Patents

Literature

100results about How to "Play a toughening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin adhesive and preparation method thereof

ActiveCN103450835AImprove toughnessPlay a toughening effectNon-macromolecular adhesive additivesEpoxy resin adhesivesRoom temperatureResin adhesive

The invention provides an epoxy resin adhesive comprising a component A and a component B. The component A comprises 70-85 parts by weight of bisphenol A epoxy resin, 15-30 parts by weight of toughness modified bisphenol A epoxy resin and 20-40 parts by weight of a first filler; and the component B comprises 40-70 parts by weight of a polymercaptan curing agent, 30-60 parts by weight of a modified amine curing agent and 15-30 parts by weight of a second filler. According to the two-component epoxy resin adhesive provided by the invention, introduction of the toughness modified bisphenol A epoxy resin into the component A and compound of the modified amine curing agent and polymercaptan curing agent in the component B improve toughness of the epoxy resin adhesive, and the epoxy resin adhesive can be quickly cured at room temperature.

Owner:浙江东大树脂科技股份有限公司

Nucleocapsid structure polyvinyl chloride impact modifier, and its preparing method and use

InactiveCN1743371AImprove toughening efficiencyImprove the interface binding forceElastomerCross-link

Owner:HEBEI UNIV OF TECH

Preparation method of halogen-free flame-retardant polylactic acid fiber

ActiveCN103122498AReduce dosagePromote pyrolysis into charFlame-proof filament manufactureMonocomponent polyesters artificial filamentMasterbatchGreen environment

The invention relates to a preparation method of halogen-free flame-retardant polylactic acid fiber, which comprises the following steps of: (1) mixing polylactic acid slices with a flame retardant agent, performing melt blending at 180-220 DEG C, and cooling and granulating to obtain flame-retardant polylactic acid masterbatch; (2) mixing the polylactic acid slices with a synergist, performing melt blending at 190-220 DEG C, and cooling and granulating to obtain synergistic polylactic acid masterbatch; and (3) mixing the polylactic acid slices, the flame-retardant polylactic acid masterbatch, the synergistic polylactic acid masterbatch and a dispersing agent, spinning to obtain nascent fiber, and performing drafting post processing of the nascent fiber to obtain halogen-free flame-retardant polylactic acid fiber. The polylactic acid composite fiber material provided by the invention has good spinning formability and excellent fiber quality; the flame retardant agent is a halogen-free flame retardant agent, and the halogen-free flame-retardant polylactic acid fiber is safe and non-toxic in the using and burning process, thereby being green environment-friendly fiber; and the halogen-free flam-retardant polylactic acid fiber can be applied to the fields with high requirement for flame retardance such as clothing, trim, home textile and the like, and has broad market prospect.

Owner:DONGHUA UNIV +1

Method for preparing impact modifier of polyvinyl chloride in new type structure of hud

InactiveCN1916046AImprove toughening efficiencyImprove the interface binding forceElastomerResin matrix

This invention relates to a method for preparing polyvinyl chloride impact modifier with core / shell structure. The method comprises: utilizing acrylate monomer as the raw material, performing seed emulsion polymerization by semi-continuous adding the raw material to obtain crosslinked polymer latex with elastomer core / transition layer structure, adding vinyl chloride monomer and other monomers into the high-pressure kettle, and performing emulsion polymerization to obtain polyvinyl chloride impact modifier with core / shell structure. The impact modifier has polyvinyl chloride as the shell, thus can improve the compatibility with polyvinyl chloride resin matrix when blending, and effectively exert the functions of polyacrylate elastomer core and functional groups. The impact modifier can improve the impact property, weathering resistance and heat stability of polyvinyl chloride materials. Besides, the cost of the impact modifier is lower than that of polyacrylate impact modifier, thus can increase the added value of polyvinyl chloride resin and broaden the applications of polyvinyl chloride resin.

Owner:HEBEI UNIV OF TECH

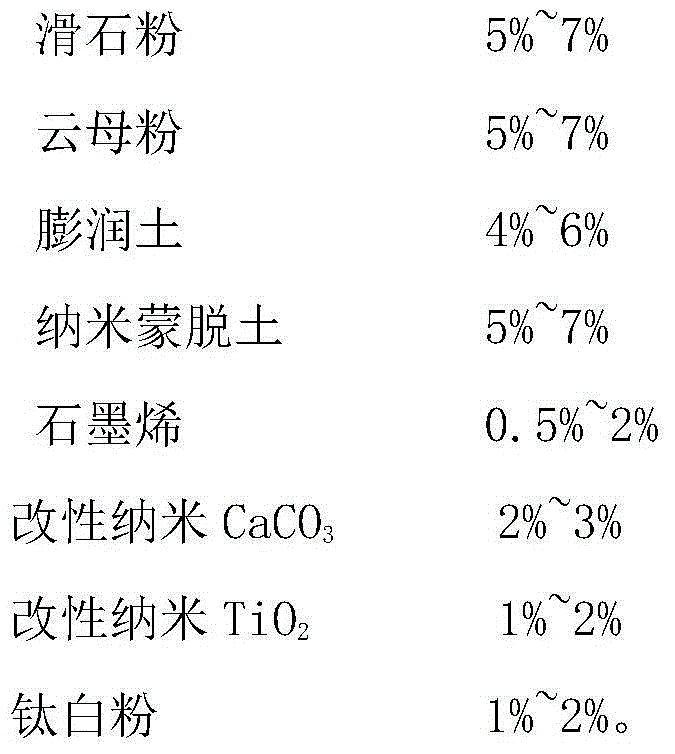

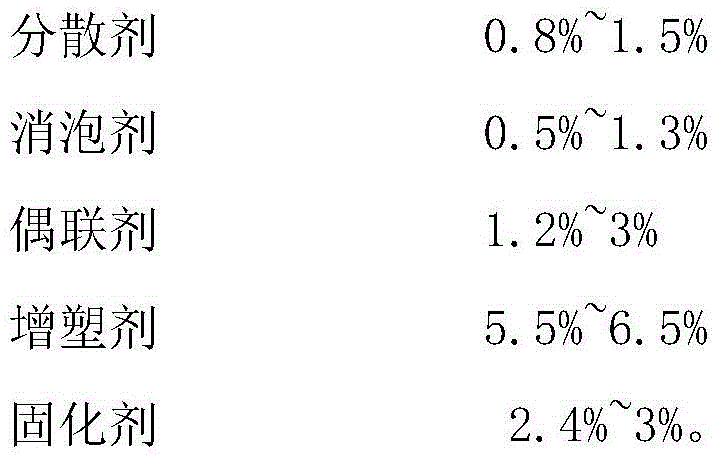

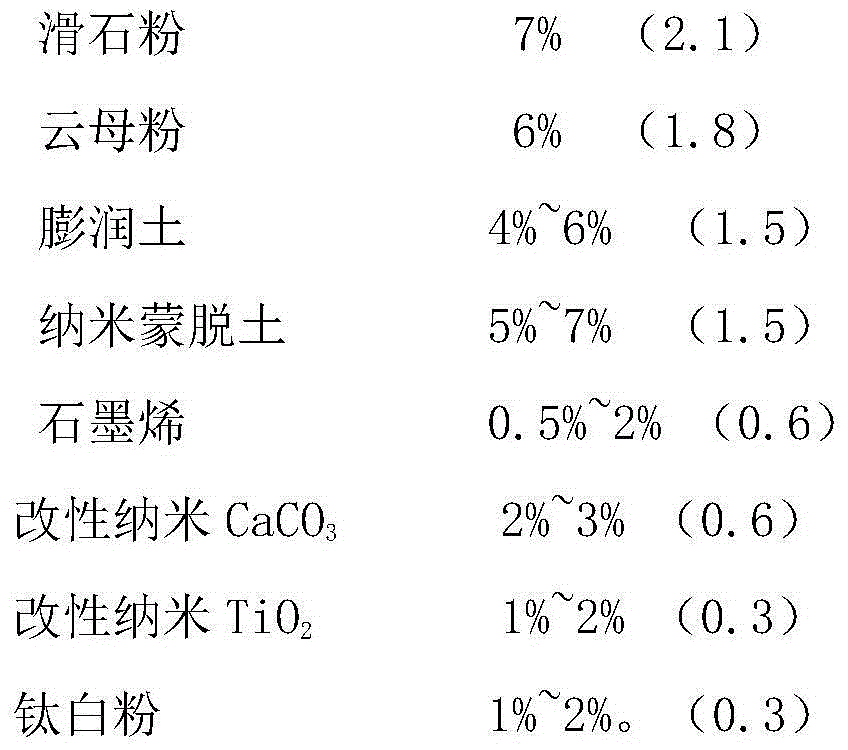

Epoxy resin coating in marine steel pipe 3PE anticorrosive coating and preparation method thereof

InactiveCN104449249AReduce dosageAvoid crackingAnti-corrosive paintsEpoxy resin coatingsEpoxyShrinkage rate

The invention discloses an epoxy resin coating in a marine steel pipe 3PE anticorrosive coating and a preparation method thereof. The epoxy resin anticorrosive coating comprises the following components in percentage by weight: 55-65 percent of epoxy resin, 23.5-36 percent of filler and pigments and 10.4-15.3 percent of aids, wherein the epoxy resin comprises the following components in percentage by weight: 39-47 percent of E-12 epoxy resin and 16-23 percent of novolac epoxy resin. Talcum powder, mica powder, bentonite and titanium dioxide are properly added into the epoxy resin to serve as partial fillers. The use amount of the resin can be relatively reduced, the cost is reduced, the physical and mechanical properties can be improved; particularly, the elasticity modulus is increased, the cure shrinkage rate is reduced, the seawater impact resistance is increased, and the seawater resistance is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Artificial tooth base resin-nano zirconium oxide composite material and preparation thereof

InactiveCN101214196AImprove wear resistanceImprove the finishImpression capsDentistry preparationsPink colorFlexural strength

