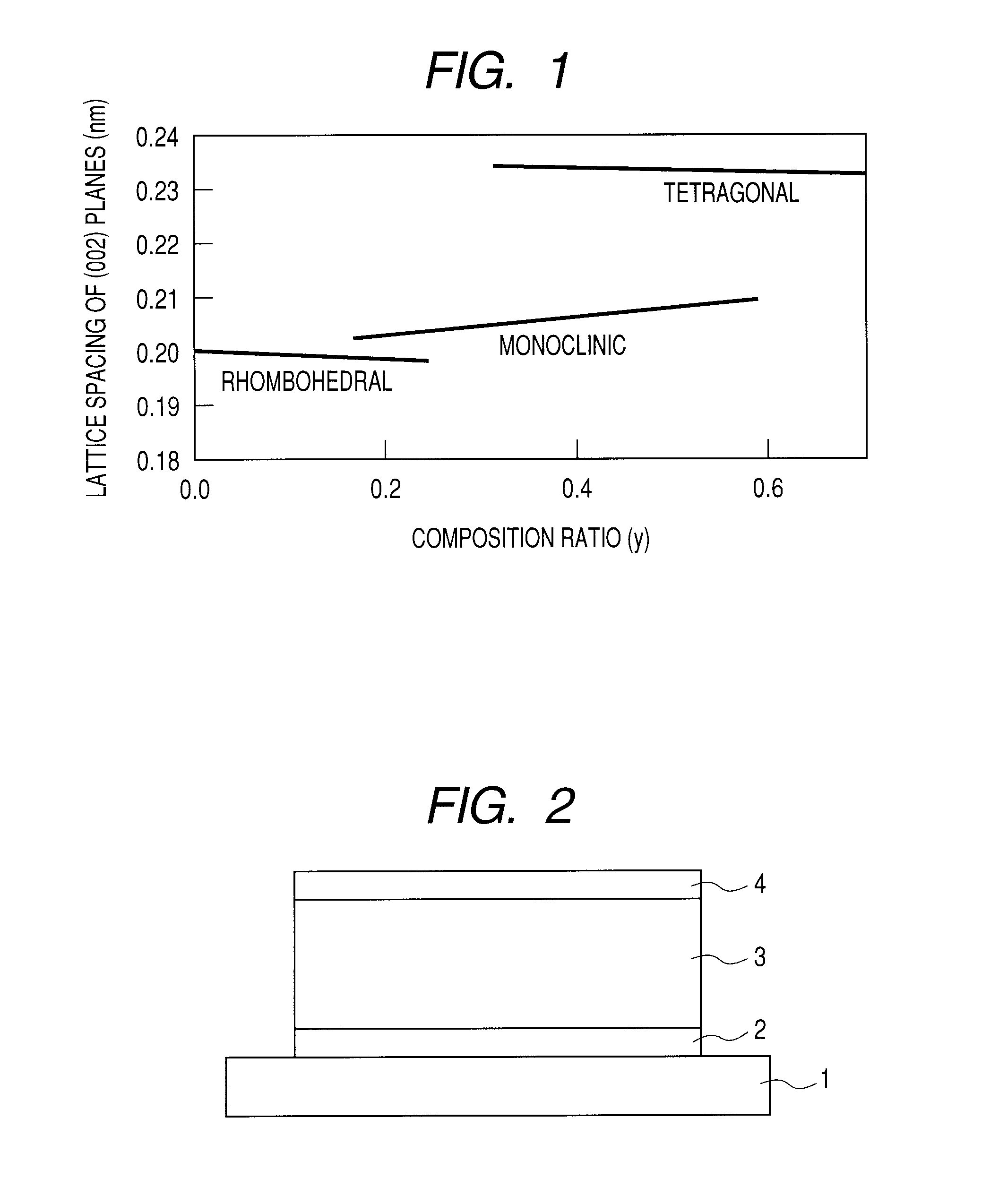

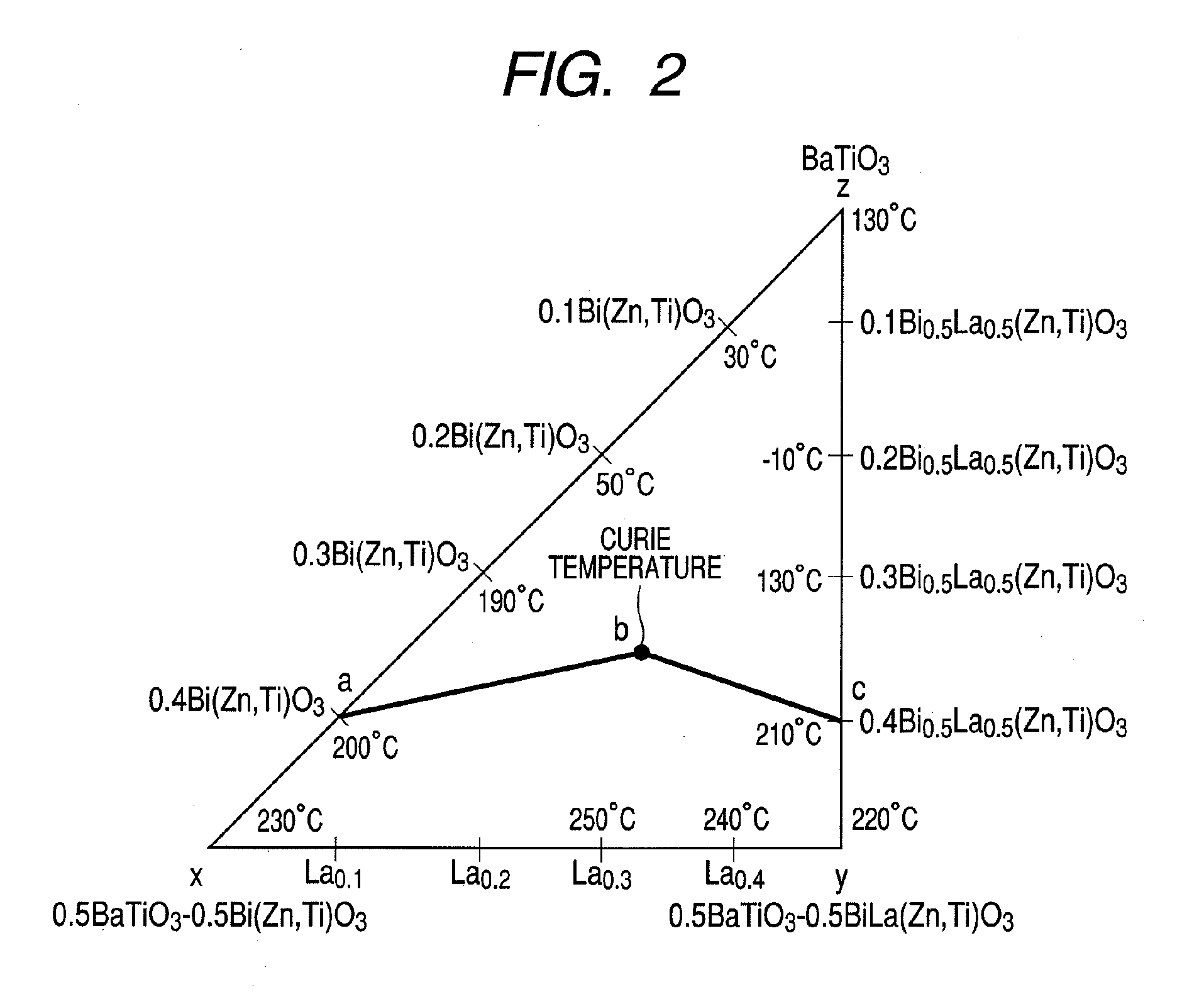

Piezoelectric material

ActiveCN101971381AExcellent piezoelectric propertiesSolving Polarization Handling DifficultiesAlkaline earth titanatesPiezoelectric/electrostrictive device manufacture/assemblyRare-earth elementBi element

Provided is a piezoelectric material including a lead-free perovskite-type composite oxide which is excellent in piezoelectric characteristics and temperature characteristics and is represented by the general formula (1): xABO3-yA'BO3-zA''B'O3 in which A is a Bi element; A' is a rare earth element including La; B is at least one element selected from Ti, Zn, Sn and Zr; A'' is at least one element selected from Ba, Sr and Ca; B' is at least one element selected from divalent, trivalent, pentavalent, tetravalent, and hexavalent elements; and x is a value of 0.10 or more and 0.95 or less, y is a value of 0 or more and 0.5 or less, and z is a value of 0 or more and 0.7 or less, provided that x + y + z = 1.

Owner:UNIVERSITY OF YAMANASHI +5

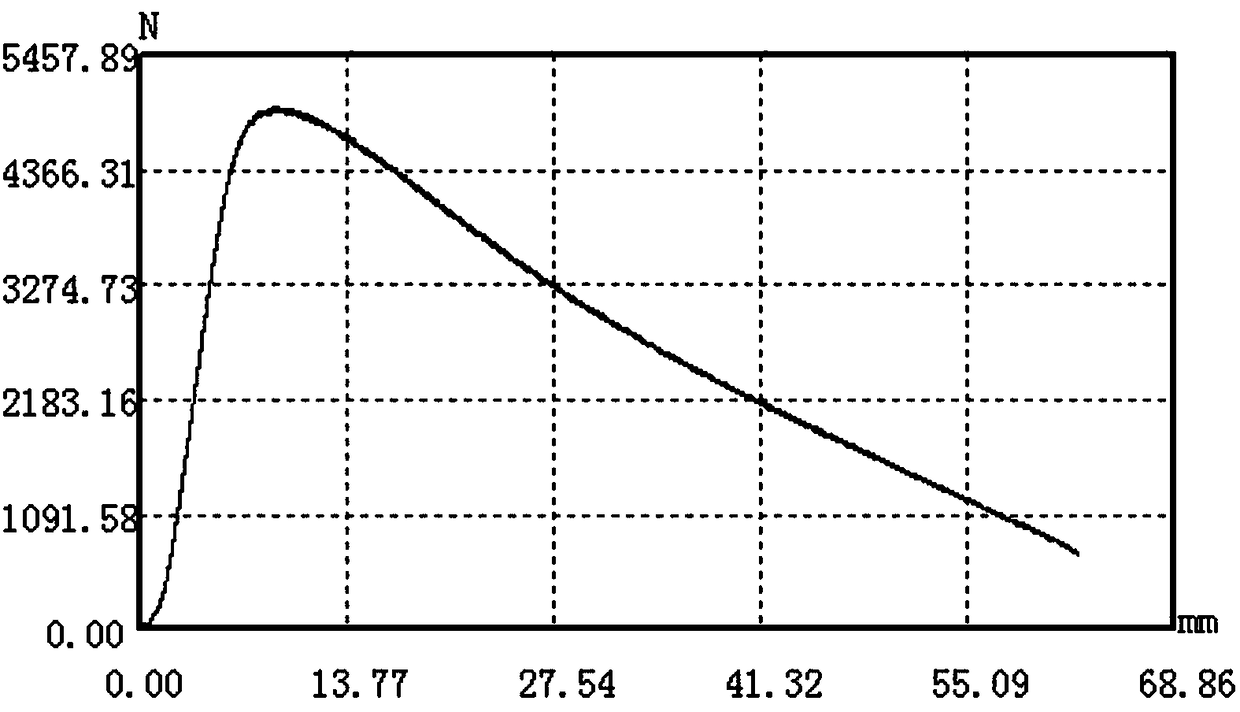

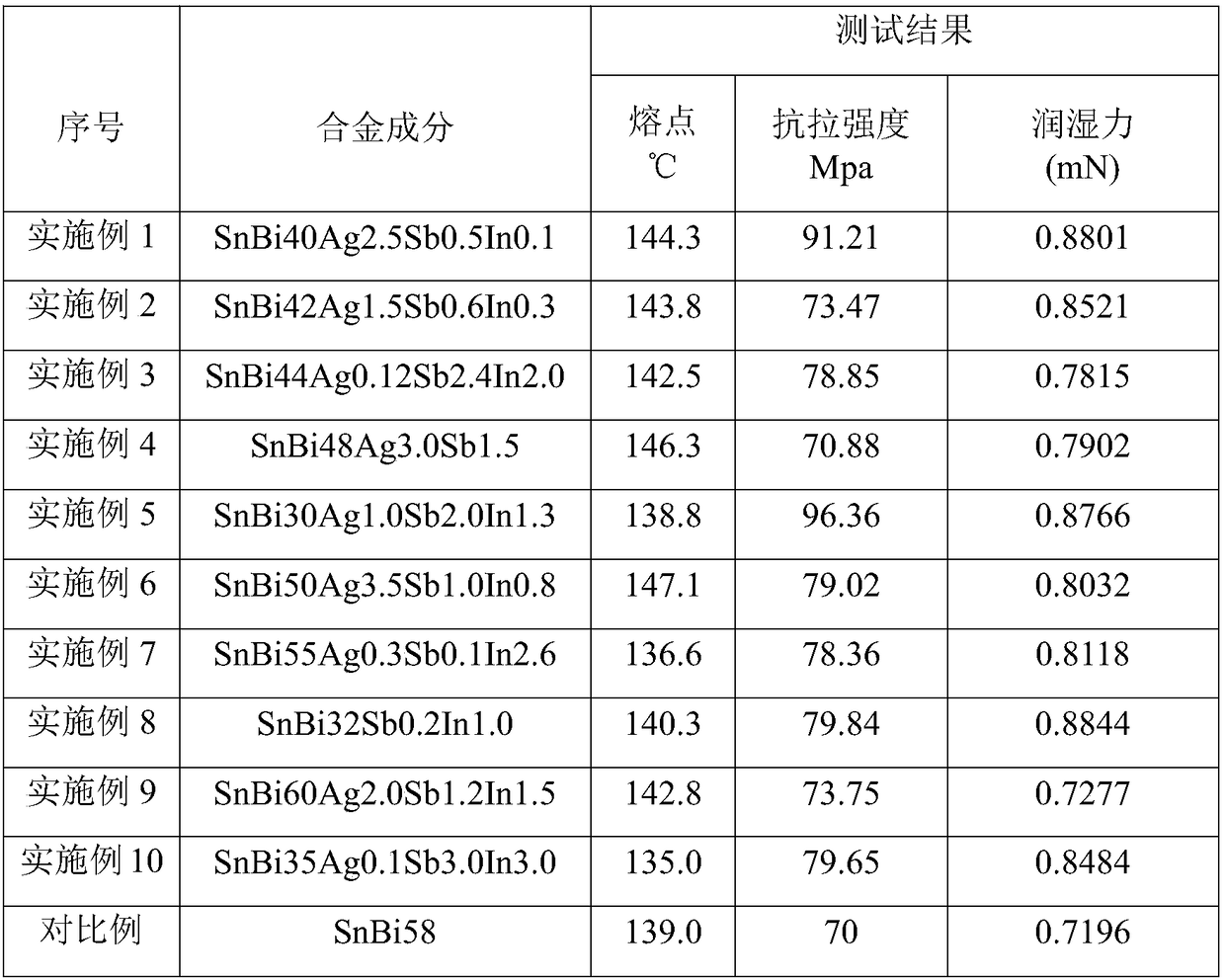

SnBiAgSbIn low-temperature lead-free solder alloy

InactiveCN108526748AReduce surface tensionCost controlWelding/cutting media/materialsSoldering mediaRare-earth elementBi element

The invention discloses a SnBiAgSbIn low-temperature lead-free solder alloy, belonging to the technical field of low-temperature solder alloys. Low-temperature lead-free solder is prepared from the following ingredients in percentage by weight: 30-60% of Bi, 0-3.5% of Ag, 0.1-3% of Sb, 0-3.0% of In, 0-0.11% of Ge, 0-0.11% of P, more than two kinds of rare earth elements, the balance of Sn and unavoidable impurities. The alloy can be used for inhibiting the segregation of a Bi element, improving the mechanical property of welding spots, and solving the problems that in the process of using binary SnBi solder at present, the welding spots can generate cavities easily, the mechanical performance is poor, and the welding spots are easy to peel off and the like.

