Patents

Literature

170 results about "Polyol synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

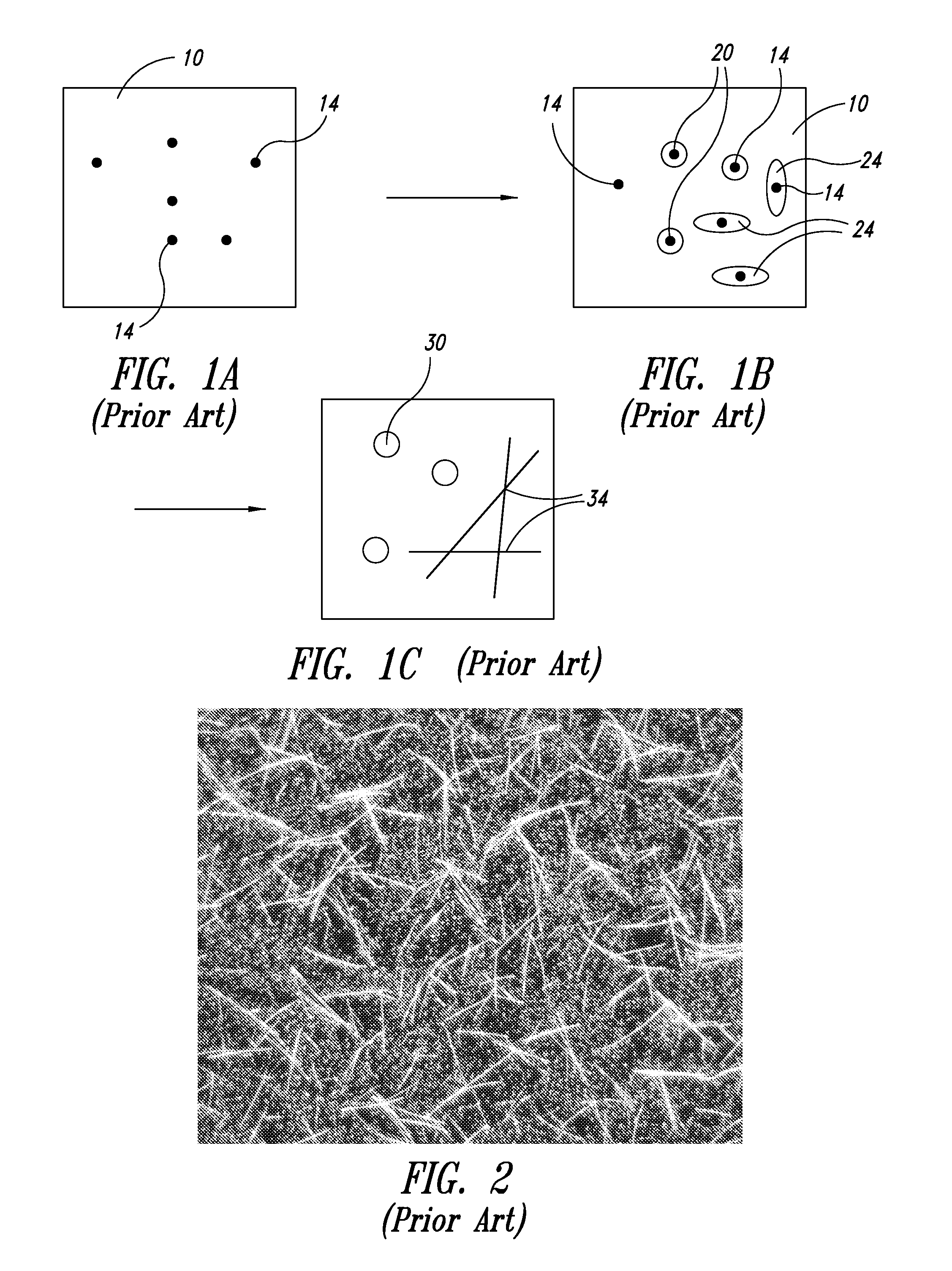

The polyol synthesis is a popular method of preparing metal nanostructures, yet the mechanism by which metal ions are reduced is poorly understood.

Methods for controlling metal nanostructures morphology

InactiveUS20110048170A1Achieve consistencyMaterial nanotechnologyPolycrystalline material growthPolyol synthesisMetal nanowires

Owner:CHAMP GREAT INTL

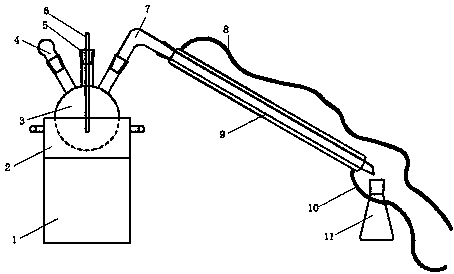

Structural flame retardant type spray coating material of polyurethane elastomer and construction method

InactiveCN1563234ANo addedFast curingPolyurea/polyurethane coatingsPolyurethane elastomerSpray coating

A fire-resisting and spraying type of polyurethane elastomer consists of A composition being semi-prepolymer prepared from low functional degree of polyisocyanic acid ester and polyether-polyalcohol as well as B composition prepared from amine chain extender, fire resisting polyether and end azyl polyether. The application method includes mixing the two compositions uniformly, sending the mixture to spraying gun by material conveying tube, increasing pressure to spray mixture on object surface for forming fire resisting type of sprayed polyurethane and polyether elastomer material instantly.

Owner:JIANGSU CHEM RES INST

Synthesis method of solvent resistant solvent type urethane elastomer

The invention discloses a synthesizing method of solvent resistant polyurethane elastomer, which is made of polyester polyol and diisocyanate step by step or in one step, wherein the polyester polyol is reacted by succinic acid and polyol to synthesize the solvent resistant polyurethane elastomer; the obtained polyurethane elastomer is soaked in the solvent such as alcohol, toluene, ditoluene, acetone, cyclohexanone, methyl ethyl ketone and so on for 48h with weight increasing rate less than 70%; the hardness scale of the solvent resistant polyurethane elastomer is within A0-95 degree, which is applied to make solvent resistant polyurethane printed rubber-covered roll, silk-screen printing blade and so on.

Owner:SHANDONG INOV POLYURETHANE

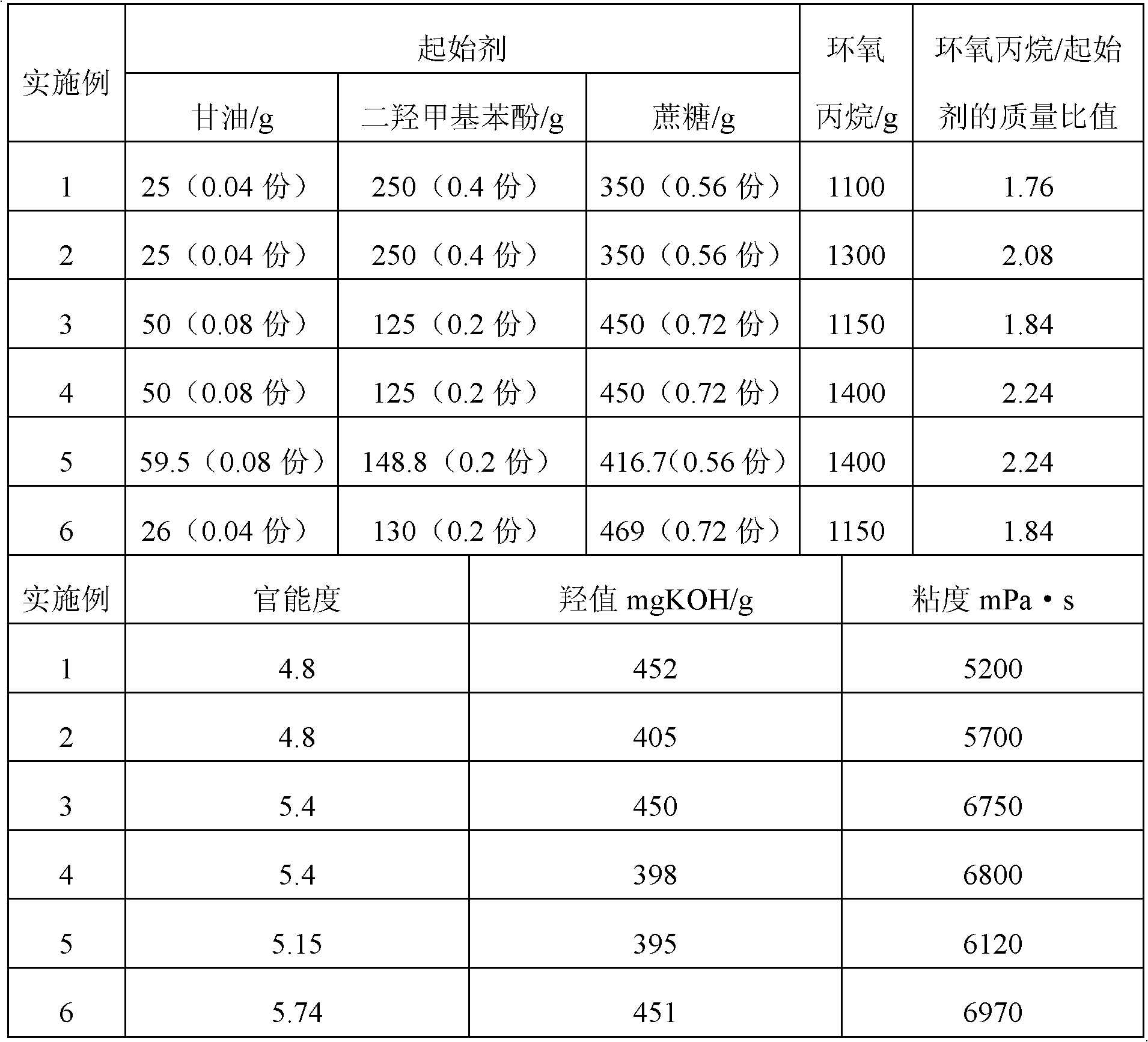

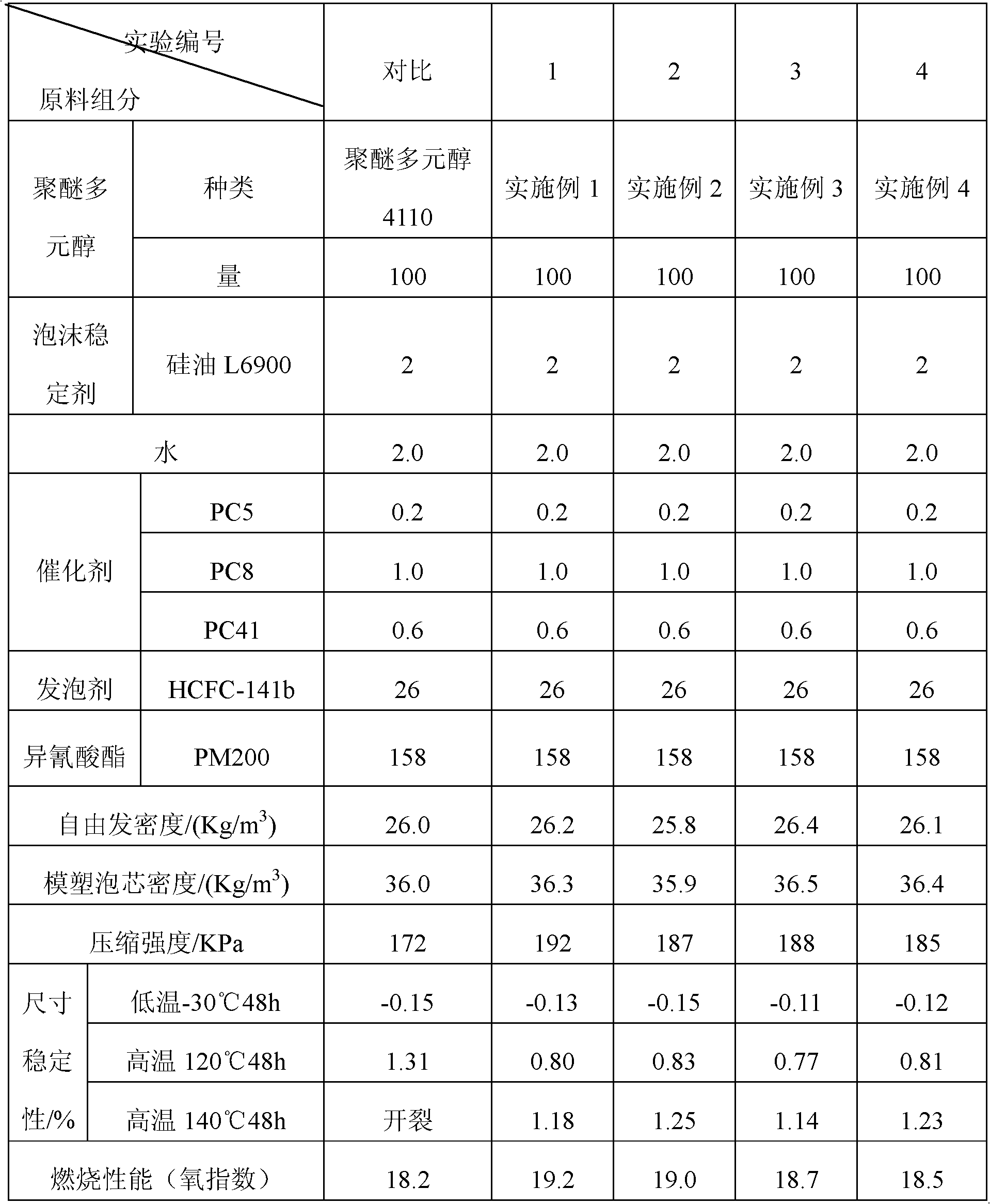

Polyether glycol, polyurethane rigid foamed plastic and preparation methods thereof

InactiveCN102050945ALow viscosityHigh functionalitySugar derivativesEther preparation from oxiranesPolymer scienceSucrose

The invention discloses a preparation method of polyether glycol. The method comprises the following step: preparing the polyether glycol from compound initiator, polyether glycol synthetic catalyst and propylene oxide by using a conventional polyether glycol synthesis method, wherein the compound initiator comprises the following components in parts by weight: 0.04-0.08 part of glycerol, 0.2-0.4 part of dihydroxymethylphenol and 0.56-0.72 part of sucrose; and the mass ratio of the propylene oxide to the compound initiator is 1.7-2.3. The invention also discloses polyether glycol prepared by using the method, a method for preparing polyurethane rigid foamed plastic from the polyether glycol, and polyurethane rigid foamed plastic. The polyether glycol disclosed by the invention has the advantages of low viscosity and high functionality, and has favorable processing properties when being used as a raw material. The polyurethane rigid foamed plastic prepared from the polyether glycol has the advantages of excellent high-temperature resistance, high flame resistance and high compression strength.