The present invention provides false tooth base resin applied to the oral cavity repair, which is nanometer zirconia composite material. Firstly, silane coupling agent Z-6030 is used to decorate the surface of the nanometer zirconia. The raw material components are 0.5 percent to 5.0 percent of silane coupling agent Z-6030 and 95 percent to 99.5 percent of the nanometer zirconia. The nanometer zirconia decorated by the coupling agent is obtained. Then the nanometer zirconia decorated by the coupling agent is synthesized with polymethyl methacrylate. The material components are 1 percent to 5 percent of the nanometer zirconia decorated by the coupling agent and 95 percent to 99 percent of the polymethyl methacrylate. The nanometer zirconia composite material is obtained, the flexural strength of which can be 95.61MPa. The nanometer zirconia composite material manufactured by the present invention has high flexural strength, easy polishing, good finish degree, pink color, easy adjustment and good biological compatibility and is the novel resin with good biological and mechanical performance, which can be widely applied to the dentistry.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +1

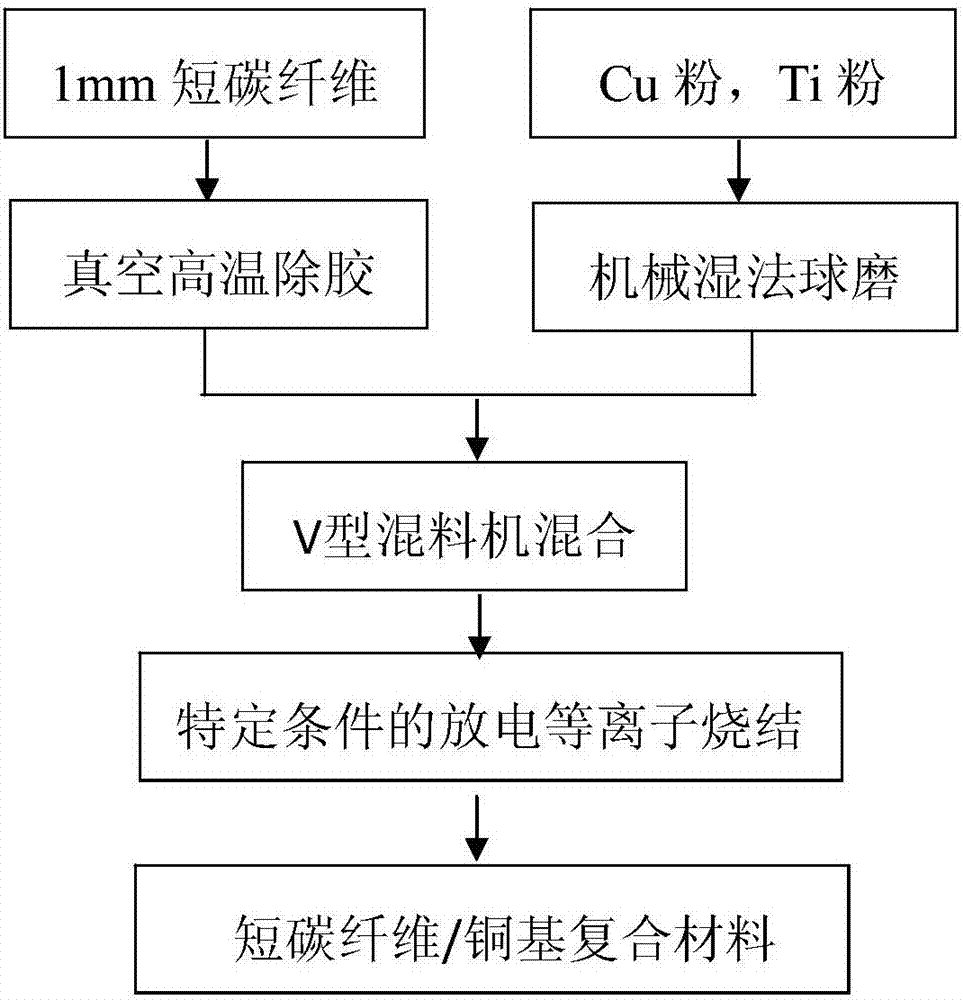

Preparation method for short carbon fiber/copper composite material

The invention relates to a preparation process for a short carbon fiber / copper composite material, in particular to a preparation method for a 1mm short carbon fiber reinforced Cu matrix composite material. The preparation method comprises the following steps: uniformly mixing a copper source, a titanium source and short carbon fibers which are uniformly mixed, and adopting discharge plasma sintering to obtain the short carbon fiber / copper composite material. Sintering parameters are that a temperature is 790-880 DEG C, temperature keeping time is 10-30 minutes, and sintering pressure is 5-25 MPa; copper in the copper source is zero valence; and titanium in the titanium source is zero valence. The preparation method is low in preparation process and is low in energy consumption, and the obtained product is excellent in performance.

Owner:CENT SOUTH UNIV

Method of preparing flame-retarding anti-microbial polylactic acid fibers, spinning fibers into yarn and making fabric

InactiveCN105239194ASpin wellImprove qualityFlame-proof filament manufactureMelt spinning methodsFiberYarn

The invention relates to a method of preparing flame-retarding anti-microbial polylactic acid fibers, spinning the fibers into yarn and making a fabric. The method comprises the first step of mixing polylactic acid slices with flame retardants and antibacterial agents, melt-blending the mixture at the temperature between 180 DEG C and 220 DEG C and conducting cooling and pelleting to obtain flame-retarding anti-microbial polylactic acid master batches, the second step of mixing polylactic acid slices with synergists, melt-blending the mixture at the temperature between 190 DEG C and 220 DEG C and conducting cooling and pelleting to obtain synergetic polylactic acid master batches, and the third step of mixing polylactic acid slices, the flame-retarding anti-microbial polylactic acid master batches, the synergetic polylactic acid master batches and dispersants, conducting spinning to obtain nascent fibers, and pulling and processing the nascent fibers to obtain the flame-retarding anti-microbial polylactic acid fibers.

Owner:王庆

Composite thermal insulation mortar and manufacturing method thereof

InactiveCN104030643AImprove energy saving effectImprove crack resistanceSolid waste managementRice strawEmulsion

The invention discloses composite thermal insulation mortar which solves the problem that the thermal insulation property of existing thermal insulation mortar is not good and achieves recycling of crop straws. The composite thermal insulation mortar is composed of, by weight, 70-80 parts of cement, 10-15 parts of coal ash, 5-20 parts of calcium hydroxide, 10-20 parts of rice straw fibers, 30-40 parts of glass beads, 0.5-0.8 part of cellulose ether, 0.1-0.2 part of starch ether, 0.01-0.05 part of air entraining agents, 1-4 parts of emulsion powder and 150-190 parts of water, wherein the cement, the coal ash and the calcium hydroxide account for 100 parts. According to the composite thermal insulation mortar, the crop straws are fully utilized and recycled; meanwhile, the rice straw fibers of agricultural waste and the coal ash of industrial waste can be utilized, and the composite thermal insulation mortar is environmentally friendly, low in energy consumption and capable of being widely applied to thermal insulation of internal walls and external walls of buildings.

Owner:SICHUAN INSITITUTE OF BUILDING RES

Preparation method for high-toughness material of polypropylene/shear thickening fluid microcapsule

InactiveCN103506057AReserved natureImprove toughnessMicroballoon preparationMicrocapsule preparationOrganic solventThickened fluids

The invention relates to a preparation method for a high-toughness material of a polypropylene / shear thickening fluid microcapsule. The method comprises the following steps: firstly, dispersing nano silicon dioxide in polypropylene glycol under a high-speed mixing effect of a high-speed shearing and emulsifying machine to obtain a shear thickening fluid; secondly, uniformly mixing the prepared shear thickening fluid with water according to a certain ratio to obtain a uniform solution; thirdly, adding an emulsifier and an organic solvent into the uniform solution and mixing through a mixer to obtain a uniform water-in-oil emulsion; fourthly, transferring the water-in-oil emulsion into a three-mouth flask and adding isocyanate for reaction to obtain a shear thickening fluid microcapsule; fifthly, carrying out melt blending on polypropylene and the shear thickening fluid microcapsule in one or a combination of more of an open mixer, an internal mixer and an extruder to obtain the high-toughness material of the polypropylene / shear thickening fluid microcapsule. Compared with a general toughening polypropylene material, the rigidity of polypropylene cannot be reduced while the toughness of polypropylene is enhanced, the heat resistance and the processing flowability of polypropylene are improved, and the shear thickening fluid microcapsule is changed into solid powder which is more convenient to form in comparison with liquid.

Owner:EAST CHINA UNIV OF SCI & TECH

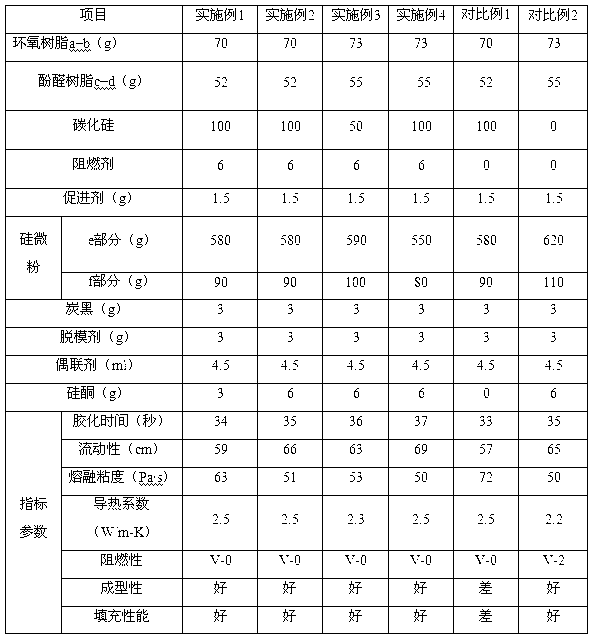

Green and environment-friendly epoxy resin composition for high-power device packaging

InactiveCN102850724AFlexibleMalleableSemiconductor/solid-state device detailsSolid-state devicesEpoxyHazardous substance

A green and environment-friendly epoxy resin composition for high-power device packaging comprises an epoxy resin, a phenolic resin, an inorganic filler, a high thermal conductivity filler, a curing accelerant, silicone, a release agent, a coloring agent and a fire retardant, wherein the fire retardant is formed by matching aluminum hydroxide and zinc borate. The epoxy resin and the curing agent phenolic resin use environment-friendly mixed components which are free of harmful substances, and the silicone containing epoxy groups is added, so that a molecular chain has certain flexibility and malleability due to high molecular weight of the silicone, and a certain toughening effect is achieved. The green and environment-friendly epoxy resin composition is low in melt viscosity, good in mobility and operability, applicable to the green high-power device packaging and capable of meeting high radiating performance requirements of semiconductors, achieving good formability and operability during packaging processes and meeting halogen-free and antimony-free requirements of green packaging.