Owner:云南锡业新材料有限公司

Piezoelectric material

ActiveUS8034250B2Excellent piezoelectric propertiesHigh curie temperatureAlkaline earth titanatesPiezoelectric/electrostrictive device manufacture/assemblyRare-earth elementBi element

Owner:UNIVERSITY OF YAMANASHI +5

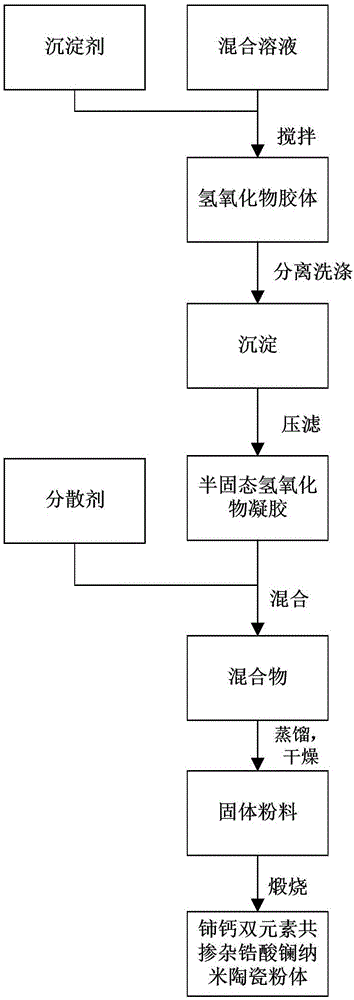

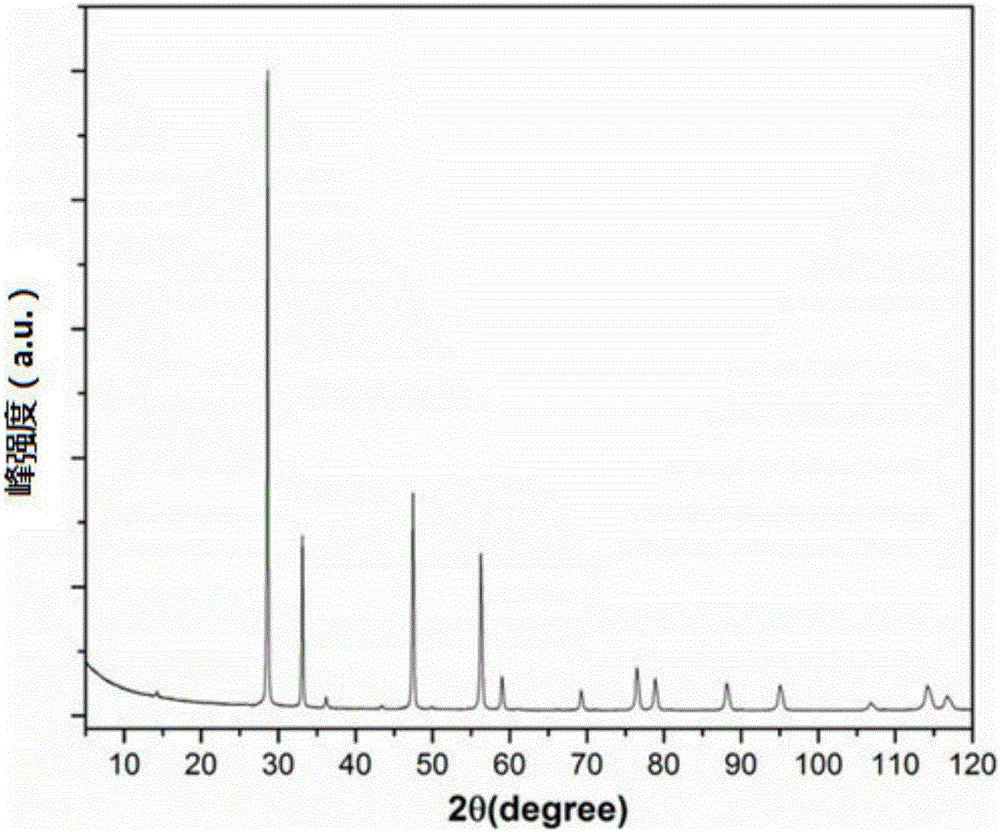

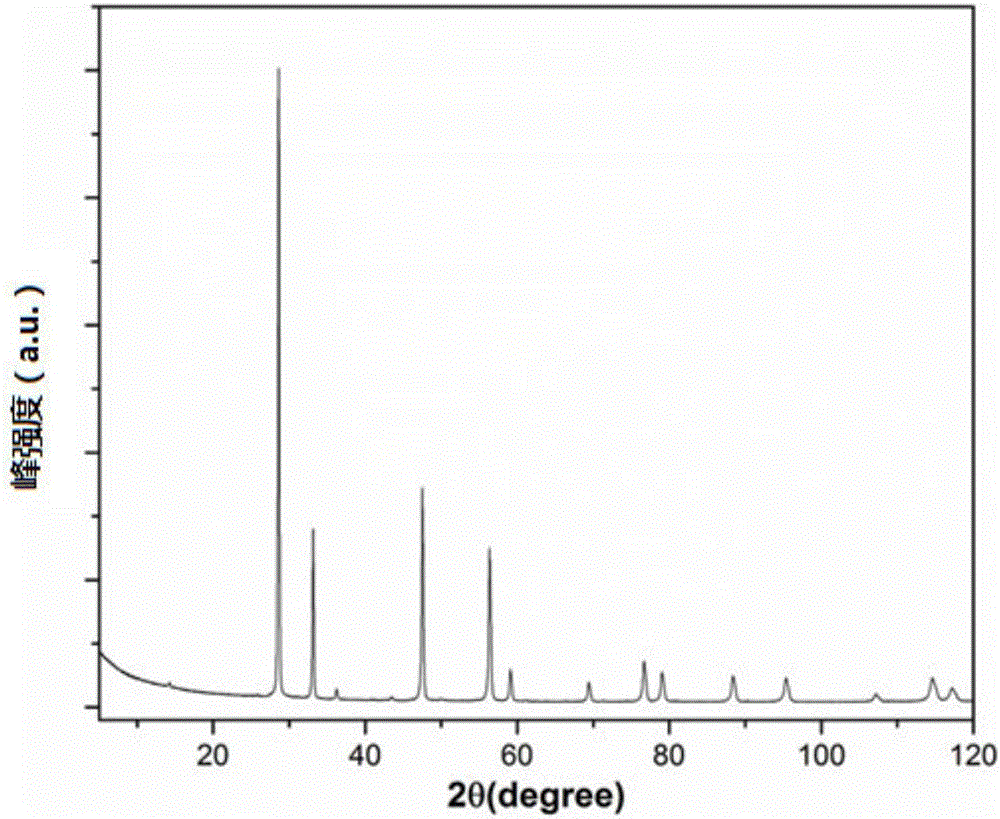

Cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder and preparation method thereof

The invention provides cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder and a preparation method thereof. The preparation method includes following steps: preparing a mixed solution, and mixing the same with a precipitant to obtain hydroxide colloid; separating and washing the hydroxide colloid to obtain precipitate; press-filtering the precipitate to obtain semi-solid-state hydroxide gel; well mixing the semi-solid-state hydroxide gel with a dispersant to obtain a mixture; distilling the mixture, and drying to obtain solid powder; calcining the solid powder to obtain the cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder. The structural formula of the cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder is (La1-2xCexCax)2(Zr0.7Ce0.3)2O7, wherein x is greater than or equal to 0.05 and smaller than or equal to 0.2. The preparation method is few in process and easy to control.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