Owner:SHANGHAI DONGDA POLYURETHANE

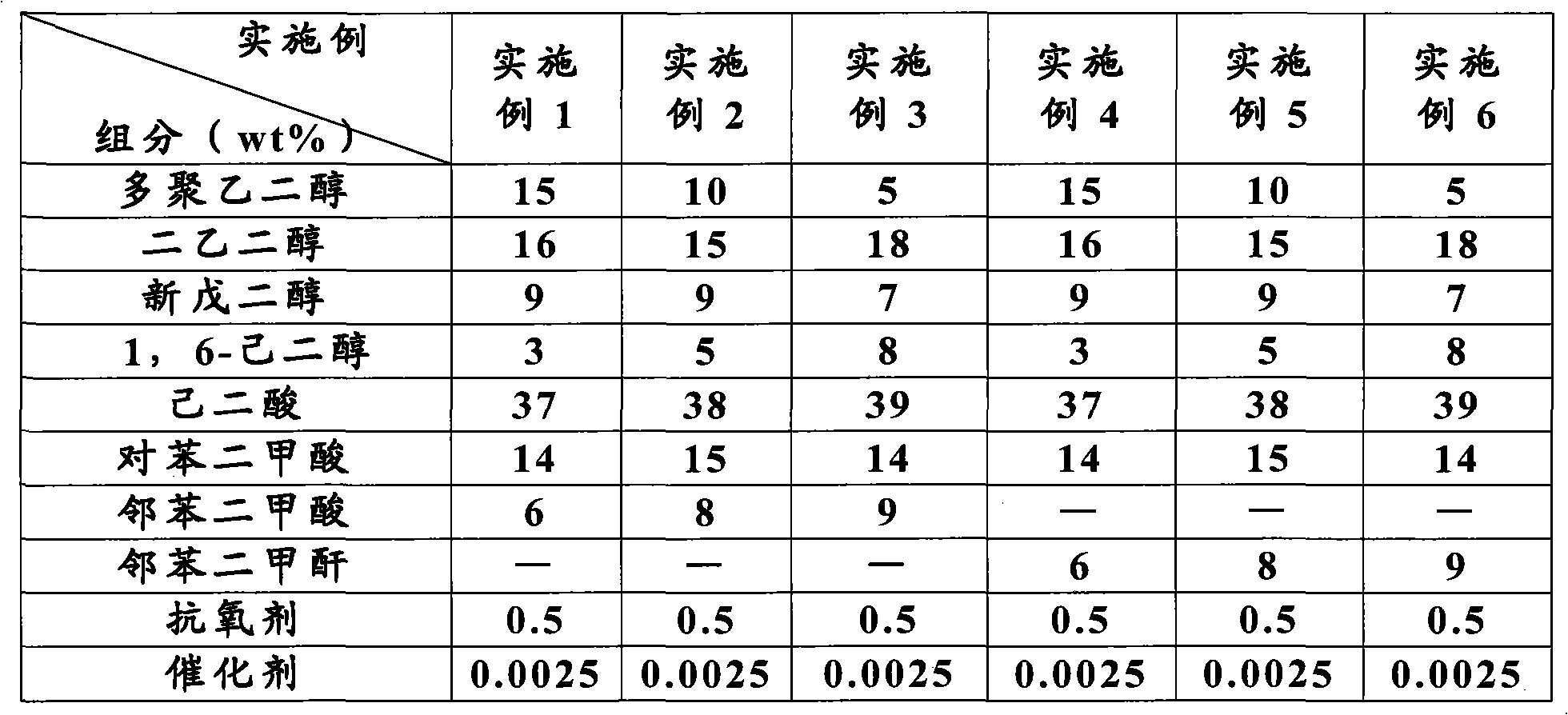

Polyester polyol and polyurethane resin for superfine fiber synthetic leather

The invention relates to polyester polyol for synthesizing a polyurethane resin for superfine fiber synthetic leather and the polyurethane resin synthesized by polyester polyol. The polyester polyol comprises the following starting materials: 5-15wt% of polyethylene glycol, 50-65wt% of mixed dicarboxylic acid and 15-35wt% of mixed diols. The assistants adopted during synthesis include a catalyst and an antioxidant. The polyurethane resin synthesized by polyester polyol obtained by adopting the technical scheme is especially suitable for processing the superfine fiber post-dyed synthetic leathers, the degree of dyeing of the polyurethane resin for superfine resins is improved, the polyurethane resin is not easy to decolor and polyester polyol has high moisture absorption, thus ensuring the final superfine resin products to have good handfeel.

Owner:XUCHUAN CHEM SUZHOU

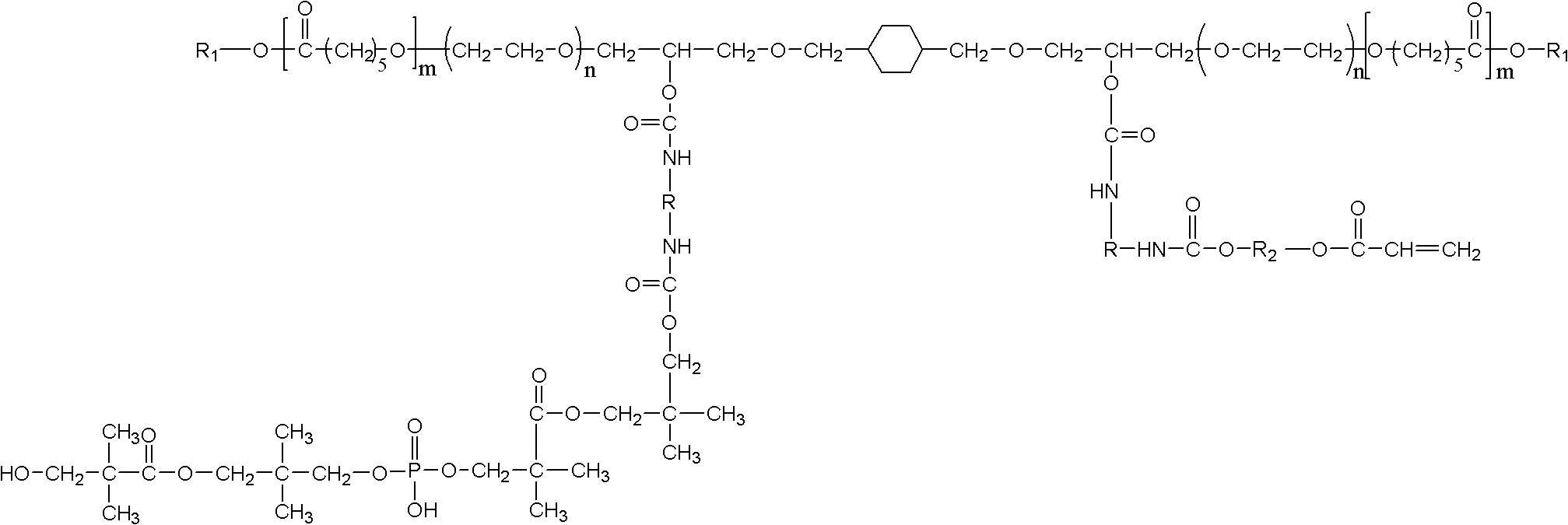

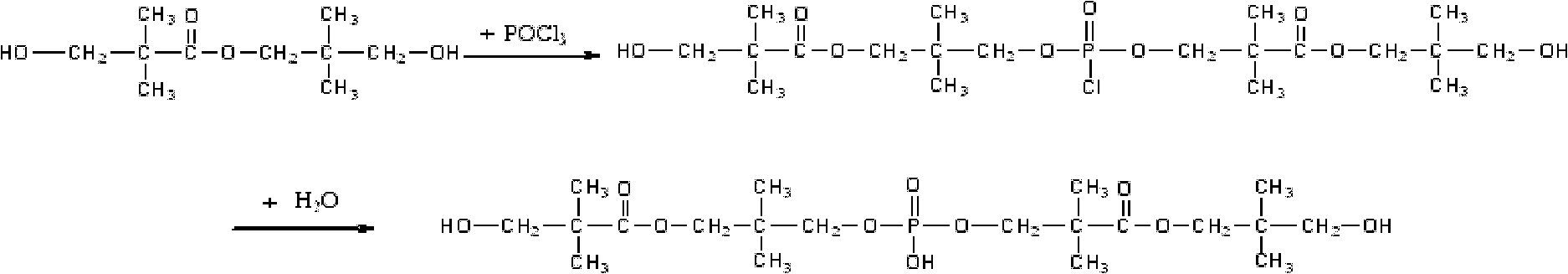

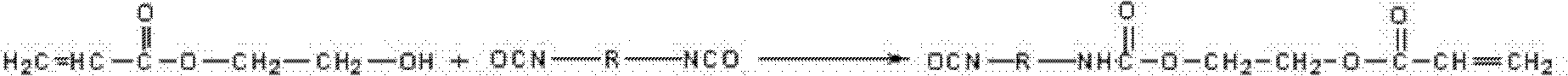

Polyurethane-acrylate oligomer, and synthesis method and application thereof

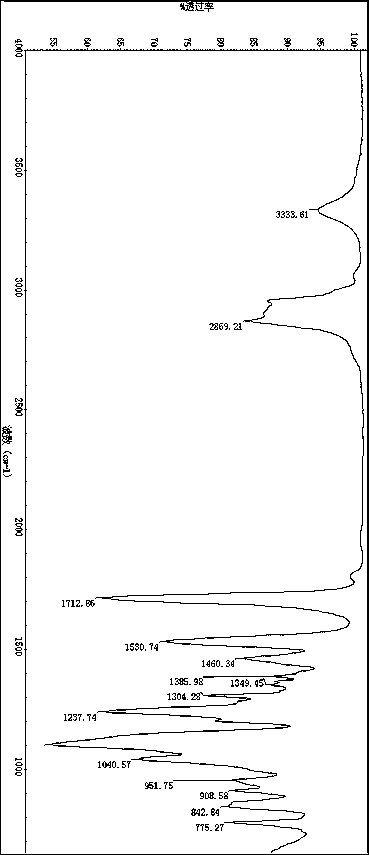

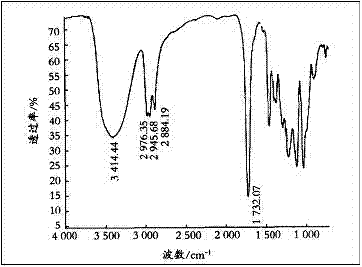

ActiveCN102633984AGood storage stabilityImprove adhesionPhotomechanical apparatusPolyol synthesisDibutyl tin dilaurate

The invention discloses a polyurethane-acrylate oligomer, and a synthesis method and application thereof. The synthesis method comprises the steps of synthesis of phosphate, synthesis of semi-additive product, synthesis of new polyalcohol and synthesis of polyurethane-acrylate oligomer, wherein the synthesis of the polyurethane-acrylate oligomer comprises the following steps: dissolving dibutyltin dilaurate in acetone, dropwisely adding into the hydroxy ester type diisocyanate-phosphate type diisocyanate mixed semi-additive product and the synthesized new polyalcohol, and keeping at 40-50 DEG C until the 2274cm<-1> absorption peak in the reaction mixture infrared spectrum completely disappears. The invention also provides a photo-imageable composition which comprises the polyurethane-acrylate oligomer, a high-molecular adhesive polymer, a polyfunctional group acrylate and a photoinitiator. The phosphate monomer is introduced into the resin chain, thereby enhancing the adhesive force of the product for the base material and obviously enhancing the flexibility; and the polyurethane-acrylate oligomer can be used for image transfer products, such as printed substrates, touch screens and plasma display panels.

Owner:CHANGXING PHOTOELECTRIC MATERIAL +1

Technique for preparing polyester polyol

The invention relates to a technique for preparing polyester polyol. The technique mainly comprises the steps of rapid heating esterification, normal-pressure catalysis and micromolecule dihydric alcohol supplement which are conducted synchronously for alcohol to acid ratio stabilization, pressure reduction condensation polymerization and pressure reduction cooling. Total reaction time is 12-15 hours. By the adoption of the technique, reaction time can be effectively shortened, energy consumption can be reduced, controllability and repeatability are high, the technological process is stable, the problems that in the existing polyester polyol synthesis process, dihydric alcohol loss is serious, reaction time is long, efficiency is low, acid hydroxyl value controllability is poor, and acid regurgitation occurs when temperature reduces are solved, and the synthesized polyester polyol is controllable in acid hydroxyl value, excellent in color and stable in reactivity.