Owner:JIANGSU ZHONGPENG NEW MATERIAL

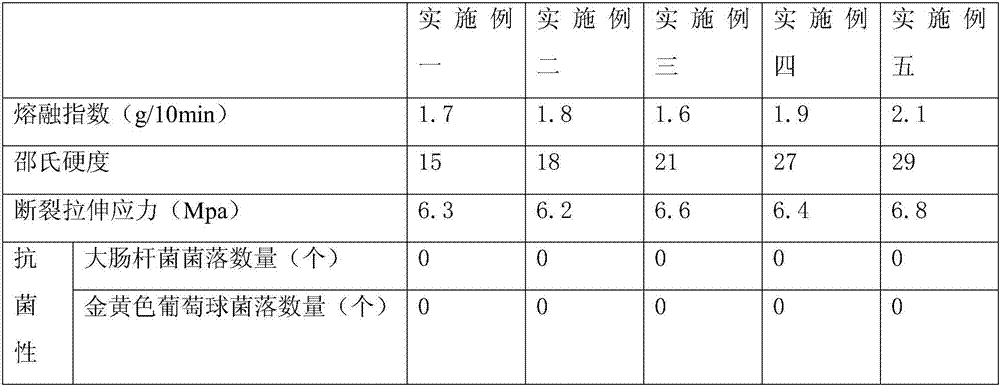

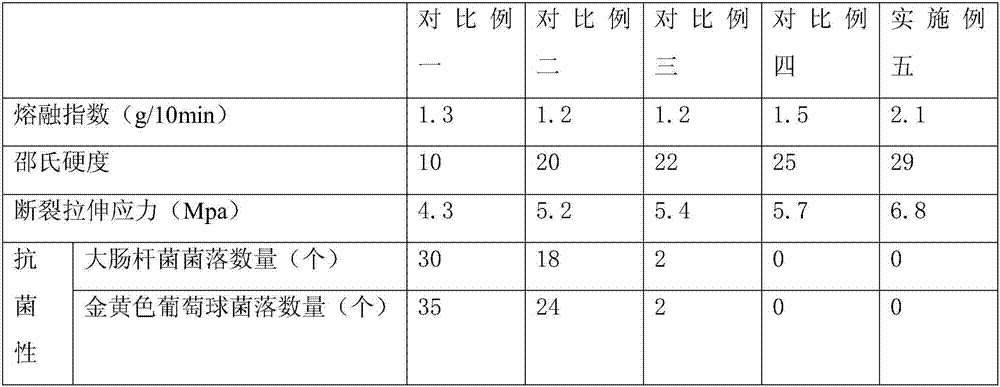

Baby product TPE (Thermoplastic Elastomer) and preparation method of baby product TPE

The invention discloses a baby product TPE (Thermoplastic Elastomer) and a preparation method of the baby product TPE, and solves the problems that: adding a plasticizer in the TPE material causes baby allergies easily, and as the plasticizer contains phthalate ester in environmental estrogen and forms pseudo-hormone easily, the hormone content in the body is affected, the original mechanism of internal secretion is further disturbed and the endocrine dyscrasia of a baby is caused. The key point of the technical scheme is as follows: the material of the baby product TPE comprises the following components by mass: 20-40 parts of SEBS (Styrene Ethylene Butylene Styrene block copolymer), 50-60 parts of cosmetics grade white oil, 5-15 parts of shell powder, 5-15 parts of polyolefin, 5-10 parts of a compatilizer, 0.5-1.5 parts of a slipping agent, 0.1-0.3 part of an antioxygen, 0.1-0.2 part of an antiaging agent and 0.1-0.5 part of an antibacterial agent, no plasticizer is added, and the condition that the allergy of the baby skin is caused by the addition of the plasticizer is avoided.