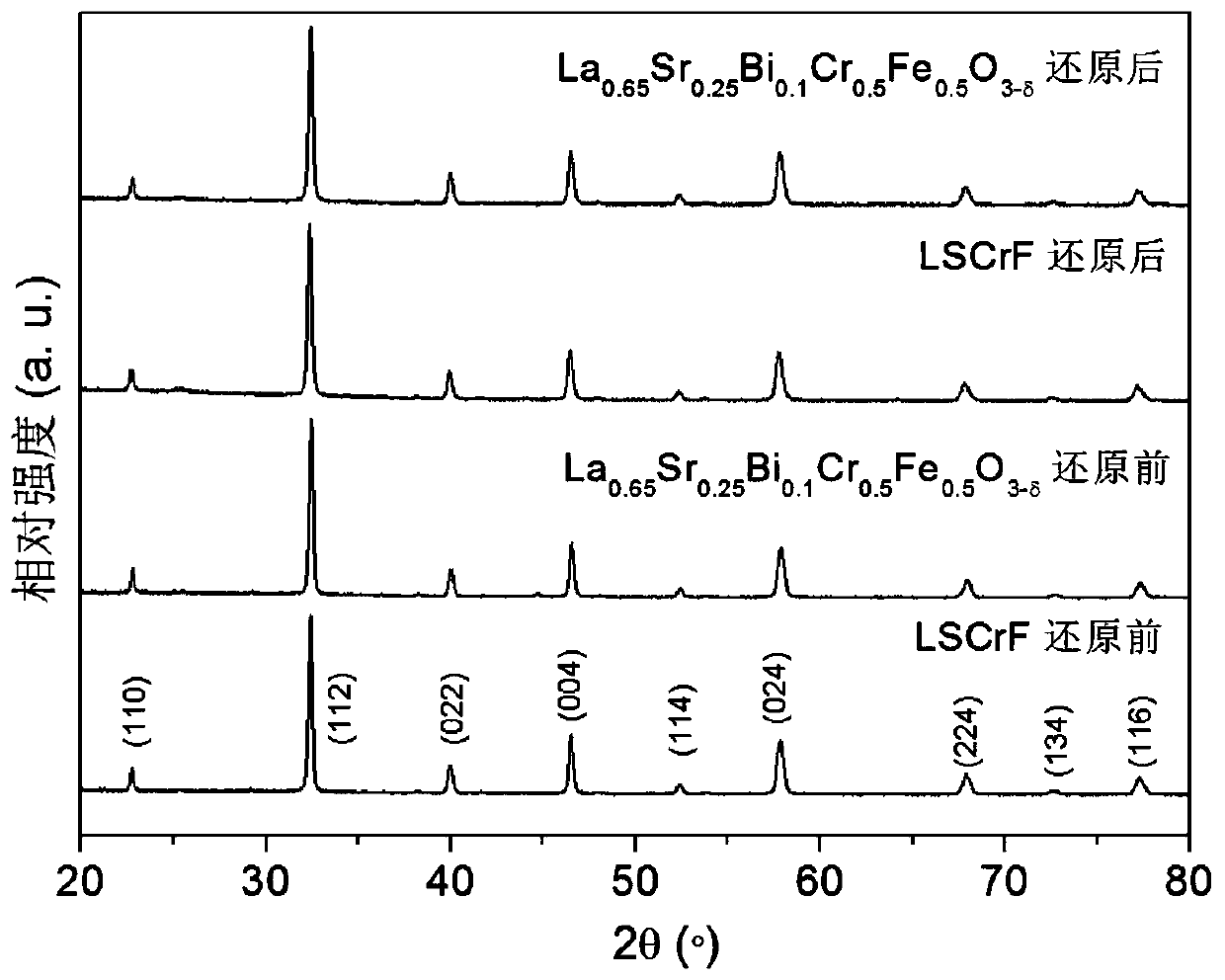

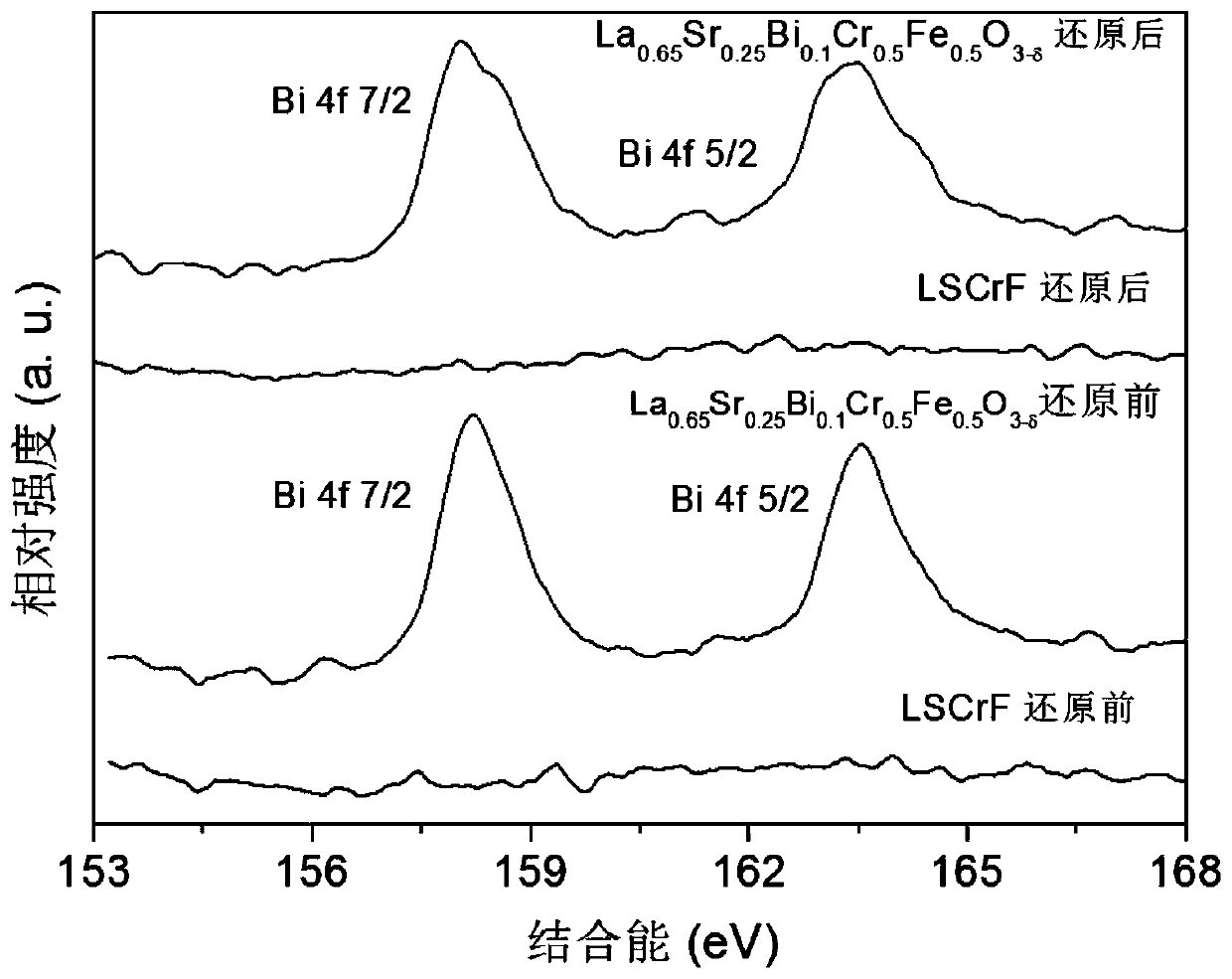

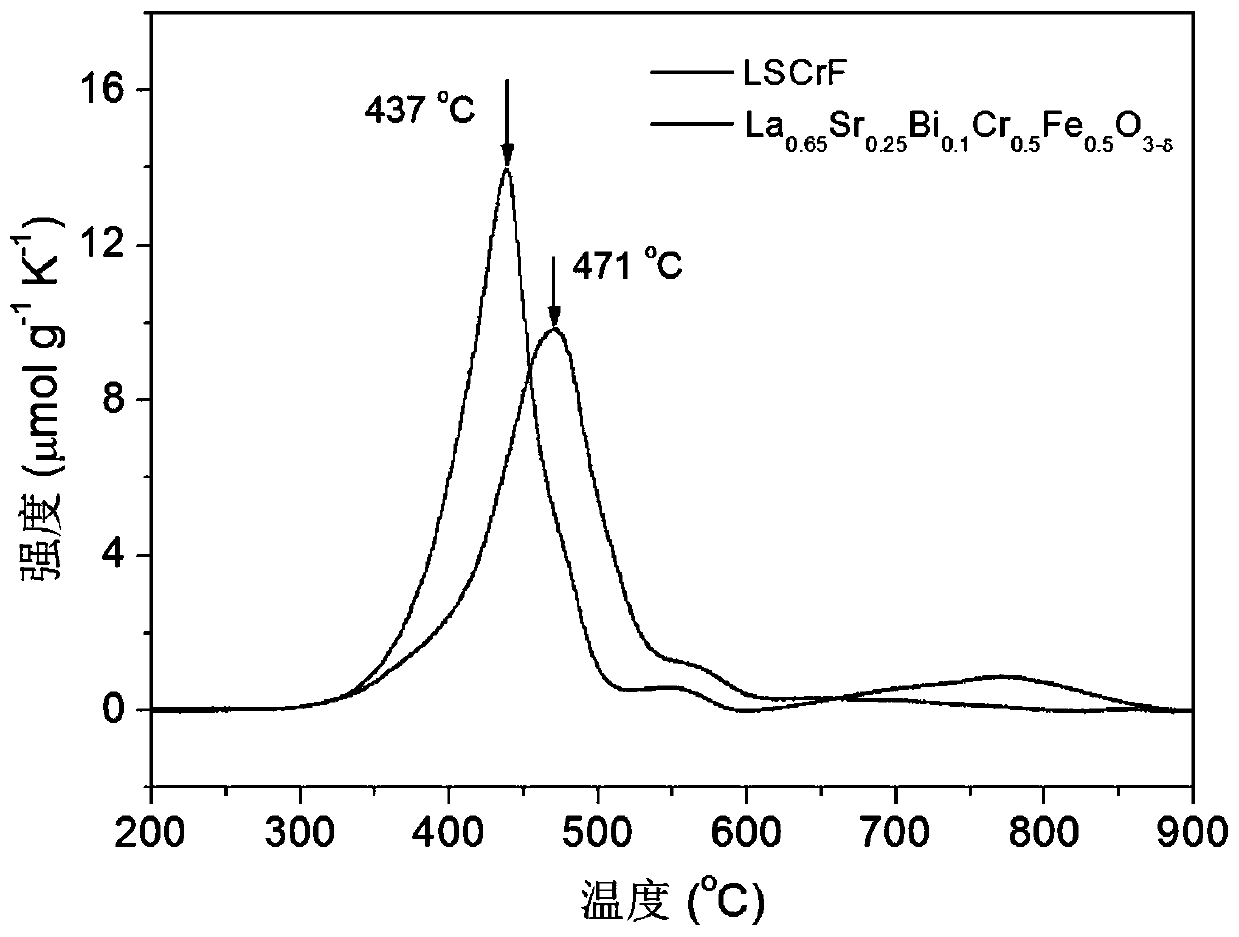

Bismuth-doped solid oxide battery fuel electrode material and preparation method and application thereof

The invention provides a bismuth-doped solid oxide battery fuel electrode material and a preparation method and application thereof. According to the bismuth-doped solid oxide battery fuel electrode material, the chemical formula is La1-x-zM1xBizCr1-yM2yO3-delta, wherein M1 is alkaline earth metal, M2 is transition metal, 0 < x < 1.0, 0 < y < 1.0, z is the doping amount of Bi. The catalytic activity of the Bi-doped LSCrF perovskite type fuel electrode material is obviously enhanced; and the Bi-doped perovskite oxide fuel electrode material keeps better chemical and structural stability under oxidation atmosphere, reduction atmosphere and high temperature conditions and has better chemical compatibility and thermal compatibility with typical electrolyte materials. In addition, the Bi element is cheaper and easier to obtain, the preparation method of Bi doping is also simpler and easier to operate and the application in the solid oxide battery can be facilitated.

Owner:UNIV OF SCI & TECH OF CHINA

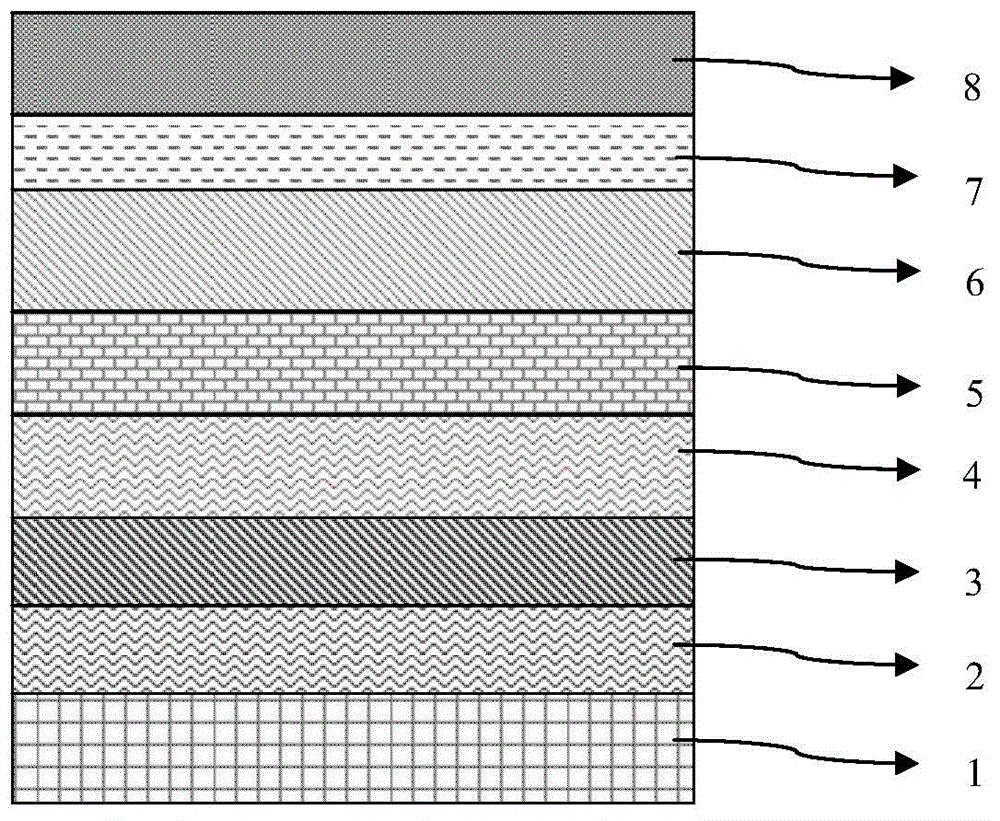

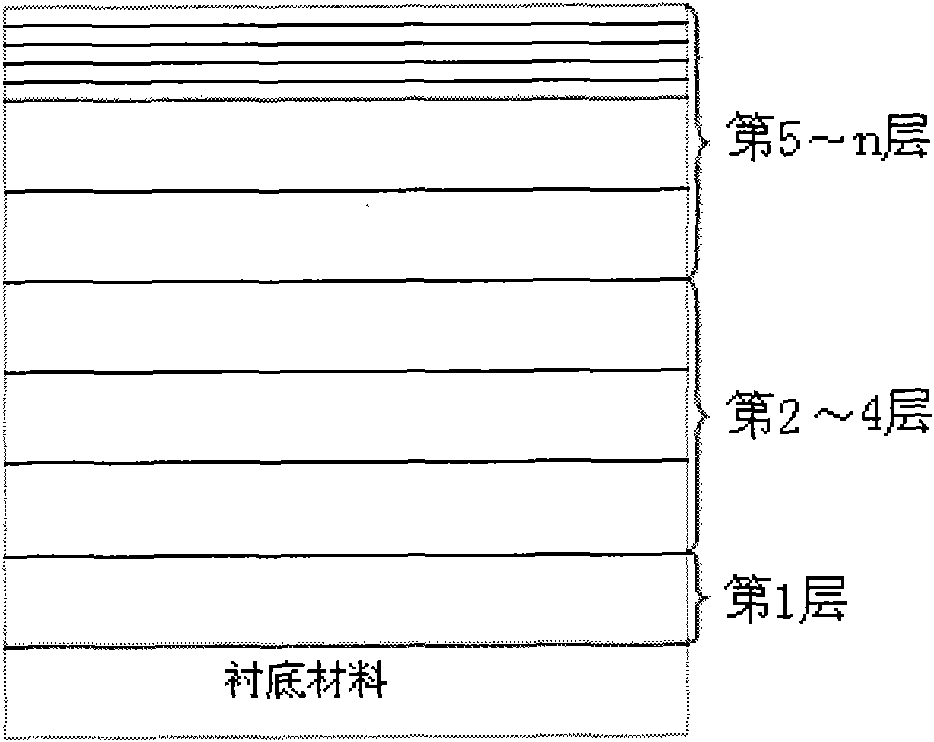

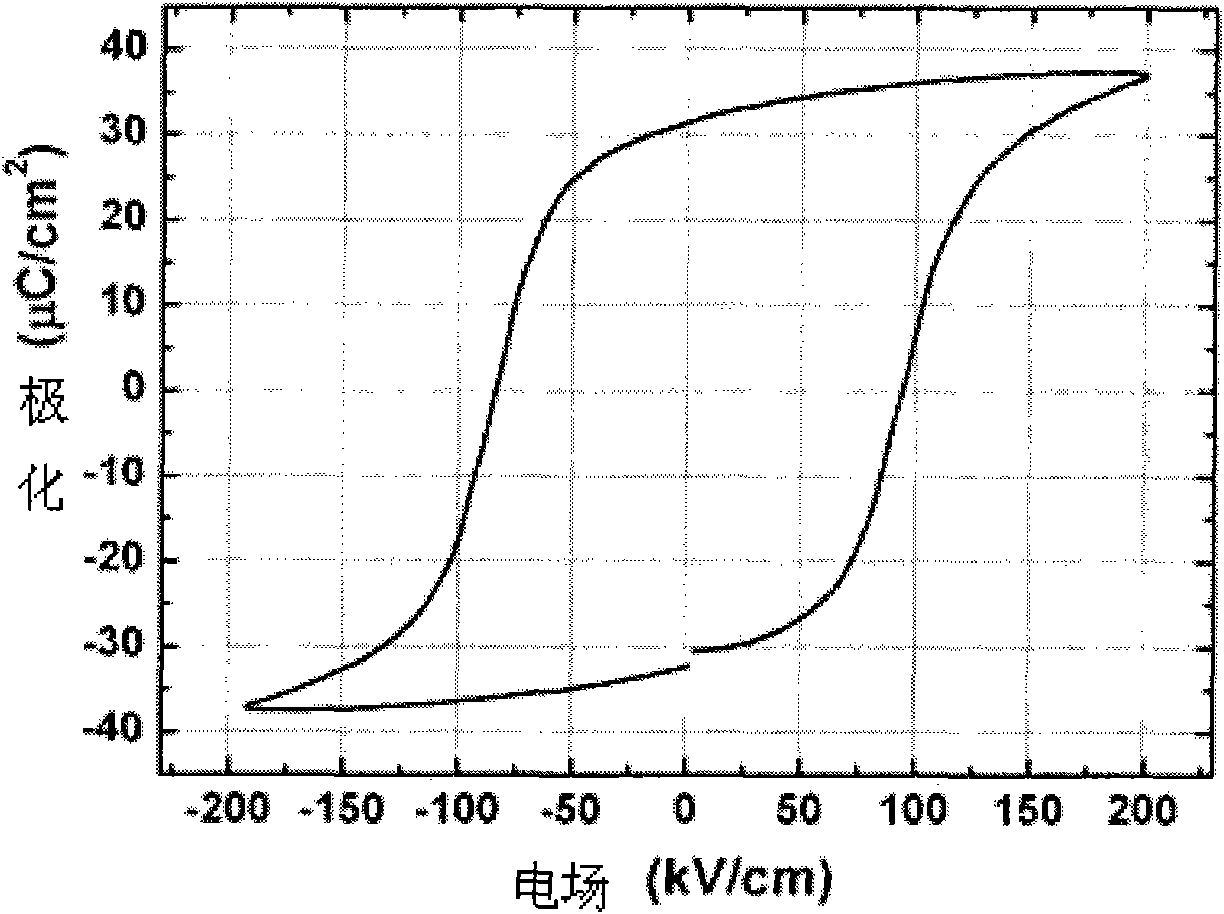

Lanthanide-doped bismuth titanate film and preparation method thereof

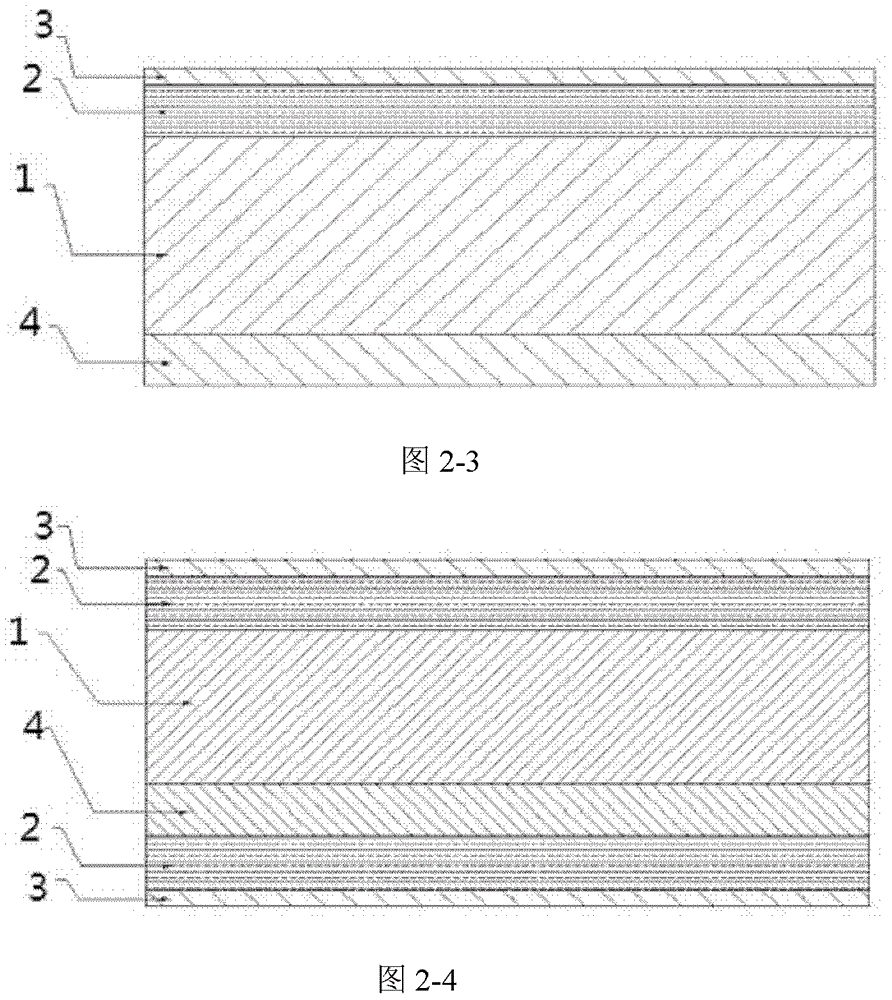

The invention discloses a lanthanide-doped bismuth titanate film. The film comprises at least five layers of materials, and the component of each layer of material is Bi(4-x)(1+y)LnxTi3O12, wherein Ln is one of lanthanides, x is a molar equivalent weight of the lanthanide, and x is more than or equal to 0.1 and less than or equal to 0.85; and excessive Bi element is added, y is the excessive percentage based on the weight of Bi, the y in the first layer of material is 5 to 15 percent, the y in the second to fourth layer of material is 10 to 20 percent, and the y in the fifth to over fifth layer of material is 15 to 25 percent. The invention also discloses a preparation method for the film. The preparation method of the invention has low cost and simple operation; and the prepared film (100) has high orientation preferential degree, improves the rectangular degree of polarized and ferroelectric hysteresis loops and the like, and is suitable for application.