Owner:MIRACLL CHEM

Method for preparing polyurethane from straw fermentation residua through polyatomic alcohol liquefaction

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

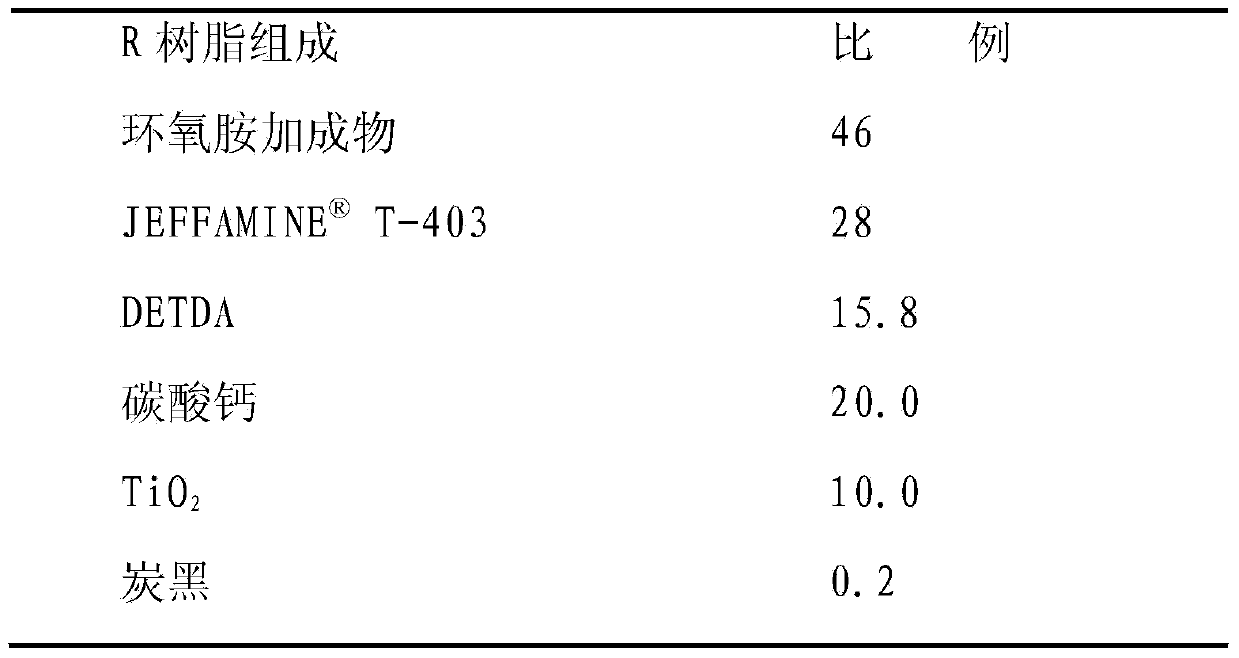

Spray polyurea elastomer applied to marine drilling platform corrosion prevention as well as preparation method and construction method thereof

ActiveCN103740247ANot affected by ambient temperatureNot affected by ambient humidityLiquid surface applicatorsAnti-corrosive paintsElastomerSalt resistance

The invention provides a spray polyurea elastomer applied to marine drilling platforms as well as a preparation method and construction method thereof. The problems of poor adhesion and poor corrosion resistance in the marine environments in the prior art can be solved. The spray polyurea elastomer comprises components A and R and is characterized in that the component A is a semi-prepolymer synthesized by 10-40 parts of polyisocyanates, 20-90 parts of epoxy modified polyether polyol and 0-50 parts of polyether polyol by weight; the component R comprises 15-60 parts of epoxy amine adduct, 0-30 parts of amine-terminated polyether resin, 15-40 parts of chain extender and 5-25 parts of filler by weight. The spray polyurea elastomer material has good physical properties and high adhesion, simultaneously has excellent oil resistance, salt mist resistance, bacterium resistance, aging resistance and construction properties, can be shaped randomly, and can be widely applied to the parts with relatively high corrosion prevention requirements, such as platform decks, pile legs and the like of the marine drilling platforms.

Owner:MARINE CHEM RES INST

High speed railway ballast glue and preparation method and application method thereof

ActiveCN102703017ANon-macromolecular adhesive additivesBallastwayPolyurethane adhesivePolymer science

The invention discloses high speed railway ballast glue which is high-performance bi-component polyurethane adhesive composed of polyether polyol, isocyanate, prepolymer, catalyst, pigment and other high-performance auxiliaries. A component A is mixture made by well mixing 40-90% of the polyether polyol, 2-10% of small molecular chain extender, 0-10% of the pigment, and 0-10% of the auxiliaries. A component B is synthetic polyurethane prepolymer made of 65-85% of polyisocyanate, 5-20% of plasticizer, and 5-30% of the polyether polyol. The high speed railway ballast glue has the advantages of high firming strength, effectiveness in adhesion, convenience for construction and the like. The high speed railway ballast glue has fine adhering effect for ballast without using any prime coat. The high speed railway ballast glue is low in viscosity and high in permeability, has adjustable reaction time, is high in mechanical property and elasticity, emits no toxic and irritating gases, and has high weatherability.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

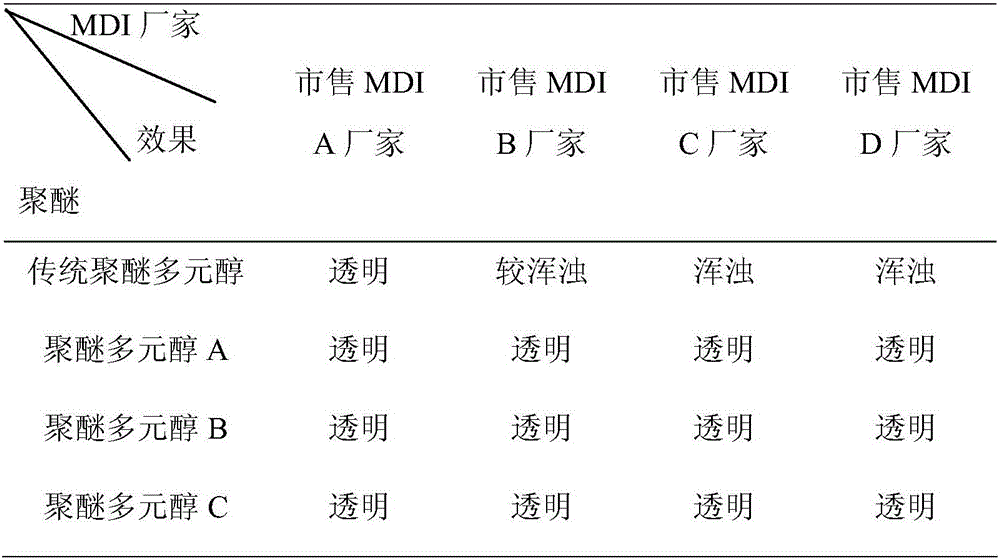

Preparation method of low unsaturation degree and high intersolubility high molecular weight polyether polyol

Belonging to the technical field of polyether polyol synthesis, the invention in particular relates to a preparation method of low unsaturation degree and high intersolubility high molecular weight polyether polyol. The method consists of: adding an alkali metal catalyst into an initiator, adding epoxypropane dropwise to carry out polymerization reaction, at the end of the reaction using phosphoric acid to perform neutralization, adding water and an adsorbent, and then conducting drying and filtering to obtain the intermediate polyether polyol; and adding a bimetallic catalyst into the intermediate polyether polyol, and adding epoxypropane and ethylene oxide dropwise to carry out polymerization reaction, thus obtaining polyether polyol. The polyether polyol prepared by the method provided by the invention greatly improves the transparency of a pure MDI prepolymer system, and improves the process tolerance level and product performance.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

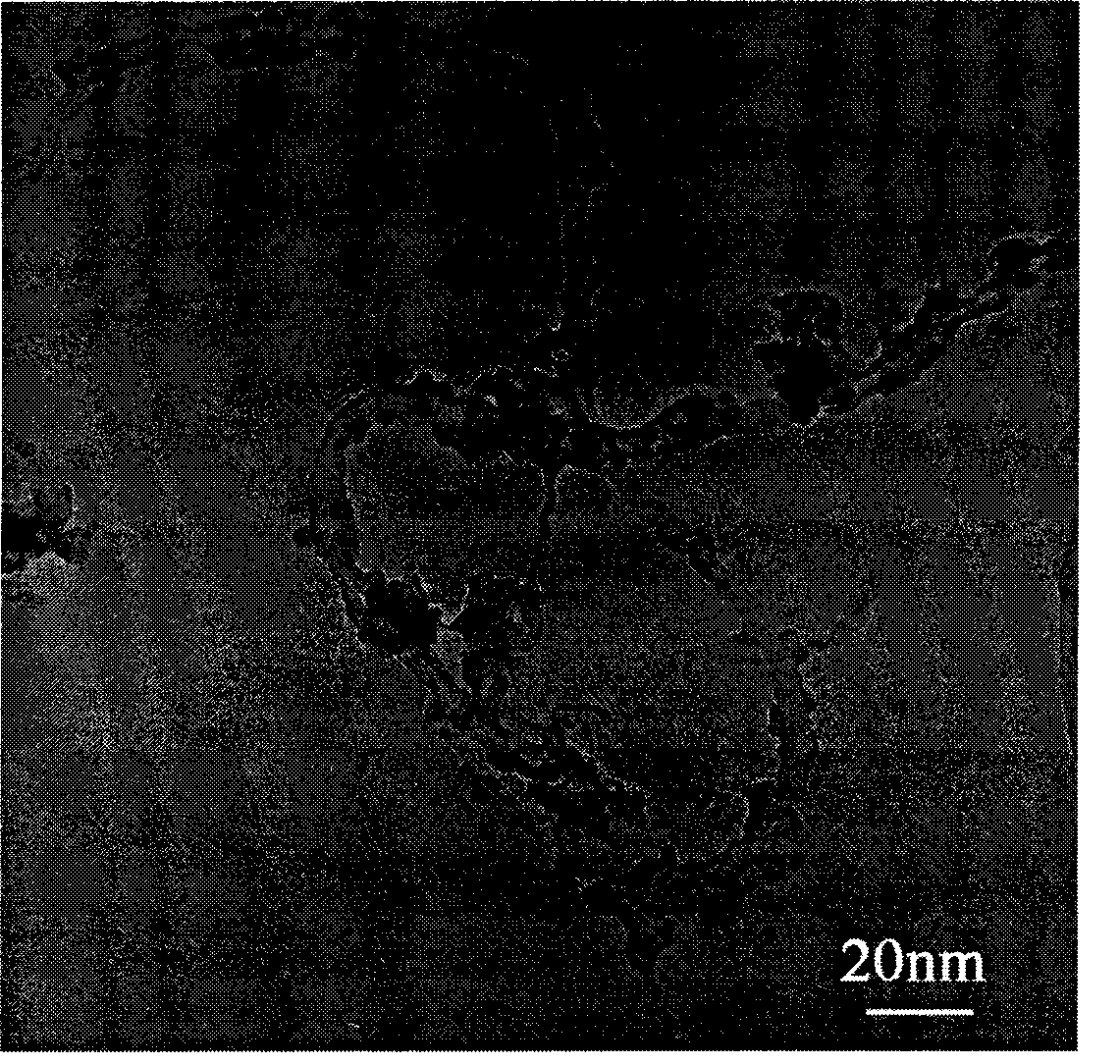

Method for preparing Bi2Te3 / carbon nano-tube composite material

InactiveCN101503176AImprove thermoelectric performanceSimple processNanostructure manufactureThermoelectric device manufacture/treatmentThermoelectric materialsPolyol synthesis

The invention discloses a method for preparing Bi2Te3 carbon nano tube composite material, which adopts microwave polyol synthesis technique: 1) Bi element compound and Te element compound or Te elementary substance are respectively dissolved in glycol according to the mol ratio of Bi: Te determined by the chemical composition of Bi2Te3 and then stirred and mixed together; 2) ultrasonic dispersion is carried out on the processed carbon nano tube in the glycol, and the pH value is adjusted to be 11-14; 3) according to the mass ratio of 0.1:1-2:1 between the carbon nano tube and the Bi2Te3, the mixed solution in the step 1) is titrated in the solution of the step 2) for reaction at the temperature of 140-190 DEG C in a state of microwave radiation; after the reaction, the products are separated centrifugally and washed, and the solid products are collected and dried. The technique is simple and rapid, and the prepared Bi2Te3 carbon nano tube composite material can be used for improving the thermoelectric property of Bi2Te3-based thermoelectric material. Furthermore, the method can be widely applied to the fields such as physics, chemistry, micro-electronics, material, etc.

Owner:ZHEJIANG UNIV

Method for synthesis of polylactide polyol by lactide and polyol

InactiveCN103396535ALow viscosity average molecular weightHigh viscosity average molecular weightTin dioxidePropanoic acid

The invention relates to a method for obtaining polylactide polyol by a way of ring-opening polymerization of lactide with lactide and a polyol as direct raw materials. The method includes the following steps: A, lactide purification: a crude product lactide is purified, and lactide with the content of more than 99.5% and the optical purity of more than 99% is obtained; B, synthesis of polylactide polyol: the purified lactide and the polyol are added into a reaction kettle, then a catalyst is added according to a lactide weight ratio of 0.5 / 1000-1 / 1000 into the reaction kettle for polymerization, and polylactide polyol with the viscosity average molecular weight of 100-5000 is obtained, wherein the catalyst is a composite catalyst comprising one or more of zinc lactate, zinc oxide, zinc powder, diethyl zinc, tin lactate, tin oxide, tin dioxide, stannous oxide, stannous lactate, stannous octoate, stannous chloride, tin powder, propionic acid or tetrabutyl titanate. The method has simple process and easy operation, is suitable for industrialized production applications, and has no 'three wastes' emissions.

