Epoxy resin toughening curing agent and preparation method thereof

A technology of epoxy resin and curing agent, applied in the field of epoxy resin curing agent, can solve the problems of poor impact resistance, poor weather resistance, affecting the bonding strength and other properties of the adhesive, short pot life, etc., and achieve long storage period. , excellent toughening effect, improve the effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

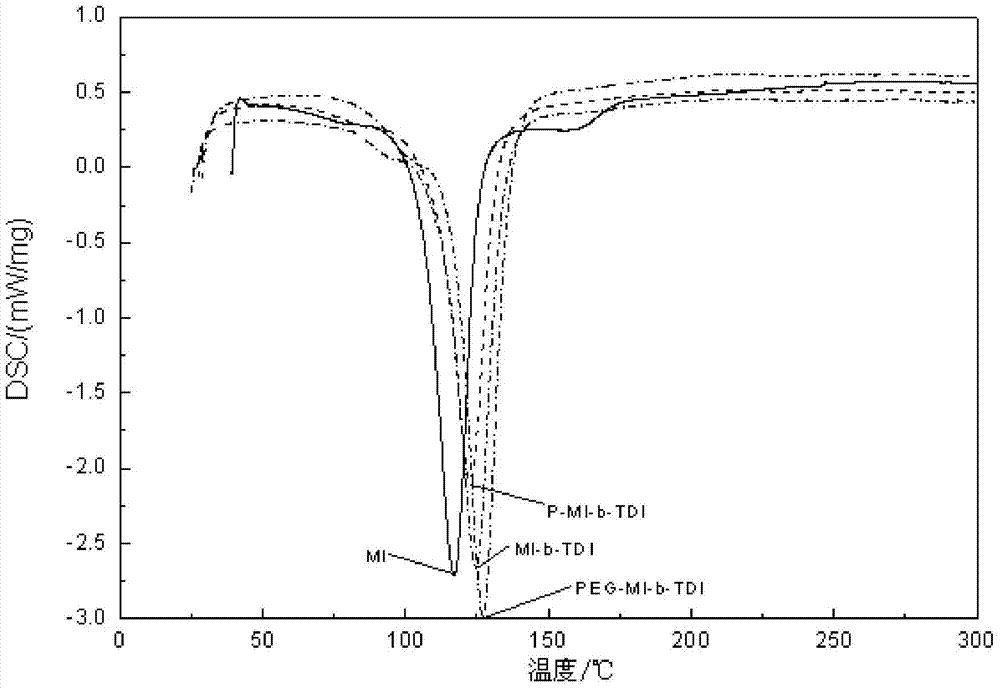

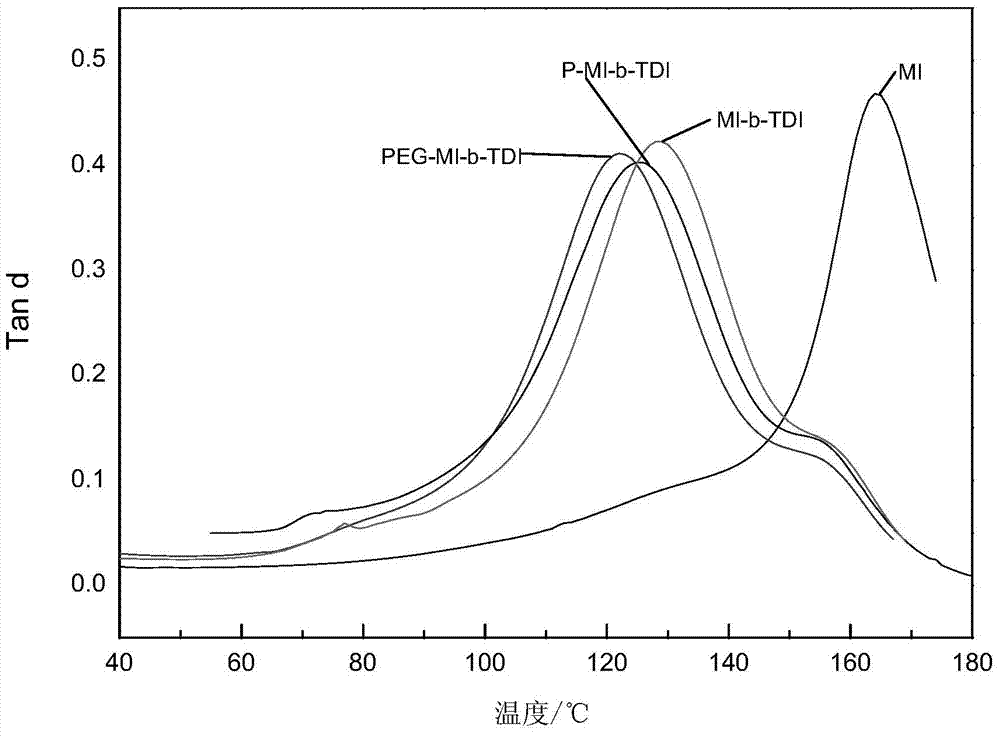

[0011] Specific embodiment one: the preparation method of epoxy resin toughening curing agent in the present embodiment is to carry out according to the following steps: with toluene diisocyanate and dendritic polyester polyol by proportioning n NCO :n OH Mix at a ratio of 100:30 (molar ratio), then add acetone, the amount of acetone accounts for 80% of the mass of TDI, the temperature is controlled at 45°C and the reaction is stirred for 1 hour, then press n NCO :n (—NH+—OH) =1:1.1 (molar ratio) by adding imidazole, controlling the temperature at 60°C until the mass content of -NCO is less than 3% and basically unchanged, that is to obtain the toughening curing agent for epoxy resin ( figure 1 and 2 marked as P-MI-b-TDI).

[0012] Utilize following test to verify effect of the present invention:

specific Embodiment approach 2

[0026] Specific embodiment two: the preparation method of epoxy resin toughening curing agent is carried out according to the following steps in the present embodiment: with toluene diisocyanate and dendritic polyester polyol by proportioning n NCO :n OH Mix at 100:40, then add butanone, the amount of butanone accounts for 100% of the TDI mass, control the temperature at 50°C and stir for 1 hour, then press n NCO :n (—NH+—OH) =1:1.1 by adding imidazole, and controlling the temperature at 60°C until the mass content of -NCO is less than 3% and remains basically unchanged, that is, the epoxy resin toughening and curing agent is obtained.

[0027] The epoxy resin toughening and curing agent in this embodiment has a storage period of more than 180 days, an impact strength of 16.092 MPa, and a tensile shear strength of 11.012 MPa.

specific Embodiment approach 3

[0028] Specific embodiment three: the preparation method of epoxy resin toughening curing agent is carried out according to the following steps in the present embodiment: with toluene diisocyanate and dendritic polyester polyol by proportioning n NCO :n OH Mix at 100:1, then add N,N-dimethylformamide, the amount of N,N-dimethylformamide accounts for 50% of the mass of TDI, the temperature is controlled at 48°C and the reaction is stirred for 1 hour, then press n NCO :n (—NH+—OH) =1:1.1 by adding imidazole, and controlling the temperature at 60°C until the mass content of -NCO is less than 3% and remains basically unchanged, that is, the epoxy resin toughening and curing agent is obtained.

[0029] The epoxy resin toughening and curing agent in this embodiment has a storage period of more than 180 days, an impact strength of 16.102 MPa, and a tensile shear strength of 10.830 MPa.

[0030] Specific embodiment three: the preparation method of epoxy resin toughening curing agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com