Owner:UNIV OF JINAN

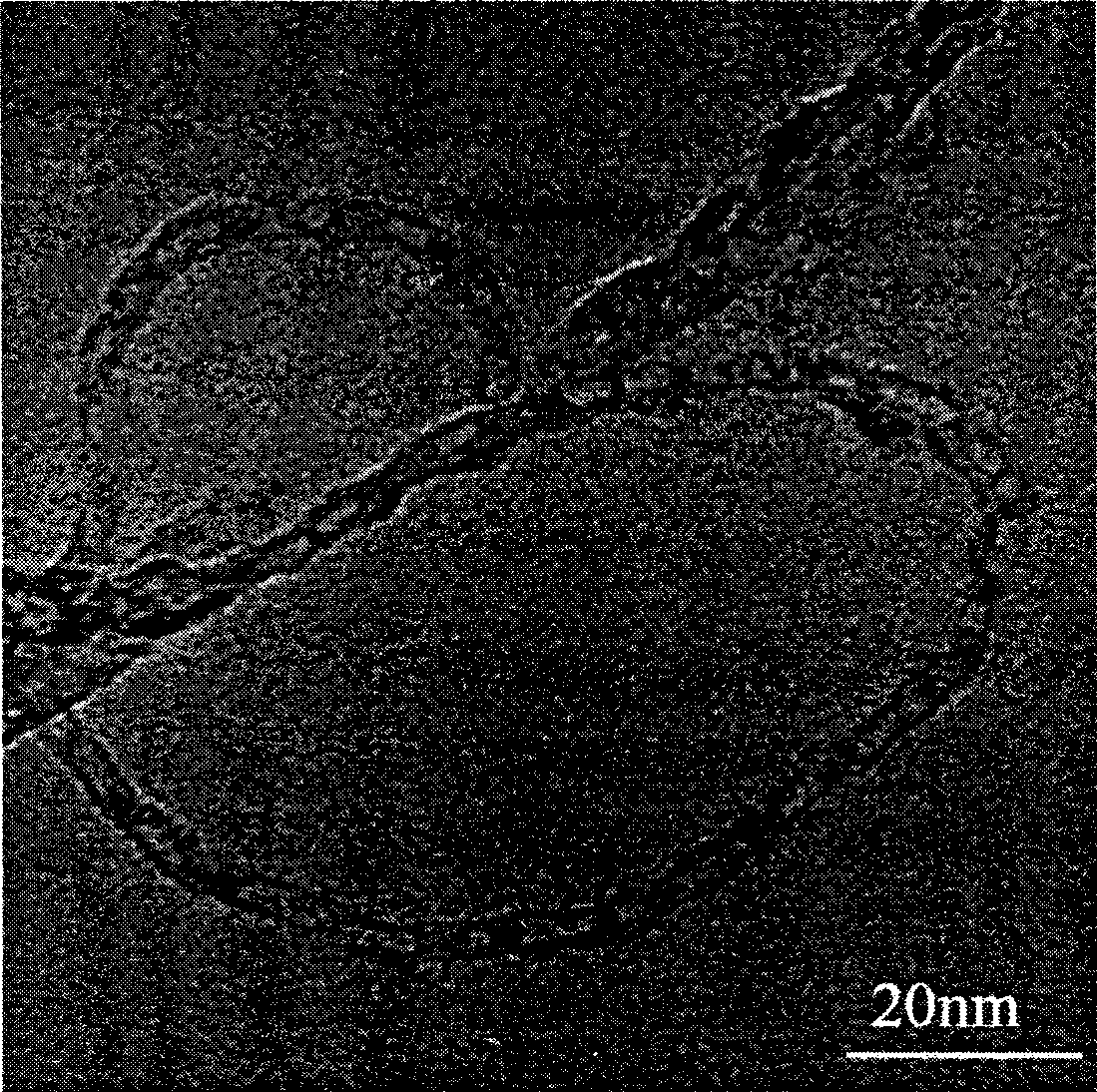

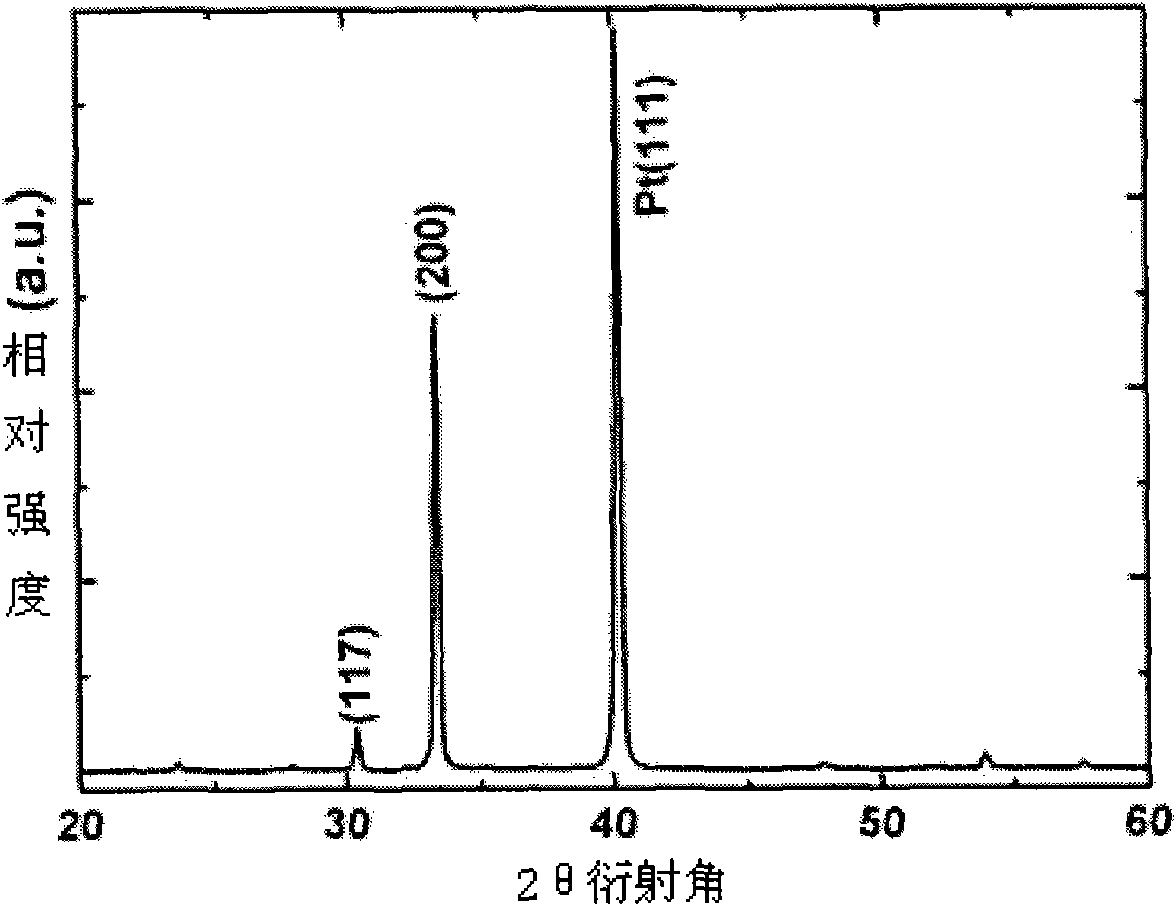

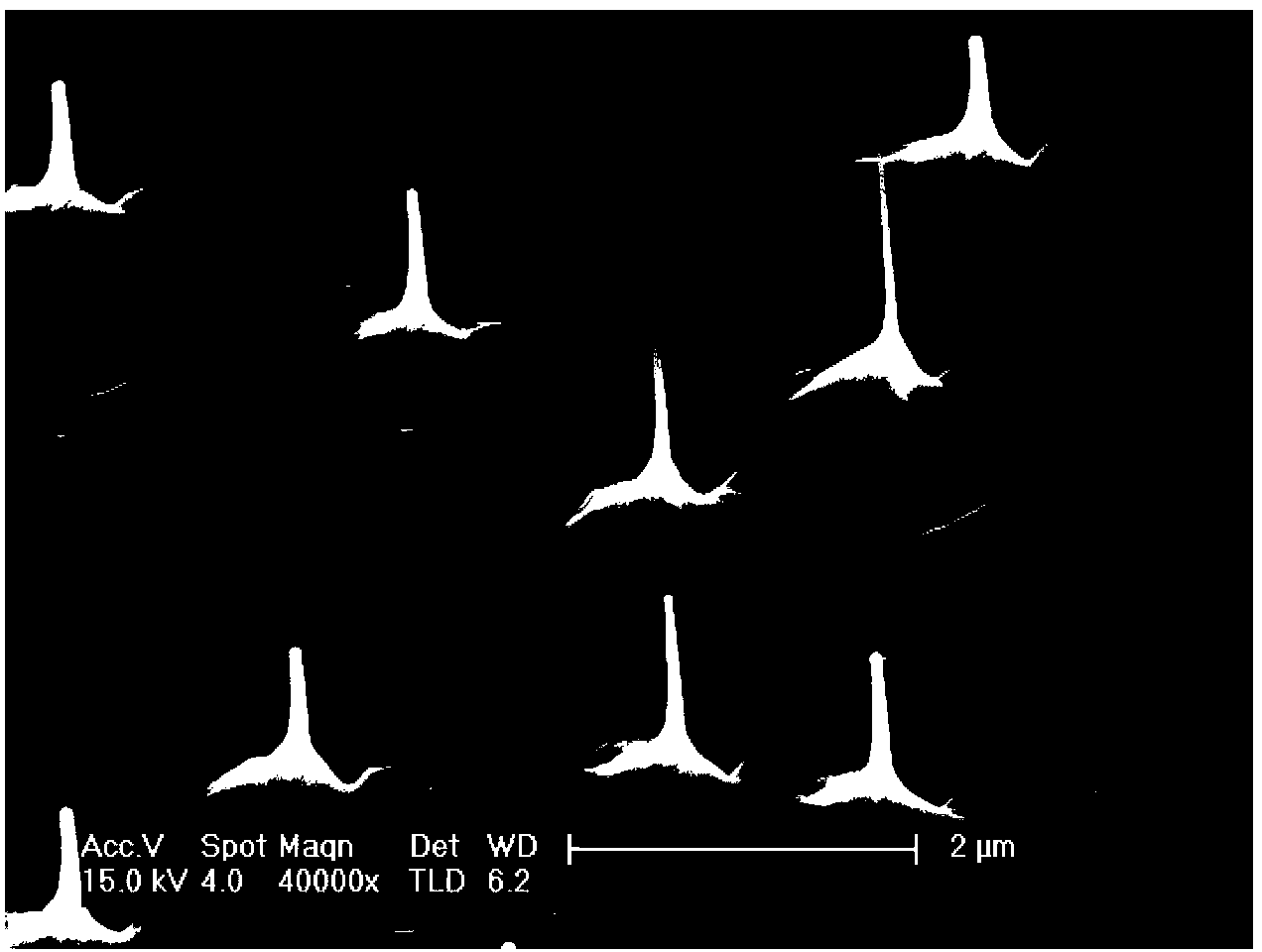

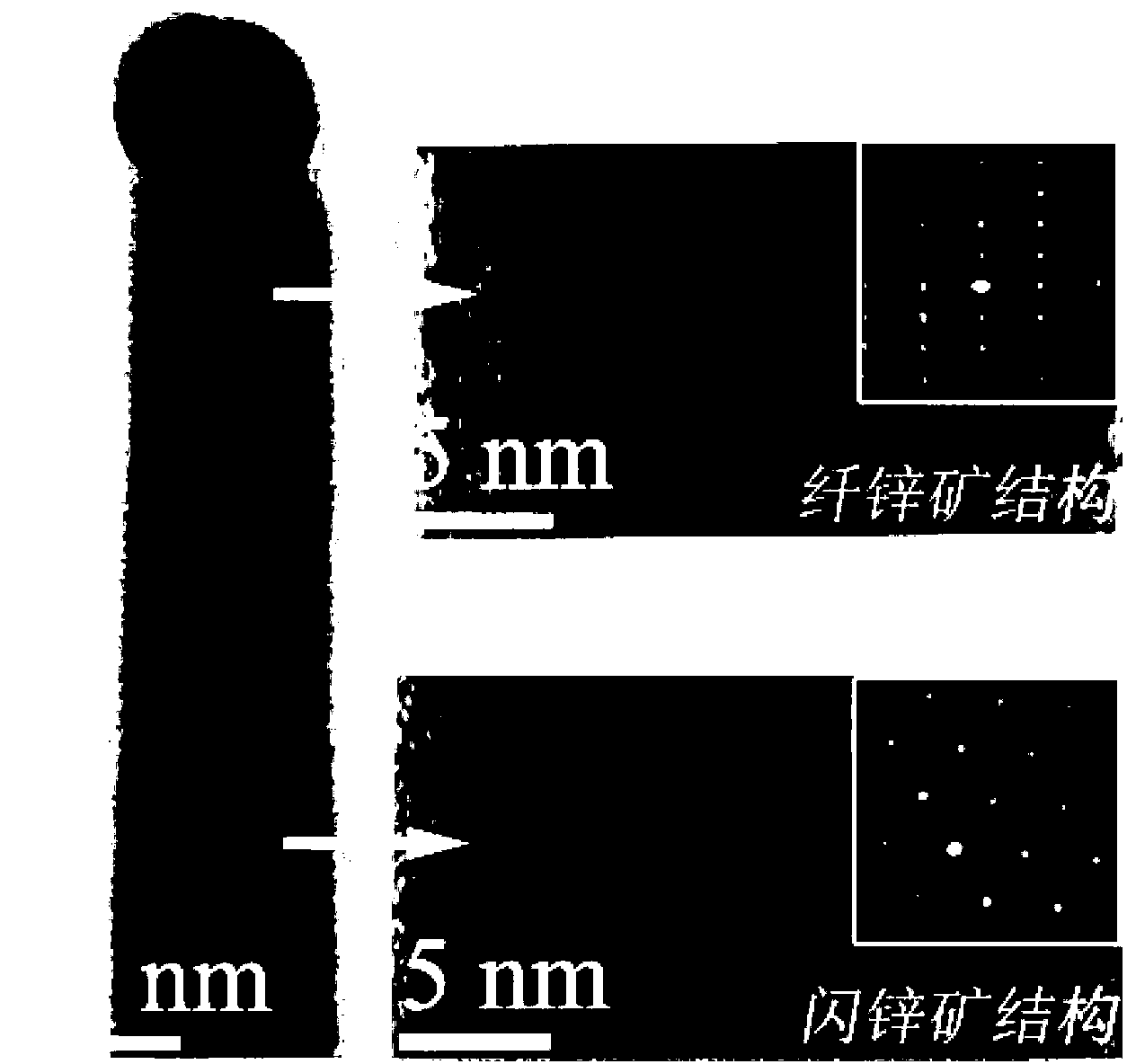

Molecular beam epitaxial (MBE) growth method of Bi element regulated and controlled GaAs-based nanowire crystal structure