Owner:SHENZHEN ESUN IND

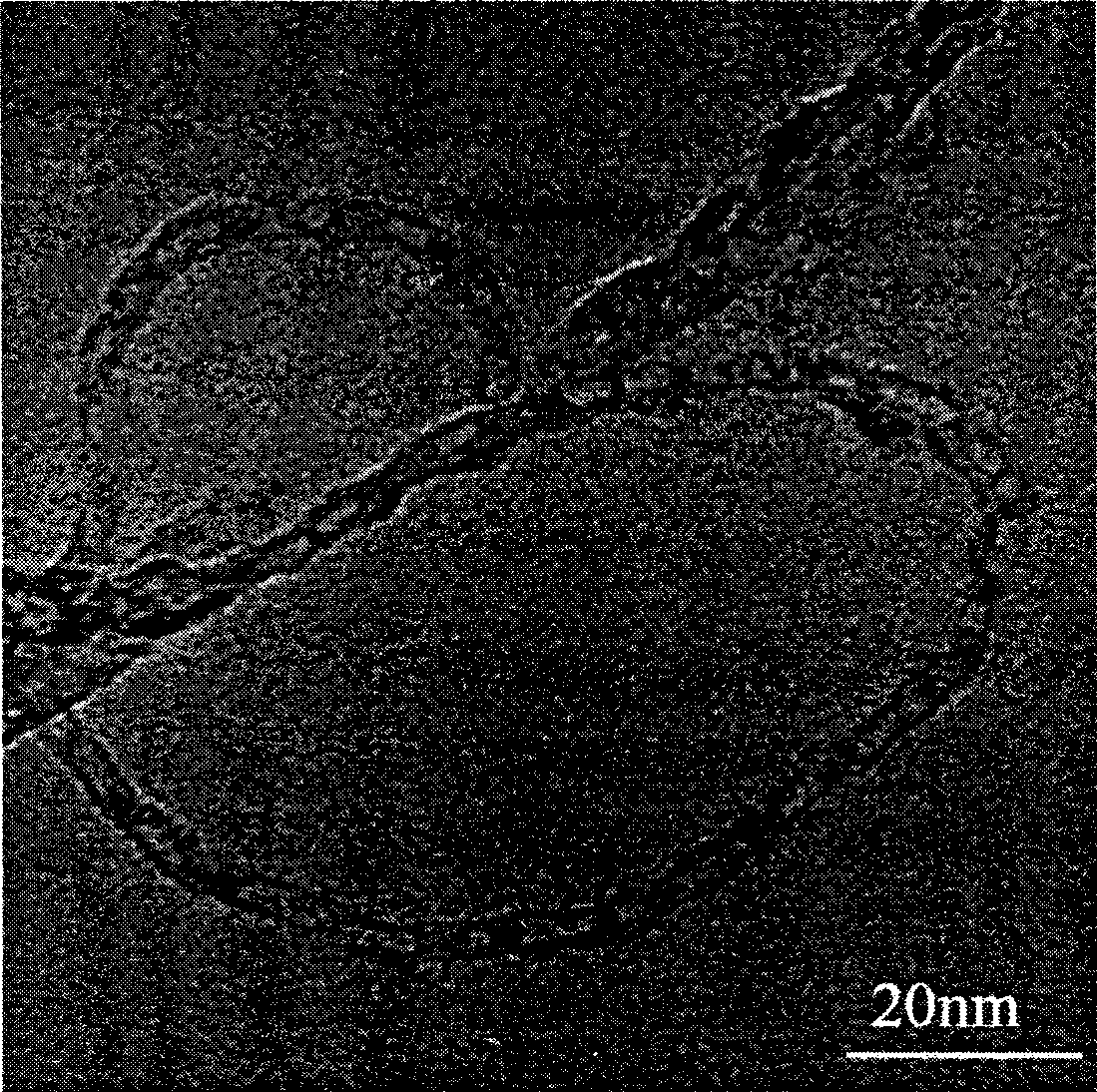

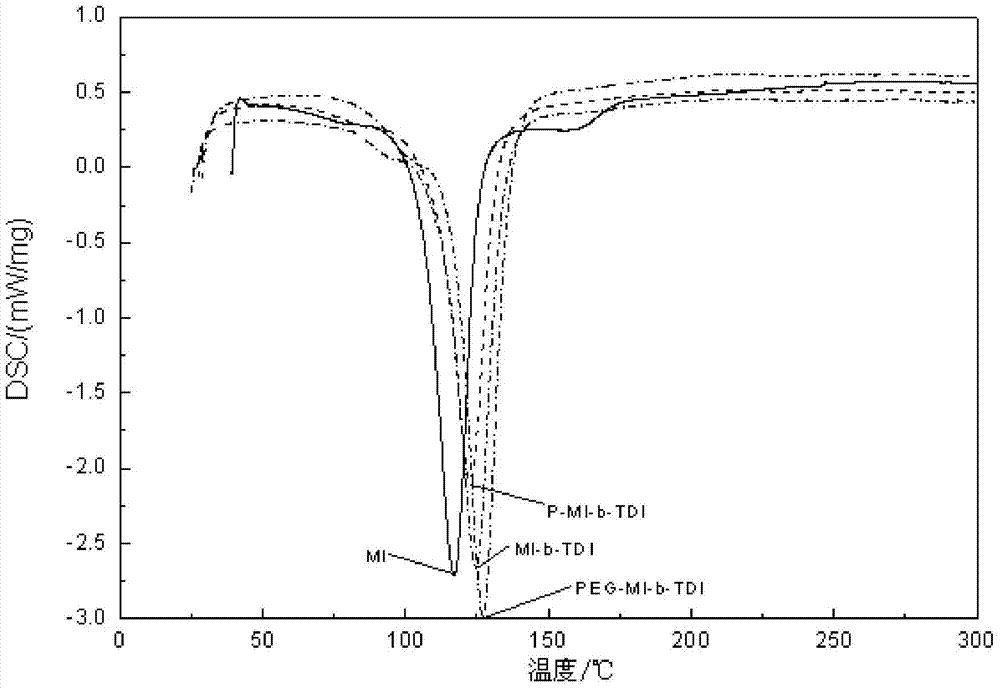

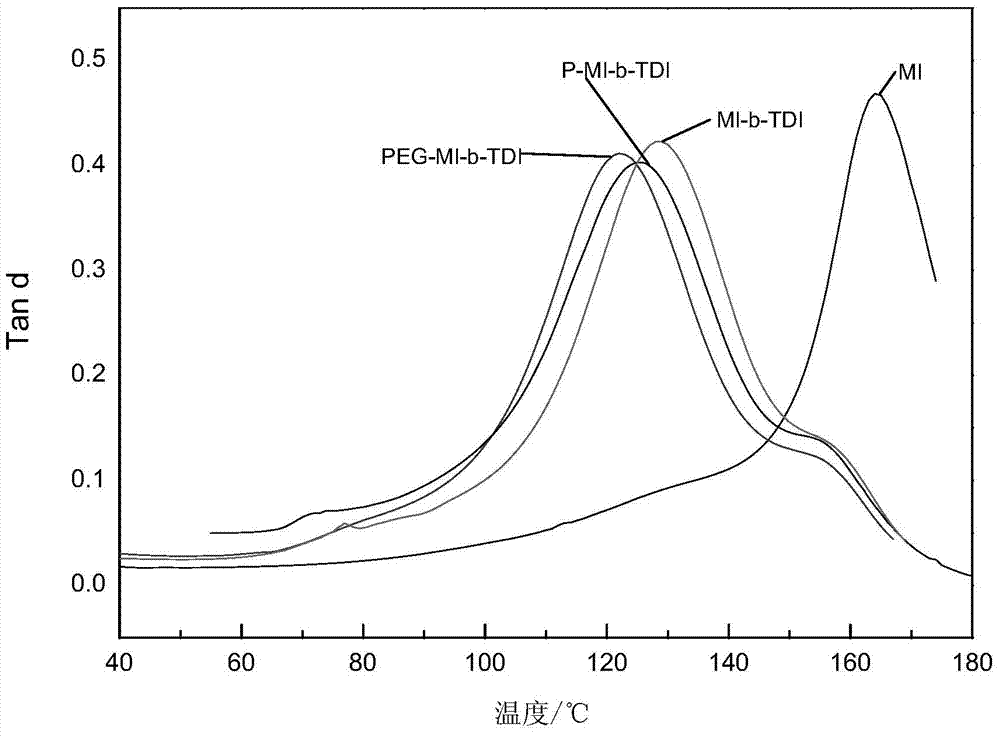

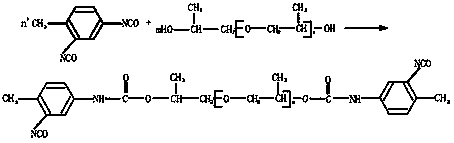

Epoxy resin toughening curing agent and preparation method thereof

An epoxy resin toughening curing agent and a preparation method thereof belong to the field of epoxy resin curing agent. The invention solves the technical problems that epoxy resin is brittle and that an enclosing isocyanate epoxy resin toughening curing agent has high viscosity and short storage time. The epoxy resin toughening curing agent is prepared by synthesizing a prepolymer from toluene diisocyanate and dendritic polyester polyol and conducting imidazole blocking. The method is as below: mixing toluene diisocyanate and dendritic polyester polyol, then adding a solvent, reacting under stirring at 45-50 DEG C for 1 h, then adding imidazole, reacting at temperature controlled at 60 DEG C until weight content of -NCO is less than 3% and basically unchanged. The epoxy resin toughening curing agent provided by the invention has low viscosity, long storage period more than 180 days, impact strength about 16.089 MPa, tensile shear strength of about 10.810 MPa and excellent processability, and the epoxy resin toughening curing agent is a curing agent as well as a toughening agent for epoxy resin, and has excellent toughening effect.

Owner:QIQIHAR UNIVERSITY

Preparation method of polyether polyol used for water-soluble polyurethane grouting materials

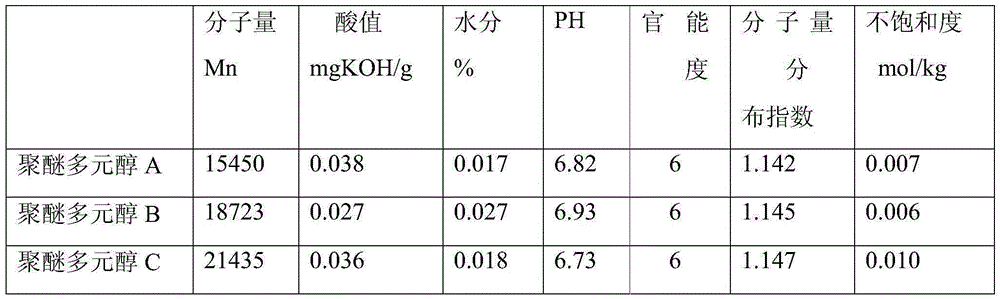

The invention belongs to the technical field of polyether polyol synthesis and particularly relates to a preparation method of polyether polyol used for water-soluble polyurethane grouting materials. A front-segment polymerization reaction includes the steps that firstly, neosorb, an alkali metal catalyst and solvent are added into a reaction kettle, and a midbody polyether polyol is obtained; a rear-segment polymerization reaction includes the steps that the midbody polyether polyol is taken and placed into a reaction kettle, epoxide is dropwise added to the midbody polyether polyol continuously, and the polyether polyol is obtained. The degree of functionality of the obtained polyether is 6, and the molecular weight is 15000-22000. After the polyether which is high in degree of functionality, super high in molecular weight and low in degree of unsaturation is made into the water-soluble polyurethane grouting materials, higher water efficiency and strength are achieved. In an overall polymerization reaction, the ethylene oxide accounts for 50-90% of total epoxide, the activity of the polyether can be improved, and a higher solid water speed is achieved in the obtained water-soluble polyurethane grouting materials.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Ageing-resisting anti-abrasion ceramic composite material special for hydraulic architecture

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +2

Rigid foam composite polyether polyol and preparation method thereof

The invention relates to a preparation method of rigid foam composite polyether polyol. The method comprises the steps that a polyether polyol mixed initiator and a polyether polyol synthetic catalystare gradually introduced into an epoxy compound on the conditions that the reaction temperature is 80-135 DEG C, and the reaction pressure does not exceed 0.4 Mpa, the mixture is subjected to ring-opening polymerization, and the composite polyether polyol is obtained; the polyether polyol mixed initiator comprises polyether triols taking glycerin as an initiator and polyether diols taking propylene glycol as an initiator, and the mass ratio of polyether triols to polyether diols is (3-6):1. The rigid foam composite polyether polyol has the advantages of being low in viscosity, high in degreeof functionality, high in reactivity and the like, and rigid foam plastic polyurethane prepared by taking the composite polyether polyol as a cross-linking agent has the excellent surface performanceand strength.