Owner:余姚优信塑业有限公司

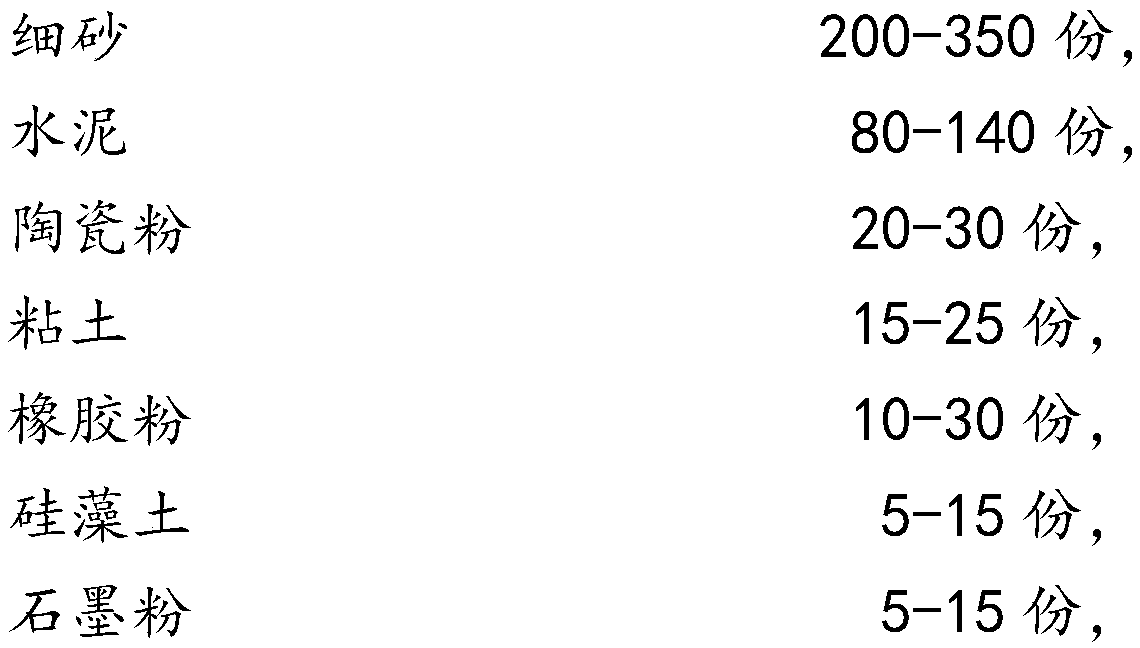

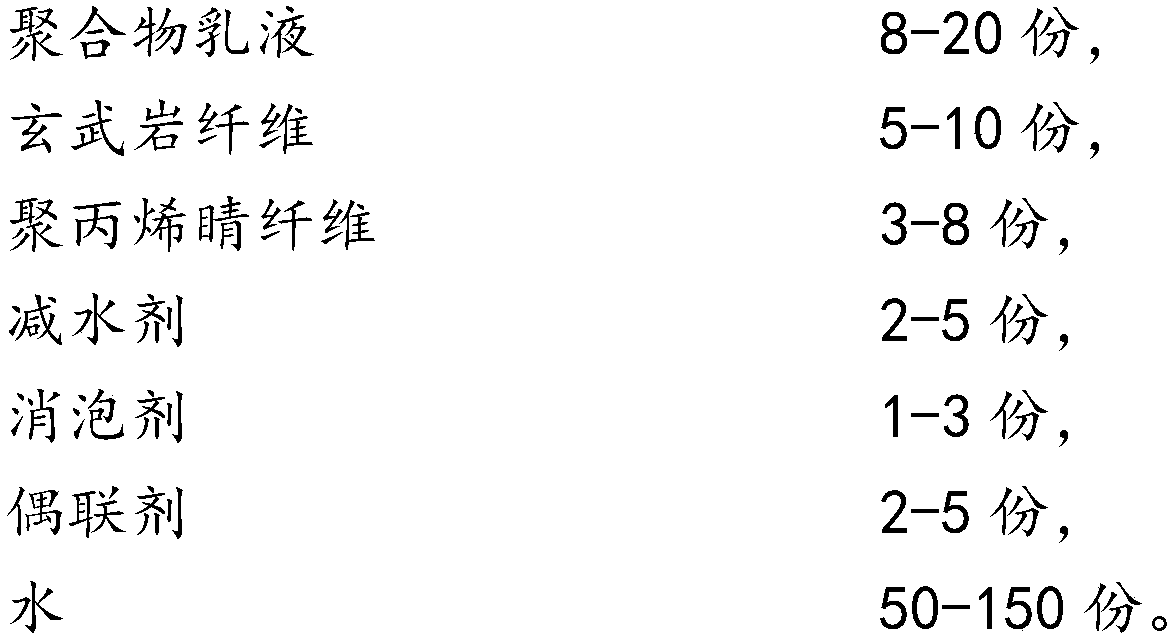

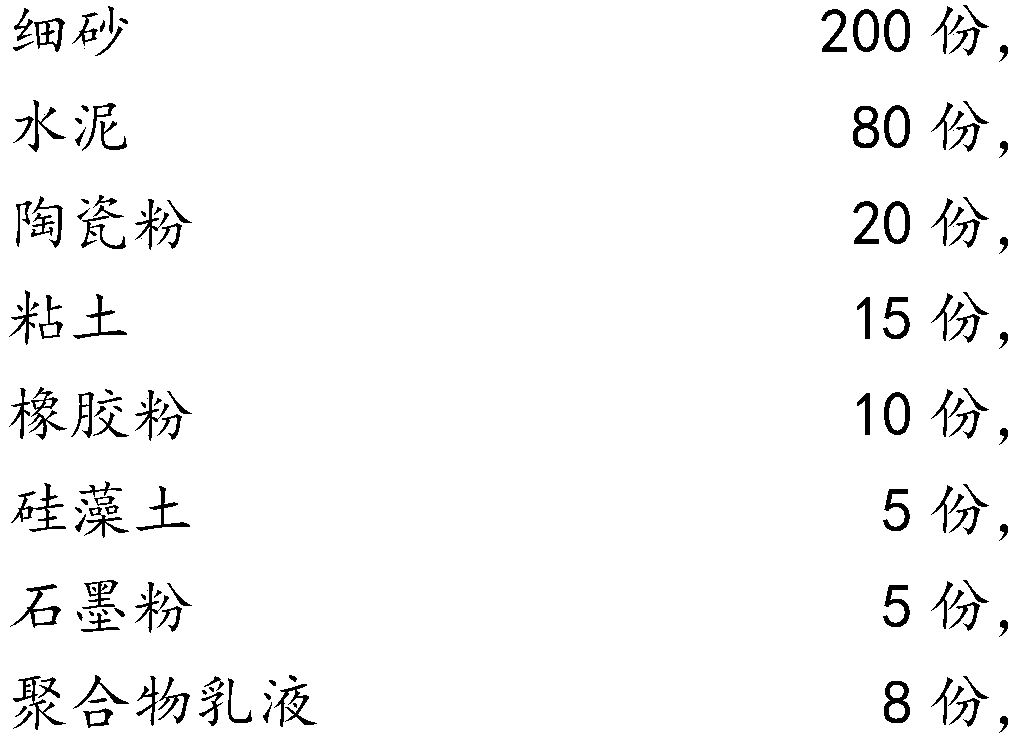

Polymer cement-based modified mortar

The invention discloses polymer cement-based modified mortar. The polymer cement-based modified mortar comprises the following raw materials in parts by mass: 200 to 350 parts of fine sand, 80 to 140parts of cement, 20 to 30 parts of ceramic powder, 15 to 25 parts of clay, 10 to 30 parts of rubber powder, 5 to 15 parts of diatomite, 5 to 15 parts of graphite powder, 8 to 20 parts of polymer emulsion, 5 to 10 parts of basalt fiber, 3 to 8 parts of polyacrylonitrile fiber, 2 to 5 parts of a water-reducing agent, 1 to 3 parts of a defoaming agent, 2 to 5 parts of a coupling agent and 50 to 150 parts of water. The polymer cement-based modified mortar has advantages of high structural strength, high waterproofness, high toughness, high bending strength, high volume stability, high durability,high freezing resistance, high early strength and good use effect, and is not liable to crack.

Owner:SUZHOU BIZUNION ARCHITECTURAL ENG CO LTD

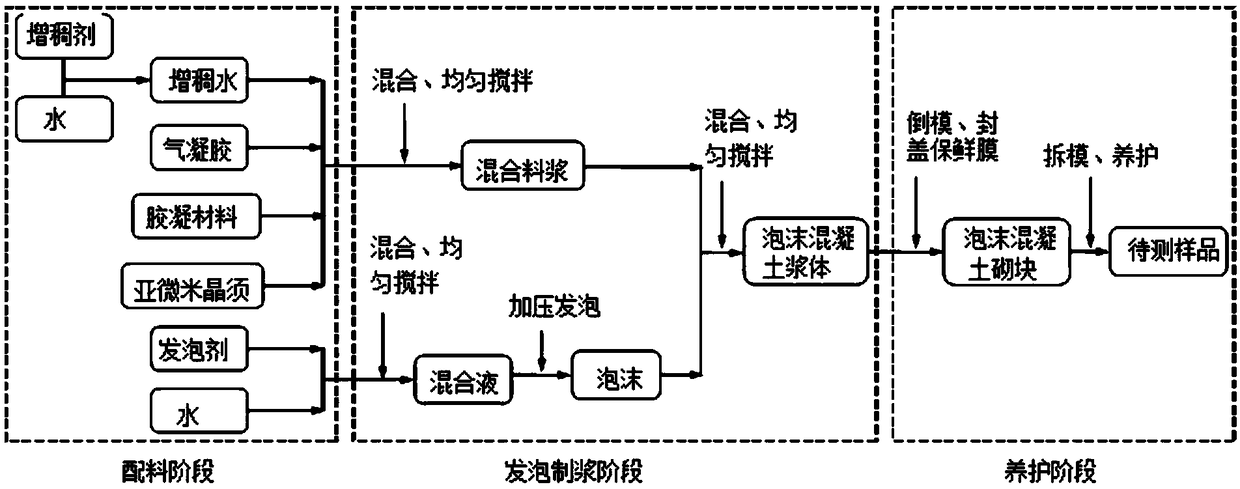

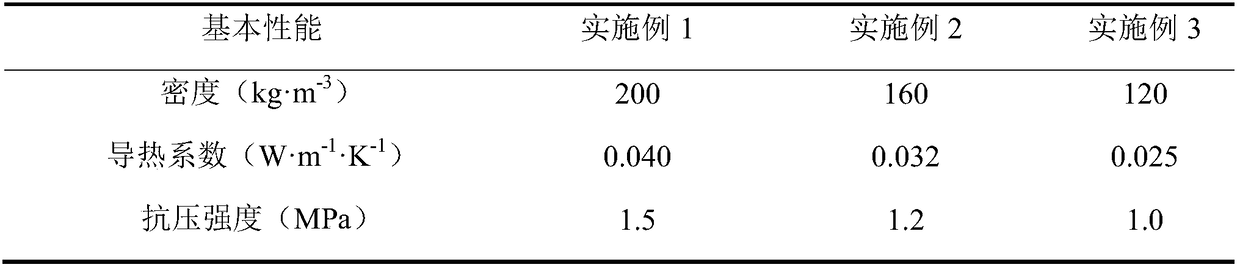

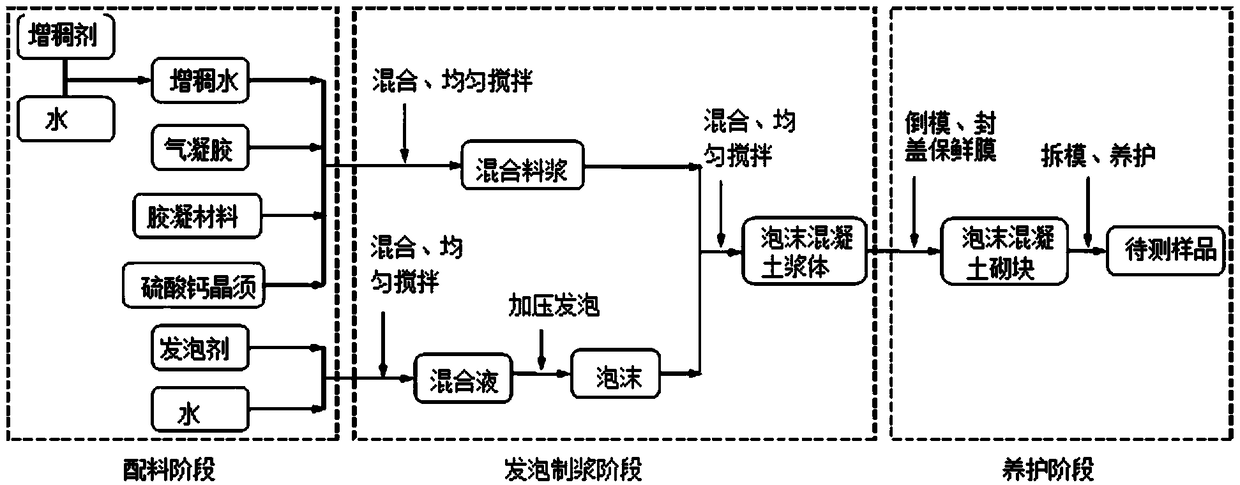

Submicron inorganic whisker reinforced aerogel foam concrete and preparation method thereof

ActiveCN109467360AImproved stomatal distributionImprove mechanical propertiesCeramicwareFoam concreteFoaming agent

The invention discloses submicron inorganic whisker reinforced aerogel foam concrete and a preparation method thereof. The preparation raw materials of the submicron inorganic whisker reinforced aerogel foam concrete comprise a cementing material, aerogel powder, submicron inorganic whiskers, a thickening agent, a foaming agent and water, wherein the mass ratio of the cementing material to the aerogel powder to the submicron inorganic whiskers is 1:(0.01-0.3):(0.001-0.01); the diameter of the submicron inorganic whiskers is 100 nm-1 [mu]m, and the length-diameter ratio of the submicron inorganic whiskers is 10-10000; and the size of the submicron inorganic whiskers is closer to the size of nanopores of the aerogel, so that the reinforcement effect is better. The submicron inorganic whiskerreinforced aerogel foam concrete disclosed by the invention has ultralow density and ultralow heat conductivity and also has good compressive strength, and can be applied to the fields such as heat preservation of building walls, road filling, and sound insulation of barriers, thereby having broad application prospects.

Owner:GUANGZHOU UNIVERSITY

Calcium sulfate whisker aerogel foam concrete and preparation method thereof

ActiveCN109400064AImprove mechanical propertiesGood flexibilityCeramicwareFoam concreteLongest Diameter

The invention discloses calcium sulfate whisker aerogel foam concrete and a preparation method thereof. The calcium sulfate whisker aerogel foam concrete comprises cementing materials, aerogel powder,calcium sulfate whiskers, thickening agents, foaming agents and water, the weight ratio of the cementing materials, the aerogel powder to the calcium sulfate whiskers is 1:(0.01-0.3):(0.001-0.01), the diameter of the calcium sulfate whiskers is 1-10 micrometers, the long-diameter ratio of the calcium sulfate whiskers is 10-500, low-cost calcium sulfate whiskers are mixed into an aerogel foam concrete substrates, calcium sulfate whiskers with high long-diameter ratio have high flexibility and are high in bonding efficiency, so that expansion of cracks of the aerogel foam concrete substrates can be decreased, mechanical property and block forming property of the aerogel foam concrete are remarkably improved, and a preparation process is simplified, and the concrete can be widely applied tothe field of heat insulation of building walls, filling of roads, sound insulation of barriers and the like.