InactiveCN103320866AGrowth Made EasyAchieve controlled growthPolycrystalline material growthFrom condensed vaporsNanowireCrystal structure

The invention discloses a molecular beam epitaxial (MBE) growth method of a Bi element regulated and controlled GaAs-based nanowire crystal structure. A Bi element is introduced as an activating agent during the growing process of nanowires in an MBE growth chamber, the ionicity of GaAs is reduced, and the formation of a nanowire zinc blende structure is promoted. The method is characterized in that the Bi evaporator source temperature is regulated during the process of nanowire growth according to the beam equivalent partial pressure of a Ga element so as to control the beam equivalent partial pressure of the Bi element and to ensure that the ratio of the beam equivalent partial pressure of the Bi element to that of the Ga element is x, and the value of x can influence the regulating and controlling ability of the Bi element to the nanowire crystal structure and influence the feature and the phase structure purity of the nanowires. The method has the benefits that the growth of the GaAs-bases nanowires with the zinc blende crystal structure can be easily realized without changing the growth process conditions of MBE, and thus the method is beneficial to the controlled growth of the GaAs-based nanowires with the wurtzite and zinc blende structure and the formation of a homogeneous heterophase heterogeneous structure of the nanowires, and provides an excellent material for preparing nanoscale photoelectronic devices.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

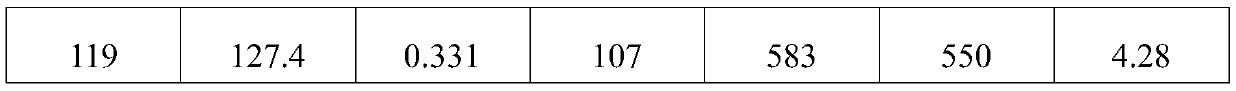

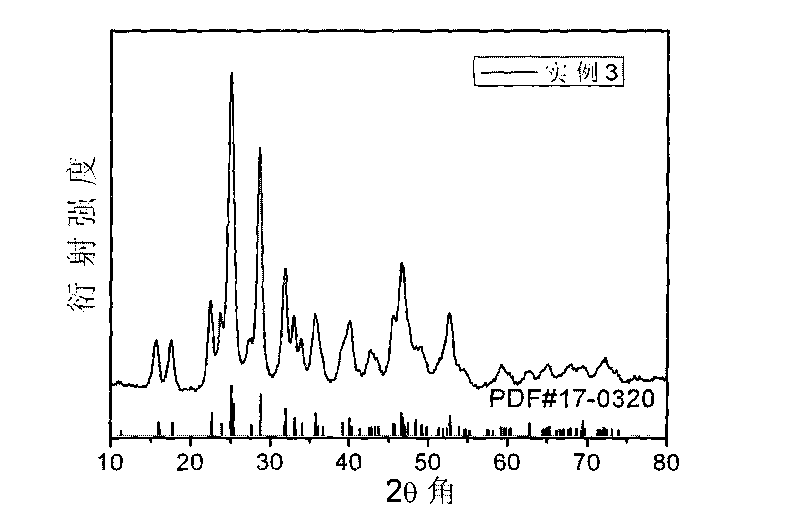

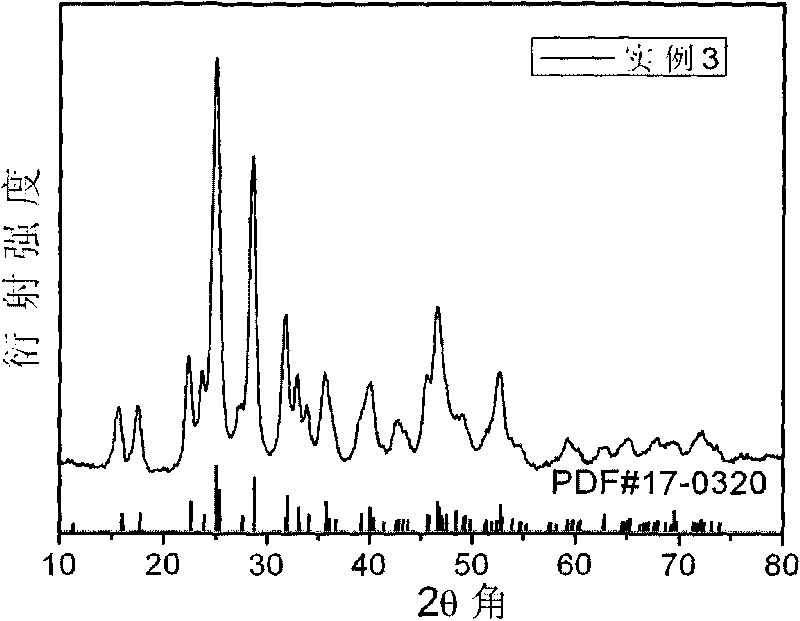

Bismuth ferrate-barium titanate-bismuth zinc titanate-bismuth aluminate high-temperature lead-free piezoelectric ceramic and preparation method thereof

The invention discloses a bismuth ferrate-barium titanate-bismuth zinc titanate-bismuth aluminate high-temperature lead-free piezoelectric ceramic and a preparation method thereof. The composition general formula of the piezoelectric ceramic is: xBiFeO3-yBaTiO3-zBi(Ti0.5Zn0.5)O3+tBiAlO3+mP+nMnCO3+2.5%Bi2O3, wherein x, y, z, t, m and n represent mole fractions, 0.6<=x<=0.8, 0.15<=y<=0.3, 0.05<=z<=0.15, 0<t<=0.10, 0<m<=0.1, 0<n<=0.1, and 2.5% mol of Bi2O3 is used to make up the volatilization of the Bi element in the sintering process, and is used as a sintering aid; and P is one or a combination of several sintering aids of Ba(W0.5Cu0.5)O3, CuO and Li2CO3. The preparation method comprises the working procedures of batching according to the composition general formula, ball milling, molding,glue discharge, sintering and the like. The high-temperature lead-free piezoelectric ceramic is prepared, the Curie temperature T<c> is up to 596 DEG C, the depolarization temperature T<d> is up to 580 DEG C, and the highest piezoelectric constant is up to 137 pC / N. The system ceramics are expected to be applied in high temperature fields such as aerospace, nuclear power, petroleum exploration and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

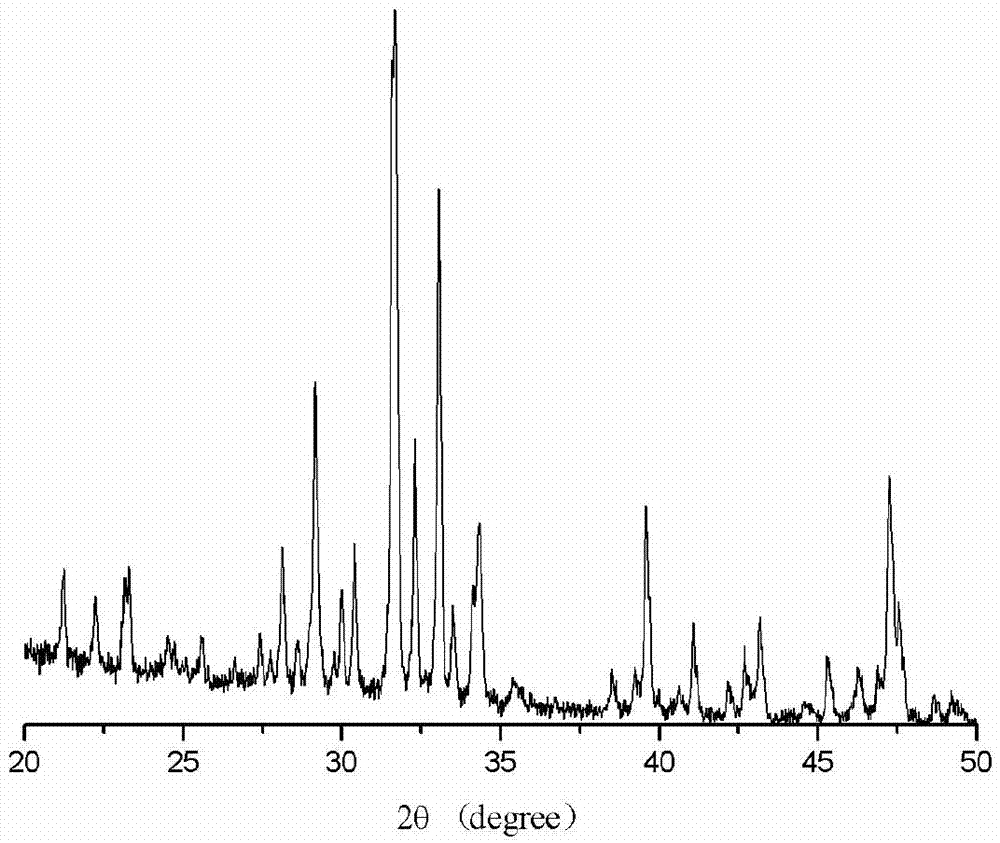

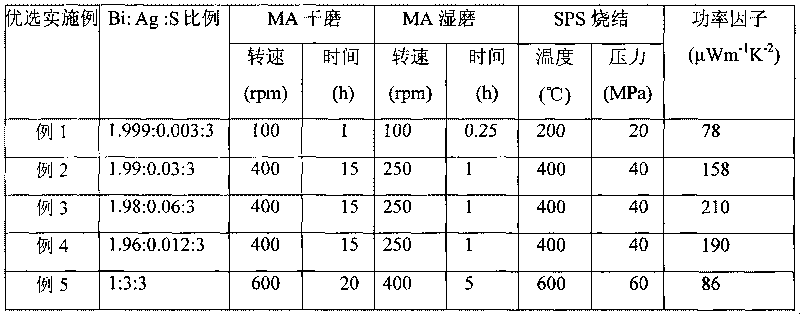

Bi2-xAg3xS3 thermoelectric material and preparation method thereof

InactiveCN101752495AGood size controlEasy to operateThermoelectric device manufacture/treatmentThermoelectric device junction materialsHigh densityHigh volume manufacturing

The invention discloses a Bi2-xAg3xS3 thermoelectric material and a preparation method thereof, which belongs to the technical field of energy source materials. By the invention, the Bi2-xAg3xS3 is prepared according to the stoichiometric proportion of Bi, S and Ag, wherein x respects the mole fraction of Ag and the value range of x is more than or equal to 0.001 and less than or equal to 1. The powder simple substances of Bi element, S element and Ag element with high purity (99.99 percent) are prepared according to the stoichiometric proportion of final product, are synthesized into powder in a mechanical alloying way and sintered into block bodies by using discharge plasma. The material has the advantages that the doping of the Ag greatly reduces the resistivity of the material and a higher optimal value can be acquired while the thermal conductivity has little change. The preparation method has the advantages of simple operation, low cost, easily-obtained material, short time, controllable particle size, high density, good mechanical property, great improvement of thermoelectric properties in comparison with Bi2S3 and suitability for large-batch production.

Owner:UNIV OF SCI & TECH BEIJING

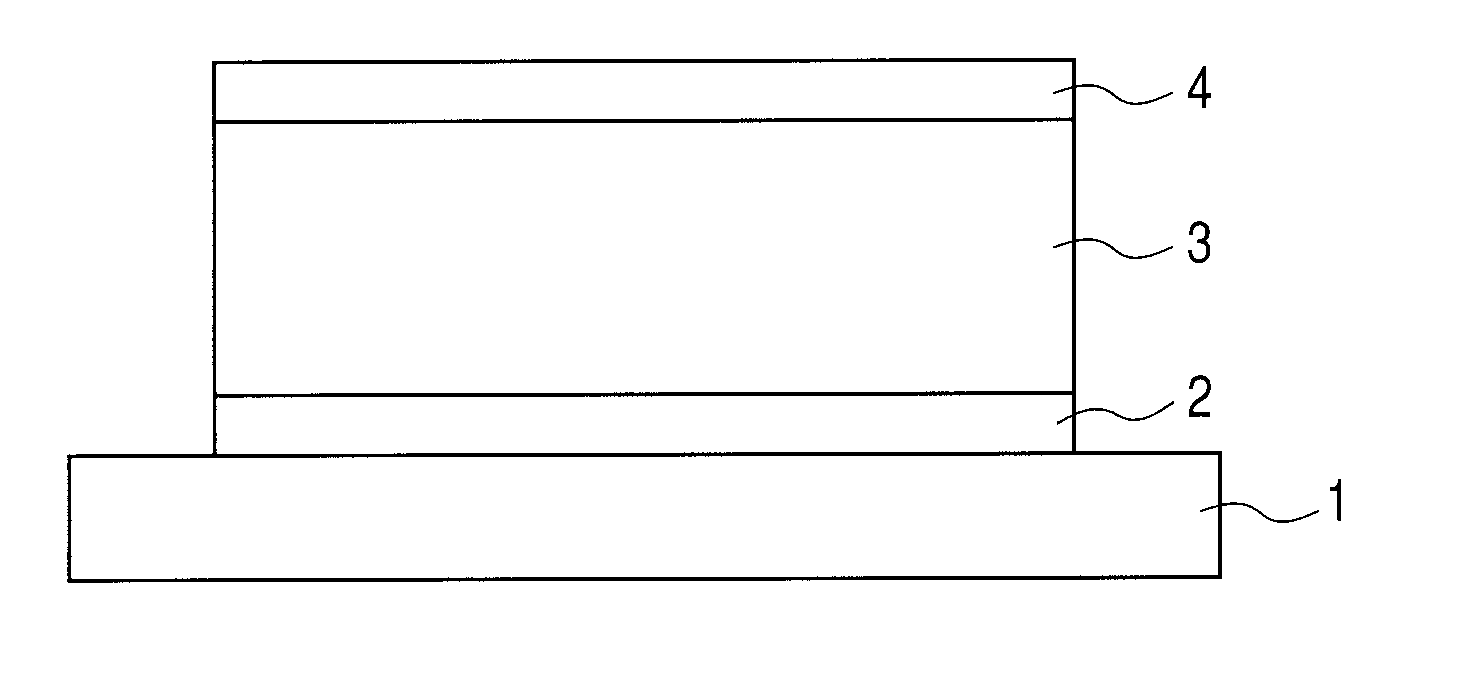

Piezoelectric material

ActiveUS8980117B2Excellent piezoelectric propertiesSatisfactory piezoelectric characteristicPiezoelectric/electrostriction/magnetostriction machinesSolid-state devicesCurie temperatureBi element

Provided is a piezoelectric material having a high Curie temperature and satisfactory piezoelectric characteristics, the piezoelectric material being represented by the following general formula (1):A(ZnxTi(1-x))yM(1-y)O3 (1)where A represents a Bi element, M represents at least one element selected from Fe, Al, Sc, Mn, Y, Ga, and Yb; x represents a numerical value of 0.4≦x≦0.6; and y represents a numerical value of 0.17≦y≦0.60.