Owner:SHANGHAI DONGDA CHEM

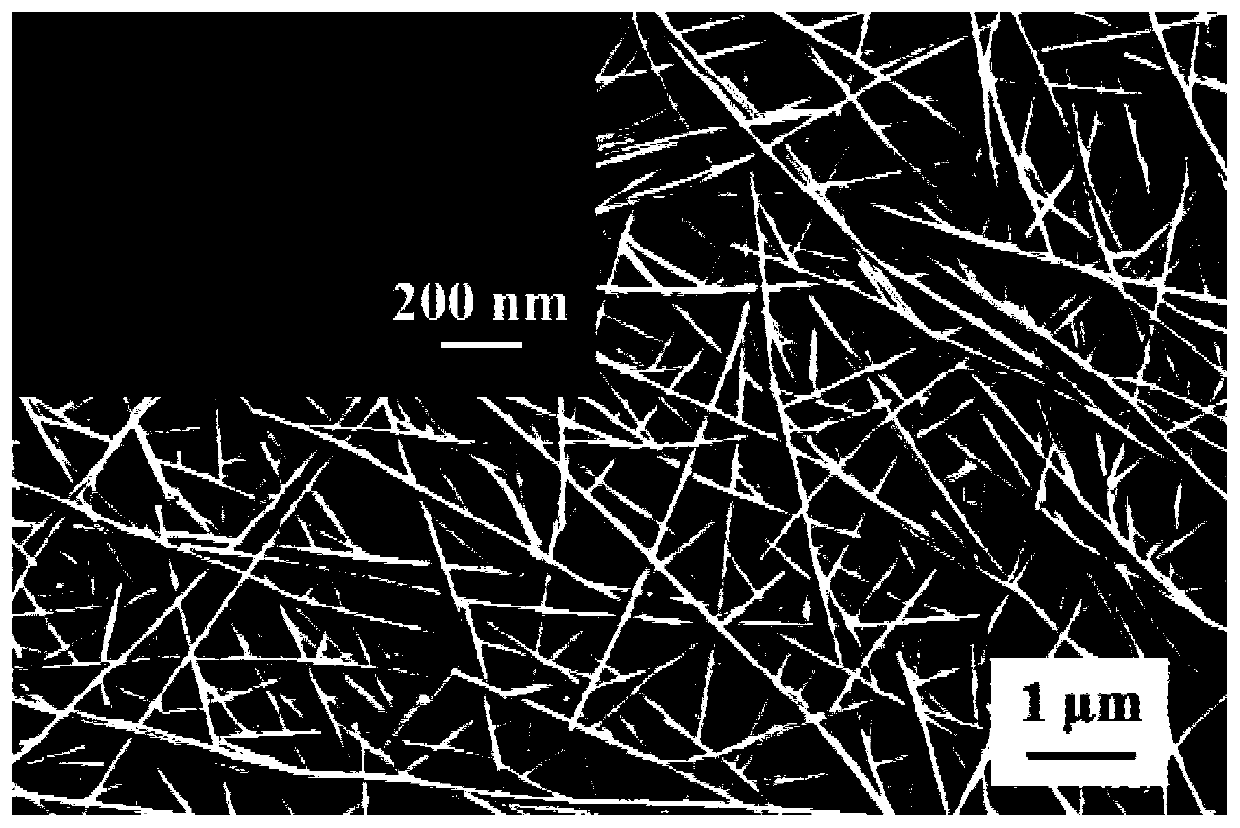

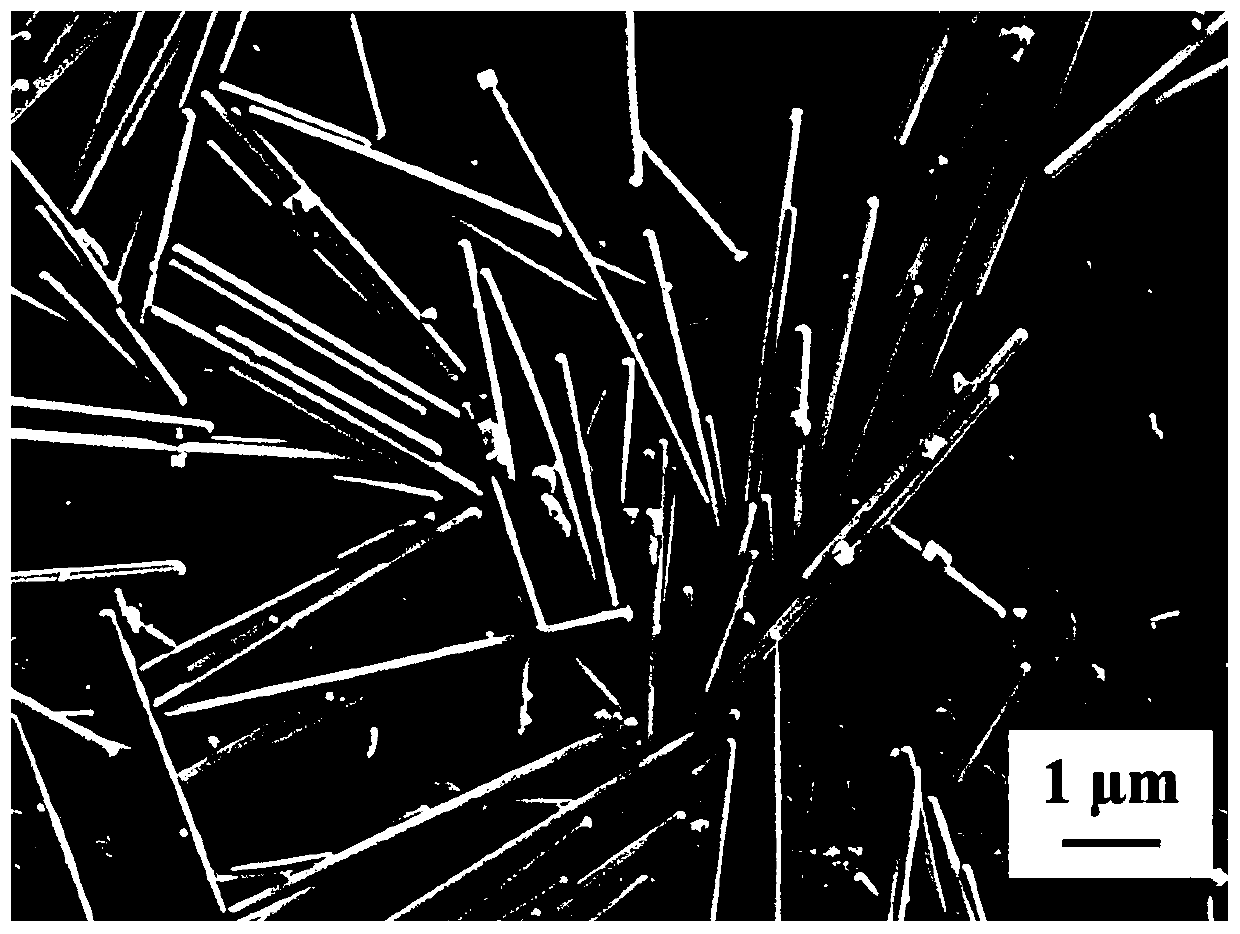

Large-length-diameter ratio silver nanowire based on one-pot polyol method and preparation method and application thereof

InactiveCN110586928AReduce particle contentEasy to manufactureMaterial nanotechnologyTransportation and packagingOrganic solar cellMetal chloride

The invention belongs to the technical field of synthesis of metal nanowires, and particularly relates to a large-length-diameter ratio silver nanowire based on a one-pot polyol method and a simple, efficient and rapid preparation method and application thereof. The preparation method comprises the steps that a PVP solution, a metal chloride solution and an AgNO3 solution are evenly mixed and react for 1-2 hours at a constant temperature of 120-160 DEG C through a one-pot method, and then cooling and centrifugation are conducted to obtain a dispersion solution of the large-length-diameter ratio silver nanowire. According to the preparation method, the one-pot synthesis method is adopted, and the controllability of a polyol synthesis method and the uniformity of a hydrothermal method are effectively combined to realize simple, efficient and rapid preparation of the large-length-diameter ratio silver nanowire. After centrifugal cleaning, the silver nanowire dispersion solution with an extremely low particle content is obtained. The silver nanowire has a diameter of 30-50nm, a length of 30-40 [mu]m and a length-diameter ratio of 1000 and has a broad application prospect in the fieldsof touch screen panel, organic solar cells, organic light-emitting diodes, and the like.

Owner:SOUTH CHINA UNIV OF TECH

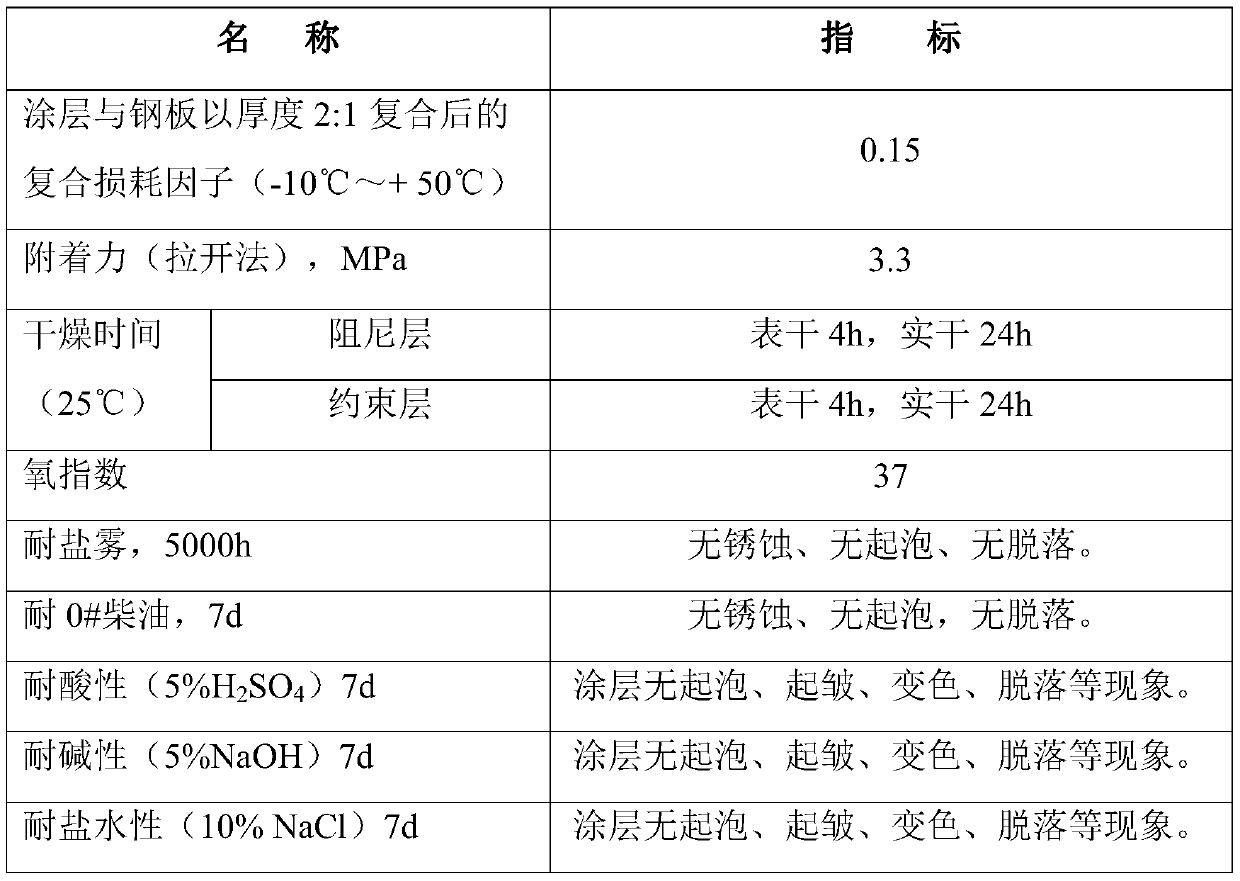

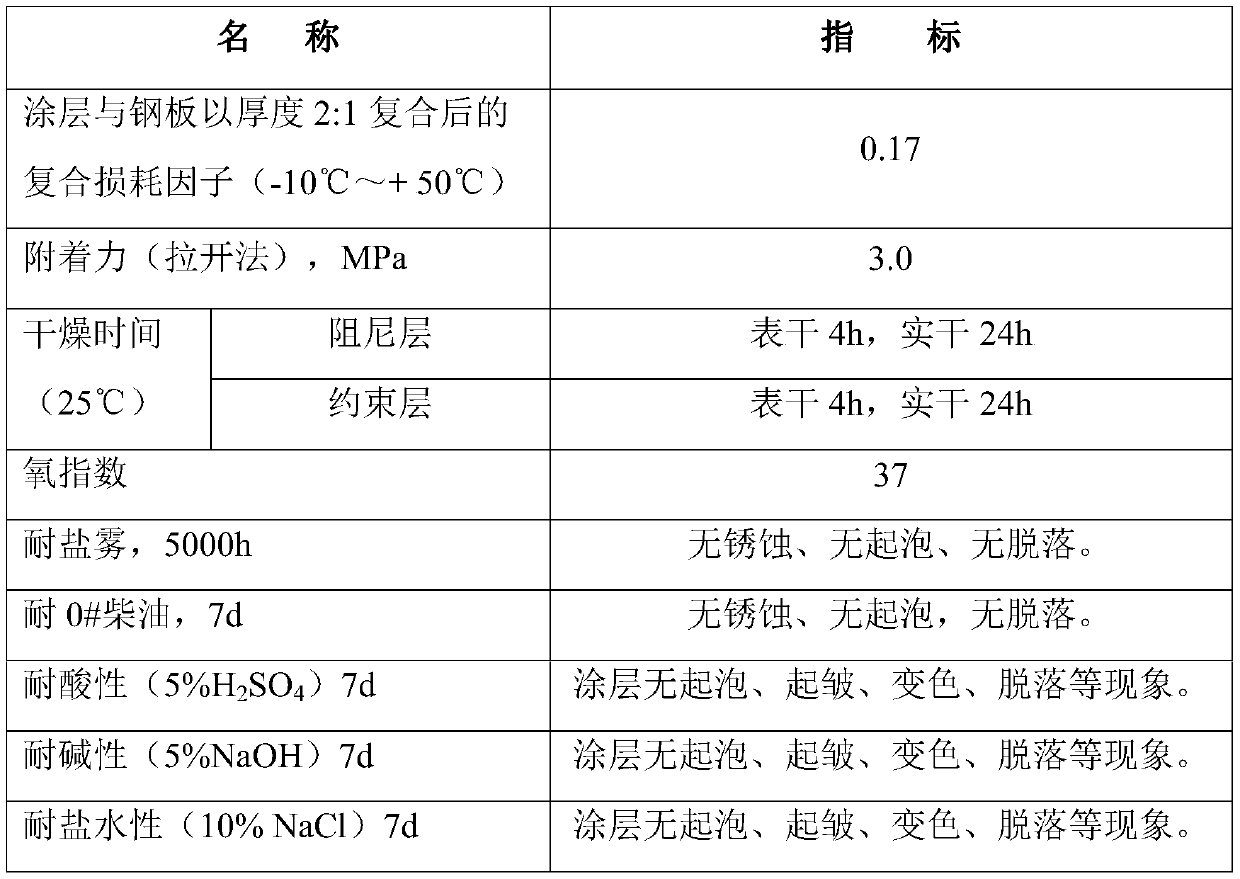

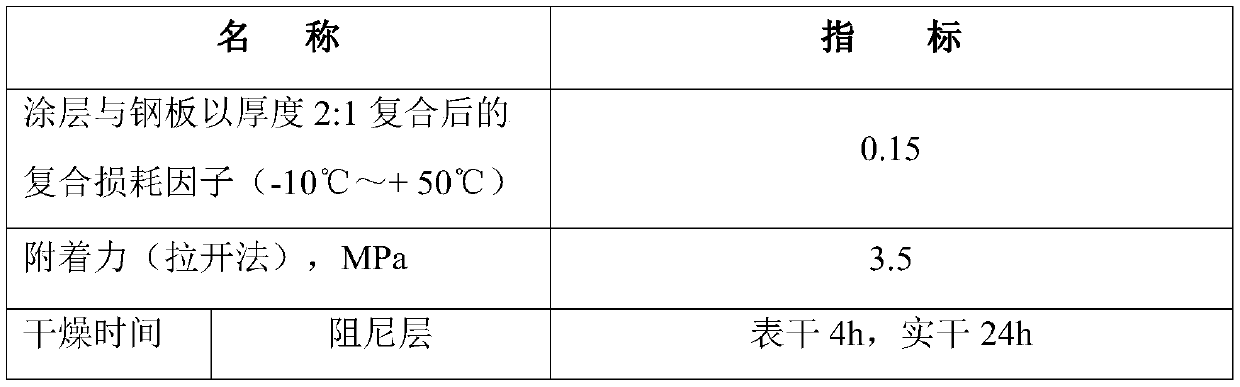

Spray-coating damping coating for ships and preparation method= thereof

InactiveCN111548721ALow viscosityImprove construction efficiencyFireproof paintsAnti-corrosive paintsPolymer sciencePtru catalyst

The invention provides a spray-coating damping coating for ships and a preparation method thereof, and belongs to the technical field of special functional materials. The spray-coating ship damping coating has a damping constraint structure, and a damping layer is a bi-component solvent-free polyurethane coating; the spray-coating ship damping coating comprises a component A and a component B, wherein the component A is a prepolymer synthesized by diisocyanate and polyol; the component B comprises a chain extender, polyol, a damping modifier, a damping pigment filler, a dispersing agent, a defoaming agent, a base material wetting agent, a catalyst, an adhesion promoter, a water removal agent and hollow microspheres; wherein the restraint layer is a double-component solvent-free epoxy resincoating and comprises a component A and a component B, the component A comprising liquid epoxy resin, an active diluent, a dispersing agent, a defoaming agent, a liquid flame retardant, a thixotropicagent, body filler and hollow microspheres, the component B comprising a modified amine curing agent, a defoaming agent, a thixotropic agent, benzyl alcohol and hollow microspheres. The coating disclosed by the invention can be sprayed for construction, is low in surface density and high in composite loss factor, has the loss factor of more than or equal to 0.15 at the temperature of -10 DEG C to50 DEG C, has excellent flame retardant property, and also has excellent sound insulation, heat insulation, corrosion prevention and other properties.