Owner:GUANGZHOU UNIVERSITY

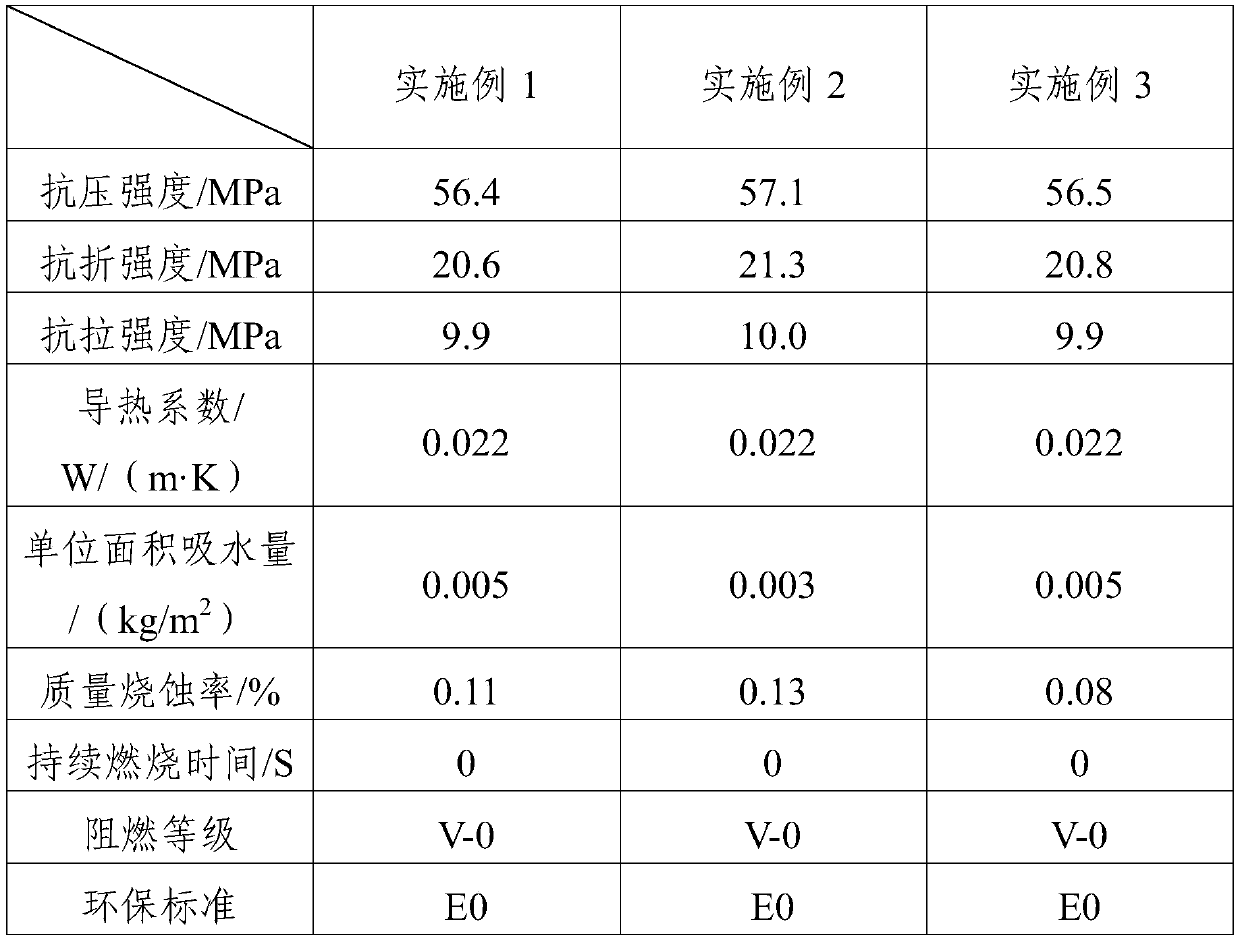

Multi-element modified phenolic resin/basalt fiber composite board and preparation method thereof

InactiveCN111087752AHigh thermal decomposition temperatureSmall water absorptionEpoxyPolymer science

The invention provides a multi-element modified phenolic resin / basalt fiber composite board and a preparation method thereof, and relates to the field of building materials. The multi-element modifiedphenolic resin / basalt fiber composite board is prepared from the following raw materials in parts by weight: 130 to 150 parts of multi-element modified phenolic resin, 50 to 60 parts of basalt fiber,30 to 50 parts of carboxyl-terminated nitrile rubber modified epoxy resin, 1 to 3 parts of thiourea modified diethylenetriamine, 10 to 20 parts of graphite powder, 1 to 3 parts of butyl titanate, 1 to 3 parts of polyvinyl acetal, 5 to 10 parts of nanometer cerium borate, 20 to 30 parts of basic magnesium sulfate whiskers, 10 to 20 parts of aluminum borosilicate whiskers, 3 to 6 parts of ammoniumpolyphosphate, 10 to 20 parts of barium hydroxide, 7 to 12 parts of melamine, 4 to 8 parts of a silane coupling agent and 120 to 130 parts of absolute ethyl alcohol. The multi-element modified phenolic resin / basalt fiber composite board provided by the invention has excellent compression resistance, fracture resistance and tensile property, reaches a heat conductivity coefficient of 0.022 W / (m.K)and a flame retardant grade of V-0, and has excellent heat preservation and flame retardant properties.

Owner:安徽验讯网络科技有限公司

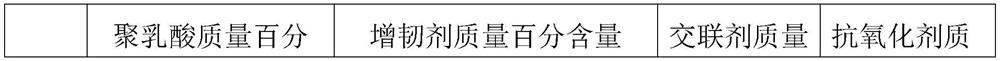

Polylactic acid composition, and toughened transparent material and preparation method thereof

The invention relates to a polylactic acid composition. The polylactic acid composition comprises, by mass, 75-95% of a polylactic acid resin, 1.5%-15% of a toughening agent and 0.1%-6% of other auxiliary agents, wherein the toughening agent is composed of epoxy oil and polyether polyol in a mass ratio of (2-3): 5, and the refractive index of the epoxy oil is 1.471 to 1.478. The invention also relates to a toughened transparent material formed by the polylactic acid composition. The invention further relates to a preparation method of the toughened transparent material.

Owner:GUANGZHOU HUAXINKE ENTERPRISE

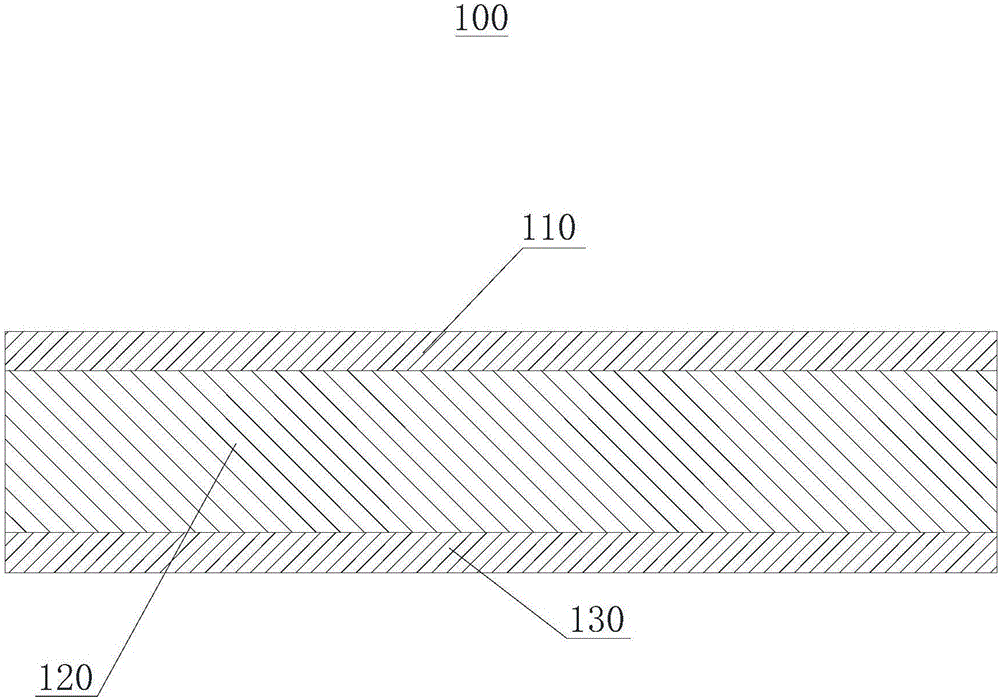

Composite plastic sheet and making method thereof

ActiveCN106003939AImprove resistance to external forcesStable structureSynthetic resin layered productsElastomerPolyolefin

The invention discloses a composite plastic sheet. The composite plastic sheet comprises a first composite layer, a second composite layer and a third composite layer, and the second composite layer is arranged between the first composite layer and the third composite layer. A making method of the composite plastic sheet comprises the steps that first raw materials are mixed to prepare first composite layer resin and third composite layer resin, wherein the first raw materials comprise, by weight, 82-88 parts of polypropylene, 5-8 parts of metallocene polyolefin elastomer, 3-6 parts of polyethylene and 2-5 parts of color masterbatches; second raw materials are mixed to prepare second composite layer resin, wherein the second raw materials comprise, by weight, 78-83 parts of polypropylene, 3-6 parts of metallocene polyolefin elastomer, 4-7 parts of polyethylene, 5-9 parts of filler and 2-5 parts of color masterbatches; the second composite layer resin is arranged between the first composite layer resin and the third composite layer resin, and multi-layer coextrusion is conducted. The plastic sheet which is good in toughness and impact strength is effectively obtained through a simple technological method.

Owner:丹东鑫马高科技塑料包装有限公司

Method for manufacturing aluminum oxide toughened composite zirconium oxide false tooth porcelain block

ActiveCN108484165AImprove fracture toughnessPlay a toughening effectArtificial teethSpherical granuleAdhesive

The invention discloses a method for manufacturing an aluminum oxide toughened composite zirconium oxide false tooth porcelain block, relates to a method for manufacturing a zirconium oxide false tooth porcelain block and aims to solve the problems that a conventional full-porcelain zirconium oxide false tooth porcelain block is large in brittleness and small in fracture toughness, multiple long bridge teeth are hard to manufacture, and breakage and porcelain fracture can be easily caused when the long bridge teeth are used. The method comprises the following steps: I, preparing mixed powder of zirconium oxide and aluminum oxide; II, preparing composite powder; III, preparing a solution for pelletizing the composite powder; IV, preparing slurry; V, preparing composite spherical granules ofwhich the particle size is 10-30 micrometers; VI, pressing; VII, applying an adhesive, and performing thermal treatment; VIII, sintering, thereby obtaining the aluminum oxide toughened composite zirconium oxide false tooth porcelain block. By adopting the method, the aluminum oxide toughened composite zirconium oxide false tooth porcelain block can be manufactured.