Owner:CANON KK +3

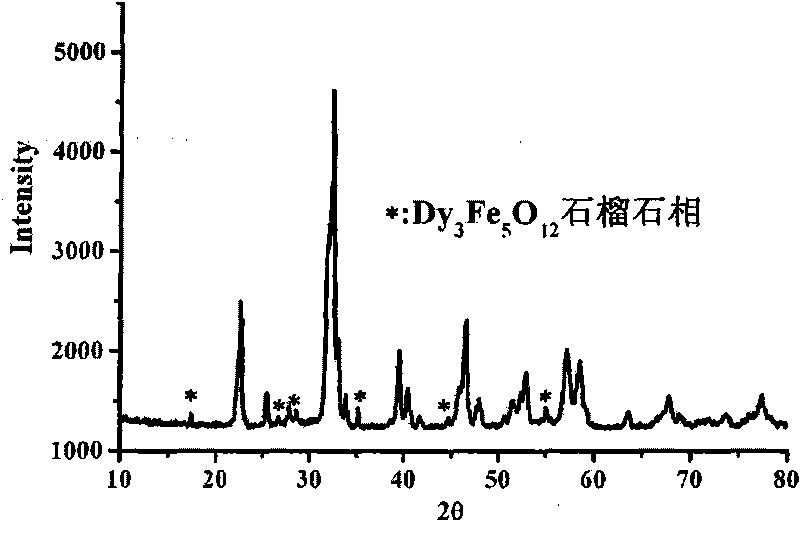

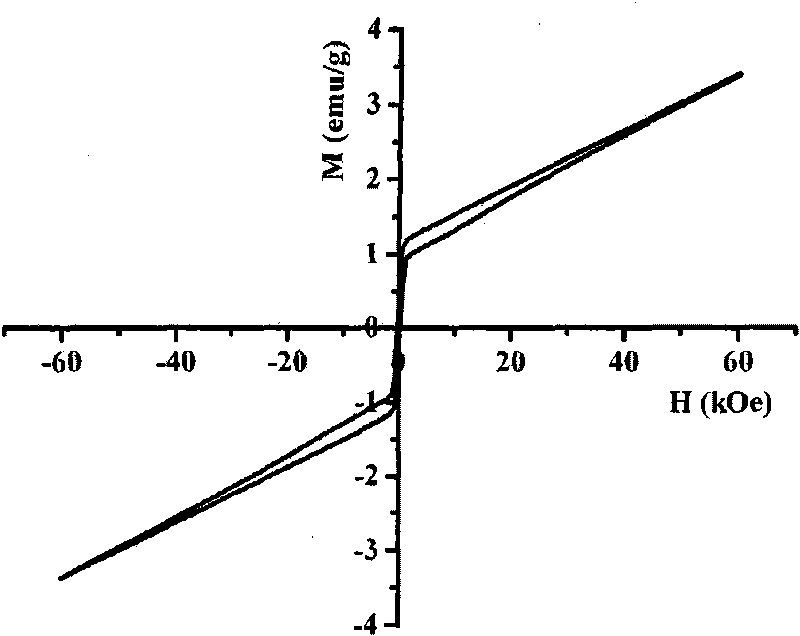

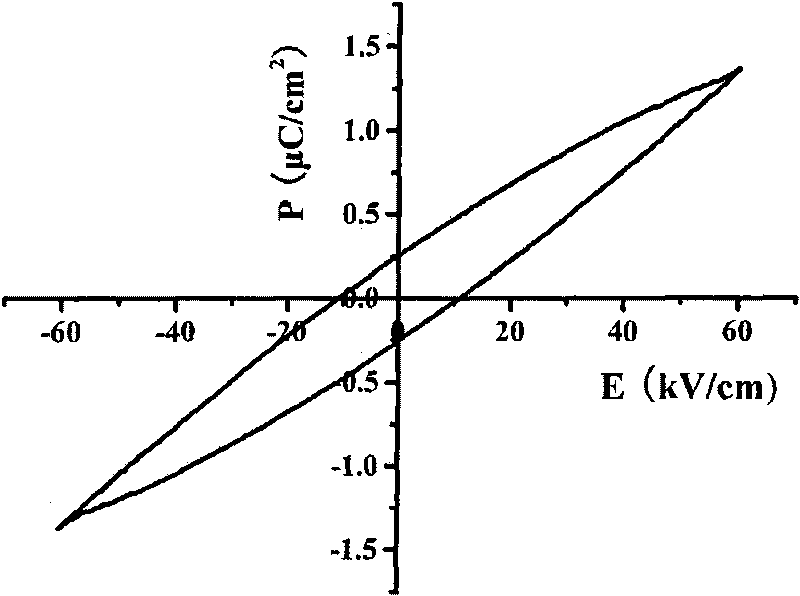

Method for preparing BiFeO3 based multiferroic composite material

InactiveCN101723660AImprove magnetic propertiesImprove ferroelectric propertiesBi elementMultiferroics

The invention discloses a method for preparing a BiFeO3 based multiferroic composite material. Positions of a Bi element and a Fe element are simultaneously doped with dysprosium and titanium in different ratios, and a ferrimagnetic garnet minor phase is generated in the finally obtained sample through autonomous induction so as to form the multiferroic composite material. The method for preparing the material comprises the following steps: weighing bismuth oxide, ferric oxide, dysprosia and titanium dioxide powder in a certain ratio, fully mixing and grinding uniformly, tabletting, roasting in a tube furnace or chamber furnace at 650 DEG C for one hour, and cooling along with the furnace to room temperature; and secondarily grinding and tabletting the obtained product, sintering in the tube furnace again at different temperatures from 820 to 970 DEG C according to different component ratios for about 20 minutes by a method similar to rapid sintering, and preparing the compact block multiferroic composite material. Simultaneously, the dysprosium element is replaced by a gadolinium element, and the BiFeO3 based multiferroic composite material with improved ferroelectricity and magnetism can also be obtained.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Preparing process for high thermoelectric properties BiTe material

InactiveCN101199995AImprove thermoelectric performanceSolution to short lifeThermoelectric device manufacture/treatmentVacuum pumpingBi element

The invention relates to the preparation method of a high thermoelectricity BiTe material, which is characterized in that the invention comprises the following preparation steps: 1) select Bi element-containing and Te element-containing powder to sinter and prepare BiTe base materials; 2) put the prepared materials into the center of the moulding die; 3) put the die with prepared material into hot pressing device, making vacuum pumping, air inflating and prepurging treatment; 4) heat the material up to 300 to 570 DEG C, exert 20 to 80 MPa pressure, and keep for 1.5 to 10h, then execute moulding treatment; 5) preserve the molded material for 2 to 10h for annealing treatment at the temperature of 150 to 450 DEG C, then the high thermoelectricity BiTe material is obtained after being taken out. Because the moulding treatment is adopted, the thermoelectricity performance of BiTe is improved, thereby laying a good foundation for preparing the thermoelectric generator with long service life and high efficiency.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Piezoelectric material

ActiveUS20110012050A1Excellent piezoelectric propertiesImprove featuresAlkaline earth titanatesPiezoelectric/electrostrictive device manufacture/assemblyRare-earth elementBi element

Owner:UNIVERSITY OF YAMANASHI +5

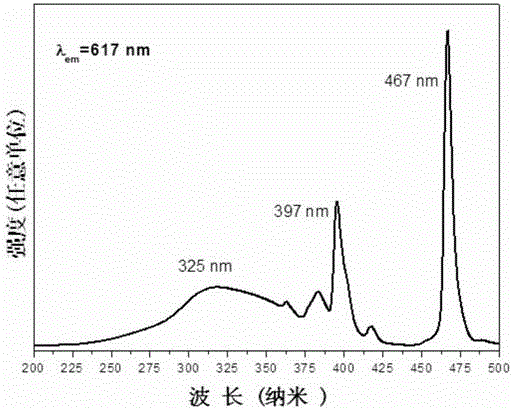

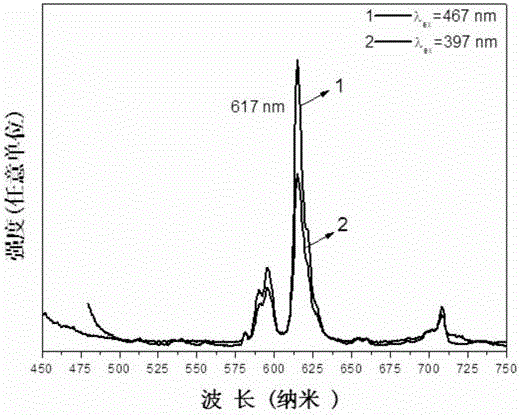

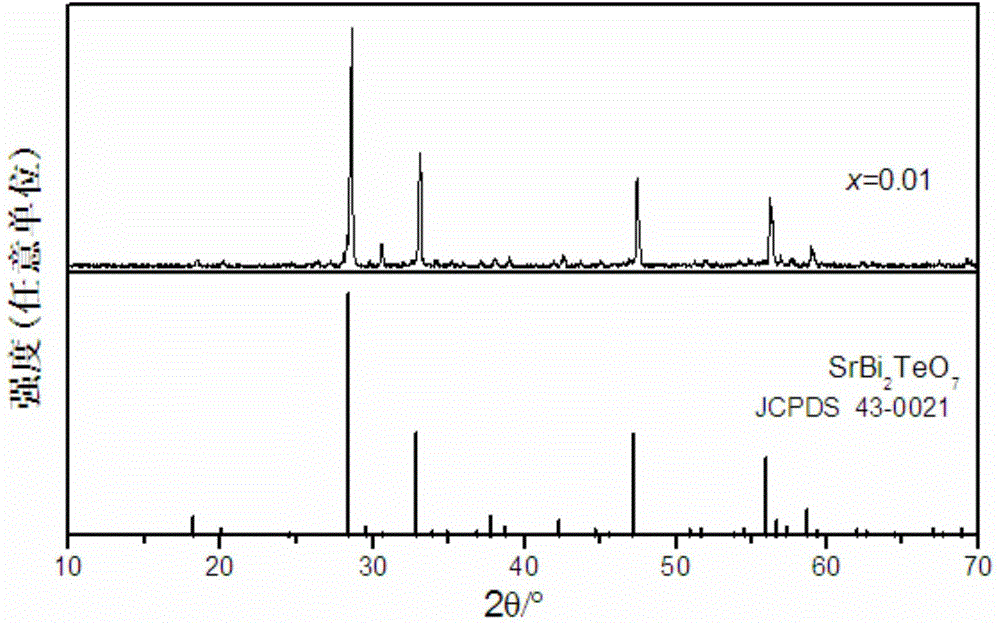

Red fluorescent powder and preparation method thereof

InactiveCN104371731APromote absorptionEfficient use ofLuminescent compositionsAir atmosphereUltraviolet lights

The invention discloses a red fluorescent powder and a preparation method thereof. The chemical composition formula is SrBi2(1-x)Eu2xTeO7, wherein x is mole percent of the doping element Eu relative to the Bi element, and x is greater than or equal to 0.01 and smaller than or equal to 0.90. The preparation method comprises the following steps: by using strontium oxide or carbonate as the raw material of strontium element, bismuth oxide or nitrate as the raw material of bismuth element, tellurium dioxide or tellurium trioxide as the raw material of tellurium element and europium oxide or nitrate as the raw material of europium element, mixing and grinding in an agate mortar to obtain an initial mixture, sintering at 800-900 DEG C in an air atmosphere for 2-8 hours, and grinding to obtain the product. The luminescent material can effectively absorb ultraviolet light and blue light within the range of 300-500nm; the generated main emission peak is 617nm red light emission; and the fluorescent powder has the advantages of high luminescent intensity, high color purity and favorable color coordinates, and is suitable to be used as the red light part of the luminescent material for LED (light-emitting diode).

Owner:NORTHWEST A & F UNIV

Piezoelectric material and devices using the same

ActiveUS9082975B2Improve insulation performanceImprove conversion efficiencyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesBi elementMetal