Owner:QINGDAO AIR NEW MATERIALS

Flame-resistant type polyether polyol for sponges and preparation method thereof

InactiveCN109400866AHigh synergistic flame retardant performanceFlame retardantPolyesterPolyol synthesis

The invention relates to flame-resistant type polyether polyol for sponges and a preparation method thereof, and belongs to the technical field of polyether polyol synthesis. The invention further provides a scientific and reasonable, simple and easy preparation method. The flame-resistant type polyether polyol for the sponges referred is prepared through the mode that polyester 1000 and tris(hydroxymethyl) phosphorous oxide (THPO) are used as initiators and subjected to ring-opening polymerization with propylene oxide and ethylene oxide by using a modified bimetallic cyanide complex catalyst . According to the flame-resistant type polyether polyol for the sponges referred, raw materials are simple and easy to obtain, the cost is low, the structure is stable, and the anti-flammability is good.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Method for removing acid value during polyester polyol synthesis process

The invention relates to a method for removing the acid value during a polyester polyol synthesis process. According to the invention, organic dicarboxylic acid (anhydride or ester) and polyol (including diol) are molten in a reactor; nitrogen gas is introduced into the reactor; a reaction is carried out under a temperature of approximately 150 DEG C, such that water is produced; the water produced in the reaction is gradually distilled out; with the distillation of water, the temperature in the reaction kettle is gradually increased; acid value is measured during the process; under a temperature of 170-230 DEG C, when the acid value is not higher than 30mgKOH / g, 15-100ppm of organic catalyst is added, and water and low-molecular-weight polyester polyol produced in the reaction are removed by vacuuming, such that the acid value is lower than 2mgKOH / g; the temperature is reduced to 50-100 DEG C, and a certain amount of alkaline alcohol solution is dropwise added with a dropping speed of 2-200ml / min; a reaction is carried out for 0.5-3h; the temperature is increased to above 100 DEG C, and alcohol substances in the alkaline alcohol solution are distilled out, such that polyester polyol with acid value not higher than 0.5mgKOH / g is obtained. With the method, polyester polyol acid value removing is easy, cost is low, and the process is simple.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

Preparation method of polyether polyol for all-water blown polyurethane foam capable of resisting high temperature of 220 DEG C

InactiveCN104086764ASimple operation processRaw materials are easy to getPolyol synthesisThermal insulation

The invention relates to a preparation method of polyether polyol for all-water blown polyurethane foam capable of resisting high temperature of 220 DEG C, and belongs to the technical field of polyether polyol synthesis. The preparation method is as follows: carrying out ring-opening reaction by taking a compound initiator and epoxy propane as main raw materials, wherein the compound initiator is a mixture of pentaerythritol, trimethylolpropane and methyl o-phenylenediamine; neutralizing a polymerization product by phosphoric acid, adsorbing by a compound silicate adsorbent, dehydrating, filtering, adding a compound efficient antioxidant, and uniformly mixing to obtain polyether polyol for the all-water blown polyurethane foam capable of resisting high temperature of 220 DEG C. The polyether polyol has extremely good high-temperature resistance, has lower viscosity at the same time, and can be independently used as a main polyether for being applied to a high-temperature-resistant all-water blown polyurethane rigid foam system; the obtained foam is resistant to a high temperature of 220 DEG C, and can be completely used for thermal-insulation heat-insulation construction of high-temperature pipelines such as an overheated vapor pipeline and a hot oil pipeline.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

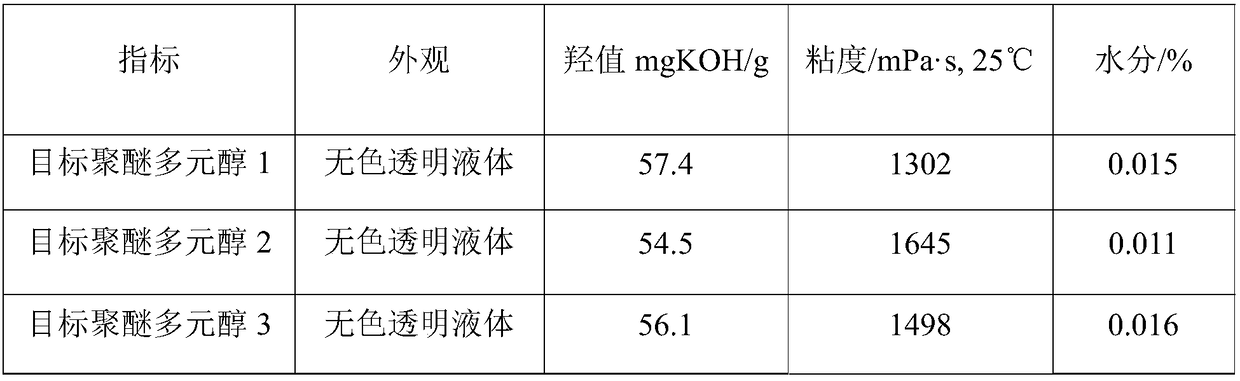

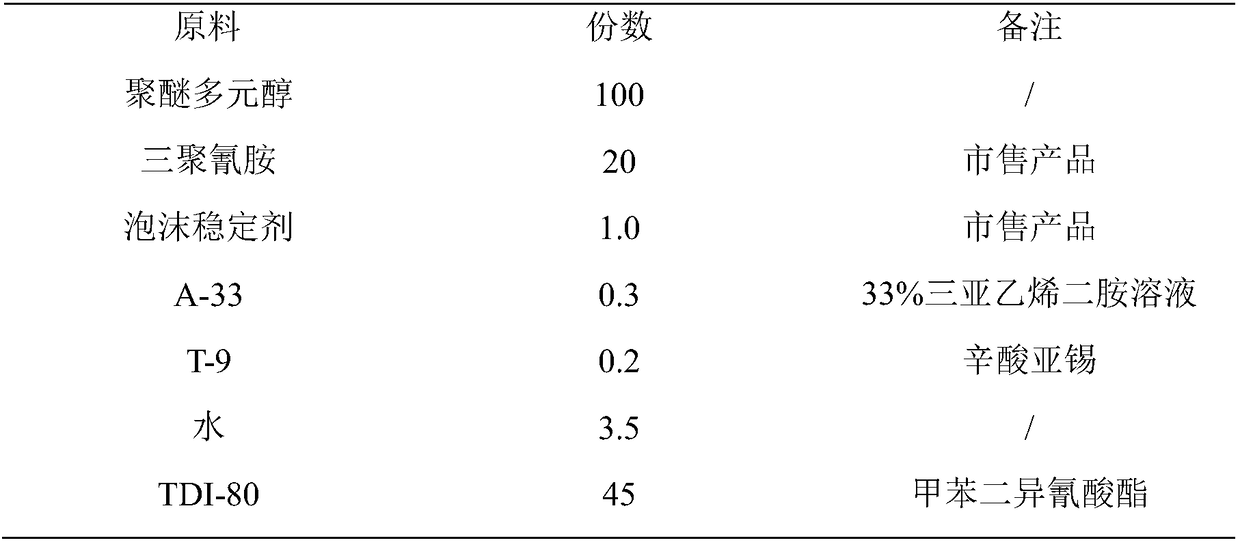

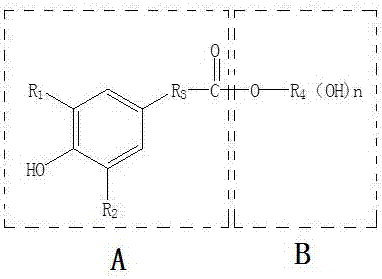

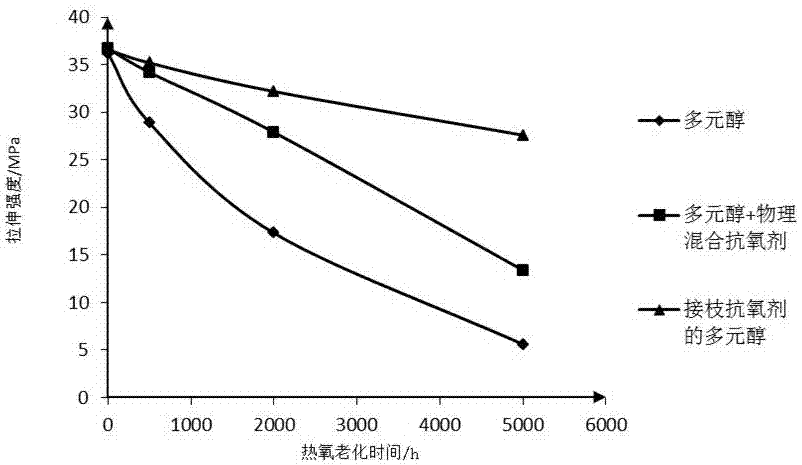

Polyol grafted with antioxidant molecule

ActiveCN107382710AImprove antioxidant capacityPreparation from carboxylic acid halidesOrganic compound preparationPolyol synthesisAging resistance

The invention relates to the field of polyol synthesis, and in particular relates to a polyol grafted with a hindered phenol type antioxidant and a preparation method thereof. The preparation method comprises the following steps: firstly carrying out acylating chlorination on a terminal structure of the hindered phenol type antioxidant, then reacting with hydroxyls by virtue of acyl chloride, and grafting the hindered phenol type antioxidant to polyol, wherein hindered phenol type antioxidant molecules account for 2-40wt% of the total mass of the polyol grafted with antioxidant molecules. The polyol grafted with the antioxidant molecules can inhibit migration of the antioxidant molecules in a service process and improve thermal-oxidative aging resistance of a macromolecular material.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