Owner:哈尔滨宇航精创科技有限公司

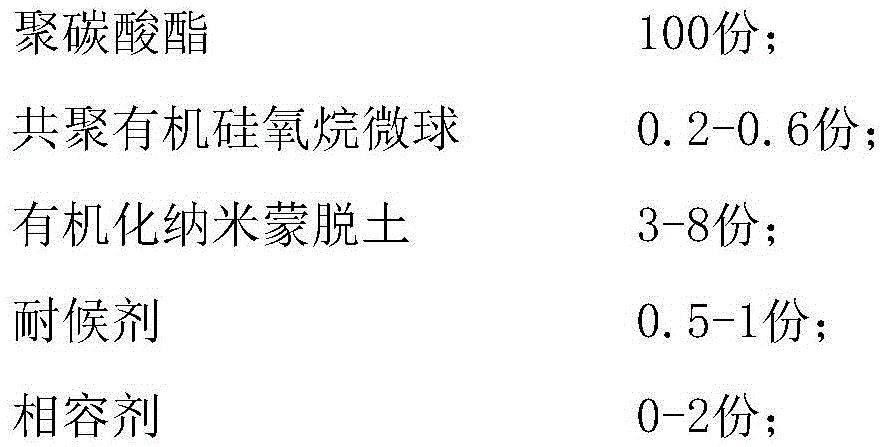

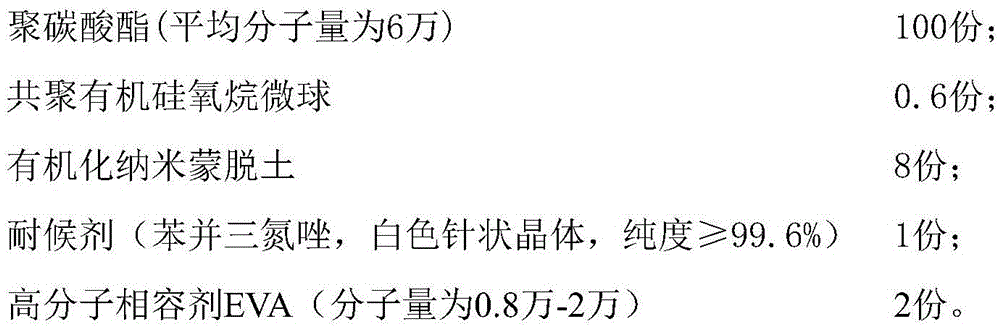

Flame-retardant, high-transmittance and weather-proof polycarbonate composite used for LED lampshade and preparation method

The invention belongs to the technical field of polycarbonate composites, and particularly discloses a flame-retardant, high-transmittance and weather-proof polycarbonate composite used for an LED lampshade and a preparation method. The polycarbonate composite is prepared from raw materials including, by weight, 100 parts of polycarbonate, 0.2-0.6 part of copolymerized organic siloxane microspheres, 3-8 parts of organic nano-montmorillonite, 0.5-1 part of weather-proof agent, compatilizer and 0-2 parts of other auxiliaries. The prepared flame-retardant, high-transmittance and weather-proof polycarbonate composite has excellent chemical performance and processing performance, has the advantages of high transmittance, high flame retardance, excellent weather resistance and the like, can meet requirements of LED illumination lampshades, and is simple in process and beneficial to wide application and popularization.

Owner:HUBEI ENG UNIV

Curing method of nanocrystalline magnetic core

ActiveCN112309703AReduce internal stressImprove performanceTransformers/inductances magnetic coresOrganic non-macromolecular adhesiveDipropylene glycol diacrylatePhenyl group

The invention discloses a curing method of a nanocrystalline magnetic core, and belongs to the technical field of magnetic core material preparation. The method comprises the following steps: firstly,mixing 40-60 parts of polyurethane modified epoxy resin, 15-30 parts of bisphenol A epoxy acrylate, 8-15 parts of dipropylene glycol diacrylate, 2-4 parts of 1-hydroxycyclohexyl phenyl ketone, 0.2-1part of an antifoaming agent, 0.3-1.5 parts of a wetting agent and 0.5-1.5 parts of a leveling agent, and uniformly stirring to form a glue solution; then, soaking the nanocrystalline magnetic core subjected to heat treatment in the glue solution, wherein the soaking time is 30-60s; and finally, airing the impregnated magnetic core till that there is no residual glue solution on a surface, and then curing the impregnated magnetic core through a UV photocuring instrument, wherein a curing temperature ranges from 25 DEG C to 30 DEG C, and the curing time ranges from 5s to 15s. The method is easyto operate and low in cost, a stress borne by the cured magnetic core can be greatly reduced, and the cured magnetic core can keep good performance.

Owner:FUYANG NORMAL UNIVERSITY +1

High-power packaging epoxy resin composition with good forming performances

InactiveCN102863744AImprove liquidityReduce melt viscosityOther chemical processesEpoxyFire retardant

A high-power packaging epoxy resin composition with good forming performances contains epoxy resin (A), phenolic resin (B), inorganic filler (C), high thermal conductive filler (D), solidification accelerator (E), silane coupling agent (F), silicone (G), releasing agent (H), colorant (I) and flame retardant (J). The high thermal conductive filler selects silicon carbide which has a thermal conductive coefficient of 83.6W / m-K. The epoxy resin composition is treated by adding the silicone with epoxy group, and the melt viscosity of the obtained composition is 50-80Pa s. The high-power packaging epoxy resin composition with the good forming performances has the advantages that the epoxy resin composition has good mobility and operating performance, so that problems of incomplete filling, poor operability and the like can be solved, and requirements of packaging clients on product packaging processes and high-power packaging heat radiation can be met.

Owner:JIANGSU ZHONGPENG NEW MATERIAL

ABS (acrylonitrile-butadiene-styrene) alloy material and preparation method thereof

ActiveCN103951929AImprove the lubrication effectReduce coefficient of frictionWear resistantAntioxidant

The invention provides a high-rigidity wear-resistant ABS (acrylonitrile-butadiene-styrene) alloy material which comprises the following components in parts by mass: 50-85% of ABS, 10-40% of PMMA (polymethyl methacrylate), 0-5% of PTFE (polytetrafluoroethylene), 0-5% of self-made anti-wear agent, 0-5% of organic silicone oil, 0.2-1% of lubricant and 0.2-1% of antioxidant. The high-rigidity wear-resistant ABS alloy material has the advantages of high surface hardness, small friction factor, high gloss, favorable toughness and the like; and the preparation method of the alloy material is simple in manufacturing procedure and low in composite cost. Thus, the invention is especially applicable to the industries of electronics / electrical appliances, home appliances and the like.

Owner:青岛中新华美塑料有限公司

Biological fiber filled PBT composition and preparation method thereof

The invention provides a biological fiber filled PBT composition and a preparation method thereof. The composition comprises the following components in parts by weight: 80-100 parts of polybutylene terephthalate, 1-5 parts of montmorillonite, 1-10 parts of biological fibers, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The preparation method comprises the following steps: weighing the polybutylene terephthalate, montmorillonite, antioxidant and lubricant and mixing to obtain a blend; and adding the blend through a primary feed inlet of a twin-screw extruder, and meanwhile, adding and extruding the biological fibers through a side feed inlet, and granulating the mixture through a circulating cooling water channel to obtain the composition. Compared with the prior art, as the natural biological fibers provided by the invention are compatible with PBT well, the biological fibers have a quite good dispersing and immersing effect in a matrix, so that the problem of great shrinking percentage of a material is solved and the surface effect thereof is also improved, and the invention provides a PBT enhanced composition which is high in strength and excellent in surface effect.

Owner:SHANGHAI KUMHOSUNNY JINSHAN PLASTICS CO LTD

Preparation method of polypropylene plastic particles

The invention discloses a preparation method of polypropylene plastic particles. The polypropylene plastic particles are prepared from the following raw materials in parts by weight: 100-120 parts ofmodified polypropylene, 16-20 parts of talcum powder, 10-15 parts of a flame retardant, 3-5 parts of a bacteriostatic agent, 2-3 parts of calcium stearate and 4-8 parts of a dispersing agent. The preparation method comprises the following steps: uniformly mixing the substances according to the formula ratio, and then carrying out melt blending, extrusion and granulation. According to the invention, the modified polypropylene is used as a plastic matrix, has higher impact resistance, and is grafted with -COOH functional groups, so that the compatibility and binding force of the matrix with theflame retardant and the bacteriostatic agent can be increased, the flame retardant, the bacteriostatic agent and the like are uniformly dispersed in the matrix, and the polypropylene particles are endowed with good flame retardance and bacteriostatic performance; and through auxiliary matching of talcum powder and calcium stearate with specific particle sizes, the rigidity of PP can be improved, the toughness of polypropylene can also be improved, and the polypropylene plastic which is excellent in mechanical property and has flame-retardant and antibacterial functions is obtained.