Owner:CANON KK +2

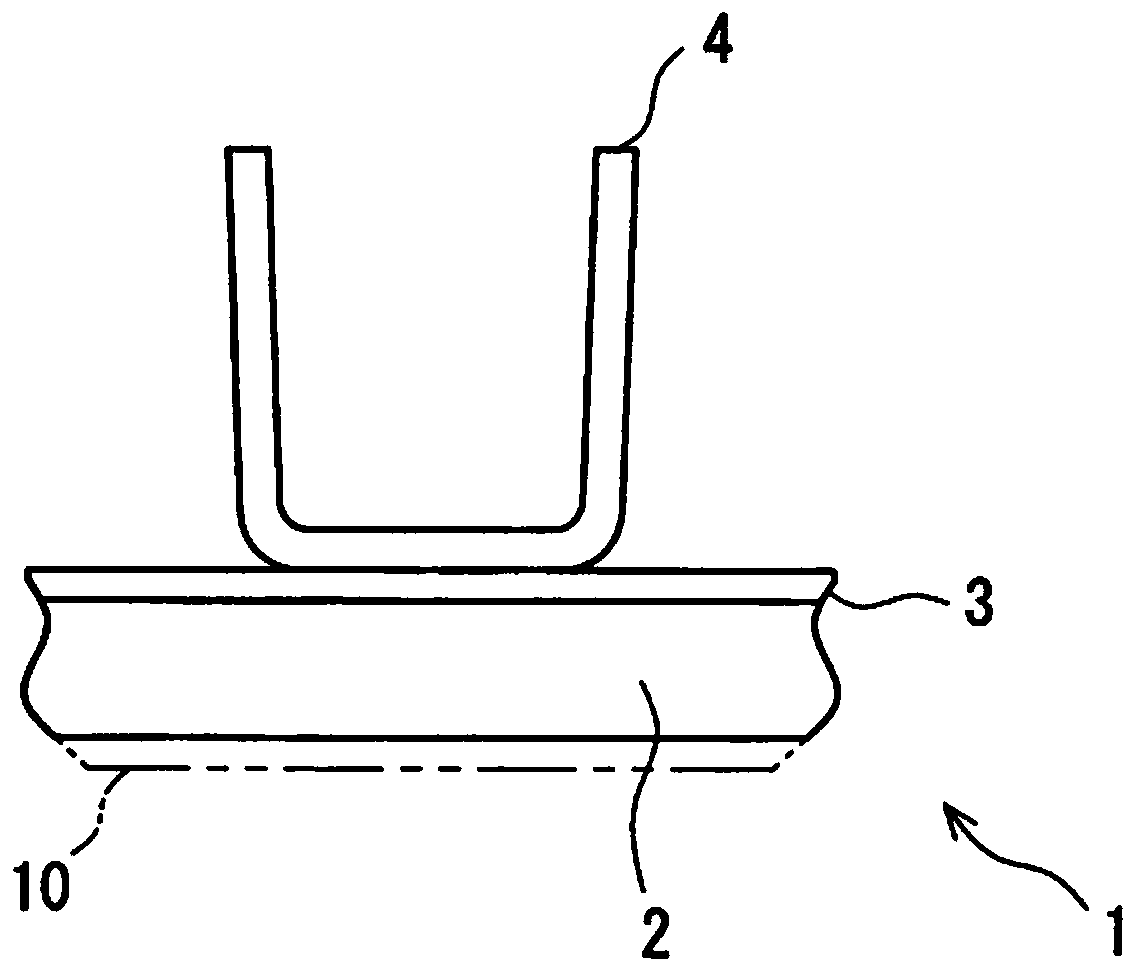

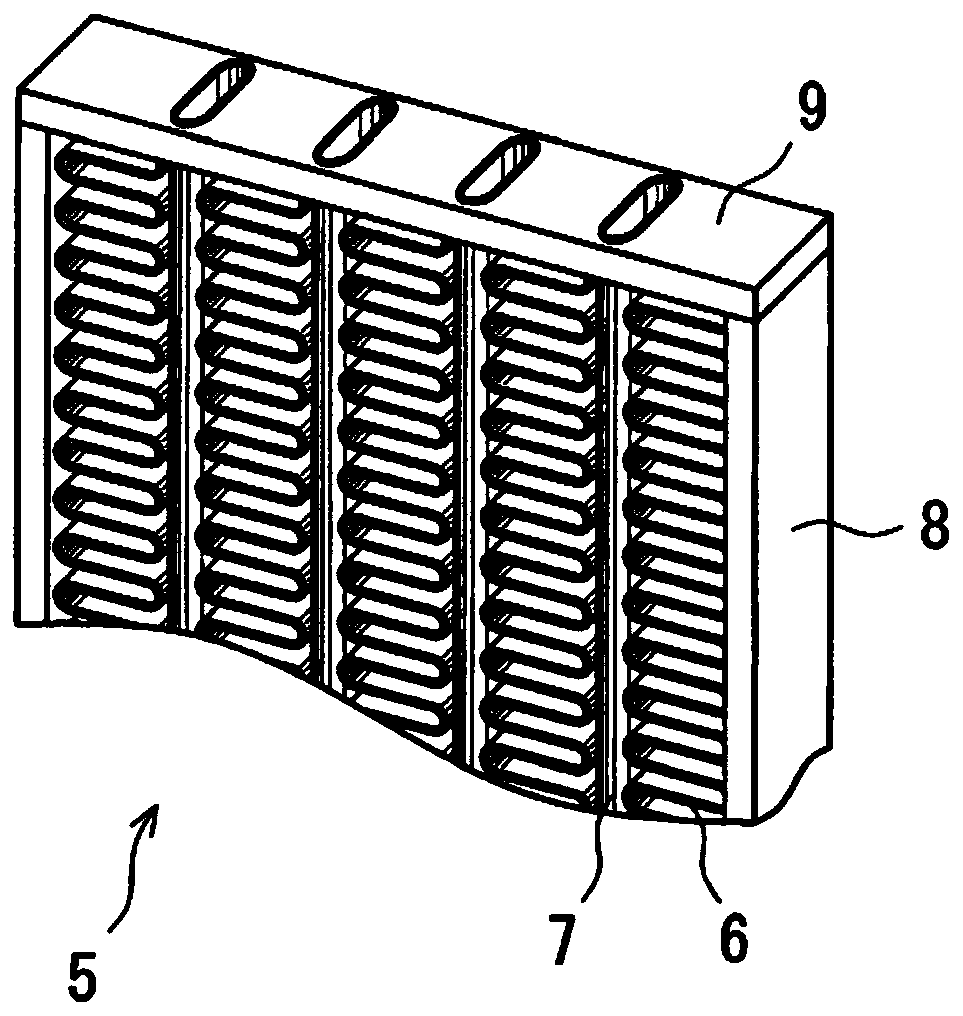

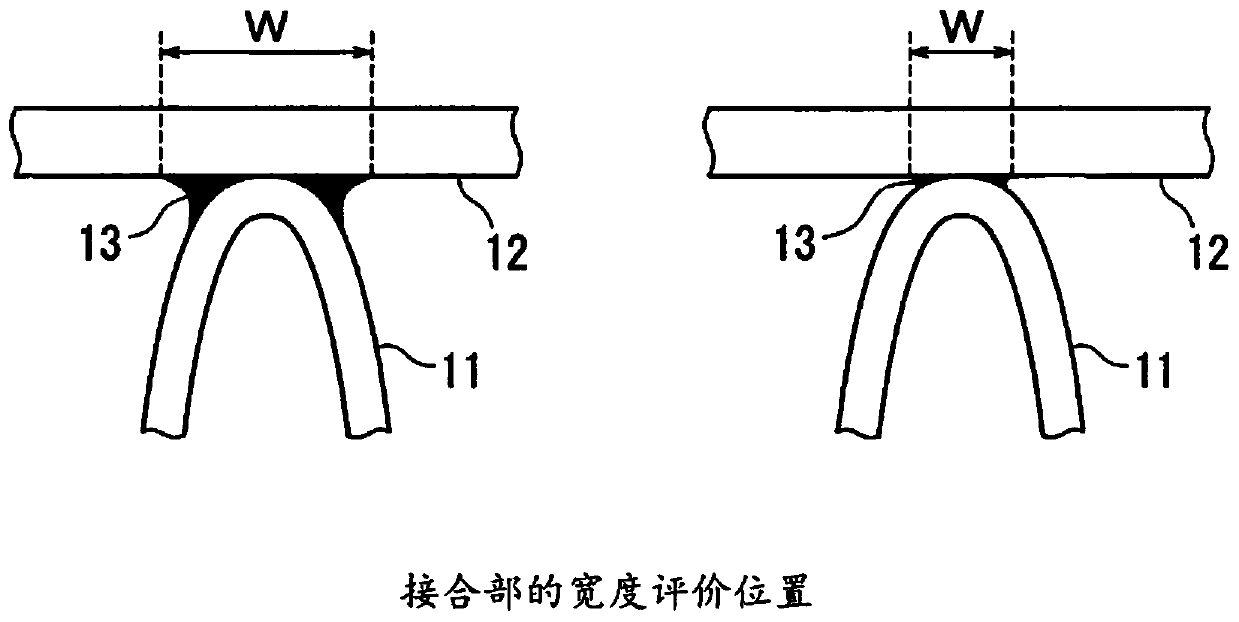

Flux-free aluminum brazing sheet

ActiveCN110719965AGood and stable brazed jointStationary conduit assembliesWelding/cutting media/materialsBi elementNon oxidative

The invention provides an aluminum brazing sheet for fluxless brazing, which is used for brazing in a non-oxidizing atmosphere without using a flux and without a reduced pressure. Al-Si-Mg-Bi series solder coatings containing 0.01 to 2.0% of Mg, 1.5 to 14.0% of Si, and 0.05 to 1.5% of Bi by mass% is located on the outermost surface by covering one or both sides of the core material. The Mg-Bi-based compound contained in the Al-Si-Mg-Bi-based solder has an equivalent circle diameter of 0.01 [mu] m or more and less than 5. There are more than 10 Mg-Bi compounds with a diameter of 0 [mu] m in thefield of view per 10,000 [mu] m2; The field of view of 10,000 m2 is less than two. When the particles of Bi element contained in the brazing material are viewed from the surface layer surface beforebrazing, the particles of Bi element having a diameter of 5.0 [mu] m or more in terms of equivalent circle diameter per 10,000 [mu] m2 Field of view is less than 5.

Owner:MA ALUMINUM CORP

Piezoelectric material

ActiveUS20110268965A1Excellent piezoelectric propertiesSatisfactory piezoelectric characteristicSolid-state devicesSemiconductor/solid-state device manufacturingBi elementCurie temperature

Provided is a piezoelectric material having a high Curie temperature and satisfactory piezoelectric characteristics, the piezoelectric material being represented by the following general formula (1):A(ZnxTi(1-x))yM(1-y)O3 (1)where A represents a Bi element, M represents at least one element selected from Fe, Al, Sc, Mn, Y, Ga, and Yb; x represents a numerical value of 0.4≦x≦0.6; and y represents a numerical value of 0.17≦y≦0.60.

Owner:CANON KK +3

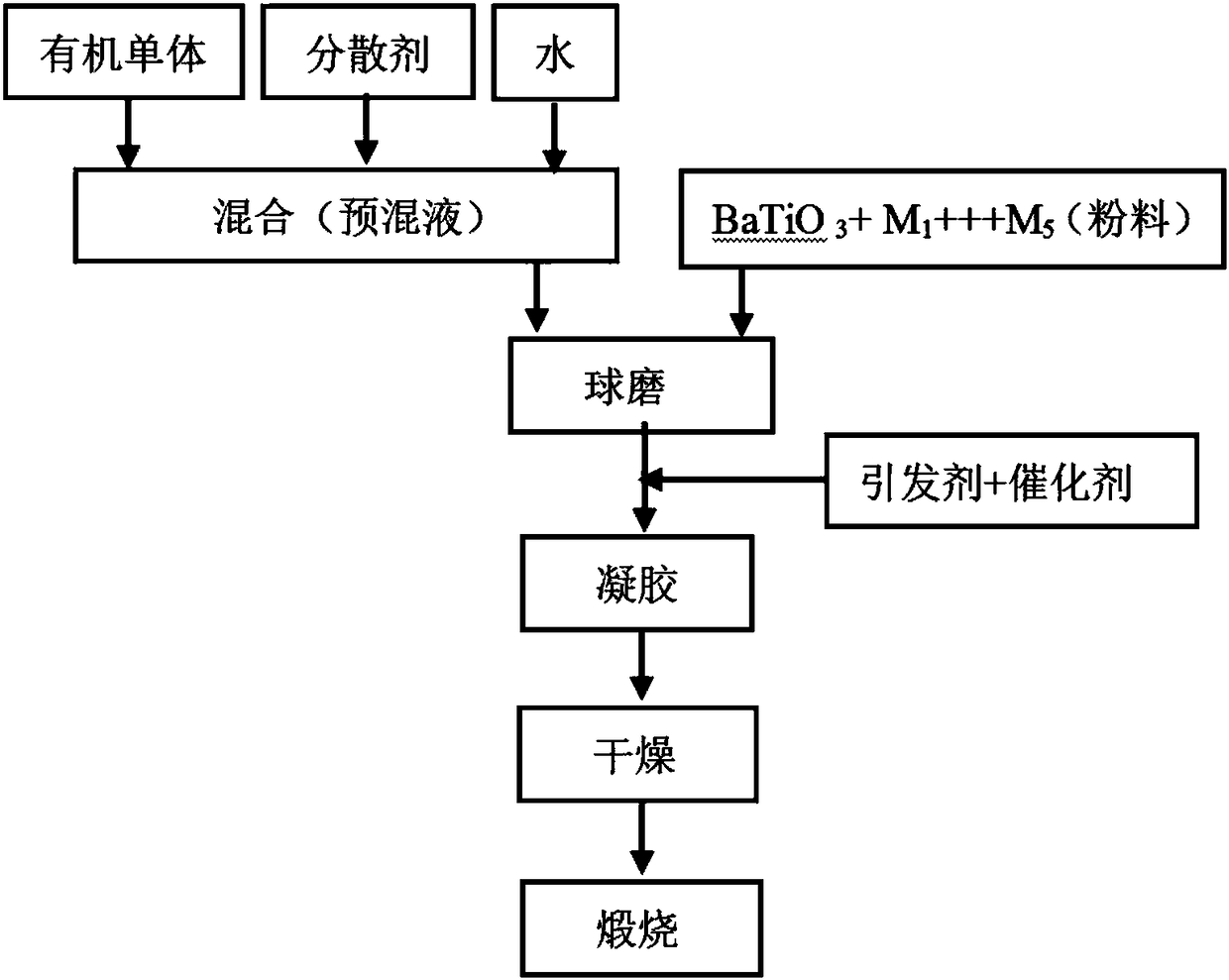

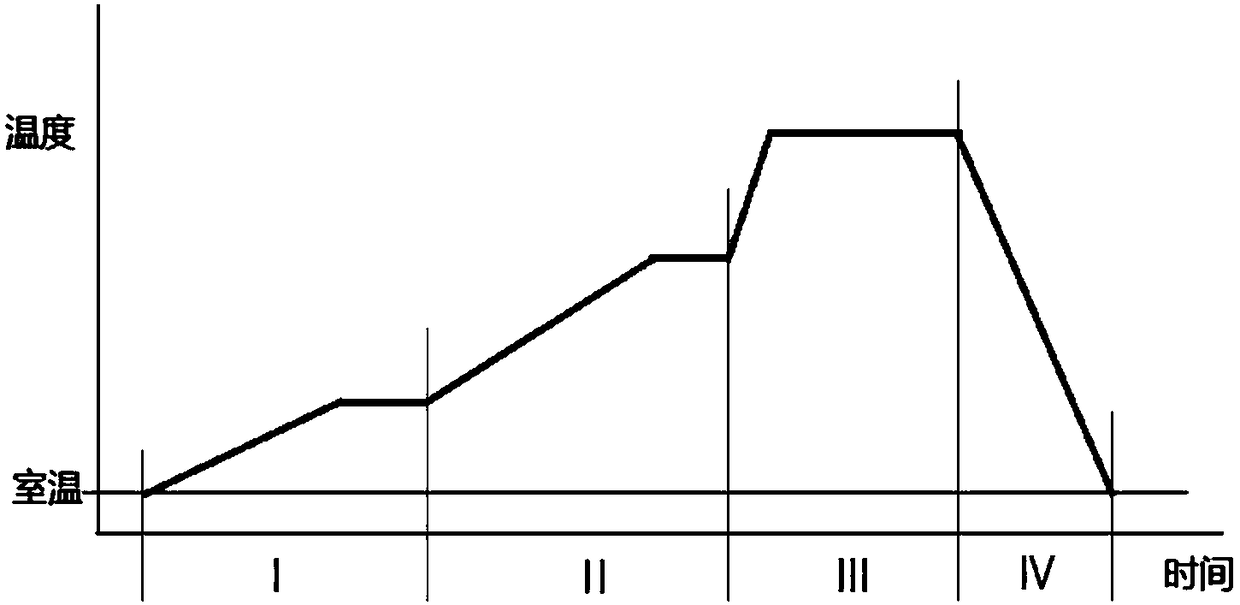

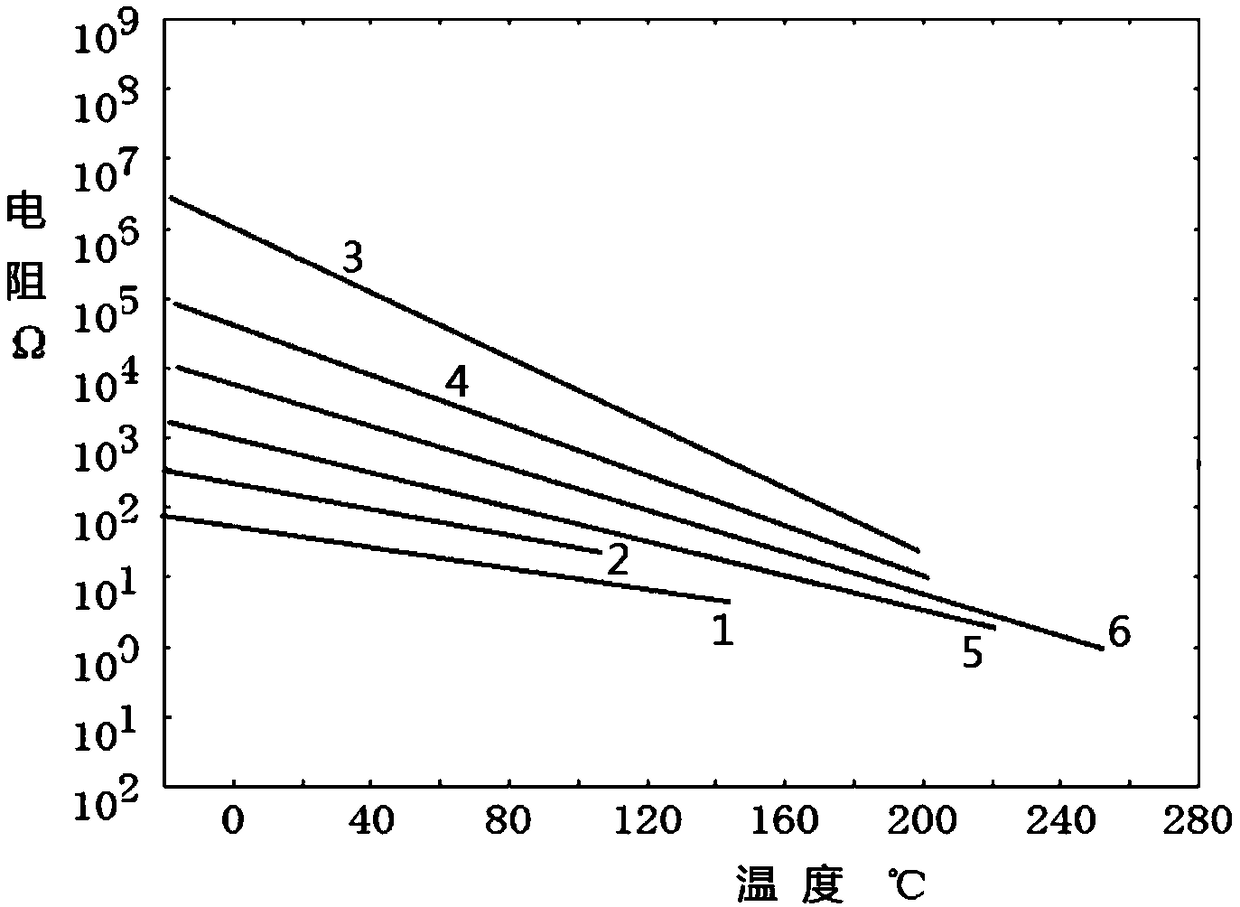

Wide-temperature range negative temperature coefficient heat-sensitive ceramic material and preparation method thereof

ActiveCN108546114AMeasuring temperature range widthAccurate measurementBased wideNegative temperature

The invention discloses a wide-temperature range negative temperature coefficient heat-sensitive ceramic material and a preparation method thereof. Raw materials of the negative temperature coefficient heat-sensitive ceramic material comprise BaTiO3, TiO2, M1O, M2O, M3O, M4O and M5O, wherein M1 is at least one of Sm, Nd, Y, La and Nb elements; M2 is at least two of Si, Al and Ti elements; M3 is acombination of the Ca element and at least one of Sr and Pb elements; M4 is at least one of Sb and Bi elements; and M5 is at least one of Na, K and Li elements. The barium titanate-based wide-temperature range NTC heat-sensitive ceramic material with the measuring temperature range being 300 DEG C or more is obtained through improving and further optimizing the key composition components of the ceramic material and the whole process flow and condition parameters in all reaction steps of the corresponding preparation method and doping and modifying a barium titanate-based semiconductor heat-sensitive ceramic.