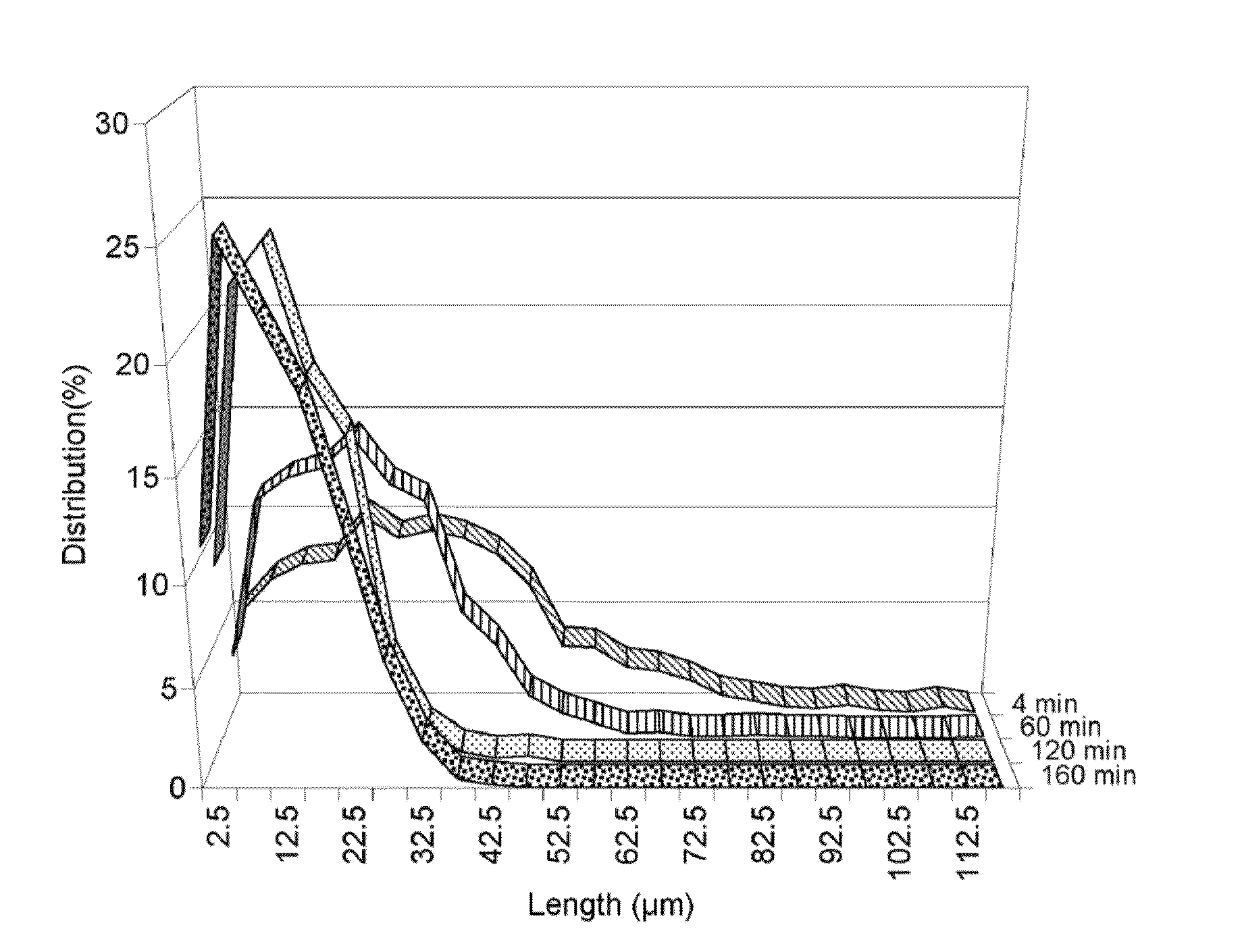

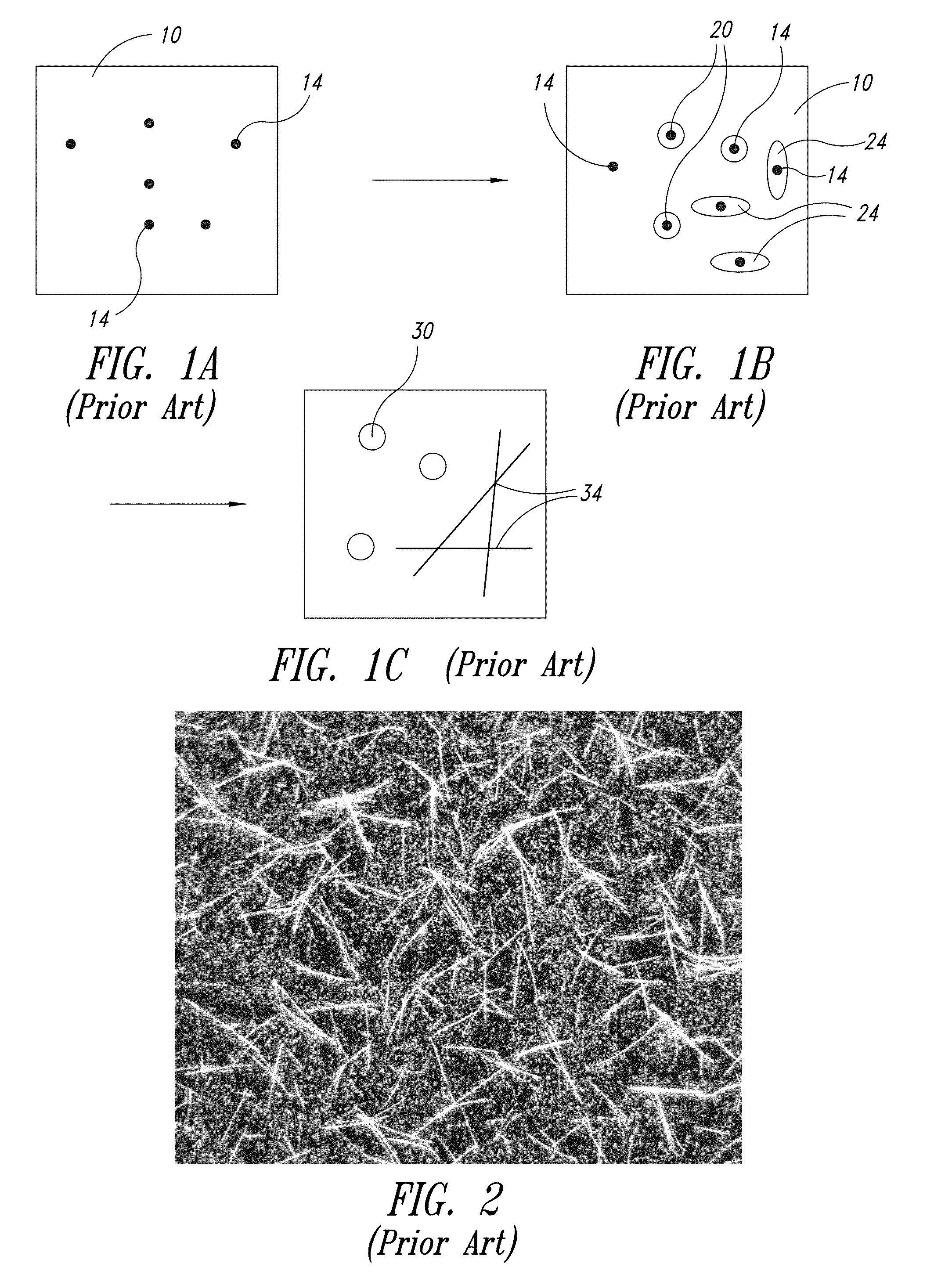

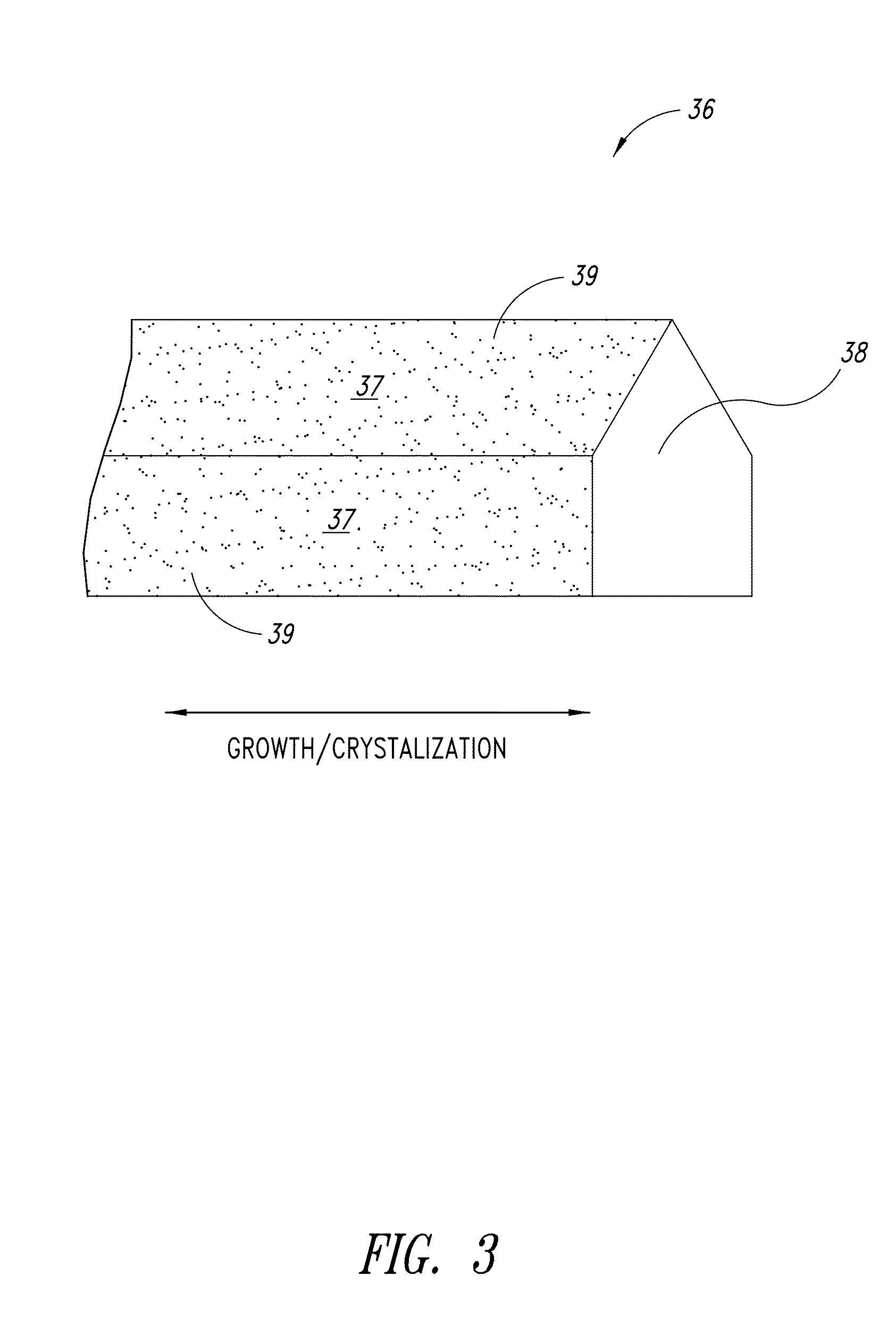

Methods for controlling metal nanostructures morphology

InactiveUS8512438B2Material nanotechnologyPolycrystalline material growthPolyol synthesisMetal nanostructures

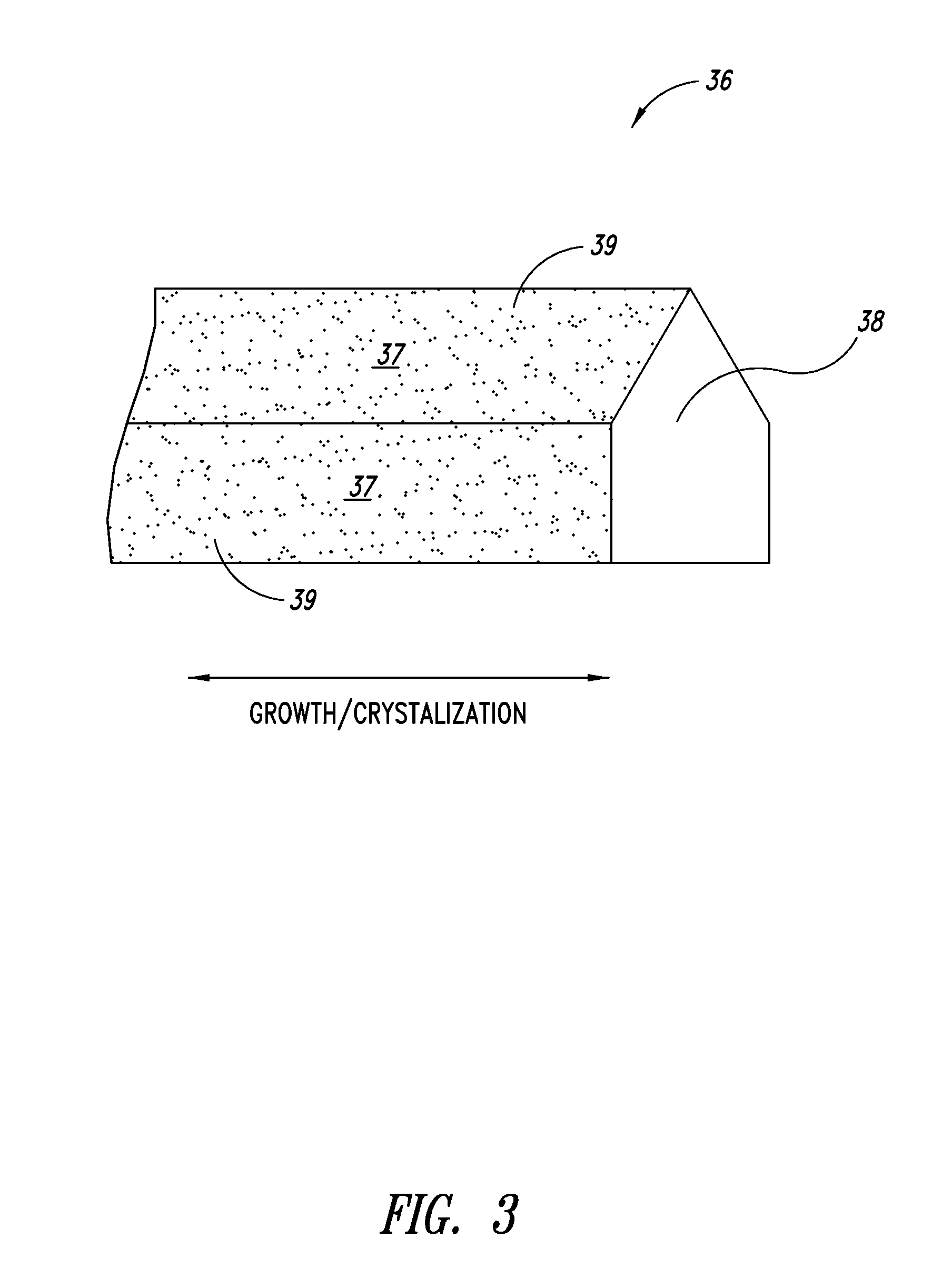

Described herein are methods of controlling metal nanowire morphologies by adjusting the reaction conditions of a polyol synthesis. In particular, by purging the reaction with an inert gas, batch-to-batch consistency can be achieved.

Owner:CHAMP GREAT INTL

Two-component modified polyurethane sustained or controlled release coating material with chelation function

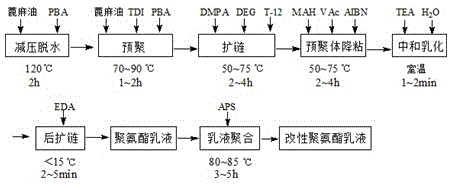

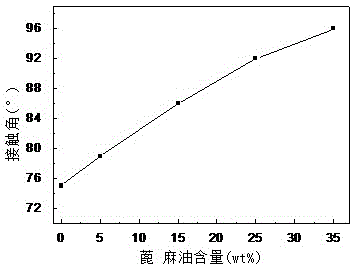

The invention discloses a two-component modified polyurethane sustained or controlled release coating material with the chelation function, and belongs to the technical field of high polymer material preparation. The two-component modified polyurethane sustained or controlled release coating material is characterized in that a polyurethane prepolymer is synthesized through diisocyanate, castor oil and polyhydric alcohols at first, an unsaturated monomer is added before emulsification to lower viscosity, then chain extension is performed, and an unsaturated monomer with the chelation and hydrophilic function is introduced through in-site emulsion polymerization. By adjusting and controlling the crosslinking degree and hydrophility of the coating material, the nutrient release speed can be controlled so as to meet the requirements of different crops for nutrients. A chelation group in the material can activate medium trace elements in soil, and polyvinyl acetate and other hydrophilic chain segments have the moisture and fertilizer retention function, so that the fertilizer utilization rate is greatly improved, no organic solvent is used in the synthetic process, and the material is environmentally friendly and free of pollution.