Owner:马健珂

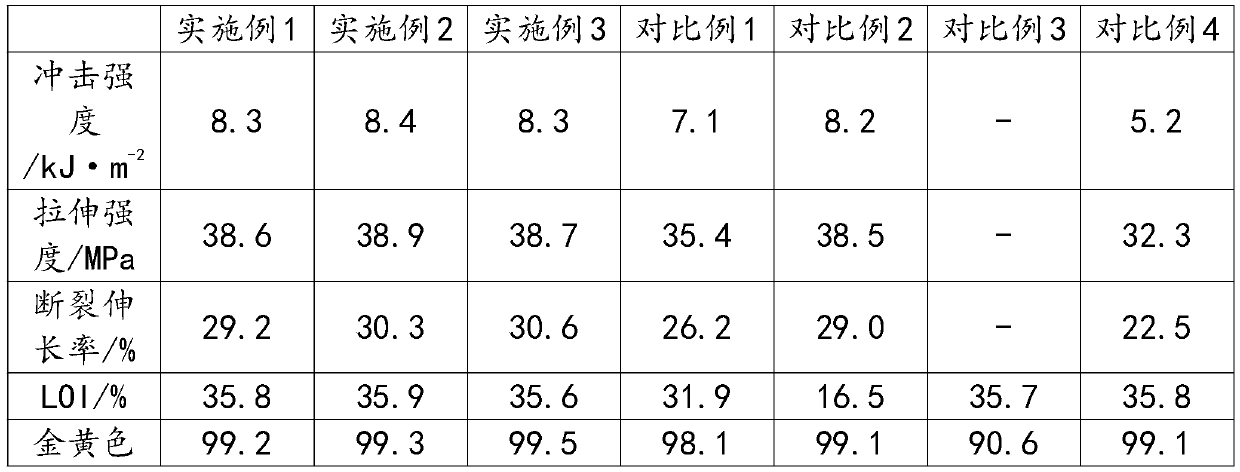

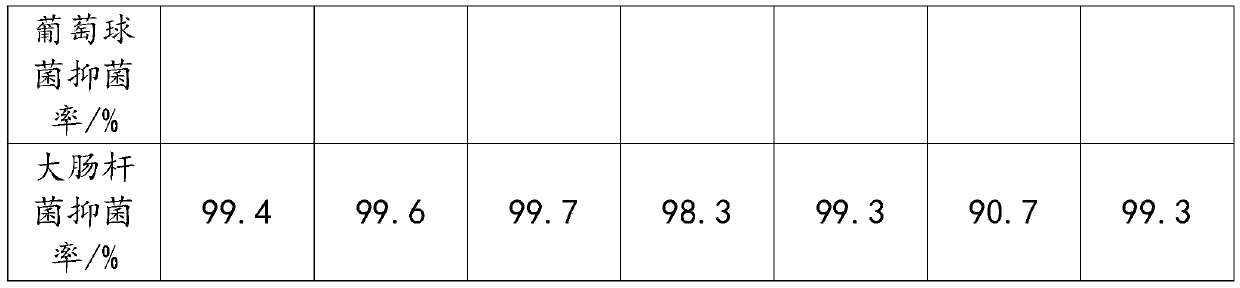

An aerogel composite material comprising submicron whiskers and clay and a preparing method thereof

An aerogel composite material comprising submicron whiskers and clay and a preparing method thereof are provided. The composite material comprises the submicron whiskers, the clay and an adhesive auxiliary. The submicron whiskers fill clay / adhesive auxiliary sol prepared from the clay and the adhesive auxiliary to prepare the composite material. The diameter of the submicron whiskers ranges from 100 nm to 1 mum, the length / diameter ratio is 10-10000, and the submicron whiskers have good combinability with clay aerogel. The prepared submicron whisker / clay aerogel composite material is significantly improved in mechanical performance and blocking performance.

Owner:GUANGZHOU UNIVERSITY

PVC composition for inspection wells and preparation method thereof

The invention discloses a PVC composition for inspection wells and a preparation method thereof, and belongs to the PVC processing technical field. The composition is composed of the following components by the weight percentage: 50-70% of a PVC compound, 20-30% of an acrylonitrile-styrene-butadiene copolymer resin, and 10-20% of a composite rigid particle modifier. The PVC compound is composed of the following components in parts by weight: 100 parts of PVC resin, 5-8 parts of a calcium zinc stabilizer, 1.5-3.5 parts of a lubricant, 0.8-1.5 parts of a weather resistance modifier, and 1-2 parts of a colorant. The composite rigid particle modifier is a compound obtained by compounding AS resin and nano calcium carbonate according to the weight ratio of 1 to (4-6). The composition adopts rigid particles for toughening, so that the ring stiffness and the tensile strength of the composition are greatly improved under the condition without reduction of the impact strength of the composition; and the cost is low, and the production method is simple, convenient and controllable.