Owner:HUAZHONG UNIV OF SCI & TECH

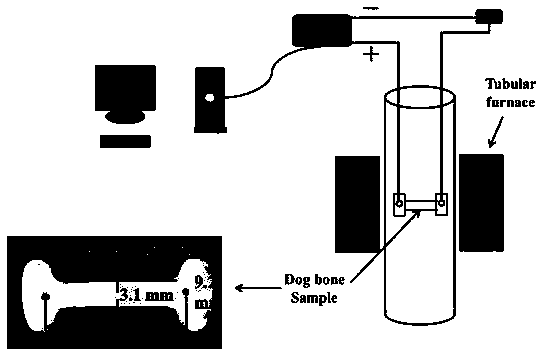

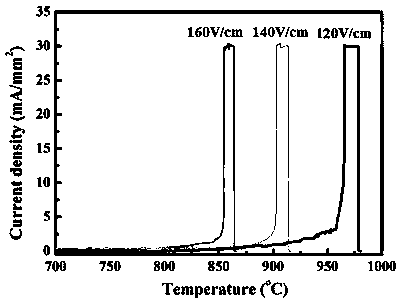

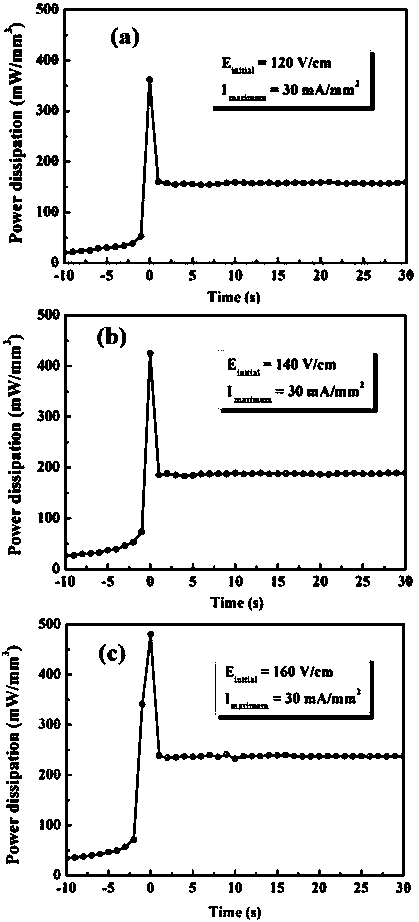

Method for rapidly sintering NBT piezoelectric ceramic at low temperature

The invention discloses a method for rapidly sintering an NBT piezoelectric ceramic at a low temperature. According to the method, an electric field is applied to both ends of a ceramic blank when theNBT piezoelectric ceramic is sintered. Under the action of the electric field, rapid densification of the ceramic can be realized at the low temperature, and the problems of Bi element volatilizationand high energy consumption caused by long-time sintering of NBT at a high temperature in the traditional sintering process are solved. The NBT piezoelectric ceramic prepared with the method providedby the invention is high in density and has application prospects.

Owner:SHAANXI UNIV OF SCI & TECH

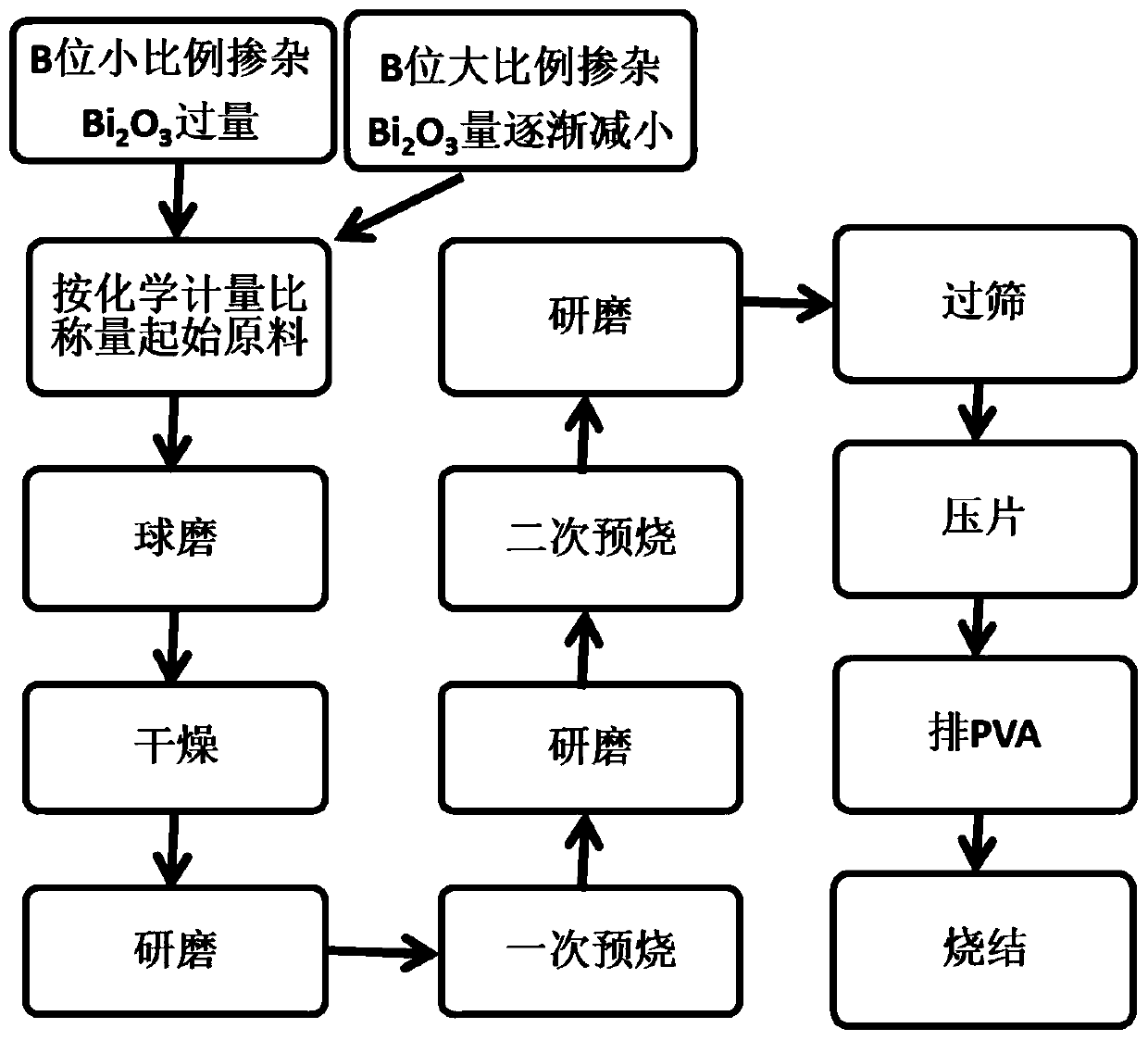

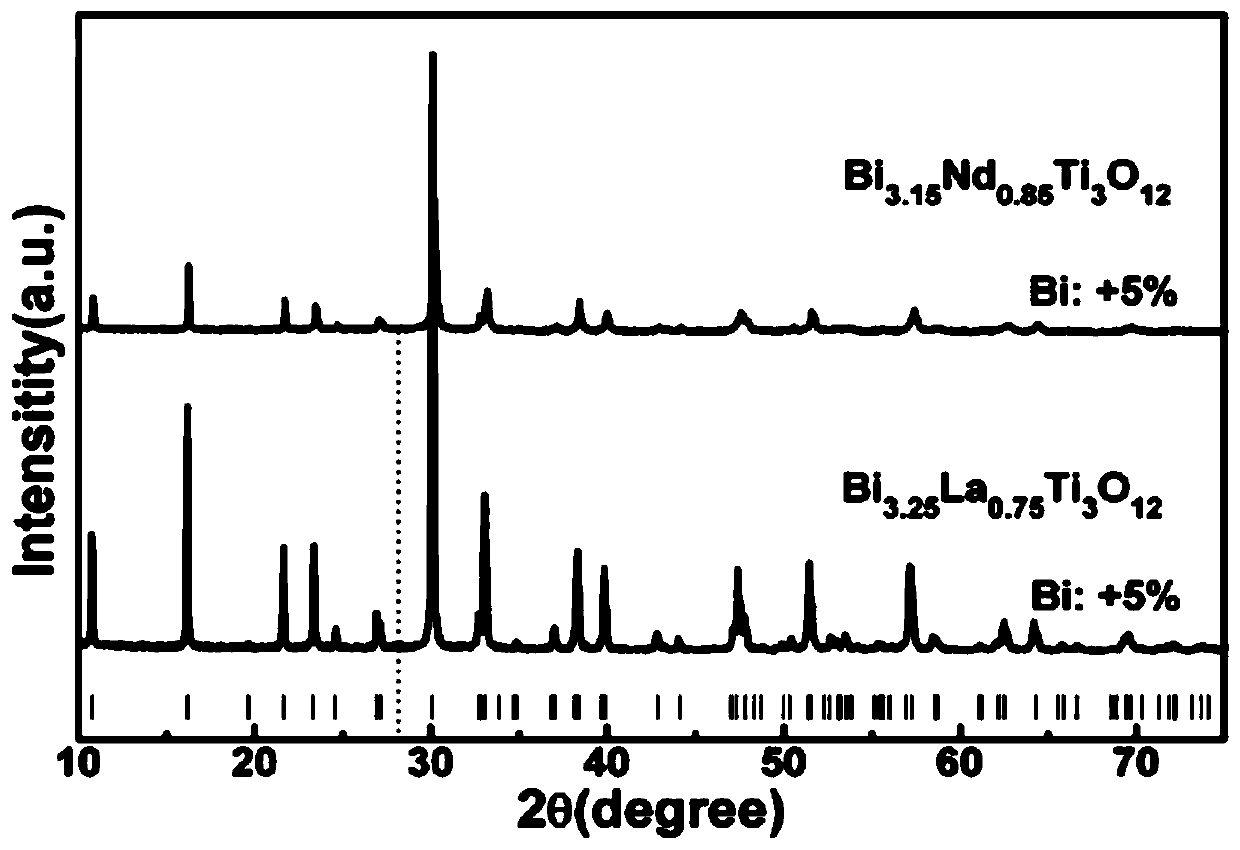

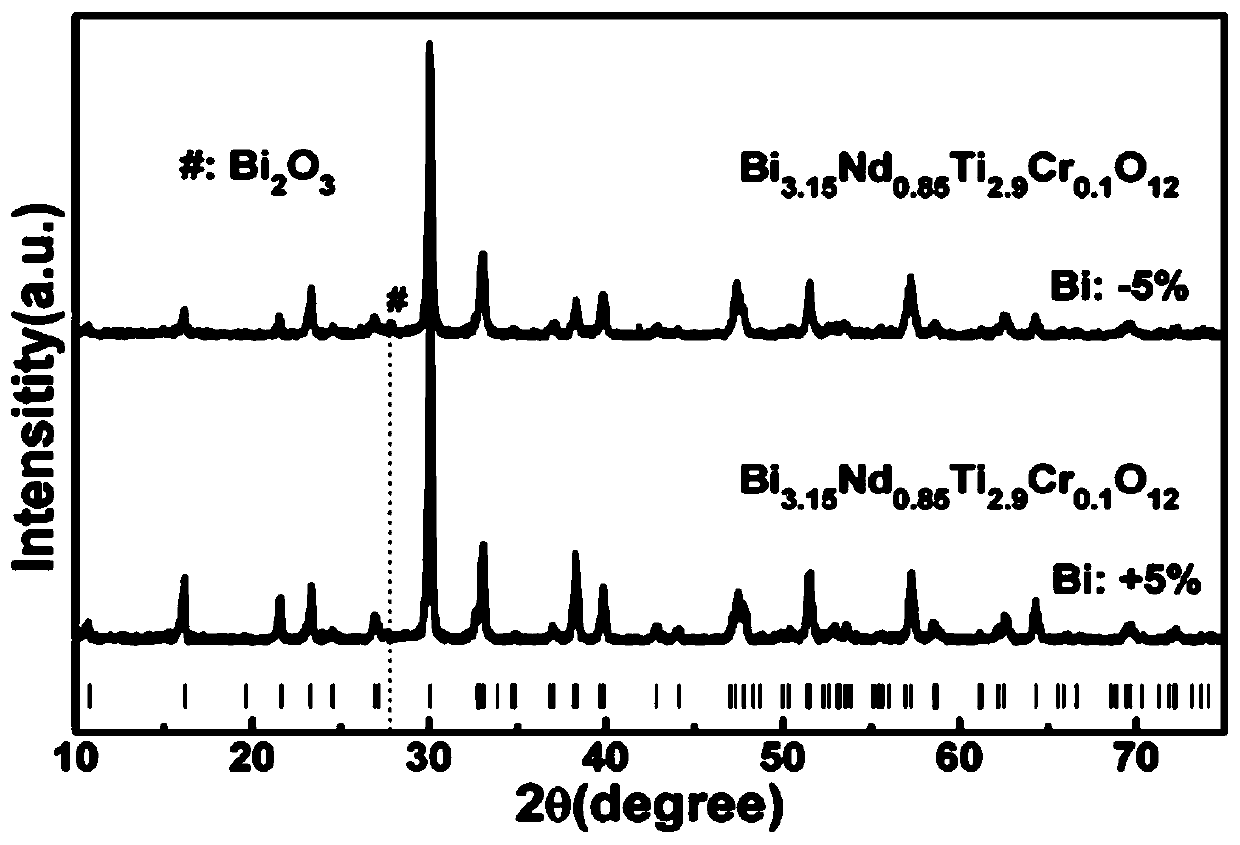

Preparation method of bismuth system ceramic

ActiveCN110092658AAchieve the effect of preparing pure phase ceramic samplesEasy to operateBi elementChemical measurement

The invention relates to a preparation method of a bismuth system ceramic. When a starting material is weighed according to a stoichiometric ratio and the doping proportion of B-position ions in the starting material is small, the use amount of Bi2O3 is increased on the basis of the original ratio; and when the doping proportion of the B-position ions in the starting material is large, the use amount of Bi2O3 is reduced on the basis of the original ratio. The problem of many uncertain factors in subsequent performance test due to impureness and impure phase of a prepared Bi system material, caused by easy volatilization of the Bi element in the high-temperature sintering process of conventional methods, is solved.

Owner:XINXIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com