Owner:安徽德睿轩科技服务有限公司

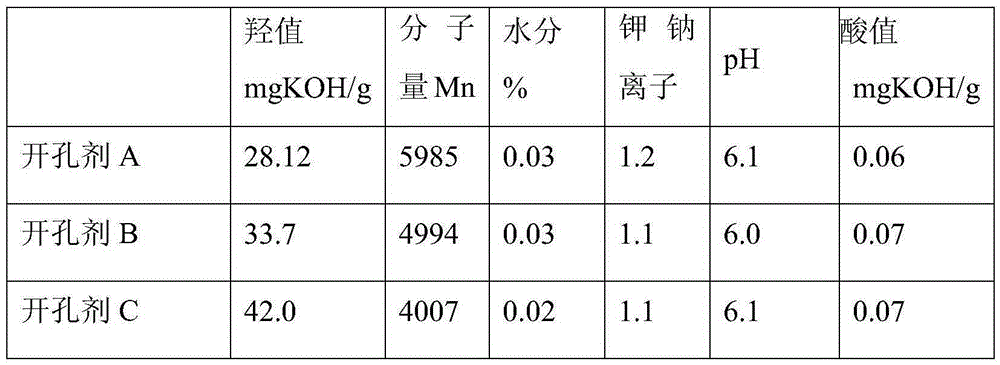

Preparation method of opening agent for high resilience polyurethane foam

The invention belongs to the technical field of polyether polyol synthesis, and particularly relates to a preparation method of an opening agent for high resilience polyurethane foam. The preparation method comprises the following steps that an alkali metal catalyst is added to an initiator for a reaction, after high temperature dehydration is conducted, propylene epoxide and ethylene oxide are dropwise added to conduct a polymerization reaction, after the reaction is completed, phosphoric acid is added for neutralization, magnesium silicate is added for adsorption, drying and filtering are conducted, and the opening agent is obtained. The preparation method of the opening agent for the high resilience polyurethane foam is simple in technology and easy to achieve; the opening agent prepared through the preparation method can improve the foam opening performance, prevent closed pores and improve a foaming structure, and a product has good resilience, compressibility and comfort.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

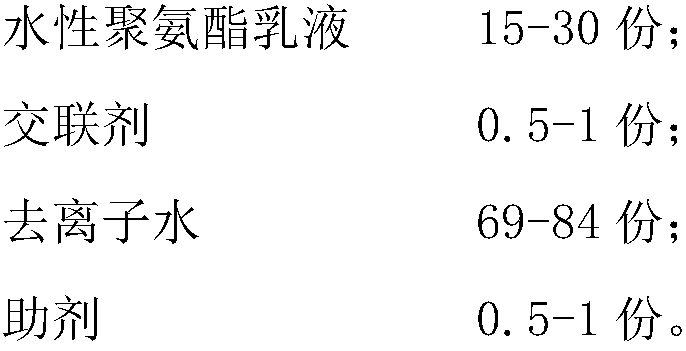

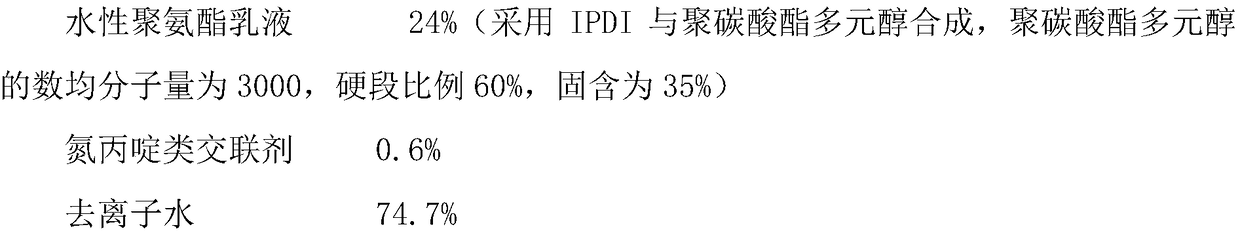

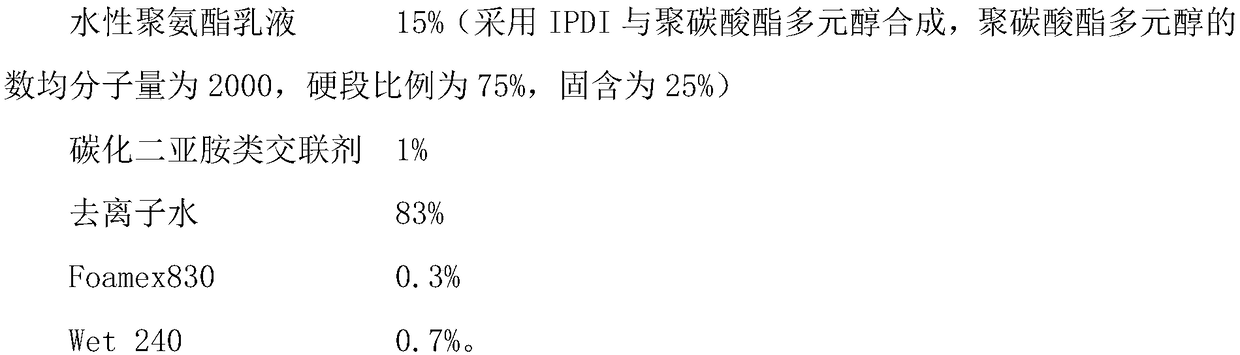

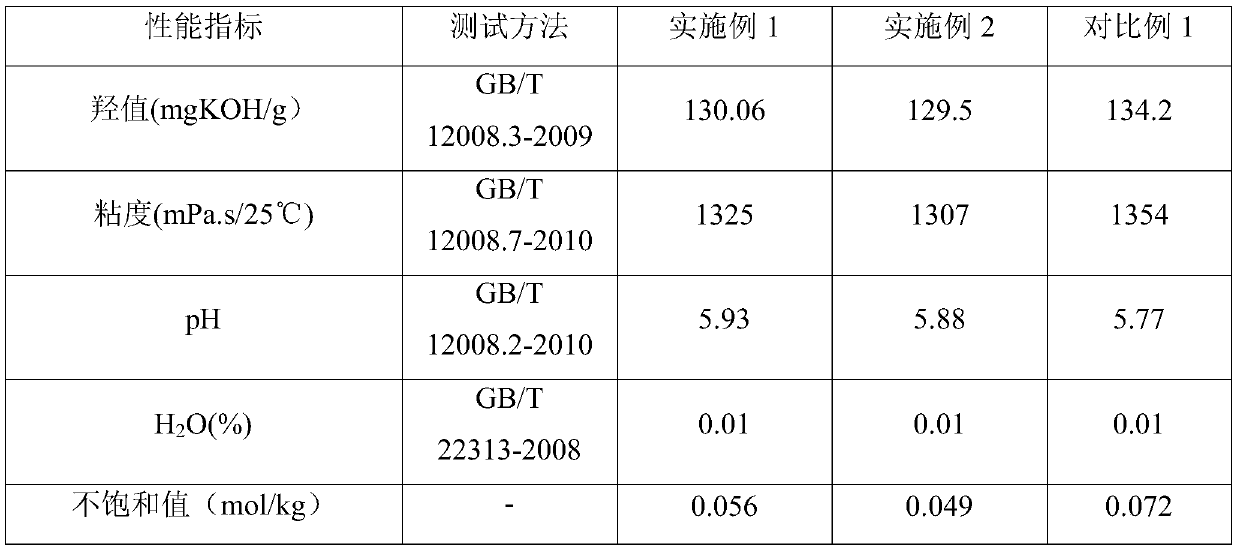

Anti-bending waterborne transfer coating and preparation method thereof

ActiveCN108329813AOvercoming the problem of intolerance to bendingImprove bending resistancePolyurea/polyurethane coatingsCross-linkPolyol synthesis

The invention provides an anti-bending waterborne transfer coating and a preparation method thereof. The coating is prepared from the following components in parts by weight: 15-30 parts of waterbornepolyurethane emulsion, 0.5-1 part of a cross-linking agent, 69-84 parts of deionized water and 0.5-1 part of an aid, wherein the waterborne polyurethane emulsion is synthesized from IPDI and polycarbonate polyol. The problem of irresistance to bending commonly existing in the existing transfer coating is effectively solved, bending performance of transfer paper during printing and cigarette wrapping is improved, and paper or printing bursting can be avoided. The waterborne transfer coating is environmentally friendly due to adoption of a waterborne resin system and the absence of any volatileorganic solvents.

Owner:SHANGHAI WEIKAI CHEM +2

Preparation method of high-functionality polyether polyol

The invention belongs to the technical field of polyether polyol synthesis, and particularly relates to a preparation method of high-functionality polyether polyol, wherein the preparation method comprises the following steps: (1) by using a high-functionality initiator or a mixed initiator containing the high-functionality initiator as an initiator, adding alkylene oxide under the action of a catalyst, and carrying out a polymerization reaction to obtain oligomer polyether polyol; and (2) adding an initiator which is the same as the initiator in the step (1), a catalyst and alkylene oxide into the oligomer polyether polyol obtained in the step (1), and carrying out a polymerization reaction to obtain the high-functionality polyether polyol. According to the invention, a step-by-step secondary feeding mode is adopted, the high-viscosity initiator system is diluted to a certain extent, the olefin oxide addition reaction is easier to start, the problems of long initiation time and non-uniform polymerization are solved, the unsaturated value index of a polyether polyol product is lower, the actual hydroxyl value of the product is closer to the theoretical hydroxyl value, and the product can meet higher use requirements.

Owner:SHANDONG BLUSR DONGDA CHEM

Solvent-free synthesis method for ultra-low temperature resistant polyurethane pressure-sensitive adhesive

InactiveCN104277756AHigh bonding strengthGood for healthPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention discloses a solvent-free synthesis method for an ultra-low temperature resistant polyurethane pressure-sensitive adhesive. By adopting a prepolymer method, the method includes: firstly, synthesizing an -NCO- terminated prepolymer from toluene diisocyanate (TDI) and bifunctional polyether polyol (N-220), and then mixing the prepolymer with trifunctional polyether polyol (N-330), coating release paper with the mixture, and carrying out heating curing to obtain an ultra-low temperature resistant polyurethane pressure-sensitive adhesive film. The ultra-low temperature resistant polyurethane pressure-sensitive adhesive prepared by the method provided by the invention has normal temperature bonding strength of greater than or equal to 1.0MPa (aluminum-aluminum), and -196DEG C bonding strength of greater than or equal to 13MPa (aluminum-aluminum). The adhesive is suitable for rapid bonding of parts used in an ultra-low temperature environment.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

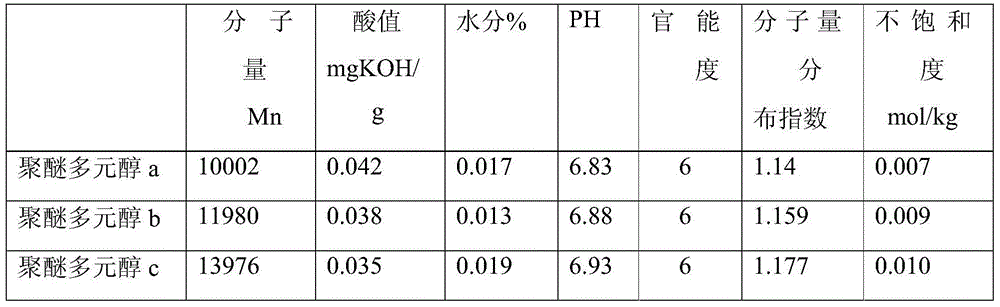

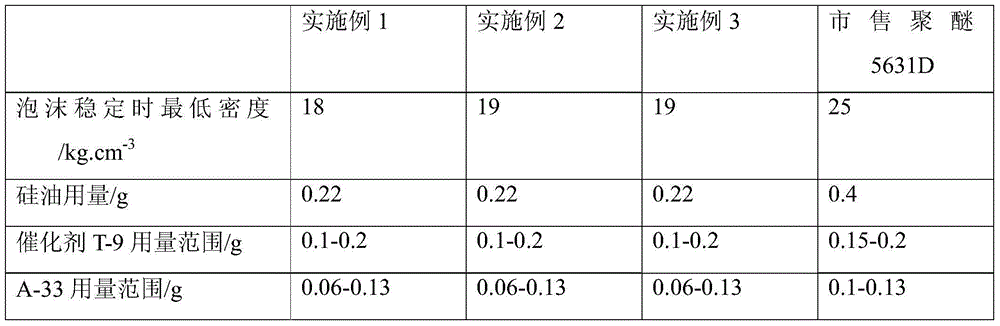

Preparation method for flexible foam polyether polyol for low-density sponge

InactiveCN104403095AOvercoming the problem of inactivation at the late stage of the reactionExcellent operating latitudePolyol synthesisLow density

The invention belongs to the field of polyether polyol synthesis technologies, and particularly relates to a preparation method for flexible foam polyether polyol for low-density sponge. Only neosorb is used as an initiator, and the polyether polyol is prepared through the two-stage polymerization technique. The preparation method provided by the invention has the advantages that the degree of functionality of the prepared polyether polyol reaches 6, the molecular weight of the prepared polyether polyol can reach between 10,000 and 14,000, and the prepared polyether polyol has the characteristics of low degree of unsaturation and narrow molecular weight distribution, so as to solve the problem of subsequent reaction inactivation of conventional catalysts; moreover, compared with the traditional polyether polyol used for low-density sponge products, the polyether polyol prepared through the invention achieves a lower density as well as higher operation tolerance, dimensional stability, flexibility and the like, so that the application range is wider, and the application requirement for high-quality low-density sponge is met.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com