Owner:CHINA PETROLEUM & CHEM CORP

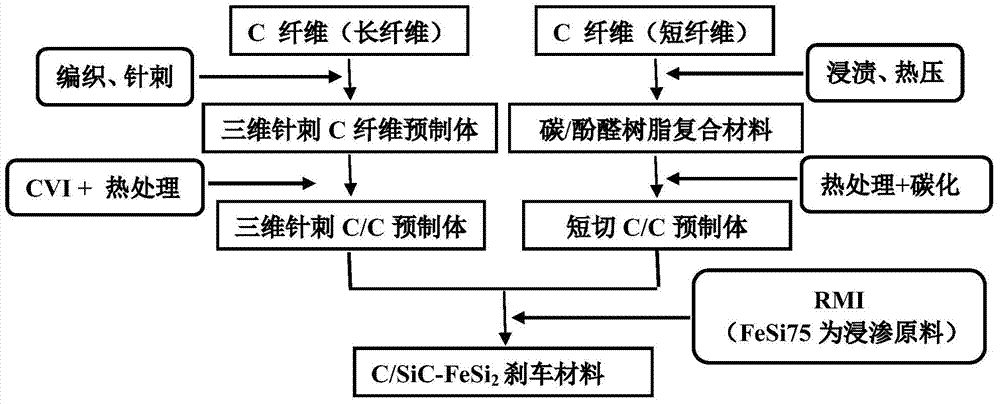

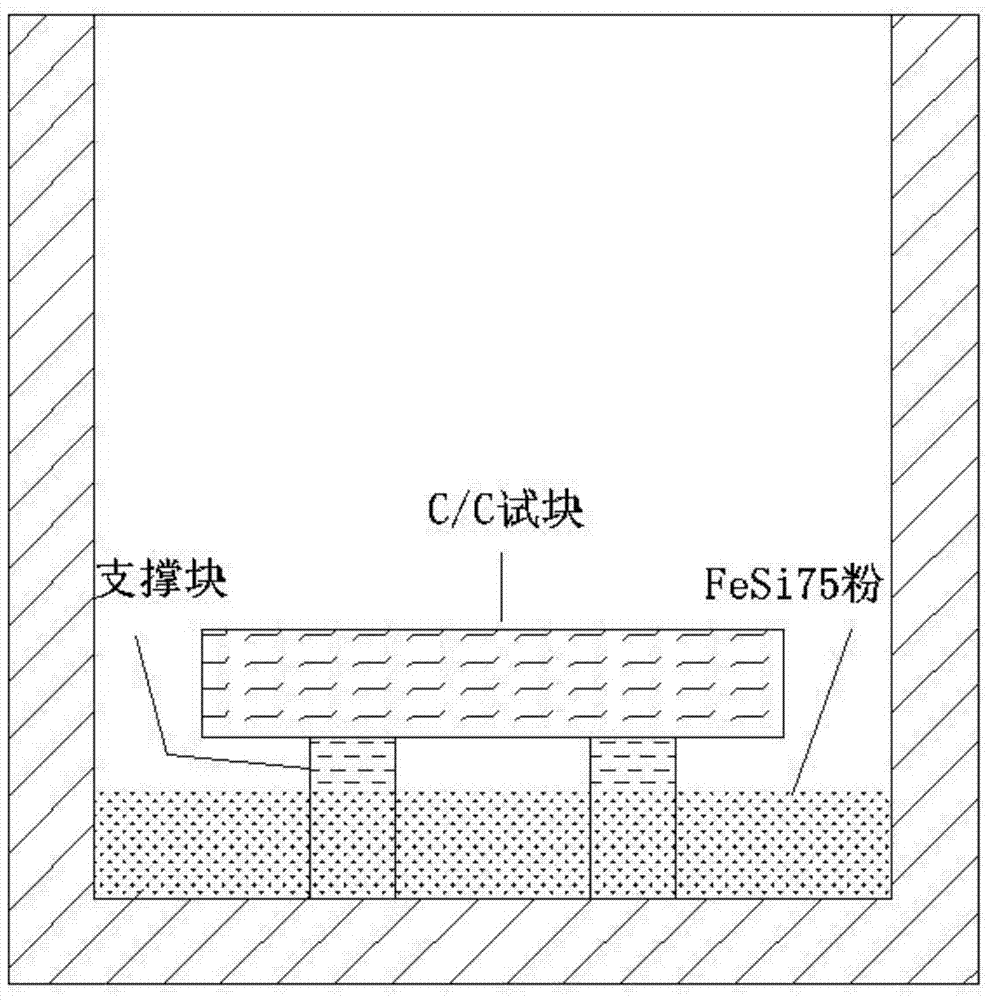

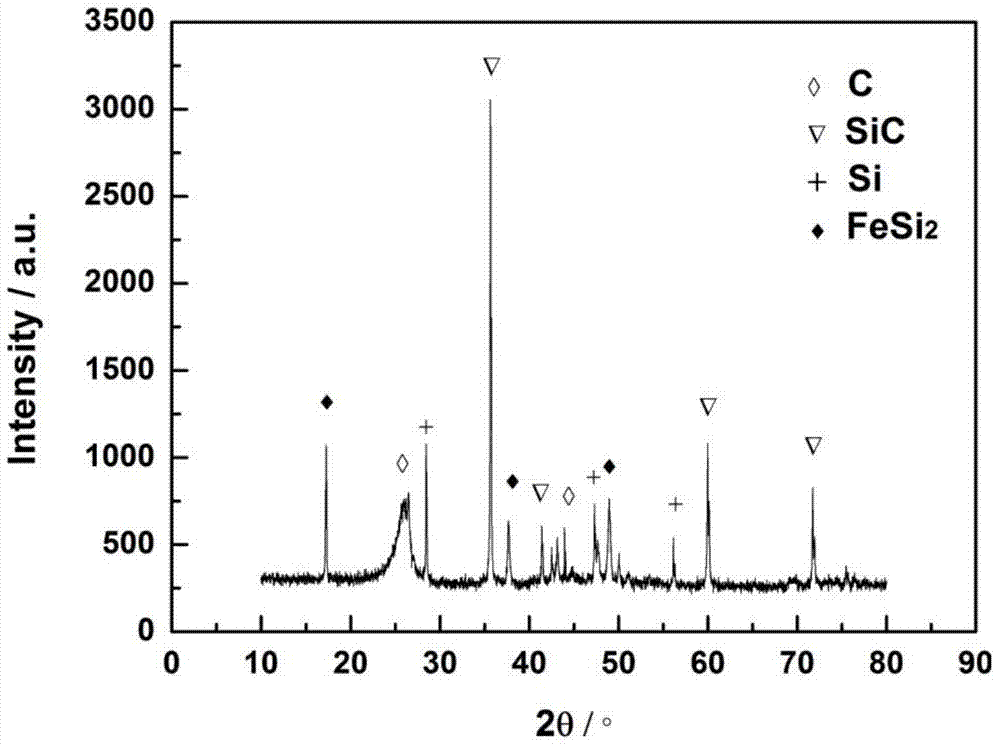

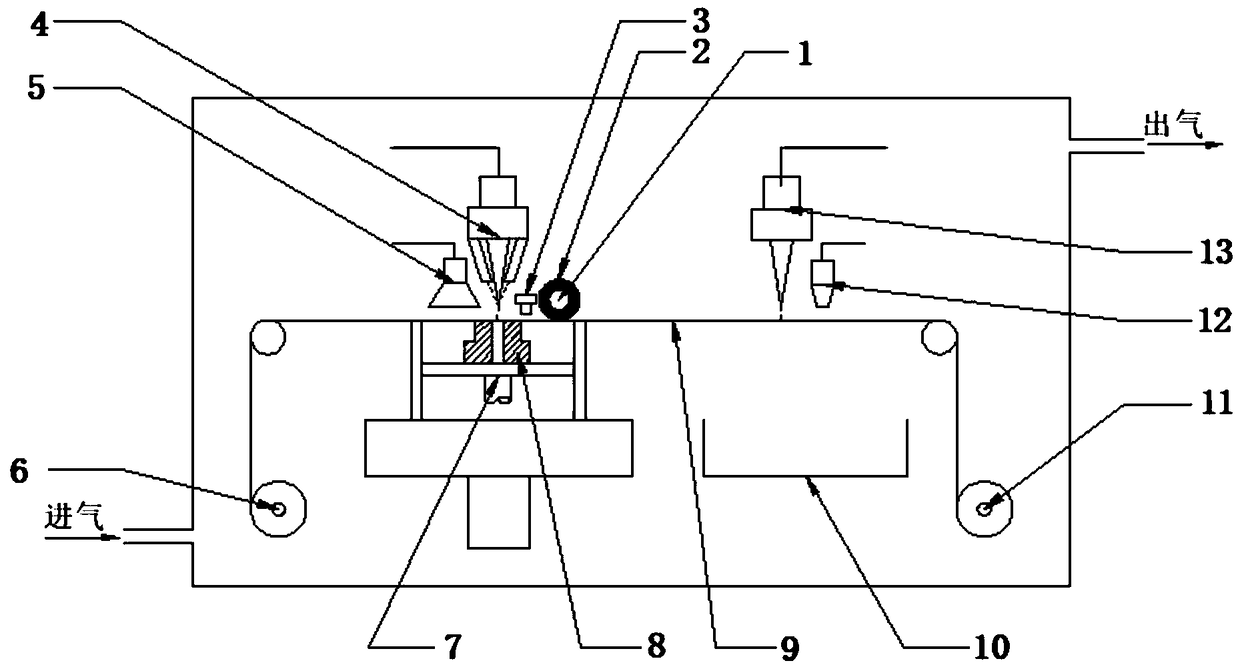

Preparation method of FeSi2 modified C/SiC braking material

InactiveCN104844243AImprove mechanical propertiesGood for heat dissipationRaw materialNanotechnology

The invention relates to a preparation method of a FeSi2 modified C / SiC braking material. A method combining CVI with RMI is adopted to prepare the FeSi2 modified three-dimensional needled C / SiC braking material. The preparation method includes: taking FeSi75 alloy powder as a RMI infiltration raw material; obtaining the FeSi2 modified C / SiC braking material through a reactive melt infiltration (RMI) process. By the preparation method, raw material cost is lowered remarkably, and RMI process temperature is lowered; a FeSi2 phase is introduced into a C / SiC composite material, so that strength and heat conductivity of the braking material are improved, friction stability is improved, and wear rate is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

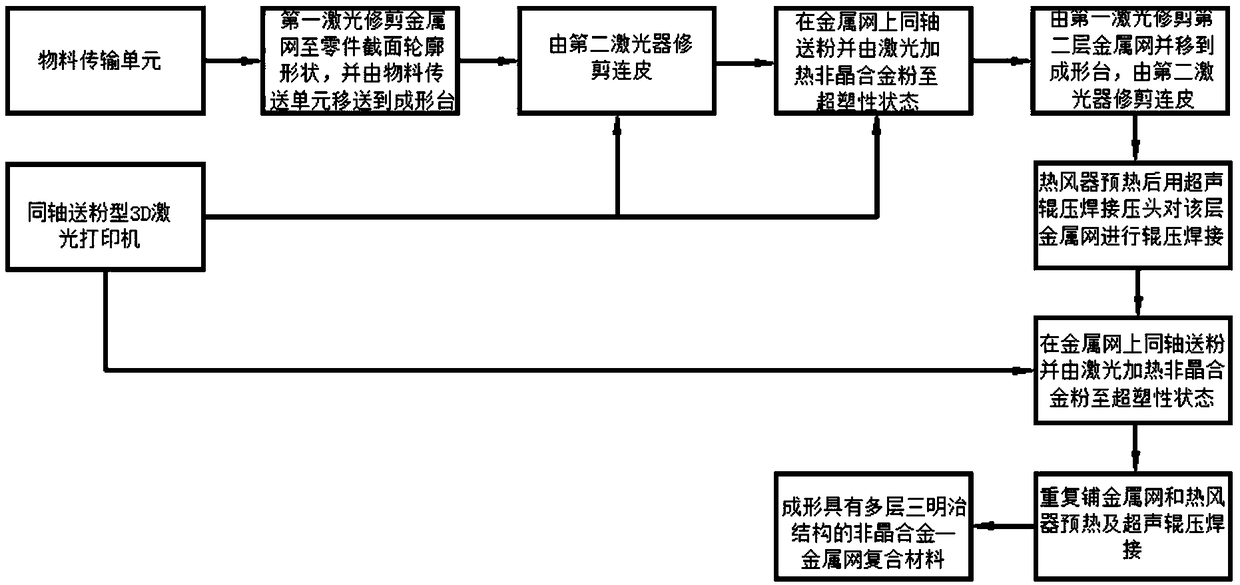

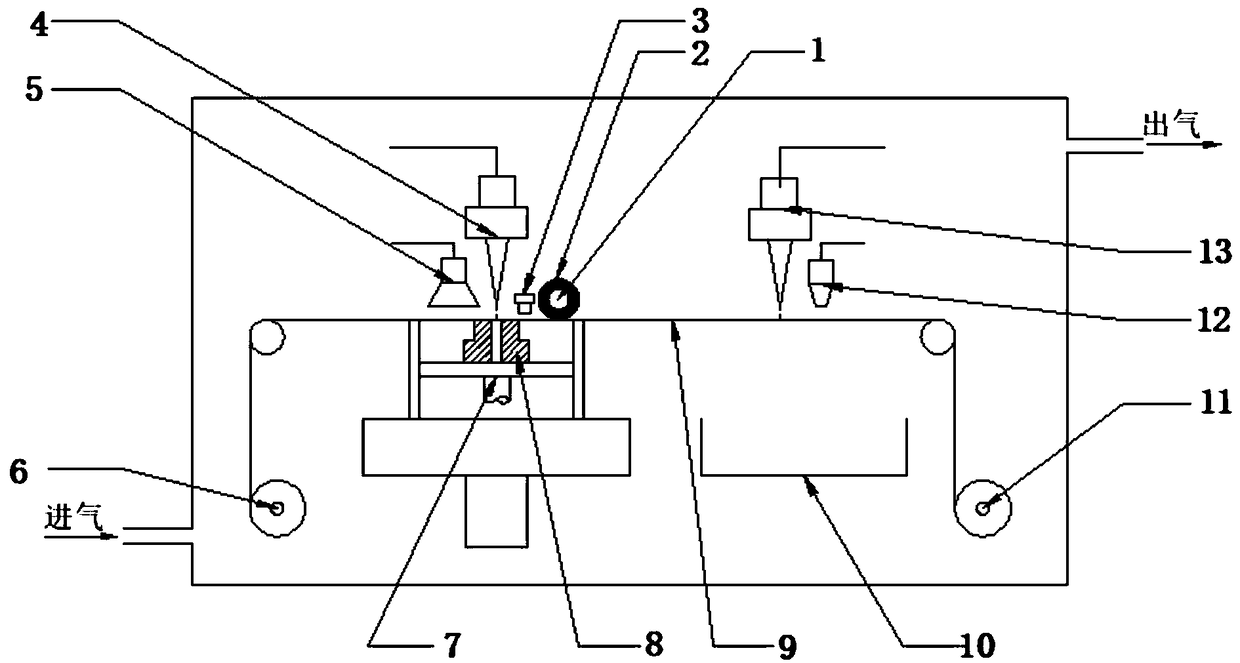

Integrated device and method for preparing and forming amorphous alloy composite material

ActiveCN109128167AAchieve metallurgical bondingIncrease productivityAdditive manufacturing apparatusIncreasing energy efficiencyThermoplasticManufacturing technology

The invention belongs to the field of amorphous alloy composite material additive material manufacturing technology and thermoplastic forming, particularly relates to an integrated device and method for preparing and forming amorphous alloy composite material. By reference to a 3D laser printing technology and a roller feeding device principle, by using the advantages of foil build-up welding technology, the forming method of amorphous alloy powder or amorphous alloy foil is targeted to redesign, the integrated device and method for forming the amorphous alloy composite material with large size and complex parts of amorphous alloy with metal net multilayer sandwich structure is correspondingly obtained, and thus the existing technical problems of the limitation of size and shapes, and poorcompact degree in a block amorphous alloy composite material forming device and method are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

High-strength plastic inspection well and preparation method thereof

The invention provides a high-strength plastic inspection well and a preparation method thereof. The plastic inspection well is prepared from the following raw materials in parts by weight: 20-30 parts of high-density polyethylene, 20-30 parts of polyvinyl chloride, 5-10 parts of powdery nitrile-butadiene rubber, 3-5 parts of stainless steel fiber, 1-3 parts of aid, 0.5-2 parts of coupling agent, 3-6 parts of acrylonitrile-butadiene-styrene copolymer, 1-2 parts of compatilizer, 5-10 parts of mica powder, 5-10 parts of montmorillonite, 1-3 parts of boron nitride fiber, 10-15 parts of polysulfone resin and 5-10 parts of polyoxymethylene. Through the reasonable configuration of the raw materials, the prepared material has excellent comprehensive properties; and the processed inspection well has high strength, rigid, impact strength and corrosion resistance and favorable surface gloss, thereby being better adapted to an underground harsh environment.

Owner:四会市恒星智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com